Marvel 30IMTBSFL, 30IMTBBOR, 30IMTWWFL, 30IMTBBFL, 30IMATWWFR Installation Guide

...

Installation

Operation

and

Maintenance

Instructions

Tall Door Clear Ice Models

MARVEL

30iMT

30iMAT

3OiMT

TABLE OF CONTENTS

Unpacking your ice machine.........................

Removing the packaging......................

Warranty Registration .....................

Installing your ice machine......................

Selecting the location..........................

Outdoor Installation ....................................

Cabinet Clearances ....................................

Leveling legs .....................................

Grounding method..............................

Electrical Requirements........................

Installing the drain ...........................................

Optional drain pump installation......................

Connecting the water supply.............................

Dimensions for 30iMT & 3OiMT solid door.......

Recommended Rough in Opening Dimensions

for 30iMT & 3OiMT solid door......................

Dimensions for 3oiMT solid overlay door.

Recommended Rough in Opening Dimensions

for 30iMT solid overlay door........

Dimensions for 30iMAT solid door...................

Recommended Rough in Opening Dimensions

for 30iMAT solid door..................................

Dimensions for 30iMAT solid overlay door.......

Recommended Rough in Opening Dimensions

for 30iMAT solid overlay door......

Full Overlay Panel Installation Instructions....

Operation, Care, and Cleaning......................................15

Operation (Turning on the ice machine)........

Care of the Ice machine...............................

Cleaning the Ice Machine............................................15

Ice Production (Things to Remember)..............

Filler panel kit installation instructions (optional)...

Troubleshooting Guide.........................

Preparing the ice machine for storage............

Obtaining Service ..............................

Household Product Warranty................

............

...............

.................

...............

......

............

.................2

.......

..............

........

..............

..............

............

......................

..........

..............3

...........

........

....................

.........

.......

.............3

............

.............

..............

..............

...............8

...............9

.................9

.............

..............

.............

...............11

.................

.............

...........

............

..........

.............

.............

....................24

...

2

....

.2

..3

..3

..3

...

.3

...3

..4

..5

.7

..8

. 10

.10

..11

.12

...15

....15

..16

.17

......18

.....22

...

..23

1

UNPACKING YOUR ICE MACHINE

NOTE

Important Safety Instructions

Warnings and safety instructions appearing in this

guide are not meant to cover all possible conditions and situations that may occur. Common sense,

caution, and care must be exercised when installing,

maintaining, or operating this appliance.

Recognize Safety Symbols,

Words, and Labels.

CAUTION-Hazards or unsafe practices which could

result in personal injury or property or product damage.

WARNING-Hazards or unsafe practices which could

result in personal injury.

Note to Customer

This merchandise was carefully packed and thoroughly

inspected before leaving our plant. Responsibility for its safe

delivery was assumed by the retailer upon acceptance of the

shipment. Claims for loss or damage sustained in transit

must be made to the retailer.

DO NOT RETURN DAMAGED MERCHANDISE TO THE

MANUFACTURER - FILE THE CLAIM WITH THE RETAILER.

If the unit was shipped or has been laying on its back for

any period of time allow the ice machine to sit upright for a

period of at least 24 hours before plugging in. This will assure oil returns to the compressor. Plugging the ice machine

in immediately may cause damage to internal parts.

Warranty Registration

It is important you send in your warranty registration card

immediately after taking delivery of your ice machine or you

can register online at www.marvelrefrigeration.com.

NOTE-Important information to make a problem free

installation.

Remove Packaging

Your ice machine has been packed for shipment with

all parts that could be damaged by movement securely

fastened. Cut the banding material at the bottom of the

carton, unfold the cartoning at the bottom and remove

the carton from the appliance. Remove the plastic bag,

styrofoam corner posts and any tape holding the door

closed and internal components in place.

The owners manual is shipped inside the ice machine in

a plastic bag along with the warranty registration card.

Important

Keep your carton packaging until your ice machine has

been thoroughly inspected and found to be in good condition. If there is damage, the packaging will be needed

as proof of damage in transit. Afterwards please dispose

of all items responsibly in particular the plastic bags

which can be a suffocation hazard.

The following information will be required when registering

your unit.

Model Number

Serial Number

Date of Purchase

Dealers name and address

The model number and serial number can be found on the

serial plate which is located inside the ice machine at the

bottom of the cabinet.

Help Prevent Tragedies

Child entrapment and suffocation are not problems of the

past. Junked or abandoned refrigerators are still dangerous. Even if they sit out for “just a few days”.

