Marvel 30iM Use and Care Guide

Marvel Ice Machine

Installation

Operation &

Maintenance

Instructions

Part of AGA Foodservice Group

Remove Packaging

Your ice machine has been packed for shipment

with all parts that could be damaged by movement

securely fastened. Before installing the ice

machine, be sure all packing materials and tape

have been removed.

Important

Save the carton packaging until your ice machine

has been thoroughly inspected and found to be in

good condition. If there is damage, the packaging

will be needed as proof of damage sustained in

transit.

Note to Customer

This ice machine was carefully packed and thoroughly inspected before leaving our plant.

Responsibility for its safe delivery was assumed by

the carrier upon acceptance of the shipment. As

directed on the side of the packaging carton,

claims for loss or damage sustained in transit must

be made on the carrier as follows:

Exterior Damage

Make a thorough damage notation on the delivery

receipt and have the driver acknowledge by signing and dating. Send a written request asking for

an inspection report from the carrier representative

and the date the inspection was requested. Retain

the inspection report and receipt for filing of a

claim.

Concealed Damage

This must be reported to the carrier within fifteen

days. Obtain an inspection report from the carrier.

Retain the inspection report for filing of the claim.

DO NOT RETURN DAMAGED MERCHANDISE

TO THE MANUFACTURER - FILE THE CLAIM

WITH THE CARRIER.

1

STARTING OUT

Select Location

The proper location will ensure peak performance of your ice machine. Choose a location

away from heat and out of direct sunlight. Best

performance will be maintained when installed

within the following parameters:

