Page 1

INSTALLATION

Before the dryer is removed from service or discarded,

INSTRUCTIONS

ORIGINAL INSTRUCTIONS

COmmeRCIAL STACked

WASheR/dRyeR

GAS OR eLeCTRIC

INSTRUCTIONS

D’INSTALLATION

INSTRUCTIONS ORIGINALES

LAve-LINGe/SèChe-LINGe SUpeRpOSéS

à USAGe COmmeRCIAL

à GAz OU éLeCTRIqUe

MLE22PD

MLE22PN

MLG22PD

MLG22PN

INSTRUCCIONES

DE INSTALACIÓN

INSTRUCCIONES ORIGINALES

LAvAdORA/SeCAdORA

COmeRCIALeS ApILAdAS

A GAS O eLéCTRICAS

ISTRUZIONI

D’INSTALLAZIONE

ISTRUZIONI ORIGINALI

LAvATRICe/ASCIUGATRICe

COmmeRCIALe A COLONNA

A GAS O eLeTTRICA

www.maytagcommerciallaundry.com W10920982A

Page 2

TABLE OF CONTENTS

Page

Stacked Washer/Dryer Safety .................................................. 3

Stacked Washer/Dryer Disposal ............................................... 6

Tools & Parts .................................................................................. 7

Alternate Parts and Accessories ............................................... 8

Specifications ................................................................................. 8

Dimensions/Clearances ............................................................. 9

Stacked Washer/Gas Dryer Installation Requirements ... 10

Stacked Washer/Electric Dryer

Installation Requirements ........................................................ 13

Dryer Venting Requirements ................................................... 15

Dryer Gas Supply Requirements ............................................ 17

Installing Stacked Washer/Dryer ............................................ 18

Washer Drain System ................................................................ 21

Leveling ......................................................................................... 22

Complete Installation ................................................................ 23

Reversing Dryer Door Swing ................................................... 23

Stacked Washer/Dryer Maintenance Instructions ............ 26

If You Need Assistance ............................................................. 27

Technical Specifications – Gas Dryer ................................... 28

Electronic Control Setup Instructions .................................. 30

Warranty ........................................................................................ 36

ÍNDICE

Página

Seguridad de la lavadora/secadora apiladas ...................... 74

Eliminación de la lavadora/secadora apiladas .................. 77

Herramientas y piezas ................................................................ 78

Piezas y accesorios adicionales ............................................. 79

Especificaciones ............................................................................ 79

Dimensiones y espacios libres ................................................ 80

Requisitos de instalación de la lavadora/secadora

a gas apiladas ............................................................................... 81

Requisitos de instalación de la lavadora/

secadora eléctricas apiladas ................................................... 84

Requisitos de ventilación de la secadora ............................ 86

Requisitos del suministro de gas de la secadora .............. 89

Instalación de la lavadora/secadora apiladas .................... 90

Sistema de desagüe de la lavadora ........................................ 93

Nivelación .......................................................................................94

Complete la instalación ............................................................. 95

Cómo invertir el cierre de la puerta de la secadora ...........95

Instrucciones de mantenimiento

de la lavadora/secadora apiladas ...........................................98

Si necesita ayuda .........................................................................99

Especificaciones técnicas – secadora a gas ..................... 100

Instrucciones de programación

del control electrónico ............................................................. 102

Garantía ....................................................................................... 109

TABLE DES MATIÈRES

Page

Sécurité du lave-linge/sèche-linge superposés ................. 37

Élimination du lave-linge/sèche-linge superposés ........... 41

Outils et pièces ............................................................................ 42

Pièces supplémentaires et accessoires ................................ 43

Spécifications .................................................................................43

Dimensions/Distances de dégagement ................................ 44

Exigences d’installation pour

le lave-linge/sèche-linge à gaz superposés ........................ 45

Exigences d’installation pour le lave-linge/sèche-linge

électriques superposés ............................................................. 48

Exigences concernant l’évacuation du sèche-linge .......... 50

Spécifications de l’alimentation en gaz

du sèche-linge .............................................................................. 53

Installation du lave-linge/sèche-linge superposés ........... 54

Système d’évacuation du lave-linge ....................................... 57

Nivellement .....................................................................................58

Achever l’installation ...................................................................59

Inversion du sens d’ouverture de la porte

du sèche-linge ...............................................................................59

Instructions d’entretien du lave-linge/

sèche-linge superposés .............................................................62

Si vous avez besoin d’assistance ............................................63

Fiche technique – sèche-linge à gaz ..................................... 64

Instructions de réglage du tableau

de commande électronique ...................................................... 66

Garantie .......................................................................................... 73

2

INDICE

Pagina

Sicurezza della lavatrice/asciugatrice impilati ................ 110

Eliminazione della lavatrice/asciugatrice impilati .......... 113

Attrezzi e componenti ............................................................. 114

Parti ed accessori alternati .................................................... 115

Specifiche ..................................................................................... 115

Dimensioni/spazi ...................................................................... 116

Requisiti dell’installazione della lavatrice/asciugatrice

a gas impilati ............................................................................. 117

Requisiti dell’installazione della lavatrice/asciugatrice

elettrica impilati ........................................................................ 120

Requisiti di scarico dell’asciugatrice .................................. 122

Requisiti di alimentazione del gas dell’asciugatrice ..... 124

Installazione della lavatrice/asciugatrice impilati ......... 125

Sistema dello scolo della lavatrice ..................................... 128

Livellamento ............................................................................... 129

Completamento dell’installazione ....................................... 130

Inversione della rotazione di apertura

dell’asciugatrice ........................................................................ 130

Istruzioni di manutenzione della lavatrice/

asciugatrice impilati ................................................................. 133

Se avete bisogno dell’assistenza ........................................ 134

Dati tecnici – asciugatrice a gas .......................................... 135

Configurazione dei controlli elettronici ............................. 137

Garanzia ...................................................................................... 144

Page 3

STACKED WASHER/DRYER SAFETY

n It is recommended that the owner post, in a prominent location, instructions for the customer’s use in the event the customer

smells gas. This information should be obtained from your gas supplier.

n Post the following warning in a prominent location.

FOR yOUR SAFeTy

1. DO NOT USE OR STORE PETROL OR OTHER FLAMMABLE MATERIALS IN THIS APPLIANCE OR NEAR THIS APPLIANCE.

2. DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS APPLIANCE WHILE IT IS IN OPERATION.

3. DO NOT MODIFY THIS APPLIANCE.

WARNING –

This is an additional safety alert symbol that alerts you to the risk of re.

RISK OF FIRE/FLAMMABLE MATERIALS

3

Page 4

STACKED WASHER/DRYER SAFETY

Before the dryer is removed from service or discarded,

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of fire, electric shock, or injury to persons when using the washer/

dryer, follow basic precautions, including the following:

n Read all instructions before using the

washer/dryer.

n This dryer is intended only for drying clothes

and textiles that have been washed in water.

Do not use for any other purpose.

n WARNING: If you smell gas, do not use

the dryer or any electrical equipment nearby.

Warn other people to clear the area. Contact

the dryer owner immediately.

n Do not place items exposed to cooking

oils in your dryer. Items contaminated with

cooking oils may contribute to a chemical

reaction that could cause a load to catch fire.

n If it is unavoidable that fabrics that contain

vegetable or cooking oil or that have been

contaminated by hair care products be

placed in a tumble dryer, they should first be

washed in hot water with extra detergent –

this will reduce, but not eliminate, the hazard.

n Do not wash or dry articles that have been

previously cleaned in, washed in, soaked in,

or spotted with petrol, dry-cleaning solvents,

other flammable, or explosive substances

as they give off vapors that could ignite or

explode.

n Items that have been soiled with substances

such as acetone, alcohol, petrol, kerosene,

spot removers, turpentine, waxes, and wax

removers should be washed in hot water

with extra detergent before being dried

in the dryer.

n Do not add gasoline, dry-cleaning solvents,

or other flammable, or explosive substances

to the wash water. These substances give

off vapors that could ignite or explode.

n Do not dry unwashed items in the dryer.

n Do not use this dryer if industrial chemicals

have been used for cleaning. The possible

presence of residual quantities of aggressive

or decomposed chemicals in the load may

produce damage to the dryer and harmful

fumes.

SAVE THESE INSTRUCTIONS

4

Page 5

STACKED WASHER/DRYER SAFETY

n Do not allow children to play on or in

the washer/dryer. Close supervision of

children is necessary when the washer/

dryer is used near children. Cleaning and

user maintenance shall not be made by

children without supervision. Children of less

than 3 years should be kept away unless

continuously supervised.

n This appliance is intended, but not limited,

to be used in public areas.

n This washer/dryer is not intended for use by

persons (including children) with reduced

physical, sensory, or mental capabilities, or

lack of experience or knowledge, unless they

have been given supervision or instruction

concerning use of the dryer by a person

responsible for their safety.

n Before the washer/dryer is removed from

service or discarded, remove the doors to

the washer/dryer compartments.

n Do not reach into the washer/dryer if the tub,

agitator, or drum is moving.

n Opening the dryer door will stop the function

of the dryer.

n When loading or re-loading the dryer,

avoid touching hot metal parts of the

drum (burn risk).

n Remove all objects from pockets such as

lighters and matches.

n The appliance must be disconnected from

its power source during service and when

replacing parts.

n If drum rotation is blocked due to trapped

textiles, disconnect the dryer from the

electrical supply before gently removing

the blockage.

n If the dryer is not heating, or appears to be

defective or damaged, do not use it. Contact

the owner.

n Do not install or store the washer/dryer

where it will be exposed to the weather.

n Do not tamper with controls.

n Clean dryer lint screen before or after

each load.

n Do not use this dryer without the lint screen

in place.

SAVE THESE INSTRUCTIONS

n Under certain conditions, hydrogen gas

may be produced in a hot water system that

has not been used for 2 weeks or more.

HYDROGEN GAS IS EXPLOSIVE. If the hot

water system has not been used for such a

period, before using the washer, turn on all

hot water faucets and let the water flow from

each for several minutes. This will release

any accumulated hydrogen gas. As the gas

is flammable, do not smoke or use an open

flame during this time.

n Do not repair or replace any part of the

washer/dryer or attempt any servicing unless

specifically recommended in this Use and

Care Guide or in published user-repair

instructions that you understand and have

the skills to carry out. If the supply cord

is damaged, it must be replaced by the

manufacturer, its service agent, or similarly

qualified persons in order to avoid a hazard.

n Fabric softeners, or similar products, should

be used as specified by the fabric softener

instructions.

n Items such as foam rubber (latex foam),

shower caps, waterproof textiles, rubberbacked articles, and clothes or pillows fitted

with foam rubber pads should not be dried

in the tumble dryer.

n The final part of a tumble dryer cycle occurs

without heat (cool-down cycle) to ensure

that the articles are left at a temperature that

ensures that the items will not be damaged.

n WARNING: Never stop a tumble dryer

before the end of the drying cycle unless

all items are quickly removed and spread out

so that the heat is dissipated. (Avoids risk of

spontaneous combustion).

n WARNING: The appliance must not be

supplied through an external switching

device, such as a timer, or connected to a

circuit that is regularly switched on and off

by a utility.

n In case of electrical supply failure, remove

the load quickly and spread it out to avoid

risk of spontaneous combustion.

5

Page 6

STACKED WASHER/DRYER SAFETY

n Keep area around the exhaust opening

and adjacent surrounding areas free from

the accumulation of lint, dust, and dirt.

n Ventilation openings in the base shall not

be obstructed by a carpet or similar object.

n The fresh air ventilation openings into the

room and into the dryer must not be blocked

or sealed.

n Emergency stop control: After installation,

access to mains plug or disconnection from

mains supply via a double-pole switch must

be ensured at all times in order to ensure

immediate deactivation of the dryer in case

of emergency.

n The interior of the dryer and dryer exhaust

vent should be cleaned periodically by

qualified service personnel.

SAVE THESE INSTRUCTIONS

n See “Electrical Requirements” section for

earthing instructions.

n Adequate ventilation has to be provided to

avoid the back-flow of gases into the room

from appliances burning fuels, including

open fires.

n The new hose-sets supplied with the

appliance are to be used. Old hose-sets

should not be reused.

n Only authorised spare parts shall be used

in the event of failure.

STACKED WASHER/DRYER DISPOSAL

This appliance is marked according to the European directive 2012/19/EU on Waste Electrical and Electronic Equipment

(WEEE).

By ensuring this product is disposed of correctly, you will help avoid potential negative consequences for the environment

and human health, which could otherwise be caused by inappropriate waste handling of this product.

The symbol on the product, or on the documents accompanying the product, indicates that this appliance may not be

treated as household waste. Instead it shall be handed over to the applicable collection point for the recycling of electrical

and electronic equipment.

Disposal must be carried out in accordance with local environmental regulations for waste disposal.

For more detailed information about treatment, recovery and recycling of this product, please contact your local city ofce,

your household waste disposal service or the shop where you purchased the product.

