Marvel MPRO24DZ Operation Manual

Installation

Operation

and

Maintenance

Instructions

Built In

Wine Cellars

M18SZ

M24SZ

M24DZ

MPRO24DZ

Note: Wine Cellars are designed exclusively for the storage of

wine. Wine Cellars cannot aain storage temperatures suitable

for fresh food storage.

CONTENTS

Unpacking the wine cellar .....................................................3

Tools required ..................................................................3

Warranty registration ...........................................................4

Dimensions for M(XX)SZ with Glass Door ...........................5

Dimensions for M24DZ with Glass Door ...............................6

Dimensions for M24DZ with Glass Overlay Door...................7

Dimensions for MPRO24DZ with Glass Door .......................8

Pre installation considerations ............................................9

Rough in opening ...........................................................9

Select location ................................................................9

Electrical requirements .................................................10

Corner installation .........................................................10

Installing the cabinet .........................................................11

Anti tip bracket considerations .......................................11

Leveling the unit ................................................................12

Installing the power module ..............................................12

Placing power module on top of cabinet .........................12

Power module electrical connections .............................13

Installing the grille .............................................................14

Custom Grille and Door Overlay Panels ............................17

Mounting Grille Overlay Panel ......................................17

Overlay Door Panel Instructions ....................................18

Hinge and gasket adjustments ..........................................20

Installing side panels .........................................................21

Installing the kickplate .......................................................21

Installation checks ............................................................22

Common installation errors ..............................................22

Use and care guide ...........................................................23

Operation of your wine cellar ...........................................23

Defrosting .......................................................................24

Cleaning .........................................................................24

Condenser cleaning procedure ......................................24

Energy saving tips .............................................................25

Product sounds ................................................................25

Troubleshooting guide ......................................................26

Obtaining service ..............................................................26

Warranty ...........................................................................27

Important Safety Instructions

Warnings and safety instructions appearing in this guide

are not meant to cover all possible conditions and situa-

tions that may occur. Common sense, caution, and care

must be exercised when installing, maintaining, or operat-

ing this appliance.

Recognize Safety Symbols,

Words, and Labels.

!

WARNING

WARNING-Hazards or unsafe practices with

high probability of personal injury or property / product damage.

!

CAUTION

CAUTION-Hazards or unsafe practices which could

result in personal injury or property or product damage.

NOTE

NOTE-Important information to help assure a problem

free installation and operation.

is committed to building a quality product

in an environmentally friendly manner. Our processes are

tightly controlled and closely monitored. We have achieved

certications in ISO 9001 for quality assurance, ISO 14001

for environmental management, and OHSAS 18001 for oc-

cupational health and safety from Lloyd’s Register Quality

Assurance.

2

UNPACKING YOUR WINE CELLAR

!

WARNING

EXCESSIVE WEIGHT HAZARD

Use two or more people to move product.

Failure to do so can result in back or other injury.

Remove Interior Packaging

Your wine cellar has been packed for shipment with all

parts that could be damaged by movement securely fastened. Remove internal packing materials and any tape

holding internal components in place. The owners manual

is shipped inside the product in a plastic bag along with the

warranty registration card, and other accessory items.

Important

Keep your carton and packaging until your wine cellar has

been thoroughly inspected and found to be in good condi-

tion. If there is damage, the packaging will be needed as

proof of damage in transit. Afterwards please dispose of all

items responsibly in particular the plastic bags which can

be a suffocation hazard.

!

CAUTION

Help Prevent Tragedies

Child entrapment and suffocation are not problems of the

past. Junked or abandoned refrigerators are still dangerous

- even if they sit out for "just a few days".

If you are getting rid of your old refrigerator, please follow

the instructions below to help prevent accidents.

Before you throw away your old refrigerator or freezer:

• Take off the doors or remove the drawers.

• Leave the shelves in place so children may not easily

climb inside.

Tools to have available for installation:

• Phillips screwdriver

• Flat blade screwdriver

• Hex head nut drivers size 1⁄4" and 5⁄16"

• Level

• Drill and drill bit (#6 - .204)

• Open end wrenchs size 1⁄4", 7⁄16" and 1⁄2"

• Slip joint pliers

• Adjustable wrench

• Tape measure

• Hex socket and ratchet size 7⁄16"

• 3/32" Hex key (Allen wrench)

Note to Customer

This merchandise was carefully packed and thoroughly

inspected before leaving our plant. Responsibility for its

safe delivery was assumed by the retailer upon acceptance

of the shipment. Claims for loss or damage sustained in

transit must be made to the retailer.

DO NOT RETURN DAMAGED MERCHANDISE TO THE

MANUFACTURER - FILE THE CLAIM WITH THE RE-

TAILER.

!

CAUTION

If the power module was shipped or has been laying on

its side for any period of time allow the power module to

sit upright for a period of at least 24 hours before plugging

in. This will assure oil returns to the compressor. Plugging

the power module in immediately may cause damage to

internal parts.

