Page 1

Installation & Operations Manual for

MDT SERIES

Open Display Merchandisers

PN 063-90000

Rev 1-28-10LN

Page 2

2

Page 3

TABLE OF CONTENTS

Page Numbers

INTRODUCTION………………………………….……………………………………………………………………4

WARNING LABELS AND SAFETY INSTRUCTIONS………..…..……………………………………………… 5

PRE-INSTALLATION INSTRUCTIONS………………………..…..………………………………….…………… 6

Spection for ShippingDamage……………………………………………………….………………………… 6

INSTALLATION INSTRUCTIONS………………………………………………………………………………….. 6

Store Conditions………..…………………………….…………………………………….…………………… 6

Location…………………………………………………………………………………….. ………………….…7

Leveling………………………………………………………………………………………………..…………. 7

Joining Sections…………………………………………………………………………………..……………… 8

Installing Joining Trim MD…………………………………………………………………….………………... 9

Installing Joining Trim MDT…….……………………………………………………………….…………….. 10

Installing the Endskirts and Kickplate………………………………………………………………..……….. 11

Removing and Replacing Bumper Trim………………………………………………………………………. 11

Removing and Replacing the Ends……………………………………………………………………….…. 12

Removing and Replacing the Canopy………………….…………………………………………………….. 12

Plumbing…………………………………………………………………………………………………………. 13

Electrical……..…………………………………………………………………………..………………………. 13

Piping…………………………………………………………………………………………………………….. 14

Refrigeration System Evacuating and Charging…………………………………………………………….. 15

EPR Valve/Temperature Control……………………………………………………………………………… 15

Control Settings…………………………………………………………………………………………………. 15

STARTING PROCEDURE…………………………………………………………………………………………... 16

FINAL CHECK LIST………………………………………………………………………………….………………. 16

LOADING……………………………………………………………………………………………………………… 17

CLEANING…………………………………………………………………………………………………………….. 17

NIGHT CURTAINS……………………………………………………………………………………………………. 17

SERVICE INSTRUCTIONS………………………………………………………………………………………….. 18

MASTER-BILT PART NUMBERS………………………………………………………………………………….. 19

SALE AND DISPOSAL………………………………………………………………………………………………. 20

WIRING DIAGRAMS.…………………………………………………………….……………………….……….21-23

MD REFRIGERATION SIZING CHART……………………………………………………………………………. 24

3

Page 4

INTRODUCTION

Thank you for purchasing a Master-Bilt cabinet. This manual contains important instructions for installing, using

and servicing a Master-Bilt MD series endless open air case. Read all these documents carefully before installing

or servicing your equipment. This manual should be left in the care of the store owner or manager.

NOTICE

Read this manual before installing your cabinet. Keep the manual and refer to it before doing any service

on the equipment. Failure to do so could result in personal injury or damage to the cabinet.

DANGER

Improper or faulty hook-up of electrical components of the refrigeration units can result in severe injury or

death.

All electrical wiring hook-ups must be done in accordance with all applicable local, regional or national

standards.

NOTICE

Installation and service of the refrigeration and electrical components of the cabinet must be performed by

a refrigeration mechanic and/or a licensed electrician.

The portions of this manual covering refrigeration and electrical components contain technical instructions intended

only for persons qualified to perform refrigeration and electrical work.

This manual cannot cover every installation, use or service situation. If you need additional information, call or

write us:

Customer Service Department

Master-Bilt Products

Highway 15 North

New Albany, MS 38652

Phone (800) 684-8988

Fax (800) 684-8988

4

Page 5

WARNING LABELS AND SAFETY INSTRUCTIONS

This symbol is the safety-alert symbol. When you see this symbol on your cabinet or in

this manual, be alert to the potential for personal injury or damage to your equipment.

Be sure you understand all safety messages and always follow recommended precautions

and safe operating practices.

NOTICE TO EMPLOYERS

You must make sure that everyone who installs, uses or services your cabinet is thoroughly familiar with

all safety information and procedures.

Important safety information is presented in this section and throughout this section and throughout the manual.

The following signal words are used in the warnings and safety messages:

DANGER: Severe injury or death will occur if you ignore the message.

WARNING: Severe injury or death can occur if you ignore the message.

CAUTION: Minor injury or damage to your cabinet can occur if you ignore the message.

NOTICE: This is important installation, operation or service information. If you ignore the

message, you may damage your cabinet.

The warning and safety labels shown throughout this manual are placed on your Master-Bilt Products

cabinet at the factory. Follow all warning label instructions. If any warning or safety labels become lost or

damaged, call your customer service department at (601) 534-9061 for replacements.