If you are getting rid of your old refrigerator, please follow

the instructions below to help prevent accidents.

Before you throw away your old refrigerator or freezer:

Take off the doors or remove the drawers.•

Leave the shelves in place so children may not easily •

climb inside.

2

INSTALLING YOUR ICE MACHINE

Select Location

The proper location will ensure peak performance of your

appliance. We recommend a location where the unit will

be out of direct sunlight and away from heat sources. To

assure your product performs to specifications the recommended installation location temperature range is from 55

to 80°F (13 to 27°C) for indoor built in units, 55 to 90°F

(13 to 32°C) for indoor freestanding units.

Outdoor Installation

Only the 3OiMT model is suitable for outdoor installations.

A ground fault circuit interrupter electrical receptacle is to

be used to supply electrical power to the refrigerator for

outdoor applications. Contact an electrician if you need

to install one to supply electrical power to your outdoor

wine cellar. Do not install in an environment where the unit

will be exposed to direct sun exposure as this may result in

unsatisfactory performance.

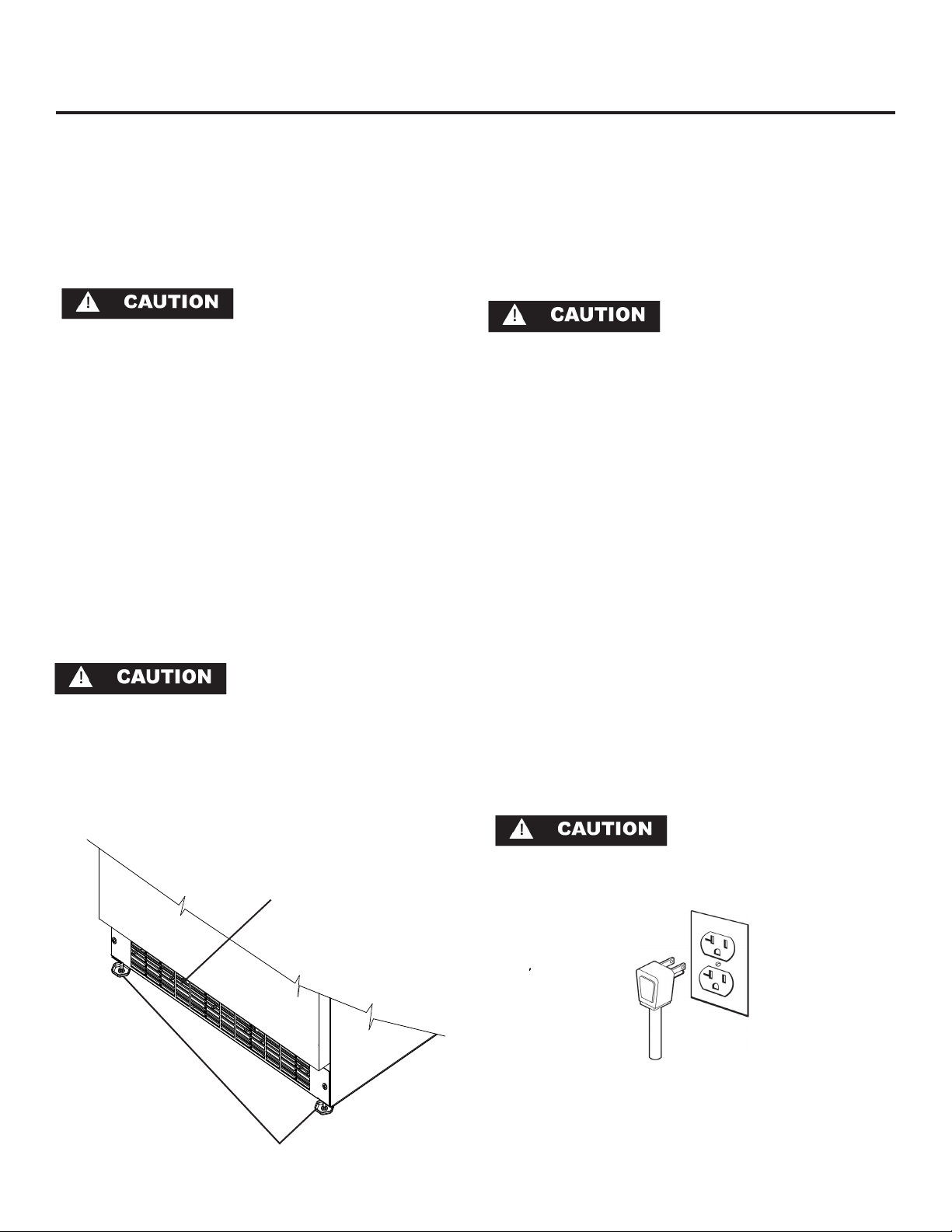

Cabinet Clearance

Ventilation is required from the bottom front section of the

unit. Keep this area open and clear of any obstructions.