3

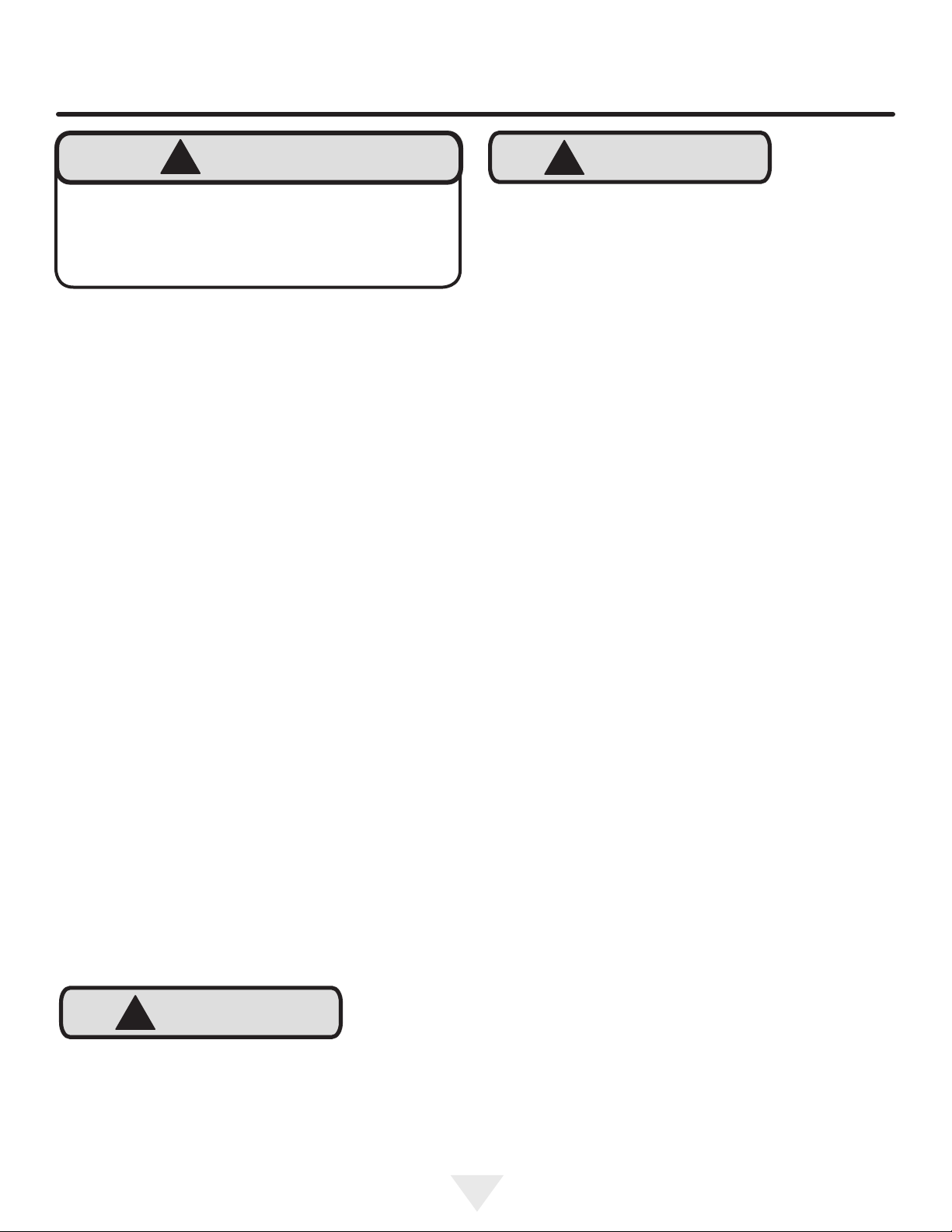

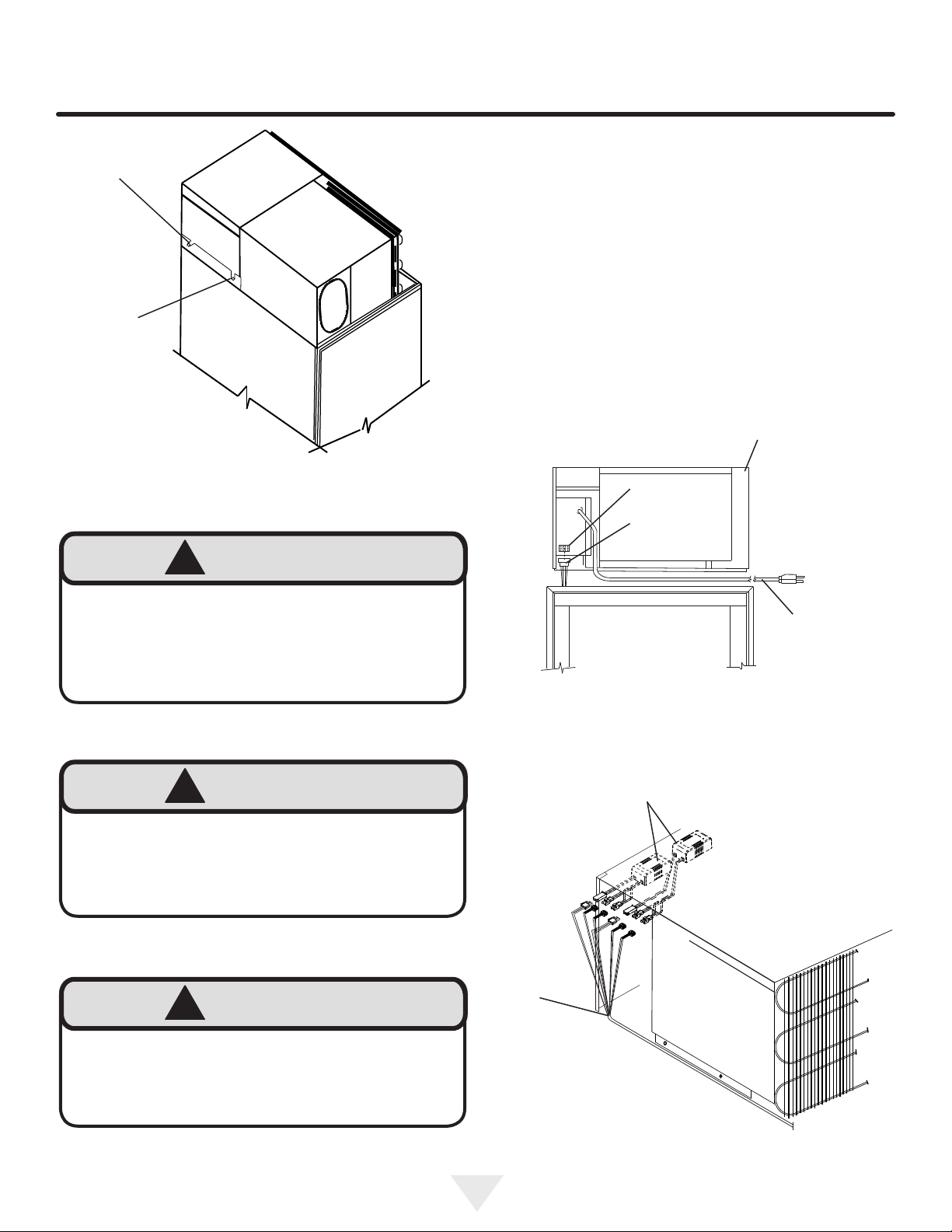

WARRANTY REGISTRATION

Power module serial

plate is behind the

grille on the front of

the power module-

Cabinet serial plate is on the

inside top liner toward the right

side-

Figure 1

Serial plate

locations

Warranty Registration

It is important you send in your warranty registration card

immediately after taking delivery of your wine cellar.

The following information will be required when registering

your unit.

Service Number

Serial Number

Date of Purchase

Dealer’s name and address

The service number and serial number can be found on the

serial plates which are located on the power module and

the cabinet. See gure 1 above for locations.

