Page 1

MAC-7&8

Featuring Advanced Master Controller 2.0 Technology

Reverse Cycle Defrost

Installation & Operations Manual

02-14-145revision

©2015 Master-Bilt Products, an unincorporated division of Standex International Corporation.

All rights reserved.

Page 2

TABLE OF CONTENTS

Page

Introduction .....................................................................................................3

Warning Labels and Safety Instructions+++++++++++++++..4

General Information ........................................................................................5

Condensing Unit Specifications...................................................................................... 5

Delivery Inspection ......................................................................................................... 5

Handling and Placement of Condensing Unit ...............................................6

Evaporator Coils..............................................................................................7

Ice Machine and Drink Machine Remote Circuits.........................................9

Electrical ..........................................................................................................9

Refrigerant Lines .............................................................................................9

Evaporator Suction Outlet Temperature Sensor Location ........................10

MAC-7 and MAC-8 Wiring Diagram with Reverse Cycle Defrost ..............11

Leak Check ....................................................................................................12

Evacuation, Dehydration and Start-Up ........................................................12

Charging Procedure ................................................................................................ 12-14

Evacuation Procedure .................................................................................................. 12

Drain Lines and heater .................................................................................15

Final Check List .............................................................................................16

Periodic Check of Entire System .................................................................17

Sale and Disposal .........................................................................................17

2

Page 3

Introduction

Thank you for purchasing Master-Bilt refrigeration equipment. This manual contains important

instructions for installation. Read this manual carefully before installing or servicing your Master-Bilt

refrigeration equipment. Also, for complete technical information of our walk-in cooler and freezer

refrigeration systems, please consult

Operation Manual and the Master Controller 2.0 Installation & Operation Manual.

NOTICE

Installation and service of the refrigeration and electrical components must be performed by a

refrigeration mechanic or licensed electrician.

DANGER

Improper or faulty hook-up of electrical components of the refrigeration units can result in severe

injury or death.

All electrical wiring hook-ups must be done in accordance with all applicable local, regional or

national standards.

NOTICE

Read this manual before installing your refrigeration. Keep the manual and refer to it before doing

any service. Failure to do so could result in personal injury or equipment damage.

The portions of this manual covering refrigeration and electrical components contain technical instructions

intended only for persons qualified to perform refrigeration and electrical work.

This manual cannot cover every installation, use or service situation. If you need additional information,

contact us:

Master-Bilt Condensing Unit and Refrigeration System Installation &

Parts and Technical Service Department

Master-Bilt Products

908 Highway 15 North

New Albany, MS 38652

Phone (800) 684-8988

Fax (800) 232-3966

E-Mail: service@master-bilt.com

3

Page 4

Warning Labels and Safety Instructions

This symbol is the safety-alert symbol. When you see this symbol on your cabinet or

in this manual, be alert to the potential for personal injury or damage to your

equipment.

Be sure you understand all safety messages and always follow recommended precautions and safe

operating practices.

NOTICE TO EMPLOYERS

You must make sure that everyone who installs, uses or services your refrigeration equipment is

thoroughly familiar with all safety information and procedures.

Important safety information is presented in this section and throughout the manual. The following signal

words are used in the warnings and safety messages:

DANGER: Severe injury or death will occur if you ignore the message.

WARNING: Severe injury or death can occur if you ignore the message.

CAUTION: Minor injury or damage to your cabinet can occur if you ignore the message.

NOTICE: This is important installation, operation or service information. If you ignore the

message, you may damage your cabinet.

The warning and safety labels shown throughout this manual are placed on your Master-Bilt

Products refrigeration unit at the factory. Follow all warning label instructions. If any warning or

safety labels become lost or damaged, call Master-Bilt’s customer service department at (800) 6848988 for replacements.

This label is located on the condensing unit.

4

Page 5

General Information

Please read this manual prior to installing your Master-Bilt equipment. This information is based on good

refrigeration practice and should be used as a guide for installation and operations.

Delivery Inspection

Be sure to check for damage when this equipment is delivered by the carrier. Indicate damage on the

carrier’s Bill of Lading so that a claim may be filed.

