Page 1

INSTALLATION INSTRUCTIONS COMMERCIAL DRYER

Electric

INSTRUCTIONS POUR L’INSTALLATION

D’UN SECHE-LINGE COMMERCIAL

Electrique

INSTRUCCIONES DE INSTALACIÓN

SECADORA COMERCIAL

Eléctrica

ISTRUZIONI DI INSTALLAZIONE

ASCIUGATRICE COMMERCIALE

Elettrica

MDE17MN MDE17CS

W10184536A

www.maytagcommerciallaundry.com

Page 2

TABLE OF CONTENTS

DRYER SAFETY............................................................................ 2

INSTALLATION REQUIREMENTS .............................................. 3

Tools and Parts.......................................................................... 3

Location Requirements.............................................................. 4

Electrical Requirements ............................................................ 5

Venting Requirements .............................................................. 5

TABLE DES MATIERES

SECURITE DU SECHE-LINGE ..................................................9

EXIGENCES D’INSTALLATION..................................................9

Outillage et pièces ......................................................................9

Exigences d’emplacement ......................................................10

Spécifications électriques .......................................................11

Exigences concernant l’évacuation ..........................................12

ÍNDICE

SEGURIDAD DE LA SECADORA............................................16

REQUISITOS DE INSTALACIÓN ............................................16

Piezas y herramientas ..........................................................16

Requisitos de ubicación........................................................17

Requisitos eléctricos ............................................................18

Requisitos de ventilación ....................................................18

INSTALLATION INSTRUCTIONS – ELECTRIC DRYER.......... 7

Install Leveling Legs....................................................................7

Electrical Connection..................................................................7

Connect Vent ..............................................................................7

Complete Installation ................................................................7

MAINTENANCE INSTRUCTIONS .............................................8

INSTRUCTIONS D’INSTALLATION – SECHE-LINGE

ELECTRIQUE............................................................................14

Installation des pieds de nivellement........................................14

Raccordement électrique ........................................................14

Raccordement du conduit d’évacuation ................................14

Achever l’installation ................................................................14

INSTRUCTIONS D’ENTRETIEN...............................................15

INSTRUCCIONES DE INSTALACIÓN –

SECADORA ELÉCTRICA ........................................................20

Instación de las patas niveladoras........................................20 .

Conexión eléctrica ................................................................20

Conexión del ducto de escape ............................................21

Complete la instalación ........................................................21

INSTRUCIONES DE MAINTENEMIENTO...............................21

INDICE

SICUREZZA DELL’ASCIUGATRICE ........................................ 22

REQUISITI D’INSTALLAZIONE ................................................ 22

Attrezzi e componenti.............................................................. 22

Requisiti di ubicazione ............................................................ 23

Requisiti elettrici ...................................................................... 24

Requisiti di scarico .................................................................. 24

ISTRUZIONI D’INSTALLAZIONE – ASCIUGATRICE

ELETTRICA ............................................................................ 26

Installazione dei piedini di regolazione ....................................26

Connessione elettrica ..............................................................26

Connessione dello scarico ......................................................26

Completamento dell’installazione ............................................26

ISTRUZIONI DI MANUTENZIONE .........................................27

2

Page 3

You can be killed or seriously injured if you don't immediately

You

can be killed or seriously injured if you don't

follow

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

follow instructions.

instructions.

DANGER

WARNING

DRYER SAFETY

FOR YOUR SAFETY

Do not store or use petrol or other flammable vapors in the vicinity of this or any other appliance.

INSTALLATION REQUIREMENTS

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools

listed here.

Tools needed

■ 20 cm (8") or 25 cm (10")

Pipe wrench

■ 20 cm (8") or 25 cm (10")

adjustable wrench

■ Flat-blade screwdriver

■ Phillips screwdriver

■ Adjustable wrench that

opens to 2.5 cm (1") or

hex-head socket wrench

■ Level

■ 8 mm (

■ Utility knife

■ Vent clamps

■ Caulk gun and caulk

■ Pliers

■ Putty knife

5

⁄16") socket wrench

(for installing new

exhaust vent)

Parts supplied

Remove parts bag from dryer drum. Check that all parts were

included.

■ Foot boot (4)

■ Dryer foot (4)

3

Page 4

Location Requirements

IMPORTANT: Observe all governing codes and ordinances.

■ Check code requirements: Some codes limit or do not permit

installation of clothes dryers in garages, closets, or sleeping

quarters. Contact your local building inspector.

NOTE: The dryer must not be installed in an area where it will be

exposed to water and/or weather.

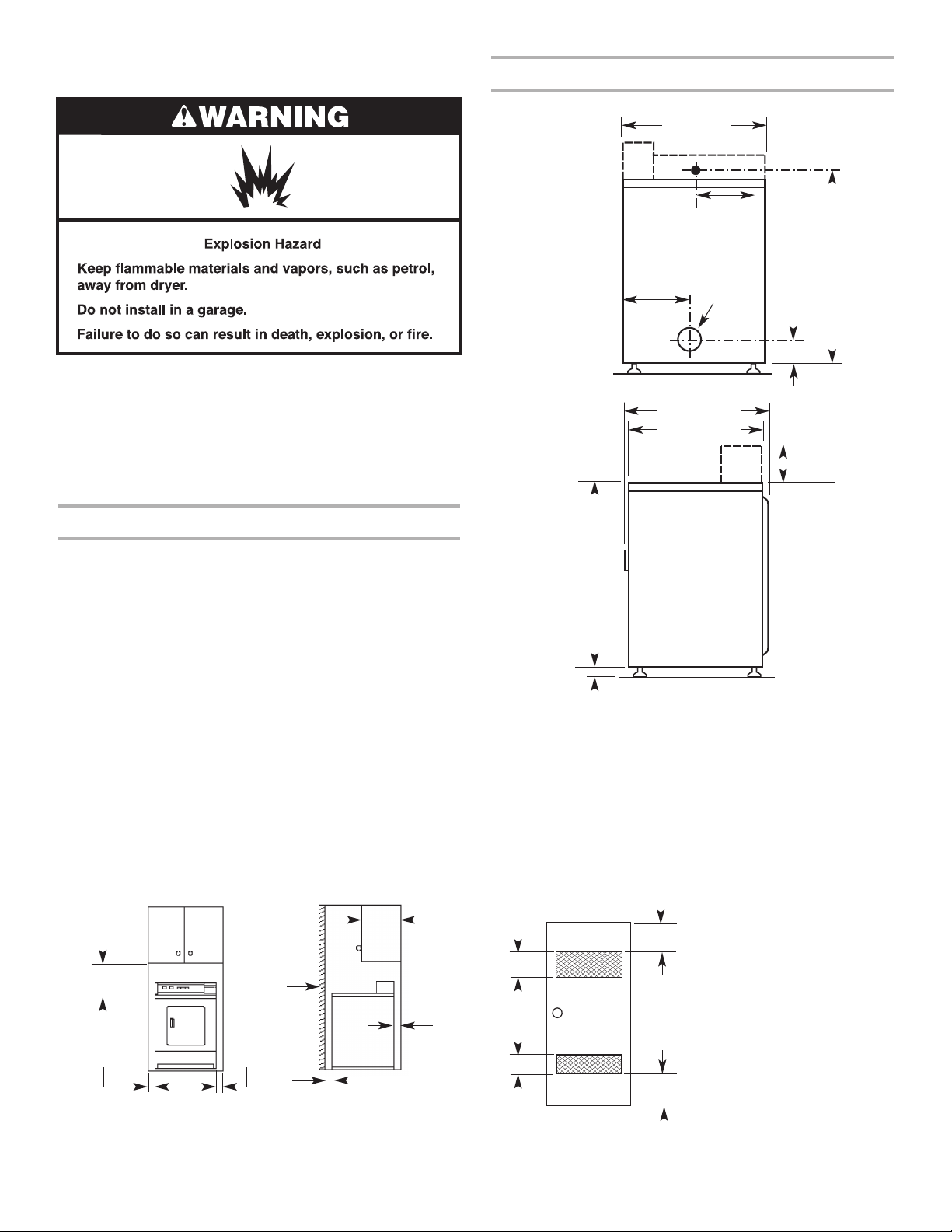

Recessed Area and Closet Installation Instructions

This dryer may be installed in a recessed area or closet.

This dryer must not be installed behind a lockable door,

a sliding door, or a door with a hinge on the opposite side

to that on the dryer.

The installation spacing is in cm and is the minimum allowable.

Additional spacing should be considered for ease of installation,

servicing, and compliance with local codes and ordinances.

If closet door is installed, the minimum unobstructed air opening

in the top and bottom is required. Louvered doors

with equivalent air openings are acceptable.

The dryer must be exhausted outdoors.

No other fuel-burning appliance may be installed in the same

closet as the dryer.

Product Dimensions 68.6 cm (27") dryer

8.6 cm (27")

6

LECTRIC

88.9 cm

(35")

2.5 cm

(1")

E

BACK VIEW

3 cm

3

13")

(

74.3 cm (291/4")

67.3 cm (261/2")

SIDE VIEW

5.6 cm

3

14")

(

10.2 cm (4")

dia.

EXHAUST

12.1 cm

(4

3

⁄4")

0 cm (7

2

4 cm

9

(37")

7

)

⁄8"

Minimum Installation Clearances

35.6 cm

(14") max.

