Page 1

MCR-33-101

Full-length

evaporator coil

and vertical fan

tower provide

evenly distributed

cooling.

ITEM NO. __________________________________________________

PROJECT __________________________________________________

LOCATION _________________________________________________

DATE _________________________ QTY. _______________________

MCR-33-101 &

MCR-33-102 SERIES

Roll-in & Pass-Thru

Blast Chillers

ROLL-IN MODELS PASS-THRU MODELS

❑ MCR-33-101 ❑ MCR-33-101PT

❑ MCR-33-102 ❑ MCR-33-102PT

FEATURES

FEATURES

CONSTRUCTION

• Stainless steel interior and exterior

with polyurethane foamed-in-place

insulation

• Interior light

• Door gasket heater

• High velocity forced air convection

through evaporator coil

• HACCP compliant recording thermometer for blast chiller ambient

air temperature (requires printer to

have record)

• 4 food temperature probes with sequential readout display in MCR-33101, 8 probes in MCR-33-102

• Automatic chill cycle control with

food temperature probes

DOORS

• Door dimensions: 30" x 78"

• Flush mounted

• 36" high 16 ga. stainless steel kickplate on door exterior

REFRIGERATION SYSTEM

• An air- or water-cooled condensing

unit will be supplied depending on

application.

CONTROL PANEL

• HACCP compliant recording features

• Surface mounted on exterior of blast

chiller

• On/off switch

• Digital readout of interior ambient

temperature

• Digital cycle timer

• Microprocessor control system

enclosed in easily accessible box

• Automatic air defrost cycle

• Automatic hold cycle

• Audible alarm at end of chilling cycle

RACK

• Racks provided:

– MCR-33-101 .............................. 1

– MCR-33-102 .............................. 2

• Stainless steel construction

• Accomodates 26 pans, 12" x 20" x

1

2

/2", two per each of 13 ledges

• Ledges on 4

• Each pan holds up to 10 pounds of

food for total rack quantity of 260 lbs.

• Rack dimensions: 24

deep x 68

• Rack mounted on heavy-duty swivel

casters

1

/2" spacing

5

/16" high

1

/2" wide x 27"

COOLING TIME

• Maximum load of 260 pounds of

food requires approximately 90 minutes per cooling cycle depending on

food density and input temperature

of food

WARRANTY

• Standard limited one year extended

compressor (optional four year extended warranty available), one year

limited parts, limited 10 year panel

OPTIONS

❑ Optional nishes

❑ Add sufx “C” for correctional

model

❑ Printer package

❑ Extended four year compressor

warranty

908 Highway 15 North • New Albany, MS 38652

PHONE: 800-647-1284 or 662-534-9061 • FAX: 800-232-3966 or 662-534-6049 • www.master-bilt.com

