Page 1

TECHNICAL EDUCATION

JOB AID 8178642

ML

-

5

MODEL MTW6300TQ

AUTOMATIC WASHER

™

Page 2

FORWARD

This Maytag Job Aid, “Bravos™ Automatic Washer” (Part No. 8178642), provides the In-Home

Service Professional with information on the installation, operation, and service of the Bravos

Automatic Washer. For specific information on the model being serviced, refer to the “Use and

Care Guide,” or “Tech Sheet” provided with the washer.

The Wiring Diagram used in this Job Aid is typical and should be used for training purposes only.

Always use the Wiring Diagram supplied with the product when servicing the washer.

™

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide information that will enable the In-Home Service Professional to properly diagnose malfunctions and repair the Bravos™ Automatic Washer.

The objectives of this Job Aid are to:

Understand and follow proper safety precautions.

•

Successfully troubleshoot and diagnose malfunctions.

•

Successfully perform necessary repairs.

•

Successfully return the washer to its proper operational status.

•

WHIRLPOOL CORPORATION assumes no responsibility for any repairs made on

our products by anyone other than Authorized In-Home Service Professionals.

Copyright © 2007, Whirlpool Corporation, Benton Harbor, MI 49022

- ii -

Page 3

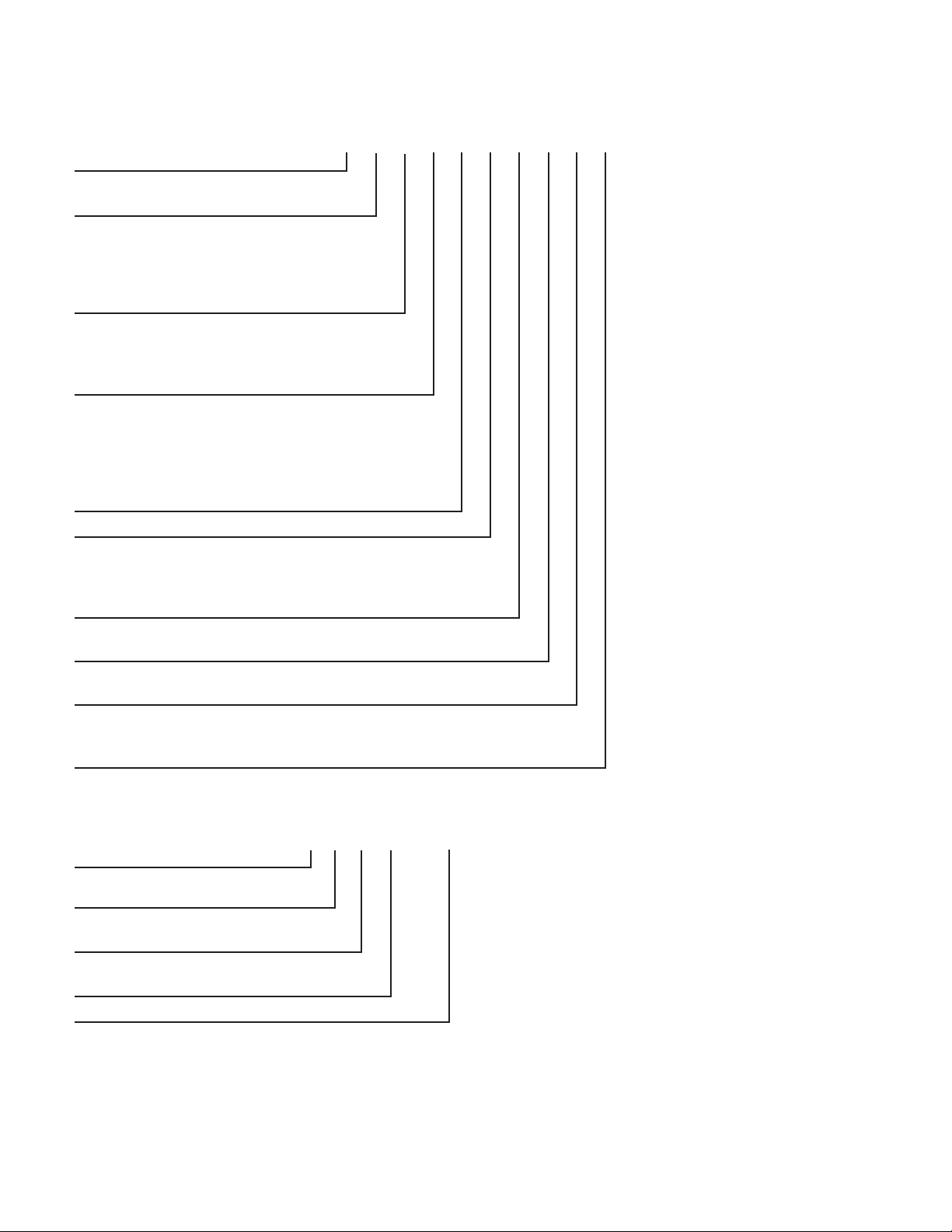

TABLE OF CONTENTS

Page

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Washer Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Model & Serial Number Designations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Model & Serial Number Label & Tech Sheet Locations . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-1

1-3

INSTALLATION INFORMATION

Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

PRODUCT OPERATION

Theory Of Operation

Washer Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Washer Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COMPONENT ACCESS

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Removing The Encoder And The User Interface Board

Removing The Water Inlet/Dispenser Valve Assembly, Power Supply Cord,

And Machine/Motor Control & Pressure Transducer . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing A Dispenser, The Fresh Fill Inlet Valve, And The Lid Lock . . . . . . . . . . . . . . . .

Removing The Lid And A Lid Hinge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing The Basket & Basket Hub

Removing The Drain And Recirculation Pumps

Removing The Drive Motor & Rotor Position Sensor

Removing The Tub

Accessing The Pressure Transducer Tubing, Recirculation Tube,

And Drain Pump Harness

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

3-3

3-13

. . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4-4

4-6

4-9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

COMPONENT TESTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Water Inlet/Dispenser Valve Assembly

Drain Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Recirculation Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Lid Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Drive Motor Stator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

DIAGNOSTICS & TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Display Fault/Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Diagnostic Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Diagnostic Tests

Troubleshooting Guide

Troubleshooting Tests

Accessing & Removing The Electronic Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

6-15

- iii -

Page 4

— NOTES —

- iv -

Page 5

GENERAL

DANGER

WARNING

WASHER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance.

Always read and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word

“DANGER” or “WARNING.” These words mean:

You can be killed or seriously injured if you don’t

immediately follow instructions.

You can be killed or seriously injured if you don’t

follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the

chance of injury, and tell you what can happen if the instructions are not followed.

1-1

Page 6

MODEL & SERIAL NUMBER DESIGNATIONS

MODEL NUMBER

MODEL NUMBER M T W 6 3 00 T Q 0

BRAND

M = Maytag

ACCESS / FUEL

T = Top Load G = Gas

F = Front Load H = Horizontal

W = Work Space V = Vertical

E = Electric

PRODUCT

W = Washer P = Pedestal

D = Dryer B = Combo

T = Thin Twin C = Compact

SERIES

1 = Innovation 6 = Oasis

2 = Commercial 7 = Merloni

3 = Compact 8 = Horizon

4 = Stack 9 = Duet/Combo

5 = LEAP

PRICE POINT LEVELS (1 - 7)

TRADE PARTNER

00 = Brand 30 = NATM

10 = SBC 40 = Lowe’s

20 = Best Buy

YEAR OF INTRODUCTION

T = 2007

COLOR CODE

Q = White

ENGINEERING CHANGE

0 = Basic Original Release

1 = First Revision

SERIAL NUMBER

SERIAL NUMBER C U 41 10200

MANUFACTURING SITE

C = Clyde, Ohio

YEAR OF PRODUCTION

U = 2007

WEEK OF PRODUCTION

41 = 41st Week

PRODUCT SEQUENCE NUMBER

1-2

Page 7

MODEL & SERIAL NUMBER LABEL &

TECH SHEET LOCATIONS

The Model/Serial Number Label and Tech Sheet locations are shown below.

Model/Serial Number Location

Tech Sheet Location

(Access Under Cabinet Top)

1-3

Page 8

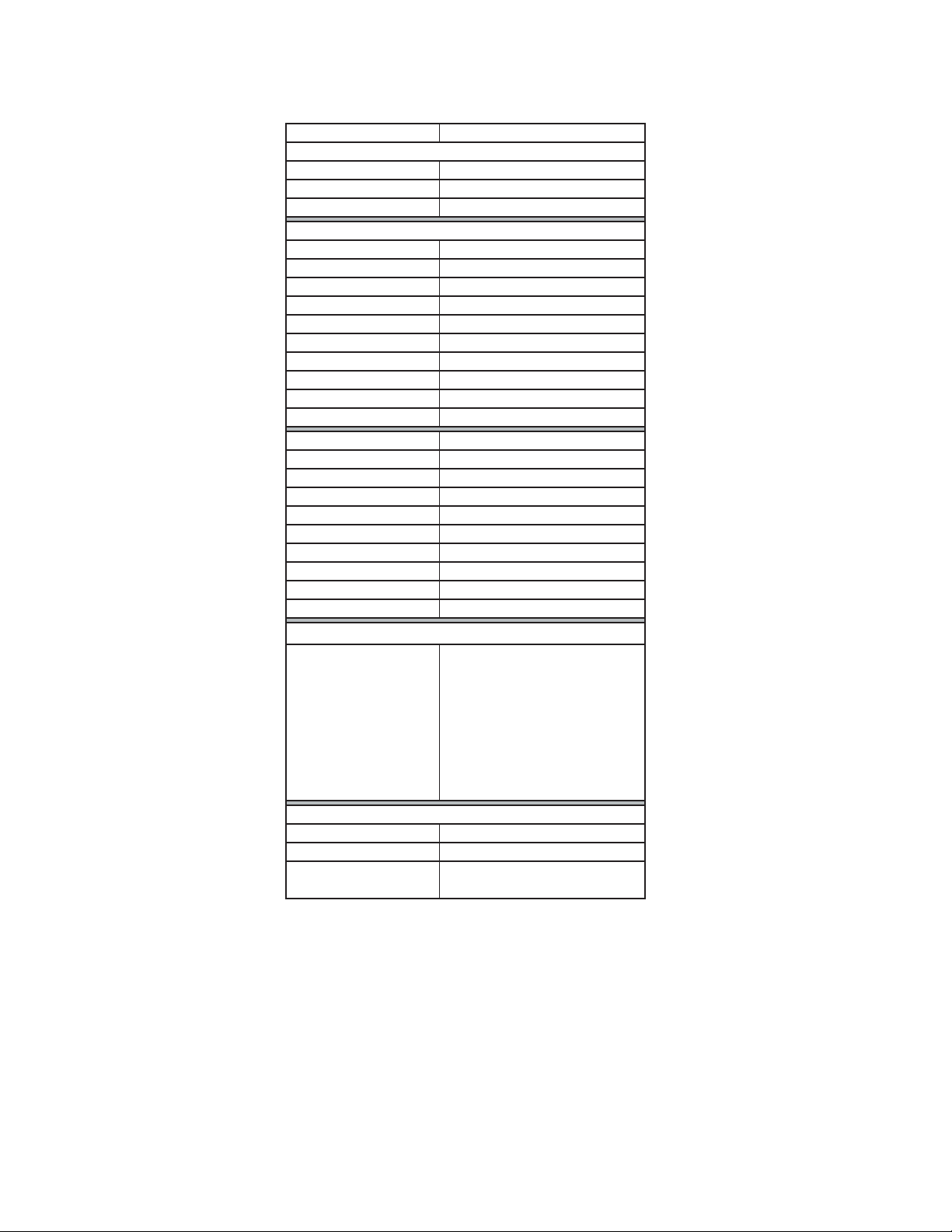

SPECIFICATIONS

MODEL NUMBERS MTW6300TQ

PRIMARY FEATURES

CAPACITY (DOE) 3.8 CU. FT.