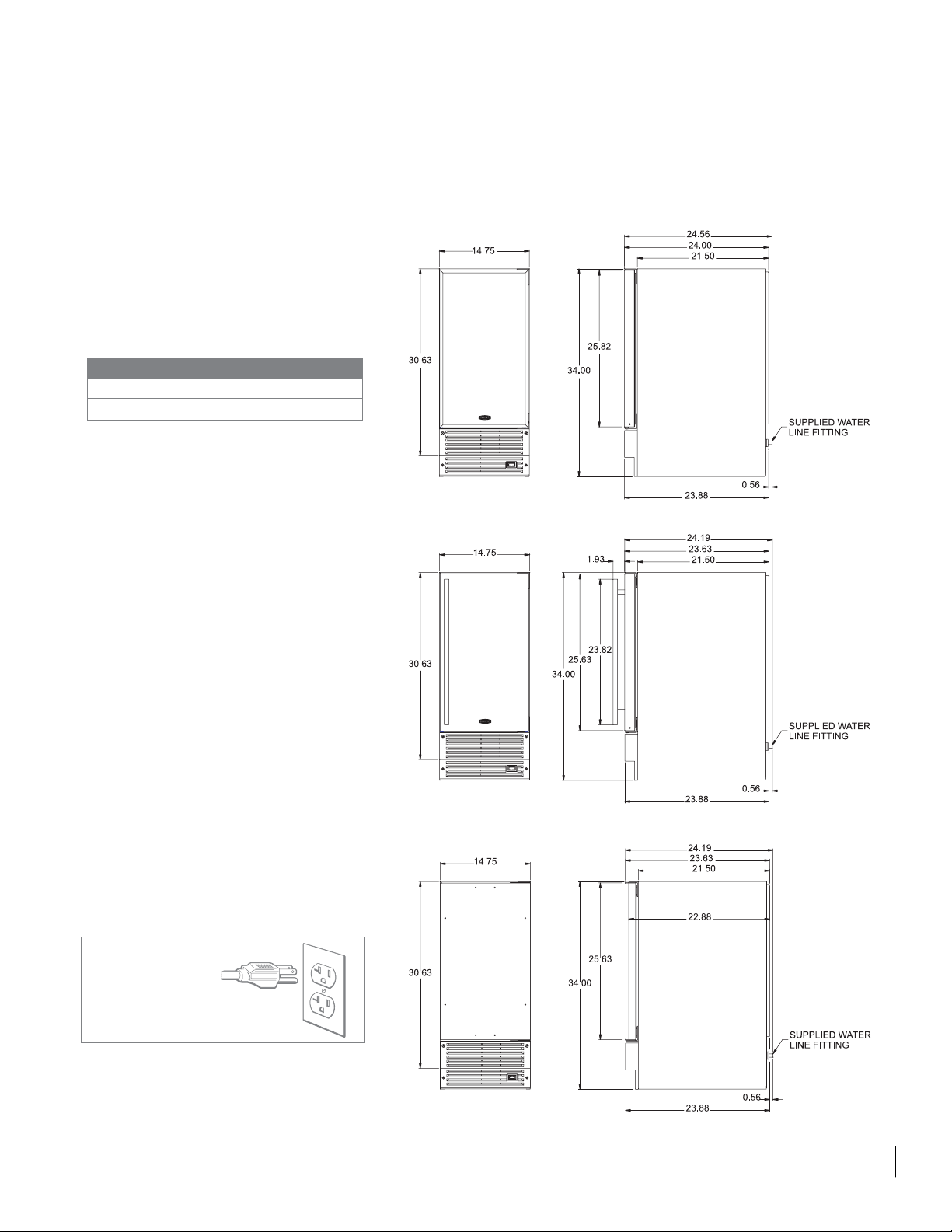

Cabinet Clearance

Ventilation is required for the bottom front section

of the unit where the grille is located. Keep this

area open and clear of any obstructions.

Adjacent cabinets and countertop can be built

around the unit as long as no top trim or countertop is installed lower than the top of the hinge.

Make certain that the glides supplied with the ice

machine are installed according to instructions.

Make certain your ice machine is level. Leveling

adjustments can be made by raising or lowering

the glides on the bottom of the unit.

Electrical Connection

Check the serial nameplate for the correct power

supply. Use only the electrical power supply

specified on the serial nameplate. Do not use an

extension cord.

Grounding Method

This ice machine is equipped with a power supply

cord with ground. It must be plugged into a mating

grounding type receptacle in accordance with the

National Electrical Code and applicable local

codes and ordinances.

THIS UNIT SHOULD NOT, UNDER ANY

CIRCUMSTANCES, BE UNGROUNDED.

2

INSTALLATION

Ideal Ambient Temperature Range*

built-in

freestanding

* Ice Machine will not perform correctly in ambient temperatures less than 55°F.

55-80°F

55-90°F

RPE style door

Note: The plug shown is

for 115VAC unit. The

prongs on your model

may vary from that

shown if your unit is

other than 115VAC.

