Page 1

Maxtor MaXLine II 250/300GB

Product Manual

January 2, 2004

Part Number: 1904

Page 2

©

January 2, 2004 Maxtor Corporation. All rights reserved. Printed in U.S.A.

This publication could include technical inaccuracies or typographical errors. Changes are

periodically made to the information herein – which will be incorporated in revised editions

of the publication. Maxtor may make changes or improvements in the product(s) described

in this publication at any time and without notice.

Maxtor

®

and MaxFax® are registered trademarks of Maxtor Corporation, registered in the

U.S.A. and other countries. Maxtor MaXLine II 250/300GB, AutoTransfer, AutoRead,

AutoWrite, DisCache, DiskWare, Defect Free Interface, and WriteCache are trademarks of

Maxtor Corporation. All other brand names or trademarks are the property of their manufacturers.

Maxtor reserves the right to make changes and improvements to its products, without

incurring any obligation to incorporate such changes or improvements into units previously

sold or shipped.

This product or document is protected by copyright and distributed under licences restricting its use, copying, distributing, and decompilation. No part of this product or document

may be reproduced in any form by any means without prior written authorization of Maxtor

and its licensors, if any.

RESTRICTED RIGHTS LEGEND: Use, duplication, or disclosure by the government is subject

to restrictions as set forth in subparagraphs (c)(1)(ii) of the Rights in Technical Data and

Computer Software clause at DFARS 252.227-7013 and FAR 52.227-19.

THIS PUBLICATION IS PROVIDED “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY, FITNESS FOR A PARTIULAR PURPOSE, OR NON-INFRINGEMENT.

You can request Maxtor publications from your Maxtor Sales Representative or order them

directly from Maxtor.

Publication Number: Part Number: 1904

Page 3

Before You Begin

Thank you for your interest in Maxtor hard disk drives. This manual provides technical information for OEM engineers and systems integrators regarding the installation and use of

Maxtor hard drives. Drive repair should be performed only at an authorized repair center. For

repair information, contact the Maxtor Product Support Center at 1-800-2MAXTOR.

CAUTION: Maxtor hard drives are precision products. Failure to follow these precautions

and guidelines outlined here may lead to product failure, damage and invalidation

of all warranties.

1 BEFORE unpacking or handling a drive, take all proper electro-static discharge

(ESD) precautions, including personnel and equipment grounding. Stand-alone

drives are sensitive to ESD damage.

2 BEFORE removing drives from their packing material, allow them to reach room

temperature.

3 During handling, NEVER drop, jar, or bump a drive.

4 Once a drive is removed from the Maxtor shipping container, IMMEDIATELY

secure the drive through its mounting holes within a chassis. Otherwise, store

the drive on a padded, grounded, antistatic surface.

5 NEVER switch DC power onto the drive by plugging an electrically live DC source

cable into the drive's connector. NEVER connect a live bus to the drive's interface connector.

6 ELECTRICAL GROUNDING - For proper operation, the drive must be securely fas-

tened to a device bay that provides a suitable electrical ground to the drive baseplate.

Please do not remove or cover up Maxtor factory-installed drive labels. They contain information required should the drive ever need repair.Thank you for your interest in Maxtor hard

disk drives. This manual provides technical information for OEM engineers and systems integrators regarding the installation and use of Maxtor hard drives. Drive repair should be performed only at an authorized repair center. For repair information, contact the Maxtor

Customer Service Center at 800-2MAXTOR or 1-303-678-2015.

Corporate Headquarters:

500 McCarthy Blvd.

Milpitas, California 95035

Tel: 408-894-5000

Fax: 408-362-4740

Page 4

Table of Contents

Table of Contents

Chapter 1

INTRODUCTION 1

1.1 Maxtor Corporation ......................................................................... 1-1

1.2 Manual Organization ........................................................................ 1-1

1.3 Abbreviations ................................................................................. 1-2

1.4 Conventions ................................................................................... 1-2

Chapter 2

PRODUCT DESCRIPTION

2.1 Product Description ......................................................................... 2-1

2.2 Key Features .................................................................................. 2-1

2.3 Product Features ............................................................................. 2-2

2.4 Cache Management ......................................................................... 2-4

2.5 Major HDA Components................................................................... 2-5

2.6 Subsystem Configuration ................................................................. 2-6

2.7 Cylinder Limitation Jumper Description .............................................. 2-7

Chapter 3

PRODUCT SPECIFICATIONS

3.1 Models and Capacities ..................................................................... 3-1

3.2 Drive Configuration.......................................................................... 3-2

3.3 Performance Specifications............................................................... 3-3

3.4 Physical Dimensions ........................................................................ 3-3

3.5 Power Requirements ........................................................................ 3-5

3.6 Power Mode Definitions ................................................................... 3-5

3.7 EPA Energy Star Compliance ............................................................ 3-5

3.8 Environmental Limits........................................................................ 3-6

3.9 Shock and Vibration (TBD) ............................................................... 3-7

3.10 Reliability Specifications.................................................................. 3-8

3.11 EMC/EMI ...................................................................................... 3-9

3.11.1 Radiated Electromagnetic Field Emissions - EMC Compliance .......3-9

3.11.2 Canadian Emissions Statement ................................................3-9

3.12 Safety Regulatory Compliance ......................................................... 3-9

Maxtor MaXLine II 250/300GB i

Page 5

Table of Contents

Chapter 4

HANDLING AND INSTALLATION

4.1 Hard Drive Handling Precautions ....................................................... 4-1

4.2 Electro-Static Discharge (ESD) .......................................................... 4-1

4.3 Unpacking and Inspection................................................................. 4-2

4.4 Repacking ...................................................................................... 4-5

4.5 Physical Installation ......................................................................... 4-5

Chapter 5

ATA BUS INTERFACE AND ATA COMMANDS

5.1 INTRODUCTION .............................................................................. 5-1

5.2 MECHANICAL INTERFACE ............................................................... 5-1

5.2.1 Signal Cable and Connector .......................................................5-1

5.3 ELECTRICAL INTERFACE ................................................................. 5-1

5.3.1 ATA Bus Interface ....................................................................5-1

5.4 REGISTER ADDRESS DECODING....................................................... 5-2

5.5 COMMAND INTERFACE ................................................................... 5-2

5.5.1 General Feature Set ..................................................................5-2

5.5.2 Supported Commands ..............................................................5-2

Chapter 6

SERVICE AND SUPPORT

6.1 Product Support/Technical Assistance/Customer Service...................... 6-1

Appendix A

BREAKING THE 137 GIGABYTE STORAGE BARRIER

A.1 Breaking the 137 Gigabyte Storage Barrier ........................................ A-1

A.1.1 History .................................................................................. A-1

A.1.2 Solving the 137 Gigabyte Capacity Barrier ................................. A-3

A.1.3 How is the Extension Implemented? .......................................... A-3

A.1.4 What Do the Drives Need to Meet the Spec? .............................. A-3

A.1.5 What Else is Involved? ............................................................. A-3

A.1.6 What is the Next Barrier? ......................................................... A-4

Maxtor MaXLine II 250/300GB ii

Page 6

List of Figures

Figure 2-1 PCBA Jumper Location and Configuration ................................................... 2-7

Figure 3-1 Outline and Mounting Dimensions .............................................................. 3-4

Figure 4-1 Single Pack Shipping Container .................................................................... 4-3

Figure 4-2 20 Pack Shipping Container .......................................................................... 4-4

vii Maxtor MaXLine II 250/300GB

Page 7

1.1 Maxtor Corporation

Maxtor Corporation has been providing high-quality computer storage

products since 1982. Along the way, we’ve seen many changes in data

storage needs. Not long ago, only a handful of specific users needed more

than a couple hundred megabytes of storage. Today, downloading from

the Internet and CD-ROMs, multimedia, networking and advanced office

applications are driving storage needs even higher. Even home PC

applications need capacities measured in gigabytes, not megabytes.

Support

Maxtor provides a variety of customer support options, all designed to

make sure the user gets fast, helpful, accurate information to help resolve

any difficulties. These options include a broad, searchable knowledge

base of FAQ’s, product manuals, installation guides, information on

previously resolved problems, software downloads, and contact by

phone or E-mail with a support person. For more information, visit

Chapter 1

INTRODUCTION

www.maxtor.com/en/support

1.2 Manual Organization

This hard disk drive reference manual is organized in the following

method:

Chapter 1–Introduction

Chapter 2–Product Description

Chapter 3–Product Specifications

Chapter 4–Handling and Installation

Chapter 5–ATA Bus Interface and ATA Commands

Chapter 6–Service and Support

Appendix A–Breaking the 137GB Storage Barrier

Maxtor MaXLine II 250/300GB 1-1

Page 8

1.3 Abbreviations

Abbreviation Description Abbreviation Description

ATA AT attachment MB megabyte

bpi bits per inch Mbits/sec megabits per second

CHS cylinder - head - sector MB/sec megabytes per second

db decibels MHz megahertz

Introduction

DA double amplitude

ms millisecond

(represents pk-pk shaker

displacement)

dBA decibels, A weighted MSB most significant bit

DMA direct memory access mV millivolts

ECC error correction code ns nanoseconds

fci flux changes per inch PIO programmed input/output

G acceleration RPM revolutions per minute

GB gigabyte tpi tracks per inch

Hz hertz UDMA ultra direct memory

access

KB kilobyte µsec microsecond

LBA logical block address(ing) V volts

LSB least significant bit W watts

mA milliamperes

1.4 Conventions

If there is a conflict between text and tables, the table shall be accepted

as being correct.

