289 SERIES

FLOW METER TRANSMITTERS

INSTRUCTION MANUAL

289 SERIES TRANSMITTER

289-763 Pickup Coil/Amplifier, Amphenol Connector

289-773 Pickup Coil/Amplifier, Weather-Tight, Explosion-Proof*

TABLE OF CONTENTS

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . .Pg 2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Pg 3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Pg 4

User Options & Adjustments . . . . . . . . . . . . . . . . . . . . .Pg 5

Maximum Transmission Distance . . . . . . . . . . . . . . . . . .Pg 6-7

Typical K-Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Pg 8

Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Pg 9

*U.L.Class I, Group C & D

Class II, Group E, F & G

289-760-350 © 1987 (Rev 5/06), Max Machinery, Inc.

Max Machinery, Inc. reserves the right to make changes to the product in this Instruction

Manual to improve performance, reliability, or manufacturability. Consequently, contact

MMI for the latest available specifications and performance data.

Although every effort has been made to ensure accuracy of the information contained in

this Instruction Manual, MMI assumes no responsibility for inadvertent errors.

289-760-350 © 1987 (Rev 5/06) Max Machinery, Inc. ( 2 )

The 289 Series Transmitter has an inductive pickup which senses the motion of an internal

flow meter gear. As the tooth of a gear moves under the core of the pickup, a voltage is

induced in a coil wound around the core. The gear is fastened to the rotor shaft of the 240

Series meter, which allows its rotational rate to be directly proportional to the flow rate.

The output of the pickup coil is amplified and squared before being sent to the output

terminals. The resulting pulse train is relatively insensitive to interference and can be

transmitted as far as generally required.

General Description

( 3 ) 289-760-350 © 1987 (Rev 5/06) Max Machinery, Inc.

Specifications

289-763/773 5V Square Wave Output:

Power Requirements:

Voltage (5V regulator on PCA) . . . . . . . . . . . . . . . . . . . . .5-24VDC

Nominal (3.5-30V Max)

Current (No Load)

Supply Voltage Operating Calibrating

3.5V 1.1mA 1.6mA

5.0 - 24.0V 1.8mA 3.0mA

Output Signal

Shape . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Square Wave

Amplitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5V

Rise and Fall Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3µS

Output Impedance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<200ohms

Maximum Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5kHz

Minimum Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1/50Hz

Output vs Load: (Supply > 5.2V)

Load mA Output Low Output Hi

0.1mA 0V 5.00V

1.0mA 0V 4.85V

5.0mA 0V 4.25V

10.0mA 0V 3.45V

Temperature Limits (All Models):

Operating

Electronics . . . . . . . . . . . . . . . . . . . . . . . . . .-5 to 150F (-20 to 65C)

Pickup Coil . . . . . . . . . . . . . . . . . . . . .-148 to 450F (-100 to 232C)

Storage

Electronics . . . . . . . . . . . . . . . . . . . . . . . . .-40 to 175F (-40 to 80C)

Pickup Coil . . . . . . . . . . . . . . . . . . . . .-148 to 450F (-100 to 232C)

289-760-350 © 1987 (Rev 5/06) Max Machinery, Inc. ( 4 )

Installation

Mounting: The Model 289 transmitter screws on and off of the flow meter. Because of the

random location of the starting point of the threads, one transmitter will probably not line up

with the "in" and "out" ports of the flow meter like another will. The electrical outlet of the

transmitter can be rotated one turn by loosening the clamping screw. (See drawing, page 2)

Moisture Protection: The electrical circuitry of the weather-tight, explosion proof transmitter

is enclosed in a liquid and vapor tight enclosure. All joints are sealed by welding or by "O"rings. If this sealed condition is to be maintained, the conduit connection to the enclosure

should be made liquid and vapor tight by using pipe dope or a potting fitting (U.L. requires a

potting fitting within 18" of the transmitter.). If a transmitter is located outside and this

precaution is not taken, moisture may form inside the housing. This will cause the circuitry to

give an inaccurate output or possibly no output at all. In the long run it will cause corrosion

and failure. The amphenol connector versions of the 289 Series Transmitter offer moderate

protection from moisture and dust but are not totally sealed.