38.1 cm

(15")*

0 cm (0")

Closet

door

0 cm

(0")

0 cm (0")

2.5 cm (1")

Recessed front view Closet side view

Additional clearances for wall, door, and floor moldings may be required or if

external exhaust elbow is used.

4

310 cm

(48 in2.)*

Front

View

155 cm

(24 in2.)*

2

closet

door

2

7.6 cm (3")

*Opening is the minimum for a

closet door.

Louvered doors with equivalent air

openings are acceptable.

7.6 cm (3")

Page 5

Electrical Requirements

WARNING

Fire Hazard

Use a heavy metal vent.

D

o not use a plastic vent.

Do not use a metal foil vent.

Failure to follow these instructions can result in death

or fire.

This dryer is supplied without an electric cord and plug. It must

e connected by a competent electrician to a single-phase

b

electricity supply at the voltage shown on the dataplate, using a

suitable fixed wiring installation in accordance with local and

ational wiring regulations.

n

A 3-wire circular cord of minimum conductor size 2.5 mm

■

cross-section area should be used.

■ A 30A supply fuse should be used, and a switch having a

contact separation in both poles that provides full

isconnection under over-voltage category III conditions must

d

be incorporated into the fixed wiring in accordance with local

wiring regulations. The dryer should be positioned so that the

isconnection switch is easily accessible to the user.

d

■ A cord clamp bush is provided on the dryer, and should be

tightened on completion of wiring. The electrical mains

terminals are located behind the small rear access panel

(terminal block cover), and connections should be made in

accordance with the terminal markings. Remember to replace

the terminal access panel (terminal block cover).

NOTE: In accordance with the European EMC Directive

(2004/108/EC), the maximum electricity supply system

impedance to which the electric dryer should be connected

is declared to be 0.302 Ohm + j0.189 Ohm.

If codes permit and an additional earth bond wire is used, it is

recommended that a qualified electrician determine that the earth

bond path is adequate.

2

Recommended Earthing Method

■ It is your responsibility to contact a qualified electrical installer

to ensure that the electrical installation is adequate and in

conformance with all local codes and ordinances.

Venting Requirements

WARNING: To reduce the risk of fire, this dryer MUST BE

EXHAUSTED OUTDOORS.

■ Adequate ventilation has to be provided to avoid the backflow

of gases into the room from appliances burning other fuels,

including open fires (i.e. available airflow into the room should

match airflow out from the room).

■ The dryer vent must not be discharged into a flue which is

used for exhausting fumes from appliances burning gas or

other fuels, chimney, wall, ceiling, or a concealed space of

a building.

■ Do not use an exhaust hood with a magnetic latch.

■ Do not install flexible metal vent in enclosed walls, ceilings,

or floors.

■ 102 mm (4") heavy metal vent and clamps must be used.

■ Use clamps to seal all joints. Vent must not be connected

or secured with screws or other fastening devices which

extend into the interior of the vent. Do not use duct tape.

IMPORTANT: Observe all governing codes and ordinances.

Use a heavy metal vent. Do not use plastic or metal foil vent.

Rigid metal vent is recommended to prevent crushing

and kinking.

Flexible metal vent must be fully extended and supported when

the dryer is in its final position. Remove excess flexible metal vent

to avoid sagging and kinking that may result in reduced airflow

and poor performance.

An exhaust hood should cap the vent to prevent rodents and

insects from entering the home or business.

Exhaust hood must be at least 30.5 cm (12") from the ground

or any object that may be in the path of the exhaust (such as

flowers, rocks, or bushes).

If using an existing vent system, clean lint from the entire length

of the system and make sure exhaust hood is not plugged with

lint. Replace any plastic or metal foil vent with rigid metal or

flexible metal vent.

5

Page 6

Plan installation to use the fewest number of elbows and turns.

A

Exhaust Air Flow

A. Good

B. Better

B

Allow as much room as possible when using elbows or making

turns. Bend vent gradually to avoid kinking.

Vent outlet is located at the center of the bottom dryer back.

The vent can be routed up, down, left, right, behind the dryer,

or straight out the back of the dryer.

Each vent should enter the main vent at an angle pointing in the

direction of the airflow. Vents entering from the opposite side

should be staggered to reduce the exhausted air from interfering

with the other vents.

The maximum angle of each vent entering the main vent should

be no more than 30°.

A

0° max.

3

ir flow

a

B

A. Individual dryer vent

B. Main vent

Vent System Length

Maximum length of vent system depends upon the type of vent

used, number of elbows, and type of exhaust hood.

Maximum Vent Length

102 mm (4") Diameter Exhaust Hoods

Rigid Metal Vent

No. of 90° turns

0

1

2

3

4

Box Hood and Louvered Style

19.5 m (64 ft.)

16.5 m (54 ft.)

13.4 m (44 ft.)

10.7 m (35 ft.)

8.2 m (27 ft.)

Angled Hood Style

17.7 m (58 ft.)

14.6 m (48 ft.)

11.6 m (38 ft.)

8.8 m (29 ft.)

6.4 m (21 ft.)

If dryer is installed in a confined area, such as a bedroom,

bathroom, or closet, provision must be made for enough air

for combustion and ventilation. (Check governing codes and

ordinances.) See “Recessed Area and Closet Installation

Instructions” in the “Location requirements” section.

A 10.2 cm (4") outlet hood is preferred. However, a 6.4 cm

1

⁄2"

) outlet exhaust hood may be used. A 6.4 cm (21⁄2"

(2

)

outlet creates greater back pressure than other hood types.

For permanent installation, a stationary vent system is required.

Multiple Dryer Venting

■ A main vent can be used for venting a group of dryers. Main

vent should be sized to remove 5663 l/min (200 CFM) of air

per dryer. Large-capacity lint screens of proper design may be

used in the main vent if checked and cleaned frequently. The

room where the dryers are located should have make-up air

equal to or greater than the airflow of all the dryers in the

room.

■ Back-draft Damper Kit, Part No. 3391910, is available from

your dealer and should be installed in each dryer’s vent to

prevent exhausted air from returning into the dryers and to

keep the exhaust in balance within the main vent.

Unobstructed air openings are required.

Keep air openings free of dry cleaning fluid fumes. Fumes create

acids which, when drawn through the dryer heating units, can

damage dryers and loads being dried.

A clean-out cover should be located on the main vent for periodic

cleaning of the vent system.

If an exhaust hood cannot be used:

B

A

C

D

Min.

30 cm (12") clearance

above any accumulation

of snow, ice, or debris such

A. Exhaust hood or elbow

B. Wall

C. Main collector vent

D. Horizontal vent

E. 180° sweep elbow

F. Vertical vent

G. Roof

as leaves.

E

C

61 cm (24") min.

above highest

F

point of building

G

The outside end of the main vent should have a sweep elbow

directed downward. If the main vent travels vertically through the

roof, rather than through the wall, install a 180° sweep elbow on

the end of the vent at least 61 cm (2 ft.) above the highest part

of the building. The opening in wall or roof shall have a diameter

13 mm (

1

⁄2

") larger than the vent diameter. The vent should be

centered in the opening.

Do not install screening or cap over the end of the vent.

6

Page 7

INSTALLATION INSTRUCTIONS – ELECTRIC DRYER

WARNING

Electric Shock Hazard

This dryer must be earthed.

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or

electric shock.

Install Leveling Legs

NOTE: Slide dryer onto cardboard or hardboard before moving to

avoid damaging floor covering.

1. Using two or more people, move dryer to desired installation

location.

2. Take tape off front corners of dryer. Open dryer and remove

the literature and parts packages. Wipe the interior of the

drum thoroughly with a damp cloth.

3. Take two of the cardboard corners from the carton and place

them on the floor in back of the dryer. Firmly grasp the body

of the dryer and gently lay it on its back on the cardboard

corners.

4. With one of the legs in hand, check the ridges for a diamond

marking. That’s how far the leg is supposed to go into the

hole.

5. Start to screw the leveling legs into the holes by hand. (Use a

small amount of liquid detergent to lubricate the screw

threads so it is easier to turn the legs.) Use a 1" (25 mm)

wrench or socket wrench to finish turning the legs until you

reach the diamond mark. Then fit a protective foot boot over

each foot.

Now stand the dryer up.

6. Remove cardboard or hardboard from under dryer. Adjust the

legs of the dryer up or down until the dryer is level.

Connect Vent

. Using a 102 mm (4") clamp, connect vent to exhaust outlet

1

in dryer. If connecting to existing vent, make sure the vent is

clean. The dryer vent must fit over the dryer exhaust outlet

nd inside the exhaust hood. Make sure the vent is secured

a

to exhaust hood with a 102 mm (4") clamp.

2. Move dryer into final position. Do not crush or kink vent.

Make sure dryer is level.

Complete Installation

1. With dryer in final position, place level on top of the dryer, first

side to side; then front to back. If the dryer is not level, adjust

the legs of the dryer up or down until the dryer is level.

2. Switch on power supply.

3. Check dryer operation (some accumulated time may be on

the timer due to factory testing).

Insert coins in slide and press slide in slowly. (Operating time

will accumulate per number of coins and type of timing cam

used.) Push START/RESTART button. Using a full heat cycle

(not the air cycle), let the dryer run for at least five minutes.

Dryer will stop when time is used up.