Key Words

The names of abbreviations, commands, fields and acronyms used as

signal names are in all uppercase type (e.g., IDENTIFY DRIVE). Fields

containing only one bit are usually referred to as the “name” bit instead

of the “name” field.

Names of drive registers begin with a capital letter (e.g., Cylinder High

register).

Maxtor MaXLine II 250/300GB 1-2

Page 9

Introduction

Numbering

Numbers that are not followed by a lowercase “b” or “h” are decimal

values. Numbers that are followed by a lowercase “b” (e.g., 01b) are

binary values. Numbers that are followed by a lowercase “h” (e.g., 3Ah)

are hexadecimal values.

Signal Conventions

Signal names are shown in all uppercase type.

All signals are either high active or low active signals. A dash character

(-) at the end of a signal name indicates that the signal is low active. A

low active signal is true when it is below ViL and is false when it is

above ViH. A signal without a dash at the end indicates that the signal is

high active. A high active signal is true when it is above ViH and is false

when it is below ViL.

When a signal is asserted, it means the signal is driven by an active circuit to its true state.

When a signal is negated, it means the signal is driven by an active circuit to its false state.

When a signal is released, it means the signal is not actively driven to any

state. Some signals have bias circuitry that pull the signal to either a true

or false state when no signal driver is actively asserting or negating.

.

Maxtor MaXLine II 250/300GB 1-3

Page 10

2.1 Product Overview

MaXLine II hard disk drive is part of a family of highly durable, 1-inchhigh hard disk drives manufactured to meet the highest product quality

standards. These hard drives use non-removable, 3 1/2-inch hard disks

and are available with ATA interfaces.

Maxtor has combined leading edge technologies with the largest ATA

drive storage capacity available today to create the highly durable

MaXLine II hard disk drive. Innovative features and design make it

ideally suited for applications requiring large storage capacity.

2.2 Key Features

Chapter 2

PRODUCT DESCRIPTION

• ANSI ATA-5/6 compliant PIO Mode 4 interface (Enhanced

IDE)

• Supports ATA-6 UltraDMA Mode 5 (100 MBytes/sec) and

Maxtor Ultra ATA/133 MBytes/second data transfer rates

• Supports 48-bit addressing

• 2 MB buffer with multi-adaptive cache manager

• 5400 RPM spin speed

• 10 ms seek time

• Zone density and ID-less recording

• Outstanding shock resistance at 300 Gs

• High durability with 50K contact start/stop cycles

• Advanced multi-burst on-the-fly Error Correction Code (ECC)

• Extended data integrity with ECC protected data and fault

tolerant servo synchronization fields

• Supports EPA Energy Star Standards (Green PC Friendly) with

ATA powering savings commands

• Auto park and lock actuator mechanism

• Low power consumption

Maxtor MaXLine II 250/300GB 2-1

Page 11

• Maxtor Quiet Drive Technology

• SMART Capability

Note: Maxtor defines 1 Gigabyte (GB) as 10

bytes of data. Total accessible capacity varies depending on

operating environment.

2.3 Product Features

Functional/Interface

Maxtor hard drives contain all necessary mechanical and electronic parts

to interpret control signals and commands from an AT-compatible host

computer. See Chapter 3 Product Specifications, for complete drive

specifications.

Zone Density Recording

The disk capacity is increased with bit density management – common

with Zone Density Recording. Each disk surface is divided into 16

circumferential zones. All tracks within a given zone contain a constant

number of data sectors. The number of data sectors per track varies in

different zones; the outermost zone contains the largest number of data

sectors and the innermost contains the fewest.

Product Description

9

or 1,000,000,000

Read/Write Multiple Mode

This mode is implemented per ANSI ATA/ATAPI-6 specification. Read/

Write Multiple allows the host to transfer a set number of sectors

without an interrupt request between them, reducing transfer process

overhead and improving host performance.

UltraDMA-Mode 5

Maxtor hard drives fully comply with the new ANSI Ultra DMA protocol,

which greatly improves overall AT interface performance by

significantly improving burst and sustained data throughput.

Multi-word DMA-Mode 2

Supports multi-word Direct Memory Access (DMA) mode transfers.

Maxtor Quiet Drive Technology

Maxtor Quiet Drive technology provides users with the lowest possible

noise levels and best overall sound quality from their drives.

Sector Address Translation

All Maxtor hard drives feature a universal translate mode. In an AT/

EISA-class system, the drive may be configured to any specified

combination of cylinders, heads and sectors (within the range of the

drive's formatted capacity). Maxtor hard drives power-up in a translate

mode.

Maxtor MaXLine II 250/300GB 2-2

Page 12

Product Description

MODELS CYL HD SPT MAX LBA CAPACITY

5A250J0 486,344 16 63 490,234,752 250GB

5A300J0 627,651 16 63 585,940,320 300GB

Logical Block Addressing

The Logical Block Address (LBA) mode can only be utilized in systems

that support this form of translation. The cylinder, head and sector

geometry of the drive, as presented to the host, differs from the actual

physical geometry. The host AT computer may access a drive of set

parameters: number of cylinders, heads and sectors per track, plus

cylinder, head and sector addresses. However, the drive can’t use these

host parameters directly because of zoned recording techniques. The

drive translates the host parameters to a set of logical internal

addresses for data access.

The host drive geometry parameters are mapped into an LBA based on

this formula:

LBA = (HSCA - 1) + HHDA x HSPT + HNHD x HSPT x HCYA

= (HSCA - 1) + HSPT x (HHDA + HNHD x HCYA)

where HSCA = Host Sector Address, HHDA = Host Head Address

HCYA = Host Cylinder Address, HNHD = Host Number of

Heads

HSPT = Host Sectors per Track

The LBA is checked for violating the drive capacity. If it does not, the

LBA is converted to physical drive cylinder, head and sector values. The

physical address is then used to access or store the data on the disk

and for other drive related operations.

Defect Management Zone (DMZ)

Each drive model has a fixed number of spare sectors per drive, all of

which are located at the end of the drive. Upon detection of a bad

sector that has been reassigned, the next sequential sector is used.

For example, if sector 3 is flagged, data that would have been stored

there is “pushed down” and recorded in sector 4. Sector 4 then

effectively becomes sector 3, as sequential sectors are “pushed down”

across the entire drive. The first spare sector makes up for the loss of

sector 3, and so maintains the sequential order of data. This push down

method assures maximum performance.

On-the-Fly Hardware Error Correction Code (ECC)

>24 symbols, single burst, guaranteed

Maxtor MaXLine II 250/300GB 2-3

Page 13

Software ECC Correction

24 symbols, single burst, guaranteed

Automatic Park and Lock Operation

Immediately following power down, dynamic braking of the spinning

disks delays momentarily allowing the read/write heads to move to an

inner mechanical stop. A small fixed magnet holds the rotary actuator

in place as the disk spins down. The rotary actuator is released only

when power is again applied.

2.4 Cache Management

Buffer Segmentation

The data buffer is organized into two segments: the data buffer and the

micro controller scratch pad. The data buffer is dynamically allocated

for read and write data depending on the commands received. A

variable number of read and write buffers may exist at the same time.

Read-Ahead Mode

Normally, this mode is active. Following a read request, disk read-ahead

begins on the first sector and continues sequentially until the allocated

buffer is full. If a read request is received during the read-ahead

operation, the buffer is examined to determine if the request is in the

cache. If a cache hit occurs, read-ahead mode continues without

interruption and the host transfer begins immediately.

Product Description

Automatic Write Reallocation (AWR)

This feature is part of the write cache and reduces the risk of data loss

during deferred write operations. If a disk error occurs during the disk

write process, the disk task stops and the suspect sector is reallocated

to a pool of alternate sectors located at the end of the drive. Following

reallocation, the disk write task continues until it is complete.

Write Cache Stacking

Normally, this mode is active. Write cache mode accepts the host write

data into the buffer until the buffer is full or the host transfer is

complete. A command complete interrupt is generated at the end of the

transfer.

A disk write task begins to store the host data to disk. Host write

commands continue to be accepted and data transferred to the buffer

until either the write command stack is full or the data buffer is full. The

drive may reorder write commands to optimize drive throughput.

Maxtor MaXLine II 250/300GB 2-4

Page 14

2.5 Major HDA Components

Drive Mechanism

A brushless DC direct drive motor rotates the spindle at 5400 RPM

(±0.1%). The dynamically balanced motor/spindle assembly ensures

minimal mechanical run-out to the disks. A dynamic brake provides a

fast stop to the spindle motor upon power removal. The speed tolerance

includes motor performance and motor circuit tolerances.

