Page 1

BOTTOM MOUNT REFRIGERATORS, FREEZERS & MERCHANDISERS

Installation, Operation and Maintenance Technical Instructions

FREEZERS : F23-S, F23-SH

F49-S, F49-SH

F72-S, F72-SH

REFRIGERATORS : R23-S, R23-SH, R23-G

R49-S, R49-SH, R49-G

R72-S, R72-SH, R72-G

MERCHANDISERS : GR26H, GR48S, GR72H

- 1 – 05/15 Rev. G 146526

Page 2

A. GENERAL

1. SPECIFICATION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A3

1) GENERAL

2) MAIN COMPONENTS

2. REFRIGERATION CYCLE - - - - - - - - - - - - - - - - - - - - - - - - - - A9

3. TROUBLE SHOOTING - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A11

1) CHECKING THE POWER SUPPLY

2) CHECKING THE POWER SUPPLY OF CONT ROL BOARD

3) CHECKING THE CONTROL PART OF REFRIGERATION CYCLE

4) CHECKING THE DEFROST PART

5) WHEN THE UNIT DOES NOT COOL

6) WHEN THERE IS A ABNORMAL NOISE

7) WHEN THE TEMPERATURE DOES NOT DISPLAY

8) WHEN THE LAMP DOES NOT LIGHT

9) CHECKING SENSOR

4. FEATURE CHART - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A22

5. WIRING DIAGRAM - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A28

6. REPLACEMENT OF COMPONENTS - - - - - - - - - - - - - - - - - - A37

- 2 – 05/15 Rev. G 146526

Page 3

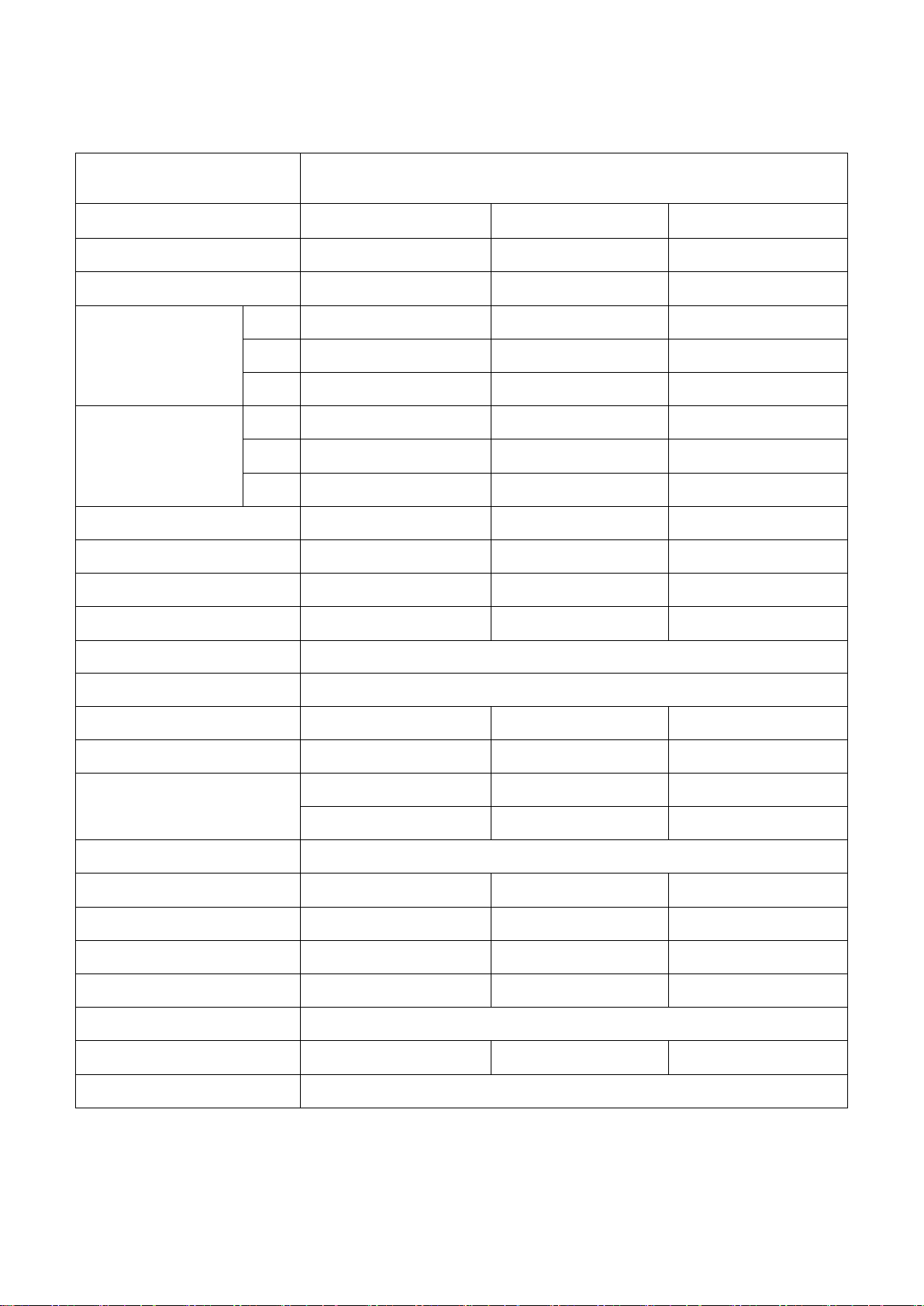

1. SPECIFICATION

(27.4”)

(55.2”)

(78.0”)

(27.4”)

(55.2”)

(78.0”)

(23.6”)

(51.4”)

(74.2”)

(23.6”)

(51.4”)

(74.2”)

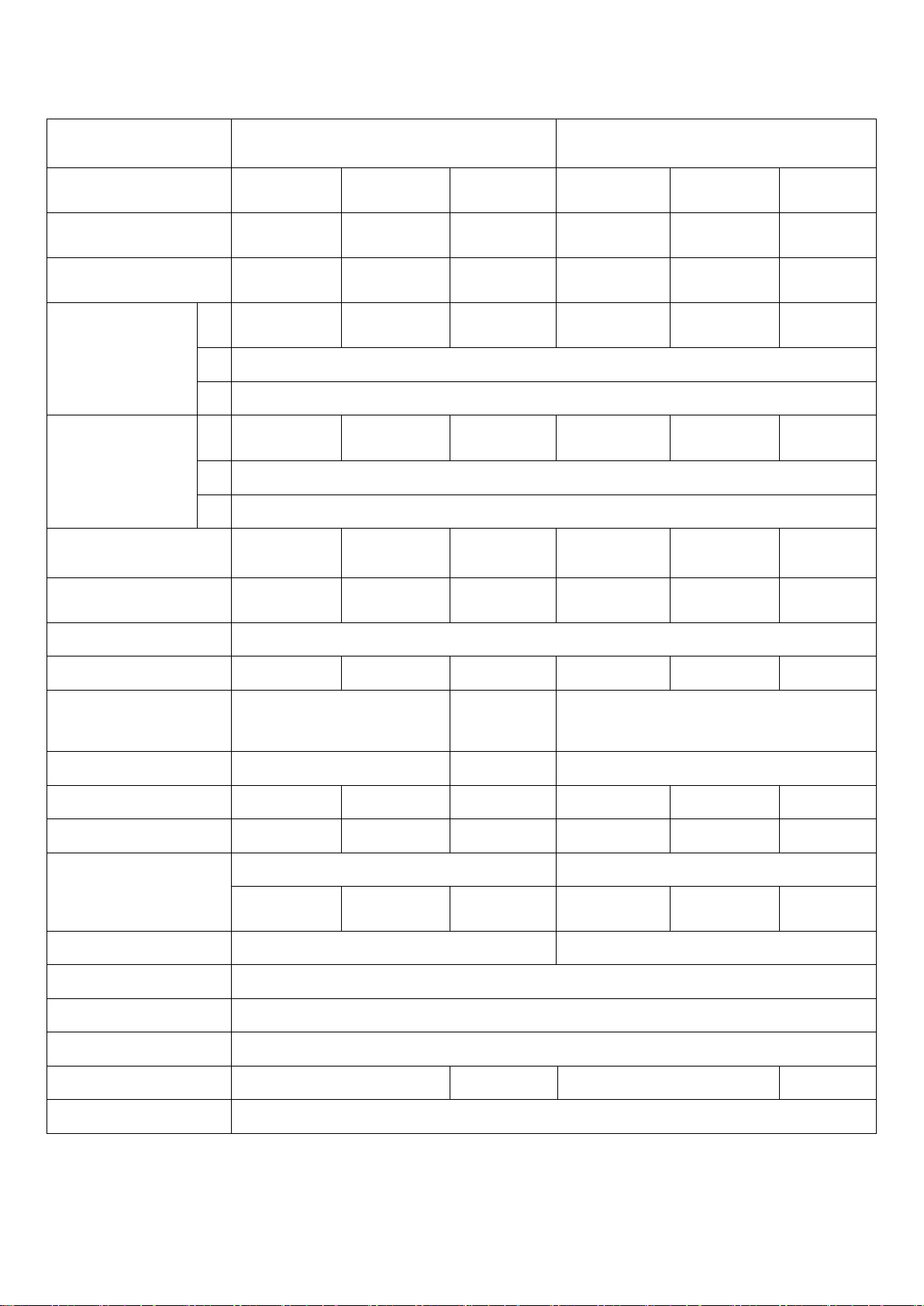

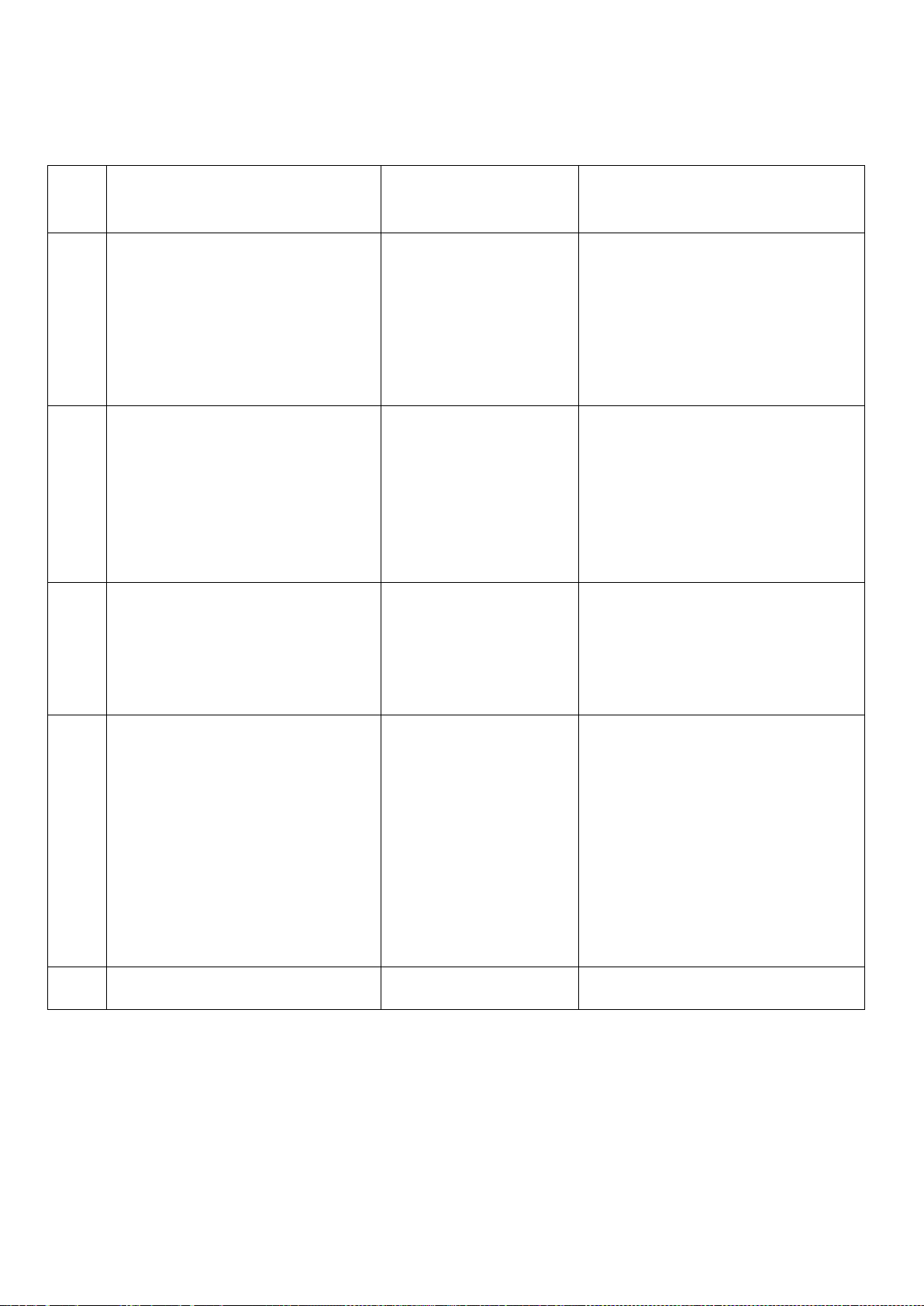

1.1 GENERAL - SOLID DOOR FREEZER & REFRIGERATOR (FULL DOOR / HALF DOOR)

PRODUCT

MODEL

Capacity

Net Capacity

Exterior Dimension

(Including casters

Door Handles)

Interior Dimension

Product Weight

(W)

(D)

(H)

(W)

(D)

(H)

SOLID (FULL/HALF) DOOR

F23-S /

F23-SH

650ℓ(23ft3)/

648ℓ(22.9ft3)

552ℓ(19.5ft3)/

551ℓ(19.4ft3)

695㎜

600㎜

124㎏(273 lb)/

126㎏(278 lb)

FREEZER

F49-S /

F49-SH

1,385ℓ(49ft3)/

1,381ℓ(48.8ft3)

1,195ℓ

(42.2 ft3)/

1,191ℓ(42.1 ft3)

1,400㎜

1,305㎜

194㎏(428 lb)/

198㎏(437 lb)

F72-S /

F72-SH

2,035ℓ(72ft3)/

2,028ℓ(71.6ft3)

1,790ℓ

(63.2ft3)/

1,782ℓ(63ft3)

1,980㎜

838 ㎜ (33”)

2,127 ㎜ (83.7”)

1,885㎜

635 ㎜ (25”)

1,545 ㎜ (60.8”)

255㎏(562 lb)/

260㎏(573 lb)

SOLID (FULL/HALF) DOOR

R23-S /

R23-SH

650ℓ(23ft3)/

648ℓ(22.9ft3)

552ℓ

(19.5ft3)/

551ℓ(19.4ft3)

695㎜

600㎜

121㎏(267 lb)/

123㎏(271 lb)

REFRIGERATOR

R49-S /

R49-SH

1,385ℓ(49ft3)/

1,381ℓ(48.8ft3)

1,195ℓ

(42.2 ft3)/

1,191ℓ(42.1 ft3)

1,400㎜

1,305㎜

186㎏(410 lb)/

190㎏(419 lb)

R72-S /

R72-SH

2,035ℓ(72ft3)/

2,028ℓ(71.6ft3)

1,790ℓ

(63.2ft3)/

1,782ℓ(63ft3)

1,980㎜

1,885㎜

253㎏(558 lb)/

258㎏(569 lb)

Door Type

Swing 1EA/

Swing 2EA

Swing 2EA/

Swing 4EA

Swing 3EA/

Swing 6EA

Swing 1EA/

Swing 2EA

Swing 2EA/

Swing 4EA

Door Material Stainless steel (STS)

Shelves 4EA 8EA 12EA 4EA 8EA 12EA

AC 115V

Power Voltage AC 115V/60Hz

Plug in - Installation NEMA 5-15P NEMA 14-20P

/208-230V

60Hz

AC 115V/60Hz

NEMA 5-15P

Amps 8.5A 9.5A 9.0A 7.5A 7.5A 10.0A

Compressor 3/5HP 3/4HP 9/8HP 3/8HP 3/8HP 1/2HP

R-404A R-134a

Refrigerant

Range of Temperature

Door auto-close equipment

340 g

(12.0 oz)

630 g

(22.2 oz)

670 g

(23.6 oz)

210 g

(7.5 oz)

270 g

(9.5 oz)

Below -18℃ (0°F) 0℃ ~ 4℃ (+32°F ~ +40°F)

Auto-close for Spring

Door stop 120˚ Stop

Swing 3EA/

Swing 6EA

400 g

(14.0 oz)

Air suction equipment Air damper

Caster 4” × 4EA 4” × 6EA 4” × 4EA 4” × 6EA

Condensing unit Sliding Type

◈ Above specifications are subjected to ch ange without prior notice for quality improvement.

◈ The nameplate(includes Serial Nu mb er ) is l ocated on the upper left of the cabi net interior.

- 3 – 05/15 Rev. G 146526

Page 4

(23 ft3)

(49 ft3)

(72 ft3)

(19.5 ft3)

(42.2 ft3)

(63.2 ft3)

(27.4”)

(55.2”)

(78.0”)

(23.6”)

(51.4”)

(74.2”)

(278 lb)

(441 lb)

(597 lb)

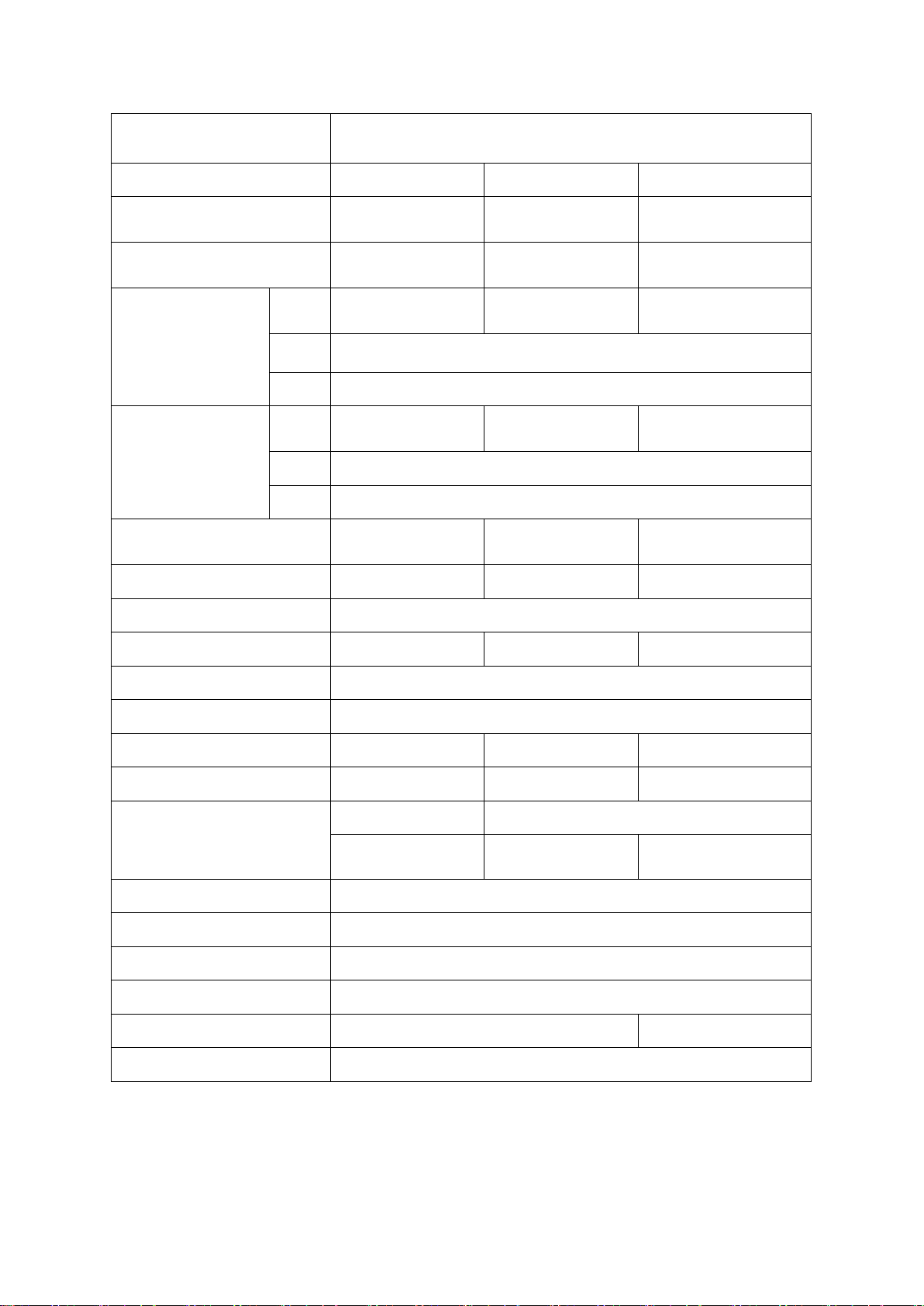

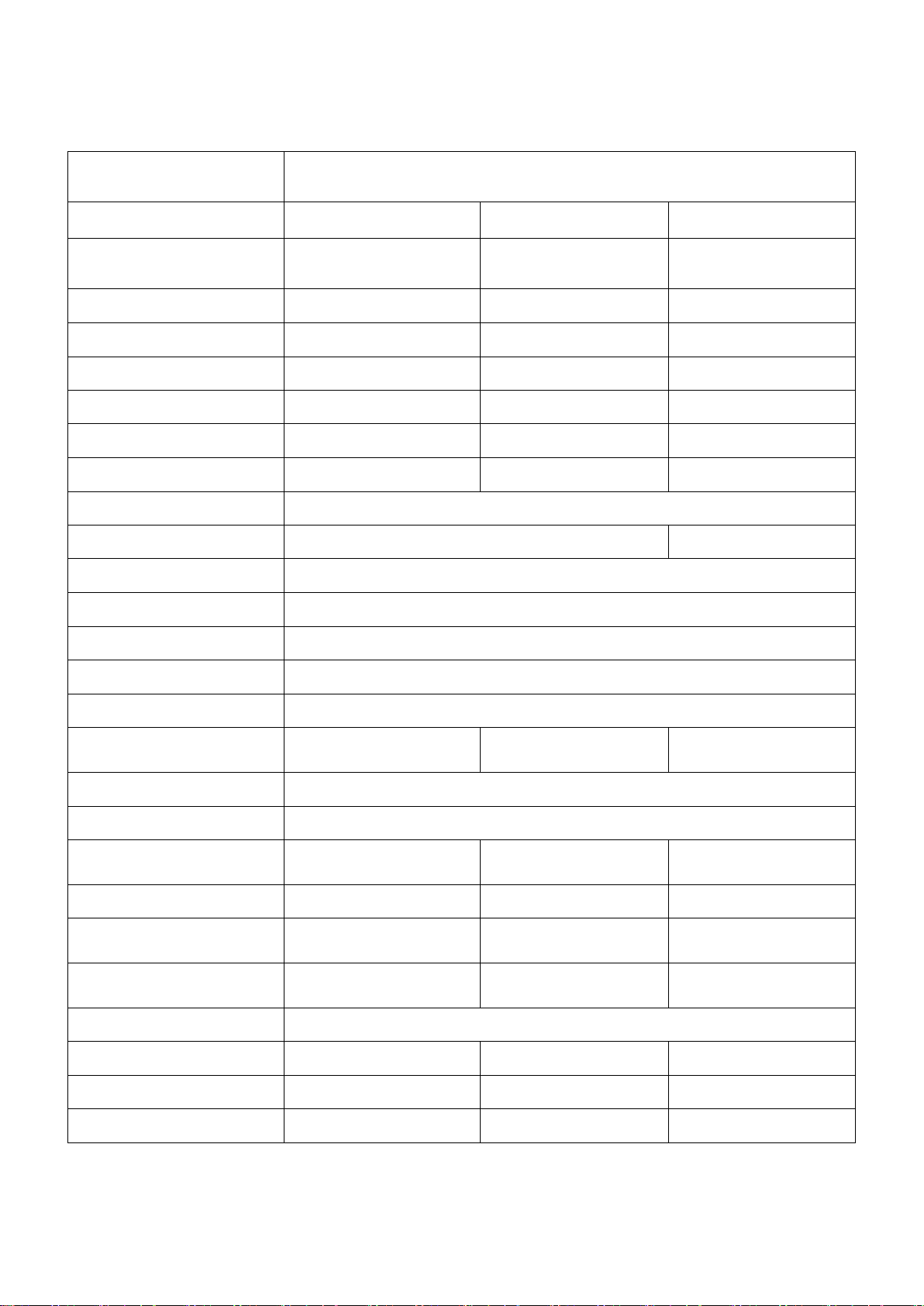

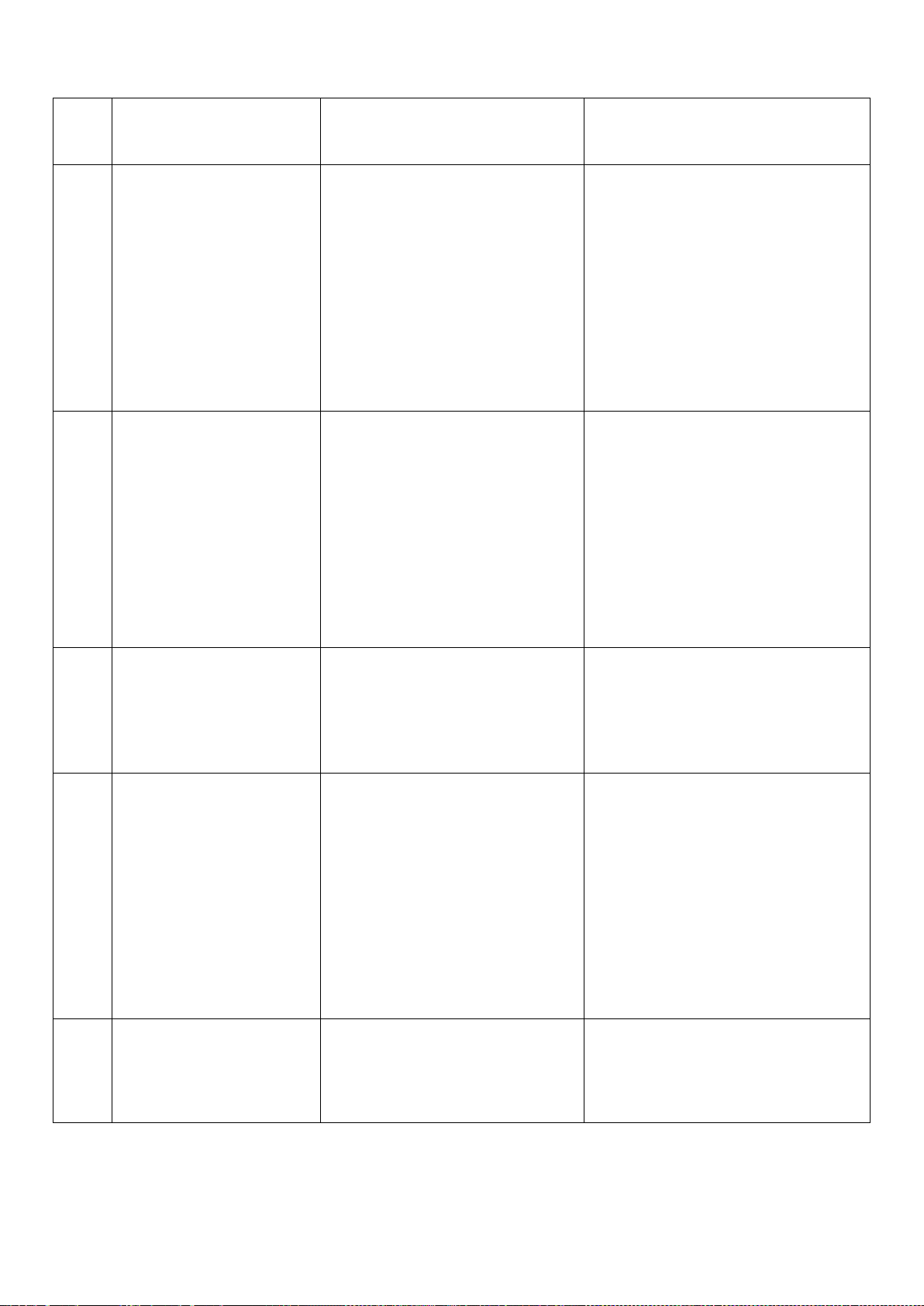

1.2 GENERAL - GLASS DOOR REFRIGERATOR

PRODUCT

MODEL R23-G R49-G R72-G

Capacity

Net Capacity

Exterior Dimension

(Including casters

Door Handles)

Interior Dimension

Product Weight

Door Type Swing 1EA Swing 2EA Swing 3EA

(W)

(D)

(H)

(W)

(D)

(H)

GLASS (FULL) DOOR REFRIGERATOR

650 ℓ

552 ℓ

695㎜

600㎜

126㎏

1,385 ℓ

1,195 ℓ

1,400㎜

835 ㎜ (32.9”)

2,127 ㎜ (83.7”)

1,305㎜

635 ㎜ (25”)

1,545 ㎜ (60.8”)

200㎏

2,035 ℓ

1,790 ℓ

1,980㎜

1,885㎜

271㎏

Door Material Stainless steel (STS)

Shelves 4EA 8EA 12EA

Power Voltage AC 115V/60Hz

Plug in - Installation NEMA 5-15P

Amps 5.0A 7.5A 8.0A

Compressor 3/8HP 3/5HP 3/5HP

R-134a R-404A

Refrigerant

Range of Temperature

Door auto-close equipm ent Auto-close for Spring

Door stop 120˚ Stop

Air suction equipment Air damper

Caster 4” × 4EA 4” × 6EA

Condensing unit Sliding Type

220 g

(7.8 oz)

320 g

(11.3 oz)

0℃ ~ 4℃ (+32°F ~ +40°F)

640 g

(22.6 oz)

◈ Above specifications are subjected to ch ange without prior notice for quality improvement.

◈ The nameplate(includes Serial Nu mb er ) is l ocated on the upper left of the cabi net interior.

- 4 – 05/15 Rev. G 146526

Page 5

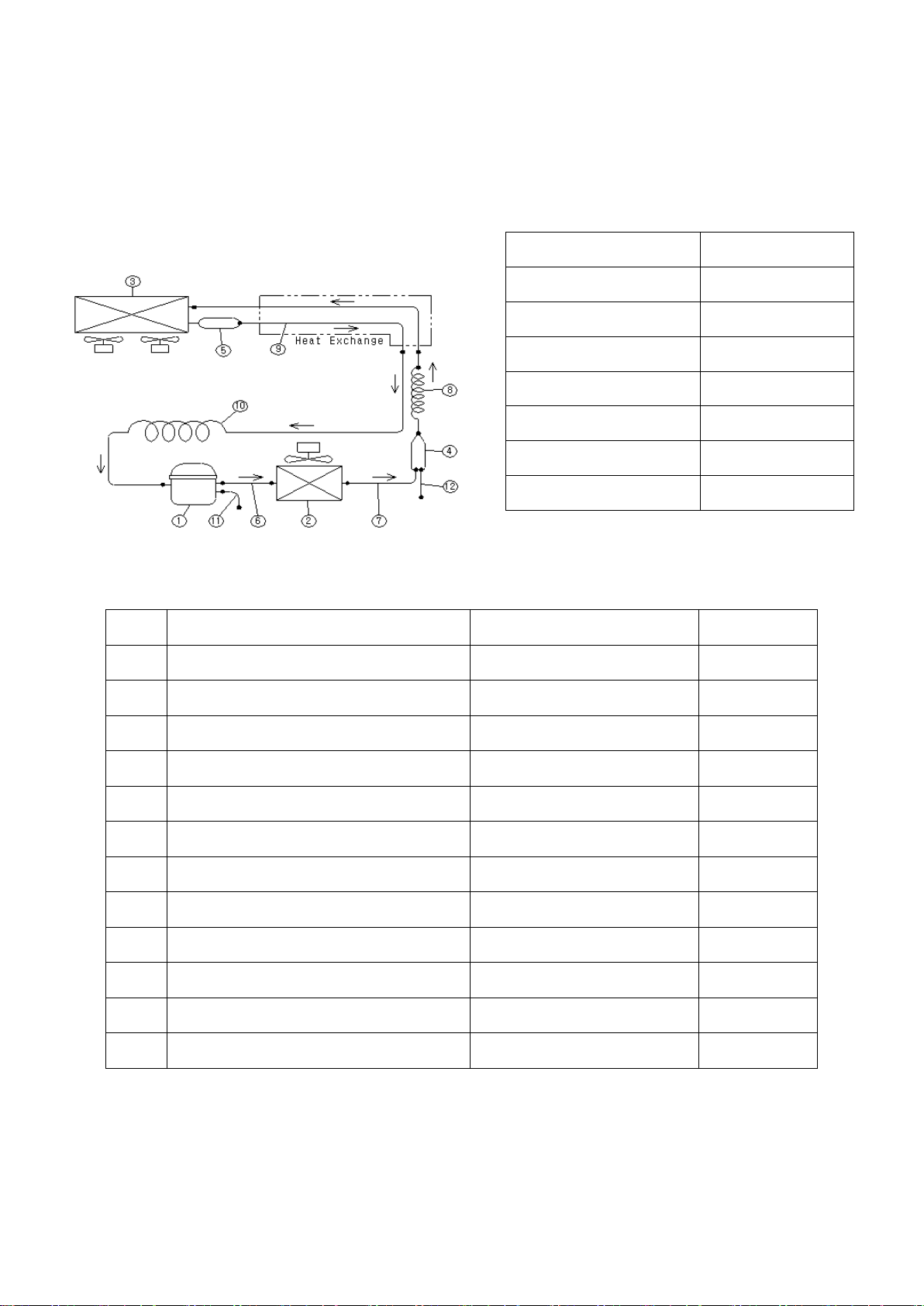

2.1 MAIN COMPONENTS - SOLID DOOR FREEZER & REFRIGERATOR

France)

France)

CAJ4461Y(A)

France)

Type of Compressor

motor

189~227㎌

/ 165V

315㎌ /

160V

Evaporator pipe

Diameter

12.7mm

(1/2”)

12.7mm

(1/2”)

Condenser pipe

Diameter

Interior Temp.

