Maytag MDG20PDAGW, MDE20PNAGW, MDG20PNAGW, MDG20MNAGW, MDE20PDAGW Installation Instructions

...Page 1

INSTALLATION INSTRUCTIONS

Original instructiOns

cOmmercial gas Or electric Dryer

mODels

mDg20PDagW, mDg20PnagW, mDg20mnagW, anD mDg20csagW

mDe20PDagW, mDe20PnagW, mDe20mnagW, mDe20csagW,

INSTRUCTIONS D’INSTALLATION

instructiOns D’Origine

sèche-linge À gaz Ou Électrique À usage cOmmercial

mODèles

mDg20PDagW, mDg20PnagW, mDg20mnagW, anD mDg20csagW

mDe20PDagW, mDe20PnagW, mDe20mnagW, mDe20csagW,

INSTRUCCIONES DE INSTALACIÓN

instrucciOnes Originales

secaDOra a gas O elÉctrica cOmerciale

mODelOs

mDg20PDagW, mDg20PnagW, mDg20mnagW, anD mDg20csagW

mDe20PDagW, mDe20PnagW, mDe20mnagW, mDe20csagW,

ISTRUZIONI D’INSTALLAZIONE

istruziOni Originali

asciugatrice a gas O elettrica cOmmerciale

mODelli

mDg20PDagW, mDg20PnagW, mDg20mnagW, anD mDg20csagW

mDe20PDagW, mDe20PnagW, mDe20mnagW, mDe20csagW,

www.maytagcommerciallaundry.com

W10868681B

Page 2

TABLE OF CONTENTS

DRYER SAFETY ................................................................................3

FOR THE OWNER

MAINTENANCE INSTRUCTIONS ..................................................6

IF YOU NEED ASSISTANCE .........................................................6

FOR WHIRLPOOL AUTHORIZED SERVICE PERSON

TOOLS & PARTS ..............................................................................7

SPECIFICATIONS ............................................................................7

DIMENSIONS/CLEARANCES .................................................... 8

DRYER INSTALLATION REQUIREMENTS ............................... 9

INSTALLING LEVELING LEGS AND COIN BOX ..................... 10

LEVELING ........................................................................................ 11

ELECTRIC DRYER INSTALLATION REQUIREMENTS ........ 12

GAS DRYER INSTALLATION REQUIREMENTS ................... 13

DRYER VENTING REQUIREMENTS ....................................... 15

GAS SUPPLY CONNECTION .................................................... 17

TECHNICAL SPECIFICATIONS–GAS DRYER ....................... 18

COMPLETE INSTALLATION ....................................................... 20

REVERSING DRYER DOOR SWING ........................................ 21

ELECTRONIC CONTROL SETUP INSTRUCTIONS

(PD & PN MODELS) ..................................................................... 22

DRYER DISPOSAL ........................................................................ 27

WARRANTY ................................................................................... 28

ÍNDICE

SEGURIDAD DE LA SECADORA ................................................ 56

PARA EL PROPIETARIO

INSTRUCCIONES DE MANTENIMIENTO ................................ 59

SI NECESITA ASISTENCIA ......................................................... 59

PARA EL PERSONAL DE SERVICIO AUTORIZADO

DE WHIRLPOOL

HERRAMIENTAS Y PIEZAS ........................................................ 60

ESPECIFICACIONES .................................................................... 60

DIMENSIONES Y ESPACIOS LIBRES ..................................... 59

REQUISITOS DE INSTALACIÓN DE LA SECADORA ........... 62

INSTALACIÓN DE LAS PATAS NIVELADORAS Y

CAJA DE MONEDAS ..................................................................... 63

NIVELACIÓN ................................................................................... 64

REQUISITOS DE INSTALACIÓN DE LA

SECADORA ELÉCTRICA.............................................................. 65

REQUISITOS DE INSTALACIÓN DE LA

SECADORA A GAS ....................................................................... 66

REQUISITOS DE VENTILACIÓN DE LA SECADORA ........... 68

CONEXIÓN DEL SUMINISTRO DE GAS ................................. 71

ESPECIFICACIONES TÉCNICAS - SECADORA A GAS ...... 72

INSTALACIÓN COMPLETA ......................................................... 74

CÓMO INVERTIR EL SENTIDO DE APERTURA

DE LA PUERTA ............................................................................... 75

INSTRUCCIONES DE PROGRAMACIÓN DEL CONTROL

ELECTRÓNICO (SOLO MODELOS PD Y PN) ......................... 76

ELIMINACIÓN DE LA SECADORA ............................................ 81

GARANTÍA ....................................................................................... 82

2

TABLE DE MATIÈRES

SÉCURITÉ DE LE SECHE-LINGE ................................................29

POUR LE PROPRIÉTAIRE

INSTRUCTIONS D’ENTRETIEN .................................................. 32

SI VOUS AVEZ BESOIN D'ASSISTANCE ................................ 31

POUR LE PERSONNEL D’ENTRETIEN AUTORISÉ

PAR WHIRLPOOL

OUTILS ET PIÈCES ....................................................................... 33

SPÉCIFICATIONS .......................................................................... 33

DIMENSIONS/DÉGAGEMENT ................................................... 34

EXIGENCES D’INSTALLATION DE LE SECHE-LINGE .......... 35

INSTALLATION DES PIEDS DE NIVELLEMENT ET

DE LA BOÎTE À MONNAIE .......................................................... 36

NIVELLEMENT ................................................................................ 37

EXIGENCES D’INSTALLATION DE LE

SECHE-LINGE ÉLECTRIQUE ...................................................... 38

EXIGENCES D’INSTALLATION DE LE

SECHE-LINGE À GAZ ................................................................... 39

EXIGENCES CONCERNANT L’ÉVACUATION

DE LE SECHE-LINGE .................................................................... 41

RACCORDEMENT A LA CANALISATION DE GAZ ................ 43

CARACTÉRISTIQUES TECHNIQUES —

SECHE-LINGE À GAZ ................................................................... 44

ACHEVER L’INSTALLATION ........................................................ 46

INVERSION DU SENS D’OUVERTURE

DE LA PORTE (FACULTATIF) ...................................................... 47

INSTRUCTIONS DE RÉGLAGE DU

TABLEAU DE COMMANDE ÉLECTRONIQUE

(MODÈLES PD ET PN SEULEMENT) ........................................ 49

MISE AU REBUT DE LE SECHE-LINGE ................................... 54

GARANTIE ...................................................................................... 55

SOMMARIO

SICUREZZA DELL'ASCIUGATRICE ............................................83

PER IL PROPRIETARIO

ISTRUZIONI PER LA MANUTENZIONE ................................... 86

COME RICHIEDERE ASSISTENZA .......................................... 86

PER IL PERSONALE DI ASSISTENZA

AUTORIZZATO WHIRLPOOL

ATTREZZI E PARTI ........................................................................ 87

SPECIFICHE ................................................................................... 87

DIMENSIONI/SPAZI ................................................................... 88

REQUISITI PER L'INSTALLAZIONE

DELL'ASCIUGATRICE ................................................................... 89

INSTALLAZIONE DEI PIEDINI DI REGOLAZIONE

E GETTONIERA .............................................................................. 90

LIVELLAMENTO ............................................................................. 91

REQUISITI DELL’INSTALLAZIONE

DELL’ASCIUGATRICE ELETTRICO ............................................ 92

REQUISITI DELL’INSTALLAZIONE

DELL’ASCIUGATRICE A GAS .................................................... 93

REQUISITI DI SCARICO DELL'ASCIUGATRICE ..................... 95

COLLEGAMENTO DI ALIMENTAZIONE DEL GAS ................. 97

CARATTERISTICHE TECNICHE - ASCIUGATRICE

A GAS .............................................................................................. 98

COMPLETAMENTO DELL'INSTALLAZIONE ........................... 96

INVERTIRE IL SENSO DI APERTURA DELLO

SPORTELLO (FACOLTATIVO) ...................................................101

ISTRUZIONI DI CONFIGURAZIONE DEI COMANDI

ELETTRONICI (SOLO MODELLI PD E PN) ........................... 102

ELIMINAZIONE DELL'ASCIUGATRICE ................................... 107

GARANZIA ................................................................................... 108

Page 3

DRYER SAFETY

WARNING – “Risk of Fire”

This is an additional safety alert symbol that alerts you to the risk of fire.

WA RNING

- Clothes dryer installation and service must be performed by a Whirlpool authorized

installer.

- Install the clothes dryer according to the manufacturer’s instructions and local codes.

by the appliance manufacturer as suitable for use with clothes dryers. Flexible venting

materials are known to collapse, be easily crushed, and trap lint. These conditions will

-To reduce the risk of severe injury or death, follow all installation instructions.

- Save these instructions.

-

“Risk of Fire”

3

Page 4

DRYER SAFETY

■ It is recommended that the owner post, in a prominent location, instructions for the customer’s use in the event the customer

smells gas. This information should be obtained from your gas supplier.

■ Post the following warning in a prominent location.

FOR YOUR SAFETY

1. DO NOT USE OR STORE GAS OR OTHER FLAMMABLE MATERIALS IN THIS APPLIANCE OR NEAR THIS APPLIANCE.

2. DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS APPLIANCE WHILE IT IS IN OPERATION.

3. DO NOT MODIFY THIS APPLIANCE.

WARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could result in serious injury, death or property

damage.

–

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

–

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

•

Do not touch any electrical switch; do not use any phone in your building.

•

Clear the room, building, or area of all occupants.

•

Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

•

instructions.

If you cannot reach your gas supplier, call the fire department.

•

–

Installation and service must be performed by a qualified installer, service agency, or

the gas supplier.

4

Page 5

DRYER SAFETY

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of re, electric shock, or injury to persons when using the dryer, follow basic precautions,

including the following:

■ Read all instructions before using the dryer.

■ This dryer is intended only for drying clothes and textiles

that have been washed in water. Do not use for any other

purpose.

■ WARNING: If you smell gas, do not use the dryer or any

electrical equipment nearby. Warn other people to clear

the area. Contact the dryer owner immediately.

■ Do not place items exposed to cooking oils in your dryer.

Items contaminated with cooking oils may contribute

to a chemical reaction that could cause a load to catch

re. To reduce the risk of re due to contaminated loads,

the nal part of a tumble dryer cycle occurs without heat

(cool down period). Avoid stopping a tumble dryer before

the end of the drying cycle unless all items are quickly

removed and spread out so that the heat is dissipated.

■ If it is unavoidable that fabrics that contain vegetable or

cooking oil or that have been contaminated by hair care

products be placed in a tumble dryer, they should rst

be washed in hot water with extra detergent – this will

reduce, but not eliminate the hazard.

■ Do not dry articles that have been previously cleaned

in, washed in, soaked in, or spotted with gas,

dry-cleaning solvents, other ammable, or explosive

substances as they give off vapors that could ignite

or explode.

■ Items that have been soiled with substances such as

acetone, alcohol, gas, kerosene, spot removers,

turpentine, waxes, and wax removers should be washed

in hot water with extra detergent before being dried in

the dryer.

■ Do not dry unwashed items in the dryer.

■ Do not use this dryer if industrial chemicals have been

used for cleaning. The possible presence of residual

quantities of aggressive or decomposed chemicals in the

load may produce damage to the dryer and harmful fumes.

■ Do not allow children to play on, in, or with the dryer.

Close supervision of children is necessary when the dryer

is used near children.

■ This dryer is not intended for use by persons (including

children) with reduced physical, sensory, or mental

capabilities, or lack of experience or knowledge,

unless they have been given supervision or instruction

concerning use of the dryer by a person responsible for

their safety.

■ Before the dryer is removed from service or discarded,

remove the door to the dryer compartment.

■ Do not reach into the dryer if the drum is moving.

■ Do not open door while dryer is in operation. It will stop.

■ When loading or re-loading the dryer, avoid touching hot

metal parts of the drum (burn risk).

■ Remove all objects from pockets such as lighters and

matches.

■ Cleaning and user maintenance shall not be made by

children without supervision.

■ WARNING: The appliance must not be supplied through

an external switching device, such as a timer, or connected

to a circuit that is regularly switched on and off by a utility.

■ The dryer must not be installed behind a lockable door, a

sliding door, or a door with a hinge on the opposite side to

that of the dryer in such a way that full opening of the dryer

door is restricted.

SAVE THESE INSTRUCTIONS

■ The appliance is intended, but not limited, to be used in

public areas.

■ Children of less than 3 years should be kept away unless

continuously supervised.

■ The appliance must be disconnected from it's power

source during service and when replacing parts.

■ If drum rotation is blocked due to trapped textiles,

disconnect the dryer from the electrical supply before

gently removing the blockage.

■ If the dryer is not heating, or appears to be defective or

damaged, do not use it. Contact the owner.

■ Do not install or store the dryer where it will be exposed

to the weather.

■ Do not tamper with controls.

■ Clean dryer lint screen before or after each load.

■ Do not use this dryer without the lint screen in place.

■ Do not repair or replace any part of the dryer or attempt

any servicing unless specically recommended in this

Installation Instructions that you understand and have the

skills to carry out.

■ Fabric softeners, or similar products, should be used as

specied by the fabric softener instructions.

■ Items such as foam rubber (latex foam), shower caps,

waterproof textiles, rubber-backed articles and clothes or

pillows tted with foam rubber pads should not be dried

in the tumble dryer.

■ The nal part of a tumble dryer cycle occurs without

heat (cool-down cycle) to ensure that the articles are left

at a temperature that ensures that the items will not be

damaged.

■ WARNING: Never stop a tumble dryer before the end of

the drying cycle unless all items are quickly removed and

spread out so that the heat is dissipated. (Avoids risk of

spontaneous combustion).

■ In case of electrical supply failure, remove the load

quickly and spread it out to avoid risk of spontaneous

combustion.

■ Keep area around the exhaust opening and adjacent

surrounding areas free from the accumulation of lint, dust,

and dirt.

■ The fresh air ventilation openings into the room and into

the dryer must not be blocked or sealed.