Figure 2

Power module

serial plate

Figure 3

Cabinet

serial plate

4

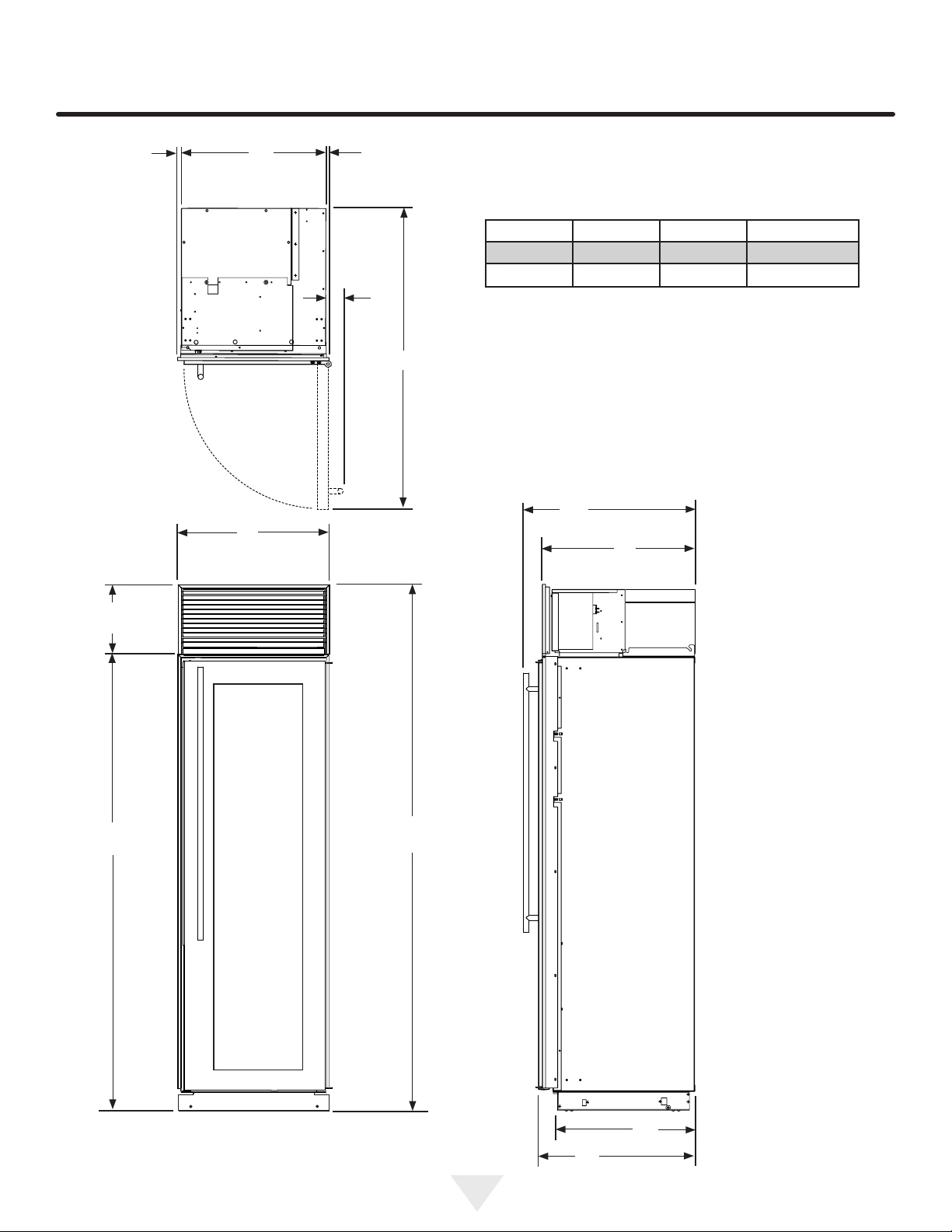

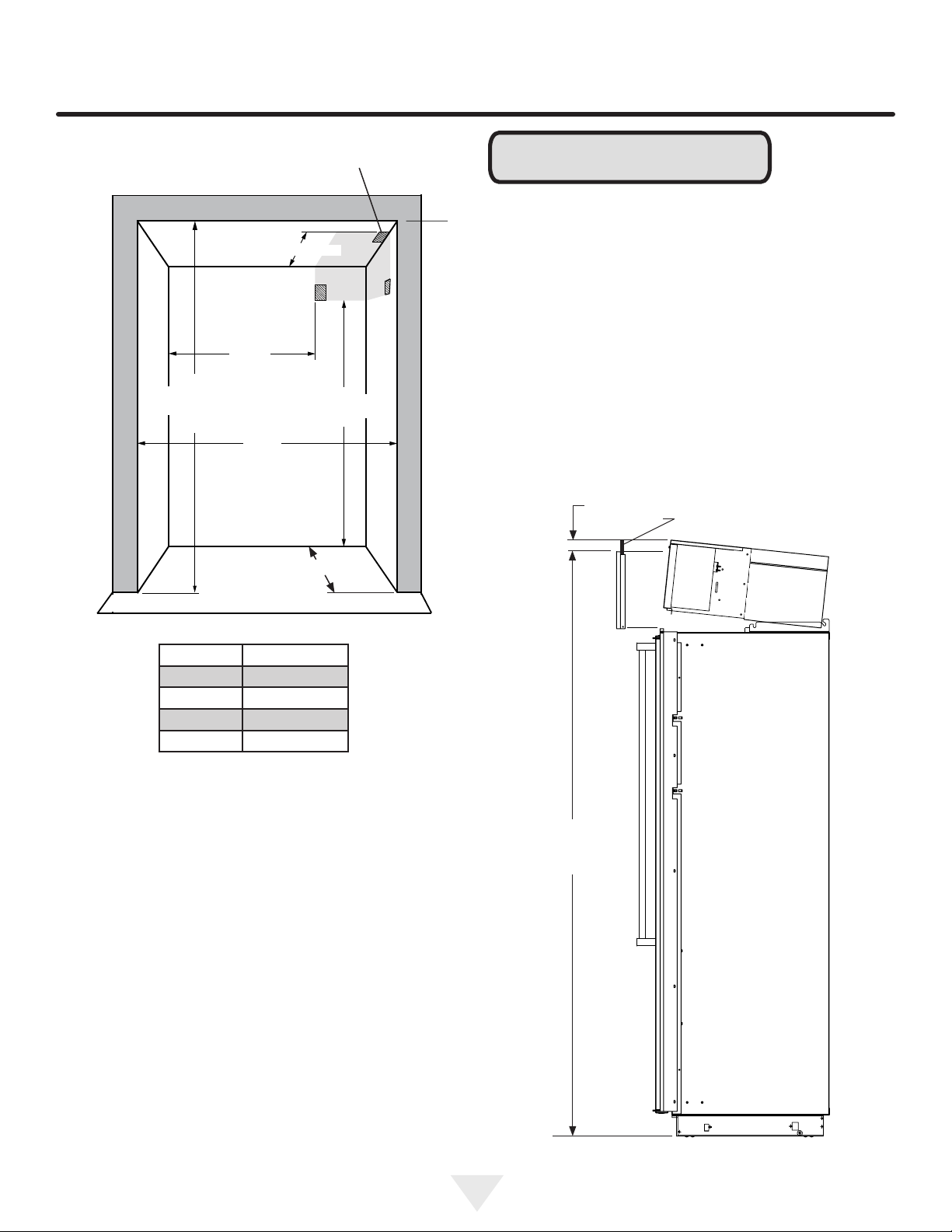

PRODUCT DIMENSIONS FOR M(XX)SZ WITH GLASS DOOR

1

⁄2"

(12.7mm)

"A"

"B"

1

⁄2"

(12.7mm)

29⁄16"

(6.5cm)

Electrical Requirements:

A grounded 115 volt, 60 cycle, single phase, 15 amp

dedicated circuit is required. Follow all local building codes

when installing electrical and unit.

MODEL "A" "B" "C"

M18SZ-BGX 18" (45.7cm) 17" (43.2cm) 4111⁄16" (105.9cm)

M24SZ-BGX 24" (61cm) 23" (58.4cm) 4711⁄16" (121.1cm)

"C"

273⁄16"

(69.1cm)

241⁄2"

(62.2cm)

11"

(27.9cm)

73" to 735⁄8"

(185.4cm to 187cm)

84" to 845⁄8"

(213.4cm to 214.9cm)

251⁄8"

(63.8cm)

197⁄8"

(50.5cm)

To kickplate

To face of door

5

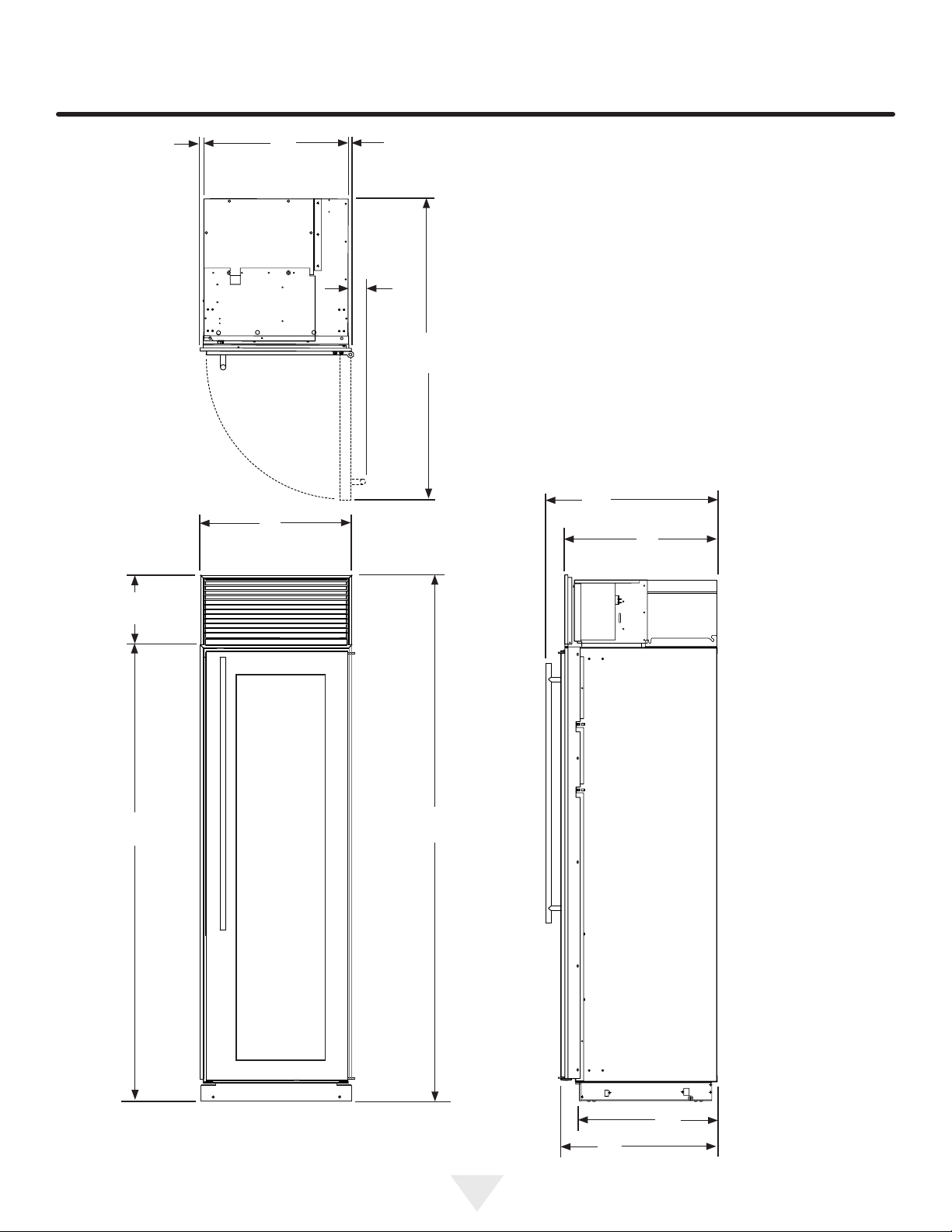

PRODUCT DIMENSIONS FOR M24DZ-BGX WITH GLASS DOOR

1

⁄2"

(12.7mm)

23"

(58.4cm)

24"

(61cm)

1

⁄2"

(12.7mm)

29⁄16"

(6.5cm)

(121.1cm)

Electrical Requirements:

A grounded 115 volt, 60 cycle, single phase, 15 amp

dedicated circuit is required. Follow all local building codes

when installing electrical and unit.

4711⁄16"

273⁄16"

(69.1cm)

241⁄2"

(62.2cm)

11"

(27.9cm)

73" to 735⁄8"

(185.4cm to 187cm)

84" to 845⁄8"

(213.4cm to 214.9cm)

251⁄8"

(63.8cm)

197⁄8"

(50.5cm)

