Maytag MDG22PN, MDG22PD Installation Instructions

COMMERCIAL DRYER INSTALLATION INSTRUCTIONS

Gas

INSTRUCTIONS D’INSTALLATION D’UN SECHE-LINGE COMMERCIAL

À gaz

INSTRUCCIONES DE INSTALACIÓN – SECADORA COMERCIAL

A gas

ISTRUZIONI D’INSTALLAZIONE – ASCIUGATRICE COMMERCIALE

A gas

MDG22PN MDG22PD

W10239199B

www.maytagcommerciallaundry.com

TABLE OF CONTENTS

DRYER SAFETY ............................................................................3

DRYER DISPOSAL ........................................................................4

INSTALLATION REQUIREMENTS ..............................................4

Tools and Parts ..........................................................................4

Location Requirements ..............................................................4

Electrical Requirements – Gas Dryer ........................................6

as Supply Requirements ........................................................6

G

Venting Requirements ................................................................7

TABLE DES MATIÈRES

SECURITE DU SECHE-LINGE ................................................18

ELIMINATION DU SECHE-LINGE ..........................................19

EXIGENCES D’INSTALLATION................................................19

Outillage et pièces ....................................................................19

Exigences d’emplacement ......................................................20

Spécifications électriques – sèche-line à gaz .........................21

Spécifications de l’alimentation en gaz ..................................22

Exigences concernant l’évacuation..........................................23

INSTALLATION INSTRUCTIONS – GAS DRYER ....................9

Install Leveling Legs....................................................................9

Make Gas Connection................................................................9

Connect Vent ..............................................................................9

Complete Installation ................................................................9

MAINTENANCE INSTRUCTIONS ..........................................10

ECHNICAL SPECIFICATIONS – GAS DRYER......................10

T

REVERSING THE DOOR SWING (OPTIONAL).......................11

ELECTRONIC CONTROL SETUP ..........................................13

WARRANTY..............................................................................17

INSTRUCTIONS D’INSTALLATION –

SECHE-LINGE A GAZ ..............................................................25

Installation des pieds de nivellement........................................25

Raccordement à la canalisation de gaz ..................................25

Raccordement du conduit d’évacuation ................................25

Achever l’installation ................................................................25

INSTRUCTIONS D’ENTRETIEN...............................................26

FICHE TECHNIQUE – SECHE-LINGE A GAZ ........................26

INVERSION DU SENS D’OUVERTURE DE LA PORTE .........27

REGLAGE DE LA CARTE

DE CIRCUITS ELECTRONIQUES ..........................................29

GARANTIE ................................................................................33

ÍNDICE

SEGURIDAD DE LA SECADORA............................................34

ELIMINACIÓN DE LA SECADORA ..........................................35

REQUISITOS DE INSTALACIÓN ............................................35

Piezas y herramientas ..........................................................35

Requisitos de ubicación ........................................................35

Requisitos eléctricos – secadora a gas ................................36

Requisitos del suministro de gas............................................37

Requisitos de ventilación ....................................................38

INDICE

SICUREZZA DELL’ASCIUGATRICE ........................................ 49

L’ELIMINAZIONE DELL’ASCIUGATRICE ................................ 50

REQUISITI D’INSTALLAZIONE ................................................ 50

Attrezzi e componenti.............................................................. 50

Requisiti di ubicazione ............................................................ 50

Requisiti elettrici – asciugatrice a gas .................................... 51

Requisiti di alimentazione del gas .......................................... 52

Requisiti di scarico ................................................................53

INSTRUCCIONES DE INSTALACIÓN –

SECADORA A GAS ................................................................40

Instalación de las patas niveladoras ....................................40

Conexión del suministro de gas............................................40

Conexión del ducto de escape ............................................40

Complete la instalación ........................................................40

INSTRUCCIONES DE MANTENIMIENTO ..............................41

ESPECIFICACIONES TÉCNICAS – SECADORA A GAS ......41

CÓMO INVERTIR EL SENTIDO DE APERTURA

DE LA PUERTA .......................................................................42

PROGRAMACIÓN DEL CONTROL ELECTRÓNICO ............44

GARANTÍA................................................................................48

ISTRUZIONI D’INSTALLAZIONE – ASCIUGATRICE

A GAS ...................................................................................... 55

Installazione dei piedini di regolazione ....................................55

Eseguire il collegamento gas....................................................55

Connessione dello scarico ......................................................55

Completamento dell’installazione ............................................56

ISTRUZIONI DI MANUTENZIONE .........................................57

DATI TECNICI – ASCIUGATRICE A GAS ..............................57

INVERSIONE DELLA ROTAZIONE DI APERTURA ...............58

CONFIGURAZIONE DEI CONTROLLI ELETTRONICI ..........60

GARANZIA ..................................................................................64

2

You can be killed or seriously injured if you don't immediately

You

can be killed or seriously injured if you don't

follow

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

follow instructions.

instructions.

DANGER

WARNING

DRYER SAFETY

WARNING: For your safety, the information in this manual must be followed to minimize

the risk of re or explosion, or to prevent property damage, personal injury, or death.

– Do not store or use petrol or other ammable vapors and liquids in the vicinity of this

or any other appliance.

– WHAT TO DO IF YOU SMELL GAS:

•

Do not try to light any appliance.

•

Do not touch any electrical switch; do not use any phone in your building.

•

Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

•

If you cannot reach your gas supplier, call the re department.

– Installation and service must be performed by a qualied installer, service agency, or

the gas supplier.

•

Clear the room, building, or area of all occupants.

FOR YOUR SAFETY

1. DO NOT USE OR STORE PETROL OR OTHER FLAMMABLE MATERIALS IN THIS APPLIANCE OR NEAR THIS APPLIANCE.

2. DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS APPLIANCE WHILE IT IS IN OPERATION.

3. DO NOT MODIFY THIS APPLIANCE.

3

DRYER DISPOSAL

INSTALLATION REQUIREMENTS

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools

listed here.

Tools needed:

■ 200 mm (8") or 250 mm

(10") Pipe wrench

■ 200 mm (8") or 250 mm

(10") Adjustable wrench

■ Flat-blade screwdriver

■ Phillips screwdriver

■ Adjustable wrench that

opens to 25 mm (1") or

hex-head socket wrench

■ Level

Parts supplied:

Remove parts bag from dryer drum. Check that all parts were

included.

■ Foot boot (4)

■ Dryer foot (4)

NOTE: The circuit diagram for this dryer is located inside the

lower front panel.

■ 8 mm (5/16") socket wrench

■ Utility knife

■ Vent clamps

■ Pipe-joint compound

resistant to LP gas

■ Sealing gun and sealing

compound (for installing

new exhaust vent)

■ Pliers

■ Putty knife

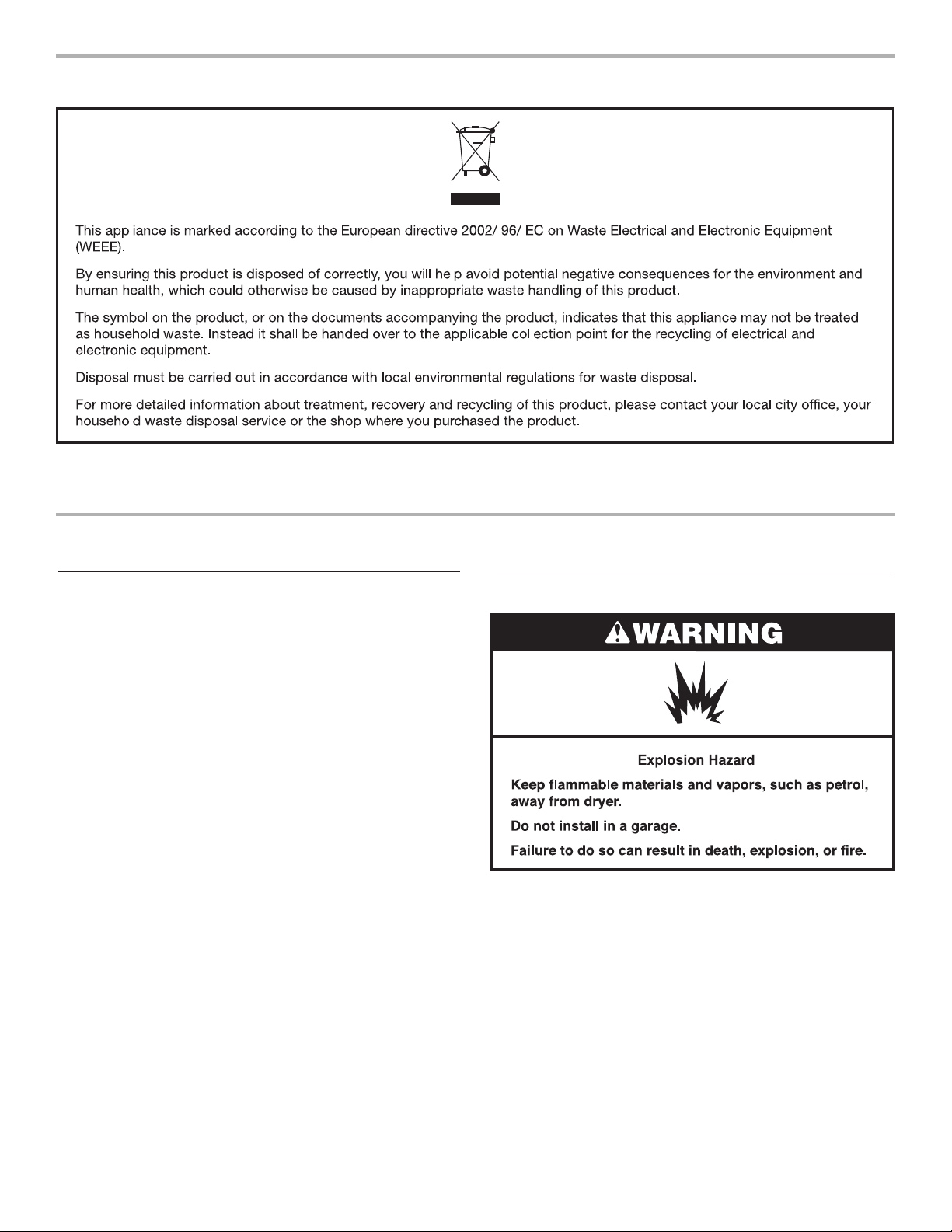

Location Requirements

If installing a gas dryer:

IMPORTANT: Observe all governing codes and ordinances.

■ Check code requirements: Some codes limit or do not permit

installation of clothes dryers in garages, closets, or sleeping

quarters. Contact your local building inspector.

■ Make sure that lower edges of the cabinet, plus the back and

bottom sides of the dryer, are free of obstructions to permit

adequate clearance of air openings for combustion air. See

“Recessed Area and Closet Installation Instructions” on the

next page for minimum spacing requirements.

■ Do not install on carpet.

NOTE: The dryer must not be installed in an area where it will be

exposed to water and/or weather.