Rotary Actuator

All Maxtor hard drives employ a rotary voice coil actuator which

consists of a moving coil, an actuator arm assembly and stationary

magnets. The actuator moves on a low-mass, low-friction center shaft.

The low friction contributes to fast access times and low power

consumption.

Read/Write Electronics

An integrated circuit mounted within the sealed head disk assembly

(near the read/write heads) provides up to eight head selection

depending on the model. It also provides read pre-amplification and

write drive circuitry.

Product Description

Read/Write Heads and Media

Low mass, low force giant magneto-resistive read/write heads record

data on 3.5-inch diameter disks. Maxtor uses a sputtered thin film

medium on all disks for Maxtor hard drives.

Air Filtration System

All Maxtor hard drives are assembled in a Class 100 controlled

environment. Over the life of the drive, a 0.1 micron filter and breather

filter located within the sealed head disk assembly (HDA) maintain a

clean environment to the heads and disks. Maxtor drives are designed

to operate in a typical office environment with minimum environmental

control.

Microprocessor

The microprocessor controls the following functions for the drive

electronics:

• Command execution

• Cache management

• Data correction and error recovery

• Diagnostic execution

• Data sequencing

• Head positioning (including error recovery)

•Host interface

Maxtor MaXLine II 250/300GB 2-5

Page 15

• Index detection

• Spin speed control

• Seeks

•Servo

•SMART

• 48-bit addressing

2.6 Subsystem Configuration

Dual Drive Support

Two drives may be accessed via a common interface cable, using the

same range of I/O addresses. The drives have a jumper configuration as

device 0 or 1 (Master/Slave), and are selected by the drive select bit in

the Device/Head register of the task file.

All Task File registers are written in parallel to both drives. The interface

processor on each drive decides whether a command written to it

should be executed; this depends on the type of command and which

drive is selected. Only the drive selected executes the command and

activates the data bus in response to host I/O reads; the drive not

selected remains inactive.

Product Description

A master/slave relationship exists between the two drives: device 0 is

the master and device 1 the slave. When the Master is closed (factory

default, figure 2-1), the drive assumes the role of master; when open,

the drive acts as a slave. In single drive configurations, the Master

jumper must be closed.

Cable Select Option

CSEL (cable select) is an optional feature per ANSI ATA specification.

Drives configured in a multiple drive system are identified by CSEL’s

value:

– If CSEL is grounded, then the drive address is 0.

– If CSEL is open, then the drive address is 1.

Maxtor MaXLine II 250/300GB 2-6

Page 16

+12VDC

+12VDC return

+5VDC return

+5VDC

Pin 1

ATA Interface Connector

Pin 40

Figure 2-1 PCBA Jumper Location and Configuration

J41

J42

Power

Connector

Product Description

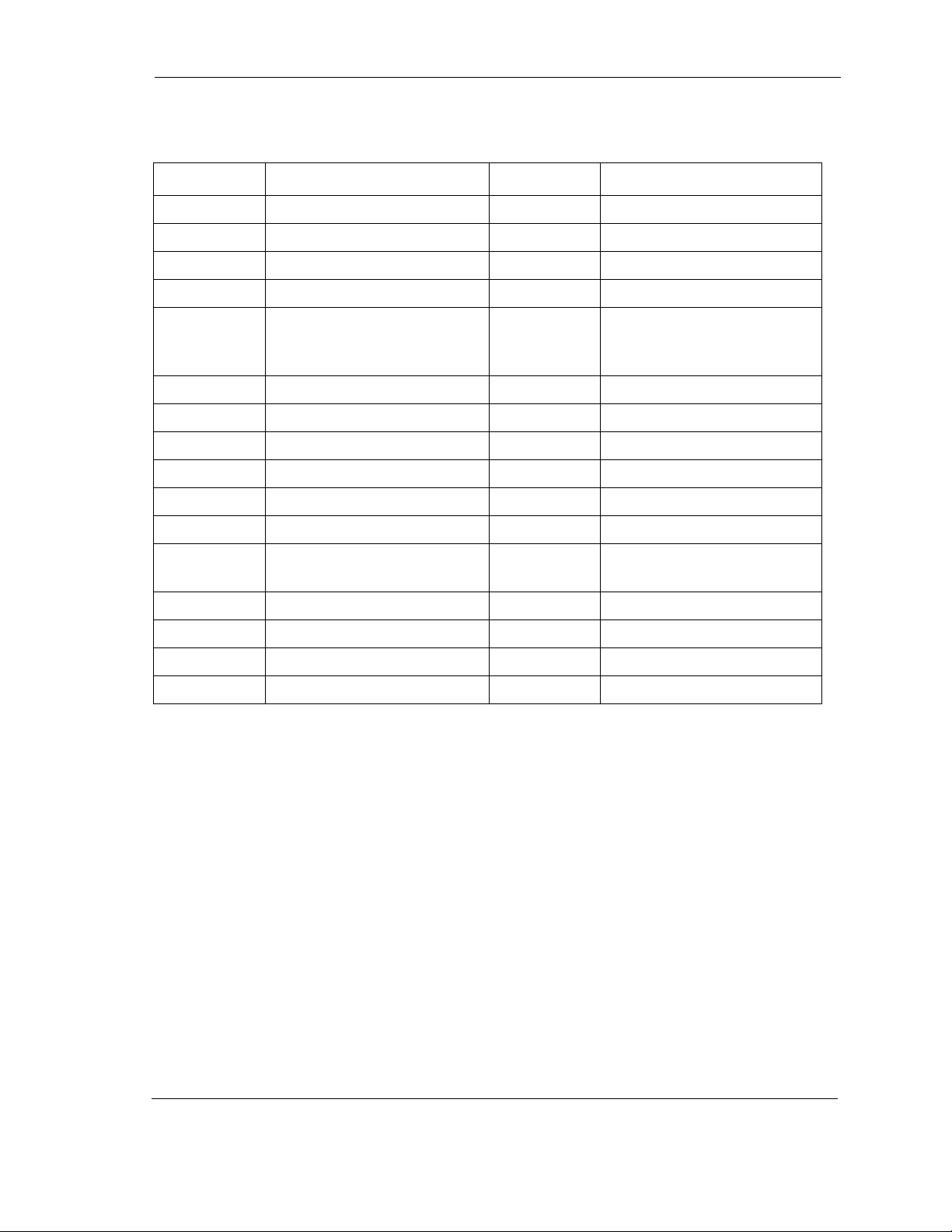

JUMPER CONFIGURATION

Master/Slave

Only drive in single drive system

Master drive in dual drive system

Slave drive in dual drive system

Cable Select

Disabled

Enabled*

Cylinder Limitation

Disabled*

Enabled

Factory Reserved O O

Key * = Default C = Closed (jumper installed) O = Open (no jumper installed)

2.7 Cylinder Limitation Jumper Description

On some older BIOS', primarily those that auto-configure the disk drive,

a hang may occur. The Cylinder Limitation jumper reduces the capacity

in the Identify Drive allowing large capacity drives to work with older

BIOS. The capacity reported when J45:J46 is closed will be as follows:

drives less than or equal to 32GB will report 2.1GB. Drives greater than

32GB will report 32GB.

J49

J50

C

C

O

J47

J48

O

C

J45

J46

O

C

J43

J44

J41

J42

Maxtor MaXLine II 250/300GB 2-7

Page 17

PRODUCT SPECIFICATIONS

3.1 Models and Capacities

MODELS 5A250J0 5A300J0

Chapter 3

Formatted Capacity

(GB LBA Mode)

GB means 1 billion bytes.

Total accessible capacity varies depending on operating environment.

The MaXLine exceeds the 137GB capacity barrier imposed by the 28 bit

addressing schemes common to many current BIOS and drivers. If your

system has 28 bit addressing logic your drive will appear to only have

137GB of capacity. You can upgrade your system to break this barrier

by installing a Maxtor PCI card kit (Maxtor p/n K01PCAT133). You may

also be able to upgrade your system by downloading new BIOS and/or

Drivers. Please visit our website www.maxtor.com/bigdrive for more

information and links to diagnostic and upgrade software.

For more information on breaking the 137GB capacity barrier please

refer to Appendix A.

