Page 1

Multipress 10.1

Installation Manual

ENG

Page 2

Index

Index 2

Safety Intructions 3

Scope of Delivery 4 – 6

Fixing Materials - Multipress 7 – 9

Parts List - Multipress 10 – 11

Assembly - Multipress 11 – 34

Assembly - Training Bench 35 – 39

Exploded Drawing - Training Bench 40

Parts List - Training Bench 41

Care, Cleaning & Maintenance 42

Disposal 42

Recommended Accessories 42

Training Recommendations 43 – 44

Warranty 45

Notes 46

Repairs Contract / Notication of a Damage Claim 47

© 2015 by Maxxus Group GmbH & Co. KG

All rights reserved

This publication may not be reproduced, stored in retrieval system, or transmitted on whole or in part, in any form or by any means, electronic, mechanical, photocopying,

recording, or otherwise, without the prior written permission of Maxxus Group GmbH & Co. KG.

Errors, colour and technical modication subject to change, reproduction as well as electronic duplication only with written permission of Maxxus Group GmbH & Co. KG.

2

Page 3

Safety Instructions

Please read and observe all sections of this Operating Manual. Thorough attention should be paid to the safety, service and

maintenance instructions and to the given training information at all times

It is very important to adhere strictly to the service and maintenance instructions contained in this Manual. This training

device is only to be used for its intended purpose. This means that it is to be used for body workouts by adults only.

If this equipment is used for any other purposes than intended, there is a possible risk of accident, damage to health or

damage to the training device. The Distributor cannot be held responsible in this case.

Training Environment

− Select a suitable space for your training device to provide an optimum amount of free space and highest level of safe-

ty.

− Ensure that the load capacity of the oor or ground of the chosen area is sucient for the load.

− Make sure that the area is well ventilated and that an optimum amount of oxygen is available during training. Avoid

draughts.

− It is not permitted to locate your training device in busy areas or areas near to main walkways (emergency exits, doors

or passageways)

− Your training device is not suitable for outside use and so storage and training can only take place in a temperate, dry

clean room.

− Operation and storage of your training device in wet areas such as in swimming pools, saunas etc. is not possible.

− Make sure that your training device is kept on at, hard and clean ground both in operation and at standstill. Any une-

ven surfaces must be removed or made good.

− It is recommended that a oor covering (carpet, mat, etc.) should be placed under the device to protect damageable

oors such as wood, laminates, oor tiles etc. We recommend placing MAXXUS® oor protection mats permanently

under the device. Please ensure that these mats cannot slip or slide.

− Do not put this training device on pale or white coloured carpets or rugs as the feet of the device may leave marks.

− Make sure that your training device is kept out of contact with hot items and is kept at a safe distance from any sourc-

es of heat e.g. central heating, hot stoves, furnaces, ovens or open res.

Personal Safety Instructions for Training

− You should go to the doctor and have a health check before you start working out.

− Stop training immediately if you feel physically unwell or are experiencing any breathing diculties.

− Always start your training session at a low workload increasing it slowly but steadily throughout. Reduce the workload

again towards the end of your training session.

− Suitable sports shoes and clothes should always be worn during training sessions. Make sure that loose clothes do not

get caught up in any moving parts of the device.

− Your training device is only to be used by one person at a time.

− Check each time before a training session to see if your device is in perfect condition. Never use your training device if

it is faulty or defective.

− You are only permitted to carry out repairs to the device yourself after having contacted our Service Department and

on receipt of explicit permission to do so. Only original spare parts may be used at any time.

− Improper repairs or structural modications (attachment of non-permissible parts, removal of original parts etc) are not

permitted. This can impair the technical safety of the device and cause risk for the user.

− Your training device must be cleaned after each use. Remove all dirt including body sweat or any other liquids.

− Your training device is not suitable for use by children.

− Third parties, especially children and animals, must be kept at an appropriate safety distance during training.

− Check before each training session if there are any items underneath the training device and remove them without fail.

Never use the training device when items are underneath it.

− Do not allow children to use your training device as a toy or climbing frame at any time.

− Ensure that no body parts of your own or of third parties ever come into contact with any of the moving mechanisms.

− Warn anyone present at your training sessions, especially children, of the possible risk. This applies to the areas

where weight plates, weight stacks or barbells.

− Check all parts at regular intervals (at least once a month) and make sure that all screws and nuts are tightened prop-

erly.

The construction of this training device is based on state of the art technology and highest modern technical safety standards.

This training device is to be used by adults only!

Extreme misuse and/or unplanned training can cause damage to your health!

ENG

Any manipulation of or interference with the device can cause damage to the device and be a danger to people.

If you have any questions or queries contact your specialist dealer or the MAXXUS Service Team and they will be pleased

to help you further.

