Discontinued

INSTRUCTION MANUAL

286-300 SERIES TRANSMITTERS

286-

313: Transmitter with Amphenol Connector

286-

323: Transmitter, Weather-Tight, Explosion Proof*

286-

3x4:

Transmitter with Output Level Shifter Option

286-31x-

General Description...................................................

Specifications............................................................

Mechanical Installation.............................................

Outputs, Options, and Indicators...............................

Calibration.................................................................Pg 9

Maximum Transmission Distance.............................

K-

factors....................................................................

Appendix A: Remote Mount Transmitter .................

Appendix B: Output Level Shifter Option................

Schematics:

5xx: Transmitter with Remote PCA

286-313181-000-

TABLE OF

201 RVDT Schematic

250 Interconnect Schematic

CONTENTS

Pg 2

Pg 3

Pg 4

Pg 6

Pg 11

Pg 13

Pg 14

Pg 16

-5

-8

-10

-12

-15

* U.L. Class I, Group C & D

Class II, Group E, F & G

286-300-

nd

2

Max Machinery, Inc.

performance, reliability, or manufacturability. Contact

performance data.

Although every effort h

manual,

MMI

assumes no responsibility for inadvertent errors.

reserves the right to make changes to the product in this instruction manual to improve

as been made to ensure accuracy of the information contained in this instruction

350 © 2002,

Rev: 4/03, added Appendix A and B

Max Machinery, Inc.

MMI

for the latest available specifications and

Discontinued

General Description

General Description

The 286Meter into a frequency proportional to the flow rate. This is accomplished using a differential transformer

technique, which puts no torque requirements on the flow measuring elements and enables extremely fast

output response rates. A microprocessor measures position changes of the metering elements and generates

the corresponding output pulse stream.

When used with the

variations in rotational velocity of

output frequency.

The 286This simplifies matching of flow meter and transmit

The Model 286 features an antidither output buffer. If the flow reverses (for less than ½ revolution of

the flow meter), and then returns to the forward direction, the transmitter pulse output will represent only

the total forward flow. The two-phase output is not buffered; it is an instantaneous indicator of metering

element position. The antidithering is a useful feature when the flow stops or is very low, and vibration or

hydraulic noise causes th

3XX Series Transmitter converts the rotary motion of the metering elements insi

3XX Series circuitry has self

de a

Max

Series 210 Piston Flow Meters, these transmitters will compensate for cyclical

the metering pistons (inherent in the four piston design) to give a steady

-calibration routines that can be initiated with the push of a button.

ter in the event that field maintenance is required.

e flow metering elements to reverse direction.

Max

Flow

The transmitter can be powered from a 4.5V to 30VDC supply. The user can select between two types

of outputs: a square wave output or a two

square wave output. The user can select from square wave outputs of 24, 50, 100, 200, 300, 500, 600 or

1000 pulses per revolution, or two-phase outputs of 12, 25, 50, 100, 150, 250, 300 or 500 pulses per

revolution (on each phase).

-phase output where the frequency of each phase is half that of th

e

(2)

286-300-

350 © 2002,

Max Machinery, Inc.

Discontinued

Specifications

Specifications

Supply Voltage........................................................................

Supply Current....................................

Output

Maximum Rotor RPM...........................................................................

Minimum Rotor RPM..................................................................................

Pulse Width Variation

Output Lag

Ambient Temper

Estimated Microprocessor Memory Lifetime

Antidither Range

(5.0V Supply) ..........................................................................................Hi Lo

No Load..............................................................................................

2.5k Load to Common........................................................................ 4.60 V 0.04 V

2.5k Load to +5 Volts.........................................................................

Short Circuit Current

Output Impedance...............................................................................100

Rise Time ...............................................................................

Fall Time................................................................................

Maximum Frequency .........................................................................

Minimum Frequency..............................................................................

2

................................................................................................

Electronics

Stator .......................................................................

80°C....................................................................................................

55°C and below................................................................................

Pulse Output..........................................................................

Switching of Pin #6

4.5 VDC to 30 VDC

12mA Typical, 20mA Maximum (+ Load)

1

.........................................................................

0.15 uS (90%)

0.15 uS (90%)

3600 RPM

(between consecutive rising edges) ..................

ature Limits

Storage........................................................................-40°C to 85°C

Operation....................................................................-40°C to 80°C

3

-40°C to 130°C (265°F)

4

1/2 Revolution

………………………………………….1/4 Revolution

4.80 V 0.04 V

4.80 V 0.25 V

45 mA

60 kHz

0 RPM

15% max

0.25 mS

20 yrs.

>50 yrs.

0 Hz

1

Continuous Short Circuit is not recommended. The sum of output currents during operation should not exceed 30 mA (i

mA on one output or 15 mA on two outputs).

2

Events are seen as output transitions 0.25 mS after they occur

3

Temperature of metered fluid will affect transmitter temperature, see pg. 4

4

See pg. 8 for more information

286-300-

350 © 2002,

Max Machinery, Inc.