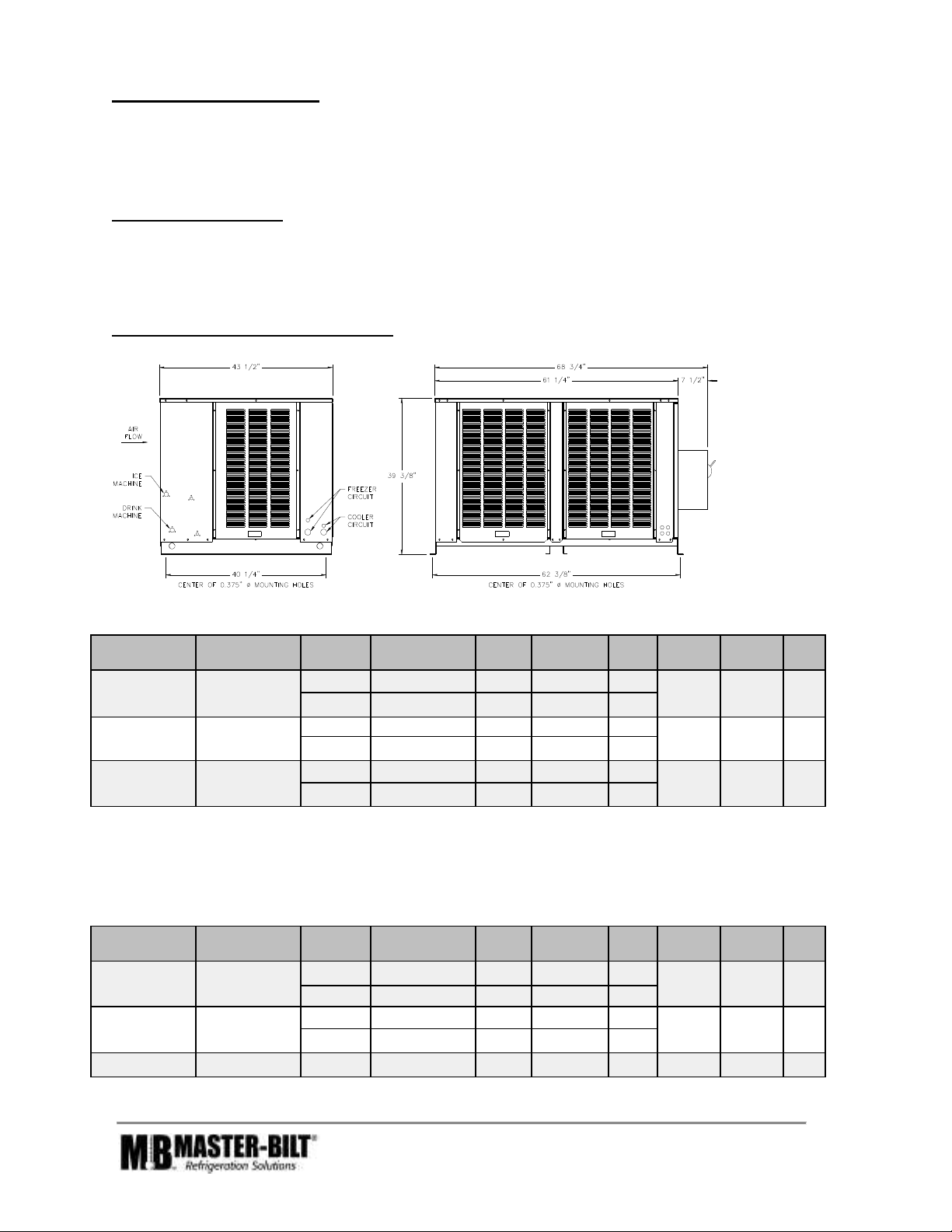

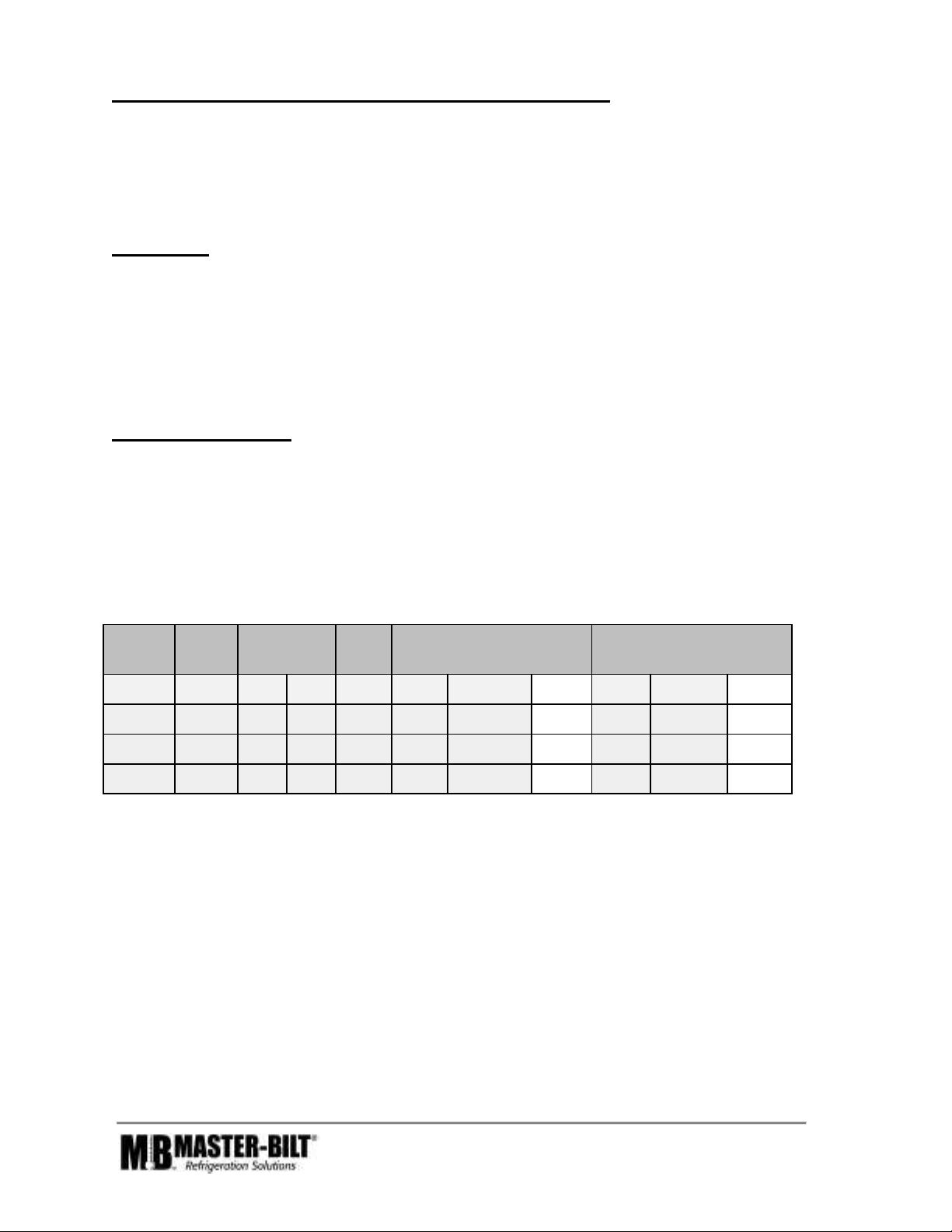

Condensing Unit Specifications

Table 1. Specifications for system where evaporators use condensing unit power

Model

R62R11B4CS* MAC-7

R62R11B3CS* MAC-8

R62R11B5CS* MAC-8C

Sales

Nomanclature

Location Compressor

Cooler ZS11KAE-TF5 R404A 208-230/3 1 1/2

Freezer ZS30K4E-TF5 R404A 208-230/3 4

Cooler ZS11KAE-TF5 R404A 208-230/3 1 1/2

Freezer ZS38K4E-TF5 R404A 208-230/3 5

Cooler ZS11KAE-TF5 R404A 208-230/3 1 1/2

Freezer ZS45K4E-TF5 R404A 208-230/3 6

* NOTE: For coated condenser coil, this place is “C”

Important Notice: Do not use reverse cycle defrost when the ambient is lower than -20oF.

Refrig

.