Indication

PRODUCT

MODEL

Compressor

(Manufacture)

Compressor

Capacity(kcal/h)

SOLID (FULL/HALF) DOOR

FREEZER

F23-S /

F23-SH

NEK2150GK

(Embraco)

F49-S /

F49-SH

CAJ2432Z(A)

(Tecumseh-

F72-S /

F72-SH

CAJ2446Z(H)

(Tecumseh-

LBP 628 LBP 808 LBP 1219 LBP 303 HBP 1586

SOLID (FULL/HALF) DOOR

REFRIGERATOR

R23-S /

R23-SH

R49-S /

R49-SH

SK1A1C-L2W

(Samsung-Korea)

R72-S /

R72-SH

(Tecumseh-

CSR CSIR

Compressor O.L.P T0873/G9 GA3PJU00 MST00AHN 4TM795TFBZZ-53 GA3SJU81

Compressor Relay

Starting Capacitor

Running Capacitor

RVA9AD3C-

121

25 ㎌ / 400V 30 ㎌ / 400V 15 ㎌ / 160V 12㎌ / 250V

3ARR3*5R* 3ARR3*3A* J531Q34E220M350-3 3ARR18A100B

88 ㎌ / 160V 125 ㎌ / 125V 250 ㎌ / 160V

-

Type of Evaporator Cu pipe + Al fin + Blue color coating

9.52mm (3/8")

9.52mm (3/8")

Cooling Fan Motor IS3225LTSA, 120V/60Hz

Type of Condenser Cu pipe + Al fin

9.52mm (3/8")

Condenser Fan Motor MA7425W1, 120V/60Hz

Dryer OD 25.4mm (1"), XH-9, 30g(1.06oz)

Temperature Control Thermistor

Running Indication Digital Display

Digital Display

Interior Lamp

(Incandescent lamp)

40W × 1EA 40W × 2EA 40W × 1EA 40W × 2EA

Defrost for evaporator Heated defrost (Control of thermistor) Off cycle

Defrost sheath heater 450W 670W 944W -

Defrost pan heater 60W 90W 128W -

Drain heater 9W -

Door switch SP201R-7DR, AC125V

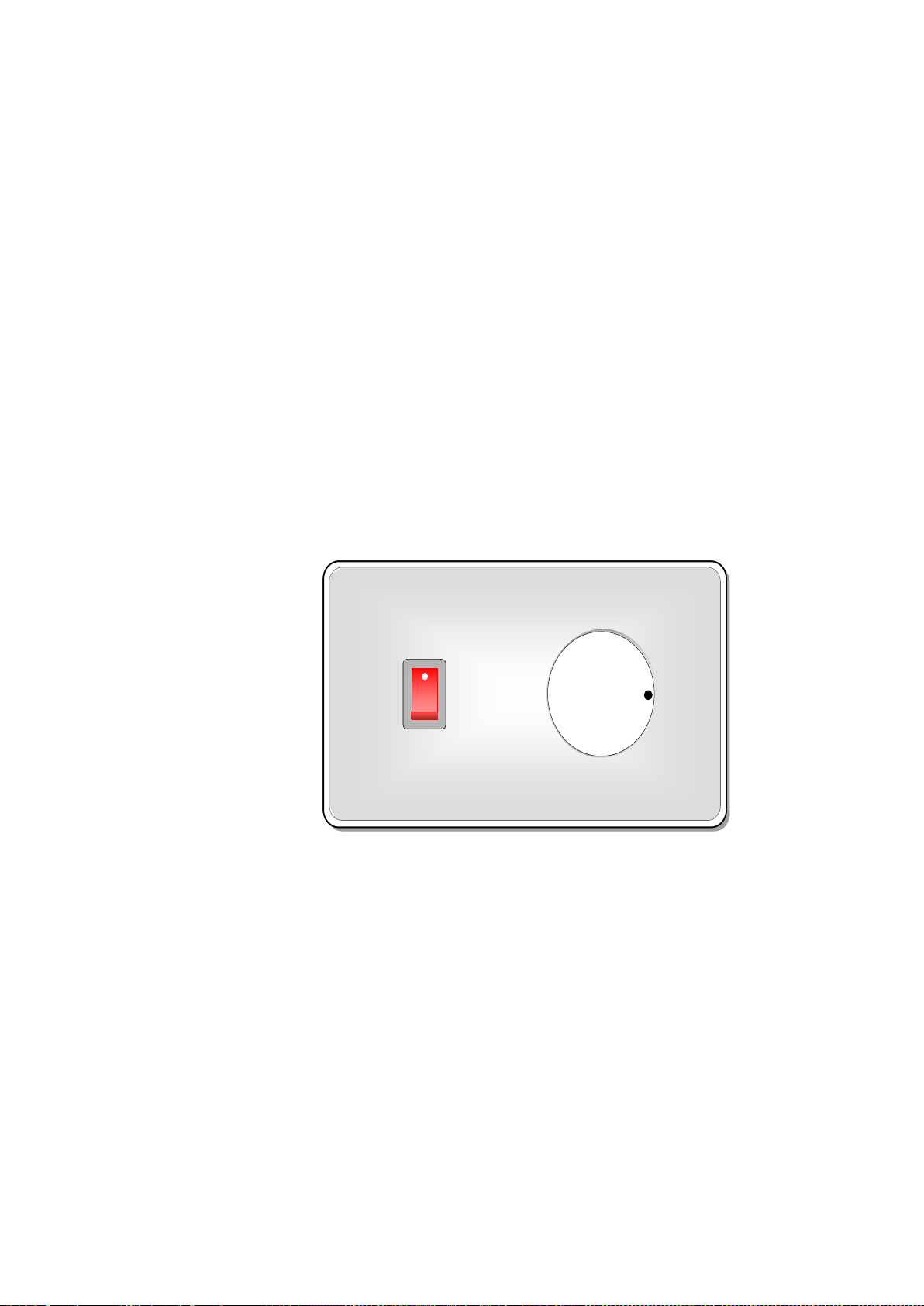

Power switch SL112A, AC125V/12A

- 5 – 05/15 Rev. G 146526

Page 6

Type of Compressor

motor

2.2 MAIN COMPONENTS - GLASS DOOR REFRIGERATOR

PRODUCT

MODEL R23-G R49-G R72-G

Compressor

(Manufacture)

Compressor Capacity(kcal/h)

Compressor O.L.P 4TM795TFBZZ-53 T0873/G9

Compressor Relay J531Q34E220M350-3 RVA9AD3C-121

Starting Capacitor

Running Capacitor

Type of Evaporator Cu pipe + Al fin + Blue color coating

Evaporator pipe Diameter 9.52mm (3/8") 12.7mm (1/2”)

Cooling Fan Motor IS3225LTSA, 120V/60Hz

(Samsung-Korea)

GLASS (FULL) DOOR REFRIGERATOR

SK1A1C-L2W

LBP 303 LBP 628

CSR

125 ㎌ / 125V 189~227 ㎌ / 165V

12 ㎌ / 250V 25 ㎌ / 400V

NEK2150GK

(Embraco)

Type of Condenser Cu pipe + Al fin

Condenser pipe Diameter 9.52mm (3/8")

Condenser Fan Motor MA7425W1, 120V/60Hz

Dryer OD 25.4mm (1"), XH-9, 30g(1.06oz)

Temperature Control Thermistor

Running Indication Digital Display

Interior Temp. Indication Digital Display

Interior Lamp (LED) 6W x 1EA 6W x 2EA 6W x 3EA

Defrost for evaporator Off cycle

Defrost sheath heater -

Defrost pan heater -

Drain heater -

Door switch SP201R-7DR, AC125V

Power switch SL112A, AC125V/12A

Light switch RL1-3, 16A/250V, ON-OFF

- 6 – 05/15 Rev. G 146526

Page 7

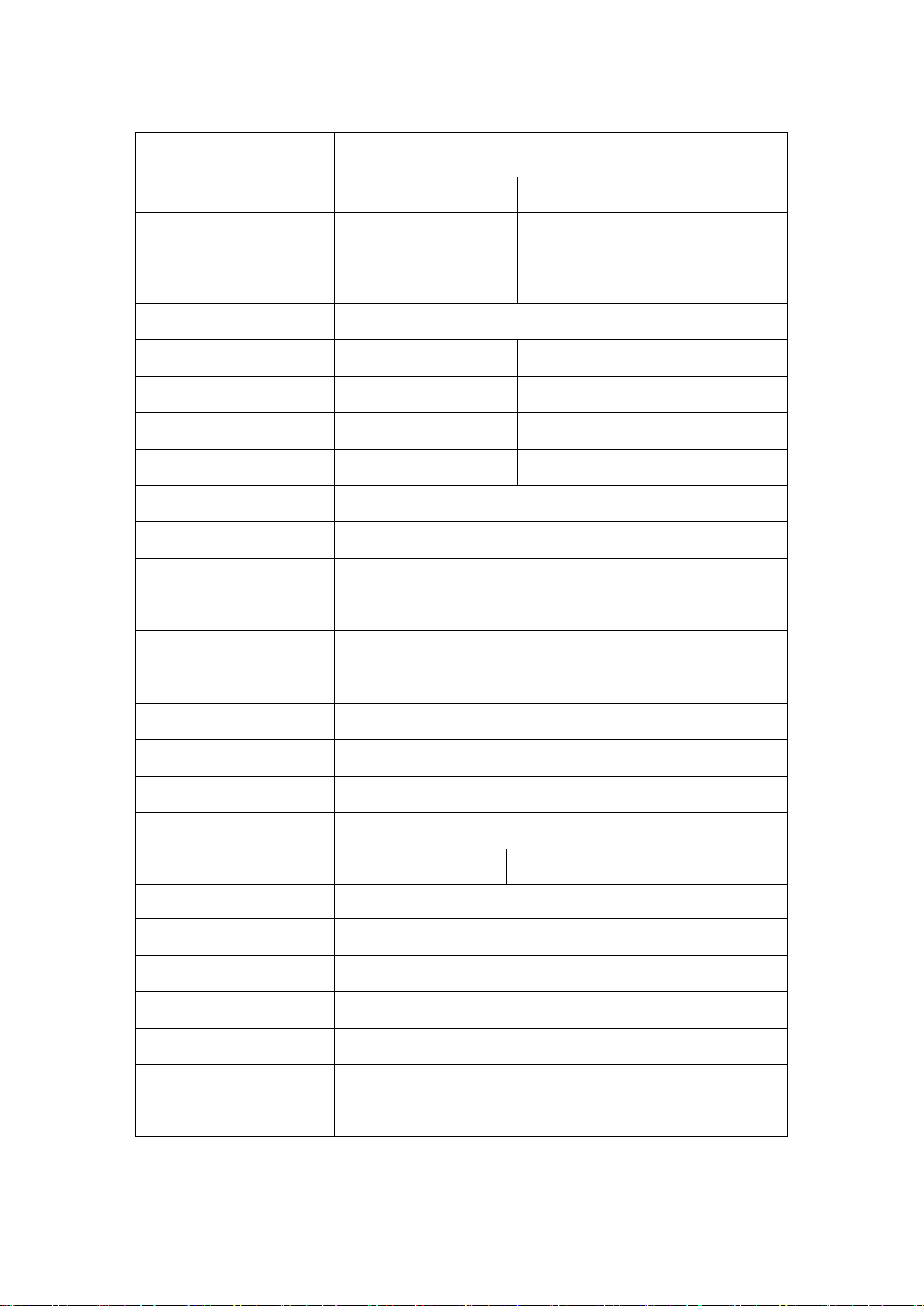

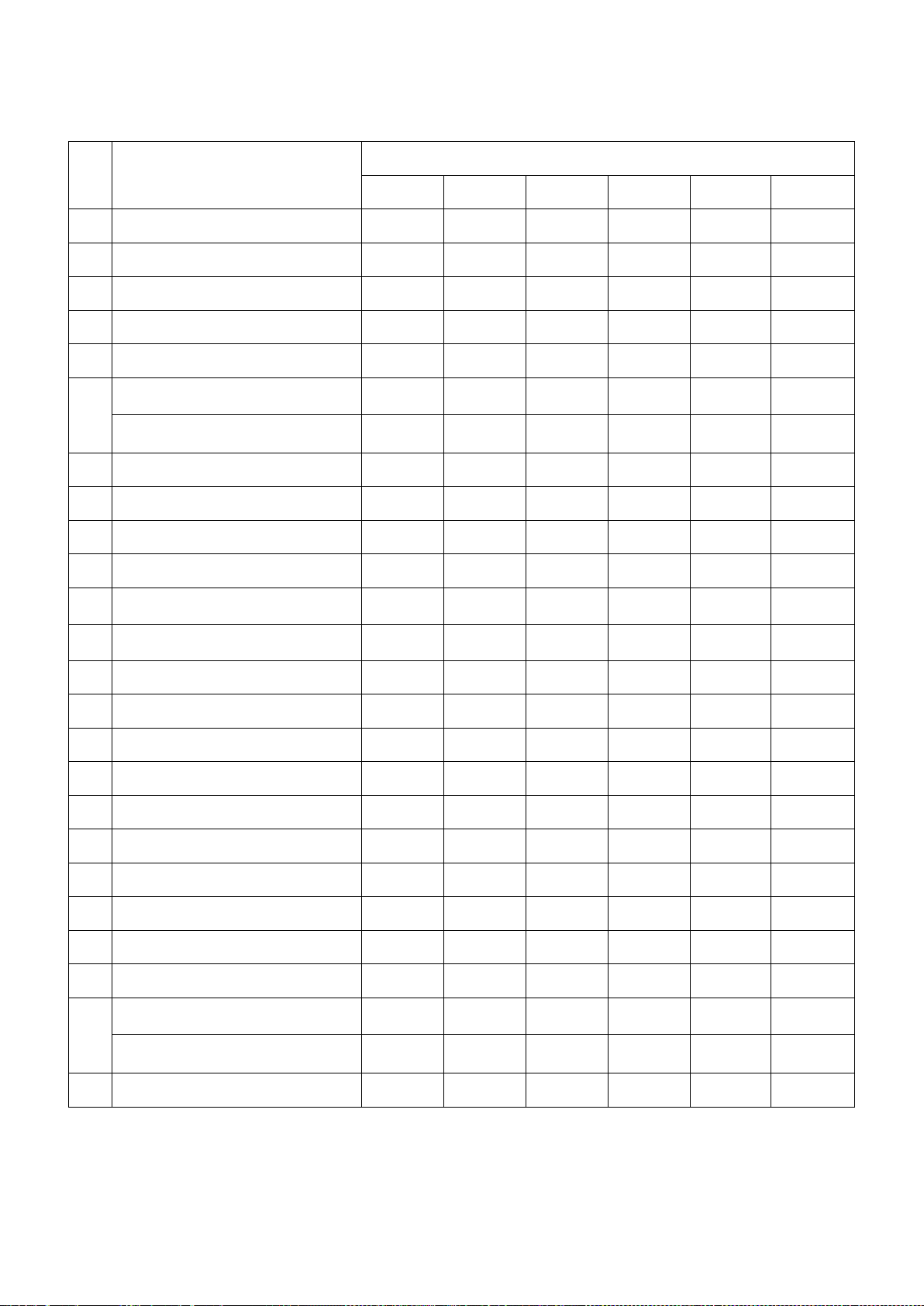

3.1 GENERAL - MERCHANDISERS

PRODUCT

MODEL GR26H GR48S GR70H

Capacity

Net Capacity

Exterior Dimension

(Including casters

Door Handles)

Interior Dimension

Net Weight

Door Type Swing 1EA Sliding 2E A Swing 3EA

Door Material Glass + PVC Glass + PVC Glass + Al

Shelves 4EA 8EA 12EA

(W)

(D)

(H)

(W)

(D)

(H)

MERCHANDISERS

736 ℓ (26 ft

677 ℓ (23.9 ft

3

) 1359 ℓ (48 ft3) 1982 ℓ (70 ft3)

3

) 1339 ℓ (47.3 ft3) 1877 ℓ (66.3 ft3)

720㎜ (28.4”) 1,350 ㎜ (53.2”) 1,980㎜ (78”)

844㎜ (33.3”) 780 ㎜ (30.7”) 835 ㎜ (32.9”)

2,017㎜ (79.4”) 2,012 ㎜ (79.2”) 2,126 ㎜ (83.7”)

640㎜ (25”) 1,280 ㎜ (50.4”) 1,885 ㎜ (74.2”)

719㎜ (28.3”) 642 ㎜ (25.3”) 635㎜ (25”)

1,584㎜ (62.4”) 1,562 ㎜ (61.5”) 1,545 ㎜ (60.8”)

130㎏ (287 lb) 215㎏ (474 lb) 325㎏ (716 lb)

Power Voltage AC 115V/60Hz

Plug in - Installation NEMA 5-15P

Amps 3.9A 10.0A 11.9A

Compressor 1/4 HP 1/2 HP 1/2 HP

R-134a R-134a R-134a

Refrigerant

300g (10.6 oz) 460g (16.2 oz) 500g (17.6 oz)

Range of Temperature

0℃ ~ 4℃ (32℉ ~ 40℉)

Door auto-close equipm ent Auto-close for Spring Auto-close for slope Auto-close for Spring

Door stop equipment 120˚ Stop - 120˚ Stop

Air suction equipment - - Air damper

Caster Adjust foot 4EA Adjust foot 6EA Adjust foot 6EA

Condensing unit Sliding Type

Door switch - - -

Power(or Lamp) switch SL112A, AC125V/12A

◈ Above specifications are subjected to ch ange without prior notice for quality improvement.

◈ The nameplate(includes Serial Nu mb er ) is l ocated on the upper left of the cabi net interior.

- 7 – 05/15 Rev. G 146526

Page 8

4.1 MAIN COMPONENTS - MERCHANDISERS

PRODUCT

MODEL GR26H GR48S GR70H

Compressor

(Manufacture)

Compressor Capacity(kcal/h) LBP 256 HBP 1946 HBP 1946

Type of Compressor motor RSCR CSIR CSIR

Compressor O.L.P 4TM444NHBYY CRA38014 CRA38014

Compressor Relay J531Q32E4R7M1802 3ARR3*2M* 3ARR3*2M*

Starting Capacitor -

Running Capacitor

Type of Evaporator Cu pipe + Al fin

Evaporator pipe Diameter 9.52 mm (3/8") 12.7mm (1/2”)

Cooling Fan Motor IS3225LTSA, 120V/60Hz

Type of Condenser Cu pipe + Al fin

SK182C-L2U

(SAMSUNG)

12 ㎌/250V

MERCHANDISERS

CAJ4476Y(A)

(Tecumseh-France)

250 ㎌/160V 250 ㎌/160V

- -

CAJ4476Y(A)

(Tecumseh-France)

Condenser pipe Diameter 9.52 mm (3/8")

Condenser Fan Motor MA7425W1, 120V/60Hz

Dryer OD 25.4mm (1"), XH-9, 30g(1.06oz)

Temperature Control

Running Indication -

Interior Temp. Indication -

Interior Lamp

(Fluorescent lamp)

Ad. Panel Fluorescent Lamp 20W × 1EA 32W × 1EA 32W × 2EA

Ballast 32W(Double)×1EA 32W(Double)×1EA 32W(Double)×2EA

Ballast Name

(Manufacture)

Defrost for evaporator Off cycle

Defrost sheath heater - - -

Defrost pan heater - - -

Thermostat

(GNF-250L)

32W × 1EA 32W × 1EA 32W × 2EA

B232I120RH-A

(ADVANCE)

Thermostat

(GNF-240L)

B232I120RH-A

(ADVANCE)

Thermostat

(GNF-246L)

B232I120RH-A

(ADVANCE)

Drain heater - - -

- 8 – 05/15 Rev. G 146526

Page 9

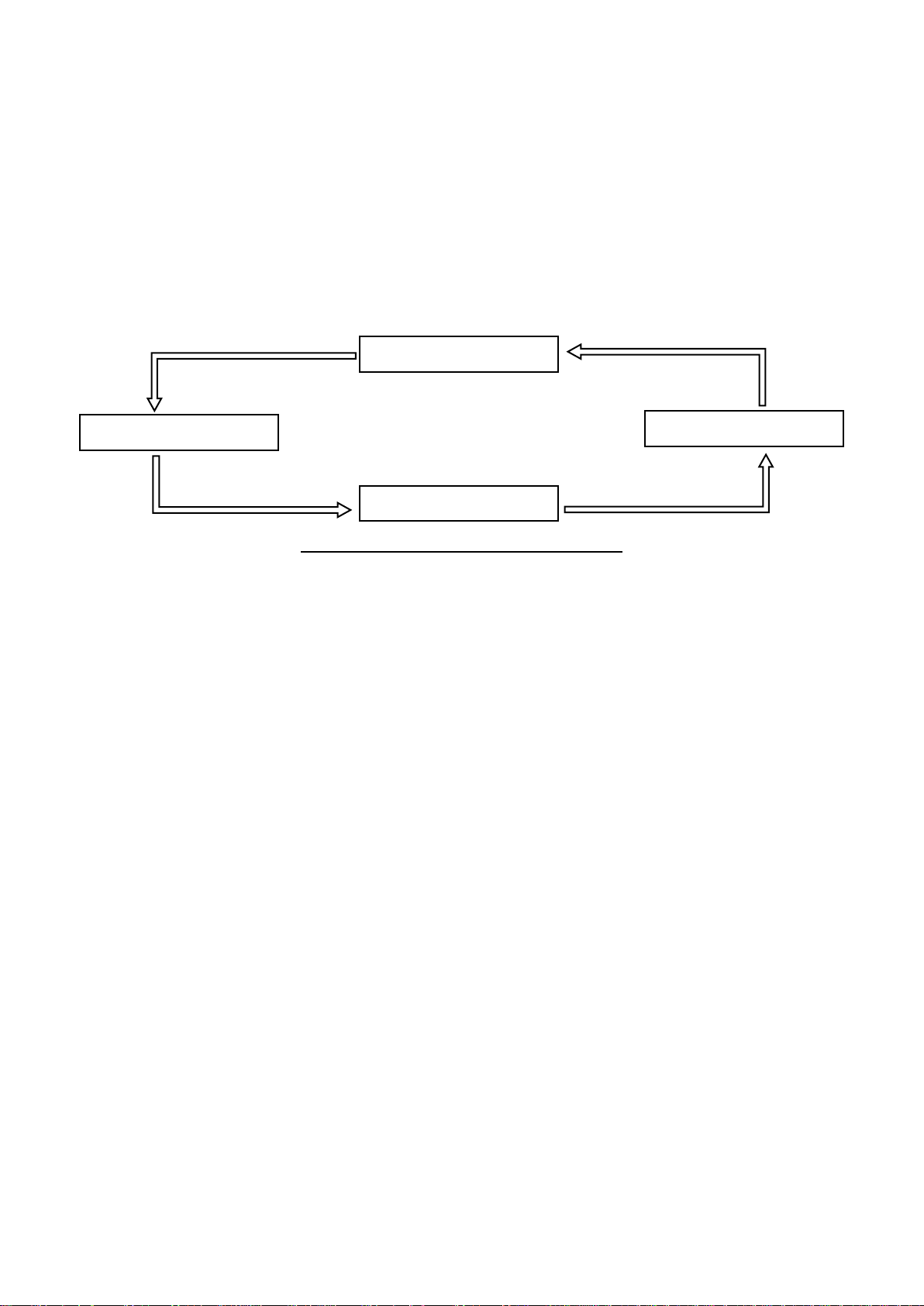

2. REFRIGERATION CYCLE

CONDENSER

EVAPORATOR

CAPILLARY TUBE

COMPRESSOR

Mechanical refrigeration is accomplished by continuously circulating, evaporating, and condensing a fixed

supply of refrigerant in a closed system. Evaporation occurs at allow temperature and pressure while

condensation occurs at high temperature and pressure. Thus it is possible to transfer heat fom an area of

low temperature (i.e., refrigerated compartment) to an area of high temperature (i.e., surrounding of

refrigerator).

THE BASE REFRIGERATION CYCLE

Beginning the cycle at the evaporator inlet the low pressure liquid expands, absorbs heat (so refrigerator

inner-cabinet is cooled), and evaporates, changing to allow low pressure gas at the evaporator outlet.

The compressor pumps this gas from the evaporator, increases its pressure, and discharges the high

pressured- temperature gas to the condenser.

The condenser lets high pressured- temperature gas emit the heat (so surrounding of the condenser is

warmed) in order to make it condense.

The capillary tube prevents high pressured- temperature liquid from entering the evaporator in order to

lower the pressure in the evaporator and control the flow of refrigerant into the evaporator automatically.

Eventually the desired air temperature in refrigerator inner-cabinet is reached, the thermostat (temperature

controller) will break the electrical circuit to the compressor motor and stop the compressor.

- 9 – 05/15 Rev. G 146526

Page 10

As the temperature of the air rises, the thermostat (or controller) remakes the electrical circuit. The

compressor starts, and cycle continues.

The schematic refrigeration (or freezing) cycle of F23/F49/F72/R23/R49/R72/GR26/GR48/GR70 is like

below.

MODEL COMPRESSOR

F23-S/SH, R49/R72-G NEK2150GK

F49-S/SH CAJ2432Z(A)

F72-S/SH CAJ2446Z(H)

R23/R49-S/SH,R23-G SK1A1C-L2W

R72-S/SH CAJ4461Y(A)

GR26H SK182C-L2U

GR48S, GR70H CAJ4476Y(A)

No. Part Name Description Remark

1 COMPRESSOR

2 CONDENSER C1220TS-O,H

3 EVAPORATOR C1220TS-O,H

4 DRYER C1220T-H

5 ACCUMULATOR C1220T-1/4H

6 DISCHARGE PI PE C1220T-O

7 DRYER CONNECT PIPE C1220T-O

8 CAPILLARY TUBE C1220T-H

9 SUCTION PIPE (INNER-CABINET) C1220T-O

10 SUCTION PIPE (COMPRESSOR) C1220T-O

11 CHARGE PIPE (COMPRESSOR) C1220T-O

12 CHARGE PIPE (DRYER) C1220T-O

- 10 – 05/15 Rev. G 146526

Page 11

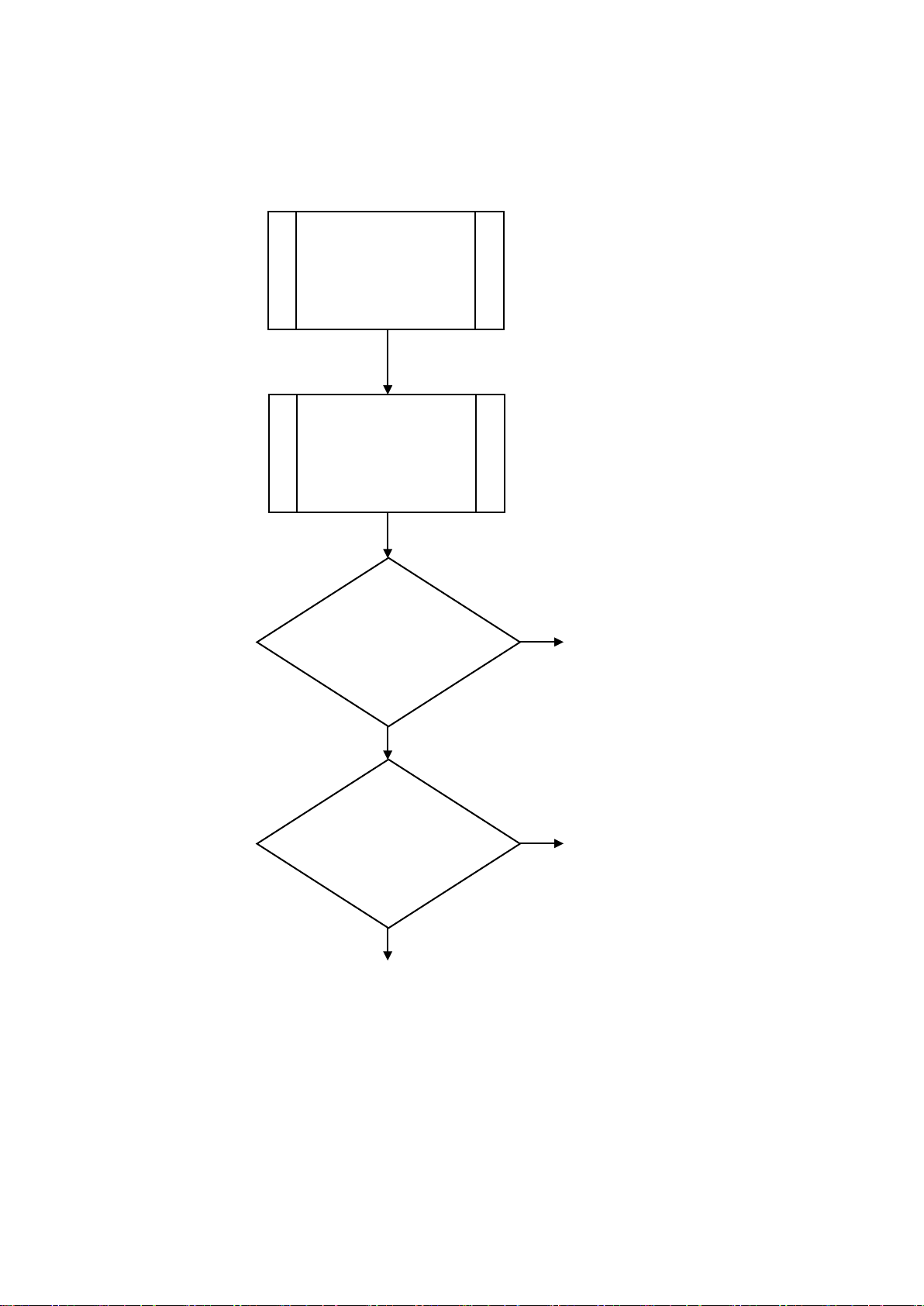

3. TROUBLESHOOTING

Is the rated voltage

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

Is the power cord

Is the power cord

Is the power switch

Is the power cord

Is the rated voltage

Is the power cord

Plug in

Plug in

Correct

Correct

Defective

Defective

power cord

NORMAL

NORMAL

Move to “ON” position

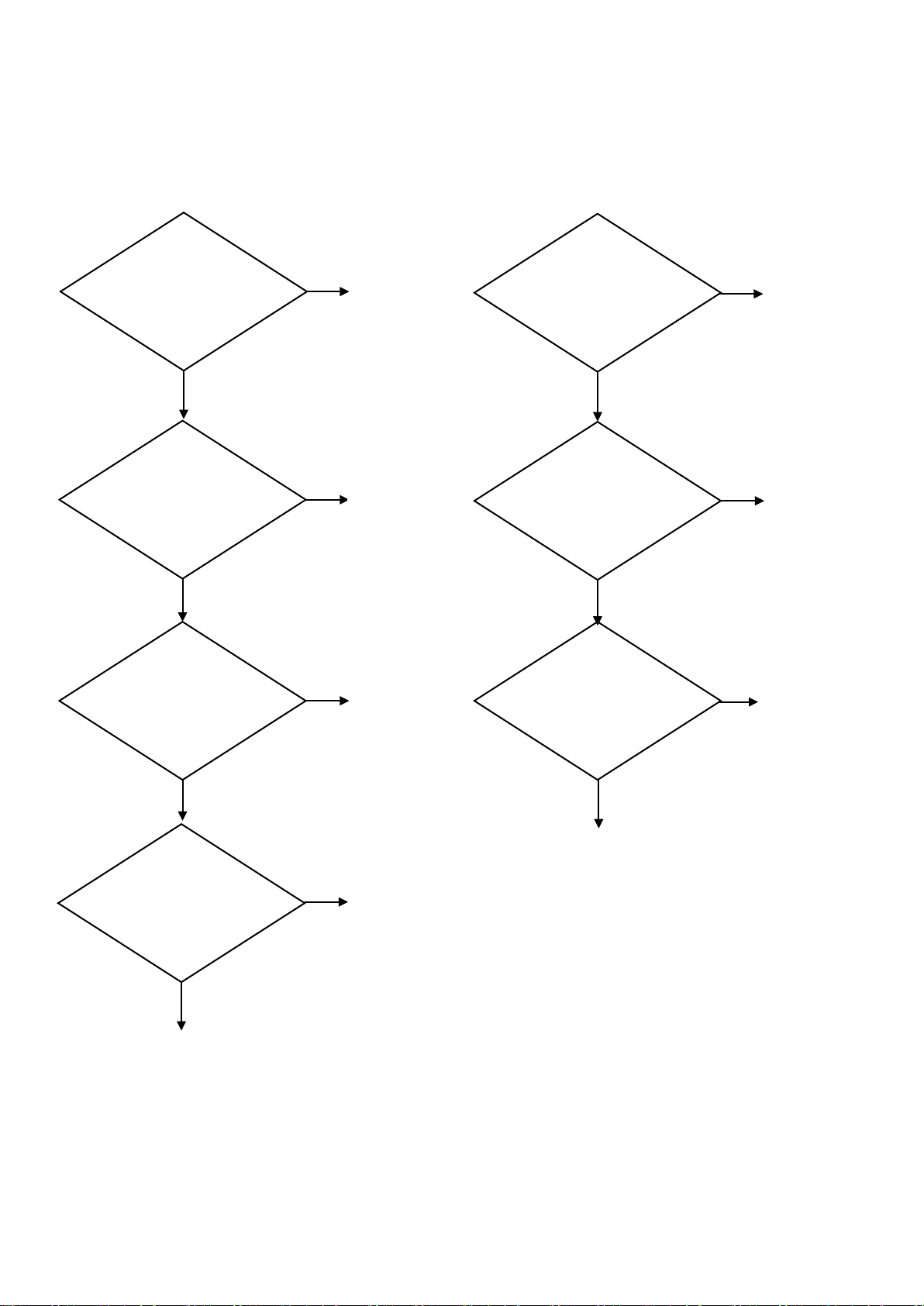

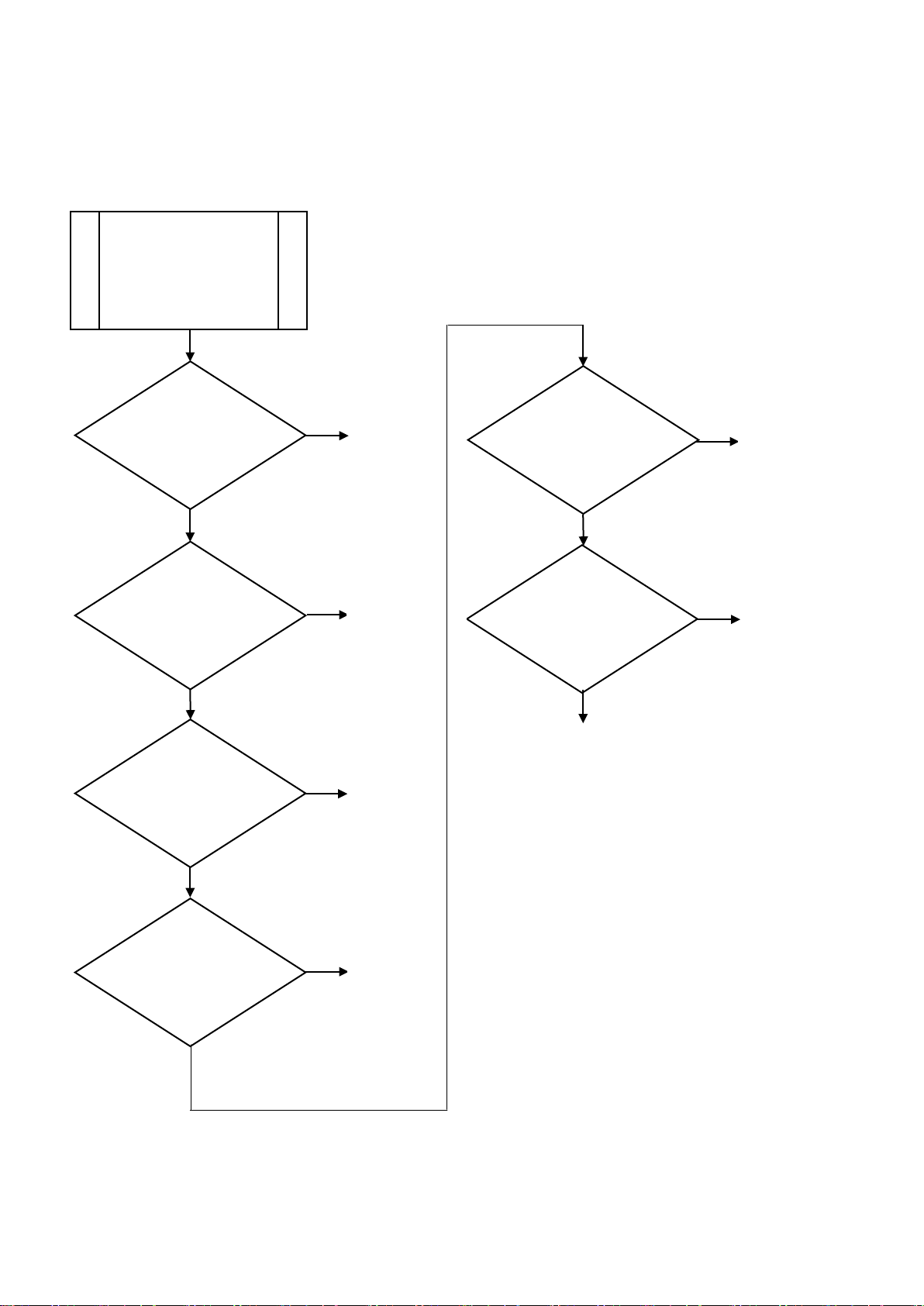

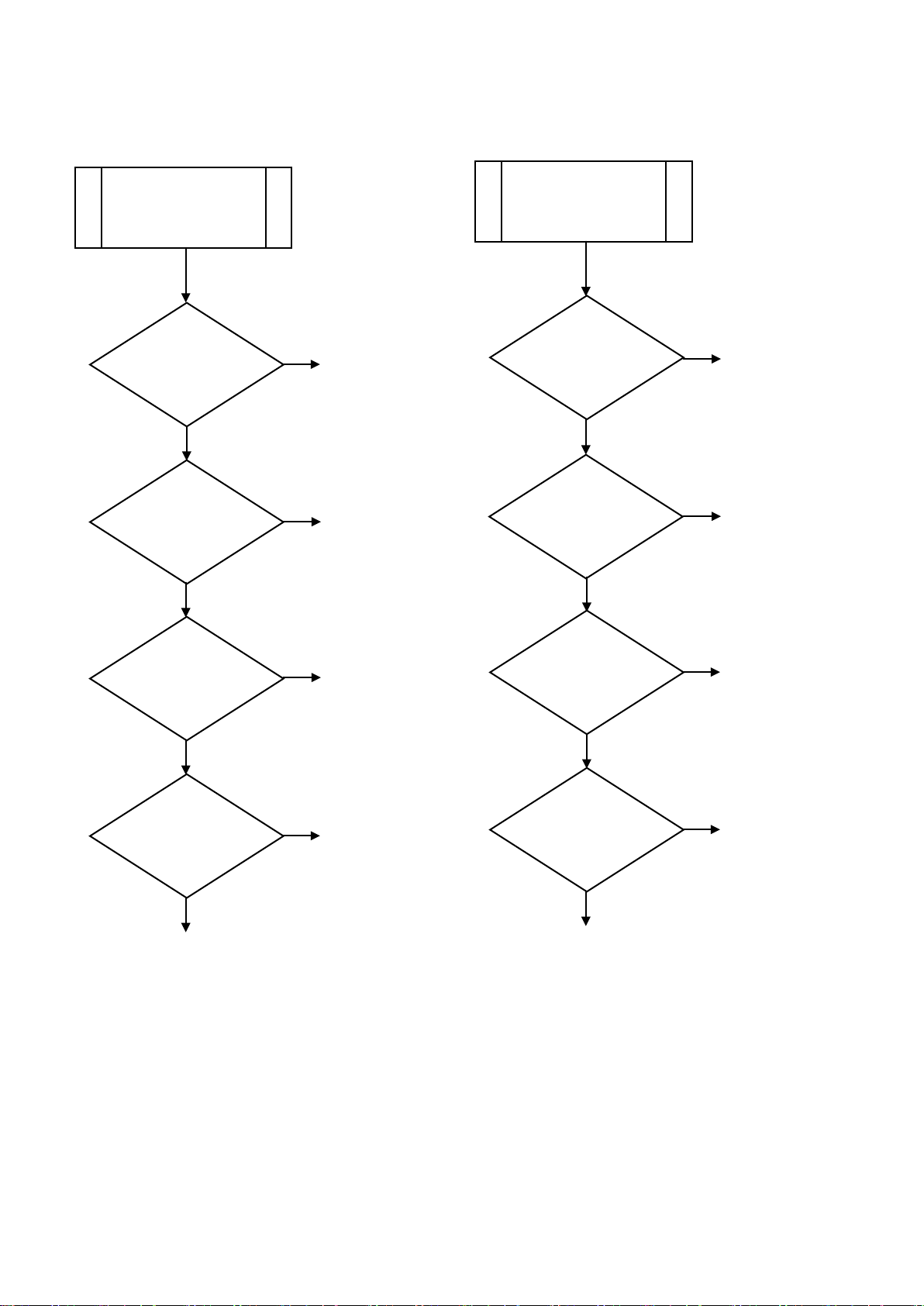

1) CHECKING THE P O WE R SUPP LY

① F23 / F49 / F72 / R23 / R49 / R72 ② GR26H / GR48S / GR70H

Plugged in?

supplied?

normal?

