INSTRUCTION MANUAL

Instruction Manual, MMI assumes no responsibility for inadvertent errors.

Discontinued

272-5X5 ANALOG TRANSMITTER

(210 SERIES FLOW METERS)

272-5X7 ANALOG TRANSMITTER

(220/240 SERIES FLOW METERS)

272-5X8 BIDIRECTIONAL TRANSMITTER

(210/240 SERIES FLOW METERS)

TABLE OF CONTENTS

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 3

Installation:

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 4

Moisture Protection . . . . . . . . . . . . . . . . . . . . . . . . . .Page 4

Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Pages 4-5

Electronic Protection . . . . . . . . . . . . . . . . . . . . . . . . .Page 5

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 6

User Options and Adjustments:

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 7

Output Voltage Span . . . . . . . . . . . . . . . . . . . . . . . . .Page 8

PCA Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 8-9

Over Range Indication . . . . . . . . . . . . . . . . . . . . . . .Page 11

Ripple Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . .Page 11-12

General Considerations:

Response Rate, Accuracy . . . . . . . . . . . . . . . . . . . . .Page 13

Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 14

Schematics:

272-515-200

272-517-200

272-518-200

181-000-250

272-515-201

272-500-350 © 1990, Max Machinery, Inc. (Rev 8/00)

Max Machinery, Inc. reserves the right to make changes to the product in this Instruction Manual

to improve performance, reliability, or manufacturability. Consequently, contact MMI for the latest

available specifications and performance data.

Although every effort has been made to ensure accuracy of the information contained in this

GENERAL DESCRIPTION

Discontinued

The 272 Series Transmitters convert the rotary motion of a flow meter into a voltage proportional to

flow. A magnet sealed within the flow meter housing rotates in step with the metering elements. The

varying magnetic field is sensed by an external stator with a two phase winding. The resulting AC

voltage is scaled and converted to DC.

The 272-5X8 Transmitters use two Hall Effect sensors in addition to the stator coil to measure the

position of the magnet as well as its velocity. This allows bidirectional flow rate monitoring with a ±

10V output.

The electronics utilize low current, chopper stabilized op amps for stable and extremely accurate

results over widely varying environmental conditions.

The Model 272 transmitter’s flow monitoring technique results in a quick response to flow changes

with negligible mechanical drag on the metering elements. Since the sending magnet is totally

sealed within the flow meter, problems associated with dynamic seals are eliminated.

Page 2 272-500-350 © 1996 (Rev. 8/00) Max Machinery, Inc.

SPECIFICATIONS

Discontinued

Output Voltage Range

272-5X5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0 to 10V Typical

272-5X7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0 to 10V Typical

272-5X8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0 to ±10V Typical

13.5 V Maximum

Accuracy

Linearity (input RPM vs Output Voltage) . . . . . . . . . . . . . . . . .0.05% Typical

0.10% Maximum

Zero Offset (Referred to Output: 0 to 10 V) . . . . . . . . . . . . . . . . .3mV Typical

5mV Maximum

Temperature Range

272-5X5 and 272-5X7

Electronics:

Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-10°C to 65°C

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-40°C to 70°C

Stator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -40°C to 130°C

272-5X8

Electronics:

Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-10°C to 65°C

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-40°C to 70°C

Stator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-40°C to 90°C

Temperature Coefficients

Flow Meter Magnet . . . . . . . . . . . . . . . . . . . . . . . . . .0.5% per 100°C

Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.2% per 100°C

Zero (Referred to Output: 0 to 10 V) . . . . . . . . . . . . .1 Mv per 100°C

Supply Voltage and Current *

272-5X5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .±15V±5% @ 5.9mA

272-5X7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .±15V±5% @ 23mA

272-5X8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .±15V±5% @ 26mA

* Substitution of op amps will increase current consumption slightly. See schematic tables.