Voltage HP

System

MCA

35 40

43 50

46 60

System

MOP

Table 1.1 Specifications for system where evaporators use separate power source

Model

R62R11B4CS MAC-7

R62R11B3CS MAC-8

R62R11B5CS MAC-8C Cooler ZS11KAE-TF5 R404A 208-230/3 1 1/2

Sales

Nomanclature

Location Compressor

Cooler ZS11KAE-TF5 R404A 208-230/3 1 1/2

Freezer ZS30K4E-TF5 R404A 208-230/3 4

Cooler ZS11KAE-TF5 R404A 208-230/3 1 1/2

Freezer ZS38K4E-TF5 R404A 208-230/3 5

Refrig

.

Voltage HP

System

MCA

32 40

39 50

42 50

System

MOP

Wt.

LBS

717

717

717

Wt.

LBS

717

717

717

5

Page 6

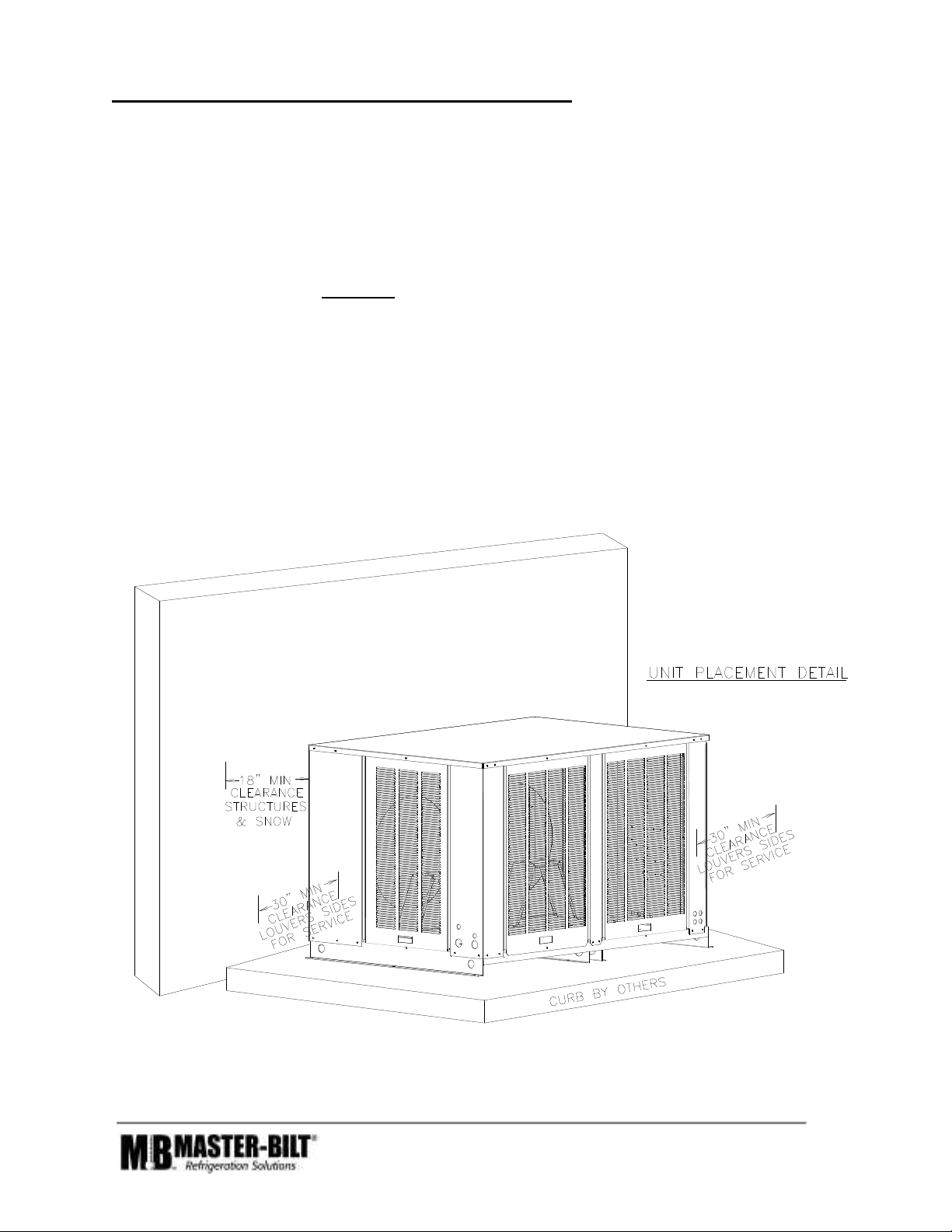

Handling and Placement of Condensing Unit

To minimize damage to the unit housing, it is recommended that the crate not be removed until the unit is

moved to its final location.