250GB 300GB

Maxtor MaXLine II 250/300GB 3-1

Page 18

3.2 Drive Configuration

MODELS 250GB 300GB

Product Specifications

Sectors per Drive

(max LBA)

490,234,752 585,940,320

Integrated Interface Maxtor Ultra ATA/133 (ATA-5/ATA-6)

Recording Method PRML

Servo Type Embedded

Number of Servo

Sectors

256

Data Zones per Surface 16

Data Sectors per Track

(ID/OD)

Areal

Density

(Gbits/in

2

max ID/OD)

Flux Density

(kfci, ID/OD)

Recording Density

(kbpi,

ID/OD)

(80/160 disk configuration)

(80/160 disk configuration)

(80/160 disk configuration)

581/1126

61.5/53

673/574

646/550

Track

Density

(K TPI)

93

Maxtor MaXLine II 250/300GB 3-2

Page 19

3.3 Performance Specifications

MODELS 250GB 300GB

Seek Times (typical read, ms)

Track-to-Track <1.0

Product Specifications

Average (normal seek)

Full Stroke

(normal seek)

Average Latency (ms) 5.55

Controller Overhead (ms) <0.3

Rotation Speed

(RPM ±0.1%)

Data Transfer Speed (MByte/sec max)

To/From Interface

(Maxtor Ultra ATA/133,

up to)

To/From Media (OD/ID up to

nn.n, where nn.n is the

maximum transfer rate

possible)

Sustained (ID/OD up to

nn.n, where nn.n is the

maximum transfer rate

possible)

336Mbits/sec (OD) / 192Mbits/sec (ID)

≤ 10

24.0

5400

133

24/42

Data Buffer Size

(MB)/Type

Drive Ready Time

(typical sec)

2/SDRAM

<8.6

3.4 Physical Dimensions

PARAMETER VALUE

Height (maximum in mm) 26.1

Width (typical mm) 101.6

Depth

(Inches and mm) 5.787 in. max/147.0 mm max.

Maxtor MaXLine II 250/300GB 3-3

Page 20

PARAMETER VALUE

Weight (maximum in grams) < 610 grams

Product Specifications

Figure 3-1 Outline and Mounting Dimensions

Maxtor MaXLine II 250/300GB 3-4

Page 21

3.5 Power Requirements

MODE 12V (MA) 5V (MA) POWER (W)

Spin-up (peak) 1817.1 742.7 25.5

Seek 594.4 592.8 10.1

Read/Write 312 596 6.7

Idle 268.5 590.2 6.2

Standby 36.3 148.8 1.18

Sleep 36.3 146.8 1.17

3.6 Power Mode Definitions

Spin-up

The drive is spinning up following initial application of power and has

not yet reached full speed.

Product Specifications

Seek

A random access operation by the drive.

Read/Write

Data is being read from or written to the drive.

Idle

The drive is spinning, the actuator is parked and powered off and all

other circuitry is powered on.

The drive is capable of responding to read commands within 40 ms.

Standby

The motor is not spinning. The drive will leave this mode upon receipt

of a command that requires disk access. The time-out value for this

mode is programmable. The buffer is active to accept write data.

Sleep

This is the lowest power state – with the interface set to inactive. A

software or hardware reset is required to return the drive to the Standby

state.

3.7 EPA Energy Star Compliance

Maxtor Corporation supports the goals of the U.S. Environmental

Protection Agency’s Energy Star program to reduce the electrical power

consumption of computer equipment.

Maxtor MaXLine II 250/300GB 3-5

Page 22

3.8 Environmental Limits

Product Specifications

PARAMETER OPERATING

Temperature 5°C to 55°C

(with no ARR impact)

0

°C to 60°C

(margin demonstrated

Thermal Gradient 30

Relative Humidity 5% to 95% (non-condensing)

Wet Bulb 30

Altitude (relative to sea level) -650 to 10,000 feet -650 to 40,000 feet

Acoustic Noise

2

° C per hour (maximum)

° C (maximum)

IDLE MODE

1

)

(Track Following at Speed)

Ball Bearing 2.9 bel average

3.3 bel maximum

3.9 bel average

4.2 bel maximum

NON-OPERATING/

STORAGE

low temperature (-40

high temperature (71

per MIL-STD-810E, method

501.3, climatic category;

hot-induced conditions.

NORMAL SEEK MODE

Notes:

° C)

° C)

1. Margin Demonstrated implies the product will operate at the stated

conditions with an acceptable impact to the ARR specification for

any OEM requiring those values in their purchase specification.

2. The testing performed by Maxtor is consistent with ISO 7779.

Variation in acoustic levels from the idle specification may occur

due to offline activity according to the SMART specification and/

or atmospheric conditions.

Maxtor MaXLine II 250/300GB 3-6

Page 23

Product Specifications

3.9 Shock and Vibration

PARAMETER OPERATING NON-OPERATING

Mechanical Shock R=0.988/shock at 60 Gs;

R= 0.999/shock at 30 Gs

Rotational Shock R=0.988 @ 2000 rad/sec

Rotational Random

Vibration

5 - 2000 Hz

4.51 rad/sec

2

RMS Overall

Random Vibration 5 - 2000 Hz

0.45 GRMS

Swept Sine Vibration

(0.25 octave/minute,

peak amplitude)

5-1500Hz

Frequency (Hz) / Acceleration (Gpk)

5=0.38” DA

8.8=0.38” DA

9=1.500

90=1.500

600=0.060

1500=0.060

2 msec, 1/2 sine

R=0.90@>= 300G

R=0.95@>= 250G

2

R=0.95 @ 20K rad/sec2,

0.5ms to 1ms input

R=0.99 @ 15K rad/sec

2

,

0.5ms to 1ms input

2 - 300 Hz

96.5 rad/sec2 RMS

PSD:

7 - 800 Hz at 3.08 GRMS

No Damage

Maxtor MaXLine II 250/300GB 3-7

Page 24

3.10 Reliability Specifications

Annualized Return Rate

<1.0% Annualized Return Rate (ARR) indicates the average against

products shipped.

Start/Stop Cycles

>50,000 This indicates the average minimum cycles for reliable start/

stop function.

R=0.9998@ >4500, R=0.9995 @ >7500, R=0.5 @ >= 50000

Data Reliability

<1 per 10e15 bits read

Data errors (non-recoverable). Average data error rate

allowed with all error recovery features activated.

Component Design Life

5 years (minimum)

Product Specifications

Component design life is defined as a.) the time period

before identified wear-out mechanisms impact the failure

rate, or b.) the time period up to the wear-out point when

useful component life expires.

3.11 EMC/EMI

3.11.1 Radiated Electromagnetic Field Emissions - EMC Compliance

The hard disk drive mechanism is designed as a subassembly for

installation into a suitable enclosure and is therefore not subject to

Subpart J of Part 15 of FCC Rules (47CFR15) or the Canadian

Department of Communications Radio Interference Regulations.

Although not required, the disk mechanism has been tested within a

suitable end-use product and found to comply with Class B limits of the

FCC Rules and Regulations of the Canadian Department of

Communications.

The CE Marking indicates conformity with the European Union Low

Voltage Directive (73/23/EEC) when the disk mechanism is installed in

a typical personal computer. Maxtor recommends that testing and

analysis for EMC compliance be performed with the disk mechanism

installed within the user's end-use application.

3.11.2 Canadian Emissions Statement

This digital apparatus does not exceed the Class B limits for radio noise

emissions from digital apparatus as set out in the radio interference

regulations of the Canadian department of communications.

Maxtor MaXLine II 250/300GB 3-8

Page 25

Le present appareil numerique n'emet pas de bruit radioelectriques

depassant les limites applicables aux appareils numeriques de Class B

prescrites dans le reglement sur le brouillage radioelectrique edicte pa le

ministere des communications du Canada.

3.12 Safety Regulatory Compliance

All Maxtor hard drives comply with relevant product safety standards

such as CE, CUL, TUV and UL rules and regulations. As delivered,

Maxtor hard drives are designed for system integration before they are

used.

Product Specifications

Maxtor MaXLine II 250/300GB 3-9

Page 26

HANDLING AND INSTALLATION

4.1 Hard Drive Handling Precautions

• If the handling precautions are not followed, damage to the

hard drive may result whichmay void the warranty.

• During handling, NEVER drop, jar, or bump a drive. Handle

the drive by its sides and avoid touching the printed

circuit board assembly (PCBA).

• Hard drives are sensitive to electrostatic discharge (ESD)

damage. Use proper ESD practices by grounding yourself

and the computer system the hard drive will be installed in.

• Allow the hard drive to reach room temperature BEFORE

installing it in your computer system.

Chapter 4

• NEVER switch DC power onto the drive by plugging an

electrically live DC source cable into the drive's connector.

NEVER connect a live connector to the hard drive's IDE

interface connector.

• ELECTRICAL GROUNDING - For proper operation, the drive

must be securely fastened to a device bay that provides a

suitable electrical ground to the drive baseplate.

4.2 Electrostatic Discharge (ESD)

To better avoid problems associated with ESD, Maxtor advises that

anyone handling a disk drive use a wrist strap with an attached wire

connected to an earth ground. Failure to observe these precautions voids

the product warranty.

To reduce the incidence of ESD-related problems, Maxtor recommends

that any electronics manufacturing plans include a comprehensive ESD

program, the basic elements and functions of which are outlined here:

ESD Program Element ESD Program Function

Management Institute and maintain

Maxtor MaXLine II 250/300GB 4-1

Page 27

Chief coordinator Organize and enforce

Multi-department committee Evaluate and improve

Employee training Educate and inform

ESD program supplies typically include: wrist- and foot-worn grounding

straps; counter-top and floor antistatic matting; wrist strap testers; ESD

video and training materials. Sources for such supplies include:

Static Control Systems – 3M Desco-Charleswater

225-4S, 3M Center 3651 Walnut Avenue

St. Paul, MN 55144 Chino, CA 91710

Maxtor also offers a complete video training package, “Care and Handling

of Maxtor Disk Drives.” Contact your Maxtor representative for details.