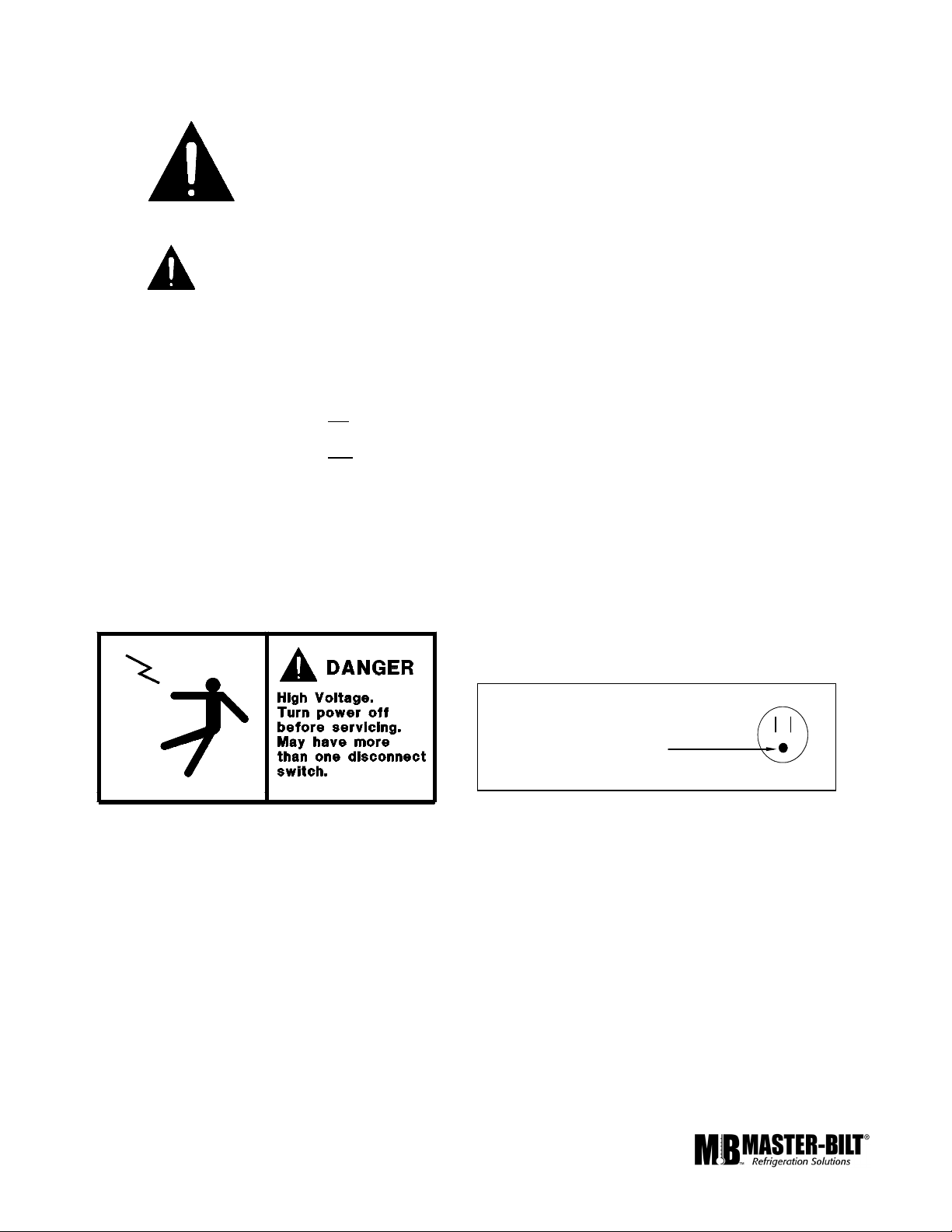

CAUTION!

GROUND REQUIRED

FOR SAFE OPERATION

This label is located on top of the electrical control This label is attached to the cabinet power cord

label and on the wiring channel. on models with a power cord.

5

Page 6

PRE-INSTALLATION INSTRUCTIONS

INSPECTION FOR SHIPPING DAMAGE

You are responsible for filing all freight claims with the delivering truck line. Inspect all cartons and crates for

damage as soon as they arrive. If damage is noted to shipping crates or cartons or if a shortage is found, note this

on the bill of lading (all copies) prior to signing.

If damage is discovered when the cabinet is uncrated, immediately call the delivering truck line and follow up the

call with a written report indicating concealed damage to your shipment. Ask for an immediate inspection of your

concealed damage item. Crating material must be retained to show the inspector from the truck line.

INSTALLATION INSTRUCTIONS

GENERAL INSTRUCTIONS

1. Be sure the equipment is properly installed by competent service people.

2. Keep the equipment clean and sanitary so it will meet your local sanitation codes.

3. Rotate your stock so that older stock does not accumulate. A "First-In, First-Out" rotation practice will keep the

products in good salable condition.

4. Product should not be put in the case for at least 6 hours after it is started.

5. Stock cases as quickly as possible, exposing only small quantities to store temperatures for short periods of

time.

6. When replacing burned out fluorescent tubes, be sure that the electrical power to the lighting circuit is turned off.

STORE CONDITIONS

The Master-Bilt MD cases are designed to operate in the controlled environment of an air conditioned store. The

store temperature should be at or below 75°F and a relative humidity of 55% or less. At higher temperature or

humidity conditions, the performance of these cases may be affected and the capacity diminished. It is not

uncommon in a newly constructed store for the temperature and humidity to be above design conditions. These

excessive conditions may produce sweating in the case until the store is operational and the ambient environment

is more desirable.

