Marvel MPRO6DZE Operation Manual

Installation

Operation

and

Maintenance

Instructions

Dual Zone

Wine Cellar

6SDZE (Marvel)

MPRO6DZE (Professional)

Note: Wine Cellars are designed exclusively for the storage of wine. Wine Cellars cannot attain storage temperatures suitable for fresh food storage.

CONTENTS

Unpacking your wine cellar.............................

Removing interior packaging......................

Warranty Registration ..................

Installing your wine cellar.........................

Selecting the location..........................

Cabinet Clearances ................................

Leveling legs ...........................

Electrical Connection ......................

Using Your Sentry System™ Control ............................

Dimensions for MPRO6DZE glass door........................

Recommended Rough in Opening Dimensions

for MPRO6DZE glass door.......................

Dimensions for 6SDZE glass door.

Recommended Rough in Opening Dimensions

for 6SDZE glass door........

Dimensions for 6SDZE and MPRO6DZE glass

overlay door...................................................................

Recommended Rough in Opening Dimensions

for 6SDZE and MPRO6DZE glass overlay door .......

Full Overlay Panel Installation Instructions....

Features ........................................................................

Care and Cleaning ........................

Cleaning front grille ...........................

Cleaning the cabinet...................................................

Cleaning the interior..................................

Cleaning the wine shelves..........................................

Cleaning the door gasket...........................................

Removing the wine shelves............................

Replacing the light tubes.............................

Energy Saving Tips ......................................................

Troubleshooting Guide.........................

Obtaining Service .......................

Household Product Warranty................

.........

.......

......................

...........

...

.............................

................................

................

........................

........

......

..........

.......................

...............

.............

...........

................

...................

.........

.........

.........

...........

...................

........

..........

.....

......

....

............

.............

.....

.............

...

........

....

..........

.........

..........

.......

......

....

......

3

3

3

4

4

4

4

5

6

8

8

9

9

10

10

11

15

16

16

16

16

16

16

16

16

16

17

18

19

is committed to building a quality product

in an environmentally friendly manner. Our processes are

tightly controlled and closely monitored. We have achieved

certications in ISO 9001 for quality assurance, ISO 14001

for environmental management, and OHSAS 18001 for oc-

cupational health and safety from Lloyd’s Register Quality

Assurance.

2

NOTE

UNPACKING YOUR WINE CELLAR

Important Safety Instructions

Warnings and safety instructions appearing in this guide

are not meant to cover all possible conditions and situa-

tions that may occur. Common sense, caution, and care

must be exercised when installing, maintaining, or operat-

ing this appliance.

Recognize Safety Sym-

bols, Words, and Labels.

If the unit was shipped or has been laying on its back for

any period of time allow the wine cellar to sit upright for a

period of at least 24 hours before plugging in. This will ensure oil returns to the compressor. Plugging the wine cellar

in immediately may cause damage to internal parts.

Warranty Registration

It is important you send in your warranty registration card

immediately after taking delivery of your wine cellar.

WARNING-Hazards or unsafe practices with high

probability of personal injury or property / product damage.

CAUTION-Hazards or unsafe practices which could

result in personal injury or property or product damage.

NOTE-Important information to help assure a problem

free installation and operation.

Remove Interior Packaging

Your wine cellar has been packed for shipment with all

parts that could be damaged by movement securely fastened. Remove internal packing materials and any tape

holding internal components in place. The owners manual

is shipped inside the product in a plastic bag along with the

warranty registration card, and other accessory items.

The following information will be required when registering

your unit.

Service Number

Serial Number

Date of Purchase

Dealer’s name and address

The service number and serial number can be found on the

serial plate which is located inside the wine cellar on the left

side toward the top of the liner. See Figure 1.

Figure 1

Important

Keep your carton and packaging until your wine cellar has

been thoroughly inspected and found to be in good condi-

tion. If there is damage, the packaging will be needed as

proof of damage in transit. Afterwards please dispose of all

items responsibly in particular the plastic bags which can

be a suffocation hazard.

Note to Customer

This merchandise was carefully packed and thoroughly

inspected before leaving our plant. Responsibility for its

safe delivery was assumed by the retailer upon acceptance

of the shipment. Claims for loss or damage sustained in

transit must be made to the retailer.

DO NOT RETURN DAMAGED MERCHANDISE TO THE

MANUFACTURER - FILE THE CLAIM WITH THE RE-

TAILER.

Help Prevent Tragedies

Child entrapment and suffocation are not problems of the

past. Junked or abandoned refrigerators are still dangerous

- even if they sit out for "just a few days".

If you are getting rid of your old refrigerator, please follow

the instructions below to help prevent accidents.

Before you throw away your old refrigerator or freezer:

• Take off the doors or remove the drawers.

• Leave the shelves in place so children may not easily

climb inside.

3

INSTALLING YOUR WINE CELLAR

Select Location

The proper location will ensure peak performance of your

appliance. We recommend a location where the unit will

be out of direct sunlight and away from heat sources. To

ensure your product performs to specications the recommended installation location temperature range is from 55

to 100°F (13 to 38°C).

Cabinet Clearance

Ventilation is required from the bottom front section of the

unit. Keep this area open and clear of any obstructions.

Adjacent cabinets and counter top can be installed around

the unit as long as the front grille remains unobstructed.