3

Page 4

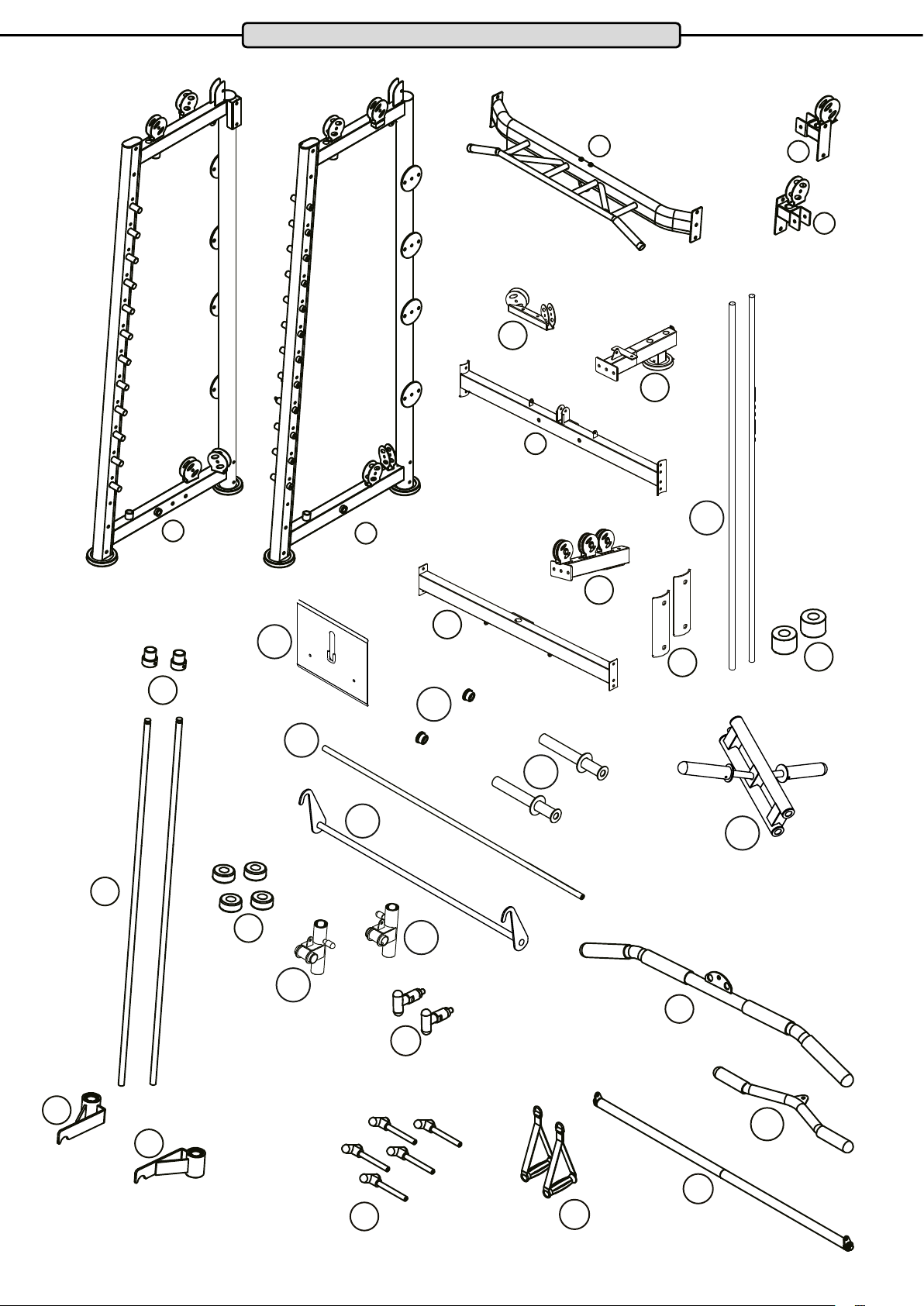

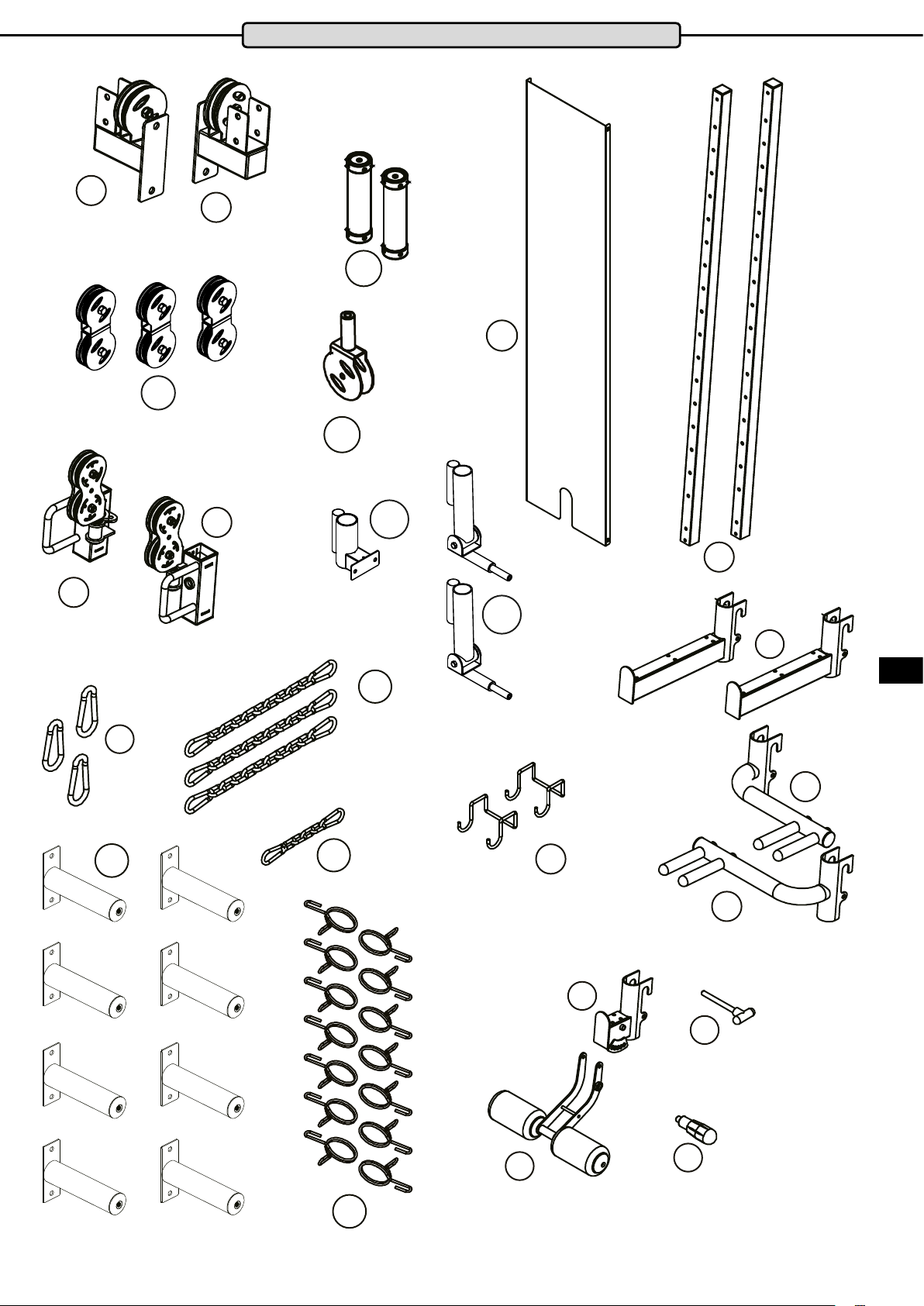

Scope of Delivery – Multipress

4

5

6

85

86

1

2

3

29

76

17

22

25

32

90

23

16

57

24

20

28

18

7

74

31

30

26

27

69

36

70

75

4

Page 5

51

Scope of Delivery – Multipress

52

49

63

40

44

54

73

61

55

45

77

56

78

80

ENG

37

67

72

68

62

81

84

82

5

83

Page 6

Scope of Delivery – Multipress

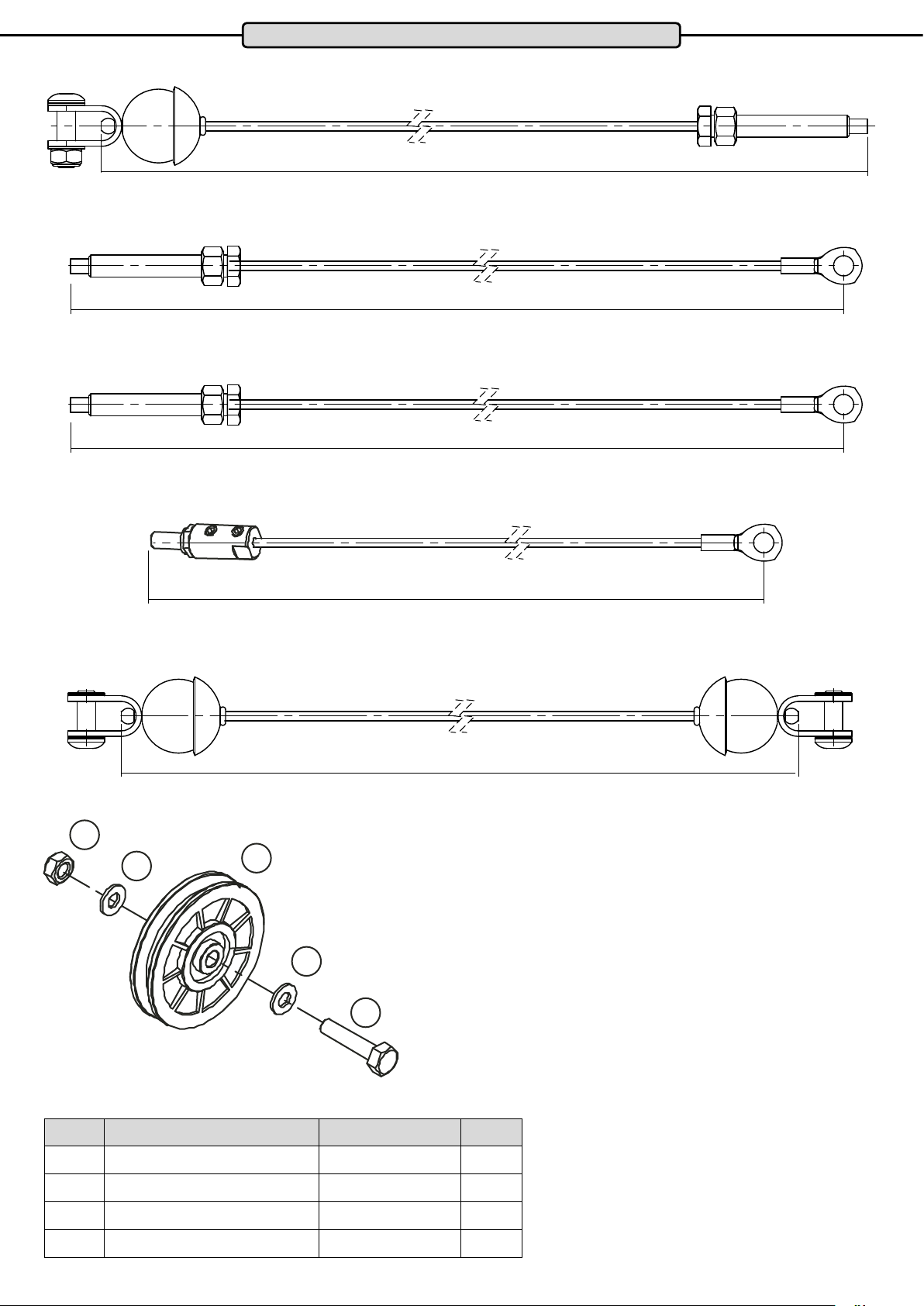

Traction Cable (39) - Length 4.430 mm

Traction Cable (42) - Length 1.860 mm

2x Traction Cable (47) - Length 2.380 mm

10

2x Traction Cable (58) - Length 3.580 mm

Traction Cable (59) - Length 10.690 mm

9

38

Note:

When assembling the rollers (38) only tighten the screws so far

that they are turned into the nut.

Do not over-tighten the screws as this may cause the rollers to

9

block.

41

Part Description Size Qty

9 Washers Ø10 50

10 Safety Nut M10 25

38 Roller Ø95 x Ø10,5 25

41 Socket Head Screw M10 x 45 25

6

Page 7

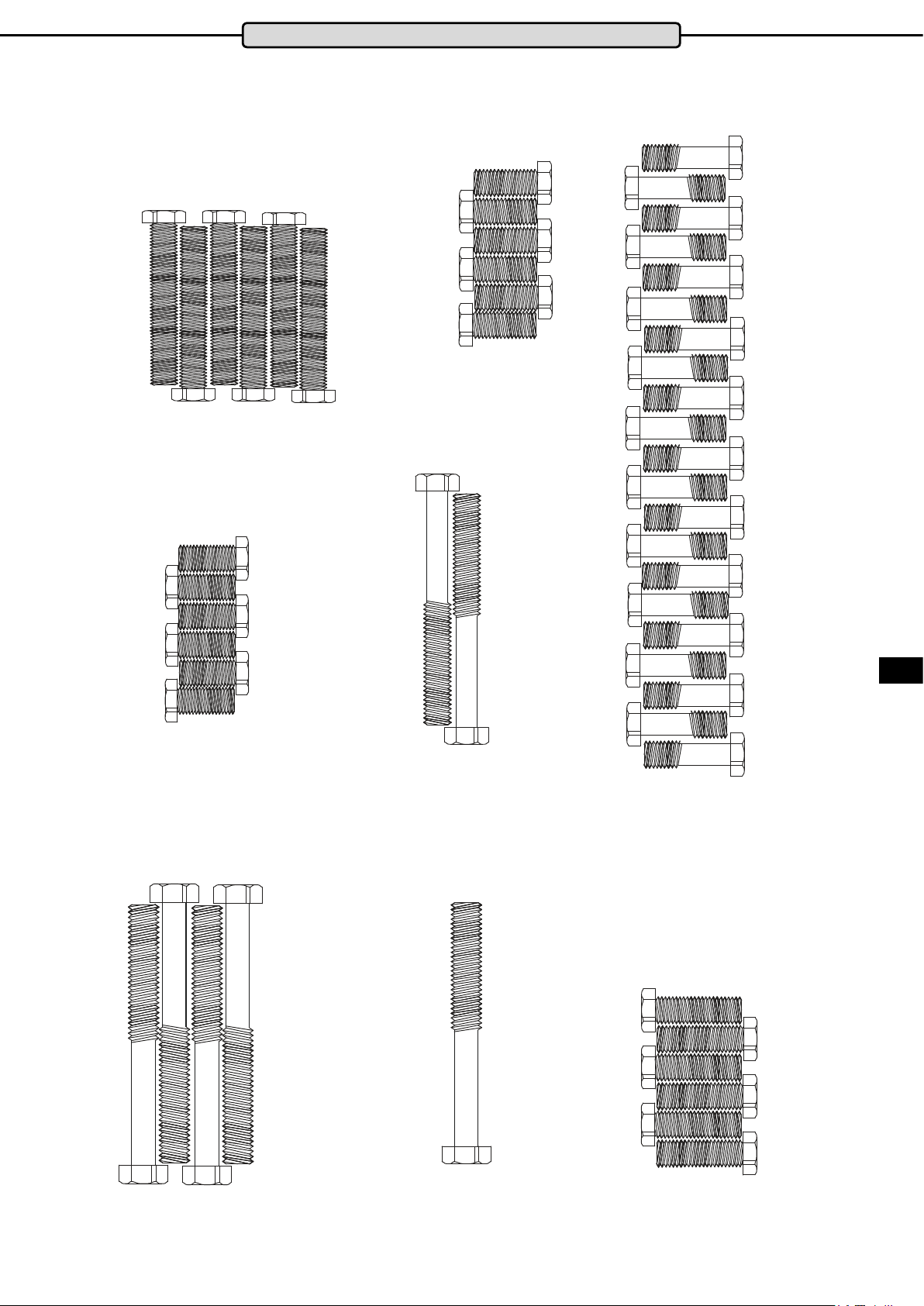

Fixing Materials – Multipress

M10x70 6PCS (53)