MODEL NOMENCLATURE:

MLE – Maytag Stacked Laundry Electric Dryer PD – Electronic Control – Coin Drop Enabled

MLG – Maytag Stacked Laundry Gas Dryer PN – Electronic Control – Non-Pay

22 – Stacked Washer/Dryer Model

6

Page 7

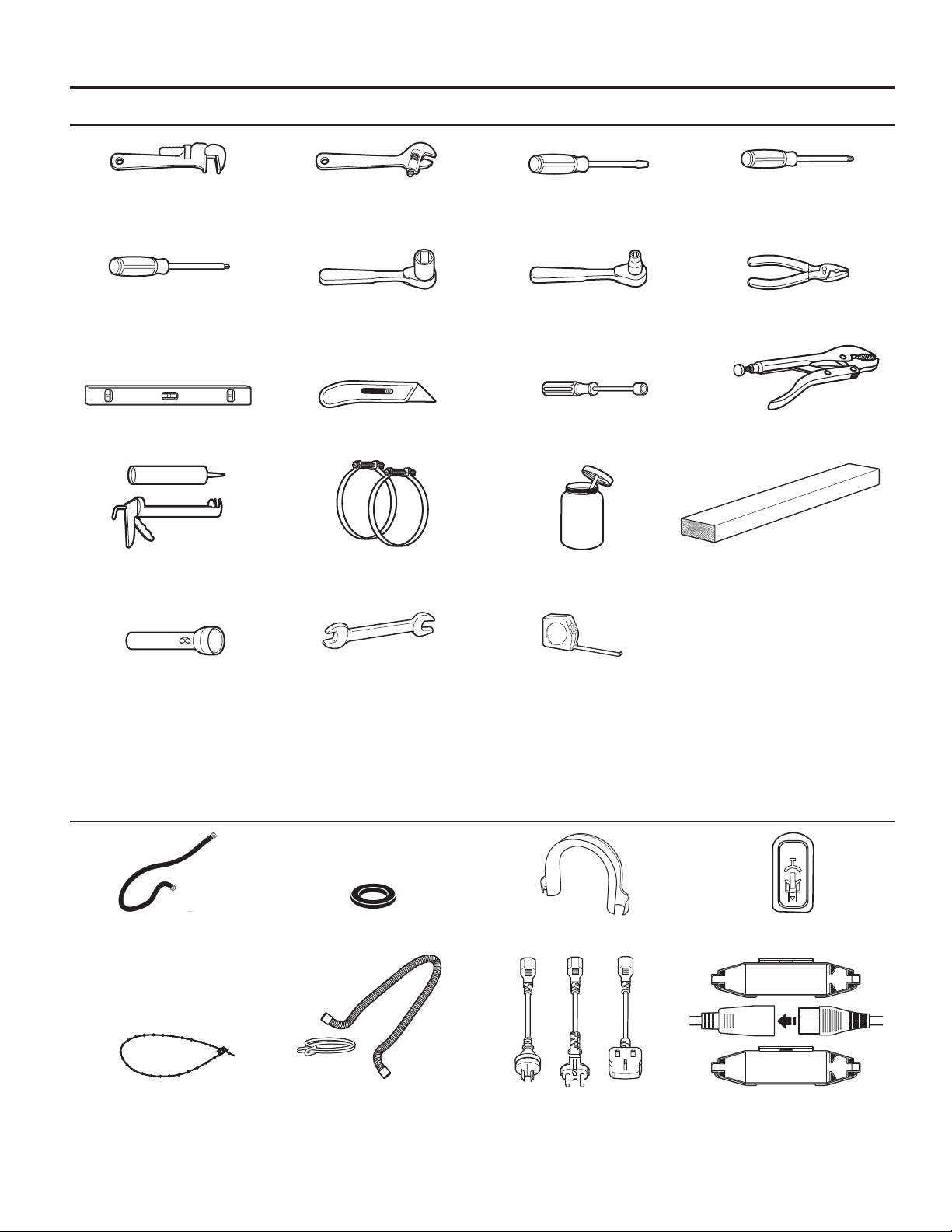

TOOLS & PARTS

Tools Needed:

203 mm (8") 203 mm (8") or 254 mm (10") Flat-Blade Screwdriver Phillips Screwdriver

or 254 mm (10") Adjustable Wrench

Pipe Wrench that opens to 25 mm (1")

Torx T-20† Security 25 mm (1") Hex-Head 8 mm (5/16") Socket Wrench Pliers

Screwdriver or Bit Socket Wrench (that open to 39 mm [19/16"])

Level Utility Knife 6 mm (1/4") Nut Driver Locking Pliers

Caulk Gun and Caulk Vent Clamps Pipe-Joint Compound 686 mm (27") Wood Block

(for installing new exhaust vent) suitable for gas type

Flashlight (optional) 13 mm (1/2") and 14 mm Ruler or Measuring Tape

(9/16") Open-End Wrenches

Parts Supplied:

Water Inlet Hoses (2) Inlet Hose Washers (4) U-Shaped Hose Form Transit Bolt Hole Plug (4)

Beaded Tie Strap Drain Hose/Clamp Export Power Cord Export Power Cord

Adapters Adapter Cover

†TORX and T-20 are registered trademarks of Acument Intellectual Properties, LLC.

7

Page 8

ALTERNATE PARTS AND ACCESSORIES

Alternate Parts

Your installation may require additional parts. If you are interested

in purchasing one of the items listed here, contact your authorised

Maytag distributor.

If You Have You Will Need to Buy

Overhead sewer Standard 76 L (20 gal.) 990 mm

(39") tall drain tub or utility sink, sump

pump and connectors (available from

local plumbing suppliers)

25 mm (1") standpipe 51 mm (2") diameter to 25 mm (1")

diameter Standpipe Adapter

Part Number 3363920

Connector Kit Part Number 285835

Drain hose too Extension Drain Hose Part

short Number 285863

Connector Kit Part Number 285835

Lint clogged drain Drain Protector Part Number 367031

Connector Kit Part Number 285835

Floor drain system Siphon Break, Part Number 285834

Connector Kit (x2) Part Number 285835

Extension Drain Hose Part

Number 285863

Water faucets Two longer water fill hoses:

beyond reach 1.8 m (6 ft.) 90° bend hose

of fill hoses Part Number 76314

3.0 m (10 ft.) Part Number 350008

Accessories

Enhance your washer/dryer with these premium accessories.

For more high-quality items or to order, contact your authorised

Maytag distributor.

Part Number Accessory

8212526 Washer drip tray, fits under all

31682 All-purpose appliance cleaner

1903WH Laundry supply storage cart

279818 Three-way dryer venting kit

285834 Siphon break kit

SPECIFICATIONS

These units are sold in multiple regions with different

requirements for measuring capacity. Below are a few

of the valid forms of measure posted on this product:

Dry Linen Capacity: A weight measure that reflects a minimum

threshold for dry volume capacity that is needed for import tariff

purposes.

IEC Capacity: The capacity measure that represents the maximum

capacity of dry linens and textiles which the manufacturer declares

can be treated in a specific cycle.

Dry Linen Capacity

10.5 kg (23 lb)

IEC Capacity

8.5 kg (19 lb)

Sound Level

LpA: 58 dB(A) (Kpa+/-10 dB(A))

8

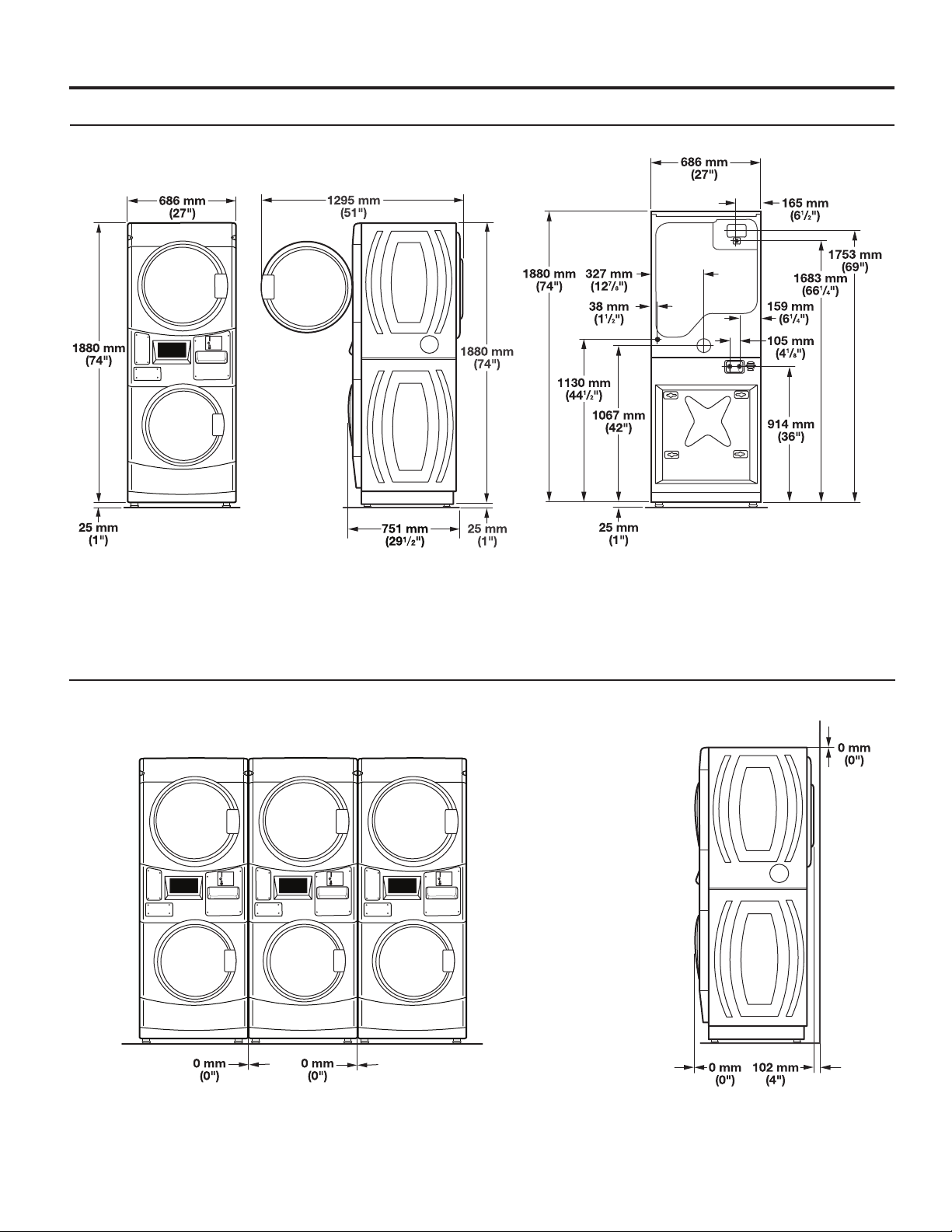

Page 9

Dimensions

DIMENSIONS/CLEARANCES

Front View

Back ViewSide View

Clearances

Side Clearances

Back/Top Clearances

9

Page 10

STACKED WASHER/GAS DRYER INSTALLATION REQUIREMENTS

AUSTRALIA AND NEW ZEALAND FOR FULL DETAILS OF INSTALLATION REQUIREMENTS REFER TO AS/NZS 5601.1 GAS INSTALLATIONS

Stacked Washer/Gas Dryer Location

Stacked washer/gas dryer installation clearances

n The location must be large enough to allow the washer and dryer

doors to be fully opened.

n Additional spacing should be considered for ease of installation

and servicing. The doors open more than 180°. The washer door

is not reversible.

n Additional clearances might be required for wall, door,

and floor mouldings.

n Companion appliance spacing should also be considered.

When installing a gas dryer:

IMPORTANT: Observe all governing codes and ordinances.

n Check code requirements: Some codes limit or do not permit

installation of clothes dryers in garages, closets, or sleeping

quarters. Contact your local building inspector.

NOTE: For installation in Australia and New Zealand, install

Selecting the proper location for your washer/dryer improves

performance and minimises noise and possible washer “walk.”

Your washer/dryer can be installed in a basement, laundry room,

or recessed area. See “Drain System.”

Companion appliance location requirements should also be

considered.

IMPORTANT: Do not install or store the washer/dryer where

it will be exposed to the weather. Do not store or operate the

washer/dryer in temperatures at or below 0°C (32°F). Some

water can remain in the washer and can cause damage in

low temperatures. Proper installation is your responsibility.

You will need:

n A water heater set to deliver 49°C (120°F) water to the washer.

n An earthed electrical outlet located within 1.8 m (6 ft.) of

where the power cord is attached to the back of the washer.

See “Electrical Requirements.”

n Hot and cold water faucets located within 1.2 m (4 ft.)

of the hot and cold water fill valves, and water pressure

of 137.9–689.6 kPa (20–100 psi).

n A level floor with a maximum slope of 25 mm (1") under

entire washer/dryer. Installing the washer/dryer on soft floor

surfaces, such as carpets or surfaces with foam backing, is

not recommended.

n A sturdy and solid floor to support the washer/dryer with a total

weight (water and load) of 204 kg (450 lbs).

n A floor drain under the bulkhead. Prefabricated bulkheads with

electrical outlets, water inlet lines, and drain facilities should be

used only where local codes permit.

dryer in accordance with AS/NZS 5601.1 and local governance

codes.

n Make sure that lower edges of the cabinet, plus the back and

bottom sides of the washer, are free of obstructions to permit

adequate clearance of air openings for combustion air. See

“Recessed Area and Closet Installation Instructions” below

for minimum spacing requirements.

n Do not install on carpet.

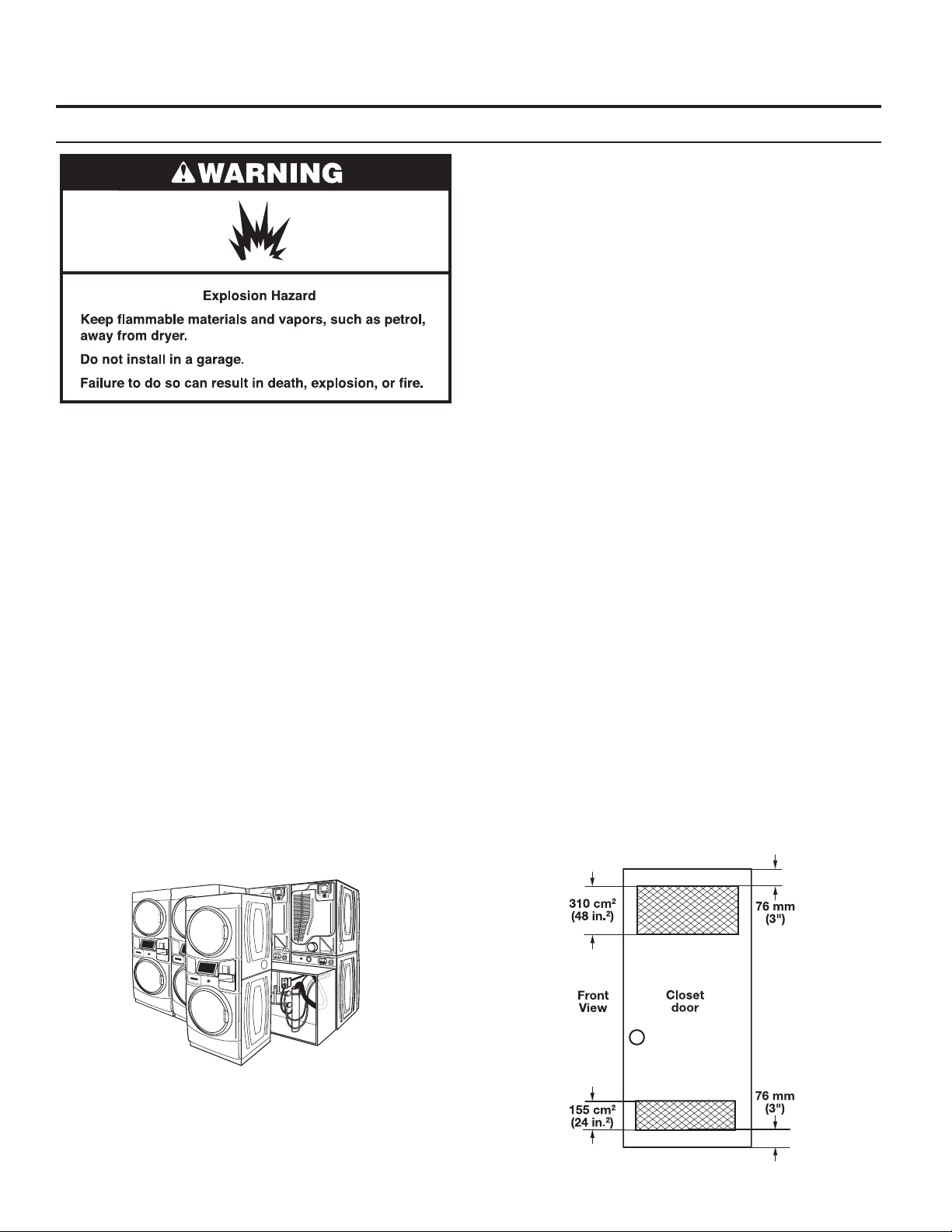

Recessed Area and Closet Installation Instructions

This washer/dryer may be installed in a recessed area or closet.

