Page 1

INSTALLER: LEAVE THESE INSTRUCTIONS WITH THE APPLIANCE

INSTALLATION MANUAL

Gas 30²²²² Wide Free-standing

Double Oven Range

PLEASE KEEP THIS MANUAL FOR FUTURE REFERENCE

THE MANUAL IS INTENDED TO ASSIST IN THE INITIAL INSTALLATION AND ADJUSTMENTS OF THE RANGE.

CLEARANCE DIMENSIONS

SPECIAL WARNING

Only qualified personnel should

install or service this range.

Read “Safety Instructions” in the

Use & Care book before using

range.

Range may be installed with zero inches clearance

adjacent to (against) combustible construction at the rear

and on the sides below the cooktop. For complete

information in regard to the installation of wall cabinets

above the range and clearances to combustible wall

above the cook top see the installation drawings. For

SAFETY CONSIDERATIONS do not install a range in any

combustible cabinetry which is not in accord with the

installation drawings.

Improper installation, adjustment,

alteration, service, maintenance or

use of range can result in serious

injury or property damage.

· ALL RANGES CAN TIP AND

CAUSE INJURIES TO

PERSONS.

· INSTALL ANTI-TIP DEVICES

PACKED WITH RANGE.

· FOLLOW ALL INSTALLATION

INSTRUCTIONS.

ENGLISH '''' PP. 1-11

ESPAÑOL '''' pág. 12-22

FRANCAIS '''' p. 23-33

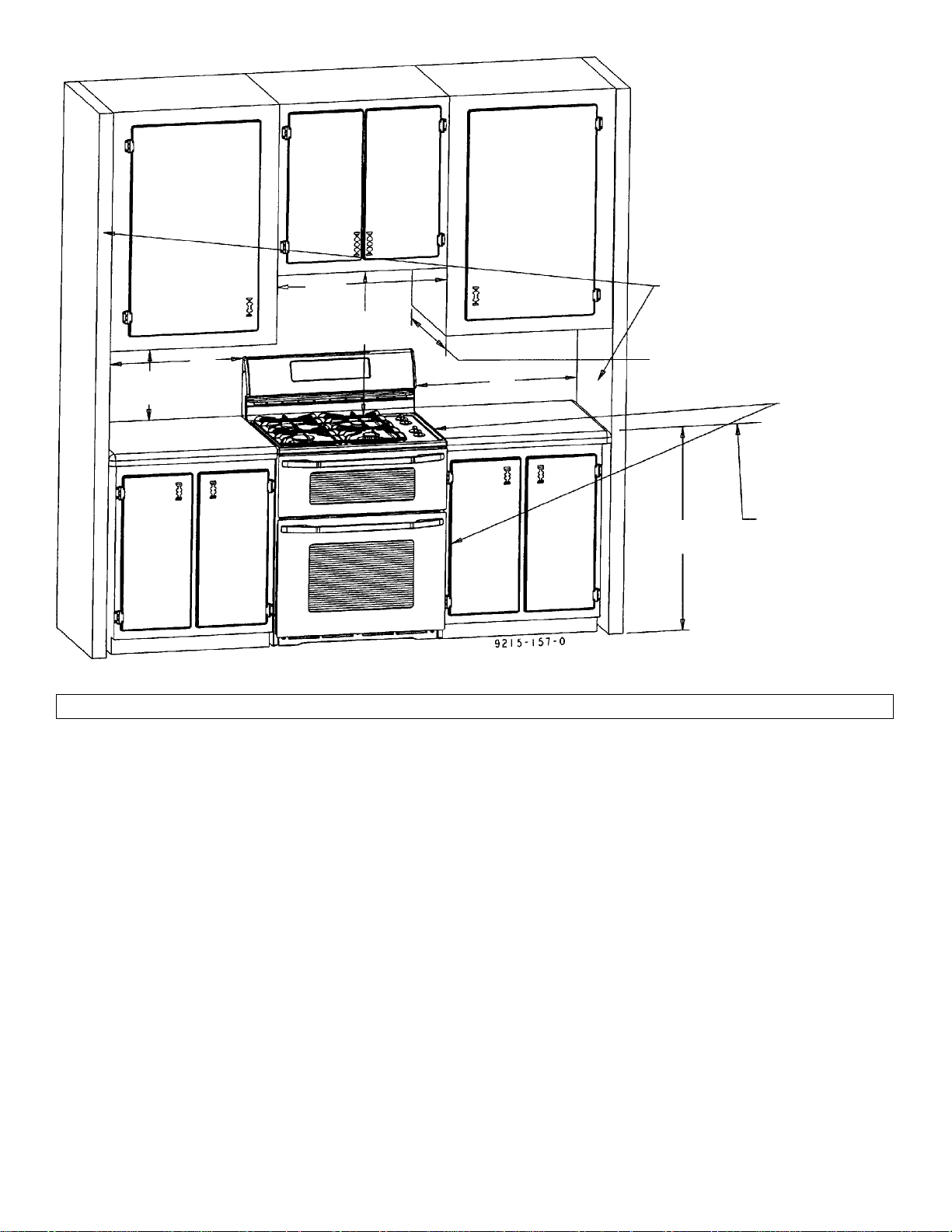

*NOTE: 30 inch (76.2 cm) dimension between cook top

and wall cabinet shown on illustration does not apply to

ranges with an elevated oven or microwave. The 30 inch

(76.2 cm) dimension may be reduced to not less than 24

inches (61 cm) when the wall cabinets in a domestic

home are protected with fireproof materials in accordance

with American National Standards - National Fuel Gas

Code or in mobile homes when they are protected with

fireproof materials in accordance with the Federal

Standard for Mobile Home Construction and Safety.

To eliminate the risk of burns or fire by reaching over

heated surface units, cabinet storage space located

above the surface units should be avoided. If cabinet

storage is to be provided, the risk can be reduced by

installing a range hood that projects horizontally a

minimum of 5 inches (13 cm) beyond the bottom of the

cabinets.

CAUTION: This range has been designed in

accordance with the requirements of various safety

agencies and complies with the maximum allowable

wood cabinet temperatures of 194°F. If this range is

installed with cabinets that have a lower working

temperature than 194°F, discoloration, delamination

or melting may occur.

Your range may not be equipped with some of the features referred to in this manual.

8101P407-60

(05-02-00)

Page 2

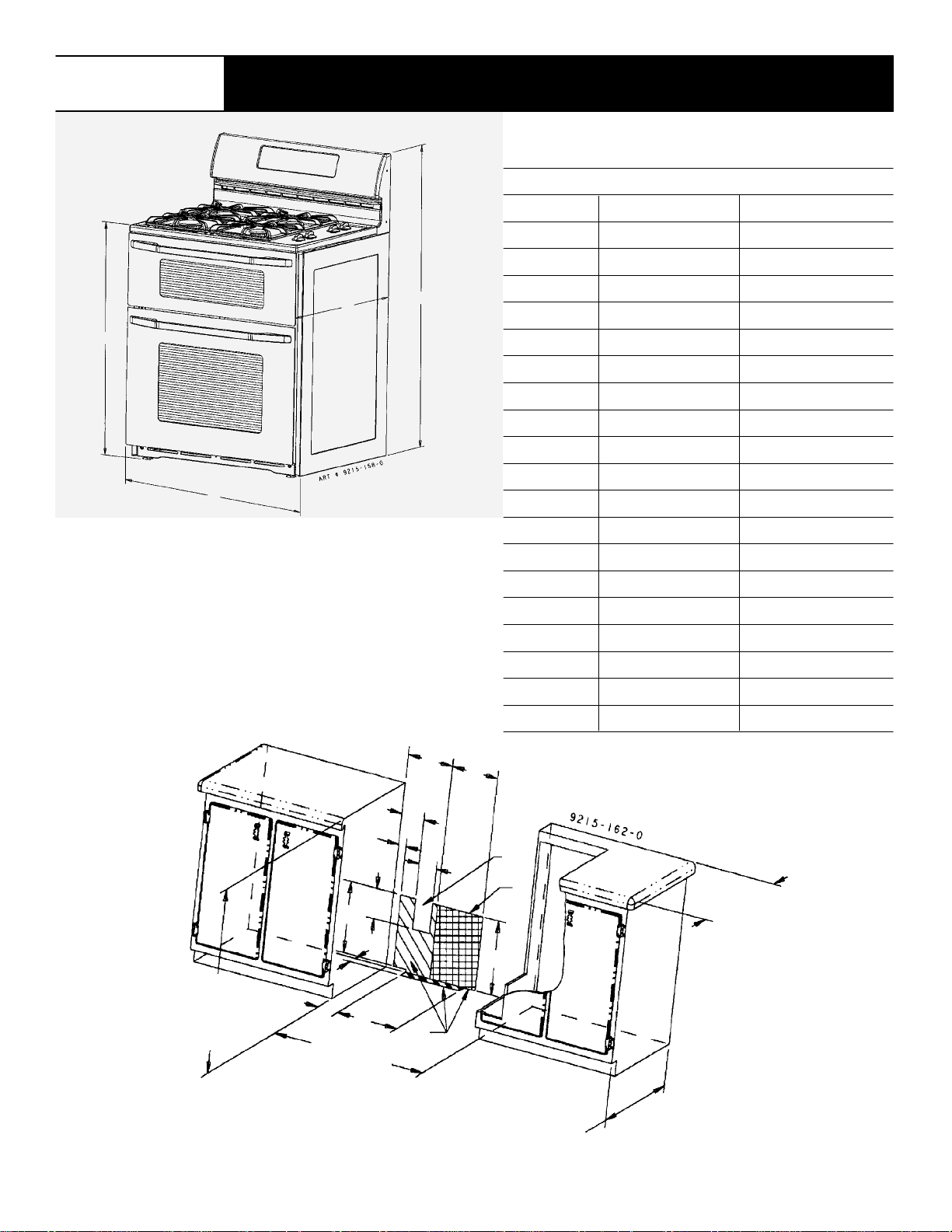

30²

²

²²

FREE-STANDING RANGES

Gemini Double Oven Range

Dimensions

T

U

V

Notes:

1. Provide for a 120 volt grounded electrical outlet in this

area. Outlet MUST be flush.

2. Recommended gas line location.

3. Clearance for pressure regulator.

4. Excluding handle, dimension given is from wall to front

of oven door.

5. May vary slightly depending upon leveling leg

adjustment.

S

JJJJ

A

B

C

D

E

F

G

H

J

K

L

M

N 4 10.2

P 12 30.5

R 14 1/2 36.8

S 46 3/4 118.7

4

T 26 5/16 66.8

5

U 35 7/8 91.1

V 29 7/8 75.9

Inches

25

24

30

36

9

91/4

41/2

11/2

31/2

13

6

2

Centimeters

63.5

61

76.2

91.4

22.9

23.5

11.4

3.8

8.9

33

15.2

5.1

“D”

STANDARD

COUNTER TOP

HEIGHT

K

N

“C”

CABINET

OPENING

P

H

M

E

G

J

L

2

F

3

1

R

“B”

STANDARD CABINET DEPTH

-2-

“A”

STANDARD

COUNTER

TOP DEPTH

Page 3

*(SEE NOTE ON FRONT PAGE)

ANY COMBUSTIBLE SURFACE

13² (33 CM) MAX. DEPTH OF

CABINETS ABOVE COOKTOP

0² (0 CM) CLEARANCE

BETWEEN ADJACENT

COMBUSTIBLE AND

THE BACK AND SIDES

OF THE RANGE

BELOW THE COOKING

SURFACE.

36²

(91.4 CM)

NOTE: COOKTOP

MUST BE FLUSH OR

ABOVE COUNTERTOP

18²

(45.7 CM) MIN.

“A”

30²

(76.2 CM)

(76.2 CM) MIN.

30²

*

“A”

DIMENSION “A” SIDE CLEARANCE ABOVE COOKING SURFACE = 3 INCHES (7.6 CM) (MINIMUM)

Check the range serial plate to see if the range is

approved for installation in mobile homes and/or

recreational park trailers. Serial plate is located on flip-up

plate at rear of upper left hand corner of backguard.

If approved, the following items are applicable:

Mobile Homes

The installation of a range designed for mobile home

installation must conform with the Manufactured Home

Construction and Safety Standard, Title 24 CFR, Part

3280 [formerly the Federal Standard for Mobile Home

Construction and Safety, Title 24 HUD, (Part 280)] or,

when such standard is not applicable, the Standard for

Manufactured Home Installations, ANSI A225.1/NFPA

501A, or with local codes.

In Canada the range must be installed in accordance with

the current CSA Standard C22.1 - Canadian Electrical

Code Part 1 and Section Z240.4.1 - Installation

Requirements for Gas Burning Appliances in Mobile

Homes (CSA Standard CAN/CSA - Z240MH).

Recreational Park Trailers

The installation of a range designed for recreational park

trailers must conform with state or other codes or, in the

absence of such codes, with the Standard for

Recreational Park Trailers, ANSI A119.5-latest edition.

In Canada the range must be installed in accordance with

CAN/CSA - Z240.6.2 - Electrical Requirements for R.V.’s

(CSA Standard CAN/CSA - Z240 RV Series) and Section

Z240.4.2 - Installation Requirements for Propane

Appliances and Equipment in R.V.’s (CSA Standard

CAN/CSA - Z240 RV Series).

Locating The Range

Place range in a well lit area.

Do not set range over holes in the floor or other locations

where it may be subject to strong drafts. Any opening in

the wall behind the range and in the floor under the range

should be sealed. Make sure the flow of cooling/

ventilation air is not obstructed below the range.

NOTE: A range should NOT be installed over kitchen

carpeting.