To kickplate

To face of door

6

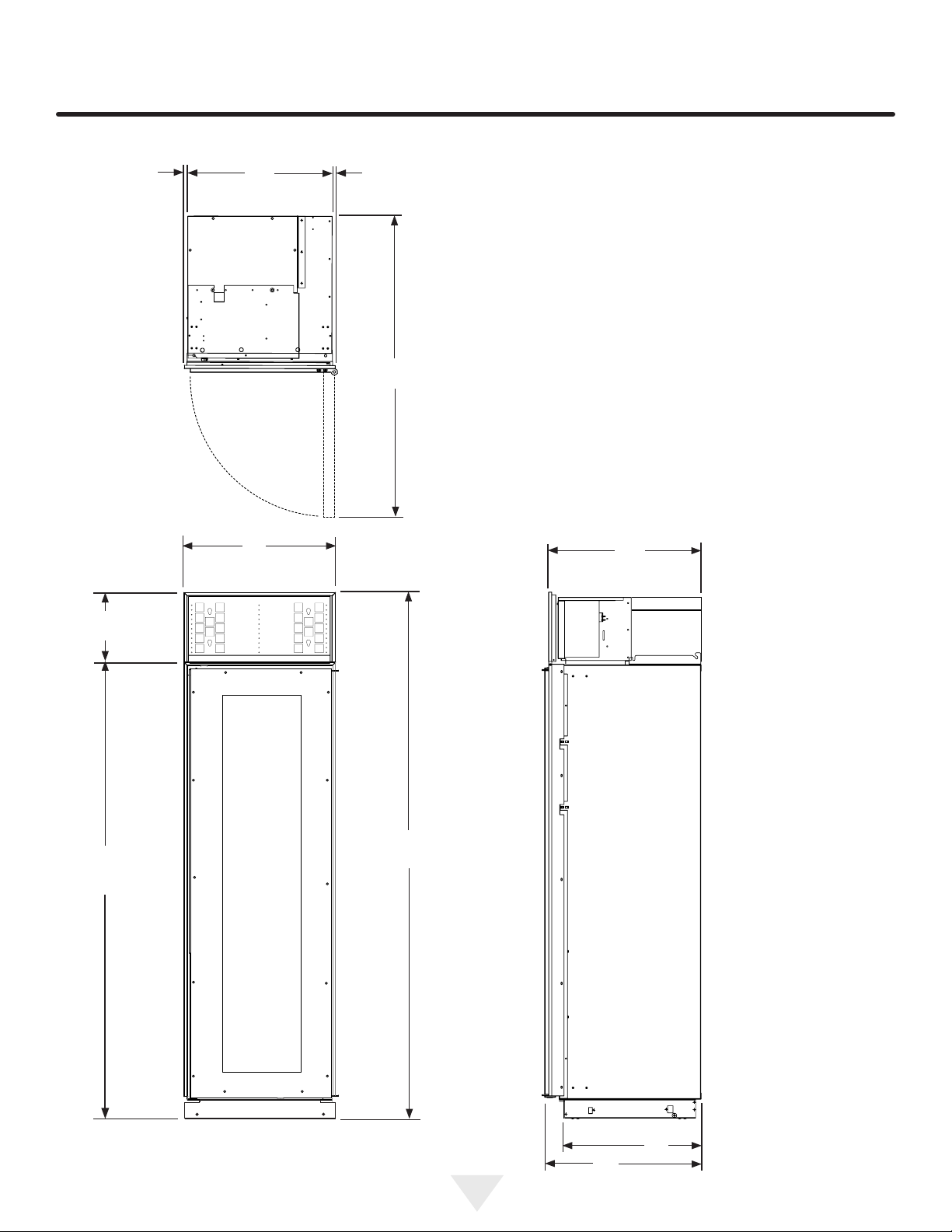

PRODUCT DIMENSIONS FOR M24DZ-BGP WITH GLASS OVERLAY DOOR

Electrical Requirements:

1

⁄2"

(12.7mm)

23"

(58.4cm)

1

⁄2"

(12.7mm)

4711⁄16"

(121.1cm)

A grounded 115 volt, 60 cycle, single phase, 15 amp

dedicated circuit is required. Follow all local building codes

when installing electrical and unit.

11"

(27.9cm)

73" to 735⁄8"

(185.4cm to 187cm)

24"

(61cm)

241⁄2"

(62.2cm)

84" to 845⁄8"

(213.4cm to 214.9cm)

251⁄8"

(63.8cm)

197⁄8"

(50.5cm)

To kickplate

To face of door

7

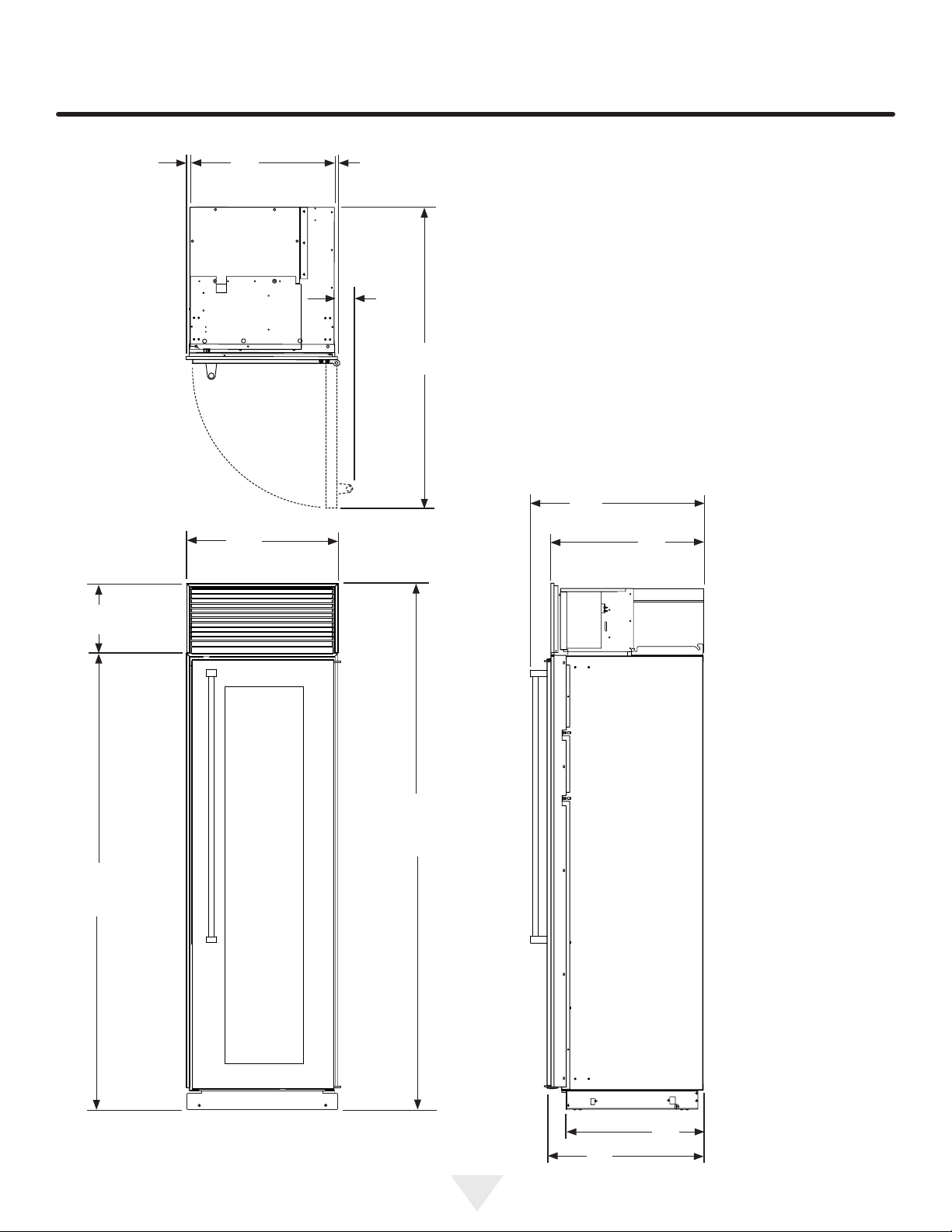

PRODUCT DIMENSIONS FOR MPRO24DZ-BGX WITH GLASS DOOR

Electrical Requirements:

1

⁄2"

(12.7mm)

23"

(58.4cm)

24"

(61cm)

1

⁄2"

(12.7mm)

3"

(7.6cm)

4711⁄16"

(121.1cm)

A grounded 115 volt, 60 cycle, single phase, 15 amp

dedicated circuit is required. Follow all local building codes

when installing electrical and unit.

275⁄8"

(70.2cm)

241⁄2"

(62.2cm)

11"

(27.9cm)

73" to 735⁄8"

(185.4cm to 187cm)

84" to 845⁄8"

(213.4cm to 214.9cm)

251⁄8"

(63.8cm)

197⁄8"

(50.5cm)

To kickplate

To face of door

8

PRE INSTALLATION CONSIDERATIONS

Electrical receptacle location

for 18" wide models (M18SZ)-

22" (55.9cm)

20"(50.8cm) minimum

24" wide models

841⁄4" to 847⁄8"

(214cm) to (215.6cm)

781⁄2" (199.4cm)

Minimum, typical

"Cut out

width"

24" (61cm)

NOTE

Floor under product MUST be at or above the same level

of the surrounding nished oor, for ease of installation and

removal of unit

When planning your rough in opening a 3" removable ller

panel is recommended above the grille. To remove the

power module from the cabinet the front has to be tilted up

as shown in Figure 5 when removed for service.

-3" (7.6cm) removable ller

recommended

Figure 4

Model Cut-Out Width

M18SZ 171⁄2" (44.4cm)

M24SZ 231⁄2" (59.7cm)

M24DZ 231⁄2" (59.7cm)

MPRO24DZ 231⁄2" (59.7cm)

Table A

Select Location

Locate the wine cellar in the coolest part of the room, out of

direct sunlight and away from heating ducts or registers.

Do not place the wine cellar next to heat-producing appli-

ances such as a range, oven or dishwasher. If this is not

possible, a section of cabinetry or an added layer of insula-

tion between the two (2) appliances will help the wine cellar

operate more efciently.

Do NOT install the wine cellar where the temperature will

drop below 65 degrees F (18 degrees C) or rise above 90

degrees F (32 degrees C). The compressor will NOT be

able to maintain proper temperatures.

845⁄8"

(214.9cm)

Maximum

Figure 5

9

PRE INSTALLATION CONSIDERATIONS

Electrical Requirements:

Provide a 115 volt, 60 cycle, single phase 15 amp, AC receptacle. It is recommended that a separately fused circuit

(a time delay fuse or circuit breaker is recommended),

serving only this appliance, be provided. Electrical opening

should be placed 781⁄2" (199.4cm) minimum from the oor.

(See Figure 4).

This product is factory equipped with a power supply

cord that has a three-pronged, grounded plug. It must be

plugged into a mating grounding type receptacle in accordance with the National Electrical Code and applicable

local codes and ordinances. If the circuit does not have a

grounding type receptacle, it is the responsibility and obligation of the customer to provide the proper power supply.

The unit must be installed according to your local building

codes and ordinances.