Adjacent cabinets and counter top can be installed around

the unit as long as the grille and door access remain unobstructed.

Leveling Legs

Adjustable legs at the front and rear corners of the unit

should be set so the unit is firmly positioned on the floor

and level from side to side and front to back. Turn leveling

legs clockwise to raise unit, counterclockwise to lower it.

(See Figure 1).

Do not splash or spray water from a hose on the ice •

machine. Doing so may cause an electrical shock,

which may result in severe injury or death.

This unit should not, under any circumstances, be •

ungrounded.

Grounding Method

This product is factory equipped with a power supply cord

that has a three-pronged, grounded plug. It must be

plugged into a mating grounding type receptacle in accordance with the National Electrical Code and applicable local codes and ordinances (see Figure 2). If the circuit does

not have a grounding type receptacle, it is the responsibility

and obligation of the customer to exchange the existing

receptacle in accordance with the National Electrical Code

and applicable local codes and ordinances. The third

ground prong should not, under any circumstances, be cut

or removed.

Front Grille

Do not obstruct the front grille. The openings within the

front grille provide air to flow into and exit from the refrigerator condenser. For this reason it is important this area to

not be obstructed and be kept clean. Marvel does not recommend the use of custom made grilles as air flow may be

restricted because of inadequate openings. (See Figure 1).

Front Grille,

keep this

area open.

Figure 1

Leveling Legs

3

Electrical Connection

115 volts, 3 amps running max. 15 amp dedicated circuit

required. 3 prong grounded receptacle required.

Do not use an extension cord

with this appliance.