USABLE CAPACITY

MAX SPIN SPEED 950

EXTERIOR

LID FINISH POWDER COAT

LID SOLID

TOP FINISH POWDER COAT

AGITATOR DUAL ACTION

SOUND PACK Q. WASH

TUB WRAP NO

MASTIC (FRONT) 1 - 4 X 12 PIECE

CABINET PAD NO

LID SEALS NO

MAIN DRIVE MOTOR BRUSHLESS PERM MAGNET

DISPENSERS

MAIN DETERGENT YES

TYPE FLUSH

CAPACITY 2/3 CUP

BLEACH YES

TYPE FLUSH/TIMED

CAPACITY 1 CUP

FABRIC SOFTENER YES

TYPE AGITATOR CUP

CAPACITY 1/2 CUP

18 LBS (8.16 KG)

3 (ECONOMY)

CYCLE DEFINITIONS

# OF CYCLES

WRINKLE CONTROL

COLORS / JEANS

OPTIONS

FINAL SPIN SPEEDS VARIABLE / NON SELECTABLE

SOAK PRE SOAK

CATALYST OPTIONS

7

SUPER WASH

NORMAL

WHITES

DELICATE

HANDWASH

STAIN CYCLE

EXTRA RINSE

1-4

Page 9

MODEL NUMBERS MTW6300TQ

SECONDARY

EOC OFF / LOW / HIGH

TIME REMAINING YES

TEMPS 4 ATC

ATC TEMPS H/C , W/W, W/C, C/C

AUTO WATER LEVEL YES

WATER LEVELS

SOIL LEVELS

STATUS LED’S

ADDITIONAL

COLORS WHITE

SIZE ( W X D X H ) 28 X 27 X 42 IN (71.2 X 68.5 X 106.6 CM)

WEIGHT (IN CARTON) 165 LBS (74.8 KG)

SMALL - 3.1

MEDIUM - 8.5˝ (22 CM) ABOVE BASKET BOTTOM

LARGE - 9.5˝ (24 CM) ABOVE BASKET BOTTOM

SUPER - 12˝ (30 CM) ABOVE BASKET BOTTOM

˝ (8 CM) ABOVE BASKET BOTTOM

3

WASH (4) / STATUS (3)

SOAK

WASH

RINSE

SPIN

CLEAN

ADD-A-GARMENT

LID LOCK

1-5

Page 10

— NOTES —

1-6

Page 11

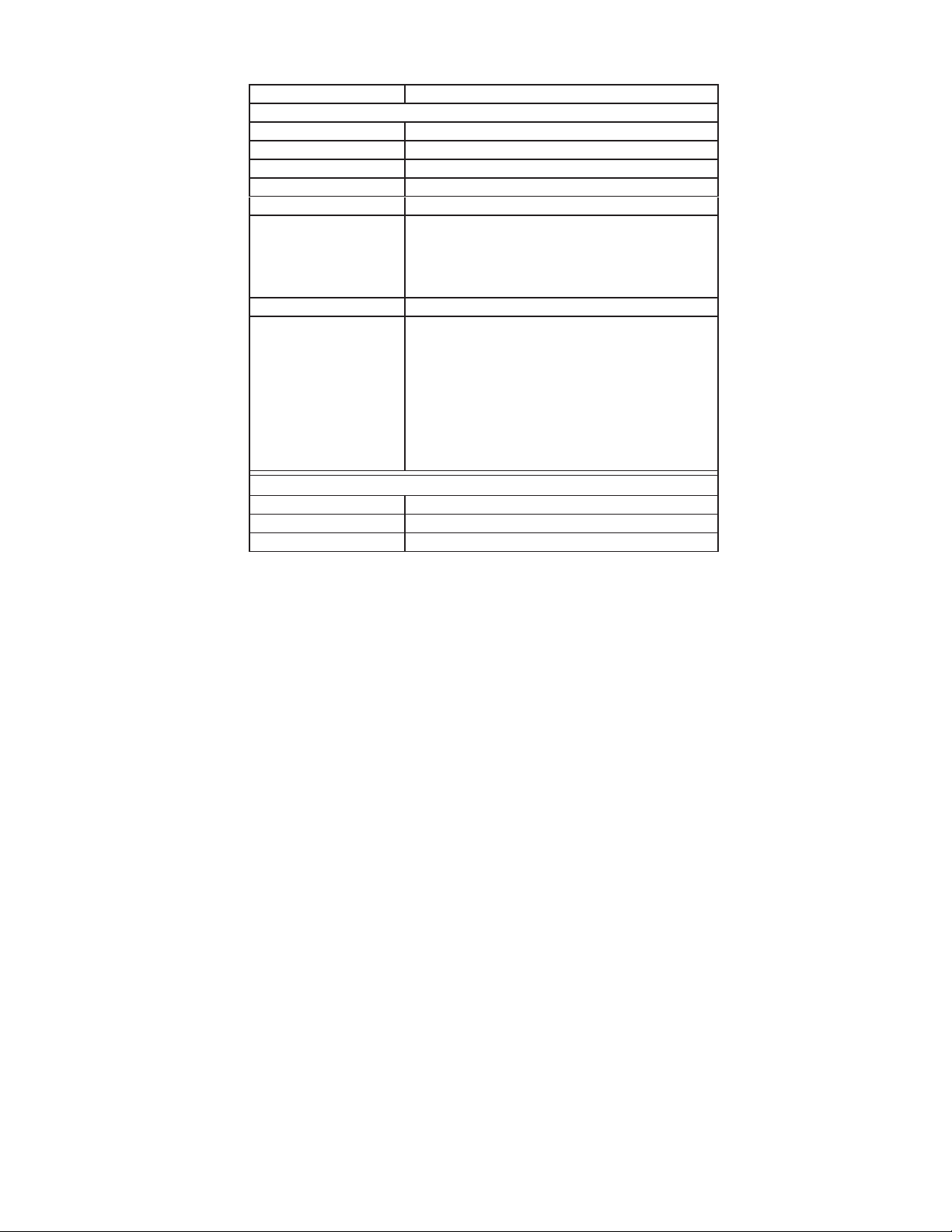

INSTALLATION INFORMATION

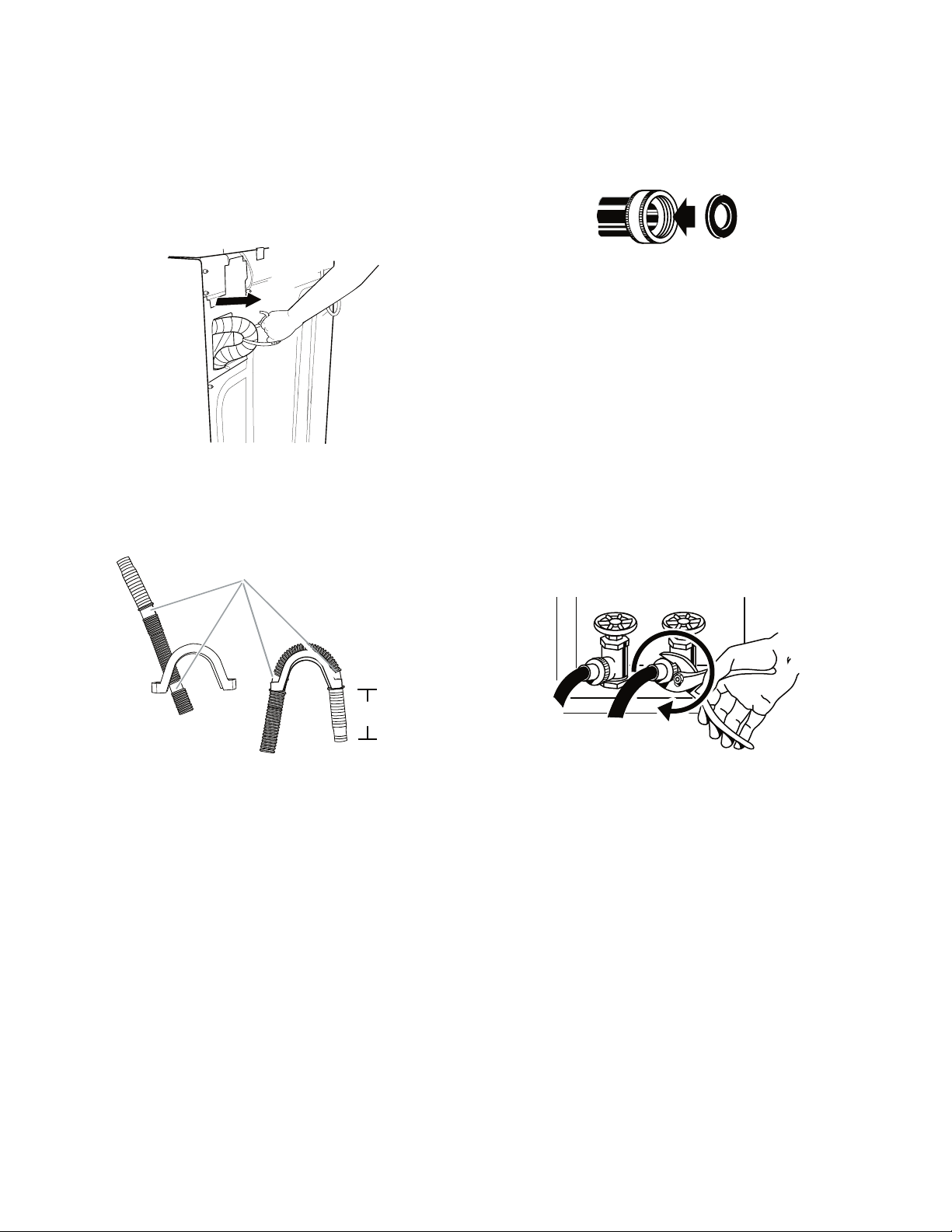

A. Drain hose form

B. Water inlet hoses (2

)

C. Flat water inlet hose washers (4

)

D. Beaded tie stra

p

A B

C

D

If You Have: You Will Need to Buy:

Laundry tub or

standpipe taller

than 96˝ (2.4 m)

Sump pump system (if not already

available)

1˝ (2.5 cm)

diameter

standpip

e

2˝ (5 cm) diameter to 1˝ (2.5 cm)

diameter standpipe adapter,

Part Number 3363920 and

connector kit

Part Number 285835

Overhead sewer Standard 20 gal. (76 L) 39˝ (99 cm) tall

drain tub or utility sink, sump pump and

connectors (available from local

plumbing su

ppliers)

Floor drain Siphon break, Part Number 285834;

additional drain hose,

Part Number 8318155 and connector

kit, Part

Number 285835

Water faucets

beyond reach of

fill hose

s

2 longer water fill

hoses:

6 ft (1.8 m) Part

Number 76314,

10 ft (3.0 m) Part Number 350008

Lint clogged drain Drain protector, Part

Number 367031

INSTALLATION REQUIREMENTS

TOOLS AND PARTS

Gather the required tools and parts before

starting installation. The parts supplied are in

the washer basket.

Tools needed for connecting the drain

hose and water inlet hoses:

Pliers that open to 1-9/16˝ (3.95 cm)

•

Flashlight (optional)

•

NOTE: Replace inlet hoses after 5 years of

use to reduce the risk of hose failure. Record

hose installation or replacement dates for fu

ture reference.

Parts Supplied:

Tools needed for securing the drain hose

and leveling the washer:

Adjustable or open end wrench 9/16˝

•

(14 mm)

Level

•

•

Wood block

Ruler or measuring tape

•

Alternate Parts

-

2-1

Page 12

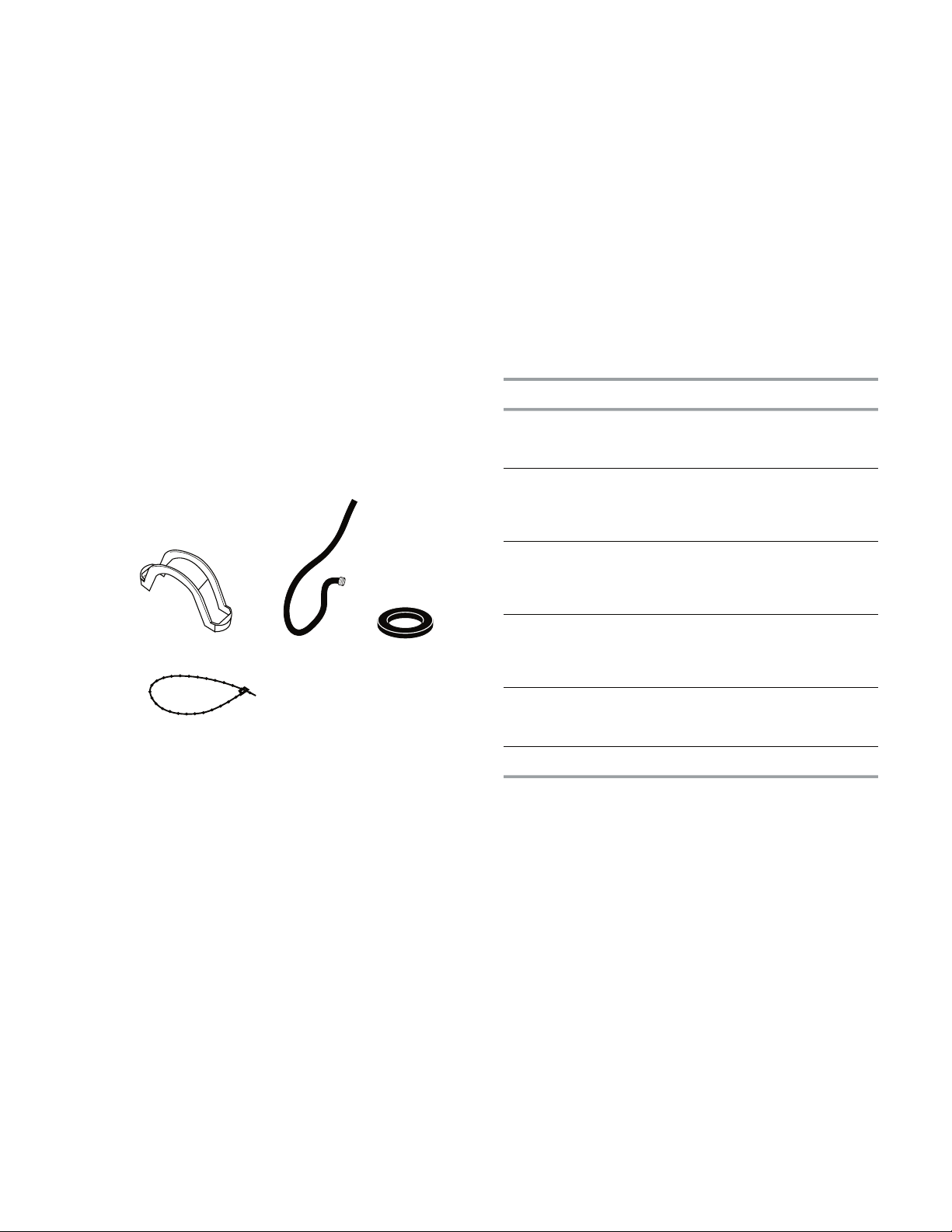

LOCATION REQUIREMENTS

A. Front view

B. Side view

C. Closet door with vents

A

B

C

17"*

(43.2 cm)

1"

(2.5 cm)

1"

(2.5 cm)

27-1/2

"

(69.9 cm)

1"*

(2.5 cm)

27"

(68.6 cm)

5"*

(12.7 cm)

14"* max.