This washer/dryer must not be installed behind a lockable door,

a sliding door, or a door with a hinge on the opposite side to that

of the washer/dryer in such a way that a full opening of the washer/

dryer is restricted. For recessed area and closet installations,

minimum clearances can be found on the warning label on the

rear of the dryer or in “Dimensions/Clearances.”

The installation spacing is in millimeters and is the minimum

allowable. Additional spacing should be considered for ease

of installation, servicing, and compliance with local codes and

ordinances.

If closet door is installed, the minimum unobstructed air opening in

the top and bottom is required. Louvered doors with equivalent air

openings are acceptable.

The dryer must be exhausted outdoors.

No other fuel-burning appliance may be installed in the same

closet as the washer/dryer.

NOTE: For installation in Australia and New Zealand, refer to

AS/NZS 5601.1 for ventilation requirements.

10

Page 11

STACKED WASHER/GAS DRYER INSTALLATION

Stacked Washer/Gas Dryer Electrical Requirements

REQUIREMENTS

EARTHING INSTRUCTIONS

n For an earthed cord-connected dryer:

This dryer must be earthed. In the event of a malfunction or

breakdown, earthing will reduce the risk of electric shock by

providing a path of least resistance for electric current. This

dryer is equipped with a cord having an equipment-earthing

conductor and an earthing plug. The plug must be plugged into

an appropriate outlet that is properly installed and earthed in

accordance with all local codes and ordinances.

IMPORTANT: Observe all governing codes and ordinances.

You will need an earthed electrical outlet located within 610 mm

(2 feet) of either side of the washer/dryer.

This washer/dryer is supplied/fitted with an electrical supply cord

and plug. It should be connected to electrical supply socket at

the voltage shown on the rating plate. The minimum supply fuse

capacity should be 10A. The washer/dryer must be positioned so

that the plug is clearly visible and accessible. This plug also provides

the function of an emergency stop control for the user. If the fitted

plug is not used, the electrical connection must be carried out by a

competent electrician in accordance with local or national codes.

If the supply cord is damaged, it must be replaced with a specially

terminated cord by an authorised service agent or a similarly

competent person in order to avoid a hazard.

Do not use an adapter.

Do not use an extension cord.

NOTE: In accordance with the European EMC Directive (2014/30/

EU), the maximum electricity supply system impedance to which

the gas dryer should be connected is declared to be 0.054 Ohm +

j0.034 Ohm.

NOTE: Electrical safety standards: The manufacturer has chosen

compliance with IEC/EN 60335 standards as the most appropriate

for this product.

WARNING : Improper connection of the equipment-

earthing conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly earthed. Do not modify the plug provided with the

dryer; if it will not fit the outlet, have a proper outlet installed

by a qualified electrician.

SAVE THESE INSTRUCTIONS

Using the universal cord included with this dryer:

The gas dryer is equipped with a universal cord with

interchangeable plugs.

1. To use the universal cord, select the plug end that fits your

electrical outlet, and plug it into the adapter on the supply cord.

2. Secure the plug end in place on the cord by aligning the two

cover halves over the cord adapter and clipping them together.

If codes permit and an additional earth bond wire is used, it is

recommended that a qualified electrician determine that the earth

bond path is adequate.

11

Page 12

STACKED WASHER/GAS DRYER INSTALLATION

REQUIREMENTS

Stacked Washer/Gas Dryer Gas Supply Requirements

Natural gas (France/Belgium):

This dryer is also certified for France/Belgium for use with G20/

G25 gases (20 mbar/25 mbar) with appropriate conversion.

No attempt should be made to convert this appliance from the

gas specified on the gas rating label for use with a different gas

without consulting the serving gas supplier. Gas conversion must

be done by a qualified gas service technician. Conversion kit, part

number (W10181947) is available for purchase from your dealer.

Full instructions are supplied with the kit.

Supply line requirements:

Provide a rigid gas supply line to the washer/dryer location. It

should be minimum 12.5 mm (1/2") ID. When acceptable to the

gas supplier and local codes, 10 mm (3/8") ID rigid supply line

may be used for lengths under 6.1 m (20'). Pipe-joint compounds

resistant to the action of L.P. gas must be used.

NOTE: For installation in Australia and New Zealand, refer

to AS/NZS 5601 for pipe sizing details. All piping is to be

in accordance with AS/NZS 5601.1 – Gas Installations.

Gas connection to the dryer itself should be made by means

of a flexible gas hose suitable for the appliance and gas category

in accordance with national installation regulations. If in doubt,

IMPORTANT: Observe all governing codes and ordinances.

In Australia and New Zealand, refer to AS/NZS 5601.1 –

Gas Installations.

Gas Supply

Before installation, check that the local gas distribution conditions,

nature of gas and pressure, and the adjustment of the appliance

are compatible. Burner information will be found on the model/

serial rating plate in the door recess of the dryer. If this information

does not agree with the type of gas available, see your dealer.

Natural Gas:

This dryer is factory adjusted for use with NATURAL GAS (G20),

and no further adjustment should be required at installation.

L.P. Gas:

This dryer is also certified for use with L.P. gas with appropriate

conversion. No attempt shall be made to convert the appliance

from the gas specified on the model/serial rating plate for use

with a different gas without consulting the serving gas supplier.

Conversion must be done by a competent service technician.

L.P. Gas conversion kit for countries with 50 Hz power, except

for France and Belgium, part number W10571757, is available

for purchase from your dealer. Gas conversion kit (Australia), part

number W10571729, is available for purchase from your dealer.

Full instructions are supplied with the kit.

contact the gas supplier. It should be minimum 10 mm (3/8") ID.

A means of restraint should be used between the washer/dryer

and the wall to avoid straining of the rigid gas supply when the

washer/dryer is moved. An appropriate length of chain and a wall

hook is recommended.

The dryer gas inlet connection is a 3/8" NPT thread. An adapter is

supplied for conversion to standard ISO 228-1 thread (3/8" BSP).

Check for leaks by using an approved noncorrosive leak-detection

solution. Bubbles will show a leak. Correct any leak found. A

pressure measurement tapping is provided on the gas valve

within the dryer, accessible after removal of the lower front panel.

The dryer must be disconnected from the gas supply piping

system during any pressure testing of that system.

12

Page 13

STACKED WASHER/ELECTRIC DRYER INSTALLATION

Stacked Washer/Electric Dryer Location

Selecting the proper location for your washer/dryer improves

performance and minimises noise and possible washer “walk.”

Your washer/dryer can be installed in a basement, laundry room,

or recessed area. See “Drain System.”

Companion appliance location requirements should also be

considered.

IMPORTANT: Do not install or store the washer/dryer where it will

be exposed to the weather. Do not store or operate the washer/

dryer in temperatures at or below 0°C (32°F). Some water can

remain in the washer and can cause damage in low temperatures.

Proper installation is your responsibility.

You will need:

n A water heater set to deliver 49°C (120°F) water to the washer.

n An earthed electrical outlet located within 1.8 m (6 ft.) of where

the power cord is attached to the back of the washer. See

“Electrical Requirements.”

n Hot and cold water faucets located within 1.2 m (4 ft.)

of the hot and cold water fill valves, and water pressure

of 137.9–689.6 kPa (20–100 psi).

n A level floor with a maximum slope of 25 mm (1") under

entire washer/dryer. Installing the washer/dryer on soft floor

surfaces, such as carpets or surfaces with foam backing, is not

recommended.

n A sturdy and solid floor to support the washer/dryer with a total

weight (water and load) of 204 kg (450 lbs).

n A floor drain under the bulkhead. Prefabricated bulkheads with

electrical outlets, water inlet lines, and drain facilities should be

used only where local codes permit.

REQUIREMENTS

Stacked washer/electric dryer installation clearances

n The location must be large enough to allow the washer

and dryer doors to be fully opened.

n Additional spacing should be considered for ease of installation

and servicing. The doors open more than 180°. The washer door

is not reversible.

n Additional clearances might be required for wall, door, and floor

mouldings.

n Companion appliance spacing should also be considered.

Recessed Area and Closet Installation Instructions

This washer/dryer may be installed in a recessed area or closet.

This washer/dryer must not be installed behind a lockable door, a

sliding door, or a door with a hinge on the opposite side to that of

the washer/dryer in such a way that a full opening of the washer/

dryer door is restricted. For recessed area and closet installations,

minimum clearances can be found on the warning label on the rear

of the dryer or in “Dimensions/Clearances.”

The installation spacing is in millimeters and is the minimum

allowable. Additional spacing should be considered for ease

of installation, servicing, and compliance with local codes and

ordinances.

If closet door is installed, the minimum unobstructed air opening in

the top and bottom is required. Louvered doors with equivalent air

openings are acceptable.

The dryer must be exhausted outdoors.

No other fuel-burning appliance may be installed in the same

closet as the washer/dryer.

13

Page 14

STACKED WASHER/ELECTRIC DRYER INSTALLATION

REQUIREMENTS

Stacked Washer/Electric Dryer Electrical

Requirements

This washer/dryer is supplied without an electric cord and plug. It

must be connected by a competent electrician to a single-phase

electricity supply at the voltage shown on the dataplate, using

a suitable fixed wiring installation in accordance with local and

national wiring regulations.

n A 3-wire circular cord of minimum conductor size 4 mm2

cross-section area should be used.

n A 25A supply fuse should be used, and a switch having

a contact separation in both poles that provides full

disconnection under over-voltage category III conditions must

be incorporated into the fixed wiring in accordance with local

wiring regulations. The washer/dryer should be positioned

so that the disconnection switch is clearly visible and easily

accessible to the user. This disconnection switch also provides

the function of an emergency stop control for the user.

n A cord clamp bush is provided on the washer/dryer, and

should be tightened on completion of wiring. The electrical

mains terminals are located behind the small rear access panel

(terminal block cover), and connections should be made in

accordance with the terminal markings. Remember to replace

the terminal access panel (terminal block cover).

NOTE: In accordance with the European EMC Directive

(2014/30/EU), the maximum electrical supply system impedance

to which the electric dryer should be connected is declared to be

0.054 Ohm + j0.034 Ohm.

NOTE: Electrical safety standards: The manufacturer has

chosen compliance with IEC/EN 60335 standards as the most

appropriate for this product.

This is 3-wire appliance which must be earthed.

If codes permit and an additional earth bond wire is used, it is

recommended that a qualified electrician determine that the earth

bond path is adequate.

Recommended Earthing Method

It is your responsibility to contact a qualified electrical installer

to ensure that the electrical installation is adequate and in

conformance with all local codes and ordinances.

14

Page 15

DRYER VENTING REQUIREMENTS

WARNING: To reduce the risk of fire, this dryer MUST BE

EXHAUSTED OUTDOORS.

IMPORTANT: Observe all governing codes and ordinances.

In Australia and New Zealand, refer to AS/NZS 5601.1 –

Gas Installations.

n Following these venting requirements will minimise ducting

air noise.

n Adequate ventilation has to be provided to avoid the backflow

of gases into the room from appliances burning other fuels,

including open fires (i.e. available airflow into the room should

match airflow out from the room).

n Dryer exhaust must not be connected into any gas vent,

chimney, wall, ceiling, attic, crawlspace, or a concealed space

of a building. Only rigid or flexible metal vent shall be used for

exhausting.

n Do not use an exhaust hood with a magnetic latch.

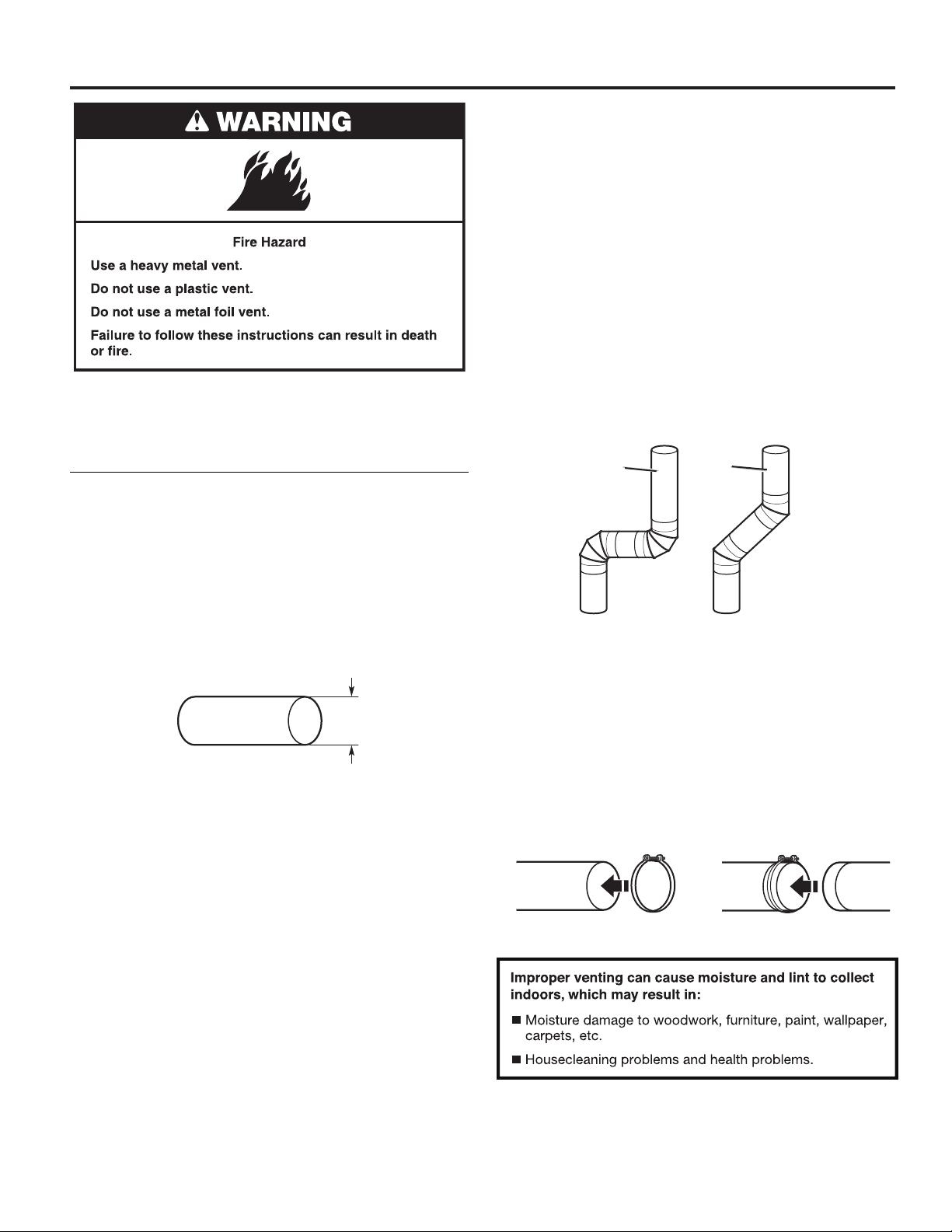

102 mm

(4")

102 mm (4") Heavy, Metal Exhaust Vent

n Only a 102 mm (4") heavy, metal exhaust vent and clamps may

be used.

n Do not use plastic or metal foil vent.

n Exhaust air must not be discharged into a flue which is used for

exhausting fumes from appliances burning gas or other fuels.

n Forced ventilation of fresh air is required.

n Exhaust air must be exhausted to the outside to avoid

suffocation.

n If exhaust is connected to a commonly used exhaust system,

it is required to install flap valves at each connection or

alternative adequate countermeasures.

n Exhaust air must not be connected to an exhaust channel

of a furnace.