M10x25 6PCS (33)

M10x20 6PCS (34)

M10x45 21PCS (41)

ENG

M10x75 2PCS (71)

M10x100 4PCS (8)

7

M10x95 1PCS (35)

M10x50 6PCS (46)

Page 8

Fixing Materials – Multipress

M12x30 4PCS (60)

Ø10 97PCS (9)

M12x75 4PCS (11)

M12x70 4PCS (50)

M8x20 24PCS (64)

Ø12 6PCS (87)

Ø8 4PCS (65)

M8x10 4PCS (21)

M12x75 4PCS (11)

8

Page 9

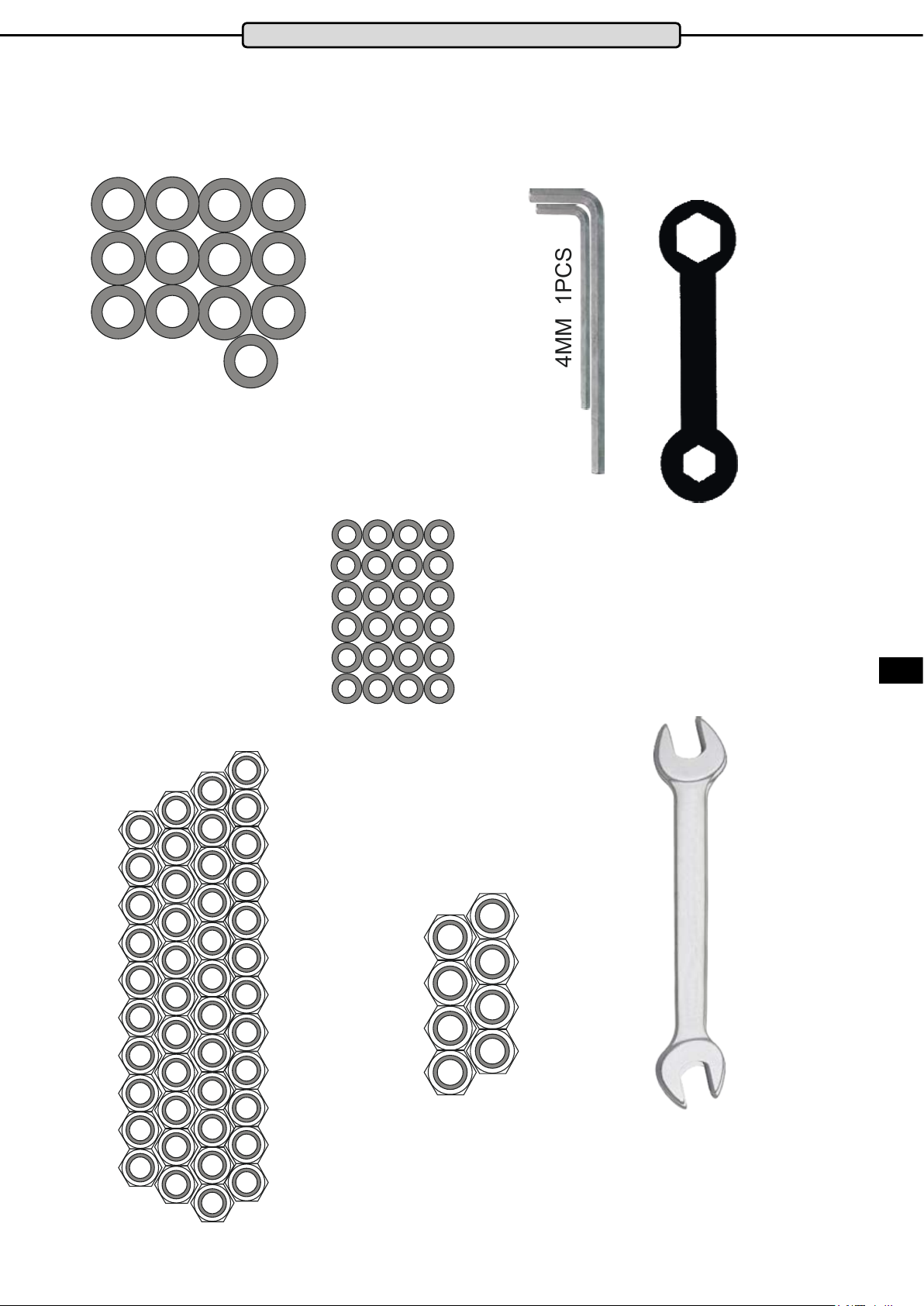

Fixing Materials – Multipress

4MM 1PCS

Ø12 26PCS (12)

Ø8 24PCS (66)

8MM 1PCS

14-17 1PCS

ENG

M10 45PCS (10)

9

17-19 2PCS

M12 8PCS (13)