(35.6 cm)

3"*

(7.6 cm)

3"*

(7.6 cm)

24 in. *

(155 cm )

2

2

48 in. *

(310 cm )

2

2

Selecting the proper location for your washer

improves performance and minimizes noise

and possible washer “walk.”

The washer can be installed in a basement,

laundry room, closet, or recessed area. See

“Drain System,” page 2-3.

IMPORTANT: Do not install or store the washer where it will be exposed to the weather.

Proper installation is your responsibility.

You will need:

•

A water heater set to deliver 120°F (49°C)

water to the washer.

•

A grounded electrical outlet located with

in 4 ft (1.2 m) of where the power cord is

attached to the back of the washer. See

“Electrical Requirements,” page 2-4.

Hot and cold water faucets located within

•

3 ft (90 cm) of the hot and cold water fill

valves, and water pressure of 20-100 psi

(138-690 kPa) for best performance.

A level floor with a maximum slope of

•

1˝(2.5 cm) under entire washer. Installing the washer on carpeting is not recom

mended.

A sturdy floor to support the washer

•

weight (washer, water and load) of 315 lbs

(143 kgs).

Do not store or operate your washer in tem

peratures at or below 32°F (0°C). Some wa

ter can remain in the washer and can cause

damage in low temperatures.

INSTALLATION SPACING FOR RECESSED

AREA AND CLOSET INSTALLATIONS

The following spacing dimensions are rec

ommended for this washer. This washer has

been tested for installation with spacing of 0

(0 cm) clearance on the sides. Recommend

ed spacing should be considered for the fol

lowing reasons:

Additional spacing should be considered

•

for ease of installation and servicing.

Additional spacing should be considered

•

on all sides of the washer to reduce noise

transfer.

For closet installation with a door, minimum

•

-

ventilation openings in the top and bottom

of the door are required. Louvered doors

with equivalent ventilation openings are

acceptable.

Companion appliance spacing should also

•

be considered.

-

-

-

* Required spacing

-

˝

-

-

2-2

Page 13

A

B

(99 cm)

39"

DRAIN SYSTEM

C

D

39"

(99 cm)

28"

(71 cm)

The washer can be installed using the standpipe drain system (floor or wall), the laundry

tub drain system, or the floor drain system.

Select the drain hose installation method you

need. See “Tools and Parts,” page 2-1.

LAUNDRY TUB DRAIN SYSTEM (VIEW C)

The laundry tub needs a minimum 20 gal.

(76 L) capacity. The top of the laundry tub

must be at least 39

and no higher than 96

˝ (99 cm) above the floor

˝ (244 cm) from the

bottom of the washer.

STANDPIPE DRAIN SYSTEM—WALL OR

FLOOR (VIEWS A & B)

The standpipe drain requires a minimum di

ameter standpipe of 2

˝ (5 cm). The minimum

carry-away capacity can be no less than 17

gal. (64 L) per minute. A 2

˝ (5 cm) diameter to

1˝ (2.5 cm) diameter standpipe adapter kit is

available. See “Tools and Parts,” page 2-1.

The top of the standpipe must be at least 39

(99 cm) high and no higher than 96

˝ (244 cm)

˝

from the bottom of the washer.

FLOOR DRAIN SYSTEM (VIEW D)

The floor drain system requires a siphon break

that may be purchased separately. See “Tools

and Parts,” page 2-1.

The siphon break must be a minimum of 28˝

(71 cm) from the bottom of the washer. Addi

tional hoses might be needed.

-

2-3

Page 14

ELECTRICAL REQUIREMENTS

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can

result in death, fire, or electrical shock.

A 120 volt, 60 Hz., AC only, 15- or 20-

•

amp, fused electrical supply is required. A

time-delay fuse or circuit breaker is recom

mended. It is recommended that a sepa

rate circuit serving only this appliance be

provided.

This washer is equipped with a power sup-

•

ply cord having a 3 prong grounding plug.

To minimize possible shock hazard, the

•

cord must be plugged into a mating, 3

prong, grounding-type outlet, grounded

in accordance with local codes and ordi

nances. If a mating outlet is not available,

it is the personal responsibility and obli

gation of the customer to have the prop

erly grounded outlet installed by a qualified

electrician.

GROUNDING INSTRUCTIONS

For a grounded, cord-connected washer:

This washer must be grounded. In the event

of a malfunction or breakdown, grounding

will reduce the risk of electrcal shock by

providing a path of least resistance for elec

tric current. This washer is equipped with a

cord having an equipment-grounding con

ductor and a grounding plug. The plug must

be plugged into an appropriate outlet that

is properly installed and grounded in accor

dance with all local codes and ordinances.

WARNING: Improper connection of the

equipment-grounding conductor can result

in a risk of electric shock. Check with a quali

fied electrician or serviceman if you are in

doubt as to whether the appliance is properly

-

-

-

-

-

grounded.

Do not modify the plug provided with the

appliance—if it will not fit the outlet, have a

proper outlet installed by a qualified electri

cian.

For a permanently connected washer:

This washer must be connected to a ground

ed metal, permanent wiring system, or an

equipment-grounding conductor must be

run with the circuit conductors and connect

ed to the equipment-grounding terminal or

lead on the appliance.

-

-

-

-

-

-

-

If codes permit and a separate ground wire

•

is used, it is recommended that a qualified

electrician determine that the ground path

is adequate.

Do not ground to a gas pipe.

•

Check with a qualified electrician if you are

•

not sure the washer is properly grounded.

Do not have a fuse in the neutral or ground

•

circuit.

2-4

Page 15

INSTALLATION INSTRUCTIONS

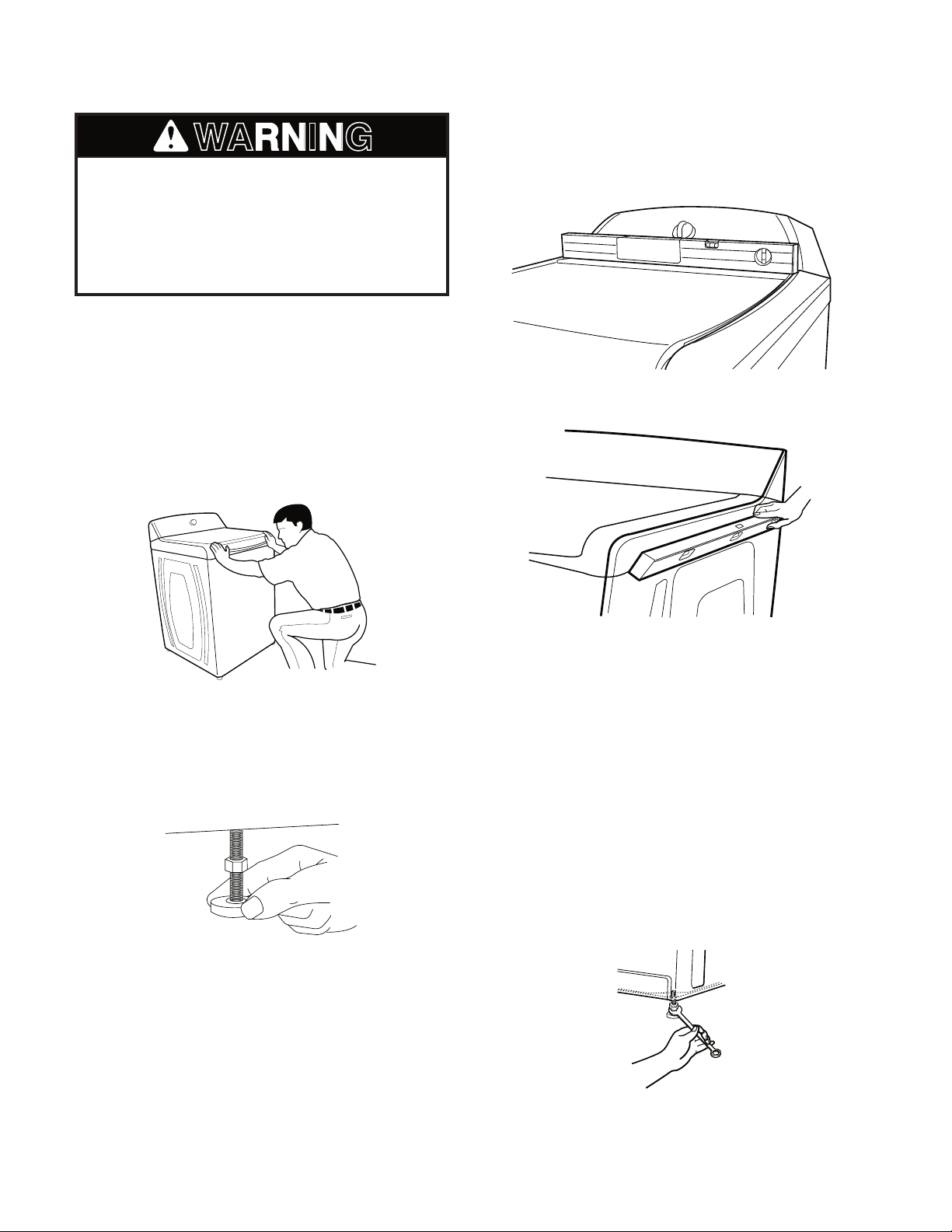

WARNING

Excessive Weight Hazard

Use two or more people to move and

install washer.

Failure to do so can result in back or

other injury.

NOTE: To avoid floor damage, set the washer

onto cardboard before moving across floor.

IMPORTANT:

•

Be sure the foam shipping base has been

removed from the bottom of the washer as

directed in the Unpacking Instructions.

If foam shipping base has not been re-

•

moved, be sure lid is secured with tape be

fore laying washer on its back.

Removing the foam shipping base is nec-

•

essary for proper operation.

REMOVE SHIPPING BASE

AND PACKING RING

6. Remove tape from lid. Open lid and remove foam packing ring from washer tub.

Keep foam packing ring in case you need

to move the washer in the future.

CONNECT THE DRAIN HOSE

Proper connection of the drain hose protects

your floors from damage due to water leak

age. Read and follow these instructions.

The drain hose is connected to your washer

and is stored inside the washer cabinet.

-

1. Place cardboard supports from shipping

carton on floor behind washer for sup

port.

2. Secure the lid with tape.

3. Using 2 or more people, tip the washer

onto its back and place on cardboard

supports.