-3-

Page 4

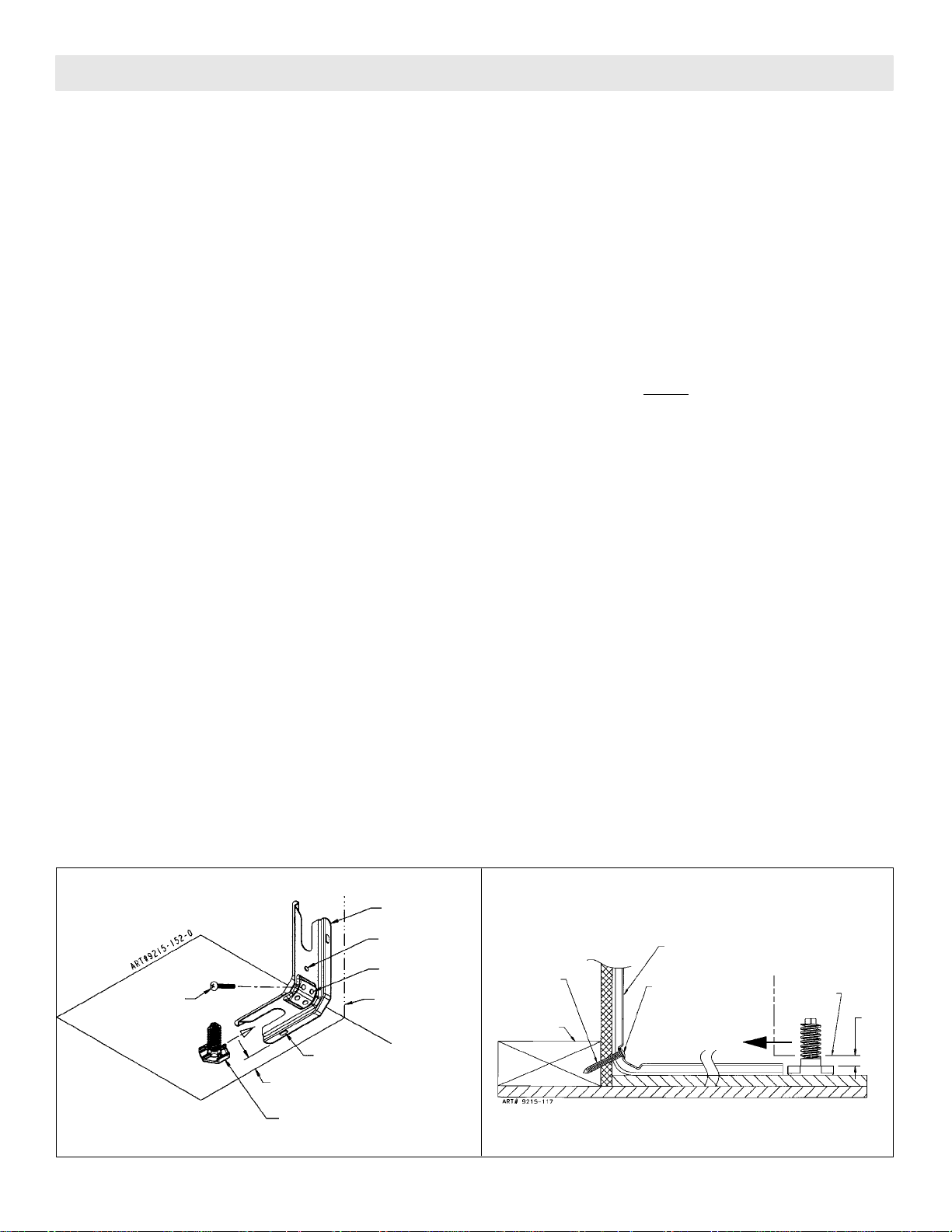

ANTI-TIP DEVICE INSTALLATION INSTRUCTIONS

NOTE: A risk of range tip over exists if the appliance is

not installed in accordance with the provided installation

instructions. The proper use of this device minimizes the

risk of TIP-OVER. In using this device the consumer must

still observe the safety precautions as stated in the USE

and CARE MANUAL and avoid using the oven doors as a

step stool.

Installation instructions are provided for wood and cement

in either floor or wall. Any other type of construction may

require special installation techniques as deemed

necessary to provide adequate fastening of the ANTI-TIP

bracket to the floor or wall. The bracket must be installed

to engage the right rear leveling foot.

STEP 1 - Locating The Bracket (see figure 1)

A. Determine where the right rear “EDGE” of the range

will be located and mark the floor or wall.

B. Place the BRACKET 15/16² (24 mm) from the marked

“EDGE” toward center of opening and against the

back wall as shown in figure 1, with orientation hole

against wall.

C. Use the bracket as a template and mark the required

holes, as shown in figure 1 for the type of construction

you will be using.

STEP 2 - Anti-Tip Bracket Installation

A. Wood Construction:

1. Floor: Locate the center of the two holes identified

in figure 1 as “HOLES FOR FLOOR”. Drill a 1/8²

(3 mm) pilot hole in the center of each hole (a nail

or awl may be used if a drill is not available).

Secure the ANTI-TIP bracket to the floor with the

two screws provided. Proceed to STEP 3.

2. Wall: Locate the center of the two holes identified

in figure 1 as “HOLES FOR WALL. Drill an angled

1/8² (3 mm) pilot hole in the center of each hole

as shown in figure 2. (A nail or awl may be used if

a drill is not available). Secure the ANTI-TIP

bracket to the wall with the two screws provided

as shown in figure 2. Proceed to STEP 3.

B. Cement or Concrete Construction:

1. Suitable screws for concrete construction can be

obtained at a hardware store. Drill the required

size hole for the screws obtained into the

concrete at the center of the holes identified in

figure 1 as “HOLES FOR FLOOR”. Secure the

ANTI-TIP bracket to the floor. Proceed to STEP 3.

STEP 3 - Range Installation

A. For safety considerations as well as optimum

performance, adjust the range so it is level and to

desired height prior to installing in cabinet opening.

NOTE: Cooktop MUST

countertop.

Levelness may be checked by placing a spirit level or

a large pan of water on the cooktop or oven rack.

Adjust the range by tipping it forward or back and

rotate the leveling feet as required.

NOTE: A minimum clearance of 1/4² (6 mm) is

required between the range and the leveling foot that

will engage the anti-tip bracket, (see figure 2).

CAUTION: Damage to the range may occur if range

is moved or lifted by grasping the main top, backguard

or door handles.

B. Align the range to its designated location and prepare

to slide it back into position. Connect gas line and

plug in power cord to outlet following guidelines

outlined in connecting the range and remainder of

installation instructions.

C. Slide range in place visually inspecting to verify that

power cord and gas line are freely routed and

contained within recessed area of back panel.

D. To check the range for proper installation of the

anti-tip bracket, use a flashlight and look underneath

the bottom of the range to see that the right rear

leveling foot is engaged in the bracket slot.

be flush or above

ATTACH ANTI-TIP

BRACKET WITH

(2) LONG SCREWS

15/16² (24 MM) FROM

EDGE OF RANGE

LEVELING FOOT

FIGURE 1

ANTI-TIP BRACKET

ORIENTATION HOLE

HOLES FOR WALL

MARKED EDGE OF

RANGE

HOLES FOR FLOOR

(EACH SIDE)

SCREWS MUST

ENTER WOOD

OR METAL

WALL PLATE

-4-

NOTE: USE A MINIMUM OF (2) SCREWS

TO INSTALL ANTI-TIP BRACKET

TO THE WALL OR FLOOR.

ANTI-TIP

BRACKET

SCREW BRACKET

TO WALL

SLIDE IN TO SECURE

FIGURE 2

RANGE

BOTTOM

1/4²

(6 MM)

MIN.

Page 5

CONNECTING THE RANGE

Electric Supply

The appliance, when installed, must be electrically

grounded in accordance with local codes or, in the

absence of local codes, with the National Electrical Code,

ANSI/NFPA 70.

In Canada the range must be installed in accordance with

the current CSA Standard C22.1 - Canadian Electrical

Code Part 1.

Electrical Supply Connection

The range requires 120 volts, 60 cycle alternating current

from a grounded outlet with a 15 amp circuit breaker. See

serial plate for rating, located on flip-up plate at the rear of

upper left hand corner of backguard.

Electrical Grounding Instructions

This appliance is equipped with a (three-prong)

grounding plug for your protection against shock

hazard and should be plugged directly into a properly

grounded receptacle. Do not cut or remove the

grounding prong from this plug.

Gas Supply

Installation of this range must conform with local codes or,

in the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1-latest edition.

In Canada the range must be installed in accordance with

the current CGA Standard CAN/CGA-B149 - Installation

Codes for Gas Burning Appliances and Equipment and/or

local codes.

NOTE: If oven burners do not ignite, check oven gas

shut-off valve position.

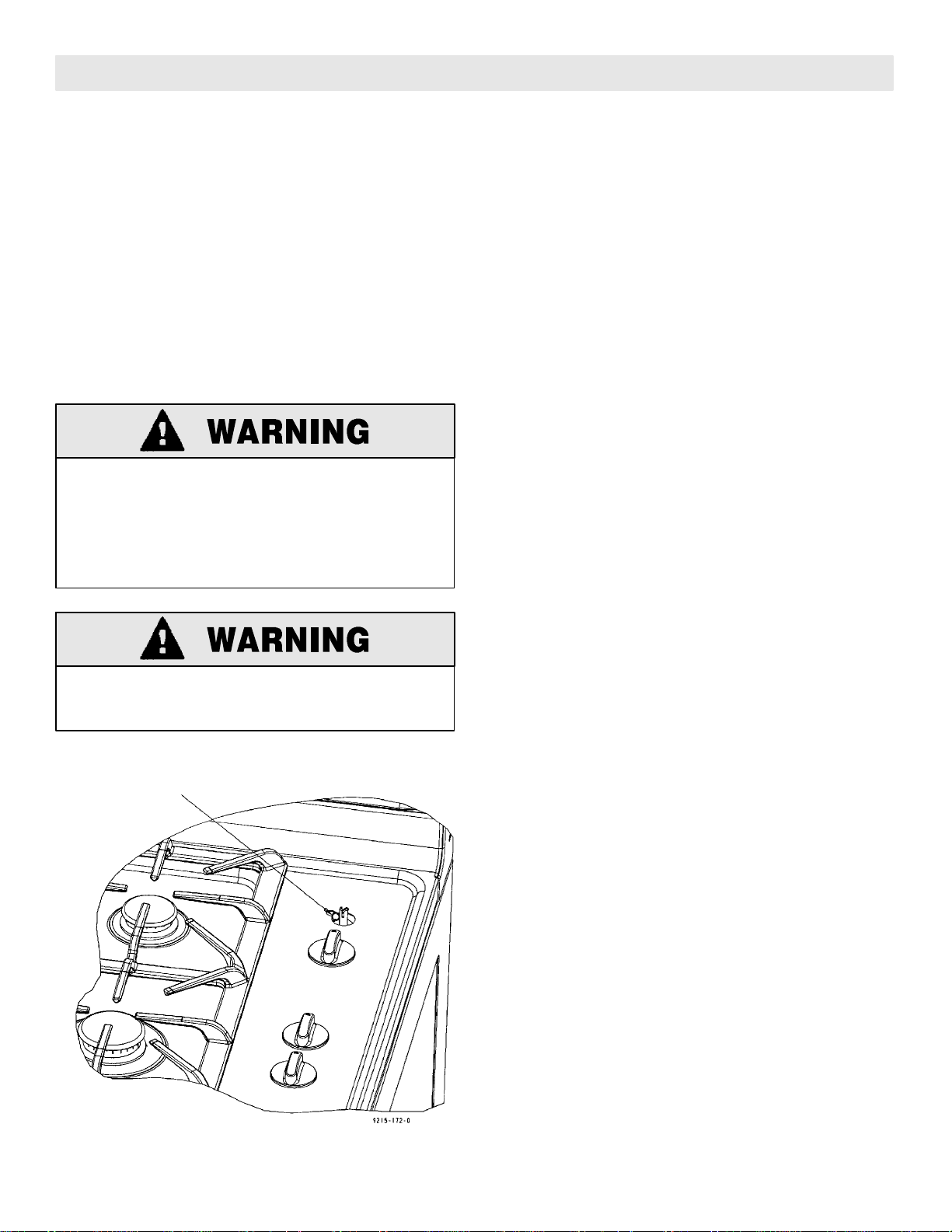

Oven Gas Shut-Off Valve (See figure 3)

1. Remove rear burner knob.

2. Remove spill guard.

3. Rotate to 9:00 position to turn on and 12:00 position to

turn off.

Checking Pressure Of House Piping

System

1. The appliance and its individual shutoff valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 1/2 lbs./sq. in. (3.5 kPa) (13.8 in. water

column).

2. The appliance must be isolated from the gas supply

piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than

1/2 lbs./sq. in. (3.5 kPa) (13.8 in. water column).

DISCONNECT ELECTRICAL SUPPLY

BEFORE SERVICING THE APPLIANCE.