4

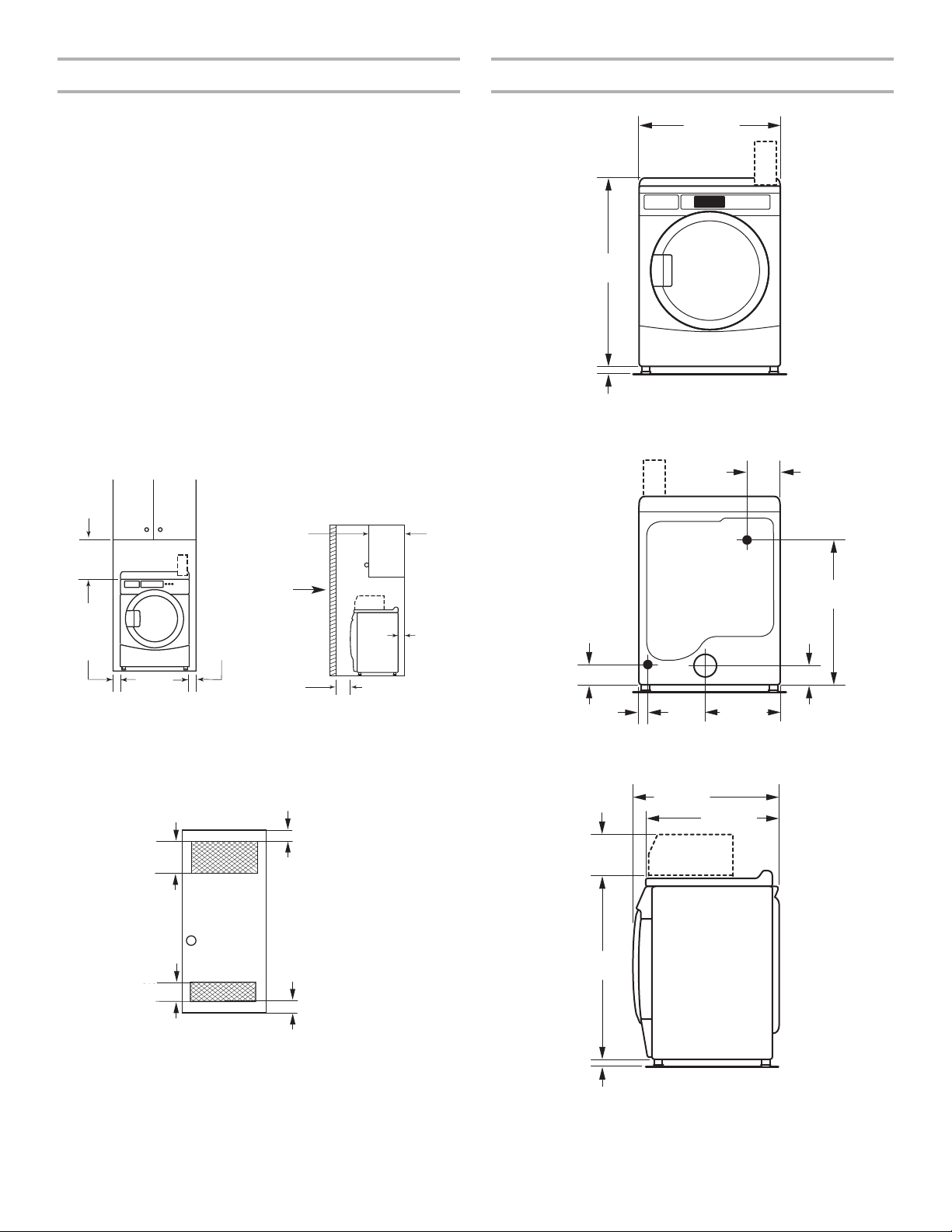

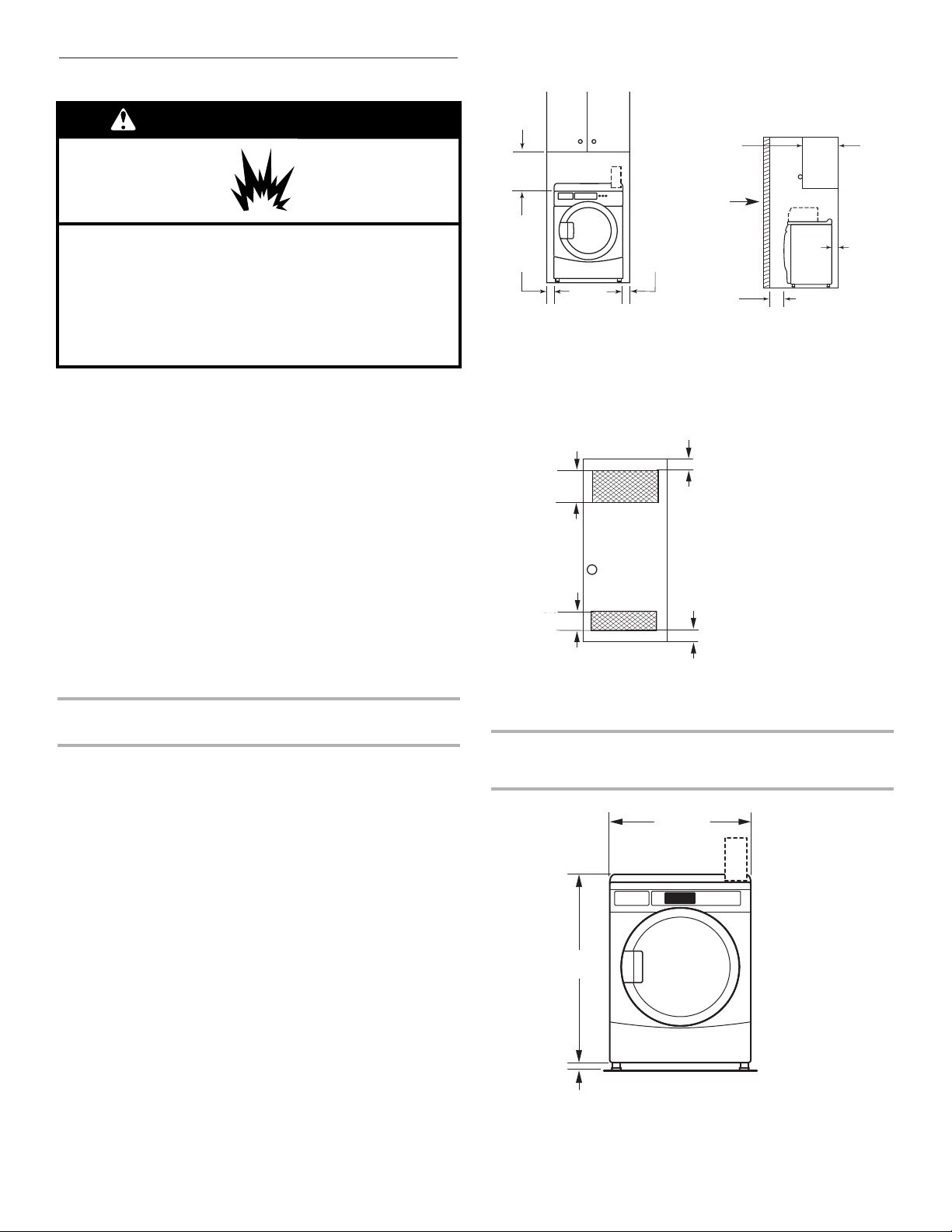

ecessed Area and Closet Installation Instructions

381 mm

(15")

0 mm

(0")

0 mm

(0")

356 mm

(14") max

25 mm (1")

0 mm

(0")

686 mm

(27")

965 mm

(38")

25 mm

(1")

32 mm

(11/4")

159 mm

(6

1

/4")

152 mm

(5

7

/8")

733 mm

(28

3

/4")

83 mm

(3

1

/2")

330 mm

(13")

736 mm

(29")

921 mm

(36

1

/4")

203 mm

(8")

25 mm

(1")

695 mm

(271/4")

24 in.

2

(155 cm2)

48 in.

2

(310 cm2)

3"

(76 mm)

3"

(76 mm)

Closet

door

Front

View

R

his dryer may be installed in a recessed area or closet.

T

This dryer must not be installed behind a lockable door,

a sliding door, or a door with a hinge on the opposite side

o that of the dryer.

t

The installation spacing is in millimeters and is the minimum

allowable. Additional spacing should be considered for ease

of installation, servicing, and compliance with local codes

and ordinances.

If installed in a closet with a door, the minimum unobstructed air

opening in the top and bottom is required. Louvered doors with

equivalent air openings are acceptable.

The dryer must be exhausted outdoors.

No other fuel-burning appliance may be installed in the same

closet as the dryer.

Minimum Installation Clearances

roduct Dimensions 686 mm (27") dryer

P

FRONT VIEW

Closet

door

Recessed front view

Additional clearances for wall, door, and floor moldings may be required or if

external exhaust elbow is used.

2

310 cm

(48 in2.)*

155 cm

(24 in2.)*

Front

View

closet

door

2

Closet side view

76 mm

(3")

*Opening is the minimum

for a closet door.

Louvered doors with

equivalent air openings

are acceptable.

76 mm

(3")

ELECTRIC

GAS

BACK VIEW

SIDE VIEW

5

Electrical Requirements – Gas Dryer

E

ARTHING INSTRUCTIONS

SAVE THESE INSTRUCTIONS

IMPORTANT: Observe all governing codes and ordinances.

You will need an earthed electrical outlet located within 610 mm

(2 feet) of either side of the dryer.

his dryer is supplied/fitted with an electricity supply cord and

T

plug. It should be connected to electricity supply socket at the

voltage shown on the rating plate. The minimum supply fuse

capacity should be 5A. The dryer must be positioned so that the

plug is clearly visible and accessible. This plug also provides the

function of an emergency stop control for the user. If the fitted

plug is not used, the electrical connection must be carried out

by a competent electrician in accordance with local or national

codes.

If the supply cord is damaged, it must be replaced with a

specially terminated cord by an authorized service agent or

a similarly competent person in order to avoid a hazard.

Do not use an adapter.

Do not use an extension cord.

NOTE: In accordance with the European EMC Directive

(2004/108/EC), the maximum electricity supply system

impedance to which the gas dryer should be connected

is declared to be 0.054 Ohm + j0.034 Ohm.

NOTE: Electrical safety standards: The manufacturer has

chosen compliance with IEC/EN.60335 standards as the most

appropriate for this product.

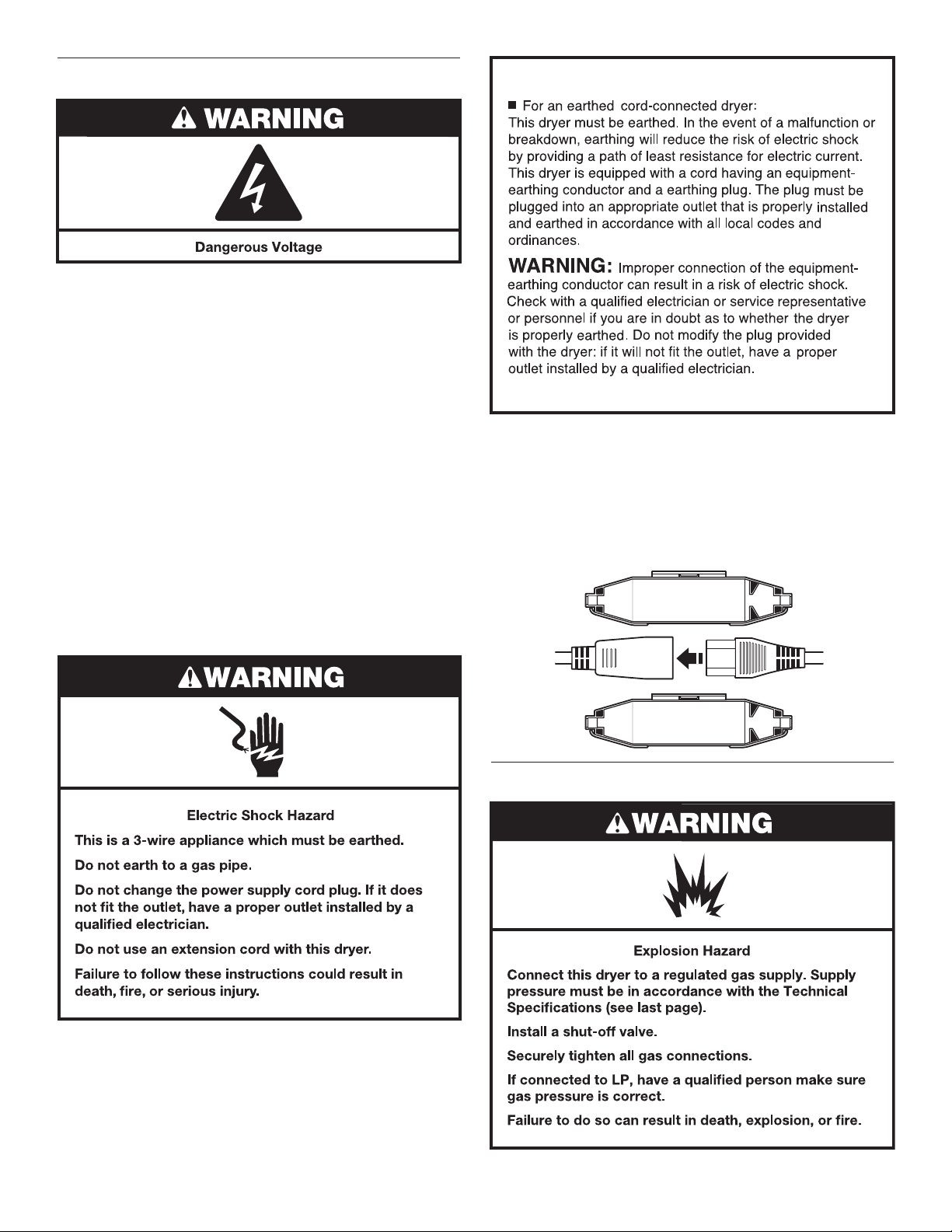

Using the universal cord included with this dryer:

The gas dryer is equipped with a universal cord with

interchangeable plugs.