4. Remove foam shipping base.

-

5. Set washer upright.

2-5

Page 16

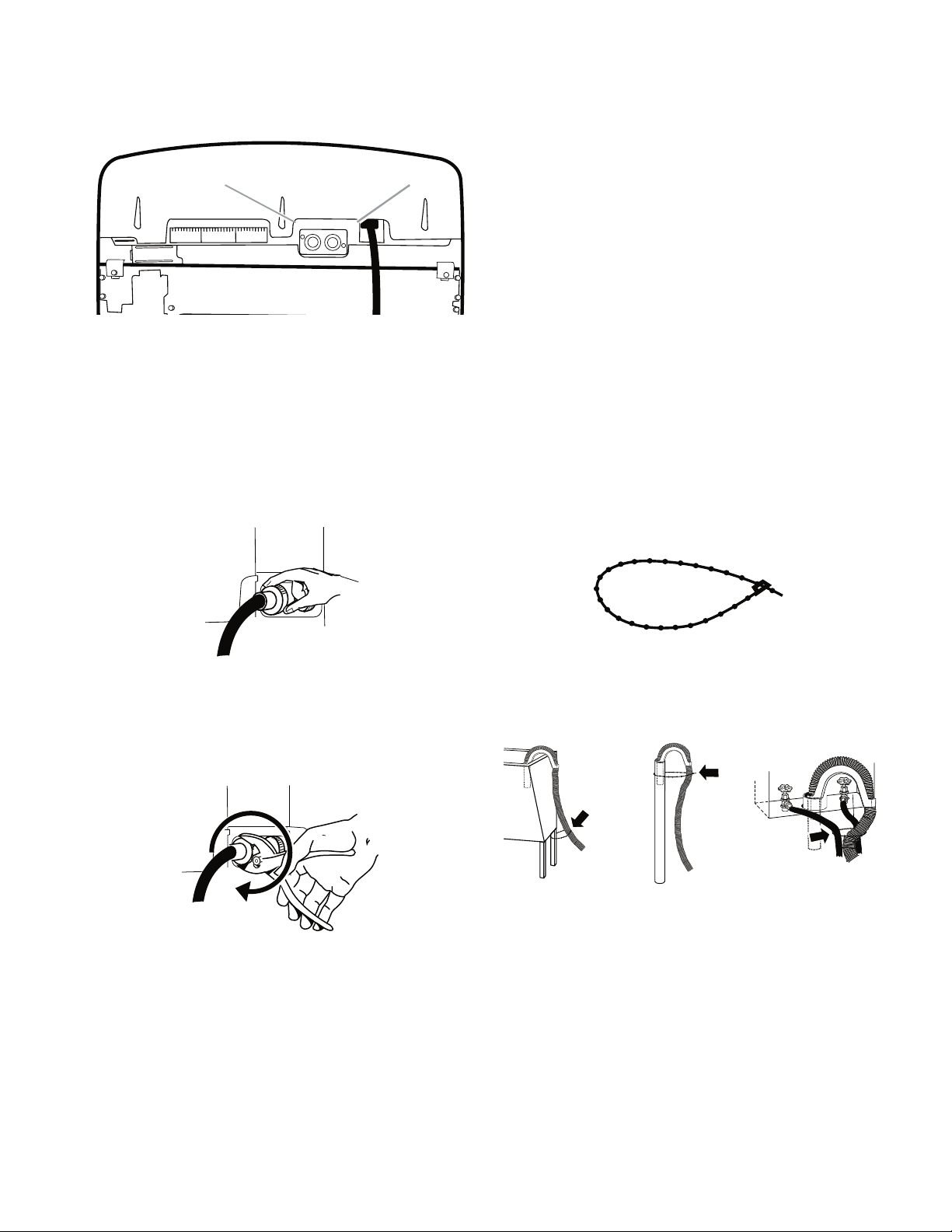

REMOVE DRAIN HOSE

A. Coupling

B. Washer

A B

sfeiler esoh niarD .A

e

soh niard fo dne ecalP .mrof fo dne eno otni esoh niard fo d

ne

deeF.1

.feiler esoh niard eht otni mrof

fo dne re

hto

eht

otni deef

dna mrof eht fo pot eht revo es

oh

eht dneB

.2

esoh niard rehto eht otni mrof eht fo dne rehto eht hcattA .mrof eht

.mrof eht dnoyeb )mc 4.11("4-1/2 dnetxe tsum esoh ehT .feiler

"

5

.

4

)

m

c

4.

11(

A

Tighten the couplings with an additional two-thirds turn.

FROM WASHER CABINET

Pull the corrugated drain hose out of the

washer by first grabbing the pull tie. Continue

to pull the hose until the end emerges. Do not

force excess drain hose back into the rear of

the washer.

LAUNDRY TUB DRAIN

OR STANDPIPE DRAIN

Connecting the drain hose form to the cor

rugated drain hose

CONNECT THE INLET HOSES

1. Insert new flat washers (supplied) into

each end of the inlet hoses. Firmly seat

the washers in the couplings.

CONNECT THE INLET HOSES TO

THE WATER FAUCETS

Make sure the washer basket is empty.

2. Attach the hose labeled hot to the hot

water faucet. Screw on coupling by hand

until it is seated on the washer.

3. Attach the hose labeled cold to the cold

water faucet. Screw on coupling by hand

-

until it is seated on the washer.

4. Using pliers, tighten the couplings with

an additional two-thirds turn.

To keep drain water from going back into

the washer:

Do not force excess drain hose into stand-

•

pipe. Hose should be secure but loose

enough to provide a gap for air.

•

Do not lay excess hose on the bottom of

the laundry tub.

FLOOR DRAIN

Do not install the drain hose form on to the

corrugated drain hose. You may need addi

tional parts. See Floor drain under “Tools and

Parts,” page 2-1.

NOTE: Do not overtighten or use tape or sealants on the valve. Damage to the valves can

result.

Clear the water lines

Run water through both faucets and inlet

•

hoses, into a laundry tub, drainpipe or buck

et, to get rid of particles in the water lines

that might clog the inlet valve screens.

Check the temperature of the water to

•

make sure that the hot water hose is con

nected to the hot water faucet and that the

cold water hose is connected to the cold

water faucet.

-

2-6

Page 17

CONNECT THE INLET HOSES

COLD

HOT

A. Hot water inlet valve

B. Cold water inlet valv

e

HO

T

COL

D

A

B

COLD

HO

T

Beaded tie strap

CBA

TO THE WASHER

1. Attach the hot water hose to the inlet

valve labeled hot.

2. Attaching one hose coupling first makes

it easier to tighten the connection with pli

ers.

Check for leaks

Turn on the water faucets and check for

•

leaks. A small amount of water might en

ter the washer. You will drain this in a later

step.

NOTE: Replace inlet hoses after 5 years of

use to reduce the risk of hose failure. Record

hose installation or replacement dates for fu

ture reference.

If you connect only one water hose, you

•

must cap off the remaining water inlet

port.

Periodically inspect and replace hoses

•

if bulges, kinks, cuts, wear, or leaks are

found.

-

SECURE THE DRAIN HOSE

-

-

3. Screw on coupling by hand until it is seated on the washer.

4. Using pliers, tighten the coupling with an

additional two-thirds turn.

NOTE: Do not overtighten or use tape or sealants on the valve. Damage to the valves can

result.

5. Attach the cold water hose to the inlet

valve labeled cold.

6. Screw on coupling by hand until it is seated on the washer.

1. Drape the power cord over the console.

2. Remove any cardboard used to move

washer.

3. Fasten the drain hose to the laundry tub

leg or drain standpipe with the beaded tie

strap. See view A or B.

If the washer faucets and the drain stand-

pipe are recessed, put the formed end of

the drain hose into the standpipe. Tightly

wrap the tie strap around the water inlet

hoses and the drain hose. See view C.

7. Using pliers, tighten the coupling with an

NOTE: Do not overtighten or use tape or sealants on the valve. Damage to the valves can

result.

additional two-thirds turn.

2-7

Page 18

LEVEL THE WASHER

WARNING

Level the front.

Level the side

.

Excessive Weight Hazard

Use two or more people to move and

install washer.

Failure to do so can result in back or

other injury.

One washer foot has been installed at a different height on the washer. The other three

feet were preset at the factory. Properly level

ing your washer will minimize noise and vibra

tion.

1. Slide the washer to its final location.

2. Push on upper front panel to be sure the

washer is on its rear feet.

4. Check the levelness of the washer by

first placing a level on the lid near the

console. Next, place the level on the side

of the washer in the crease between the

top of the washer and the cabinet.

-

-

3. Lower right front foot until it contacts the

floor. By hand, firmly rotate foot as much

as an additional 1-1/2 turns. The other

three feet have been preset at the fac

tory.

5. If the washer is not level, move the washer out slightly, tip back, prop up the front

of the washer on a wood block. Adjust the

feet up or down as necessary by twisting

-

the feet. Repeat steps 1 through 4 until

washer is level.

6. Use a 9/16˝ or 14 mm open-end wrench

to turn the locknut counterclockwise on

the foot tightly against the washer cabi

net.

IMPORTANT: If the locknut is not tight against

the washer cabinet, the washer may vibrate.

-

2-8

Page 19

COMPLETE INSTALLATION

WARNING

1. Check the electrical requirements. Be

sure that you have the correct electrical

supply and the recommended grounding

method. See “Electrical Requirements,”

page 2-4.

2. Check that all parts are now installed. If

there is an extra part, go back through the

steps to see which step was skipped.

3. Check that you have all of your tools.

4. Keep the foam packing ring from the

washer tub for future relocation of the

washer. Dispose of or recycle all other

packaging materials.

5. Check that the water faucets are on.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can

result in death, fire, or electrical shock.

6. Check for leaks around faucets and inlet

hoses.

7. Plug into a grounded 3 prong outlet.

8. Remove any protective film or tape remaining on the washer.

9. Read “Washer Use,” page 3-3.

10. To test and to clean your washer, mea

sure 1/2 of the detergent manufacturer’s

recommended amount of powdered or

liquid detergent for a medium size load

and pour it into the detergent dispenser.

Close the lid. Press POWER. Select a

normal cycle and press Start. Allow it to

complete one whole cycle.

-

2-9

Page 20

— NOTES —

2-10

Page 21

PRODUCT OPERATION

THEORY OF OPERATION

INTRODUCTION

The Bravos™ Automatic Washer represents a

new design that differs from the traditional top

load machine. This washer operates without a

transmission, motor coupler, belt, basket drive

tube, or brake assembly.

NEW COMPONENTS

The washer has the following new components:

Drive Motor—The drive motor is an electronically commutated direct drive 3-phase brush

less DC design that moves the impeller/agitator

and spin basket without the use of a transmis

sion. The motor is comprised of a stator that

is bolted to the base of the washer tub and a

rotor that is attached to the drive shaft. The

motor direction and speed is controlled by the

machine/motor controller, and is monitored by

a rotor position sensor, (RPS), located on the

stator.

Recirculation PumpDrain Pump

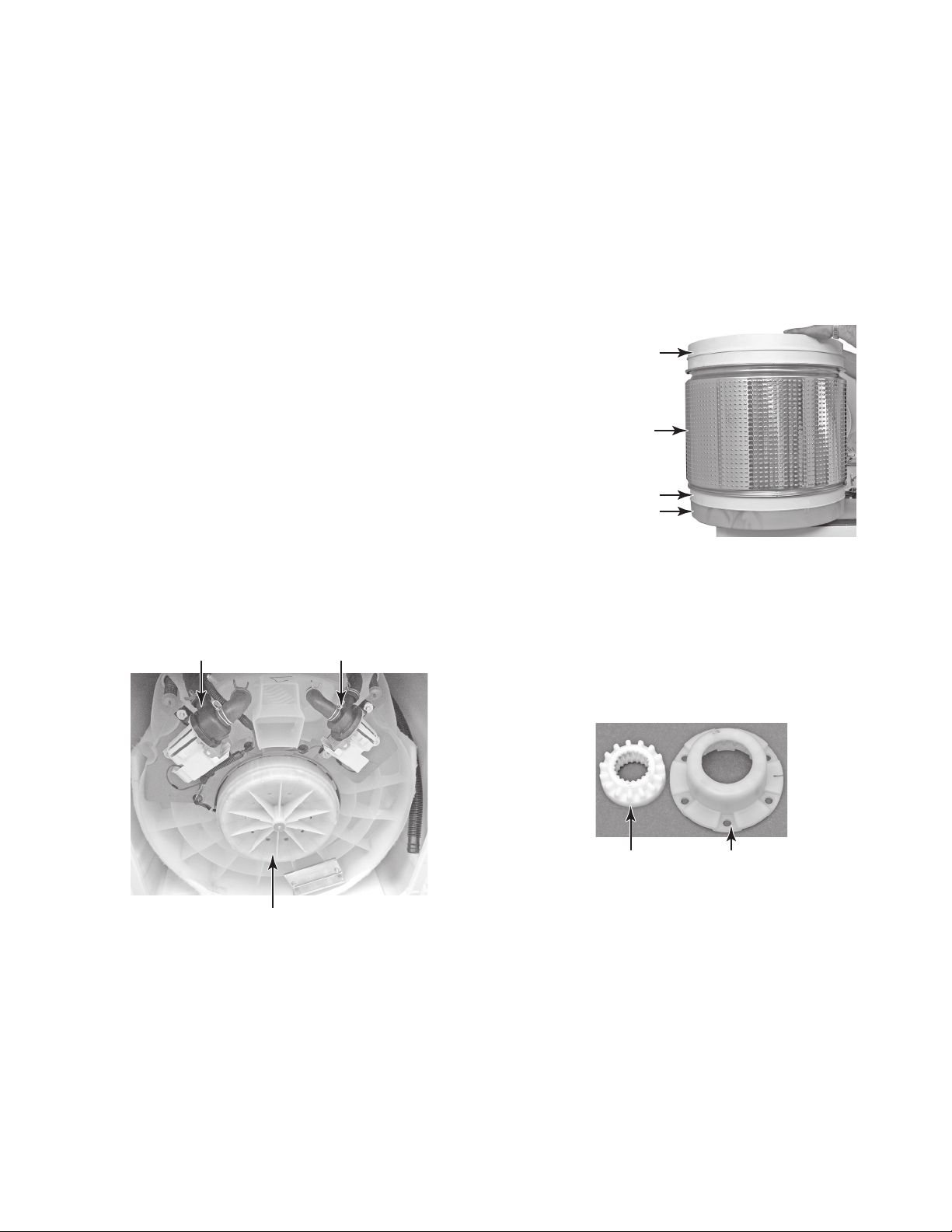

Basket—The basket is designed with a tra

ditional balance ring at the top and a flotation

chamber at the base. The outside surface of

the basket is punched to allow lint to catch on

the holes during the wash cycle. When the

water drains, the lint will be flushed off and

out the drain.

Balance Ring

-

-

Flotation Chamber

Basket Hub—The basket hub consists of two

splined components that engage or disengage

based on the position of the basket in the

vertical direction. The outer hub component

is fastened to the bottom of the basket, while

the inner component is attached to the end of

the drive shaft.