Full Wrap

Style Door

Overlay/Designer

Style Door

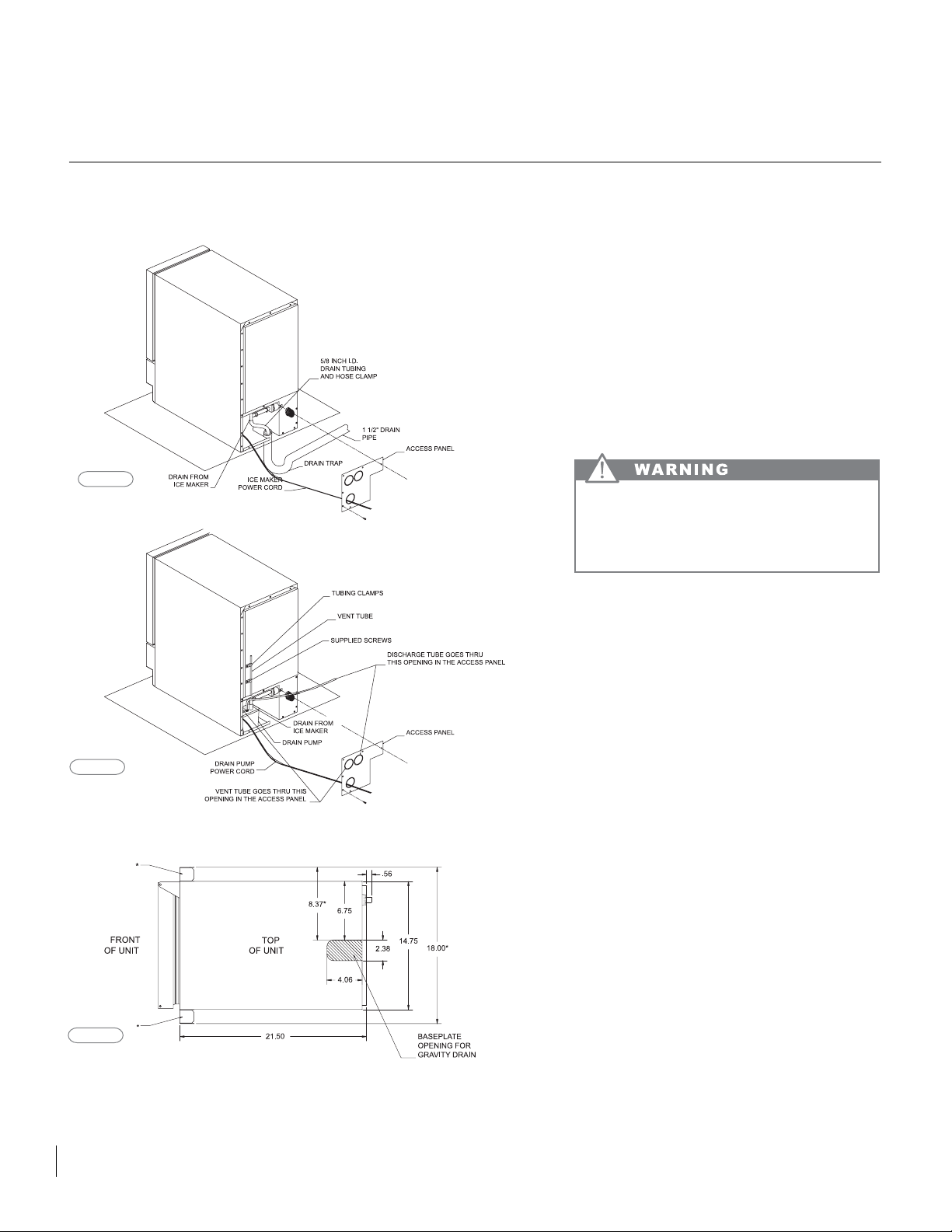

Drain Plumbing

Your ice machine uses a gravity drain, (figure 1)

that requires 5/8" I.D. tubing from the back of the

ice machine to a plumbed connection to a sanitary

sewer. Remove the access panel to plumb in drain

connection. Gravity drain location for built-in units

can be within the area shown in figure 3. An optional drain pump, (figure 2) can be purchased for your

ice machine if a gravity drain is not accessible.

OBSERVE AND FOLLOW ALL LOCAL CODES

WHEN INSTALLING ICE MACHINE.

3

INSTALLATION: DRAIN PLUMBING

Gravity Drain Location

* With optional filler kit

FAILURE TO USE ADEQUATE DRAINAGE

SYSTEM WILL RESULT IN SURROUNDING

WATER DAMAGE AND/OR POOR ICE

PRODUCTION.