Plugged in?

supplied?

normal?

power cord

“OFF” position?

- 11 – 05/15 Rev. G 146526

Page 12

2) CHEKING THE POWER SUPPLY OF CONTROL BOARD

NO

YES

Is the rated

Check wirin g

NO

YES

NO

YES

Is the coil winding

open?

Defective

NO

YES

Is the secon dary

normal

NO

YES

Is the DC 24V

Check C/B

NO

YES

Does the contact

continue?

Defective

Defective fuse

Defective

NORMAL

① F23 / F49 / F72 / R23 / R49 / R72

voltage supplied

to the C/B?

Does the fuse f ail?

of transformer

output volt, of trans,

transformer

transformer

NOTES

* C/B: Control Board

(Printed Circuit Board)

* Fuse Spec: AC250V, 8A

* Trans forme r Spec.

Primary: AC1 15V

Secondary: AC12V (Red wire)

AC20V (Blue wire)

supplied to c oil part

in relay?

part in relay

Relay

- 12 – 05/15 Rev. G 146526

Page 13

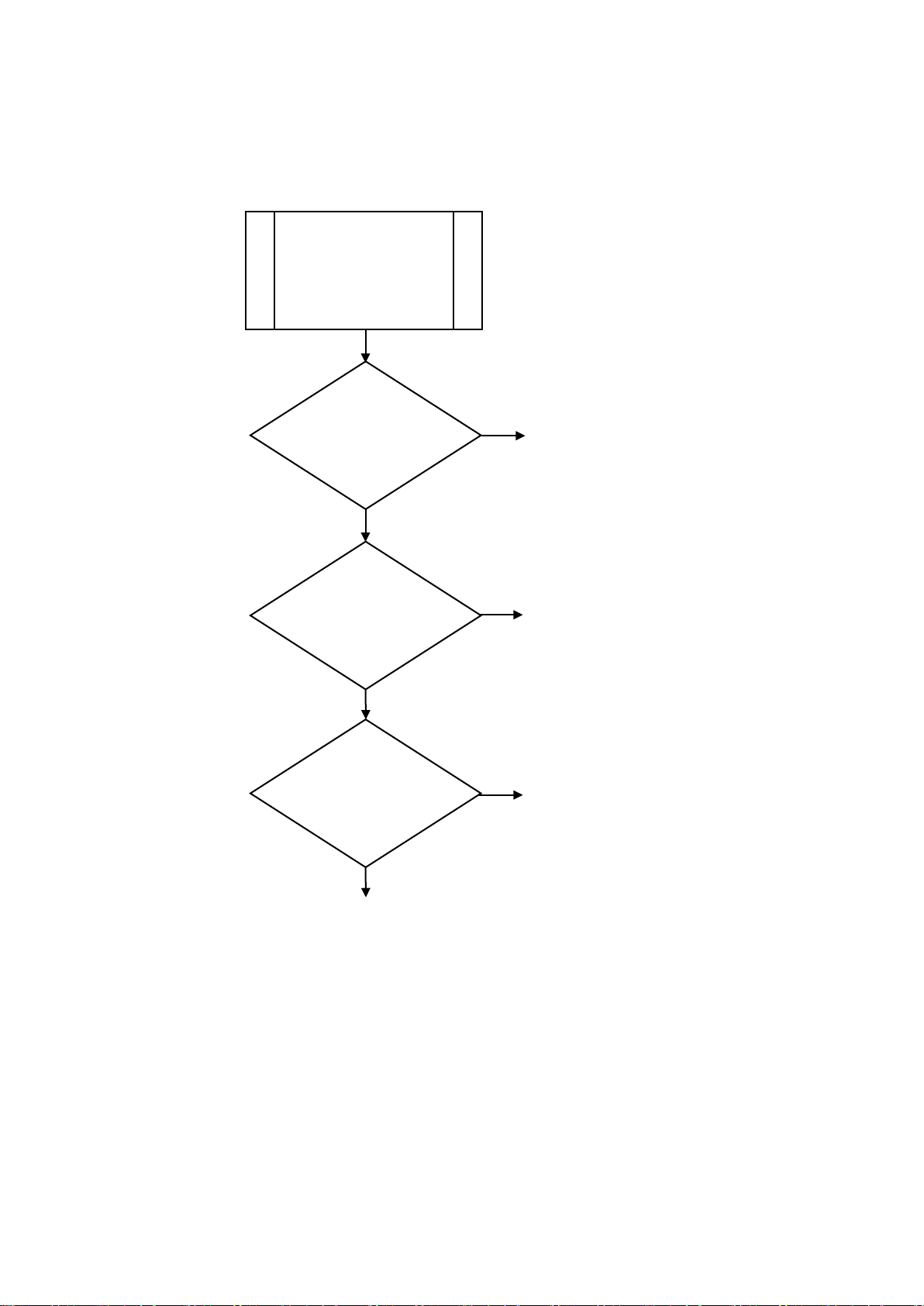

3) CHECKING THE CONTROL PART OF REFRIGERATION CYCLE

NO

YES

NO

YES

NO

YES

Check the

in compress or

Defective

OLP

NO

YES

Check the

in compress or

Defective

relay

NO

YES

Are the sens ors in

properly?

NO

YES

Defective

T-sensor

NO

YES

Is the tem p.

properly?

Defective

MICOM

NO

YES

Check the

point

Temperature

Check the

control board

① F23 / F49 / F72 / R23 / R49 / R72

Check the

power supply

Is the to comp.

connected pro per ly?

Are the relay

& OLP in comp.

assembled properly?

continuity of OLP

Correct

Correct

C/B connected

Check the re sistance

of T-Sensor

displayed i n D/B

Correct

continuity of relay

power supply of

temperature set

resetting

Defective compressor

NOTES

* C/B: Control Board

* D/B: Display Board

* OLP: Over load Protector

- 13 – 05/15 Rev. G 146526

Page 14

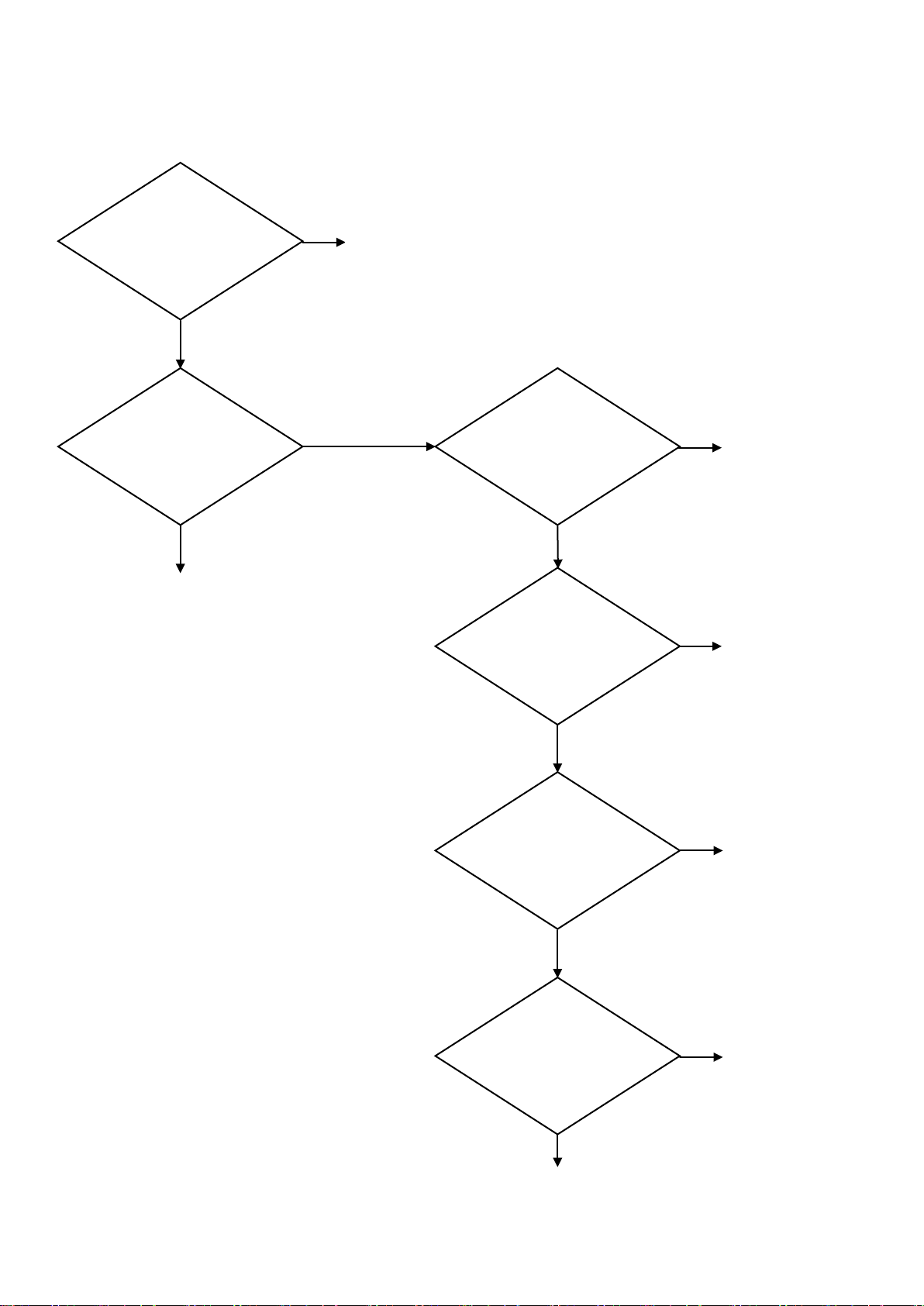

② GR26H / GR48S / GR70H

NO

YES

When the

run?

Defective

thermostat

NO

YES

Is the to comp.

NO

YES

Are the relay

NO

YES

Check the

in compress or

Defective compressor

NO

YES

Check the

in compress or

Defective

relay

Defective OLP

Check the

power supply

thermostat is OF F.

Does the comp.

connected pro per ly?

& OLP in comp.

assembled properly?

continuity of OLP

Correct

Correct

continuity of relay

- 14 – 05/15 Rev. G 146526

Page 15

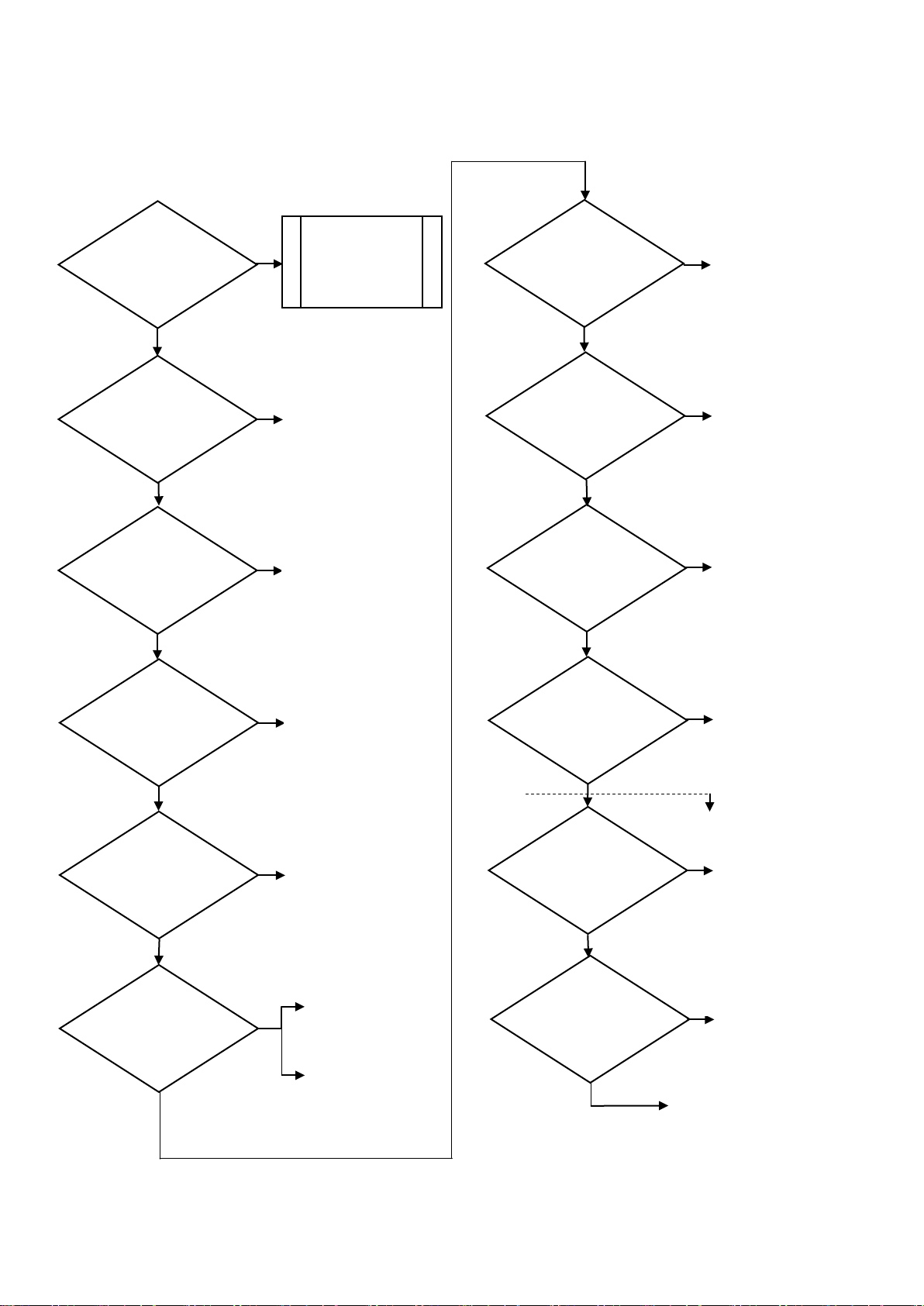

4) CHECKING THE DEFROST PART

NO

NO

YES

NO

YES

Defective

D-Sensor

NO

YES

Defective

NO

Does the B/M

NO

YES

Defective

Control Board

Check

Defective

YES

YES

① F23 / F49 / F72

Check the

power supply

Do the B/M and D-

Sensor located in

place?

Do the wiring to the

heater and B/M

connected properly?

Check the

resistance of

D-sensor

Correct

wiring

continue below

41℉(5℃)

Dose the defrost

output on C/B normal

in defrost mode?

Defective MICOM

Bi-Metal

Are the defrost

heaters normal?

NOTES

* C/B: Control Board

heater

* B/M: Bi-Metal

(Temp. Limiting Controller)

- 15 – 05/15 Rev. G 146526

Page 16

② R23 / R49 / R72

NO

YES

NO

NO

YES

Defective

D-Sensor

Defective

Control Board

Defective micom

YES

Check the

power supply

Do the D-Sensor

located in place ?

Check the

resistance of

D-sensor

Dose the defrost

output on C/B normal

in defrost mode?

Correct

NOTES

* C/B: Control Board

- 16 – 05/15 Rev. G 146526

Page 17

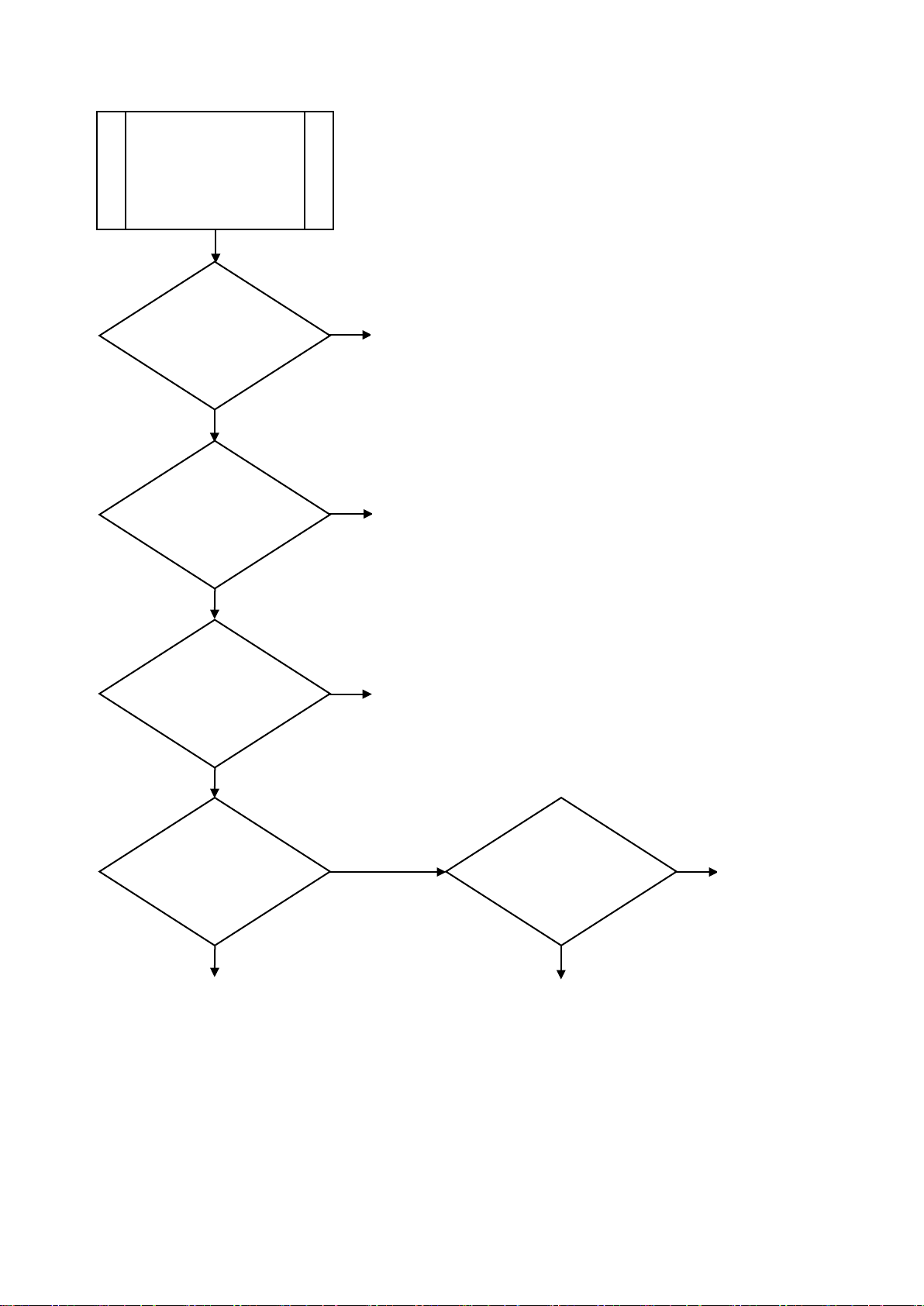

5) WHEN THE UNIT DOES NOT COOL

Apply spacer

YES

Does the

NO

YES

Is the unit

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

Does the cond.

YES

NO

NO

YES

Is the

NO

YES

YES

NO

YES

NO

Freezer: Check

Refrigerator:

Excluding GR26H, GR48S

Defective

door switch

Check compressor

① All Models

compressor run

normally?

located in a

level place?

Is the temperature

set point proper?

Check

the control part of

refrigeration cycle

Correct

Temperature

resetting

Is there

dust on condenser

fin?

(eva.) fan motor rotate

normally?

Does the

refrigerant leak?

Clean

Defective

motor, fan

Correct

Are the goods

loaded properly?

Does the cool air

leak?

Does the frost

form excessively

in evaporator?

Correct

Check

door gasket

the defrost part

forced defrost

refrigerant line

restricted?

Is the contact of

door switch normal?

When door closed.

Are the door S/We pushed

by the top of door?

Correct

between door switch

and the top of door

- 17 – 05/15 Rev. G 146526

Page 18

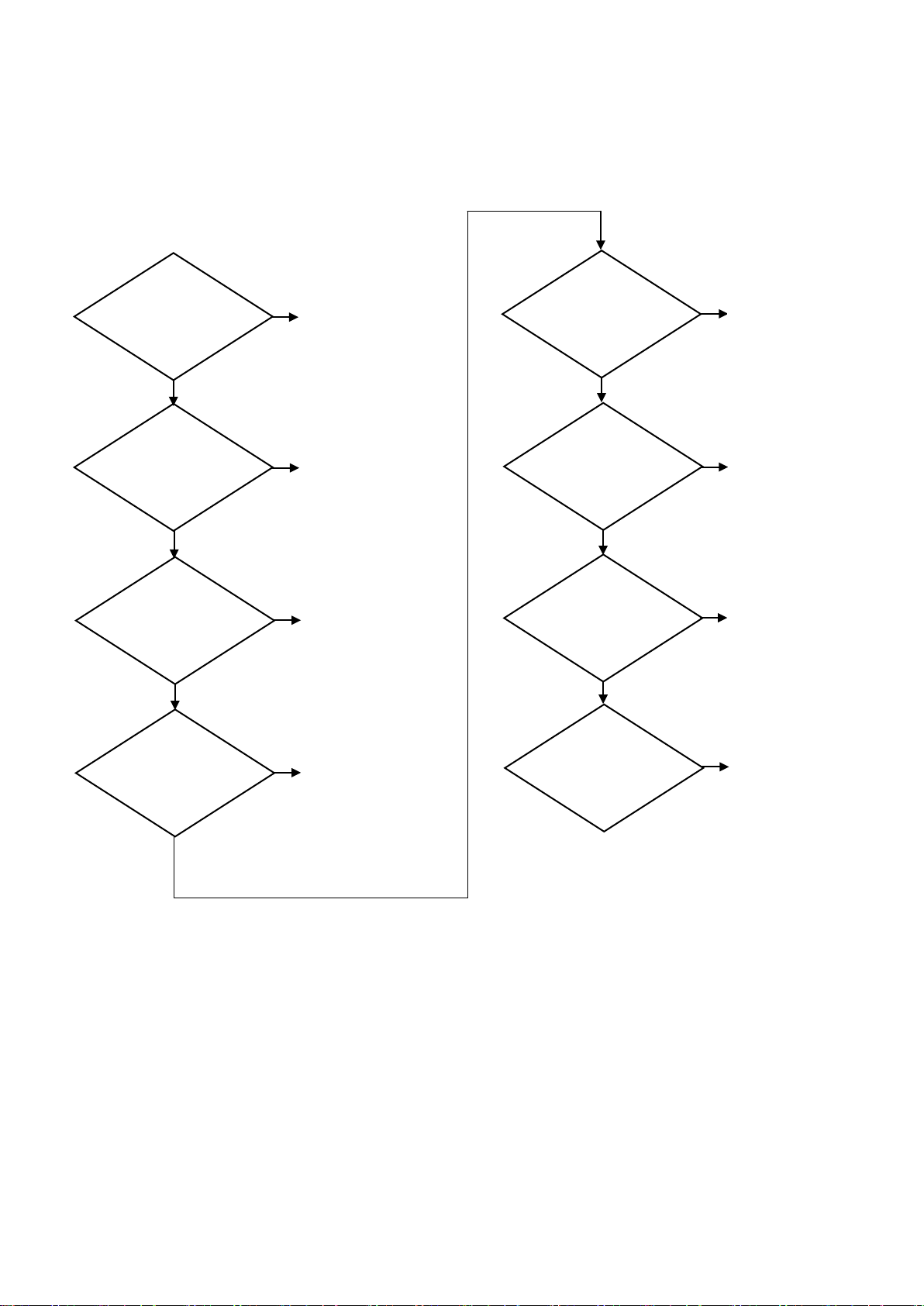

6) WHEN THERE IS A ABNORMAL NOISE

Is the unit

NO

YES

NO

YES

NO

YES

Reform to

NO

YES

YES

NO

NO

YES

NO

YES

Comp. is running

not cool

YES

Defective

Defective

Defective

① All Models

located in a

level place?

Is the high

voltage supplied?

Are the pipes

rattled?

Are the parts

assembled tightly?

Correct

Adjust

voltage

be free of

contact

Tighten

Are the fans bent?

Do the fans

rotate well?

Is there any

noise in motor?

but the unit does

fan

fan, motor

motor

- 18 – 05/15 Rev. G 146526

Page 19

NO

YES

Is the connect ion

Check the

in control b oard

NO

YES

7) WHEN THE TEMPERATURE DOES NOT DISPLAY

① F23 / F49 / F72 / R23 / R49 / R72

Check the

power supply

power supply

between C/B and D/B

properly?

Is the micom

inserted on C /B

properly?

Replace display board

NOTES

* C/B: Control Board

Tighten

Tighten

* D/B: Display Board

- 19 – 05/15 Rev. G 146526

Page 20

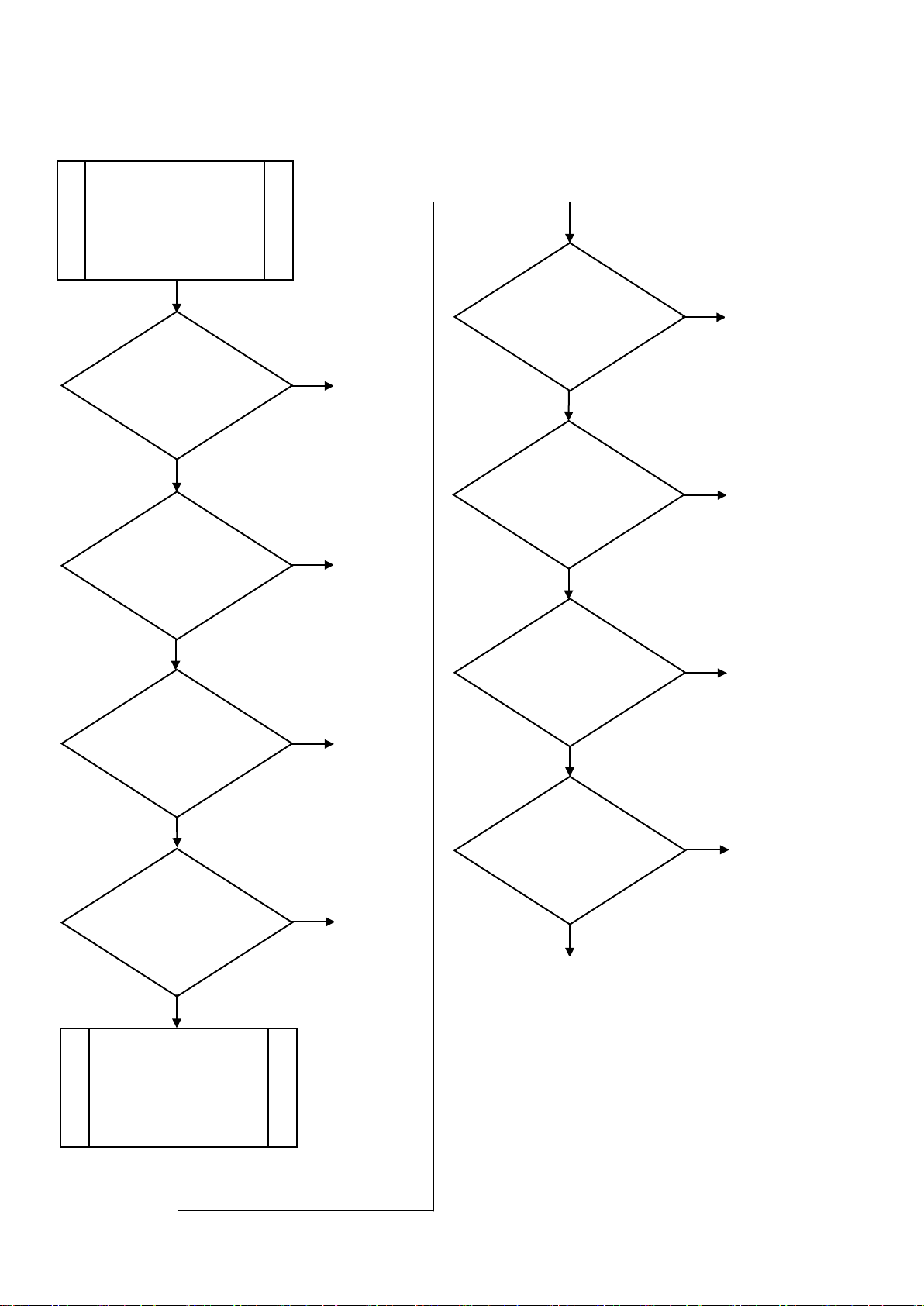

8) WHEN THE LAMP DOES NOT LIGHT

Adjust the lamp

YES

Check the

Check the

with socket

Defective

NO

YES

Is the lamp

Defective

NO

YES

Check the

lamp switch

NO

YES

Check wiring

* Incandescence Lamp: 40W

Adjust the lamp

NO

YES

Check the

Check the

with socket

Defective

NO

YES

Is the lamp

Defective

lamp switch

NO

YES

Check the

lamp switch

Defective

ballast

NO

YES

Check wiring

* Fluorescent Lamp: 32W

① F23 / F49 / F72 / R23 / R49 / R72 ② GR26H / GR48S / GR70H

power supply

connecting points

defective?

for good connection

lamp

power supply

connecting points

defective?

for good connection

lamp

continuity of

When door closed.

Are the door S/We pushed

by the top of door?

lamp switch

Apply spacer

between door switch

and the top of door

continuity of

Check the

continuity of

ballast

- 20 – 05/15 Rev. G 146526

Page 21

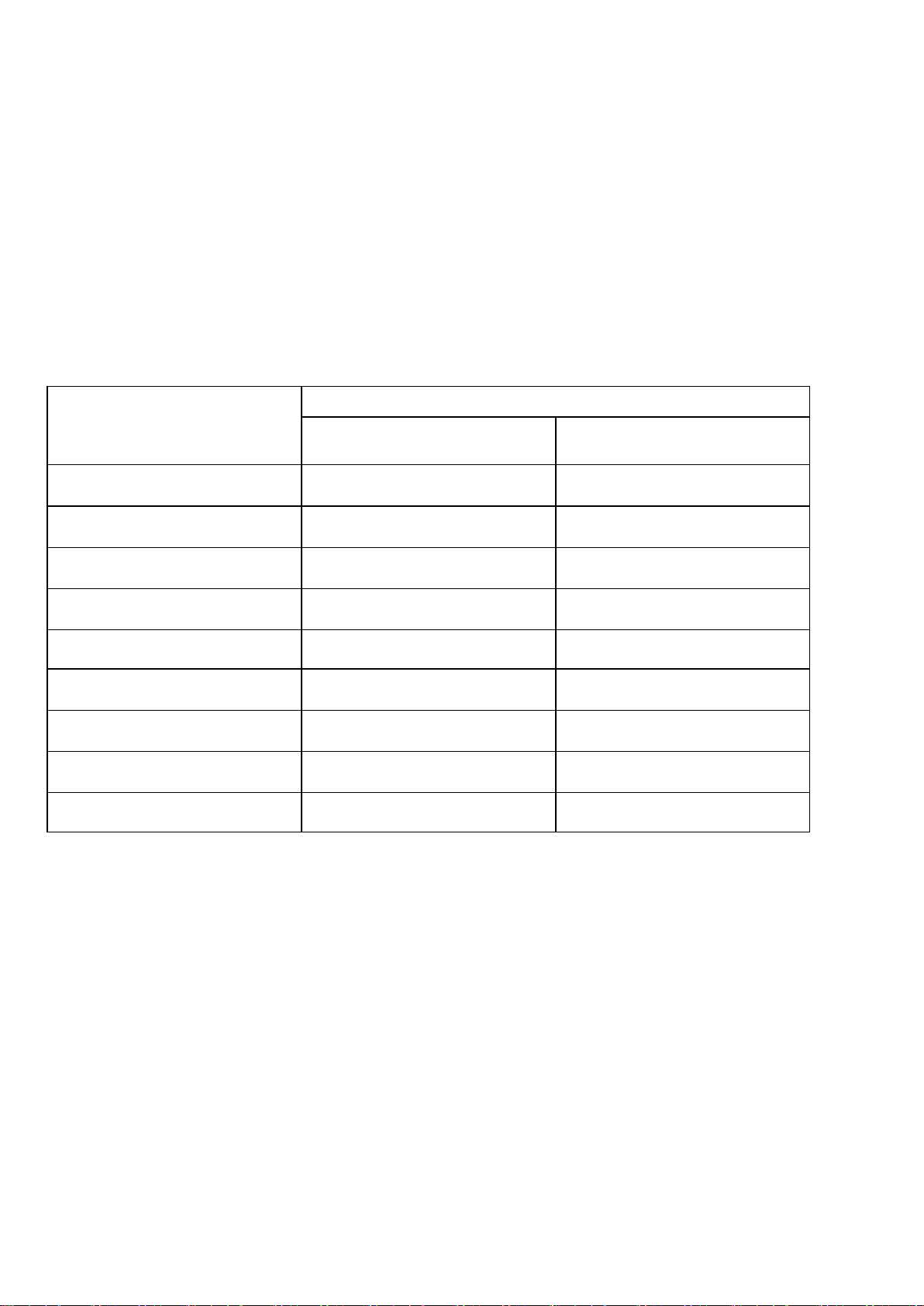

9) CHECKING SENSOR

Sensor assembly consists of T-sensor (lead wire: orange) and D-sensor (lead wire: blue).

The T-s ensor is used for cabinet temperature control and the D-sensor is used for defrost control.

The resistance of the sensor varies depending on temperature.

If you Immerse the sensor in a glass containing ice water for 2 minutes and then check for the resistance

between sensor leads, the normal reading is 7.88 ㏀ (T-sensor) / 30 ㏀ (D-sensor).