Basket

Balance Ring

-

Drive Motor

3-1

Inner Hub

(Drive Shaft)

Continued on the next page.

Outer Hub

(Basket)

Page 22

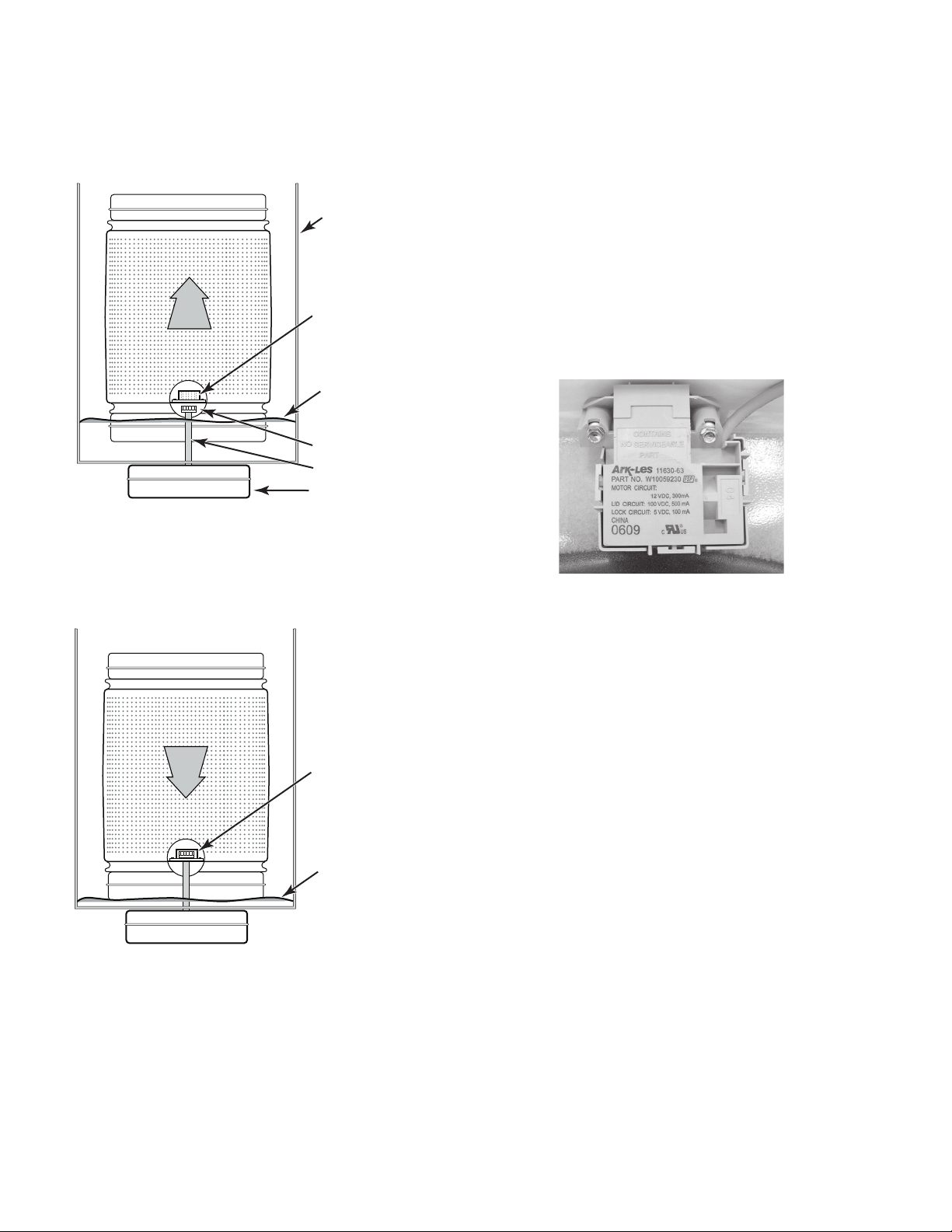

As the tub fills with water, the basket begins to

float and to rise. The splined hub components

now separate, and allow the basket to move

independently of the drive shaft.

Tub

Outer Basket Hub

Disengages

Water Level

Rises & Basket

Floats

Inner Hub Free

Drive Shaft

(Drive Motor)

When the tub drains, the basket drops back to

it’s original position, and the hub components

re-engage, connecting the basket to the shaft,

and permitting the basket to spin.

Lid Lock Mechanism—Since this washer

does not utilize a brake, a lid lock is used to

prevent access during the spin cycles. During

the drain and spin portions of the cycle, a lid

lock mechanism will lock the lid. The lid locks

are based on cycle phase. In general, the lid

locks when the basket spins greater than 23

rpm. After main wash, the lid is locked, and

remains locked until the end of the cycle. The

lid must be closed for the machine to fill, wash,

drain, or spin. Magnets in the washer lid close

a reed switch in the lid lock. This acts as the

lid switch.

Outer Basket Hub

Re-engages With Inner

Drive Shaft Hub

Water Level Drains

& Basket Drops

3-2

Page 23

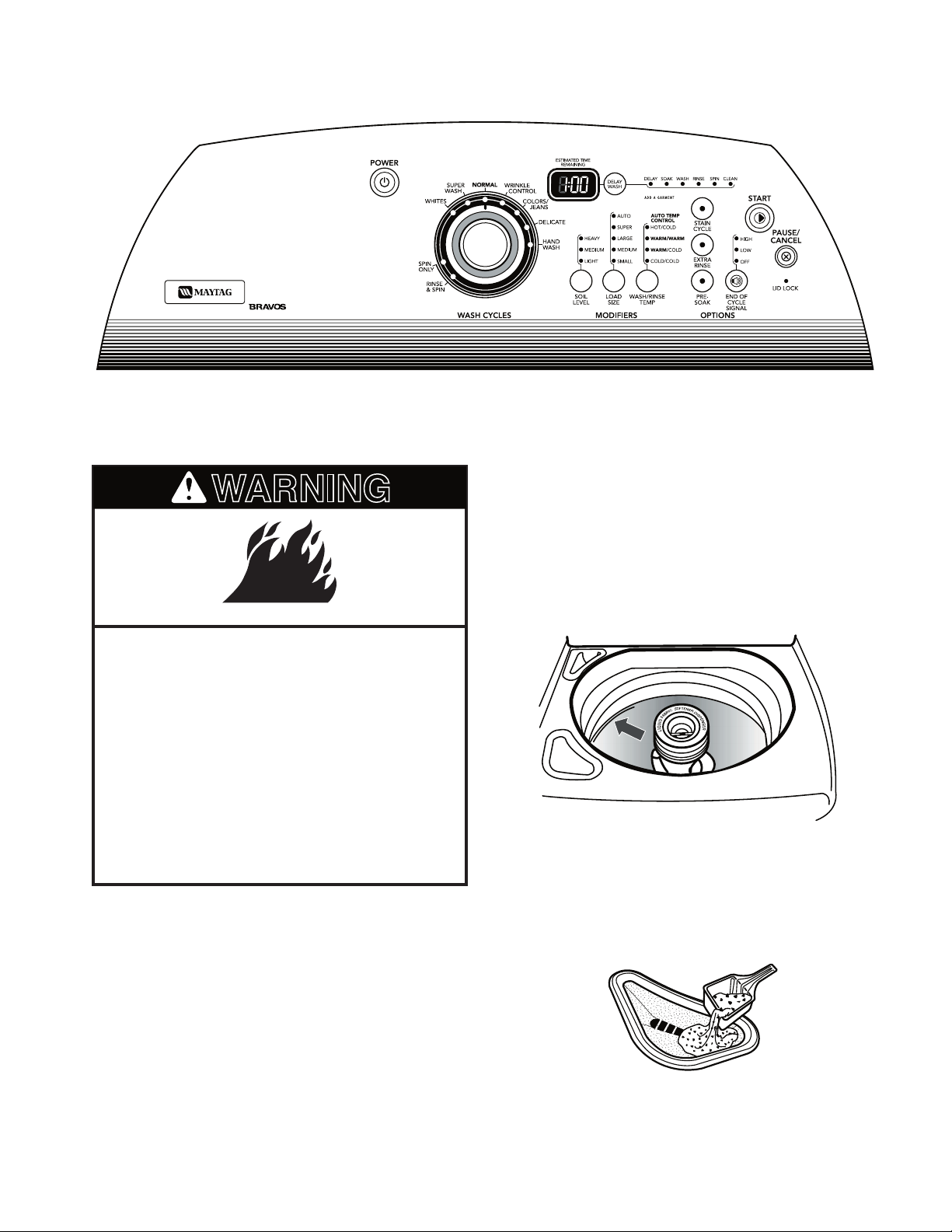

WASHER USE

WARNING

NOTE: Your washer model may differ slightly.

STARTING THE WASHER

Fire Hazard

Never place items in the washer that

are dampened with gasoline or other

flammable fluids.

No washer can completely remove oil.

Do not dry anything that has ever had

any type of oil on it (including cooking

oils).

Doing so can result in death, explosion,

or fire.

The following is a guide to starting your washer.

Periodic references to other sections of this

manual provide more detailed information.

1. Place a load of sorted clothes into the

washer.

•

Load evenly to maintain washer bal

ance. Mix large and small items.

Load only to the top of the basket as

•

shown. Overloading can cause poor

cleaning. Items should move easily

through the wash water.

2. Pour measured powdered or liquid detergent into the detergent dispenser. Do not

put detergent directly into the wash tub or

onto clothes in the washer.

-

3-3

Page 24

3. Add color-safe bleach, (powdered or liquid)

to the detergent dispenser, if needed. Be

sure to match powdered color-safe bleach

with powdered detergent or match liquid

color-safe bleach with liquid detergent.

4. Pour measured liquid chlorine bleach into

the liquid chlorine bleach dispenser, if

needed. Bleach is automatically dispensed

at the proper time during the wash cycle.

Do not overfill. Do not dilute. Do not use

•

more than 1 cup (250 mL) for a full load.

Use less with a smaller load size.

Follow the garment and the chlorine

•

bleach manufacturer’s directions for

proper use.

To avoid spilling, use a cup with a pour

•

ing spout. Do not let bleach splash, drip,

or run down into the washer basket.

At the end of the cycle, a small amount

•

of water may be left in the dispenser.

This is normal.

NOTE: Use only liquid chlorine bleach

in this dispenser.

5. Pour measured liquid fabric softener into

the fabric softener dispenser, if desired.

IMPORTANT: Dilute all fabric softener with

water for a total of 1/2 cup (118 mL).

NOTES:

Use only liquid fabric softener in this

•

dispenser.

Do not use fabric softener dispensing

•

balls in this washer. Dispensing balls will

not operate correctly with this washer.

6. Close the washer lid.

7. Press POWER. This turns on the washer

display.

8. Select a Wash Cycle. See “Cycles,” page

3-6.

9. Adjust the Modifiers, if desired. See “Modifiers,” page 3-8.

10. Select desired Options. See “Options,”

page 3-9.

11. Select Delay Wash, if desired. See “Delay

Wash,” page 3-9 in the “Modifiers” sec

tion.

12. Press START. The wash cycle begins, and

the display shows the estimated remaining

-

time. The lid will lock.

NOTE: If you do not press Start within 5

minutes of pressing Power, the washer

automatically drains and shuts off.

PAUSING OR RESTARTING

THE WASHER

ADD A GARMENT

You can place additional clothing in the wash

when the “Add a Garment” status light is glow

ing without sacrificing wash performance.

To add a garment or pause the washer at

any time:

-

-

Do not overfill. The dispenser holds

•

1/2 cup (118 mL).

Do not spill or drip any fabric softener

•

onto the clothes.

1. Press PAUSE/CANCEL once.

2. Wait until the Lid Lock light turns off, then

open the lid.

3. Add items.

3-4

Page 25

To restart the washer:

1. Close the lid and press START.

2. To unlock the lid after the Add a Garment

period, press PAUSE/CANCEL once.

Pressing PAUSE/CANCEL twice will can

cel the wash cycle.

STOPPING THE WASHER

You can stop the wash cycle and drain the tub

by pressing the PAUSE/CANCEL button twice

or the Power button once.

CHANGING CYCLES, MODIFIERS

AND OPTIONS

You can change Cycles, Modifiers and Options

anytime before Start is pressed. Not all Modifiers

and Options are available for all cycles.

A short tone sounds when a change is se-

•

lected.

Three short tones sound if an unavailable

•

combination is selected. The last selection

will not be accepted.

CHANGING CYCLES AFTER PRESSING

START

CHANGING MODIFIERS AND OPTIONS

AFTER PRESSING START

You can change a Modifier or Option anytime

before the selected Modifier or Option begins

by choosing the desired Modifiers and/or Op

tions.

NOTE: An error tone will sound if your selection is unavailable.

TO MANUALLY DRAIN THE WASHER AND

SPIN THE LOAD

1. Press PAUSE/CANCEL twice to cancel

the wash cycle and drain the washer.

2. Press POWER.

3. Turn knob to select DRAIN & SPIN.

4. Press START.

When the spin is complete, the lid unlocks.

Items can be removed from the washer.