The Master-Bilt MD-06/08 should not be positioned where it is directly exposed to rays of the sun or near a direct

source of radiant heat or air flow. No HVAC return or supply air ducts may be located near case openings. This will

adversely affect the case air flow and will result in poor performance. Do not open windows or doors that will affect

the case air flow. The maximum air velocity near the case air return is 50 FPM. If this case is to be located against

a wall there should be at least a 6” space between the wall and the back of the case. This space will allow for the

circulation of air behind the case which will prevent condensation on the exterior surfaces.

These cases should always be loaded properly. This unit will operate differently when loaded or unloaded. Consult

the section of this manual that specifies loading procedures.

A P-trap is included with each case. It is important that each case has a P-trap installed. Consult the section of

this manual for installing and piping the drain.

To comply with Sanitation requirements; the cabinet must be mounted on legs (6” high min.) or casters or the base

must be sealed to the floor (MDT) with an N.S.F. listed silicone sealant. Minimum clearance allow at least a 4”

space between the wall and the back of the case. This space will allow for the circulation of air behind the case

which will prevent condensation on the exterior surfaces.

6

Page 7

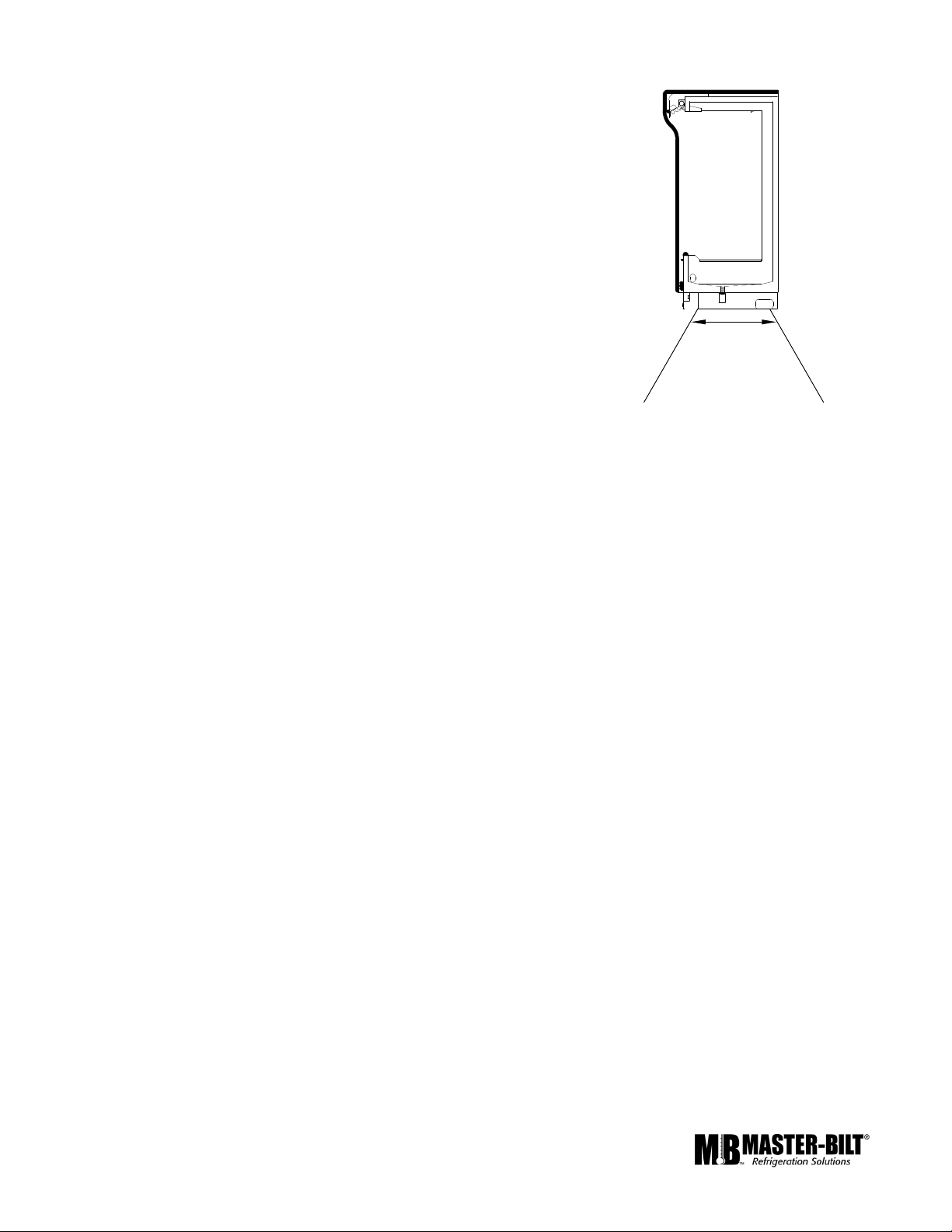

LOCATION

Make sure that the floor will support this equipment is of adequate strength to

prohibit sagging. After confirming the dimensions of case, measure off and

mark on the floor the exact location of the cases for the entire lineup. Snap

chalk lines where the base skids of the case are to be located as shown in

Figure 1.