Page 10

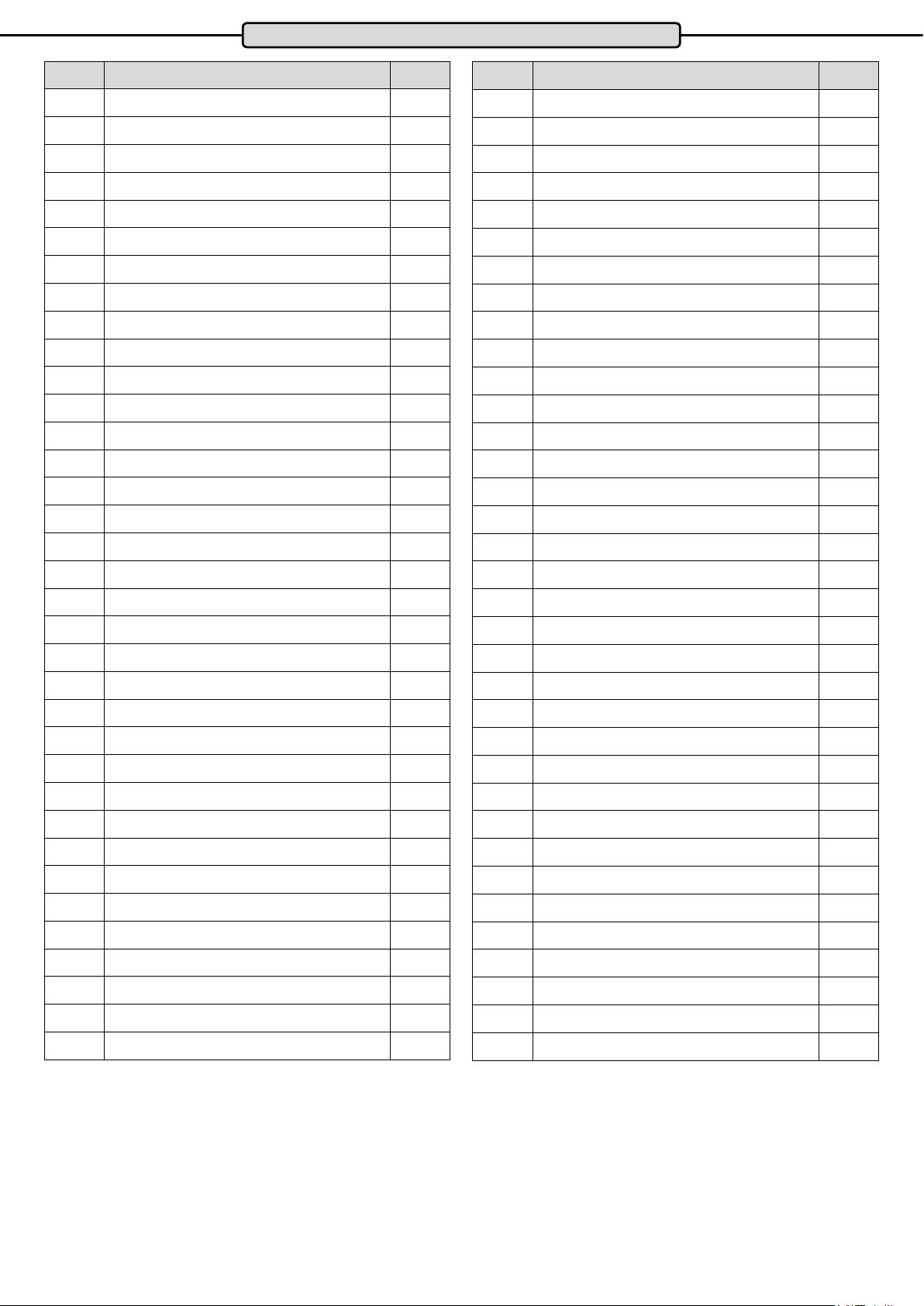

Parts List – Multipress

Part Description Qty

1 T Frame, base 1

2 Side Frame, left 1

3 Side Frame, right 1

4 Pull-up, cross-beam 1

5 Roller retainer, left 1

6 Roller retainer, right 1

7 Mounting plate 2

8 Hex. Head Screw M10 x 100 4

9 Washer Ø10 97

10 Safety Nut M10 45

11 Hex. Head Screw M12x75 4

12 Washer Ø12 26

13 Safety Nut M12 8

14 Safety Nut Ø25xM12x35 24

15 Safety Nut Ø25x98 x M12 24

16 Dumbbell Bar 1

Part Description Qty

36 Draw Bar, short 1

37 Chain with Carabiner, long 3

38 Roller Ø95xØ1.5x24.4 25

39 Traction Cable - Length 4.430mm 1

40 Double Roller 3

41 Hex. Head Screw M10x45 21

42 Traction Cable – Length 1.860mm 1

43 –

44 Single Roller Holder 1

45 Chain with Carabiner, short 1

46 Hex. Head Screw M10x50 6

47 Traction Cable – Length 2.380mm 2

48 Cable Guide 4

49 Traction Weight 2

50 Hex. Head Screw M12x70 4

51 Roller Holder, left 1

17 Guide Pipe 2

18 Weight Sleeve 2

19 Hex. Head Screw M12x25 2

20 End Piece, round 2

21 Headless Screw M18x10 2

22 Fixing Bushing 2

23 Guide Element, left 1

24 Guide Element, right 1

25 Rubber Damper, Ø60xØ58xØ26x25 4

26 Safety Hook, left 1

27 Safety Hook, right 1

28 T-Cross Bar 1

29 Guide Pipe, rear 2

30 Weight Slide 1

31 Rubber Damper Ø60xØ27x42 2

32 Foot Plate 1

33 Hex. Head Screw M10x25 6

52 Roller Holder, right 1

53 Hex. Head Screw M10x70 6

54 Guide Frame w. Double Roller, left 1

55 Guide Frame w. Double Roller, right 1

56 Guide Pipe, square 2

57 Locking Pin 2

58 Traction Cable – Length 3.580mm 2

59 Traction Cable – Length 10.690mm 1

60 Hex. Head Screw M12x30 4

61 Barbell Sleeve 10

62 Spring Clip 14

63 Cover Plate 1

64 Hex. Head Screw M8x20 24

65 Spring Washer 4

66 Washer 24

67 Push-up Grip, left 1

68 Push-up Grip, right 1

34 Hex. Head Screw M10x20 6

35 Hex. Head Screw M10x95 1

69 Locking Pin Ø10x75 5

70 Draw/Push Bar 1

10

Page 11

Parts List – Multipress

Part Description Qty

71 Hex. Head Screw M10x75 2

72 Hook 2

73 Carabiner Hook 3

74 Pull Bar, long 1

75 Pull Grip 2

77 Dumbbell Bar Holder, xed 1

78 Dumbbell Bar Holder, moving 1

80 Shelf, long 2

81 Mounting for Leg Stabiliser 1

82 Leg Holster w. Curved Cushion 1

83 Threaded Spring Clip Grip 1

84 Locking Pin Ø10x100 1

85 Roller Guide 1

86 Foot, rear 1

87 Spring plate Ø12 6

90 Basic Pipe f. Barbell Bar 1

Assembly – Multipress

Carefully unpack all delivered parts. Have someone there to help you as some of the training device parts are bulky and

heavy.

Check that all the parts and xing materials (screws, nuts, etc.) have been delivered.

Assemble the parts carefully as any damages or defects occurring due to mistakes made at the time of assembly are not

covered by the warranty or guarantee. Therefore, read through the assembly instructions carefully before you start assem-

bling, follow each assembly step exactly as described and keep to the correct sequence of assembly as instructed.

Assembly of the training device must be carried out thoroughly by an adult person only.

Assemble the training device in a location which is level, clean and clear of obstructions. 2 people are required to carry out

the assembly.

Please be aware a possible risk of injury at the time of assembly and at each time of using this device exists. For this reason, always be careful and thorough in your actions when assembling this device.

Make sure that the parts necessary for each stage of assembly are only hand tightened together and only tighten parts

completely when all parts have been tted together perfectly.

Training can only start when the training device has been fully assembled.

ENG

11

Page 12

38

48

9

10

9

46

4x

Assembly – Multipress

Assembly Step 1:

Fix the traction weights (49) with a washer Ø12 (12) to each threaded end of the traction cable (47). Then put a traction

weight (49) in the rear pipe on the left and right-side frame (2-left/3-right) – see here the circle section diagram.

Now, mount the two rollers (38), each with a hexagonal head screw M10x50 (46), two washers Ø10 (9), a cable guide (48)

and a safety nut M10 (10) in the two upper roller holders on the left-hand side frame (2). Make sure that the position of each

cable guide (48) is correct.

Feed the other looped end of the traction cable (47) through the cable guides (48) and over the two previously mounted

rollers (38). Then feed the traction cable through the hole in the left-hand side frame and pull down.

Repeat the same procedure on the right-hand side.

2x Traction Cable (47) - Length 2.380 mm

10

9

4x

38

48

9

46

12

Page 13

Assembly – Multipress

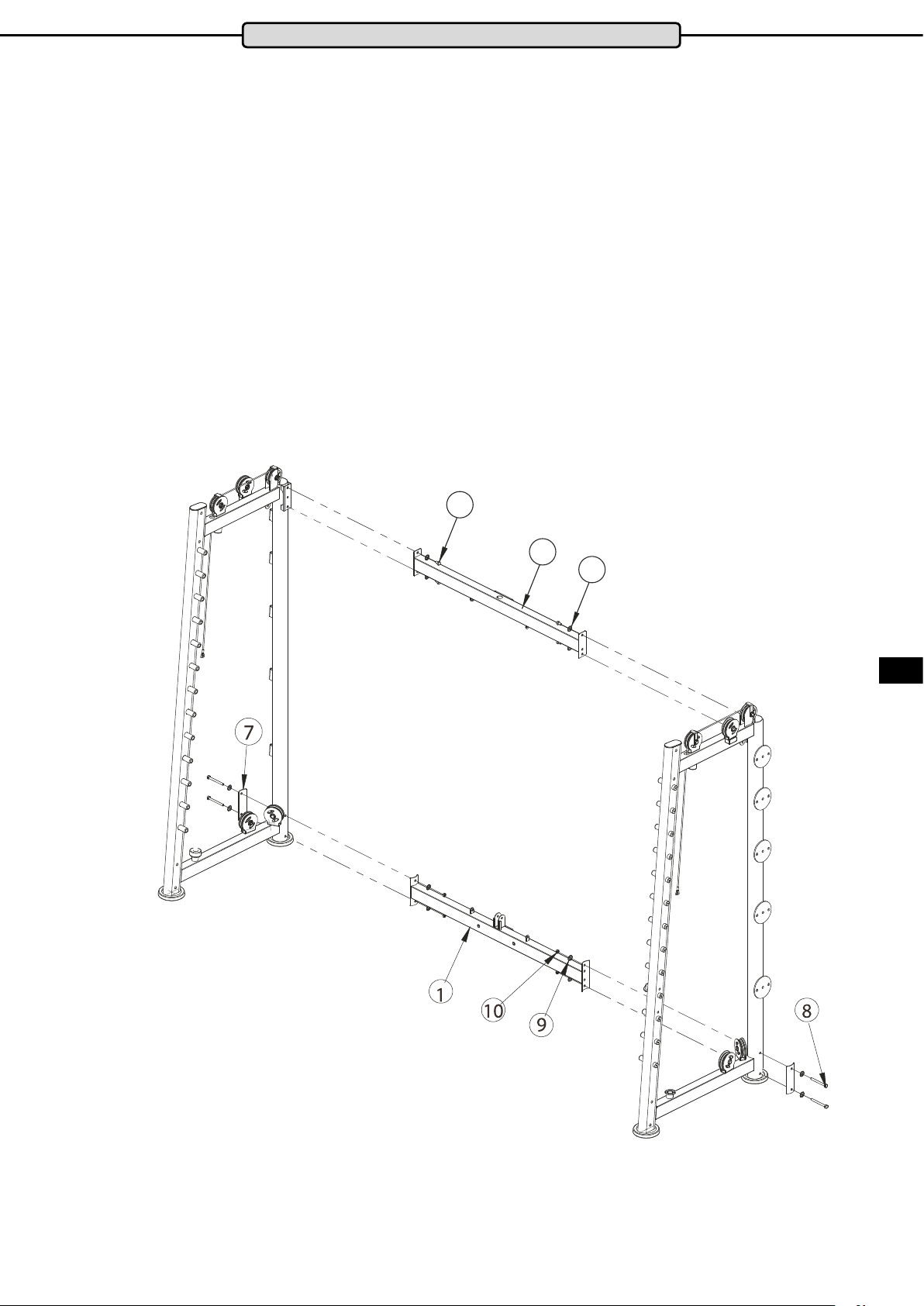

Assembly Step 2

Connect the left-hand side frame (2) the right-hand side frame (3) and the rear side frames to the base frame (1) at the

bottom. For this use on each side; 2 hexagonal head screws M10x100 (8), four washers Ø10 (9), two safety nuts M10 (10)

and a curved mounting plate (7). To stick the screws (8) through the frames (2) you will need to lift the traction weights (49)

mounted here in Step 1 as these will otherwise be blocking the drill holes.

With cross beam (28), connect the left-hand side frame (2) and the right-hand side frame (3) to the rear sides at the top. To

do this use two hexagonal head screws M10x20 (34) and two washers Ø10 (9) on each side.

NOTE:

Please only hand tightened all screws until all components are tting perfectly. Only after this, should the screws be rmly

tightened.