■ Emergency stop control: After installation, access to

mains plug (gas dryer) or mains supply (electric dryer)

via a double-pole switch must be maintained at all times

in order to ensure immediate deactivation of the dryer in

case of emergency.

■ The interior of the dryer and dryer exhaust vent should

be cleaned periodically by Whirlpool authorized service

personnel.

■ See “Electrical Requirements” section for earthing

instructions.

■ Adequate ventilation has to be provided to avoid the

back-ow of gases into the room from appliances burning

fuels, including open res.

5

Page 6

MAINTENANCE INSTRUCTIONS

■ Clean lint screen before and after each cycle.

■ Removing accumulated lint:

From inside the dryer cabinet:

Lint should be removed every 2 years or more often,

depending on dryer usage. Cleaning should be done by

a Whirlpool authorized person.

From the exhaust vent:

Lint should be removed every 2 years, or more often,

depending on dryer usage.

■ Keep area around dryer clear and free from combustible

materials, gas, and other ammable vapors and liquids.

■ Keep dryer area clear and free from items that would

obstruct the ow of combustion and ventilation air.

If dryer does not operate, check the following:

■ Electrical supply is connected.

■ Circuit breaker is not tripped or house fuse is not blown.

■ Door is closed. Listen closely to hear the door switch

activate.

■ Controls are set in a running or “on” position.

■ For gas dryers, check that gas supply shut-off valves are

set in open position.

WARNING: Improper connection of the equipment-earthing conductor can result in a risk of electric

shock. It is your responsibility to check with a qualied electrician or service representative if you are in doubt

as to whether the dryer is properly earthed and meets all local codes and ordinances. Do not modify the plug

provided with the dryer: If it will not t the outlet, have a proper outlet installed by a qualied electrician.

IF YOU NEED ASSISTANCE

If you need help, contact the dealer from whom you purchased the appliance, or a Maytag designated service company. When

calling, please know the purchase date and the complete model and serial number of your appliance. This information will help us to

better respond to your request.

IF YOU NEED SERVICE:

Contact your authorized Maytag Commercial Laundry distributor. To locate your authorized Maytag Commercial Laundry distributor,

visit www.maytagcommerciallaundry.com.

For written correspondence:

Maytag Commercial Laundry Service Department

2000 N M 63

Benton Harbor, Michigan 49022-2632 USA

6

Page 7

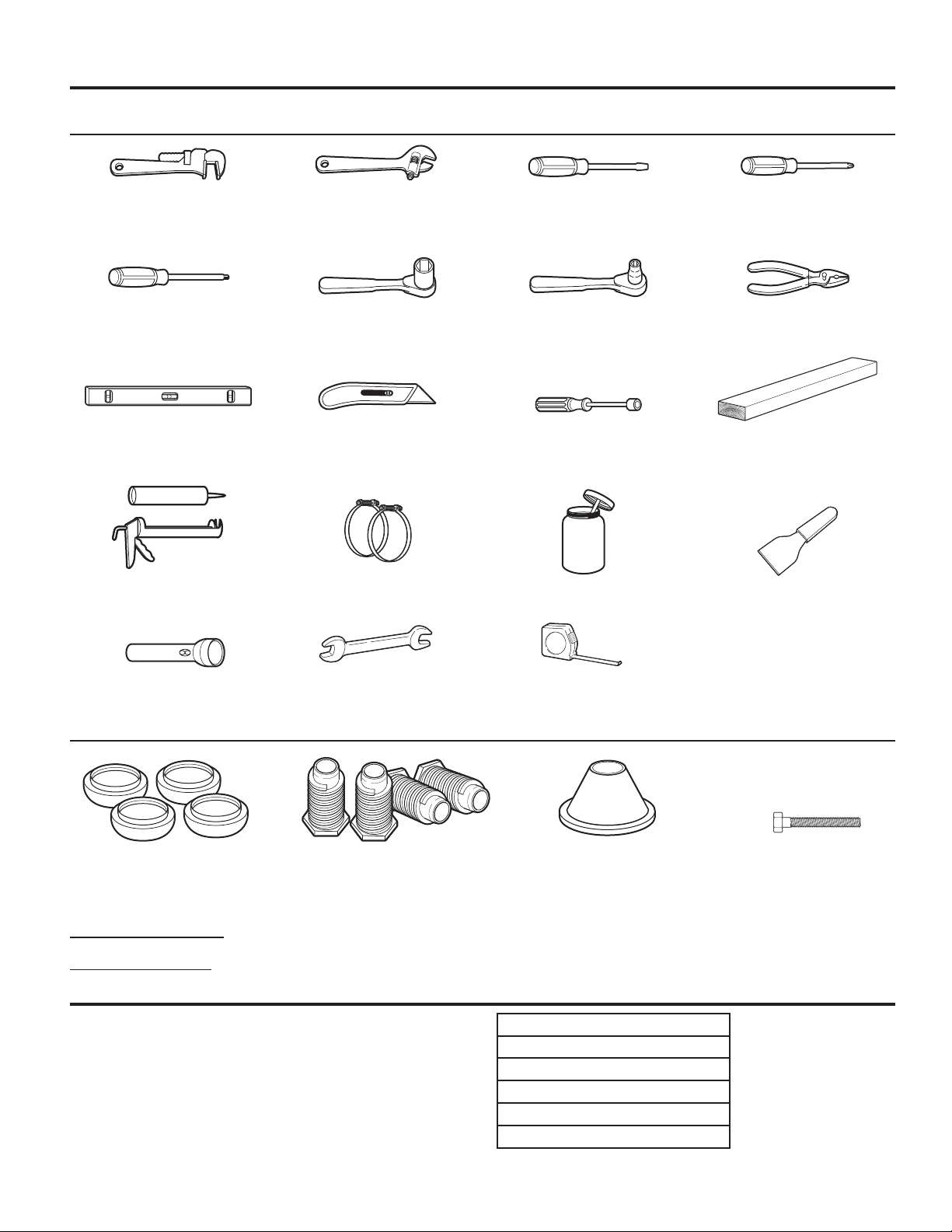

TOOLS & PARTS

Tools Needed:

203 mm (8") 203 mm (8") or 254 mm (10") Flat-Blade Screwdriver Phillips Screwdriver

or 254 mm (10") Adjustable Wrench

Pipe Wrench (that opens to 25 mm (1"))

Torx T-20† Security 25 mm (1") Hex-Head 8 mm (5⁄16") Socket Wrench Pliers (that open to

Screwdriver or Bit Socket Wrench 39 mm [19/16"])

Level Utility Knife 6 mm (1/4") Nut Driver 686 mm (27")

Wood Block

Caulk Gun and Caulk Vent Clamps Pipe-Joint Compound Putty Knife

(for installing new exhaust vent) Suitable for Gas Type

Flashlight (optional) 25 mm (1") Ruler or Measuring Tape

Open-End Wrenches

Parts Supplied:

Foot Boots (4) Leveling Legs (4) Security Cone 5/16" Hex Head – 18 x 2

Security Bolt

NOTE: The circuit diagram for this dryer is located inside

the lower front panel, within the Tech Sheets.

Technical Specications:

220 – 240 V, 50 Hz. AC

4575W

Total mass: 68 kg max.

SPECIFICATIONS

These units are sold in multiple regions with different

requirements for measuring capacity. Below are a few of

the valid forms of measure posted on this product:

Dry Linen Capacity: A weight measure that reects a minimum

threshold for dry volume capacity that is needed for import

tariff purposes.

IEC Capacity: The capacity measure that represents the

maximum capacity of dry linens and textiles which the

manufacturer declares can be treated in a specic cycle.

†

TORX and T20 are trademarks of Acument Intellectual Properties, LLC.

Dry Linen Capacity

10.5 kg (23 lb)

IEC Capacity

9.0 kg (20 lb)

Sound Level

LpA: 58 dB(A) (Kpa+/-10 dB(A))

1

⁄2"

7

Page 8

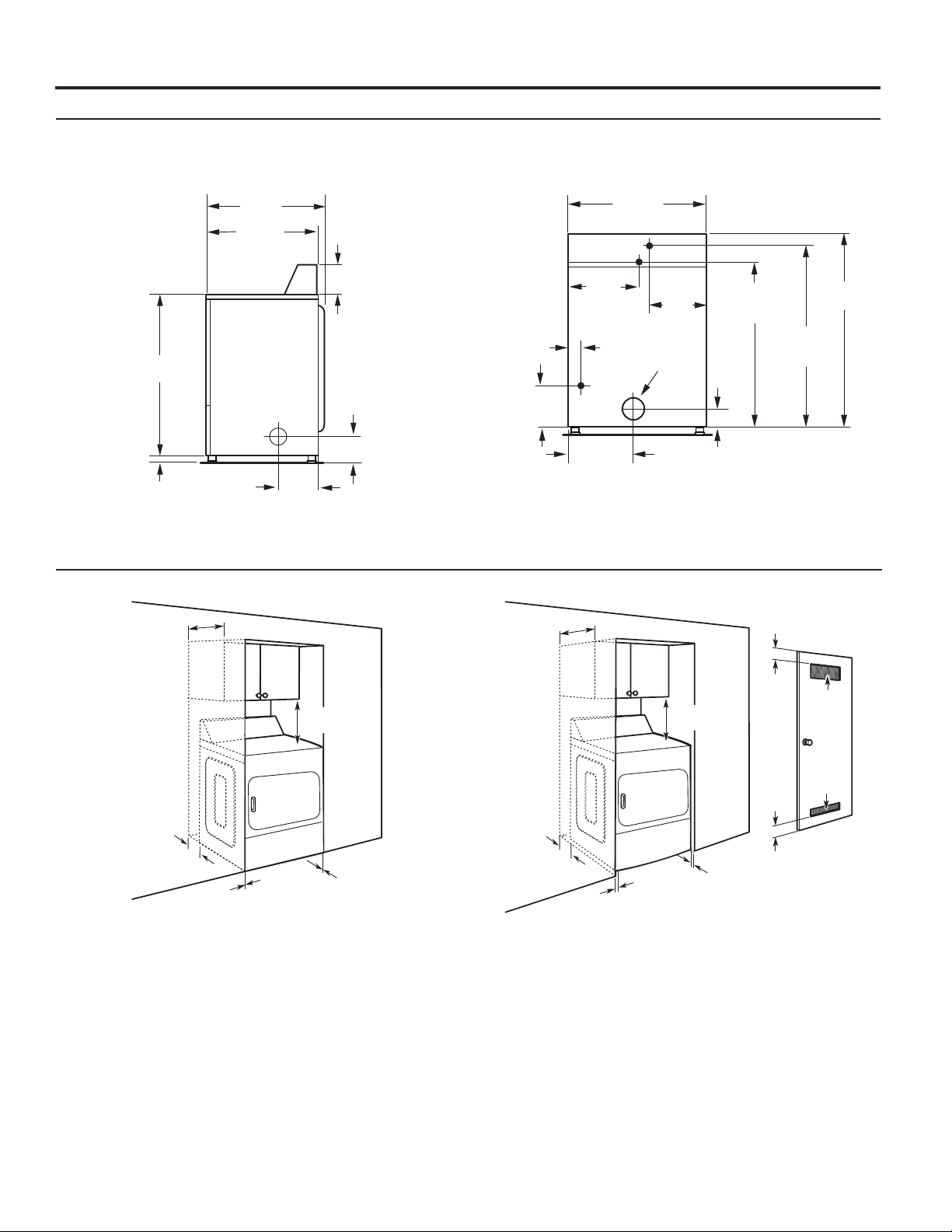

DIMENSIONS/CLEARANCES

Dimensions

Side View Back View

889 mm

25 mm

Clearances

Front View, Recessed Opening Side View, Recessed In Closet

356 mm

(14" max)

(35")

(1")

191 mm

1

/2")

(7

743 mm

(291/4")

660 mm

(26")

210 mm

1

(8

/4")

83 mm

1

(3

/4")

38 mm

(11/2")

140 mm

(5

356 mm

(14" max)

1

/2")

Electric

343 mm

(131/2")

Gas

343 mm

1

(13

/2")

686 mm

(27")

102 mm

(4" dia)

273 mm

(103/4")

914 mm

(36")

(electric models)

(gas models)

83 mm

1

/4")

(3

953 mm

1

/2")

(37

1042 mm

(41")

0 mm

(0")

0 mm

(0")

381 mm

(15")

0 mm

(0")

127 mm

(5")

25 mm

(1")

381 mm

(15")

25 mm

(1")

Closet Door to

Front of Dryer

76 mm

(3"/3")

76 mm

(3"/3")

310 cm

(48"2/48"2)

155 cm

(24"2/24"2)

2

2

8

Page 9

DRYER INSTALLATION REQUIREMENTS

(Australia and New Zealand – for full details of installation requirements refer to AS/NZS 5601.1)

Location Requirements

Recessed Area and Closet Installation Instructions

This dryer may be installed in a recessed area or closet. For

recessed area and closet installations, minimum clearances

can be found on the warning label on the rear of the dryer

or in “Dimensions/Clearances.”

The installation spacing is in millimeters and is the minimum

allowable. Additional spacing should be considered for ease

of installation, servicing, and compliance with local codes and

ordinances.

If closet door is installed, the minimum unobstructed air

opening in the top and bottom is required. The unobstructed

opening needs to be 1 square inch per 1,000 Btu (252 kcal)

of gas burner output. Output on North American gas dryers

is typically 22,000 Btu; however, Canadian dryers may have

lower output. Louvered doors with equivalent air openings are

acceptable.

Your dryer can be installed in a basement, laundry room, or

recessed area.

This dryer is not intended for installation in a mobile home.

Companion appliance location requirements should also be

considered.

IMPORTANT: Do not install or store the dryer where it

will be exposed to the weather. Proper installation is your

responsibility.

The dryer must be exhausted outdoors.

No other fuel-burning appliance may be installed in the same

closet as the dryer.

NOTE: For installation in Australia and New Zealand, refer to

AS/NZS 5601.1 for ventilation requirements.

You will need:

■ An grounded electrical outlet located within 1.8 m (6 ft.) of

where the power cord is attached to the back of the dryer.