NOTE: Dryer door must be closed for dryer to operate. When

door is open, dryer stops, but timer continues to run. To

restart dryer, close door and push START/RESTART button.

4. If drying time is too long, make sure lint screen is clean.

5. Now start the dryer and allow it to complete a full heat cycle

(not air cycle) to make sure it is working properly.

Electrical Connection

This is a 3-wire dryer which must be earthed.

This dryer is supplied without an electric cord and plug; it must

be connected by a competent electrician. See “Electrical

Requirements.”

7

Page 8

MAINTENANCE INSTRUCTIONS

Maintenance instructions:

■ Clean lint screen after each cycle.

■ Removing accumulated lint:

• From inside the dryer cabinet:

Lint should be removed every 2 years or more often,

depending on dryer usage. Cleaning should be done by a

qualified person.

• From the exhaust vent:

Lint should be removed every 2 years, or more often,

epending on dryer usage.

d

f dryer does not operate check the following:

I

■ Electric supply is connected.

■ Circuit breaker is not tripped or house fuse is not blown.

■ Door is closed.

■ Controls are set in a running or “ON” position.

■ START button has been pushed firmly.

f you need assistance:

I

Contact your authorized Maytag Commercial Laundry distributor.

When you call, you will need the dryer model number and serial

number. Both numbers can be found on the serial-rating plate

located on your appliance. Or visit:

www.MaytagCommercialLaundry.com.

8

Page 9

SECURITE DU SECHE-LINGE

Risque possible de décès ou de blessure grave si vous ne

suivez pas immédiatement les instructions.

Risque possible de décès ou de blessure grave si vous

ne suivez pas les instructions.

Tous les messages de sécurité vous diront quel est le danger potentiel et vous disent comment réduire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

Votre sécurité et celle des autres est très importante.

Nous donnons de nombreux messages de sécurité importants dans ce manuel et sur votre appareil ménager. Assurez-vous de

t

oujours lire tous les messages de sécurité et de vous y conformer.

AVERTISSEMENT

DANGER

Voici le symbole d’alerte de sécurité.

Ce symbole d’alerte de sécurité vous signale les dangers potentiels de décès et de blessures graves à vous

et à d’autres.

Tous les messages de sécurité suivront le symbole d’alerte de sécurité et le mot “DANGER” ou

“AVERTISSEMENT”. Ces mots signifient :

POUR VOTRE SÉCURITÉ

Ne pas entreposer ni utiliser de l'essence ou d'autres produits liquides ou gazeux inflammables à proximité de cet appareil ou de

tout autre appareil électroménager.

EXIGENCES D’INSTALLATION

Outillage et pièces

Rassembler les outils et pièces nécessaires avant de commencer

l’installation. Lire et respecter les instructions d’installation

fournies avec chacun des outils de cette liste.

Outillage nécessaire

■ Clé à tuyauterie de 20 cm

(8") ou 25 cm (10")

■ Clé à molette de 20 cm (8")

ou 25 cm (10")

■ Tournevis à lame plate

■ Tournevis Phillips

■ Clé à molette avec

ouverture jusqu’à 25 mm

(1") ou clé à douille

hexagonale

■ Niveau

■ Clé à douille de 8 mm (

■ Couteau utilitaire

■ Brides de fixation

■ Pistolet à calfeutrage et

composé de calfeutrage

(pour l’installation d’un

nouveau circuit

d’évacuation)

■ Pince

■ Couteau à mastic

5

⁄16")

Pièces fournies

Retirer le sac de pièces du tambour du sèche-linge. Vérifier

la présence de toutes les pièces.

■ Patin (4)

■ Pied du sèche-linge (4)

9

Page 10

Exigences d’emplacement

Risque d'explosion

Garder les matières et les vapeurs inflammables, telle

que l'essence, loin de la sécheuse.

Ne pas installer dans un garage.

Le non-respect de ces instructions peut causer

un décès, une explosion ou un incendie.

AVERTISSEMENT

istances de séparation minimales

D

8,1 cm

3

15")*

(

0 cm (0")

P

p

0 cm (0")

35,6 cm

(14") max.

orte du

lacard

cm

0

0")

(

,5 cm (1")

2

IMPORTANT : Respecter les dispositions de tous les codes et

règlements en vigueur.

■ Déterminer les exigences des codes : Certains codes limitent

ou prohibent l’installation d’un sèche-linge dans un garage, un

placard, ou une chambre à coucher. Consulter l’inspecteur

local des bâtiments.

REMARQUE : Le sèche-linge ne doit pas être installé en un

endroit où il serait exposé à de l’eau ou aux intempéries.

Instructions pour l’installation dans un placard

ou un encastrement

Cette sécheuse peut être installée dans un placard ou un

encastrement. Ce sèche-linge ne doit pas être installé derrrière

une porte verrouillable, coulissante, ou une porte avec charnière

du côté opposé de l’emplacement de celle du sèche-linge.

Les distances de séparation sont exprimées en centimètres;

il s’agit des distances minimales. Il est utile de prévoir des

distances de séparation supérieures pour faciliter l’installation

et les travaux d’entretien, ou si ceci est exigé par les codes

et règlements locaux.

Si la porte du placard est installée, on doit respecter la taille

minimale des ouvertures d’entrée d’air au sommet et en bas.

On peut utiliser une porte à claire-voie offrant une surface de

passage d’air équivalente.

Le circuit d’évacuation du sèche-linge doit être relié à l’extérieur.

Aucun autre appareil utilisant un combustible ne doit être installé

dans le même placard.

Encastrement, vue avant

n doit prévoir un espacement additionnel pour tenir compte éventuellement

O

es moulures du mur, de la porte et du plancher, ou si le circuit d’évacuation

d

omporte un coude.

c

2

310 cm

2

48 po

)*

(

.

vue

avant

2

155 cm

(24 po2.)*

* Taille minimale de l’ouverture pour la porte du placard. On peut utiliser une

porte à claire-voie offrant une surface de passage d’air équivalente.

Porte du

placard

Placard, vue latérale

7,6 cm (3")

7,6 cm (3")

10

Page 11

imensions du produit – Sèche-linge

D

de 68,6 cm (27")

8,6 cm (27")

6

ÂBLE

C

LECTRIQUE

É

VUE ARRIÈRE

33 cm

(13")

74,3 cm ( 291⁄4")

67,3 cm (261⁄2")

5,6 cm

3

14")

(

ia. 102 mm

d

4")

(

BOUCHE DE

ÉCHARGE

D

12,1 cm

3

4

(

⁄4"

4 cm

9

(37")

)

20 cm (7

Spécifications électriques

Ce sèche-linge est livré sans cordon d’alimentation électrique et

ans prise. Il doit être raccordé par un électricien compétent à

s

une source d’alimentation électrique monophasée, de tension

telle qu’indiquée sur la plaque signalétique en utilisant un

âblage fixe approprié, conformément aux règlements locaux

c

et nationaux.

■ Un cordon circulaire à 3 fils avec des conducteurs d’au moins

2,5 mm

■ Un fusible de 30A doit être utilisé sur l’alimentation et un

s

dans le câblage fixe pour assurer une déconnexion totale

en cas de survoltage de catégorie III, conformément aux

r

linge doit être placé de façon à ce que le sectionneur soit

facile d’accès pour l’utilisateur.

■ Une garniture de serre-fil pour le d’alimentation est fournie

avec le sèche-linge et doit être serrée une fois le câblage

terminé. Les bornes de raccordement au secteur se trouvent

derrière le petit panneau d’accès arrière (couvercle du boîtier

de connexion), et les connexions doivent être réalisées

conformément au marquage des bornes. Ne pas oublier de

remettre en place le panneau d’accès du boîtier de connexion

(couvercle du boîtier de connexion).

REMARQUE : Conformément à la directive européenne CEM

7

⁄8")

(2004/108/EC), l’impédance maximale du système

d’alimentation électrique auquel le sèche-linge électrique doit

être connecté est de 0,302 Ohm + j0,189 Ohm.

2

de section doit être utilisé.

ectionneur bipolaire sur les deux lignes doit être incorporé

èglements locaux en matière de raccordement. Le sèche-

88,9 cm

(35")

2,5 cm

(1")

VUE LATÉRALE

Si les codes le permettent et si un conducteur supplémentaire

de mise à la terre est utilisé, il est recommandé qu’un électricien

qualifié inspecte le parcours du fil de mise à la terre.

Méthode recommandée pour la mise à la terre

■ Il incombe à l’utilisateur de contacter un électricien qualifié

afin de veiller à ce que l’installation électrique soit réalisée de

façon adéquate et en conformité avec les exigences de tous

les codes et règlements locaux.

11

Page 12

Exigences concernant l’évacuation

Risque d’incendie

Utiliser un conduit d’évacuation en métal lourd.

N

e pas utiliser un conduit d’évacuation en plastique.

Ne pas utiliser un conduit d’évacuation en feuille

de métal.

Le non-respect de ces instructions peut causer

un décès ou un incendie.

AVERTISSEMENT

de peluches. Remplacer tout conduit de plastique ou de feuille

métallique mince par un conduit métallique flexible ou rigide.

Planifier l’installation pour introduire le nombre minimal de coudes

et de changements de direction.

AVERTISSEMENT : Pour réduire le risque d’incendie, ce

sèche-linge DOIT ÉVACUER L’AIR À L’EXTÉRIEUR.