figure 1

figure 2

figure 3

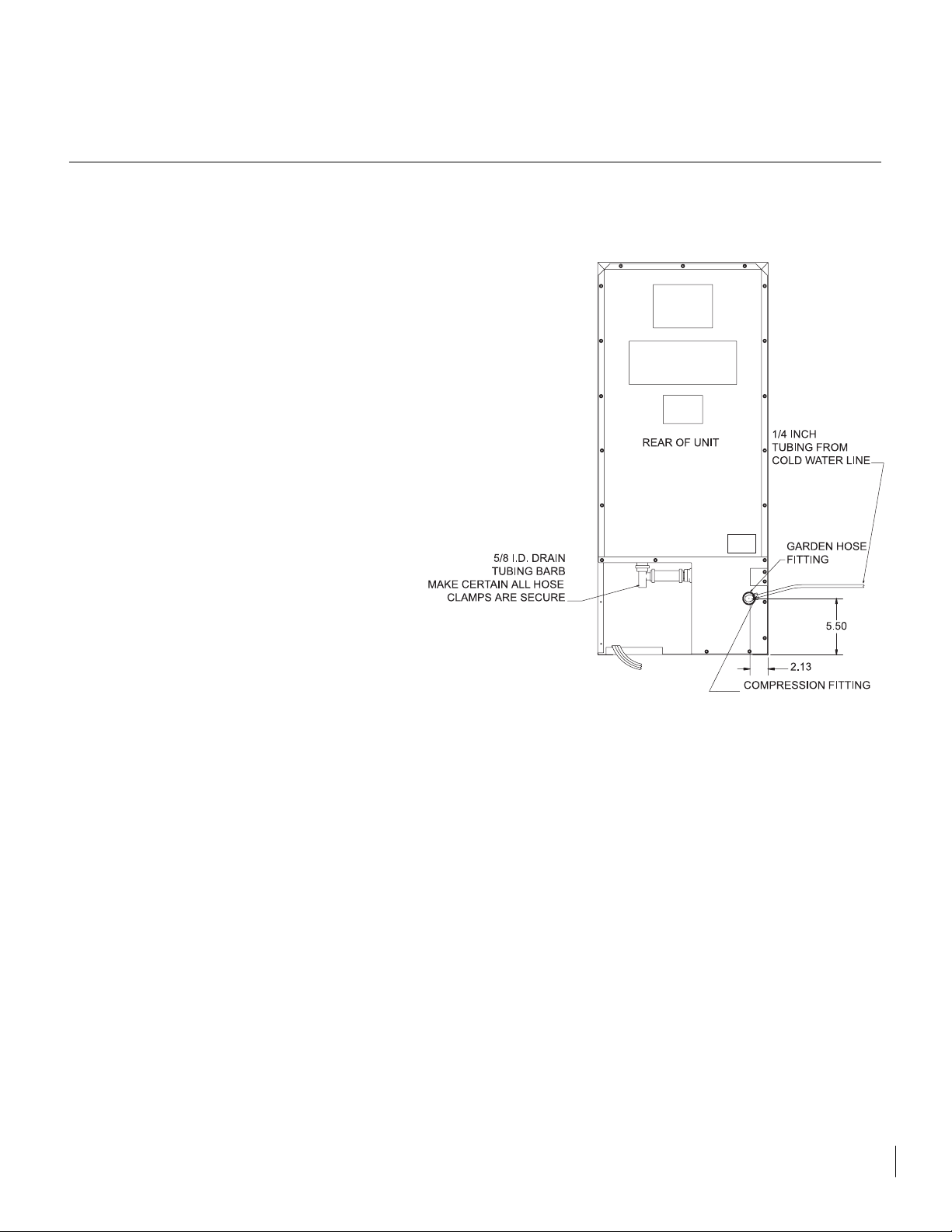

Water Supply

This ice machine must be connected to a potable,

active cold water supply line delivering water

pressure at a minimum of 20 psi and maximum of

120 psi.

• Water connection is made through a right angle

garden hose fitting. See garden hose fitting for

detailed instruction sheet.

• A water filter is recommended for this unit. A

quality filter can remove particles as well as

remove taste and odors from water. Do not use

any thread sealers.

• Softened water is not recommended. This will

produce mushy, cloudy ice cubes that will stick

together.

• De-ionized water is not recommended. This

water will not form solid ice cubes.

• Awater specialist can recommend proper water

treatment.

• After installation of water line, turn on water and

check for any leaks. Additional tightening may be

needed.

• Allow for extra water line for built-in installations

for easy removal of unit and to help prevent the

water line from kinking.