The following should be considered when placing the unit:

A. The condenser coil (air inlet) should not be located so as to restrict air flow into the coil or direct

facing of sunlight. A minimum of 12” is required (18” is preferred) between the face of the coil and a

wall or other vertical obstruction.

B. Keep snow accumulation 18” to 30” away from condenser coils (air inlets) at all times.

C. A minimum of 30” is required on the three louvered sides to allow access for maintenance.

D. Do not position multiple units so that the air discharge of one is into the air intake condenser of

another.

E. The roof mounting curb for the MAC units should be designed in such a way as to fully support all

four of the bottom rails.

Holes are provided in the base supports for mounting bolts and for bridle lift rods.

6

Page 7

Evaporator Coils

To minimize damage to the evaporator coil, it is recommended that the carton (or crate) not be removed

until the evaporator coil is moved close to its final location. When the container is removed from the

evaporator coil, extreme care must be used when lifting and mounting to the ceiling, to prevent sheet

metal damage. Consult evaporator “Operating and Installation

Instructions” for proper installation details.

Dimensional Data

Table 2.

Model Description

EMHZ0133B**

EMRZ0143B**

EMRZ0183B**

EMRZ0203B**

The evaporator units are built in with Master Controller 2.0 system. It has standard demand defrost

features. The number of defrosts per day varies depending on moisture condition in the freezer. For more

information of a Master Controller 2.0 System, please consult the Master Controller 2.0 System I/O

Manuals.

Specifications of evaporators

MAC-7,8

COOLER

MAC-7

FREEZER

MAC-8

FREEZER

MAC-8C

FREEZER

Capacity

Refrig. BTUH*

R404A 13300

R404A 14000

R404A 18200

R404A 21700

* Based on 10°F TD, +25oF SST for med-temp, -20oF SST for low-temp

** 208-230V / 1 phase /EC Motors, W/Master Controller, Electric Expansion Valve pre-mounted

Connection

Inlet Outlet Drain

1/2

OD

1/2

OD

5/8

OD

5/8

OD

7/8

OD

7/8

OD

1 1/8

OD

1 1/8

OD

Amps (230)

Mtrs Htrs

3/4

1.24

MPT

3/4

1.86 4.0 10 10 82 55.25 63.5 3

MPT

3/4

2.48 5.2 10 10 101 73.25 81.5 4

MPT

3/4

MPT

3.1 6.5 10 10 125 86.25 94.5 5

MCA MOP

10 10 61 41.25 49.5 2

Wt.

lbs.

“A”

in

“W”

in

No.

Fan

7

Page 8

For non standard units other than listed in previously

pages, please consult factory for deltail specifications

and wiring diagrams. The non standard units are

larger size freezer compressor, three phase power

supply to evaporator defrost heaters, reverse cycle

defrost systems, etc.

8

Page 9

Ice Machine and Drink Machine Remote Circuits

Each MAC-7 and MAC-8 condenser is equipped with two remote circuits for use with the stores ice

machine and/or drink machine. These circuits are factory charged with nitrogen and sealed with quick

connect fittings (1/2” for entering condenser and 3/8” for leaving condenser). Each circuit has a BTUH

capacity of 16,800 BHUH (at 10F TD), an internal volume of 155 cubic inches and has approximately 667

CFM of air flow.

Electrical

Electric power supply must match the condensing unit power requirements indicated on the unit data

plate. The typical wiring diagram is provided in this manual. A system wiring diagram is located on the

inside of the electrical box cover. All field wiring may enter the electrical box through the holes provided in

the side of the box. All field wiring should be done in a professional manner, in accordance with any and

all governing codes. Double check all wiring connections, including factory terminals, before start-up of

condensing unit.

Refrigerant Lines

Refrigeration lines must be properly sized. For line sizing data see Table 3 below. Horizontal suction lines

should be sloped toward the compressor at least 1/2” every 10 feet to insure good oil return. All vertical

suction risers should be trapped at the bottom. Certain installations may require multiple P-traps which

should be placed one every 15 to 20 feet. Insulate all suction lines with at least 3/4” thick Armaflex

insulation. Insuslate the indoor portion of liquid line with at least ½” thick Armaflex to prevent

condensate water dripping on ceilings during defrost.