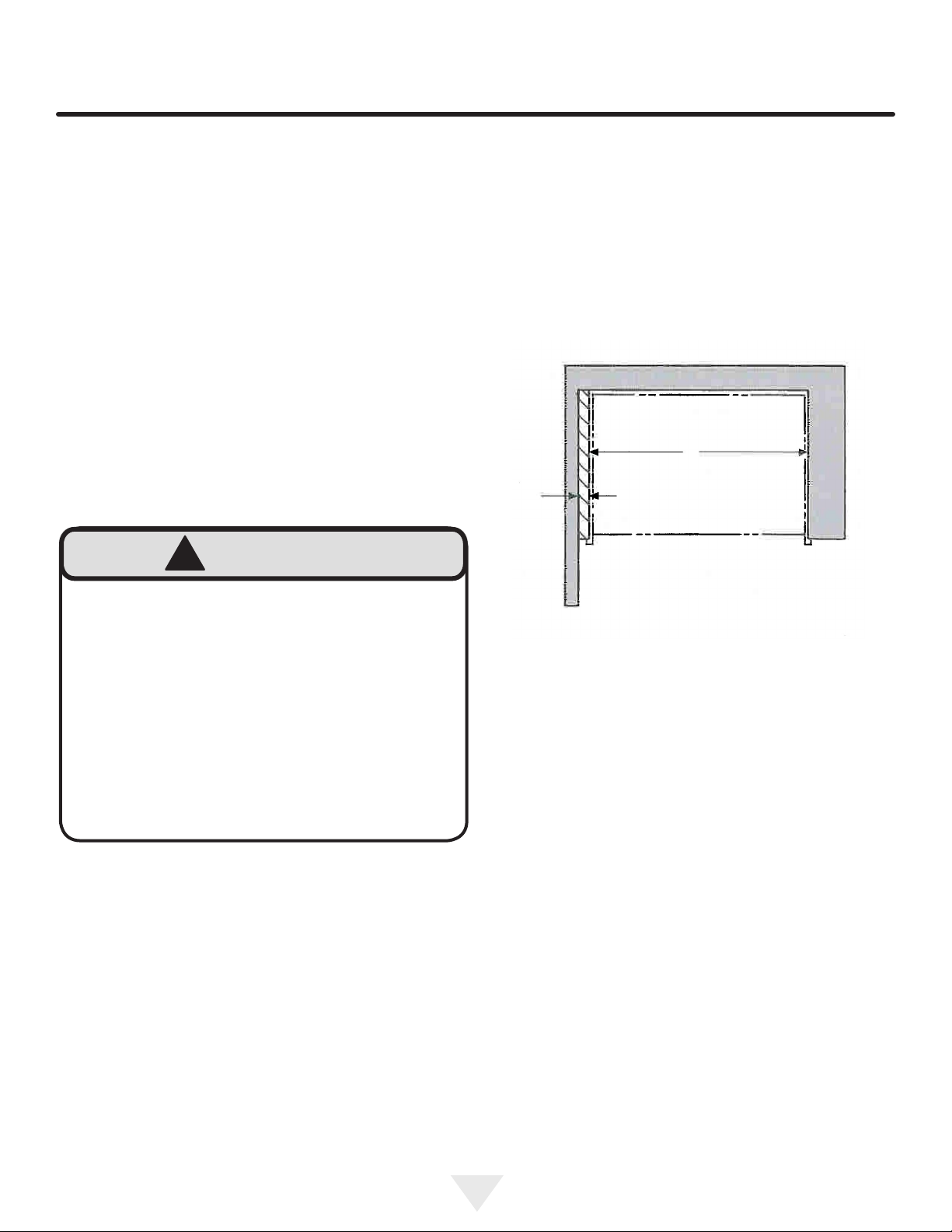

!

WARNING

Corner Installation

For the door to be opened to a full 90°, a 3" (7.6cm) ller

will have to be added to the hinge side of the door. This is

to allow for door handle clearance when opened to the wall.

See Figure 6.

The enclosure must permit the wine cellar to be removed

for service.

Cabinet Width

3" Min.

Filler

Cabinet Outline

Electrical Shock Hazard

• Do not use an extension cord with this appliance.

They can be hazardous and cause decient

operation.

• This unit should not, under any circumstances, be

installed to an un-grounded electrical supply.

• Do not remove the grounding prong from the

power cord.

• Do not use an adapter.

• Do not splash or spray water from a hose on

the appliance. Doing so may cause an electrical

shock, which may result in severe injury or death.