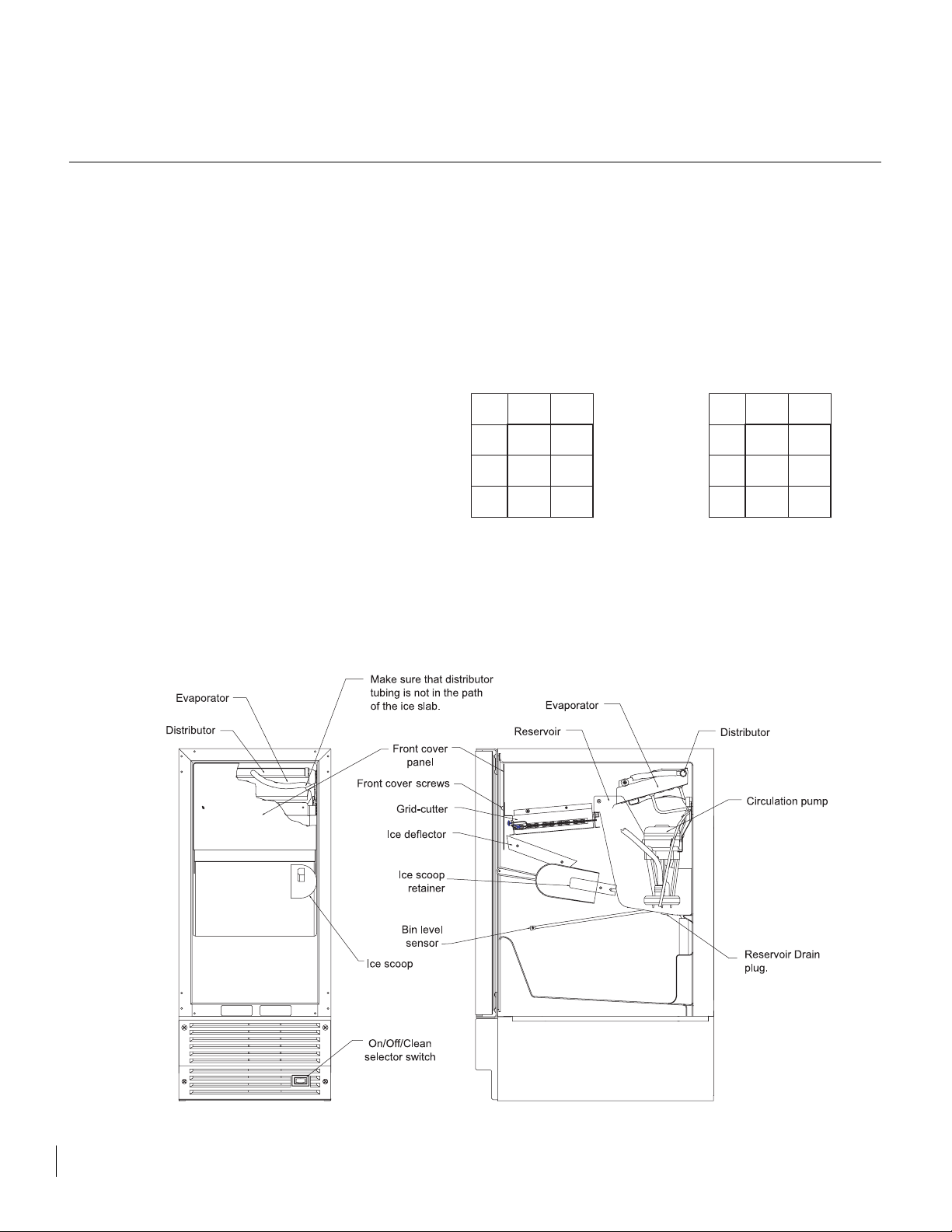

Operation

Your ice machine is unique in forming ice. It uses

fractional freezing to form a slab of ice that is clear

and has less mineral content than the water it is

produced from. This is accomplished by running

water over the cold evaporator plate which gradually freezes the water to produce the ice slab. Mineral deposits are left in the reservoir.

When the ice slab reaches the correct thickness

determined by the temperature of the evaporator

plate, the electronic control switches to the harvest cycle to harvest the ice. During the harvest

cycle, the ice slab falls from the evaporator to the

ice grid cutter. Here, the ice slab is cut into 3/4"

squares by the grid cutter's heated wires. During

the harvest cycle, the drain valve will remain open

for 45 seconds to drain the reservoir of remaining

deposits. After that, the water valve open will open

for 2 minutes providing 2 quarts of water to the

reservoir for the next ice production cycle.

The ice machine will keep producing ice until the

ice machine's bin is full and will restart automatically when ice needs to be replenished in the bin.

4

WATER SUPPLY

5

CARE OF THE UNIT

Care of Unit

1. Avoid leaning on the cabinet door. You may

bend the door hinge or tip the unit.

2. Exercise caution when sweeping, vacuuming,

or mopping near the front of the unit. Damage

to the grille and/or switch can occur.

3. Periodic cleaning of the inside of the ice

machine components and inside of unit (see

Cleaning Your Ice Machine section).

4. Periodic checking and/or cleaning of the front

grille and condenser coils as needed.