MANIFOLD

SHUT-OFF VALVE

OVEN GAS SHUT-OFF VALVE

FIGURE 3

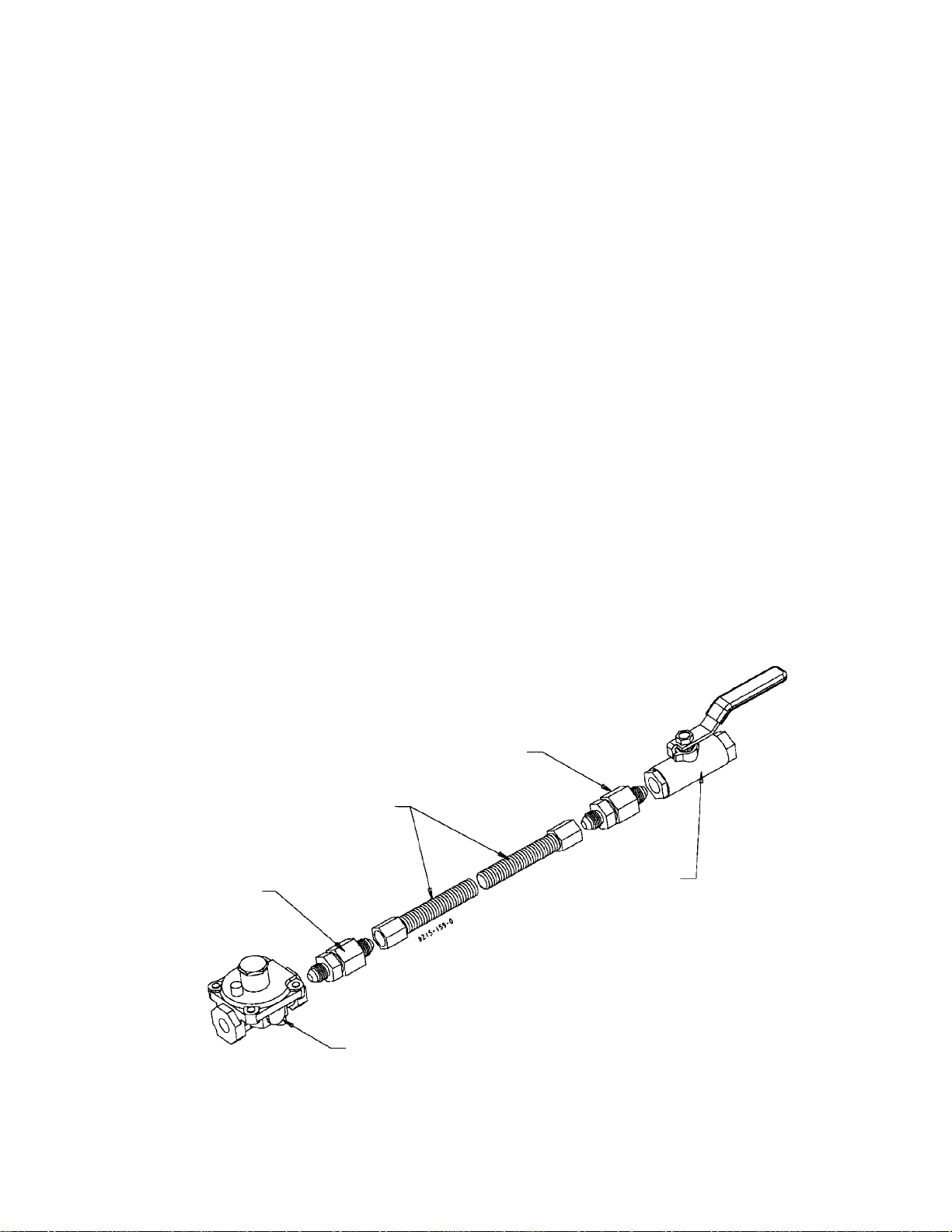

Gas Supply Connection (See figure 4)

A TRAINED SERVICEMAN OR GAS APPLIANCE

INSTALLER MUST MAKE THE GAS SUPPLY

CONNECTION. Leak testing of the appliance shall be

conducted by the installer according to the

instructions given in section h.

NATURAL GAS SUPPLY LINE MUST HAVE A NATURAL

GAS SERVICE REGULATOR. INLET PRESSURE TO

THIS APPLIANCE SHOULD BE REDUCED TO A

MAXIMUM OF 14 INCHES WATER COLUMN (0.5

POUNDS PER SQUARE INCH (P.S.I.) LIQUEFIED

PETROLEUM (L.P.)

MUST HAVE A L.P. GAS PRESSURE REGULATOR.

INLET PRESSURE TO THIS APPLIANCE SHOULD BE

REDUCED TO A MAXIMUM OF 14 INCHES WATER

COLUMN (0.5 P.S.I.). INLET PRESSURES IN EXCESS

OF 0.5 P.S.I. CAN DAMAGE THE APPLIANCE

PRESSURE REGULATOR AND OTHER GAS

COMPONENTS IN THIS APPLIANCE AND CAN

RESULT IN A GAS LEAK.

NOTE: This range is shipped from the factory set for

Natural Gas at 5² water column pressure.

Gas supply pressure for testing regulator must be at

least 1²²²² water column pressure above manifold

pressure shown on serial plate.

/PROPANE GAS SUPPLY LINE

-5-

Page 6

If conversion to LP Gas is required, convert regulator

before installation. Oven/broil and top burner

conversion can be made from front of range.

a. A GAS SHUT-OFF VALVE SHOULD BE PUT IN AN

ACCESSIBLE LOCATION IN THE SUPPLY LINE

AHEAD OF THE RANGE, FOR TURNING ON AND

TURNING OFF GAS SUPPLY. Range is to be

connected to house piping with flexible metal

connectors for gas appliances. CONNECTOR NUTS

MUST NOT BE CONNECTED DIRECTLY TO PIPE

THREADS. THE CONNECTORS MUST BE

INSTALLED WITH ADAPTORS PROVIDED WITH THE

CONNECTOR.

b. The house piping and/or range connector used to

connect the range to the main gas supply must be

clean, free of metal shavings, rust, dirt and liquids (oil

or water). Dirt, etc. in the supply lines can work its way

into the range manifold and in turn cause failure of the

gas valves or controls and clog burners and/or pilot

orifices.

CAUTION: DO NOT LIFT OR MOVE RANGE BY

GRASPING MAIN TOP, DOOR HANDLES, OR

BACKGUARD.

e. Before connecting range, apply pipe thread compound

approved for LPG to all threads.

f. Use only a flexible connector to connect range to gas

supply at appliance pressure regulator using adaptors

supplied with connector. Regulator supplied with range

has 1/2² NPT female connection.

NOTE: It is recommended to use a CSA certified

flexible connector no longer than 36² (91.4cm)witha

minimum BTU/HR rating of 88,200.

See serial plate for type of gas range has been

manufactured for, located on flip-up plate at rear of

upper left hand corner of backguard.

g. Turn on main gas valve at meter, and relight pilots at

other gas appliances.

h. Apply a non-corrosive leak detection fluid to all joints

and fittings in the gas connection between the supply

line shut-off valve and the range. Include gas fittings

and joints in the range if connections were disturbed

during installation. Check for leaks! Bubbles appearing

around fittings and connections will indicate a leak. If a

leak appears, turn off supply line gas shut-off valve,

tighten connections, turn on the supply line gas shut off

valve, and retest for leaks.

c. Turn off all pilots and main gas valve of other gas

appliances.

d. Turn off main gas valve at meter.

FLEXIBLE CONNECTOR

ADAPTOR

CAUTION: NEVER CHECK FOR LEAKS WITH A

FLAME.

WHEN LEAK CHECK IS COMPLETE, WIPE OFF ALL

RESIDUE.

ADAPTOR

SHUT-OFF VALVE

REGULATOR

FIGURE 4

-6-

Page 7

RANGE ADJUSTMENTS

Top Section - Electric Ignition

To operate, push and turn top burner knob to the LITE

position. The top burner will light. To turn OFF spark after

the top burner has ignited turn knob to HI setting.

NOTE: Top burners are not adjustable.

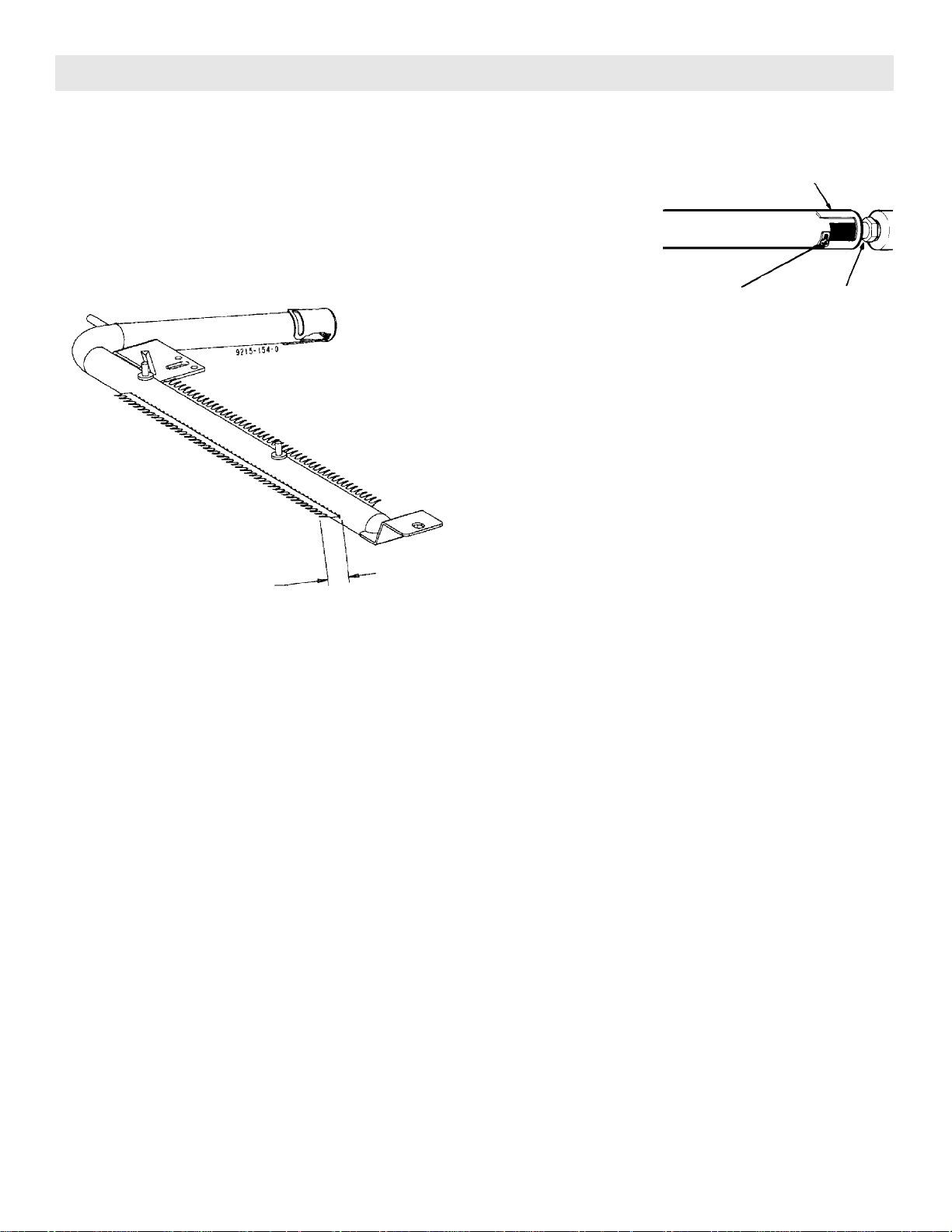

Air Shutter - Oven and Broil Burner

a. The approximate length of the flame of oven burner is a

1/2 (12.7 mm) inch distinct inner blue flame, figure 5.

b. Oven/Broil Burner flame can be checked as follows:

1. Yellow flame on

burner - open

burner air shutter

to the widest

9215-153-0

AIR SHUTTER

2

opening that will

not cause the

flame to lift or blow

off the burner

when cold. (See

#2 on figure 6).

2. Distinct blue flame

3

LOCK

SCREW

1

ORIFICE

HOOD

FIGURE 6

but lifting - close burner

air shutter to the point where it will not cause the

flame to lift orblow off the burner when cold. (See #2

on figure 6).

1/2² (12.7 mm) FLAME

INNER CONE

FIGURE 5

-7-

Page 8

GAS CONVERSION

General

This range is equipped with double coaxial (universal)

orifices on bake and broil burners, a convertible appliance

pressure regulator and replaceable top burner orifices.

The unit serial plate states which gas it was adjusted for

at the factory. To convert the unit to either Natural gas or

LP gas will require adjustment of the oven orifice hoods,

air shutters on the oven burners, replacement of top

burner orifices and adjustment of the appliance pressure

regulator converter cap.

natural gas, the appliance pressure regulator must be

converted to regulate natural gas.

Follow the instructions below to convert the regulator for

use with LP gas. (This appliance is shipped from the

factory adjusted for use with natural gas.)

1. Unscrew the hex shaped cap from the neck of the

regulator. (A wrench may be required to loosen the

cap.)