272-500-350 © 1996 (Rev. 8/00) Max Machinery, Inc. Page 3

INSTALLATION OF Model 272 TRANSMITTER

Discontinued

Mounting: The Model 272 transmitter screws on and off of the flow meter. Because of the

random location of the starting point of the threads, one transmitter will probably not line up

with the “in” and “out” ports of the flow meter like another will. The electrical outlet of the

transmitter can be rotated clockwise or counter clockwise one turn by loosening the clamp-

ing screw at the base of the transmitter housing.

Two flats are provided for screwing the transmitter on to the flow meter. Care should be

taken when slipping the transmitter on and off. The wire of the stator is fine gauge and is

easily damaged.

Moisture Protection: The weather tight version of the transmitter has its electronic

circuitry enclosed in a liquid and vapor tight enclosure. All joints are sealed by welding or

by “O”-rings. If this sealed condition is to be maintained, the conduit connection to the

enclosure should be made liquid and vapor tight by using pipe dope or a potting fitting. If a

transmitter is located outside and this precaution is not taken, moisture may form inside the

housing. This will cause the circuitry to give an inaccurate output or possibly no output at

all. In the long run it will cause corrosion and failure. The amphenol connector 272 Models

offer moderate protection from moisture and dust, but are not totally sealed.

(Mounting, Protection)