Temperature Considerations: High ambient temperatures (120°F/50°C) should be avoided if

possible. It is a good idea to locate the transmitter away from hot spots such as steam pipes,

ovens and heaters. The electronics of the 289 Series Transmitters are rated for operation up to

65°C or 150°F. Because some heat travels from the flow meter to the transmitter

electrical enclosure, the temperature the electronics see is a function of both the ambient

and the flow meter temperature. The graph below shows the relationship between the

maximum ambient transmitter temperature and the fluid temperature through the flow meter.

The pickup coil of the 289 Series Transmitter is insulated with an epoxy that is rated to

232°C/450°F. This is the maximum flow meter fluid temperature.

( 5 ) 289-760-350 © 1987 (Rev 5/06) Max Machinery, Inc.

User Options & Adjustments

289-763/773 TRANSMITTER

Grounding: S2-l connects Common and Case directly together. S2-2 connects Common and

Case through 4.7 µF capacitors. By using either switch the effects of electrical noise on the

transmitter can be reduced. If the system is not grounded at the indicator or if the flow meter

is not physically grounded through its plumbing, use S2-l. If the system is grounded at the

indicator, use S2-2. This allows electrical noise between the case and the circuitry of the

transmitter to be reduced without causing ground loop problems. To activate either switch,

depress the side of the switch that is numbered.

Sensitivity Adjustment R2, S1, LED: For best results, the transmitter amplifier sensitivity

should be adjusted to match the output voltage of the particular pickup and flow meter it is

mated to. This is typically factory calibrated, but should be checked if the coil or circuit board

is changed or if the transmitter is switched from one flow meter to another.

To adjust the sensitivity, set the flow rate through the flow meter to approximately midrange.

Press the Sensitivity Adjustment Switch (S1): One or both sides of the LED should come on.

Turn the Sensitivity pot (R2) FCW then turn it CCW just until both sides of the LED show

equal brightness or are on for about equal periods of time (if the frequency is low).

Outputs: The Model 289 transmitter output is generally sent to a signal conditioner display

such as the Max 120, which provides signal dampening, scaling, and rate/total displays; as

well as supplying power to the transmitter. A complete line of LCD display instrumentation is

also available from MAX for flow rate, total, batching, and flow control .

S1 Sensitivity

Adjust Switch

Coil Connectors

R2 Sensitivity Adjust

Amphenol Pinout (Optional)

A = Ground

B = Common

C = 5 to 24VDC

D = Square Wave Output

E = No Connection

F = No Connection

Sensitivity Adjust LED

Amphenol

Connection Option

Signal (White) (D)

Power (Red) (C)

Common (Black) (B)

Ground (Green) (A)

S2-1 Ground

S2-2 Filter

289-760-350 © 1987 (Rev 5/06) Max Machinery, Inc. ( 6 )

Maximum Transmission Distance

MAXIMUM TRANSMISSION DISTANCE

The graph below shows typical conductor capacitance load vs. cable length for several types

of cable. For instance, 1,000 ft. of 7 conductor #18 gauge stranded wire will put a 0.04 µF

capacitive load on the output of the Model 289 transmitter.

( 7 ) 289-760-350 © 1987 (Rev 5/06) Max Machinery, Inc.

Maximum Transmission Distance

MAXIMUM TRANSMISSION DISTANCE

(continued)