See “Electrical Requirements.”

■ A level oor with a maximum slope of 25 mm (1") under

entire dryer. Installing the dryer on soft oor surfaces,

such as carpets or surfaces with foam backing, is not

recommended.

Dryer installation clearances

■ The location must be large enough to allow the dryer door

to be fully opened.

■ Additional spacing should be considered for ease of

installation and servicing. The door opens more than 180°.

■ Additional clearances might be required for wall, door, and

oor moldings.

■ Additional spacing of 25 mm (1") on all sides of the dryer

is recommended to reduce noise transfer.

When installing a dryer:

IMPORTANT: Observe all governing codes and ordinances.

■ Check code requirements: Some codes limit or do not

permit installation of clothes dryers in garages, closets,

or sleeping quarters. Contact your local building inspector.

NOTE: For installation in Australia and New Zealand,

install dryer in accordance with AS/NZS 5601.1 and local

governance codes.

■ Gas Dryers only: Make sure that lower edges of the

cabinet, plus the back and bottom sides of the dryer, are

free of obstructions to permit adequate clearance of air

openings for combustion air. See “Recessed Area and

Closet Installation Instructions” below for minimum spacing

requirements.

Front

View

Closet

Door

9

Page 10

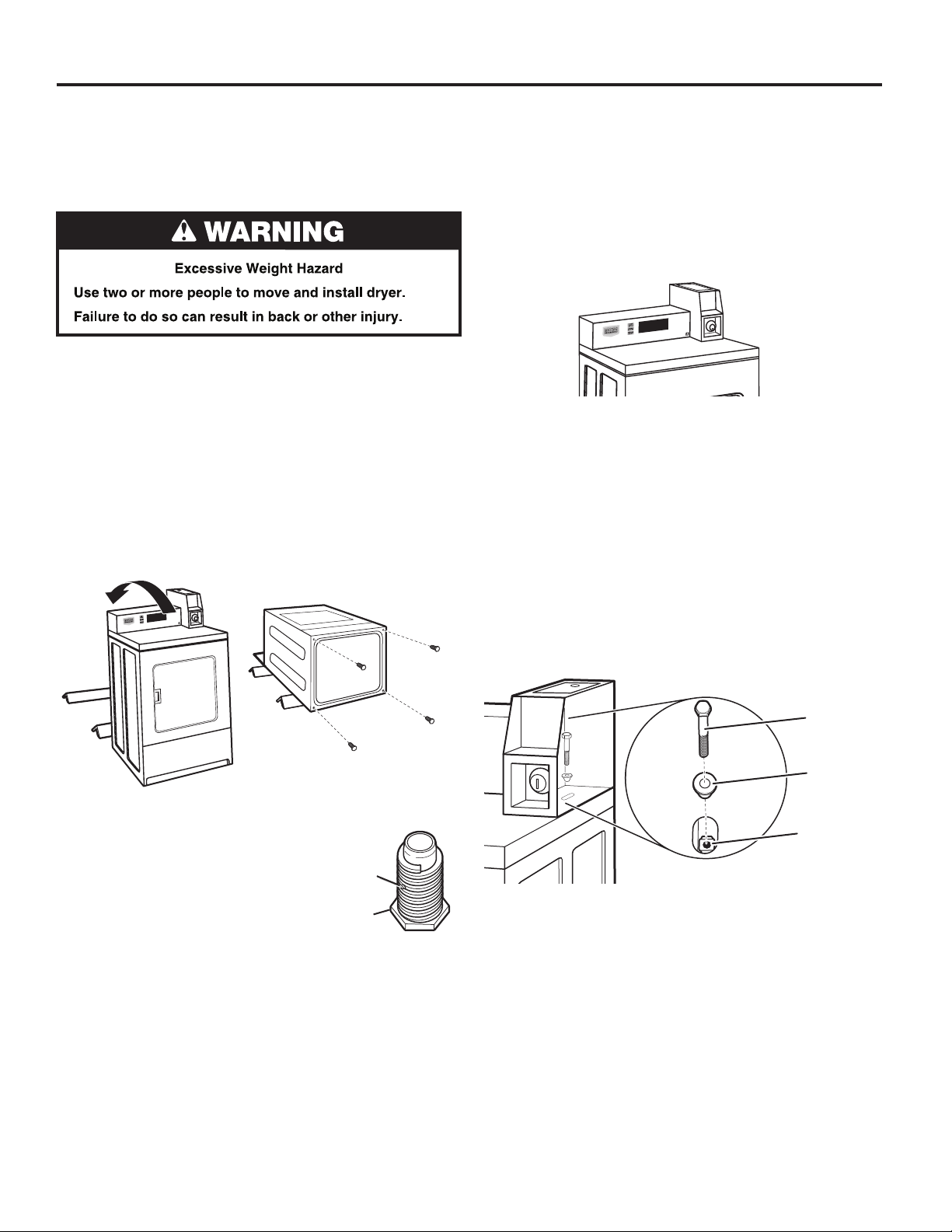

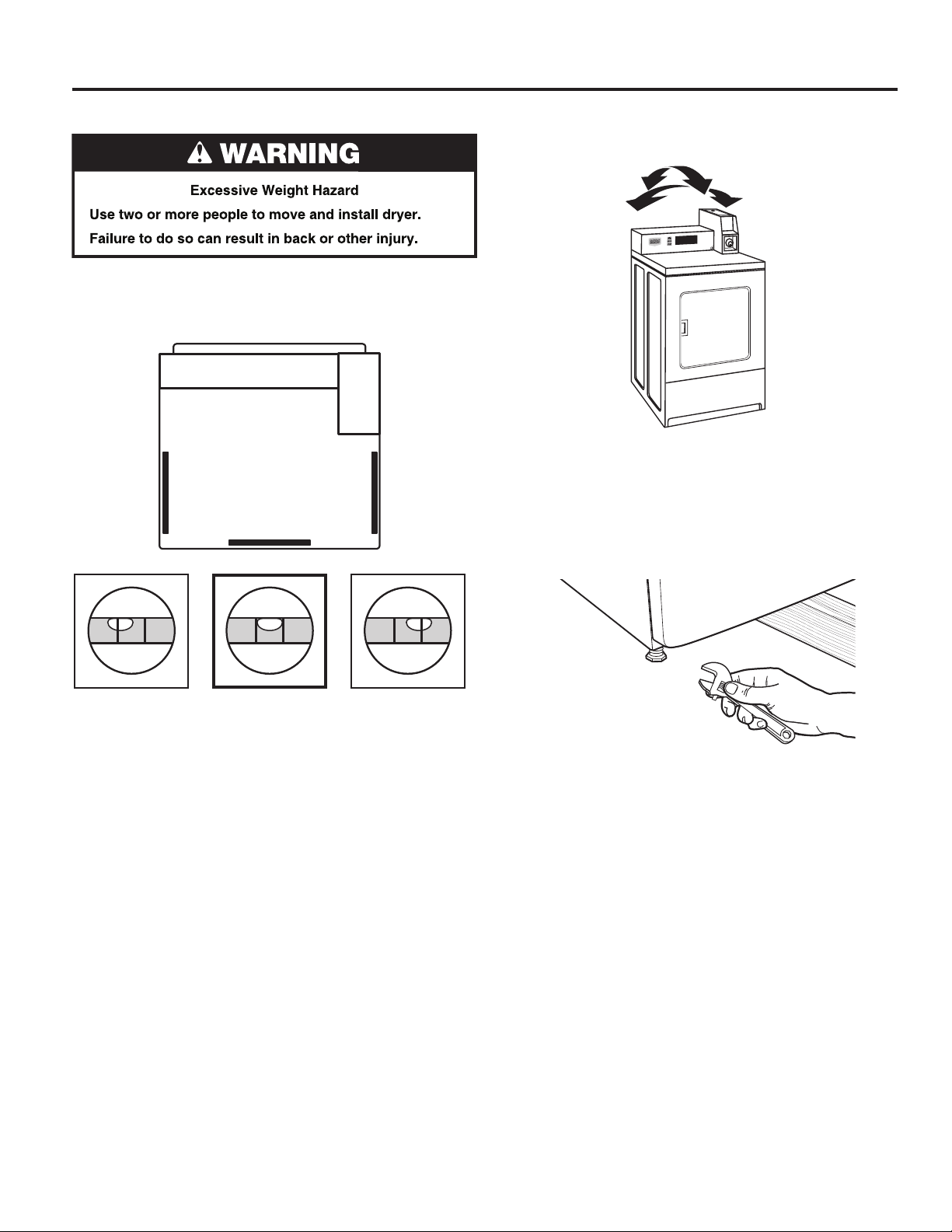

INSTALLING LEVELING LEGS AND COIN BOX

The console houses the electronic control board. The board is

factory set for a dry time of 30 minutes. Consult the tech sheet

found inside the dryer toe panel to reset dry time and for other

options.

The card reading mechanism is not included, but is available

from your usual industry sources.

1. Prepare dryer for leveling legs

NOTE: Slide dryer onto cardboard or hardboard before moving

to avoid damaging oor covering.

Using two or more people, move dryer to desired installation

location.

Take tape off front corners of dryer. Open dryer and remove

the literature and parts packages. Wipe drum interior with a

damp cloth to remove any dust.

Take two cardboard corners from the dryer carton and place

them on the oor in back of the dryer. Firmly grasp the body of

the dryer and gently lay it on its back on the cardboard corners.

Disconnect power before making electrical connections.

The meter case houses the factory-installed accumulator timer

with actuating arm or service switch.

The service door lock and key and coin box lock and key

may not be included but are available from the usual industry

sources.

1. Install coin box

Remove the service door of the meter case by lifting it up

at the back. Install the money-accepting device. (Refer to

manufacturer’s instructions for proper installation.)

Replace the meter case service door. Put the coin vault with

lock and key in the meter case opening.

Remove cardboard or hardboard from under dryer. Adjust the

legs of the dryer up or down until the dryer is level.

2. Install added security device

Check that power is not supplied to the dryer.

Open and remove the service door.

Insert the narrow part of the security cone into the oblong hole

in the bottom rear of the meter case assembly.

Pass the security bolt through this cone and thread it by hand

into the cage nut below the oblong hole.

Tighten the security bolt by hand a few turns before using a

wrench to tighten until snug.

(appearance may vary)

2. Screw in leveling legs

Examine leveling legs and nd diamond

marking. Screw legs into leg holes by

hand. Use an adjustable wrench or

Diamond

Marking

25 mm (1") hex-head socket wrench

to nish turning legs until diamond

marking is no longer visible. Then t

Foot

a covered foot boot over each leg foot.

To protect the oor, use a large piece of cardboard from the

dryer carton. Stand dryer up on the cardboard. Slide the dryer

until it is close to its nal location. Leave enough room for

electrical connection and to connect the exhaust vent.

A longer leveling foot is available if needed on extremely sloped

oors, Part Number 279810.

Security

security

Bolt

bolt

Security

security

Cone

cone

Cage

cage nut

Nut

NOTE: Installing the security bolt provides added security, but

will add to the service time when the top needs to be removed

for servicing the dryer.

10

Page 11

LEVELING

Leveling your dryer properly reduces excess noise and vibration.

1. Remove cardboard from beneath dryer. Place a level on top

edges of dryer, checking each side and front. If not level,

tip dryer and adjust legs up or down as shown in Step 3,

repeating as necessary.

2. Grip dryer from top and rock back and forth, making sure all

four legs are rmly on oor. Repeat, rocking dryer from side

to side. If dryer rocks, go to Step 3 and adjust leveling legs.

3. If dryer is not level, use a 25 mm or 1" open-end or

adjustable wrench to turn the leveling leg counterclockwise

to lower the dryer or clockwise to raise the dryer. Recheck

levelness of dryer and that all four legs are rmly in contact

with the oor. Repeat as needed.

HELPFUL TIP: You may want to prop up front of dryer

about 102 mm (4") with a wood block or similar object that

will support weight of dryer.

Not Level LEVEL Not Level

11

Page 12

ELECTRIC DRYER INSTALLATION REQUIREMENTS

Electrical Requirements

IMPORTANT: Observe all governing codes and ordinances.

This dryer is supplied without an electric cord and plug. It

must be connected by a Whirlpool authorized service person

to a single-phase electricity supply at the voltage shown

on the dataplate, using a suitable xed wiring installation in

accordance with local and national wiring regulations.

■ A 3-wire circular cord of minimum conductor size 2.5 mm

cross-section area should be used.

■ A 25 A (minimum) supply fuse should be used, and a switch

with a clear OFF marking having a contact separation in

both poles that provides full disconnection under overvoltage category III conditions must be incorporated into the

xed wiring in accordance with local wiring regulations by

a Whirlpool authorized service person. The dryer should be

positioned so that the disconnection switch is clearly visible

and easily accessible to the user. This disconnection switch

also provides the function of an emergency stop control for

the user.

■ A cord clamp bush is provided on the dryer, and should

be tightened on completion of wiring. The electrical mains

terminals are located behind the small rear access panel

(terminal block cover), and connections should be made

in accordance with the terminal markings. Remember to

replace the terminal access panel (terminal block cover).

NOTE: In accordance with the European EMC Directive

(2004/108/EC), the maximum electrical supply system

impedance to which the electric dryer should be connected

is declared to be 0.054 Ohm + j0.034 Ohm.

NOTE: Electrical safety standards: The manufacturer has

chosen compliance with IEC/EN.60335 standards as the

most appropriate for this product.

2

If codes permit and an additional ground bond wire is used, it

is recommended that a qualied electrician determine that the

ground bond path is adequate.

Recommended Earthing Method

It is your responsibility to contact a qualied electrical installer

to ensure that the electrical installation is adequate and in

conformance with all local codes and ordinances.

.