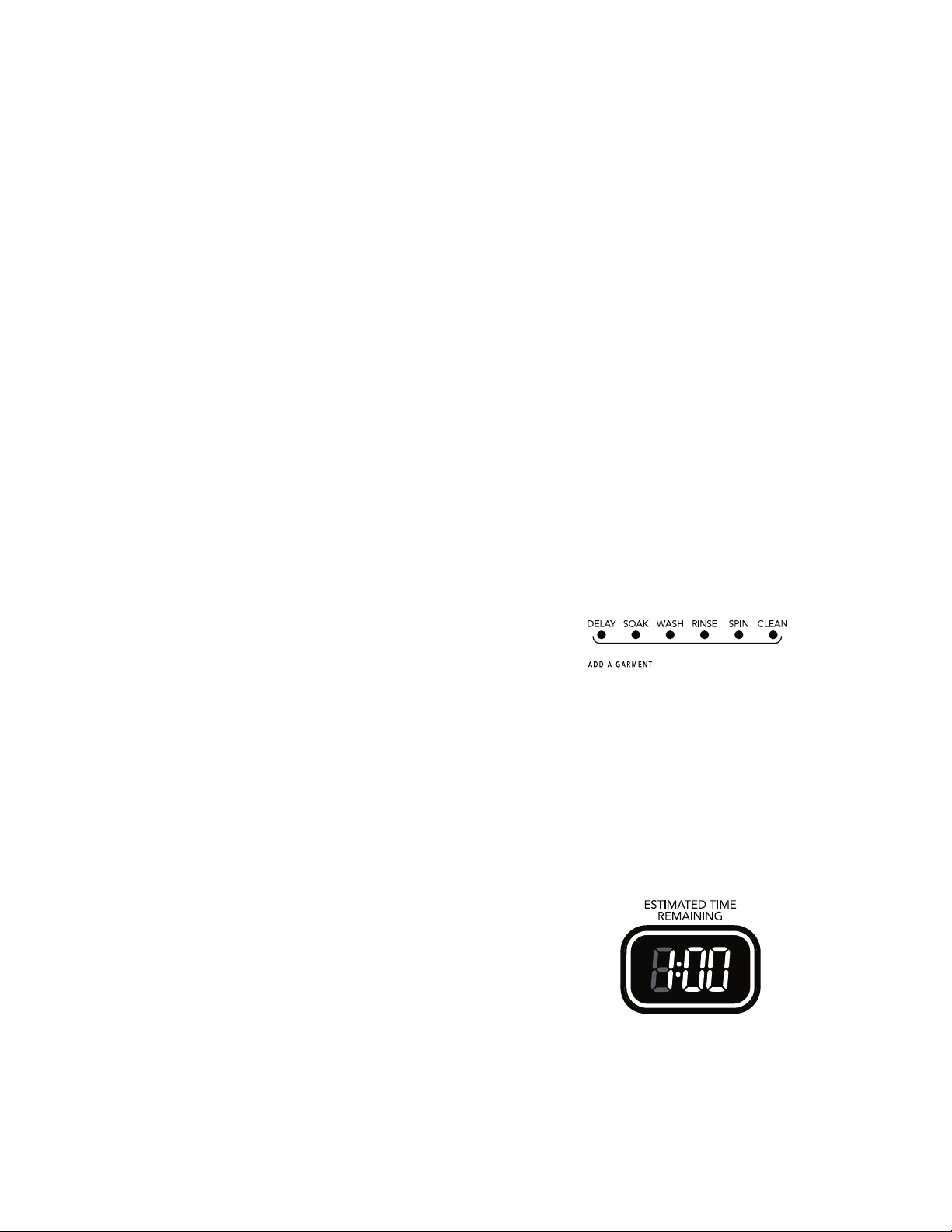

STATUS LIGHTS

These lights show which portion of the cycle the

washer is operating. They also indicate when

you can add other garments to the wash load.

-

1. Press PAUSE/CANCEL twice to cancel

the cycle. The washer will drain.

2. Press POWER.

3. Select the desired wash cycle.

4. Select the desired Modifiers and Op

tions.

5. Press START.

The washer restarts at the beginning of the

new cycle.

NOTE: If you do not press Start within 5 minutes

of pausing the washer, the washer automati

cally shuts off.

INDICATOR LIGHTS

An indicator light shows which Cycle, Modifiers

and Options you have selected.

-

ESTIMATED TIME REMAINING

When a wash cycle is started, the estimated

time remaining for the cycle, including fills and

drains, will be displayed. The time will count

down to the end of the cycle.

-

3-5

Page 26

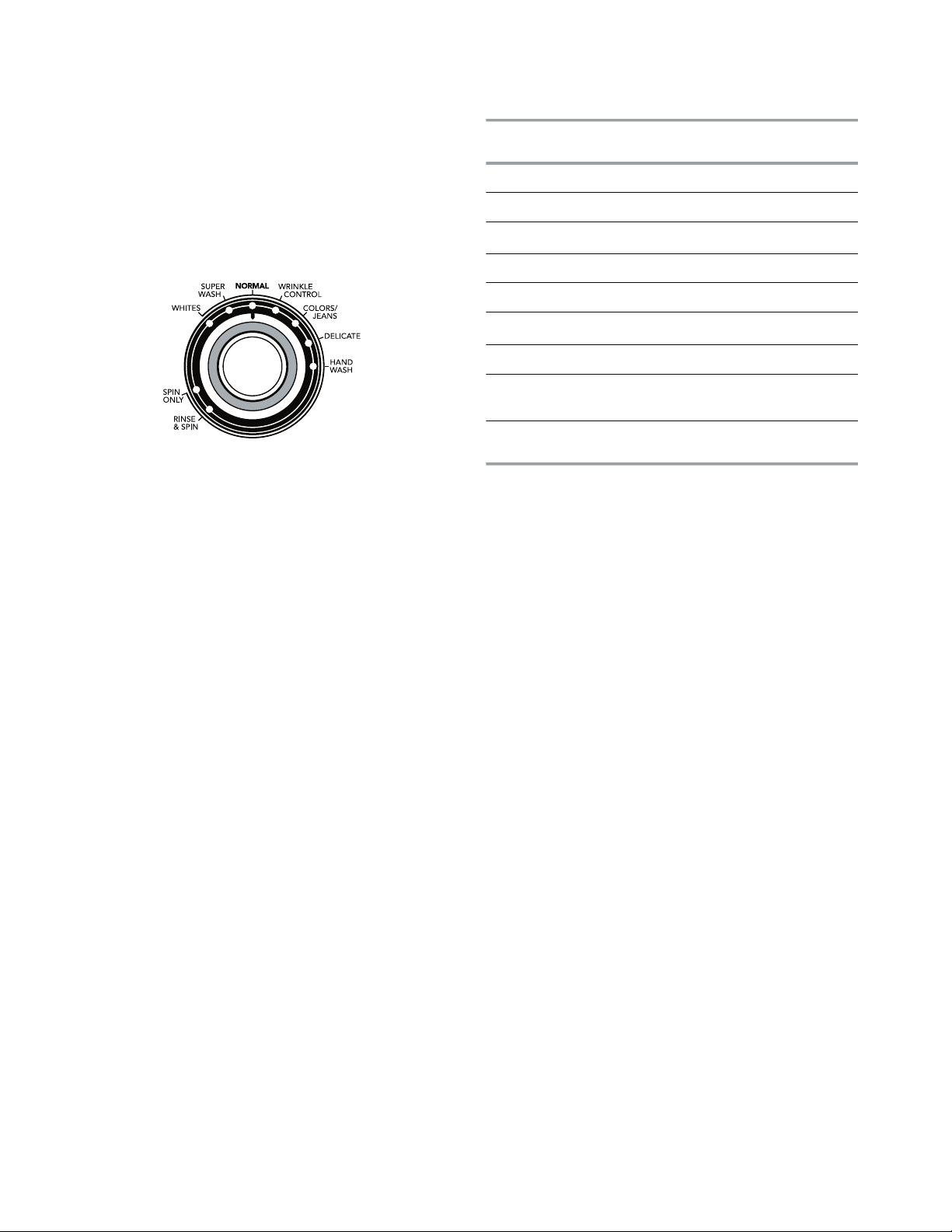

CYCLES

Cycle Preset

Minute

s

Soil

Level

*

Wash/Rinse

Temp

Wh

ites 73 Heavy Hot/Cold

Super Wash

68 Heavy Hot/Cold

Normal

46 Normal Warm/Cold

Wrinkle Control

46 Medium Warm/Cold

Colors/Jean

s 45 Normal Cold/Cold

Delicate 35 Medium Warm/Cold

Handwash

36 Light Cold/Cold

Rinse & Spin

33 Not

applicable

Not

applicable

Spin Only

16 Not

applicable

Not

applicable

Turn the knob to choose the right wash cycle

for the type of fabrics you are washing. When

the knob points to a cycle, the indicator light

for the cycle will glow. If the default settings

for the Modifiers and Options are suitable for

your wash load, you may press Start to begin

the wash cycle.

PRESET CYCLE SETTINGS

PRESET CYCLE SETTINGS

For ease of use, preset cycle settings provide

the recommended fabric care settings for each

cycle.

To use the preset cycle settings:

1. Press POWER.

2. Select the cycle you want by turning the

knob. The preset cycle settings will be

displayed (see the following chart).

NOTE: The preset cycle times may vary

slightly depending on your model.

3. Press START. The wash cycle will begin.

* Cycle time in minutes will appear in the display while

you are making selections. The total cycle time will

appear, including an estimated time for drain and fill

times, once Start is pressed.

NOTE: Load only to the top of the basket.

Overloading can cause poor cleaning. See

“Starting The Washer,” page 3-3.

WHITES

This cycle introduces liquid chlorine bleach

to the load at the proper time for improved

whitening of your heavily soiled white fabrics.

Cycle combines high-speed wash action and

high-speed spin. The default option setting for

this cycle is Extra Rinse to thoroughly remove

detergent and bleach. For maximum soil and

stain removal, liquid chlorine bleach should

be used.

3-6

Page 27

SUPER WASH

HANDWASH

Use this cycle for heavily soiled cotton or sturdy

items. Cycle combines high-speed wash action

and high-speed spin. Stain Cycle is the default

option for this cycle, but it may be turned off.

See “Changing Cycles, Modifiers and Options,”

page 3-5.

NORMAL

Use this cycle for normally soiled cottons and

linens, such as sheets, blankets, and towels.

This cycle combines medium-high speed wash

action and high-speed spin.

WRINKLE CONTROL

Use this cycle to wash loads of no-iron fabrics

such as sport shirts, blouses, casual business

clothes, permanent press and blends. This

cycle uses medium-speed wash action, a me

dium-speed spin and a cool down process to

reduce wrinkling.

COLORS / JEANS

Use this cycle for dark or highly dyed natural

fabrics such as jeans or other cotton items

that may be susceptible to dye loss. This cycle

uses low to medium-speed wash action and

high-speed spin. For best results use cold or

warm water.

DELICATE

Use this cycle to clean lightly soiled special

care garments or for items labeled as “Machine

Washable Wool.” (Check label instructions to

make sure that the garment is washable.) This

cycle uses intermittent-low speed wash action

and low-speed spin for the gentlest fabric care

with less wrinkling.

When washing waterproof items, such as plastic-lined mattress pads, shower curtains, tar

paulin (tarps) or waterproof or water-resistant

sleeping bags, use the Delicate or Handwash

cycle with the lowest spin speed setting avail

able for the washer model that you have.

Garments are labeled “Handwash” be

cause:

-

The fiber construction may be sensitive to

•

wash action.

The fabric contains sensitive dyes that may

•

bleed.

NOTE: Some “Handwash” items naturally

shrink when washed. Keep this in mind when

you purchase items labeled “Handwash.”

Items that shrink should be dried flat. When

these items are still wet, “block” them by

gently stretching to the original measure

ments.

-

-

-

-

Use this cycle to wash lightly soiled garments

indicating “Machine Washable Silks” or “Gentle”

cycle on the care label. This cycle uses lowspeed wash action and low spin speeds for

increased fabric care and less wrinkling.

When washing waterproof items, such as plastic-lined mattress pads, shower curtains, tar

paulin (tarps) or waterproof or water-resistant

sleeping bags, use the Delicate or Handwash

cycle with the lowest spin speed setting avail

able for the washer model that you have.

RINSE & SPIN

Use this option to get a deep rinse followed by

a high-speed spin. The time display will include

an estimate of how long it will take to fill and

drain the washer.

-

-

3-7

Page 28

When to use Rinse & Spin:

Wash Water Temperature Suggested Fabrics

Ho

t Whites and pastels

Warm Bright colors

Cold

Colors that bleed or fade

For loads that need rinsing only.

•

For completing a cycle after the power has

•

been off.

To use or change Rinse & Spin setting:

1. Turn knob to RINSE & SPIN until the Rinse

& Spin indicator light glows.

2. Press START

SPIN ONLY

An extra drain and spin may help shorten dry

ing times for some heavy fabrics or specialcare items. Spin Only may also be used for

draining the washer after canceling a cycle or

completing a cycle after a power failure.

To use or change Spin Only setting:

1. Turn knob to SPIN ONLY until the Spin

Only indicator light glows.