34

28

9

ENG

13

Page 14

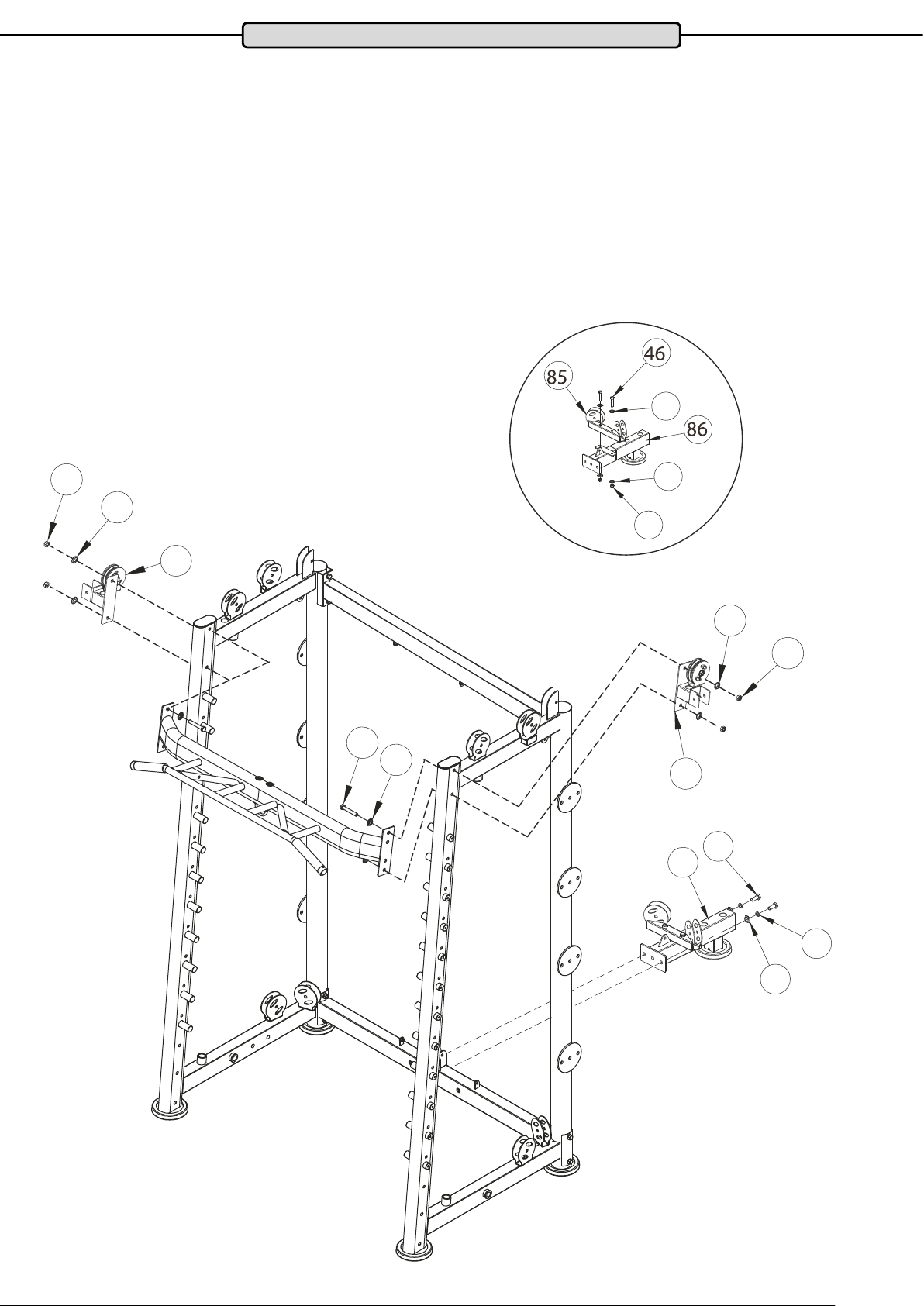

Assembly – Multipress

Assembly Step 3

First mount the roller guide (85) to the rear foot (86) using two hexagonal head screws M10x50 (46), four washers Ø10 and

two safety nuts M10 (10)

see here the circled segment diagram.

Then x rear foot (86) onto base frame (1) using two hexagonal head screws M12x30 (60), two spring plates Ø12 and two

washers Ø12 (12).

Now connect the left-hand side frame (2) and the right-hand side frame (3) to the front at the top with the pull-up cross

beam (4). To do this use on both sides; two hexagonal screws M12x75 (11), four washers Ø12 (12), two safety nuts M12

(13) and similarly to mount the left roller holder (5) to the outside of the left side frame and the right roller holder (6) to the

right-hand side frame.

NOTE:

Please only hand tightened all screws until all components

are tting perfectly. Only after this, should the screws be rmly tightened.

9

13

9

12

10

5

12

13

11

12

6

60

86

14

87

12

Page 15

Assembly – Multipress

Assembly Step 4:

Hook-in the dumbbell bar (16) with the holding hooks to the left and right-hand side frames. Slide the basic pipe for the

barbell bar (90) through the grip bar with hooks (16).

Tipp: First lubricate or fat the surface of the basic pipe (90) with some multi-function fat or with a silicon spray.

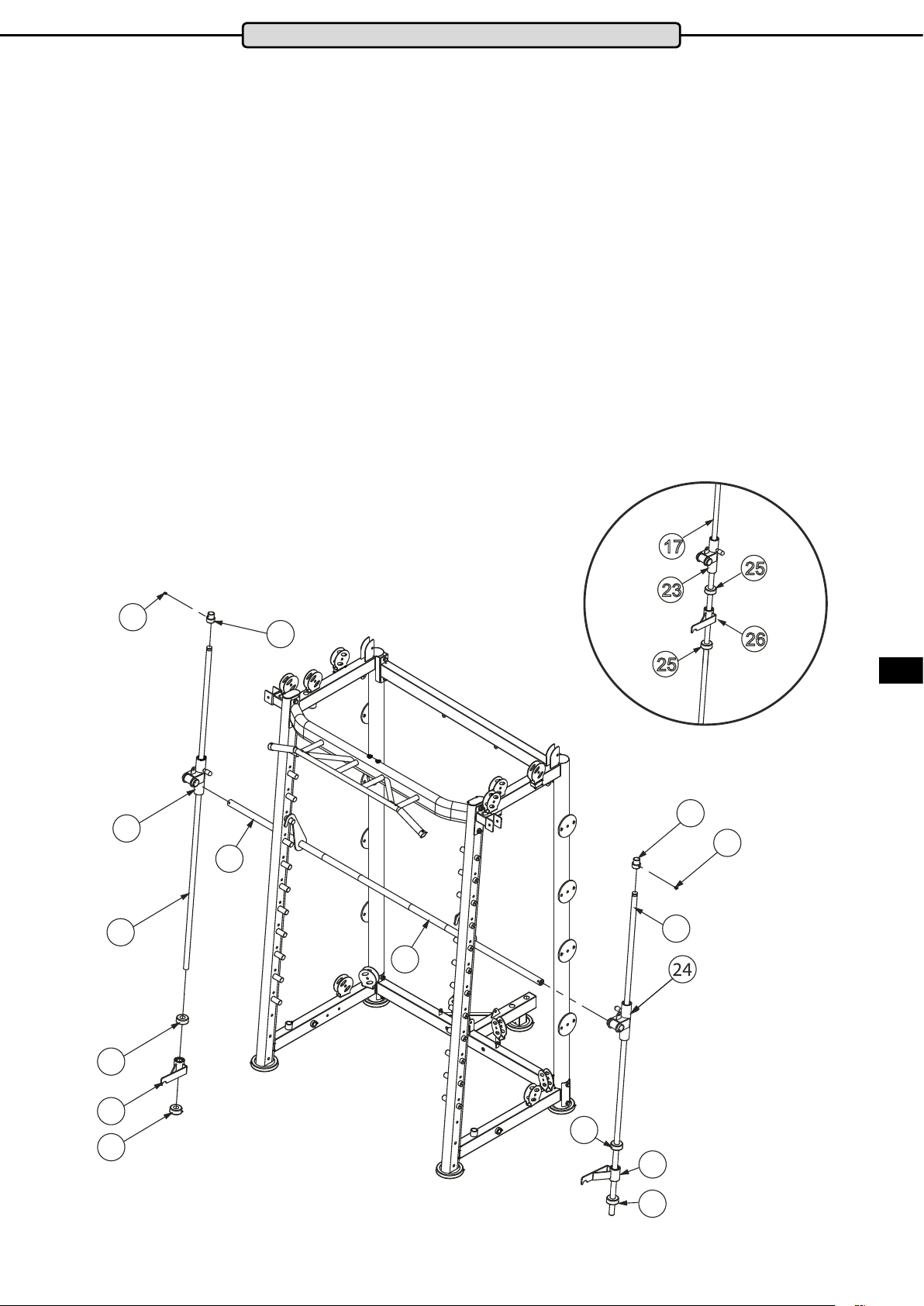

Assembly of the left Guide Pipe (17)

Slide the following parts onto the guide pipe (see circled segment diagram):

- Guide element (23) – Rubber Damper, round (25) – Safety Hook, left (26) – Rubber Damper, round (25)

Please make sure here of the sequence and direction! Take utmost care when placing the guide element (23) into the guide

pipe. There are ball bearings inside the guide element which could become damaged if guide element gets jammed in the

pipe.

Place the xing bushing (22) from above onto the guide pipe (17).

Slide the guide element, left (23) with the guide pipe (17) onto the left dumbbell bar (16) mounting.

Then place the guide pipe in the lower mounting of the left side frame.

Finally, place the top end of the guide pipe with the xing bushing (22) in upper mounting of the left-hand side frame and x

the bushing by tightening the headless screw M8x10 (21)

Follow the same procedure with the right guide pipe (17).

23

17

21

90

22

16

17

23

25

25

26

ENG

22

21

17

25

26

25

25

27

25

15

Page 16

Assembly – Multipress

Assembly Step 4.1:

Slide a weight sleeve (18) on the right and left ends of the dumbbell bar (16). Fix each of these with an end piece, round

(20), a washer Ø12 (12) and a hexagonal head screw M12x25 (19).

19

20

12

87

18

90

90

18

12

19

20

8

7

16

Page 17

Assembly – Multipress

Assembly Step 5:

Fix the loop on the end traction cable (47), which you already assembled in Step 1, using one of each of the following; hexagonal head screw M10x25 (33), two washers Ø10 (9) and a safety nut M10 (10) to the left and right-hand guide elements

on the dumbbell bar – see circled segment diagram.

10

ENG

9

17

9

33

Page 18

Assembly – Multipress

Assembly Step 6

Place the rear guide pipes (29) in the mountings on the weight slide (30).

Make sure that both dumbbell plate mountings on the weight slide are pointing upwards.

Slide on the two round rubber dampers (31) from below onto the guide pipes (29).

Then place the guide pipes in the drill holes in the lower T-frame using one screw M10x20 (34) and a washer Ø10 (9) on

each side.

Place the upper T-cross bar (28) on the guide pipes (29) between the two side frames. Fix the T-cross bar (28) on the right

and left to the base frame using two hexagonal head screws M10x20 (34) and two washers Ø10 (9) on each side. Fix then

the rear guide pipe (29) to the upper T-cross bar (28) using a hexagonal head screw M10x95 (35) and a washer Ø10 (9).

Mount foot plate (32) using two hexagonal head screws M10x25 (33) and two washers Ø10 (9) to the lower T-cross bar.

NOTE:

Please only hand tightened all screws until all components are tting perfectly.

Only after this, should the screws be rmly tightened.