12

Page 13

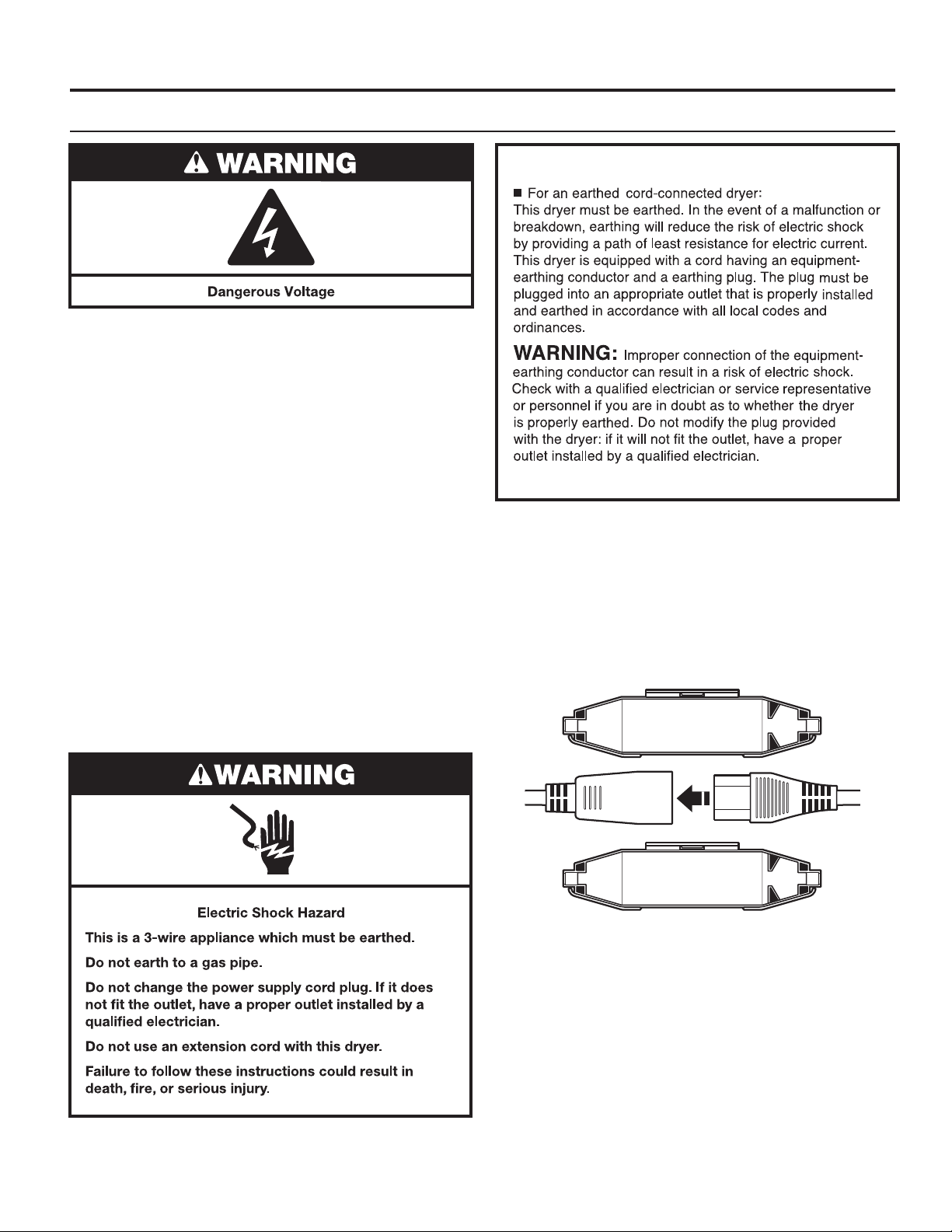

GAS DRYER INSTALLATION REQUIREMENTS

Electrical Requirements

IMPORTANT: Observe all governing codes and ordinances.

You will need a grounded electrical outlet located within

610 mm (2 feet) of either side of the dryer.

This dryer is supplied/tted with an electrical supply cord and

plug. It should be connected to electrical supply socket at the

voltage shown on the rating plate. The minimum supply fuse

capacity should be 10 A. The dryer must be positioned so that

the plug is clearly visible and accessible. This plug also provides

the function of an emergency stop control for the user. If the

tted plug is not used, the electrical connection must be carried

out by a competent electrician in accordance with local or

national codes.

If the supply cord is damaged, it must be replaced with a

specially terminated cord by an authorized service agent or

a similarly competent person in order to avoid a hazard.

Do not use an adapter.

Do not use an extension cord.

NOTE: In accordance with the European EMC Directive

(2004/108/EC), the maximum electricity supply system

impedance to which the gas dryer should be connected is

declared to be 0.054 Ohm + j0.034 Ohm.

NOTE: Electrical safety standards: The manufacturer has

chosen compliance with IEC/EN.60335 standards as the

most appropriate for this product.

EARTHING INSTRUCTIONS

SAVE THESE INSTRUCTIONS

Using the universal cord included with this dryer:

The gas dryer is equipped with a universal cord with

interchangeable plugs.

1. To use the universal cord, select the plug end that ts

your electrical outlet, and plug it into the adapter on

the supply cord.

2. Secure the plug end in place on the cord by aligning

the 2 cover halves over the cord adapter and clipping

them together.

If codes permit and an additional ground bond wire is used, it

is recommended that a qualied electrician determine that the

ground bond path is adequate.

13

Page 14

GAS DRYER INSTALLATION REQUIREMENTS

Gas Supply

Supply line requirements:

Provide a rigid gas supply line to the dryer location. It should

be minimum 12.5 mm (1/2") ID. When acceptable to the gas

supplier and local codes, 10 mm (3/8") ID rigid supply line may

be used for lengths under 6.1 m (20'). Pipe-joint compounds

resistant to the action of L.P. gas must be used.

NOTE: For installation in Australia and New Zealand, refer to

AS/NZS 5601 for pipe sizing details. All piping is to be in

accordance with AS/NZS 5601.1 – Gas Installations.

Gas connection to the dryer itself should be made by means

of a exible gas hose suitable for the appliance and gas

category in accordance with national installation regulations. If

in doubt, contact the gas supplier. It should be minimum

10 mm (3/8") ID.

A means of restraint should be used between the dryer and the

wall to avoid straining of the rigid gas supply when the dryer

is moved. An appropriate length of chain and a wall hook is

recommended.

The dryer gas inlet connection is a 3/8" NPT thread. An adapter

is supplied for conversion to standard ISO.228-1 thread

(3/8" BSP).

IMPORTANT: Observe all governing codes and ordinances.

In Australia and New Zealand, refer to AS/NZS 5601.1 – Gas

Installations.

Gas Supply

Before installation, check that the local gas distribution

conditions, nature of gas and pressure, and the adjustment of

the appliance are compatible. Burner information will be found

on the model/serial rating plate in the door recess of the dryer.

If this information does not agree with the type of gas available,

see your dealer.

Natural Gas:

This dryer is factory adjusted for use with NATURAL GAS (G20),

and no further adjustment should be required at installation.

L.P. Gas:

This dryer is also certied for use with L.P. (propane or butane)

gases with appropriate conversion. No attempt shall be made

to convert the appliance from the gas specied on the model/

serial rating plate for use with a different gas without consulting

the serving gas supplier.

Conversion must be done by a Whirlpool authorized service

technician. Gas conversion kit (European Country), part number

W10233219, is available for purchase from your dealer. Gas

conversion kit (Australia), part number W10315369, is available

for purchase from your dealer. Full instructions are supplied

with the kit.

Check for leaks by using an approved noncorrosive leakdetection solution. Bubbles will show a leak. Correct any leak

found. A pressure measurement tapping is provided on the gas

valve within the dryer, accessible after removal of the lower

front panel.

The dryer must be disconnected from the gas supply piping

system during any pressure testing of that system.

Natural Gas (France/Belgium):

This dryer is also certied for France/Belgium for use with G20/

G25 gases (20 mbar/25 mbar) with appropriate conversion. No

attempt should be made to convert this appliance from the gas

specied on the gas rating label for use with a different gas

without consulting the serving gas supplier. Gas conversion

must be done by a Whirlpool authorized gas service technician.

Conversion kit, part number (W10181947) is available for

purchase from your dealer. Full instructions are supplied with

the kit.

14

Page 15

DRYER VENTING REQUIREMENTS

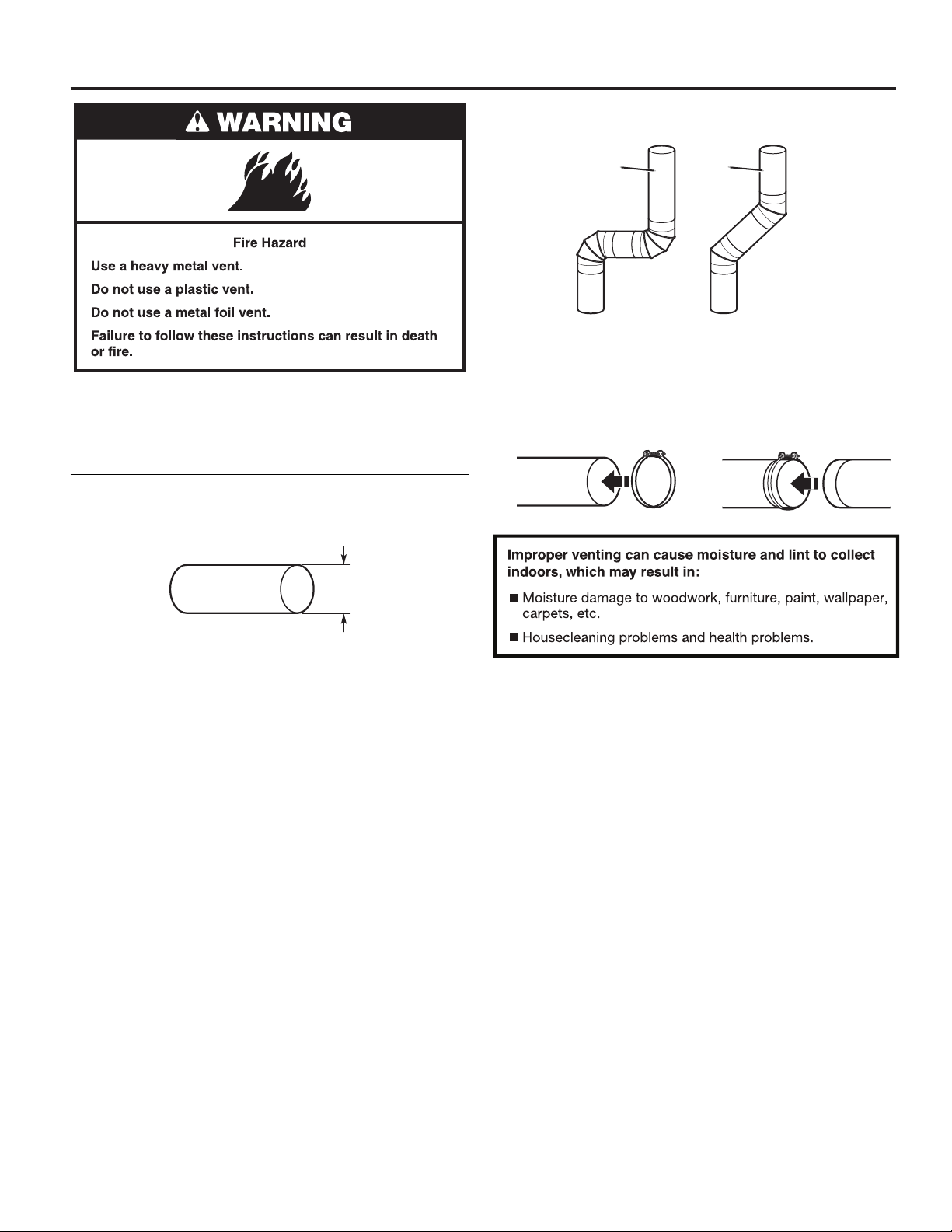

Elbows:

■ 45° elbows provide better airow than 90° elbows.

WARNING: To reduce the risk of re, this dryer MUST BE

EXHAUSTED OUTDOORS.

IMPORTANT: Observe all governing codes and ordinances.

In Australia and New Zealand, refer to AS/NZS 5601.1 – Gas

Installations.

Dryer exhaust must not be connected into any gas vent,

chimney, wall, ceiling, attic, crawlspace, or a concealed space

of a building. Only rigid or exible metal vent shall be used for

exhausting.

102 mm

(4")

Good

Better

Clamps:

■ Use clamps to seal all joints.

■ Exhaust vent must not be connected or secured with screws

or other fastening devices that extend into interior of duct

and catch lint. Do not use duct tape.

102 mm (4") Heavy, Metal Exhaust Vent

■ Only a 102 mm (4") heavy, metal exhaust vent and clamps

may be used.

■ Do not use plastic or metal foil vent.

Rigid metal vent:

■ Recommended for best drying performance and to avoid

crushing and kinking.

Flexible metal vent: (Acceptable only if accessible to clean)

■ Must be fully extended and supported in nal dryer location.

■ Remove excess to avoid sagging and kinking that may result

in reduced airow and poor performance.

■ Do not install in enclosed walls, ceilings, or oors.

■ The total length should not exceed 2.4 m (7

NOTE: If using an existing vent system, clean lint from entire

length of the system and make sure exhaust hood is not

plugged with lint. Replace plastic or metal foil vents with rigid

metal or exible metal vents. Review “Vent System Chart” and

if necessary, modify existing vent system to achieve best drying

performance.

3

⁄4 ft.).