Table 3.

Appropriate Line Sizes

System Room

MAC-7

MAC-7,8

MAC-8

MAC-8C

Freezer 7/8” 1/2” 1 1/8” 1 1/8” 1 1/8”

Cooler 7/8” 3/8” 7/8” 7/8” 7/8”

Freezer 7/8” 5/8” 1 1/8” 1 1/8” 1 1/8”

Freezer 7/8” 5/8” 1 1/8” 1 3/8” 1 3/8”

Note: P-trap and vertical suction riser should one size down than the horizontal suction pipe.

Connection

Suct Liq.

Max.

Riser

Suction Line*

< 75 >75’, < 150’ >150’

Consult

Factory

Consult

Factory

Consult

Factory

Consult

Factory

Liquid LIne

5/8”

5/8”

Consult

Factory

Consult

Factory

Consult

Factory

Consult

Factory

< 75 >75’, < 150’ >150’

1/2” 5/8”

3/8” 3/8”

5/8”

5/8”

It is recommended that all brazed joints be made with silver alloy-type solders. A small amount of dry

nitrogen should be fed into the tubing during brazing operations to minimize formation of scale and

oxidation inside the tubing. Also, use care to keep tubing free of foreign matter and moisture. Purge the

pipe with high pressure dry nitrogen before brazing the last joint. Remove all remaining flux from the joints

after brazing. Remote refrigeration must be installed in accordance with all governing codes. Copper

tubing must be refrigeration grade, ACR or in accordance with all governing codes.

9

Page 10

Evaporator Suction Outlet Temperature Sensor Location

The sensor should be mounted on the suction line about 6” or more away from the evaporator as

indicated in the picture below. The sensor should be mounted on 10:00 to 2:00 O’clock position for true

vapor temperature reading. Use metal strap provided by factory to fasten the sensor bulb. Apply insulation

around the suction line after installation.

:

10

Page 11

MAC-7 and MAC-8 Wiring Diagram with Reverse Cycle Defrost

N.O.

N.O.

Note: Evaporators and condensing unit powers are from same power sources. The actual wiring

diagram for each system is attached on the back of the electric box cover.

11

Page 12

Leak Check

⁰⁰⁰⁰

When all refrigeration line connections have been made, the complete system, including factory

connections, should be leak checked. Failure to do so may waive factory warranty. Remove the low

pressure transducer before pressurizing for leak check. Charge the system 300 PSIG with dry-nitrogen

and check each joint and connection with soap bubble for leak. Install the pressure transducer back after

the pressure is released.

Evacuation, Dehydration and Start-Up

A vacuum of 500 microns or less must be pulled to properly dehydrate the system. This requires a twostage vacuum pump with an electronic vacuum indicator. The vacuum level has to be maintained to be

sure no moisture is inside the oil.

CAUTION: Do not operate the compressor while the system is in a vacuum. This will waive factory

warranty for Scroll compressor.

Evacuation Procedure

A. Open all condensing unit service valves and relieve system pressure. Also, open any line valves

installed in the system and energize all solenoid valves to facilitate evacuation.

B. Connect the vacuum pump to the high and low sides of the system using 1/4” or larger copper lines

or 1/4” ID hoses with high vacuum designation.

C. Leaks or moisture will be indicated if the system pressure rises when the vacuum line is closed off.

D. A final vacuum of 500 microns should be pulled and maintained before charging. Charge

the high side until the system pressure is equal to the pressure in the refrigerant cylinder.

Charging Procedure

A. Preliminary

1. Calculate the preliminary refrigerant charge using the following Formula:

Preliminary Charge = (Rated Tons of Refrigeration x 3 lbs of R-404A) + (Liquid Line Refrigerant

Volume)

Rated Tons for various compressors in MAC-7-8 are given below in Table 4.