Inlet pressure to the appliance pressure regulator should

be as follows for both operation and checking of appliance

pressure regulator setting:

INLET PRESSURE IN NATURAL LP

INCHES OF WATER COLUMN

GAS GAS

Minimum 6 11

Maximum 14 14

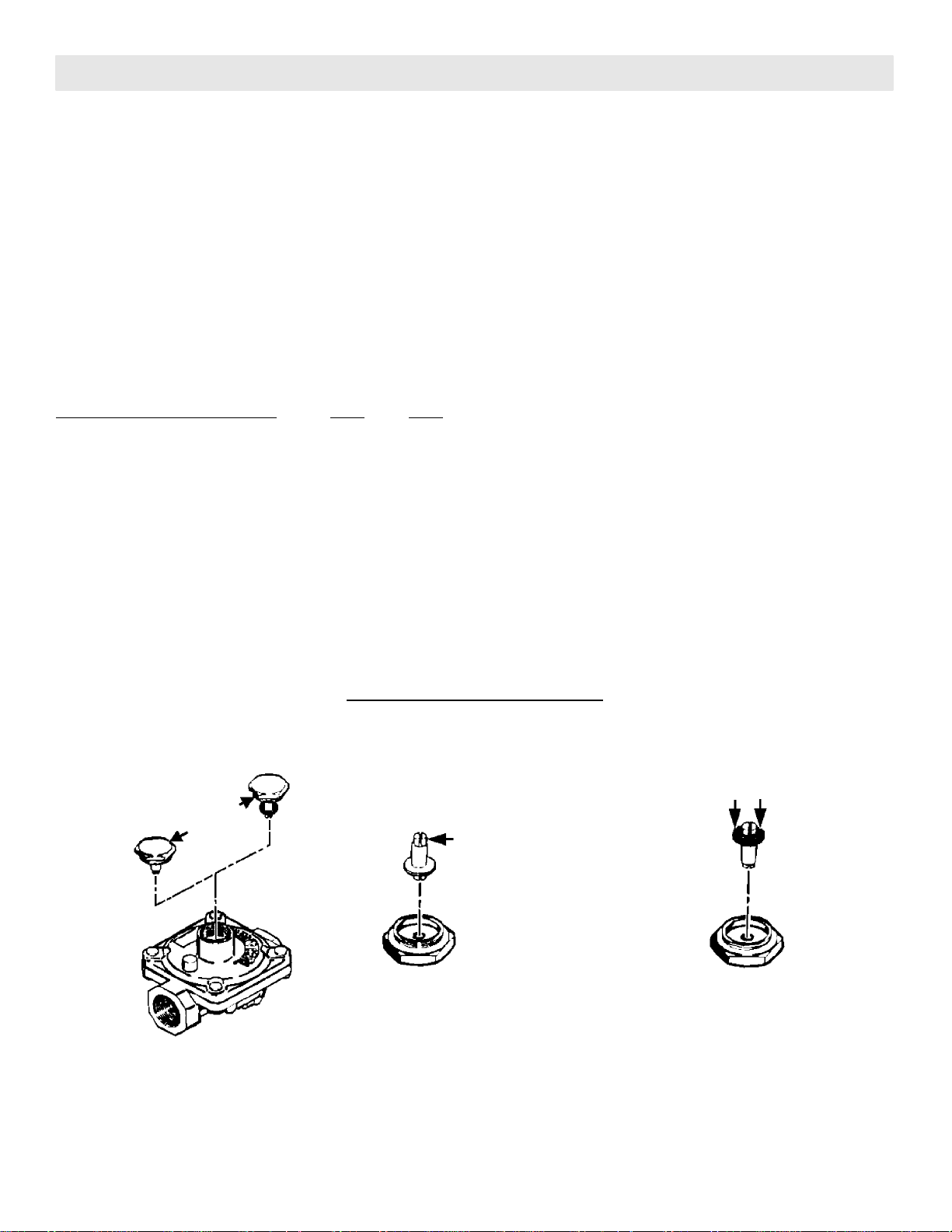

Appliance Pressure Regulator Conversion

(See figure 7)

The unit appliance pressure regulator must be set to

match the type gas supply used. If converting from natural

gas to LP gas, the appliance pressure regulator must be

converted to regulate LP gas. If converting from LP gas to

MAXITROL REGULATOR

LP

CONVERTER

CAP AND PIN

NAT

NAT

2. Within the cap is a plastic pin. Remove this pin from the

cap by applying sideward pressure to the pin. (See

illustration.)

3. Invert the pin and snap it back into place within the cap

by applying even finger pressure at opposing edges of

the pin’s circular disc. The pin must be seated firmly

and squarely in the cap.

Pin replacement may be most easily accomplished by

placing the cap on a flat horizontal surface, as shown in

the illustration, and applying downward finger pressure

at the edges of the pin’s disc.

4. Screw the cap securely back into place in the neck of

the pressure regulator. (The cap need not be

wrench-tightened upon replacement. Firm finger

tightening will secure the cap.)

APPLY DOWNWARD FINGER

PRESSURE AT DISC EDGES

TO REPLACE PIN IN CAP

APPLY SIDEWARD

FINGER PRESSURE

TO REMOVE PIN

FROM CAP

LP

FIGURE 7

-8-

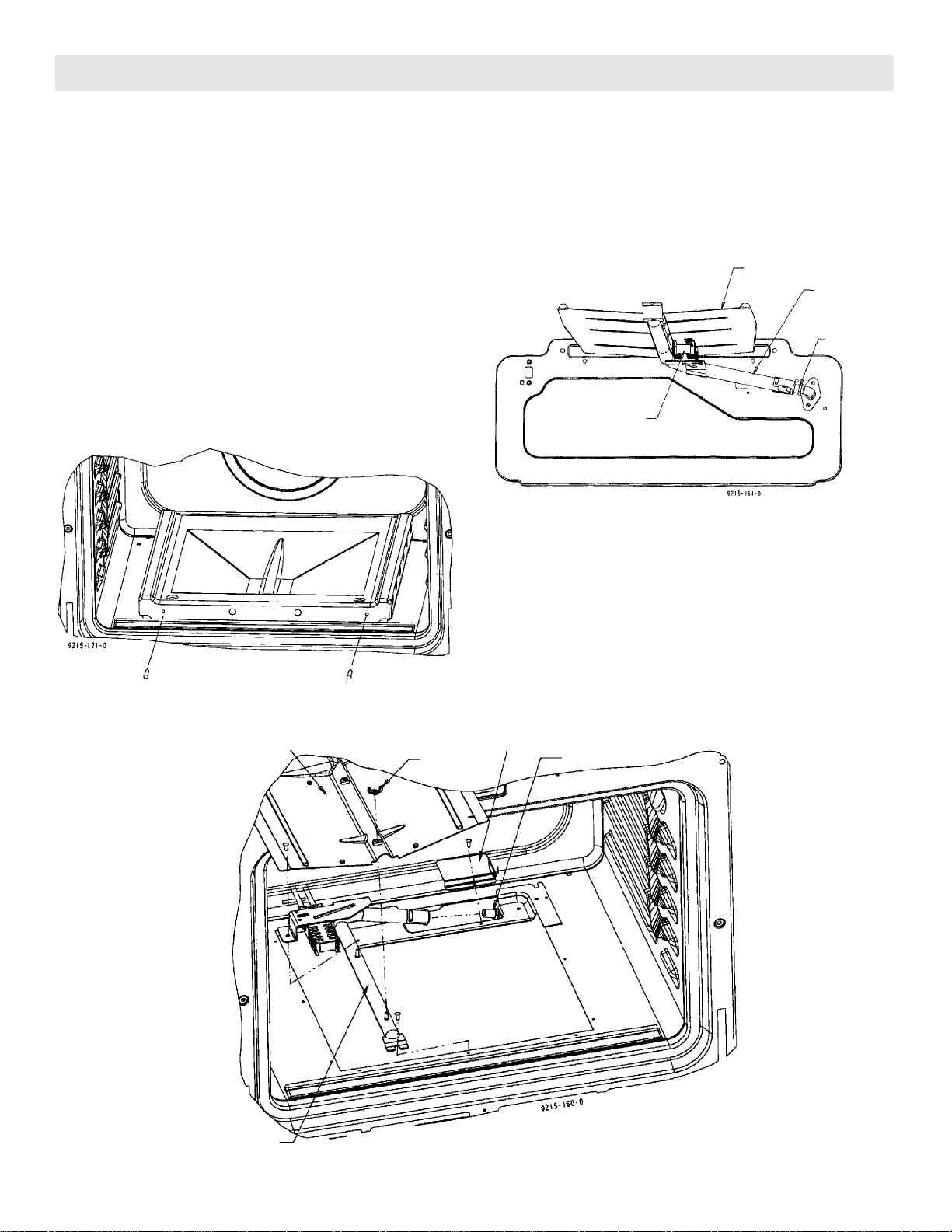

Page 9

BAKE AND BROIL BURNERS TO LP/PROPANE GAS

To convert Bake Burner Orifice (upper and lower):

Remove both oven doors and follow these steps: (See

figures 8A & 8B).

a. Remove oven bottom by taking out two screws at front.

(8A)

b. Remove oven baffle by taking off wing nuts. (8B)

c. Remove front and rear screws from oven burner and

remove burner. (8B) Be careful not to damage ignitor.

d. Remove the cover over the orifice by taking out one

screw. (8B)

e. Usea1/2² (12.7 mm) socket wrench to turn the orifice

hood clockwise (down) approximately 2 to 2 1/2 turns

until it bottoms out on the pin.

CAUTION: Use care to not over tighten.

f. Re-assemble parts.

To convert Broil Burner Orifice: (Figure 8C)

Located in right rear corner of top oven only, use a 1/2²

(12.7 mm) open end wrench to turn the orifice hood

clockwise (down) approximately 2 to 2 1/2 turns until it

bottoms out on the pin.

CAUTION: Use care to not over tighten.

SHIELD

BURNER

ORIFICE

HOOD

IGNITOR

Figure 8C

Broil Burner Orifice

Figure 8A

Bake Burner Orifice

BAFFLE

WING NUT

COVER

ORIFICE HOOD

BURNER

Figure 8B

-9-

Page 10

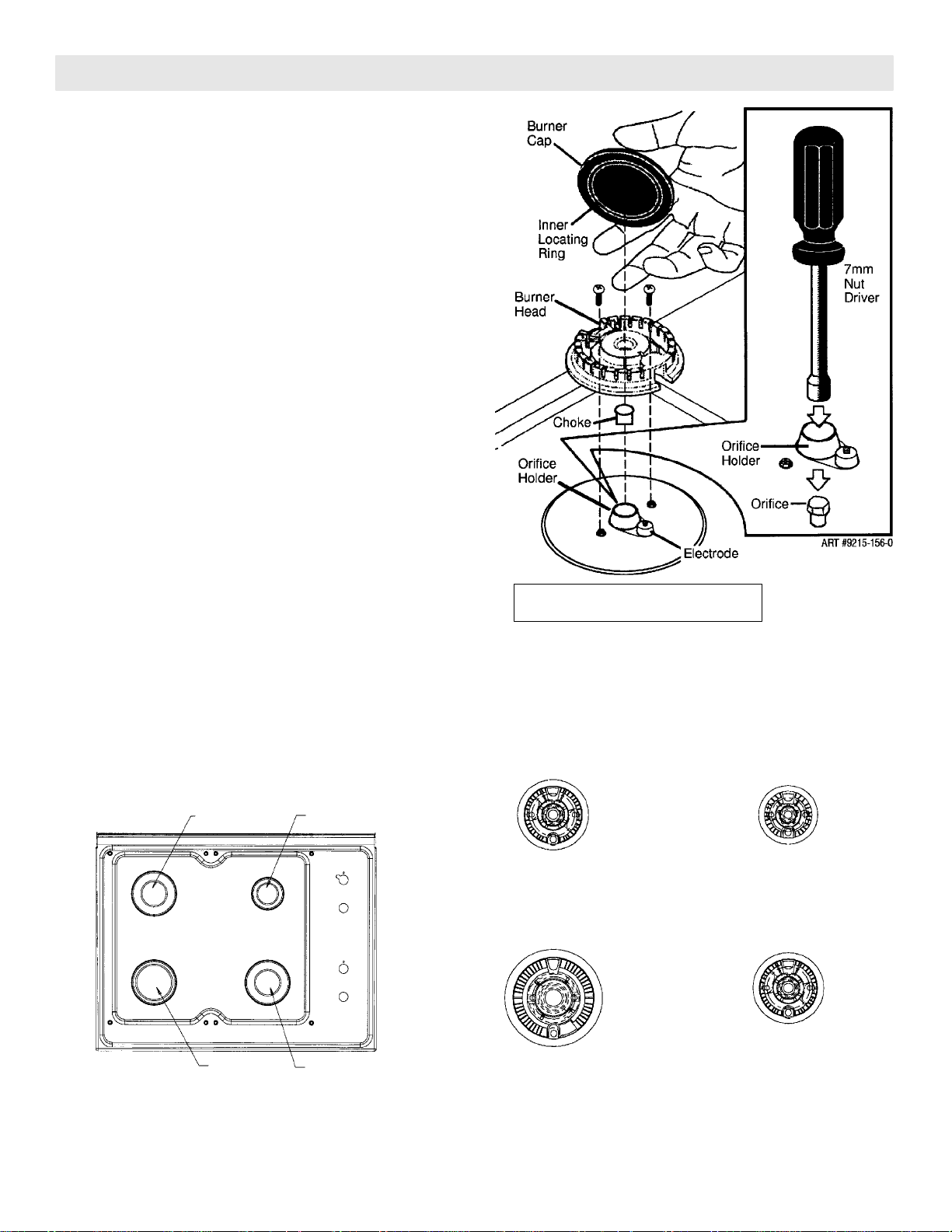

SURFACE BURNERS TO LP/PROPANE GAS

CAUTION: This cooktop is not removable. Do not attempt

to remove this cooktop. Save the natural gas orifices

removed from the appliance for possible future conversion

to natural gas.

For All Burner Locations:

a. Remove the top grates and burner caps.

b. Remove the burner head by removing two screws.

(See figure 9). NOTE: Convert one burner at a time to

avoid incorrect installation.

c. IMPORTANT: Replace these two screws after

removing burner head. The screws will secure orifice

holder and avoid damage to electrode or tubing while

changing orifice.

d. Remove the four factory installed natural gas orifices

from the center of the orifice holders using a 7mm nut

driver (see figure 9). Remember to keep the original

natural gas orifices for later conversion to natural gas.

e. Replace the orifice in each of the four orifice holders

with the correct LP/propane gas orifice (see figure 10).

IMPORTANT: Make sure orifice is securedin nut driver

before attempting to replace orifice. Tighten each orifice

until snug. Use caution not to over tighten.

f. Remove screws when orifice change is complete, and

remount burner heads.

MPORTANT: Choke must be added to left front

I

orifice holder only, as shown in figure 9.

g. Replace the burner caps and grates using caution

when replacing each burner cap so that electrode is not

damaged.

Surface Burner Configuration

9.2K NO COLOR

5K BLUE

IMPORTANT: Choke must be added

to left front orifice holder only.

Figure 9

NATURAL GAS ORIFICE TO LP ORIFICE CONVERSION

FOR EACH TYPE OF BURNER

9,200 BTU NATURAL GAS

CONVERTS TO 9,100 BTU LP GAS

INSTALL ORIFICE (NO COLOR)

.90 MM FOR LP

5,000 BTU NATURAL GAS

CONVERTS TO 4,000 BTU LP GAS

INSTALL (BLUE) ORIFICE

.64 MM FOR LP

ART# 9215-163-0

16K RED

FRONTOFTOP

1 BLUE ORIFICE

2 NO COLOR ORIFICES

1 RED ORIFICE

9.2K NO COLOR

16,000 BTU NATURAL GAS

CONVERTS TO 14,000 BTU LP GAS

INSTALL (RED) ORIFICE

1.14 MM FOR LP

-10-

ART# 9215-155-0

9,200 BTU NATURAL GAS

CONVERTS TO 9,100 BTU LP GAS

INSTALL ORIFICE (NO COLOR)

.90 MM FOR LP

Figure 10

Page 11

HOW TO REMOVE RANGE FOR SERVICING

Follow these procedures to remove appliance for

servicing:

1. Slide range forward to disengage range from the

anti-tip bracket.