15

Page 16

DRYER VENTING REQUIREMENTS

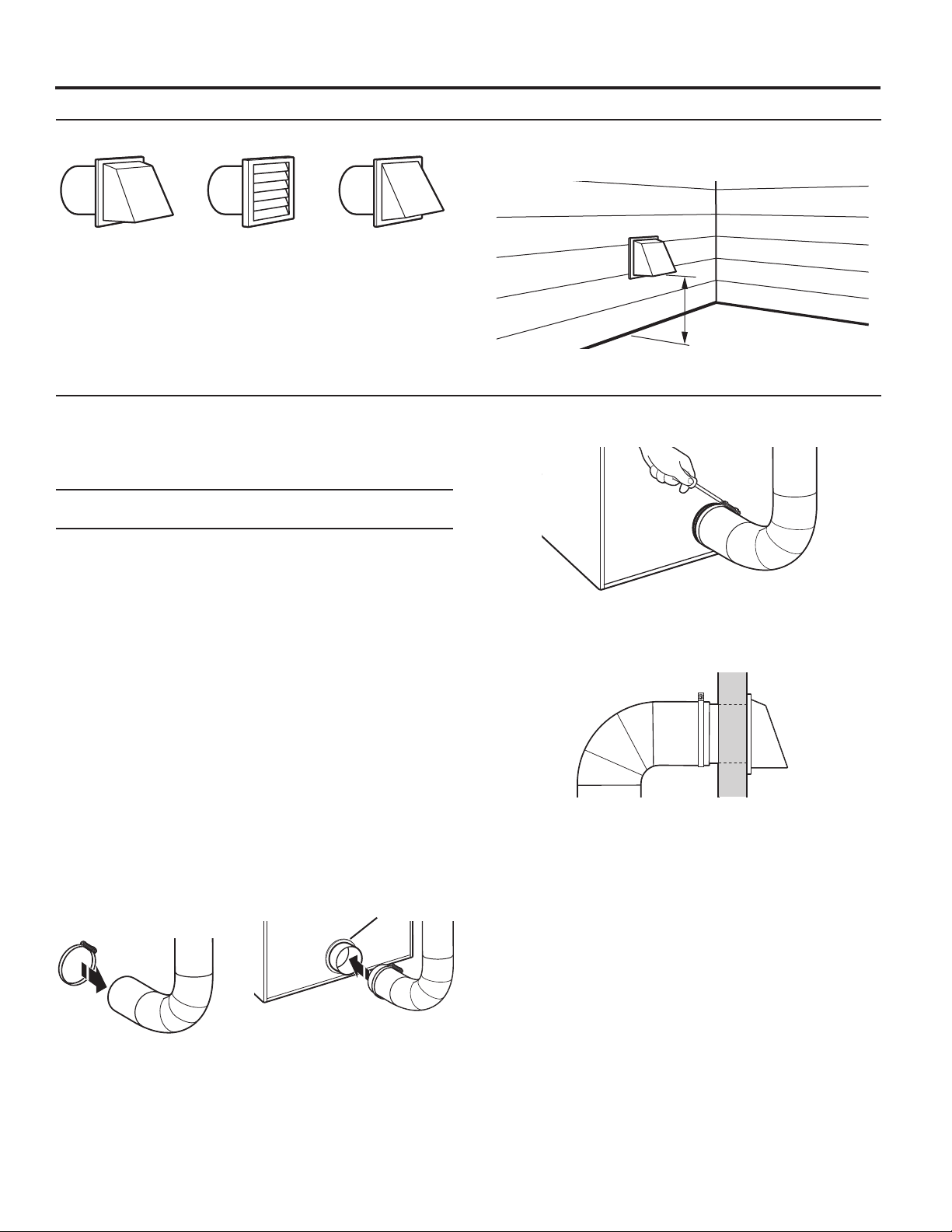

Vent Hoods

102 mm (4") Diameter Exhaust Hoods

Exhaust hood must be at least 305 mm (12") from the ground

or any object that may be in the path of the exhaust (such as

owers, rocks, bushes, or snow).

Box Hood Louvered Hood Angled Hood

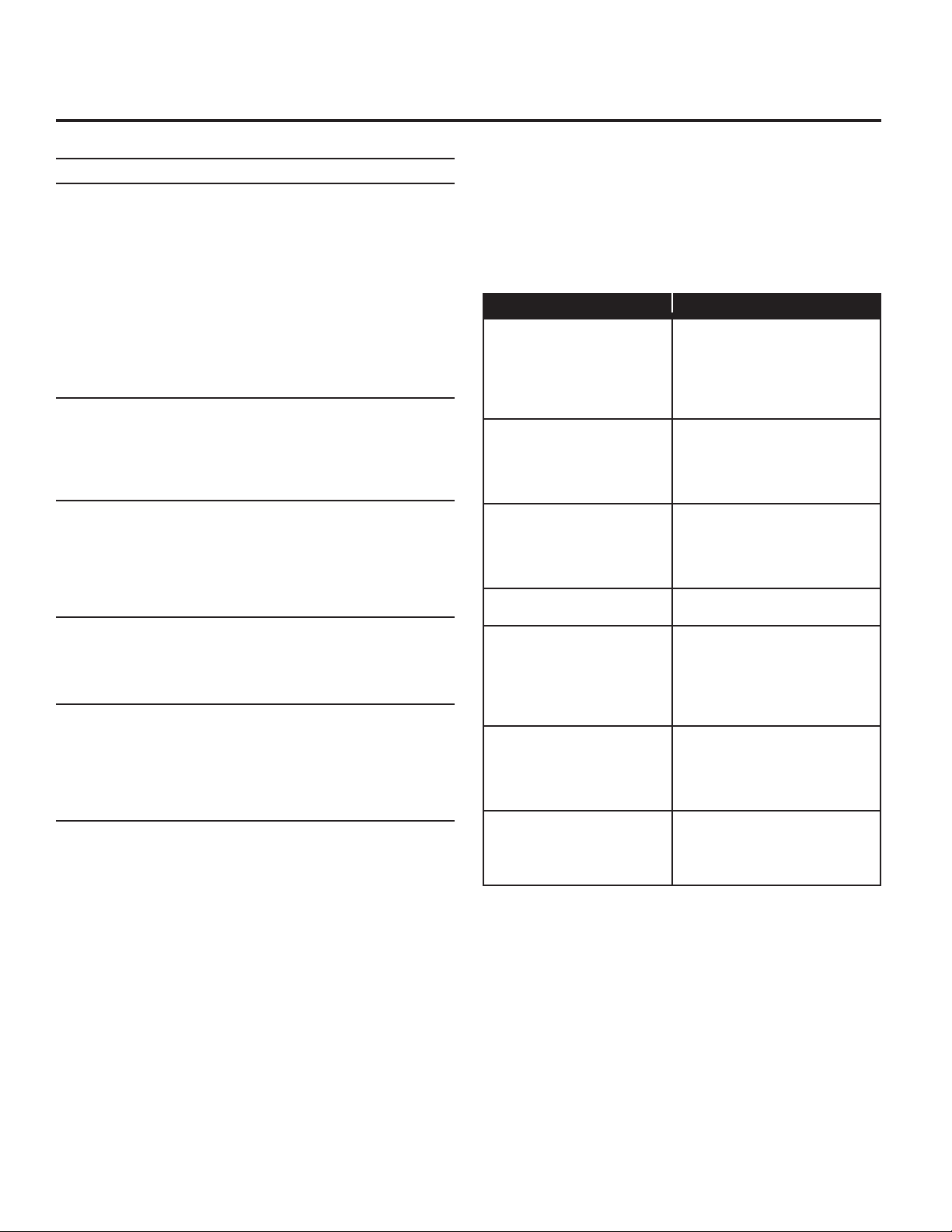

Vent System Length

Maximum Vent Length/Vent Connection

Maximum length of vent system depends upon the type of vent

used, number of elbows, and type of exhaust hood.

Vent System Chart (Rigid Metal Vent)

No. of 90˚ Turns

0 39.6 m (130 ft.) 39.3 m (129 ft.)

1 38.1 m (125 ft.) 36.3 m (119 ft.)

2 35.1 m (115 ft) 33.2 m (109 ft.)

3 32.3 m (106 ft.) 30.5 m (100 ft.)

4 29.9 m (98 ft.) 28.0 m (92 ft.)

For vent systems not covered by the vent specication chart,

see your parts distributor.

Provision must be made for enough air for combustion and

ventilation. (Check governing codes and ordinances.) See

“Recessed Area and Closet Installation Instructions” in the

“Location Requirements” section.

A 102 mm (4") outlet hood is preferred. However, a 64 mm

(21⁄2") outlet exhaust hood may be used. A 64 mm (21⁄2") outlet

creates greater back pressure than other hood types. For

permanent installation, a stationary vent system is required.

Connect Vent

1. If connecting to existing vent, make sure the vent is clean.

2. Using a 102 mm (4") clamp, connect vent to exhaust outlet

in dryer.

Box and

Louvered Hood

Angled Hood

Vent Collar

12" min.

305 mm min.

(305 mm)

(12")

3. Tighten hose clamp with Phillips screwdriver.

4. Make sure the vent is secured to exhaust hood with

a 102 mm (4") clamp.

5. Move dryer into nal position. Do not crush or kink vent.

Make sure dryer is level.

NOTE: Testing for proper ventilation should be done with a

Manometer. Minimum: 0.01" (0.2 mm). Maximum: 0.6" (16 mm).

NOTE: Do not remove vent collar.

16

Page 17

DRYER VENTING REQUIREMENTS

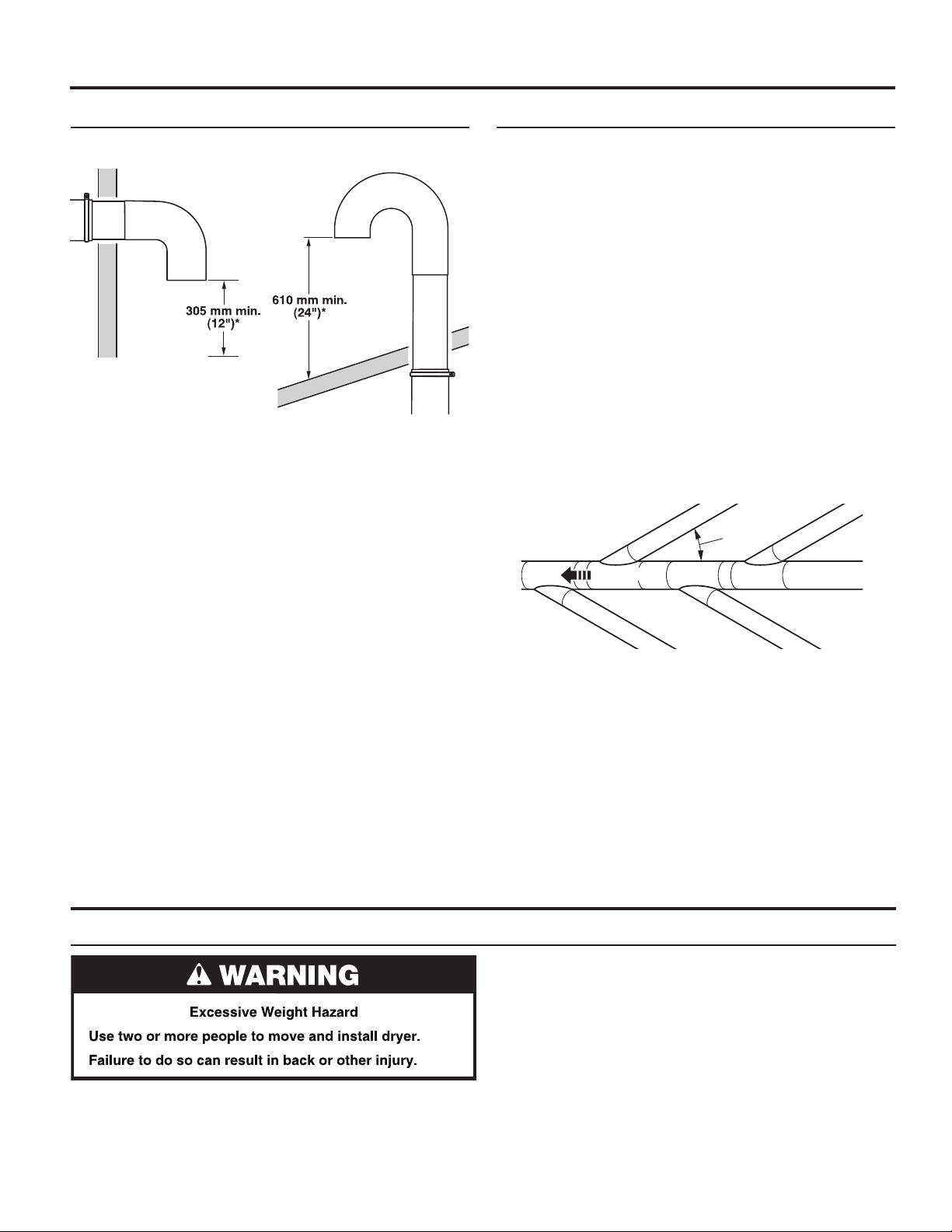

If an Exhaust Hood Cannot be Used Multiple Dryer Venting

The outside end of main vent should have a sweep elbow

directed downward.

* Minimum clearance above

any accumulation of snow,

ice, or debris such as leaves

If main vent travels vertically through the roof, rather than

through wall, install a 180° sweep elbow on end of vent at least

610 mm (2 ft.) above surface of roof.

The opening in wall or roof shall have a diameter 13 mm (1⁄2")

larger than vent diameter. Vent should be centered in opening.

Do not install screening over end of vent for best performance.

A main vent can be used for venting a group of dryers. The

main vent should be sized to remove 5663 l/min. (200 CFM) of

air per dryer. Large-capacity lint screens of proper design may

be used in main vent if checked and cleaned frequently. The

room where the dryers are located should have make-up air

equal to or greater than CFM of all the dryers in the room.

Back-draft dampers are available from your distributor and

should be installed in the vent of each dryer to keep exhausted

air from returning into dryers and to keep exhaust in balance

within main vent. Unobstructed return air openings are required.

Although usually each single-load dryer should have an

unobstructed outdoor air opening of 154 cm2 (24 in.2) (based

on 6.5 cm2 [1 in.2] per 252 kcal [1,000 Btu]), common make-up

air openings are also acceptable. Set up common openings so

the make-up air is distributed equally to all of the dryers. Keep

in mind that the coverage area must be increased by 33% to

account for the use of registers or louvers over the openings.

Also, make-up air openings should not be installed near the

location where exhaust vents exit the building.

Each vent should enter the main vent at an angle pointing in

the direction of the airow. Vents entering from the opposite

side should be staggered to reduce the exhausted air from

interfering with the other vents.

30˚ max.