Figure 2

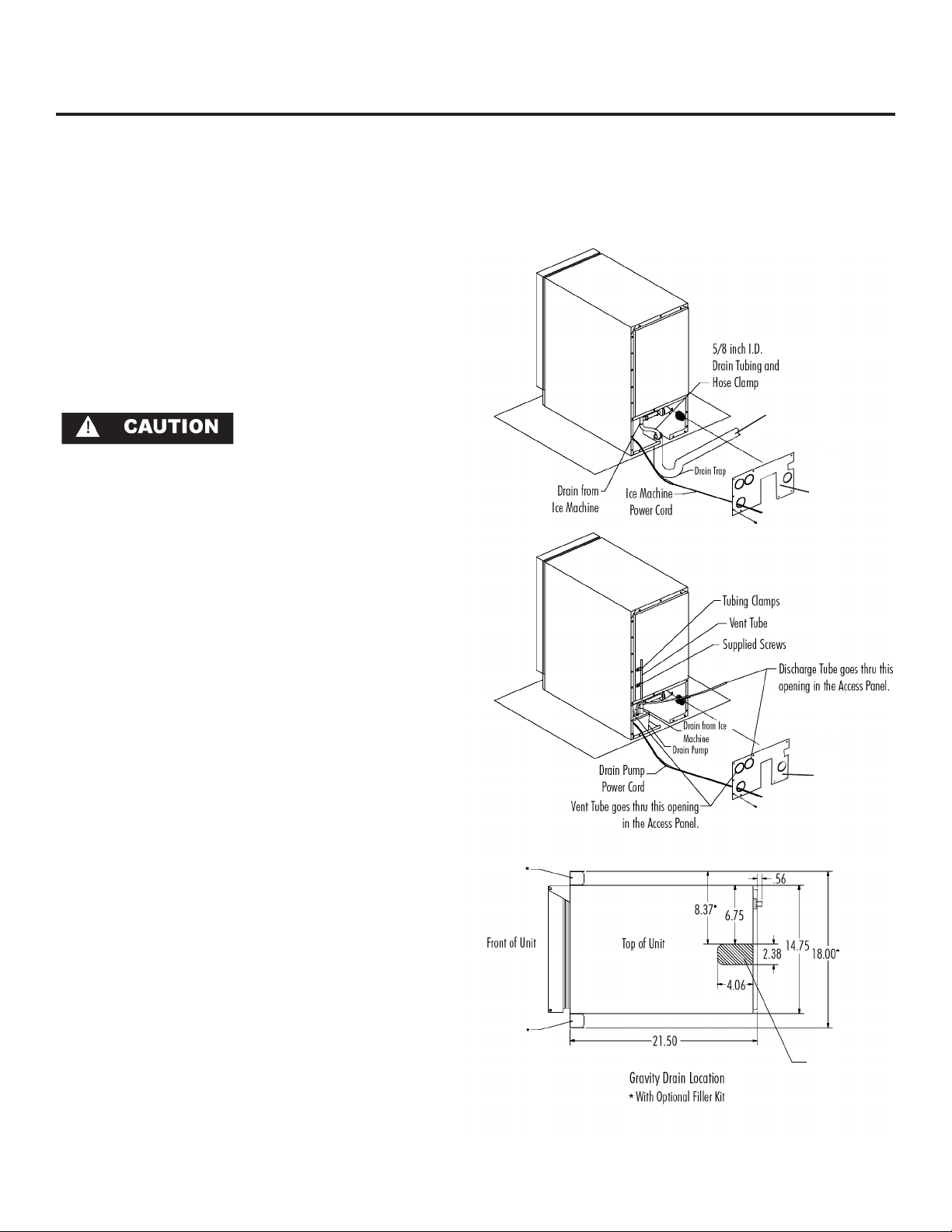

Drain Plumbing

Your ice machine uses a gravity drain (Figure 3) that requires 5/8” I.D. tubing from the back of the ice machine

to a plumbed connection to a sanitary sewer. Remove the

access panel to plumb in drain connection. Gravity drain

location for built-in units can be within the area shown

in Figure 5. An optional drain pump (Figure 4) can be

purchased for your ice machine if a gravity drain is not accessible. See page 5 for optional drain pump installation.

Observe and follow all local codes when installing ice

machine.

Failure to use adequate drainage system will result in

surrounding water damage and/or poor ice production.

INSTALLING THE DRAIN PLUMBING

Figure 3

1-1/2” Drain pipe

Access

panel

Figure 4

Access

panel

Figure 5

Drain

Access

4

OPTIONAL DRAIN PUMP INSTALLATION

The Marvel Drain Pump is designed to remove drain water

from ice machines installed in areas without direct drainage access. The sealed reservoir pump collects the melted

ice water and pumps it to a maximum lift of eight (8) feet

through 3/8” I.D. vinyl tubing to a drain.

This pump has been evaluated for use with water

only.

NOTE: Despite the ease of installation, reasonable care

and safe methods should be practiced. Do NOT work

with energized electrical equipment in a wet area. Read

and follow the installation instructions listed in this

manual.

Risk of electric shock - This pump is supplied with a

grounding conductor and grounding-type attachment

plug. To reduce the risk of electric shock, be certain that

it is connected only to properly grounded, groundingtype receptacle.

Maintenance

The following items require review on a regular basis.

Check that the inlet tubing from the ice machine 1.

drain to the drain pump is open and is free of foreign

material. Inspect the screen at the top of the inlet tube

to ensure there is nothing blocking water flow to the

pump.

Check that the vent line is open, free of kinks/sharp 2.

bends, so that air flows freely from the pump reservoir.

Check that the discharge tubing is free of foreign ma-3.

terial (algae, etc.) and kinks/bends. Confirm that the

check valve is operational by observing that the water

flow is evident in one (1) direction only - out of the

pump. Remove and clean as required.

Troubleshooting

NOTICE: If the drain pump reservoir (not the ice machine

bin) reaches overfill condition, the power to the ice machine will be shut off.

Materials Supplied

1- Marvel 115VAC/60Hz Drain Pump

1- 20 ft. x 3/8 in. I.D. Discharge Tubing

1- 18 in. x 3/8 in. I.D. Vent Tubing

1- Installation Kit (contents below)

1- 1-3/4 in. x 5/8 in. I.D. Inlet Tubing

1- 8 in. x 5/8 in. I.D. Inlet Tubing

2- Tubing Clips (secures vent tubing to back of ice

machine)

2- Small Tubing Clamps (secures vent and discharge

tubing)

2- Large Tubing Clamps (secures inlet tubing)

2- #8 x 3/8” Screws

Tools Required

Pliers

Phillips Screwdriver

Flat Blade Screwdriver

5/16” Hex Head Driver

If the ice machine is not working, check the following:

Make sure there is power at the receptacle.•

Make sure the ice machine is turned on.•

Make sure the ice bin is not full.•

Then check the drain pump:

The pump does not run:

Make sure the pump is plugged in and there is power •

to the receptacle.