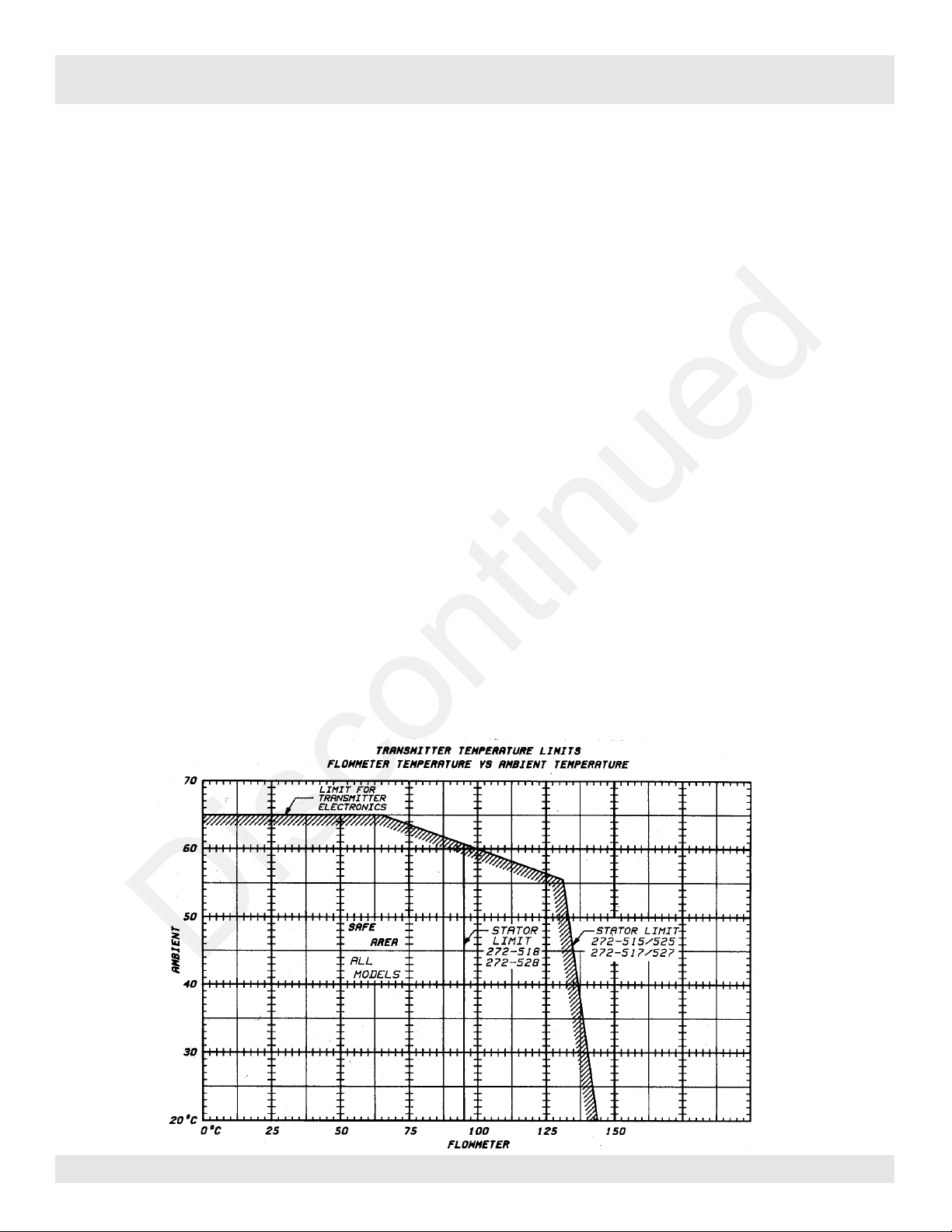

Temperature Considerations: High ambient temperatures (120°F/50°C) should be avoided if

possible. It is a good idea to locate the transmitter away from hot spots such as steam pipes,

ovens and heaters. The electronics of the 272 Series Transmitters are rated for operation up

to 65°C or 150°F. Because some heat travels from the flow meter to the transmitter

electrical enclosure, the temperature the electronics see is a function of both the

ambient and the flow meter temperature. Figure 3 shows the relationship between the

aximum ambient transmitter temperature and the fluid temperature through the flow meter.

Page 4 272-500-350 © 1996 (Rev. 8/00) Max Machinery, Inc.

INSTALLATION OF Model 272 TRANSMITTER

Discontinued

Temperature Considerations: (continued)

The stator of the Model 272 transmitters is insulated with an epoxy that is rated to 125°C. This

limits the maximum flow meter fluid temperature to 130°C when using the Models 272-5X5 or

272-5X7. The 272-5X8 bidirectional transmitter uses Hall effect devices that are rated to 90°C.

This is the maximum fluid temperature when using the Model 272-5X8.

Transmitter Maximum Flow Meter Fluid Temperature

(Maximum: 65°C) @ Ambient of 50°C

272-5X5 130°C

272-5X7 130°C

272-5X8 90°C

The output of the Model 272 will be affected by changes in the temperature of the flow meter.

This is because the magnet that generates the voltage in the stator is affected slightly by

temperature. Fig. 4 shows typical percentages of error.

(Dimensions)

Electronic Protection: Diodes have been placed in the input and output circuits to guard against

excessive or reversed voltages in the event connections are made incorrectly. The diodes are

rated at 1/2 amp and will take one amp for a few seconds. If the sourcing current exceeds this

amount, the diodes will eventually fail, and damage to the transmitter may result.

272-500-350 © 1996 (Rev. 8/00) Max Machinery, Inc. Page 5

INSTALLATION

Discontinued

Page 6 272-500-350 © 1996 (Rev. 8/00) Max Machinery, Inc.

USER OPTIONS AND ADJUSTMENTS

Discontinued

Transmitters calibrated at the factory with a flow meter are shipped with a calibration sheet

and will not require further adjustment. Transmitters shipped alone will have to be phased to

the flow meter and wet calibrated.

Grounding Switches: S2-1: This switch connects circuit common to the transmitter case

through two back to back 15 µF @ 20V capacitors. S2-2: This switch connects common and

case ground directly together.

By using either S2-1 or S2-2 the effects of electrical noise on the transmitter can be reduced.

Excessive electrical noise can result in a zero offset of the output signal and a reduction of

accuracy. It is good practice to have a circuit directly connected to ground at one point. This

will probably be at the indicator or receiving end of the signal.