GAS SUPPLY CONNECTION (on some models)

Make Gas Connection

1. Connect gas supply to dryer. If the exible gas hose has

10 mm (3/8") BSP thread, use the supplied conversion

thread adapter. Use pipe-joint compound resistant to the

action of L.P. gas for gas connections.

Air Flow

Air ow

The maximum angle of each vent entering the main vent should

be no more than 30°.

Keep air openings free of dry cleaning uid fumes. Fumes

create acids which, when drawn through the dryer heating

units, can damage dryers and items being dried.

A clean-out cover should be located on the main vent for

periodic cleaning of the vent system.

NOTE: For more dryer venting information, please refer to

Whirlpool document W10100920.

If necessary for service, open the toe panel. Use a putty

knife to press on the 2 toe panel locks located at the top

of the toe panel. Pull downward on the toe panel to open.

Toe panel is hinged at the bottom.

2. Open the shut-off valve in the gas supply line and make

sure the dryer has its own gas supply opened.

3. Test all connections by brushing on an approved

noncorrosive leak-detection solution. Bubbles will show

a leak. Correct any leaks found.

17

Page 18

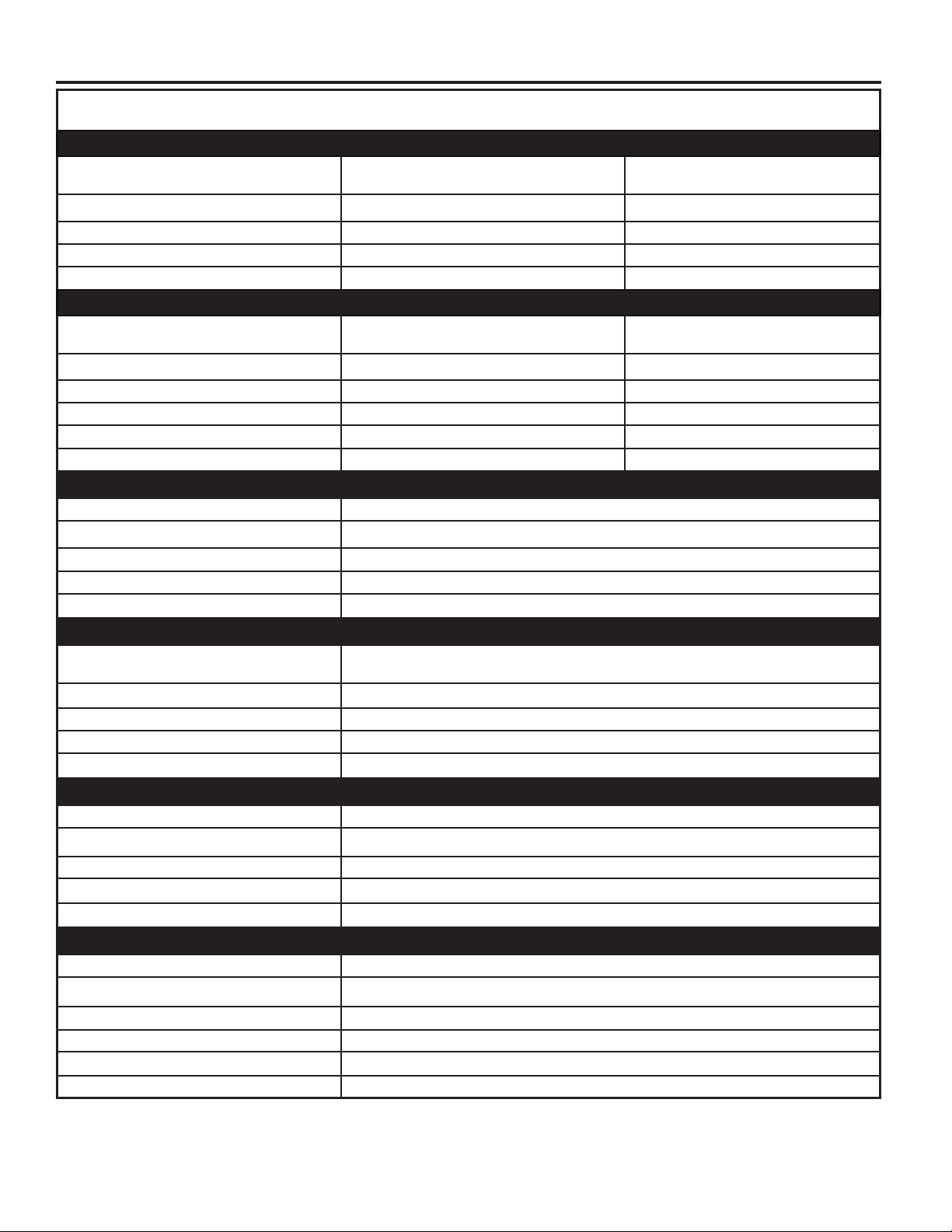

TECHNICAL SPECIFICATIONS – GAS DRYER

220–240 V~50 Hz 1 ph 3 A max. IP24 Clothes capacity: 9.0 kg max. Sound pressure level, Lpa: 58 dBA (uncertainty, Kpa: +/-10

dBA) Total mass: 68 kg max.

Factory set for NATURAL GAS: Injector size: 2.2 mm Heat input gross: 5.9 kW

European Country:

European Gas Category: II

CH, CZ, CY, ES, GB, GR,

IE, IT, LT, PT, SI, SK, TR

2H3+

Gas Flow Rate: 0.562703 m3/hr 0.562703 m3/hr

Supply Pressure (G20): 20 mbar 20 mbar

Factory Adjusted Pressure: 7.4 mbar 7.4 mbar

With L.P. Gas Conversion Kit: Injector size: 1.25 mm Heat input gross: 6.4 kW

European Country:

European Gas Category:

CH, CZ, CY, ES, GB, GR,

IE, IT, LT, PT, SI, SK, TR

II

2H3+

Butane Supply Pressure (G30): 28-30 mbar 30 mbar

Adjusted Pressure: N/A N/A

L.P. Supply Pressure (G31): 37 mbar 30 mbar

Adjusted Pressure: N/A N/A

With France/Belgium NATURAL GAS conversion kit: Injector size 1.65 mm Heat input gross: 5.9 kW

European Country: FR, BE

European Gas Category:

I

2E+

Supply Pressure (G20): 20 mbar

Supply Pressure (G25): 25 mbar

Adjusted Pressure: N/A

Factory set for NATURAL GAS: Injector size: 2.2 mm Heat input gross: 5.9 kW

Country:

European Gas Category: I

AT, BG, CH, CZ, DK, EE, ES, FI, GB, GR, HR,

IE, IS, IT, LT, LV, NO, PT, RO, SE, SI, SK, TR

2H

Gas Flow Rate: 0.562703 m3/hr

Supply Pressure (G20): 20 mbar

Factory Adjusted Pressure (G20): 7.4 mbar

Factory set for NATURAL GAS: Injector size: 2.2 mm Heat input gross: 5.9 kW

Country: LU, RO

European Gas Category: II

2E3B/P

Gas Flow Rate: 0.562703 m3/hr

Supply Pressure (G20): 20 mbar

Factory Adjusted Pressure (G20): 7.4 mbar

With L.P. Gas Conversion Kit: Injector size: 1.25 mm Heat input gross: 6.4 kW

Country: LU, RO

European Gas Category: II

2E3B/P

Butane Supply Pressure (G30): 30 mbar

Adjusted Pressure: N/A

L.P. Supply Pressure (G31): 30 mbar

Adjusted Pressure: N/A

BG, CY, CZ, DK, EE, FI, GR,

HR, IT, LT, NO, RO, SE, SI, SK

II

2H3B/P

BG, CY, CZ, DK, EE, FI, GR,

HR, IT, LT, NO, RO, SE, SI, SK

II

2H3B/P

18

Page 19

TECHNICAL SPECIFICATIONS – GAS DRYER

Factory set for NATURAL GAS: Injector size: 2.2 mm Heat input gross: 5.9 kW

Country: DE, LU, PL, RO

European Gas Category:

Gas Flow Rate: 0.562703 m3/hr

Supply Pressure (G20): 20 mbar

Factory Adjusted Pressure (G20): 7.4 mbar

Factory set for Australia/New Zealand NATURAL GAS: Injector size: 2.2 mm Heat input gross: 5.9 kW

Country: AU, NZ

Supply Pressure (G20): minimum 1.13 kPa

Adjusted Pressure (Test Point Pressure): 0.74 kPa

Nominal Hourly Gas Consumption: 21.1 MJ/h

With Australia L.P. Gas Conversion Kit: Injector Size: 1.40 mm Heat input gross: 6.54 kW

Country: AU, NZ

L.P. Supply Pressure: 2.75 kPa

Adjusted Pressure: 2.75 kPa

Nominal Hourly Gas Consumption: 23 MJ/h

Factory set for NATURAL GAS: Injector size: 2.2 mm Heat input gross: 5.0 kW

Country: NL

European Gas Category:

I

2L

Gas Flow Rate: 0.562703 m3/hr 0.562703 m3/hr

Gas Flow Rate: 25 mbar 25 mbar

Factory Adjusted Pressure (G25) : 7.4 mbar 7.4 mbar

With L.P. Gas Conversion Kit: Injector size: 1.25 mm Heal input gross: 6.4 kW

Country: MT, PL NL

European Gas Category

I

3B/P

Butane Supply Pressure (G30) 30 mbar

Adjusted Pressure: N/A

L.P. Supply Pressure: 30 mbar

Adjusted Pressure: N/A

NOTE: Conversion kit: From Natural Gas to L.P. Gas - Europe: Whirlpool Part No. W10233219.

Conversion kit: From Natural Gas to L.P. Gas - Australia: Whirlpool Part No. W10315369.

Conversion kit: From Natural Gas to Natural Gas - France/Belgium: Whirlpool Part No. W10181947.

Manufacturer: Whirlpool Corporation, Benton Harbor, Michigan 49022, U.S.A.

Manufacturing Site: Whirlpool Corporation, 1300 Marion-Agosta Rd., Marion, OH, 43302, U.S.A.

EU Representatives: Whirlpool EMEA S.p.A., Via Carlo Pisacane, 1, 20016 Pero (MI) Italy

I

2E

II

2L3B/P

II

2L3B/P

19

Page 20

COMPLETE INSTALLATION

1. Check the electrical requirements. Be sure that you have

the correct electrical supply and the recommended earthing

method. See “Electrical Requirements.”

2. Check that all parts are now installed. If there is an extra

part, go back through the steps.

3. Check that you have all of your tools.

4. Dispose of/recycle all packaging materials.

WARNING

Electric Shock Hazard

This dryer must be earthed.

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or

electric shock.

5. Plug into an grounded outlet, or connect power.

6. Check dryer operation. Close dryer door. Set the cycle.

Operating time will accumulate per number of coins.

Using a full heat cycle (not the air cycle), let the dryer run

for at least ve minutes. Dryer will stop when time is used

up. Make sure the dryer turns off.

NOTE: Dryer door must be closed for dryer to operate.

When door is open, dryer stops, but timer continues to run.

7. Gas Models only: Open the dryer door. Check that the

inside of the dryer is warm. If the burner does not ignite

and you can feel no heat inside the dryer, shut off dryer for

5 minutes. Check that all supply valve controls are in “ON”

position and that the electrical cord is plugged in. Repeat

ve-minute test.

8. If drying time is too long, make sure that the lint screen is

clean and that there are no obstructions to airow in the

dryer vent system.

9. Restart the dryer and allow it to complete a full heat cycle

(not air cycle) to make sure it is working properly.

20

Page 21

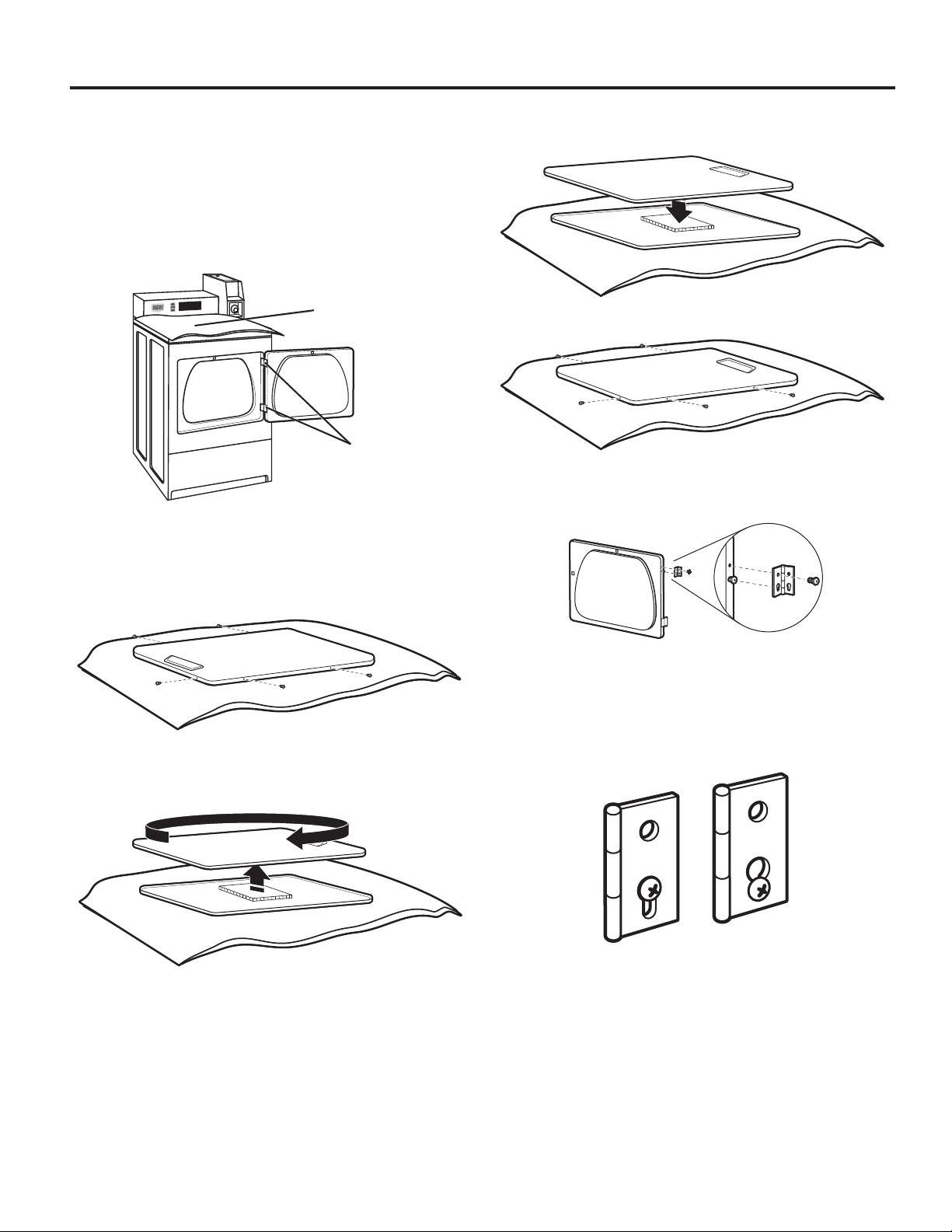

REVERSING DRYER DOOR SWING (OPTIONAL)

You can change your door swing from a right-side opening

to left-side opening, if desired.