Check the inlet screen for debris and clean as needed.•

Make certain the vent line is free of kinks/sharp bends •

or restrictions.

Make certain there is enough water to activate the •

drain pump. It will take at least one (1) quart of water

to activate the drain pump.

The pump runs, but no water is pumped out:

Check that the vent is clear and free of restrictions.•

Check the discharge line to make certain there are no •

restrictions.

Make sure that the discharge tubing has not exceeded •

the maximum lift of eight (8) feet and the horizontal

run is not greater than twenty (20) feet.

The pump runs and then quickly turns off repeatedly:

Check to make certain the drain pump is level.•

Check that the vent is clear and free of restrictions.•

5

30iM Installation

NOTE

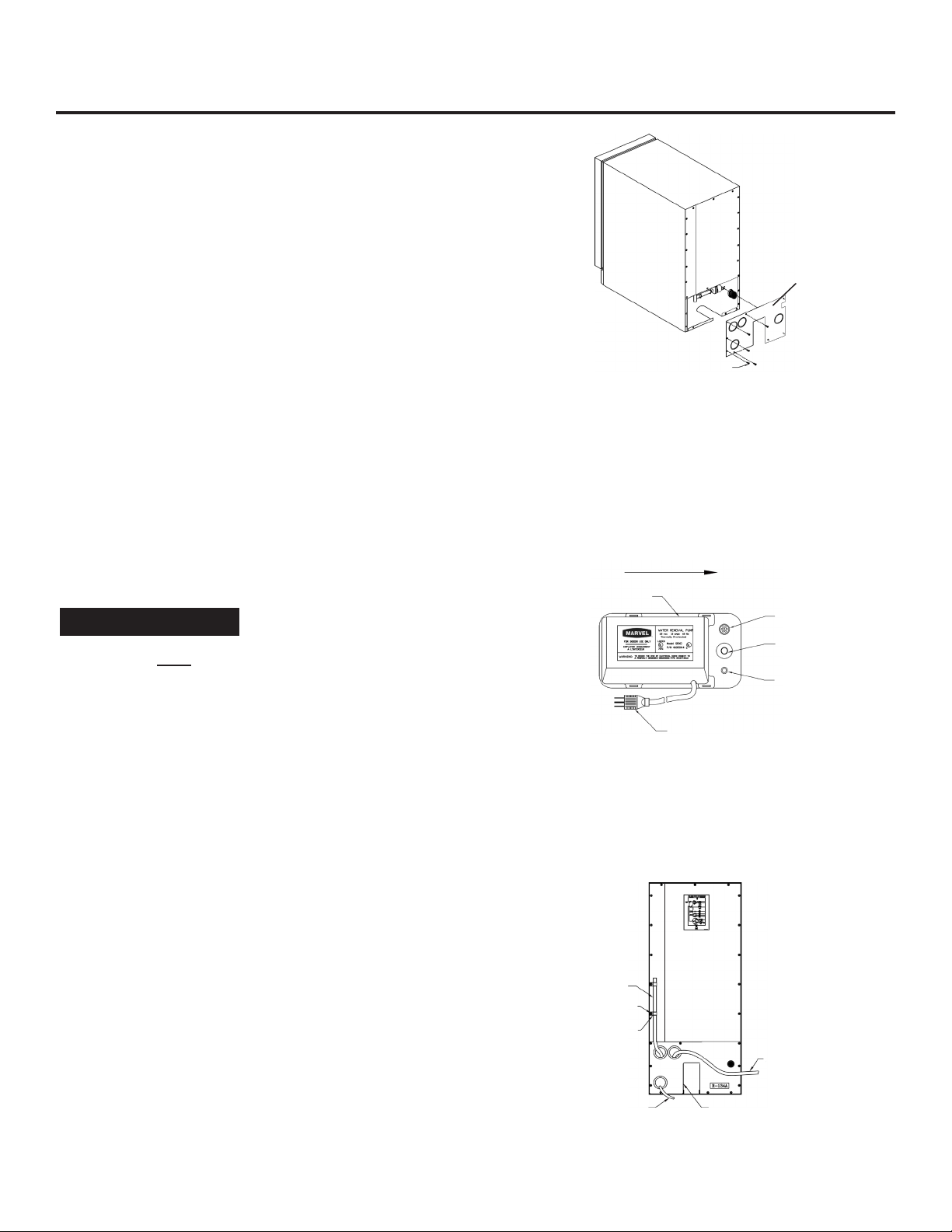

Turn the ice machine to gain access to the rear of the 1.

unit. Remove the access panel by removing the ten

(10) screws (see Figure 6).