Table 4

NOTE: For Liquid Line Refrigerant Volume, Reference Table 5 Below

Capacity

Compressor

(Tons) Evap Temp (

ZF13 1.17 -20

ZF15 1.46 -20

ZF18 1.77 -20

CS10 1.13 25

F)

12

Page 13

Table 5

Length

Lbs. of R-404A to fill Liquid line by Length

Liquid Line Size (in.ODS)

Feet 3/8" 1/2" 5/8"

5 0.18 0.32 0.52

10 0.36 0.64 1.04

15 0.54 0.96 1.56

20 0.72 1.28 2.08

25 0.9 1.6 2.6

30 1.08 1.92 3.12

50 1.8 3.2 5.2

75 2.7 4.8 7.8

100 3.6 6.4 10.4

150 5.4 9.6 15.6

FOR EXAMPLE:

Calculate the Preliminary Charge for a ZF13 compressor with a 25 ft. liquid line, ½” ODS Copper

Rated Tons of Capacity (From Table 4) = 1.17

Amount of Refrigerant to Fill a ½” ODS Liquid Line, 25 ft. long (From Table 5) = 1.6 lbs.

Preliminary Charge = (Rated Tons of Refrigeration x 3 lbs of R-404A) + (Liquid Line Refrigerant

Volume)

Preliminary Charge = (1.17 x 3) + 1.6 = 5.11 lbs (This value is also given in Table 6 below)

2. Weigh in the preliminary charge from Calculations, or from Table 6

3. Be sure all service valves are “open”.

4. Start the system by “flipping on” the disconnect on the side of the electrical box.

5. Check evaporator fan motors after start-up. Medium temperature, air defrost fans run

continuously (the cooler) , low temperature fans provided with electric defrost (the

freezer) will be delayed by the fan control.

6. During pulldown, expect evaporator superheat to be high, as the box is under a very high load.

As the room temperature approaches set point, the superheat will begin to drop, and begin to

approach the superheat setpoint, designated in the controller programming, typically 10⁰F.

Continue to let the box temperature fall. This is a good opportunity to calibrate the adjustable low

pressure controller. Recommended set points are as follows:

Cut Out = 2 psig Cut-In = 20 psig

7. When the box temperature approached set point, this is the time test the defrost cycle.

The reaction of the compressor during a defrost cycle is a good time to determine if the system is

charged properly. The following sequence will likely be seen if the charge is not correct.

13

Page 14

IF SHORT CYCLING ON THE LOW PRESSURE CONTROL AT THE BEGINNING OF THE DEFROST,

THE SYSTEM IS UNDERCHARGED.

IF SHORT CYCLING ON THE HEAD PRESSURE CONROL AT THE END OF THE DEFROST, THE

SYSTEM IS OVERCHARGED.

IF THE PRELIMINARY CHARGE IS USED, YOU WILL NOT SEE AN OVERCHARGE.

IF ANY SHORT CLYCING IS OBSERVED AT THE BEGINNING OF THE DEFROST CYCLE. ADD 1/2

INCRIMENTS OF R-404A UNTIL THE SHORT CYCLING GOES AWAY. ALLOW THE SYSTEM TO

PULL BACK DOWN TO TARGET ROOM TEMPERATURE, THEN TEST SYSTEM AGAIN WITH A

MANUAL DEFROST. REPEAT UNTIL NO SHORT CYCLING IS SEEN.

NOTE: DO NOT BLAME SHORT CYCLING ON THE CHARGE UNTIL THE LOW PRESSURE

SETPOINTS ABOVE HAVE BEEN CONFIRMED.

8. Since the Master Control Refrigeration System is designed to operate at a floating head

pressure, low head pressure may be seen at low amblent condition. For example, at a box

temperature of –10oF and an outside ambient temperature of 50oF, the suction pressure should

be at the neiborhood of 15 to 18 PSIG, the head pressure should be at the neiborhood of 125150 PSIG.

Note: Do not overcharge the system!

Table 6. Preliminary Refrigerant Charges by Compressor/Line Size/Length

Line Size 1/2 5/8 5/8 3/8

Length ZF13 ZF15 ZF18 CS10

5.0 3.8 4.9 5.8 3.6

10.0 4.1 5.4 6.3 3.7

15.0 4.5 5.9 6.9 3.9

20.0 4.8 6.5 7.4 4.1

25.0 5.1 7.0 7.9 4.3

30.0 5.4 7.5 8.4 4.5

50.0 6.7 9.6 10.5 5.2

75.0 8.3 12.2 13.1 6.1

Line Size 5/8 5/8 5/8 3/8

Length ZF13 ZF15 ZF18 CS10

100.0 13.9 14.8 15.7 7.0

150.0 19.1 20.0 20.9 8.8

9. Check operating pressures while charging and on initial pulldown to prevent damage if

problem occurs.