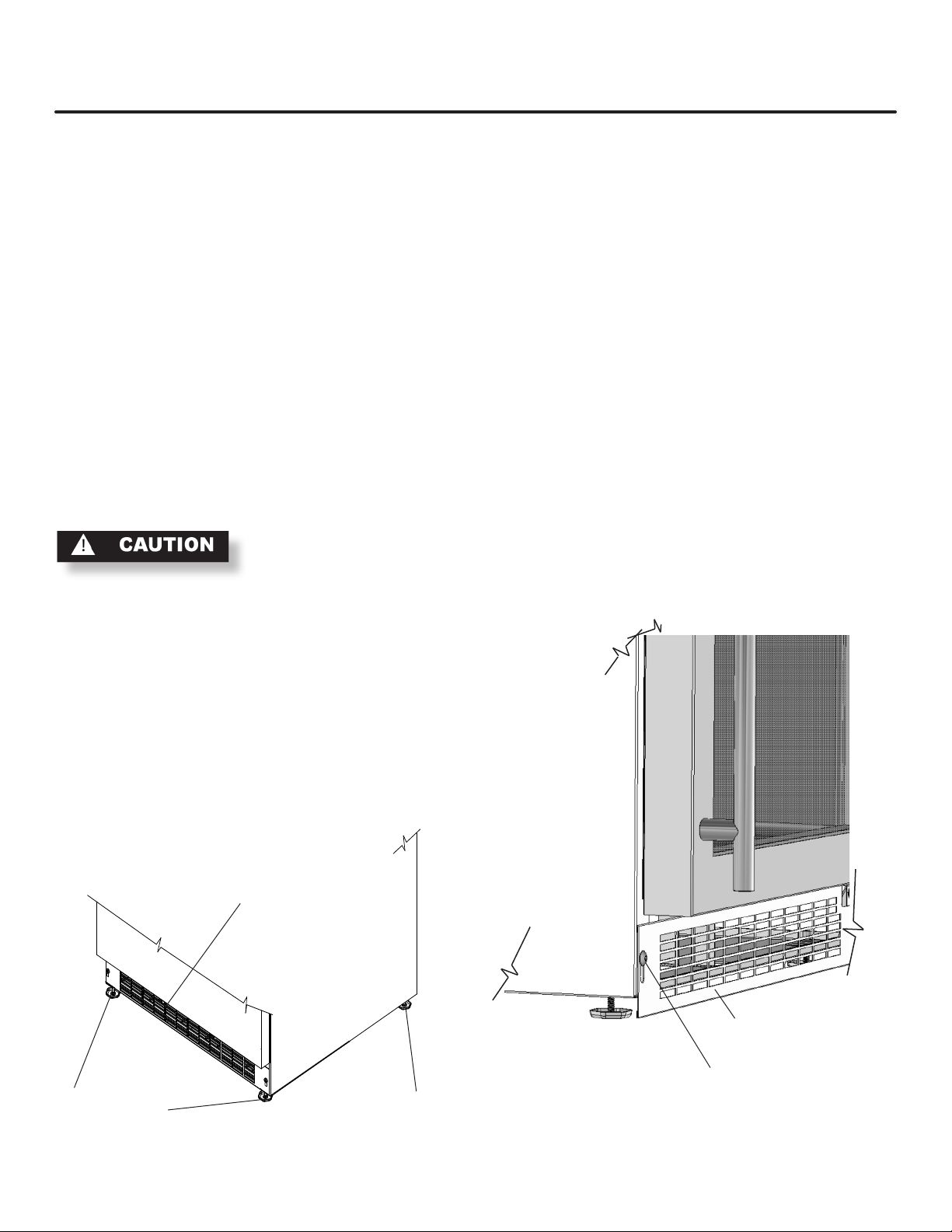

Front Grille

Do not obstruct the front grille. The openings within the

front grille allow air to ow through the condenser heat exchanger. Restrictions to this air ow will result in increased

energy usage and loss of cooling capacity. For this reason

it is important this area to not be obstructed and the grille

openings kept clean. AGA MARVEL does not recommend

the use of custom made grilles as air ow may be restricted

because of inadequate openings. (See Figure 2).

Leveling Legs

Adjustable legs at the front and rear corners of the unit

should be set so the unit is rmly positioned on the oor

and level from side to side and front to back. The overall

height of your Marvel refrigerator may be adjusted from

337⁄8" (86.1cm) with the leveling legs turned in, and up to

347⁄8" (88.6cm) with the leveling legs extended.

To adjust the leveling legs, place the refrigerator on a solid

surface and protect the oor beneath the legs to avoid

scratching the oor. With the assistance of another person,

lean the refrigerator back to access the front leveling legs.

Raise or lower the legs to the required dimension by turning the legs. Repeat this process for the rear by tilting the

refrigerator forward using caution to prevent the door from

opening. On a level surface check the refrigerator for levelness and adjust accordingly.

The front grille screws may be loosened and the grille adjusted to the desired height. When adjustment is complete

tighten the two front grille screws. (See Figure 3).

Front

Leveling Legs

Front Grille,

keep this area

open.

Figure 2

Rear

Leveling

Legs

Front grille

Figure 3

Front grille

screw

4

NOTE

ELECTRICAL CONNECTION

• Do not splash or spray water from a hose on the

wine cellar. Doing so may cause an electrical

shock, which may result in severe injury or death.

• This unit should not, under any circumstances, be

installed to an un-grounded power supply.

Electrical Connection

A grounded 115 volt, 15 amp dedicated circuit is required.