Plug the ice machine’s power plug into the outlet on 2.

the drain pump. Place the drain pump in the left, rear

opening of the ice machine with the inlet, vent, and

discharge fittings to the rear of the unit (see Figure 7).

Install 1-3/4 in. x 5/8 in. I.D. inlet tubing to drain 3.

barb on ice machine and then on the inlet of the drain

pump. Clamp both ends of the tube with the large

tubing clamps.

Connect the 18 in. x 3/8 in. I.D. formed vent tube to 4.

the vent on the drain pump and secure with one (1) of

the small tubing clamps.

Route a short section of the 20 ft. x 3/8 in. I.D. tube 5.

through the opening in the access panel and connect

it to the discharge of the drain pump. Secure with the

small tubing clamp.

Route the vent tube and the drain pump power cord 6.

through the remaining openings in the access panel as

shown in Figure 8. Reinstall the panel and secure.

Secure the vent tube to the back of the ice machine 7.

using the supplied tubing clips and screws as shown in

Figure 8.

The vent tube must be attached and secured or water

damage may occur. Make certain there are no kinks in

the tube. The drain pump will not operate correctly with

a partially blocked vent line.

Connect the discharge tube to a suitable drain. Cut 8.

excess tubing as needed. Do NOT allow sags or kinks

in the tubing that will restrict flow.

Make certain that the drain pump is level in the ice 9.

machine’s rear opening.

Plug the power cord of the drain pump into a properly 10.

grounded 115VAC receptacle.

Test the drain pump by slowly pouring water into the 11.

ice machine ice storage bin. Approximately one (1)

quart of water is required to activate the drain pump.

Test the operation of the safety switch by turning the ice 12.

machine on and completely restricting the discharge

line while the pump is operating. Pour more water into

the ice machine’s ice storage bin until the ice machine

turns off. The drain pump will continue to operate.

Remove the discharge tube restriction and allow the

water to be pumped out. The power to the ice machine will be restored when the water in the pump

returns to normal.

Place the ice machine in the installed location. En-13.

sure that all tubing and power cords are not pinched,

kinked, or disturbed.

OPTIONAL DRAIN PUMP INSTALLATION

Access Panel

Screws

Figure 6

Towards the Rear

of the Ice Machine

Receptacle for

Ice Machine’s Plug

Vent Tube

Screws

Tubing Clips

Drain Pump’s

Power Cord

To Wall Receptacle

Figure 7

Access Panel

Figure 8

Inlet Tube

Fitting

Discharge

Tube Fitting

Vent Tube

Fitting

To Drain

6

CONNECTING THE WATER SUPPLY

NOTE

Water Supply

The ice machine must be connected to a potable, active

cold water supply line delivering water pressure at a minimum of 20 psi and a maximum of 120 psi.

Water connection is made through a right angle •

garden hose fitting supplied with the ice machine. See

Figure 10 for detailed instructions. DO NOT USE ANY

THREAD SEALERS.

A water filter can be used with this unit. A quality filter •

can help remove particles as well as remove taste and

odors from water.

DO NOT USE A “REVERSE OSMOSIS” FILTERING •

DEVICE.

Softened water is not recommended. This will produce •

soft, cloudy ice cubes that will stick together.

De-ionized water is not recommended. This water will •

not form solid ice cubes.

A water specialist can recommend proper water treat-•

ment.

After installation of water line, turn on water and check •

for any leaks. Additional tightening may be needed.

Allow for extra water line for built-in installations for •

easy removal of unit and to help prevent the water line

from kinking.