.e.: 30

(3)

Discontinued

Mechanical Installation

Installation

Mounting:

the starting point of the threads, one transmitter will probably not line up with the “in” and “out”

flow meter like another will. The electrical outlet of the transmitter can be rotated clockwise or counter

clockwise one turn by loosening the clamping screw. See the Transmitter Diagram (

Two flats are provided for installing the transmitter on the flow meter. Care should be taken when installing

and removing the transmitter. The wire of the stator is of fine gauge and can be easily damaged.

Moisture Protection:

circuitry enclosed in a liquid-tight and vapora weather tight condition is desired, either the Amphenol or the weatherwill work. To

explosion proof transmitter is required, a potted seal fitting must be used.

If a transmitter is located outside and is not properly sealed, moisture may form

will cause the circuitry to give an inaccurate output or, in some cases, no output at all. In the long run, this

will cause corrosion and failure.

The Model 286 transmitter screws on and off of the flow meter. Due to the random location of

The Amphenol and the weather-

seal the weather-tight transmitter, pipe dope must be used on the liquid

ports of the

next page

tight, explosion-proof transmitte

tight enclosure. All joints are sealed by welding or O-rings. If

tight, explosion

-tight conduit. If an

inside the housing. This

).

rs both have their

-proof transmitter

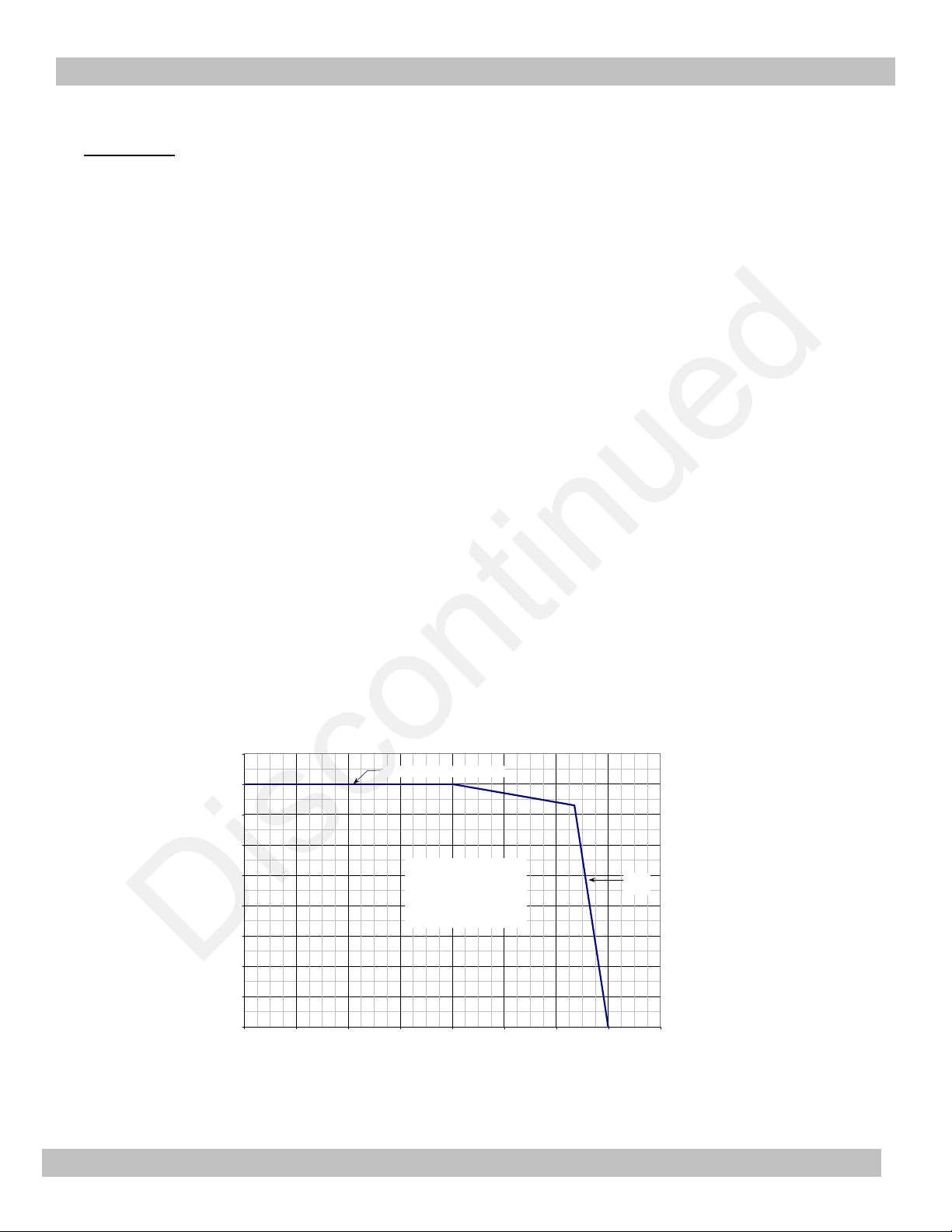

Temperature Considerations: High ambient temperatures (> 120°F/ 50°C) should

It is a good idea to locate the transmitter away from hot spots such as steam pipes, ovens and heaters. The

electronics of the 286 Series Transmitters are rated for operation up to 80° C (175° F). Because some heat

travels from

function of both the ambient and the flow meter temperature. The graph below shows the relation between

the maximum ambient transmitter temperature and the flu

the flow meter to the transmitter electrical enclosure, the temperature of the electronics is a

id temperature through the flow meter.