By activating S2-1, electrical noise between the case and the circuitry of the transmitter can

be considerably reduced, without causing ground loop problems. If the system is not ground-

ed at the indicator or if the flow meter is not physically grounded through its plumbing, use

S2-2. To activate either switch, depress the side of the switch that is numbered.

Amphenol Connectors (See above) are use on Transmitter Models 272-5X5, 5X7 & 5X8.

272-500-350 © 1996 (Rev. 8/00) Max Machinery, Inc. Page 7

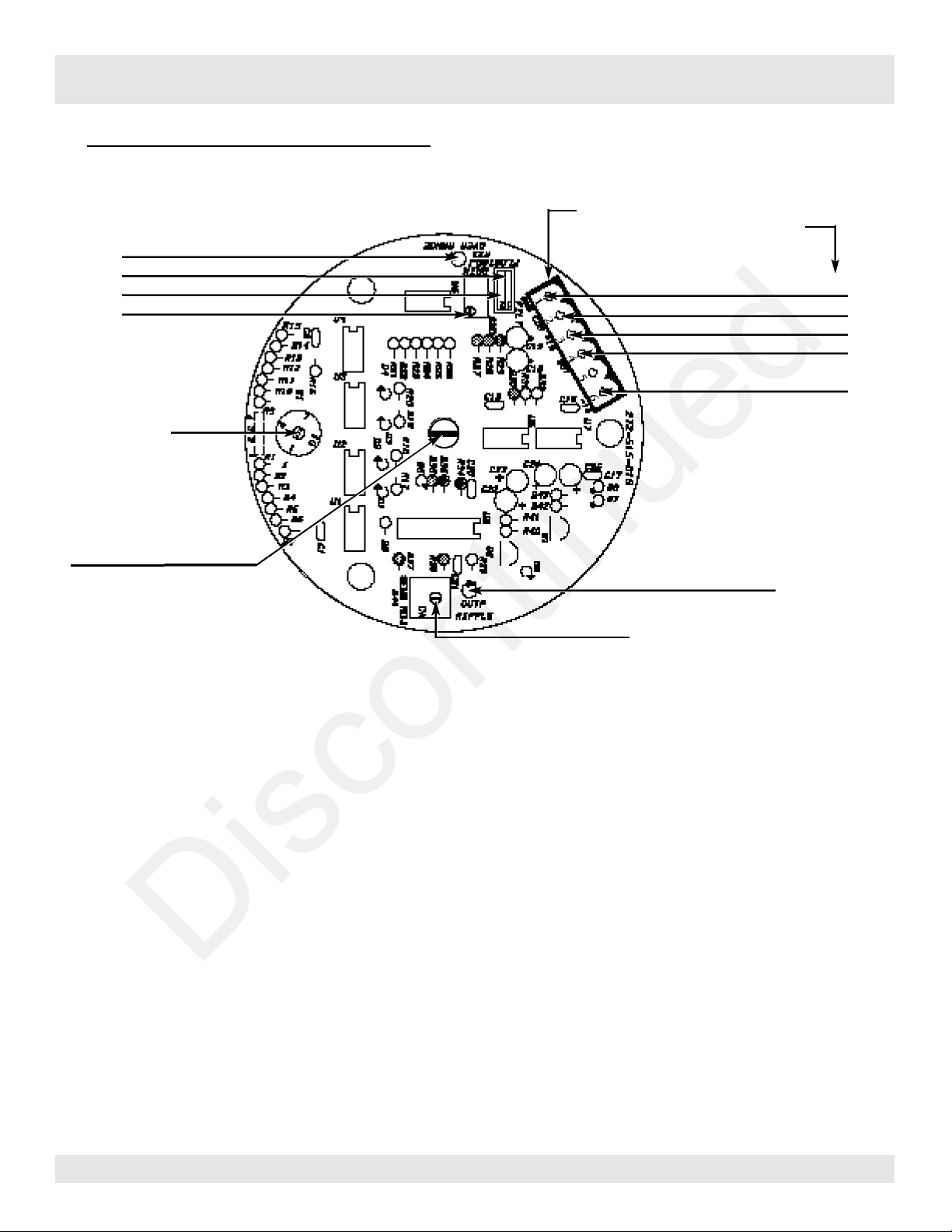

USER OPTIONS AND ADJUSTMENTS

Green Ground (A)