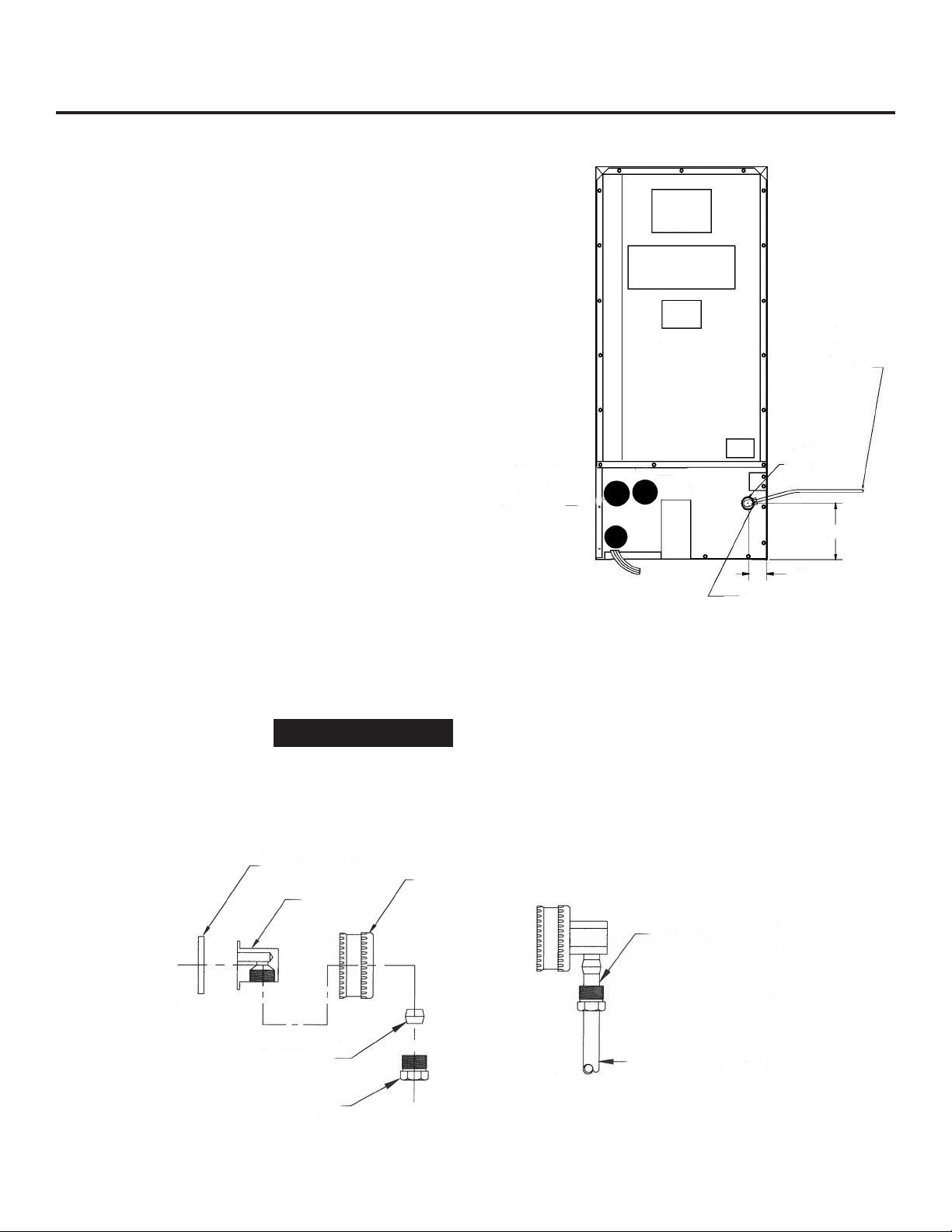

1/4 inch

Tubing from

Cold Water Line

Garden Hose

Fitting

2-7/32” (57mm)

Compression Fitting

5-1/2”

(140mm)

Figure 9

The water line fitting supplied with your icemaker is to be used

on a 1/4 inch copper water supply line only. Do not attach a

plastic supply line using this fitting.

Rubber Washer

Adapter

Compression Fitting

Compression Nut

Fitting Valve

1/4 inch Copper

Water Supply Line (*)

From Water Supply

to Ice Maker

7

Figure 10

(*) Supplied by Customer

14-7/8”

(37.8cm)