For most loads, use the time recommended

•

in the preset cycle settings.

For heavy soil and sturdy fabrics, press Soil

•

Level to select more wash time, if needed.

For light soil and delicate fabrics, press Soil

•

Level to select less wash time, if needed.

LOAD SIZE

This washer automatically selects Auto for the

water level when the cycle is selected. The

Auto feature senses the size of the load and

-

adds the correct amount of water for the load

size. You can also manually change the water

level settings.

WASH/RINSE TEMP

Select a water temperature based on the type

of load you are washing. Use the warmest

wash water safe for fabrics. Follow garment

label instructions.

2. Press START.

MODIFIERS

Modifiers allow you to further customize the

cycles and save energy.

SOIL LEVEL

Soil level (wash time) is preset for each wash

cycle. See “Preset Cycle Settings” in “Cycles.”

As you press the Soil Level pad, the cycle time

(minutes) will increase or decrease in the Esti

mated Time Remaining display and a different

wash time will appear. To get the minimum wash

time, press the pad until the indicator light next

to Light Soil Level illuminates. This is the short

est wash time available for that cycle.

Warm rinses leave the loads drier and more

comfortable to handle than cold rinses. How

ever, warm rinses also increase wrinkling.

Cold rinses may help with wrinkling and save

energy.

TEMPERATURE GUIDE

NOTE: In wash water temperatures colder than

°F (15.6°C), detergents do not dissolve well.

60

Soils may be difficult to remove.

-

-

-

3-8

Page 29

AUTO TEMP CONTROL

elc

yC

nia

tSelcyC

)elcyc

hsaw eh

t ot

e

mi

t

sddA

(

se

ti

hW

noit

p

O

hsaW repu

S tluafeD

lamro

N

no

itp

O

l

o

rtnoC elkn

irW n

o

itp

O

snaeJ/sroloC

noit

pO

Delicate Not Available

Handwash Option

Rinse & Spin Not Available

Spin Only Not Available

To change the Delay Wash time:

Auto Temp Control (ATC) electronically senses

and maintains a uniform wash and rinse wa

ter temperature. ATC regulates incoming hot

and cold water and is automatically turned on

when a cycle is selected. (See “Preset Cycle

Settings,” page 3-6 in “Cycles.”)

ATC is available with Warm/Warm, Warm/Cold

and Cold/ Cold settings. The water temperature

in the Hot/Cold setting depends on the water

temperature at the water inlet faucets.

ATC ensures consistent cleaning.

•

Today’s detergents work well at temperatures

•

above 60°F (15.6°C).

DELAY WASH

You can use the Delay Wash feature to delay

the start of a wash cycle for up to 8 hours (de

pending on your model).

1. Load the washer and fill the dispensers.

2. Close the washer lid.

•

Press PAUSE/CANCEL.

-

•

Press DELAY WASH to select the desired

delay time.

Press START to begin the countdown.

•

To cancel Delay Wash:

Press START again to begin the cycle right

away or press PAUSE/CANCEL twice.

OPTIONS

Use these pads to select the desired options

for your wash cycle.

-

3. Press POWER.

4. Select the desired Cycle, Modifiers and

Options.

5. Press DELAY WASH. 1H (one hour) will be

displayed in the time display window. The

indicator light for Delay Wash will glow.

6. For a longer delay time, press DELAY

WASH. The Start time will increase by

1-hour steps.

7. Press START. The countdown in hours to

the wash cycle will show in the time display

window and the indicator light will begin to

flash.

NOTE: The Start indicator light will not

flash when Delay Wash is chosen. You

must press Start to initiate a countdown

for the cycle to begin.

STAIN CYCLE

This option provides enhanced cleaning action for tough stains. The Super Wash cycle

automatically includes Stain Cycle. Choosing

Stain Cycle will add approximately 10 minutes

to a cycle. Stain Cycle should be started on a

dry load only and cannot be selected after the

tub has started filling with water.

Stain Cycle may be selected as an option with

other cycles. See table for details.

3-9

Page 30

EXTRA RINSE

PAUSE/CANCEL

An extra rinse can be used to aid in the removal

of detergent or bleach residue from garments.

This option provides an additional rinse with

the same water temperature as the first rinse.

This is the default rinse setting for the Whites

cycle.

PRE SOAK

Use this option for set-in stains and soil that

need extra time for removal. Soaking in this

washer is different than in a conventional

washer. The washer sprays the load with water

and detergent at extra-low spin speed followed

by a brief pause. This action is repeated. Pre

Soak cycles through a series of sprays followed

by a pause to allow the detergent to work on

the soils. The Pre Soak feature is followed by

the selected cycle. Using Pre Soak will extend

your wash cycle.

END OF CYCLE SIGNAL VOLUME

The End of Cycle Signal produces an audible

sound when the wash cycle is finished. This

signal is helpful when you are removing items

from the washer as soon as it stops. Select

High, Low, or Off.

OPERATING CONTROLS

Press PAUSE/CANCEL once to pause or stop

the washer at any time. Press PAUSE/CAN

CEL once to unlock the lid and add a garment.

Press START to complete the cycle from where

it was stopped. Press PAUSE/CANCEL twice

to stop the wash cycle. The washer will then

drain and turn off.

LID LOCK

When the Lid Lock status light glows, the washer

lid is locked.

NOTE: You must wait until the lid lock light

turns off before the lid can be opened.

NORMAL SOUNDS

Your new washer may make sounds your old

one didn’t. Because the sounds might be un

familiar, you may be concerned about them.

These sounds are normal.

DURING WASHING

If you select the Stain Cycle option, you will

hear a spin/spray noise at the start of the

cycle.

DURING DRAIN

If water is drained quickly from your washer

(depending on your installation), you may hear

air being pulled through the pump during the

end of draining.

-

-

POWER

Press POWER to turn the washer on or off.

START

Press START to start your washer after a cycle

has been selected. Be sure all desired Modi

fiers and Options have been selected. The lid

must be closed for the washer to start.

DURING WASH AND SPIN

This washer does not have a transmission. The

motor provides direct drive for agitation and

spin. You will hear sounds that are different

from those of a conventional washer.

-

3-10

Page 31

WASHER CARE

CLEANING YOUR WASHER

Use a soft, damp cloth or sponge to wipe up

any spills such as detergent or bleach from the

outside of your washer.

Clean your washer interior by mixing 1 cup (250

mL) of chlorine bleach and 2 cups (500 mL) of

detergent. Pour this mixture into your washer

and run it through a complete cycle using hot

water. Select the Super Load Size. Repeat this

process if necessary.

Remove any hard water deposits using only

cleaners labeled as washer safe.

Cleaning the liquid fabric softener dispenser:

1. To remove the fabric softener dispenser

from the agitator, wrap both hands behind

the top of the fabric softener dispenser

and interlock fingers. Lift up while pulling

toward you.

2. Separate the top and base of the dispenser.

Rinse all three dispenser parts (the base,

the inner cone-shaped cup and the top)

under warm water.

3. For ease of assembly, reassemble the

dispenser with the parts upside down.

WATER INLET HOSES

Replace inlet hoses after 5 years of use to

reduce the risk of hose failure. Periodically in

spect and replace inlet hoses if bulges, kinks,

cuts, wear or leaks are found.

When replacing your inlet hoses, mark the date

of replacement on the label with a permanent

marker.

VACATION, STORAGE, AND

MOVING CARE

Install and store your washer where it will not

freeze. Because some water may stay in the

hoses, freezing can damage your washer. If

storing or moving your washer during freezing

weather, winterize it.

Non-use or vacation care:

Operate your washer only when you are at

home. If you will be on vacation or not using

your washer for an extended period of time,

you should:

Unplug washer or disconnect power.

•

Turn off the water supply to the washer. This

•

helps avoid accidental flooding (due to a water

pressure surge) while you are away.

-

IMPORTANT: Be sure the inner cone-

shaped cup is straight and placed com

pletely in the top of the dispenser before

installing the base.

4. Reinstall the dispenser. Be sure it is completely seated. The rim must be tight to the

top of the agitator.

NOTE: To avoid damage to the washer or cloth

ing, do not wash clothes with the liquid fabric

softener dispenser removed or add detergent

or bleach to this dispenser; it is for liquid fabric

softener only.

To winterize washer:

-

1. Shut off both water faucets.

2. Disconnect and drain water inlet hoses.

3. Put 1 qt (1 L) of R.V.-type antifreeze in the

basket.

4. Run washer on the Rinse & Spin setting

-

for about 30 seconds to mix the antifreeze

and remaining water.

5. Unplug washer or disconnect power.

3-11

Page 32

To use washer again:

WARNING

To transport the washer:

1. Flush water pipes and hoses. Reconnect

water inlet hoses. Turn on both water

faucets.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can

result in death, fire, or electrical shock.

2. Plug in washer or reconnect power.

3. Run the washer using any cycle and a

Super Load Size water level to clean the

washer and remove the antifreeze, if used.

Use 1/2 the manufacturer’s recommended

amount for a medium-size load.

1. Shut off both water faucets.

2. Disconnect and drain water inlet hoses.

3. If the washer will be moved during freez

ing weather, put 1 qt (1 L) of R.V.-type

antifreeze in the basket. Run washer on

the Rinse & Spin setting for about 30 sec

onds to mix the antifreeze and remaining

water.

4. Disconnect the drain from the drain sys

tem.

5. Unplug the power cord.

6. Place the inlet hoses into the basket.

7. Drape the power cord and drain hose over

edge into the basket.

8. Place foam packing ring from the original

shipping materials in the top of washer. If

you do not have the original foam packing

ring, place heavy blankets, towels, etc. into

basket opening. Close the lid and put a

piece of tape over the lid and down to the

front of the washer. Keep lid taped until the

washer is placed into the new location.

Reinstalling the washer

1. Follow the “Installation Instructions,”

page 2-5 to locate, level and connect the

washer.

-

-

-

2. Run the washer using any cycle and a

Super Load Size water level to clean the

washer and remove the antifreeze, if used.

Use 1/2 the manufacturer’s recommended

amount for a medium-size load.

3-12

Page 33

TROUBLESHOOTING

WASHER AND COMPONENTS

Washer displaying code messages

“LF” (Washer is taking too long to fill)

•

Check the following:

Are the water inlet hoses kinked or

clogged?

Are the water inlet valve screens clear?

Press PAUSE/CANCEL to clear display.

Is the drain hose installed properly? See

“Connect the Drain Hose,” page 2-5.

“Ld” (Washer is taking too long to drain

•

water from the wash tub)

Check the following:

Is the drain hose kinked or clogged?

Is the drain hose installed properly? See

“Connect the Drain Hose,” page 2-5. Press

PAUSE/CANCEL to clear display.

“uL” (Unbalanced Load)

•

If the load is unbalanced, the washer will

display this code while running an imbal

anced load correction routine at the end of

the wash cycle and before the final spin. If

the code remains and the wash cycle dial

is flashing after the recovery routine has

stopped, open lid and redistribute the load.

Close lid and press START.

“oL” (Over Load)

•

Is the washer overloaded? The washer has

attempted to fill and begin the wash cycle.

If the washer is overloaded, it will drain any

water and detergent that was added dur

ing the fill. To correct the overload, remove

several items and add detergent. Close lid

and press START.

“Sd” (Suds Detected)

•

Did you add too much detergent?

Always measure detergent. Follow detergent

manufacturer’s directions.

If excessive suds are detected, the washer

will display this code while running a suds

reduction correction routine at the end of

the wash cycle. The suds reduction routine

removes extra suds and assures proper

rinsing of your garments. If the code remains

and the wash cycle dial is flashing after the

recovery routine has stopped, re-select your

desired cycle using cold water. Press START.

Do not add detergent.

“lid” (Lid Opened)

•

Is the lid open? Close the lid to clear the

display.

“HC” (Cold and Hot hoses switched)

•

This code will appear at the end of the wash

cycle to indicate that the cold and hot water

inlet hoses are switched. If an error code

-

-

does not appear but you are experiencing

poor washing performance, check to see

whether the inlet hoses are reversed. See

“Connect the Inlet Hoses,” page 2-6.

“dL” (Door/Lid cannot lock)

•

Indicates lid is not locked. Check for items

caught in the lid keeping it from closing. Press

PAUSE/CANCEL once to clear the code.

“dU” (Door/Lid cannot unlock)

•

Is there excessive weight on the lid, such as

a basket of laundry? Excessive weight will

keep the lid from unlocking. Press PAUSE/

CANCEL once to clear the code.

F _ _ “F##” code

•

Press PAUSE/CANCEL once to clear code.

Press START. If code appears again, call for

service.

3-13

Page 34

Noisy, vibrating, off-balance

Is the washer level? Does the washer rock

•

when pushed against the corners?

The washer must be level. The front and rear

feet must be in firm contact with the floor.

Check that the locknuts are tightened. See

“Level the Washer,” page 2-8.

•

Is the floor flexing, sagging or not level?

Flooring that flexes or is uneven can con

tribute to noise and vibration of the washer.

˝ (1.9 cm) piece of plywood under the

A 3/4

washer will reduce the sounds. See “Loca

tion Requirements,” page 2-2.

Is the load balanced?

•

Evenly distribute the load in the washer

basket and make sure the height of the load

does not exceed the top row of basket holes.