Black Common (B)

Red +15V (C)

White Signal (D)

Blue -15V (F)

Removable Connector

Amphenol Connector

(Std. on 272-515)

Ripple Indicator LED

Ripple Adjustment Sensitivity

(CW = More Sensitive)

(See Grounding Options Below)

S2-1 Filter

S2-2 Ground

Fine Gain Trimmer 2.5:1

Output Overrange LED

Range Switch

2.15:1

6 Steps

Stator Adjustment Screw

Discontinued

Information for 272-5X5 transmitters:

(PCA Drawings)

Output Voltage Span Adjustments: These adjustments are used to match the specific flow

meter and flow range to provide the optimum output signal; and to make the indicator read in

engineering units if required.

Range Switch: This switch changes the output voltage by steps of 2.15 to 1. It is used to set the

output voltage to the approximate value desired.

Fine Gain Adjustment: This is a 20 turn potentiometer that is used to precisely adjust the output voltage of the Model 272. The adjustment range is 2.5 to 1.

Reverse Gain Trimmer: Sets the output voltage in reverse flow to equal the voltage at the same

forward flow rate.

Any full scale voltage can be used. One volt, two volts or 8.888 will work just as well as

10.000. If the Model 272 is operating a digital voltmeter directly, the span can be adjusted to

make the voltmeter read directly in engineering units. In such a case, some RC damping will be

required.

Page 8 272-500-350 © 1996 (Rev. 8/00) Max Machinery, Inc.

Green Ground (A)

Black Common (B)

White Signal (D)

Red +15V (C)

Blue -15V (F)

Phase A Out*

Phase B Out*

Ripple Adjustment Sensitivity

(CW = More Sensitive)

Ripple Indicator LED

Removable Connector

Amphenol Connector

(Std. on 272-518)

S2-1 Filter

S2-2 Ground

Fine Gain Trimmer 2.5:1

Output Overrange LED

Offset Trimmer

Stator Adjustment Screw

Offset Trimmer

Reverse Gain Trimmer

Range Switch

2.15:1

6 Steps

272-500-350 © 1996 (Rev. 8/00) Max Machinery, Inc. Page 9

Green Ground (A)

Black Common (B)

White Signal (D)

Red +15V (C)

Blue -15V (F)

Removable Connector

Amphenol Connector

(Std. on 272-517)

S2-1 Filter

S2-2 Ground

Output Overrange LED

Fine Gain Trimmer 2.5:1

Range Switch

2.15:1

6 Steps

* 1 CYCLE PER FLOW METER REVOLUTION +/- 7.5V SQUARE WAVE (NOT REQUIRED BY MAX INDICATORS.)

USER OPTIONS AND ADJUSTMENTS

Information for 272-5X7 transmitters:

Information for 272-5X8 transmitters:

Discontinued

USER OPTIONS AND ADJUSTMENTS

Discontinued

Table I list the approximate volumetric displacements of flow meters that can be used with the 272

transmitters. Use this table to calculate the RPM of the flowmeter at maximum flow.