Resistance (㏀)

Temperature (℉/℃)

T-sensor (±6.5%) D-sensor (±5.5%)

-5 / -21 23.04 79.17

0 / -18 19.76 68.92

10 / -12 14.65 52.61

23 / -5 10.10 37.55

32 / 0 7.88 30.00

41 / 5 6.20 24.13

50 / 10 7.91 19.53

60 / 16 3.82 15.56

70 / 21 3.00 12.48

- 21 – 05/15 Rev. G 146526

Page 22

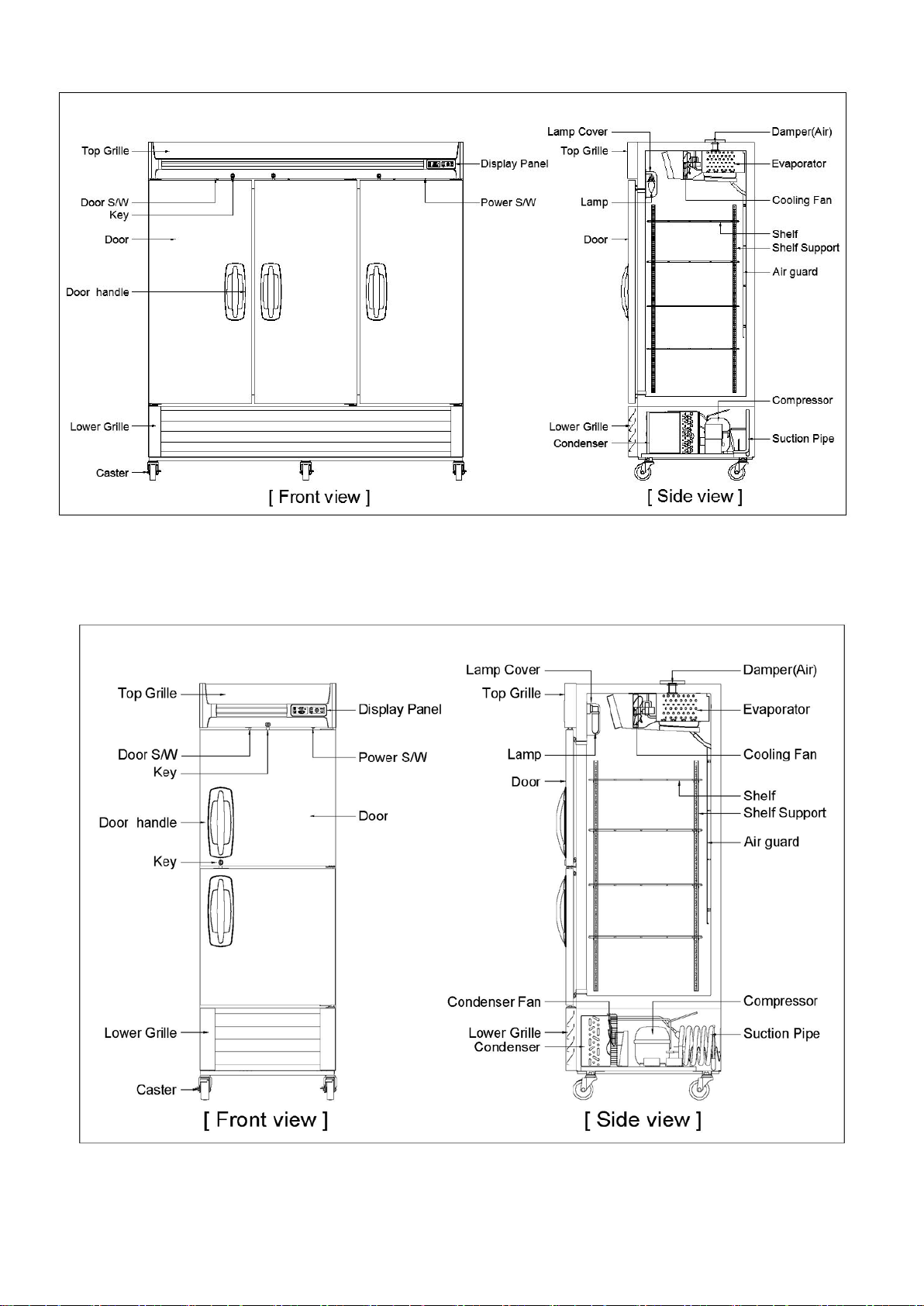

4. FEATURE CHART

1) F23/R23-S

2) F49/R49-S

- 22 – 05/15 Rev. G 146526

Page 23

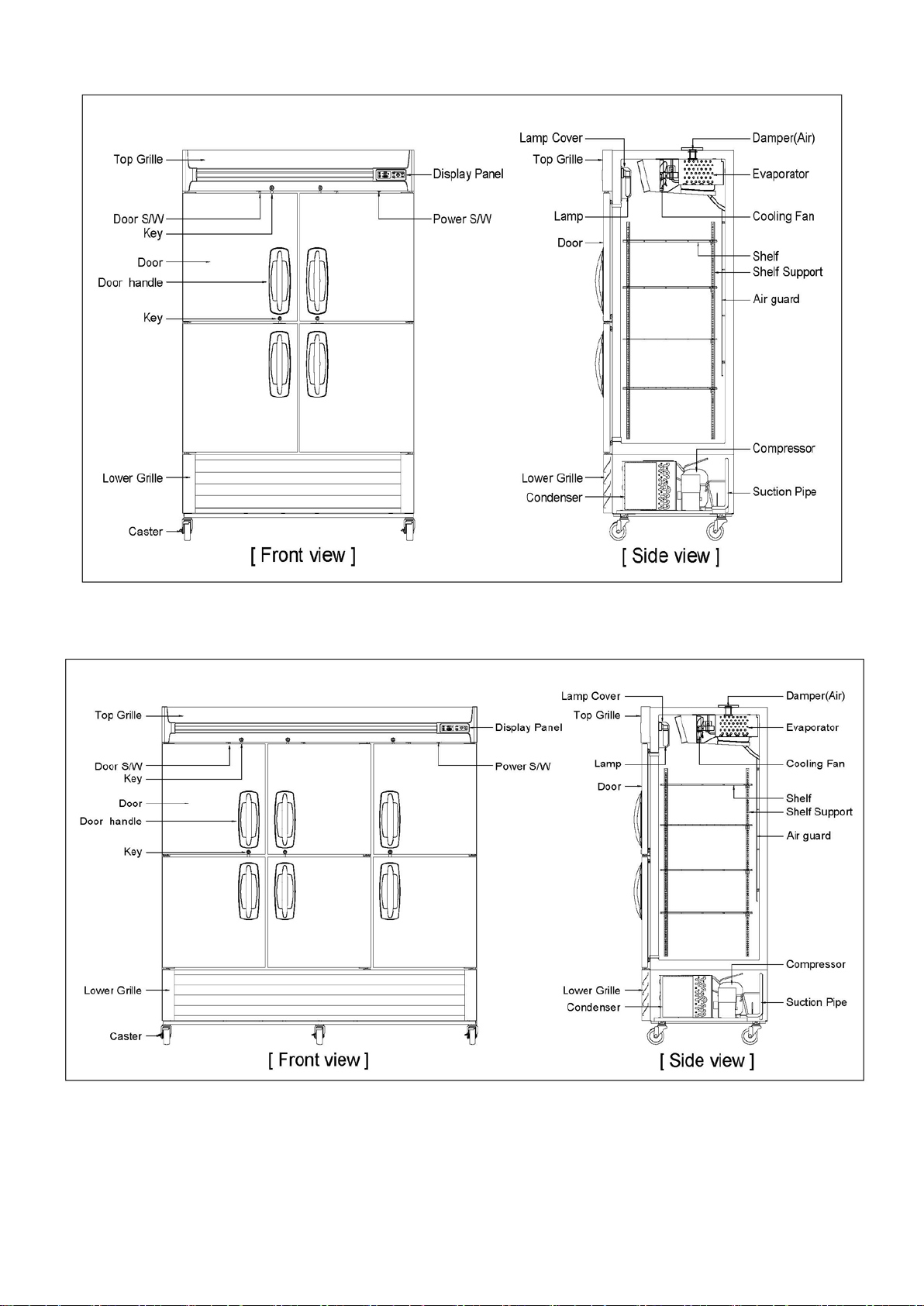

3) F72/R72-S

4) F23/R23-SH

- 23 – 05/15 Rev. G 146526

Page 24

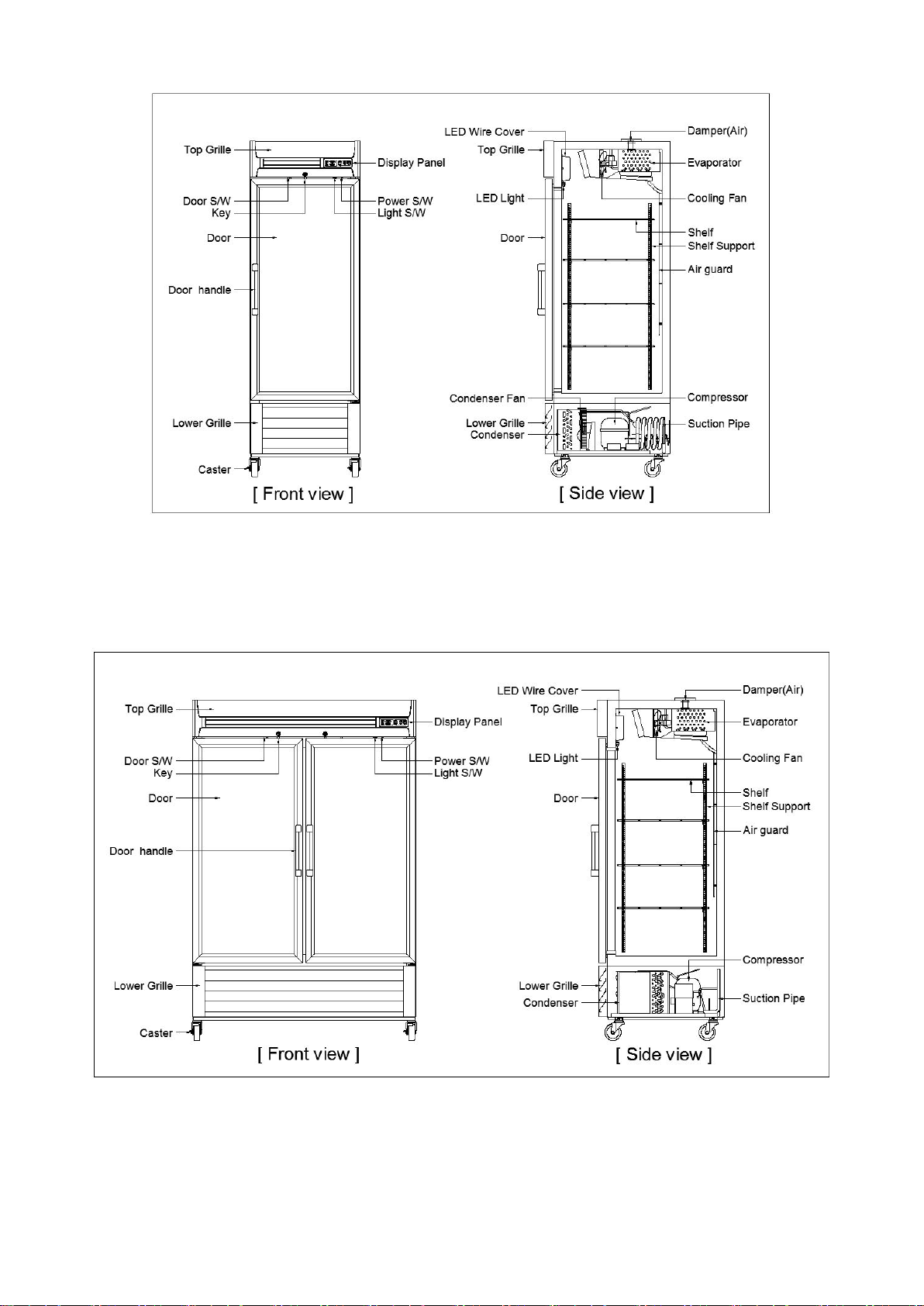

5) F49/R49-SH

6) F72/R72-SH

- 24 – 05/15 Rev. G 146526

Page 25

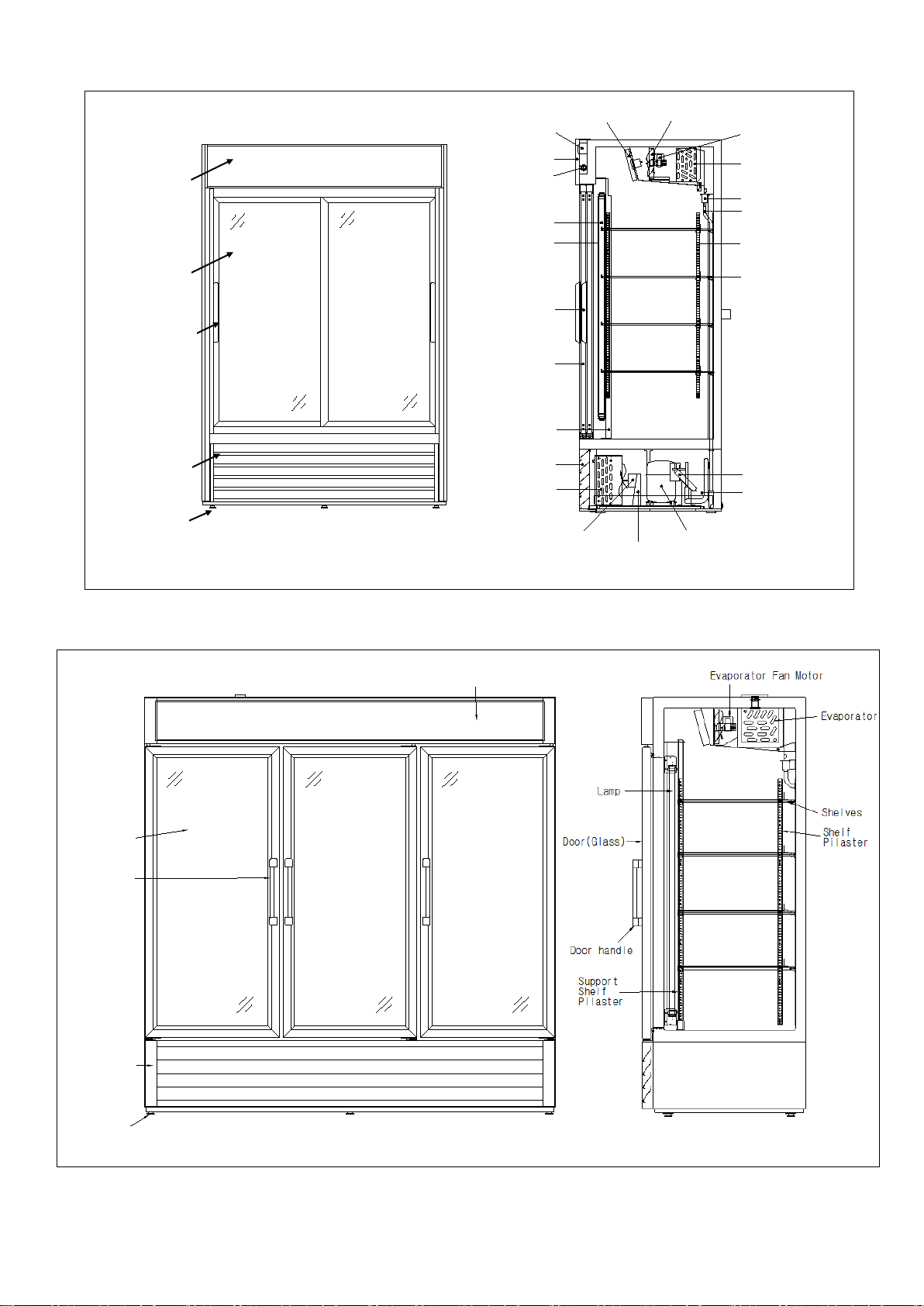

7) R23-G

8) R49-G

- 25 – 05/15 Rev. G 146526

Page 26

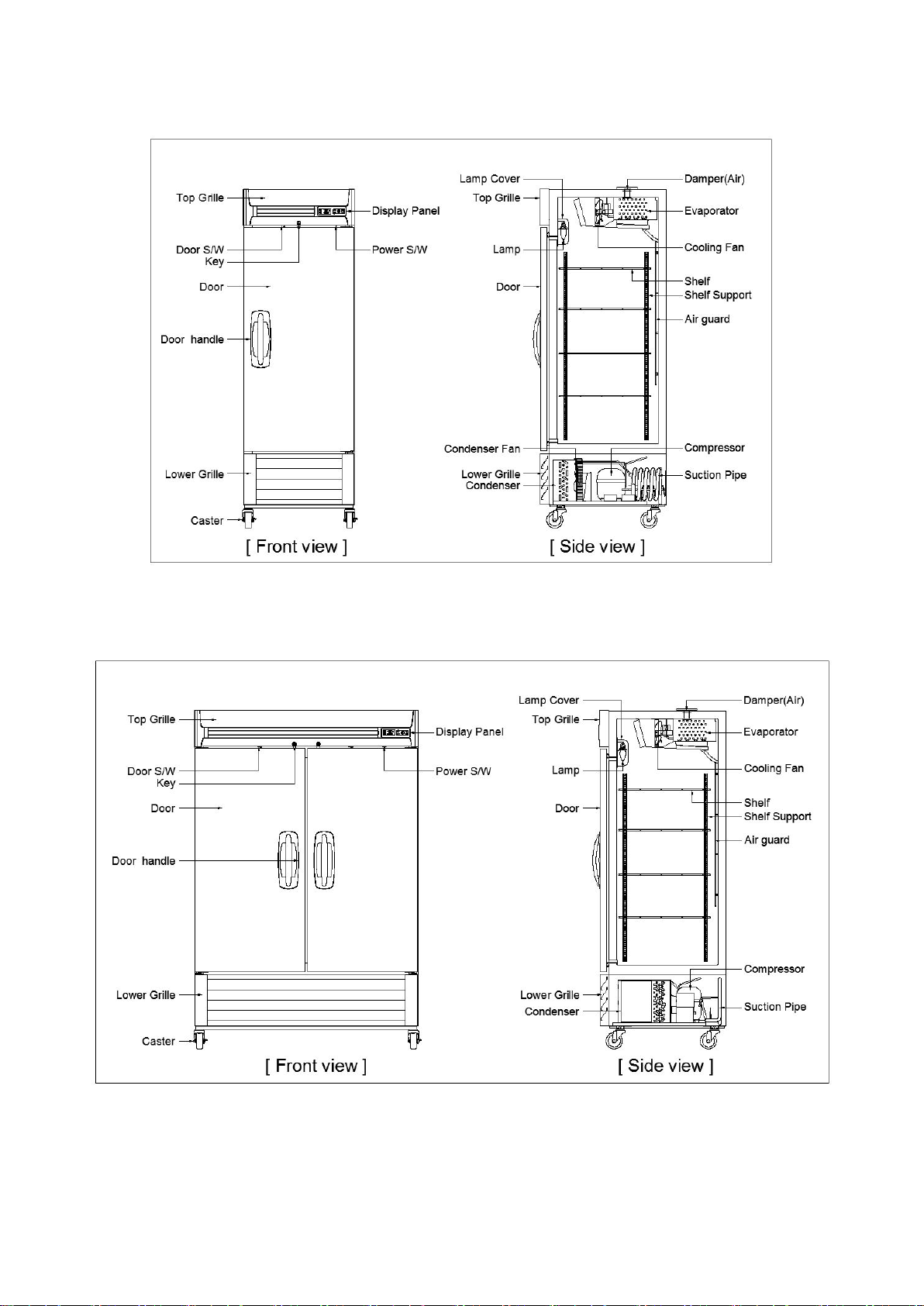

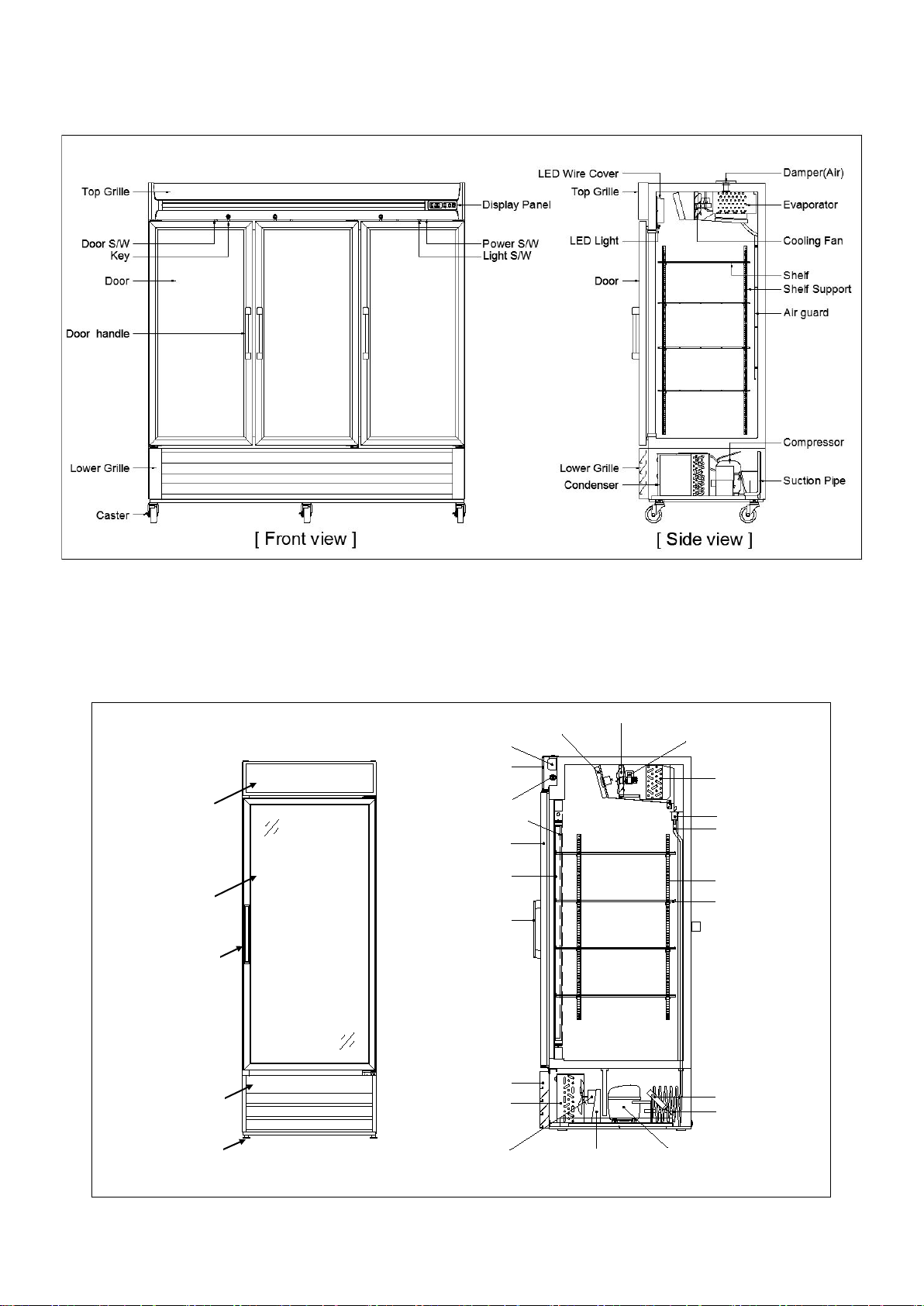

9) R72-G

DOOR HANDLE

CONDENSER

COMPRESSOR

EVAPORATOR

SHELF

SHELF SUPPORT

DRAIN HOSE

FAN COVER

WATER COLLECTOR

LAMP

DOOR FRAME

AD. PANEL

DRYER

CONDENSER FAN MOTOR

COOLING FAN

COOLING FAN MOTOR

SUCTION PIPE

BALLAST

LOWER GRILLE

MOTOR BRKT

LAMP

COVER LAMP

AD. Panel

Door (Glass)

Lower grille

Adjust foot

Door handle

[ Front view ]

[ Side view ]

10) GR26H

- 26 – 05/15 Rev. G 146526

Page 27

11) GR48S

Door(Glass)

Door handle

Adjust foot

Lower grille

AD. Panel

[ Front view ]

[ Side view ]

EVAPORATOR

COOLING FAN

COOLING FAN MOTOR

BALLAST

AD. PANEL

WATER COLLECTOR

DRAIN HOSE

SHELF SUPPORT

SHELF

CONDENSER

LOWER GRILL

DOOR HANDLE

DOOR FRAME

COMPRESSOR

SUCTION PIPE

COOLING FAN COVER

LAMP

LAMP TUBE

DRIER

CONDENSER FAN MOTOR

MOTOR BRKT

CENTER POST

LAMP

AD. Panel

Door (Glass)

Lower grille

Adjust foot

Door handle

[ Front view ]

[ Side view ]

12) GR70H

- 27 – 05/15 Rev. G 146526

Page 28

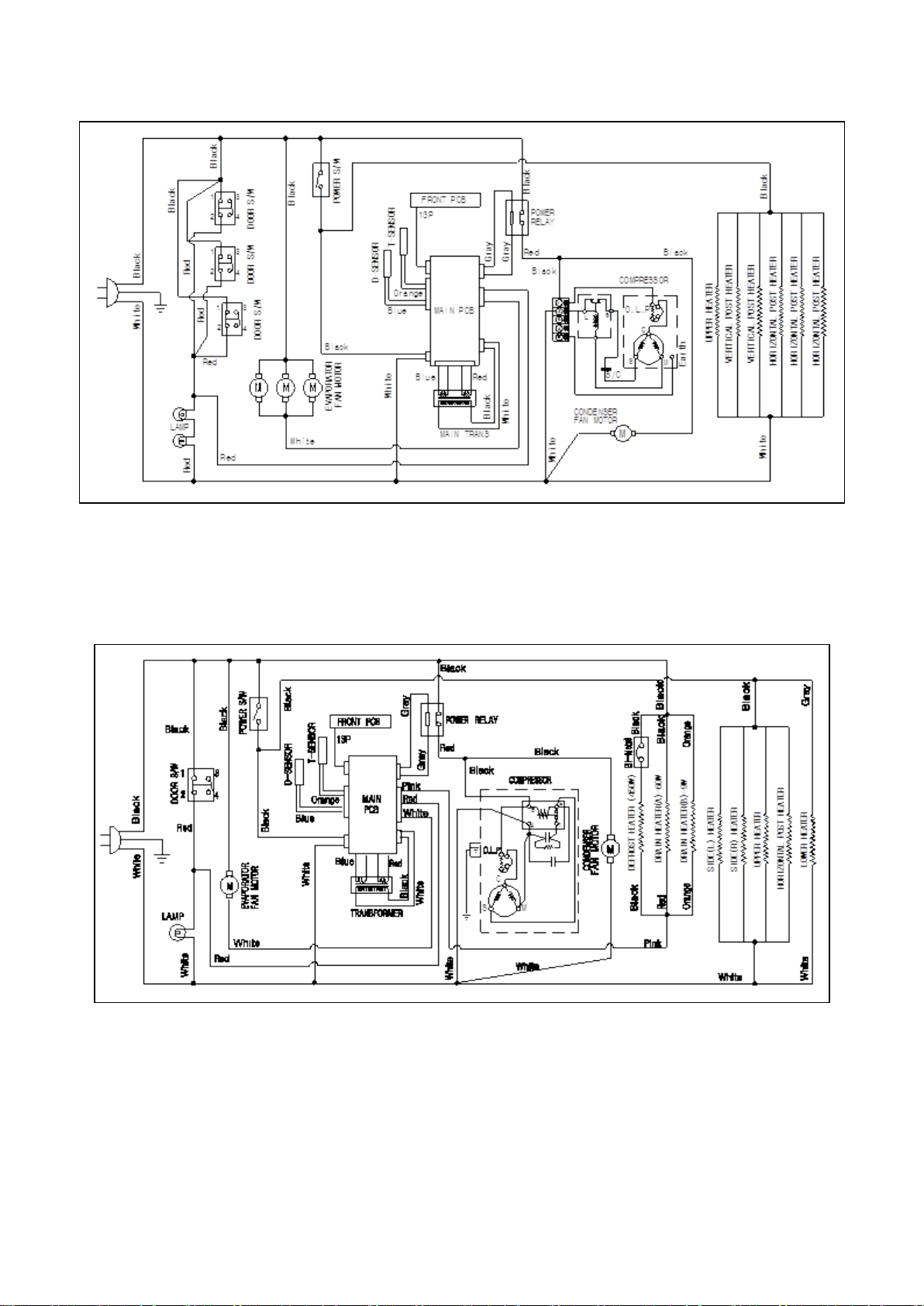

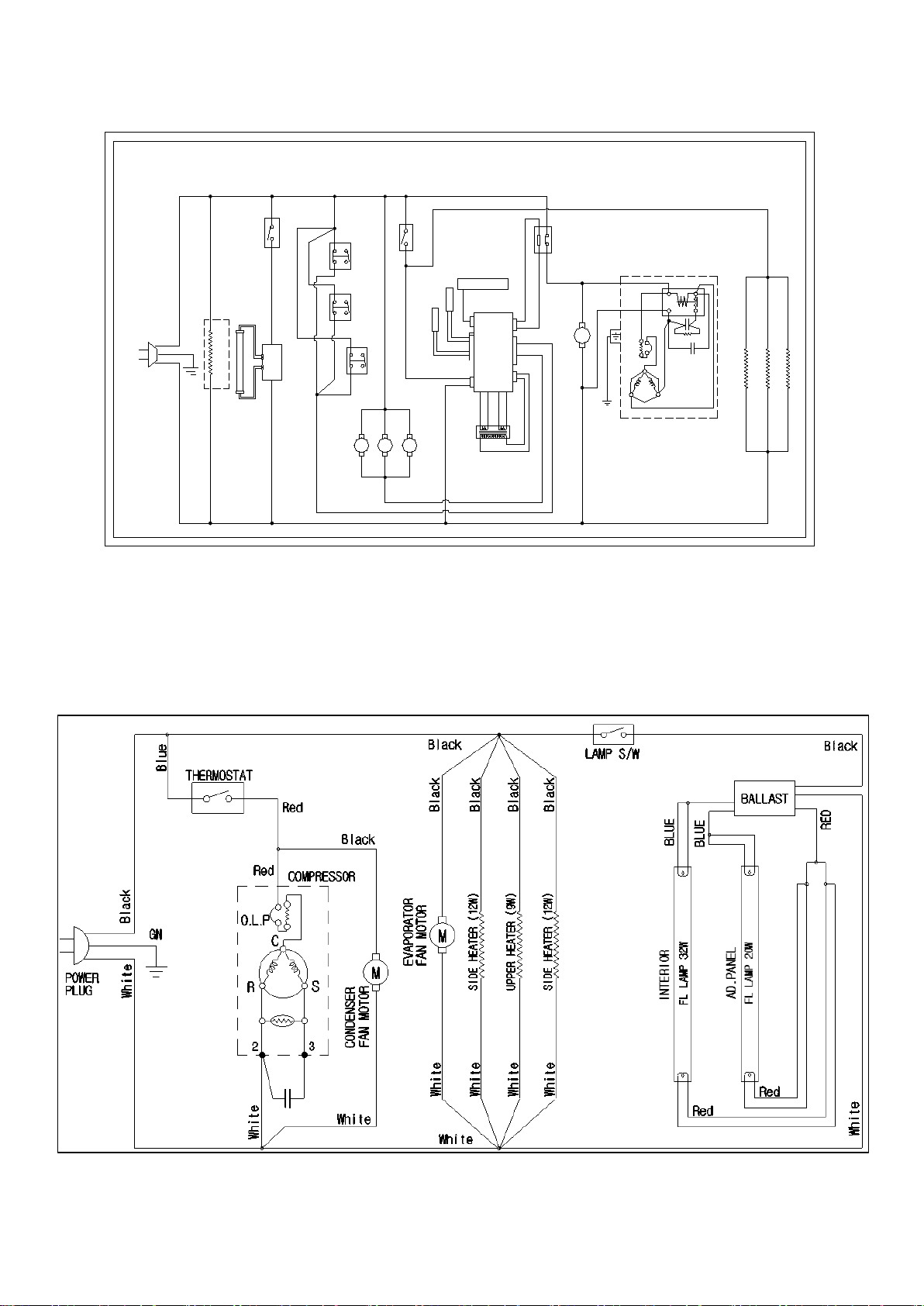

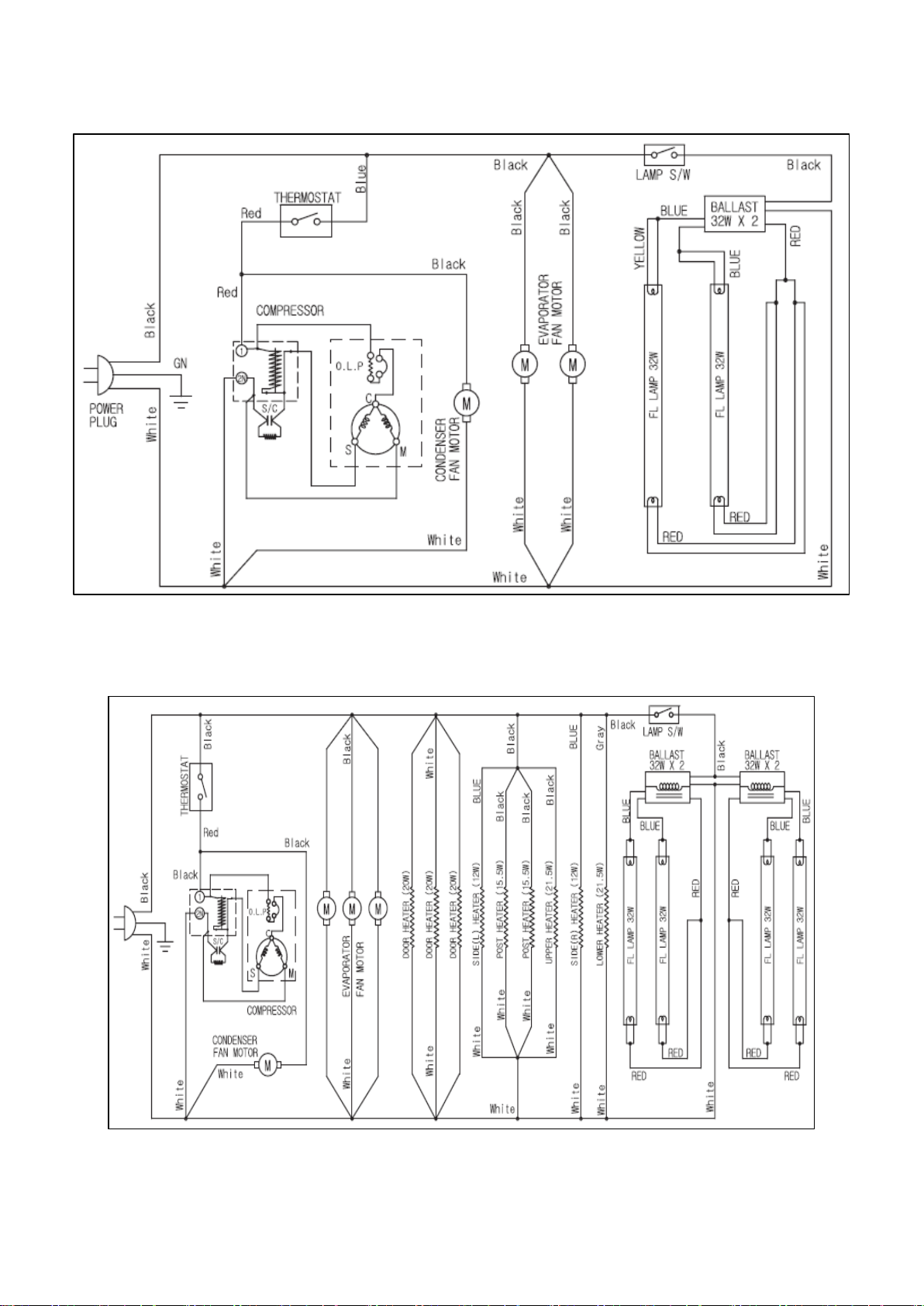

5. WIRING DIAGRAMS

1) F23-S

2) F49-S

- 28 – 05/15 Rev. G 146526

Page 29

3) F72-S

4) R23-S

- 29 – 05/15 Rev. G 146526

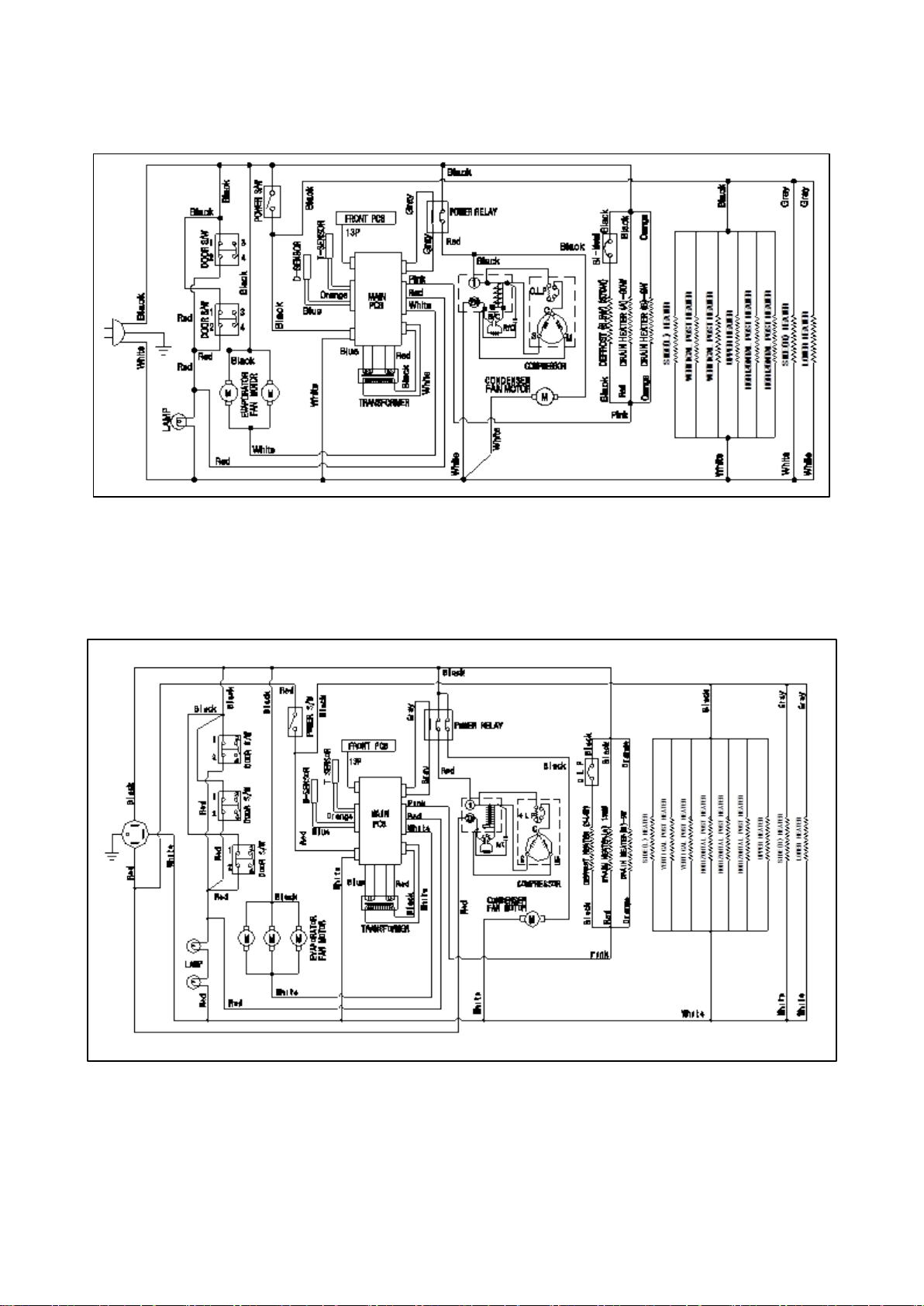

Page 30

5) R49-S

6) R72-S

- 30 – 05/15 Rev. G 146526

Page 31

7) R23-SH

8) R49-SH

- 31 – 05/15 Rev. G 146526

Page 32

9) R72-SH

10) F23-SH

- 32 – 05/15 Rev. G 146526

Page 33

11) F49-SH

12) F72-SH

- 33 – 05/15 Rev. G 146526

Page 34

COMPRESSOR: SK1A1C-L2W

MODEL : R23-G ( REFRI GERATOR)

