Page 1

S Model & Ice Beverage

Manitowoc

QuietQube® Ice Machines

with CVD® Technology

Installation, Use & Care Manual

This manual is updated as new information and models are released.

Visit our website for the latest manual. www.manitowocice.com

This manual contains English and French text

America’s #1 Selling Ice Machine

Part Number 000006505 11/10

Page 2

Section 1

General Information

Section 2

Installation

Table of Contents

Model Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Ice Deflector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Bin Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Dispenser Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Location Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Minimum/Maximum Temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Ice Machine Clearance Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Condensing Unit Clearance Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Water Supply and Drains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Potable Water Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Drain Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Water Supply and Drain Line Sizing/Connections . . . . . . . . . . . . . . . . . . . . . . . 7

Cooling Tower Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Electrical Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Fuse/Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Minimum Circuit Ampacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Ground Fault Circuit Interrupter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

CVD Condensing Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

QuietQube

Refrigeration System Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Refrigeration Line Set Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Electronic Bin Thermostat Instructions IB600C/IB800C/IB1000C Only . . . . . . . 15

Ice Machine Head Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

®

Section 3

Operation

Ice Making Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Safety limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Operational Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Ice Thickness Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2 Part Number 000006505 11/10

Page 3

Section 4

Maintenance

Section 5

Customer Support

Table of Contents (continued)

Cleaning and Sanitizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Cleaning/Sanitizing Procedure Differences . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Exterior Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Cleaning / Sanitizing Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Cleaning Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Sanitizing Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Procedure to Clean Heavily Scaled Ice Machines . . . . . . . . . . . . . . . . . . . . . . . . 21

Cleaning Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Sanitizing Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Parts Removal for Cleaning/Sanitizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Door Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Exterior Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Cleaning the Condenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Removal from Service/Winterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Before Calling for Service Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Safety Limit Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Commercial Ice Machine Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Residential Ice Machine Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Part Number 000006505 11/10 3

Page 4

Model Numbers

!

Warning

!

Warning

!

Warning

!

Warning

!

Warning

!