Transmitter High Temperature Limits

90

80

70

60

50

40

Ambient Temp (°C)

30

20

10

0

0

20 40 60 80 100 120 140 160

Limit for Transmitter Electronics

SAFE

OPERATING

REGION

Flow Meter Fluid Temp (°C)

Stator

Limit

be avoided if possible.

The stator of the 286 transmitters is insulated with an electrical coating that is rated to 130°C which limits

the maximum flow meter fluid temperature to about 130°C (265°F).

(4)

286-300-

350 © 2002,

Max Machinery, Inc.

Discontinued

Mechanical Installation

Transmitter Diagram

Retaining

Ring

O-Ring

O-Ring

Connector

1/

2" NPT or

Weather tight

Amphenol

Circuit Board

Clamp Screw

LOOSEN TO ROTATE

ELECTRICAL HOUSING

Stator Assembly

O-Ring

Wrench Flats

Rotor Assembly

Transmitter - Flowmeter

Threaded Connection

210 Series

Flow Meter

IN

(5)

286-300-

350 © 2002,

Max Machinery, Inc.

Discontinued

Options & Stat

Outputs, Options & Indicators

Outputs, Options and Indicators

Connections:

The interconnect drawing number 181

information on interfacing to Max signal conditioners and indicators.

Output Protection:

Voltage should no

accidentally applied to an output, resistors and diodes will protect the circuitry. Higher voltages will

destroy the resistors and/or diodes.

Grounding:

S1-1: This

S1

-2: This switch, (labeled FILTER) connects Common and Case through two back-to-

capacitors.

By using either S1-1 or S1

system is not grounded at the indicator or if the flowmeter is not physically grounded through its

plumbing, use S1

noise between the case and the trans

problems. To activate either switch, depress the side that is numbered on the switch (and labeled

‘GND’ or ‘FILTER’ on the printed circuit board).

us Indicators

t be applied to any output (terminals 4, 5, and 6). If a low voltage,

switch, (labeled GND) connects Common and Case directly together.

-2, the effects of electrical noise on the transmitter ca

-1. If the system is grounded at the indicator, use S1-2. This allows electrical

-000-250 at the end of this manual provides detailed

n be reduced. If the

mitter circuitry to be reduced without causing ground loop

5V or less, is

back 15 uF

Meter Selection:

S4-1: Depress side that cor

Flow Meters, and 220/240 is for

When used with

constant rotationa

rate. If this switch is placed in the wrong position (for either a 210 or 220/240 meter), the output

frequency will oscillate

Two

-Phase or Square Wave Select:

S4

-2: Depress side that corresponds to desired output. ‘2PH’ gives a 2with the two phases separated by 90° (Ph A on Terminal 5 and Ph B on Terminal 6). The ‘COMB

OUT’ setting gi

a single output of double the frequency (Combined Output on Terminal 4, Direction on Terminal 6).

If S4-2 is set wrong, an unexpected output signal will result since the

for the two distinct output options (see chart below).

responds to meter type. The 210 setting is for

Max

Series 220 Gear and 240 Helix meters.

Max

Series 210 Piston Flow Meters, the Model 286 will compensate for the non

l velocity of the crankshaft, yielding a steady output frequency at a constant flow

20% about its nominal value, four cycles per

ves a single square wave output that combines the information in the two phases into

Terminal Output Signals vs. S4-2 Setting

Connector

Terminal(s)

4,5

6

S4-2 = 'COMB OUT'

(combined output)

Pulse Output

Direction

S4-2 = '2Ph'

(2-phase output)

Phase A

Phase B

Max

Series 210 Piston

revolution.

phase quadrature output

same output circuitry is used

-

(6)

286-300-

350 © 2002,

Max Machinery, Inc.