This product is factory equipped with a power supply

cord that has a three-pronged, grounded plug. It must be

plugged into a mating grounding type receptacle in accordance with the National Electrical Code and applicable

local codes and ordinances (see Figure 4). If the circuit

does not have a grounding type receptacle, it is the responsibility and obligation of the customer to provide the proper

power supply. The third ground prong should not, under

any circumstances, be cut or removed.

Electrical Extension cords

should not be used. They can

behazardousandcausedecientoperation.Thewall

receptacle should be located near the product and be

a polarized type with adequate ground protection. The

product must be installed to your local building codes

and ordinances.

Figure 4

Ground fault circuit interrupters (GFCI) are prone to nuisance tripping which will cause the unit to shut down.

GFCI’s are generally not used on circuits with powered

equipment that must run unattended for long periods of

time, unless required to meet local building codes and

ordinances.

5

ON OFF Door Ajar

Power Failure

Hi / Low Temp Upper

Hi / Low Temp Lower

NOTE

USING YOUR SENTRY SYSTEM™ CONTROL

Figure 5 "Dual Zone"

Glass Door Models

Initial Power-Up:

Your product will start upon plug-in to power receptacle.

The Sentry System LED will be displaying "power failure"

on dual-zone models, (Figure 5), to indicate that a power

outage has occurred. This is normal as the product was

powered-up at the factory for quality assurance testing.

Momentarily press and release the "ON/OFF" keypad to

reset the control alarm status. The LED should indicate no

alarms. To turn the unit ON/OFF, press and hold the "ON/

OFF" key for a minimum of 5 seconds.

Status

message

Compartment temperatures will be controlled to the temperature displayed when SET mode is exited.

It is suggested to allow 24 hours after changing the storage

compartment set-point temperatures before making further

adjustments. This will allow the content temperatures to

stabilize at the new set-point temperature. Frequent door

openings may prolong this stabilization period.

Set Display Temperature Units:

Your control is factory set to display temperature in °Fahrenheit as indicated by °F in the upper right corner of the

temperature display. If this is the desired temperature

units, no action is required. If you prefer to display temperature in °Celsius, momentarily press the "°F/°C" keypad.

°C should now be displayed in the upper right corner of the

temperature display. You may "toggle" between °F or °C

temperature display at any time by momentarily pressing

the "°F/°C" keypad.

Set Your Desired Storage Compartment Temperature:

Your control is factory set to 55°F. This is the ideal longterm storage temperature for "both" red and white wines.

The storage compartment temperature can be adjusted

throughout the full range of red and white wine serving

temperatures, (40°F > 65°F).

The control allows independent temperature control for

both the upper and lower storage compartments. On Dual

Zone models, momentarily pressing the "Set" keypad will

select each compartment individually as indicated by SET

being displayed in the "Upper" or "Lower" compartment

temperature display. While SET is displayed, you may

press the "Warmer" or "Colder" keypads to adjust the storage compartment set-point to your desired temperature. To

exit SET mode, momentarily press the "Set" keypad until

SET is no longer displayed in either the Upper or Lower

displays, or SET mode will time-out after 10 seconds of

inactivity.

Interior Lighting:

A door activated interior compartment light is provided for

your convenience. On glass door models only, this light

may also be used to enhance the display of your wines

through the glass door. To activate the display lighting

mode on glass door models, momentarily press the "Light"

keypad, (Figure 5). When activated, the interior light will

remain on when the door is closed.

Important: Use the display lighting option only when needed. The interior light generates heat which will increase the

energy consumption of your product.

Alarms:

All Sentry control systems will alert you to conditions that

could affect the storage compartment temperature. All

alarm conditions can be silenced and re-set by momentarily

pressing the "ON/OFF" keypad.

• Door Open Alarm – If the door remains open for over

ve(5) minutes, an audible alarm will occur and the

indicator LED will display "Door Ajar". Closing the door

will terminate and re-set this alarm condition.

• High / Low Temperature – If your storage compartment

experiences an excessive temperature excursion from

the set-point temperature for an extended period of

time, an audible alarm will sound, and will display "Hi

/ Low Temp". This condition may result from exces-

sive usage/door openings, warm content loading, or

product malfunction. It is recommended that you check

the condition of the stored items, and if alarm recurs,

you should initiate a service call to conrm your unit is

operating properly, (see Trouble Shooting section for

details).

6

USING YOUR SENTRY SYSTEM™ CONTROL

• Power Interrupt – The Sentry control indicator LED will

display "Power Failure", to notify you that a power out-

age has occurred. It is recommended that you check

the condition of your stored items.

• The Sentry alarms may be enabled or disabled by

pressing and holding the SET key for 5 seconds.

Conrmation of turning the Sentry alarms on or off will

be given by the control beeping 3 times. When Sentry

alarms are enabled, the display will show green "ON".

When Sentry alarms are disabled, the display will show

amber "OFF".

Sabbath Mode:

Your product may be placed into Sabbath mode if desired.

During this time the displays, audible alarms/keypad conrmations, and lights will be disabled. To activate Sabbath

mode, press and hold the "Set" keypad while pressing the

"°F/°C" keypad four(4) times within seven(7) seconds. The

display will conrm activation by "ashing" SA seven(7)

times before blanking the display. Sabbath mode will auto-

matically deactivate after 72 hours, or you may cancel it at

any time by repeating the keypad activation sequence. All

control functions and set-point temperatures will remain as

they were prior to entering Sabbath mode.