4.3 Unpacking and Inspection

Handling and Installation

Phone: (909) 627-8178

Fax: (909) 627-7449

www.charleswater.com

Retain any packing material for reuse. Inspect the shipping container for

evidence of damage in transit. Notify the carrier immediately in case of

damage to the shipping container.

As they are removed, inspect drives for evidence of shipping damage or

loose hardware. If a drive is damaged (and no container damage is

evident), notify Maxtor immediately for drive disposition.

Maxtor MaXLine II 250/300GB 4-2

Page 28

Handling and Installation

Figure 4-1 Single-Pack Shipping Container

Maxtor MaXLine II 250/300GB 4-3

Page 29

Handling and Installation

20-pack cover

BC label (facing up)

Product in sealed

static shielding bag

20-pack tray

Sleeve

Carton tape

Carton

Figure 4-2 20-Pack Shipping Container

Maxtor MaXLine II 250/300GB 4-4

Page 30

4.4 Repacking

If a Maxtor drive requires return, repack it using Maxtor packing

materials, including the antistatic bag.

4.5 Physical Installation

The detailed installation instructions for Maxtor hard drives are provided

in the Installation Guide. To obtain a copy of the Installation Guide please

visit Maxtor’s web site at www.maxtor.com and select the product

family to view or download the correct installation information for this

product.

Handling and Installation

Maxtor MaXLine II 250/300GB 4-5

Page 31

Chapter 5

ATA BUS INTERFACE AND ATA COMMANDS

This chapter describes the interface between Maxtor MaXLine II 250/

300GB hard disk drives and the ATA bus. The commands that are issued

from the host to control the drive are listed, as well as the electrical and

mechanical characteristics of the interface.

5.1 INTRODUCTION

Maxtor MaXLine II 250/300GB hard disk drives use the standard ATA/

ATAPI interface. Support of various options in the standard are

explained in the following sections.

5.2 MECHANICAL INTERFACE

5.2.1 Signal Cable and Connector

The MaXLine II hard disk drive contains a 40-pin unitized connector for

both signal and power connections as well as configuration jumpers.

The dimensions and specifications of the unitized connector comply

with Annex. A in the ATA/ATAPI standard.

The MaXLine II drives require the use of an 80 conductor cable (ATA/

ATAPI-6, Annex. A, Figure A.4 and description) to support the drive’s

Ultra DMA capability.

5.3 ELECTRICAL INTERFACE

5.3.1 ATA Bus Interface

5.3.1.1 Electrical Characteristics

Signals on the ATA interface are assigned to connector pins according to

Annex. A in the ATA/ATAPI-6 standard for the 80 conductor cable

assembly. The signaling protocol complies with clause 9 and signal timing

complies with clause 10 of the standard.

The MaXLine II hard disk drives support all Ultra DMA Data Transfer

modes (0 - 5) defined in the ATA/ATAPI-6 standard. In addition, these

drives support Mode 6, and can send and receive data at the full 133MB/

s transfer rate.

Maxtor MaXLine II 250/300GB 5-1

Page 32

Hosts may assert the RESET- signal for longer than the minimum. When

power is applied with RESET- asserted, the MaXLine II disk media will not

begin to spin up until RESET- is negated. This may reduce maximum

current consumption for the overall system.

5.4 REGISTER ADDRESS DECODING

The MaXLine II hard disk drives allow their host systems to address the

full set of command and control registers as specified in clause 7 of the

ATA/ATAPI-6 standard. This includes the 48-bit Address feature set

described in clause 6.

5.5 COMMAND INTERFACE

5.5.1 General Feature Set

The µProcessor, Disk Controller, and ATA Interface electronics are

contained in a proprietary ASIC developed by Maxtor.

5.5.2 Supported Commands

ATA Bus Interface and ATA Commands

The MaXLine II hard disk drives support all the mandatory commands

from the general feature set for devices not supporting the Packet

command feature set. Refer to the ATA/ATAPI-6 standard for a detailed

description of these commands.

Table 5-1 lists the supported commands.

Table 5-1 Supported Commands

Command

CHECK POWER MODE 98h, E5h

DEVICE CONFIGURATION FREEZE LOCK B1h C1h

DEVICE CONFIGURATION IDENTIFY B1h C2h

DEVICE CONFIGURATION RESTORE B1h C0h

DEVICE CONFIGURATION SET B1h C3h

DOWNLOAD MICROCODE 92h 07h, 01h

EXECUTE DRIVE DIAGNOSTIC 90h

Command

Code

Feature

Register

Value(s)

FLUSH CACHE E7h

IDENTIFY DRIVE ECh

Maxtor MaXLine II 250/300GB 5-2

Page 33

Table 5-1 Supported Commands

ATA Bus Interface and ATA Commands

Command

IDLE 97h, E3h

IDLE IMMEDIATE 95h, E1h

NOP 00h

READ BUFFER E4h

READ DMA C8h, C9h

READ LONG 22h, 23h

READ MULTIPLE C4h

READ NATIVE MAX ADDRESS F8h

READ SECTOR(S) 20h, 21h

READ VERIFY SECTOR(S) 40h, 41h

SECURITY DISABLE PASSWORD F6h

SECURITY ERASE PREPARE F3h

Command

Code

Feature

Register

Value(s)

SECURITY ERASE UNIT F4h

SECURITY FREEZE LOCK F5H

SECURITY SET PASSWORD F1h

SECURITY UNLOCK F2h

SEEK 70h

SET FEATURES EFh Note 1

SET MAX ADDRESS F9h 00h

SET MAX SET PASSWORD F9h 01h

SET MAX LOCK F9h 02h

SET MAX UNLOCK F9h 03h

SET MAX FREEZE LOCK F9h 04h

SET MULTIPLE MODE C6h

SLEEP 99h, E6h

Maxtor MaXLine II 250/300GB 5-3

Page 34

Table 5-1 Supported Commands

ATA Bus Interface and ATA Commands

Command

SMART DISABLE OPERATIONS B0h D9h

SMART ENABLE OPERATIONS B0h D8h

SMART ENABLE/DISABLE ATTRIBUTE AUTOSAVE B0h D2h

SMART EXECUTE OFF-LINE IMMEDIATE B0h D4h

SMART READ DATA B0h D0h

SMART READ LOG B0h D5h

SMART RETURN STATUS B0h DAh

SMART SAVE ATTRIBUTE VALUES B0h D3h

SMART WRITE LOG B0h D6h

STANDBY 96h, E2h

STANDBY IMMEDIATE 94h, E0h

WRITE BUFFER E8h

Command

Code

Feature

Register

Value(s)

WRITE DMA CAh, CBh

WRITE MULTIPLE C5h

WRITE PIO OVERLAP 34h

WRITE SECTOR(S) 30h, 31h

Note: 1. As defined in the ATA/ATAPI-6 standard.

Maxtor MaXLine II 250/300GB 5-4

Page 35

SERVICE AND SUPPORT

6.1 Product Support/Technical Assistance/Customer Service

For Product Service and Support Information please visit our site at:

Chapter 6

www.maxtor.com

technical support.

for warranty service or www.maxtorkb.com for

Maxtor MaXLine II 250/300GB 6-1

Page 36

BREAKING THE 137 GIGABYTE STORAGE

This appendix provides information about the 137GB storage barrier. It

discusses the history, cause and the solution to overcome this barrier.

A.1 Breaking the 137 Gigabyte Storage Barrier

Capacity barriers have been a fact of the personal computer world since

its beginnings in the early 1980’s. At least 10 different capacity barriers

have occurred in the storage industry over the last 15 years. The most

notable barriers seen previously have been at 528 megabytes and then at

8.4 gigabytes.

The most recent barrier which will be surmounted in 2001, is the 137gigabyte limit or a single ATA drive. The first ATA devices to exceed 137

gigabytes will be four-platter hard disk drives with 40 gigabytes per

platter, yielding 160 gigabytes per drive. These drives will be available in

the second half of 2001. Later in the same year, capacity will continue to

grow to 60 gigabytes per platter, and a three-disk, 180-gigabyte device

will be available and shipping.

Appendix A

BARRIER

The ANSI NCITS T13 Technical Committee (also known as the ANSI ATA

committee) has broken this barrier by incorporating a proposal from

Maxtor into the ATA/ATAPI-6 draft standard that defines a method for

48-bit addressing on a single drive, giving more than 144 petabytes

(144,000 gigabytes) of storage.

In addition, the proposal from Maxtor that was incorporated into ATA/

ATAPI-6 defines a method for extending the maximum amount of data

that can be transferred per command for ATA devices from 256 sectors

(about 131 kilobytes) to 65,536 sectors (about 33 megabytes). This new

method is particularly useful for applications that use extremely large

files, such as those for A/V or multimedia.

The following sections will describe issues surrounding the 137-gigabyte

barrier and the solution for breaking it.