■ Une aération adéquate est nécessaire pour éviter le retour des

gaz dans la pièce en provenance d’appareils ménagers qui

utilisent d’autres carburants comme combustible, y compris

les feux ouverts (autrement dit le débit d’air entrant dans la

pièce doit être égal au débit qui en sort).

■ L’évent du sèche-linge ne doit pas être connecté à un conduit

d’évacuation de gaz, une cheminée, un mur, un plafond ou un

vide de construction.

■ Ne pas utiliser un clapet d’évacuation à fermeture

magnétique.

■ Ne pas installer le conduit métallique flexible dans les cavités

fermées des murs, plafonds ou planchers.

■ Utiliser un conduit d’évacuation en métal lourd de 4"

(102 mm) et des brides de fixation.

■ Utiliser des brides de fixation pour sceller tous les joints.

L’évent ne doit pas être connecté ou fixé avec des vis ou

autres dispositifs d’accrochage qui se prolongent à l’intérieur

de l’évent. Ne pas utiliser de ruban adhésif en toile.

IMPORTANT : Respecter les dispositions de tous les codes et

règlements en vigueur.

Utiliser un conduit d’évacuation en métal lourd. Ne pas utiliser un

conduit de plastique ou en feuille métallique.

On recommande d’utiliser un conduit métallique rigide pour

réduire les risques d’écrasement et de déformation.

Un conduit métallique flexible doit être totalement déployé et

soutenu lorsque le sèche-linge est à sa position finale. Enlever

tout excès de conduit flexible pour éviter tout affaissement/

déformation susceptible de réduire le débit d’air et le rendement

du sèche-linge.

Terminer le conduit d’évacuation par un clapet de décharge pour

empêcher les rongeurs et insectes d’entrer dans l’habitation ou

l’entreprise.

Le clapet de décharge doit être situé à au moins 12" (30,5 cm)

au-dessus du sol ou de tout autre objet susceptible de se trouver

sur le trajet de l’air humide rejeté (par exemple, fleurs, roches ou

arbustes).

Lors de l’utilisation d’un circuit d’évacuation existant, nettoyer les

peluches sur toute la longueur du système et veiller à ce que la

bouche de décharge ne soit pas obstruée par une accumulation

12

A

Débit d’évacuation

A. Bon débit d’évacuation

B. Meilleur débit d’évacuation

B

Si des coudes sont utilisés ou des changements de direction

effectués, prévoir autant d’espace que possible. Plier le conduit

graduellement pour éviter de le déformer.

La bouche de sortie est située à l’arrière du sèche-linge, en

bas/au centre.

On peut acheminer le conduit d’évacuation par le haut, par le

bas, par la gauche, par la droite, derrière le sèche-linge ou en

ligne droite depuis l’arrière du sèche-linge.

Longueur du circuit d’évacuation

La longueur maximale du circuit d’évacuation dépend du type de

conduit utilisé, du nombre de coudes et du type de bouche de

décharge.

Longueur maximale du conduit

Clapet de décharge de 102 mm (4") de diamètre

Conduit

métallique rigide

Nombre d’angles

à 90°

0

1

2

3

4

Clapets de type boîte et

à persiennes

19,5 m (64 pi)

16,5 m (54 pi)

13,4 m (44 pi)

10,7 m (35 pi)

8,2 m (27 pi)

Si le sèche-linge est installé dans un espace réduit tel qu’une

chambre à coucher, une salle de bain ou un placard, on doit

prévoir une arrivée d’air en quantité suffisante pour la combustion

et la ventilation. (Consulter les codes et règlements en vigueur.)

Voir “Instructions pour l’installation dans un encastrement ou

dans un placard” de la section "Exigences d’emplacement".

L’emploi d’une bouche de décharge de 102 mm (4") est

préférable. On peut cependant utiliser une bouche de 64 mm

1

⁄2"). Une bouche de décharge de 64 mm (21⁄2") peut causer

(2

une plus forte rétropression que les autres genres de bouches.

Pour une installation permanente, un système d’évacuation

fixe est requis.

Clapet incliné

17,7 m (58 pi)

14,6 m (48 pi)

11,6 m (38 pi)

8,8 m (29 pi)

6,4 m (21 pi)

Page 13

Évacuation multiple du sèche-linge

■ Un conduit d’évacuation principal peut être utilisé pour un

groupe des sèche-linges. Le conduit d’évacuation principal

evrait être d’un diamètre suffisant pour évacuer 5663 l/min

d

3

(200 pi

de forte capacité et de conception adéquate peuvent être

u

inspectés et nettoyés fréquemment. La pièce où se trouvent

les sécheuses devrait recevoir un apport d’air de débit égal

o

sèches-linges installés dans la pièce.

■ Des ensembles antirefoulement, n° de pièce 3391910, sont

disponibles chez votre marchand et devraient être installés

dans le conduit d’évacuation de chaque sèche-linge pour

empêcher l’air évacué de retourner dans les sèche-linges et

pour maintenir une pression équilibrée dans le conduit

principal d’évacuation. Des orifices de passage

d’air non obstrués sont requis.

Chaque conduit d’évacuation devrait pénétrer dans le conduit

principal à un angle pointant dans la direction du débit d’air.

Les conduits raccordés au conduit principal de part et d’autre

devraient être disposés en quinconce pour que l’air évacué

par un sèche-linge ne puisse perturber l’évacuation d’un autre

sèche-linge.

/min) d’air par sèche-linge. Des filtres à peluches

tilisés dans le conduit principal d’évacuation s’ils sont

3

min) de débit de tous les

u supérieur au débit total (pi

A

débit d’air

/

30° max.

B

Si une bouche de décharge ne peut être utilisée :

B

A

0 cm (12") min. au-dessus

3

de toute accumulation de

neige, glace, ou débris

comme des feuilles.

A. Bouche de décharge ou

coude de déviation

B. Mur

C. Cheminée principale de

mise à l’air libre

D. Conduit horizontal

E. Coude de déviation à 180°

F. Conduit vertical

G. Toit

D

C

F

C

E

61 cm (2 pi) min.

au-dessus du

point le plus

é

G

levé du bâtiment

L’extrémité extérieure du conduit principal devrait être munie d’un

coude de déviation dirigé vers le bas. Si le conduit principal suit

une trajectoire verticale à travers le toit, plutôt qu’à travers le mur,

installer un coude de déviation de 180° à l’extrémité du conduit et

dépassant d’au moins 61 cm (2 pi) au-dessus de la partie la plus

élevée du bâtiment. L’ouverture murale ou dans le toit doit avoir

un diamètre supérieur de 13 mm (

1

⁄2") à celui du conduit

d’évacuation. Le conduit d’évacuation devrait être centré dans

l’ouverture.

Ne pas installer une grille ou un couvercle sur l’extrémité du

conduit d’évacuation.

A. Conduit individuel d’évacuation du sèche-linge

B. Conduit principal d’évacuation

L’angle maximal entre le conduit connecté à un sèche-linge et le

conduit principal ne devrait pas dépasser 30°.

Faire en sorte que les vapeurs générées par les liquides de

nettoyage à sec ne puissent pas atteindre les orifices d’entrée

d’air; ces vapeurs créent des composés acides qui, lorsqu’ils

sont attirés vers les unités de chauffage des sécheuses, peuvent

endommager les sèche-linges et le linge en cours de séchage.

Une bouche de nettoyage devrait être installée dans le conduit

principal d’évacuation pour les nettoyages périodiques du

système d’évacuation.

13

Page 14

INSTRUCTIONS D’INSTALLATION – SECHE-LINGE ELECTRIQUE

Installation des pieds de nivellement

NOTE : Placer le sèche-linge sur une feuille de carton ou un

panneau de bois dur avant de la déplacer sur le plancher, afin

d’éviter d’endommager le revêtement du sol.

1. À l’aide de deux personnes ou plus, déplacer le sèche-linge à

l’emplacement d’installation désiré.

2. Enlever le ruban adhésif dans les angles avant du sèche-linge.

Ouvrir le sèche-linge; enlever les brochures et sachets de

pièces. Essuyer parfaitement la surface interne du tambour

avec un chiffon humide.

3. Prendre deux cornières de carton de l’emballage et les placer

sur le plancher à l’arrière du sèche-linge. Saisir fermement le

sèche-linge et la placer doucement en appui sur la face

arrière, sur les cornières de carton.

4. Prendre l’un des pieds et identifier la marque en losange dans

le filetage. Ce repère indique jusqu’où le pied doit être vissé

dans le trou.

5. Commencer à visser à la main les pieds avant dans les trous.

(Utiliser une petite quantité de détergent liquide pour lubrifier

la section filetée, pour qu’il soit plus facile de tourner les

pieds). Utiliser une clé de 25 mm (1") ou une clé à douille pour

visser les pieds jusqu’au repère. Placer ensuite un patin de

protection sur chaque pied.

Placer maintenant la sécheuse verticalement.

6. Retirer la feuille de carton ou le panneau de bois dur placé

sous le sèche-linge. Régler les pieds du sèche-linge vers le

haut ou vers le bas jusqu’à ce que le sèche-linge soit

d’aplomb.

Raccordement électrique

Ce sèche-linge est livré sans cordon d’alimentation électrique et

sans prise; il doit être raccordé par un électricien compétent. Voir

“Spécifications électriques”.