Figure 1

LEVELING

It is very important that this equipment be perfectly level. This will allow for proper and complete drainage of the

evaporator coil and for proper case alignment. A perfectly level area is generally not available where the

equipment is to be installed. Mark the location of all case joining points front and back. Use a transit to locate the

highest point on the chalk lines. This point will be a reference point for determining shim-pack heights. Using the

reference point, mark the difference directly on the floor to each joining point front and back. Shim each joining

point to equal the reference point as required. Tape all shims in place. If the installation is an entire lineup install

the case that will be positioned at the highest point first. Check that the equipment in the lineup is level as the

installation proceeds.

7

Page 8

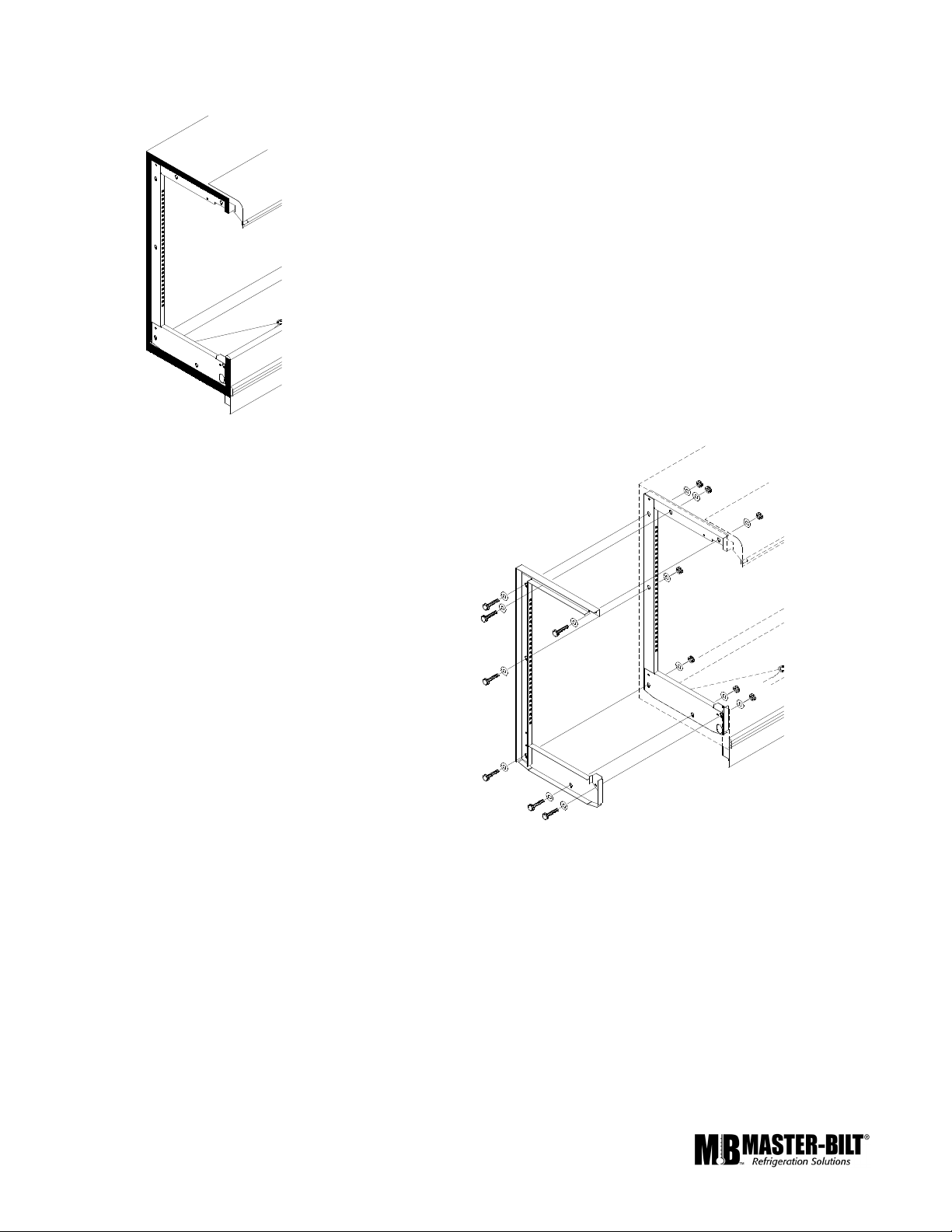

JOINING SECTIONS

Remove the case from its shipping skid. Set the first case into its desired position

with required shims in preparation for joining it with its adjacent case.

The joining gasket for cases in a lineup is factory installed and is shown in black in

Figure 2. This gasket is only required on one end of cases in a lineup as only one

gasket is needed between two cases. Inspect the gasket to insure that it is

properly located and is not damaged. The cases are now ready to be joined

together. Remove the second case from its shipping skid and move it into position

against the end of the first case. Properly level the second case with the

appropriate shims

Figure 2

Bolt the cases together through the seven holes that

are provided in the steel end frame as shown in

Figure 3. Tighten the bolts until all seams are fully

closed. Do not over tighten. Repeat the above

process for all other cases in the lineup.