1. To use the universal cord, select the plug end that fits

your electrical outlet, and plug it into the adapter on the

supply cord.

2. Secure the plug end in place on the cord by aligning

the 2 cover halves over the cord adapter and clipping

them together.

If codes permit and an additional earth bond wire is used, it is

recommended that a qualified electrician determine that the earth

bond path is adequate.

6

Gas Supply Requirements

IMPORTANT: Observe all governing codes and ordinances.

Gas Supply

102 mm

(4")

Improper venting can cause moisture and lint to collect

indoors, which may result in:

Moisture damage to woodwork, furniture, paint, wallpaper,

carpets, etc.

Housecleaning problems and health problems.

WARNING

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent.

Do not use a metal foil vent.

Failure to follow these instructions can result in death

or fire.

efore installation, check that the local gas distribution

B

onditions, nature of gas and pressure, and the adjustment

c

f the appliance are compatible. Burner information will be

o

ound on the model/serial rating plate in the door recess of

f

he dryer. If this information does not agree with the type

t

f gas available, see your dealer.

o

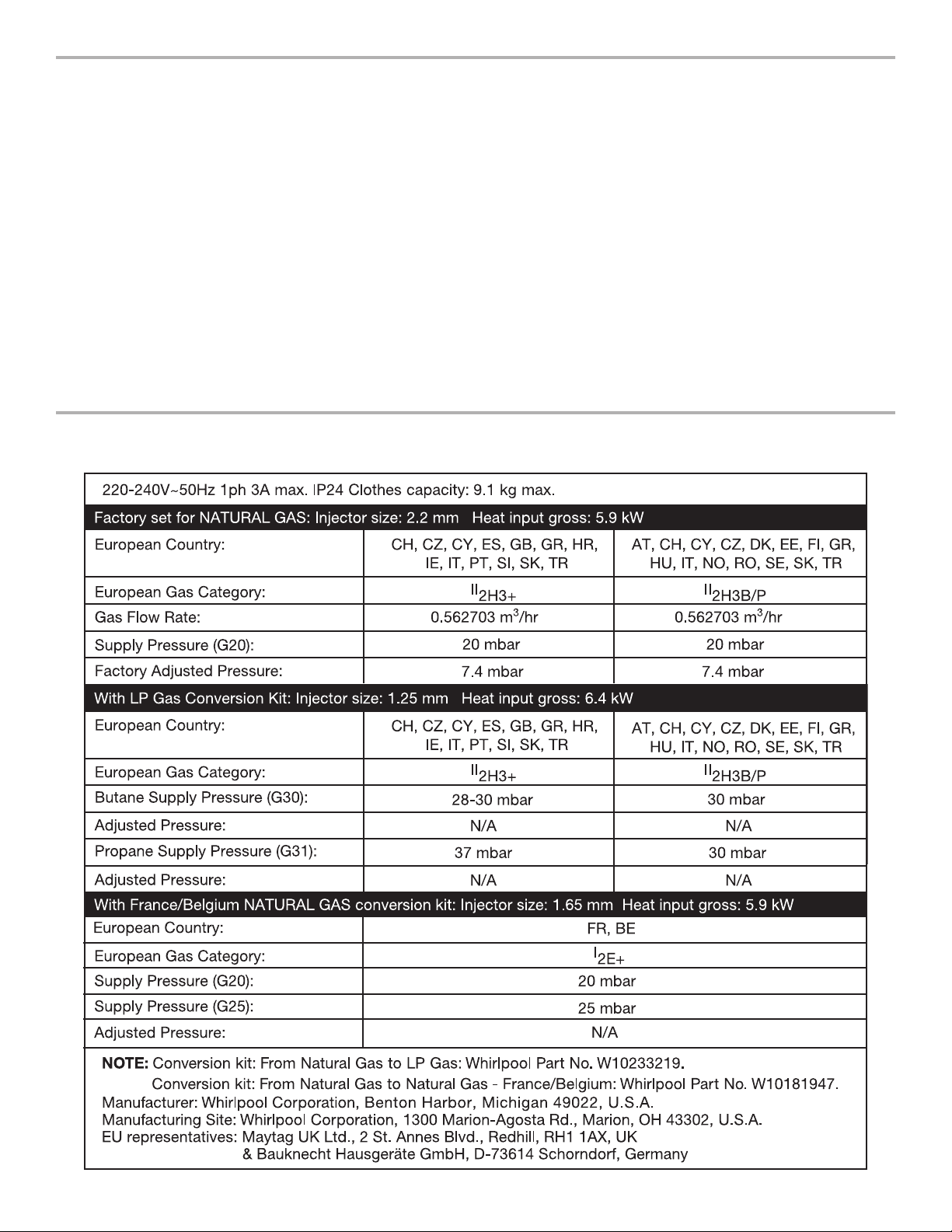

Natural Gas:

his dryer is factory adjusted for use with NATURAL GAS (G20),

T

nd no further adjustment should be required at installation.

a

L.P. Gas:

his dryer is also certified for use with L.P. (propane or butane)

T

ases with appropriate conversion. No attempt shall be made to

g

onvert the appliance from the gas specified on the model/serial

c

ating plate for use with a different gas without consulting the

r

serving gas supplier.

Conversion must be done by a competent service technician.

Gas conversion kit, part number W10233219, is available for

purchase from your dealer. Full instructions are supplied with

the kit.

Natural gas (France/Belgium):

This dryer is also certified for France/Belgium for use with

G20/G25 gases (20 mbar/25 mbar) with appropriate conversion.

No attempt should be made to convert this appliance from the

gas specified on the gas rating label for use with a different gas

without consulting the serving gas supplier. Gas conversion must

be done by a qualified gas service technician. Conversion kit, part

number (W10181947) is available for purchase from your dealer.

Full instructions are supplied with the kit.

Supply line requirements:

Provide a rigid gas supply line to the dryer location. It should be

minimum 12.5 mm (1/2") ID. When acceptable to the gas supplier

and local codes, 10 mm (3/8") ID rigid supply line may be used

for lengths under 6.1 m (20'). Pipe-joint compounds resistant to

the action of L.P. gas must be used.

Gas connection to the dryer itself should be made by means

of a flexible gas hose suitable for the appliance and gas category

in accordance with national installation regulations. If in doubt,

contact the gas supplier. It should be minimum 10 mm (3/8") ID.

A means of restraint should be used between the dryer and

the wall to prevent straining of the rigid gas supply when the

dryer is moved. An appropriate length of chain and a wall hook

is recommended.

The dryer gas inlet connection is a 3/8" NPT thread. An adapter is

supplied for conversion to standard ISO.228-1 thread (3/8" BSP).

Check for leaks by using an approved noncorrosive leakdetection solution. Bubbles will show a leak. Correct any leak

found. A pressure measurement tapping is provided on the

gas valve within the dryer, accessible after removal of the lower

front panel.

The dryer must be disconnected from the gas supply piping

system during any pressure testing of that system.

Venting Requirements

WARNING: To reduce the risk of fire, this dryer MUST BE

EXHAUSTED OUTDOORS.

■ Following these venting requirements will minimise ducting

air noise.

■ Gas dryers should only be installed in a room if the room

meets the appropriate ventilation requirements specified

in the national installation regulations. Make sure the room

containing the dryer has an adequate air supply for gas

combustion and drying operation. A window or equivalent

means of ventilation must be opened in the room when the

dryer is in use (an equivalent form of opening includes an

adjustable louver, hinged panel, or other means of ventilation

that opens directly to outside air). Adequate ventilation has to

be provided to avoid the backflow of gases into the room

from other fuel-burning appliances, including open fires (i.e.

available airflow into the room should match airflow out from

the room).

■ The design of the flue system should be such that any

condensate formed when operating the dryer from cold

shall either be retained and subsequently re-evaporated or

discharged. Following these instructions should adequately

meet this requirement.

■ Dryer exhaust must not be connected into any gas vent,

chimney, wall, ceiling, attic, crawlspace, or a concealed space

of a building. Only rigid or flexible metal vent shall be used for

exhausting.

■ Do not use an exhaust hood with a magnetic latch.

■ Do not install flexible metal vent in enclosed walls, ceilings,

or floors.

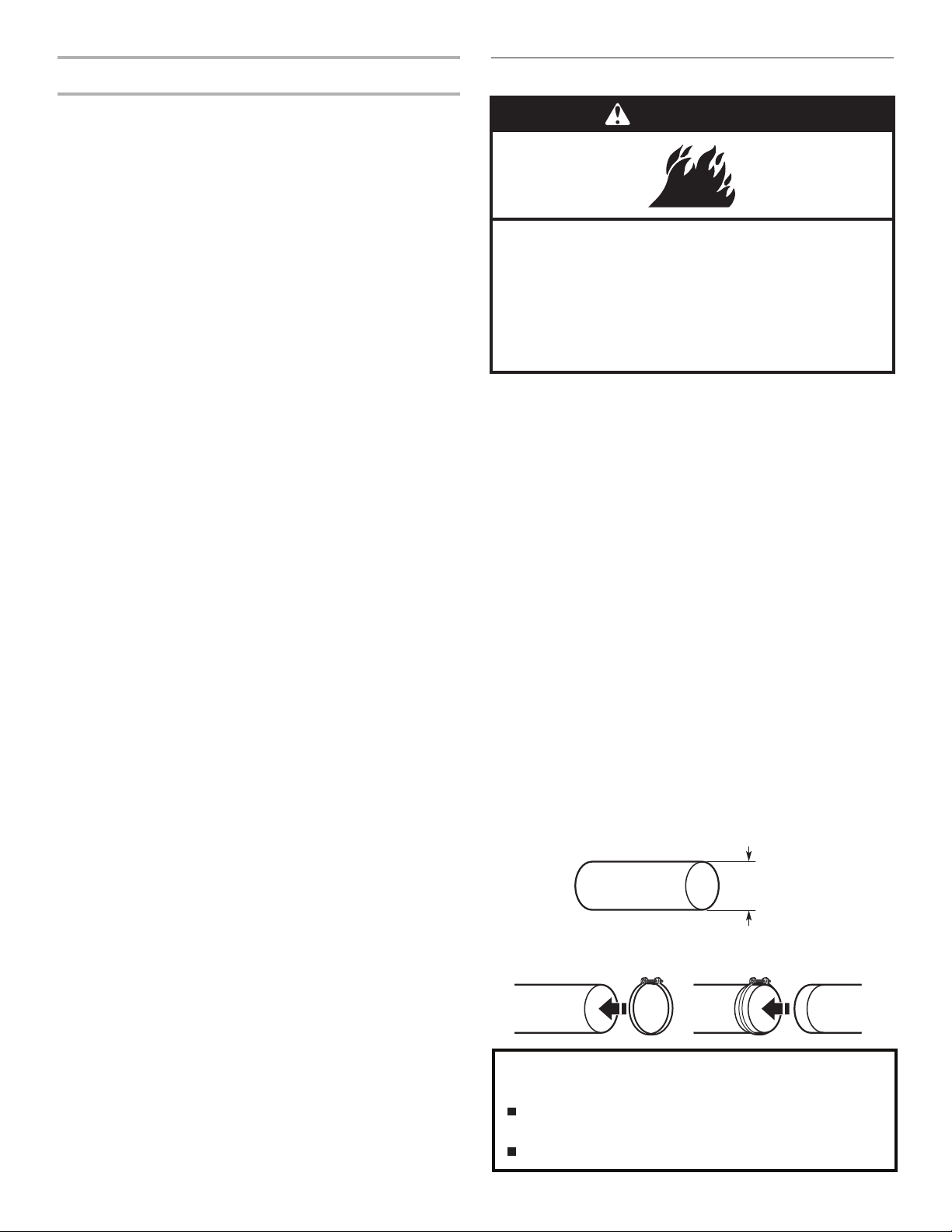

■ Only a 102 mm (4") heavy metal exhaust vent and clamps

may be used.