14

Page 15

Drain Lines

a. Copper lines must be used for drains. Plastics are not acceptable.

b. Drain lines must exit the freezer or cooler as quickly as possible and must have a pitch of at least 1/8”

inch/foot downward or meet the local code requirements.

c. Drain lines must have individual traps for the cooler and the freezer and the trap cannot be inside the

freezer.

d. Drain line heater should be routed through the back (right side) of the freezer evaporator through the

designated knockout and wired to “X” and “N” as shown in the diagram.

e. Clip and secure the wire along the back bottom of the evaporator to thel drain line.

f. The drain line heater tape must be wrapped the entire drain line inside the freezer, starting at the

bottom of the evaporator coil. The heater must extend through the wall of the freezer to include the

trap.

g. There should be approximately 2 feet of heater tape per 1 foot of drain line with no overlapping. The

heat tape should be routed in such a way that it does not contact any defrost heateer or pan heater

element.

h. The entire length of drain lines inside both the cooler and the freezer should be wrapped with 3/4” thick

Armaflex-type insulation.

***Refer to section-diagram below for wire hook-up.

DrainLine heater

15

Page 16

Final Check List

A. Check high-low pressure control setting for freezer unit.

Recommended Low Pressure Settings: Cut-in 26 PSIG, Cut-out 2 PSIG or Differential 24

Recommended High Pressure Setting: 400 PSIG Cut-out

B. Check operating pressures vs. box temperature and ambient temperatue.

Suction Pressure measured at around 15 PSIG when -10F box temp is reached.

Head pressure is floating but the if the TD ( = Condensing Temperature – Ambinet

Temperature ) is higher than 25 F, the system may be over charged or non-condensable gas

inside the system.

C. Check electrical requirements of unit to power supply voltage.

The power supply voltage should match the Lead Color Voltage of the 24VAC primary input

voltage. If NOT, switch the leads.

D. Set desired temperature range:

a. Cooler temperature is preset at 35oF cut-out, 38oF cut-in.

b. Freezer temperature is preset at –10oF cut-out, -5oF cut-in.

E. Check the operating True Superheat (SH) for proper refrigeration charge.

Never use level of fullness of sight glass to determine the charging level. Always use

weighing scale and Superheat Approach Charging Method mentioned above.

F. Check compressor oil level.

G. Check compressor crankcase heater operation.

H. Check systems for proper defrost operation.

Adjust the defrost termination set point (dS) to clear all frost if needed.

I. Check condensing unit for vibrating or rubbing tubing. Dampen or clamp as required.

J. Open all valves completely counter clockwise.

K. Check packing nuts on all service valves.

L. Insure that all covers and panels are fully secured to the unit.

M. Refer to the Master Controller Manual for system control.

N. Call Factory if there’s any doubt.

16

Page 17

Periodic Check of Entire System

A periodic check of the entire system should be done at least once every 4 months. Be sure to check all

electrical connections, wiring, insulators, contactors, fan motors and motor mounts, defrost heaters, and

drain line heaters. The condenser coil surface, the evaporator coil surface, and the drain pan should be

cleaned. Check the sequence of operations of the system, the safety controls, the defrost controls, and

the drain line. Check that all flare connections are tight and tighten as required.

Sale And Disposal

Owner Responsibility

If you sell or give away your Master-Bilt walk-in or refrigeration system you must make sure that all safety

labels and the proper Installation and Operations Manual are included with it. If you need replacement

labels or manuals, Master-Bilt will provide them free. Contact the customer service department at MasterBilt at (662) 534-9061.

The customer service department at Master-Bilt should be contacted at the time of sale or disposal of your

walk-in or refrigeration system so records may be kept of its new location.

If you sell or give away your Master-Bilt cabinet and you evacuate the refrigerant charge before shipment,

Master-Bilt recommends that the refrigerant charge be properly recovered in complience with section 608

of the Clean Air Act effective November 1995 and in accordance with all applicable local, regional, or

national standards.

17

Loading...

Loading...