Figure 3

8

Page 9

INSTALLING JOINING TRIM, MD

A trim kit for joining sections consists of three pieces: the canopy joiner trim, the frontwall joiner trim, and the

kickplate joiner trim. Begin by removing all of the bumper trim and retainers on the canopy and the frontwall. Refer

to the section of this manual for removing and replacing bumper trim. The canopy joiner trim is attached by

locating the holes in the top of the canopy that will line up with the holes in the canopy joiner trim. Remove the

screws that are in the canopy and move the canopy joiner trim into position. Replace the screws that will retain the

canopy joiner trim at the top. Now, mark and drill two 1/8” dia. holes in the bottom of the canopy where the bottom

holes of the canopy joiner trim will align. Pop rivet the trim into place using 1/8” pop-rivets as shown in Figure 4.

The frontwall trim will attach to the frontwall using a good two-sided adhesive tape or silicon caulking. The bumper

on the top and the front of the frontwall will help to hold this trim in place, but an adhesive is also needed. The

kickplate joiner trim will attach to the adjoining kickplates using self-drilling screws as shown in Figure 4.

Figure 4

9

Page 10

INSTALLING JOINING TRIM, MDT

A trim kit for joining sections consists of three pieces: the canopy joiner trim, the frontwall joiner trim, and the

kickplate joiner trim. Begin by removing the bumper trim and retainers on the frontwall. Refer to the section of this

manual for removing and replacing bumper trim. The canopy joiner trim is attached by locating the holes in the top

of the canopy that will line up with the holes in the canopy joiner trim. Remove the screws that are on the

underside of the canopy and move the canopy joiner trim into position. Replace the screws that will retain the

canopy joiner trim at the bottom. Use #10 self-drilling screws to secure the canopy joiner trim at the top. The

frontwall trim will attach to the frontwall using a good two-sided adhesive tape or silicon caulking. The bumper on

the top and the front of the frontwall will help to hold this trim in place, but an adhesive is also needed. The

kickplate joiner trim will attach to the adjoining kickplates using sheet metal screws as shown in Figure 5.

Figure 5

CANOPY

JOINER TRIM

FRONTWALL

JOINER TRIM

KICKPLATE

JOINER TRIM

10

Page 11

INSTALLING THE ENDSKIRTS AND KICKPLATE

The kickplate should be installed prior to attaching the endskirts.

The endskirts are shipped loose. Secure the kickplate to the

flange of the wire raceway using the supplied sheet metal screws.

Use the supplied sheet metal screws to secure the kickplate to

the bottom edge of the frame and the electrical raceway. The

bottom of the kickplate should be in contact with the floor. Refer

to Figure 6 for the placement of the Kickplate. The endskirt will

attach to the ends of the lineup using the supplied #10x1/2 self

drilling screws as shown in Figure 6.

REMOVING AND REPLACING BUMPER TRIM

All of the bumper trim on the MD line is of the same type. To remove a section,

begin at one end and unsnap the bumper from the retainer. A screwdriver may

have to be used to get the bumper started as shown in Figure 7. Use the proper

safetey precautions when removing the bumper. The endcaps and the the

bumper retainer can now be removed by removing the screws that attach the

pieces to the cabinet. Be sure to use the same type screws to replace the

retainer and the endcaps.

Figure 7

Figure 6

11

Page 12

REMOVING AND REPLACING THE ENDS

The ends are manufactured so that they will accept a 1/2” bolt. These bolts should not be removed. The ends are

bolted to the cabinet as shown in Figure 8 through a keyslot rather than a hole. To remove an end simply

untighten the bolts, lift up on the end and remove the end from the cabinet as shown in Figure 9. If you should

accidently remove a bolt, be sure to replace the bolt before

attempting to replace

the end onto the end

frame. When

replacing an end make

sure that the cabinet is

completely sealed but

do not overtighten the

bolts and remember to

inspect the gasket

material prior to

replacement. Reverse

the procedure to

replace the ends.

Figure 8

Figure 9

REMOVING AND REPLACING THE CANOPY (MD ONLY)

Before the canopy can be removed, the light bar must be unplugged from the cabinet. There is a light plug access

cover on the top of the canopy on the right end as shown in Figure 10. Remove this cover using a phillips head

screw driver to reveal the light plug and unplug the male end from the female end. Now the canopy can be

removed. While carefully supporting the canopy, use a phillips head screwdriver to remove the #10 self-drilling

sheet metal screws that attach the canopy to the cabinet as shown in Figure 11. Reverse this procedure to

replace the canopy making sure that the male plug and the female plug are fully plugged into each other.

Figure 10 Figure 11

12

Page 13

PLUMBING

Each MD case has a P-trap shipped loose. It is

very important that this trap be installed as it will

result in diminished peformance of the case without

it. There is a P-trap access cover which can be

removed for better admittance to the trap as shown

in Figure 12. The PVC P-trap assembly must be

glued to the PVC adapter on the bottom of the drain.

The drain can be run to the front or back or through

the skids. The top of the 1-1/2” drain can be

accessed by removing the center insulated bottom panel.

An access cover can then be removed from the evaporator fan

cover. The drain is located at the center of the case in the drain pan.