Raccordement du conduit d’évacuation

1. À l’aide d’une bride de fixation de 102 mm (4"), relier le

conduit d’évacuation à la bouche d’évacuation du sèchelinge. Si on utilise le conduit d’évacuation existant, s’assurer

qu’il est propre. Le conduit d’évacuation du sèche-linge doit

tre fixé sur la bouche d’évacuation du sèche-linge et dans

ê

le clapet d’évacuation. S’assurer que le conduit d’évacuation

est fixé au clapet d’évacuation à l’aide d’une bride de

fixation de 102 mm (4").

2. Placer la sécheuse à l’emplacement final désiré. Ne pas

écraser ni deformer le conduit d’évacuation. Vérifier que le

sèche-linge est de niveau.

Achever l’installation

1. Une fois le sèche-linge à son emplacement final, placer un

niveau sur le sommet du sèche-linge, transversalement, puis

dans le sens avant arrière. Si le sèche-linge n’est pas

d’aplomb, ajuster les pieds pour modifier la hauteur et établir

un bon aplomb du sèche-linge.

2. Brancher le sèche-linge ou reconnecter la source de courant

électrique.

3. Contrôler le bon fonctionnement du sèche-linge (la minuterie

peut indiquer un temps de service cumulatif du fait de tests

effectués à l’usine).

Insérer les pièces dans le mécanisme à coulisse et enfoncer

doucement le mécanisme à glissière (le temps de

fonctionnement sera accumulé, selon le nombre de pièces et

le type de la came utilisé). Appuyer sur le bouton

START/RESTART (mise en marche/remise en marche). Faire

fonctionner le sèche-linge pendant au moins cinq minutes –

programme de séchage avec chaleur (pas le programme de

séchage à l’air). Le sèche-linge s’arrêtera à l’expiration de la

période ainsi déterminée.

NOTE : Il faut que la porte soit fermée pour que le sèche-linge

puisse fonctionner. Le sèche-linge s’arrête dès l’ouverture de

la porte, mais la minuterie continue de fonctionner. Pour

remettre le sèche-linge en marche, fermer la porte et appuyer

sur le bouton START/RESTART.

4. Si le temps de séchage est trop long, s’assurer que le filtre

à peluches est propre.

5. Mettre le sèche-linge en marche; la laisser exécuter un

programme complet avec chaleur (pas le programme

de séchage à l’air) pour vérifier qu’elle fonctionne

correctement.

Cet appareil est un sèche-linge à 3 conducteurs qui doit être relié

à la terre.

14

Page 15

INSTRUCTIONS D’ENTRETIEN

Instructions d’entretien :

■ Nettoyer le filtre à peluches après chaque utilisation.

■ Comment enlever les peluches accumulées :

• De l’intérieur du sèche-linge :

Il faut retirer les peluches tous les 2 ans ou plus souvent,

selon l’utilisation du sèche-linge. Le nettoyage doit être

effectué par une personne qualifiée.

• Du conduit d’évacuation :

Il faut retirer les peluches tous les 2 ans ou plus souvent,

elon l’utilisation du sèche-linge.

s

i le sèche-linge ne fonctionne pas, vérifier ce qui suit :

S

■ Le circuit d’alimentation électrique est bien connecté.

■ Les disjoncteurs ne sont pas ouverts et les fusibles sont intacts.

■ La porte est fermée.

■ Les boutons de commande sélectionnent une configuration de

onctionnement ou sont placées sur “ON”.

f

■ Le bouton START (mise en marche) a été enfoncé fermement.

Si vous avez besoin d’assistance :

Veuillez communiquer avec votre distributeur d’ensemble

de buanderie commercal Maytag autorisé. Lors de l’appel,

vous aurez besoin des numéros de modèle et de série du

sèche-linge. Les deux numéros sont indiqués sur la plaque

signalétique de l’appareil. Ou visitez le site Web

www.MaytagCommercialLaundry.com.

15

Page 16

SEGURIDAD DE LA SECADORA

REQUISITOS DE INSTALACIÓN

Piezas y herramientas

Reúna las herramientas y piezas necesarias antes de comenzar la

instalación. Lea y siga las instrucciones provistas con cualquiera

de las herramientas enlistadas aquí.

Herramientas necesarias

■ Llave para tubos

de 20 cm (8") ó

25 cm (10")

■ Llave ajustable de 20 cm

(8") ó 25 cm (10")

■ Destornillador de

hoja plana

■ Destornillador Phillips

■ Llave ajustable que se abra

a 25 mm (1") o llave de

cubo de cabeza hexagonal

■ Nivel

■ Llave de boca

de 8 mm (

■ Cuchillo para uso general

■ Abrazaderas para ducto

■ Pistola y masilla para

5

⁄16")

calafateo (para instalar el

nuevo ducto de escape)

■ Pinzas

■ Cuchillo para masilla

Piezas suministradas

Retire la bolsa de piezas del tambor de la secadora. Verifique

que estén todas las piezas.

■ Cuñas (4)

■ Patas de la secadora (4)

16

Page 17

Requisitos de ubicación

Dimensiones del producto:

Secadora de 68,6 cm (27")

68,6 cm (27")

IMPORTANTE: Observe todos los códigos y reglamentos

aplicables.

■ Verifique los requisitos del código: Algunos códigos limitan,

o no permiten, la instalación de la secadora engarajes,

armarios o en dormitorios. Póngase en contacto con el

inspector de construcciones de su localidad.

NOTA: No debe instalarse la secadora en un área en donde

pueda estar expuesta al agua y/o a la intemperie.

Instrucciones para la instalación empotrada

o en armario

Esta secadora podrá instalarse en un área empotrada o

en un clóset. No debe instalarse esta secadora detrás de una

puerta que se pueda cerrar con llave, una puerta corrediza o una

puerta con bisagra del lado opuesto a la secadora.

El espacio de instalación es en centímetros (pulgadas) y es el

mínimo permitido. Debe considerarse espacio adicional para

facilitar la instalación, el servicio técnico y el cumplimiento de

los códigos y ordenanzas locales.

Si se instala la puerta del armario, se requieren aperturas mínimas

de ventilación sin obstrucciones en la parte superior e inferior de

la puerta. Se aceptan puertas tipo persianas con aperturas de

aire equivalentes.

La secadora deberá ventilarse al exterior.

No se puede instalar otro electrodoméstico que usa combustible

en el mismo clóset en que se encuentra la secadora.

88,9 cm

(35")

2,5 cm

(1")

ELÉCTRICA

35,6 cm

(14")

VISTA POSTERIOR

33 cm

(13")

02 mm (4")

1

ia.

d

ALIDA

S

4,3 cm (29

7

67,3 cm (261/2")

1

/4"

VISTA LATERAL

4 cm

9

37")

(

2,1 cm

1

3

4

)

(

⁄4"

)

7

⁄8")

20 cm (7

Espacios mínimos para la instalación

35,6 cm

(14") máx.

38,1 cm

(15")*

0 cm (0")

Vista frontal en

lugar empotrado

Se podrían necesitar espacios libres adicionales para las molduras de la pared,

de la puerta y del piso, o si se usa un codo externo de ventilación.

Puerta del

armario

0 cm

(0")

0 cm (0")

2,5 cm (1")

Vista lateral en

un armario

2

310 cm

(48 pulg2.)*

Vista

frontal

2

155 cm

(24 pulg2.)*

Puerta del

armario

7,6 cm (3")

* La apertura es la mínima para

la puerta del armario.

Se aceptan puertas tipo persianas

con aperturas de aire equivalentes.

7,6 cm (3")

17

Page 18

Requisitos eléctricos

Esta secadora se suministra sin cable eléctrico ni enchufe. Debe

er conectada por un electricista competente a un suministro

s

eléctrico monofásico al voltaje mostrado en la placa, usando una

instalación apropiada de cableado fijo de acuerdo a las normas

e cableado locales y nacionales.

d

Debe usarse un cable circular de tres hilos de tamaño mínimo

■

de conductor con un área de sección transversal de 2,5 mm².

■ Debe usarse un fusible de suministro de 30 A y deberá

incluirse un interruptor con un contacto de separación en

mbos polos que provea una desconexión completa bajo

a

condiciones de voltaje excesivo de categoría III en el

cableado fijo, de acuerdo con las normas de cableado

ocales. La secadora deberá colocarse de manera tal que

l

el interruptor de desconexión esté fácilmente accesible

para el usuario.

■ La secadora viene provista con una abrazadera de sujeción

para cables, la cual debe apretarse al completar el cableado.

Las terminales eléctricas principales están ubicadas detrás

del pequeño panel de acceso trasero (cubierta del bloque

terminal), y las conexiones deben hacerse de acuerdo a las

marcas del terminal. Recuerde que debe volver a colocar el

panel de acceso del terminal (cubierta del bloque terminal).

NOTA: De acuerdo a la Directiva EMC Europea (2004/108/EC) la

impedancia máxima del sistema de suministro de electricidad

máxima a la cual la secadora eléctrica debe estar conectada es

0,302 Ohm + j0,189 Ohm.

Si los códigos lo permiten y se emplea una ligadura de conexión

a tierra adicional, es recomendable que un electricista calificado

determine si la trayectoria de conexión a tierra de la ligadura es

adecuada.

Método recomendado de conexión a tierra

■ Es su responsabilidad ponerse en contacto con un instalador

eléctrico calificado para asegurarse de que la instalación

eléctrica sea adecuada y de conformidad con todos los

códigos y ordenanzas locales.