Remove the Door Assembly

1. Place a towel or soft cloth on top of dryer or work space to

avoid scratching of the surface.

2. Open dryer door. Remove bottom screws from cabinet side

of hinges. Loosen (do not remove) top screws from cabinet

side of hinges.

Towel

Hinges

3. Lift door until top screws in cabinet are in large part of hinge

slot. Pull forward off screws. Set door (handle side up) on

top of dryer. Remove top screws from cabinet.

4. Remove screws attaching hinges to door.

5. Remove screws at top, bottom, and side of door (5 screws).

7. Be certain to keep cardboard spacer centered between

doors. Reattach outer door panel to inner door panel so

handle is on the side where hinges were just removed.

8. Reattach screws at top, bottom, and side of door (5 screws).

9. Attach door hinges to dryer door so that larger hole is at

the bottom of the hinge and the hinge pin is toward the

door front.

6. Holding door over towel on dryer, grasp sides of outer door

and gently lift to separate it from inner door. Do not use a

putty knife to pry apart. Do not pull on door seal or plastic

door catch.

10. Remove the 4 screws that attach 2 plugs on the left side.

Attach plugs to right side using the same 4 screws.

11. Insert screws into bottom holes on left side of cabinet.

Tighten screws halfway. Position door so large end of door

hinge slot is over screws. Slide door up so screws are in

bottom of slots. Tighten screws. Insert and tighten top

screws in hinges.

12. Close door and check that door strike aligns with door

catch. If needed, slide door catch left or right within slot

to adjust alignment.

21

Page 22

ELECTRONIC CONTROL SETUP INSTRUCTIONS

(PD & PN MODELS ONLY)

IMPORTANT

Electrostatic Discharge (ESD)

Sensitive Electronics

ESD problems are present everywhere. ESD may damage

or weaken the electronic control assembly. The new control

assembly may appear to work well after repair is nished,

but failure may occur at a later date due to ESD stress.

■ Use an anti-static wrist strap. Connect wrist strap to

green ground connection point or unpainted metal in the

appliance.

-OR-

Touch your nger repeatedly to a green ground connection

point or unpainted metal in the appliance.

■ Before removing the part from its package, touch the

anti-static bag to a green ground connection point or

unpainted metal in the appliance.

■ Avoid touching electronic parts or terminal contacts;

handle electronic control assembly by edges only.

■ When repackaging failed electronic control assembly

in anti-static bag, observe above instructions.

General Information

BLANK DISPLAY –

inoperative. Enter set-up mode to view diagnostic code.

“0 MINUTES” SHOWING IN DISPLAY – This indicates the

cycle is complete and the dryer cannot be operated. Coins

dropped or debit inputs during this condition will be stored in

escrow but cannot be used until normal operation is restored

by opening and closing the door. If a door switch has failed,

it must be replaced before normal operation can be restored.

COLD START (Initial rst use) – Dryer is programmed at the

factory as follows:

5 minutes dry time/quarter (coin 1)

$1.50 dry price (xed cycle with top off)

WARM START (after power failure) – A few seconds after

power is restored, if a cycle was in progress at the time of the

power failure, “RESELECT CYCLE” will ash in the display,

indicating a button needs to be pressed to restart dryer.

PRICING – After the door is opened and then closed following

the completion of a cycle, the display indicates the cycle price

(unless set for free operation). As coins are dropped or debit

inputs arrive, the display will change to lead the user through

the initiation of a cycle.

There are four (4) types of dryer pricing:

Fixed “Vend” Pricing

A dryer set up for “Fixed Cycle” operation can only accept

additional time accumulated by increments equal to the length

of a complete dry cycle. A maximum of 99 minutes may be

purchased; no additional credit is given for coins dropped with

99 minutes in the display.

This condition indicates the dryer is

Accumulator Pricing

If the price is set to one coin 1, then accumulator pricing

is in effect. Cycle time can be purchased one coin at a time up

to the maximum time of 99 minutes. Stacked models will credit

all money to a cycle with a single button press while in accumulator

pricing.

Fixed Cycle With Top Off Pricing

A dryer set to offer “Top Off” capability will allow time to be

added to an existing dry cycle in increments equal to the

number of minutes of dry time per quarter (coin 1), up to 99

minutes, regardless of the cost required to start the dryer. No

credit is given for coins or debit inputs entered when the control

is displaying 99 minutes.

FREE CYCLES – This is established by setting the cycle price

to zero. When this happens, “SELECT CYCLE” will appear

rather than a cycle price. Any cycle started as a free cycle will

automatically terminate when the door is opened.

DEBIT CARD READY – This dryer is debit card ready. It

will accept a variety of debit card systems, but does NOT

come with a debit card reader. Refer to the debit card reader

manufacturer for proper dryer setup. In models converted to

a Generation 1 debit card system, debit pulses represent the

equivalent of one coin (coin 1).

Display

After the dryer has been installed and plugged in, the display

will show “0 minutes.”

Single Load Models

0

MINUTES

Once the unit has been plugged in and the dryer door opened

and closed, the display will show the price.

Single Load Models

PRICE

1.50

22

Page 23

ELECTRONIC CONTROL SETUP INSTRUCTIONS

(PD & PN MODELS ONLY)

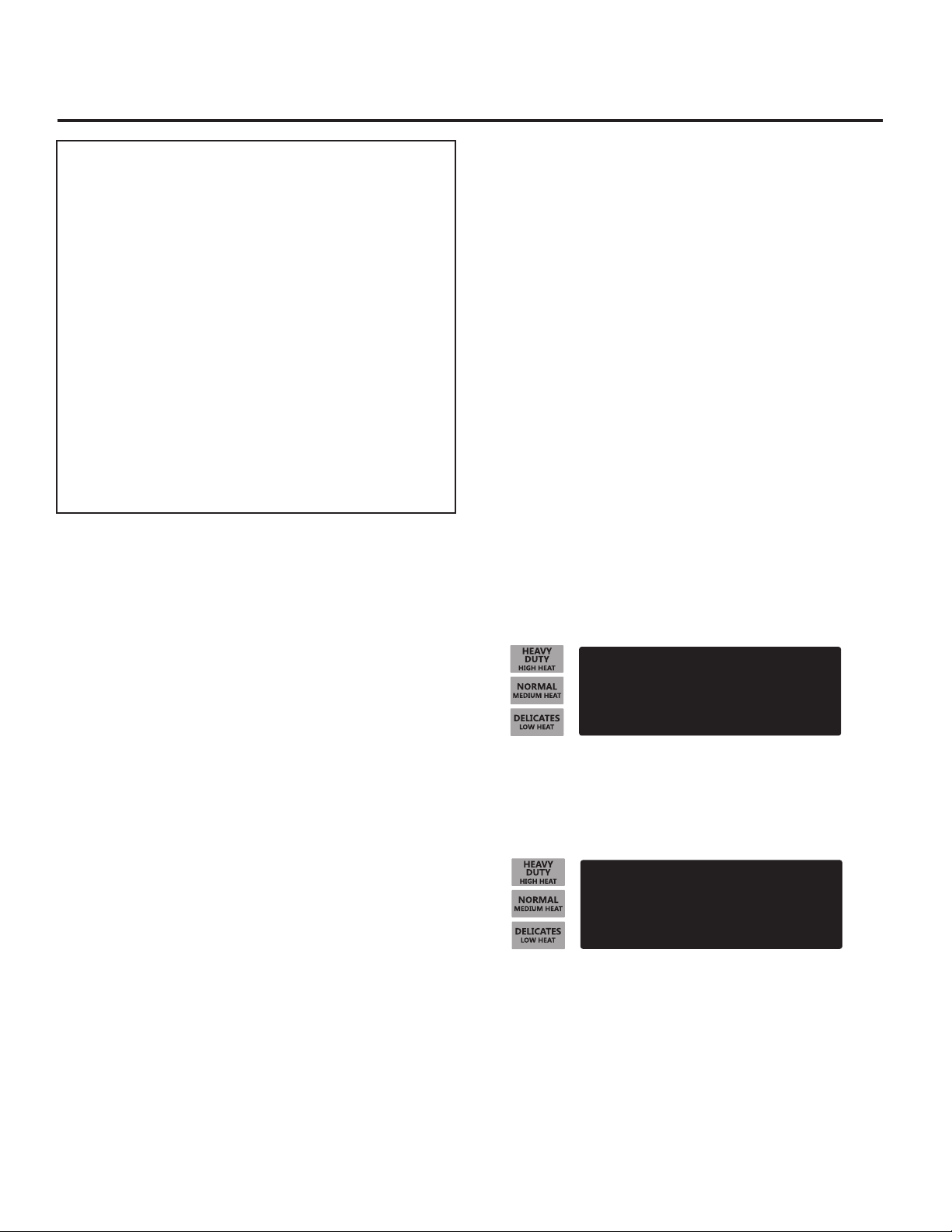

Control Set-up Procedures

IMPORTANT: Read all instructions before operating.

The fabric setting buttons along with the digital display are

used to set up the dryer controls. The display can contain

4 numbers and/or letters and a decimal point. These are used

to indicate the set-up codes and related code values available

for use in programming the appliance.

How to Use the Buttons to Program the Controls

1. The HEAVY DUTY button is used to adjust the values

associated with set-up code. Pressing the button will

change the value by increments. Rapid adjustment is

possible by holding down the button.

2. The NORMAL button will advance through the set-up

codes. Pressing the button will advance to the next

available set-up code. Holding down the NORMAL button

will automatically advance through the set-up codes at a

rate faster than 1 per second.

3. The DELICATES button is used to select or deselect options.

Start Operating Set-up

■ Single Load Models: Insert service door key, turn, and lift to

remove service door.

IMPORTANT: The console must not be opened unless power

is rst removed from the dryer. To access connector AA1:

Unplug dryer or disconnect power.

g

Open console, disconnect plug on AA1, close console.

g

Plug in dryer or reconnect power.

g

The dryer is now in the set-up mode.

NOTE: This dryer is preset at the factory and does not require

any programming. However, if you want to change the settings,

follow the “Set-Up Codes” guide to the right.

■ Units are pre-set at the factory for xed cycle price with top

off.

Set-Up Codes

■ The NORMAL button will advance you from code to code.

■ The HEAVY DUTY button will change the code value.

■

The DELICATES button will select or deselect options.

The set-up code is indicated by the one or two left-hand

characters. The set-up code value is indicated by the two or

three right-hand characters.

Code Explanation

606 REGULAR CYCLE PRICE

606 Represents the number of quarters (coin 1) needed

to start the dryer; may adjust from 0–39 (See

VALUE OF COIN 1 b.05). Advance from 0–39 by

pressing the HEAVY DUTY button. Factory default

of 6 quarters = $1.50.

• Press the NORMAL button once to advance to next

code.

705 REGULAR DRY TIME

705 Represents the number of minutes per quarter (coin 1).

Factory default of 5 minutes per coin.

Example: 6 quarters x 5 minutes = 30 minutes.

By pressing the HEAVY DUTY button, value adjusts

from 1–75 minutes.

• Press the NORMAL button once to advance to

next code.

800 TYPE OF DRYER PRICING

800 Fixed Cycle with Top Off. For detailed description,

see “General User Information.”

• Press the NORMAL button once to advance to

next code.

9 00 CYCLE COUNTER OPTION

This option is either NOT SELECTED “OFF” or

SELECTED “ON.”

9 00 Not Selected “OFF.”

9 0C Selected “ON” and not able to be deselected.

• Press the DELICATES button 3 consecutive times

to select “ON.” Once selected “ON” it cannot be

deselected.

• Press the NORMAL button once to advance to

next code.

If cycle counter (9 0C) is selected, the following

is true:

1 00 Cycles in HUNDREDS 1 02 = 200

2 00 Cycles in ONES 2 25 = 25

TOTAL CYCLES = 225

This is “VIEW ONLY” and cannot be cleared.

• Press the NORMAL button once to advance to next code.

23

Page 24

ELECTRONIC CONTROL SETUP INSTRUCTIONS

(PD & PN MODELS ONLY)

Code Explanation

1. 00 MONEY COUNTER OPTION

This option is either NOT SELECTED “OFF” or

SELECTED “ON.”

1. 00 Not Selected “OFF.”

1. 0C Selected “ON.”

• Press the DELICATES button 3 consecutive times

to select “ON” and 3 consecutive times to remove

(Not Selected “OFF”). Counter resets by going from

“OFF” to “ON.”

1. C0 Selected “ON” and not able to be deselected.

• To select “ON” and not able to be deselected,

rst select “ON,” then within 2 seconds, press the

DELICATES button twice, the HEAVY DUTY button

once, and exit set-up mode.

• Press the NORMAL button once to advance to

next code.

2. 00 SPECIAL PRICING OPTIONS

This option is either NOT SELECTED “OFF” or

SELECTED “ON.”