2. Shut off gas supply to appliance.

3. Disconnect electrical supply to appliance, if equipped.

4. Disconnect gas supply tubing to appliance.

5. Reverse procedure to reinstall. If gas line has been

disconnected, check for gas leaks after reconnection.

NOTE: A qualified servicer should disconnect and

reconnect the gas supply.

The servicer MUST follow installation instructions

provided with the gas appliance connector and the

warning label attached to the connector.

6. To prevent range from accidentally tipping, range must

be secured to the floor by sliding rear leveling leg into

the anti-tipbracket.

SERVICE-PARTS INFORMATION

When your range requires service or replacement parts,

contact your dealer or authorized service agency. Please

give the complete model and serial number of the range

which is located on flip-up plate at the rear of upper left

hand corner of backguard.

-11-

Page 12

INSTALADOR: DEJE ESTAS INSTRUCCIONES CON EL ELECTRODOMÉSTICO

MANUAL DE INSTALACIÓN

Estufa individual de gas de

horno doble de 30²²²² de ancho

CONSERVE ESTE MANUAL PARA REFERENCIA FUTURA

EL MANUAL TIENE LA FINALIDAD DE AYUDARLE EN LA INSTALACIÓN Y LOS AJUSTES DE LA ESTUFA.

ADVERTENCIA ESPECIAL

Solamente el personal calificado

deberá instalar o prestar servicio a

esta estufa.

Lea las “Instrucciones de seguridad”

en el libro de Uso y cuidado antes de

usar la estufa.

La instalación, el ajuste, la alteración,

el servicio de mantenimiento o el uso

incorrectos de la estufa pueden

causar lesiones graves o daños

materiales.

ADVERTENCIA

· TODAS LAS ESTUFAS PUEDEN

LADEARSE Y CAUSAR LESIONES

A LAS PERSONAS.

· INSTALE LOS SOPORTES

EST ABILZADORES QUE SE

INCLUYEN CON LA ESTUFA.

· SIGA TODAS LAS INSTRUCCIONES

DE INST ALACIÓN.

ENGLISH '''' PP. 1-11

ESPAÑOL '''' pág. 12-22

FRANCAIS '''' p. 23-33

DIMENSIONES DEL HUECO

La estufa puede instalarse con cero pulgadas de espacio

adyacente (contra) la construcción combustible en la parte

trasera y lateral debajo de la superficie para cocinar. Para

obtener la información completa relacionada con la

instalación de los gabinetes de pared colocados encima de

la estufa y los espacios a las paredes combustibles encima

de la superficiepara cocinar, vea los dibujos de instalación.

Por RAZONES DE SEGURIDAD no instale la estufa en

ningún tipo de gabinetes combustibles que no estén en

conformidad con los dibujos de instalación.

*NOTA: La dimensión de 30 pulgadas (76.2 cm) entre la

superficie para cocinar y el gabinete de pared en la

ilustración no corresponde a las estufas con el horno

elevado o de microondas. La medida de 30 pulgadas

(76.2 cm) puede reducirse a no menos de 24 pulgadas

(61 cm) cuando los gabinetes de pared en una casa están

protegidos con materiales a prueba de incendios en

conformidad con las Normas Nacionales Estadounidenses,

los Códigos Nacionales de Gas Combustible o en cas as

móviles, cuando estén protegidas con materiales a prueba

de incendios en conformidad con las Normas Federales

para la Construcción y Seguridad de Casas Móviles.

Para eliminar el riesgo de quemaduras o incendios al tratar

de alcanzar artículos por encima de las unidades calientes

de la superficie, debe evitarse el almacenaje de artículos

en los gabinetes ubicados por encima de las unidades de

la superficie. Si se proporciona un espacio de almacenaje,

puede reducirse el riesgo instalando una campana de

estufa que sobresalga horizontalmente cuando menos

5 pulgadas (13 cm) más allá del fondo de los gabinetes.

PRECAUCIÓN: Esta estufa ha sido diseñada de

acuerdo con los requisitos de varias agenc ias de

seguridad y cumple con las temperaturas máximas

permitidas para madera de 194°F. Si la estufa se

instala con gabinetes que tienen una temperatura de

trabajo menor de 194°F, podría ocurrir decoloración,

delaminación o derretimiento.

Es posible que su estufa no esté equipada con algunas de las características mencionadas en este manual.

Page 13

DE 30²

²

²²

ESTUFAS INDIVIDUALES

Estufa Gemini con horno doble

Dimensiones

T

U

V

Notas:

1. En esta área provea un tomacorriente eléctrico de 120

voltios conectado a tierra. El tomacorriente DEBE estar

al ras.

2. Ubicación recomendada para la tubería de gas.

3. Espacio libre para el regulador de presión.

4. Con excepción del asa, las dimensiones

proporcionadas son de la pared a la parte delantera de

la puerta del horno.

5. Podría variar levemente dependiendo del ajuste de la

pata niveladora.

S

E

JJJJ

A

B

C

D

E

F

G

H

J

K

L

M

N 4 10.2

P 12 30.5

R 14 1/2 36.8

S 46 3/4 118.7

4

T 26 5/16 66.8

5

U 35 7/8 91.1

V 29 7/8 75.9

F

Pulgadas

25

24

30

36

9

91/4

41/2

11/2

31/2

13

6

2

Centímetros

63.5

61

76.2

91.4

22.9

23.5

11.4

3.8

8.9

33

15.2

5.1

“D”

ALTURA ESTÁNDAR

ALAPARTE

SUPERIOR DEL

MOSTRADOR

H

K

M

N

P

“C”

ABERTURA

DEL

GABINETE

G

J

L

2

PROFUNDIDAD ESTÁNDAR DEL GABINETE

3

1

R

“B”

-13-

“A”

PROFUNDIDAD

ESTÁNDAR

DEL MOSTRADOR

Page 14

*(VEA LA NOTA EN LA PRIMERA PÁGINA)

18²

(45.7 CM) MÍN.

“A”

30²

(76.2 CM)

(76.2 CM) MÍN.

30²

*

“A”

CUALQUIER SUPERFICIE COMBUSTIBLE

13² (33 CM) PROFUNDIDAD MÁXIMA

DE LOS GABINETES POR ENCIMA

DE LA SUPERFICIE PARA COCINAR

0² (0 CM) DE ESPACIO

LIBRE ENTRE LA

PARTE ADYACENTE

COMBUSTIBLE Y LA

PARTE POSTERIOR Y

LOS LADOS DE LA

ESTUFA DEBAJO DE

LA SUPERFICIE PARA

COCINAR.

36²

(91.4 CM)

NOTA: LA SUPERFICIE

PARA COCINAR DEBE

ESTAR AL RAS O POR

ENCIMA DEL

MOSTRADOR

LA DIMENSIÓN “A” ES EL ESPACIO LIBRE LATERAL ENCIMA DE LA SUPERFICIE PARA COCINAR =

3 PULGADAS (7.6 CM) (MÍNIMO)

Revise la placa del número de serie y vea si la estufa está

aprobada para instalarse en casas móviles y vehículos de

recreación. Esta placa se encuentra ubicada en la placa

abatible en la esquina superior izquierda de la parte posterior

del protector.

Si está aprobada, se aplicarán los siguientes puntos:

Casas móviles

La instalación de una estufa diseñada para casas móviles

debe estar en conformidad con las Normas de Seguridad y

Construcción de Casas Prefabricadas (Manufactured Home

Construction and Safety Standard), Título 24 CFR, Parte

3280 [anteriormente Federal Standard for Mobile Home

Construction and Safety, Title 24 HUD, (Part 280)] o, cuando

dichas normas no correspondan, con las Normas para

Instalaciones en Casas Prefabricadas (Standard for

Manufactured Home Installations), ANSI A225.1/NFPA 501A,

o con los códigos locales.

En Canadá la estufa debe instalarse de acuerdo con las

Normas CSA C22.1 actuales, Código Eléctrico Canadiense,

Parte 1 y la Sección Z240.4.1 (Canadian Electrical Code),

Requisitos de instalación para aparatos que queman gas

(Installation Requirements for Gas Burning Appliances in

Mobile Homes) en casas móviles (CSA Standard CAN/CSA Z240MH).

Vehículos para parques de

recreación

La instalación de una estufa diseñada para vehículos

recreativos debe estar en conformidad con los códigos

estatalesuotroso,encasodenoexistir,conlasNormas

para Vehículos Recreativos (Standard for Recreational Park

Trailers), ANSI A119.5-última edición.

En Canadá la estufa debe instalarse en conformidad con los

Requisitos Eléctricos para Vehículos Recreativos (Electrical

Requirements for R.V.’s) (CSA Standard CAN/CSA - Z240

RV Series) CAN/CSA — Z240.6.2 — y la Sección Z240.4.2 —

Requisitos de Instalación para aparatos y equipo de gas

propano en vehículos recreativos (Installation Requirements

for Propane Appliances and Equipment in R.V.’s) (CSA

Standard CAN/CSA - Z240RV Series).

Ubicación de la estufa

Coloque la estufa en un área bien iluminada.

No coloque la estufa sobre agujeros del piso ni en otros

lugares en donde podría estar sujeta a ráfagas de viento

fuertes. Deberán sellarse los orificios en la pared detrás de

laestufayenelpisodebajodelamisma.Asegúresedeque

no estén obstruidos el flujo de combustión ni el de

ventilación.

NOTA: NO debe instalarse una estufa sobre alfombras de

cocina.

-14-

Page 15

INSTRUCCIONES DE INSTALACIÓN DEL DISPOSITIVO ESTABILIZADOR

NOTA: Existe la posibilidad de que la estufa se ladee si no

está instalada de acuerdo con las instrucciones de

instalación que se proporcionan. El uso correcto de este

dispositivo reduce el riesgo de LADEO. Al usar este

dispositivo el consumidor aún debe seguir las precauciones

de seguridad que se dictan en el MANUAL DE USO Y

CUIDADO y debe evitar utilizar las puertas del horno como

banquillo.

Las instrucciones de instalación se proporcionan para las

construcciones de madera y cemento tanto en piso como en

pared. Cualquier otro tipo de construcción podría necesitar

técnicas especiales de instalación según se determine

necesario para proporcionar la sujeción adecuada del

soporte ESTABILIZADOR al piso o a la pared. El soporte

debe instalarse para que enganche la pata niveladora del

lado derecho.

PASO 1 — Ubicación del soporte (vea la figura 1)

A. Determine en dónde se ubicará el “BORDE” derecho

posterior de la estufa y marque el piso o la pared.

B. Coloque el SOPORTE a 15/16² (24 mm) del “BORDE”

marcado hacia el centro de la abertura y contra la pared

posterior según se muestra en la figura 1, con el orificio

de orientación hacia la pared.

C. Use el soporte como plantilla y marque los orificios

necesarios, según se muestra en la figura 1, para el tipo

de construcción que se utilizará.

PASO 2 - Instalación del soporte e stabilizador

A. Construcción de madera:

1. Piso: Ubique el centro de los dos orificios que se

identifican en la figura 1 como “ORIFICIOS PARA

EL PISO”. Taladre un agujero piloto de 1/8² (3 mm)

en el centro de cada orificio (puede utilizarse un

clavo o una lezna si no tiene una broca). Asegure el

soporte ESTABILIZADOR al piso con los dos

tornillos que se adjuntan. Continúe con el PASO 3.

2. Pared: Ubique el centro de los dos orificios que se

identifican en la figura 1 como “ORIFICIOS PARA

LA PARED”. Taladre un agujero piloto en ángulo, de

1/8² (3 mm) en el centro de cada orificio según se

muestra en la figura 2. (Puede utilizarse un clavo o

una lezna si no tiene una broca). Asegure el soporte

ESTABILIZADOR a la pared con los dos tornillos

que se adjuntan según se muestra en la figura 2.

Continúe con el PASO 3.

B. Construcción de cemento o concreto:

1. En una ferretería pueden obtenerse los tornillos

adecuados para las construcciones de concreto.

Taladre un agujero del tamaño necesario para los

tornillos que se tengan, en el concreto en el centro

de los orificios que se identifican en la figura 1 como

“ORIFICIOS PARA EL PISO”. Asegure el soporte al

piso. Continúe con el PASO 3.

PASO 3 — Instalación de la estufa

A. Por consideraciones de seguridad así como para

obtener el mayor rendimiento, ajuste la estufa de

manera que esté bien nivelada y a la altura deseada

antes de instalarla en la abertura del gabinete.

NOTA: La superficie para cocinar DEBE estar al ras

o por encima del mostrador.

La nivelación puede verificarse colocando un nivel de

burbuja o un recipiente grande con agua en la superficie

para cocinar o en la parrilla del horno. Ajuste la estufa

ladeándola hacia adelante o atrás y girando las patas

niveladoras según sea necesario.

NOTA: Se requiere un espacio libre de cuando menos

1/4² (6 mm) entre la estufa y la pata niveladora que se

enganchará al soporte estabilizador, (vea la figura 2).

PRECAUCIÓN: Pueden ocurrir daños a la estufa si ésta

se mueve o levanta sujetándola por la superficie

principal, por el protector o por las asas de la puerta.

B. Alinee la estufa en la ubicación deseada y prepárela

para deslizarla hacia atrás en su lugar. Conecte la

tubería de gas y conecte el cordón eléctrico en el

tomacorriente siguiendo las directrices indicadas en la

conexión de la estufa y el resto de las instrucciones de

instalación.