Maxtor MaXLine II 250/300GB A-1

Page 37

A.1.1 History

Many of the “barriers” in the past resulted from BIOS and operating

system issues caused by failure to anticipate the remarkable increases in

device storage capacity by the people who designed hard disk structures,

access routines, and operating systems many years ago. They thought,

“Who will ever have xxx much storage?” In some cases, the barriers were

caused by hardware or software bugs not found until hard disks had

grown in size beyond a certain point where the bugs would occur.

Past barriers often frustrated people trying to add a new hard disk to an

older system when they discovered that not all of the designed capacity

of the hard disk was accessible. This inability to access the entire drive is

referred to as a “capacity barrier” and it has been seen and overcome

many times in the computer and disk drive industry.

The 137-gigabyte barrier is the result of the original design specification

for the ATA interface that provided only 28 bits of address for data. This

specification means a hard disk can have a maximum of 268,435,456

sectors of 512 bytes of data which puts the ATA interface maximum at

137.4 gigabytes.

Breaking the 137GB Storage Barrier

Maxtor MaXLine II 250/300GB A-2

Page 38

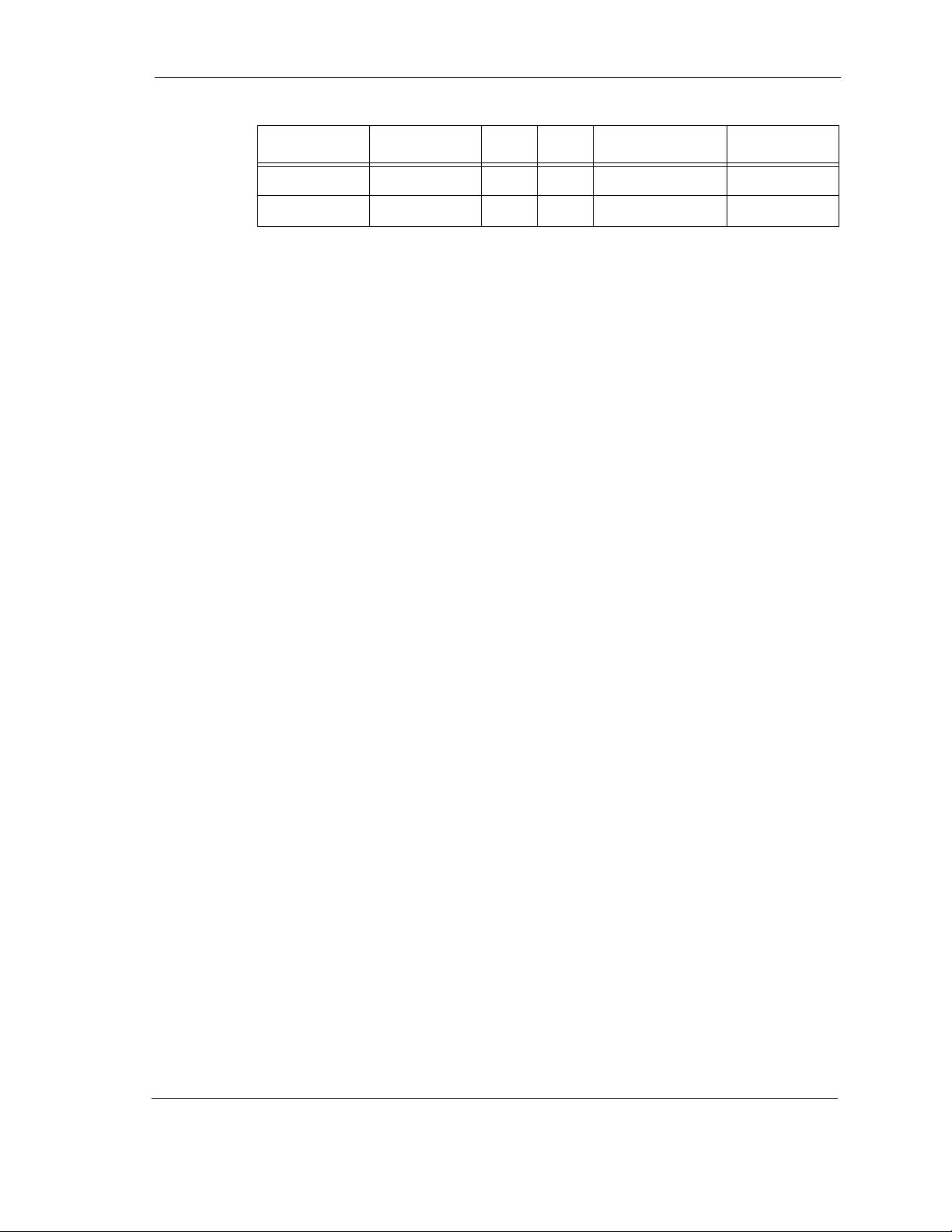

10,000, 000

t

1,000, 000

Breaking the 137GB Storage Barrier

100,000

10,000

1,000

100

10

DOS

5.x

4.x

3.x

10MB

16MB

Win95A

Win 3.x

32MB

128MB

Win98

Win95(osr2)

4GB

2GB

528MB

Win2000

WinME

33GB

8GB

137GB

WinXP

1980 1985 1990 1995 2000 2005

10 megabytes:early PC/XT limi

16 megabytes: FAT 12 limit

32 megabytes: DOS 3.x limit

128 megabytes: DOS 4.x limit

528 megabytes: Early ATA BIOSs without BIOS extensions

2.1 gigabytes: DOS file system partition limit

4.2 gigabytes: CMOS extended CHS addressing limit (not widely experienced)

8.4 gigabytes: BIOS/Int13 24-bit addressing limit

32 gigabytes: BIOS limit

Maxtor MaXLine II 250/300GB A-3

Page 39

A.1.2 Solving the 137 Gigabyte Capacity Barrier

As described earlier, the issue causing the 137-gigabyte barrier is the 28bit addressing method of the original ATA specification. A change to

expand this method was required to provide more address bits for the

interface, allowing significant growth for many years to come. A critical

issue in expanding the addressing capability was maintaining

compatibility with the existing installed base of products.

A new ATA standard, ATA/ATAPI-6, has been in the works for some

time, and the latest draft of this standard resolves this issue by increasing

the maximum number of bits used for addressing from 28 to 48. This

solution increases the maximum capacity of an ATA device to 144

petabytes while maintaining compatibility with current ATA products.

A.1.3 How is the Extension Implemented?

The 48-bit Address feature set provides a method to address devices with

capacities up to approximately 144 petabytes by increasing the number

of bits used to specify logical block addresses (LBAs) from 28 to 48. The

feature set also provides a method to increase the number of sectors that

can be transferred by a single command from 256 to 65,536 by

increasing the number of bits specifying sector count to 16 bits.

Breaking the 137GB Storage Barrier

New commands specific to this feature set have been defined so that

devices can implement the new feature set in addition to previously

defined commands. Devices implementing the 48-bit Address feature set

commands will also implement commands that use 28-bit addressing in

order to maintain interoperability with older system components. In

addition, 8-bit and 48-bit commands may be intermixed.

The 48-bit Address feature set operates in LBA addressing only. Support

of the 48-bit Address feature set is indicated in the IDENTIFY DEVICE

response data. In a device implementing the 48-bit Address feature set,

the registers used for addressing are, in fact, a two-byte deep FIFO. Each

time one of these registers is written, the new content written is placed

into the “most recently written” location and the previous content of the

register is moved to “previous content” location. A host may read the

“previous content” of the registers by first setting a bit in the Device

Control register to 1 and then reading the desired register.

A.1.4 What Do the Drives Need to Meet the Spec?

The challenge to drive manufacturers is to develop and implement new

interface chips on drives that can accept and decode the new 48-bit

addressing scheme. Many functions of decoding the commands sent to

and from the drive are automated in the silicon of the drive interface

ASIC, and this is where drive manufacturers must update their designs.

Maxtor is the leader in development efforts and is the first to deliver a

product with the capacity and drive technology to deliver greater than

137 gigabytes of capacity.

Maxtor MaXLine II 250/300GB A-4

Page 40

A.1.5 What Else is Involved?

Effort is required from OS vendors to increase storage device addressing

up to 48 bits or more. This increase will be a significant challenge for

many OS vendors that have 32-bit code models. Adapting to 48-bit

commands will be easy, but most vendors will stop filling data at the 32bit boundary and pad the upper 16 bits with zeros, leaving that space

empty.

The BIOS companies will also have to perform some work to recognize

the increased capacity of the devices attached to the bus and allow the

extended 48-bit commands to pass on to the devices. Boot partitions will

also be an issue for the capacity of the drive if the BIOS does not

recognize the 48-bit addressing scheme at or before the system boots the

OS from the hard drive.

Independent software driver efforts for legacy operating systems

(Windows NT 4, Windows 98, and so on) will need to be implemented to

allow higher-capacity devices to work on installed systems and recognize

the maximum available capacity of the drive over the 137-gigabyte limit.

A.1.6 What is the Next Barrier?