TABLE 1: METER MAXIMUM FLOW AND DISPLACEMENT

FLOWMETER MAXIMUM FLOW DISPLACEMENT PER REVOLUTION

MODEL CC/MIN GAL/MIN CC GALLONS

213 1,800 0.48 0.870 .00023

214 10,000 2.64 10.5 .00285

215 40,000 10.6 47.6 .0128

216 100,000 26.4 169.5 .0446

220 10,000 2.64 9.12 .0024

221 55,000 14.5 23.5 .0062

222 75,000 19.8 47.4 .0125

241 189,000 50.0 62.1 .0164

251 189,000 50.0 62.1 .0164

242 540,000 143.0 182.0 .0480

243 1,400,000 370.0 574.0 .152

244 3,500,000 925.0 1700.0 .456

245 8,000,000 2114.0 6060.0 1.60

FOR EXAMPLE: THE MODEL 213 MAXIMUM RPM IS: 1800 CC/MIN ÷ 0.870 CC/REV = 2069 RPM.

Table II list the RPM range of each Range Switch setting for all three 272 transmitters. Use this

table to estimate the correct range position.

TABLE 2: RPM RANGE VS SWITCH POSITION

(RPM AT10V OUT)

272-5X5 272-5X7 272-5X8

SWITCH MAX MIN MAX MIN MAX MIN

POSITION GAIN GAIN GAIN GAIN GAIN GAIN

1 1985 5559 2197 6157 1985 5559

2 794 2224 879 2460 794 2224

3 318 889 351 984 318 889

4 127 356 141 394 127 356

5 51 142 36.3 117 51 142

6 20.3 57 21 53 20.3 57

Page 10 272-500-350 © 1996 (Rev. 8/00) Max Machinery, Inc.

USER OPTIONS AND ADJUSTMENTS

Discontinued

Output Over Range Indication: This LED will start to blink if the transmitter output amplifier

begins to saturate (clip). This happens when the flow rate or gain is too high and will cause the

output voltage to be less than it should be. Figure 9 shows what happens as output saturation

occurs.

The diagram below shows what happens as output saturation occurs.

(Over Range Indication)

The flow rate in a system may have as much as 50% to 100% ripple. This may be caused by the

pump, by lots of air in the line and a slightly sticky flow meter, or by other reasons. The maxi-

mum output voltage of the Model 272 must be kept low enough so that the output is not saturated.

This may mean that the average full scale output voltage will have to be much less than 10 V to

avoid clipping the peaks in the output signal (See Fig. 10).

Ripple Adjustment (272-5X5 and 272-5X8 Transmitters Only)

This adjustment will have to be made if the transmitter is unscrewed from the flow meter.

The 272-5X5 and the 272-5X8 are made to compensate for the non uniform rotational rate of

the 210 series piston meters. To take advantage of this feature, the stator of the Model 272

must be positioned correctly for each meter it is mated to.

272-500-350 © 1996 (Rev. 8/00) Max Machinery, Inc. Page 11

USER OPTIONS AND ADJUSTMENTS

Discontinued

If this is not done, the electrical output of a meter and its transmitter will have as much as

50% ripple superimposed on the DC component of the output signal. The frequency of this

ripple will be four times the RPM of the meter. Such a situation will require more damping

than otherwise and will result in a slower responding system.

Ripple Adjustment Sensitivity: Increases and decreases the sensitivity of the ripple detection

circuit.

Ripple Indication : LED

Stator Adjustment Screw: Rotates the transmitter pickup coil.

The flow meter must have a flow through it for this adjustment to be useful. It is advisable to

adjust the ripple at the lower end of the flow range; although if the flow rate is less than 2% of

the flow meter’s full scale capability you may have problems with this procedure. An oscillo-

scope attached to the output signal of the Model 272 can also be used.

Increase the Sensitivity Adjustment (cw) just until the Ripple LED next to it starts to turn on.

Then turn the Stator Adjustment Screw in a direction that decreases the brightness or turns off

the Ripple LED. Once again increase the Sensitivity potentiometer until the LED just comes on

and again turn the stator adjustment in a direction that minimizes the LED. Repeat this process

until any further change in the position of the stator screw causes the LED brightness to

increase rather than decrease.