18

Page 19

Assembly – Multipress

Assembly Step 7

Connect the end of the traction cable (39) with the thread connection on the weight slide.

Feed the traction cable (39) up and over single rollers (1) and (2) and assemble rollers (1) and (2) onto the T-frame. Then

feed traction cable (39) over the upper rollers on double roller (40) and then over roller (4) on the T-frame.

Now feed traction cable (39) down and over single roller (4) on the lower T-frame and towards the front through the hole in

the foot plate. Fix single roller (4) to the lower T-frame.

Double Roller (40) Traction Cable (39) - Length 4.430 mm

10

5x

Single Roller (4)

9

38

9

Single Roller (2)

Single Roller (1)

Single Roller (3)

41

ENG

19

40

39

Single Roller (5)

Page 20

Assembly – Multipress

NOTES: Assembly of the Traction Cable:

To feed the traction cable through the rollers or through the hole in foot plate, undo and remove the screw and nut at the

ball end of the cable. Then remove the U-bracket and the ball and metal cup plate. Replace these parts on the end of the

traction cable once you have nished assembling it.

20

Page 21

Assembly – Multipress

Assembly Step 8

Fix the single roller holder (44) and washer Ø10 (12) onto the thread on the end of the traction cable (42). Then feed the

other looped end of the traction cable (42) over the lower roller of double roller (40) mounted in Step 4. Now hang one of

the carabiner hooks on the chain onto the looped end of the traction cable and the second carabiner on chain (45) to the

loop on the lower T-frame.

Single Roller Holder (44) Traction Cable (42) - Length 1.860 mm

Chain with 2 Carabiner Hooks (45)

1x

10

9

38

9

41

ENG

Lower Roller on

Double Roller (40)

21

Page 22

Assembly – Multipress

12

42

44

22

Page 23

Assembly – Multipress

Assembly Step 9

Fix the lower left roller holder (51) with 2 hexagonal head screws M12x70, four washers Ø12 and two safety nuts M12 (13)

to the left-hand side frame.

Repeat this procedure on the right-hand side.

Roller holders have been correctly assembled if the roller on the right-hand roller holder is turning slightly to the right and

the left-hand roller is turning slightly to the left.

Roller Holder, Left (51)

Roller Holder, Right (52)

2x

10

9

38

9

41

ENG

13

12

51

12

50

23

50

12

12

52

13

Page 24

Assembly – Multipress

Assembly Step 10

Place the left-hand guide frame with double roller (54) onto one of the guide pipes (56). Make sure that it is correctly

aligned. Then x guide frame (54) with a locking pin (57) on the guide pipe (56).

Now x the square guide pipe (56) to the top and bottom of the left-hand side frame. At the top use a hexagonal head screw

M10x75 (71), two washers Ø10 (9) and a safety nut M10 (10) and at the bottom use two hexagonal head screws M10x70

(53), four washers Ø10 (9) and two safety nuts M10 (10).

Repeat this procedure on the right-hand side.

10

9

71

54

57

56

71

53

56

24

57

53

55

10

9

Page 25

Assembly – Multipress

Assembly Step 11

Fix the end of the traction cable (58) (threaded retainer – not the looped end!) using a safety nut M10 (10)

and a washer Ø10 (9) to the left-hand guide frame with double roller (54).

Feed through the looped end of the traction cable (58) upwards through the hole in the connecting piece

between the left-hand guide pipe and the left-hand side frame.

Then feed the traction cable further on over the two rollers attached on the side of the left-hand guide frame.

Then pull the cable downwards and put it in the top roller of double roller (40).

Now bring traction cable (58) back upwards and x it onto the attachment loop on the left-hand side frame.

To do this use a hexagonal head screw M10x25 (33), two washers Ø10 (9) and a safety nut M10 (10).

Repeat this procedure on the right-hand side.

CAUTION:

Check that the cable on the threaded retainer is rmly screwed in with the three socket head screws.

To be on the safe side, screw the socket head screws up tight again!

Threaded Retainer Attachment Loop

9

41

38

33

2x Traction Cables (58) – Length 3.580 mm

10

9

38

2x Double Rollers (40)

41

58

9

40

10

6x

10

9

41

9

ENG

38

41

33

25

9

58

10

40

Page 26

Firmly tighten up

the socket head

screws again

before assembling

traction cable (58)

Assembly – Multipress

58

9

58

10

9

10

10

26

9

9

41

Page 27

Assembly – Multipress

Assembly Step 12

Mount the 10 rollers (38) on the appropriate roller holders using a hexagonal head screw M10x45 (41), two washers Ø10

and a safety nut M10 (10) – see diagram and description on the next page.

Loosen the ball bracket at the end of traction cable (59) – see diagram and description on the next but one page.

Feed the traction cable from the front through the double roller on the right-hand guide frame (55) and down through the

lower front roller on the right-hand side frame. Continue the process further as shown in the diagram. When you get to

the front roller on the left-hand side frame, feed the traction cable upwards through this roller, and outwards from the rear

through the double roller on the left-hand guide frame (54) – see diagram and description on the next page.

Finally t the ball bracket you removed earlier back onto the end of traction cable (59).

Traction Cable (59) – Length 10.690 mm

54

55

10

10x

10

38

38

9

41

ENG

41

9

9

9

59

27

Page 28

Assembly – Multipress

Position to mount the rollers in:

I, K, K L, M, N, O, P, Q

Roller sequence in the traction cable assembly (59):

Guide frame, right (55) - H - I - J - K - L - N - O- P - Q - R - T – guide frame, left (54)

Note:

M and N are to be attached to the single roller holder (44)

already assembled in Step 4.

Single Roller Holder (44)

M

R

54

P

Q

M

N

L

55

J

N

O

H

28

K

I

Page 29

Assembly – Multipress

NOTES: Assembly of the Traction Cable:

To feed the traction cable through the rollers or through the hole in foot plate, undo and remove the screw and nut at the

ball end of the cable. Then remove the U-bracket and the ball and metal cup plate. Replace these parts on the end of the

traction cable once you have nished assembling it.

Q

O

P

N

K

M

ENG

L

J

29

I

Page 30

Assembly – Multipress

Assembly Step 13

Fix four barbell sleeves (61) onto the appropriate mounts on the right and left-hand side frames. To do this use for each

barbell sleeve (61); 2 hexagonal head screws M12x30 (60), four washers Ø12 (12) and two safety nuts M12 (13).

Place one spring clip (62) on each barbell sleeve (61). These will later be used to prevent the dumbbell plates from slipping

down or falling.

64

66

61

61

66

64

62

30

Page 31

Assembly – Multipress

Assembly Step 14

Attach cover plate (63) to the top and bottom T-cross bar. For each connection upper and lower 2 hexagonal head screws

M8x20 (64), two spring plates Ø8 (65) and two washers Ø8 (66).

Please ensure that cover plate (63) is assembled behind footplate (32), assembled in Assembly Step 3, on the lower

T-cross bar

64

65

63

66

ENG

32

31

Page 32

Assembly – Multipress

Assembly Step 15

Fix the movable dumbbell bar bracket (78) to the right-hand side frame.

For this use a hexagonal head screw (M10x20 (34) and a washer Ø30xØ10,5 (79)

Then x the dumbbell bar bracket (77) to the left-hand side frame.

For this use two hexagonal screws M10x70 (53), four washers Ø10 (9) and two safety nuts M10 (10).

53

77

9

10

9

34

79

78

32

Page 33

Fitting the Accessories

73

Assembly – Multipress

72

37

73

74

67

69

69

68

70

36

75

37

ENG

80

69

82

81

69

69

83

84

Leg Stabiliser

Before using this accessory, x the leg holster to the

curved cushion (82) and the threaded spring-clip grip

(83) onto the leg stabiliser mounting (81).

Place then the complete unit to the front of the right-

hand side frame and x it with locking pin (84)

33

Page 34

Assembly – Multipress

On completion of assembly please check again if all the screws have been tightened properly. Please also check that all

traction cables have not slipped and are running correctly over the rollers.

Be sure to clean all six chrome guide pipes before using the device for the rst time.

We recommend MAXXUS® degreaser spray for cleaning and MAXXUS® lubricant spray for lubrication of tubes and pipes.

Never use Teon based lubricants to lubricate the pipes and bars.

Clean and lubricate the sliding tubes 1 x per month. The traction cables should be cleaned regularly with a damp cloth and

soapy water. We recommend to repeat this every 4 months.

Chrome Guide Pipes of the

Traction Slide

Chrome Guide Pipes for the

Barbell Bar

Chrome Guide Pipes of the

Traction Elements

34

Page 35

Assembly – Training Bench

ENG

35

Page 36

Assembly – Training Bench

Assembly Step 1

Fix the rear oor bar (2) to base bar (3) using two hexagonal head screws M10x75 (6), four washers Ø10 (33), two safety

nuts M10 (52) and straight retaining plate (7).

Place standpipe (51) onto front oor bar (1) and x it with two hexagonal screws M12x75 (55), four washers Ø12 (54) and

two safety nuts (53).

Fix the standpipe (51) to the base bar (3). For this use two hexagonal screws M10x100 (5), four washers Ø10 (33), and two

safety nuts M10 (52) and the bent mounting plate (4).

33

6

7

52

4

2

3

51

53

54

1

Assembly Step 2

Fix support tube (17) each with two hexagonal head screws M8x20 (19), two washers Ø8 (32) and distance tube (30) on

the rear mount of the sliding carriage (16)

Then place the two guide pipes (20) in the left and right mounts on the base bar (3) and in the mount on standpipe (17) and

x them each with two aluminium caps (21) and two headless screws M10x16 (56)

55

33

5

56

17

21

20

19

16

30

32

3

36

Page 37

Assembly – Training Bench

Assembly Step 3

Now x the base frame (18) to the front mount of the sliding carriage (16). For this use two hexagonal head screws M8x20 (19), two

washers Ø8 (32) and a distance tube (30).

18

30

32

19

Assembly Step 4

Fix swivel bracket (35) using two hexagonal head screws M10x20 (39), two washers Ø10 (33) and distance tube (42) to the

mount on standpipe (51). To x swivel bracket (35) secure it with a safety split pin (59).