Rigid metal vent:

n Recommended for best drying performance and to avoid

crushing and kinking.

Flexible metal vent: (Acceptable only if accessible to clean)

n Must be fully extended and supported in final dryer location.

n Remove excess to avoid sagging and kinking that may result

in reduced airflow and poor performance.

n Do not install in enclosed walls, ceilings, or floors.

n The total length should not exceed 2.4 m (73⁄4 ft.).

n An exhaust hood should cap the vent to keep rodents and

insects from entering the building.

NOTE: If using an existing vent system, clean lint from entire length

of the system and make sure exhaust hood is not plugged with

lint. Replace plastic or metal foil vents with rigid metal or flexible

metal vents. Review “Vent System Chart” and if necessary, modify

existing vent system to achieve best drying performance.

Elbows:

n 45° elbows provide better airflow than 90° elbows.

Good

n Plan installation to use the fewest number of elbows and turns.

n Allow as much room as possible when using elbows or making

turns. Bend vent gradually to avoid kinking.

n Vent outlet is located at the centre of the bottom dryer back.

n The vent can be routed up, down, left, right, behind the dryer,

or straight out the back of the dryer.

Better

Clamps:

n Use clamps to seal all joints.

n Exhaust vent must not be connected or secured with screws

or other fastening devices that extend into interior of duct and

catch lint. Do not use duct tape.

15

Page 16

DRYER VENTING REQUIREMENTS

IN AUSTRALIA AND NEW ZEALAND, REFER TO AS/NZS 5601.1 GAS INSTALLATIONS

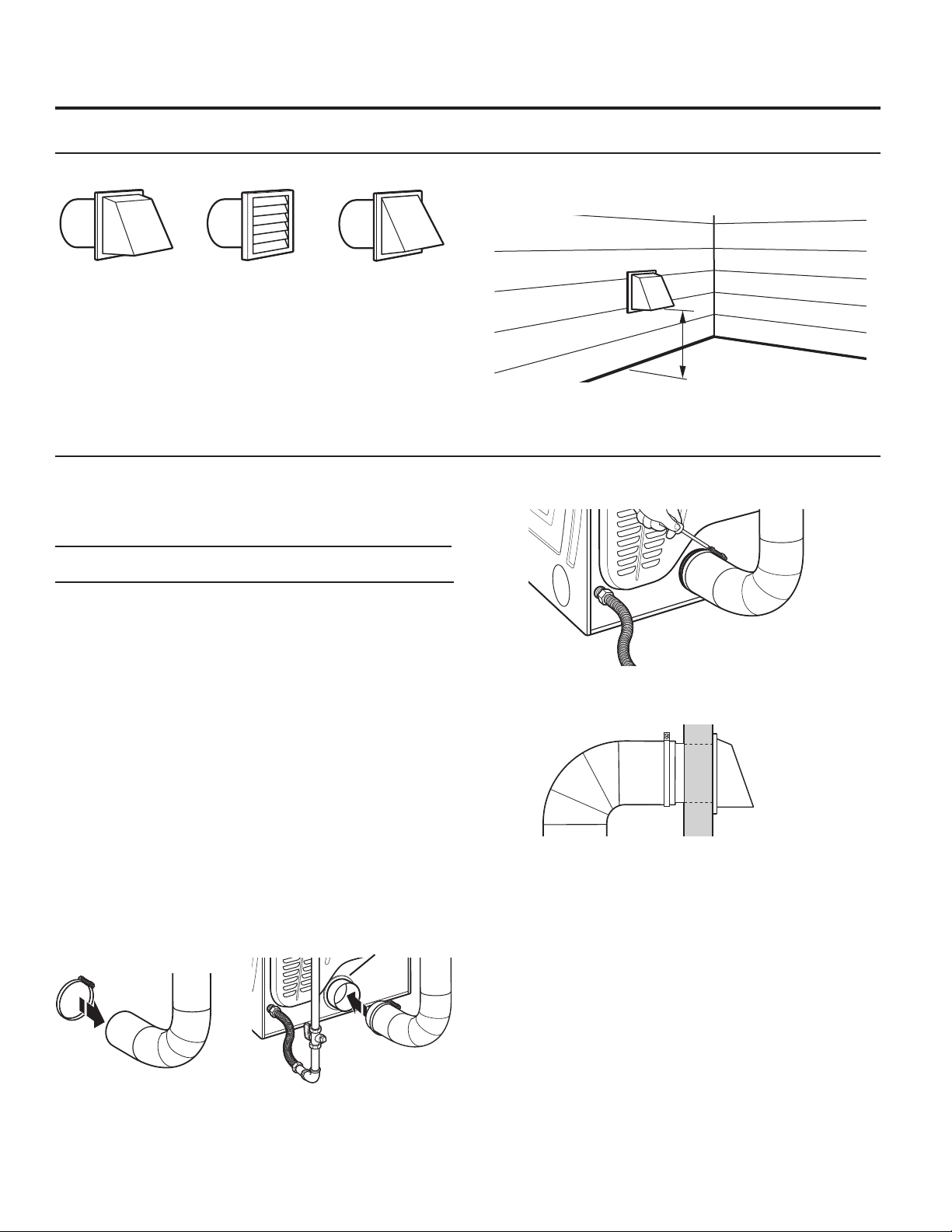

Vent Hoods

102 mm (4") Diameter Exhaust Hoods

Box Hood Louvered Hood Angled Hood

Vent System Length

Maximum Vent Length/Vent Connection

Maximum length of vent system depends upon the type of vent

used, number of elbows, and type of exhaust hood.

Exhaust hood must be at least 305 mm (12") from the ground or

any object that may be in the path of the exhaust (such as flowers,

rocks, bushes, or snow).

12" min.

305 mm min.

(305 mm)

(12")

3. Tighten hose clamp with Phillips screwdriver.

Vent System Chart (Rigid Metal Vent)

No. of Box and Angled

90˚ Turns Louvered Hood Hood

0 39.6 m (130 ft.) 39.3 m (129 ft.)

1 38.1 m (125 ft.) 36.3 m (119 ft.)

2 35.1 m. (115 ft) 33.2 m (109 ft.)

3 32.3 m (106 ft.) 30.5 m (100 ft.)

4 29.9 m (98 ft.) 28.0 m (92 ft.)

For vent systems not covered by the vent specification chart,

see your parts distributor.

Provision must be made for enough air for combustion and

ventilation. (Check governing codes and ordinances.) See

“Recessed Area and Closet Installation Instructions” in the

“Stacked Washer/Gas Dryer Location” and “Stacked Washer/

Electric Dryer Location” sections.

A 102 mm (4") outlet hood is preferred. However, a 64 mm

(21⁄2") outlet exhaust hood may be used. A 64 mm (21⁄2") outlet

creates greater back pressure than other hood types. For

permanent installation, a stationary vent system is required.

Connect Vent

1. If connecting to existing vent, make sure the vent is clean.

2. Using a 102 mm (4") clamp, connect vent to exhaust outlet

in dryer.

Vent Collar

4. Make sure the vent is secured to exhaust hood with a 102 mm

(4") clamp.

5. Move dryer into final position. Do not crush or kink vent.

Make sure dryer is level.

NOTE: Do not remove vent collar.

16

Page 17

DRYER VENTING REQUIREMENTS

IN AUSTRALIA AND NEW ZEALAND, REFER TO AS/NZS 5601.1 GAS INSTALLATIONS

If an Exhaust Hood Cannot be Used Multiple Dryer Venting

The outside end of main vent should have a sweep elbow directed

downward.

* Minimum clearance above

any accumulation of snow,

ice, or debris such as

leaves

If main vent travels vertically through the roof, rather than through

wall, install a 180° sweep elbow on end of vent at least 610 mm

(2 ft.) above surface of roof.

The opening in wall or roof shall have a diameter 13 mm (1⁄2")

larger than vent diameter. Vent should be centred in opening.

Do not install screening over end of vent for best performance.

A main vent can be used for venting a group of dryers. The main

vent should be sized to remove 5663 l/min. (200 CFM) of air per

dryer. Large-capacity lint screens of proper design may be used in

main vent if checked and cleaned frequently. The room where the

dryers are located should have make-up air equal to or greater than

CFM of all the dryers in the room.

Unobstructed air openings are required for make up combustion

air. A static opening of 24 square inches (1 inch2 per 1,000 BTU

of burner) is the minimum required for each dryer in operation.

A common opening may be used if the return air is distributed

equally to all dryers in operation.

Back-draft Damper Kit is available from your distributor and should

be installed in the vent of each dryer to keep exhausted air from

returning into dryers and to keep exhaust in balance within main

vent. Unobstructed return air openings are required.

Each vent should enter the main vent at an angle pointing in the

direction of the airflow. Vents entering from the opposite side

should be staggered to reduce the exhausted air from interfering

with the other vents.

Air ow

30˚ max.

DRYER GAS SUPPLY REQUIREMENTS

(All piping is to be in accordance with AS/NZS 5601.1 – Gas Installations)

Make Gas Connection

1. Remove red cap from gas pipe.

2. Connect gas supply to dryer. If the flexible gas hose has

10 mm (3/8") BSP thread, use the supplied conversion thread

adapter. Use pipe-joint compound resistant to the action of L.P.

gas for gas connections.

If necessary for service, open the toe panel. Use a putty knife

to press on the two toe panel locks located at the top of the

toe panel. Pull downward on the toe panel to open. Toe panel

is hinged at the bottom.

The maximum angle of each vent entering the main vent should be

no more than 30°.

Keep air openings free of dry cleaning fluid fumes. Fumes create

acids which, when drawn through the dryer heating units, can

damage dryers and items being dried.

A clean-out cover should be located on the main vent for periodic

cleaning of the vent system.

3. Open the shut-off valve in the gas supply line.

4. Test all connections by brushing on an approved, noncorrosive

leak-detection solution. Bubbles will show a leak. Correct any

leaks found.