Requistos de ventilación

ADVERTENCIA: Para reducir el riesgo de incendio,

esta secadora DEBE VENTILARSE HACIA EL EXTERIOR.

■ Deberá proveerse una ventilación adecuada para evitar

el contraflujo de gases de aparatos que consuman otros

combustibles, incluidos fuegos abiertos, en la habitación (por

ejemplo, el flujo de aire disponible que entre en la habitación

deberá coincidir con el flujo de aire que sale de la misma).

■ El conducto de escape de la secadora no puede

descargarse en un conducto de humo usado para humos

de salida de aparatos que consumen/queman gas u otros

combustibles, una chimenea, pared, techo o espacio oculto

de un edificio.

■ No use un conducto de escape de plástico con pestillo

magnético.

■ No instale el ducto de escape de metal flexible en paredes,

techos o pisos encerrados.

■ Deben usarse abrazaderas y ductos de escape de metal

pesado de 102 mm (4").

■ Utilice abrazaderas para sellar todas las juntas. No debe

conectarse ni asegurarse el ducto de escape con tornillos

ni con ningún otro dispositivo que se extienda hacia el

interior de dicho conducto. No utilice cinta para ductos.

IMPORTANTE: Observe todos los códigos y reglamentos

aplicables.

Use un conducto de escape de metal pesado. No use conducto

de escape de plástico o de hoja de metal. Se recomienda un

ducto de escape de metal rígido para evitar que se aplaste o

se tuerza.

El ducto de escape de metal flexible debe extenderse y

sostenerse por completo cuando la secadora está en su

ubicación final. Quite el exceso del ducto de metal flexible para

evitar que se doble y se tuerza, lo cual podría dar lugar a una

reducción del flujo de aire y a un rendimiento insuficiente.

Una capota de ventilación debe tapar el ducto de escape para

evitar el ingreso de roedores e insectos a la casa o comercio.

La capota de ventilación debe estar al menos a 30,5 cm (12") del

piso o de cualquier objeto que pueda encontrarse en el paso del

escape (tales como flores, piedras o arbustos).

Si se usa un sistema de ventilación existente, limpie la pelusa

que está en toda la longitud del sistema y asegúrese de que la

capota de ventilación no esté obstruida con pelusa. Reemplace

cualquier ducto de escape de plástico o de hoja de metal por

uno de metal rígido o flexible.

18

Page 19

Planifique la instalación a fin de usar el menor número posible de

codos y vueltas.

A

Flujo de aire de escape

A. Bueno

B. Mejor

B

Cuando use codos o haga vueltas, deje todo el espacio que sea

posible. Doble el ducto gradualmente para evitar torceduras.

La salida de ventilación está ubicada en el centro de la parte

posterior de la secadora inferior.

El ducto de escape puede ser dirigido hacia arriba, hacia abajo,

a la izquierda, derecha, detrás de la secadora o directamente

hacia atrás por la parte posterior de la misma.

Largo del sistema de ventilación

La longitud máxima del sistema de ventilación depende del tipo

de ducto que se use, el número de codos y el tipo de capota

de ventilación.

Longitud máxima del ducto de escape

Capotas de ventilación de 102 mm (4") de diámetro

Ventilación para múltiples secadoras

■ Puede usarse un ducto principal para ventilar un grupo de

secadoras. La ventilación principal debe ser del tamaño

como para eliminar 5663 l/min (200 pies cúbicos por minuto)

de aire por secadora. Pueden usarse filtros de pelusa de

gran capacidad con diseño apropiado en la ventilación

principal si se revisan y se limpian frecuentemente. La

habitación en donde estén ubicadas las secadoras deberá

tener aire suficiente o mayor de todas las secadoras en la

habitación.

o

■ Los juegos reguladores de tiro de contratiro, pieza N

391910, están disponibles con su distribuidor y deben

3

instalarse en cada ducto de escape de las secadoras para

prevenir que el aire de escape regrese a las secadoras y

ara mantener al escape en balance con la ventilación

p

principal. Se requieren aberturas de aire sin obstrucción.

Cada ducto de escape debe entrar en la ventilación principal a

un ángulo que apunte en la dirección del flujo de aire. Los ductos

de escape que entren por el lado opuesto deben alternarse para

lograr que el aire de escape reduzca su interferencia con otros

ductos de escape.

El ángulo máximo de cada ducto que entra en el ducto principal

deberá ser no más de 30°.

A

30° máx.

flujo de aire

B

.

Ducto de escape

de metal rígido

N° de vueltas de 90°

0

1

2

3

4

Capota de ventilación tipo caja

y tipo persiana

19,5 m (64 pies)

16,5 m (54 pies)

13,4 m (44 pies)

10,7 m (35 pies)

8,2 m (27 pies)

Capota de

ventilación angular

17,7 m (58 pies)

14,6 m (48 pies)

11,6 m (38 pies)

8,8 m (29 pies)

6,4 m (21 pies)

Si la secadora está instalada en un área cerrada tal como un

dormitorio, baño o clóset, deberán tomarse las provisiones

necesarias para que haya aire suficiente para la combustión y la

ventilación. (Verifique los códigos y reglamentos aplicables.) Vea

“Instrucciones para la instalación empotrada o en clóset” en la

sección “Requisitos de ubicación”.

Se prefiere una capota de salida de 102 mm (4"). Aún así, podrá

usarse una salida de escape de 64 mm (2½"). Una salida de

64 mm (2½") ocasiona mayor contrapresión que los otros tipos

de capotas. Para una instalación permanente, se necesita un

sistema fijo de ventilación.

A. Ducto de escape individual de la secadora

B. Ducto principal

Mantenga las aberturas de aire libres de los gases de los líquidos

de limpieza en seco. Los gases producen ácidos, los cuales

pueden dañar las secadoras y las cargas que se estén secando

cuando pasan a través de las unidades de calentamiento de las

secadoras.

Debe ubicarse una cubierta de limpieza en el ducto principal para

una limpieza periódica del sistema de ventilación.

19

Page 20

i no puede usarse una capota de ventilación:

S

B

A

D

Espacio mínimo de 30 cm (12")

or encima de cualquier

p

cumulación de nieve, hielo o

a

esechos tales como hojas.

d

El extremo exterior de la ventilación principal debe tener un

codo curvado dirigido hacia abajo. Si el ducto principal viaja

verticalmente a través del techo, en lugar de la pared, instale un

C

codo curvado a 180° en el extremo del ducto de escape, por lo

menos a 61 cm (2 pies) sobre la parte más alta del edificio. La

abertura de la pared o del techo debe tener un diámetro de

13 mm (1/2") más grande que el diámetro del ducto. El ducto

debe estar centrado en la abertura.

No instale una malla metálica ni una tapa sobre el extremo

del ducto.

E

A. Capota de ventilación

o codo

B. Pared

C. Ducto colector principal

D. Ducto horizontal

E. Codo curvado a 180°

F. Ducto vertical

G. Techo

INSTRUCCIONES DE INSTALACIÓN – SECADORA ELÉCTRICA

Instalación de las patas niveladoras

C

1 cm (24") mín.

6

obre el punto

s

F

más alto del

dificio

e

G

de 25 mm (1") o una llave de cubo para terminar de girar las

patas, hasta llegar a la marca con forma de diamante. Luego

haga encajar una cubierta protectora sobre cada pata.

Ahora ponga la secadora de pie.

6. Quite el cartón o madera que se encuentra debajo de la

secadora. Incline las patas de la secadora hacia arriba o hacia

abajo hasta que la misma quede nivelada.

NOTA: Deslice la secadora sobre un pedazo de cartón o

madera dura antes de moverla por el piso para no dañar el

acabado de éste.

1. Con la ayuda de dos o más personas, mueva la secadora

al lugar deseado para su instalación.

2. Remueva la cinta de las esquinas frontales de la secadora.

Abra la secadora y saque los paquetes que contienen la bolsa

con documentos y las piezas. Limpie el interior del tambor

minuciosamente con un paño húmedo.

3. Tome dos de los esquinales de cartón de la caja y colóquelos

sobre el piso, en la parte posterior de la secadora. Sujete con

firmeza el cuerpo de la secadora y colóquela sobre su parte

posterior, encima de los esquinales de cartón.

4. Con una de las patas a mano, fíjese en las ranuras para

encontrar la marca en forma de diamante. Hasta ahí es

donde la pata debe introducirse en el orificio.

5. Comience a atornillar las patas niveladoras en los orificios

con la mano. (Use una pequeña cantidad de detergente

líquido para lubricar las roscas del tornillo, y hacer de esa

manera más fácil el girar las patas.) Use una llave de tuercas

20

Conexión eléctrica

Ésta es una secadora de 3 hilos y debe estar conectada a tierra.

Esta secadora se ha suministrado sin cable eléctrico ni enchufe y

debe ser conectada por un electricista calificado. Vea “Requisitos

eléctricos”.

Page 21

Conexión del ducto de escape

1. Usando una abrazadera de 102 mm (4"), conecte el ducto

de escape a la salida de aire en la secadora. Si se conecta

a un ducto de escape existente, asegúrese de que el mismo

esté limpio. El ducto de escape de la secadora debe encajar

sobre la salida de aire de la secadora y dentro de la capota

de ventilación. Cerciórese de que el ducto de escape esté

asegurado a la capota de ventilación con una abrazadera

de 102 mm (4").