C. Deslice la estufa en su lugar inspeccionándola

visualmente para verificar que el cordón eléctrico y la

tubería de gas estén dirigidos libremente y contenidos

dentro del área ahuecada del panel posterior.

D. Para revisar que el soporte estabilizador de la estufa

esté instalado correctamente, use una linterna y vea por

debajo de la parte inferior de la estufa para comprobar

que la pata de nivelación posterior derecha esté

enganchada en la ranura del soporte.

FIJE EL

SOPORTE

ESTABILIZADOR

CON

DOS (2)

TORNILLOS

LARGOS

NOTA: USE CUANDO MENOS DOS (2)

SOPORTE

ESTABILIZADOR

ORIFICIO DE

ORIENTACIÓN

ORIFICIOS PARA

LA PARED

BORDE MARCADO

DE LA ESTUFA

ORIFICIOS PARA EL PISO

(A CADA LADO)

15/16² (24 MM) DEL BORDE

DE LA ESTUFA

PATA NIVELADORA

TORNILLOS PARA INSTALAR EL SOPORTE

ESTABILIZADOR A LA PARED O AL PISO.

LOS TORNILLOS

DEBEN ENTRAR

EN METAL O

MADERA

PLACA DE LA

PARED

SOPORTE

ESTABILIZADOR

ATORNILLE EL SOPORTE

ALAPARED

DESLÍCELA PARA

ASEGURARLA

FIGURA 1 FIGURA 2

-15-

PARTE

INFERIOR

DE LA

ESTUFA

1/4²

(6 MM)

MÍN.

Page 16

CONEXIÓN DE LA ESTUFA

Suministro eléctrico

El electrodoméstico, cuando se instala, debe estar

conectado a tierra de acuerdo con los códigos locales o, en

la ausencia de ellos, con los Códigos Eléctricos Nacionales,

ANSI/NFPA 70.

En Canadá la estufa debe instalarse de acuerdo con las

Normas CSA C22.1, parte 1 actuales (Canadian Electrical

Code Part 1).

Conexión del suministro eléctrico

La estufa requiere una corriente alterna de 60 ciclos,

120 voltios del tomacorriente con un cortacircuitos de

15 amperios. Vea la placa de datos para saber la

clasificación, la placa está ubicada en la placa abatible, en la

esquina superior izquierda de la parte posterior del protector.

ADVERTENCIA

Instrucciones de la c onexión eléctrica a tierra

Este electrodoméstico está equipado con una clavija de

tres puntas conectada a tierra para brindarle protección

contra peligros de descargas eléctricas y deberá

conectarse directamente en un tomacorriente conectado

a tierra. No corte ni quite la punta de tierra de esta

clavija.

ADVERTENCIA

DESCONECTE EL SUMINISTRO ELÉCTRICO

ANTES DE REALIZAR SERVICIO EN ESTE

ELECTRODOMÉSTICO.

VÁLVULA DE CIERRE

DEL MÚLTIPLE

Suministro de gas

La instalación de esta estufa debe estar en conformidad con

los códigos locales o en ausencia de ellos, con el Código

Nacional de Gas Combustible, ANSI Z223.1, última edición.

En Canadá debe instalarse en conformidad con las Normas

CGA CAN/CGA-B149 actuales y con los Códigos de

Instalación para Aparatos y Equipos de Gas Combustible y/o

con los códigos locales.

NOTA: Si los quemadores del horno no encienden, revise la

posición de la válvula de cierre de gas del horno.

Válvula de cierre de gas del horno (Vea la

figura 3)

1. Quite la perilla del quemador posterior.

2. Quite el protector contra derrames.

3. Gírela a la posición: 9:00 para encenderla y a las 12:00

para apagarla.

Revisión de la presión del sistema de

tubería de la casa

1. El electrodoméstico y su válvula de cierre individual deben

estar desconectadas del sistema de tubería de suministro

de gas durante toda prueba de presión de ese sistema a

presiones de prueba por encima de 1/2 lb./pulg cuadrada

(3.5 kPa) (13.8 pulg de columna de agua).

2. El electrodoméstico debe estar aislado del sistema de

tuberíadesuministrodegascerrandolaválvuladecierre

individual manual durante toda prueba de presión del

sistemadetuberíadesuministrodegasapresionesde

prueba iguales o menores de 1/2 lb./pulg cuadradas

(3.5 kPa) (13.8 pulg de columna de agua).

Conexión del suministro de gas (Vea la figura 4)

UN TÉCNICO CAPACITADO DE SERVICIO O UN

INSTALADOR DE APARATOS DE GAS DEBE N

REALIZAR LA CONEXIÓN DEL SUMINISTRO DE GAS.

Las pruebas de fugas del aparato deberá realizarlas el

instalador de acuerdo con las instrucciones de la

sección h.

VÁLVULA DE CIERRE DE GAS DEL HORNO

FIGURA 3

LA TUBERÍA DE SUMINISTRO DE GAS NATURAL DEBE

TENER UN REGULADOR DE SERVICIO. LA PRESIÓN DE

ENTRADA AL APARATO DEBE REDUCIRSE A NO MÁS

DE UNA COLUMNA DE AGUA DE 14 PULGADAS

(0.5 LIBRAS POR PULGADA CUADRADA (P.S.I.). LA

TUBERÍA DE PETRÓLEOLIQUADO (LP) O GAS

PROPANO DEBE TENER UN REGULADOR DE PRESIÓN

DE GAS LP. LA PRESIÓN DE ENTRADA AL APARATO

DEBE REDUCIRSE A NO MÁS DE UNA COLUMNA DE

AGUA DE 14 PULGADAS (0.5 P.S.I.). LAS PRESIONES DE

ENTRADA MAYORES DE 0.5 P.S.I.PUEDEN DAÑAR EL

REGULADOR DE PRESIÓN DEL APARATO Y OTROS

COMPONENTES DE GAS DEL APARATO Y PUEDEN

CAUSAR FUGAS DE GAS.

NOTA: Esta estufa se embarca de fábrica ajustada para

usarse con gas natural a una presión de 5 pulg de columna

de agua.

La presión del suministro de gas para el regulador de

presión debe tener una presión mínima de 1 pulgada de

columna de agua por encima de la presión que muestre

el múltiple en la placa de datos.

-16-

Page 17

Si se requiere la conversión a gas LP, convierta el

regulador antes de la instalación. La conversión del

quemador superior, del horno y del asador pueden

hacerse por el frente de la estufa.

a. DEBE INSTALARSE UNA VÁLVULA DE CIERRE EN

UN LUGAR ACCESIBLE EN LA TUBERÍA DE

SUMINISTRO, ANTESDE LLEGAR A LA ESTUFA

PARA CERRAR Y ABRIR EL SUMINISTRO DE GAS.

La estufa necesita conectarse a la tubería de la casa

con conectores flexibles o semirrígidos de metal para

aparatos de gas. LAS TUERCAS DE CONEXIÓN NO

DEBEN ESTAR CONECTADAS DIRECTAMENTE EN

LAS ROSCASDE LA TUBERÍA.LOS CONECTORES

DEBEN INSTALARSE CON LOS ADAPTADORES

PROPORCIONADOS CON EL CONECTOR.

b. La tubería de la casa y el conector de la estufa que se

usen para conectar la estufa al suministro de gas

principal deben estar limpios, sin desechos de metal, sin

corrosión, suciedad ni líquidos (aceite o agua). La

suciedad y cosas por el estilo en las tuberías de

suministro pueden ir a dar al múltiple de la estufa y

causar fallas en las válvulas o controles del gas y tapar

los quemadores o los orificios del piloto.

PRECAUCIÓN: NO LEVANTE NI MUEVA LA ESTUFA

SOSTENIÉNDOLA DE LA PUERTA NI DEL

PROTECTOR POSTERIOR.

c. Apague todos los pilotos y la válvula principal del gas de

otros electrodomésticos de gas.

d. Apague la válvula principal de gas en el medidor.

e. Antes de conectar la estufa, aplique a todas las roscas

compuesto para roscas de tubería que esté aprobada

para gas propano.

f. Use solamente un conec tor flexible para conectar la

estufa al suministro de gas en el regulador de presión

del electrodoméstico, usando los adaptadores

proporcionados con el conec tor. El regulador que se

adjunta con la estufa tiene una conexión hembra de

1/2² NPT.

NOTA: Se recomienda usar un conec tor flexible

certificado CSA que no sea más largo de 36² (91.4 cm)

con una clasificación BTU/HR mínima de 88,200.

Vea la placa de datos para saber para qué tipo de gas

se ha fabricado la estufa, está ubicada en la placa

abatible en la esquina superior izquierda de la parte

posterior del protector.

g. Abra la válvula de gas del medidor, y vuelva a enc ender

los pilotos en los demás electrodomésticos de gas.

h. Aplique un líquido de detección de fugas que no sea

corrosivo a todas las uniones y adaptadores entre la

válvula de cierre de la tubería de s uministro y la estufa.

Incluya los accesorios y las uniones de gas de la estufa

si de alguna forma se alteraron las conexiones durante

la instalación. Revise si hay fugas. La pres encia de

burbujas alrededor de los adaptadores y los conectores

indicará que hay fugas. Si esto ocurre, cierre la válvula

de cierre de la tubería de suministro de gas , apriete las

conexiones, abra la válvula de cierre de la tubería de

gas y vuelva a revisar si hay fugas.

PRECAUCIÓN: NUNCA REVISE LAS FUGAS DE GAS

CON UNA LLAMA ENCENDIDA.

CUANDO TERMINE DE REVISAR LAS FUGAS,

LIMPIE TODOS LOS RESIDUOS.

ADAPTADOR

ADAPTADOR

CONECTOR FLEXIBLE

VÁLVULA DE

CIERRE

REGULADOR

FIGURA 4

-17-

Page 18

AJUSTES DE LA ESTUFA

Sección superior — Encendido eléctrico

Para operarlo, empuje y gire la per illa del quemador a la

posición LITE (ENCENDER).El quemador superior se

encenderá. Para APAGAR la chispa después de que el

quemador se encienda, gire la perilla al ajuste HI (ALTO).

NOTA: Los quemadores superiores no son ajustables.

Obturador de aire — Quemador del horno y

del asador

a. El largo aproximado de la llama del quemador del horno

debe ser de 1/2 (12.7 mm) pulgada, con el interior

azulado y bien definida, figura 5.

b. La llama del quemador del horno o del asador pueden

revisarse del modo siguiente:

1. Llama amarilla en

el quemador —

abra el obturador

de aire del

quemador a la

9215-153-0

OBTURADOR DE AIRE

2

posición más

abierta que no

haga que se

levante o apague

la llama cuando el

quemador esté

frío. (Vea el No. 2

en la figura 6).

2. Llama definida azul

3

TORNILLO

DE FIJACIÓN

FIGURA 6

1

CAPUCHA

DEL

ORIFICIO

pero levantándose — cierre el obturador de aire del

quemador hasta el punto en donde no se levante la

llamacuandoelquemadorestéfrío.(VeaelNo.2enla

figura 6).

1/2² (12.7 mm) CONO

INTERIOR DE LA LLAMA

FIGURA 5

-18-

Page 19

CONVERSIÓN DEL GAS

General

Esta estufa está equipada con orificios dobles coaxiales

(universales) en los quemadores de hornear y as ar, un

regulador de presión convertible del electrodoméstico y

orificios reemplazables de los quemadores superiores. La

placa de datos de la unidad establece para qué tipo de gas

se ajustó la estufa en la fábrica. Para convertir la unidad a

gas natural o a gas propano, se requerirá un ajuste de las

capuchas de orificio, los obturadores de aire de los

quemadores del horno, el reemplazo de los orificios de los

quemadores superiores y el ajuste del regulador de

presión de la tapa del conv ertidor del electrodoméstico.

La presión de entrada al regulador de presión del

electrodoméstico debe ser según s e indica a continuación

para funcione y se pueda revisar el ajuste del regulador de

presión del electrodoméstico:

PRESIÓN DE ENTRADA

EN PULGADAS DE GAS GAS

COLUMA DE AGUA

Mínima 6 11

Máxima 14 14

Conversión del regulador de presión del

electrodoméstico (Vea la figura 7)

El regulador de presión del electrodoméstico debe es tar

ajustado de manera que coincida c on el tipo de gas que se

use. Si se va a convertir de gas natural a gas LP, el

regulador de presión del electrodoméstico debe convertirse

para regular gas LP. Si la conv ers ión es de gas LP a gas

NATURAL LP

natural, el regulador de presión del electrodoméstico debe

convertirse para regular gas natural.

Siga las instrucciones que aparecen a continuación para

convertir el regulador a gas LP. (Este electrodoméstico se

embarca de fábrica para usarse con gas natural.)

1. Destornille la tapa con forma hexagonal del cuello del

regulador. (Puede ser necesario usar una llave inglesa

para aflojar la tapa.)

2. Dentro de la tapa hay un pasador de plástico. Quite este

pasador de la tapa aplicando presión lateral al pasador.

(Vea la ilustración.)

3. Invierta el pasador y colóquelo a presión otra vez en su

lugar dentro de la tapa aplicando una presión uniforme

con el dedo en los bordes opuestos del disco circular del

pasador. El pasador debe quedar bien asentado y firme

en la tapa.

El reemplazo del pasador puede realizarse con más

facilidad si se coloca la tapa en una superficie horizontal

plana, según se muestra en la ilustración, y aplicando

presión con los dedos hacia abajo en los bordes

opuestos del disco del pas ador.

4. Atornille la tapa con firmeza otra vez en su lugar en el

cuello del regulador de presión. (No se necesita apretar

con una llave inglesa la tapa cuando se coloque de

nuevo. El apretar la tapa manualmente con firmeza será

suficiente para asegurarla.)