Page 2

MASTER-CHILL™ MCR-33-101 & MCR-33-102 SERIES

ROLL-IN & PASS-THRU BLAST CHILLERS

BLAST CHILLER TECHNICAL SPECIFICATIONS

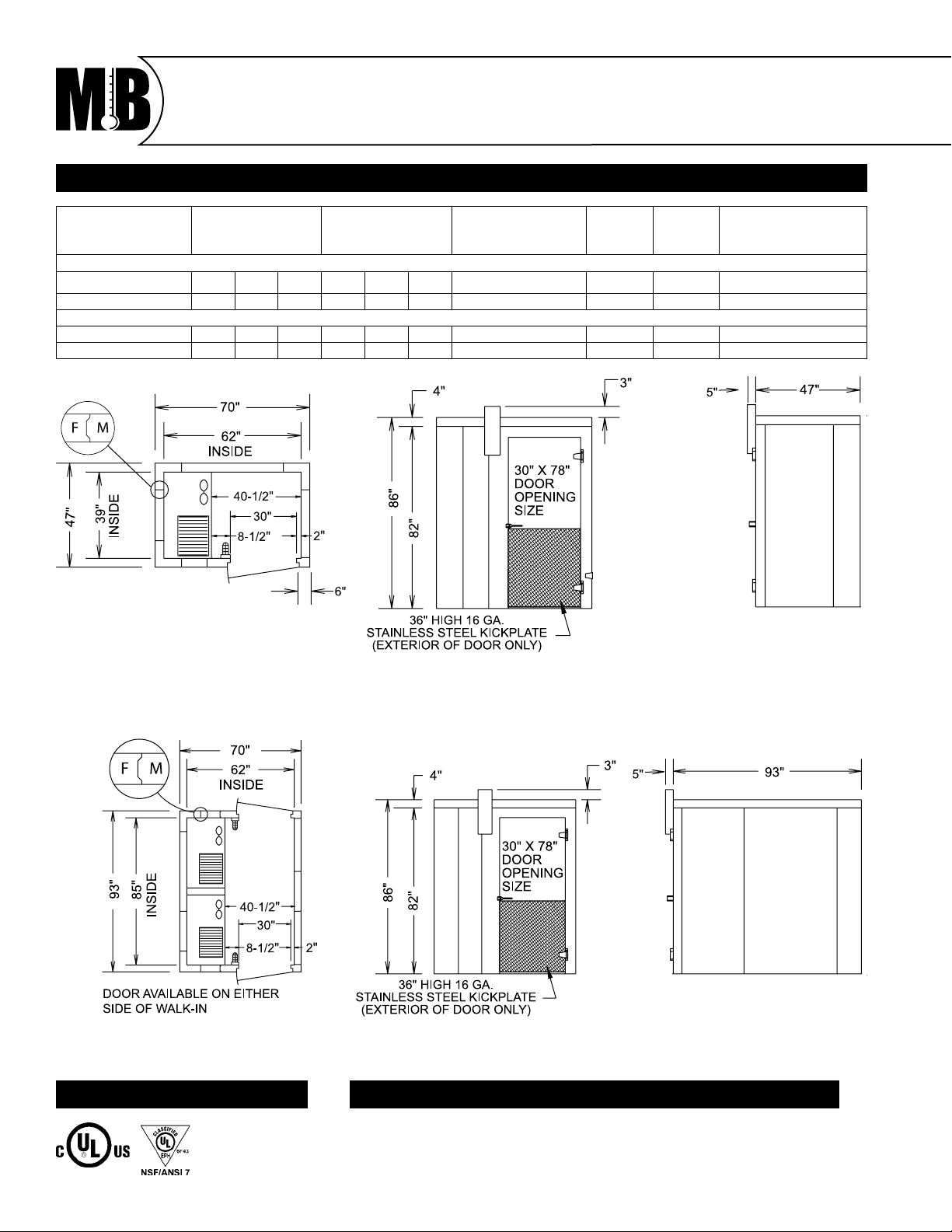

DIMENSIONS

(in inches)

MODEL L D* H* L D* H* VOLTS MCA FUSE SHIP WT. LB/KG

ROLL-IN

MCR-33-101 70 52 89 1778 1194 2184 208-230/1ph/4-wire 9 15 1500/682

MCR-33-102 70 98 89 1778 2362 2184 208-230/1ph/4-wire 16 20 3000/1364

PASS-THRU

MCR-33-101PT 70 52 89 1778 1194 2184 208-230/1ph/4-wire 9 15 1500/682

MCR-33-102PT 70 98 89 1778 2362 2184 208-230/1ph/4-wire 16 20 3000/1364

*Depth and height include control panel.

DIMENSIONS

(in millimeters) MAX.

MCR-33-101 PLAN VIEW MCR-33-101 SIDE VIEW

MCR-33-102 PLAN VIEW

MCR-33-101 ELEVATION VIEW

MCR-33-102 ELEVATION VIEW

MCR-33-102 SIDE VIEW

LISTINGS HOOKUP

Hardwire, remote refrigeration.

2

Page 3

REFRIGERATION SYSTEM TECHNICAL SPECIFICATIONS

All condensing units must include a suction accumulator.

Pull down time reects time neces-

sary to lower listed quantity of food from 140°F to 40°F. All units listed contain R-404A refrigerant.

BTUH

COND.

UNIT

MODEL* H.P.