Heavy metal

exhaust vent

■ Use clamps to seal all joints. Vent must not be connected or

secured with screws or other fastening devices which extend

into the interior of the vent and catch lint. Do not use duct tape.

7

IMPORTANT: Observe all governing codes and ordinances.

3

0˚ max.

a

ir ow

12" min.

(305 mm)

24" min.

(610 mm)

Use a heavy metal vent. Do not use plastic or metal foil vent.

Rigid metal vent is recommended for best drying performance

and to avoid crushing and kinking.

Flexible metal vent must be fully extended and supported when

the dryer is in its final position. Remove excess flexible metal vent

to avoid sagging and kinking that will result in reduced airflow

and poor performance.

The total length of flexible metal vent should not exceed 2.4 m

3

(7

⁄4 ft.).

n exhaust hood should cap the vent to keep rodents and

A

nsects from entering the building.

i

Exhaust hood must be at least 305 mm (12") from the ground

or any object that may be in the path of the exhaust (such as

flowers, rocks, bushes, or snow).

If using an existing vent system, clean lint from the entire length

of the system and make sure exhaust hood is not plugged with

lint. Replace any plastic or metal foil vent with rigid metal or

flexible metal vent.

Plan installation to use the fewest number of elbows and turns.

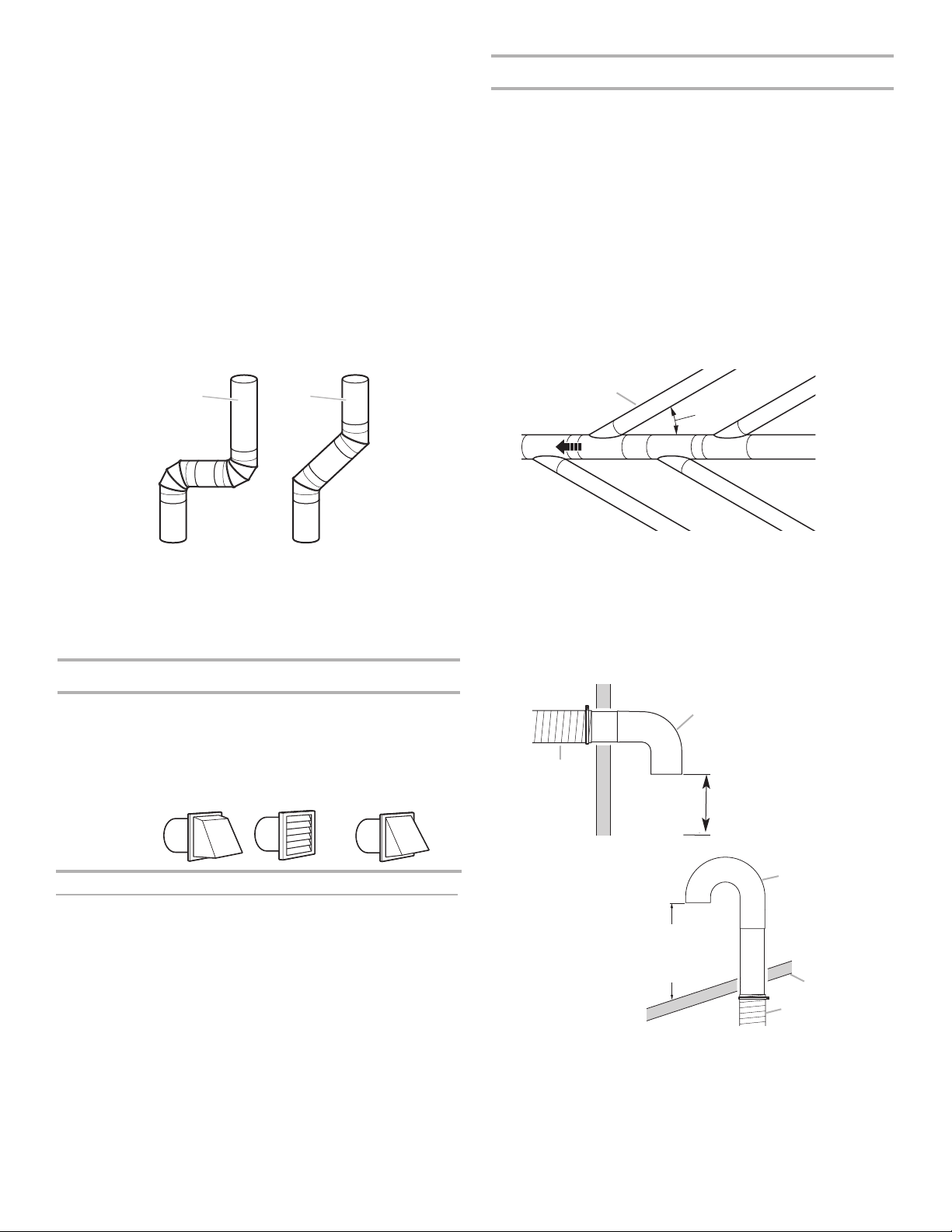

Multiple Dryer Venting

■ A main vent can be used for venting a group of dryers. Main

vent should be sized to remove 5663 l/min (200 CFM) of air

per dryer. Large-capacity lint screens of proper design may be

used in the main vent if checked and cleaned frequently. The

room where the dryers are located should have make-up air

equal to or greater than the airflow of all the dryers in the

room.

■ A back-draft damper kit is needed and is available from a

commercial laundry distributor; it should be installed in the

vent of each dryer to keep exhausted air from returning

into the dryers and to keep the exhaust in balance within

the main vent. Unobstructed return air openings are required.

Each vent should enter the main vent at an angle pointing in the

direction of the airflow. Vents entering from the opposite side

should be staggered to reduce the exhausted air from interfering

with the other vents.

The maximum angle of each vent entering the main vent should

be no more than 30°.

A

Exhaust Air Flow

A. Good

B. Better

B

Allow as much room as possible when using elbows or making

turns. Bend vent gradually to avoid kinking.

Vent outlet is located at the center of the bottom dryer back.

The vent can be routed up, down, left, right, behind the dryer,

or straight out the back of the dryer.

Vent System Length

Maximum length of vent system depends upon the type of vent

used, number of elbows, and type of exhaust hood.

Maximum Vent Length

102 mm (4") Exhaust Hoods

Box Louvered

64 mm (21⁄2") Angled

A

B

A. Individual dryer vent

B. Main vent

Keep air openings free of dry cleaning fluid fumes. Fumes create

acids which, when drawn through the dryer heating units, can

damage dryers and items being dried.

A clean-out cover should be located on the main vent for periodic

cleaning of the vent system.

If an exhaust hood cannot be used:

B

A

D

C

Min.

300 mm (12") clearance

above any accumulation

of snow, ice, or debris such

as leaves.

Rigid Metal Vent

No. of 90° turns

0

1

2

3

4

Box Hood and Louvered Style

39.6 m (130 ft.)

38.1 m (125 ft.)

35.1 m (115 ft.)

32.3 m (106 ft.)

98 m (98 ft.)

Angled Hood Style

If dryer is installed in a confined area, such as a bedroom,

bathroom, or closet, provision must be made for enough air

for combustion and ventilation. (Check governing codes and

ordinances.) See “Recessed Area and Closet Installation

Instructions” in the “Location requirements” section.

A 102 mm (4") outlet hood is preferred. However, a 64 mm

(21⁄2"

) outlet exhaust hood may be used. A 64 mm (21⁄2"

outlet creates greater back pressure than other hood types.

For permanent installation, a stationary vent system is required.

8

39.3 m (129 ft.)

36.3 m (119 ft.)

33.2 m (109 ft.)

30.5 m (100 ft.)

28 m (92 ft.)

)

A. Exhaust hood or elbow

B. Wall

C. Main collector vent

D. Horizontal vent

E. 180° sweep elbow

F. Vertical vent

G. Roof

610 mm (24")

min. above

highest point

of building

E

F

G

C

The outside end of the main vent should have a sweep elbow

directed downward. If the main vent travels vertically through the

roof, rather than through the wall, install a 180° sweep elbow on

the end of the vent at least 610 mm (2 ft.) above the highest part

of the building. The opening in wall or roof shall have a diameter

13 mm (

1/2

") larger than the vent diameter. The vent should be

centered in the opening.

Do not install screening or cap over the end of the vent.

INSTALLATION INSTRUCTIONS – GAS DRYER

WARNING

Electric Shock Hazard

This dryer must be earthed.

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or

electric shock.

Install Leveling Legs

NOTE: Slide dryer onto cardboard or hardboard before moving to

avoid damaging floor covering.

1. Using two or more people, move dryer to desired installation

location.

2. Take tape off front corners of dryer. Open dryer and remove

the literature and parts packages. Wipe the interior of the

drum thoroughly with a damp cloth.

3. Take two of the cardboard corners from the carton and place

them on the floor in back of the dryer. Firmly grasp the body

of the dryer and gently lay it on its back on the cardboard

corners.

4. With one of the legs in hand, check the ridges for a diamond

marking. That’s how far the leg is supposed to go into the

hole.

5. Start to screw the leveling legs into the holes by hand.

(Use a small amount of liquid detergent to lubricate the screw

threads so it is easier to turn the legs.) Use a 25 mm (1")

wrench or socket wrench to finish turning the legs until you

reach the diamond mark. Then fit a protective foot boot over

each foot.

6. Now stand the dryer up.

7. Remove cardboard or hardboard from under dryer. Adjust

the legs of the dryer up or down until the dryer is level.

Connect Vent

1. Using a 102 mm (4") clamp, connect vent to exhaust outlet

in dryer. If connecting to existing vent, make sure the vent is

clean. The dryer vent must fit over the dryer exhaust outlet

and inside the exhaust hood. Make sure the vent is secured

to exhaust hood with a 102 mm (4") clamp.

2. Move dryer into final position. Do not crush or kink vent.

Make sure dryer is level.

3. Check to be sure there are no kinks in the flexible gas line.

Complete Installation

1. With dryer in final position, place level on top of the

dryer, first side to side, then front to back. If the dryer is

not level, adjust the legs of the dryer up or down until the

dryer is level.

Make Gas Connection

1. Remove red cap from gas pipe.

2. Connect gas supply to dryer. If the flexible gas hose has 3/8"

BSP thread, use the supplied conversion thread adapter. Use

pipe-joint compound resistant to the action of L.P. gas for gas

connections.

If necessary for service, open the toe panel. Use a putty knife

to press on the 2 toe panel locks located at the top of the toe

panel. Pull downward on the toe panel to open. Toe panel is

hinged at the bottom.

3. Open the shut-off valve in the gas supply line.

4. Test all connections by brushing on an approved noncorrosive

leak-detection solution. Bubbles will show a leak. Correct any

leaks found.

2. Plug into an earthed outlet.

3. Check dryer operation (some accumulated time may be on

the timer due to factory testing).

Press the selection button for a full heat cycle and let the

dryer run for at least five minutes. Dryer will stop when time

is used up.

NOTE: Dryer door must be closed for dryer to operate.

When door is open, dryer stops, but timer continues to run.

To restart dryer, close door and press a cycle button.