TAPA Y PASADOR DEL

CONVERTIDOR

NAT

LP

REGULADOR MAXITROL

APLIQUE PRESIÓN

LATERAL CON LOS

DEDOS PARA QUITAR

EL PASADOR DE LA

NAT

TAPA

FIGURA 7

APLIQUE PRESIÓN HACIA ABAJO

CON EL DEDO PARA QUITAR EL

PASADOR DE LA TAPA

LP

-19-

Page 20

QUEMADORES DE HORNEADO Y ASADO A GAS LP/PROPANO

Para convertir el orificio del quemador de

horneado

Quite las dos puertas del horno y siga estos pasos: (Vea las

figuras 8A y 8B).

a. Quite la parte inferior del horno sacando dos tornillos del

frente. (8A)

b. Quite el tabique del horno sacando las tuercas de

mariposa. (8B)

c. Quite los tornillos delantero y posterior del quemador del

horno y quite el quemador. (8B) Tenga cuidado de no

dañar el encendedor.

d. Quite la cubierta del orificio sacando un tornillo. (8B)

e. Use una llave de casquillos de 1/2² (12.7 mm) para girar

la capucha de orificio en el sentido de las manecillas del

reloj (hacia abajo) de2a21/2vueltasaproximadamente

hasta que llegue al fondo del pasador.

PRECAUCIÓN: Tenga cuidado para no apretarlo

demasiado.

f. Vuelva a ensamblar las piezas-.

(superior e inferior):

Para convertir el orificio del quemador de asado:

(Figura 8C)

Se encuentra ubicado en la esquina posterior derecha

solamente en el horno superior, use una llave española de

1/2² (12.7 mm) para girar la capucha de orificio en el sentido

de las manecillas del reloj (hacia abajo) de2a21/2vueltas

aproximadamente hasta que llegue al fondo del pasador.

PRECAUCIÓN: Tenga cuidado de no apretarlo demasiado.

CORAZA

QUEMADOR

CAPUCHA

DE

ORIFICIO

ENCENDEDOR

Figura 8C

Orificio del quemador de asado

Figura 8A

Orificio del quemador de horneado

TABIQUE

TUERCA

DE

MARIPOSA

CUBIERTA

CAPUCHA DE

ORIFICIO

QUEMADOR

Figura 8B

-20-

Page 21

QUEMADORES DE LA SUPERFICIE A GAS LP/PROPANO

PRECAUCIÓN: Esta superficie para cocinar no puede

quitarse, no trate de quitarla. Cons erv e los orificios de gas

natural que quite del electrodoméstico para usarlos en

caso de convertirla de nuev o a gas natural en el futuro.

En todas las ubicaciones de los quemadores:

a. Quite las parrillas superiores y las tapas de los

quemadores.

b. Quite la cabeza del quemador sacando dos tornillos.

(Vea la figura 9). NOTA: Convierta un quemador a la

vez para no instalarlos incorrectamente.

c. IMPORTANTE: Vuelva a colocar estos dos tornillos

después de quitar la cabeza del quemador. Los tornillos

asegurarán el sujetador del orificio y evitarán que se

dañe el electrodo o la tubería mientras se cambia el

orificio.

d. Quite los cuatro orificios de gas que se instalaron de

fábrica del centro de los sujetadores de los orificios

usando un destornillador de tuercas de 7 mm (vea la

figura 9). No se olvide de conserv ar los orificios

originales de gas natural para usarlos en una conversión

futura a gas natural.

e. Vuelva a colocar el orificio de c ada uno de los c uatro

sujetadores de orificios con el orificio de gas LP/propano

correcto(vealafigura10).

IMPORTANTE: Compruebe que el orificio esté bien

asegurado en el destornillador de tuercas antes detratar

de volver a instalarlo. Apriete cada orificio hasta que

quede firme. Tenga cuidado de no apretarlo demasiado.

f. Quite los torn illos cuando termine de cambiar el orificio,

y vuelva a montar las cabezas de los quemadores.

MPORTANTE: El obstructor debe añadirse

I

solamente al soporte de orificio delantero izquierdo,

como se muestra en la figura 9.

g. Coloque de nuevo las tapas de los quemadores y las

parrillas teniendo cuidado al colocar cada tapa de

quemador para que no se dañe el electrodo.

Configuración del quemador de la superficie

TAPA DE LOS

QUEMADORES

ANILLO INTERIOR

QUE LOCALIZA

CABEZA DEL

QUEMADOR

OBSTRUCTOR

SUJETADO

RES DE

ORIFICIOS

ELECTRODO

DESTORNILLADOR

DE TUERCAS

DE 7 MM

SUJETADO

RES DE

ORIFICIOS

ORIFICIO

IMPORTANTE: El obstructor debe

añadirse solamente al soporte de

orificio delantero izquierdo.

Figura 9

CONVERSIÓN DEL ORIFICIO DE GAS NATURAL A

ORIFICIO DE GAS LP

PARA CADA TIPO DE QUEMADOR

9.2K SIN COLOR

ART# 9215-163-0

FRENTE DE LA SUPERFICIE

16K ROJO 9.2K SIN COLOR

1 ORIFICIO AZUL

2 ORIFICIOS SIN COLOR

1 ORIFICIO ROJO

5K AZUL

9,200 BTU DE GAS NATURAL SE

CONVIERTEA9,100BTUDEGAS

LP INSTALE ORIFICIO (SIN

COLOR) .90 MM PARA LP

16,000 BTU DE GAS NATURAL SE

CONVIERTE A 14,000 BTU DE GAS

LP INSTALE EL ORIFICIO (ROJO)

1.14 MM PARA LP

-21-

5,000 BTU DE GAS NATURAL SE

CONVIERTEA4,000BTUDEGAS

LP INSTALE EL ORIFICIO (AZUL)

.64 MM PARA LP

ART# 9215-155-0

9,200 BTU DE GAS NATURAL SE

CONVIERTEA9,100BTUDEGAS

LP INSTALE EL ORIFICIO (SIN

COLOR) .90 MM PARA LP

Figura 10

Page 22

CÓMO QUITAR LA ESTUFA PARA DARLE SERVICIO

Siga estos procedimientos para quitar el

electrodoméstico para darle servicio:

1. Deslice la estufa hacia adelante para desengancharla

del soporte estabilizador.

2. Cierre el suministro de gas al electrodoméstico.

3. Desconecte el suministro eléctrico al electrodoméstico,

si está equipado con uno.

4. Desconecte la tubería de suministro de gas al

electrodoméstico.

5. Invierta el procedimiento para volver a instalarla. Si la

línea de gas se ha desconectado, revise si hay fugas de

gas después de la reconexión.

NOTA: El suministro de gas debe desconectarlo y

volver a conectarlo un técnico calificado.

El técnico DEBE

instalación que se proporcionan con el conector del

electrodoméstico de gas y la etiqueta de advertencia

adherida al conector.

6. Para evitar que la estufa se ladee accidentalmente, ésta

debe estar asegurada al piso deslizando la pata de

nivelación posterior dentro del soporte estabilizador.

seguir las instrucciones de

INFORMACIÓN DE LAS PIEZAS

DE SERVICIO

Cuando la estufa requiera servicio o piezas de repuesto,

comuníquese con el concesionario o la agencia autorizada

de servicio. Proporcione los números completos de modelo

y de serie de la estufa, los cuales están ubicados en la

placa abatible en la esquina superior izquierda en la parte

posterior del protector.

-22-

Page 23

INSTALLATEUR: VEUILLEZ LAISSER CES INSTRUCTIONS AVEC L’APPAREIL

MANUEL DE MISE EN SERVICE

Cuisinière à gaz amovible

de 30 pouces à deux fours

VEUILLEZ CONSERVER CE MANUEL POUR RÉFÉRENCE ULTÉRIEURE

CE MANUEL EST DESTINÉ À FACILITER LA MISE EN SERVICE ET LE RÉGLAGE INITIAUX DE LA

CUISINIÈRE DÉGAGEMENT NÉCESSAIRE.

DÉGAGEMENT DIMENSION

AVERTISSEMENT SPÉCIAL

La mise en service et le dépannage de cette

cuisinière doivent être réalisés uniquement par du

personnel qualifié.

Lire les “Mesures de sécurité” dans le manuel de

l’utilisateur avant d’utiliser la cuisinière.

Une mauvaise réalisation de la mise en place, du

réglage, de toutes modifications ou réparations

ou de l’entretien de la cuisinière ou son usage

incorrect peuvent entraîner des blessures ou des

dégâts graves.

AVERTISSEMENT

· TOUTES LES CUISINIÈRES PEUVENT

BASCULER ET PROVOQUER DES

BLESSURES.

· POSER LES DISPOSITIFS DE

STABILISATION FOURNIS AVEC

CETTE CUISINI ÈRE.

· SUIVRE TOUTES LES CONSIGNES

DE MISE EN SERVICE.

ENGLISH '''' PP. 1-11

ESPAÑOL '''' pág. 12-22

FRANCAIS '''' p. 23-33

La cuisinière peut avoir un dégagement nul (0 po/cm) par

rapport aux parois en matériaux combustibles à l’arrière et

sur les côtés au-dessous de la surface de cuisson (elle

peut être contre ces parois). Se reporter aux schémas

d’installation. Pour des RAISONS DE SÉCURITÉ, ne pas

monter la cuisinière dans une armoire en matériau

combustible qui ne soit pas conforme aux schémas

d’installation.

*REMARQUE : La dimension de 30 po (76,2 cm) entre la

surface de cuisson et l’armoire murale montrée sur

l’illustration ne s’applique pas aux cuisinières ayant un

four traditionnel ou à micro-ondes en hauteur. La

dimension de 30 po (76,2 cm) peut être réduite à 24 po

(61 cm) si les armoires murales d’un logement sont

protégées par des matériaux ininflammables

conformément aux normes American National Standards National Fuel Gaz Code ou, dans le cas de maisons

mobiles, si les armoires murales sont protégées par des

matériaux ininflammables conformément aux règlements

du Federal Standard for Mobile Home Construction and

Safety.

Pour éliminer tout risque de brûlure ou d’incendie en

essayant d’atteindre un objet placé au-dessus d’éléments

brûlants, éviter d’avoir un espace de rangement

au-dessus de la surface de cuisson. S’il doit y avoir une

armoire au-dessus de la table de cuisson, l’installation

d’une hotte dépassant d’au moins 5 po (13 cm) de sa

partie inférieure réduira les risques liés à ce type

d’entreposage.

ATTENTION : Cette cuisinière satisfait aux règles

de divers organismes de protection et aux normes

relatives à la température maximum permise de

194°F pour les armoires en bois. Si cette cuisinière

est adjacente à des armoires pouvant supporter une

température inférieure à 194°F, seulement, celles-ci

peuvent se décolorer, se délaminer ou fondre.

Votre cuisinière peut ne pas être dotée de toutes les fonctions mentionnées dans ce manuel.

Page 24

30 POUCES

CUISINIÈRES AMOVIBLES

Cuisinière Gemini à deux fours

Dimensions

T

U

V

S

Remarques :

1. Prévoir une prise de 120 V reliée à la terre dans cette

zone. La prise DOIT être encastrée.

2. Emplacement recommandé pour la conduite de gaz

3. Dégagement pour le détendeur.

4. La dimension indiquée va du mur au devant de la porte

du four, poignée non comprise.

5. Peut varier légèrement en fonction du réglage du pied

de mise à niveau.

JJJJ

A

B

C

D

E

F

G

H

J

K

L

M

Pouces

25

24

30

36

9

91/4

41/2

11/2

31/2

13

6

2

Centimètres

63,5

61

76,2

91,4

22,9

23,5

11,4

3,8

8,9

33

15,2

5,1

N 4 10,2

P 12 30,5

R 14 1/2 36,8

S 46 3/4 118,7

4

T 26 5/16 66,8

5

U 35 7/8 91,1

V 29 7/8 75,9

“D”

HAUTEUR DE

DESSUS DE

COMPTOIR

STANDARD

H

L

K

M

N

P

“C”

OUVERTURE

DANS

L’ARMOIRE

E

F

G

J

3

1

R

2

“B”

PROFONDEUR D’ARMOIRE STANDARD

-24-

“A”

PROFONDEUR

DE DESSUS DE

COMPTOIR

STANDARD

Page 25

18 PO

(45,7 CM) MIN.

“A”

30 PO

(76,2 CM)

(76,2 CM) MIN.

30 PO

*(VOIR REMARQUE EN PREMIÈRE PAGE)

TOUTE SURFACE

COMBUSTIBLE

*

13 PO (33 CM) PROFONDEUR MAX. DES

ARMOIRES AU--DESSUS DE LA SURFACE

“A”

DE CUISSON

36 PO

(91,4 CM)

DÉGAGEMENT NUL (0

CM/PO) ENTRE TOUTE

PAROI EN MATÉRIAU

COMBUSTIBLE

ADJACENTE SE

TROUVANT AU--DESSOUS

DE LA SURFACE DE

CUISSON ET L’ARRIÈRE

ET LES DEUX CÔTÉS DE

LA CUISINIÈRE.

REMARQUE : LA

SURFACE DE CUISSON

DOITÊTREÀLAMÊME

HAUTEUR QUE LE

DESSUS DU

COMPTOIR OU PLUS

HAUTE

DIMENSION “A” DÉGAGEMENT LATÉRAL AU -DESSUS DE LA SURFACE DE CUISSON = 3 POUCES (7,6 CM) (MINIMUM)

Vérifier sur la plaque signalétique de la cuisinière si elle est

homologuée pour la mise en service dans une maison

mobile et/ou une roulotte de plaisance. La plaque

signalétique se trouve sur la plaque relevable à l’arrière du

coin supérieur gauche du dosseret.

Si la cuisinière est homologuée pour cet usage, les points

suivants s’appliquent.

Roulottes de parc

La mise en service d’une cuisinière prévue pour les roulottes

de parc doit être conforme aux codes provinciaux et autres

ou, en l’absence de tels codes, avec la norme ANSI A119.2

relative aux roulottes de parc, dernière édition.