2. Mueva la secadora a su posición final. No aplaste ni

retuerza el ducto de escape. Asegúrese de que la secadora

esté nivelada.

Complete la instalación

1. Con la secadora en su posición final, coloque un nivel sobre

la secadora, primero de lado a lado; luego de adelante para

atrás. Si la secadora no está nivelada, ajuste las patas de la

secadora hacia arriba o hacia abajo hasta que esté nivelada.

2. Conecte el suministro de energía.

3. Revise el funcionamiento de la secadora (puede que haya

algo de tiempo acumulado en el temporizador debido a las

pruebas de fábrica).

Inserte las monedas en el tragamonedas y presiónelo hacia

adentro lentamente. (El tiempo de funcionamiento se

acumulará según el número de monedas y el tipo de leva de

distribución usada.) Oprima el botón de Inicio/Reinicio

(START/RESTART). Usando un ciclo completo con calor (no el

ciclo de aire), permita que la secadora funcione por lo menos

5 minutos en un ciclo de calor máximo. La secadora se

detendrá cuando se haya terminado el tiempo.

NOTA: La puerta de la secadora se debe cerrar para que la

misma funcione. Cuando se abre la puerta, la secadora se

detiene pero el temporizador continúa funcionando. Para

hacer que la secadora empiece un ciclo de nuevo, cierre

la puerta y presione el botón de Inicio/Reinicio

(START/RESTART).

. Si el tiempo de secado es muy largo, asegúrese que el filtro

4

de pelusa esté limpio.

5. Ahora ponga la secadora en marcha y permita que termine un

ciclo de calor completo (no un ciclo de aire), para asegurarse

de que está funcionando adecuadamente.

INSTRUCCIONES DE MANTENIMIENTO

Instrucciones de mantenimiento:

■ Limpie el filtro de pelusa después de cada ciclo.

■ Eliminación de pelusa acumulada:

• En el interior de la carcasa de la secadora:

Según el uso de la secadora, se debe quitar la pelusa cada

2 años, o con más frecuencia. La limpieza deberá efectuarla

una persona calificada.

• En el ducto de escape:

Según el uso de la secadora, se debe quitar la pelusa cada

2 años, o con más frecuencia.

Si la secadora no funciona, revise lo siguiente:

■ Que el suministro eléctrico esté conectado.

■ Que el cortacircuitos no se disparó o el fusible de la casa

no está quemado.

■ Que la puerta esté cerrada.

■ Que los controles estén fijados en una posición de

funcionamiento o Encendido (ON).

■ Que botón de Inicio (START) esté presionado firmemente.

Si necesita ayuda:

Póngase en contacto con su distribuidor autorizado de secadoras

comerciales de Maytag. Cuando llame, usted necesitará tener a

mano el número del modelo y de serie de la lavadora. Ambos

números se encuentran en la placa de clasificación de serie que

está ubicada en el electrodoméstico. O visite:

www.MaytagCommercialLaundry.com.

21

Page 22

Pericolo di morte o di lesioni gravi in caso di mancata

osservanza immediata delle istruzioni.

Pericolo di morte o di lesioni gravi in caso di mancata

osservanza delle istruzioni.

Tutti i messaggi di sicurezza informano l’utente sulla tipologia del pericolo, su come ridurre il rischio di lesioni e su cosa può

succedere in caso di mancata osservanza delle istruzioni.

La sicurezza dell’utente e degli altri è fondamentale.

Il presente manuale e l’elettrodomestico stesso contengono numerosi importanti messaggi sulla sicurezza.

Leggere e seguire sempre tutti i messaggi di sicurezza.

Questo è il simbolo che indica un pericolo.

Questo simbolo avverte l’utente dei possibili pericoli mortali per sé e per gli altri.

Tutti i messaggi di sicurezza sono contrassegnati dal simbolo di allarme sicurezza e dalle parole

“PERICOLO” o “AVVERTENZA”. Significato:

PERICOLO

AVVERTENZA

SICUREZZA DELL’ASCIUGATRICE

PER LA SICUREZZA DELL’UTENTE

Non conservare o utilizzare benzina, né altri vapori infiammabili in prossimità di questa o qualsiasi altre apparecchiature.

REQUISITI D’INSTALLAZIONE

Attrezzi e componenti

Raccogliere gli attrezzi e i componenti necessari prima di iniziare

l’installazione.

Attrezzi necessari

■

Chiave per tubi da 20 cm

(8") or 25 cm (10")

■ Chiave regolabile da 20 cm

(8") or 25 cm (10")

■ Cacciavite a testa piatta

■ Cacciavite Phillips

■ Chiave regolabile con

apertura a 2,5 cm (1") o

chiave a tubo esagonale

■ Livello

■ Chiave a tubo da 8 mm

(5/16")

■ Coltello multiuso

■ Morsetti per lo scarico

■ Pistola per presellatura e

presello (per l’installazione

del nuovo scarico)

■ Pinza

■ Spatola per stucco

Componenti in dotazione

Rimuovere il sacchetto dei componenti dalla lavatrice.

Controllare che vi siano inclusi tutti i pezzi necessari.

■ Protezione piede (4)

■ Piede asciugatrice (4)

22

Page 23

Requisiti di ubicazione

Dimensioni del prodotto asciugatrice

da 68,6 cm (27")

68,6 cm (27")

IMPORTANTE: rispettare le normative e le ordinanze governative.

■ Controllare i requisiti normativi: alcune normative limitano o

proibiscono l’installazione di asciugatrici in garage, armadi o

luoghi dove si dorme. Contattare l’ispettore edilizio locale.

NOTA: non installare l’asciugatrice in una zona esposta ad acqua

e/o intemperie.

Istruzioni di installazione incassata e in armadi

È possibile installare l’asciugatrice incassata o in un armadio.

Non installare l’asciugatrice dietro a una porta bloccabile,

scorrevole o con la cerniera nella parte opposta dell’asciugatrice.

Lo spazio di installazione è in centimetri e rappresenta il minimo

consentito.

Per agevolare le operazioni di installazione e assistenza, e per

rispettare la conformità con le normative locali, è opportuno

considerare spazio aggiuntivo.

Se si installa una porta dell’armadio, è necessaria un’apertura non

ostruita nella parte superiore e inferiore. Sono accettabili porte a

persiana o simili.

Lo scarico dell’asciugatrice deve essere diretto all’esterno.

Non installare altre apparecchiature a combustione nello stesso

armadio dell’asciugatrice.

88,9 cm

(35")

2,5 cm

(1")

ELETTRICA

35,6 cm

(14")

VISTA POSTERIORE

33 cm

(13")

0,2 cm (4")

1

ia.

d

CARICO

S

74,3 cm (291/4")

67,3 cm (261/2")

VISTA LATERALE

2,1 cm

1

4

(

20 cm (7

4 cm

9

37")

(

3

)

⁄4"

7

⁄8")

Spazi minimi di installazione

35,6 cm

(14") max.

38,1 cm

(15")*

0 cm (0")

Porta

dell’armadio

0 cm

(0")

0 cm (0")

2,5 cm (1")

Vista frontale incassata Vista laterale armadio

Può essere necessario spazio aggiuntivo per pareti, sportelli e porte, oppure nel

caso in cui venga utilizzato un gomito di scarico esterno.

2

310 cm

(48 pollici2)*

Vista

frontale

2

155 cm

(24 pollici2)*

Porta

dell’armadio

7,6 cm (3")

*L’apertura rappresenta il minimo

per la porta dell’armadio.

Sono accettabili porte a persiana

o simili.

7,6 cm (3")

23

Page 24

Requisiti elettrici – Asciugatrice elettrica

L’asciugatrice è sprovvista di cavo elettrico e presa. La

onnessione a una fonte di elettricità a fase singola deve essere

c

eseguita da un elettricista esperto, in rispetto della tensione

espressa sulla targhetta dei dati, tramite l’installazione di un cavo

isso che rispetti i requisiti di cablaggio locali e nazionali.

f

Utilizzare un cavo a sezione circolare a tre fili, con sezione

■

trasversale del conduttore di dimensioni minime di 2,5 mm2.

■ Utilizzare un fusibile di alimentazione da 30 A e incorporare

un interruttore dotato di separazione dei contatti in entrambi

poli, che fornisca la disconnessione totale in condizioni di

i

sovratensione di categoria III, al cablaggio fisso in rispetto dei

requisiti di cablaggio locali. Posizionare l’asciugatrice in modo

he l’interruttore di disconnessione sia facilmente accessibile.

c

■ L’asciugatrice è provvista di una boccola per il morsetto del

cavo da serrare una volta terminato il cablaggio. I terminali

della rete elettrica sono posizionati dietro il piccolo pannello

di accesso posteriore (coperchio di blocco dei terminali).

Eseguire le connessioni rispettando i contrassegni dei

terminali. Ricordarsi di sostituire il pannello di accesso ai

terminali (coperchio di blocco dei terminali).

NOTA: in rispetto della Direttiva europea EMC (2004/108/CE),

l’impedenza massima del sistema di alimentazione elettrica a

cui connettere l’asciugatrice è dichiarata pari a 0,302 Ohm +

j0,189 Ohm.