4. If the burner does not ignite and you can feel no heat inside

the dryer, shut off dryer for five minutes. Check that all supply

valve controls are in “ON” position and that the electrical cord

is plugged in. Repeat five-minute test.

9

MAINTENANCE INSTRUCTIONS

Maintenance instructions:

■ Clean lint screen after each cycle.

■ Removing accumulated lint (disconnect dryer from electricity

and gas supplies before starting this task):

rom inside the dryer cabinet:

• F

Lint should be removed every 2 years or more often,

depending on dryer usage. Cleaning should be done

by a qualified person.

• From the exhaust vent:

int should be removed every 2 years, or more often,

L

depending on dryer usage.

TECHNICAL SPECIFICATIONS – GAS DRYER

f dryer does not operate, check the following:

I

■ Electric supply is connected.

■ Circuit breaker is not tripped or house fuse is not blown.

■ Door is closed.

■ Controls are set in a running or “ON” position.

■ Selected cycle button has been pressed firmly.

■ Check that gas supply shut-off valves are set in open position.

If you need assistance:

Contact your authorized Maytag®Commercial Laundry distributor

or visit: www.MaytagCommercialLaundry.com. When you call,

you will need the dryer model number and serial number.

Both numbers can be found on the serial-rating plate located

on your dryer.

10

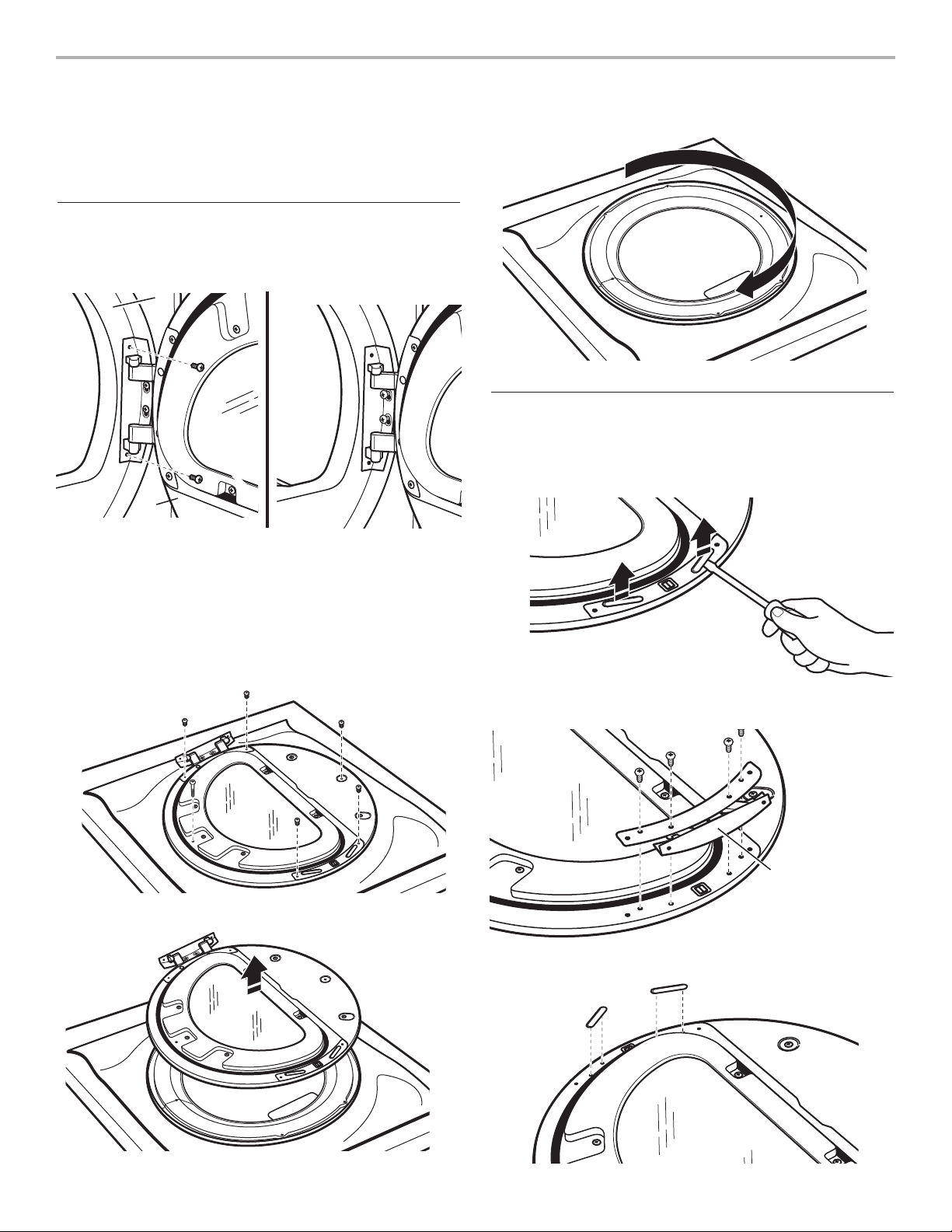

REVERSING THE DOOR SWING

ou can change your door swing from a right-side opening to

Y

left-side opening, if desired.

Place a towel or soft cloth on top of the dryer or work space

to protect the surface.

Remove the Door Assembly

1. Remove the 2 screws that hold the door hinge on the front

panel of the dryer. Partially loosen the 2 screws in on the side

of the hinge and lift the door off the screws.

A.

B.

A. Dryer front panel

B. Door assembly

5. Rotate outer door 180°.

Reverse Hinge

1. Use a small flat-blade screwdriver to remove 2 plug strips

from the inner door. Slide the head of the screwdriver under

the plugs, being certain not to scratch the inner door surface.

Lift up.

2. Lay the door assembly on a flat, protected surface with the

inside (inner door assembly) facing up.

3. Remove the 6 Phillips-head screws to release the outer door

assembly from the inner door assembly, as indicated below.

See illustration. It is important that you remove only the 6

indicated screws.

4. Lift the inner door assembly off the outer door assembly.

2. Remove the 4 screws that attach to the inner door hinge

and move the hinge to the other side. Reinstall the 4 screws.

A.

A. Door hinge

3. Reinstall plug strips on opposite side of the inner door.

11

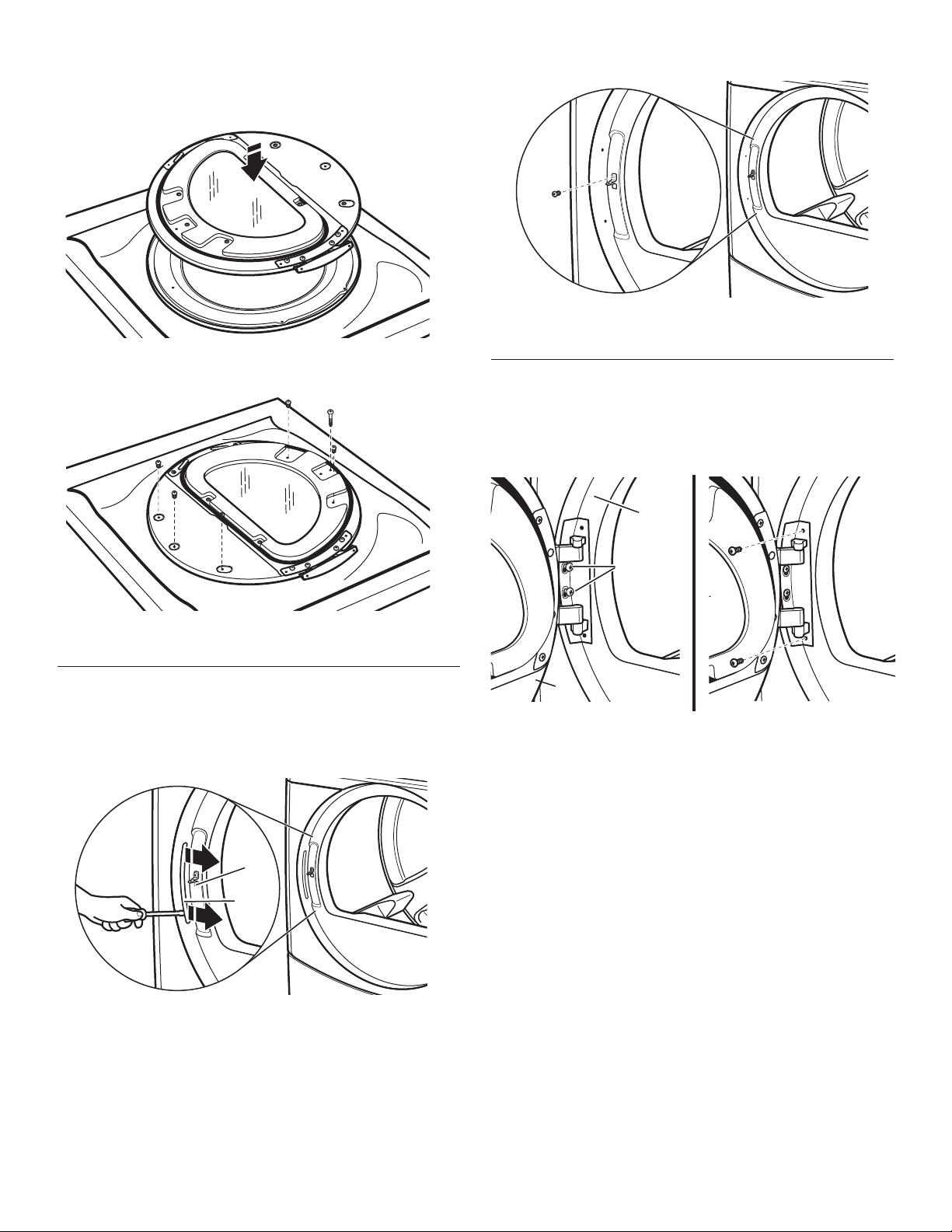

4. Check for fingerprints on the glass. Clean glass if necessary.

5. Place the inner door assembly inside the outer door assembly.

To fit correctly, the inner door assembly edge fits completely

inside the outer door assembly edge.

6. Reassemble the inner and outer door assemblies with

the 6 screws.

2. Remove the strike using a T-20 security Torx®driver.

3. Install strike on the opposite side.

Reinstall the door

1. Reattach door to dryer front panel with the 4 screws. Partially

install the 2 screws on the door opening side first, and fit the

keyhole openings in the hinge over the screws. Then install

the remaining screws and tighten all 4 screws.

Reverse the strike

1. Use a small flat-blade screwdriver to remove plug strip from

the dryer door opening. Slide the head of the screwdriver

under the plugs, being certain not to scratch the dryer

surface. Lift up.

B.

A.

A.

Install

these 2

screws

first

B.

A. Dryer front panel

B. Door assembly

2. Check for fingerprints on the glass. Clean glass if necessary.

3. Close door and check that it latches securely.

A. Plug strip

B. Door strike

® TORX is a registered trademark of Saturn Fasteners, Inc.

12

ELECTRONIC CONTROL SETUP

IMPORTANT

Electrostatic Discharge (ESD)

Sensitive Electronics

ESD is present everywhere. ESD may damage or weaken the

electronic control assembly. The new control assembly may

appear to work well after repair is finished, but failure may

occur at a later date due to ESD stress.

■

Use an anti-static wrist strap. Connect wrist strap to green

earth connection point or unpainted metal in the dryer.

Touch your finger repeatedly to a green earth connection point

or unpainted metal in the dryer.

■

Before removing the part from its package, touch the

anti-static bag to a green earth connection point or unpainted

metal in the dryer.

■

Avoid touching electronic parts or terminal contacts; handle

electronic control assembly by edges only.

■

When repackaging failed electronic control assembly

in anti-static bag, observe above instructions.