P OWE R

M

F RON T P CB

13P

T-SENSOR

D-SENSOR

MA I N

PCB

MAI N TRANS

M

1

2

3

4

Bl u e

Or a n g e

Gr a y

Red

Bl u e

COMP RE SS OR

DOOR S / W

UPPER HEATER

Bl a ck

Wh i t e

Bl a ckRed

E V A POR AT OR

F A N MOT OR

Bl a ck

P O WE R S / W

Wh i t e

Bl a ck

Bl a ck

Wh i t e

Bl a ck

Red

Gr a y

REL AY

M

C

O.L.P

S

CR

CS

Bl a ck

Bl a ck

Wh i t e

COND E NS OR

F A N MOT OR

Bl a ck

Wh i t e

DOOR HE A T E R

L I GHT S/ W

S.M.P.S

LED

( opt i on)

Wh i t e

P OWE R

M

F RON T P C B

13P

T-SENSOR

D-SENSOR

MA I N

PCB

MA I N T R A N S

M

1

2

3

4

Bl u e

Or a n g e

Gr a y

Red

Bl u e

DOOR S / W

Bl a ck

Wh i t e

Bl a ck

Red

E V A P ORA TOR

F A N MOT OR

Bl a ck

P O WE R S / W

Wh i t e

Bl a ck

Bl a ck

Wh i t e

Bl a ck

Red

Gr a y

REL AY

Bl a ck

Wh i t e

COND E NS OR

F A N MOT OR

1

2

3

4

DOOR S / W

Bl a ck

Red

M

UPPER HEATER

Wh i t e

P OST HEA T ER

Bl a ck

5

2

4

1

S

M

C

COMPRESSOR

O.L.P

DOOR HEATER× 2EA

L I GHT S/ W

S.M.P.S

LED× 2EA

Bl a ck

( Op t i o n )

COMPRESSOR: NEK2150GK

MODEL : R49 -G ( REFRI GERAT OR)

Wh i t e

Red

13) R23-G

6) R49-G

- 34 – 05/15 Rev. G 146526

Page 35

Bl u e

F R ONT P C B

DOOR S / W

1

3

Bl a ck

M

Wh i t e

Red

Red

2

F A N MOT OR

E V A P OR AT OR

P O WE R S / W

Wh i t e

Bl a ck

4

2

1

Bl a ck

Bl a ck

DOOR S / W

4

3

13P

PCB

UPPER HEATER

Bl a ck

Wh i t e

Red

Wh i t e

POWER RE LA Y

MA I N

Gr a y

Red

Gr a y

Bl a ck

Bl a ck

Bl a ck

P OS T HE A T E R

P OS T HE A T E R

M M

2

1

4

3

DOOR S / W

Bl a ck

Red

M

Bl a ck

Wh i t e

CON DE NS OR

F A N MOT OR

5

2

4

1

S

M

C

COMPRESSOR

O.L.P

Bl a ck

DOOR HEATER× 3 EA

L I GHT S/ W

S.M.P.S

LED× 3EA

T-SENSOR

D-SENSOR

Bl u e

Or a n g e

( opt i on)

COMPRESSOR: NEK2150GK

MODEL : R72 -G ( REFRI GERAT OR)

Wh i t e

Red

MA I N T R A NS

6) R72-G

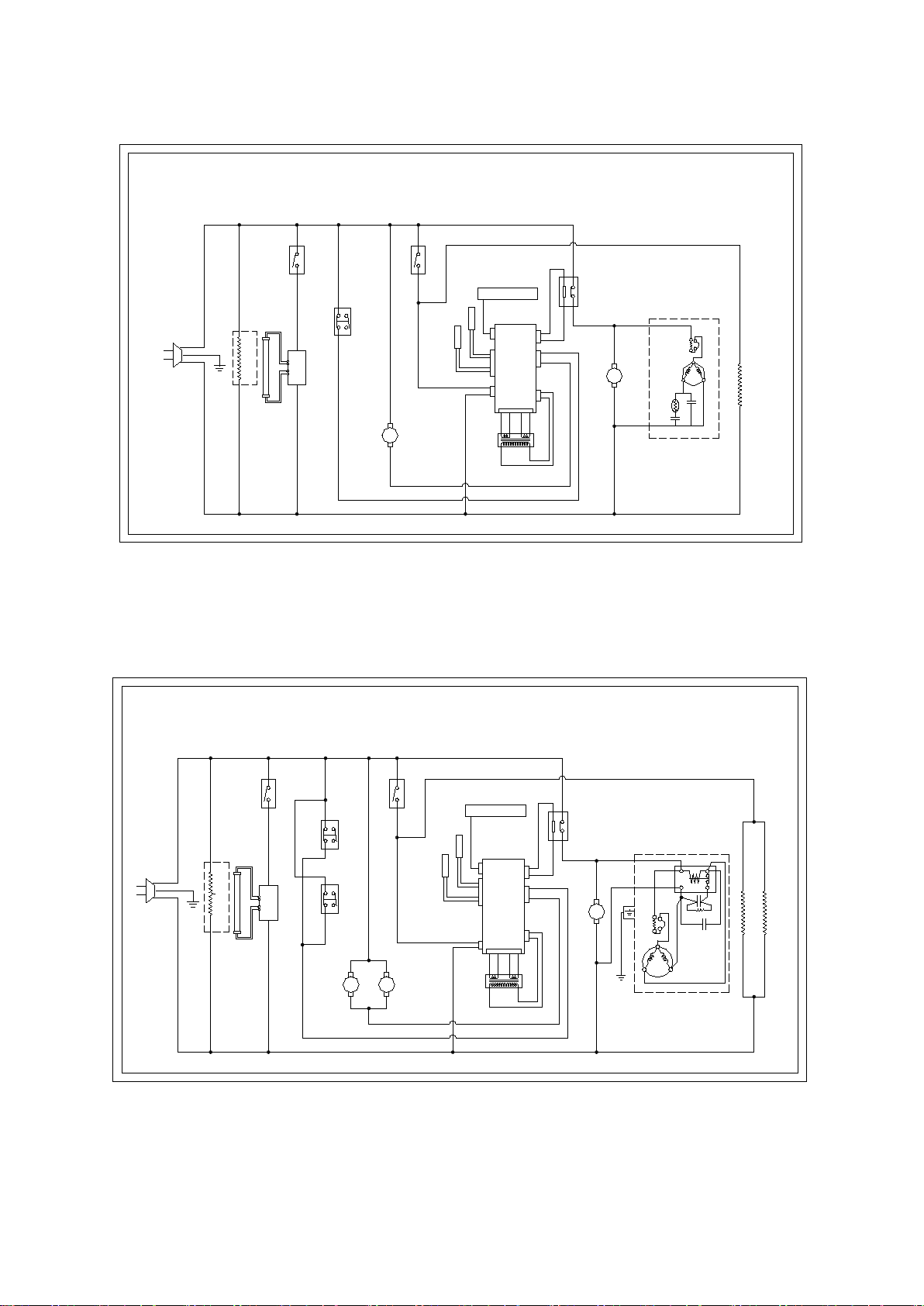

7) GR26H

- 35 – 05/15 Rev. G 146526

Page 36

8) GR48S

9) GR70H

- 36 – 05/15 Rev. G 146526

Page 37

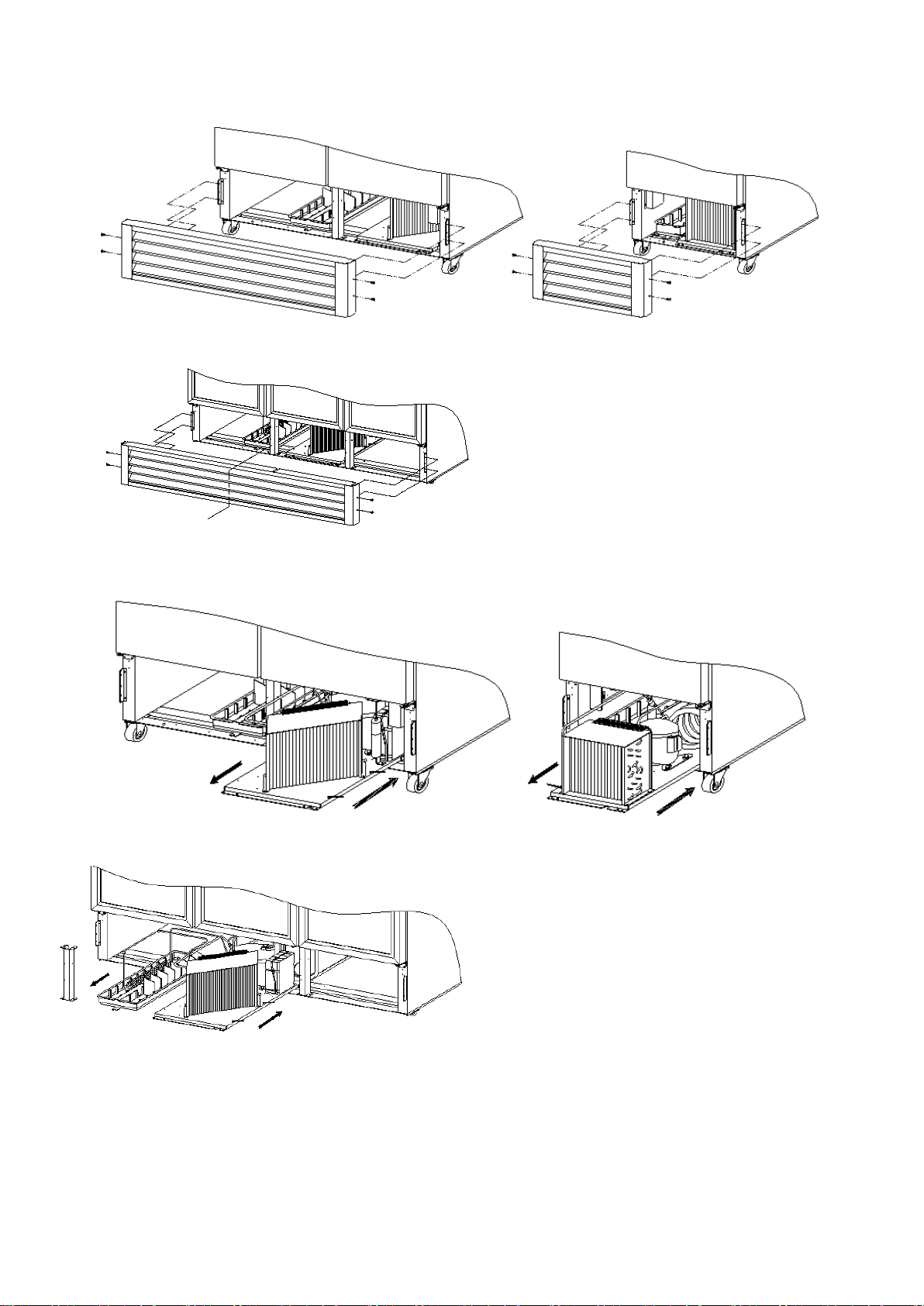

6. REPLACEMENT OF COMPONENTS

※

Disassemble

a) Separate the compressor harness out of

a) Unplug the power cord before service.

1) CONDENSING UNIT

(F49/F72/R49/R72) (F23/R23/GR26H)

b) Remove screw securing the lower grille.

* Remove screw securing the reinforce

angle.(GR48S/GR70H)

(GR48S/GR70H)

(F49/F72/R49/R72) (F23/R23/GR26H)

the terminal block.

b) Remove screws securing the unit base

plate and pull out condensing unit with care.

c) Replace the necessary com-ponent.

(GR48S/GR70H)

CAUTION

1. Please pull out or push in the unit base plate carefully to prevent capillary tube, pipes and wires

from damaging.

2. It is recommend to arrange wires after you push in the unit base plate.

- 37 – 05/15 Rev. G 146526

Page 38

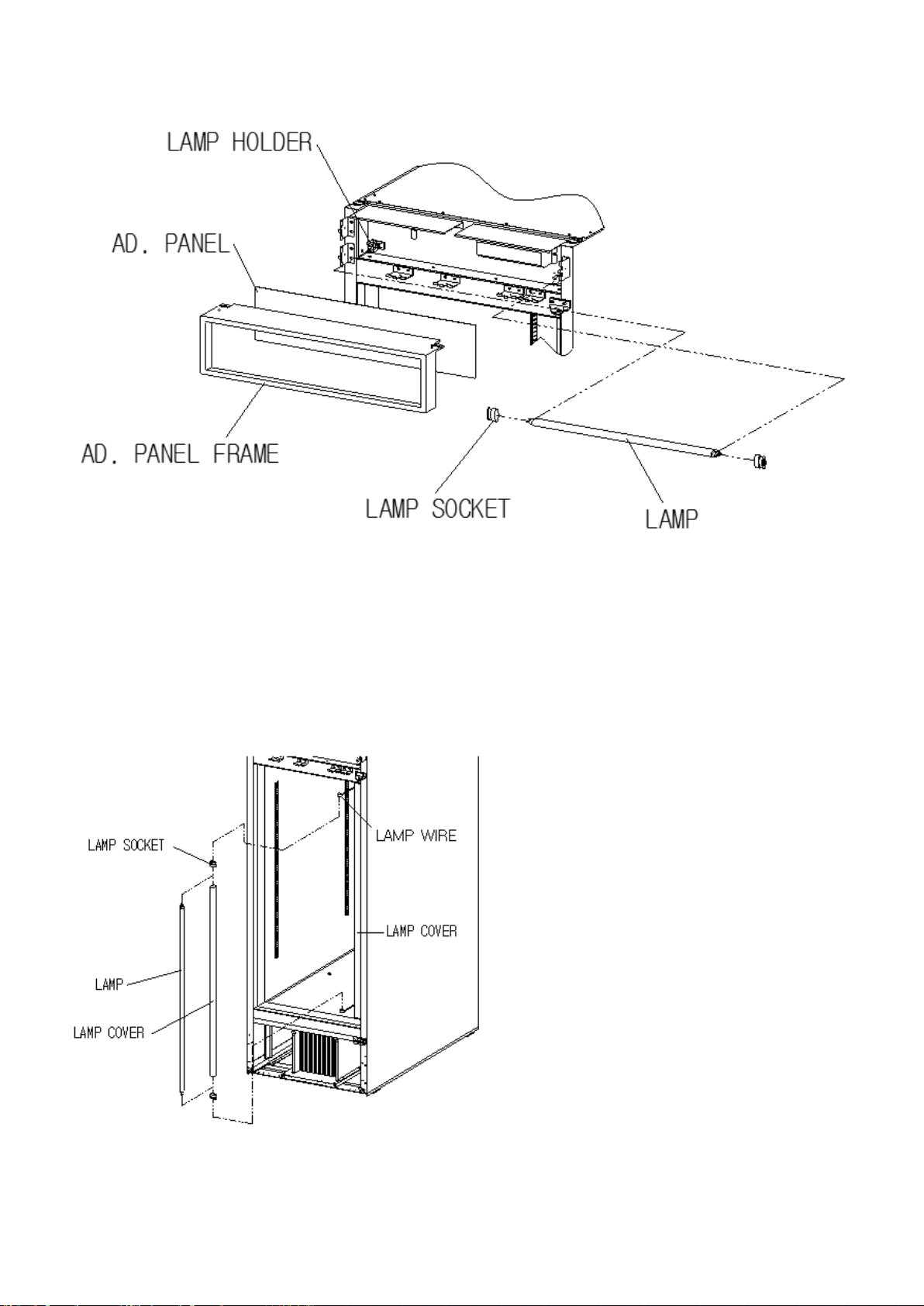

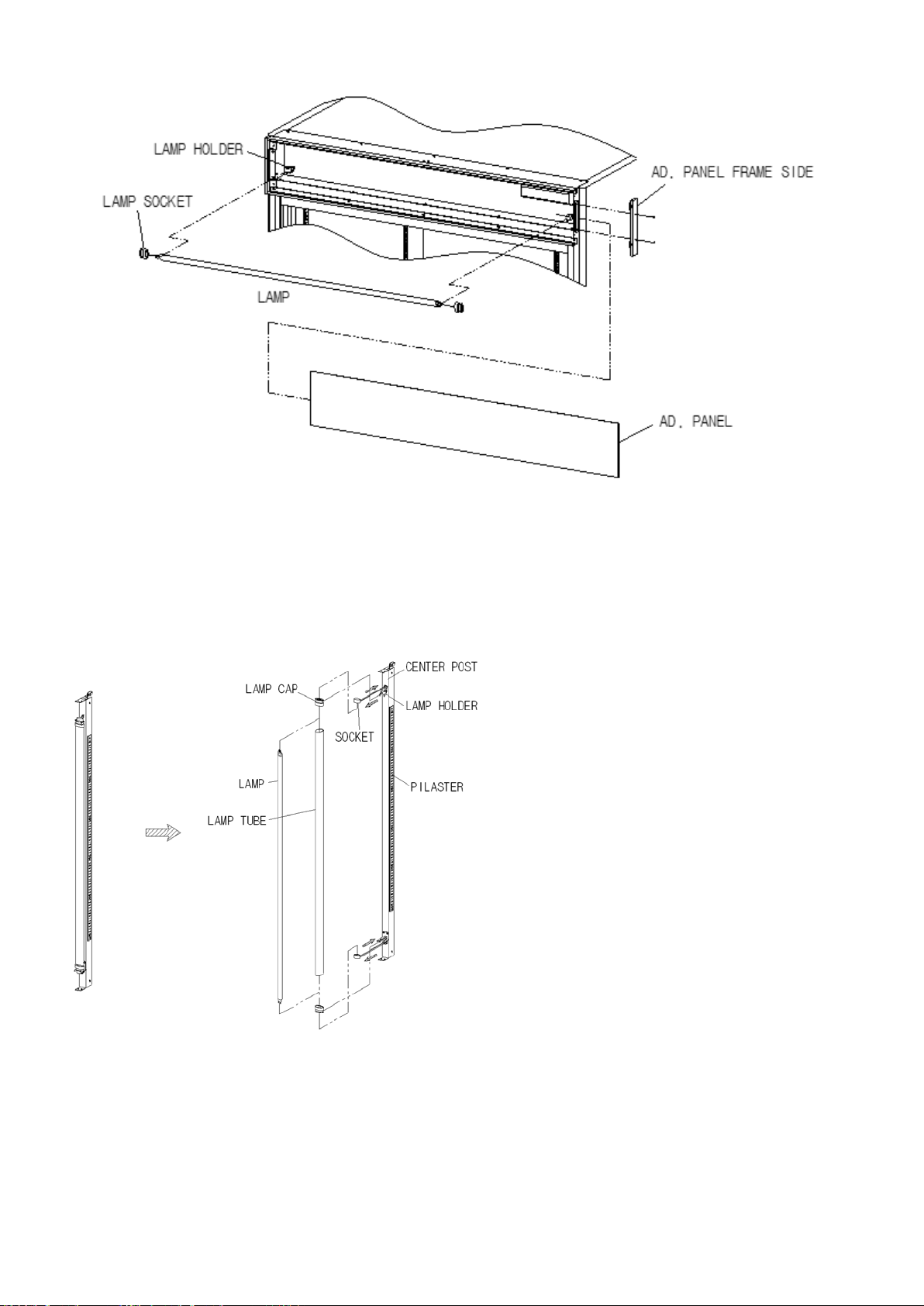

2-1) LAMP (GR26H)

a) Unplug the power cord before

a) Unplug the power cord before service.

b) Remove screw securing the Ad. Panel Frame and pull out the Ad. Panel Frame with care.

c) Separate the Ad. Panel.

d) Separate the Lamp from the Lamp Holder.

e) Separate the Lamp Socket and replace the Lamp with care.

service.

♠ Lamp Description: AC115V, F17T8/TL950

b) Separate the Lamp from the

Lamp Holder.

c) Separate the Lamp Socket and

the Lamp wire.

d) Replace the Lamp with care.

- 38 – 05/15 Rev. G 146526

Page 39

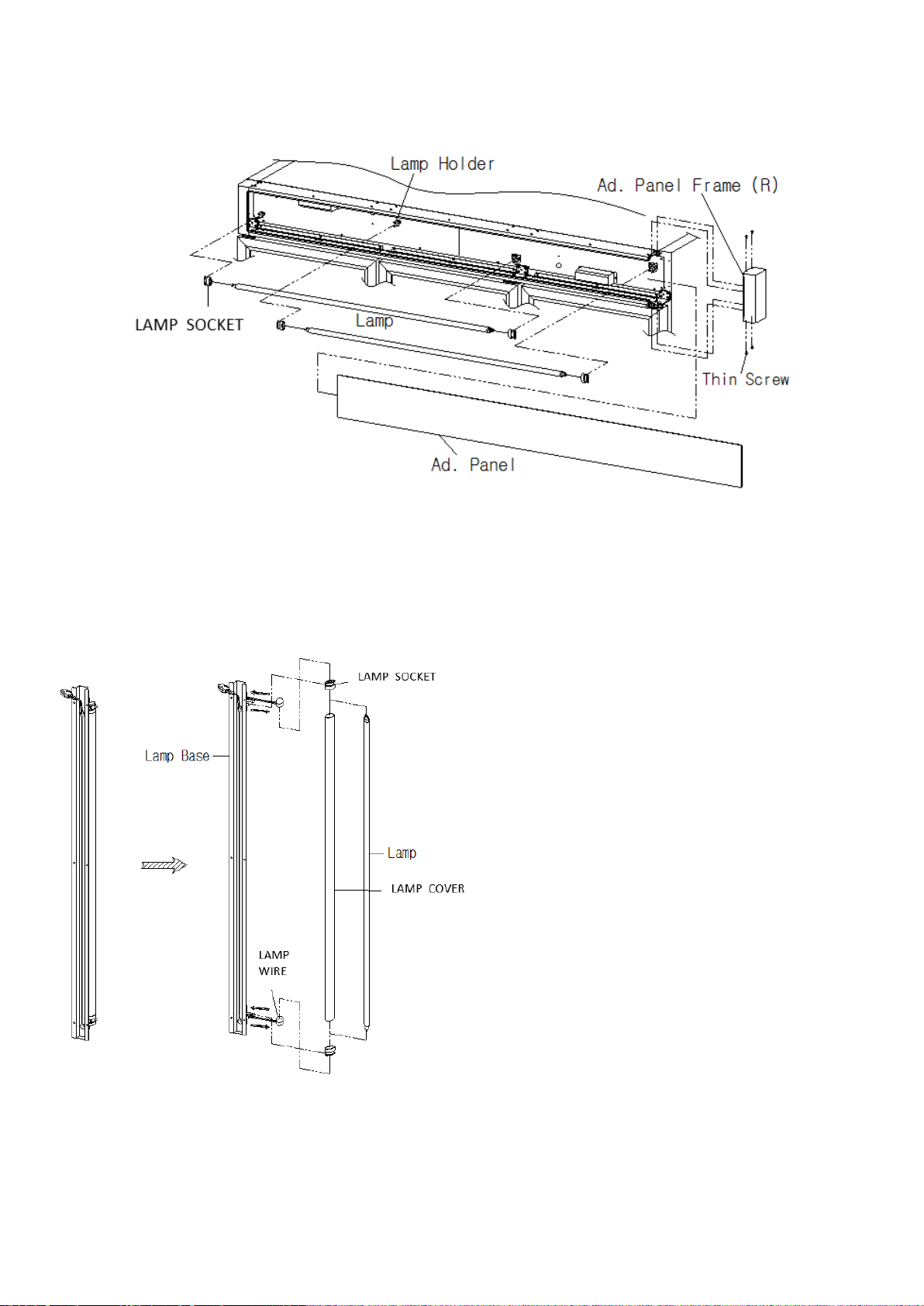

2-2) LAMP (GR48S)

a) Unplug the power cord before service.

a) Unplug the power cord before service.

b) Remove screw securing the Ad. Panel Side.

c) Separate the Ad. Panel.

d) Separate the Lamp from the Lamp Holder.

e) Separate the Lamp Socket and replace the Lamp with care.

b) Separate the Lamp from the

Lamp Holder.

c) Separate the Lamp Socket and

the Lamp wire.

♠ Lamp Description: AC115V, FHF32SSEX-D-5

d) Replace the Lamp with care

.

- 39 – 05/15 Rev. G 146526

Page 40

a) Unplug the power cord before service.

2-3) LAMP (GR70H)

a) Unplug the power cord before service.

b) Remove screw securing the Ad. Panel Frame (R).

c) Separate the Ad. Panel.

d) Separate the Lamp from the Lamp Holder.

e) Separate the Lamp socket and replace the Lamp with care.

b) Separate the Lamp from the Lamp Holder.

♠ Lamp Description: AC115V, 32W, F32T8/TL860

c) Separate the Lamp Socket and the

Lamp wire.

d) Replace the Lamp with care.

- 40 – 05/15 Rev. G 146526

Page 41

B. OPERATION AND ELECTRONIC CONTROLLER

FUNCTION

1. OPERATION FOR F23, F49, F72, R23, R49, R72 MODELS - - - - - B2

1) BASIC OPERATION

2) ELECTRONIC CONTROLLER SETTING MODE

3) NORMAL CONTROL PROCESS

4) ERROR CO DE

2. OPERATION FOR GR26H, GR48S, GR70H MODELS - - - - - - - - - B12

1) BASIC OPERATION

2) DEFROST

3) CONTROL TEMPERATURE

4) LAMP

3. INSTRUCTION FOR RE-HINGING DOOR - - - - - - - - - - - - - - - - - B13

- 41 – 05/15 Rev. G 146526

Page 42

1. OPERATION FOR F23/F49/F72(FREEZER), R23/R49/R72(REFRIGERATOR)

1) BASIC OPERATION

① Plug in the power cord and turn on the power switch located on the bottom of the top grille right side.

[ The unit should be plugged into a 115V±10%, 60Hz (F23, F49, R23, R49, R72 models) ]

[ The unit should be plugged into a 115V/208~230V, 60Hz (F72 model) ]

② Display panel will be lit for 2 seconds with buzzer then displays cabinet interior

temperature (T-sensor) and running conditions.

* Freezer : If cabinet interior temperature is higher than 14℉ (-10℃) compressor will run without

delay, and lower than 14℉ (-10℃), compressor will run after 3 minutes.

* Refrigerator : If cabinet interior temperature is higher than 50℉ (10℃) compressor will run

without delay, and lower than 50℉ (10℃), compressor will run after 3 minutes.

③ The default OPERATING TEMPERATURE SETTING

* Freezer :Temperature set point (setting mode sign [St]) is –5℉ (-20℃)

Temperature differential set point (setting mode sign [di]) is 8℉ (4℃)

Range of adjustable set point: -22℉~ 8℉(-30℃ ~ -10℃)

* Refrigerator : Temperature set point (setting mode sign [St]) is 36℉ (4℃) in solid door refrigerator

Temperature set point (setting mode sign [St]) is 35℉ (4℃) in glass door refrigerator

Temperature differential set point (setting mode sign [di]) is 8℉ (4℃)

Range of adjustable set point: 25℉~ 50℉ (2℃ ~10℃)

④ Defrost frequency

* Freezer : It is controlled by MICOM and the default defrost frequency is 6 hours.

* Refrigerator : It is controlled by MICOM and the default defrost frequency is 12 hours.

⑤ The light inside the cabinet comes on when the door is opened in Solid Door models

while light is always on in Glass Door models.

The cabinet interior cooling fan has 3 seconds delay when the door is closed.

When CO MP . is OFF, EVA. fan repeats ON and OFF according to setting times

If door is opened , EVA. fan OFF and then closed the door, EVA. fan repeats ON and OFF according

to setting times

- 42 – 05/15 Rev. G 146526

Page 43

⑥ If door is opened, door open warning sign (LED) will turn on.

If door is opened more than 30 seconds, the sound alarm beeps 3 times,

if open more than 60 seconds, the sound alarm beeps 5 times and if open more than 5 minutes,

the sound alarm will beep continuously.

⑦ Cabinet interior temperature

* Freezer : If it is higher than 14℉ (-5℃), the panel displays [Hi] and

lower than -50℉ (-40℃), the panel displays [Lo].

* Refrigerator : If it is higher than 68℉ (15℃), the panel displays [Hi] and

lower than 14℉ (-2℃), the panel displays [Lo].

- 43 – 05/15 Rev. G 146526

Page 44

2) ELECTRONIC CONTROLLER SETTI NG MODE

Display Description

St Temperature Setting Mode

di Temper ature Differential Setting Mode

th Cabinet Temperature Verification Mode

dt Def r ost Frequency Setting Mode

tb Rapid Freeze Mode (Freezer Only)

dF For c ed Defrost Mode

SE T emperatur e Unit Converter mode(℉↔℃)

※ In converting Temperature Unit (℉↔℃), 1℉ (1℃) deviation can occur.

- 44 – 05/15 Rev. G 146526

Page 45

No Setting Mode

until the desired

℉~16℉(2℃~10℃

℉~16℉(2℃~10℃

Mode

Sign

How to Setting

1.To enter this mode, press [MODE/SET] and [UP or DOWN]

simultaneously until [St] is displayed.

2. Then press [MODE/SET] to see current temperature set point.

3. To change the set point, press [UP or DOWN]

value is displayed.

4. At the end of the sequence, press [MODE/SET] to set the value.

1

Temperature

Setting

Mode

“St”

5. To display the cabinet temperature again, press [UP or DOWN]

until [th] is displayed and then press [VERIFY].

6. Range of adjustable set point : -22℉~8℉(-30℃~ -10℃) (Freezer)

Range of adjustable set point : 25℉~50℉(2℃ ~ 10℃) (Refrigerator)

1. To enter this mode, press [MODE/SET] and [UP or DOWN]

simultaneously until [di] is displayed.

2. Then press [MODE/SET] t o see current temperature differential.

3. To change the set point, press [UP or DOWN] until the desired

value is displayed.

4. At the end of the sequence, press [MODE/SET] to set the value.

Temperature

Differential

2

Setting

Mode

5. To display the cabinet temperature again, press [UP or DOWN]

until [th] is displayed and then press [VERIFY].

“di”

6. Range of adjustable set point : 4

Range of adjustable set point : 4

(The Unit of Setting : 2℉(2℃))

) (Freezer)

) (Refrigerator)

- 45 – 05/15 Rev. G 146526

Page 46

No Setting Mode

1. To enter this mode, press [MODE/SET] and [UP or DOWN]

is displayed instead of the cabinet

1. To enter this mode, press [MODE/SET] and [UP or DOWN]

to start rapid

is displayed instead of the cabinet

Defrost

Frequency

3

Setting

Mode

Mode

Sign

“dt”

How to Setting

1. To enter this mode, press [MODE/SET] and [UP or DOWN]

simultaneously until [dt] is displayed.

2. Then press [MODE/SET] to see current defrost frequency.

3. To change the defrost frequency, press [UP or DOWN] unt il the

desired value is displayed.

4. A t th e end of the sequence, press [MODE/SET] to set the value.

5. To display the cabinet temperature again, press [UP or DO WN]

until [th] is displayed and then press [VERIFY].

6. Range of adjustable defrost frequency : 4Hr to 12Hr

(The Unit of frequency : 2Hr)

Forced Defrost

4

Cancelation

5

Forced Defrost

Rapid Freeze

6

(Freezer)

Mode

of

Mode

Mode

“dF”

Flash

"dF"

"tb"

simultaneously until [dF] is displayed.

2. Then press [M AN UA L DF ] m ore than 2 seconds to start f orced

defrost.

3. During defrosting, [dF]

temperature.

1. During forced defrost, press [M ANUAL DF] more than

2 seconds to stop forced defrost.

2. The [dF] will be flash 5 times and then return to normal

display mode.

simultaneously until [tb] is displayed.

2. Then press [MODE/SET] more than 2 seconds

freeze mode.

3. During rapid freeze, [tb]

temperature.

- 46 – 05/15 Rev. G 146526

Page 47

3) NORMAL CONTROL PROCESS

1. Compressor and condenser fan motor is controlled by T-sensor and MICOM

No FUNCTION FUNC TION SPEC

1. After Power ON, Display panel will be lightened for 2 seconds with buzzer then

displays cabinet interior temperature.

1

2

Initial

Operating

Normal

Operating

2. If cabinet interior temperature is higher than 14℉(-10℃) Freezer or 50℉(10℃)

Refrigerator, compressor will run without delay, and lower than 14℉(-10℃)

Freezer or 50℉(10℃) Refrigerator, compressor will run after 3 minutes.

program.

2. Compressor ON/OFF Te mperature

Compressor ON : Temperature Setting Value +

(Temperature Differential Setting Value/2)

Compressor OFF : Temperature Setting Value (Temperature Differential Setting Value/2)

ex) St: -9℉(-23℃), d i: 10℉(6℃) ⇒ Compressor ON : -9+(10/2) = -4℉(-20℃),

Compressor OFF: -9-(10/2) = -14℉(-26℃)

St: 39℉(4℃), di: 10℉(6℃) ⇒ Compr essor ON : 39+(10/2) = 44℉(7℃),

Compressor OFF: 39-(10/2) = 34℉(1℃)

- 47 – 05/15 Rev. G 146526

Page 48

No FUNCTION FUNC TION SPEC

1. Compressor and cabinet interior cooling fan is running continuously for

It is necessary to cancel the Rapid Freeze Mode before setting the other

It prevent exceed temperature rise

out temperature

Maximum time: 30minutes

, fan

120 minutes without control by sensor.

2. It is impossible to set the other modes during Rapid Freeze Mode.

Rapid

3

Freeze

(Freezer)

modes.

3. If Defrost Mode become in the Rapid Freeze Mode duration,

Defrost Mode will start after the Rapid Freeze Mode finished.

4. Rapid Freeze Mode will be start after Defrost Mode finished not during

Defrost Mode. [tb] is displayed from starting the Rapid Freeze Mode.

1. Defrost process is like below

Process Contr olled Part Description

①

during defrosting,

② Cycle is run continuously until current

compressor cutreach.

Pre-Cool

Compress or On

Evaporator Fan On

Condenser Fan On

Defrost Heater Off

③

① Preprogrammed frequency interval

② If D-sensor is higher than 50℉,

defrost heater off

③ Maximum time: 40minutes

Defrost

(Freezer)

Defrost

Compress or Off

Evaporator Fan Off

Condenser Fan Off

Defrost Heater On

Compress or Off

Pause

4

Evaporator

Fan Delay

Evaporator Fan Off

Condenser Fan Off

Defrost Heater Off

Compress or On

Evaporator Fan Off

Condenser Fan On

Defrost Heater Off

① Time: 5minutes

① If D-sensor is lower than -4℉

delay terminated

② Maximum time: 10minutes

1. Defrost cycle can be set up by button on control panel from 4h to 12hr.

(measurement unit: 2hr / default: 12hr)

2. Defrost control change

1) Defrost start : according to the defrost cycle by set up.