Warning

Section 1

General Information

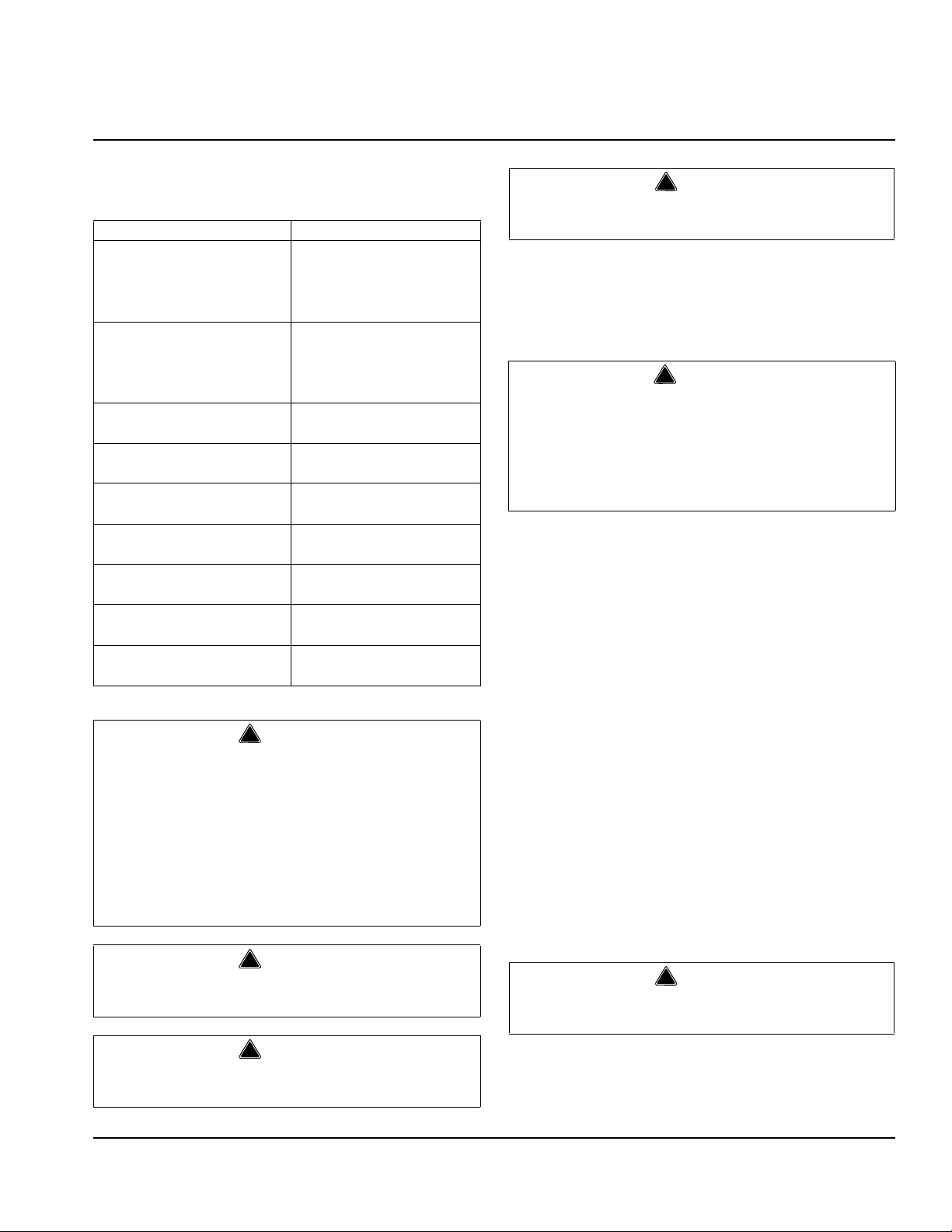

This manual covers the following models:

Ice Machine Head Section CVD® Condensing Unit

SD0682C

SY0684C

IB0684YC

IB0682DC

SD0872C

SY0874C

IB0824YC

IB0822DC

SD1072C

SY1074C

IB1024YC

IB1022DC

SD1272C

SY1274C

SD1472C

SY1474C

SD1872C

SY1874C

SD2172C

SY2174C

SD3072C

SY3074C

.

CVD0685

CVD0885

CVD1085

CVD1185

CVD1285

CVD1485

CVD1486

CVD1885

CVD2085

CVD3085

30” large capacity bins must be attached to the wall

with the bracket provided with the bin.

ICE DEFLECTOR

An ice deflector is required when the ice machine is

installed on a bin. An ice deflector is not required when

the ice machine is installed on a dispenser.

Manitowoc ice machines require a deflector when

installed on an ice storage bin.

Prior to using a non-Manitowoc ice storage system

with Manitowoc ice machines, contact the

manufacturer to assure their ice deflector is

compatible with Manitowoc ice machines.

BIN INSTALLATION

• All ice machines installed on a bin require an ice

deflector.

• Manitowoc bins have a deflector installed and require

no modifications when used with a forward facing

evaporator.

• Ice machines with multiple evaporators require a

deflector kit.

Do not operate equipment that has been misused,

abused, neglected, damaged, or altered/modified

from that of original manufactured specifications.

This appliance is not intended for use by persons

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience and

knowledge, unless they have been given

supervision concerning use of the appliance by a

person responsible for their safety.

DISPENSER INSTALLATION

• Ice Beverage ice machines require an adapter for all

installations.

• No adapter is needed for machines that match the

size of the dispenser unless required by the

dispenser manufacturer.

• No deflector is required unless specified by the

dispenser manufacturer.

• A bin thermostat to control ice level is reco mme nded.

S1470C/S1870C/S2170C ice machines are not

approved for use on Manitowoc B570 bins.

Children must be supervised to ensure they do not

play with the ice machine, bin or dispenser.

S3000C ice machines are only approved for use on

Manitowoc B1100-00/B1400-00 bins.

Part Number 000006505 11/10 4

Page 5

Section 2

!

Warning

Installation

MINIMUM/MAXIMUM TEMPERATURES

PERSONAL INJURY POTENTIAL

Remove all ice machine panels before lifting and

installing.

Location Requirements

The location selected for the ice machine must meet the

following criteria. If any of these criteria are not met,

select another location.

• The location must be free of airborne and other

contaminants.

• The location must not be near heat-generating

equipment or in direct sunlight.