The figure 11 shows the effect of the stator position on output ripple. There are four best and

four worst positions for the stator per revolution. This means that it will take a maximum of

45° on the Stator Adjustment Screw to find the best location.

Page 12 272-500-350 © 1996 (Rev. 8/00) Max Machinery, Inc.

GENERAL CONSIDERATIONS

Discontinued

Response Rate & Accuracy:

There is always a trade off in a metering system between response rate, accuracy and noise.

The three are related such that their product equals a constant. If any one of them is made

smaller, the others can be made larger.

In most metering systems, response rate and accuracy are desirable characteristics. To maxi-

mize one or both of these parameters, noise should be reduced to a minimum. Once noise

has been minimized, there is a trade off between accuracy and response rate.

(Response Rate, Accuracy & Noise)

Response Rate: When discussing response rate there are three facets to consider. They are:

the response of the flow to a change in the system setpoint, the correction of the flow to an

error induced in it, and the response of the flow rate display to a change in flow rates. These

responses are all purposely slowed down by filtering or damping so the system only reacts to

meaningful flow changes and not to such things as pump pulsations or flow meter ripple.

More damping means slower response.

Accuracy: There are three topics to consider when looking at accuracy. The first being the

display; which can typically have anywhere from two digits (1 to 99) to 4-1/2 digits (19,999)

of information. This equals a resolution of 1% to a maximum of 0.005%, respectively. The

display steadiness is also directly related to it’s accuracy. For instance, a display that jitters

from 95 to 105 in a meaningless way is not accurate to one part in 100 (1%) but only to

about 10 parts in 100 (10%).

The basic accuracy of the flow meter is a prime consideration. Typically, the accuracy of a

positive displacement meter is not as good for a fraction of its cycle as it is for one or more

complete cycles. If a system is dampened so that the response rate is longer than the period

of one revolution of the meter, the accuracy of the display is increased. The accuracy of the

system can never be better than that of the flow meter.

272-500-350 © 1996 (Rev. 8/00) Max Machinery, Inc. Page 13

GENERAL CONSIDERATIONS

Discontinued

Nosie:

Noise can be defined as any change in either the fluid flow or the electrical system that is not a meaningful

change in the flowlow or th electrical system that is not a meaningful change in the flow rate. For instance, the

ripple induced in the flow by a gear or piston pump is noise. The system will typically have to be dampened so

that its’ response time is longer than the tooth to tooth

period of the pump. Piston pumps with fewer than three

pistons create a particularly large amount of bothersome

ripple and result in a very slowly reponding system.

All positive displacement flow meters add noise to a

flow metering system. The noise is typically of two

origins. As the elements of the meter rotate, they require

varying amounts of pressure to move (See Fig. 13).

This induces pressure fluctuations between the pump (or control valve) and the flow meter. If there is any

air trapped in the line, the fluid flow will vary as the air compresses and expands. This will be sensed as a

changing flow by the flow meter and the output will contain unwanted ripple or noise. Plumbing in a flow

system should be sized and laid out to avoid air being trapped between the flow meter and the flow

controlling device (a pump or valve).

The second type of noise that must be considered is a

result of flow meter geometry and design. Because of

features such as an oval gear, or a piston/crankshaft

configuration, or due to manufacturing tolerances, the

rotation of the metering elements is not completely

uniform. For example, the 210 series meters utilize

four pistons connected to a crankshaft. The varying

rotational speed of the crankshaft is shown in Fig. 14.

To obtain the smoothest output signal, the transmitter (272-5X5 or 272-5X8) for these meters can be adjusted

to minimize this characteristic. Additionally, some amount of damping is usually necessary at the indicator.

The electronic converter of any meter will add its share of noise. For instance, DC transmitters produce some

ripple in their output due to the sinusoidal nature of the induced voltage in the armature coils.

Page 14 272-500-350 © 1996 Max Machinery, Inc.

Discontinued

Discontinued

Discontinued

Discontinued

Loading...

Loading...