Figure 6

10

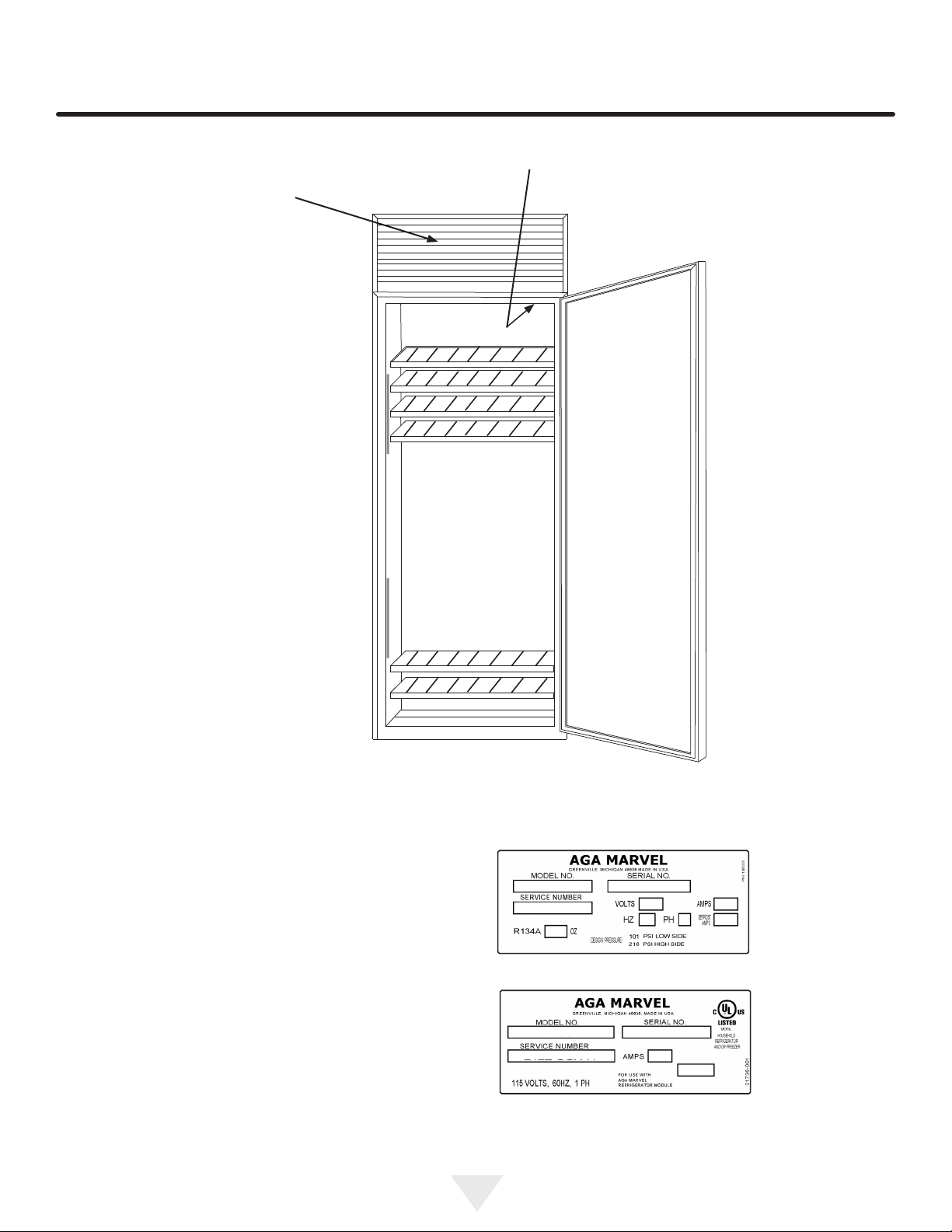

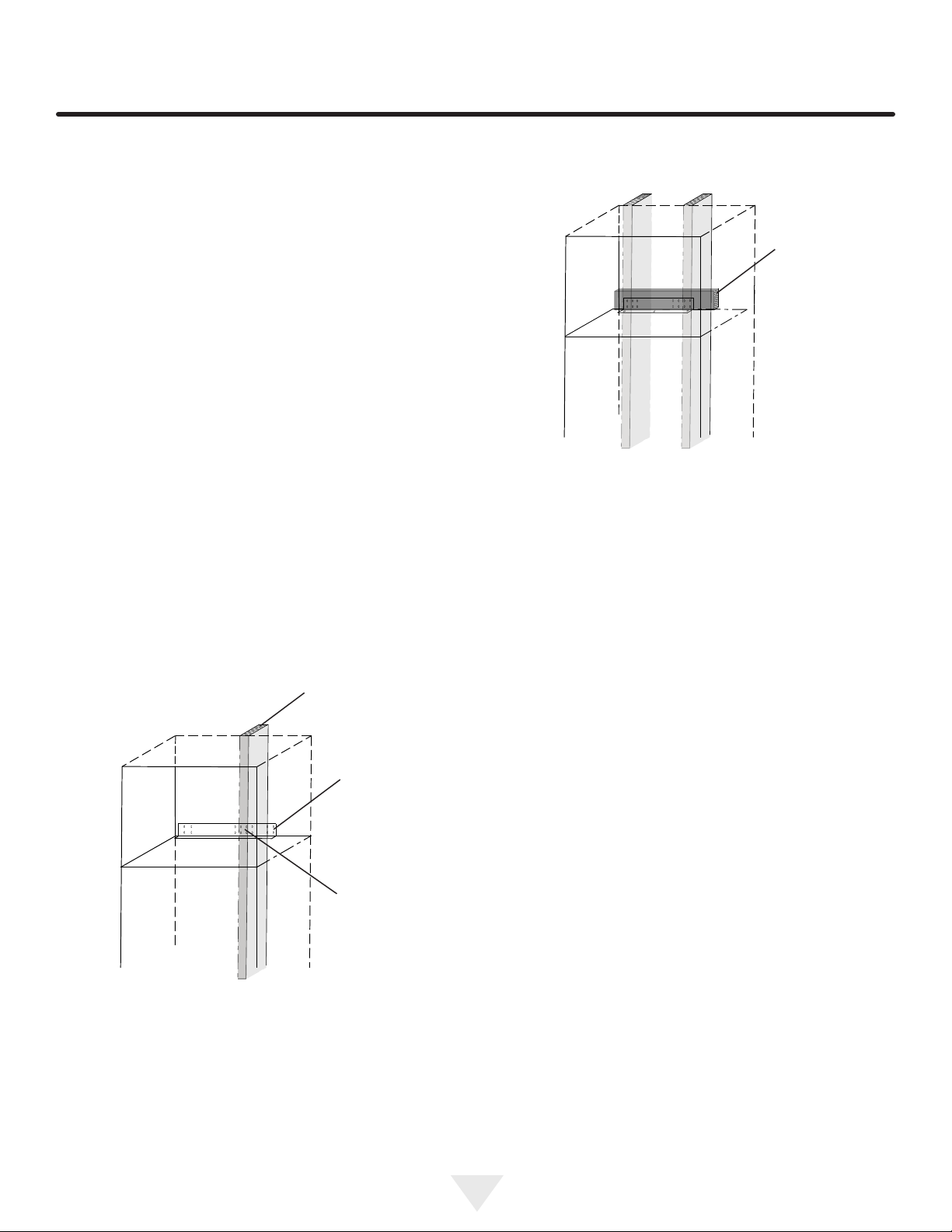

INSTALLING THE CABINET

Anti - tip Bracket considerations

Before placing the cabinet in opening, the depth of the

cut-out opening should be at least 24" (61cm). If the cut-out

opening depth is more than 24" (61cm), then a piece of

wood must be secured crosswise on the wall into the studs

at the height of the anti-tip brackets. (See Figure 8). Slide

the cabinet into position and level the cabinet with adjust-

able rear roller and front leveling legs. (See Leveling the

unit on page 12).

The anti tip bracket is fastened to the cabinet and runs the

full width of the cabinet. Locate a wall stud behind the cabi-

net and secure the anti-tip bracket with at least (2) #8 x 11⁄2”

screws provided. See Figure 7.

-Crosswise

lumber

Figure 8

Figure 7

-Wall stud

-Anti-tip

bracket

on top of

cabinet

-At least 2

screws into

wall stud.

11

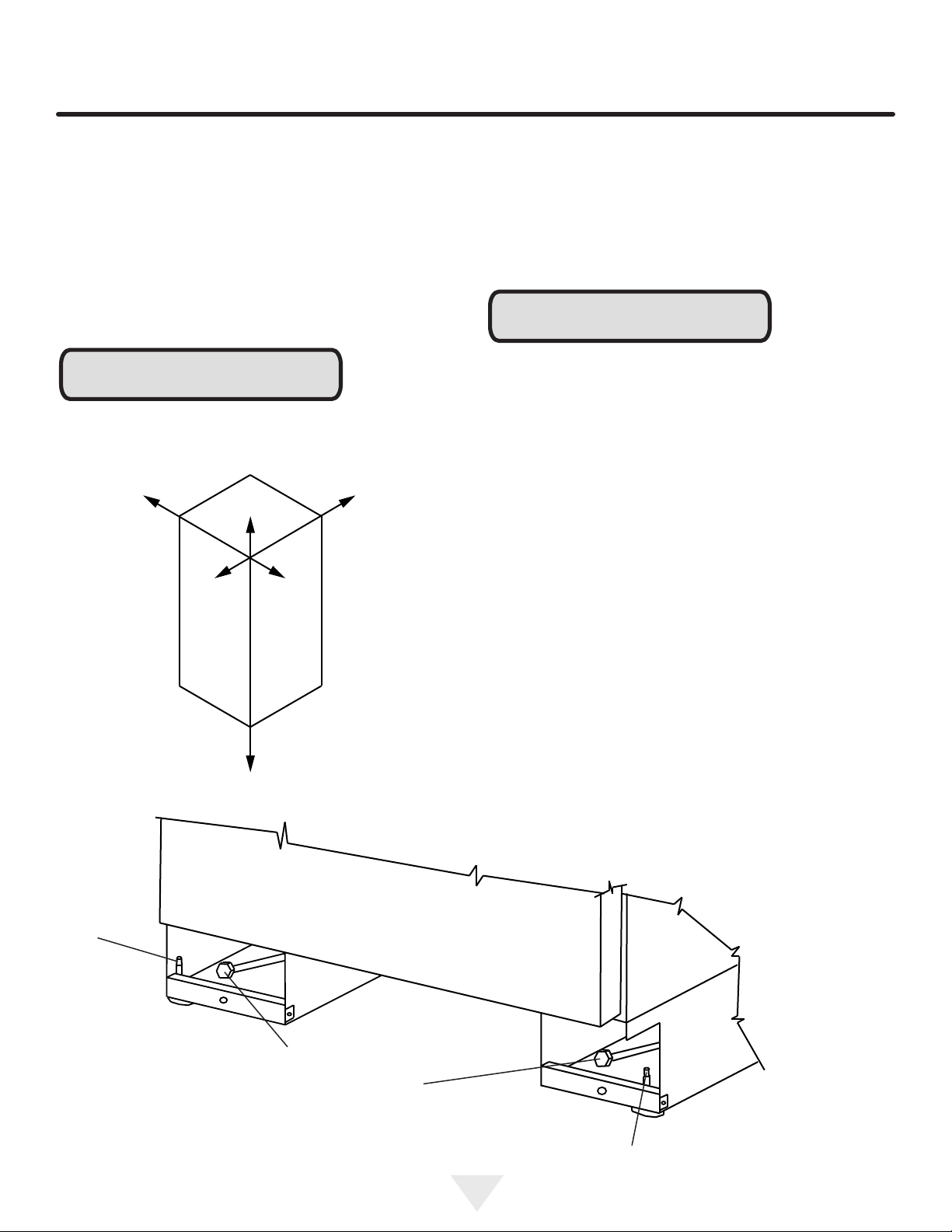

LEVELING THE UNIT AND INSTALLING THE POWER MODULE

Leveling the unit:

Unit MUST be installed level in all planes, on a oor that

is strong enough to support a fully loaded wine cellar. See

Figure 9.

This unit is equipped with front and rear rollers. Rollers will

aid during installation. Rear rollers are adjustable from the

front of the unit. Total adjustment is + 5⁄16, - 5⁄16. Turn

adjusting bolt with a 7⁄16" wrench clockwise to raise cabinet

and counterclockwise to lower cabinet. See Figure 10.

NOTE

Front leveling legs must be adjusted to the oor for leveling

and to prevent the unit from rolling during use. See

Figure 10.

Placing power module on top of cabinet:

Place module on top of the cabinet with rear shoulder

screws resting on the locator brackets behind the front

slots. Slide module toward the rear of the cabinet until the

rear shoulder screws engage the slots in the rear of the

brackets. Rest the front shoulder screws into the front slots

of the brackets.

NOTE

Check to make sure the wiring is clear and not interfering

with module seal. Do NOT start product during construc-

tion, as dust can block module condenser coils. If dust

accumulates on coils, vacuum immediately, using a soft

brush attachment.

Front

leveling

leg-

Figure 9

-Rear Roller Adjustment Bolt

(Use 7⁄16 open end wrench or

socket and ratchet)-

Figure 10

12

-Both front leveling legs must be

adjusted to oor after leveling

INSTALLING THE POWER MODULE

Rear

shoulder

screw-

Front

shoulder

screw-

Figure 11

!

WARNING

Power module electrical connections:

Make electrical connections from the top of the lower

cabinet to the junction box at left side of module. See

module diagram Figure 12.

Run the power cord in front of power module on top of

cabinet around the right side of power module to the

electrical outlet. See Figure 12.

Plug in the (6) electrical connectors for the lights coming

from the cabinet into the (2) power supplies which are

attached to the power module, see Figure 13.

Power module on

top of cabinet-

-Junction box

-Cabinet leads

TIPPING HAZARD

When installed the power module is not fas-

tened to the cabinet. It must be removed

when the cabinet is tipped or transported.

!

WARNING

EXCESSIVE WEIGHT HAZARD

Use two or more people to move product.

Failure to do so can result in back or other injury.

!

WARNING

EXPLOSION HAZARD

Do not operate the wine cellar in the presence

of explosive chemicals or fumes.