Au Canada, la mise en service de la cuisinière doit être

réalisée conformément à la norme CAN/ACN - série Z240

RV relative aux caractéristiques exigées pour l’installation

électrique dans les véhicules de plaisance et à la section

Maisons mobiles

La mise en service d’une cuisinière prévue pour les maisons

mobiles doit être conforme aux normes “ Manufactured

Home Construction and Safety Standard ”, titre 24 CFR,

partie 3280 (précédemment “ Federal Standard for Mobile

Home Construction and Safety ”, titre 24 HUD [partie 280])

ou, lorsque ces normes ne sont pas applicables, les normes

“ Standard for Manufactured Home Installations 1982”, ANSI

A225.1/NFPA 501A, ou les codes de la construction locaux.

Z240.4.2 relative aux caractéristiques techniques exigées

pour les appareils et le matériel fonctionnant au propane

dans les véhicules de plaisance (norme CAN/ACN série

Z240 RV).

Emplacement de la cuisinière

Mettre la cuisinière dans un endroit où elle recevra un

bon éclairage.

Ne pas placer la cuisinière au-dessusde trous dans le

plancher ou en tout autre endroit où elle sera exposée à de

forts courants d’air. Toute ouverture dans le mur à l’arrière

Au Canada, la mise en service de la cuisinière doit se faire

conformément aux normes ACN C22.1 du code d’électricité

canadien les plus récentes, partie 1 et section Z240-4.1

relative aux caractéristiques techniques exigées pour les

appareils à gaz utilisés dans les maisons mobiles (norme

CAN/ACN - Z240MH).

de la cuisinière et dans le plancher sous la cuisinière doit

être bouchée. S’assurer que le passage de l’air de

refroidissement/ventilation sous la cuisinière n’est pas

entravé.

REMARQUE : Une cuisinière ne doit PAS être placée sur de

la moquette.

-25-

Page 26

MISE EN PLACE DU SUPPORTDISPOSITIF DE STABILISATION

REMARQUE : La cuisinière risque de basculer si elle n’est

pas mise en place conformément aux instructions fournies.

Si le dispositif de stabilisation est utilisé correctement, il

réduit le risque que la cuisinière ne - BASCULE. Même si le

dispositif de stabilisation est utilisé correctement, le

consommateur doit observer les précautions indiquées dans

le MANUEL D’UTILISATION ET D’ENTRETIEN et éviter

d’utiliser la porte du four comme un tabouret.

Les instructions sont prévues pour un plancher ou un mur en

bois ou en ciment. Un autre matériau pourra requérir des

techniques spéciales, qu’il conviendra de déterminer, pour

assurer la fixationdu SUPPORT DE STABILISATION au

mur ou au plancher. Le support de stabilisation doit être posé

de façon à s’insérer à GAUCHE ou à DROITE du pied de

mise à niveau.

ÉTAPE 1 - Emplacement du support (voir

figure 1)

A. Déterminer où le “ BORD” arrière droit de la cuisinière se

trouvera une fois celle-ci en place et le marquer d’un

repère sur le plancher.

B. Placer le SUPPORT à 15/16 po (24 mm) de la marque “

BORD” en allant vers le centre de l’ouverture et contre le

mur arrière tel qu’indiqué à la figure 1, le trou

d’orientation étant contre le mur.

C. Utiliser le support comme gabarit et marquer

l’emplacement de tous les trous pour le type de matériau

sur lequel le support doit être fixé, tel qu’indiqué à la

figure 1.

ÉTAPE 2 - Pose du support de stabilisation

A. Bois :

1. Plancher : Déterminer le centre des deux trous

identifiés par “ TROUS POUR PLANCHER ” à la

figure 1. Percer un trou de positionnement de 1/8 po

(3 mm) au centre de chaque trou (un clou ou un

poinçon peut également être utilisé si une perceuse

n’est pas disponible). Fixer le support de

STABILISATION au plancher à l’aide des deux vis

fournies. Passer à l’ÉTAPE 3.

2. Mur : Déterminer le centre des deux trous identifiés

par “ TROUS POUR MUR ” à la figure 1. Percer un

trou de positionnement de 1/8 po (3 mm) au centre

de chaque trou (un clou ou un poinçon peut

également être utilisé si une perceuse n’est pas

disponible) tel qu’indiqué à la figure 2. Fixer le

support de STABILISATION au mur à l’aide des

deux vis fournies tel qu’indiqué à la figure 2. Passer

à l’ÉTAPE 3.

B. Ciment ou béton :

1. On trouve des vis convenant au ciment ou au béton

dans les quincailleries. Percer les trous de

positionnement de la grandeur correspondante à

celle des vis obtenues en quincaillerie au centre des

trous identifiés “ TROUS POUR PLANCHER ” à la

figure 1. Fixer le support de STABILISATION au

plancher. Passer à l’ÉTAPE 3.

ÉTAPE 3 - Mise en place de la cuisinière

A. Pour des raisons de sécurité et pour obtenir des

résultats optimums à la cuisson, régler la cuisinière de

façon à ce qu’elle soit de niveau et à la hauteur voulue

avant de la mettre en place dans l’ouverture.

REMARQUE : La surface de cuisson DOIT être au

même niveau que le comptoir ou légèrement plus

haute.

Pour vérifier le niveau, mettre un niveau à bulle ou une

grande casserole d’eau sur la surface de cuisson ou sur

la grille du four. Régler le niveau en la basculant vers

l’avant ou l’arrière et en tournant les pieds de mise à

niveau autant que nécessaire.

REMARQUE : Un dégagement minimum de 1/4 po (6

mm) est exigé entre la cuisinière et le pied de mise à

niveau qui va s’insérer dans le support de stabilisation

(voir figure 2).

ATTENTION : La cuisinière peut se trouver abîmée si

elle est déplacée et soulevée par le dessus, à l’aide du

dosseret ou par les poignées de porte.

B. Placer la cuisinière de façon à ce qu’elle puisse entrer

dans l’ouverture où elle sera encastrée et se préparer à

la pousser en place. Raccorder au gaz et brancher le

cordon d’alimentation dans la prise en suivant les

indications fournies pour le raccordement de la cuisinière

et dans le reste des consignes de mise en service.

C. Glisser la cuisinière en place en l’inspectantvisuellement

pour s’assurer que le cordon d’alimentation et la

conduite de gaz ne se trouvent pas coincés et qu’ils

s’insèrent dans la partie en creux du panneau arrière.

D. Pour vérifier si le support de stabilisation est

correctementen place, regarder sous la cuisinière et

s’assurer que le pied arrière droit est bien inséré dans la

fente du support.

FIXER LE

SUPPORT DE

STABILISATION EN

PLACE AVEC 2

LONGUES VIS

SUPPORT DE

STABILISATION

TROU

D’ORIENTATION

TROUS POUR MUR

REPÈRE DU BORD

DE LA CUISINIÈRE

TROUS POUR PLANCHER

(DE CHAQUE CÔTÉ)

15/16 PO (24 MM) DU

BORD DE LA CUISINIÈRE

PIED DE RÉGLAGE

REMARQUE : UTILISER UN MINIMUM DE 2 VIS POUR

LES VIS

DOIVENT

ENTRER

DANS LE BOIS

OU LE MÉTAL

PLAQUE

MURALE

FIXER LE SUPPORT DE STABILISATION

AU MUR OU AU PLANCHER.

SUPPORT DE STABILISATION

VISSER LE

SUPPORT AU MUR

GLISSER DANS LE SUPPORT

POUR STABILISER

FIGURE 1 FIGURE 2

-26-

FOND DE LA

CUISINIÈRE

1/4 PO

(6 MM)

MIN.

Page 27

RACCORDEMENT DE LA CUISINIÈRE

Alimentation électrique

Une fois en place, l’appareil doit être relié à la terre

conformément aux codes locaux ou, en l’absence de codes

locaux, aux normes ANSI/NFPA 70 du National Electrical

Code.

Au Canada, le raccordement de la cuisinière doit être

conforme à la norme ACN C22.1 du Code d’électricité

canadien partie 1.

Raccordement à l’alimentation électrique

La cuisinière exige une alimentation en courant alternatif

120 V et 60 Hz par prise de courant raccordée à la terre et

équipée d’un disjoncteur de 15 A. Voir la puissance nominale

requise sur la plaque relevable à l’arrière du coin supérieur

gauche du dosseret.

AVERTISSEMENT

Miseàlaterre

Cet appareil est muni d’une fiche à trois broches avec

mise à la terre pour assurer la protection contre les

risques d’électrocution et doit être branché directement

dans une prise de courant correctement reliée à la

terre. Ne pas enlever ni couper la broche de terre de

cette fiche électrique.

AVERTISSEMENT

DÉBRANCHER L’APPAREIL DE

L’ALIMENTATION ÉLECTRIQUE AVANT

TOUT DÉPANNAGE.

ROBINET D’ARRÊT DE

LARAMPEÀGAZ

Alimentation en gaz

La mise en service de cette cuisinière doit être conforme aux

codes locaux ou, en l’absence de tels codes, avec la norme

ANSI Z223.1, dernière édition, du National Fuel Gas Code.

Au Canada, la mise en service de la cuisinière doit être

conforme à la norme ACG CAN/ACG-B149 en vigueur

relative aux codes de mise en service d’appareils à gaz et/ou

aux codes locaux.

REMARQUE : Si les brûleurs du four ne s’allument pas,

vérifier la position du robinetd’arrêt.

Robinet d’arrêt de gaz du four (Voir la figure 3)

1. Enlever le bouton du brûleur arrière.

2. Enlever la plaque de protection contre les débordement.

3. Tourner à 9 heures pour allumer et à 12 heures pour

éteindre.

Vérification de la pression des conduites

du logis

1. L’appareil à gaz et son robinet d’alimentation doivent être

désolidarisés des conduites de gaz pendant toute

vérification de la pression à des pressions supérieures à

0,5 lb/po2 (3,5 kPa) (13,8 po de colonne d’eau).

2. L’appareil à gaz doit être coupé des conduites de gaz en

fermant son robinet de gaz individuel pendant toute

vérification de la pression dans les conduites de gaz à des

pressions égales ou inférieures à 0,5 lb/po2 (3,5 kPa)

(13,8 po de colonne d’eau).

Raccordement à l’alimentation engaz (voir la

figure 4)

LE RACCORDEMENT AU GAZ DOIT ÊTRE EFFECTUÉ

PAR UN TECHNICIEN AYANT REÇU LA FORMATION

APPROPRIÉE OU PAR UN INSTALLATEUR

D’APPAREILS À GAZ. La vérification de l’absence de

fuites sera effectuée par l’installateur conformément aux

directives fournies à la section h

ROBINET D’ARRÊT DU FOUR À GAZ

FIGURE 3

LA CONDUITE DE GAZ NATUREL DOIT ÊTRE ÉQUIPÉE

D’UN DÉTENDEUR POUR GAZ NATUREL. LA PRESSION

À L’ARRIVÉE DE CET APPAREIL DOIT ÊTRE DÉTENDUE

DE FAÇON À NE PAS ÊTRE SUPÉRIEURE À 14 PO DE

COLONNE D’EAU (0,5 LB/PO2 / 3,5 KPA) DANS LE CAS

DE GPL / LA CONDUITE DE GAZ PROPANE DOIT AVOIR

UN DÉTENDEUR POUR GAZ GPL. LA PRESSION À

L’ARRIVÉE DE CET APPAREIL DOIT ÊTRE DÉTENDUE

DE FAÇON À NE PAS ÊTRE SUPÉRIEURE À 14 PO DE

COLONNE D’EAU (0,5 LB/PO2/ 3,5 KPA). UNE PRESSION

À L’ARRIVÉE SUPÉRIEURE À 0,5 LB/PO2(3,5 KPA) PEUT

ENDOMMAGERLE DÉTENDEUR DE L’APPAREIL ET LES

AUTRES COMPOSANTS DE CET APPAREIL ET

POURRAIT PROVOQUER DES FUITES DE GAZ.

REMARQUE : La cuisinière est réglée au gaz naturel pour

une pression de gaz naturel de 5 po de colonne d’eau

(1,25kPa)enusine.

La pression de gaz nécessaire pour vérifier le détendeur

doit être au moins 1 po de colonne d’eau au-dessus de

la pression de rampe indiquée sur la plaque

signalétique.

-27-

Page 28

Si la conversion au gaz GPL est nécessaire, convertir

le régulateur avant la mise en place. La conversion des

brûleurs du gril/four et de la surface de cuisson peut

se faire du devant de la cuisinière.

a.UNROBINETDEGAZDEVRAÊTREPOSÉDANSUN

ENDROIT ACCESSIBLE DE LA CONDUITE DE GAZ,

EN AMONT DE LA CUISINIÈRE, POUR PERMETTRE

D’OUVRIR ET DE FERMER L’ALIMENTATION EN

GAZ. La cuisinière doit être raccordée à l’alimentation

en gaz du logis à l’aide de raccords métalliques flexibles

pour appareils à gaz. LES ÉCROUS DES RACCORDS

NE DOIVENT PAS ÊTRE VISSÉS DIRECTEMENT SUR

LE FILETAGE DES CONDUITES. LES RACCORDS

DOIVENTÊTRE RACCORDÉS À LA CONDUITE À

L’AIDEDES ADAPTATEURS FOURNIS.

e. Avant de raccorder la cuisinière au gaz, enduire tous les

filetages de pâte à filetage convenant au GPL.

f. Raccorder la cuisinière à l’alimentation en gaz au niveau

du détendeur uniquement à l’aide des adaptateurs

fournis avec le raccord. Le détendeur fourni avec la

cuisinière est équipé d’un raccord femelle de 1/2 po

NPT.

REMARQUE : Il est recommandé d’utiliser un raccor d

flexible homologué ACN d’une longueur maximum de

36 po (91,4 cm) et une puissance nominale minimum

de 88 200 BTU/h.

Voir le type de gaz pour lequel la cuisinière est prévu

sur la plaque relevable à l’arrière du coin supérieur

gauche du dosseret.

b. La conduite de gaz du logis et/ou le raccord de la