Defrost

(Refrigerator)

2) Defrost end : Comp OFF (during MAX time), Eva fan ON, dF ON (on display

screen)

3) Defrost ends regardless of time when the temp is higher than

pre-set defrost end temp.

4) 'dF' is displayed on screen for 3min after defrost end.

- Defrost end time (MAX) : 30min

- Defrost end temp : 41℉(5℃)

- 48 – 05/15 Rev. G 146526

Page 49

No FUNCTION FUNCTION SPEC

1. Temperature Setting : -5℉(-20℃), Temp.Differential Setting : 8℉(4℃) in display

℉

℉(4℃

℉(6℃

Setting

) Freezer or

Press [down] button 5 times with pressing and holding [up] button, the Error

5

6

7

Default

Setting

(Freezer)

Default

Setting

(Refrigerator)

Back UP

Error

Display

2. Displayed Temperature : -8℉(-21℃)(comp. off) ~ 0℉(-17℃)(comp. on)

owing to correction factor

3. T-Sensor Operating Temperature :

-9

(-22℃)(comp. off ) ~ -1℉(-18℃)(comp. on)

4. Defrost Frequency Setting : 6Hr

1. Temperature Setting : 36

2. Operating Temperature : 40

), Temperature Differential Setting : 8℉(4℃)

)(comp. on) ~ 32℉(2℃)(comp. off)

3. Defrost Frequency Setting : 12Hr

1. In case of unexpected power failure or power off, does not require resetting.

2. The setting is memorized.

1. If cabinet interior temp. is higher than 14℉(-5℃) Freezer or 68℉ (15℃)

Refrigerator, the panel displays [Hi], and lower than -50℉(-40℃

14℉(-2℃) Refrigerator, the panel displays [Lo].

2.

display mode is activated and it displays errors.

3. When there are more than 2 errors, the errors are displayed alternately.

4. If you press [MODE/SET] button, the error display mode will be finished

- 49 – 05/15 Rev. G 146526

Page 50

4) ERROR CODE

During normal mode (not defrost

sensor sensing is lower than

sensor sensing is

4-1) Freezer

Error

Code

C1

C2

C3

Condition Possible Cause W hen error occurring, operation

mode), D-sensor sensing is

higher than 23℉ and

Compressor does not run for

60min after compressor off

Entering defrost mode, D-sensor

sensing is higher than 50℉ and

T14℉

After defrost mode elapsed for

40minutes, Dlower than 23℉

• Ambient Temperature

too low (below-5℉)

• T-sensor defective

• D-sensor defective

• D-sensor defective

• Defrost heater

defective

1) Register “C1”

2) Compressor ON:20Minutes

3) Compressor OFF:5Minutes

4) Ope rate 2),3) three times

5) Operate Normal Mode

1) Register “C2”

2) Operate Pre-Cool step:

30Minutes

3) Defrost Heater ON: 20Minutes

4) Operate the rest Defrost Mode

1) Register “C3”

2) Operate the rest Defrost Mode

T-sensor sensing is more

than 18℉higher than temperature

C4

set point for 4hours

Additional Possible Cause: Too

many hot goods loaded!!

C- No error code • N/A N/A

• Refrigerant leak

• Control board

defective

• Door not sealing

• Not enough defrosts

• Condenser dirty

• Sensor defective

1) Register “C4”

2) Compressor ON:20Minutes

3) Compressor OFF:5Minutes

4) Operate 2),3) th ree times

5) Operate Normal Mode

- 50 – 05/15 Rev. G 146526

Page 51

4-2) Refrigerator

status more than 60

Operate 2), 3) repeatedly until

status more than 60

1) Register “C2”

Operate 2), 3) repeatedly until

After defrost mode

sensor sensing is

Sensor sensing is

more than 18°F higher

than temperature set

point for 4 hours and

3) repeatedly until

Sensor Sensing is

Error

Code

C1

C2

Condition Possible Cause When er ror occ urring

During normal mods, Tsensor sensing lasts “Lo"

minutes

During normal mode T-

sensor sensing lasts "Hi"

minutes

• T-Sensor defective

• Lead defective

• Sensor housing defective (due

to other substance)

• Sensor internal defective

1) Register "C1"

2) Compressor ON : 15 Minutes

3) Compressor OFF: 5 Minutes

4)

the error is clear

5) Operate Normal Mode

6) Defrost cycle is operated by Dsensor

2) Compressor OFF: 22 Minutes

3) Compressor ON : 15 Minutes

4)

the error is clear

5) Operate Normal Mode

C3

elapsed for 30 minutes.

Dlower than 32°F

T-

C4

more

D-

C5

over 140°F or under -

55.4°F for 1 minute

• Not enough defrosts

• Too many hot goods loaded

• Refrigerant leak

• Control board defective

• Door not sealing

• Not enough defrosts

• Condenser dirty

• Sensor defective

• D-Sensor defective

• Lead defective

- 51 – 05/15 Rev. G 146526

6) Defrost cycle is operated by Dsensor

”

1) Register "C3

2) Error check

3) Main power reset

1) Register “C4”

2) Compressor OFF: 15 Minutes

3) Compressor ON : 5 Minutes

4) Operate 2),

the error is clear

5) Operate Normal Mode

6) Defrost cycle is operated by Dsensor

1) Register "C5”

2) Defrost end is operated by time

(30 Minutes)

Page 52

2. OPERATION FOR GR26H, GR48S, GR70H MODELS

TEMP. CONTROLLER

OFF

1

2

3

46

5

7

ON

OFF

LAMP S/W Only

TEMP. CONTROLLER

OFF

1

2

3

46

5

7

ON

OFF

LAMP S/W Only

1) BASIC OPERATION

① Plug in the power cord and turn on the lamp switch located on the left of the temperature controller.

[ The unit should be plugged into a 115V±10%, 60Hz]

② The controller(Thermostat) has been preset "3" position at the factory

2) DEFROST

① This unit uses an off cycle defrost. No needs any programming.

3) CONTROL TEMPERATURE

① The temperature controller is mounted on top of the cabinet interior.

② The controller has been preset "3" position at the factory to maintain the average

cabinet temperature of 38℉ (3℃)

4) LAMP

① The light comes on when the lamp switch is on.

- 52 – 05/15 Rev. G 146526

Page 53

3. INSTRUCTION FOR RE-HINGING DOOR (F23/R23)

1

2

3

4

5

7

6

*

8

4

1

180˚

*

*

9

10

4

*

7

2

8

Re

Re--

hinging

hinging

Top Grille

Top Grille

Bottom Grille

Bottom Grille

Figure 2.

Figure 2.

Figure 1.

Figure 1.

Figure 3.

Figure 3.

Figure 4.

Figure 4.

Turn the hinge in

Turn the hinge in

A counterclockwise

A counterclockwise

direction

direction

CABINET

CABINET

DOOR

DOOR

1

2

3

4

5

7

6

*

8

4

1

180˚

*

*

9

10

4

*

7

2

8

Re

Re--

hinging

hinging

Top Grille

Top Grille

Bottom Grille

Bottom Grille

Figure 2.

Figure 2.

Figure 1.

Figure 1.

Figure 3.

Figure 3.

Figure 4.

Figure 4.

Turn the hinge in

Turn the hinge in

A counterclockwise

A counterclockwise

direction

direction

CABINET

CABINET

DOOR

DOOR

▣ To change the door mounting from right hand to left hand hinges you will need the following;

▣ Medium to large size Phillips Screwdriver

146413 Door Hinge Kit - Lower Left

146442 Door Hinge Kit - Top Left

- 53 – 05/15 Rev. G 146526

Page 54

STEP1. Remove the door (Figure 1)

a) Remove the Top Grille (seven screws)

b) Remove the Lower Grille (four screws)

c) Remove the Top Hinge (#1) (four screws)

d) Lift and remove the Door

e) Remove the Bottom Hinge (#7) (four screws)

STEP2. Convert the Door

a) Replace the Spring Guide (#4) with Bushing (#9)-(SEE 146413 HINGE KIT)

b) Replace the Bushing (#5) with the Spring Guide (#4).

STEP3. Reinstall the Door (figure 2)

a) Install Bottom Left Hinge (#1) with Bushing (#10)-(SEE 146413 HINGE KIT)

b) Set Door in place on Bottom Hinge

c) Insert Spring (#8) (silver) into Spring Guide (#4) as shown in figure 3-(SEE 146442 HINGE KIT)

d) Install the Top Hinge (#7) as shown in figure 4-(SEE 146442 HINGE KIT)

(confirm that spring ends are engaged in the spring guide and hinge)

e) Replace the Top and Lower Grilles

Note:

The silver colored spring (#8) is for left hand hinged door and the yellow color spring (#3)

is for right hand hinged doors.

The letter "L" is marked on the left hand bushings (#9 and #10)

- 54 – 05/15 Rev. G 146526

Page 55

C. SERVICE LIST AND EXPLODED VIEW

1. COMMERCIAL FREEZERS AND REFRIGERATORS - - - - - - - - - - C2

1) F23/F49/F72-S, R23/R49/R72-S SERVICE LIST & EXPLODED VIEW

2) F23/F49/F72-SH, R23/R49/R72-SH SERVICE LIST & EXPLODED VIEW

3) R23/R49/R72-G SERVICE LIST & EXPLODED VIEW

2. MERCHANDISERS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C23

1) GR26H, GR48S, GR70H SERVICE LIST & EXPLODED VI EW

- 55 – 05/15 Rev. G 146526

Page 56

1. COMMERCIAL FREEZERS AND REFRIGERATORS

Control PCB Assembly (115V)

Used thru 12/2014

Control PCB Assembly (115V)

Universal (℉/℃) PCB

Temperature Sensor

use up to 12/2011

Sensor Kit (Includes

T-sensor and D-sensor)

Front PCB Assembly

Used thru 12/2014

Front PCB Assembly

Universal (℉/℃) PCB

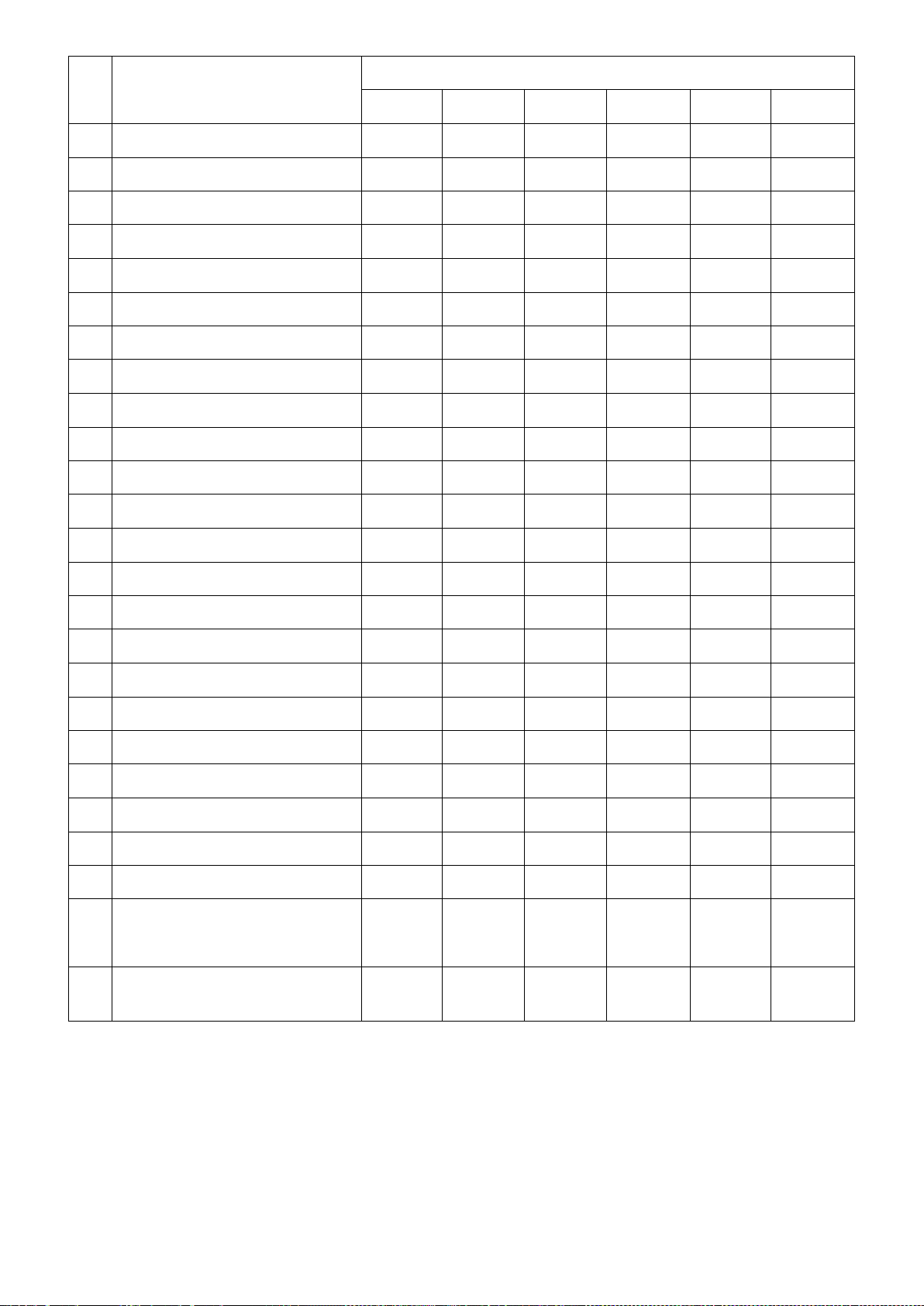

1-1. SERVICE LIST (F23/F49/F72-S , R23/R49/R72-S)

No. PART NAME

F23-S

F49-S F72-S R23-S R49-S R72-S

PART No.

1

Door Hinge Kit - Top Right 146441 146441 146441 146441 146441 146441

2 Door Hinge Kit - Top Left NA 146442 146442 NA 146442 146442

3 Door Hinge Kit - Lower Right 146412 146412 146412 146412 146412 146412

4

5

Door Hinge Kit - Lo wer Lef t NA 146413 146413 NA 146413 146413

Door Hinge Kit - Lower Center NA NA 146414 NA NA 146414

146416 146417 146418 150313 150313 150313

6

150539 150540 150541 150538 150538 150538

7 Main Transformer (115V) 146420 146420 146420 146420 146420 146420

8

9

10

11

11-1

DC Relay 146421 146421

Relay Wire Harness 146423 146423 146423 146423 146423 146423

Front PCB Wire Harness 146424 146424 146424 146424 146424 146424

146426 146428 146430 146426 146428 146430

146422

146421 146421 146421

146425 146427 146429

12

Pilaster 146411 146411 146411 146411 146411 146411

13 Shelf Clip 146489 146489 146489 146489 146489 146489

14 Door Assembly - Right Hand 146436 146437 146439 146436 146437 146439

15

16

Door Assembly - Left Hand NA 146438 146440 NA 146438 146440

Door Gasket 146444 146444 146445 146444 146444 146445

17 Lamp (115V) 146408 146408 146408 146408 146408 146408

18 Lamp Socket 146409 146409 146409 146409 146409 146409

19

20

Top Grille Assembly (115V) 146433 146434 146435 146433 146434 146435

Lamp Cover 146410 146410 146410 146410 146410 146410

21 Top Grill Cover - Right 146431 146431 146431 146431 146431 146431

146419 146419 146419 146419 146419 146419

22

150537 150537 150537 150537 150537 150537

23

Control Decal 146432 146432 146432 146432 146432 146432

- 56 – 05/15 Rev. G 146526

Page 57

No. PART NAME

146518

146518

F23-S

PART No.

F49-S F72-S R23-S R49-S R72-S

24

Light Switch 146449 146449 146449 146449 146449 146449

25 Door Lock& Key 146443 146443 146443 146443 146443 146443

26 Power Switch 146450 146450 146450 146450 146450 146450

27

28

Condensate Pan w/paper 146386 146387 146387 146386 146387 146387

Lower Grille Assembly 146388 146389 146390 146388 146389 146390

29 Caster Kit 100436 100436 100437 100436 100436 100437

30 Power Cor d 138533 138533 138657 138533 138533 138533

31

32

Evaporator Coil 146392 146394 146396 146391 146393 146395

Defrost Limit Switch 146404 146404 146404 NA NA NA

33 Defrost Heater (115V) 146397 146398 146399 NA NA NA

34 Drain Heater (115V) 146403 146403 146403 NA NA NA

35

36

Drain Pan Heater (115V) 146400 146401 146402 NA NA NA

Evaporator Fan Guard 146405 146405 146405 146405 146405 146405

37 Evaporator Fan Blade 146406 146406 146406 146406 146406 146406

38 Evaporator Fan Motor (115V) 146407 146407 146407 146407 146407 146407

39

40

Condenser Coil 146373 146375 146375 146372 146374 146375

Condenser Fan Blade 146371 146371 146371 146371 146371 146371

41 Condenser Fan Motor (115V) 146370 146370 146370 146370 146370 146370

42 Suction pipe(B) Assembly 150558 146379 146381 146376 146378 146380

43

44

Capillary Tube 146383 NA NA 146382 NA NA

Dryer 146384 146384 146385 146384 146384 146385

45 Compressor (115V) 150556 146507 146509 150311 150311 146508

46 Compressor Electrical Kit 150557 146512 146514 150312 150312 146513

146446

47 Shelf 146446 146447

48 Shelf Kit(1Shelf + 4 Clips) 146516 146517

146448 146448

146516

146446 146447

146516 146517

* Shelf: F(R) 72 - 146446 (ENDS), 146448 (CENTER)

146446

146516

* Shelf Kit: F(R) 72 - 146516 (ENDS), 146518 (CENTER)