-Power

cord

Figure 12

-Light power supplies mounted

in power module

Light

harnesses

from

cabinet-

13

Figure 13

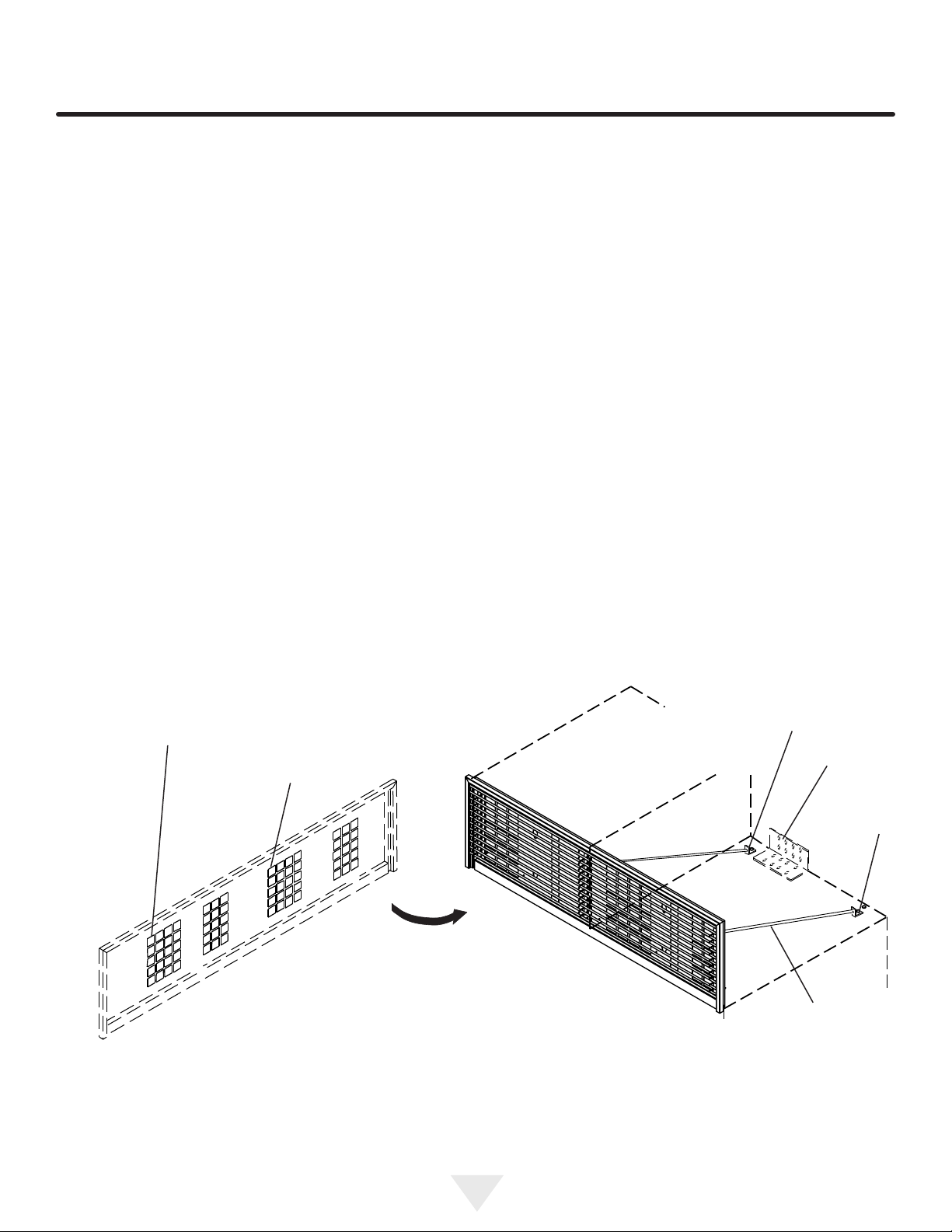

INSTALLING THE GRILLE

There are three methods that can be used to install the

grille. Pick the method that suits your installation.

Style 1: Brackets are installed on top of the cabi-

net, toward the back, and springs are used

to secure the grille.

Style 2: (Optional) Brackets are installed on top of

the cabinet, toward the front, and the grille

is secured to the brackets with screws.

Style 3: The top of the grille is fastened to the ad joining cabinetry with a screw. This style is

used primarily for the custom overlay panel

style grilles to match surrounding cabinets.

Style 1 mounting method:

1. Remove screw A in mounting bracket. Mount L-bracket

with screw A. See Figure 14.

2. Hook one end of spring (81050-000) through hole in

L-bracket. Holding the facia in position - stretch the

spring and secure the hook end to the facia through a

square top hole in the facia.

-Hook the spring(s) into

the square holes toward

the top of the grill-

Back side of

grille shown

Figure 14

Style 1

Power module

-"L" bracket

-Anti-tip

bracket

Screw "A"-

-Spring

14

INSTALLING THE GRILLE

Style 2 mounting method:

Instructions for Installing Grille Brackets

This is an optional accessory order part number

S34060-000.

1. Use the two (91180-000) screws to secure each

bracket to the cabinet top. See Figure's 15 and 16.

2. Loosen the screws at the top of the mounting bracket.

Leave .13 inches (2-3 screw threads) sticking through

the bracket.

3. Install the grille by aligning the screws in the top of the

bracket with the slots in the grille top trim.

4. Grille is installed when bottom of the grille ts behind

the cabinet trim across the front.

5. Pull grille forward about an inch at the top and retighten

the screws in the top of the bracket.

Brackets

optional-

Figure 15 Style 2

Cabinet

top trim-

313⁄16"

(96.8mm)

21⁄16" (52.3mm)

-Bottom of grille shown behind

top trim. See note #4.

2" (50.8mm)

7

⁄16" (11.2mm) reference

-Drill 4 holes 7⁄64" (2.8mm) diameter-

-Grille mounting Brackets (optional)-

Figure 16

Style 2

15

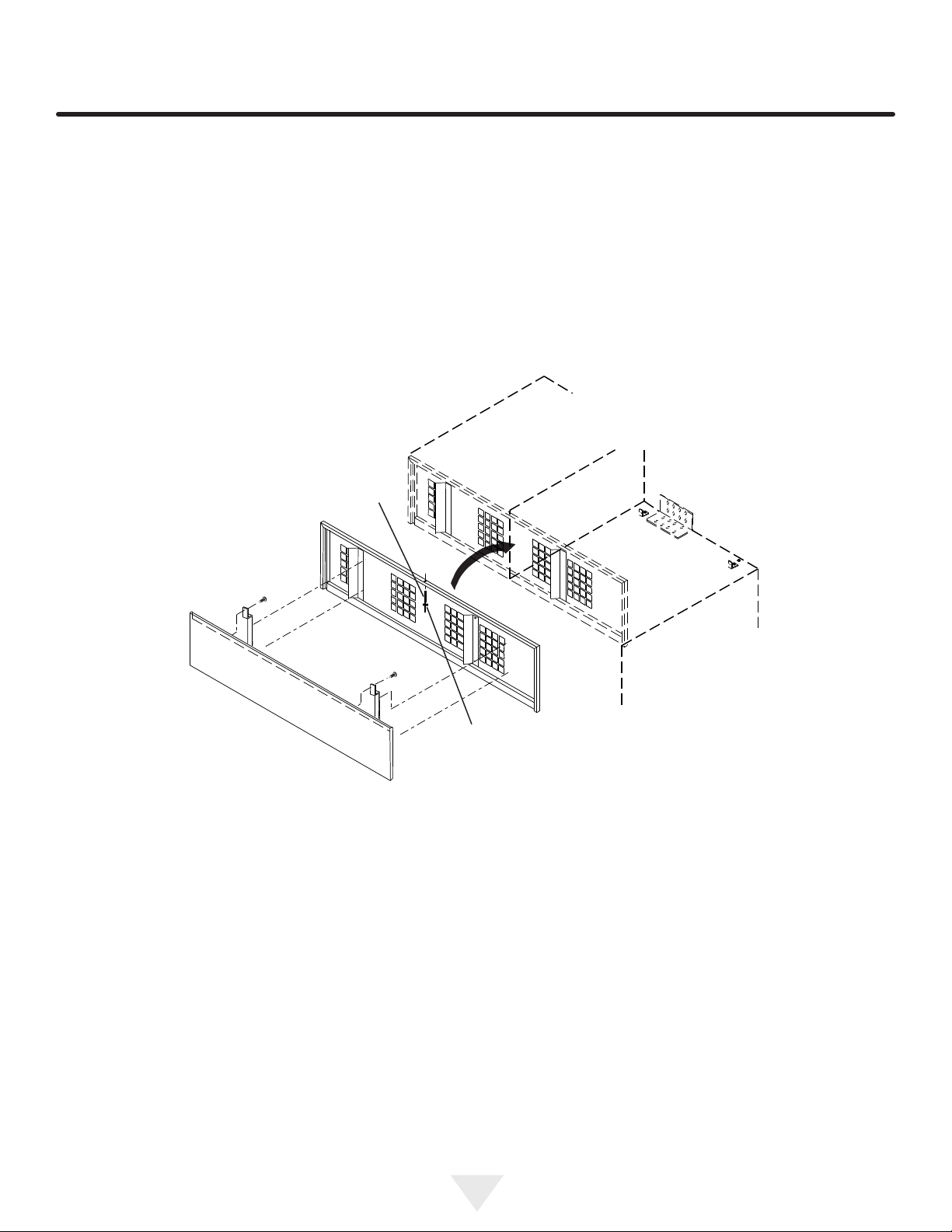

INSTALLING THE GRILLE

Style 3 mounting method:

Fasten top of grille to enclosure with screw provided.

Cover screw head with snap-on cap. See Figure 17.