Figure 12

1. Always install drains in accordance with local codes.

2. Use largest possible size pipe for drains, 1-1/2” minimum is recommended.

3. Provide as much downhill slope as possible.

4. Prevent drains from freezing. Do not install drains in contact with uninsulated suction lines.

NOTICE TO STORE OWNERS / MANAGERS

Moisture or liquid around or under the cabinet is a potential slip/fall hazard for persons walking by or

working in the general area of the cabinet. Any cabinet malfunction or housekeeping problem that creates

a slip/fall hazard around or under the cabinet should be corrected immediately.

If moisture or liquid is observed around or under a Master-Bilt cabinet, an immediate investigation should be made

by qualified personnel to determine the source of the moisture or liquid. The investigation made should determine

if the cabinet is malfunctioning or if there is a drain pipe leaking.

ELECTRICAL

WARNING

Before servicing electrical components in the case make sure all power to case is off. Always use a

qualified technician.

NOTICE

For models with electronic ballast only:

For replacement ballast, use only ballast that complies with UL Type CC rating

if unit is equipped with electronic ballast.

It is very important that full voltage and overcurrent protection requirements for condensing units, defrost heaters,

fans, doors, etc. be provided at installation. Wire sizing must be adequate to maintain full voltage under amperage

loads specified in the charts on page 24. Wiring diagrams are provided for single cabinets and for lineups on

pages 22 and 23 of this manual.

13

Page 14

PIPING

The recommended type of refrigerant used in the

Master-Bilt is R-22. Line sizes for most applications

are given in the chart on page 24. Consult the

Master-Bilt Refrigeration Unit I&O Manual for other

applications. The piping connections are made at the

left end of the coil.

These lines have been capped and should be cut with

a tubing cutter so as not to introduce copper shavings

into the system. Only clean, dry, sealed refrigeration

grade AC hard copper tubing should be used. There

is a cutout near the front of the case which is used for

bringing the lines from underneath the case. It may

be easiest to pre-fabricate the lines as shown in

Figure 12 and insert the line up through the bottom of

the case. If this is not possible there is an access

cover which can be removed for ease of brazing and

for service. Be sure to install a suction line oil trap or

‘P-trap as shown in Figure 13. The skids are

designed with a Figure 13

cutout in the rear of the skid for running refrigeration

piping through the skids as shown in Figure 14. There

is ample room for piping for the MD/MDT and for another

cabinet or lineup at the rear of the cabinet.

It is recommended that all brazed joints be made with

silver alloy-type solders. For roof top condensing units,

an inverted P-trap must be installed in the suction line

where the refrigeration lines exit onto the roof. For

vertical line runs of more than 20 feet., a riser trap must

be installed at the approximate center of the riser. The

condensing unit should be located as closely as

possible to the cabinet. Keep the refrigeration lines as

short as possible and use as few fittings as practicable,

being especially careful not to “kink” the lines. Keep the

layouts as Figure 14

simple as possible and properly support the piping to absorb vibration

and the normal expansion and contraction caused by temperature changes. All suction lines should be wellinsulated to minimize heat absorption and control condensate which could form on the suction line. If tubular

insulation is used, the ends, joints, and any other open areas (including slits necessary to fit the tubing over

installed piping) should be sealed with insulation glue. A minimum amount of flux should be used as needed and a

small amount of dry nitrogen should be fed into the tubing during brazing to minimize formation of scale and

oxidation inside the tubing. Leak check all joints with an electronic leak detector or halide torch. If leaks are found

relieve the pressure and make repairs as necessary and recheck. Thoroughly caulk or foam all refrigeration line

entry holes. All openings for wiring should be sealed with N.S.F. listed sealant to prevent air leaks and unwanted

condensation.

14

Page 15

REFRIGERATION SYSTEM EVACUATING AND CHARGING

th dry nitrogen or carbon dioxide to eliminate the possibility of

1. Blow out all refrigerant lines wi

dirt, scale, etc. remaining inside.

2. Connect all lines and leak test all connections.

3. Connect a good high vacuum pump to both the low and high side service valves.

4. Operate the pump until a vacuum of 1500 microns (0.06 inches of mercury) absolute pressure is obtained. At

this point, the vacuum should be broken by the introduction of refrigerant into the system, through a drier, until

the pressure is brought up to zero pounds gauge. Repeat this procedure two more times. During the final

evacuation, a vacuum of 500 microns (0.02 inches of mercury) absolute pressure should be obtained. After

this vacuum is reached, the system can be fully charged with refrigerant.

EPR VALVE/ TEMPERATURE CONTROL

NOTICE

The evaporator pressure regulator valve (EPR valve) is not used to control temperature in the MD case.

This cabinet is equipped with a temperature control which should be properly field wired as a control for

the system. Refer to the wiring diagrams on pages 21 to 23 of this manual.

The factory installed temperature control is located at the right

end of the evaporator fan cover as shown in

control can be exposed and adjusted by removing the bottom

panels at the bottom of the case. It is not necessary to open the

evaporator fan cover to access these controls. The sensing bulb

for the temperature control is located between the evaporator fan

covers and the fan housing in the return air. The temperature

control is adjusted by simply turning the knob clockwise for a

colder case and counter-clockwise for a warmer case. The temp

control should be set so that it cycles off when the discharge air at

the honeycomb reaches 24-26°F.