- 57 – 05/15 Rev. G 146526

Page 58

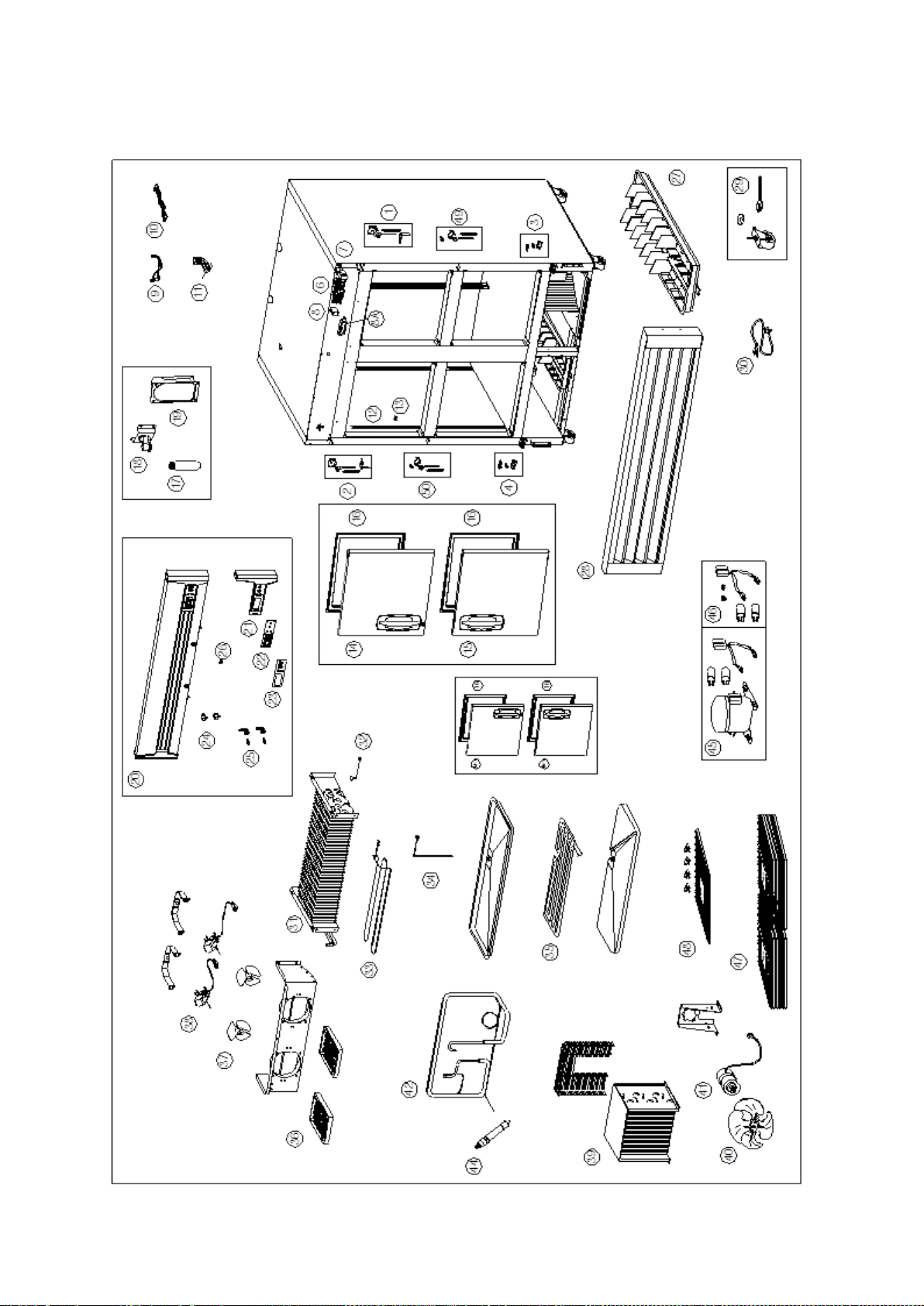

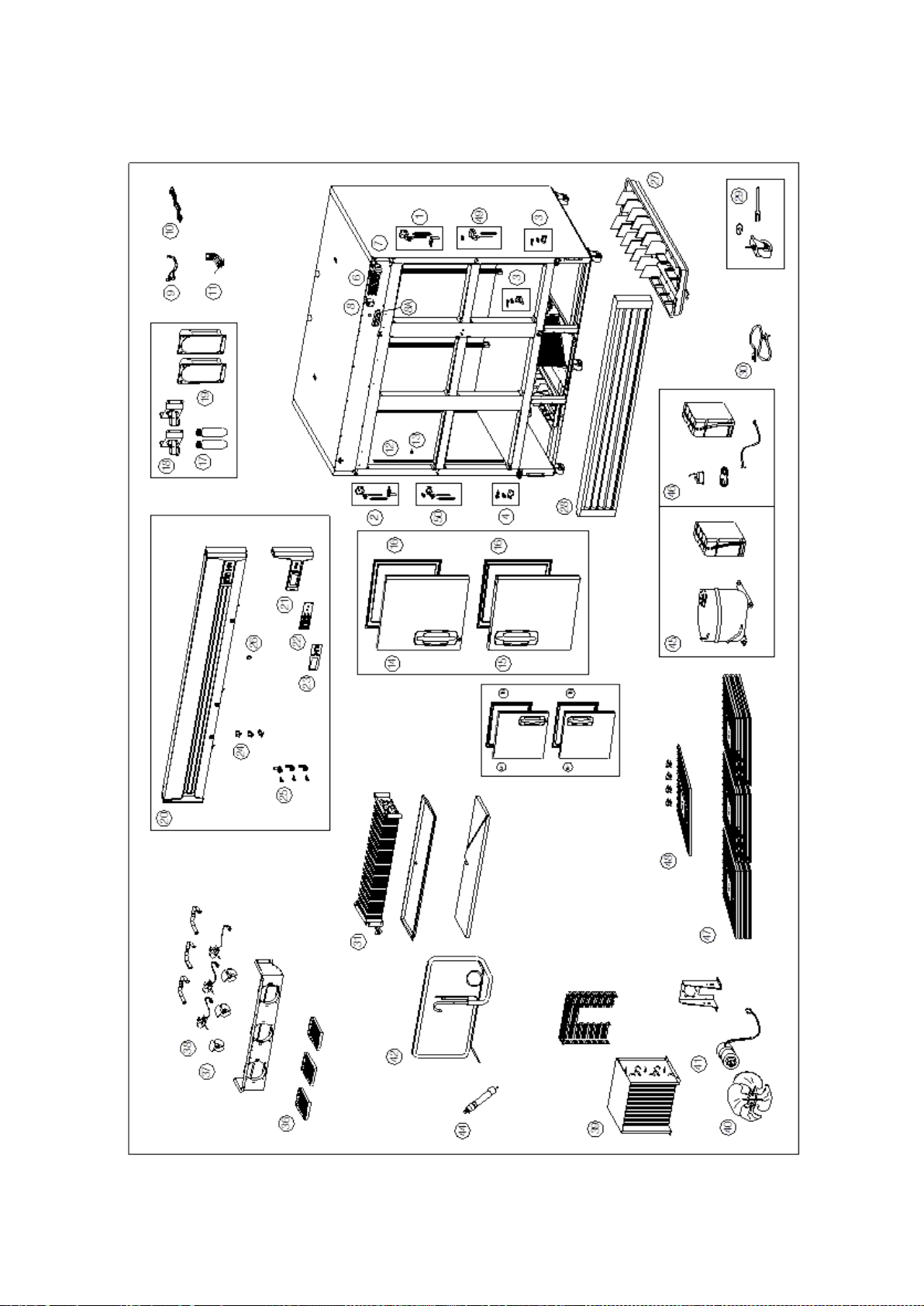

1-2. F23-S EXPLODED VIEW

- 58 – 05/15 Rev. G 146526

Page 59

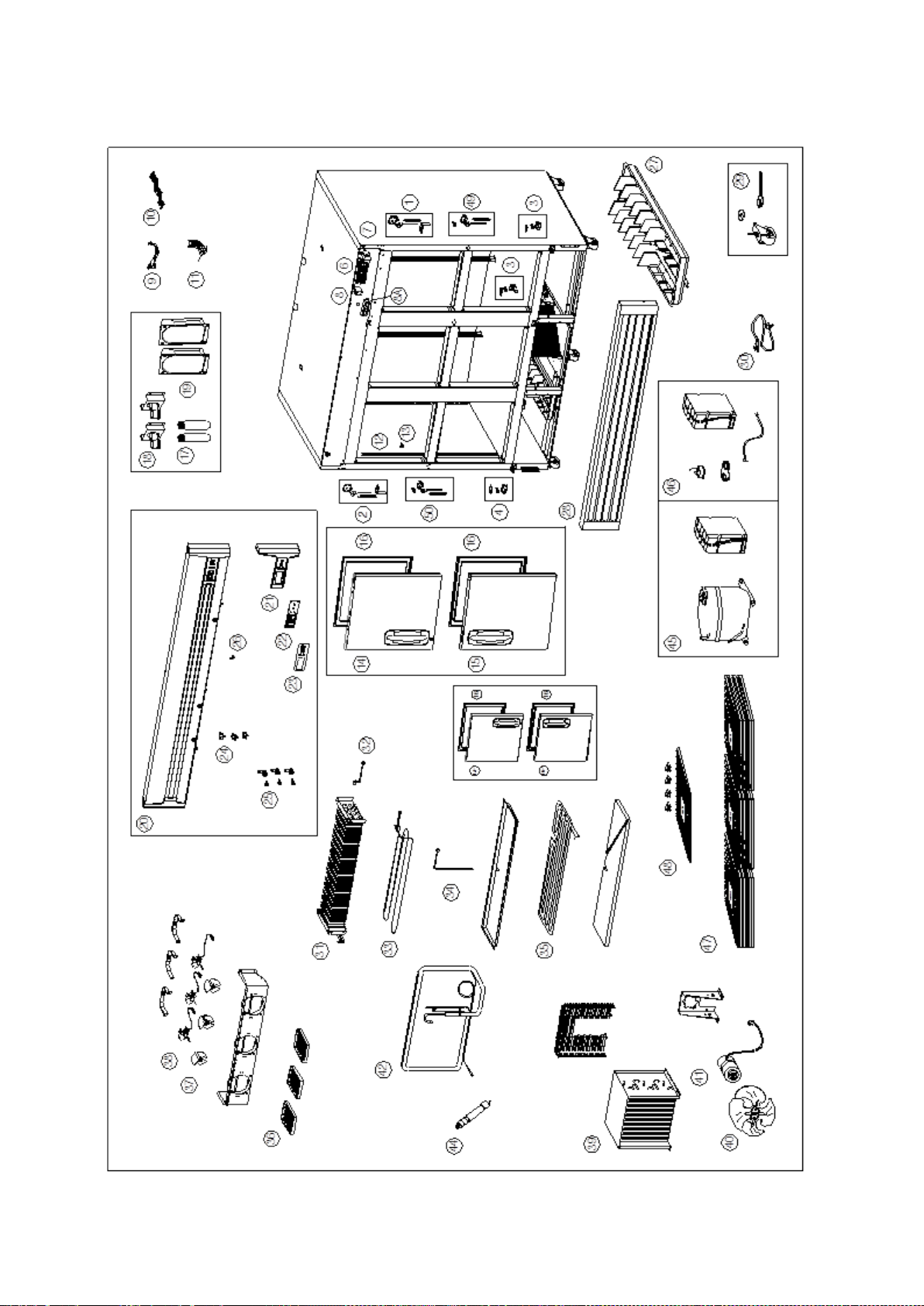

1-3. F49-S EXPLODED VIEW

- 59 – 05/15 Rev. G 146526

Page 60

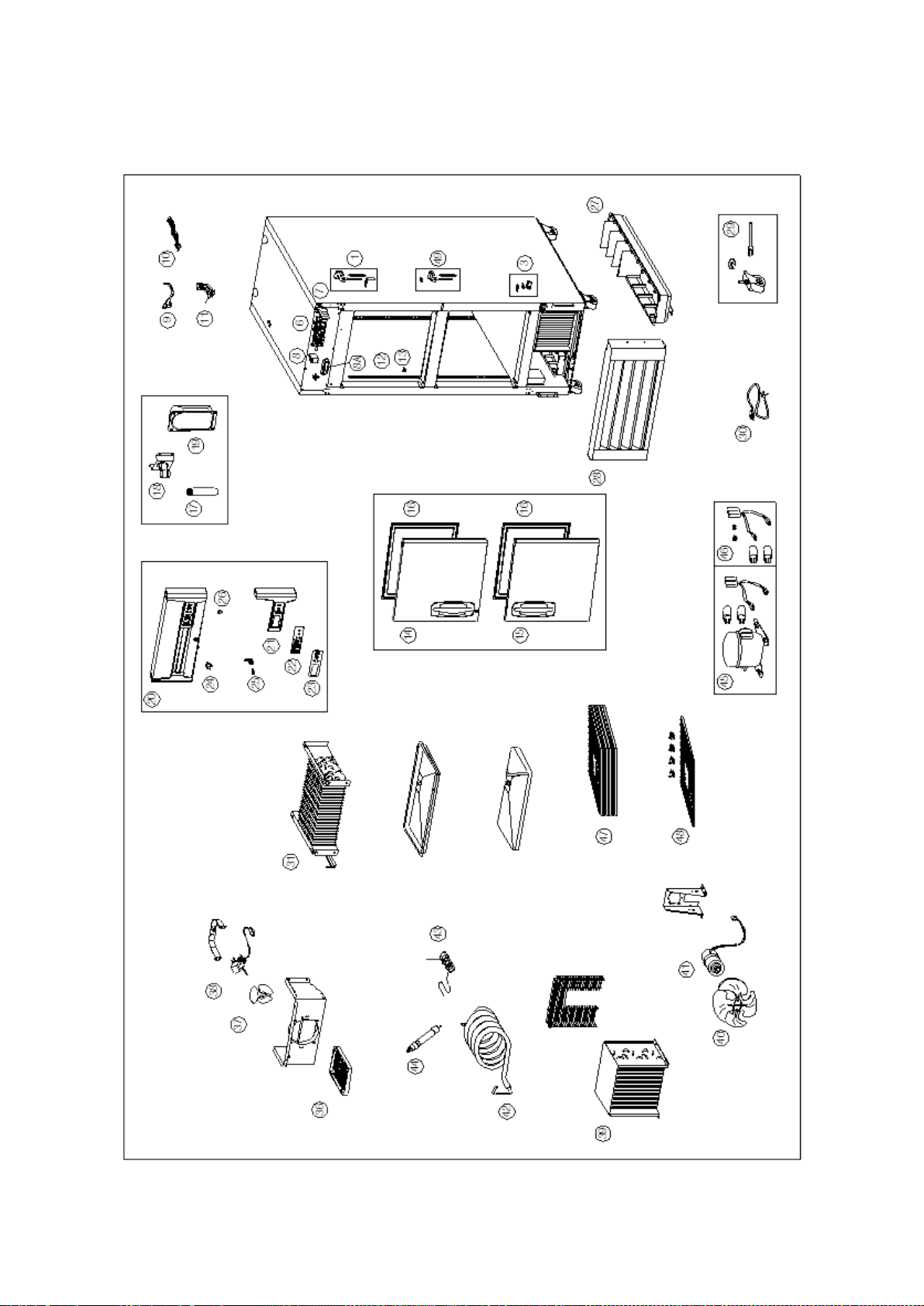

1-4. F72-S EXPLODED VIEW

- 60 – 05/15 Rev. G 146526

Page 61

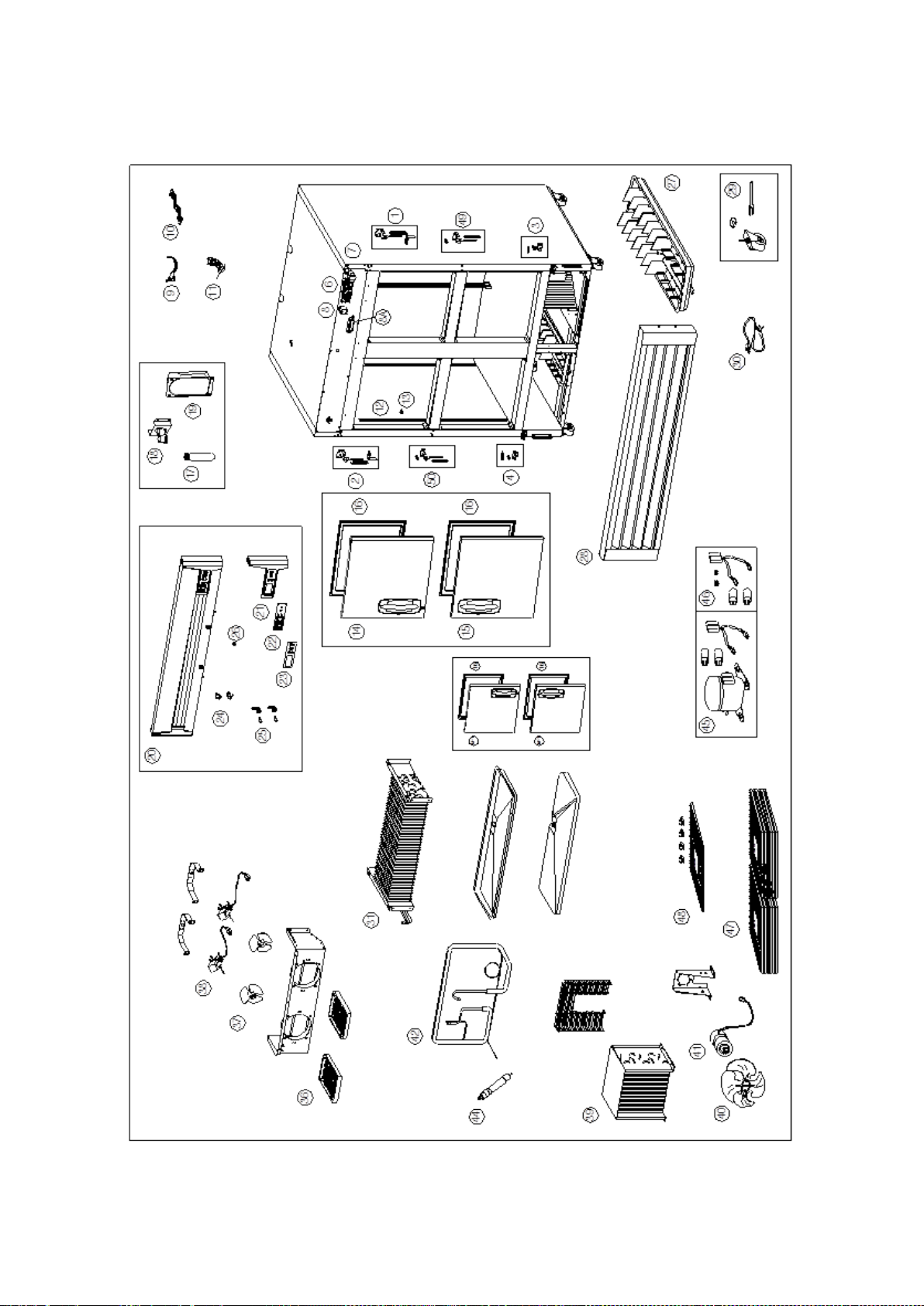

1-5. R23-S EXPLODED VIEW

- 61 – 05/15 Rev. G 146526

Page 62

1-6. R49-S EXPLODED VIEW

- 62 – 05/15 Rev. G 146526

Page 63

1-7. R72-S EXPLODED VIEW

- 63 – 05/15 Rev. G 146526

Page 64

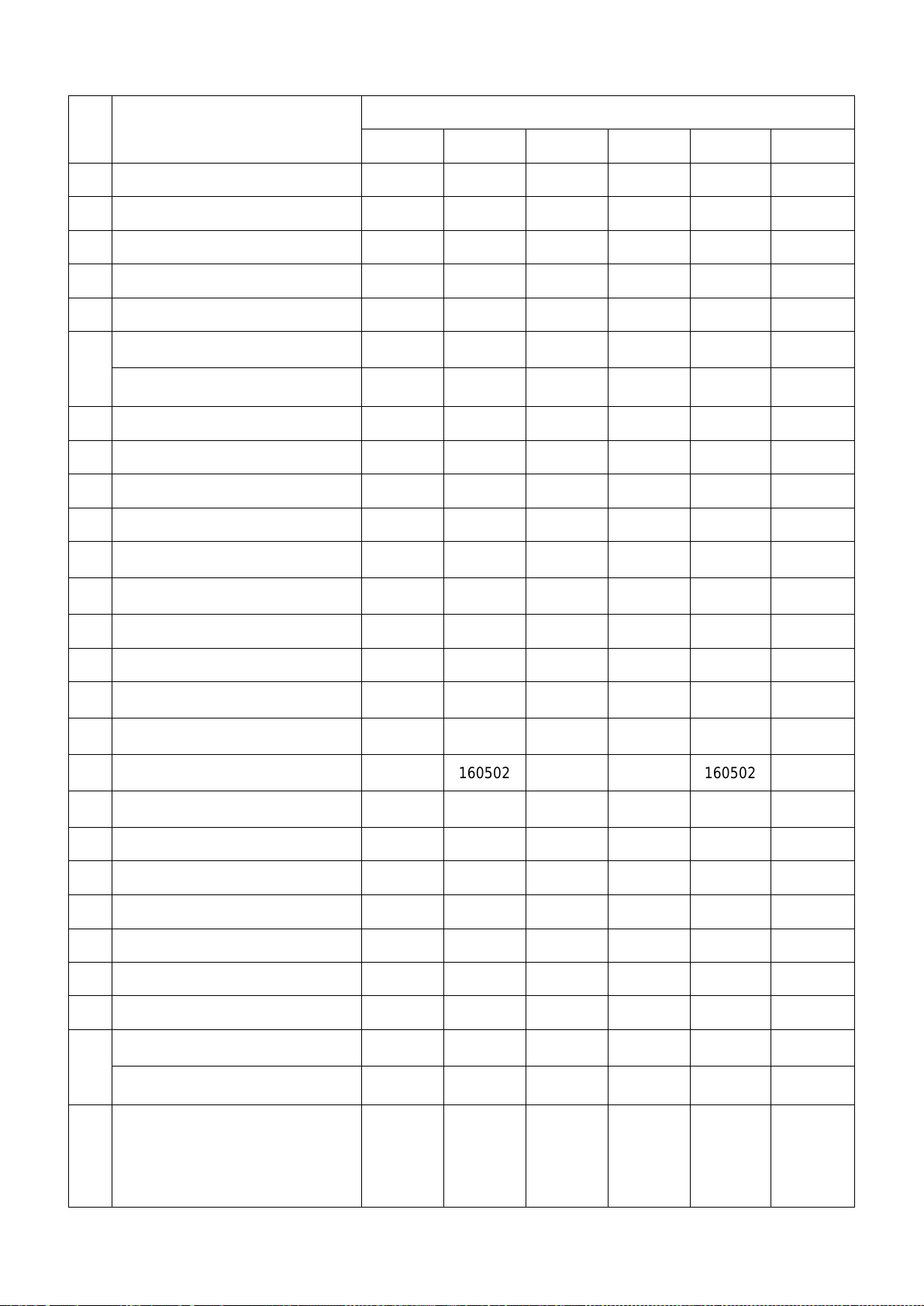

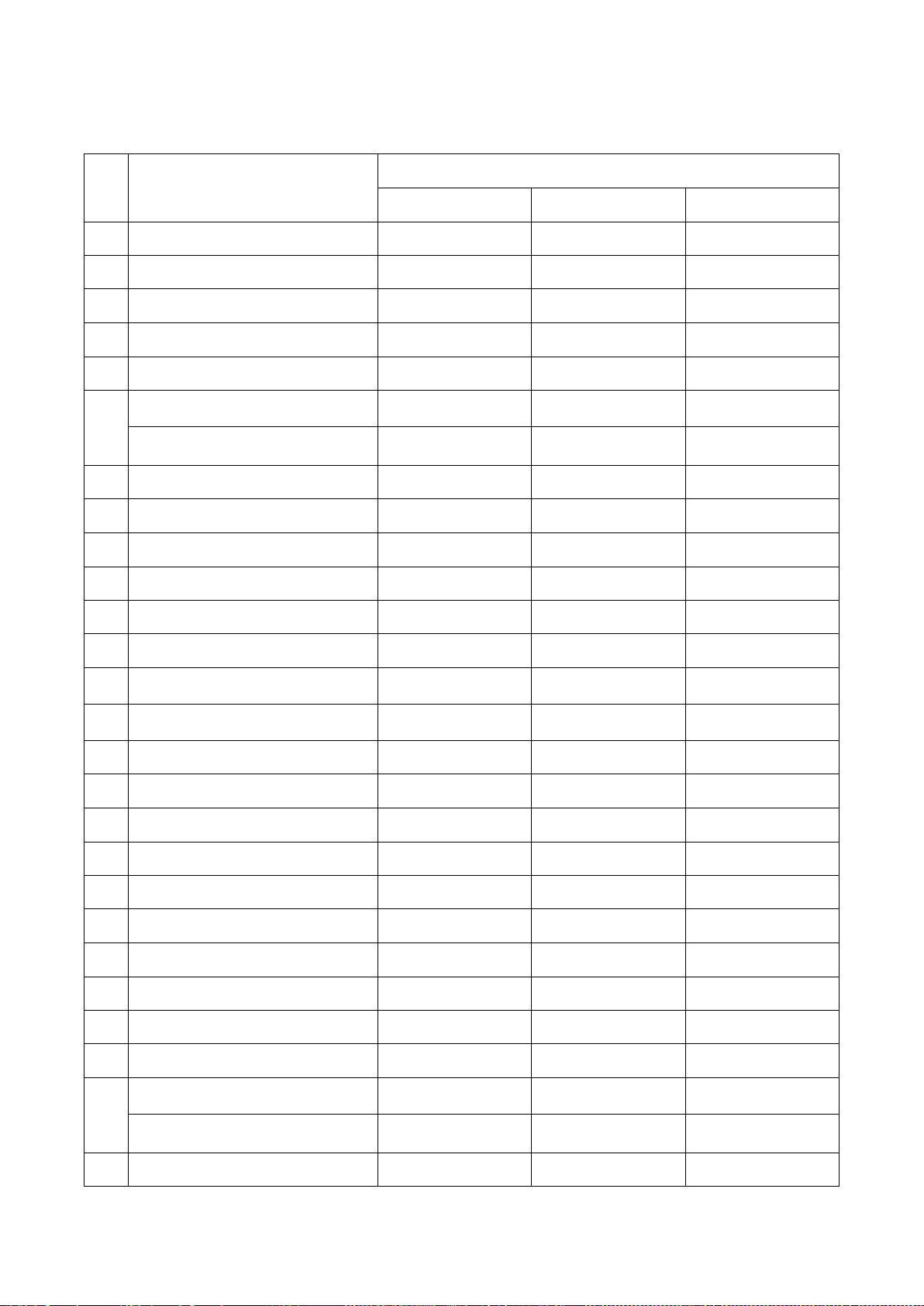

2-1. SERVICE LIST( F23/F49/F72-SH , R23/R49/R72-SH)

Control PCB Assembly (115V)

Used thru 12/2014

Control PCB Assembly (115V)

Universal (℉/℃) PCB

Temperature Sensor

use up to 12/2011

Sensor Kit (Includes

T-sensor and D-sensor)

Door Assembly - Upper Right

Hand

Door Assembly - Upper Left

Hand

Door Assembly – Lower Right

Hand

Door Assembly – Lower Left

Hand

Front PCB Assembly

Usedthru 12/2014

Front PCB Assembly

Universal (℉/℃) PCB

No. PART NAME

F23-SH F49-SH F72-SH R23-SH R49-SH R72-SH

PART No.

1

2

Door Hinge Kit - Top Right 146441 146441 146441 146441 146441 146441

Door Hinge Kit - Top Left NA 146442 146442 NA 146442 146442

3 Door Hinge Kit - Lower Right 146412 146412 146412 146412 146412 146412

4 Door Hinge Kit - Lower Left NA 146413 146413 NA 146413 146413

5

Door Hinge Kit - Lower Center NA NA 146414 NA NA 146414

146416 146417 146418 150313 150313 150313

6

150539 150540 150541 150538 150538 150538

7 Main Transformer (115V) 146420 146420 146420 146420 146420 146420

8 DC Relay 146421 146421

9

10

11

11-1

Relay Wire Harness 146423 146423 146423 146423 146423 146423

Front PCB Wire Harness 146424 146424 146424 146424 146424 146424

NA NA NA 146425 146427 146429

146426 146428 146430 146426 146428 146430

146422

146421 146421 146421

12

13

14

14-1

15

15-1

16

17

18

Pilaster 146411 146411 146411 146411 146411 146411

Shelf Clip 146489 146489 146489 146489 146489 146489

160501 160505 160510 160501 160505 160510

NA 160507 160512 NA 160507 160512

160502 160502 160511 160502 160502 160511

NA 160508 160513 NA 160508 160513

Door Gasket 160503 160503 160514 160503 160503 160514

Lamp (115V) 146408 146408 146408 146408 146408 146408

Lamp Socket 146409 146409 146409 146409 146409 146409

19 Lamp Cover 146410 146410 146410 146410 146410 146410

20

21

Top Grille Assembly (115V) 146433 146434 146435 146433 146434 146435

Top Grill Cover - Right 146431 146431 146431 146431 146431 146431

146419 146419 146419 146419 146419 146419

22

150537 150537 150537 150537 150537 150537

23 Control Decal 146432 146432 146432 146432 146432 146432

- 64 – 05/15 Rev. G 146526

Page 65

No. PART NAME

146448

146448

F23-S

PART No.

F49-S F72-S R23-S R49-S R72-S

24

Light Switch 146449 146449 146449 146449 146449 146449

25 Door Lock& Key 146443 146443 146443 146443 146443 146443

26 Power Switch 146450 146450 146450 146450 146450 146450

27

28

Condensate Pan w/paper 146386 146387 146387 146386 146387 146387

Lower Grille Assembly 146388 146389 146390 146388 146389 146390

29 Caster Kit 100436 100436 100437 100436 100436 100437

30 Power Cor d 138533 138533 138657 138533 138533 138533

31

32

Evaporator Coil 146392 146394 146396 146391 146393 146395

Defrost Limit Switch 146404 146404 146404 NA NA NA

33 Defrost Heater (115V) 146397 146398 146399 NA NA NA

34 Drain Heater (115V) 146403 146403 146403 NA NA NA

35

36

Drain Pan Heater (115V) 146400 146401 146402 NA NA NA

Evaporator Fan Guard 146405 146405 146405 146405 146405 146405

37 Evaporator Fan Blade 146406 146406 146406 146406 146406 146406

38 Evaporator Fan Motor (115V) 146407 146407 146407 146407 146407 146407

39

40

Condenser Coil 146373 146375 146375 146372 146374 146375

Condenser Fan Blade 146371 146371 146371 146371 146371 146371

41 Condenser Fan Motor (115V) 146370 146370 146370 146370 146370 146370

42 Suction pipe(B) Assembly 150558 146379 146381 146376 146378 146380

43

44

Capillary Tube 146383 NA NA 146382 NA NA

Dryer 146384 146384 146385 146384 146384 146385

45 Compressor (115V) 150556 146507 146509 150311 150311 146508

46 Compressor Electrical Kit 150557 146512 146514 150312 150312 146513

47

48

49

50

Shelf 146446 146447

Shelf Kit(1Shelf + 4 Clips) 146516 146517

Door Hinge Kit - Center Right 160504 160504 160504 160504 160504 160504

Door Hinge Kit - Center Left NA 160509 160509 NA 160509 160509

146446

146516

146518

146446 146447

146516 146517

146446

146516

146518

* Shelf: F(R) 72 - 146446 (ENDS), 146448 (CENTER)

* Shelf Kit: F(R) 72 - 146516 (ENDS), 146518 (CENTER)

- 65 – 05/15 Rev. G 146526

Page 66

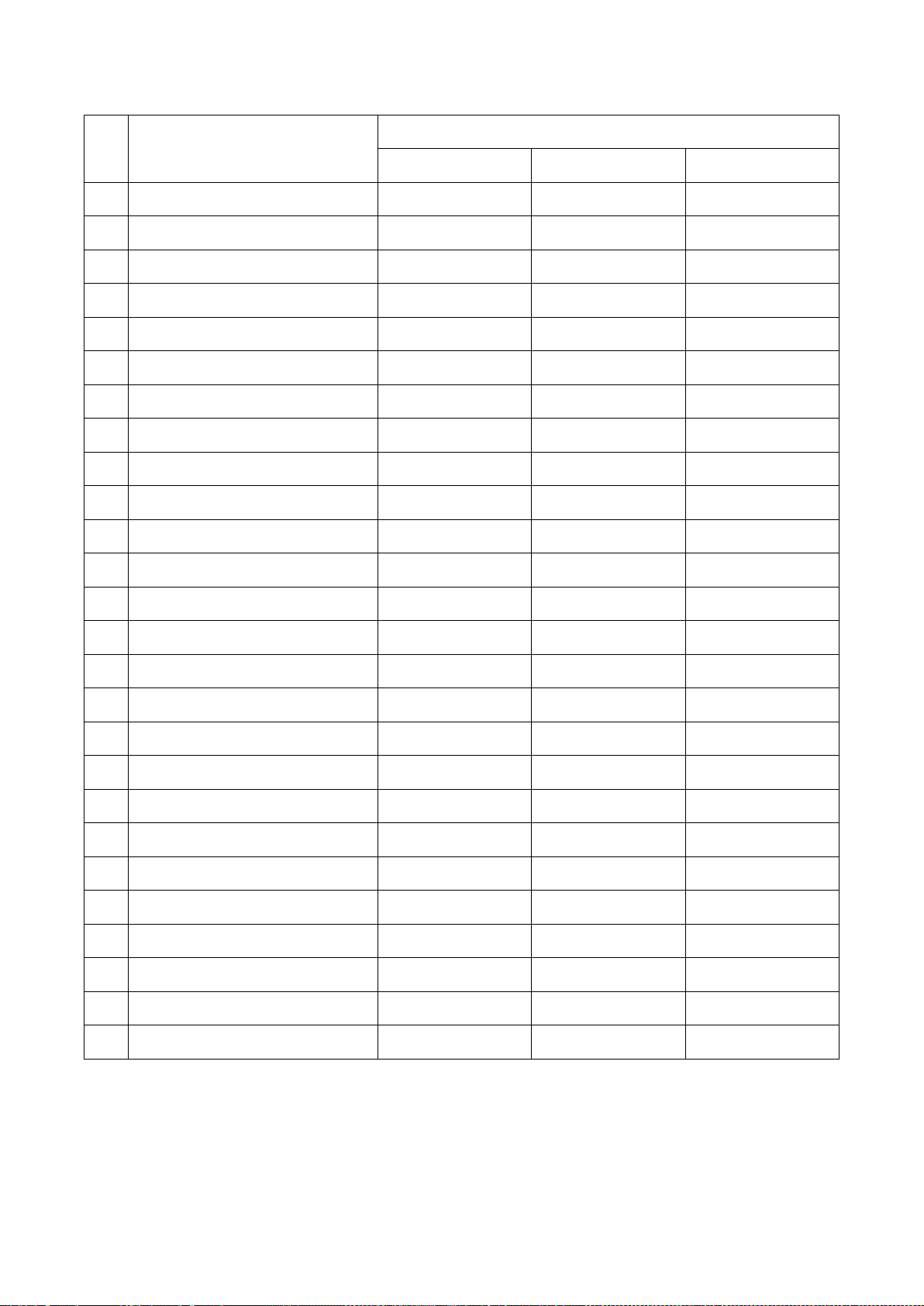

2-2. F23-SH EXPLODED VIEW

- 66 – 05/15 Rev. G 146526

Page 67

2-3. F49-SH EXPLODED VIEW

- 67 – 05/15 Rev. G 146526

Page 68

2-4. F72-SH EXPLODED VIEW

- 68 – 05/15 Rev. G 146526

Page 69

2-5. R23-SH EXPLODED VIEW

- 69 – 05/15 Rev. G 146526

Page 70

2-6. R49-SH EXPLODED VIEW

- 70 – 05/15 Rev. G 146526

Page 71

2-7. R72-SH EXPLODED VIEW

- 71 – 05/15 Rev. G 146526

Page 72

Control PCB Assembly (115V)

Used thru 12/2014

Control PCB Assembly (115V)

Universal (℉/℃) PCB

Temperature Sensor

use up to 12/2011

Sensor Kit (Includes

T-sensor and D-sensor)

Front PCB Assembly

Used thru 12/2014

Front PCB Assembly

Universal (℉/℃) PCB

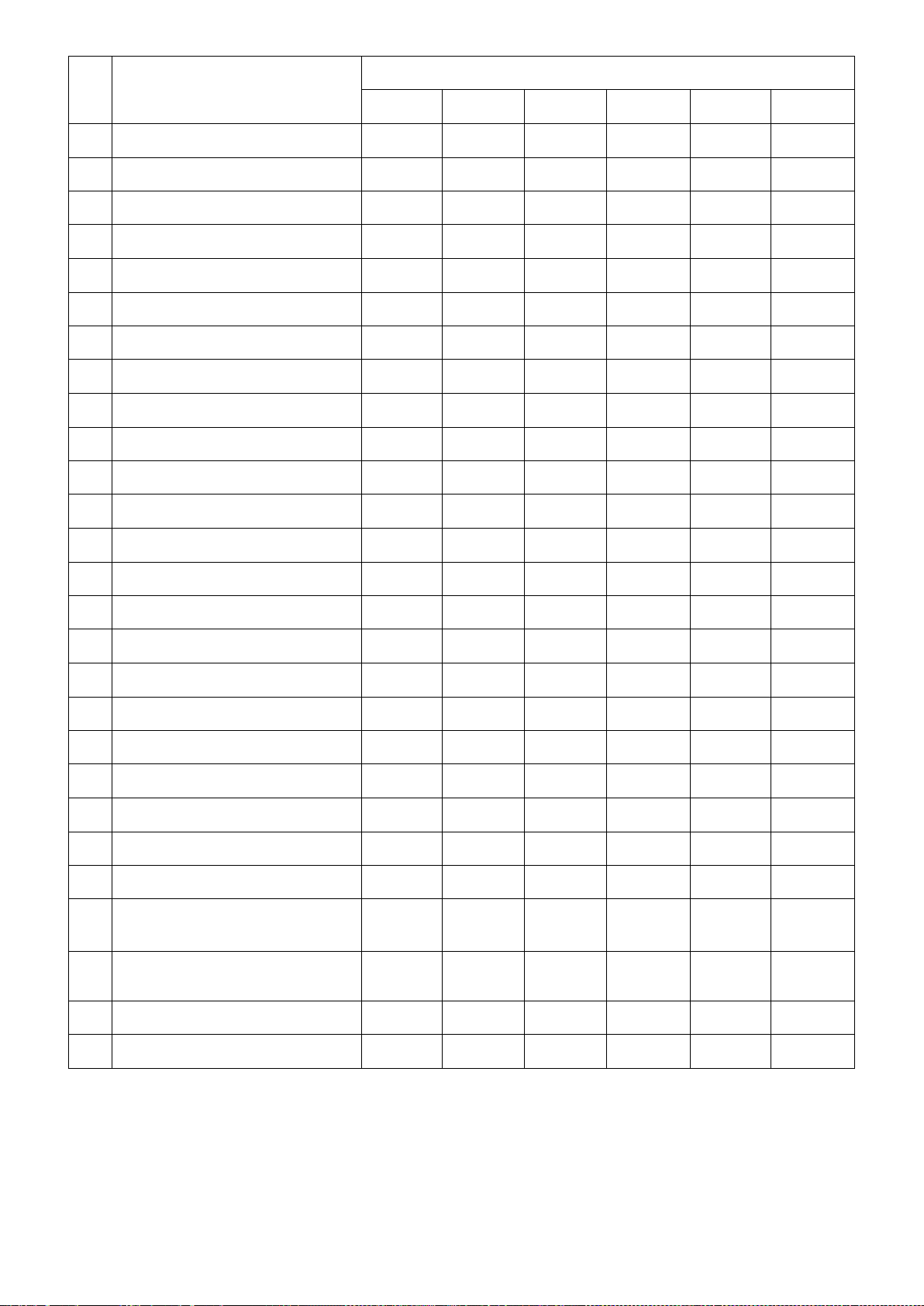

3-1. SERVICE LIST (R23/R49/R72-G)

No. PART NAME

PART No.

R23-G R49-G R72-G

1

Door Hinge Kit - Top Right 160515 160515 160515

2 Door Hinge Kit - Top Left NA 160516 160516

3 Door Hinge Kit - Lower Right 160517 160517 160517

4

5

Door Hinge Kit - Lo wer Lef t NA 160518 160518

Door Hinge Kit - Lower Center NA NA 160519

150313 150313 150313

6

150538 150538 150538

7 Main Transformer (115V) 146420 146420 146420

8

8A

DC Relay 146421 146421 146421

LED DRIVER 160530 160530 150571

9 Relay Wire Harness 146423 146423 146423

10 Front PCB Wire Harness 146424 146424 146424

10A

11

LED Wire Harness 160529 160533 160535

146425 146427 146429

11-1

12

13

14

Pilaster 146411 146411 146411

Shelf Clip 146489 146489 146489

Door Assembly - Right Hand 160520 160521 160522

146426 146428 146430

15 Door Assembly - Left Hand NA 160523 160524

16

17

18

Door Gasket 160525 160525 146482

LED (6W) 160526 160526 160526

LED Fixture 160527 160527 160527

19 LED wire cover 160528 160528 160528

20

21

Top Grille Assembly 160531 160534 160536

Top Grill Cover - Right 146431 146431 146431

146419 146419 146419

22

150537 150537 150537

23 Control Decal 146432 146432 146432

- 72 – 05/15 Rev. G 146526

Page 73

No. PART NAME

PART No.

R23-G R49-G R72-G

24

Light S/W Door Switch

146449 146449 146449

24A Light Switch 160532 160532 160532

25

26

Door Lock& Key 146443 146443 146443

Power S w it ch 146450 146450 146450

27 Condensate Pan w/paper 146386 146387 146387

28 Lower Grille Assembly 146388 146389 146390

29

30

Caster Kit 100436 100436 100437

Power Cord 138533 138533 138533

31 Evaporator Coil 146391 146393 146395

32 Defrost Limit Switch NA NA NA

33

34

Defrost Heater (115V) NA NA NA

Drain Heater (115V) NA NA NA

35 Drain Pan Heater (115V) NA NA NA

36 Evaporator Fan Guard 146405 146405 146405

37

38

Evaporator Fan Blade 146406 146406 146406

Evaporator Fan Motor (115V) 146407 146407 146407

39 Condenser Coil 146372 146374 146375

40 Condenser Fan Blade 146371 146371 146371

41

42

Condenser Fan Motor (115V) 146370 146370 146370

Suction pipe(B) Assembly 146376 146379 146381

43 Capillary Tube 146382 NA NA

44 Dryer 146384 146384 146385

45

46

Compressor (115V) 150311 150556 150556

Compressor Electrical Kit 150312 150557 150557

47 Shelf 146446 146447 146446 / 146448

48 Shelf Kit(1Shelf + 4 Clips) 146516 146517 146516 / 146518

* Shelf: F(R) 72 - 146446 (ENDS), 146448 (CENTER)

* Shelf Kit: F(R) 72 - 146516 (ENDS), 146518 (CENTER)

- 73 – 05/15 Rev. G 146526

Page 74

3-2. R23-G EXPLODED VIEW

- 74 – 05/15 Rev. G 146526

Page 75

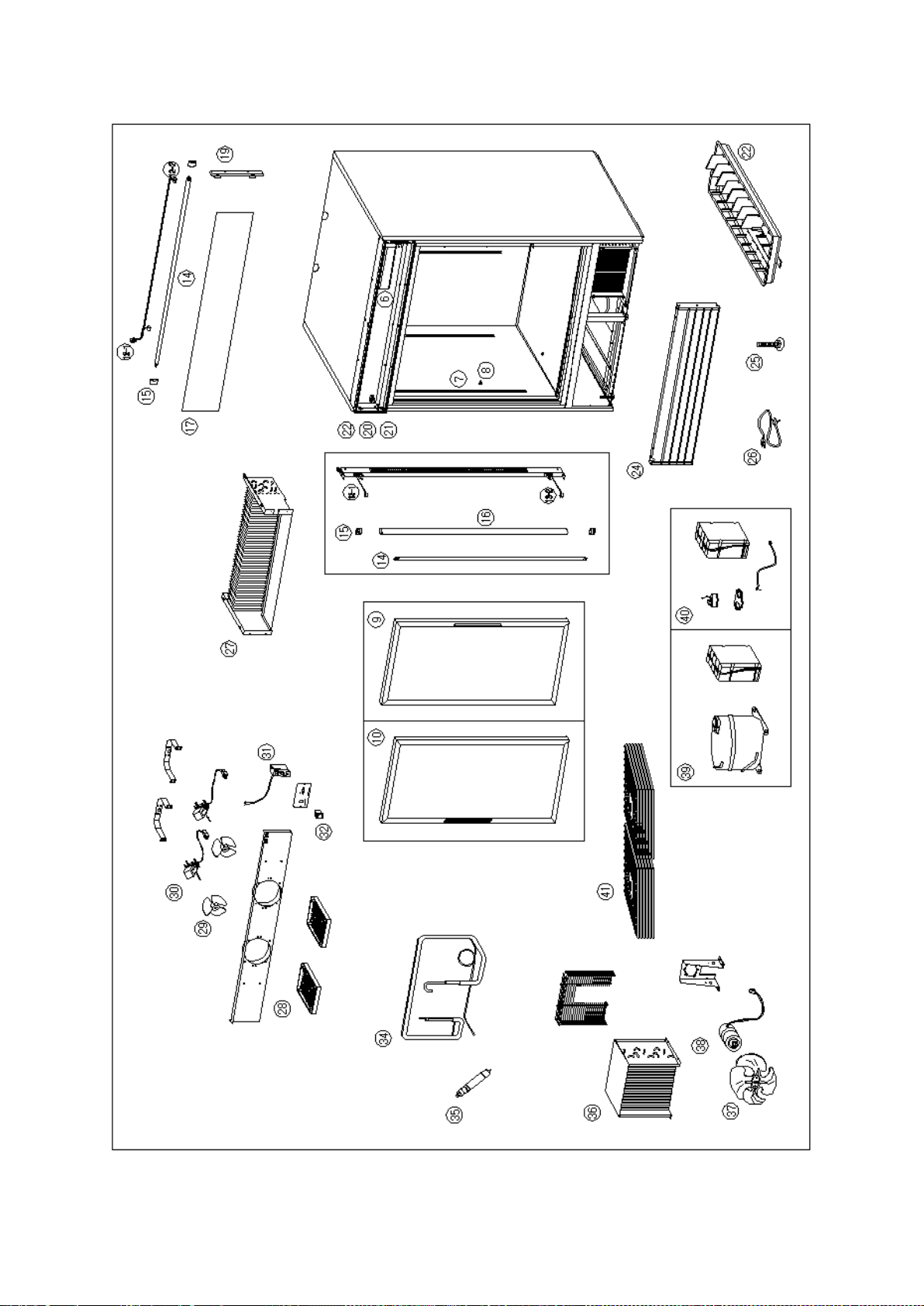

3-3. R49-G EXPLODED VIEW

- 75 – 05/15 Rev. G 146526

Page 76

3-4. R72-G EXPLODED VIEW

- 76 – 05/15 Rev. G 146526

Page 77

2. MERCHANDISERS

1-1. SERVICE LIST (GR26H, GR48S, GR70H)

PART No.

No. PART NAME

GR26H GR48S GR70H

1 Door Hinge Kit - Top Right 146481 NA 160515

2 Door Hinge Kit - Top Left NA NA 160516

3 Door Hinge Kit - Lower Right 146471 NA 160517

4 Door Hinge Kit - Lower Left NA NA 160518

5 Door Hinge Kit - Lower Center NA NA 160519

6 Ballast 146491 146491 146491

7 Pilaster 146470 146470 146470 / 146411

8 Shelf Clip 146489 146489 146489

9 Door Assembly - Right Hand 146478 146477 146476

10 Door Assembly - Left Hand NA 146480 146479

11 Door Gasket 146483 NA 146482

12-1

12-2

13-1

13-2

14 Lamp (115V) 146466 / 146467 146466 146466

15 Lamp Cover End 146468 146468 146468

16 Lamp Cover 146469 146469 146469

17 Advertising Panel - Blank 146495 146494 146493

18 Advertising Panel Frame 146497 NA NA

19 Advertising Panel Frame-Left NA 146505 146500

20 Advertising Panel Frame-Right NA 146506 146501

Advertising Panel Wire A 150190 150524 150546

Advertising Panel Wire B NA 150525 150547

Interior Light Wire A NA 150526 150548

Interior Light Wire B NA 150527 150549

21 Advertising Panel Frame-Bottom NA 146503 146498

22 Advertising Panel Frame-Top NA 146504 146499

23 Condensate Pan w/paper 146386 146460 146459

24 Lower Grille Assembly 146463 146462 146461

25 Foot Kit 146502 146502 146502

- 77 – 05/15 Rev. G 146526

Page 78

PART No.

No. PART NAME

GR26H GR48S GR70H

26 Power Cord 146475 146475 138533

27 Evaporator Coil 146465 146464 146395

28 Evaporator Fan Guard 146405 146405 146405

29 Evaporator Fan Blade 146406 146406 146406

30 Evaporator Fan Motor 146407 146407 146407

31 Temperature Control 146474 146473 146472

32 Light Switch 146450 146450 146450

33 Capillary Tube 146458 NA NA

34 Suction pipe(B) Assembly 146457 146456 146380

35 Dryer 146384 146384 146385

36 Condenser Coil 146372 146455 146375

37 Condenser Fan Blade 146371 146371 146371

38 Condenser Fan Moto 146370 146370 146370

39 Compressor 146452 146451 146451

40 Compressor Electrical Kit 146454 146453 146453

41 Shelf 146488 146486 / 146487 150507 / 150508

42 Shelf Kit(1Shelf + 4Clips) 146523 146521 / 146522 150509 / 150510

* Shelf: GR48S - 146486 (LE FT), 146487 (RIGHT)

GR70H - 150507 (ENDS), 150508 (CENTER)

* Shelf Kit: GR48S - 146521 (LEFT), 146522 (RIGHT)

GR70H - 150509 (ENDS), 140510 (CENTER)