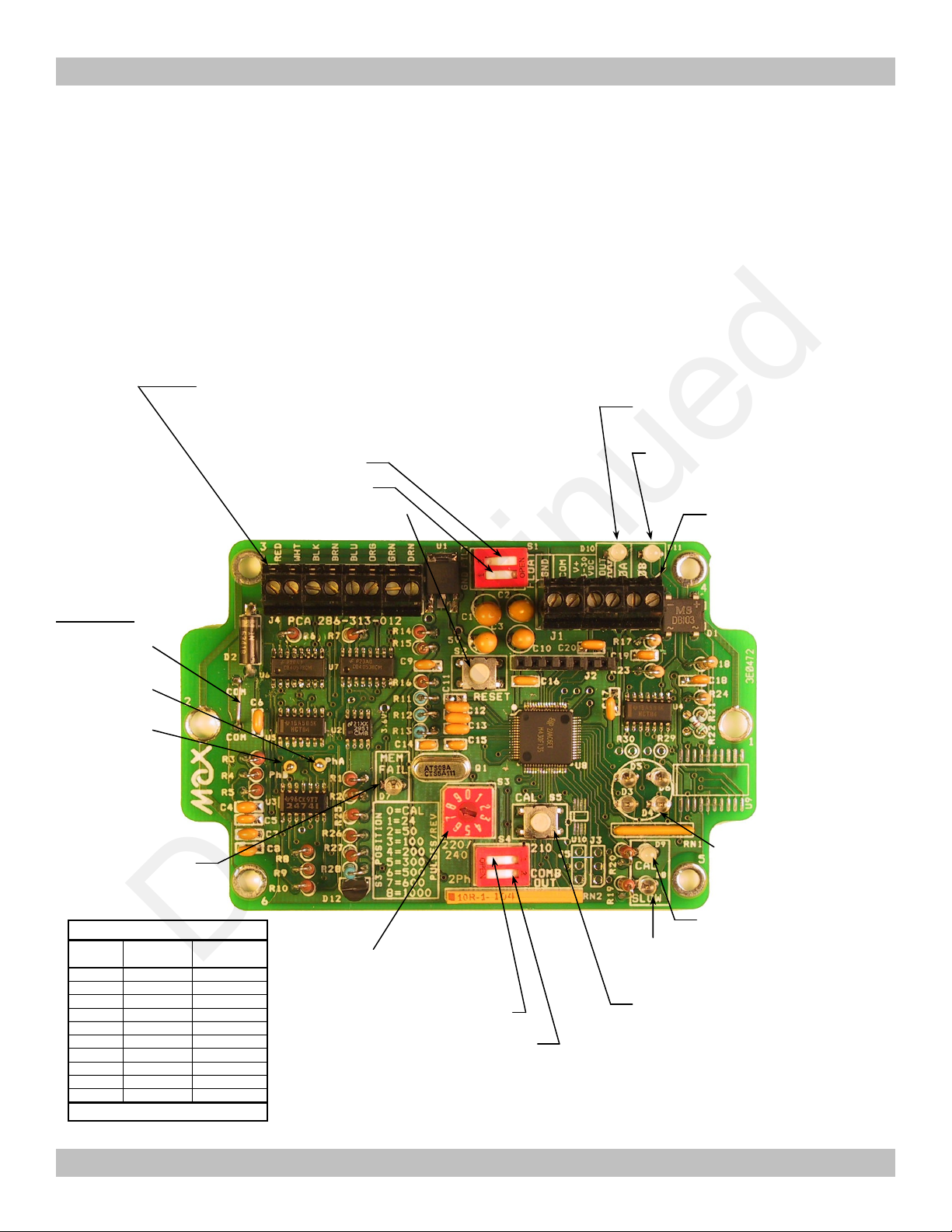

D10

D11

S4-2:

S5:

S3:

Output Frequency Select

D7

S4-1:

Stator Phase A Testpoint

Stator Phase B Testpoint

Common Testpoint

S2

: Reset Microcontroller

D3-D6

: RVDT Rotor Position

S3

2-Phase

Combined

Position

Output

Output

9**

Discontinued

Outputs, Options & Indicators

Output Frequency Select:

S3: Rotary switch allows selection of output resolutions of 24 to 1000 pulses per revolution (square

wave output), or 12 to 500 pulses per r

The resolution can be changed while the tachometer is operating, and the new value will take effect

immediately. See chart below for resolution at each switch setting.

Indication (4

S1-2: Filter

S1-1:

Ground

LED’s)

evolution (per phase) if the 2-phase output option is selected.

Terminal Block

1. Case (Green)

2. Common (Black)

3. Power 5-30VDC (Red)

4. Combined Output (White)

5. Phase A Out (Orange)

6. Phase B Out or Direction (Blue)

J2

: Header for Factory Programming Only

D8

: Flow too low to cal

ibrate

: Microcontroller Memory

Status (On = Fail)

And Calibration Enable

Cycles per Revolution

0

1

2

3

4

5

6

7

8

* Not Specified, Usually same as S3=8

0 (Calibrate)

12

25

50

100

150

250

300

500

0 (Calibrate)

24

50

100

200

300

500

600

1000

D9

: Calibration Active

: Direction/Phase B (Terminal 6

Status) (High = Green, Low = Red)

: Output/Phase A (Terminal 4/5

Status) (High = Green, Low = Red)

Select Meter Type

Output Select (2

Output) Assigns outputs of Terminals 4

D10 and D11.

Calibrate Stator Offsets

(and

Angle). Need S3 in

position 0 to start Calibration.

- Phase or Combined

*

-6 and

* Phase A leads Phase B when meter

is turning CCW (forward flow on

piston and

gear style meters, reverse

flow on helix meters). Indicated at

terminal 6 by a 5 VDC signal and the

changing of D10 to green.

286

-300-

350 © 2002,

Max Machinery, Inc.

(7)

Discontinued

Outputs, Options & Indicators

Output Indicators:

D10, D11: These bi-color (red, green) LEDs indicate the status of the outputs. If the 2-phase output

mode has been selected, the state of Phase A and Phase B are each shown on the corresponding

LEDs (‘O

‘OUT/

the direction.