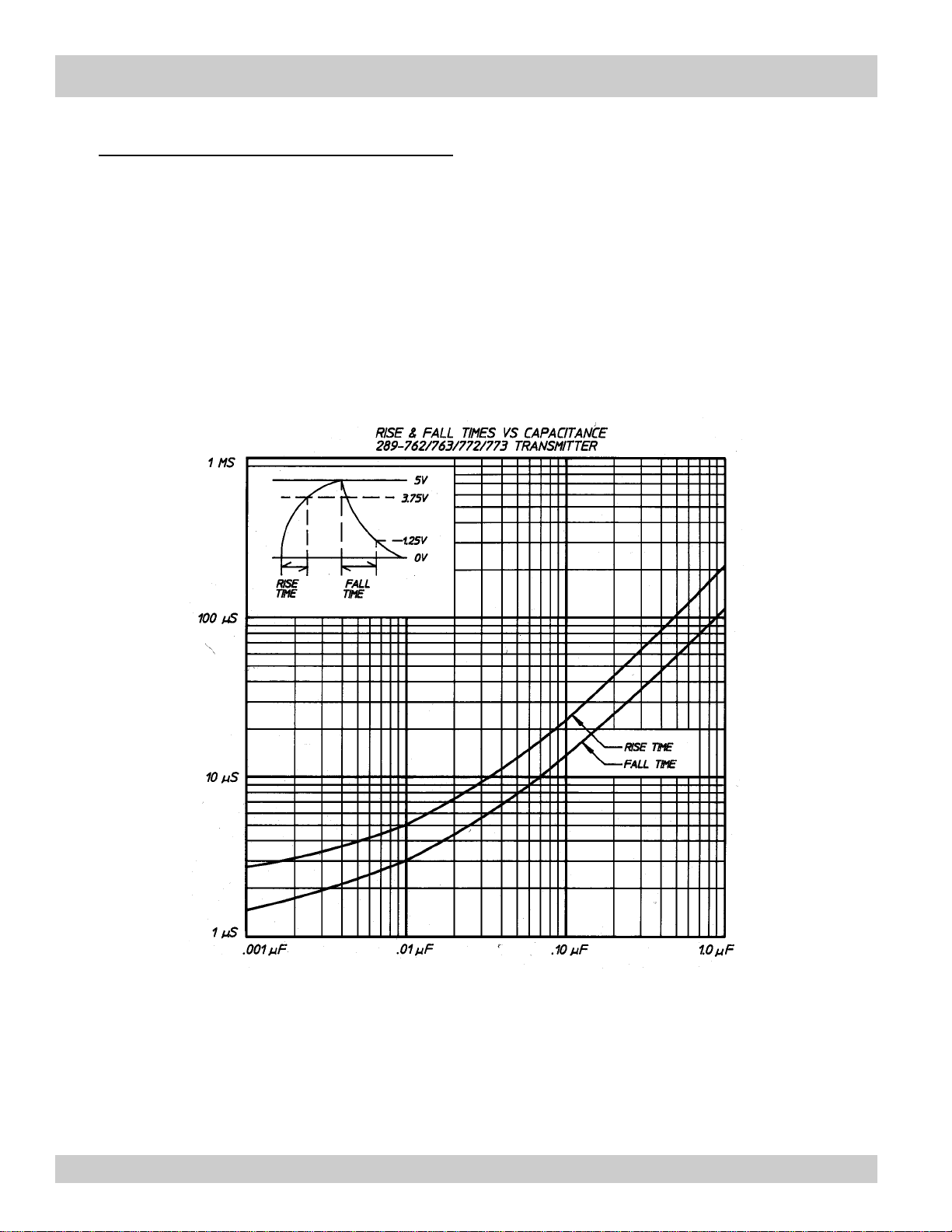

The graph below provides the relationship between output capacitance loading and rise and

fall time for the Model 289-763/773 output signal. For instance, with 0.4 µF the rise time of

the Model 289 is about 89 µS, and the fall time about 45 µS. Consequently, the absolute

maximum frequency the 289 could put out would be 1/(80 + 45) µS = 8000 Hz (frequency =

1/time). The signal would be a saw tooth pattern. Generally, the transmitter will drive 5000

feet or more of cable with no problem.

289-760-350 © 1987 (Rev 5/06) Max Machinery, Inc. ( 8 )

Typical K-Factors / Typical Connections

Typical K-Factors for 240 Series Flow Meters using the 289 Series Transmitter

241 Flow Meter (.062 Liter/Rev)

Pulses/Liter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .403

Maximum Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .190 L/min

242 Flow Meter (.182 Liter/Rev)

Pulses/Liter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .219

Maximum Rate:

SS Rotors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .450 L/min

AL Rotors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .540 L/min

243 Flow Meter (.574 Liter/Rev)

Pulses/Liter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

Maximum Rate:

SS Rotors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1000 L/min

AL Rotors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1400 L/min

244 Flow Meter (1.70 Liter/Rev)

Pulses/Liter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58.8

Maximum Rate:

SS Rotors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2400 L/min

AL Rotors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3500 L/min

Loading...

Loading...