See “Starting The Washer,” page 3-3.

•

Do you hear clicking or other noises when

the cycle changes from washing to drain

ing or spinning?

When the drive system shifts or the washer

basket settles between cycles you may hear

noises that are different from your previous

washer. These are normal washer noises.

Is the washer gurgling or humming?

•

When the washer drains, the pump will make

a continuous humming with periodic gurgling

or surging sounds as the final amounts of

water are removed. This is normal.

Are you washing a small load?

•

You will hear more splashing sounds when

washing small loads. This is normal.

•

The washer basket moves while wash

ing.

This is normal.

Washer leaks

Are the fill hoses tight?

•

•

Are the fill hose washers properly seated?

Check both ends of each hose. See “Connect

the Inlet Hoses,” page 2-6.

•

Did you pull the drain hose from the

washer cabinet and install it in a standpipe

-

-

-

-

or laundry tub?

The drain hose should be pulled from the

washer cabinet and secured to the drainpipe

or laundry tub. See “Connect The Drain

Hose,” page 2-5, and “Secure the Drain

Hose,” page 2-7.

Is the sink or drain clogged?

•

Sink and drainpipe must be able to carry

away 17 gal. (64 L) of water per minute. If

sink or drainpipe is clogged or slow, water

can back up out of drainpipe or sink.

•

Is water splashing off the tub ring or the

load?

The wash load should be balanced and not

overloaded. If the wash load is unbalanced

or overloaded, incoming water can deflect

off the load.

Is the washer properly installed?

•

The washer must be level. The feet should

be properly installed and the nuts tightened.

See “Level the Washer,” page 2-8.

•

Was the cycle interrupted and then the

Stain Cycle option selected?

The Stain Cycle option should be started

on a dry load only. The Stain Cycle option

cannot be selected after the tub has started

filling with water.

•

Check household plumbing (laundry

tubs, faucets, drainpipe, water pipes) for

leaks.

3-14

Page 35

Dispenser operation

WARNING

Are the laundry additives in the correct

•

dispensers?

Add the correct amounts of detergent (pow-

dered or liquid), liquid chlorine bleach, or

fabric softener to the correct dispenser. You

can add powdered or liquid color-safe bleach

to the detergent dispenser. Be sure to match

powdered color-safe bleach with powdered

detergent or match liquid color-safe bleach

with liquid detergent. Use only liquid chlorine

bleach in the bleach dispenser.

•

Is there water remaining in the bottom

of a dispenser? Did the dispenser drain

properly?

A small amount of water may be left in a

dispenser at the end of the cycle. This is

normal.

•

Did you put powdered or liquid color-safe

bleach into the liquid chlorine bleach

dispenser (on some models)?

Add powdered or liquid color-safe bleach

directly to the detergent dispenser. Do not

use the chlorine bleach dispenser for colorsafe bleach.

•

Is the fabric softener dispenser clogged?

Clean the fabric softener dispenser. See

“Washer Care,” page 3-11.

WASHER OPERATION

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can

result in death, fire, or electrical shock.

Washer won’t fill, rinse or agitate; washer

stops

Is the power cord plugged into a grounded

•

3 prong outlet?

Plug power cord into a grounded 3 prong

outlet.

Are you using an extension cord?

•

Do not use an extension cord.

Is there power at the plug?

•

Check electrical source or call electrician.

•

Is the indicator on the Cycle control knob

properly lined up with a cycle?

Turn the Cycle control knob to the right

slightly.

•

Are the water inlet valve screens clogged?

Turn off the water and remove inlet hoses

from the washer. Remove any accumulated

film or particles. Reinstall hoses, turn on water

and check for leaks.

•

Are the hot and cold water faucets turned

on?

Turn on the water.

3-15

Page 36

Is the water inlet hose kinked?

•

Straighten the hoses.

•

Does the water level seem too low, or

does the washer appear to not fill com

pletely?

The Auto Water Level feature senses the size

of the load and adds the correct amount of

water for the load size. A different water level

may be selected by pressing LOAD SIZE.

•

Are you using Auto Water Level?

The Auto feature senses the size of the load

and adds the correct amount of water for the

load size.

•

Has a household fuse blown, or has a

circuit breaker tripped?

Replace the fuse or reset the circuit breaker. If

the problem continues, call an electrician.

•

Is the washer in a normal pause in the

cycle?

The washer may pause during certain cycles.

Allow the cycle to continue.

Is the washer overloaded?

•

Wash smaller loads. See “Starting The

Washer,” page 3-3 for maximum load size.

Washer continues to fill or drain, or the

cycle seems stuck

Is the top of drain hose lower than the

•

control knobs on washer?

The top of the drain hose must be at least

39˝ (99 cm) above the floor. See “Drain

System,” page 2-3.

•

Does the drain hose fit too tightly in the

standpipe, or is it taped to the stand

pipe?

The drain hose should be loose yet fit se-

curely. Do not seal the drain hose with tape.

The hose needs an air gap. See “Installation

Instructions,” page 2-5.

Washer won’t drain or spin; water remains

in washer

Is the drain hose clogged, or the end of

•

the drain hose more than 96

above the floor?

See “Drain System,” page 2-3.

Is the lid open?

•

The lid must be closed during operation. The

washer will not operate with the lid open.

˝ (244 cm)

-

Is there oversudsing?

•

Cancel the current cycle. Select SPIN ONLY

to drain the load. Re-select your desired cycle

and press START. Do not add detergent. Use

cold water.

Is the lid open?

•

The lid must be closed during operation. The

washer will not operate with the lid open.

•

Did you add more items to the load once

the washer started?

Once the load is wet, there may appear to be

space for more items. Do not add more than

1 or 2 garments after the cycle has started.

For best results determine load size with dry

items only.

Wash/Rinse temperature

Are the hot and cold water inlet hoses

•

reversed?

If the hot and cold water inlet hoses are re-

versed, the washer will display an “HC” error

code at the end of the cycle. If an error code

does not appear but you are experiencing

poor washing performance, check to see

whether the inlet hoses are reversed. See

“Connect the Inlet Hoses,” page 2-6.

Are you washing many loads?

•

As your frequency of loads washed increases,

the water temperature may decrease for hot

and warm temperatures. This is normal.

3-16

Page 37

Do you have an ENERGY STAR® qualified

•

washer?

The wash water temperatures may feel cooler

to you than those of your previous washer.

This is normal.

•

Does the wash water temperature feel

lower than usual?

As washing progresses, the wash tempera-

ture will decrease slightly for hot and warm

washes. This is normal.

To reduce wrinkling, the warm rinse is regu

lated to be cooler than the warm wash.

Did you use a cold rinse?

•

Cold rinses leave loads wetter than warm

rinses. This is normal.

Did you wash an extra large load?

•

A large unbalanced load could result in a

reduced spin speed and wet clothes at the

end of the cycle. Evenly distribute the load

and make sure the height of the load does

not exceed the top row of basket holes.

Residue or lint on load

-

Did you sort properly?

•

Excessive sudsing

Is there excessive sudsing?

•

Always measure detergent. Follow deter-

gent manufacturer’s directions. If you have

very soft water, you might need to use less

detergent.

•

Was the cycle interrupted and then the

Stain Cycle option selected?

The Stain Cycle option should be started

on a dry load only. The Stain Cycle option

cannot be selected after the tub has started

filling with water.

Cycle did not run Stain Cycle option

Did you select the Stain Cycle option?

•

The Stain Cycle option must be selected for

it to be included in a wash cycle. The Stain

Cycle option should be started on a dry load

only. Stain Cycle cannot be selected after

the tub has started filling with water.

The Stain Cycle option is a default in the

Super Wash cycle and may be added to

other cycles.

CLOTHING CARE

Sort lint givers (towels, chenille) from lint

takers (corduroy, synthetics). Also sort by

color.

Did you overload the washer?

•

The wash load must be balanced and not

overloaded. Clothes should move freely. Lint

or powdered detergent can be trapped in

the load if the washer is overloaded. Wash

smaller loads. See “Starting The Washer,”

page 3-3 for maximum load size.

Did you use enough detergent?

•

Follow detergent manufacturer’s directions.

Use enough detergent to hold the lint in the

water.

Did you line dry your clothing?

•

If so, you can expect some lint on the clothing.

The air movement and tumbling of a dryer

removes lint from the load.

•

Was paper or tissue left in pockets?

Is your water colder than 60°F (15.6°C)?

•

Wash water colder than 60°F (15.6°C) may

not completely dissolve the detergent.

•

Did you use the proper Soil Level and

Wash Cycle for the load?

Load too wet

Did you use the right cycle for the load

•

being washed?

Select a cycle with higher spin speed.

Reducing wash time (duration) and wash

speed are ways to reduce lint.

•

Did you add detergent to the dispenser?

For best results, use the dispenser to dis

solve the detergent.

3-17

-

Page 38

Load is wrinkled, twisted or tangled

Did you unload the washer promptly?

•

Unload the washer as soon as it stops.

•

Did you use the right cycle for the load

being washed?

To reduce wrinkling, tangling and twisting,

select a cycle with low wash and spin speeds,

such as Delicate or Handwash/Wool.

Did you overload the washer?

•

•

Did you use enough detergent, or do you

have hard water?

Use more detergent for washing heavy soils

in cold or hard water. Water temperature

should be at least 60

dissolve and work properly. For best perfor

mance, use the detergent manufacturer’s

recommended amounts.

•

Did you follow the manufacturer’s direc

tions when adding detergent and fabric

softener?

°F (15.6°C) for soap to

-

-

The wash load must be balanced and not

overloaded. Loads should move freely during

washing to reduce wrinkling, tangling and

twisting.

•

Was the wash water warm enough to relax

wrinkles?

If safe for the load, use warm or hot wash

water. Use cold rinse water.

•

Are the hot and cold water hoses re

versed?

A hot rinse followed by spin will cause wrin-

kling. Check that the hot and cold water hoses

are connected to the correct faucets. If the

hot and cold water inlet hoses are reversed,

the washer will display an “HC” error code

at the end of the cycle. If an error code does

not appear but you are experiencing poor

washing performance, check to see whether

the inlet hoses are reversed. See “Connect

the Inlet Hoses,” page 2-6.

Measure detergent and fabric softener. Use

enough detergent to remove soil and hold

it in suspension. Dilute fabric softener and

add to the rinse portion of a cycle only. Do

not drip fabric softener onto clothes.

•

Is there above average iron (rust) in water?

You may need to install an iron filter.

•

Did you add detergent to the dispenser?

-

For best results, use the dispenser to dis

solve the detergent.

•

Did you add fabric softener directly to

the load?

Use your fabric softener dispenser. Do not

drip fabric softener onto clothes.

•

Did you use a fabric softener dispensing

ball?

Use the fabric softener dispenser provided

with the washer. Dispensing balls will not

operate correctly with this washer.

-

Stains, gray whites, dingy colors

Did you properly sort the load?

•

Dye transfer can occur when mixing whites

and colors in a load. Sort dark clothes from

whites and lights.

•

Was the wash temperature too low?

Use hot or warm washes if safe for the load.

Make sure your hot water system is adequate

to provide a hot water wash.

Did you unload the washer promptly?

•

To avoid dye transfer, unload the washer as

soon as it stops.

•

Did you add detergent, chlorine bleach or

fabric softener too late in the cycle?

Detergent, chlorine bleach, and fabric soft-

ener should be added to the dispensers

before starting the washer.

3-18

Page 39

Garments damaged

Were sharp items removed from pockets

•

before washing?

Did you overload the washer?

•

The wash load must be balanced and not

overloaded. Loads should move freely during

washing.

Empty pockets, zip zippers, snap or hook

fasteners before washing to avoid snagging

and tearing of load.

•

Were strings and sashes tied to avoid

tangling?

Straps and strings can easily become en-

tangled in the load, causing strain on seams

and tearing.

•

Were items damaged before washing?

Mend rips and broken threads in seams

before washing.

Did you add chlorine bleach properly?

•

Do not pour chlorine bleach directly onto load.

Wipe up bleach spills. Undiluted bleach will

damage fabrics. Do not place load items on

top of the bleach dispenser when loading

and unloading the washer (on some models).

Do not use more than the manufacturer’s

recommended amount for a full load.

•

Did you follow the garment manufactur

er’s care label instructions?

-

3-19

Page 40

— NOTES —

3-20

Page 41

COMPONENT ACCESS

This section instructs you on how to service each component inside the Bravos™ Automatic

Washer. The components and their locations are shown below.

COMPONENT LOCATIONS

CONSOLE & TOP CABINET COMPONENTS

User Interface

Board & Encoder

Power

Supply Cord

Water Inlet/

Dispenser

Valve Assy.

Lid Lock

Detergent

Dispenser

Liquid Bleach

Dispenser

DISPENSER & BASKET COMPONENTS

Lid Hinge

Fresh Fill

Inlet Valve

Right

Tub Ring

Machine/Motor

Control & Pressure

Transducer

Agitator

Bottom Of Tub

Basket

Tub

Drive Motor

Drain Pump

Recirculation Pump

BOTTOM COMPONENTS

4-1

Page 42

REMOVING THE ENCODER AND

WARNING

THE USER INTERFACE BOARD

Electrical Shock Hazard