Turning Off Refrigeration:

You may turn off the refrigeration system in your product for

prolonged cleaning or times when cooling is not required

such as an extended vacation, or absence from a seasonal

residence. To shut off the refrigeration system press and

hold the "ON/OFF" keypad for 5 seconds. Conrmation

will be indicated by the control display going blank. Interior

lights will continue to function for your convenience. To

resume refrigeration, press and hold the "ON/OFF" keypad

for 5 seconds.

Important: Although this action shuts down the refrigeration

system, it does not remove power from the unit. Always

remember to unplug the unit, or remove power from the

receptacle, when servicing the product.

Error Codes:

The Sentry control system continually monitors your products critical refrigeration system components for proper

operation. If a components operating parameters do not

meet normal specications, the control display will indicate

one of the following faults:

• E1 - Compressor

• E2 - Condenser Fan Motor

• E3 - Upper Compartment Sensor

• E4 - Lower Compartment Sensor

If any of these errors occur, a service call by a qualied service technician is required, (see Trouble Shooting section

for details).

7

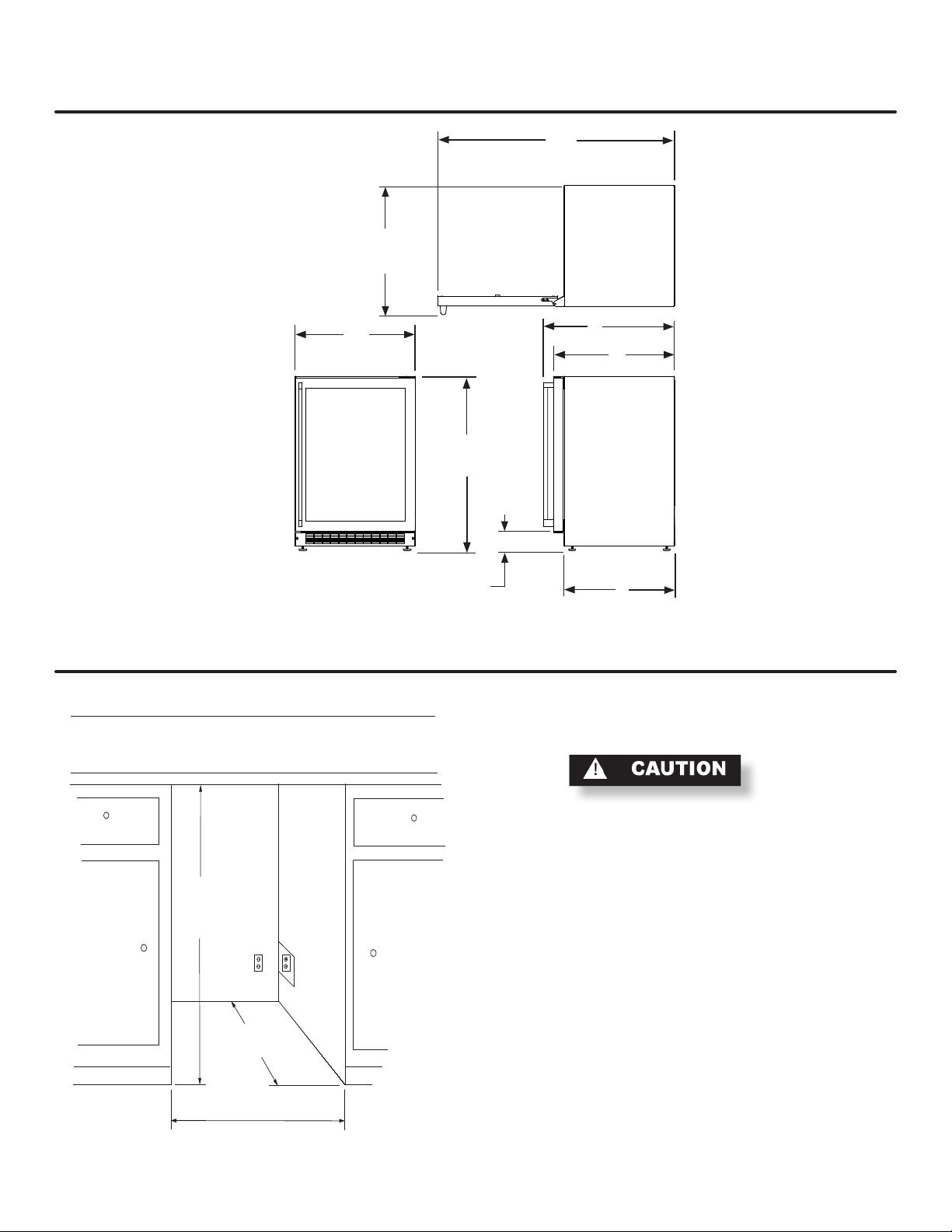

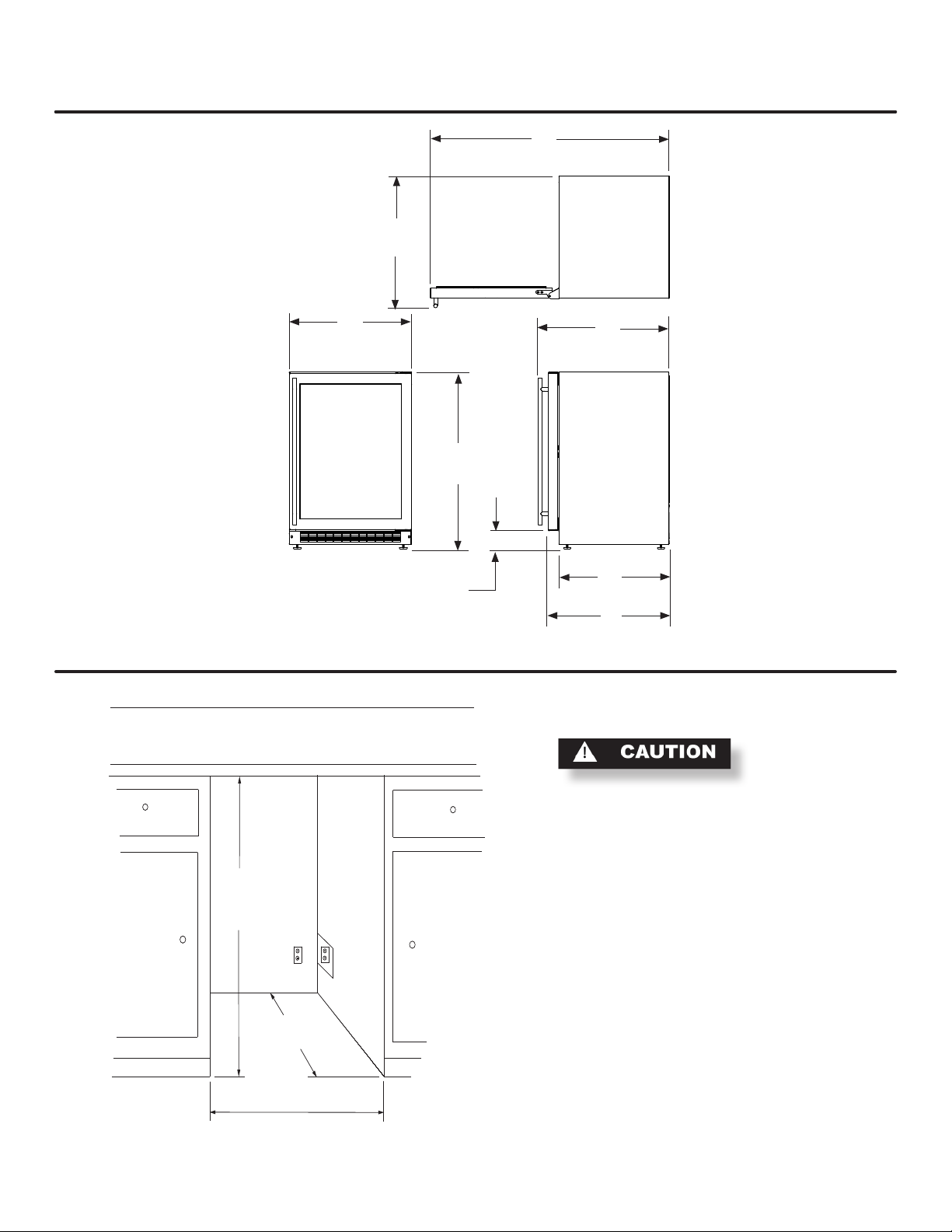

DIMENSIONS FOR MPRO6DZE GLASS DOOR

461⁄2"

(118.1cm)

25 21⁄32"

(65.2cm)

23 7⁄8"

(60.7cm)

33 7⁄8" to 34 7⁄8"

(86.1 to 88.6cm)

3" to 4"

(7.6 to 10.2cm)

261⁄4"

(66.7cm)

23 13⁄16"

(60.5cm)

219⁄16"

(54.8cm)

ROUGH IN OPENING DIMENSIONS FOR MPRO6DZE GLASS DOOR