• The location must be capable of supporting the

weight of the ice machine and a full bin of ice.

• The location must allow enough clearance for water,

drain and electrical connections in the rear of the ice

machine.

• The location must not obstruct airflow through or

around the ice machine.

• The location must not allow exhaust fan heat and/or

grease to enter the condenser.

• The location must allow electrical, water, drain and

refrigeration tubing to enter the ice machine from the

back.

• Local water conditions may require treatment of the

water to inhibit scale formation, filter sediment, and

remove chlorine odor and taste.

These ice machines are intended for use in household

and similar applications such as:

• Staff kitchen areas in shops, offices and other work

enviroments.

• Clients in hotels, motels, farmhouses, bed and

breakfast and other residential type enviroments.

• Catering and similar non-retail applications.

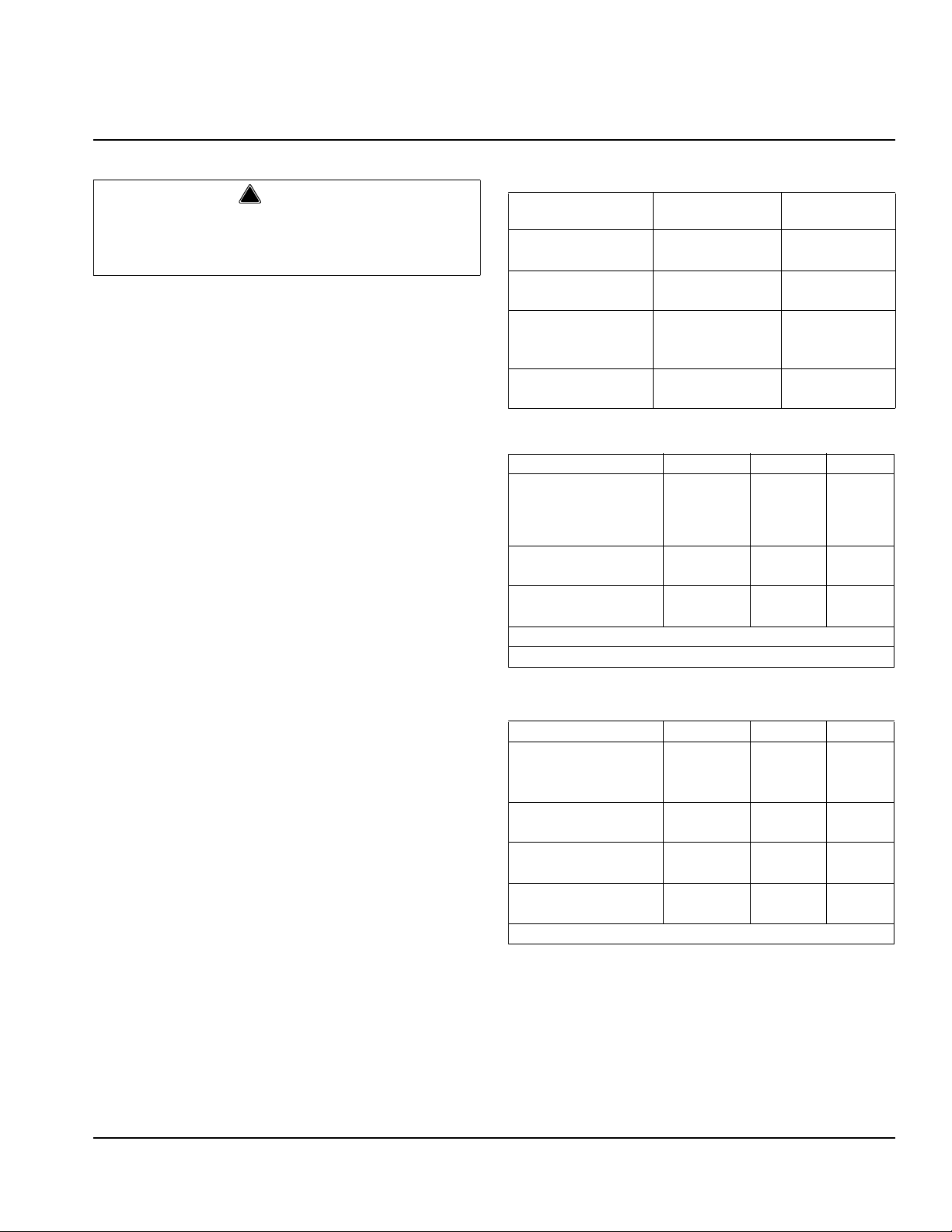

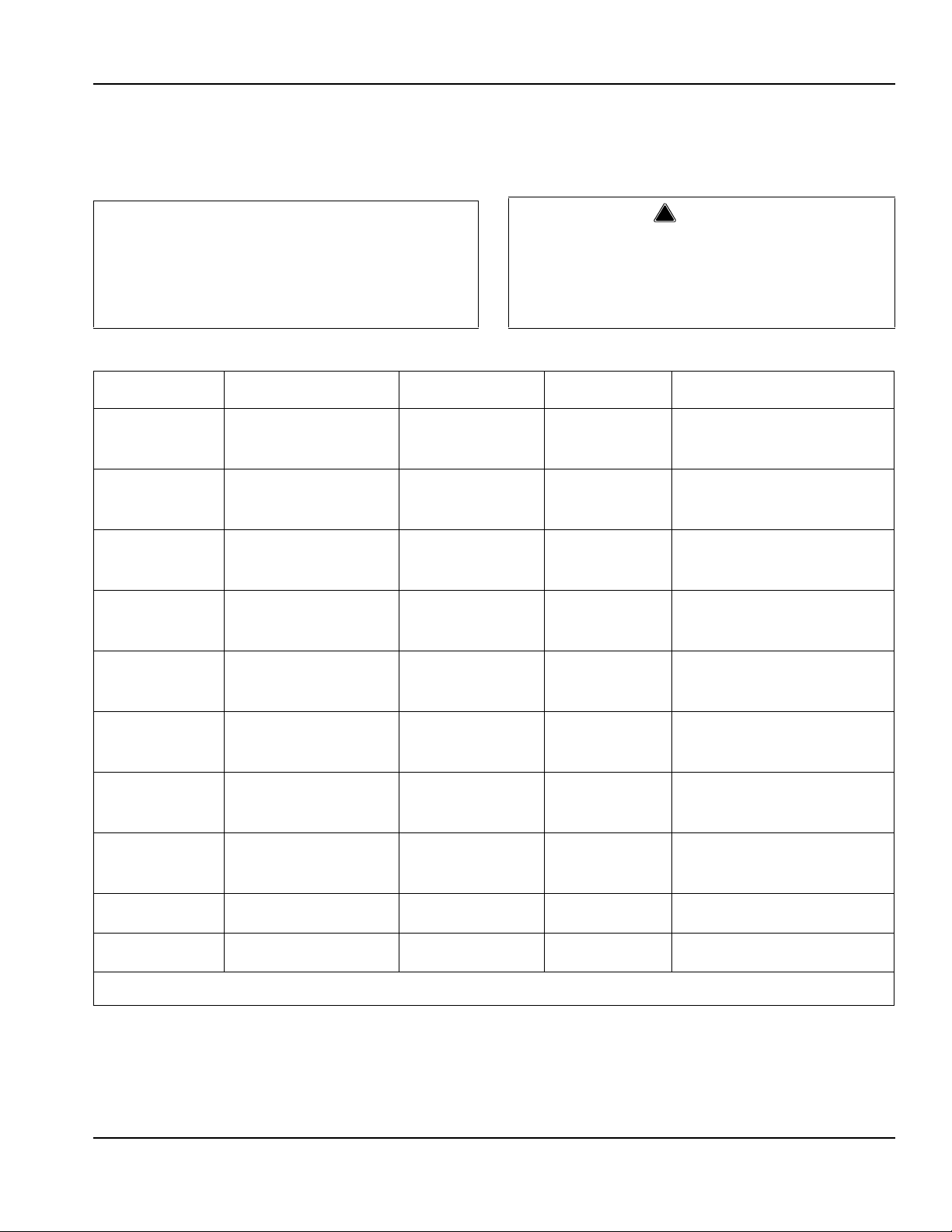

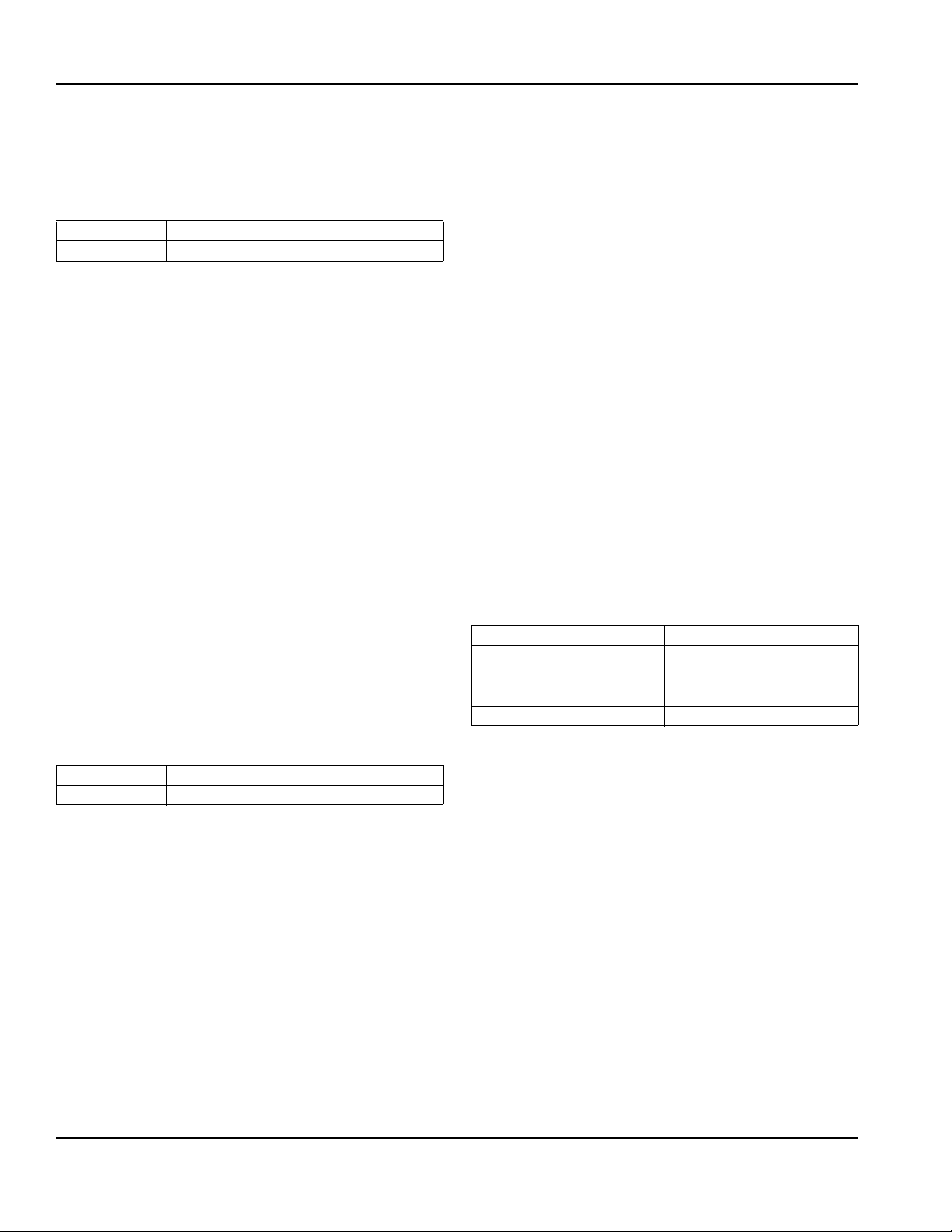

Model

All Ice Machine Head

Sections

CVD0685 - CVD1185

CVD2085 - CVD3085

CVD0885 - CVD1085

CVD1285 - CVD1485

CVD1885

CVD1486

Minimum Air

Temperature

35°F

2°C

-20°F

-29°C

-20°F

-29°C

35°F

2°C

Maximum Air

Temperature

110°F

43°C

120°F

49°C

130°F

54°C

110°F

43°C

ICE MACHINE CLEARANCE REQUIREMENTS

Model T op Back Sides

S0600C - S0800C

S1000C - S1200C

S1470C - S1870C

S2170C

IB0600C - IB0800C

IB1000C

S3000C

* Routing utilities out top - Routing utilities out back

** 24" (61 cm) is recommended on all sides

5"