16

59

ENG

39

35

51

42

33

37

Page 38

Assembly – Training Bench

Assembly Step 5

Place the three cross pipes (37) – into the swivel bracket and base – as shown in the Diagram. Push a cover plate (large

opening) (48) on to both ends of each cross pipe (37) with the opening facing outwards (see Diagram).

Slide on a round cushion (47) on the right and left ends of each cross pipe (37) and x them with a cover place (small opening) (49) and a hexagonal head screw M8x25 (50).

50

49

47

48

Assembly Step 6

37

Place the shaft pipe (34) in the upper opening of the stand pipe and x it with a grip screw (11). Fix the arm curler cushion

(40) onto mounting on shaft pipe (34) using two hexagonal head screws M8x25 (60) and two washers Ø8 (32).

At the front end of the swivel bracket, x the swivel pipe of the arm curler (36) with safety split pin (11)

32

60

34

9

36

40

11

38

Page 39

Assembly – Training Bench

Assembly Step 7

Attach back rest cushion (29) to the back-rest support tube (17) using four hexagonal screws M8x20 (19) and four washers

Ø8 (32)

29

32

19

Assembly Step 8

Attach the seat cushion (31) to the sliding carriage (16) using four hexagonal screws M8x20 (19) and four washers Ø8 (32).

17

ENG

39

16

31

32

19

Page 40

Assembly – Training Bench

38

34

40

Page 41

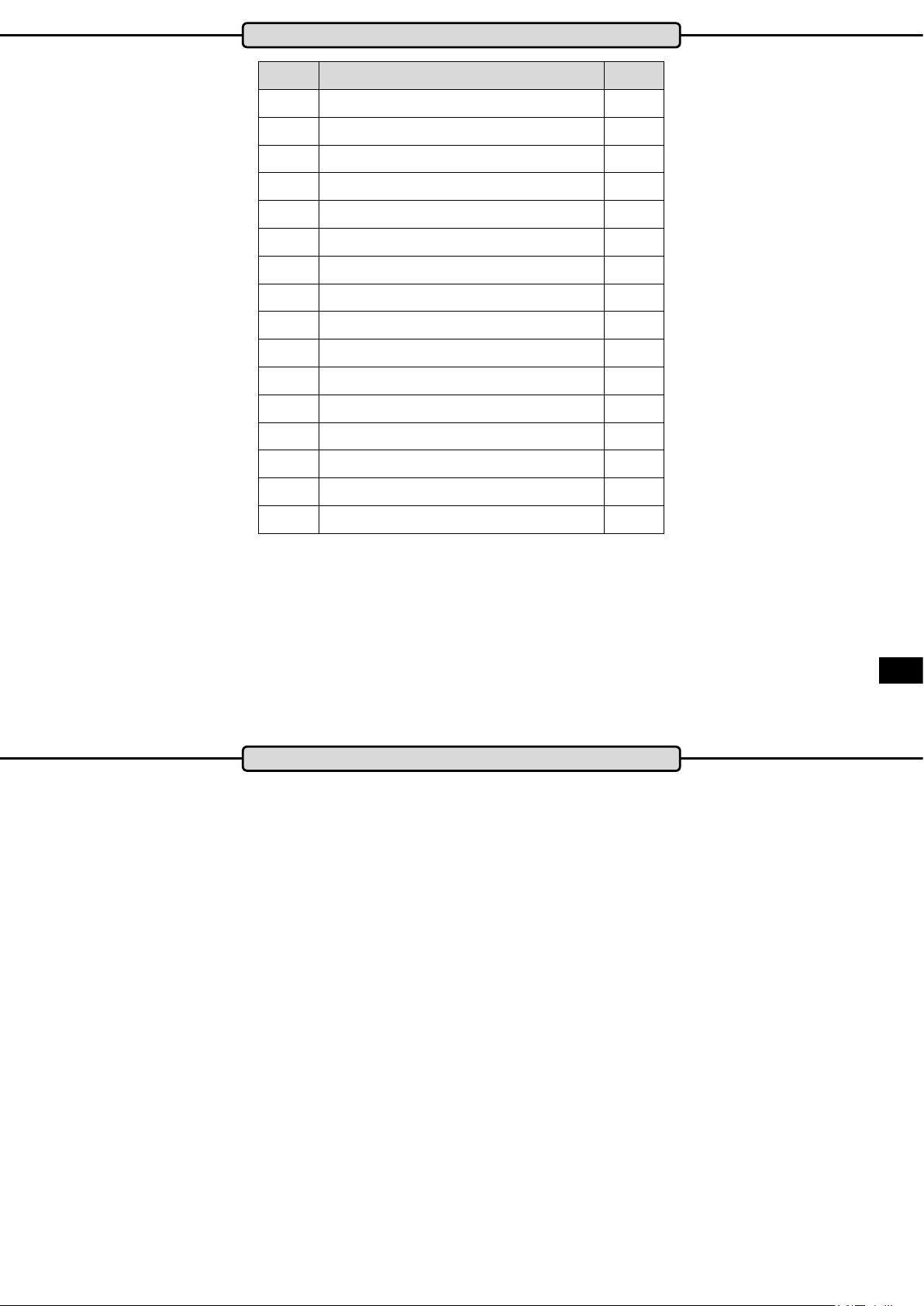

Assembly – Training Bench

Part Description Type Quantity

1 Base Bar, front 1

2 Base Bar, rear 1

3 Base Bar 1

4 Mounting Plate, bent T3,0x59x140 1

5 Hexagonal Head Screw M10x100 2

6 Hexagonal Head Screw M10x75 2

7 Mounting Plate, straight T4,0x50x140mm 1

9 Grip Screw with Locking Pin M18x1.5mm 2

16 Sliding Carriage

17 Support Tube for Back-Rest 1

18 Base Frame for Seat Cushion 1

19 Hexagonal Head Screw M8x20 12

20 Guide Pipe 2

21 Aluminium Cap, round Ø50xØ11x9,5mm 4

29 Back-Rest Cushion 840x330x50mm 1

30 Distance Tube Ø16x50mm 2

31 Seat Cushion 370x300x50mm 1

32 Washer Ø8 14

33 Washer Ø10 10

34 Shaft Pipe for Arm Curler 1

35 Swivel Bracket for Leg Curler 1

36 Swivel Bracket for Arm Curler 1

37 Cross Pipe Ø25xT2,0x450 3

38 Safety Split Pin Ø10x85 1

39 Hexagonal Head Screw M10x20 2

40 Cushion for Arm Curler 1

42 Distance Tube Ø25x67 1

47 Round Cushion 6

48 Cover Plate (large opening) 6

49 Cover Plate (small opening) 6

50 Hexagonal Head Screw M8x25 6

ENG

51 Stand Pipe 1

52 Safety Nut M10 4

53 Safety Nut M12 2

54 Washer Ø12 4

55 Hexagonal Head Screw M12x75 2

56 Headless Screw M10x20 4

59 Safety Split Pin Ø10x100 1

60 Hexagonal Head Screw M8x25 2

41

Page 42

Care, Cleaning & Maintenance

Cleaning:

Clean the training device each time after training with a damp cloth to remove any sweat and or liquids. Do not use sol-

vents. Dry o the cleaned areas thoroughly.

Regular cleaning helps to keep your device in good condition and therefore also signicantly contributes to the length of its

service life.

The costs of repairing a training device which has not been properly maintained will not be covered in any way by the warranty.

Also clean the traction cables regularly.

Cleaning and Lubricating the Chrome Guide Pipes

The barbell bar guide pipes must also be cleaned and lubricated regularly to guarantee optimum smooth running. To

achieve this clean the guide pipes with a damp cloth and some liquid soap or washing up liquid. Alternatively, you can use

the MAXXUS® degreaser spray (optionally available). After this, dry the guide pipes o thoroughly and lubricate them with

MAXXUS® lubricant spray (optionally available) leaving a thin lm on the surface.

With regular use you should lubricate the guide pipes once a month. If squeaking noises occur during training the pipes

require lubricating immediately. MAXXUS® degreaser and lubricating sprays are available from our Online Shop at www.

maxxus.de or from our Showrooms in Groß-Gerau.

Maintenance

Checking the Fixing Materials

At least 1 x Monthly you must check that the screws and nuts are tightened securely and tighten them if necessary.

Disposal

This device is recyclable. At the end of its service life you must dispose of it properly. Do not dispose the device in the normal household rubbish.

Dispose the device at a communal waste disposal facility or at a registered waste disposal company.

Observe current regulations which apply accordingly. If in doubt seek advice from your local government oce or county council as to

where you can dispose of the device properly and in an environmentally sound manner.

Recommended Accessories

These accessories are best suited for use with your training device. All products are available from

our online shop at www.maxxus.de or direct from our showroom.

MAXXUS® Floor Protection Mats

Due to its extreme density and material thickness of 0.5 cm and 1.2 cm, these mats provide per-

fect protection for oors and oor coverings against damaging, scratches and soiling through body

sweat. Noise caused by running and movement is signicantly reduced.

Available in the following sizes:

• 160 x 90 cm

• 210 x 100 cm

• 240 x 100 cm - thickness : 0,5 cm

• 100 x 100 cm - thickness : 1,2 cm

MAXXUS® Degreaser Spray - Optimum cleaner for cleaning o dirt and maintaining the guide

pipes and roller surfaces.

MAXXUS® Lubricating Spray – Optimum lubrication for guide pipes.

MAXXUS® Anti-Static Spray – Eective against the static charges created in frames, clothing and

training computers. Devices which are located on carpets or synthetic oors will become statically

charged. MAXXUS® Anti-Static Spray will deter this.

Synthetic surfaces treated with MAXXUS® Anti-Static Spray do not attract dust as quickly and will

remain clean for longer.

42

Page 43

Training Recommendations

Preparation Before Training

Before you start training make sure that not only your training device is in perfect condition, your body must also be prepared for training. Therefore, if you have not done any endurance training for some time, you should consult your GP and

undergo a tness check-up. Also discuss your training target; they will certainly be able to give you valuable advice and

information. This applies to people who are over 35, have problems with overweight, heart or circulatory system problems.

Training Plan

Essential to eective, target orientated, and motivating training is to have a forward-looking trainings plan.

Plan your tness training as an integral part of your daily routine. If you don’t have a xed plan, training can easily interfere

with regular commitments or continually be put o to another unspecied time.