17

Page 18

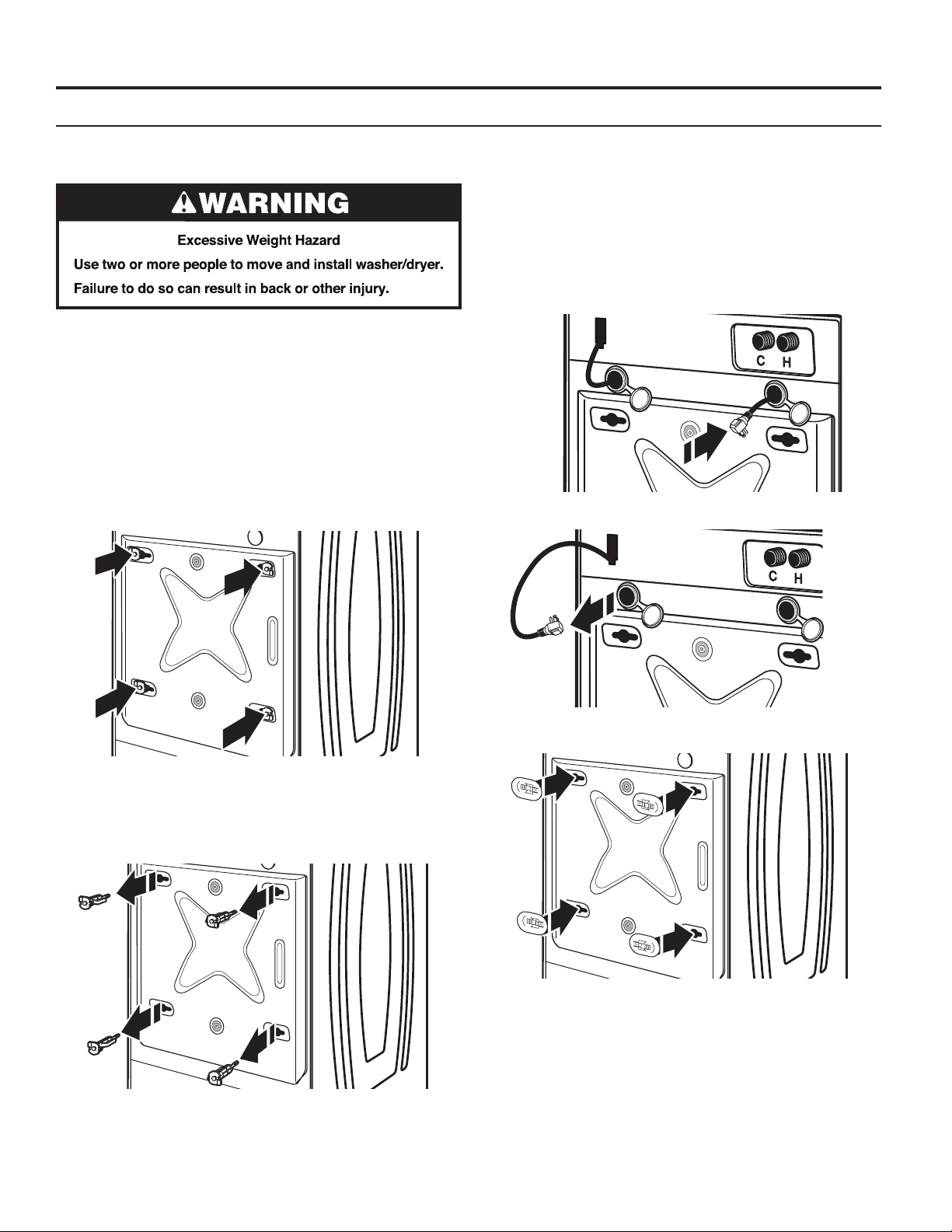

INSTALLING STACKED WASHER/DRYER

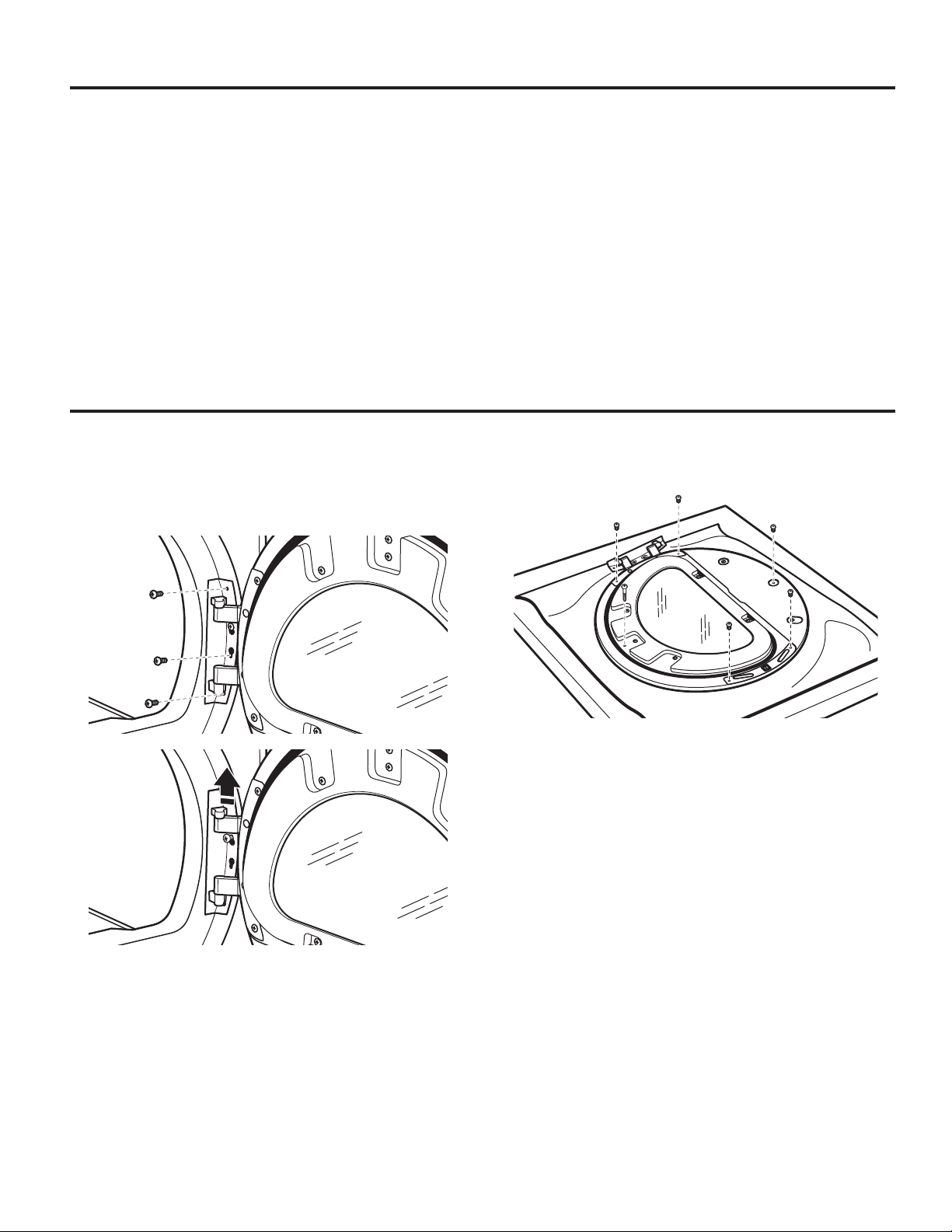

Remove Transport System

NOTE: Slide washer/dryer onto cardboard or hardboard before

moving to avoid damaging floor covering.

IMPORTANT: Position the washer/dryer so that the rear of the

washer is within approximately 900 mm (3 ft.) of its final location.

There are four shipping bolts in the rear panel of the washer that

support the suspension system during transportation. These bolts

also retain the power cord inside the washer until the bolts are

removed.

IMPORTANT: Remove the four shipping bolts at the rear of the

washer before operation.

1. Keep the washer/dryer in the upright position while removing the

shipping bolts.

2. Using a 13 mm (1/2") wrench, loosen each of the bolts.

4. Models with separate washer power cords: Push the power

cord plug into the opening on the right side of the rear panel and

pull the power cord through the opening on the left side of the

rear panel and close holes with the attached cap. Do not pull

plug end of power cord through the right side hole.

NOTE: To avoid damage to internal washer parts or the power

cord, if the cord does not pull out of the washer rear panel easily,

do not force it. Remove the washer rear panel and guide the

power cord around the obstruction and out the hole on the left

side of the rear panel.

3. Once the bolt is loose, move it to the centre of the hole

and completely pull out the bolt, including the plastic spacer

covering the bolt. Once all four bolts are removed, discard the

bolts and spacers.

18

5. Close the bolt holes with the four transport bolt hole plugs.

IMPORTANT: If the washer/dryer is to be transported, call your

product distributor or installer. To avoid suspension and structural

damage, your washer/dryer must be properly set up for relocation

by a trained professional.

Page 19

INSTALLING STACKED WASHER/DRYER

Connect Inlet Hoses

Insert new hose washers (supplied) into each end of the inlet

hoses. Firmly seat the washers in the couplings.

CouplingWasher

Connect Inlet Hoses to Water Faucets

Make sure the washer drum is empty.

1. Attach a hose to the hot water faucet. Screw on coupling

by hand until it is seated on the washer.

Connect Inlet Hoses to Washer

1. Attach the cold water hose to the washer’s cold water inlet

valve. Screw on coupling by hand until it is seated on the

washer.

2. Attach the hot water hose to the washer’s hot water inlet valve.

Screw on coupling by hand until it is seated on the washer.

2. Attach a hose to the cold water faucet. Screw on coupling

by hand until it is seated on the washer.

3. Using pliers, tighten the couplings with an additional

two-thirds turn.

NOTE: Do not overtighten or use tape or sealants on the valve.

Damage to the valves can result.

Clear Water Lines

n Run water through both faucets and inlet hoses, into a laundry

tub, drainpipe, or bucket, to get rid of particles in the water

lines that might clog the inlet valve screens.

n Check the temperature of the water to make sure that the hot

water hose is connected to the hot water faucet and that the

cold water hose is connected to the cold water faucet.

3. Using pliers, tighten the couplings with an additional

two-thirds turn.

NOTE: Do not overtighten. Damage to the valve can result.

4. Turn on the water faucets completely and check for leaks.

NOTE: Replace inlet hoses after 5 years of use to reduce the

risk of hose failure. Record hose installation or replacement

dates on the hoses for future reference.

Periodically inspect and replace hoses if bulges, kinks, cuts,

wear, or leaks are found.

19

Page 20

INSTALLING STACKED WASHER/DRYER

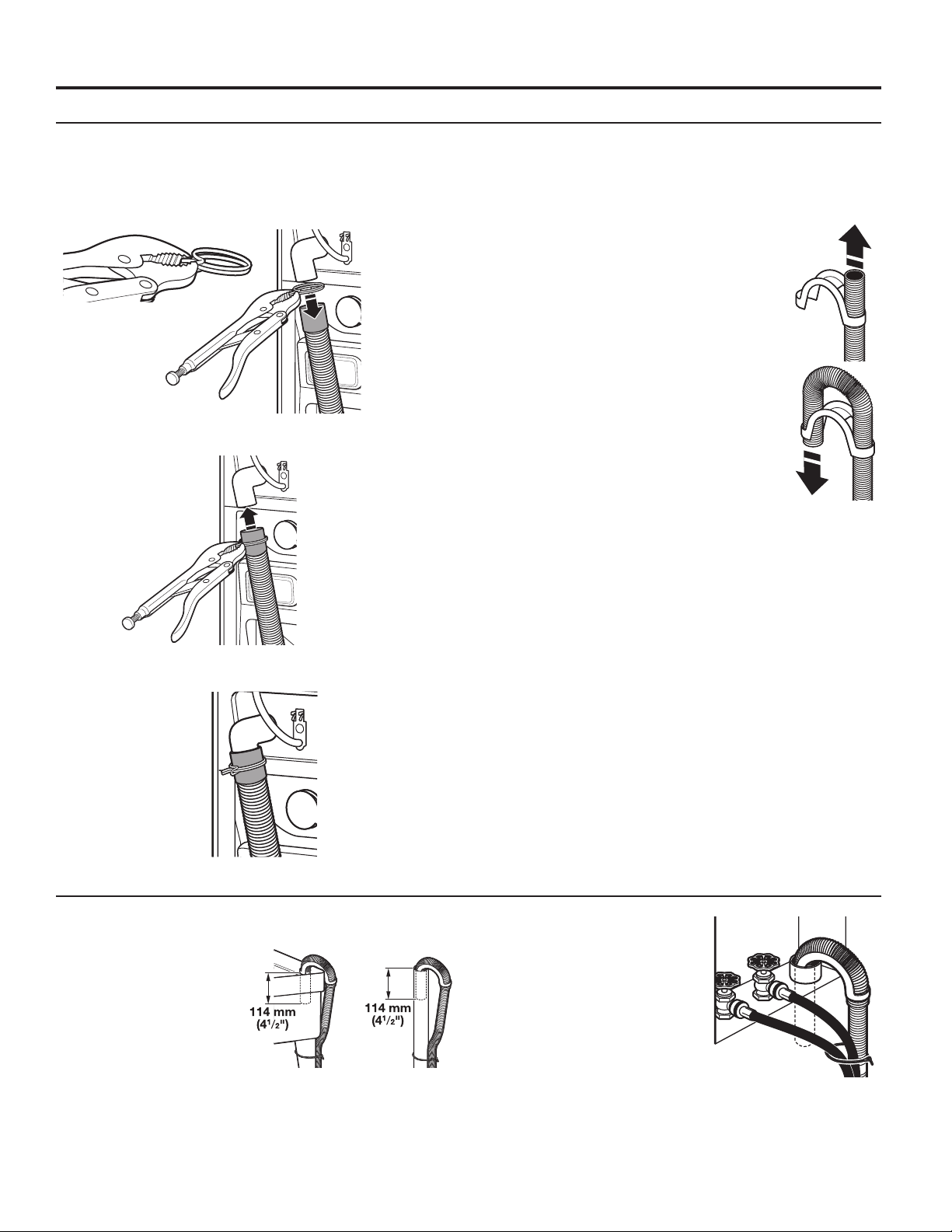

Route Drain Hose

Proper routing of the drain hose avoids damage to your floor due

to water leakage. Read and follow these instructions.

Remove drain hose from the washer drum

1. Using locking pliers, squeeze hose clamp tabs together and

insert over the end of the drain hose.

2. Slide the drain hose onto the washer connection.

4. The washer drain system can be installed using a floor drain,

wall standpipe, floor standpipe, or laundry tub.

Laundry tub drain or standpipe drain

Connect the drain hose form to the corrugated drain hose.

Snap either end of the drain hose form to the drain

hose at the point where the corrugation begins.

Bend drain hose over drain hose form and snap

into place.

NOTE: Hose must not extend more than

25 mm (1") past the end of the U bend.

To keep drain water from going back into the washer:

n Do not straighten the drain hose, do not force excess drain

hose into standpipe. Hose should be secure but loose enough

to provide a gap for air.

n Do not lay excess hose on the bottom of the laundry tub.

Floor drain

You may need additional parts. See “Alternate Parts.”

3. Once the drain hose is in place, release the pliers.

Secure Drain Hose

1. Drape the power cord over the washer top.

2. Move the washer to its final location.

3. Place the drain hose

in the laundry tub or

standpipe as shown.

4. Secure the drain hose using

the supplied beaded tie

strap.

20

5. If the washer faucets and the drain

standpipe are recessed, put the

hooked end of the drain hose in

the standpipe as shown.

NOTES:

n Do not force excess drain hose

back into the rear of the washer.

n To avoid siphoning, do not seal

the drain hose into the standpipe.

n To avoid siphoning, do not seal or

put more than 114 mm (4/") of the drain hose into drainpipe

or standpipe.

n It is the responsibility of the installer to install and secure the

drain hose into the provided plumbing/drain in a manner that

will avoid the drain hose coming out of, or leaking from, the

plumbing/drain.