13 cm

2"

5 cm

8"

20 cm

*3" - 5"

*8 - 13 cm5"13 cm

5"

13 cm

24"

61 cm

8"

20 cm

**8"

**20 cm

CONDENSING UNIT CLEARANCE REQUIREMENTS

Model Top/Sides Back Front

CVD0685 - CVD0885

CVD1085 - CVD1185

CVD1885 - CVD2085

CVD1285 - CVD1485

CVD1885

CVD1486

CVD3085

* 24" (61 cm) is recommended on top/sides

*6"

*15 cm

*6"

*15 cm

*5"

*13 cm

*6"

*15 cm

48"

122 cm

48"

122 cm

12"

30 cm

24"

122 cm

48"

122 cm

24"

61 cm

12"

30 cm

24"

122 cm

Part Number 000006505 11/10 5

Page 6

Installation Section 2

!

Warning

Installation Requirements

• The ice machine top panel can be trimmed with an

aviator snips to allow the line set, water line and

electrical connections to exit the top. Only cut out

what is needed, the back panel recess sheet met al

must support the top panel.

• The ice machine and bin must be level.

• Vent the ice machine and bin drains separately.

• Bin drain termination must have an air gap.

• The water inlet and electrical connection mus t

contain a service loop to allow future access.

• The drain line must contain a union or other suitable

means of disconnection at the ice machine.

• The ice machine and bin must be sanitized after

installation.

• Routine adjustments and maintenance procedures

outlined in this manual are not covered by the

warranty.

Water Supply and Drains

POTABLE WATER REQUIREMENTS

Local water conditions may require treatment of the

water to inhibit scale formation, filter sediment, and

remove chlorine odor and taste.

Follow these guidelines to install water inlet lines:

• Plumbing must conform to local codes.

• Do not connect the ice machine to a hot water

supply. Be sure all hot water restrictors installed for

other equipment are working. (Check valves on sink

faucets, dishwashers, etc.)

• If water pressure exceeds the maximum

recommended pressure of 80 psig (552 kPa), obtain

a water pressure regulator from your Manitowoc

distributor.

• Install a water shut-off valve and union for potable

water and water cooled condenser lines.

• Insulate water inlet lines to prevent condensation.

Connect to a potable water supply only.

DRAIN CONNECTIONS

• Drain lines must have a 1.5 inch drop per 5 feet of

run (2.5 cm per meter), and must not create traps.

• The floor drain must be large enough to

accommodate drainage from all drains.

• Run separate bin and ice machine drain lines.

Insulate them to prevent condensatio n.

• Vent the bin an d ice machine drain to the

atmosphere. The ice machine drain requires an 18"

vent. Do not vent the condenser drain on watercooled models.

• Drains must have a union or other suitable means to

allow in place disconnection from the ice machine

when servicing is required.

• Base drain - Use 1/2" CPVC tubing and silicone

sealant to connect to this optional drain.

• S3000C requires base drain connection (1" FPT).

6

Part Number 000006505 11/10

Page 7

Section 2 Installation

!

Caution

Important

WATER SUPPLY AND DRAIN LINE SIZING/CONNECTIONS

Plumbing must conform to state and local codes.

Location Water Temperature

Ice Making

Water Inlet

Water Cooled

Condenser

Ice Making

Water Drain

Base Drain ---- ---- S3000C 1" FPT S3000C 1" (25 mm) ID

Bin Drain ---- ---- 3/4" FPT 3/4" (19 mm) ID

Large Capacity

Bin Drain

FPT = Female Pipe thread ID = Inside Diameter Min = Minimum Max= Maximum

35°F (2°C) Min.

90°F (32°C) Max.

35°F (2°C) Min.

90°F (32°C) Max.

---- ---- 1/2" FPT

---- ---- 1" FPT 1" (25 mm) ID

COOLING TOWER APPLICATIONS

(Water-Cooled Models Only)

A water cooling tower installation does not require

modification of the ice machine. The water regulator

valve for the condenser continues to control the

refrigeration discharge pressure.