@ -10°F

SUCTION

TEMP.**

MCR-33-101, 200 LB. CAPACITY, 2 HOUR PULL DOWN TIME

MSLZ0101C 3 10,653 3/8 7/8 M2 11.4 200/91 20 30 11.1 77

MHLZ0121B 3 11,559 1/2 1-1/8 M2 11.4 260/118 30 45 19 105

MCLZ0111B 3 10,372 1/2 7/8 M2 11.4 330/150 24 35 14.7 86

MCLZ0111C 3 10,343 1/2 7/8 M2 11.4 330/150 19 25 10 82

MCR-33-101, 200 LB. CAPACITY, 1.5 HOUR PULL DOWN TIME

MSLZ0151C 4 14,994 1/2 7/8 M2 11.4 230/105 32 40 15 99

BSLZ0400B 4 15,047 1/2 7/8 C 41.5 510/232 42 60 26.8 129

BSLZ0400C 4 15,047 1/2 7/8 C 41.5 510/232 32 40 15 99

BSLZ0400E 4 15,047 1/2 7/8 C 41.5 510/232 20 20 8.2 50

BCLZ0280B 3 15,529 5/8 1

BCLZ0280C 3 15,529 5/8 11/

BCLZ0280E 3 15,529 5/8 11/

MCR-33-101, 250 LB. CAPACITY, 2 HOUR PULL DOWN TIME

MSLZ0151C 4 14,994 1/2 7/8 M2 11.4 230/105 32 40 15 99

MCLZ0141B 3 13,799 1/2 1

MCLZ0141C 3 13,903 1/2 11/

BSLZ0400B 4 15,047 1/2 7/8 C 41.5 510/232 42 60 26.8 129

BSLZ0400C 4 15,047 1/2 7/8 C 41.5 510/232 32 40 15 99

BSLZ0400E 4 15,047 1/2 7/8 C 41.5 510/232 20 20 8.2 49.5

BCLZ0280B 3 15,529 5/8 11/

BCLZ0280C 3 15,529 5/8 11/

BCLZ0280E 3 15,529 5/8 11/

MCR-33-101, 250 LB. CAPACITY, 1.5 HOUR PULL DOWN TIME

MSLZ0181C 5 18,945 1/2 1

MDLZ0201C 3 19,518 1/2 11/

MCR-33-101, 250 LB. CAPACITY, 1.3 HOUR PULL DOWN TIME

BSLZ0600C 6 21,651 1/2 7/8 C 41.5 550/250 41 60 23.9 156

BCLZ0400C 4 21,531 5/8 1

BCLZ0400E 4 21,531 5/8 13/

BSLZ0600E 6 21,651 1/2 7/8 C 41.5 550/250 21 25 9.3 70

MCR-33-101 250 LB. CAPACITY, LESS THAN 1 HOUR PULL DOWN TIME

BCLZ0750C 7

1

/237,322 7/8 13/

BCLZ075UE 71/237,322 7/8 13/

MCR-33-101 250 LB. CAPACITY, LESS THAN 1 HOUR PULL DOWN TIME – WATER COOLED CONDENSING UNITS

SCLZ075WC 71/239,600 5/8 13/

SCLZ075WE 71/239,600 5/8 13/

MCR-33-102, 400 LB. CAPACITY, 2 HOUR PULL DOWN TIME

MSLZ0221C 6 23,018 1/2 1

MDLZ0231C 4 22,958 1/2 11/

BCLZ040LC 4 23,171 5/8 13/

MCR-33-102, 400 LB. CAPACITY, 1.5 HOUR PULL DOWN TIME

MDLZ0291C 6 29,187 5/8 1

MCR-33-102, 500 LB. CAPACITY, 2 HOUR PULL DOWN TIME

MDLZ0291C 6 29,187 5/8 1

BSLZ0750C 71/226,006 1/2 7/8 C 41.5 550/250 54 80 30.9 189

BCLZ0600C 6 26,466 5/8 13/

BCLZ0600E 2 26,466 5/8 13/

*VOLTAGE KEY:

“B” sufx = 208-230 or 230 volt, 60 cycle, one phase

“C” sufx = 200-230 or 208-230 volt, 60 cycle, three phase

“E" sufx = 460 volt, 60 cycle, three phase

UNIT CONNECTION

SIZES

LIQUID

SUCTION

1

/

8

8

8

3

/

8

8

8

8

8

1

/

8

8

3

/

8

8

8

8

8

8

1

/

8

8

8

3

/

8

3

/

8

8

8

DIMENSIONS

SEE

DRAWING...

(PP. 4-5)

RECEIVER

PUMPDOWN

CAP. @ 90%

SHIP

WT.

(LB/KG)

MCA** MOP** RLA** LRA**

C 41.5 505/230 32 40 15 105

C 41.5 505/230 32 35 12.6 112

C 41.5 505/230 20 20 6.2 56

M2 11.4 500/227 28 40 16.7 105

M2 11.4 500/227 26 35 12.8 112

C 41.5 505/230 32 40 15 105

C 41.5 505/230 32 35 12.6 112

C 41.5 505/230 20 20 6.2 56

M3 15.2 240/109 36 55 21.4 123

M3 15.2 530/241 38 45 16.8 102

C 41.5 530/230 44 60 26.3 161

C 41.5 530/230 22 30 10.2 60

D 53.4 730/332 55 80 31.5 161

D 53.4 730/332 32 40 16.1 83

D 78.4 730/332 50 80 31.5 161

D 78.4 750/341 32 40 16.1 83

M5 17 250/114 39 60 23.9 156

M3 15.2 530/241 42 60 26.3 161

C 41.5 530/241 45 70 26.3 161

M5 17 560/255 47 70 28.2 161

M5 17 560/255 47 70 28.2 161

C 41.5 560/255 46 70 28.2 161

C 41.5 560/255 26 35 13.3 80

**Based on 90°F ambient

***Electrical ratings for condensing unit only. See National

Electrical Code if units are combined on a single circuit.

3

Page 4

REFRIGERATION SYSTEM TECHNICAL SPECIFICATIONS

UNIT CONNECTION

SIZES

LIQUID

SUCTION

DIMENSIONS

SEE

DRAWING...