If possible, create a long term monthly plan and not just from day to day or week to week. A training plan should also

include sucient motivation and distraction during training sessions. An ideal distraction is to watch TV during training as

this diverts your attention both visually and acoustically. Make sure that you reward yourself and set realistic targets such as

to losing 1 or 2kgs in four weeks or to increase your training time by 10 minutes within two weeks for example. If you reach

your targets, then reward yourself with a favourite meal which you have not allowed yourself till then.

Warm-Up Before Training

Warm-up on your training device for 3-5 minutes at minimum resistance. This will best prepare your body for the up-coming

exertion in training.

Cool-Down After Training

Do not just get o your training device immediately the training session is nished. Like with the warm-up stage you should

continue for 3-5 minutes at minimum resistance to cool down. After training you should stretch your muscles thoroughly.

Front Thigh Muscles

Support yourself with your right hand against the wall or on your training device. Bend

your knee and raise your left foot backwards so you can hold it with your left hand. Your

knee should be pointing straight down to the oor. Pull your leg backwards until you feel

a light pulling in your thigh muscles. Hold this position for 10 to 15 seconds. Let your foot

go and stand it back on the oor. Repeat the exercise with your right leg.

Inner Thigh Muscles

Sit on the oor. Pull the soles of your feet together in front of you raising your knees

slightly. Grasp the upper sides of your feet and place your elbows on your thighs. Press

your thighs down towards the oor with your arms until you feel a light pulling in your

thigh muscles. Hold this position for 10 to 15 seconds. Make sure to keep your upper

body straight throughout the exercise. Release the pressure from your thighs and slowly

stretch out your legs to the front. Stand up slowly steadily.

Legs, Calves and Buttocks

Sit on the oor. Stretch out your right leg and bend your left leg to place the sole of your

foot on your right thigh. Bend your top body over so you can stretch out your right hand

to touch your right toes. Hold this position for 10 to 15 seconds. Let go of your toes and

sit slowly and steadily up straight again. Repeat this exercise with your left leg.

ENG

Leg and Lower Back Muscles

Sit on the oor with your legs stretched out. Stretch forward with your hands and try to

grasp the tips of your toes with both hands. Hold this position for 10 to 15 seconds. Let

go of your toes and slowly and steadily sit back up straight again.

43

Page 44

Training Recommendations

Intake of Liquids

The intake of sucient liquids before and during training is vital. During a 60-minute training session it is possible to lose up to 0.5 litres

of liquid. To compensate for this loss, you can drink a mix of one third apple juice to two thirds water to replace all electrolytes and min-

erals which your body loses through sweat. 30 minutes before you begin training you should drink approx. 330 ml. Make sure that you

take in enough liquids during training.

Training Frequency

Experts recommend doing weight training 3 to 4 days a week. You will of course reach your training target quicker if you train more

regularly.

Make sure that you allow for sucient breaks in your training plan to give your body time to recover and regenerate. After each training

session you should take at least a one-day break. The rule of “less is often more” even applies to tness and weight training!

Trainings Records

To optimise your training and make it as eective as possible you should work out a training plan, before you start training, which you

either write down or create a table for in your computer. Here you should make a record of training session and how you feel during the

training session.

Here is a recommended weekly plan.

Calendar Week:_____ Year: 20____

Date Exercise Sequence 1 Sequence 2 Sequence 3 Sequence 4 Comments

___kg___Rep. ___kg___Rep. ___kg___Rep. ___kg___Rep.

___kg___Rep. ___kg___Rep. ___kg___Rep. ___kg___Rep.

___kg___Rep. ___kg___Rep. ___kg___Rep. ___kg___Rep.

___kg___Rep. ___kg___Rep. ___kg___Rep. ___kg___Rep.

___kg___Rep. ___kg___Rep. ___kg___Rep. ___kg___Rep.

___kg___Rep. ___kg___Rep. ___kg___Rep. ___kg___Rep.

___kg___Rep. ___kg___Rep. ___kg___Rep. ___kg___Rep.

Rep. = Repetition

Explanation of Terms:

Weight training exercises are usually made up of three or four training sequences. Each training sequence is normally made up of 10 to

12 repetitions of an exercise. At the end of each training sequence you should have a 1 to 2-minute recovery break.

Normally the weights used in training are increased from sequence to sequence.

A Training Session could be as follows:

1. Training Sequence – Training Weight 20 kg - 10 Repetitions

Break 1 Minute

2. Training Sequence – Training Weight 25 kg - 10 Repetitions

Break 1 Minute

3. Training Sequence – Training Weight 30 kg - 10 Repetitions

Break 1 Minute

4. Training Sequence – Training Weight 35 kg - 10 Repetitions

Break 1 Minute

44

Page 45

Warranty*

For MAXXUS® Support Team to help you as quickly as possible with service, we will require certain information about your

tness device and about you. To nd the exact spare parts required, we will need the product name, date of purchase and

serial number.

If necessary, please ll out completely the Repairs Contract/Damage Report form attached to this User Manual and send it

to us by post or by email.

Areas of Application & Warranty Periods

Depending on the model, tness devices from MAXXUS® are suitable for use in dierent areas. Find the appropriate area

of use for your tness device from the “Technical Data” in this User Manual.

Home Use:

Exclusively for private use

Warranty Period: 2 Years

Semi-Professional Use:

Use under instruction in hotels, physiotherapy practices, etc.

Use in a tness studio or similar establishment is hereby excluded!

Warranty Period: 1 Year

Professional Use:

Use in a tness studio or similar establishment under supervision by trained personnel.

Warranty Period: 1 Year

Use of your training device in an area which is not suitable for your device will cause immediate expiry of its guarantee and

cancel your right to claim warranty!

Sole private use and warranty period of 2 years assumes that the purchase invoice is made out to the end user.

Proof of Purchase and Serial Number

To claim your right to service works within the warranty period we will in each case require proof of purchase. Keep your

proof or purchase or purchase invoice in a safe place and in warranty cases send us a copy together with your Repairs

Contract/Damage Notication. This will ensure that we can process the service work as quickly as possible. So that we can

identify which model version requires to be serviced correctly, we will require; Product Name, Serial Number and Date of

Purchase.

Terms and Conditions of Warranty:

The warranty period for your training device starts on the date of purchase and applies solely to products which were purchased directly from the Maxxus Group GmbH & Co. KG, or one of the Maxxus Group GmbH & Co. KG direct and authorised distribution partners.

The warranty covers defects caused by production or material faults and only applies to devices purchased in Germany.

The warranty does not apply to damages or defects caused by culpable improper use, negligent or purposeful destruction,

lack or failure to carry out maintenance and/or cleaning measures, force majeure, operational causes and to normal wear

and tear, damages caused by penetration of liquids, damage caused by repairs or modications made with spare parts from

a dierent supplier. The warranty also does not apply for damages due to faulty assembly or damages which occur because

of faulty assembly. Certain component parts will wear out during use or from normal wear and tear. This includes for example:

▪ Cables ▪ Rollers ▪ Bearings

Signs of wear and tear on wearing parts are not items covered under the warranty. These include:

Wear and tear on wearing parts are not items covered in the warranty.

If your training device requires to be collected from your address, you will be required to dismantle and make available the

device and receive and re-assemble the device yourself. These works are not in any way covered by the warranty. Prior to

sending any component parts to our service address, please contact the service department and ensure the parts are well

packed.

Service Outside the Warranty and Ordering Spare Parts

The MAXXUS® Service Team is happy to be of assistance to help solve any problems with faults which may arise following

expiry of the warranty period, or in cases of defects arising which are not covered by the warranty.

In this case please contact us by email direct to: customerservice@maxxus.de

ENG

Orders for Spare Parts or Worn Parts should be sent along with information on the Product Name, spare part description

and number and the quantity required to: spareparts@maxxus.de

Please be informed that additional xing materials such as screws, bolts, washers etc are not included in the scope of delivery for individual spare parts. These should be ordered separately.

* Version: June/2016

45

Page 46

Notes

46

Page 47

Repairs Contract / Notication of Damage Claim

Device Details

Product Name: Multipress 10.1

Serial Number: _______________________________________

Date of Purchase: _____________________________________

Accessories: _________________________________________

Type of Use:

Private Use

Personal Details

Company: ___________________________________________

First Name: __________________________________________

Street: ______________________________________________

Post Code / Town/City: _________________________________

E-Mail: _____________________________________________

Fax. No.*: ___________________________________________

Product Group: Weight Machine

Invoice Number: ______________________________________

Where Purchased: ____________________________________

________________________________________________

Commercial Use

Contact Person: _______________________________________

Second Name: ________________________________________

House Number: _______________________________________

Country: _____________________________________________

Tel.No.: _____________________________________________

Mobile No.*: __________________________________________

*These details are optional; all other details are obligatory and must be lled-in.

Description of Fault

Please give a short and as accurate as possible description of the fault:

(eg. When, where and in what way did the fault occur. Regularity, and for what lenth of time, and in what form of use, etc ...)

A copy of proof of purchase / invoice / receipt is attached.

I acknowledge the General Business Terms and Conditions of Maxxus Group GmbH & Co. KG.

I hereby instruct the company Maxxus Group GmbH & Co. KG to repair the above-mentioned fault.

In Warranty cases I will not be charged for the costs. The costs for repairs which are excluded from liability for defects in quality will be

charged to me and must be settled immediately. In cases of repairs carried out on site, our sta are entitled to collect payment. This

agreement is conrmed with here with my signature.

ENG

Date Location Signature

Please be aware that contracts can only be processed if this form has been completed in full. Be sure to attach a copy of your pur-

chase invoice. Send the fully completed Repairs Contract / Notication of Damage Claim to:

Post*: Maxxus Group GmbH & Co KG, Service Department, Zeppelinstr. 2, 64331 Weiterstadt

Fax: +49 (0) 6151 39735 400

E-Mail**: customerservice@maxxus.de

* Please stamp with sucient postage – letters which are not sent postage paid will unfortunately not be accepted.

** Submission by E-Mail is only possible as a scanned document with original signature.

47

Page 48

Maxxus Group GmbH & Co. KG

Zeppelinstr. 2

D-64331 Weiterstadt

Germany

E-Mail: info@maxxus.de

www.maxxus.de

48

Loading...

Loading...