Microprocessor Reset:

S2: In the event that the tachometer does not appear to be operating correctly, resetting the

microprocessor by momentarily depressing S2 may solve the problem. While the reset button is

depressed, the ‘MEM FAIL’ LED will turn on, and if the memory is good, the LED should turn back

off when

RVDT Rotor Position Indication LED’s:

D3

can be a helpful troubleshooting aid when trying to determine if a meter is turning or not. Th

rotational pattern observed on the LED’s corresponds directly to the rotational speed of the RVDT

rotor. At high speeds, the LED’s will just look like they are blinking; the human eye can no longer

discern the direction of motion. At very high speeds t

will all appear to be a constant brightness. At these higher speeds, a divide

activated by pressing S5 (the ‘CAL’ button, make sure S3 is not in the 0 position, otherwise the

calibration

output frequency does not change.

A’ shows the status of the pulse output channel, and the LED labeled ‘DIR/

the button is released.

-D6: These LED’s provide a graphical representation of the position of the RVDT rotor. This

A’ and ‘DIR/

UT/

routine will be run!). This only slows down the Rotor Position indication LEDs, the

B’). If the combined output mode has been selected, the LED labeled

B’ indicates

he blinking will not even be obvious and they

-by-ten feature can be

e

‘CAL’ LED:

D9: This LED changes color (red to green or green to red) 4 times per revolution while the

microprocessor is performing the

complete, it will turn off. See Calibration Section for more information on calibration procedures.

‘SLOW’ LED:

D8: If a calibration is initiated but the flow rate is too low to give acceptab

will be aborted, and this LED will light up red for 10 seconds. See Calibration Section for more

information on calibration procedures.

‘MEMORY FAIL’ LED:

D7: The microprocessor continually checks the integrity of its progra

more memory values do not read what they are supposed to, this LED will turn on. Two possible

causes of memory failure are prolonged operation/storage at temperatures exceeding the ratings and

transient voltages applied to inp

appear to be functioning correctly and this LED is on, the unit should be sent back to the factory for

service.

calibration routine on the stator coils. When calibration is

le results, the calibration

m storage memory. If one or

uts and/or outputs that exceed ratings. If the transmitter does not

(8)

286-300-

350 © 2002,

Max Machinery, Inc.

Rotational Speed of Piston Meter Crankshaft At Constant Flow

Crankshaft Rotational

Discontinued

Calibration

Calibration

The coils of the Model 286 stator, the printed circuit b

one set. When used with any flow meter model, the calibration procedure initiates a routine that

determines the offsets needed to balance the output signals from all of the coils. When used with a 210

ser

ies piston flow meter, the calibration procedure includes an additional routine that measures the

angular position of the stator with respect to the meter. This allows the transmitter to compensate for

cyclical variations in rotational velocity of the met

1 is in the 210 position (piston meter), the calibration will automatically include both of the routines

described above. If S4

routine will be performed.

The recommended flow range for calibration is that which will turn the meter at 20-500 rpm. Lower

flow rates (resulting in rotor speeds below 20 RPM) will cause the ‘SLOW’ LED to come on and the

calibration will not take

500 RPM) but the results may not be as good as those which would be obtained at a lower flow rate. A

flow rate resulting in a flow meter rotor velocity of 100 rpm will give

When doing a calibration on a piston meter, it is critical that the flow rate remains constant (less than

10% variation) for the routine that determines the stator angle to be successful. When a steady flow

passes through a four-piston meter, the crankshaft speeds up and slows down 4 times per revolution.

The phase of this cyclic speed variation is determined during calibration by finding the position of the 4

speed peaks in a revolution. These speed peak locations are measur

run through an averaging procedure. Once this is done, the tachometer can internally compensate for the

speed variations to output a steady frequency under steady flow conditions.

oard, and the flow meter need to be calibrated as

er, resulting in a steady output frequency. When S4

-1 is in the 220/240 position (Gear or Helix Meter), only the coil balanci

place. Successful calibration will occur at higher flow rates (rotor speeds above

good calibration results.

ed for 8 revolutions (32 peaks), then

ng

-

Error can be introduced into this ph

piston pump). If there are peaks in the flow rate that overshadow the speed peaks due to the 4geometry, the calibration routine will incorrectly determine the phase of the cyclic speed variation and

will subsequently apply the compensation out of phase.

Speed

0 90

180 270 360 450 540 630 720

asing procedure if the system flow rate is pulsating (i.e.: driven by a

piston

Crankshaft Angle

286-300-

350 © 2002,

Max Machinery, Inc.

(9)

Discontinued

Calibration

The phase balancing routine that occurs for all types of meters requires 16 revolutions of the meter to

reach completion. The ‘CAL’ LED changes color (red to green or gree

or 64 blinks for the entire calibration. The angular position determination (phasing) requires 8

revolutions, so the ‘CAL’ LED will blink an additional 32 times after the 64 phase balancing blinks

when calibration is performed on a piston meter. If the flow is stopped partway through a calibration,

the blinking will stop and the calibration will not reach completion since it requires a fixed number of

meter revolutions. In such a case, a new calibration should be done at

When to Calibrate

Calibration should be performed under the following conditions:

1. The Model 286 Tachometer is mated to a flow meter to which it has not been previously

calibrated.