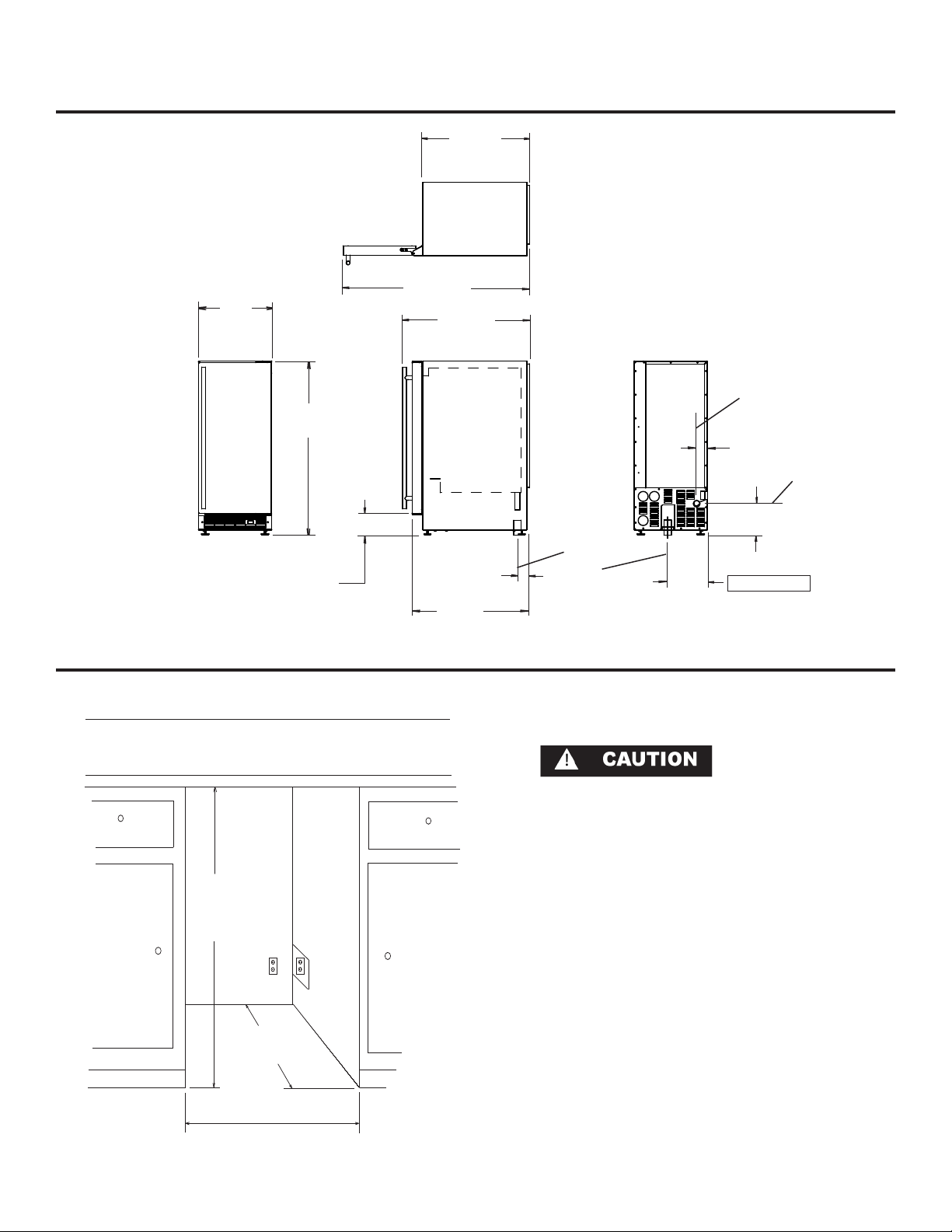

DIMENSIONS FOR 30iMT & 3OiMT SOLID DOOR

21-1/2”

(54.61cm)

37-1/16”

(95.4cm)

25-1/2”

(64.77cm)

34-1/4” to 34-1/2”

(87 to 87.6cm)

CL water supply

2” (5.08cm)

CL water supply

6” (15.24cm)

CL gravity

3” to 3-1/4”

(7.62 to 8.26cm)

2” (5.08cm)

23-5/8”

(60cm)

drain

8” (20.32cm)

Rough In Opening Dimensions, for 30iMT & 3OiMT Solid Door

Electrical Requirements: 115 volts,

3 amps running max. 15 amp

dedicated circuit required. 3 prong

grounded receptacle required.

34-1/2”

(87.6 cm)

*24” (61 cm)

standard cabinet

15” (38.1 cm)

Power outlet can be located in the

back wall behind unit. Add 1” to

depth for thickness of plug, or recess

outlet 1” into the wall. Power outlet

can also be installed in adjacent

cabinetry with a cutout for routing of

power cord. Follow all local building

codes when installing electrical and

unit.

Product weight = 100 lbs. (45.5 kg.)

depth

* Depth dimension may vary depending on

each individual installation.

8

Loading...

Loading...