- 78 – 05/15 Rev. G 146526

Page 79

1-2. GR26H EXPLODED VIEW

- 79 – 05/15 Rev. G 146526

Page 80

1-3. GR48S EXPLODED VIEW

- 80 – 05/15 Rev. G 146526

Page 81

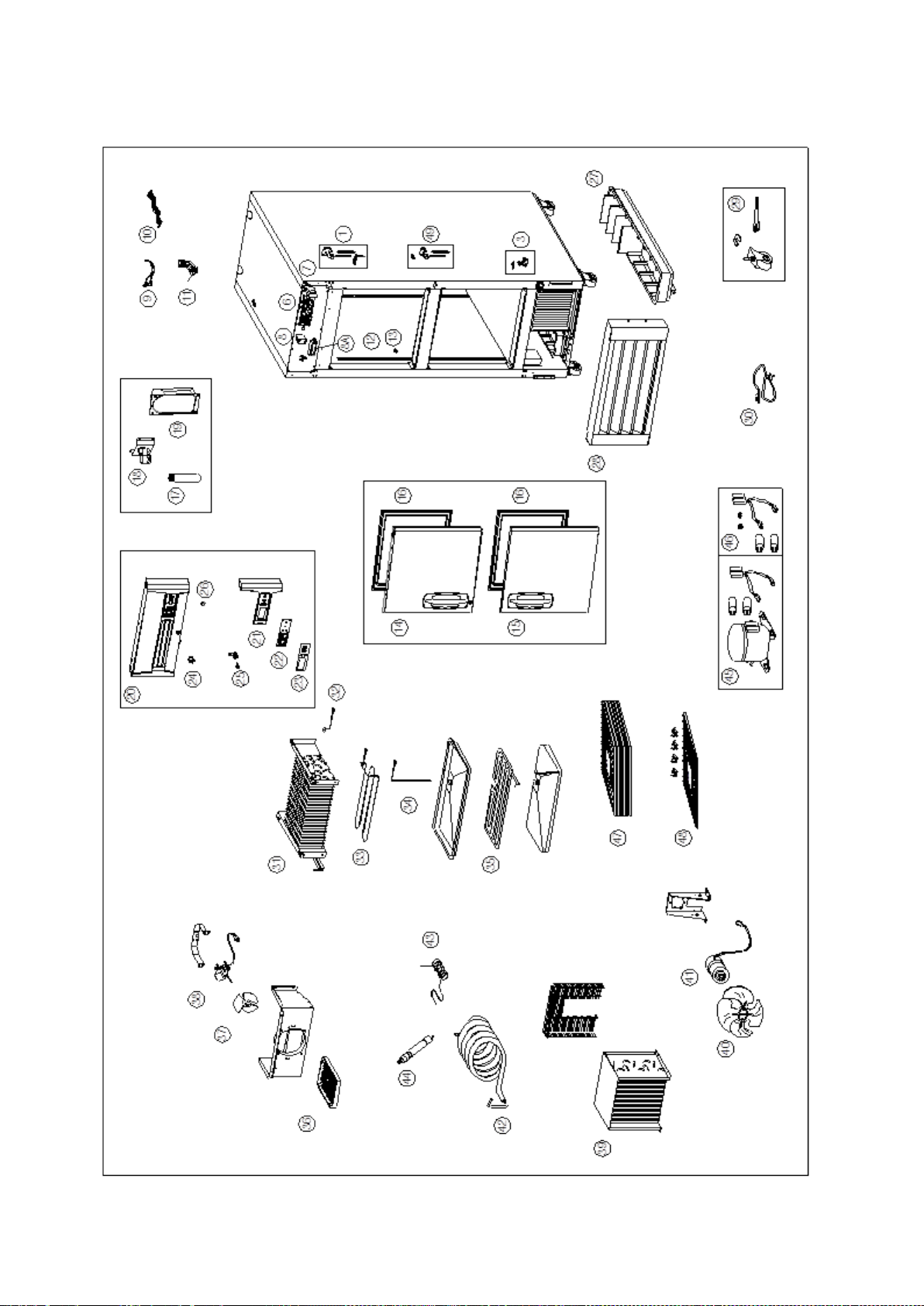

1-4. GR70H EXPLODED VIEW

- 81 – 05/15 Rev. G 146526

Page 82

D. COMPRESSOR & ACCESSORIES CHECK LIST

1. F23-S/SH, R49/R72-G - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D2

2. F49-S/SH - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D3

3. F72-S/SH - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D4

4. R23/R49-S/SH, R23-G - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D5

5. R72-S/SH - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D6

6. GR26H - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D7

7. GR48S/GR70H - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D8

- 82 – 05/15 Rev. G 146526

Page 83

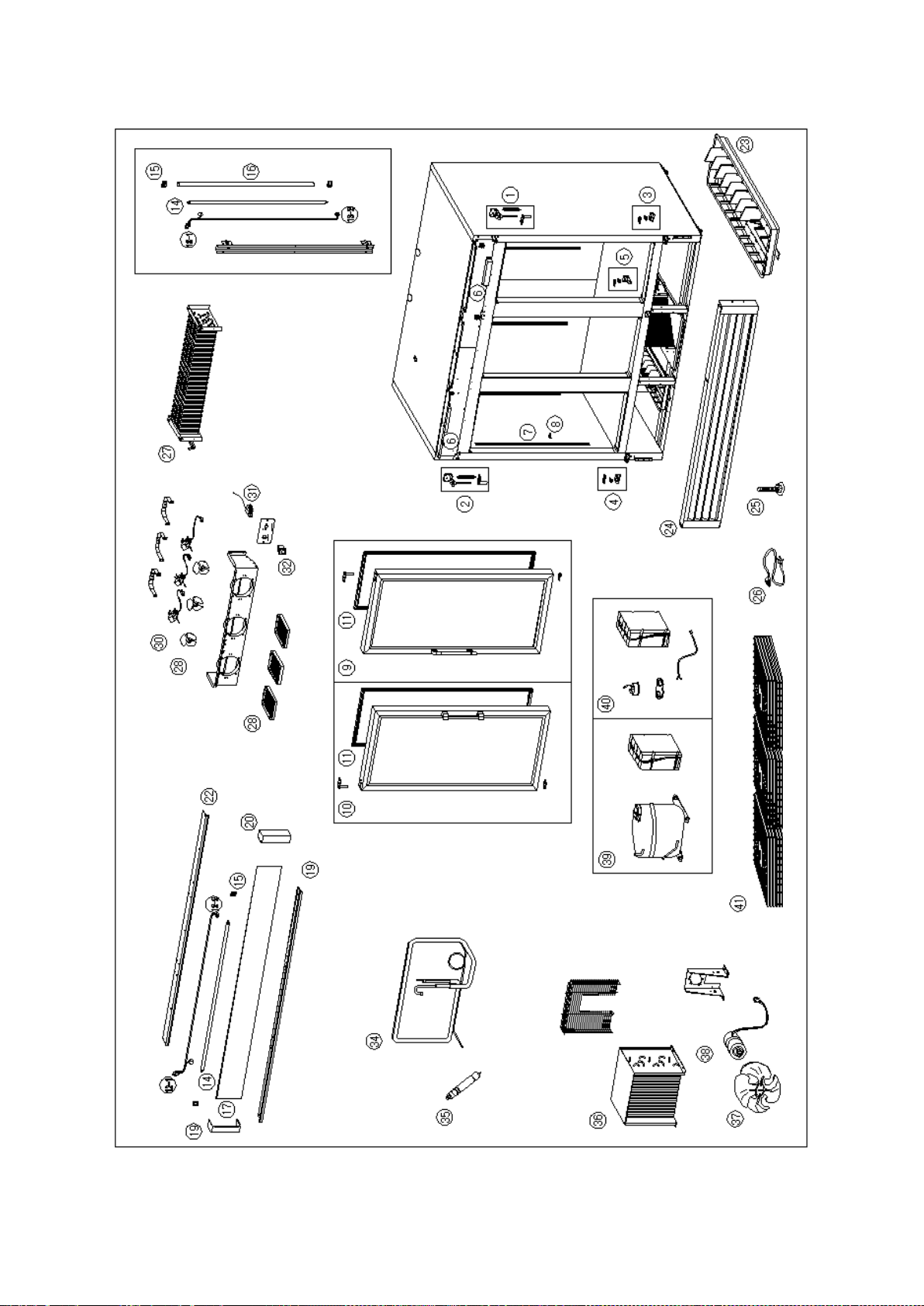

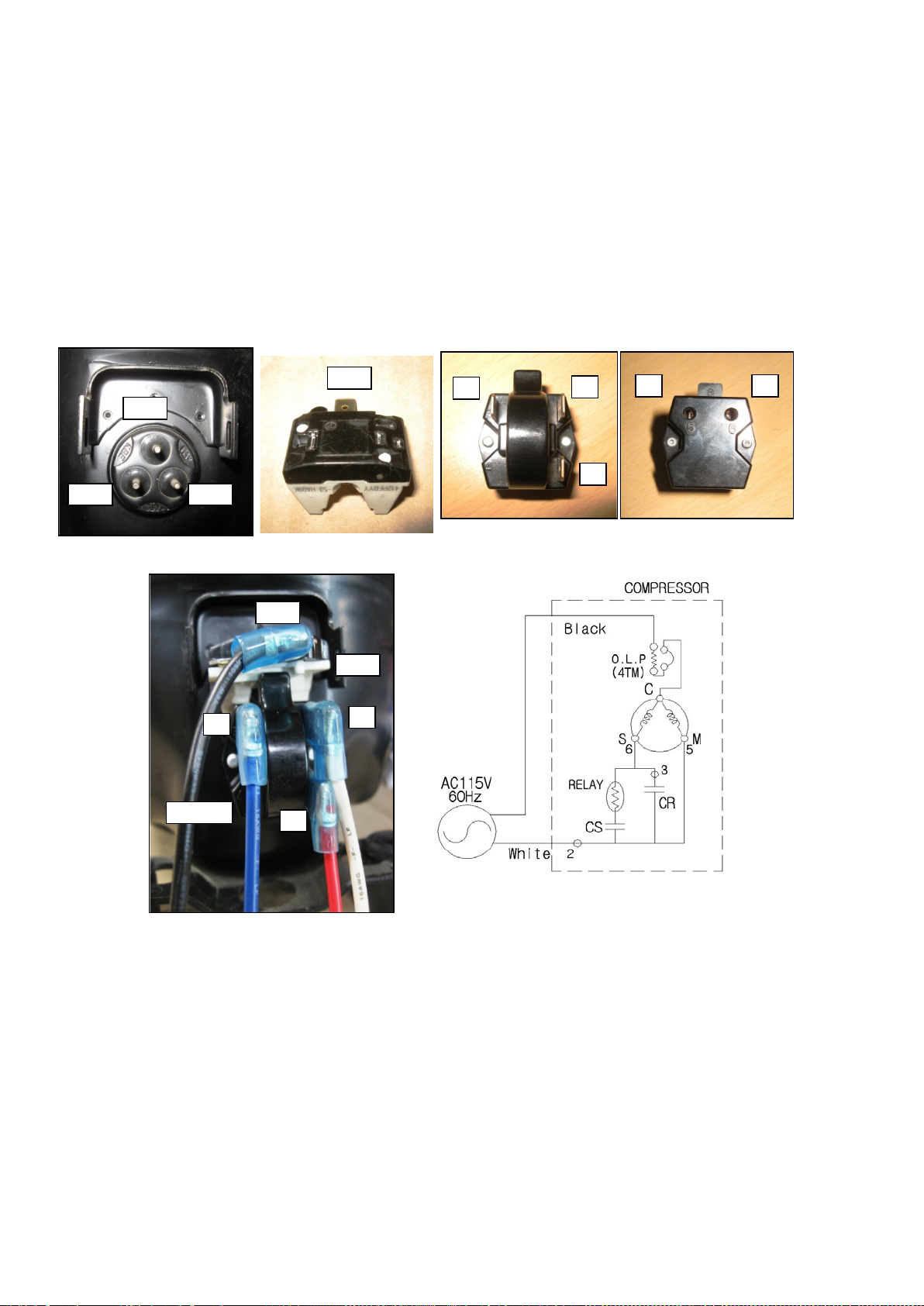

1. F23-S/SH, R49/R72-G

C

S

M 3 OLP

EARTH

① Compressor Spec. : NEK2150GK (R-404A), 115V/60Hz, CSR Type

② Maker : EMBRACO

③ Cooling Capacity : 628kcal/Hr - LBP

④ Starting Capacitor Spec. : 189~227 ㎌ / 165V

⑤ Running Capacitor Spec. : 25 ㎌ / 400V

⑥ Relay Spec. : RVA9AD3C-121

⑦ O.L.P Spec. : T0873/G9

* Comp. Winding Resistance: C - M → 0.77Ω, C - S → 4.5Ω (RT 25

* O.L.P Winding Resistance: 3- C → 0 Ω (OK), ∞

* Relay Winding Resistance: 1 -2 → 0 Ω (OK), ∞

BLACK

WIRE

WHITE

WIRE

Ω (NG)

Ω (NG)

℃(77℉))

< COMP. Wiring Diagram>

- 83 – 05/15 Rev. G 146526

Page 84

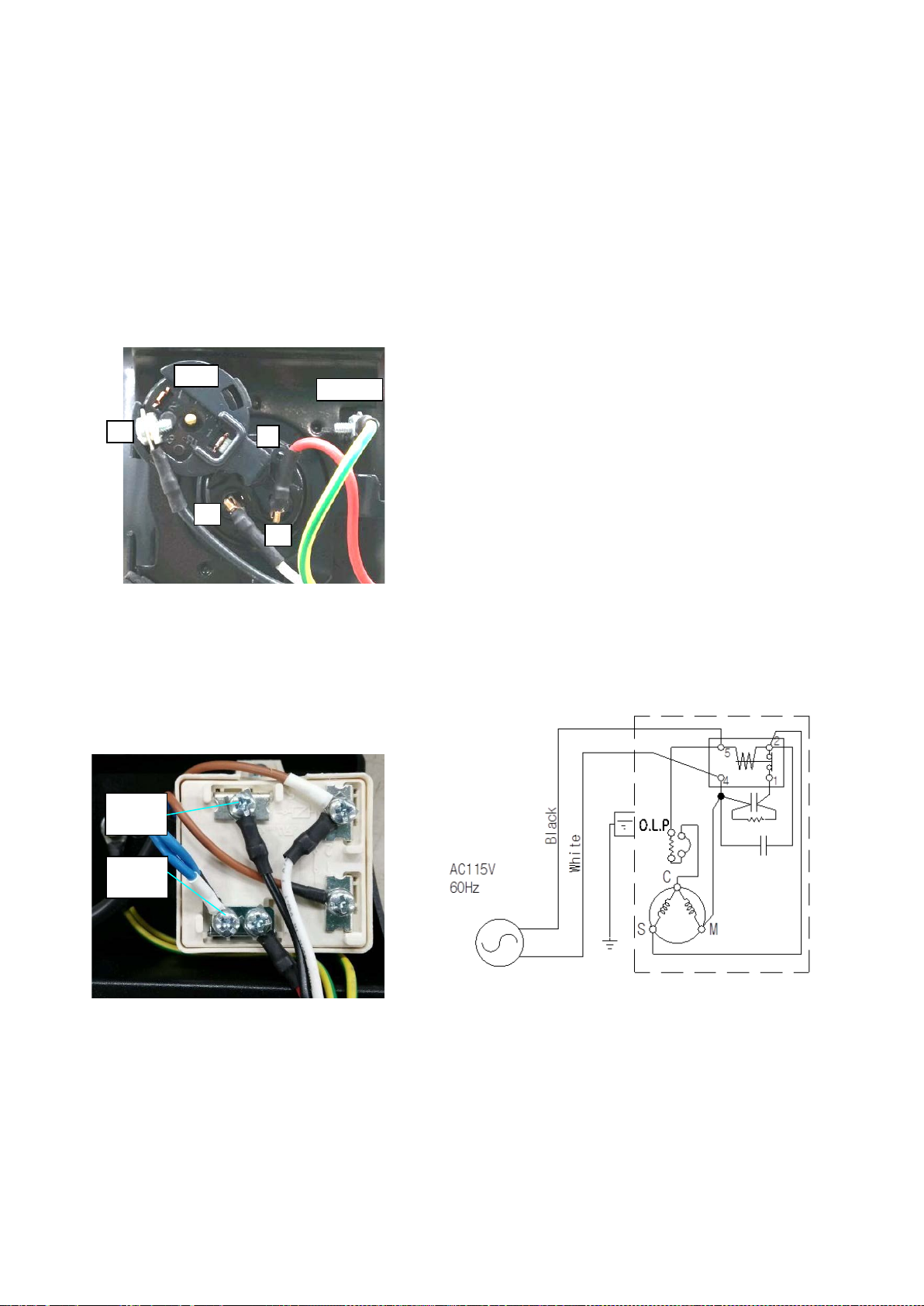

2. F49-S/SH

M

S C OLP

EARTH

3

R/C

S/C

< RELAY BOX >

2

R/C

1

Black

60Hz

AC115V

1

White

S/C

3L

5

4

2N

3

M

S

C

OLP

Black

White

2

1

RELAY

① Compressor Spec. : CAJ2432Z (A) (R-404A), 115V/60Hz, CSR Type

② Maker : TECUMSEH-FRANCE

③ Cooling Capacity : 807kcal/Hr - LBP

④ Starting Capacitor Spec. : 315 ㎌ / 160V

⑤ Running Capacitor Spec. : 30 ㎌ / 400V

⑥ Relay Spec. : 3ARR3*5R*

⑦ O.L.P Spec. : GA3PJU00

* Comp. Winding Resistance: C - M → 0.56Ω, C - S → 3.67Ω (RT 20

* O.L.P Winding Resistance: 3 - C → 0 Ω (OK), ∞

* Relay Winding Resistance: 1 - 2 → 0 Ω (OK), ∞

Ω (NG)

Ω (NG)

℃(68℉))

wire

wire

< COMP. Wiring Diagram>

- 84 – 05/15 Rev. G 146526

Page 85

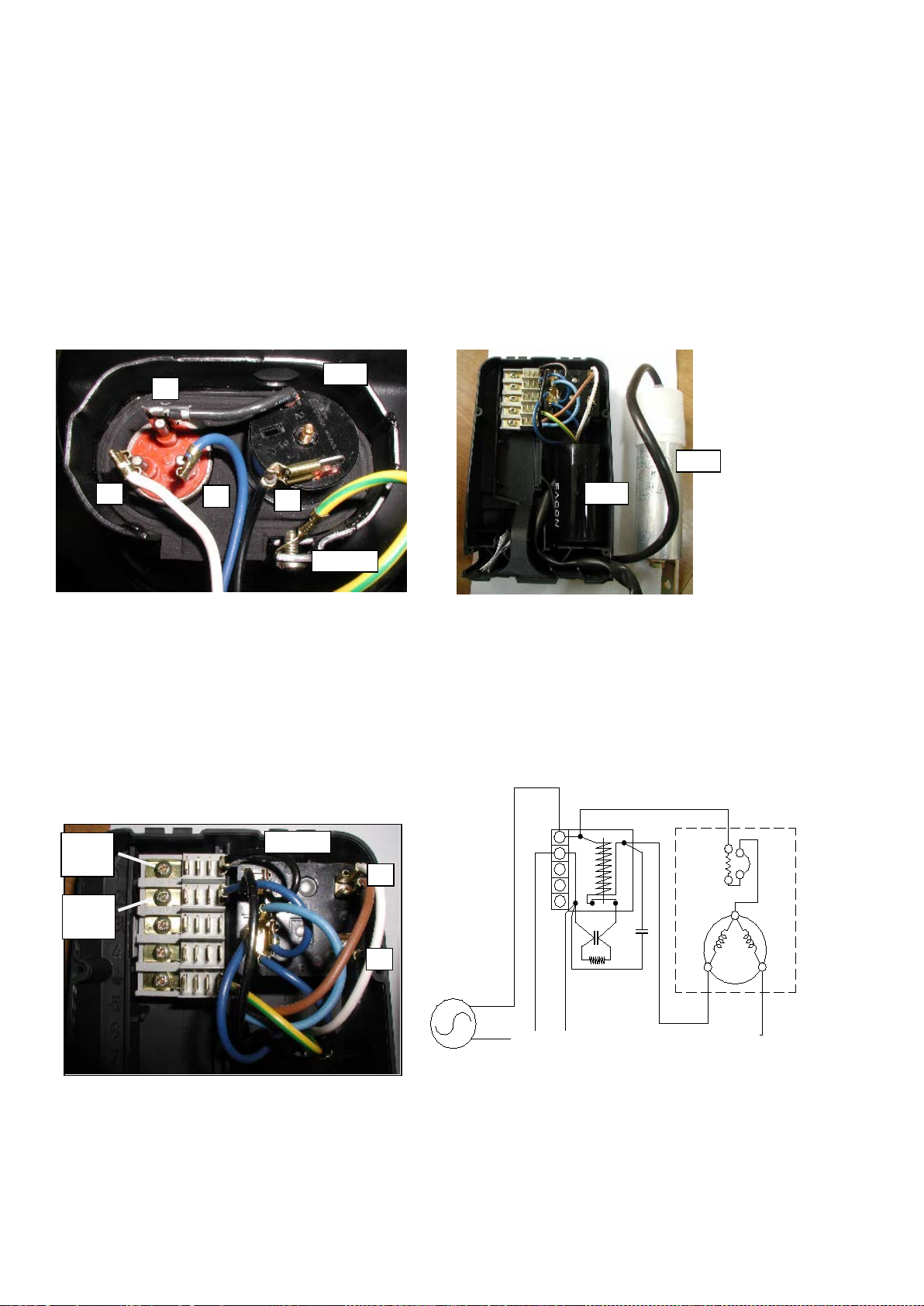

3. F72-S/SH

M S C

OLP

EARTH

3

R/C

S/C

< RELAY BOX >

Red

60Hz

Red

1

AC220V

3L

5

4

2N

M

S

C

3

2

1

R/C

S/C

OLP

Black

White

2

1

RELAY

① Compressor Spec. : CAJ2446Z (H) (R404a), 220V/60Hz, CSR Type

② Maker : TECUMSEH-FRANCE

③ Cooling Capacity : 1,219kcal/Hr - LBP

④ Starting Capacitor Spec. : 88 ㎌ / 260V

⑤ Running Capacitor Spec. : 15 ㎌ / 400V

⑥ Relay Spec. : 3ARR3*3A*

⑦ O.L.P Spec. : MST00AHN

* Comp. Winding Resistance: C - M → 1.16Ω, C - S → 8.14Ω (RT 20

* O.L.P Winding Resistance: 3 - C → 0 Ω (OK), ∞

* Relay Winding Resistance: 1 - 2 → 0 Ω (OK), ∞

Ω (NG)

Ω (NG)

wire

wire

℃(68℉))

< COMP. Wiring Diagram>

- 85 – 05/15 Rev. G 146526

Page 86

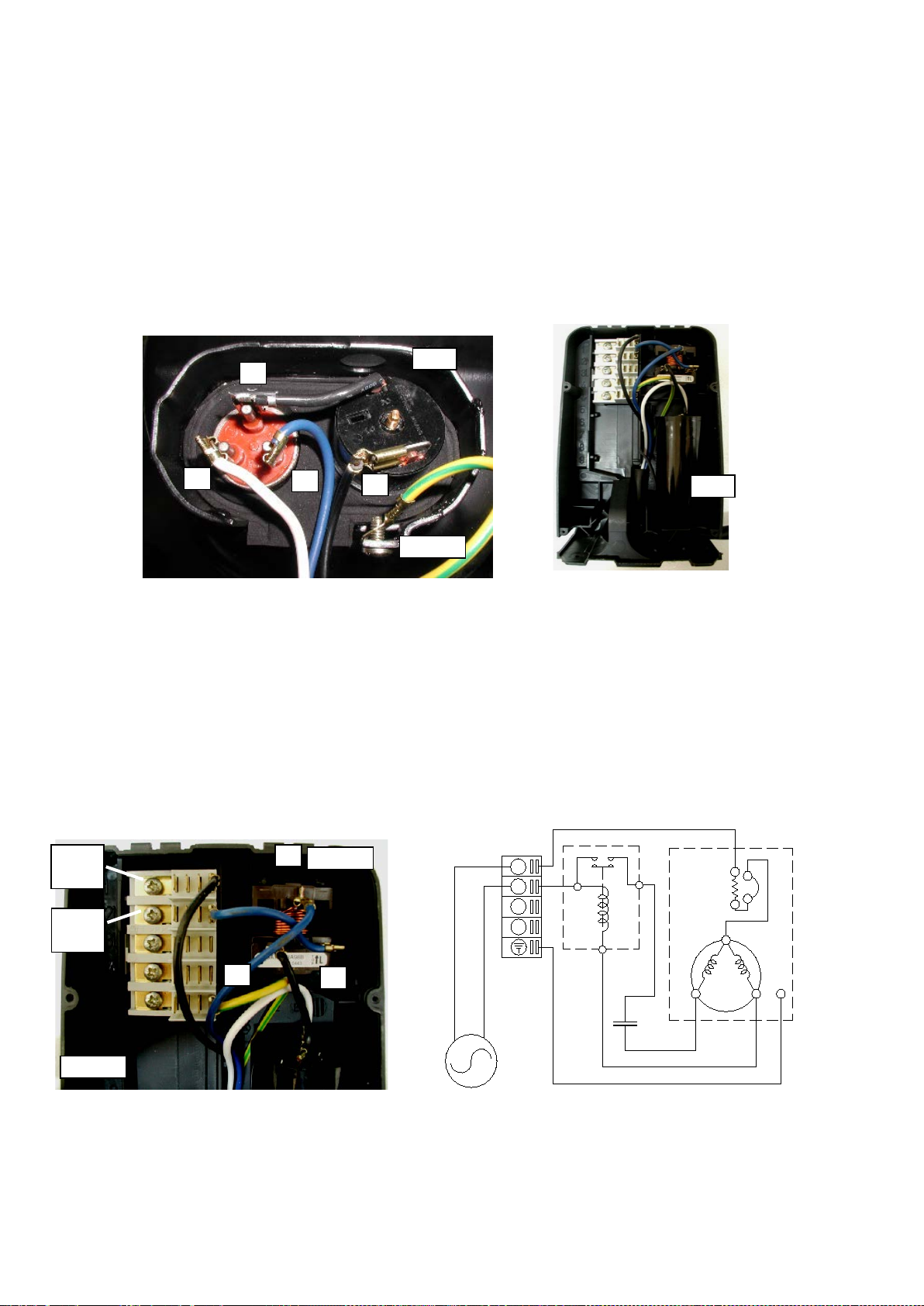

4. R23/R49-S/SH, R23-G

< COMP. Terminal >

C(1)

S(6)

M(5)

3

2 1 5

6

< RELAY >

< OLP >

4TM

OLP

RELAY

3 2 1

4TM

① Compressor Spec. : SK1A1C-L2W (R-134a), 115V/60Hz, CSR Type

② Maker : SAMSUNG -KOREA

③ Cooling Capacity : 303kcal/Hr - LBP

④ Starting Capacitor Spec. : 125 ㎌ / 125V

⑤ Running Capacitor Spec. : 12 ㎌ / 250V

⑥ Relay Spec. : J531Q34E220M350-3(220MB3)

⑦ O.L.P Spec. : 4TM795TFBZZ-53

< COMP. Wiring Diagram>

* Comp. Winding Resistance: C - M → 1.12Ω, C - S → 5.95Ω

* O.L.P Winding Resistance: 1 - 1-1 → 0 Ω (OK), ∞

Ω (NG)

* Relay Winding Resistance: M (5) - 4 → 0 Ω (OK), ∞

* PTC: 22Ω

On/Off Temperature - O/T: 140±5 ℃, C/T: 61±11℃

ST: 23A, UT: 7.48A

Ω (NG)

S (6) - 4 → ∞ Ω (OK)

- 86 – 05/15 Rev. G 146526

Page 87

5. R72-S/SH

M S C

OLP

EARTH

1

< RELAY BOX >

S/C

S/C

Earth

2

4

3

L

1

S

60Hz

AC115V

OLP

C

S

M

3

Black

White

Black

White

3 L RELAY

S

Fig.1

① Compressor Spec. : CAJ4461Y (A) (R-134a), 115V/60Hz, CSIR Type

② Maker : TECUMSEH-FRANCE

③ Cooling Capacity : 1,586kcal/Hr - HBP

④ Starting Capacitor Spec . : 250 ㎌ / 160V

⑤ Relay Spec. : 3ARR18A100B

⑥ O.L.P Spec. : GA3SJU81 or CRA38016

* Comp. Winding Resistance: C - M → 0.7Ω, C - S → 4.5Ω (RT 20

* O.L.P Winding Resistance: 1 - C → 0 Ω (OK), ∞

* Relay Winding Resistance: L - 3 → 0 Ω (OK), ∞

Ω (NG)

Ω (NG)

℃(68℉))

L - S → ∞ Ω (OK)

* Measuring the resistance, the bottom of the relay must be downward (like fig1)

wire

wire

< COMP. Wiring Diagram>

- 87 – 05/15 Rev. G 146526

Page 88

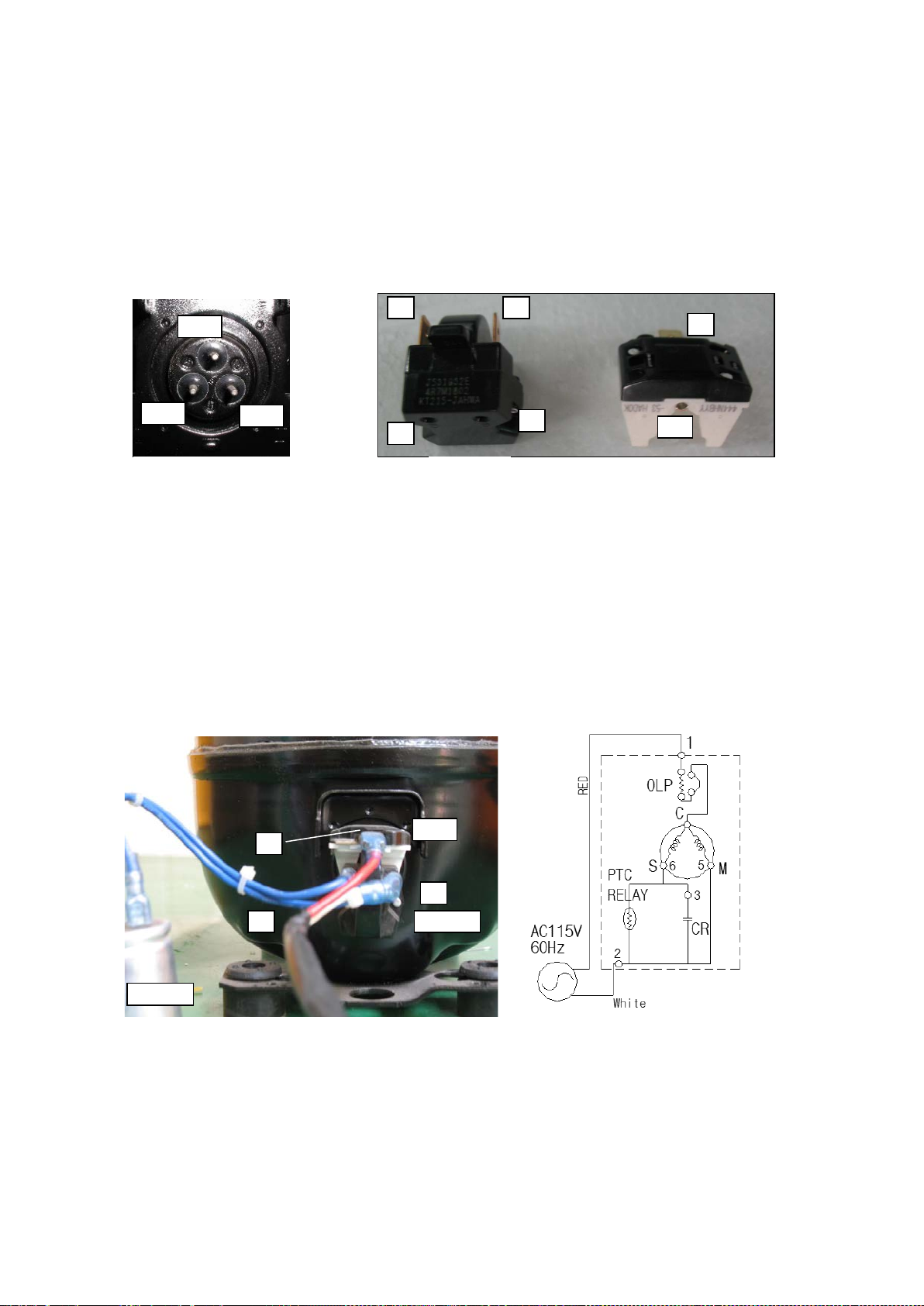

6. GR26H

< Comp. Terminal >

M(5)

S(6)

C(1)

< OLP >

< RELAY

1

1-1 2 3 5 6 1 OLP

RELAY

Fig.1

3

2

① Compressor Spec. : SK182C-L2U (R-134a), 115V/60Hz, RSCR Type

② Maker : SAMSUNG-KOREA

③ Cooling Capacity : 243kcal/Hr - LBP

④ Relay Spec. : PTHAR-T4R7M180D/J531Q32E4R7M1802

⑤ O.L.P Spec. : 4TM444 NHBYY-53

* Comp. Winding Resistance: C - M → 2.3Ω, C - S → 3.8Ω (RT 25

* O.L.P Winding Resistance: 1 - 1-1 → 0 Ω (OK), ∞

* Relay Winding Resistance: 5 - 6 → 0 Ω (OK), ∞

Ω (NG)

Ω (NG)

℃(77℉))

2 - 3 → 0 Ω (OK), ∞ Ω (NG)

* Measuring the resistance, the bottom of the relay must be downward (like fig.1)

< COMP. Wiring Diagram>

- 88 – 05/15 Rev. G 146526

Page 89

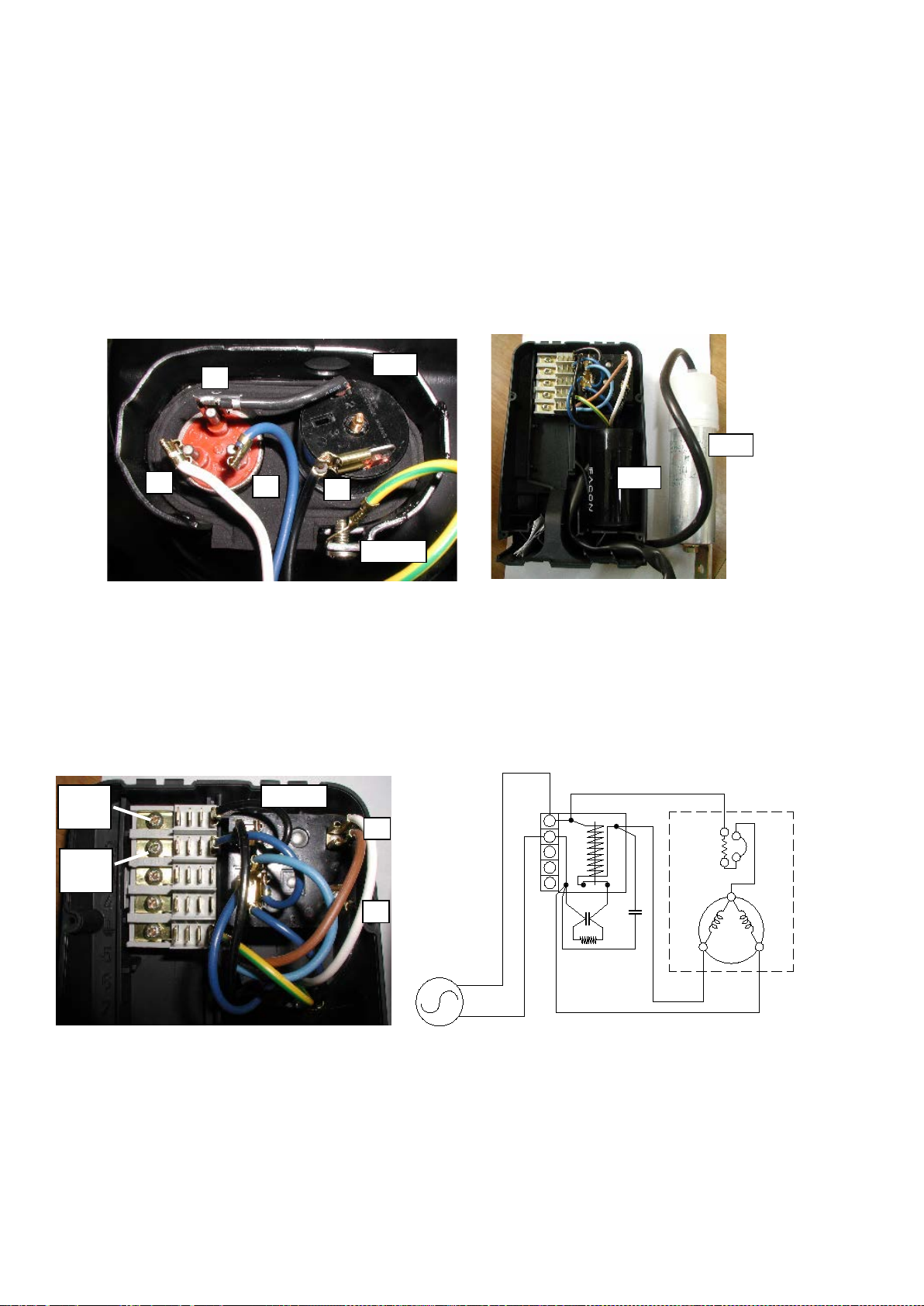

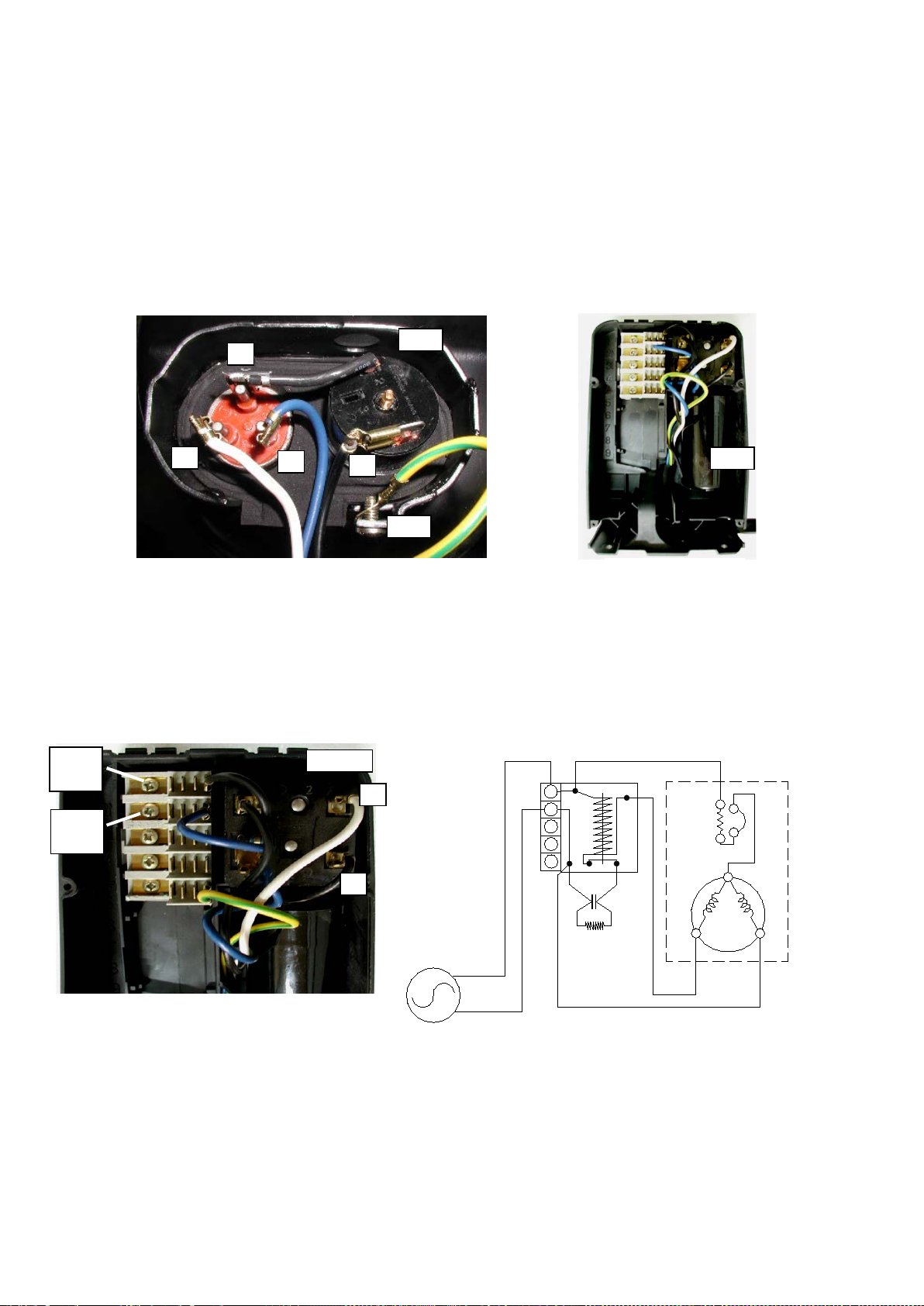

7. GR48S/GR70H

M S C

OLP

Earth

3

< RELAY BOX >

S/C

Black

White

2

1

RELAY

White

60Hz

2N

4

5

3L

AC115V

Black

1

S

M

OLP

C

3

S/C

1

2

① Compressor Spec. : CAJ4476Y (A) (R-134a), 115V/60Hz, CSIR Type

② Maker : TECUMSEH-FRANCE

③ Cooling Capacity : 1,946kcal/Hr - HBP

④ Starting Capacitor Spec. : 250 ㎌ / 160V

⑤ Relay Spec. : 3ARR3*2M*

⑥ O.L.P Spec. : CRA38014

* Comp. Winding Resistance: C - M → 0.72Ω, C - S → 3.68Ω (RT 20

* O.L.P Winding Resistance: 3 - C → 0 Ω (OK), ∞

* Relay Winding Resistance: 1 - 2 → 0 Ω (OK), ∞

Ω (NG)

Ω (NG)

wire

wire

℃(68℉))

< COMP. Wiring Diagram>

- 89 – 05/15 Rev. G 146526

Loading...

Loading...