Normal Responsibilities of the Owner

• All freight charges

• Damage sustained in transit

• Mileage charge(s) for service calls

• Proper installation including installation of leveling legs.

• Leveling of unit.

• Alterations to original equipment

• Removal or installation of additional equipment

(i.e. drain pump).

• Cleaning and normal maintenance outlined in

this manual.

• Drain and water supply plumbing to the ice

machine.

Help Prevent Tragedies

Each year, children die because they climb inside

a discarded refrigeration product, get trapped

inside and suffocate. Take precautions to prevent

such tragedies by removing the door, taping or

chaining it shut before discarding.

Cleaning Your Ice machine

Some impurities will remain and build-up in the ice

machine and stick to the ice machine's parts over

time. This build-up must be removed for proper ice

production, ice quality, and ice machine life. Your

ice machine is equipped with a cleaning mode that

will help in cleaning out these impurities.

The impurities will regularly (at the very least,

annually) need to be cleaned of this build-up,

depending on use and water hardness. You can

use an acid such as one specified for ice machine

cleaning or you can use citric acid to remove the

build-up. To clean the ice machine:

1. Switch the selector switch to the "OFF"

position.

2. Remove the drain plug at the bottom of the

reservoir to drain any remaining water and

then reinstall.

3. Add the recommend cleaner solution to the

reservoir of the ice machine. Access to the

reservoir can be obtained by removing the

front panel screws and the front panel.

Determine to proper amount of cleaner from

the ice machine cleaner manufacturer's mixture ratio based on 3 quarts of water (refer

to manufacturer's directions).

4. Replace the front cover panel and close the

door.

5. Switch the selector switch on the grille of the

ice machine the clean position. Three quarts

of water will automatically be added to the

cleaning solution.

6. The total cleaning time will end in 49 minutes. The cleaning cycle will automatically

rinse the evaporator plate and also drain the

cleaning solution and rinse water.

7. After the cleaning cycle has ended, remove

the front panel again and check that the

build up has been removed. The evaporator

plate should be clean, shiny, and smooth to

the touch. If build up is still visible, repeat

the cleaning cycle above. If build up is

removed, continue below.

8. Remove the distributor tube, hose clamp,

hose and its rubber ends.

9. Thoroughly clean the inside of the distributor tube and the spray holes. You can use

the same cleaning solution as before and an

old toothbrush to reach the inside of the distributor tube.

10. Reinstall the rubber ends, hose, and hose

clamp to the distributor and then reinstall the

distributor tube to the evaporator with the

spray holes pointed to the bottom of the

evaporator plate. Reinstall the front cover

panel with the two front panel screws.

11. Clean the ice machine's interior, ice scoop,

interior door panel and door gasket with mild

soap and water. Using two tablespoons of

baking soda in one quart of warm water

while cleaning will help remove odors. Rinse

with fresh water. Do not use any abrasive

cleaning products.

Your ice machine is now clean and sanitized and

may be put back into operation by switching the

selector witch to the "ON" position.

6

CARING FOR YOUR ICE MACHINE

Read manufacturer's warnings on ice machine

cleaner products. Personal injury can result.

7

THINGS TO REMEMBER

Things to Remember

• Allow your ice machine to run for 24-48 hours to

accumulate ice in ice machine's bin.

• Unit will cycle often between ice production and

ice harvest cycles.

• Your unit will automatically shut down when the

ice bin is full.

• Unplug your ice machine before working on

unit.

• Keep your ice machine clean for proper ice

quality, production, and unit life.

• Room and water temperatures will greatly

affect the output of ice in your unit (see table).

Ice will also melt away, especially at the start

of an empty bin, but will slow down as ice

accumulates.

PRODUCTION RATE

(LB/DAY)*

APPROXIMATE TIME TO FILL

BIN (HOURS)*

WATER TEMPERATURE °F

50

70

70

34 32

30 27

80

23 20

90

ROOM TEMPERATURE °F

*NOTE: DUE TO VARIABLES IN INSTALLATION AND USE, INDIVIDUAL RESULTS MAY VARY.

WATER TEMPERATURE °F

50

70

31

41

80

60

90

ROOM TEMPERATURE °F

70

34

58

82

Loading...

Loading...