** 341⁄8" to 351⁄8"

(86.7 to 89.2cm)

*24" (61 cm)

standard cabinet

depth

24" (61 cm)

Electrical Requirements: A grounded 115 volt,

15 amp dedicated circuit is required.

Power outlet can be located in the back wall

behind unit. Add 1" to depth for thickness of

plug, or recess outlet 1" into the wall. Power

outlet can also be installed in adjacent cabinetry with a cutout for routing of power cord.

Follow all local building codes when installing

electrical and unit.

Product weight = 136 lbs. (61.8 kg.)

* Depth dimension may vary depending on

each individual installation.

** Minimum rough in opening required is to be

larger than the adjusted height of the

cabinet.

8

DIMENSIONS FOR 6SDZE GLASS DOOR

461⁄2"

(118.1cm)

2521⁄32"

(65.2cm)

237⁄8"

(60.7cm)

337⁄8" to 347⁄8"

(86.1 to 88.6cm)

3" to 4"

(7.6 to 10.2cm)

259⁄16"

(65.0cm)

219⁄16"

(54.8cm)

235⁄8"

(60cm)

ROUGH IN OPENING DIMENSIONS FOR 6SDZE GLASS DOOR

** 341⁄8" to 351⁄8"

(86.7 to 89.2cm)

*24" (61 cm)

standard cabinet

depth

24" (61 cm)

Electrical Requirements: A grounded 115 volt, 15

amp dedicated circuit is required.

Power outlet can be located in the back wall

behind unit. Add 1" to depth for thickness of plug,

or recess outlet 1" into the wall. Power outlet

can also be installed in adjacent cabinetry with a

cutout for routing of power cord. Follow all local

building codes when installing electrical and unit.

Product weight = 136 lbs. (61.8 kg.)

* Depth dimension may vary depending on

each individual installation.

** Minimum rough in opening required is to be

larger than the adjusted height of the cabinet.