The EPR valve should not be used to control temperature. It is

installed to prevent the evaporator pressure from becoming too low in the

event of low charge, low temperature control settings, or a failed temperature

control. If the EPR valve is not properly installed the evaporator coil could begin

to ice. Actual settings will vary from location to location depending on ambient

conditions but the EPR valve should be set so that the evaporator pressure will not

go below 47-58 lbs for R-404a.

Figure 14

This will insure that the evaporator coil doesn’t operate at a temperature too low.

Figure 14

. This

CONTROL SETTINGS

EPR Valve setting 45 - 60 psig

Temperature Control - Air Discharge Temperature

Condensing Unit Defrost Settings 4 times/day (6 hours); 30 minutes fail safe

Condensing Unit Low Pressure Control Cut in – 20 lbs*: Differential 16 lbs

Condensing Unit High Pressure Control 425 lbs

*This is a standard setting; extreme cold climates may necessitate that the low pressure control be set

to a 4 lb cut-out and 20 lb. differential.

24-26°°°°F at honeycomb

15

Page 16

STARTING PROCEDURE

1. Start compressor and allow to run at least 6 hours before placing product into the MD.

DURING THIS TESTING PERIOD YOU SHOULD:

1. Check the temperature holding range against the the control setting.

2. Check the defrost control system to see that all ice is removed from the coil during each defrost cycle.

3. Check pressures.

4. Check EPR Valve for proper pressure.

FINAL CHECK LIST

A. Check high-low pressure control settings.

B. Check setting of defrost timer:

1. Four defrost/24 hours, with 30 minutes fail safe.

C. Check operating pressure.

D. Check electrical requirements of unit to power supply voltage.

E. Set temperature control for desired temperature range. Set at ‘6’ for most applications.

F. Check setting of thermostatic expansion valve for proper operation. Appprox. 10°F superheat.

G. Check sight glass for proper refrigerant charge.

H. Check EPR Valve for proper pressure setting.

I. Check system for proper defrost settings and operation.

J. Check condensing unit for vibrating or rubbing tubing. Dampen or clamp as required.

K. All valves should be completely open counter-clockwise.

L. Check packing nuts on all service valves.

M. Replace all service valve caps and latch unit covers.

N. Check refrigeration line for proper P-traps and proper locations.

O. Check drain for proper P-traps and proper locations.

16

Page 17

LOADING

Do not place product in the case until 6 hours after it is started. Stock cases as quickly as possible, exposing only

small quantities to store temperatures for short periods of time. It is important to keep stock rotated properly so

that older stock does not accumulate. A “First-In, First-Out” rotation practice will keep the products in good sellable

condition. Avoid loading the case so that product sticks out beyond the shelves or blocking the return air grille at

the bottom of the case. This will interfere with the air flow of the case and will result in diminished performance.

Figure 15

CLEANING

To avoid electrical shock, turn the power off before cleaning.

The MD series cabinets are designed so that spills will accumulate in a drain pan. The drain pan is located

underneath the return air grill. Be sure to clean all areas with a mild detergent and water periodically. DO NOT

USE ABRASIVE CLEANERS.

NIGHT CURTAINS

The MD cases are equipped with a heavy duty night curtain located just

behind the the light bulbs. All that is visible is the handle. Using the night

curtains properly will conserve a considerable amount of energy. The night

curtains should be lowered when the store is closed or the case is not in use.

There is a hook mounted on the lower front of the case that the handle of the

curtain will catch in. When raising the night curtains, do not unhook the

handle and release it as the curtain will spring back into its raised position

abruptly possibly damaging the curtain or the case. Instead, unhook the

handle and gently guide the curtain back into its raised position. This will

extend the looks and the life of the curtain.

Figure 16

17

Page 18

SERVICE INSTRUCTIONS (Trouble Shooting Guide)

1. High head pressure and high back pressure:

A. Condenser coil clogged or restricted.

B. Condenser fan motor defective.

2. Low head pressure and low back pressure:

A. Restriction in system.

B. Refrigerant undercharged.

C. Leak in system.

D. EPR valve set too low.

3. Pressures normal – cabinet warm:

A. Coil blocked with frost or ice (see #4).

B. Control set too warm.

C. Air screen disturbance.

4. Coil blocked with frost or ice:

A. Defective temperature control. F. Defrost heater not operating

B. EPR valve set too low. G. P-trap in drain not installed

C. Time clock not operating properly. H. Air screen disturbance

D. Improper time clock setting J. Evaporator fan motor defective

E. Ambient conditions above 75°F and 55%RH

5. Compressor starts and runs but cycles on overload:

A. Low voltage.

B. Dropped Phase (3 phase)

C. Overload protector defective.

D. High head pressure (see #1).

E. Relay or Capacitor Defective (1 phase)

6. Compressor will not start – hums, but cycles on overload:

A. Low voltage. D. Start capacitor defective.

B. Relay defective. E. High head pressure (see #1).

C. Overload protector defective.

7. Special service situations:

If moisture or liquid is observed around or under a Master-Bilt cabinet, an immediate investigation should

be made by qualified personnel to determine the source of the moisture or liquid. The investigation made

should determine if the cabinet is malfunctioning or if there is a simple housekeeping problem.

Moisture or liquid around or under a cabinet is a potential slip/fall hazard for persons walking by or working

in the general area of the cabinet.