GENERAL USER INFORMATION

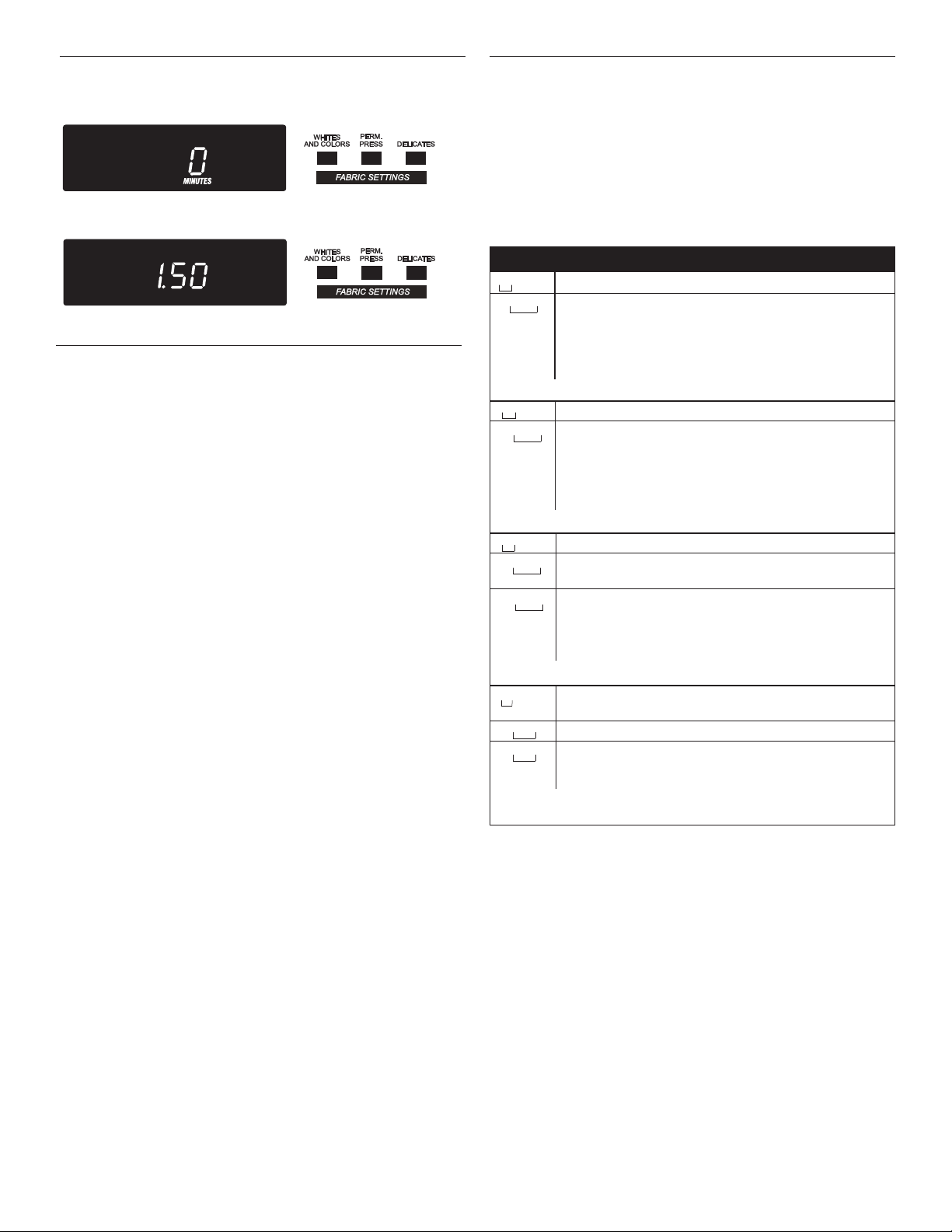

Blank display

This condition indicates the dryer is inoperative. Enter set-up mode

to view diagnostic code (see “Start Operating Set-Up”).

‘0 Minutes’ showing in display

This condition indicates the dryer cannot be operated. Coins

dropped or debit inputs during this condition will be stored in escrow

but cannot be used until normal operation is restored by opening

and closing the door. If a door switch fails, it must be replaced before

normal operation can be restored.

Cold Start (initial first use)

Dryer is programmed at the factory as follows:

■

5 minutes dry time/coin (coin 1).

■

1.50 dry price (fixed cycle with top off – PD Models).

■

0.00 dry price (fixed cycle – PN Models).

Warm Start (after power failure)

A few seconds after power is restored, if a cycle was in progress

at the time of the power failure, ‘RESELECT CYCLE’ will flash

in the display. This is to indicate the need for a fabric setting

button to be pressed to restart dryer.

-OR-

Pricing

fter the door is opened following the completion of a cycle, the

A

display indicates the cycle price (unless set for free operation). As

coins or debit inputs arrive, the display will change to lead the user

through the initiation of a cycle.

There are four (4) types of pricing:

Fixed ‘Vend’ Pricing

A dryer set up for ‘Fixed Cycle’ operation can only accept additional

time accumulated by increments equal to the length of a complete

dry cycle. A maximum of 99 minutes may be purchased; no

additional credit is given when 99 minutes is in the display.

Accumulator Pricing

If the price is set to one coin 1, then accumulator mode is in effect.

Cycle time can be purchased one coin at a time (PD models) up to

the maximum time of 99 minutes. Stacked PD dryers will credit all

money to a cycle with a single button press while in accumulator

pricing.

Fixed Cycle With Top Off Pricing

A dryer set to offer ‘Top Off’ capability will allow time to be added to

an existing dry cycle in increments equal to the number of minutes

of dry time per coin (coin 1), up to 99 minutes, regardless of the cost

required to start the dryer. No credit is given for coins or debit inputs

entered when the control is displaying 99 minutes.

PR Models: In Enhanced Debit Mode, the top off price can be set

independently. (See VALUE OF COIN 2), and the top off time is

calculated according to the following equation:

top off price

full cycle price full cycle length

Penny increment offset is not applied to top off purchases.

Free Cycles

This is established by setting the cycle price to zero. When this

happens ‘SELECT CYCLE’ will appear rather than a cycle price.

=

top off time

13

DISPLAY

PRICE

After the dryer has been installed and plugged in, the display will

show ‘0 minutes.’

Once the unit has been plugged in and the dryer door opened and

closed, the display will show the price.

CONTROL SET-UP PROCEDURES

IMPORTANT: Read all instructions before operating.

The fabric setting buttons along with the digital display are used

to set up the dryer controls.

The display can contain 4 numbers and/or letters and a decimal

point. These are used to indicate the set-up codes and related code

values available for use in programming the dryer.

How to use the key pads to program the controls

1. The WHITES AND COLORS button is used to adjust the values

associated with set-up codes. Pressing the button will increment

the value by one (1). Rapid adjustment is possible by holding

down the button.

2. The PERM. PRESS button will advance through the set-up

codes. Pressing the button will advance to the next available

set-up code. Holding down the button will automatically advance

through the set-up codes at a rate of one (1) per second.

3. The DELICATES button is used to select or deselect options.

Start Operating Set-Up

■

PD Models: Insert service door key, turn, and lift to remove

service door.

■

PN Models: Manual set-up mode can be entered by removing

connector AA1 on the circuit board.

IMPORTANT: The console must not be opened unless power is

first removed from the dryer. To access connector AA1:

Unplug dryer or disconnect power.

Open console, disconnect plug on AA1, close console.

Plug in dryer or reconnect power.

The dryer is now in the set-up mode.

Before proceeding, it is worth noting that, despite all the options

available, an owner can simply choose to uncrate a new commercial

dryer, hook it up, plug it in, and have a dryer which operates.

■

PD dryers are pre-set at the factory for fixed cycle price with

top off.

■

PN dryers are pre-set for free cycle operation so they can be run

without readers or coins.

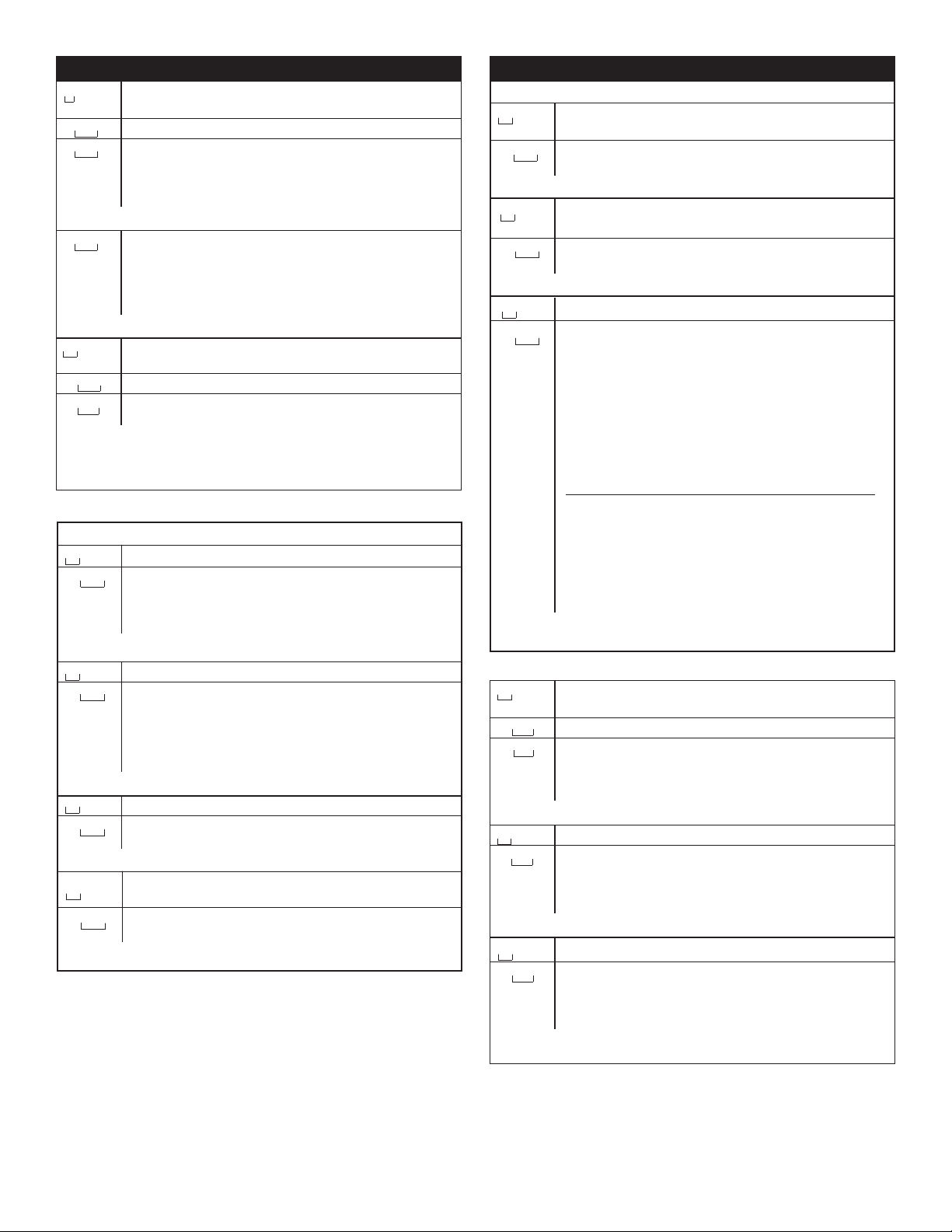

SET-UP CODES

■

The PERM. PRESS button will advance from code to code.

■

The WHITES AND COLORS button will change the code value.

■

The DELICATES button will select or deselect options.

FOR PN MODELS: The set-up codes are the same as for the PD

models except where noted.

The set-up code is indicated by the one or two left-hand characters.

The set-up code value is indicated by the two or three right-hand

characters.

CODE EXPLANATION

EGULAR CYCLE PRICE

606

606

Press the PERM. PRESS button once to advance to next code.

7 0 5

7 0 5

Press the PERM. PRESS button once to advance to next code.

8 0 0

8 0 0

8

Press the PERM. PRESS button once to advance to next code.

9 0 0

9 0 0

9 0

Press the PERM. PRESS button once to advance to next code.

R

Represents the number of coin 1; may adjust from 0–39.

(See VALUE OF COIN1 b. 05) Advance from 0–39 by pressing

theWHITESANDCOLORS button.Factorypresetfor

6 coins = 1.50.

PN MODELS ONLY: Factory preset for 0 coins.