2. 00 Not Selected “OFF,” and next available code will be

A.00.

2. SP Selected “ON.”

• Press the DELICATES button once to change this

selection.

If SPECIAL PRICING OPTION is selected, there is access to

codes “3.XX” through “9.XX.”

• Press the NORMAL button once to advance to

next code.

If money counter (1.0C or 1.C0) is selected, the following is

true:

3 00 Dollars in HUNDREDS 3 01 = $100.00

4 00 Dollars in ONES 4 68 = $ 68.00

5 00 Number of CENTS 5 75 = $ 00.75

TOTAL = $168.75

OPTIONS 3.XX – 9.XX TO USE IF SPECIAL PRICING

IS SELECTED

Code Explanation

3.06 SPECIAL CYCLE PRICE

3.06 Represents the number of quarters (coin 1)

to start the dryer; may adjust from 0–39.

(See VALUE OF COIN 1 b.05.)

• Advance from 0–39 by pressing the HEAVY DUTY

button. Factory default of 6 quarters = $1.50.

• Press the NORMAL button once to advance to

next code.

4.05 SPECIAL DRY TIME

4.05 Represents the number of minutes per quarter (coin 1).

• Factory default of 5 minutes per coin.

Example: 6 quarters x 5 minutes = 30 minutes.

• By pressing the HEAVY DUTY button, the value can

be adjusted from 1–75 minutes.

• Press the NORMAL button once to advance to

next code.

5. 00 TIME-OF-DAY CLOCK, MINUTES

5. 00 This is the TIME-OF-DAY CLOCK, minute setting;

select 0–59 minutes by pressing the HEAVY DUTY

button.

• Press the NORMAL button once to advance to

next code.

6. 00 TIME-OF-DAY CLOCK, HOURS

NOTE: Uses military time or 24 hr. clock.

6. 00 This is the TIME-OF-DAY CLOCK, hour setting; select

0–23 hours by pressing the HEAVY DUTY button.

• Press the NORMAL button once to advance to

next code.

24

Page 25

ELECTRONIC CONTROL SETUP INSTRUCTIONS

(PD & PN MODELS ONLY)

Code Explanation

7. 00 SPECIAL PRICE START HOUR

NOTE: Uses military time or 24 hr. clock.

7. 00 This is the start hour; 0–23 hours.

• Select START HOUR by pressing the HEAVY DUTY

button.

• Press the NORMAL button once to advance to

next code.

8. 00 SPECIAL PRICE STOP HOUR

NOTE: Uses military time or 24 hr. clock.

8. 00 This is the stop hour; 0–23 hours.

• Select STOP HOUR by pressing the HEAVY DUTY

button.

• Press the NORMAL button once to advance to

next code.

9. 10 SPECIAL PRICE DAY

9. 10 This represents the day of the week and whether

special pricing is selected for that day. A number

followed by “0” indicates no selection that particular

day (9.10). A number followed by an “S” indicates

selected for that day (9.1S). Days of the week (1–7) are

selected by pressing the HEAVY DUTY button. Press

the DELICATES button once to select special pricing for

each day chosen.

When exiting set-up code “9,” the display must show the

current day of week:

DISPLAY DAY OF WEEK CODE (selected)

10 Day 1 = Sunday 1S

20 Day 2 = Monday 2S

30 Day 3 = Tuesday 3S

40 Day 4 = Wednesday 4S

50 Day 5 = Thursday 5S

60 Day 6 = Friday 6S

70 Day 7 = Saturday 7S

• Press the NORMAL button once to advance to

next code.

A. 00 VAULT VIEWING OPTION

This option is either NOT SELECTED “OFF” or

SELECTED “ON.”

A. 00 Not Selected “OFF.”

A. SC Selected “ON.”

• Press the DELICATES button once to change this

selection. When selected, the money and/or cycle

counts will be viewable (if counter option(s) is

selected) when the coin box is removed.

• Press the NORMAL button once to advance to

next code.

Code Explanation

b. 05 VALUE OF COIN 1

b. 05 This represents the value of coin 1 in number of

nickels: 05 = $0.25.

• By pressing the HEAVY DUTY button, there is an

option of 1–199 nickels.

• Press the NORMAL button once to advance to

next code.

C. 20

C. 20 This represents the value of coin 2 in number of

• By pressing the HEAVY DUTY button, there is an

• Press the NORMAL button once to advance to

d.00 COIN SLIDE OPTION

This option is either NOT SELECTED “OFF” or

d.00 Not Selected “OFF.”

d.CS Selected “ON.”

• Press the DELICATES button 3 consecutive times

NOTE: If the installer sets up “CS” on a coin drop

• Press the NORMAL button once to advance to

E. 00 ADD COINS OPTION

This option is either NOT SELECTED “OFF” or

E. 00 Not Selected “OFF.”

E. AC Selected “ON.”

• Press the DELICATES button 3 consecutive times

• Press the NORMAL button once to advance to

VALUE OF COIN 2/VALUE OF DRYER TOP OFF

nickels: 20 = $1.00.

For models using Enhanced Debit, this eld represents

the value of top off in nickels.

option of 1–199 nickels.

next code.

SELECTED “ON.”

for this selection. When coin slide mode is selected,

set “b.” equal to value of slide in nickels. Set “606”

(REGULAR CYCLE PRICE) and “3.06” (SPECIAL

CYCLE PRICE) to number of slide operations.

model, it will not register coins.

next code.

SELECTED “ON.” This option causes the customer

display to show the number of coins (coin 1) to enter,

rather than the dollars-and-cents amount. The number

in the display changes as the coins are accepted.

to change this selection.

next code.

25

Page 26

ELECTRONIC CONTROL SETUP INSTRUCTIONS

(PD & PN MODELS ONLY)

Code Explanation

J. Cd PAYMENT MODE (COIN/DEBIT OPTION)

J. Cd Both coin and debit selected. Press the DELICATES

button 3 consecutive times to change this selection.

J. C_ Coins selected, debit disabled. Press the DELICATES

button 3 consecutive times to change this selection.

J._d Debit Card selected, coins disabled. Press the

DELICATES button 3 consecutive times to change

this selection.

J. Ed Enhanced Debit is self-selected when a Generation

2 card reader is installed in the dryer. The Ed option

cannot be manually selected or deselected.

• Press the NORMAL button once to advance to

next code.

L. 00 PRICE SUPPRESSION OPTION

This option is either NOT SELECTED “OFF” or

SELECTED “ON.” This option causes the customer

display to show “ADD” or “AVAILABLE” rather than

the amount of money to add. (Used mainly in debit

installations.)

L. 00 Not Selected “OFF.”

L. PS Selected “ON.”

• Press the DELICATES button once to change this

selection.

• Press the NORMAL button once to advance to

next code.

n. CE CLEAR ESCROW OPTION

This option is either NOT SELECTED “OFF” or

SELECTED “ON.” When selected, money held in

escrow for 30 minutes without further escrow or

cycle activity will be cleared.

n. 00 Not Selected “OFF.”

n. CE Selected “ON.”

• Press the DELICATES button once to change this

selection.

• Press the NORMAL button once to advance to

next code.

END of SET-UP PROCEDURES

EXIT FROM SET-UP MODE

Single-Load Models: Reinstall access door.

DIAGNOSTIC GUIDE

If the set-up mode is entered and one of the following has

occurred, the appropriate diagnostic code will be in the display.

SINGLE DRYERS

CODE EXPLANATION

d1 Dryer door sense error on

control board or due to power

line interference (cycles and

price display disabled until

diagnostic code is manually

cleared).

d4 Dryer motor control circuit

error (cycles and customer

display disabled until

diagnostic code is manually

cleared).

d5 Blocked coin 1 or coin drop

control circuit failure (coin

recognition and customer

display disabled while

blockage persists).

d9 Voltage detected below

90 VAC for 8 seconds.

d12 Motor sense error on control

board or due to power line

interference (cycles and

customer display disabled until

diagnostic code is manually

cleared).

d13 Blocked coin 2 or coin drop

control circuit failure (coin

recognition and price display

disabled while blockage

persists).

d16 Not receiving communications

from installed debit card reader

in Enhanced (Generation 2)

Debit mode.

26

Page 27

MODEL NOMENCLATURE:

MDG – Maytag Gas

MDE – Maytag Electric

20 – Model Type Number

CS – Coin Slide

MN – Timer Non-Pay

PD – Coin Drop

PN – Electronic Non-Pay

DRYER DISPOSAL

A – Series Revision

G – Global

W – White

27

Page 28

MAYTAG COMMERCIAL LAUNDRY

LIMITED WARRANTY

1. All other costs including labor, transportation, shipping, or custom duties for

covered parts.

2. Factory specified replacement parts if this commercial appliance is used for other

than normal, commercial use or when it is used in a manner that is inconsistent

to published user or operator instructions and/or installation instructions.

3. Service calls to correct the installation of your commercial appliance, to instruct

you on how to use your commercial appliance, to replace or repair house fuses,

or to correct external wiring or plumbing.

4. Service calls to repair or replace appliance light bulbs, air filters, or water filters.

Consumable parts are excluded from warranty coverage.

5. Damage resulting from improper handling of product during delivery, theft,

accident, alteration, misuse, abuse, fire, flood, acts of God, improper installation,

installation not in accordance with local electrical or plumbing codes, or use of

products not approved by Maytag.

6. Pick up and delivery. This commercial appliance is designed to be repaired

on location.

7. Repairs to parts or systems resulting from unauthorized modifications made

to the commercial appliance.

8. The removal and reinstallation of your commercial appliance if it is installed

in an inaccessible location or is not installed in accordance with published

installation instructions.

9. Damage resulting from exposure to chemicals.

10. Changes to the building, room, or location needed in order to make the

commercial appliance operate correctly.

11. Factory specified replacement parts on commercial appliances with original

model/serial numbers that have been removed, altered, or cannot be easily

determined.

12. Discoloration, rust, or oxidation of stainless steel surfaces.

13. Factory specified replacement parts as a result of incorrect diagnosis or repair

by an “unauthorized” service company.

The cost of repair or replacement under these excluded circumstances shall

be borne by the customer.

FIVE YEAR LIMITED WARRANTY

(PARTS ONLY — LABOR NOT INCLUDED)

For the first five years from the original date of

purchase, when this commercial appliance is

installed, maintained, and operated according to the

instructions attached to or furnished with the product,

Maytag brand of Whirlpool Corporation (hereafter

“Maytag”) will pay for factory specified replacement

parts to correct defects in materials or workmanship

that existed when this commercial appliance was

purchased. This limited warranty does not include

labor.

YOUR SOLE AND EXCLUSIVE REMEDY UNDER THIS

LIMITED WARRANTY SHALL BE PRODUCT REPAIR

AS PROVIDED HEREIN. Maytag recommends that

you use an “authorized” service provider to diagnose

and repair your Commercial Laundry product.

Maytag will not be responsible under this warranty

to provide additional replacement parts as a result

of incorrect diagnosis or repair by an “unauthorized”

service company. Except in the European Union, this

limited warranty is valid only when the commercial

appliance is used in the country in which it was

purchased. This limited warranty is effective from

the date of the original consumer purchase. Proof

of original purchase date is required to obtain service

under this limited warranty.

DISCLAIMER OF IMPLIED WARRANTIES

IMPLIED WARRANTIES, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR IMPLIED WARRANTY OF FITNESS FOR A

PARTICULAR PURPOSE, ARE LIMITED TO FIVE YEARS OR THE SHORTEST PERIOD ALLOWED BY LAW. Some locations may not allow

limitations on the duration of implied warranties of merchantability or fitness, so this limitation may not apply to you. This warranty gives

you specific legal rights, and you also may have other rights that vary.

LIMITATION OF REMEDIES; EXCLUSION OF INCIDENTAL AND CONSEQUENTIAL DAMAGES

YOUR SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE PRODUCT REPAIR AS PROVIDED HEREIN.

MAYTAG SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. Some locations do not allow the

exclusion or limitation of incidental or consequential damages, so these limitations and exclusions may not apply to you. This warranty

gives you specific legal rights, and you also may have other rights that vary by location.

DISCLAIMER OF REPRESENTATIONS OUTSIDE OF WARRANTY

Maytag makes no representations about the quality, durability, or need for service or repair of this major appliance other than the

representations contained in this Warranty. If you want a longer or more comprehensive warranty than the limited warranty that comes

with this major appliance, you should ask your retailer about buying an extended warranty. The benefits to you given by this warranty

are in addition to other rights and remedies available to you under a law in relation to the goods or service to which this warranty relates.

Please contact Maytag for further information on warranty terms.

04/17

IF YOU NEED SERVICE:

Contact your authorized Maytag Commercial Laundry distributor. To locate your authorized Maytag Commercial Laundry

distributor, visit www.maytagcommerciallaundry.com.

For written correspondence:

Maytag Commercial Laundry Service Department

2000 N M 63

Benton Harbor, Michigan 49022-2632 USA

FIVE YEAR LIMITED WARRANTY

WHAT IS COVERED

WHAT IS NOT COVERED

28

Page 29

SECURITE DU SECHE-LINGE

AVERTISSEMENT – “Risque d’incendie”

Ceci est un symbole supplémentaire d’alerte de sécurité vous signalant un risque d’incendie.

AVERTISSEMENT

- L'installation du sèche-linge et la maintenance doivent être réalisées par un installateur

agréé par Whirlpool.

- Installer le sèche-linge conformément aux instructions du fabricant et aux

réglementations locales.

tendance à se plier, s'écraser facilement et re

- Pour réduire le risque de blessures graves ou de mort, respecter toutes les

instructions d'installation.

- Conserver ces instructions.

-

“Risque d'incendie”

29

Page 30

SECURITE DU SECHE-LINGE

■ On recommande que le propriétaire place les instructions à l’usage du client en un lieu bien visible, au cas où le client percevrait

une odeur de gaz. Ces renseignements doivent être obtenus auprès de votre fournisseur en gaz.

■ Placer l’avertissement qui suit à un endroit bien visible.

POur VOtre securite