Breaking the 137GB Storage Barrier

While it is true that the ATA/ATAPI-6 standard defines a method to

provide a total capacity for a device of 144 petabytes, the next limit will

be imposed not by the ATA devices but by many of the popular operating

systems in use today. This limit will be at 2.2 terabytes (2,200

gigabytes). This barrier exists because many of today’s operating

systems are based on 32-bit addressing. These operating systems include

many flavors of Linux, Mac OS 9.x, and Windows 95, 98, ME, NT 4,

2000, and XP (Windows XP/64-bit also has the limit because of leveraged

32-bit code).

This barrier could be real as early as 2004 if current hard drive capacity

rate increases continue along the same growth trends.

Maxtor MaXLine II 250/300GB A-5

Page 41

Breaking the 137GB Storage Barrier

Appendix A: Terminology

• BIOS: (an acronym for Basic Input/Output System design):

The BIOS processes and redirects all data as it is being

accessed and stored.

• FAT: (an acronym for File Allocation Table): The FAT tells the

computer where data has been stored on the hard drive.

• CHS: (an acronym for Cylinders, Heads, and Sectors): The

basic layout components of a hard drive. INT 13h & INT 13h

extensions: protocols used for accessing data on hard drives.

Appendix B: Big Numbers

• 131 kilobytes = 131,000 bytes

a little more than 30 pages of text

• 33 megabytes = 33,000,000 bytes

more than 8,000 pages of text or 25 300-page books

• 137 gigabytes = 137,000,000,000 bytes

more than 100,000 books, or the contents of a good library

• 2.2 terabytes = 2,200,000,000,000 bytes

almost 2,000,000 books, or the about content of the Library of

Congress

• 144 petabytes = 144,000,000,000,000,000 bytes

120 billion books – (more than all that man has written)

• 9.4 zettabytes = 9,400,000,000,000,000,000,000 bytes

Appendix C: Resources

• Maxtor “Big Drive” web site for resource information:

http://www.maxtor.com/bigdrive

• ATA/ATAPI-6: http://www.T13.org

Maxtor MaXLine II 250/300GB A-6

Page 42

GLOSSARY

A

ACCESS – (v) Read, write, or update

information on some storage medium,

such as a disk. (n) One of these

operations.

ACCESS TIME – The interval between

the time a request for data is made by

the system and the time the data is

available from the drive. Access time

includes the actual seek time,

rotational latency, and command

processing overhead time. See also

seek, rotational latency, and overhead.

ACTUATOR – Also known as the

positioner. The internal mechanism

that moves the read/write head to the

proper track. The Maxtor actuator

consists of a rotary voice coil and the

head mounting arms. One end of each

head mounting arm attaches to the

rotor with the read/write heads

attached at the opposite end of each

arm. As current is applied to the rotor,

it rotates, positioning the heads over

the desired cylinder on the media.

ALLOCATION – The process of

assigning particular areas of the disk to

particular files. See also allocation unit.

B

BACKUP – A copy of a file, directory,

or volume on a separate storage device

from the original, for the purpose of

retrieval in case the original is

accidentally erased, damaged, or

destroyed.

BAD BLOCK – A block (usually the size

of a sector) that cannot reliably hold

data because of a media flaw or

damaged format markings.

BAD TRACK TABLE – A label affixed to

the casing of a hard disk drive that tells

which tracks are flawed and cannot

hold data. The listing is typed into the

low-level formatting program when the

drive is being installed. Because Maxtor

disk drive’s defect-management

scheme handles all such flaws

automatically, there is no need to

concern yourself with bad track tables.

BIT – Abbreviation for binary digit. A

binary digit may have one of two

values—1 or 0. This contrasts with a

decimal digit, which may have a value

from 0 to 9. A bit is one of the logic 1or

logic 0 binary settings that make up a

byte of data. See also byte.

ALLOCATION UNIT – An allocation

unit, also known as a cluster, is a group

of sectors on the disk that can be

reserved for the use of a particular file.

AVERAGE SEEK TIME – The average

time it takes for the read/write head to

move to a specific location. To

compute the average seek time, you

divide the time it takes to complete a

large number of random seeks all over

the disk by the number of seeks

performed.

BLOCK – A sector or group of sectors.

By default, a block of data consists of

512 bytes.

BPI – Abbreviation for bits per inch. A

measure of how densely information is

packed on a storage medium. Flux

changes per inch is also a term

commonly used in describing storage

density on a magnetic surface.

BUFFER – An area of RAM reserved for

temporary storage of data that is

waiting to be sent to a device that is

not yet ready to receive it. The data is

Maxtor MaXLine II 250/300GB G-1

Page 43

Glossary

usually on its way to or from the disk

drive or some other peripheral device.

BUS – The part of a chip, circuit board,

or interface designed to send and

receive data.

BYTE – The basic unit of computer

memory, large enough to hold one

character of alphanumeric data.

Comprised of eight bits. See also bit.

C

CACHE – Random-access memory

used as a buffer between the CPU and

a hard disk. Information more likely to

be read or changed is placed in the

cache, where it can be accessed more

quickly to speed up general data flow.

CAPACITY – The amount of

information that can be stored on a disk

drive. The data is stored in bytes, and

capacity is usually expressed in

megabytes.

CDB – Command Descriptor Block. The

SCSI structure used to communicate

requests from an initiator (system) to a

target (drive).

CLEAN ROOM – An environmentally

controlled dust-free assembly or repair

facility in which hard disk drives are

assembled or can be opened for

internal servicing.

CLUSTER – A group of sectors on a

disk drive that is addressed as one

logical unit by the operating system.

CONTROLLER – Short form of disk

controller. The chip or complete circuit

that translates computer data and

commands into a form suitable for use

by the disk drive.

CONTROLLER CARD – An adapter

holding the control electronics for one

or more hard disks, usually installed in

a slot in the computer.

CPU – Acronym for Central Processing

Unit. The microprocessor chip that

performs the bulk of data processing in

a computer.

CRC – Acronym for Cyclic Redundancy

Check. An error detection code that is

recorded within each sector and is used

to see whether parts of a string of data

are missing or erroneous.

CYLINDER – On a disk drive that has

more than one recording surface and

heads that move to various tracks, the

group of all tracks located at a given

head position. The number of cylinders

times the number of heads equals the

number of tracks per drive.

D

DATA SEPARATOR – On a disk drive

that stores data and timing information

in an encoded form, the circuit that

extracts the data from the combined

data and clock signal.

DEDICATED SERVO – A surface

separate from the surface used for data

that contains only disk timing and

positioning information and contains no

data.

DEFECT MANAGEMENT – A method

that is implemented to ensure long

term data integrity. Defect

management eliminates the need for

user defect maps. This is accomplished

by scanning the disk drives at the

factory for defective sectors. Defective

sectors are deallocated prior to

shipment. In addition, during regular

use, the drive continues to scan and

compensate for any new defective

sectors on the disk.

DISK – In general, any circular-shaped

data-storage medium that stores data

on the flat surface of the platter. The

most common type of disk is the

magnetic disk, which stores data as

magnetic patterns in a metal or

metal-oxide coating. Magnetic disks

come in two forms: floppy and hard.

Optical recording is a newer disk

technology that gives higher capacity

storage but at slower access times.

Maxtor MaXLine II 250/300GB G-2

Page 44

Glossary

DISK CONTROLLER – A plug-in board,

or embedded circuitry on the drive, that

passes information to and from the

disk. The Maxtor disk drives all have

controllers embedded on the drive

printed-circuit board.

DISKWARE – The program instructions

and data stored on the disk for use by

a processor.

DMA – Acronym for direct memory

access. A process by which data

moves directly between a disk drive (or

other device) and system memory

without passing through the CPU, thus

allowing the system to continue

processing other tasks while the new

data is being retrieved.

DRIVE – Short form of disk drive.

DRIVE GEOMETRY – The functional

dimensions of a drive in terms of the

number of heads, cylinders, and

sectors per track. See also logical

format.

own power supply and fan, and

connected to the system by a cable.F

FAT – Acronym for file allocation table.

A data table stored on the outer edge

of a disk that tells the operating system

which sectors are allocated to each file

and in what order.

FCI – Acronym for flux changes per

inch. See also BPI.

FILE SERVER – A computer that

provides network stations with

controlled access to shareable

resources. The network operating

system is loaded on the file server, and

most shareable devices (disk

subsystems, printers) are attached to

it. The file server controls system

security and monitors

station-to-station communications. A

dedicated file server can be used only

as a file server while it is on the

network. A non dedicated file server

can be used simultaneously as a file

server and a workstation.

E

ECC – Acronym for error correction

code. The recording of extra verifying

information encoded along with the

disk data. The controller uses the extra

information to check for data errors,

and corrects the errors when possible.

EMBEDDED SERVO – A timing or

location signal placed on the disk’s

surface on the tracks that also store

data. These signals allow the actuator

to fine-tune the position of the

read/write heads.

ENCODING – The protocol by which

particular data patterns are changed

prior to being written on the disk

surface as a pattern of On and Off or 1

and 0 signals.

EXTERNAL DRIVE – A drive mounted

in an enclosure separate from the PC or

computer system enclosure, with its

FLUX DENSITY – The number of

magnetic field patterns that can be

stored in a given length of disk surface.