2. If the circuit board of the Model 286

3. If the connector between the pickup coils and the circuit board is reversed.

n to red) 4 times per revolution,

is changed.

a steady flow rate.

4. If it is suspected that the output signal contains more frequency modulation than it should have.

(i.e.: Pulse widths vary by more than

per revolution)

Calibration Procedure

1. Ensure that S4-1 is set correctly (210 for piston meters, 220/240 for gear or helix meters).

2. Set up a steady flow rate through the meter that results in a meter

somewhere around 100 rpm. The position indication LED’s in the center of the circuit board can aid in

rpm determination (i.e.: at 100 rpm, each light will blink 10 times in 6 seconds).

3. Rotate S3 to the ‘0’ position to

4. Press the ‘CAL’ button, S5. If the ‘SLOW’ LED (D8) comes on, wait 10 seconds for it to go off,

increase the flow rate and try pressing the ‘CAL’ button again.

5. Wait for the ‘CAL’ LED (D9) to stop blinking and turn back off.

position indication LED’s in the center of the board will pause. As soon as the calibration is complete,

they will resume activity.

enable calibration.

15%, and variati

ons are not random, but cyclical at 4 times

rpm between 20 and 500, ideally

While the calibration is active, the

6. The calibration is now complete. Return S3 to the appropriate setting to get th

output pulses per revolution.

(10)

286-300-

350 © 2002,

e desired number of

Max

Machinery, Inc.

Discontinued

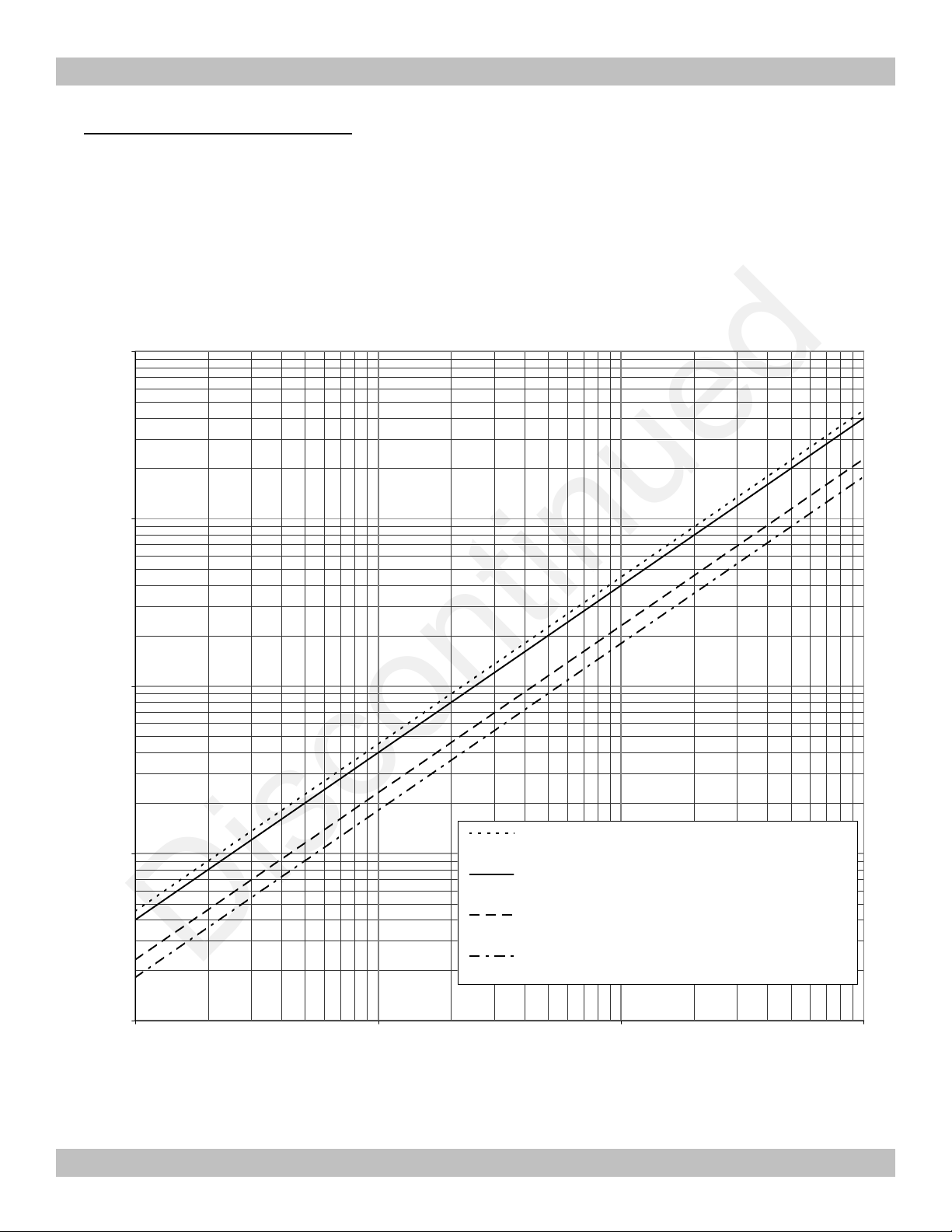

Maximum Transmission Distance

Maximum Transmission Distance

The graph below indicates typical conductor capacitance loads versus cable length for several types of

cable. For instance, 1000 feet of 7 conductor #18 gauge stran

the output of the 286-3XX Series Transmitters.