9

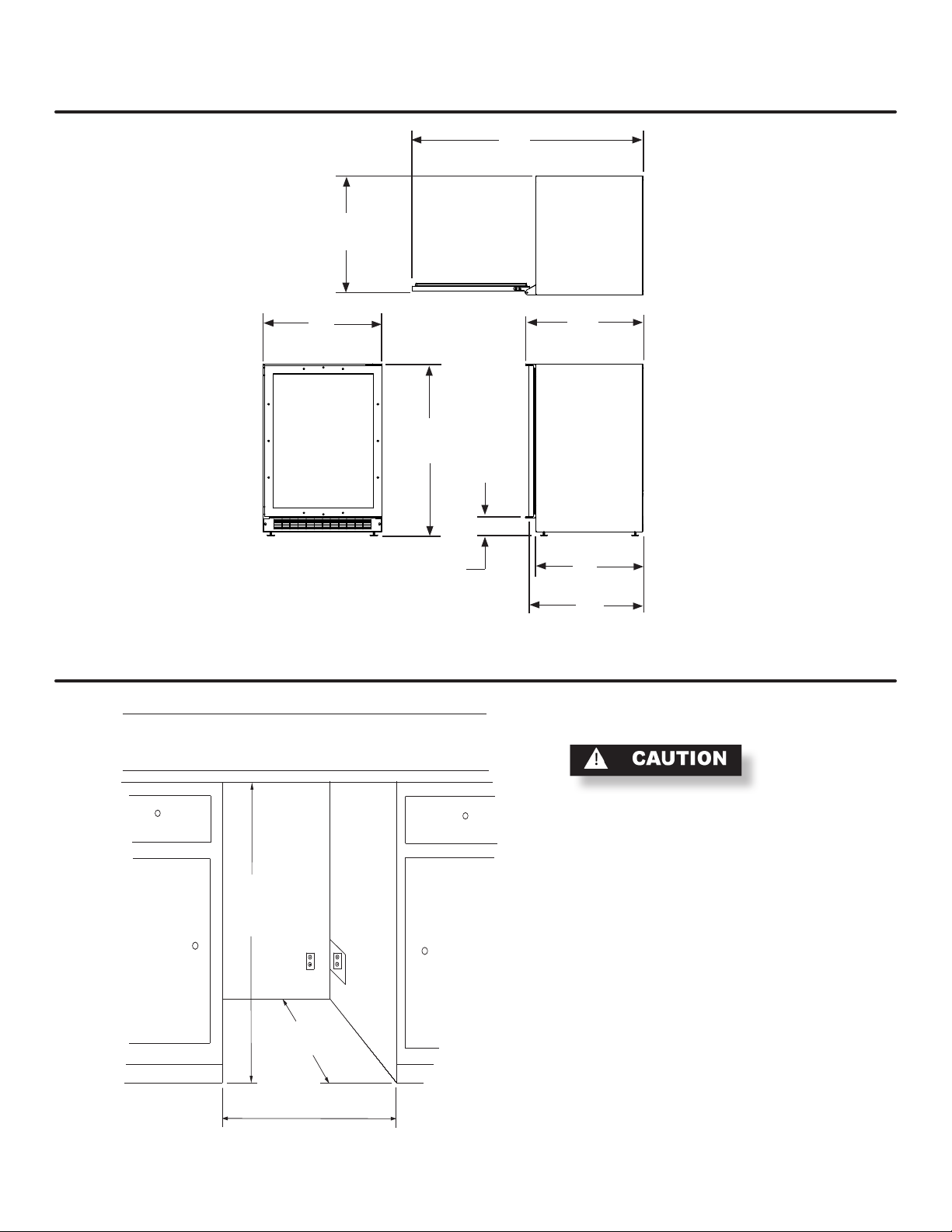

DIMENSIONS FOR 6SDZE AND MPRO6DZE GLASS OVERLAY DOOR

461⁄2"

(118.1cm)

231⁄32"

(58.5cm)

237⁄8"

(60.7cm)

337⁄8" to 347⁄8"

(86.1 to 88.6cm)

3" to 4"

(7.6 to 10.2cm)

2319⁄32"

(59.9cm)

219⁄16"

(54.8cm)

2229⁄32"*

(58.2cm)

*To face of door

without custom panel.

RECOMMENDED ROUGH IN OPENING FOR 6SDZE AND MPRO6DZE

GLASS OVERLAY DOOR

** 341⁄8" to 351⁄8"

(86.7 to 89.2cm)

*24" (61 cm)

standard cabinet

depth

24" (61 cm)

Electrical Requirements: A grounded 115 volt,

15 amp dedicated circuit is required.

Power outlet can be located in the back wall

behind unit. Add 1" to depth for thickness of

plug, or recess outlet 1" into the wall. Power

outlet can also be installed in adjacent cabinetry with a cutout for routing of power cord.

Follow all local building codes when installing

electrical and unit.

Product weight = 136 lbs. (61.8 kg.)

* Depth dimension may vary depending on

each individual installation.

** Minimum rough in opening required is to be

larger than the adjusted height of the cabinet.