Page 21

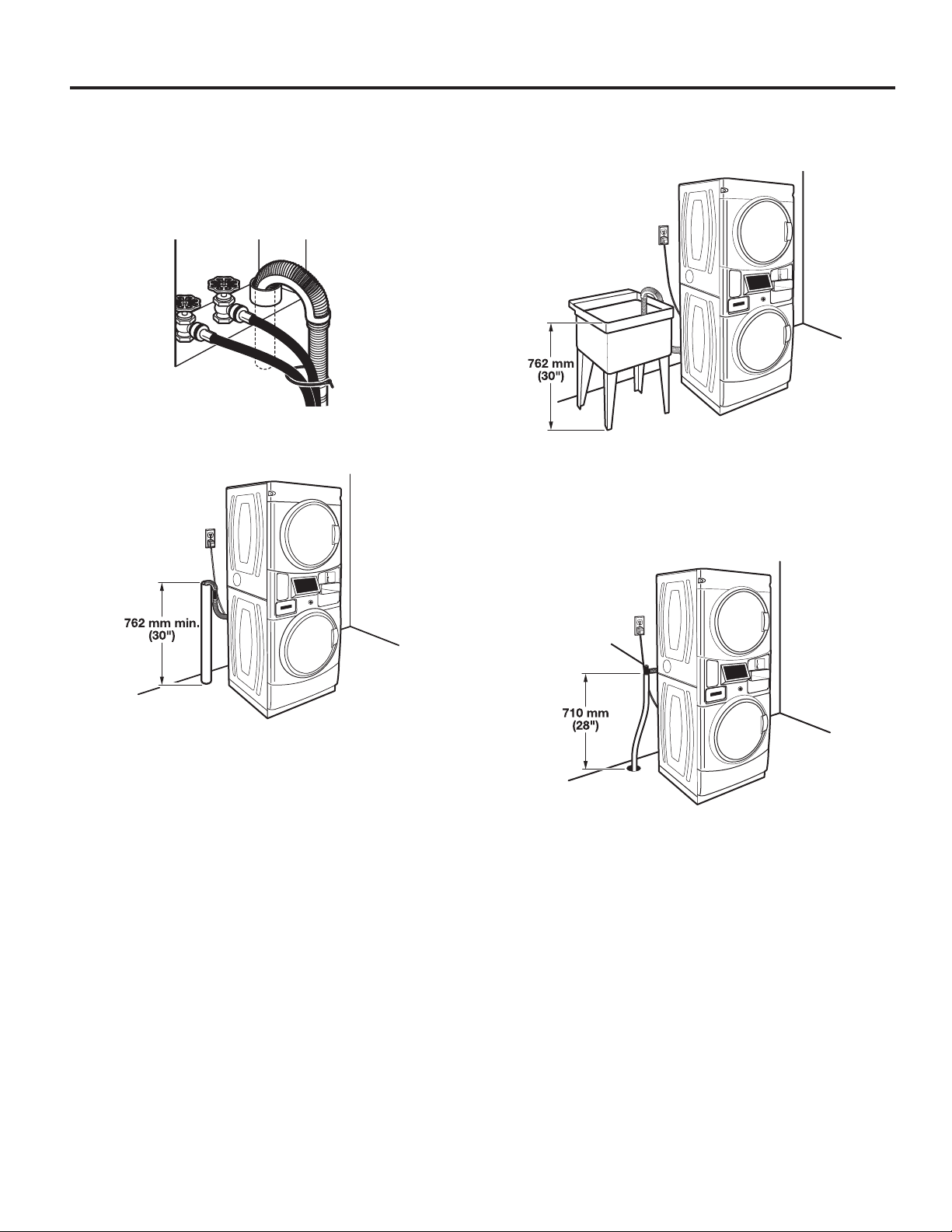

WASHER DRAIN SYSTEM

The washer can be installed using the standpipe drain system

(floor or wall), the laundry tub drain system, or the floor drain

system.

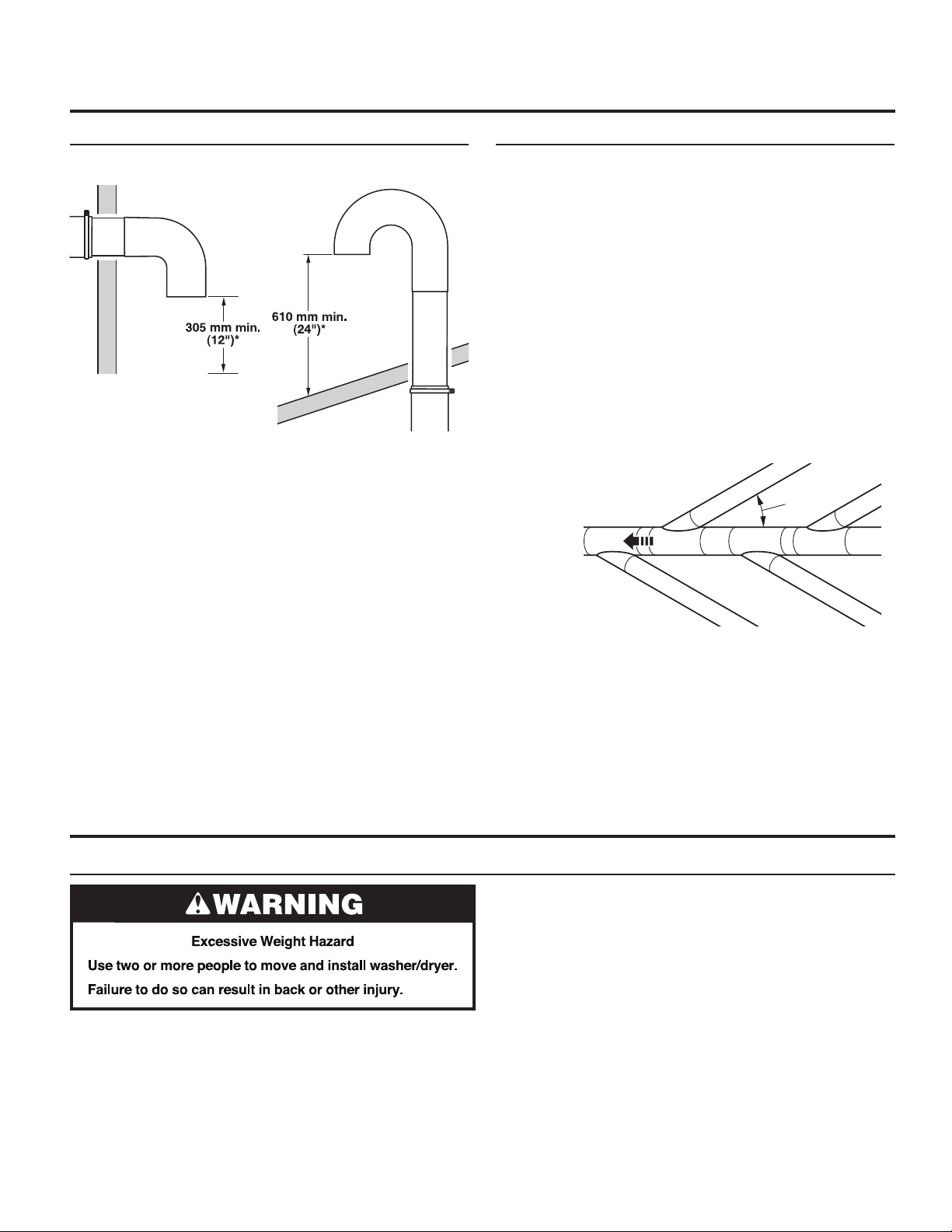

Standpipe drain system – wall or floor

The standpipe drain requires a minimum diameter standpipe of

50 mm (2"). The minimum carry-away capacity can be no less than

38 L (10 gal.) per minute.

Wall

The top of the standpipe must be at least 762 mm (30") high

and no higher than 2.4 m (96") from the bottom of the washer.

Floor

Laundry tub drain system

The laundry tub needs a minimum 76 L (20 gal.) capacity.

The top of the laundry tub must be at least 762 mm (30")

above the floor.

Floor drain system

The floor drain system requires a siphon break that may be

purchased separately.

The siphon break (Part Number 285834) must be a minimum

of 710 mm (28") from the bottom of the washer. Additional hoses

might be needed.

SyphonBreak

21

Page 22

LEVELING

Leveling Stacked Washer/Dryer

Leveling your washer/dryer properly reduces excess noise and

vibration.

1. Remove cardboard from beneath washer/dryer. Place a level on

top edges of washer/dryer, checking each side and front. If not

level, tip washer/dryer and adjust feet up or down as shown in

Steps 3 and 4, repeating as necessary.

3. If washer/dryer is not level, use a 14 mm or 9/16" open-

end or adjustable wrench to turn jam nuts clockwise (as

viewed from above) on feet until they are about 13 mm (1/2")

from the washer/dryer cabinet. Then turn the leveling foot

counterclockwise to lower the washer/dryer or clockwise to

raise the washer/dryer. Recheck levelness of washer/dryer and

that all four feet are firmly in contact with the floor. Repeat as

needed.

HELPFUL TIP: You may want to prop up front of washer/dryer

about 102 mm (4") with a wood block or similar object that will

support weight of washer/dryer.

Jam nut

4. When washer/dryer is level and all four feet are firmly in contact

with the floor, use a 14 mm or 9/16" open-end or adjustable

wrench to turn jam nuts counterclockwise (as viewed from

above) on leveling feet tightly against washer/dryer cabinet.

HELPFUL TIP: You may want to prop washer/dryer with

wooden block.

Not Level LEVEL Not Level

2. Grip washer/dryer from top and rock back and forth, making

sure all four feet are firmly on floor. Repeat, rocking washer/dryer

from side to side. If washer/dryer rocks, go to Step 3 and adjust

leveling feet. If all four feet are in firm contact with floor, go to

Step 4.

22

Page 23

COMPLETE INSTALLATION

1. Check the electrical requirements. Be sure that you have the

correct electrical supply and the recommended earthing method.

See “Electrical Requirements.”

2. Check that all parts are now installed. If there is an extra part,

go back through the steps.

3. Check that you have all of your tools.

4. Dispose of/recycle all packaging materials.

5. Check that the water faucets are on.

6. Check for leaks around faucets and inlet hoses.

7. To test and to clean your washer, measure one-half the detergent

manufacturer’s recommended amount of High Efficiency (HE)

detergent for a medium-sized load. Pour the detergent into the

detergent dispenser. Select any cycle and allow the washer

to complete one whole cycle.

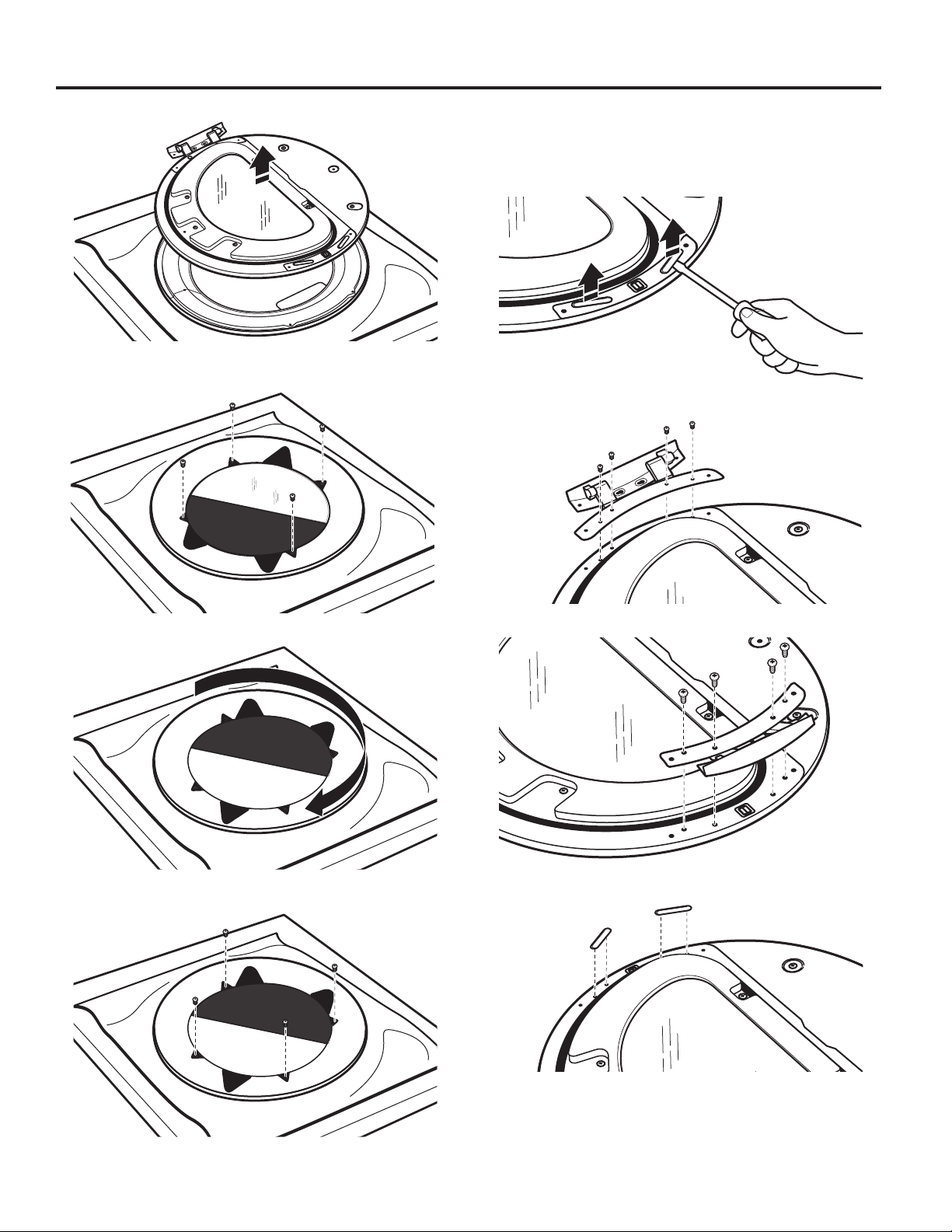

REVERSING DRYER DOOR SWING OPTIONAL

Remove the Door Assembly

1. Place a towel or soft cloth on top of dryer or work space

to avoid scratching of the surface.

2. Remove three of the four screws that hold the door hinge on the

front panel of the dryer. Partially loosen the remaining screw with

keyhole opening and lift the door off the screw.

8. Check dryer operation. Using a full heat cycle, let the dryer run

for at least 5 minutes. Dryer will stop when time is used up.

NOTE: The dryer door must be closed for the dryer to operate.

When the door is open, the dryer stops, but the timer continues

to run. To restart the dryer, close the door and press the cycle

button.

If the burner does not ignite and you can feel no heat inside

the dryer, shut off dryer for 5 minutes. Check that all supply

valve controls are in On position and that the electrical cord

is plugged in. Repeat the 5-minute test.

3. Lay the door assembly on a previously prepared flat surface

with the inside (inner door assembly) facing up, and remove six

Phillips-head screws to release outer door assembly from inner

door assembly.

NOTE: It is important that you remove only the six indicated

screws.

23

Page 24

REVERSING DRYER DOOR SWING OPTIONAL

4. Lift the inner door assembly off outer door assembly.

5. Remove four Phillips-head screws to release centre insert from

outer door ring.

Reverse Hinge

1. Use a small flat-blade screwdriver to remove the two plug strips

from the inner door. Slide the head of the screwdriver under

the plugs, without scratching the inner door surface, and lift

up the strip.