REGULAR DRY TIME

Represents the number of minutes per coin (coin 1).

Factory preset for5 minutes per coin.

Example: 6 coins x 5 minutes= 30minutes.

By pressing the WHITESAND COLORS button, you can adjust

thevalue from 1–99 minutes.

TYPE OF DRYER PRICING

FixedCycle with Top Off. Fordetailed description, see “General

User Information.”

FixedCycle. For detaileddescription, see“General User

F C

Information.”

UseDELICATES button to make this selection.

PN MODELS ONLY:Factory set forFC.

CYCLE COUNTER OPTION

This option is either SELECTED ‘ON’ or NOT SELECTED ‘OFF’.

Not Selected ‘OFF’.

Selected ‘ON’ and not able to be deselected. Press DELICATES

C

button 3 consecutive times to select ‘ON’. Once selected ‘ON’

it cannot be deselected.

14

CODE EXPLANATION

1.0 0

1.0 0

1.0

Press the PERM. PRESS button once to advance to next code.

1.C0

Press the PERM. PRESS button once to advance to next code.

2.0 0

2.0 0

2.

SP

If SPECIAL PRICING OPTION is selected, you have access to codes

‘3.’ through ‘9.’.

Press the PERM. PRESS button once to advance to next code.

OPTIONS TO USE IF SPECIAL PRICING IS SELECTED:

3. 0 6

3. 0 6

Press the PERM. PRESS button once to advance to next code.

4. 0 5

4. 0 5

Press the PERM. PRESS button once to advance to next code.

5. 0 0

5. 0 0

Press the PERM. PRESS button once to advance to next code.

6.0 0

6.0 0

Press the PERM. PRESS button once to advance to next code.

MONEY COUNTER OPTION

This option is either SELECTED ‘ON’ or NOT SELECTED ‘OFF’.

Not Selected ‘OFF’.

Selected ‘ON’.

C

Press the DELICATES button 3 consecutive times to select

‘ON’ and 3 consecutivetimesto remove (Not Selected ‘OFF’.)

Counter resets by going from ‘OFF’ to ‘ON’.

Selected ‘ON’ and not able to be deselected.

To select ‘ON’ and not able to be deselected, first select ‘ON’,

then within two seconds press the DELICATES buttontwice,

the WHITESANDCOLORSbuttononce, and exit the set-up

ode

m

.

SPECIAL PRICING OPTION

This option is either SELECTED ‘ON’ or NOT SELECTED ‘OFF’.

Not Selected ‘OFF’.

Selected ‘ON’. Press the DELICATES button once for this

selection.

SPECIAL CYCLE PRICE

Represents the number of coin 1; may adjust from 0–39.

(See VALUE OF COIN 1 b.05) Advance from 0–39 by pressing

WHITES AND COLORS. Factory preset for 6 coins = 1.50.

PN MODELS ONLY: Factory preset for 0 coins.

SPECIAL DRY TIME

Represents the number of minutes per coin (coin 1).

Factory preset for5 minutes per coin.

Example: 6 coins x 5 minutes= 30minutes.

By pressing the WHITESAND COLORS button, you can

adjust the value from 1–99minutes.

TIME-OF-DAY CLOCK, MINUTES

This is the TIME-OF-DAY CLOCK, minute setting; select 0–59

minutes by pressing the WHITES ANDCOLORSbutton.

TIME-OF-DAY CLOCK, HOURS

NOTE: Uses 24 hr. clock.

This is the TIME-OF-DAY CLOCK, hour setting; select 0–23

hours by pressing the WHITES ANDCOLORSbutton.

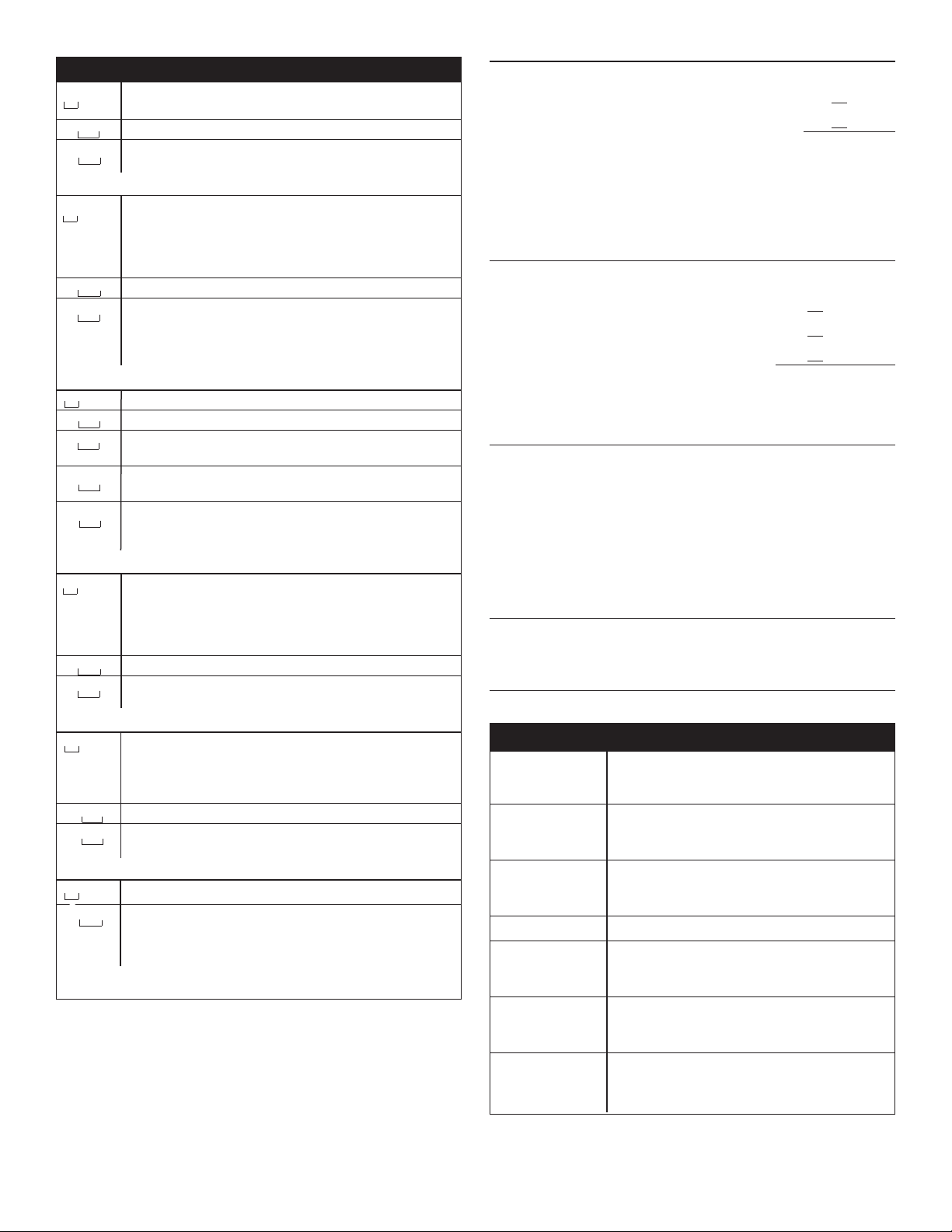

CODE EXPLANATION

PTIONS TO USE IF SPECIAL PRICINGIS SELECTED(continued):

O

7. 0 0

7. 0 0

Press the PERM. PRESS button once to advance to next code.

8. 0 0

8. 0 0

Press the PERM. PRESS button once to advance to next code.

9. 1 0

9. 1 0

Press the PERM. PRESS button once to advance to next code.

A.

00

A.

00

A.SC

Press the PERM. PRESS button once to advance to next code.

6.0 5

6.0 5

Press the PERM. PRESS button once to advance to next code.

C

.2 0

C

.2 0

Press the PERM. PRESS button once to advance to next code.

SPECIAL PRICE START HOUR

NOTE: Uses 24 hr. clock.

his is the start hour, 0–23 hours. Select STARTHOUR by

T

pressing the WHITESANDCOLORS button.

SPECIAL PRICE STOP HOUR

NOTE: Uses 24 hr. clock.

his is the stop hour; 0–23 hours. Select STOP HOUR by

T

pressing the WHITESANDCOLORS button.

SPECIAL PRICE DAY

This represents the day of the week and whether special

pricing is selected for that day. A number followed by ‘0’

indicates no selection that particular day (9.10). A number

followed by an ‘S’ indicates selected for that day (9.1S).

Days of the week (1–7) can be chosen by pressing the

WHITES AND COLORS button. Press the DELICATES button

once to select special pricing for each day chosen.

When exiting setup code ‘9.’, the display must show current

day of week:

DISPLAY DAY OF WEEK CODE (selected)

10 Day 1 = Sunday 1S

20 Day 2 = Monday 2S

30 Day 3 = Tuesday 3S

40 Day 4 = Wednesday 4S

50 Day 5 = Thursday 5S

60 Day 6 = Friday 6S

70 Day 7 = Saturday 7S

VAULT VIEWING OPTION

This option is either SELECTED ‘ON’ or NOT SELECTED ‘OFF’.

Not Selected ‘OFF’.

Selected ‘ON’. Press DELICATES button once for this

selection. When selected, the money and/or cycle counts

will be viewable (if counting is selected) when the coin box is

removed.

VALUE OF COIN 1

This represents the value of coin 1 in number of coin 2:

05 = 0.25.

By pressing the WHITESAND COLORS button you have the

option of 1–199 coins (coin 2).

VALUE OF COIN 2

This represents the value of coin 2 in number of coins per

monetary unit: for example, if coin 2 = .05, then 20 = 1.00.

By pressing the WHITESAND COLORS button you have the

option of 1–199 coins (coin 2).

15

ODE EXPLANATION

C

8.0 0

8.0 0

8.

CS

Press the PERM. PRESS button once to advance to next code.

E

. 0 0

E

. 0 0

E.AC

Press the PERM. PRESS button once to advance to next code.

J.C

J.C

J.C

J.C

J.E

Press the PERM. PRESS button once to advance to next code.

L

. 0 0

L

. 0 0

L.PS

Press the PERM. PRESS button once to advance to next code.

8.

CE

8.

CE

8.0 0

Press the PERM. PRESS button once to advance to next code.

0.0 0

0.0 0

Press the PERM. PRESS button once to advance to next code.

COIN SLIDE OPTION

This option is either SELECTED ‘ON’ or NOT SELECTED ‘OFF’.

Not Selected ‘OFF’.

Selected ‘ON’ – NOT AVAILABLE.

ADD COINS OPTION

This option is either SELECTED ‘ON’ or NOT SELECTED ‘OFF’.

This option causes the customer display to show the number

of coins (coin 1) to enter, rather than the decimal amount in

currency amount.

Not Selected ‘OFF’.

Selected ‘ON’. Press the DELICATES button 3 consecutive

times for this selection.

PN MODELS ONLY: In enhanced debit mode, this option is

not selectable.

COIN/DEBIT OPTION

8

Both coin & debit selected – NOTAVAILABLE.

8

Coins selected, debit disabled.

8

Press DELICATES button for this selection.

Debit Card selected, coins disabled. Press DELICATES

8

button for this selection – NOT AVAILABLE.

Enhanced Debit is self-selected when a Generation 2 card

8

reader is installed in the dryer. The ‘Ed’ option cannot be

manually selected or deselected – NOTAVAILABLE.

PRICE SUPPRESSION OPTION

This option is either SELECTED ‘ON’ OR NOT SELECTED ‘OFF’.

This option causes the customer display to show ‘AVAILABLE’

or ‘ADD’ rather than the amount of money to add. (Used

mainly in debit installations.)

Not Selected ‘OFF’.

Selected ‘ON’. Pressthe DELICATES button once for this

selection.

CLEAR ESCROW OPTION

This option is either SELECTED ‘ON’ OR NOT SELECTED ‘OFF’.

When selected, money held in escrow for 30 minutes without

further escrow or cycle activity will be cleared.

Selected ‘ON’.