10

NOTE

NOTE

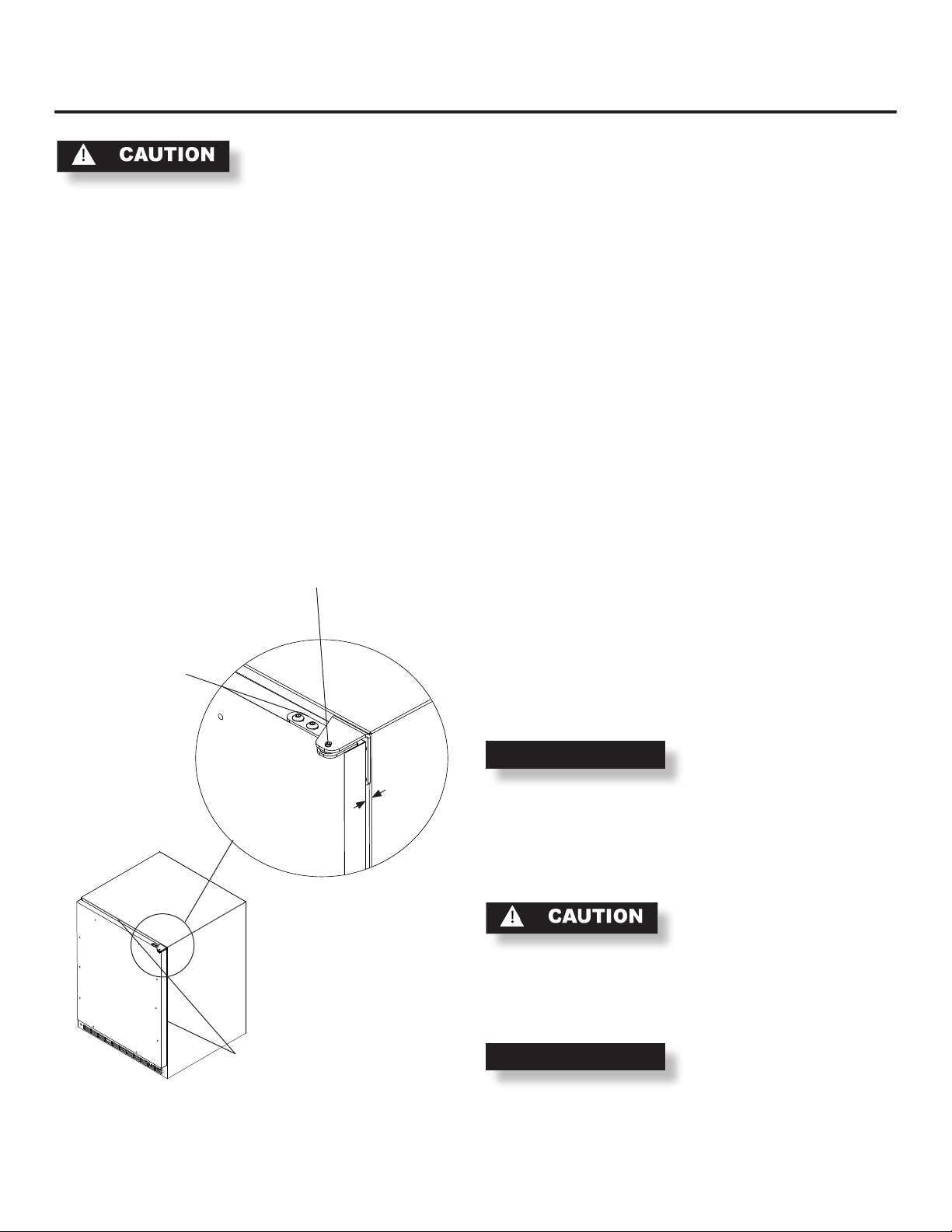

FULL OVERLAY PANEL INSTALLATION INSTRUCTIONS

Step 1: Verify door alignment

Verify that the door is aligned correctly with the cabinet

prior to fabricating the custom panel. Failure to do so could

result in mis-alignment of the custom panel with the hinge

bracket. The door should be parallel to the sides and top of

the refrigerator. If alignment is necessary the door may be

adjusted by loosening the 2 screws which secure the upper

and/or lower hinge adapter brackets, located on the top

and bottom of the door, and adjusting the door side to side.

Use a 5⁄32" allen wrench for this procedure. (See Figure 6

below). When nished aligning the door, tighten the screws

securely.

Remove top hinge

pin to remove the

Hinge adapter bracket

located on the top and

bottom of the door.

door.

Step 2: Remove door

Remove the top hinge pin from the hinge with an 1⁄8" allen

wrench. Remove the door by angling the top of the door

outward and lifting the door off the bottom hinge.

(See detail in Figure 6).

Step 3: Remove gasket

Lay the door on its front being careful not to scratch it. To

gain access to the screw holes remove the door gasket by

peeling up and out of the channel.

Step 4: Cut overlay panel

Depending on the wine cellar model cut the overlay panel

to the dimensions shown. Use Figure 7 and Table A for

glass door models.

Figure 6

Door should be

parallel to top

and sides of

refrigerator.

9

⁄32"

(7mm)

For overlay with lock option panel thickness to be

3

⁄4" (19mm) maximum to 5⁄8" (16mm) minimum.

Weight of the overlay panel should not exceed 20 pounds

(9.1 kilograms).

For the door to close properly it is necessary to maintain a

minimum space of 9⁄32" (7mm) between the door and cabi-

net ange (see Figure 6). This space can be adjusted by

adjusting the top and bottom hinge adapter brackets.