Cable Capacitance vs. Length

100

10

ded wire will put a 0.04 uF capacitive load on

1

Capacitance (uF)

0.1

0.01

1 10

2 or 4 Conductor Shielded Cable

Belden 8762 V1000 (20 GA), Belden 8723 (2 Shielded Pair)

7 Conductor Cable

National Type N W718-J (18 GA)

4 16 Gauge Wires in EMT Conduit

RG 59U Coaxial Cable

Columbia 1112 Foam

Cable Length (feet)

100

1000

286-300-

350 © 2002,

Max Machinery, Inc.

(11)

Discontinued

Maximum Transmission Distance

Maximum Transmission Distance

The graph below shows the relationship between output capacitance loading and rise and fall time for

the Model 286

the rise/fall time is 10 uS. Consequently, the absolute maximum frequency the Model 286 could transmit

would be 50 kHz (frequency = 1/time, where time include

following page for maximum frequencies possible with different flow meters.

-3XX output signal. For instance, with 0.04uF load capacitance (1000 ft. shielded cable typ.)

286-313 Output Rise and Fall Time vs. Load Capacitance

(rise and fall time measured between 10% and 90% of full output swing)

1000

(continued)

s the rise and fall times for one cycle). See

100

10

Rise and Fall Time (uS)

1

0.1

(12)

0.001

0.01

Output Capacitance Load (uF)

286-300-

0.1

350 © 2002,

1

Max Machinery, Inc.

New

Resolution

245

0.00396

0.165

5600

370

15,400

Maximum Output Frequency Range

Discontinued

K-

K-

Factors

Factors

K-factors represent the number of pulses the transmitter outputs per unit volume of fluid passing through

flow meter. This number is dependent on the flow meter and the transmitter resolution setting (switch S3).

Max Machinery indicators can be adjusted to display the desired units (ccs, lbs, gallons, quarts, etc.) by

using the K-factor.

Flow meters ar

of this K-factor is provided for each customer. The values shown below are typical. If the output resolution

setting is changed (via S3), the K-

286-3xx K-Factor Ranges (pulses/cc) with various Max flow meters*

Model

213

214

215

216

220

221

222

241

242

243

244

e multi-point calibrated at the factory. The K

factors will s

New K-factor

Combined Output

K-factor Range (pulses/cc)

Min

(@24 pulses/rev)

27.6

2.28

0.504

0.142

2.28

1.02

0.506

0.386

0.132

0.0417

0.0139

(@1000 pulses/rev)

E

Max

1150.0

95

21.0

5.9

95.0

42.5

21.1

16.1

5.50

1.74

0.579

cale proportionally:

xistingKfactor

Maximum

Rate

(liters/min)

1.8

10

40

100

3

15

38

190

540

1400

2800

-factor varies slightly with flow rate. A graph

E

xisting

Resolution

(Hz)**

Min

(@24 pulses/rev)

828 34,500

380 15,870

336 14,000

237 9,870

114 4,760

255 10,630

320 13,350

1,220 50,900

1,190 49,520

973 40,500

649 27,040

Max

(@1000 pulses/rev)

the

*typical values; may vary by up to 5% on specific flow meters.

**Maximum Count Speed of Max Machinery Indicators:

Model 120 <= 7500 Hz

Model 121 <= 20,000 Hz

If the frequency output at the application’s maximum flow rate exceeds the indicator’s c

the transmitter resolution setting (S3) will need to be adjusted to proportionally reduce the

meter/transmitter’s K

286

-300-

350 © 2002,

-Factor.

Max Machinery, Inc.

ount speed, then

(13)

Discontinued

Appendix A: Remote Mount Transmitter

286-313-500 Remote Mount Transmitter (Aluminum Housing)

286-313286-314286-314-

General

Mounting

525 Remote Mount Transmitter (Polycarbonate Ho

500 Remote Mount Transmitter with Output Level Shifter (Aluminum Housing)

525 Remote Mount Transmitter with Output Level Shifter (Polycarbonate Housing)

The 286-313located separately from the flowmeter and RVDT stator. This may be desirable when a smaller

flowmeter package is required, when the flowmeter is subjected to high ambient temperatures (ie:

environmental chamber), or for any number of other reasons. Both the remote circuit board housing and

the stator housing are fully sealed. The functionality of the remote transmitter is identical to the

standard transmitter. There are some differences in appearance and installation due to the

housing and extra connections to the remote stator cable: these are addressed in the information below.