The number is usually stated as flux

changes per inch (FCI), with typical

values in the thousands.

FLYING HEIGHT – The distance

between the read/write head and the

disk surface caused by a cushion of air

that keeps the head from contacting

the media. Smaller flying heights

permit more dense storage of data, but

require more precise mechanical

designs.

FORMAT – To write onto the disk

surface a magnetic track pattern that

specifies the locations of the tracks

and sectors. This information must

exist on a disk before it can store any

user data. Formatting erases any

previously stored data.

FORMATTED CAPACITY – The

amount of room left to store data on

the disk after the required space has

Maxtor MaXLine II 250/300GB G-3

Page 45

Glossary

been used to write sector headers,

boundary definitions, and timing

information generated by a format

operation. All Maxtor drive capacities

are expressed in formatted capacity.

FORM FACTOR – The physical outer

dimensions of a device as defined by

industry standard. For example, most

Maxtor disk drives use a 3 1/2-inch

form factor.

G

GIGABYTE (GB) – One billion bytes

(one thousand megabytes).

GUIDE RAILS – Plastic strips attached

to the sides of a disk drive mounted in

an IBM AT and compatible computers

so that the drive easily slides into

place.

H

HALF HEIGHT – Term used to describe

a drive that occupies half the vertical

space of the original full size 5 1/4-inch

drive. 1.625 inches high.

HARD DISK – A type of storage

medium that retains data as magnetic

patterns on a rigid disk, usually made

of an iron oxide or alloy over a

magnesium or aluminum platter.

Because hard disks spin more rapidly

than floppy disks, and the head flies

closer to the disk, hard disks can

transfer data faster and store more in

the same volume.

HIGH-LEVEL FORMATTING –

Formatting performed by the operating

system’s format program. Among

other things, the formatting program

creates the root directory and file

allocation tables. See also low-level

formatting.

HOME – Reference position track for

recalibration of the actuator, usually

the outer track (track 0).

HOST ADAPTER – A plug-in board that

forms the interface between a

particular type of computer system bus

and the disk drive.

I

INITIALIZE – See low level formatting.

INITIATOR – A SCSI device that

requests another SCSI device to

perform an operation. A common

example of this is a system requesting

data from a drive. The system is the

initiator and the drive is the target.

INTERFACE – A hardware or software

protocol, contained in the electronics

of the disk controller and disk drive,

that manages the exchange of data

between the drive and computer.

INTERLEAVE – The arrangement of

sectors on a track. A 1:1 interleave

arranges the sectors so that the next

sector arrives at the read/write heads

just as the computer is ready to access

it. See also interleave factor.

HARD ERROR – A repeatable error in

disk data that persists when the disk is

reread, usually caused by defects in the

media surface.

HEAD – The tiny electromagnetic coil

and metal pole piece used to create and

read back the magnetic patterns (write

and read information) on the media.

HIGH-CAPACITY DRIVE – By industry

conventions typically a drive of 1

gigabytes or more.

INTERLEAVE FACTOR – The number of

sectors that pass beneath the

read/write heads before the next

numbered sector arrives. When the

interleave factor is 3:1, a sector is

read, two pass by, and then the next is

read. It would take three revolutions of

the disk to access a full track of data.

Maxtor drives have an interleave of

1:1, so a full track of data can be

accessed within one revolution of the

disk, thus offering the highest data

throughput possible.

Maxtor MaXLine II 250/300GB G-4

Page 46

INTERNAL DRIVE – A drive mounted

inside one of a computer’s drive bays

(or a hard disk on a card, which is

installed in one of the computer’s

slots).

J

JUMPER – A tiny box that slips over

two pins that protrude from a circuit

board. When in place, the jumper

connects the pins electrically. Some

board manufacturers use Dual In-Line

Package (DIP) switches instead of

jumpers.

K

KILOBYTE (K) – A unit of measure

consisting of 1,024 (210) bytes.

L

LANDING ZONE – A position inside the

disk’s inner cylinder in a non data area

reserved as a place to rest the heads

during the time that power is off. Using

this area prevents the heads from

touching the surface in data areas upon

power down, adding to the data

integrity and reliability of the disk drive.

LATENCY – The period of time during

which the read/write heads are waiting

for the data to rotate into position so

that it can be accessed. Based on a

disk rotation speed of 3,662 rpm, the

maximum latency time is 16.4

milliseconds, and the average latency

time is 8.2 milliseconds.

LOGICAL FORMAT – The logical drive

geometry that appears to an AT

system BIOS as defined by the drive

tables and stored in CMOS. With an

installation program like Disk Manager,

the drive can be redefined to any

logical parameters necessary to adapt

to the system drive tables.

LOOK AHEAD – The technique of

buffering data into cache RAM by

reading subsequent blocks in advance

Glossary

to anticipate the next request for data.

The look ahead technique speeds up

disk access of sequential blocks of

data.

LOW-LEVEL FORMATTING –

Formatting that creates the sectors on

the platter surfaces so the operating

system can access the required areas

for generating the file structure. Maxtor

drives are shipped with the low-level

formatting already done.

LOW PROFILE – Describes drives built

to the 3 1/2-inch form factor, which

are only 1 inch high.

M

MB – See megabyte.

MEDIA – The magnetic film that is

deposited or coated on an aluminum

substrate which is very flat and in the

shape of a disk. The media is

overcoated with a lubricant to prevent

damage to the heads or media during

head take off and landing. The media is

where the data is stored inside the disk

in the form of magnetic flux or polarity

changes.

MEGABYTE (MB) – A unit of

measurement equal to 1,024 kilobytes,

or 1,048,576 bytes except when

referring to disk storage capacity.

1 MB = 1,000,000 bytes when

referring to disk storage capacity.

See also kilobyte.

MEGAHERTZ – A measurement of

frequency in millions of cycles per

second.

MHz – See megahertz.

MICROPROCESSOR – The integrated

circuit chip that performs the bulk of

data processing and controls the

operation of all of the parts of the

system. A disk drive also contains a

microprocessor to handle all of the

internal functions of the drive and to

Maxtor MaXLine II 250/300GB G-5

Page 47

Glossary

support the embedded controller.

MICROSECOND (µs) – One millionth of

a second (.000001 sec.).

MILLISECOND (ms) – One thousandth

of a second (.001 sec.).

MTTF – MTTF is a basic measure of

reliability for non-repairable systems. It

is the mean time expected until the first

failure of a piece of equipment. MTTF

is a statistical value and is meant to be

the mean over a long period of time and

large number of units. For constant

failure rate systems, MTTF is the

inverse of the failure rate. If failure rate

is in failures/million hours, MTTF =

1,000,000 / Failure Rate for

components with exponential

distributions.

MTTR – Mean Time To Repair. The

average time it takes to repair a drive

that has failed for some reason. This

only takes into consideration the

changing of the major sub-assemblies

such as circuit board or sealed housing.

Component level repair is not included

in this number as this type of repair is

not performed in the field.

N

NANOSECOND (ns)– One billionth of a

second (0.000000001 second).

O

P

PARTITION – A portion of a hard disk

devoted to a particular operating

system and accessed as one logical

volume by the system.

PERFORMANCE – A measure of the

speed of the drive during normal

operation. Factors affecting

performance are seek times, transfer

rate and command overhead.

PERIPHERAL – A device added to a

system as an enhancement to the basic

CPU, such as a disk drive, tape drive or

printer.

PHYSICAL FORMAT – The actual

physical layout of cylinders, tracks,

and sectors on a disk drive.

PLATED MEDIA – Disks that are

covered with a hard metal alloy instead

of an iron-oxide compound. Plated

disks can store greater amounts of data

in the same area as a coated disk.

PLATTER – An disk made of metal (or

other rigid material) that is mounted

inside a fixed disk drive. Most drives

use more than one platter mounted on

a single spindle (shaft) to provide more

data storage surfaces in a small

package. The platter is coated with a

magnetic material that is used to store

data as transitions of magnetic

polarity.

OVERHEAD – The processing time of a

command by the controller, host

adapter or drive prior to any actual disk

accesses taking place.

OVERWRITE – To write data on top of

existing data, erasing it.

OXIDE – A metal-oxygen compound.

Most magnetic coatings are

combinations of iron or other metal

oxides, and the term has become a

general one for the magnetic coating

on tape or disk.

POH – Acronym for power on hours.

The unit of measurement for Mean

Time Between Failure as expressed in

the number of hours that power is

applied to the device regardless of the

amount of actual data transfer usage.

See MTBF.

POSITIONER – See actuator.

R

REDUNDANT ARRAY OF

INDEPENDENT DISKS (RAID) - is a way

of storing the same data in different

places (thus, redundantly) on multiple

Maxtor MaXLine II 250/300GB G-6

Page 48

Glossary

hard disks. By placing data on multiple

disks, I/O operations can overlap in a

balanced way, improving performance.

Since multiple disks increases the

mean time between failure (MTBF),

storing data redundantly also increases

fault-tolerance.

A RAID appears to the operating

system to be a single logical hard disk.

RAID employs the technique of