Water Pressure

Min/Max

20 / 80 psi

140 / 550 kPa

Standard

20 / 150 psi

140 / 1030 kPa

High Pressure Option

20 / 350 psi

140 / 2410 kPa

Ice Machine Fitting

3/8" FPT

S3000C 1/2" FPT

1/2" FPT 1/2" (13 mm) ID

S3000C 1" FPT

• Allow for a pressure drop of 8 psi (1030 kPa)

between the condenser water inlet and the outlet of

the ice machine.

• Water exiting the condenser must not exceed 110°F

(43°C).

• Do not connect to the potable water filter system.

Minimum Tubing Size Up to

Ice Machine Fitting

3/8" (10 mm) ID

S3000C 1/2" (13 mm) ID

1/2" (13 mm) ID

S3000C 1" (25 mm) ID

It is necessary to know the amount of heat rejection, and

the pressure drop through the conden se r an d wate r

valves (inlet and outlet) when using a cooling tower on

an ice machine.

• Contact your distributor if your water pressure is

greater than 150 psig (1030 kPa). A special order

condensing unit is available that allows water

pressure up to 350 psig (2410 kPa).

• Water entering the condenser must not exceed 90°F

(32°C).

The Commonwealth of Massachusetts requires that

• Water flow through the condenser must not exceed

5 gallons (19 liters) per minute.

Part Number 000006505 11/10 7

all water-cooled models must be connected only to a

closed loop, cooling tower system.

Page 8

Installation Section 2

!

Warning

!

Warning

Important

Electrical Service

GENERAL

All wiring must conform to local, state and national

codes.

The ice machine and condensing unit must be

grounded in accordance with national and local

electrical codes.

All electrical work, including wire routing and grounding,

must conform to local, state and national electrical

codes. The following precautions must be observed:

• The ice machine must be grounded.

• A separate fuse/circuit breaker must be provide d for

each condensing unit.

• A qualified electrician must determine proper wire

size dependent upon location, materials used and

length of run (minimum circuit ampacity can be used

to help select the wire size).

• The maximum allowable voltage variation is +/-10 of

the rated voltage at compressor start-up (when the

electrical load is highest).

• Check all green ground screws in the control box and

verify they are tight before starting the ice machine.

• Verify polarity is correct. Incorrect polarity can lead to

erratic ice machine operation and a safety issue. This

is especially critical on 230 volt / 50 cycle ice

machines.

FUSE/CIRCUIT BREAKER

The ice machine head section and condensing unit are

wired independently of each other.

A dedicated circuit and a separate fuse/circuit breaker

are required for each ice machine and condensing unit.

MINIMUM CIRCUIT AMPACITY

The minimum circuit ampacity is used to help select the

wire size of the electrical supply. (Minimum circuit

ampacity is not the ice machine’s running amp load.)

The wire size (or gauge) is also dependent upon

location, materials used, length of run, etc., so it must be

determined by a qualified electrician. Manitowoc Ice

requires minimum #8 AWG for S2170C condensing unit

applications.

GROUND FAULT CIRCUIT INTERRUPTER

We do not recommend the use of a GFCI/GFI circuit

protection with our equipment. If a GFCI/GFI is required

by code use a GFCI/GFI breaker rather than outlet

which is more prone to intermittent nuisance trips than

panel circuit breakers.

For United Kingdom Only

As the colors of the wires in the mains lead of the appliance

may not correspond with the colored markings identifying

the terminals in your plug, proceed as follows:

• The wire which is colored green and yellow

connected to the terminal in the plug which is marked

with the letter E or by the earth ground symbol or

colored green or green and yellow.

• The wire colored blue must be connected to the terminal

which is marked with the letter N or colored black.

• The wire colored brown

terminal which is marked with the letter L or colored red.

must be connected to the

must be

Observe correct polarity of incoming line voltage.

8

Part Number 000006505 11/10

Page 9

Section 2 Installation

Important

!

Warning

Electrical Requirements

Local or state electrical code, length of wire run or materials used, can increase the minimum wire or breaker size

requirement. A qualified electrician must determine the wire and breaker size, although the minimum wire size must

meet or exceed the specifications in these charts. Refer to the condensing unit serial plate to verify electrical data.