Qualora le normative lo consentano, si utilizza un cavo di messa a

terra aggiuntivo, facendo determinare a un elettricista esperto il

percorso adeguato.

Metodo di messa a terra consigliato

■ Ricade sotto la responsabilità dell’utente contattare

un elettricista esperto che garantisca che l’installazione

elettrica sia adeguata e conforme a tutte le normative e

le ordinanze locali.

Requisiti di scarico

AVVERTENZA: per ridurre il rischio di incendio, LO

SCARICO DELL’ASCIUGATRICE DEVE ESSERE DIRETTO

VERSO L’ESTERNO.

■ Fornire una ventilazione adeguata per evitare il riflusso di gas

all’interno della stanza, derivanti da apparecchiature a

combustione, incluse le fiamme aperte (ovvero il flusso di aria

disponibile all’interno della stanza deve essere pari a quello

esterno).

■ Non far scaricare l’asciugatrice nella stessa canna fumaria,

parete, soffitto o spazio nascosto utilizzato per scaricare i

fumi generati da apparecchiature che bruciano gas o altri

combustibili.

■ Non utilizzare cappe con blocco magnetico.

■ Non installare uno scarico in metallo flessibile in pareti,

soffitti o pavimenti chiusi.

■ Utilizzare morsetti e uno scarico in metallo pesante

da 102 mm (4").

■ Utilizzare i morsetti per sigillare tutti i raccordi. Non connettere

o fissare lo scarico con viti o altri dispositivi di fissaggio che si

estendano all’interno dello stesso. Non utilizzare nastro

isolante.

IMPORTANT: rispettare le normative e le ordinanze governative.

Utilizzare uno scarico in metallo pesante. Non utilizzare uno

scarico in plastica o lamina metallica.

Si consiglia uno scarico in metallo rigido per prevenire piegature

e attorcigliamenti.

Stendere completamente lo scarico in metallo flessibile e

sostenerlo quando l’asciugatrice si trova alla sua estremità.

Eliminare lo scarico in metallo flessibile in eccesso per evitare

cedimenti e attorcigliamenti che possono ridurre il flusso dell’aria

e rendere scarse le prestazioni.

Coprire lo scarico con una cappa per impedire l’ingresso di

roditori e insetti in casa o nel luogo di lavoro.

La cappa di scarico deve trovarsi ad almeno 30,5 cm (12") da

terra o dagli altri oggetti presenti nel raggio di azione dello scarico

(quali fiori, pietre, cespugli).

Se si utilizza un impianto di scarico esistente, pulire tutto il

sistema, accertandosi che la cappa non sia intasata con garza.

Sostituire gli eventuali scarichi in plastica o lamina metallica con

scarichi in metallo rigido o flessibile.

24

Page 25

Piano di installazione per utilizzare il numero minimo di gomiti

e curve.

A

B

ciascuna asciugatrice per prevenire il ritorno dell’aria e per

mantenere lo scarico in equilibrio entro lo scarico principale.

Le aperture dell’aria non devono essere ostruite.

Ciascuno scarico deve entrare nello scarico principale con un

angolo che punta nella direzione del flusso d’aria. Sfalsare gli

scarichi che entrano dal alto opposto per ridurre l’interferenza

dell’aria di scarico con gli altri scarichi.

’angolo massimo di ciascuno scarico che entra in quello

L

principale non deve superare i 30°.

Flusso d’aria di scarico

A. Migliore

B. Buono

Quando si utilizzano gomiti o curve prevedere il maggiore spazio

possibile. Piegare lo scarico gradualmente per evitare

attorcigliamenti.

L’uscita di scarico si trova al centro della parte posteriore

dell’asciugatrice.

È possibile instradare lo scarico verso l’alto, il basso, a destra o a

sinistra, dietro l’asciugatrice o direttamente al di fuori della parte

posteriore.

Lunghezza dell’impianto di scarico

La lunghezza massima dell’impianto di scarico dipende dal tipo

di scarico utilizzato, dal numero di gomiti e dal tipo di cappa.

Lunghezza massima dello scarico

Diametro delle cappe di scarico 102 mm (4")

Scarico in

metallo rigido

N. di curve da 90°

0

1

2

3

4

Cappa quadrata e a persiana

19,5 m (64 piedi)

16,5 m (54 piedi)

13,4 m (44 piedi)

10,7 m (35 piedi)

8,2 m (27 piedi)

Cappa angolata

17,7 m (58 piedi)

14,6 m (48 piedi)

11,6 m (38 piedi)

8,8 m (29 piedi)

6,4 m (21 piedi)

Se l’asciugatrice viene installata in un’area ristretta, quale una

camera da letto, un bagno o un armadio, fornire aria a sufficienza

per la combustione e la ventilazione (rispettare le normative e le

ordinanze governative). Consultare “Istruzioni di installazione

incassata e in armadi”, nella sezione “Requisiti di ubicazione”.

È preferibile una cappa con uscita da 10,2 cm (4") Tuttavia, è

possibile utilizzare una cappa di scarico con uscita da 64 mm

1

/2"). Una cappa di scarico con uscita da 64 mm (21/2") genera

(2

una pressione maggiore rispetto agli altri tipi di cappa. Per

installazioni permanenti, è necessario un impianto di scarico fisso.

Scarico di asciugatrici multiple

■ Per lo scarico di un gruppo di asciugatrici è possibile

utilizzare uno scarico principale. Lo scarico principale deve

avere dimensioni tali da rimuovere 5663 l/min (200 CFM)

d’aria per asciugatrice. Nello scarico principale sono

utilizzabili filtri in garza di grande capacità progettati

appositamente. La stanza in cui vengono sistemate le

asciugatrici deve prevedere un rinnovo d’aria uguale o

maggiore al flusso d’aria di tutte le asciugatrici presenti.

■ Il kit di attenuazione del ritorno d’aria, n. parte 3391910, è

disponibile presso il rivenditore e va installato nello scarico di

A

30° max.

flusso d’aria

A. Scarico asciugatrice singola

B. Scarico principale

B

Tenere le aperture dell’aria libere da fumi dei fluidi della pulizia a

secco. I fumi generano acidi, che quando passano attraverso le

unità di riscaldamento dell’asciugatrice, possono danneggiare

asciugatrici e carichi in fase di asciugatura.

Posizionare un coperchio a sifone sullo scarico principale per la

pulizia periodica dell’impianto di scarico.

Se è impossibile utilizzare una cappa di scarico:

B

A

C

D

Min. 30 cm (12") di spazio

contro l’accumulo di neve,

ghiaccio, sporco tipo foglie.

E

A. Cappa di scarico o gomito

B. Parete

C. Scarico del collettore

principale

D. Scarico orizzontale

E. Gomito da 180°

F. Scarico verticale

G. Tetto

C

61 cm (24") min.

oltre il punto più

F

alto dell’edificio

G

L’estremità esterna dello scarico principale deve essere dotato di

un gomito diretto verso il basso. Se lo scarico principale si sposta

verticalmente sul tetto, piuttosto che sulla parete, installare un

gomito da 180° sull’estremità dello scarico almeno 61 cm (2 piedi)

oltre il punto più alto dell’edificio. L’apertura sulla parete o sul

tetto devono avere un diametro da 1,3 cm (1⁄2") maggiore di

quello dello scarico. Centrare lo scarico nell’apertura.

Non installare filtri o tappe oltre l’estremità dello scarico.

25

Page 26

ISTRUZIONI D’INSTALLAZIONE – ASCIUGATRICE ELETTRICA

AVVERTENZA

Pericolo di scossa elettrica

L’asciugatrice deve essere messa a terra.

Serrare in modo saldo tutte le connessioni elettriche.

La mancata osservanza di queste precauzioni può

provocare la morte, incendi o scosse elettriche.

Installazione dei piedini di regolazione

NOTA: far scivolare l’asciugatrice su cartone o pannelli prima di

spostarla per evitare di danneggiare il pavimento.

1. Per spostare l’asciugatrice alla posizione di installazione

occorrono due o più persone.

2. Rimuovere il nastro dagli angoli anteriori dell’asciugatrice.

Aprire l’asciugatrice e rimuovere le confezioni contenenti la

documentazione e i componenti. Pulire a fondo la parte

interna del tamburo con un panno umido.

3. Prendere due angoli di cartone della confezione e posizionarli

sul pavimento nella parte posteriore dell’asciugatrice. Afferrare

saldamente il corpo dell’asciugatrice distendendola sulla parte

posteriore sugli angoli di cartone.

4. Reggendo uno dei piedini, controllare le creste cercando il

segno a forma di diamante. È questo il modo in cui il piede

deve entrare nel foro.

5. Cominciare ad avvitare a mano i piedi di regolazione nei fori

(utilizzare una piccola quantità di liquido detergente per

lubrificare le filettature, per rendere più semplice il movimento

di rotazione). Utilizzare una chiave o una chiave a tubo da

25 mm (1") per completare l’avvitamento dei piedi fino a

raggiungere il segno a forma di diamante. Posizionare una

protezione sotto ciascun piede.

Sollevare l’asciugatrice.

6. Rimuovere il cartone o il pannello rigido. Regolare i piedi

dell’asciugatrice verso l’alto o verso il basso fino a quando

l’asciugatrice non è a livello.

Connessione elettrica

Connessione dello scarico

. Utilizzando un morsetto da 102 mm (4"), connettere

1