The cylindrical aluminum stator housing mounts on the flow meter. Care should be taken when

installing and removing the stator h

damaged. Two wrench flats are provided for installing and removing. The stator housing only needs to

be tightened with enough torque to compress the O-ring and prevent unscrewing due to m

vibrations and cable forces. 10-15 ft-lbs. of torque is sufficient. DO NOT OVERTIGHTEN!

500 and 286

-313-

525 Remote Mount Transmitters allow the tra

ousing. The wire of the stator is of fine gauge and can be easily

using)

nsmitter circuitry to be

different

echanical

The sealed aluminum or polycarbonate NEMA 4 box containing the circuit board has mounting holes in

the four corners that are accessed by removing the cover

with space for a 0.265” or smaller head. The aluminum box has 0.185” holes with space for 0.300” or

smaller head. An 8

-32 socket head cap screw works well for both.

. The polycarbonate box has 0.175” dia. holes

(14)

286-300-

350 © 2002,

Max

Machinery, Inc.

D1

0

S4-2:

S5:

S3:

Output Frequency Select

D7

S4-1:

Stator Phase B

Common

S2

: Reset Microcontroller

D3-D6

: RVDT Rotor Position

S3

2-Phase

Combined

Position

Output

Output

9**

J4: Stator Cable Terminal Block

D11

Discontinued

Appendix A: Remote Mount Transmitter

Temperature Considerations

Continuo

avoided if possible. It is a good idea to locate both of these components away from hot spots such as

steam pipes, ovens, and heaters. The circuitry in the remote enclosure is rated for operation up to 80°C,

so this is the limit on the ambient air temperature at the enclosure. At the flowmeter, the metered fluid

temperature should not exceed 130° C (265° F) (stator insulation limitation) and the ambient

temperature

Outputs, Options, Indicators

See pages 6

indicators. The diagram below points out the location of the f

Testpoints

us exposure of the stator housing and the circuitry to high ambient temperatures should be

should not exceed 105° C (220° F) (PVC cable jacket limitation).

-8 of the manual for detailed explanations of the transmitter’s outputs, options, and

Wire

Colors Denoted on PCB

“DRN” indicates the Drain wire

Connected to cable shielding

S1-2: Filter

S1-1:

Ground

eatures on the printed circuit board.

: Output/Phase A (Terminal 4 & 5

Status) (High = Green, Low = Red)

: Direction/Phase B (Terminal 6

Status) (High = Green, Low = Red)

Terminal Block

1. Case (Green)

2. Common (Black)

3. Power 5-30VDC (Red)

4. Combined Output (White)

5. Phase A Out (Orange)

6. Phase B Out or Direction (Blue)

Stator Phase A

: Microcontroller Memory

Status (On = Fail)

Cycles per Revolution

0

0 (Calibrate)

1

2

3

4

5

6

7

8

* Not Specified, Usually same as S3=8

12

25

50

100

150

250

300

500

0 (Calibrate)

24

50

100

200

300

500

600

1000

And Calibration Enable

Select Meter Type

Output Select (2- Phase

or Combined Output)

Indication (4 LED’s)

D9

: Calibration Active

D8

: Flow too low to calibrate

Calibrate Stator Offsets

(and Angle). Need S3 in

position 0 to start Calibration.

286-300-

350 © 2002,

Max Machinery, Inc.

(15)

Discontinued

Appendix B: Output Level Shifter Option

286-

314:

Transmitter with Amphenol Connector, Level Shifter Option

286-

324:

Transmitter, Weather

286-314286-314-

General

Outp

Supply Voltage........................................................................

Supply Current....................................

Output

500:

Remote Transmitter (Aluminum Housing), Level Shift

525: Remote Transmitter (Polycarbonate Housing), Level Shifter Option

Both the standard and remote transmitter circuit boards have the capability for additional circuitry that

gives output voltage levels equivalent to the power supply voltage. For example, if the transmitter is

powered with +12 Volts the output will be a 12V square wave. The circuit board used in the level

shifter version is identical to the standard circuit board, with the exception of some additional

compon

specifications, some different than those on pg. 3 due to the level shifter, are listed below. All other

specifications from pg. 3 not reprinted here remain unchanged.

ents (R29,R30, and U9) and some that are absent (R23, R24, and D1). The output

ut Level Shifter Specifications

(12.0V Supply) ........................................................................................Hi Lo

No Load..............................................................................................

2.5k Load to Common........................................................................ 11.0 V 0.1 V

2.5k Load to +12 Volts.......................................................................

Short Circuit C

Output Impedance...............................................................................100

Rise Time .................................................................................

Fall Time..................................................................................

Maximum Frequency .........................................................................

Minimum Frequency..............................................................................

urrent

5

.......................................................................

-Tight, Explosion Proof, Level Shifter Option

38mA Typical, 32-

er Option

4.5 VDC to 30 VDC

43 mA Range (+ Load)

120 mA

0.8 uS (90%)

1.0 uS (90%)

60 kHz

12.0 V 0.1 V

12.0 V 1.0 V

0 Hz

5

Continuous Short Ci

(16)

rcuit is not recommended. The output current should not exceed 30 mA per output.

286-300-

350 © 2002,

Max Machinery, Inc.

Loading...

Loading...