Notselected ‘OFF’. Pressthe DELICATES button oncefor this

selection.

HUNDREDTH INCREMENT OFFSET

This represents the hundredth increment price offset used

in Generation 2 (Enhanced Debit) PN models. Choose from

0–4 hundredth coins by pressing the WHITES AND COLORS

key pad – NOT AVAILABLE.

If cycle counter (9.0C) is selected, the following is true:

100 Represents the number of cycles in HUNDREDS. 1 02

200 Represents the number of cycles in ONES. 2 25 = 225

This is “VIEW ONLY” and cannot be cleared.

Press the PERM. PRESS button once to advance

to next code.

If money counter (1.0C or 1.C0) is selected, the following is true:

300 Currency amount in HUNDREDS. 3 01

400 Currency amount in ONES. 4 68

500 Currency amount in HUNDREDTHS. 5 75 = 100.75

TOTAL = 168.75

END OF SET-UP PROCEDURES

= 200

OTAL = 225

T

cycles

= 100.00

= 168.00

EXIT FROM SET-UP MODE

■

SINGLE LOAD PD MODELS: Reinstall access door.

■

SINGLE LOAD PN MODELS:

Unplug dryer or disconnect power.

Open console, reinsert plug into AA1, close console.

Plug in dryer or reconnect power.

DIAGNOSTIC GUIDE

If the set-up mode is entered and one of the following has occurred,

the appropriate diagnostic code will be in the display.

SINGLE DRYERS

CODE EXPLANATION

Dryer door sense error on control board or due to

power line interference (cycles and price display

disabled until diagnostic code is manually cleared).

Dryer motor control circuit error (cycles and

customer display disabled until diagnostic code

is manually cleared).

Blocked coin 1 or coin drop control circuit failure

(coin recognition and customer display disabled

while blockage persists).

Voltage detected below 180 VAC for 8 seconds.

Motor sense error on control board or due to power

line interference (cycles and customer display

disabled until diagnostic code is manually cleared).

Blocked coin 2 or coin drop control circuit failure

(coin recognition and price display disabled while

blockage persists).

Not receiving communications from installed

debit card reader in Enhanced (Generation 2)

Debit mode – NOT AVAILABLE.

d

d

d

d

d

d

d

1

4

5

9

12

13

16

16

MAYTAG®COMMERCIAL WASHER, DRYER, STACKED DRYER/

DRYER, COMMERCIAL STACK LAUNDRY, AND MULTI-LOAD

COIN OPERATED COMMERCIAL WASHERS AND DRYERS

WARRANTY

LIMITED WARRANTY ON PARTS

For the first five years from the date of purchase, when this commercial appliance is installed, maintained and operated according to the

instructions attached to or furnished with the product, Maytag brand of Whirlpool Corporation (thereafter “Maytag”) will pay for factory

specified parts or original equipment manufacturer parts to correct defects in materials or workmanship. Proof of original purchase date

is required to obtain service under this warranty.

ITEMS MAYTAG WILL NOT PAY FOR

1. All other costs including labor, transportation, or custom duties.

2. Service calls to correct the installation of your commercial appliance, to instruct you how to use your commercial appliance, to

replace or repair fuses, or to correct external wiring or plumbing.

3. Repairs when your commercial appliance is used for other than normal, commercial use.

4. Damage resulting from improper handling of product during delivery, theft, accident, alteration, misuse, abuse, fire, flood, acts of

God, improper installation, installation not in accordance with local electrical or plumbing codes, or use of products not approved

by Maytag.

5. Pickup and Delivery. This commercial appliance is designed to be repaired on location.

6. Repairs to parts or systems resulting from unauthorized modifications made to the commercial appliance.

7. The removal and reinstallation of your commercial appliance if it is installed in an inaccessible location or is not installed in

accordance with published installation instructions.

8. Chemical damage is excluded from all warranty coverage.

9. Changes to the building, room, or location needed in order to make the commercial appliance operate correctly.

DISCLAIMER OF IMPLIED WARRANTIES; LIMITATIONS OF REMEDIES

CUSTOMER'S SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE PRODUCT REPAIR AS PROVIDED

HEREIN. IMPLIED WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE,

ARE LIMITED TO ONE YEAR OR THE SHORTEST PERIOD ALLOWED BY LAW. WHIRLPOOL SHALL NOT BE LIABLE FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES. SOME STATES AND PROVINCES DO NOT ALLOW THE EXCLUSION OR LIMITATION

OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, OR LIMITATIONS ON THE DURATI ON OF IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS, SO THESE EXCLUSIONS OR LIMITATIONS MAY NOT APPLY TO YOU. THIS WARRANTY GIVES

YOU SPECIFIC LEGAL RIGHTS AND YOU MAY ALSO HAVE OTHER RIGHTS, WHICH VARY FROM STATE TO STATE OR PROVINCE

TO PROVINCE.

If you need service, please contact your authorized Maytag®Commercial Laundry distributor. To l o cate your authorized Maytag

®

Commercial Laundry distributor, or for web inquiries, visit www.MaytagCommercialLaundry.com.

1/11

For written correspondence:

Maytag

®

Commercial Laundry Service Department

2000 M-63 North

Benton Harbor, Michigan 49022 USA

10. Repairs made by a Non-Whirlpool authorized Service Technician.

17

SECURITE DU SECHE-LINGE

Risque possible de décès ou de blessure grave si vous ne

suivez pas immédiatement les instructions.

Risque possible de décès ou de blessure grave si vous

ne suivez pas les instructions.

Tous les messages de sécurité vous diront quel est le danger potentiel et vous disent comment réduire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

Votre sécurité et celle des autres est très importante.

Nous donnons de nombreux messages de sécurité importants dans ce manuel et sur votre appareil ménager. Assurez-vous de

toujours lire tous les messages de sécurité et de vous y conformer.

AVERTISSEMENT

DANGER

V

oici le symbole d’alerte de sécurité.

Ce symbole d’alerte de sécurité vous signale les dangers potentiels de décès et de blessures graves à vous

et à d’autres.

Tous les messages de sécurité suivront le symbole d’alerte de sécurité et le mot “DANGER” ou

“AVERTISSEMENT”. Ces mots signifient :

AVERTISSEMENT : Pour votre sécurité, les renseignements dans ce manuel doivent

être observés pour réduire au minimum les risques d’incendie ou d’explosion ou pour

éviter des dommages au produit, des blessures ou un décès.

– Ne pas entreposer ou utiliser de l’essence ou d’autres vapeurs ou liquides

inflammables à proximité de cet appareil ou de tout autre appareil électroménager.

– QUE FAIRE DANS LE CAS D’UNE ODEUR DE GAZ :

•

Ne pas tenter d’allumer un appareil.

•

Ne pas toucher à un commutateur électrique; ne pas utiliser le téléphone se trouvant

sur les lieux.

•

Évacuer tous les gens de la pièce, de l’édifice ou du quartier.

•

Appeler immédiatement le fournisseur de gaz d’un téléphone voisin. Suivre ses

instructions.

•

À défaut de joindre votre fournisseur de gaz, appeler les pompiers.

– L’installation et l’entretien doivent être effectués par un installateur qualifié, une

agence de service ou le fournisseur de gaz.

POUR VOTRE SÉCURITÉ

1. NE PAS UTILISER OU REMISER D’ESSENCE OU AUTRES MATÉRIAUX INFLAMMABLES DANS CET APPAREIL MÉNAGER

OU À PROXIMITÉ DE CELUI-CI.

2. NE PAS VAPORISER D’AÉROSOLS À PROXIMITÉ DE CET APPAREIL MÉNAGER LORSQU’IL EST EN FONCTIONNEMENT.

3. NE PAS MODIFIER CET APPAREIL MÉNAGER.

18

ELIMINATION DU SECHE-LINGE

EXIGENCES D’INSTALLATION

Outillage et pièces

Rassembler les outils et pièces nécessaires avant de commencer

l’installation. Lire et respecter les instructions d’installation

fournies avec chacun des outils de cette liste.

Outillage nécessaire

■ Clé à tube de 200 mm (8")

ou 250 mm (10")

■ Clé à molette de 200 mm

(8") ou 250 mm (10")

■ Tournevis à lame plate

■ Tournevis Phillips

■ Clé à molette avec

ouverture jusqu’à 25 mm

(1") ou clé à douille

hexagonale

■ Niveau

■ Clé à douille de 8 mm

(5/16")

■ Couteau utilitaire

■ Brides de fixation

■ Composé d’étanchéité des

raccords filetés – résistant

au propane

■ Pistolet à calfeutrage et

composé de calfeutrage

(pour l’installation d’un

nouveau circuit

d’évacuation)

■ Pince

■ Couteau à mastic

Pièces fournies

Retirer le sac de pièces du tambour du sèche-linge. Vérifier

la présence de toutes les pièces.

■ Patin (4)

■ Pied du sèche-linge (4)

REMARQUE : Le schéma de circuits de ce sèche-linge se trouve

à l’intérieur du panneau inférieur avant.

19

Exigences d’emplacement

Risque d'explosion

Garder les matières et les vapeurs inflammables, telle

q

ue l'essence, loin de la sécheuse.

Ne pas installer dans un garage.

Le non-respect de ces instructions peut causer

un décès, une explosion ou un incendie.

AVERTISSEMENT

686 mm

(27")

965 mm

(38")

25 mm

(1")

381 mm

(15")

0 mm

(0")

0 mm

(0")

356 mm

(14") max

25 mm (1")

0 mm

(0")

24 in.

2

(

155 cm

2

)

48 in.

2

(

310 cm

2

)

3

"

(76 mm)

3

"

(76 mm)

Closet

d

oor

Front

View

Pour l’installation d’un sèche-linge à gaz :

IMPORTANT : Respecter les dispositions de tous les codes

et règlements en vigueur.

■ Déterminer les exigences des codes : Certains codes limitent

ou prohibent l’installation d’un sèche-linge dans un garage,

un placard ou une chambre à coucher. Consulter l’inspecteur

local des bâtiments.

■ Veiller à ce que les bords inférieurs de la caisse ainsi que

l’arrière et les côtés inférieurs du sèche-linge soient exempts

d’obstructions, afin de permettre le passage adéquat de l’air

de combustion. Voir la section “Instructions d’installation

dans un placard ou un encastrement” pour l’espace de

dégagement minimal.

■ Ne pas installer sur un tapis.

NOTE : Le sèche-linge ne doit pas être installé en un endroit

où il serait exposé à de l’eau ou aux intempéries.

istances de séparation minimales

D

orte du

P

placard

lacard, vue latérale

Encastrement, vue avant

On doit prévoir un espacement additionnel pour tenir compte éventuellement

des moulures du mur, de la porte et du plancher, ou si le circuit d’évacuation

comporte un coude.

2

10 cm

3

(48 po2.)*

Vue

avant

155 cm

(24 po2.)*

Porte du

placard

2

76 mm

(3")

76 mm

(3")

P

* Taille minimale de

l’ouverture pour la porte

du placard. On peut

utiliser une porte à

claire-voie offrant une

surface de passage

d’air équivalente.

Instructions pour l’installation dans un placard

ou un encastrement

Ce sèche-linge peut être installé dans un placard ou un

encastrement. Ce sèche-linge ne doit pas être installé derrrière

une porte verrouillable, coulissante, ou une porte avec charnière

du côté opposé de l’emplacement de celle du sèche-linge.

Les distances de séparation sont exprimées en millimetre;

il s’agit des distances minimales. Il est utile de prévoir des

distances de séparation supérieures pour faciliter l’installation

et les travaux d’entretien, ou si ceci est exigé par les codes et

règlements locaux.

Si la porte du placard est installée, on doit respecter la taille

minimale des ouvertures d’entrée d’air au sommet et en bas. On

peut utiliser une porte à jalousies offrant une surface de passage

d’air équivalente.

Le circuit d’évacuation du sèche-linge doit être relié à l’extérieur.

Aucun autre appareil utilisant un combustible ne doit être installé

dans le même placard.

20

Dimensions du produit – Sèche-linge

de 686 mm (27")

VUE AVANT

Loading...

Loading...