11

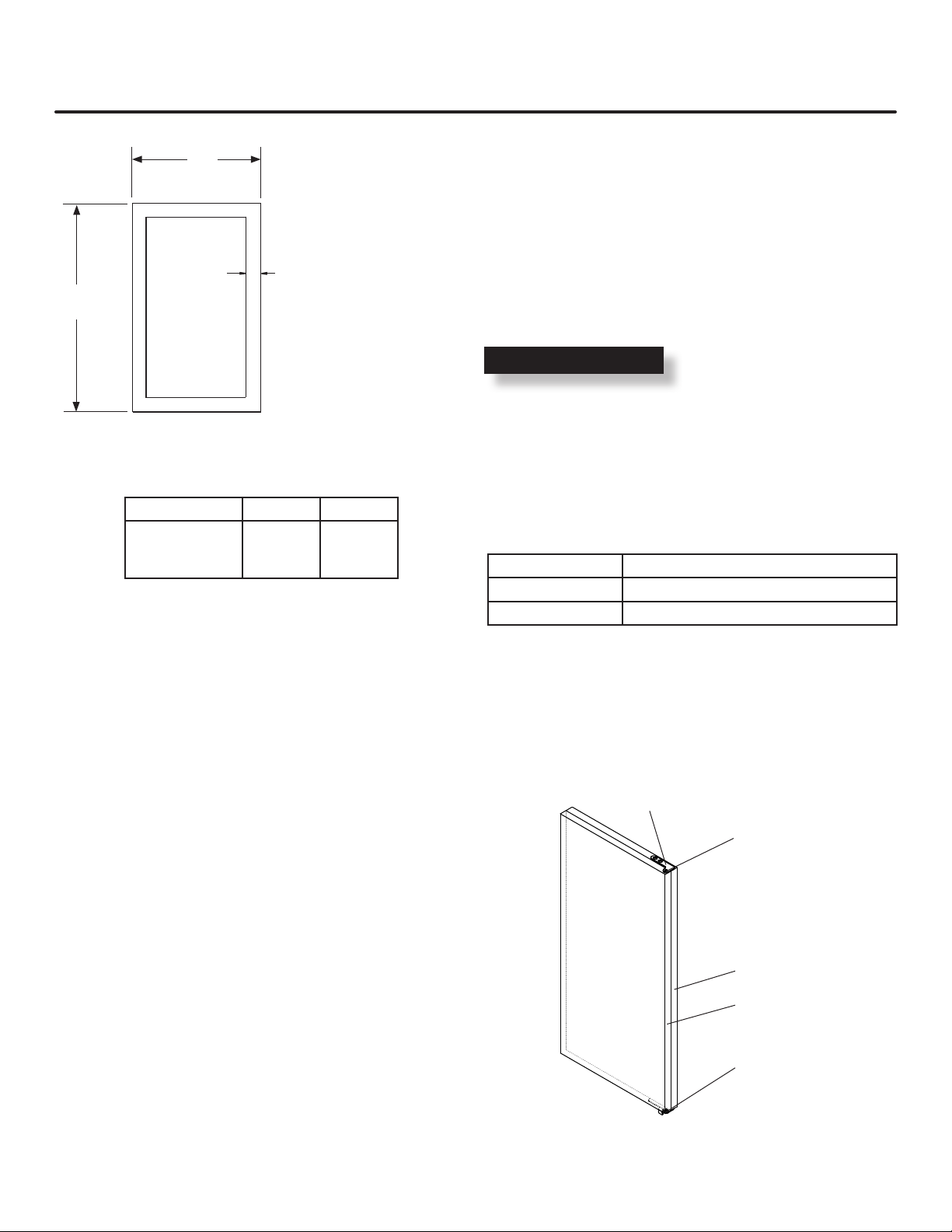

NOTE

FULL OVERLAY PANEL INSTALLATION INSTRUCTIONS

Step 6: Drill panel mounting holes

W

Re-clamp the panel to the door per step 5 and drill the

screw pilot holes for attaching the overlay panel to the door.

Select the size of the hole from Table B. Be careful not to

drill the pilot holes through the overlay panel, 1⁄2" (12.7mm)

deep for 3⁄4" (19mm) and 5⁄8" (15.7mm) panels.

123⁄32"

(38.8cm)

Typical 4

Sides

H

Front of

overlay

panel

Figure 7

Glass Door Models

If your refrigerator has a door lock proceed to Step 7. If

your refrigerator does not have a door lock proceed to

Step 9.

Model W H

6SDZE

MPRO6DZE

Glass Door Models

237⁄16"

(59.5cm)

Table A

305⁄16"

(77.0cm)

Material Type Pilot Hole for #8 Wood Screw

Hardwood

Softwood

1

⁄8" (3.2mm) Diameter. Pilot Hole

7

⁄64" (2.8mm) Diameter. Pilot Hole

Table B

Step 5: Drill hinge clearance holes in overlay

panel

Set the overlay panel on the door front, align the edges,

and clamp together. Clamp the panel rmly but be careful

not to damage the door or the panel. Mark center of hinge

adapter hole on wood panel, top and bottom. (See Figure

8). Remove wood panel from door and drill 5⁄16" (8mm) di-

ameter clearance holes into the overlay panels 3⁄4" (20mm)

deep. These will be clearance holes for the top and bottom

hinge pins.

This is also a convenient time to locate and drill the holes

for your handle. Most often the handle is to match that of

the surrounding cabinetry. If your handle attaches from the

back-side of the custom panel, locate the mounting holes

while the panel is attached to the door and cabinet. After

the panel is removed from the door, drill the mounting holes

from the front, to the recommended diameter of the handle

manufacturer. Counter bore the back-side of the panel so

the screw heads do not interfere with the surface of the

door.

12

Figure 8

Top

Hinge

Adapter

Hole in

hinge

adapter

Door

Overlay panel

Hole in bottom

hinge adapter

Loading...

Loading...