2. Remove the four screws that attach to inner door hinge.

6. Lift and rotate centre insert 180 degrees.

7. Reassemble the centre insert and outer door ring with the

four screws.

3. Move hinge to other side. Reinstall the four screws.

4. Reinstall plug strips on opposite side of the inner door.

24

5. Check for fingerprints on the glass. Clean if necessary.

Page 25

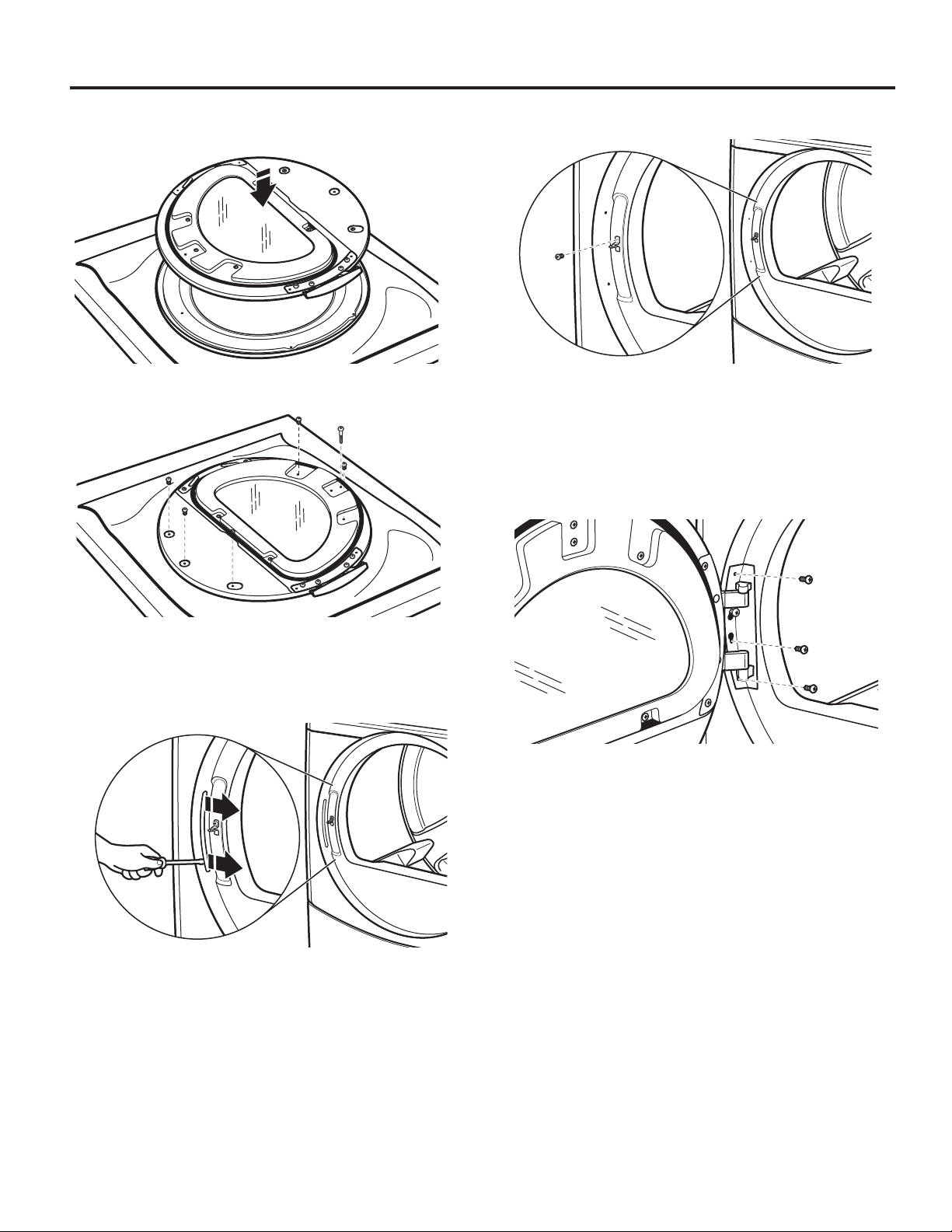

REVERSING DRYER DOOR SWING OPTIONAL

Replace the Door Assembly

1. Place the inner door assembly inside the outer door assembly.

2. Reassemble the inner and outer door assemblies with

the six screws.

2. Remove the strike using a Phillips screwdriver.

3. Insert strike on the opposite side.

Reinstall the Door

1. Partially insert the third screw from the top; then slide the

hinge onto this screw while hooking the hinge into the front

panel hole. Reattach door to dryer front panel with the remaining

three screws.

Reverse the Strike

1. Use a small flat-blade screwdriver to remove the plug strip

from the dryer door opening. Slide the head of the screwdriver

under the plugs, without scratching the dryer surface, and lift up

the strip.

2. Check for fingerprints on the glass. Clean if necessary.

3. Close door and check that it latches securely.

25

Page 26

STACKED WASHER/DRYER MAINTENANCE INSTRUCTIONS

Washer

Cleaning the Door Seal/Bellow

1. Open the washer door and remove any clothing or items from

the washer.

2. Inspect inner glass door. If debris is present, wipe it off using

a damp cloth.

3. Inspect the colored seal/bellow between the door opening and

the drum for stained areas. Pull back the seal/bellow to inspect

all areas under the seal/bellow and to check for foreign objects.

Seal/Bellow

4. If stained areas are found, wipe down these areas of the seal/

bellow:

a) Mix a dilute solution, using 177 mL (3/4 cup) of liquid chlorine

bleach, and 3.8 L (1 gal.) of warm tap water.

b) Wipe the seal/bellow area with the dilute solution, using

a damp cloth.

c) Let stand 5 minutes.

d) Wipe down area thoroughly with a dry cloth and let the

washer interior air dry with door open.

IMPORTANT:

n Wear rubber gloves when cleaning for prolonged periods.

n Refer to the bleach manufacturer’s instructions for proper use.

Maintenance Instructions:

This washer has a special cycle that uses higher water volumes

in combination with liquid chlorine bleach to thoroughly clean the

inside of the washer.

NOTES:

n Read these instructions completely before beginning the

cleaning process.

n If necessary, the cleaning cycle may be interrupted by pressing

the Start button twice. However, this will not immediately stop

the cycle. The washer will continue with several rinse and drain

steps to ensure that all remaining bleach is rinsed from the

washer.

To clean washer interior:

1. Open the washer door and remove any clothing or items from

the washer.

2. Use liquid chlorine bleach:

Open the dispenser drawer and immediately add

160 mL (2/3 cup) of liquid chlorine bleach to the bleach

compartment.

NOTE: Do not add any detergent. Use of more than 160 mL

(2/3 cup) of bleach will cause product damage over time.

3. Close the washer door and the dispenser drawer.

4. To start the Washer Cleanout cycle, first enter “Service Mode.”

Then press and hold the DELICATES button for 2 seconds.

Press the EXTRA RINSE button until P-08 is displayed; then

press the START button to start the cycle.

NOTE: The door will lock, the drum will rotate 1/2 turn, then the

door will unlock and lock again, then the Washer Cleanout Cycle

will continue.

n The washer will not fill, but the drum will rotate while

the washer runs a short sensing cycle. This will take

approximately 3 minutes.

5. The cycle will determine whether clothing or other items are

in the washer.

a) If no items are detected in the washer, it will proceed to

Step 6.

b) If any items are detected in the washer, “F-34” will be

displayed. Then the door will unlock.

n Enter the service mode and then press and hold the

START button to cancel the failure code. Then repeat

steps 1, 3, and 4 to start the cycle again.

6. Once the cycle has begun, allow the cycle to complete.

7. After the cycle is complete, leave the door open slightly to allow

for better ventilation and drying of washer interior.

26

Page 27

STACKED WASHER/DRYER MAINTENANCE INSTRUCTIONS

Washer

Always do the following to maintain washer

freshness:

n Use only HE (High Efficiency) detergent.

n Leave the door slightly open after each cycle to allow for better

ventilation and drying of washer interior.

n Clean the washer monthly using the Washer Maintenance

Procedure, using 160 mL (2/3 cup) of liquid chlorine bleach.

n If the procedure does not sufficiently improve the washer

freshness, please evaluate your installation and usage conditions

for other causes.

Cleaning the exterior

Use a soft damp cloth or sponge to wipe up any spills.

Occasionally wipe the outside of your washer to keep it looking

new. Use mild soap and water. Do not use abrasive products.

Cleaning the dispenser drawer

The dispenser drawer is removable for easy cleaning.

1. Unlock the dispenser drawer for removal by inserting a flat-blade

screwdriver into the catch release. Remove the dispenser drawer.

2. Remove the inserts (the siphon from the softener and bleach

compartments).

3. Wash the parts under running water.

NOTE: Do not wash components in the dishwasher.

4. Replace the inserts and return the dispenser to the drawer.

Water inlet hoses

Replace the inlet hoses after 5 years of use to reduce the risk of

hose failure. Periodically inspect and replace inlet hoses if bulges,

kinks, cuts, wear, or leaks are found.

When replacing your inlet hoses, record the date of replacement.

Dryer

Maintenance instructions:

n Clean lint screen before and after each cycle.

n Removing accumulated lint:

From inside the dryer cabinet:

Lint should be removed every 2 years or more often,

depending on dryer usage. Cleaning should be done

by a qualified person.

From the exhaust vent:

Lint should be removed every 2 years, or more often,

depending on dryer usage.

n Keep area around dryer clear and free from combustible

materials, gasoline and other flammable vapors and liquids.

n Keep dryer area clear and free from items that would obstruct

the flow of combustion and ventilation air.

If dryer does not operate, check the following:

n Electrical supply is connected.

n Circuit breaker is not tripped or house fuse is not blown.

n Door is closed. Listen closely to hear the door switch activate.

n Cycle selection button has been pushed firmly.

n For gas dryers, check that gas supply shut-off valves are set

in open position.

If you need help, contact the dealer from whom you purchased the

appliance, or a Maytag designated service company. When calling,

please know the purchase date and the complete model and serial

number of your appliance. This information will help us to better

respond to your request.

IF YOU NEED ASSISTANCE

Accessories

Enhance your washer/dryer with these premium accessories.

For more high-quality items or to order, contact your authorised

Maytag distributor.

Part Number Accessory

8212526 Washer drip trays; fits under all

31682 All-purpose appliance cleaner

1903WH Laundry supply storage cart

Whirlpool Corporation, Benton Harbor, Michigan 49022, U.S.A.,

Marion Division, 1300 Marion-Agosta Road, Marion, OH 43301

EU representative: Whirlpool EMEA S.p.A.,

Via Carlo Pisacane, 1, 20016 Pero (MI) Italy

27

Page 28

TECHNICAL SPECIFICATIONS GAS DRYER

220-240V~50Hz 1ph 10A max. IPX4 Clothes capacity: 9.0 kg max. Sound pressure level, LpA: 58 dB(A)

(uncertainty, Kpa: +/-10 dB(A)) Total mass: 174 kg max.

Factory set for NATURAL GAS: Injector size: 2.2 mm Heat input gross: 5.9 kW

Country: CH, CZ, CY, ES, GB, GR,

IE, IT, LT, PT, SI, SK, TR

European Gas Category: II

2H3+

Gas Flow Rate: 0.562703 m3/hr 0.562703 m3/hr

Supply Pressure (G20): 20 mbar 20 mbar

Factory Adjusted Pressure: 7.4 mbar 7.4 mbar

With L.P. Gas Conversion Kit: Injector size: 1.25 mm Heat input gross: 6.4 kW

European Country: CH, CZ, CY, ES, GB, GR,

IE, IT, LT, PT, SI, SK, TR

European Gas Category: II

2H3+

Butane Supply Pressure (G30): 28-30 mbar 30 mbar

Adjusted Pressure: N/A N/A

L.P. Supply Pressure (G31): 37 mbar 30 mbar

Adjusted Pressure: N/A N/A

With France/Belgium NATURAL GAS conversion kit: Injector size 1.65 mm Heat input gross: 5.9 kW

European Country: FR, BE

European Gas Category: I

2E+

Supply Pressure (G20): 20 mbar

Supply Pressure (G25): 25 mbar

Adjusted Pressure: N/A

Factory set for NATURAL GAS: Injector size: 2.2 mm Heat input gross: 5.9 kW

Country: AT, BG, CH, CZ, DK, EE, ES, FI, GB, GR, HR,

IE, IS, IT, LT, LV, NO, PT, RO, SE, SI, SK, TR

European Gas Category: I

2H

Gas Flow Rate: 0.562703 m3/hr

Supply Pressure (G20): 20 mbar

Factory Adjusted Pressure (G20): 7.4 mbar

CY, CZ, DK, EE, FI, GR, HR,

IT, LT, NO, RO, SE, SI, SK

II

2H3B/P

CY, CZ, DK, EE, FI, GR, HR,

IT, LT, NO, RO, SE, SI, SK

II

2H3B/P

28

Page 29

TECHNICAL SPECIFICATIONS GAS DRYER

Factory set for NATURAL GAS: Injector size: 2.2 mm Heat input gross: 5.9 kW

Country: DE, LU, PL

European Gas Category: I

Gas Flow Rate: 0.562703 m3/hr

Supply Pressure (G20): 20 mbar

Factory Adjusted Pressure (G20): 7.4 mbar

Factory set for Australia/New Zealand NATURAL GAS: Injector size: 2.2 mm Heat input gross: 5.9 kW

Country: AU, NZ

Supply Pressure (G20): minimum 1.13 kPa

Adjusted Pressure (Test Point Pressure): 0.74 kPa

Nominal Hourly Gas Consumption: 21.1 MJ/h

With Australia L.P. Gas Conversion Kit: Injector Size: 1.40 mm Heat input gross: 6.54 kW

Country: AU, NZ

L.P. Supply Pressure: 2.75 kPa

Adjusted Pressure: 2.75 kPa

Nominal Hourly Gas Consumption: 23 MJ/h

Factory set for NATURAL GAS: Injector size: 2.2 mm Heat input gross: 5.0 kW

Country: NL

European Gas Category: I

Gas Flow Rate: 0.562703 m3/hr 0.562703 m3/hr

Supply Pressure (G25): 25 mbar 25 mbar

Factory Adjusted Pressure (G25) : 7.4 mbar 7.4 mbar

Supply Pressure (G30/G31): Not Applicable 30 mbar

Factory Adjusted Pressure (G30/G31): Not Applicable Not Applicable

NOTE: Conversion kit: From Natural Gas to L.P. Gas - Europe: Whirlpool Part No. W10571757.

Conversion kit: From Natural Gas to L.P. Gas - Australia: Whirlpool Part No. W10571729.