Cut custom facia panel and mount facia bracket per the

instructions on page 17. Install facia to grille back by

inserting shoulder rivets on back of facia bracket into large

ends of teardrop holes. When all 4 rivets are engaged in

the teardrop holes slide the facia downward until shoulder

rivets bottom out in small ends of teardrop holes.

Screw-

For cutting grille facia panel

and mounting facia brackets

see page 17.

-Snap

on cap

Figure 17

16

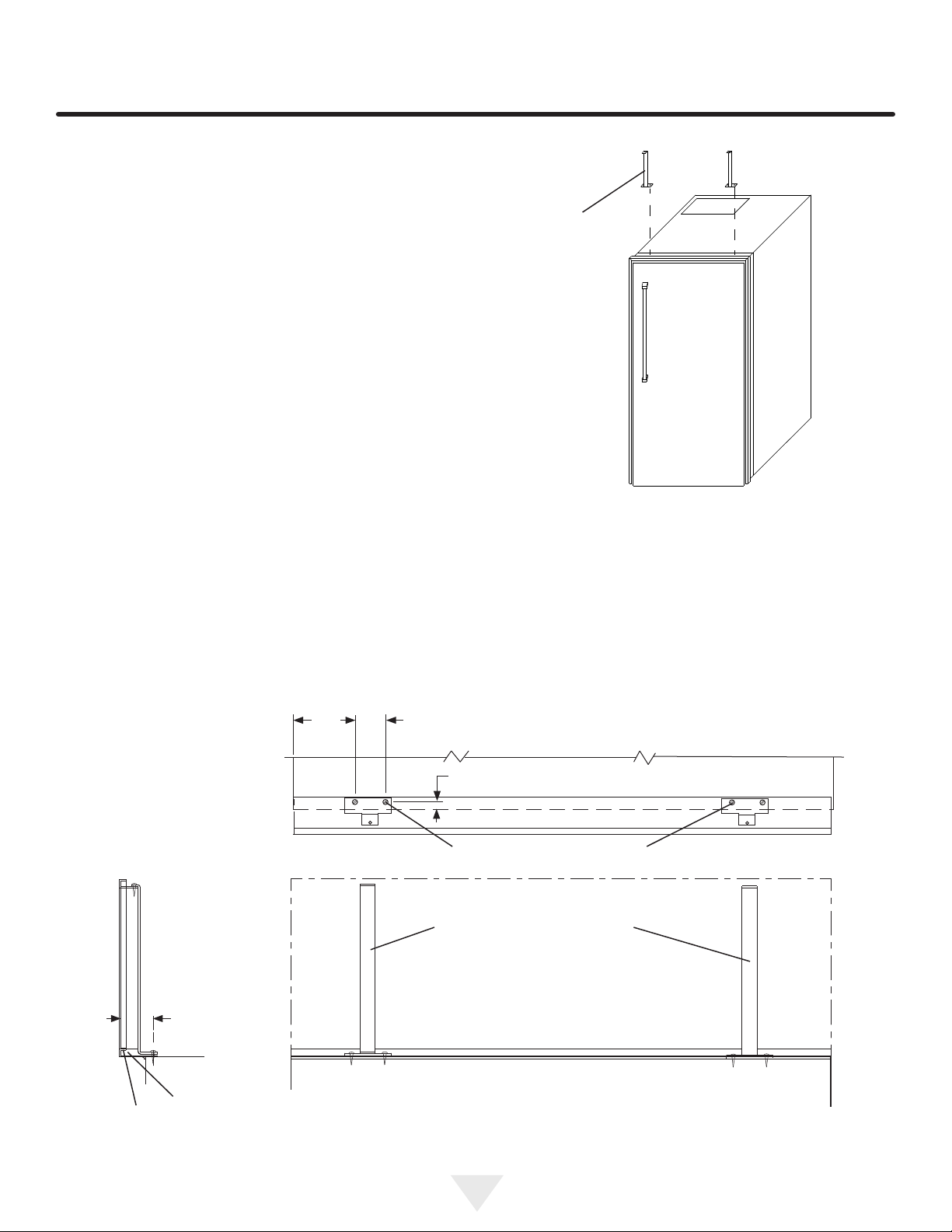

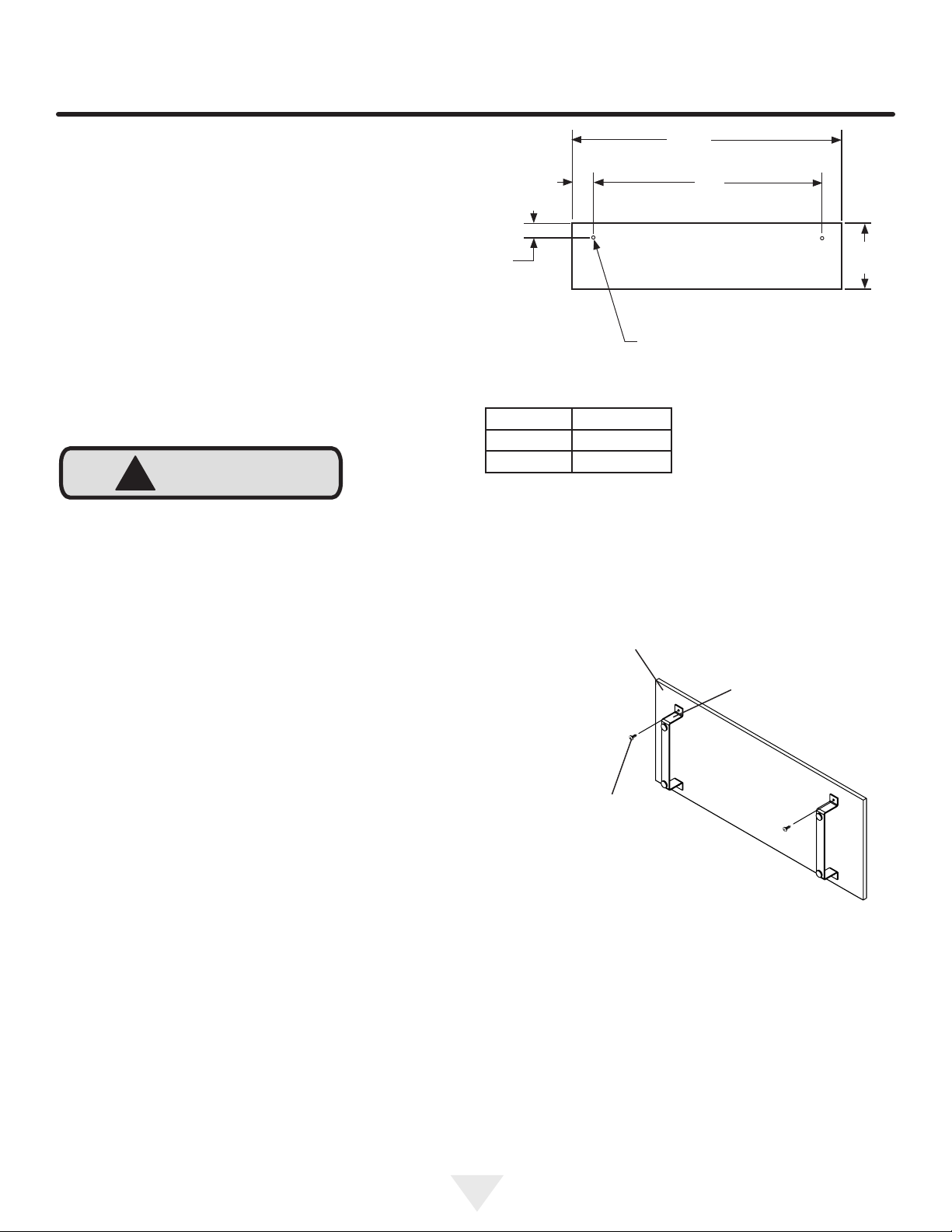

CUSTOM GRILLE FACIA AND DOOR PANELS

Mounting grille facia panel:

Cut the facia panel to the size shown in Figure 18. Drill the

two facia bracket screw pilot holes in the back side of the

facia panel as noted in Figure 18. See Table B, for sizes.

Fasten the two facia brackets to the back side of the facia

panel with 2 of the screws provided. See Figure 19.

Align the facia brackets so they are parallel to the short

edges of the facia panel and drill the remaining 2 bracket

holes using the holes in the facia brackets as guides.

Secure the bottom of the brackets with the 2 remaining

screws.

The facia panel may now be mounted to the grille back.

!

CAUTION

When cutting the facia panel for the grille do not make

it larger than the size noted in Figure 18. Air ow to the condenser in the power module would be compromised. Grille

facia panels must not exceed 20 pounds (9.1kg), panels

weighing more could cause product damage. Do NOT use

glass, mirrors, granite or similar heavy materials for panels.

221⁄32"

(6.8cm)

11⁄8"

(2.9cm)

MATERIAL HOLE SIZE

Hardwood

Softwood

1

⁄8" (3.2mm)

7

⁄64" (2.8mm)

Table B

21"

(53.3cm)

1511⁄16"

(39.8cm)

83⁄4"

(22.2cm)

Figure 18

Drill 2 holes, see Table B.

Facia panel-

Screw 2

required-

Drill bottom 2 holes

for mounting brackets and secure with

remaining 2 screws.-

-Facia bracket

Figure 19

17

Loading...

Loading...