Any cabinet malfunction or housekeeping problem that creates a slip/fall hazard around or under a cabinet should

be corrected immediately.

18

Page 19

MASTER-BILT PART NUMBERS

The table below gives Master-Bilt part numbers. Use this chart when ordering replacement parts for your MD

cases.

All quantities are one each unless otherwise noted by parentheses.

Description MD-04/MDT-04 MD-06/MDT-06 MD-08/MDT-08

Evaporator Coil 07-13230 07-13209 07-13199

Expansion Valve 09-09478 09-09468

Defrost Heater (2) 17-09273

Heater Safety 19-01307

Temperature Control 19-00844

Evaporator Fan Motor (2) 13-13124

(2) 17-09258

19-01307

19-00844

(2) 13-13124 (3) 13-13124

09-09468

(2) 17-09259

19-01307

19-00844

Evaporator Fan Blade (2) 15-13092 (2) 15-13092 (3) 15-13092

Evaporator Fan Guard (2) 25-00205 (2) 25-00205 (3) 25-00205

Drum Thermometer 19-13586 19-13586 19-13586

Discharge Honeycomb Insert 29-01517

(1.5) 29-01517

(2) 29-01517

Shelf (8) 33-01533 (12) 33-01533 (16) 33-01533

Standard 24” Flourescent Lamp N/A

Standard 36” Flourescent Lamp (2/1) 23-01577

(2/1) 23-01576

(2/1) 23-01577

N/A

(2/1) 23-01577

Standard 48” Flourescent Lamp N/A N/A (2/1) 23-01575

Lamp Shield, 36” (2/1) 25-01274 (4/2) 25-01274 (2/1) 25-01274

Lamp Shield, 48” N/A N/A (2/1) 25-01311

Ballast 23-01704

(2/1) 23-01704

(2/1) 23-01704

Lampholder (4/2) 23-50562 (8/4) 23-50562 (8/4) 23-50562

Lamp Switch 23-50793 23-50793 23-50793

Night Curtain, 4’ 56-00058 N/A (2) 56-00058

Night Curtain, 6’ N/A 56-00059 N/A

Curtain Mounting Bracket (2) 56-00061 (2) 56-00061 (5) 56-00061

Curtain Spindle Holder 56-00060 56-00060 (2) 56-00060

Curtain Hold Down Hook 56-00050 56-00050 (2) 56-00050

19

Page 20

SALE AND DISPOSAL

OWNER RESPONSIBILITY

If you sell or give away your Master-Bilt cabinet you must make sure that all safety labels and the Installation Service Manual are included with it. If you need replacement labels or manuals, Master-Bilt will provide them free.

Contact the customer service department at Master-Bilt at (800) 684-8988.

The customer service department at Master-Bilt should be contacted at the time of sale or disposal of your cabinet

so records may be kept of its new location.

20

Page 21

21

Page 22

22

Page 23

23

Page 24

MD REFRIGERATION SIZINING CHART

+15F

HIGH

+15F

140F

Suction,

AMBIENT

Suction,

Condensing

UNIT 100°F

TO 120°F** Compressor

120F

Condensing

R404A R404A

MODELS REQUIRED

NORMAL

UNIT UP TO

100°F** Compressor

AMBIENT

TOTAL

OVERALL

MHHZ0171 CS10K6E 7500 MHHZ0221 CS14K6E 8000

3 MSHZ0501 ZB38KCE 33400 MSHZ0581C ZB45KCE-TF5 30300

2 MHHZ0331 CS20K6E 17200 MHHZ0431 CS27K6E 15300

MDT-04 MDT-06 MDT-08

12'-4'

LENGTH*

4'0" 4'-4' 1

6'0" 6'-4' 1 MHHZ0171 CS10K6E 8720 MHHZ0221 CS14K6E 8000

8'0" 8'-4' 1 MHHZ0191 CS12K6E 10300 MHHZ0331 CS20K6E 10800

10'0" 10'-4' 1 1 MHHZ0301 CS18K6E 15600 MHHZ0431 CS27K6E 15300

14'0" 14'-4' 1 1 MHHZ0431 CS27K6E 23900 MHHZ0501 CS33K6E 19200

12'0"

3 MHHZ0431 CS27K6E 23900 MSHZ0501 ZB38KCE 24900

18'-4'

16'0" 16'-4' 2 MHHZ0431 CS27K6E 23900 MHHZ0501 CS33K6E 19200

20'0" 20'-4' 2 1 MHHZ0501 CS33K6E 28000 MSHZ0501 ZB38KCE 24900

18'0"

24'-4'

22'0" 22'-4' 1 2 MHHZ0501 CS33K6E 28000 MSHZ0581C ZB45KCE-TF5 30300

26'0" 26'-4' 3 1 MSHZ0501 ZB38KCE 33400 BSHZ0750C ZB56KCE-TWC 37400

24'0"

1 3 MSHZ0581C ZB45KCE-TF5 39600 BSHZ0750C ZB56KCE-TWC 37400

30'-4'

28'0" 28'-4' 2 2 MSHZ0581C ZB45KCE-TF5 39600 BSHZ0750C ZB56KCE-TWC 37400

30'0"

24

Loading...

Loading...