Conversion kit: From Natural Gas to Natural Gas - France/Belgium: Whirlpool Part No. W10181947.

Manufacturer: Whirlpool Corporation, Benton Harbor, Michigan 49022, U.S.A.

Manufacturing Site: Whirlpool Corporation, 1300 Marion-Agosta Rd., Marion, OH, 43302, U.S.A.

EU Representatives: Whirlpool EMEA S.p.A., Via Carlo Pisacane, 1, 20016 Pero (MI) Italy

2L

2E

II

2L3B/P

29

Page 30

ELECTRONIC CONTROL SETUP INSTRUCTIONS

Washer Control

NOTE: After the washer/dryer has been installed and plugged

in, the display will show “0 MINUTES” on the washer and dryer

portions of the display. After the washer and dryer doors have

been opened and closed, the display will show the price for each

machine. On washer/dryers set for free cycles, the display sections

will flash “SELECT CYCLE.”

1. PD Models: Insert coins until “SELECT CYCLE” flashes on the

display portion of the washer or dryer that is to be run.

PN Models: Sent from the factory as Free Vend. If a debit

card reader is installed, then a debit card is required rather

than coins. Generation 1 or 2 debit card systems may be used;

but when the Generation 2 debit system is used, the controls

will automatically be set to Enhanced Debit mode (J. Ed). In

Enhanced Debit mode, the card balance will also display when

a debit card is inserted into the reader.

2. Door must be closed on the desired washer/dryer before cycle

selection is made.

3. Press the fabric setting button for the washer/dryer cycle

desired. After the cycle is started, the time will display and

count down.

4. If a cycle is interrupted by opening the door or power loss,

“RESELECT CYCLE” will flash in the display. To restart the

washer/dryer, close door and reselect desired cycle.

NOTE: When set for free vend operation an ongoing dryer cycle

will cancel if the door is opened.

Dryer Control

General Washer/Dryer User Information

SCROLLING “OUT OF ORDER” MESSAGE, FOLLOWED BY A

FAILURE OR DIAGNOSTIC CODE, SHOWING IN DISPLAY –

condition indicates the washer/dryer is inoperative. Diagnostic

codes being displayed on the upper portion of the display pertain

to the dryer section, and diagnostic codes displayed on the lower

portion of the display apply to the washer section. Diagnostic

codes displayed on both the upper and lower portions of the

display pertain to the control system of both the washer and dryer.

“0 MINUTES” SHOWING IN DISPLAY – This indicates the

cycle is complete and the washer/dryer cannot be operated. Coins

dropped or debit inputs during this condition will be stored in

escrow but cannot be used until normal operation is restored by

opening and closing the door. If a door switch has failed, causing

“0 MINUTES” to remain in the display after the door is opened

and closed, it must be replaced before normal operation can be

restored.

COLD START (Initial first use) – Washer/dryer is programmed

at the factory as follows:

Washer 11-minute wash period

1.75 wash price (PD models)

0.00 wash price (PN models)

three rinses (extra rinse not enabled)

Dryer 5 minutes per coin for PD models

45 minutes dry time for PN models

1.50 dry price (fixed cycle with top off –

PD Models)

0.00 dry price (fixed cycle – PN Models)

This

30

Page 31

ELECTRONIC CONTROL SETUP INSTRUCTIONS

WARM START (after power failure) – A few seconds after

power is restored, if a cycle was in progress at the time of the

power failure, “RESELECT CYCLE” will flash in the display,

indicating the need for a key press to restart washer or dryer.

WASHER DOOR LOCK – Prior to beginning a cycle, there is

a door lock routine of lock/unlock/relock, and then cycle begins.

The door will remain locked until the end of a cycle or

approximately 2 minutes after a power interruption.

PRICING – After the door is opened and then closed following

the completion of a cycle, the display indicates the cycle price

(unless set for free operation, where the display will flash “SELECT

CYCLE”). As coins are dropped or debit inputs arrive, the display

will change to lead the user through the initiation of a cycle.

There are four (4) types of dryer pricing:

Fixed “Vend” Pricing

A dryer setup for “Fixed Cycle” operation can only accept

additional time accumulated by increments equal to the length of a

complete dry cycle. A maximum of 99 minutes may be purchased;

no additional credit is given for coins dropped with 99 minutes in

the display.

Accumulator Pricing

If the price is set to one coin 1, then accumulator pricing is

in effect. Cycle time can be purchased one coin at a time

(PD models) up to the maximum time of 99 minutes.

Fixed Cycle With Top Off Pricing

A dryer set to offer “Top Off” capability will allow time to be added

to an existing dry cycle in increments equal to the number of

minutes of dry time per coin (coin 1), up to 99 minutes, regardless

of the cost required to start the dryer. No credit is given for coins

or debit inputs entered when the control is displaying 99 minutes.

PN Models: In Enhanced Debit Mode, the top off price can be set

independently (see VALUE OF COIN 2), and the top off time is

calculated according to the following equation:

top off time = x full cycle length

top off price

full cycle price

Penny increment offset is not applied to top off purchases.

FREE CYCLES – This is established by setting the cycle price

to zero. When this happens, “SELECT CYCLE” will appear

rather than a cycle price. Any cycle started as a free cycle

will automatically terminate when the door is opened.

DEBIT CARD READY – This washer/dryer is debit card ready.

It will accept a variety of debit card systems, but does NOT

come with a debit card reader. Refer to the debit card reader

manufacturer for proper washer/dryer setup. In models converted

to a Generation 1 debit card system, debit pulses represent the

equivalent of one coin (coin 1).

Control Set-up Procedures

IMPORTANT: Read all instructions before operating.

PD/PN Models: Insert service switch key and turn

counterclockwise.

PN Models: Once a Generation 2 debit card reader is installed

(according to the reader manufacturer’s instructions), the set-up

modes can only be changed by inserting a set-up card (supplied

by the reader manufacturer) into the card slot. Inserting the service

switch key and turning will only allow access to the service mode.

The washer/dryer is now in the set-up mode. The lower fabric

setting buttons and the lower portion of the display are used to set

up the digital control for the washer. The upper three fabric setting

buttons and the upper portion of the display are used to set up the

controls for the dryer.

The display can contain four numbers and/or letters and a decimal

point on both the top and bottom display portions. These are used

to indicate the set-up codes and related code values available for

use in programming the washer/dryer.

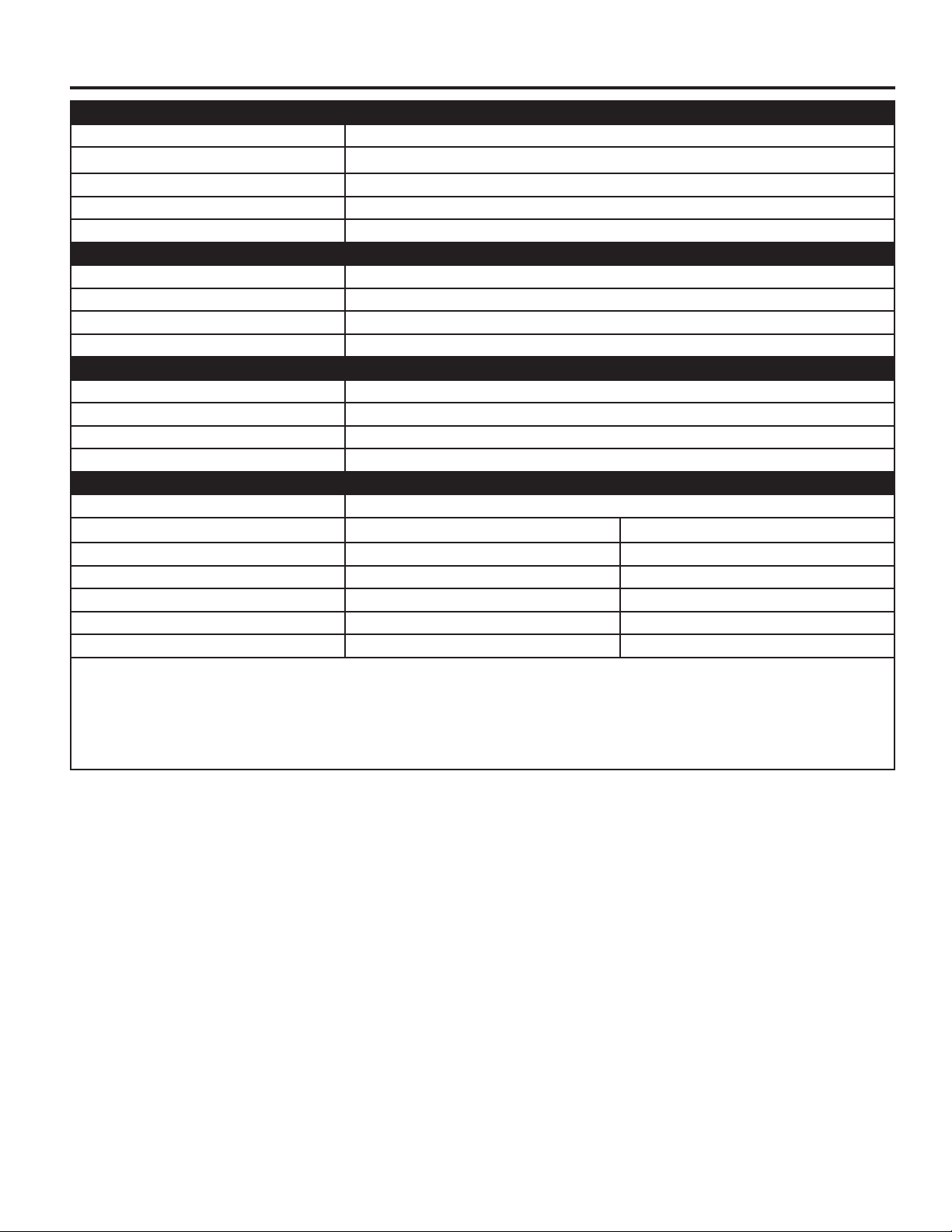

How to Use the Buttons to Program the Controls

Washer:

1. POWERWASH—Upper left button is used to adjust the

values associated with set-up codes. Pressing the button

will increment the value. Rapid adjustment is possible

by holding the button down.

2. TEMPERATURE—Lower left button is used to adjust

the values associated with set-up codes. Pressing the button

will decrement the value. Rapid adjustment is possible

by holding down the button.

3. EXTRA RINSE—Lower middle button will advance through

the set-up codes. Pressing the button will advance to the

next available set-up code. Holding the button down will

automatically advance through the set-up codes at a rate

of one per second.

4. DELICATES—the right button is used to select or deselect

options.

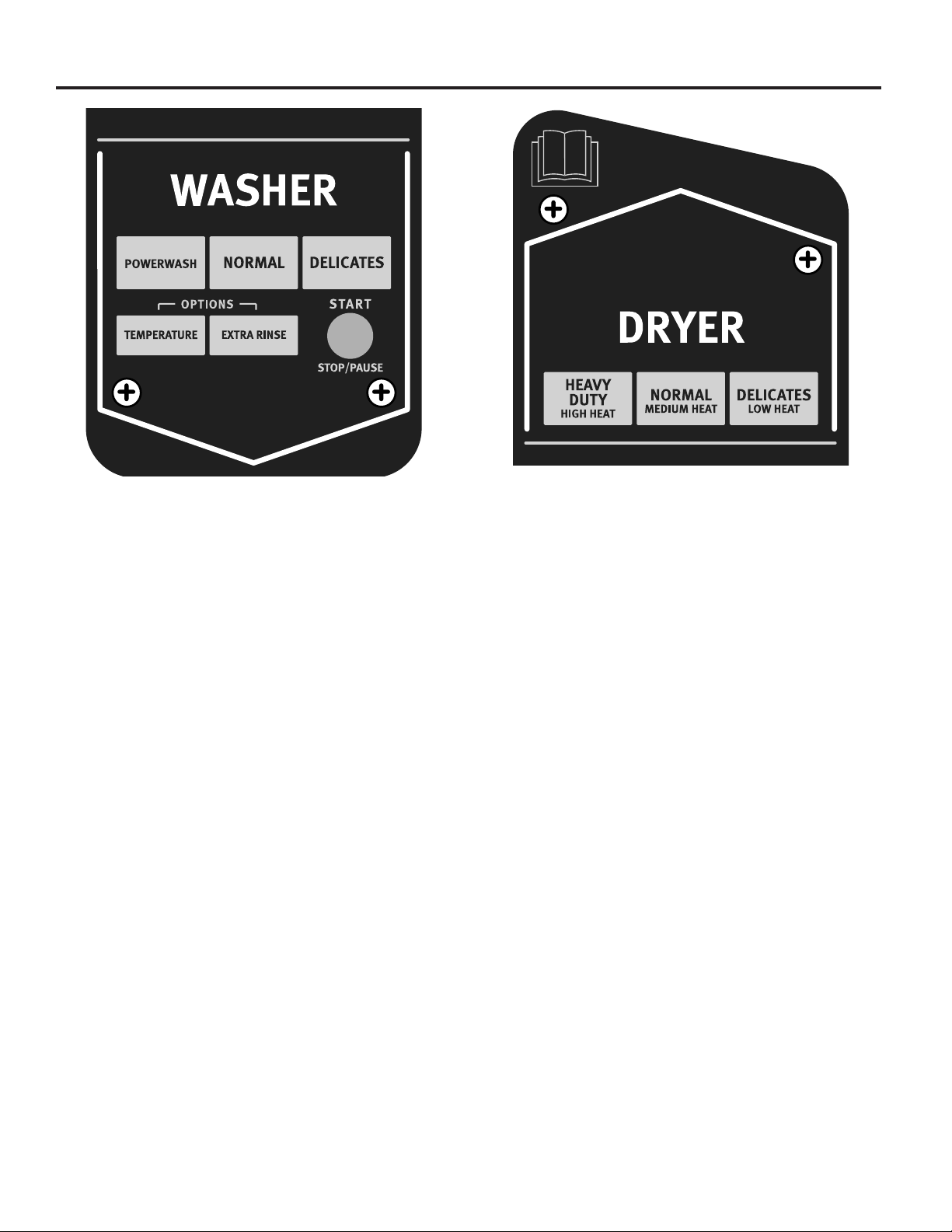

Dryer:

1. HEAVY DUTY—Left button is used to adjust the value

associated with set-up codes. Pressing the button will

increment the value. Rapid adjustment is possible by holding

down the button.

2. DELICATES—the right button is used to select or deselect

options.

31

Page 32

ELECTRONIC CONTROL SETUP INSTRUCTIONS