(PP. 4-5)

RECEIVER

PUMPDOWN

CAP. @ 90%

SHIP

WT.

(LB/KG)

MCA** MOP** RLA** LRA**

COND.

UNIT

MODEL* H.P.

BTUH

@ -10°F

SUCTION

TEMP.**

MCR-33-102, 500 LB. CAPACITY, 1.5 HOUR PULL DOWN TIME

MDLZ0331C 6 32,417 5/8 13/

BCLZ0750C 71/237,322 7/8 13/

BCLZ0750E 71/237,322 7/8 13/

MCR-33-102, 500 LB. CAPACITY, LESS THAN 1 HOUR PULL DOWN TIME

BCLZ1500C 15 70,782 7/8 1

BCLZ1500E 15 70,782 7/8 15/

8

8

8

5

/

8

8

M5 17 560/255 50 70 30.3 150

D 53.4 730/332 55 80 31.5 161

D 53.4 730/332 32 40 16.1 83

F 116.1 990/450 90 125 52.6 278

F 116.1 990/450 51 70 26.3 139

MCR-33-102, 500 LB. CAPACITY, LESS THAN 1 HOUR PULL DOWN TIME – WATER-COOLED CONDENSING UNITS

SCLZ100WC 10 54,800 7/8 13/

SCLZ100WE 10 54,800 7/8 1

8

3

/

8

E 105.3 910/414 66 100 42 215

E 105.3 910/414 34 50 18.6 106

*VOLTAGE KEY:

“B” sufx = 208-230 or 230 volt, 60 cycle, one phase

“C” sufx = 200-230 or 208-230 volt, 60 cycle, three phase

“E" sufx = 460 volt, 60 cycle, three phase

**Based on 90°F ambient

***Electrical ratings for condensing unit only. See National Electrical Code if units are combined on a single circuit.

BASE “C”

BASE “D”

BASE “E”

4

Page 5

MASTER-CHILL™ MCR-33-101 & MCR-33-102 SERIES

ROLL-IN & PASS-THRU BLAST CHILLERS

REFRIGERATION SYSTEM TECHNICAL SPECIFICATIONS (cont.)

BASE “F”

BASE “M2”

BASE “M3”

BASE “M5”

5

Page 6

BID SPECIFICATIONS

Item no. MCR-33-______

Provide______ ( ) Roll-in or

Pass-thru Blast Chiller(s)

Master-Bilt model number

MCR-33-______.

Blast chiller to be provided

with stainless steel construction

and polyurethane foamed-inplace insulation. Blast chiller will

feature high velocity forced air

convection through evaporator

coil.

Probes with sequential readout display will be supplied for

food temperature recording (four

probes in MCR-33-101 model,

eight in MCR-33-102).

An automatic chill cycle

control with food temperature

probes is also supplied.

A thermometer will be provided for recording blast chiller

ambient air temperature. Thermometer will require optional

printer for record of temperatures.

Roll-in blast chillers will con-

tain one 30" x 78" ush mounted, polyurethane foamed door.

Pass-thru models will contain

two doors. Doors will be provided with a 36" high 16 ga. stainless

steel kickplate on the exterior.

Doors will also be supplied with a

hold-open feature, magnetic gaskets and gasket heater.

Blast chillers will be provided

with an air- or water-cooled condensing unit depending on application requirements.

Blast chiller will be equipped

with a standard exterior mounted control panel featuring the

following:

• On/off switch

• Digital readout of interior ambi-

ent temperature and probe temperatures

• Digital cycle timer for timed

chilling

• Microprocessor control system

enclosed in easily accessible box

• Automatic defrost cycle and

hold cycle

• Audible alarm at end of chilling cycle

• Six programmable one-touch

preset chilling programs for

easy use

Blast chillers will be supplied

with stainless steel racks (one

rack for MCR-33-101/33-101PT,

two for MCR-33-102/33-102PT)

mounted on heavy-duty swivel

casters. Racks accommodate

26 pans, 12" x 20" x 21/2", two

per each of 13 ledges. Each pan

holds up to 10 lbs. of food for total rack quantity of 260 lbs. Dimensions of rack are 241/2" wide

x 27" deep x 685/16" high.

Blast chillers to have standard

limited one year extended compressor warranty (optional four

year extended warranty available) with one year limited parts

and limited 10 year for panels.

Blast chillers will be UL and

C-UL listed and UL EPH classied.

NOTE: All specications subject to change without notice.

908 Highway 15 North • New Albany, MS 38652

PHONE: 800-647-1284 or 662-534-9061 • FAX: 800-232-3966 or 662-534-6049 • www.master-bilt.com

©Master-Bilt Products division of Standex International, Inc. All rights reserved. Printed in U.S.A.

1287 - 2/08-web

Loading...

Loading...