Due to continuous improvements, this information is

for reference only. Please refer to the condensing

unit serial number tag to verify electrical data. Serial

tag information overrides information listed on this

page.

Connect power supply wiring directly to L1 & L2 on

the contactor. Torque screws to the torque value

specification on the contactor label. Follow all local,

state and national electrical codes.

CVD2085 ONLY

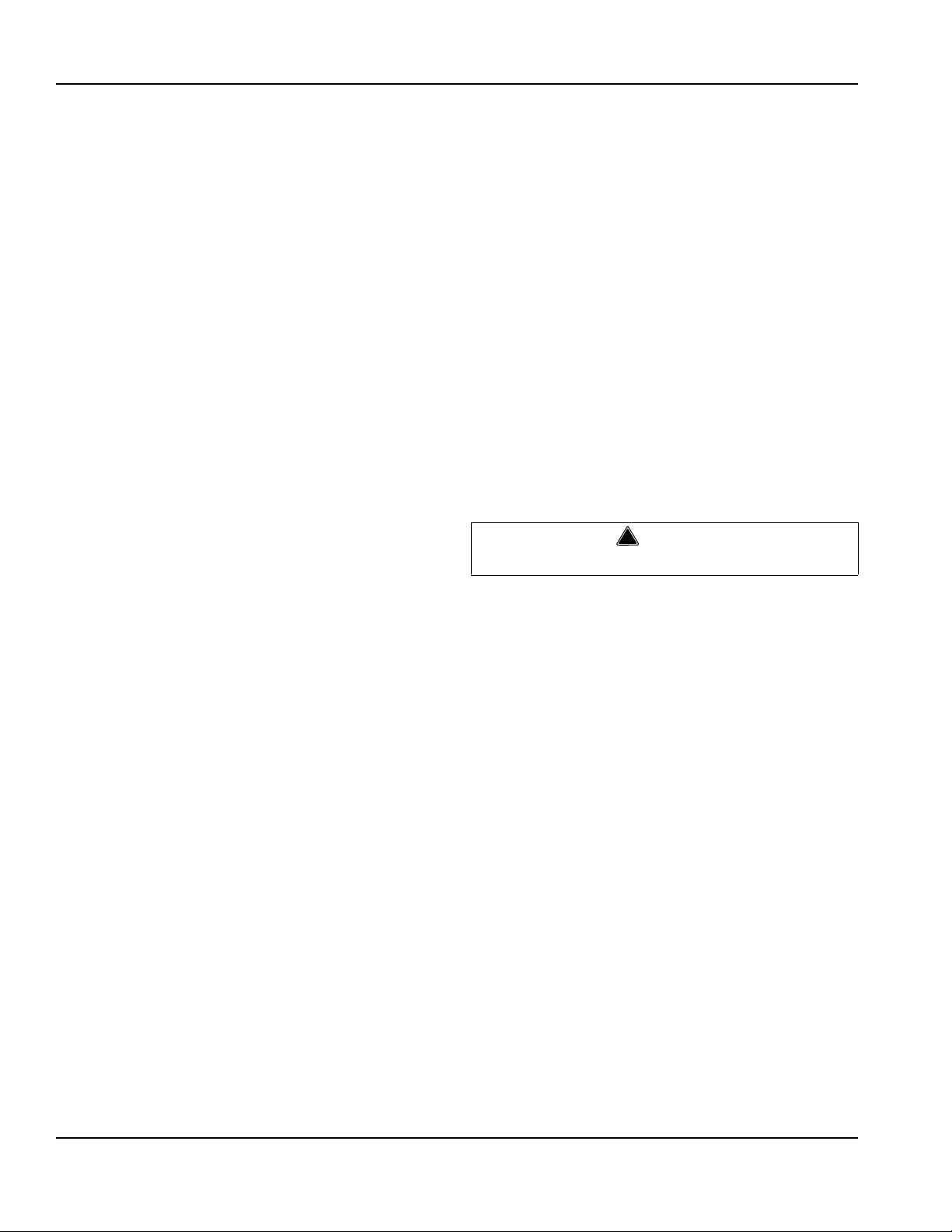

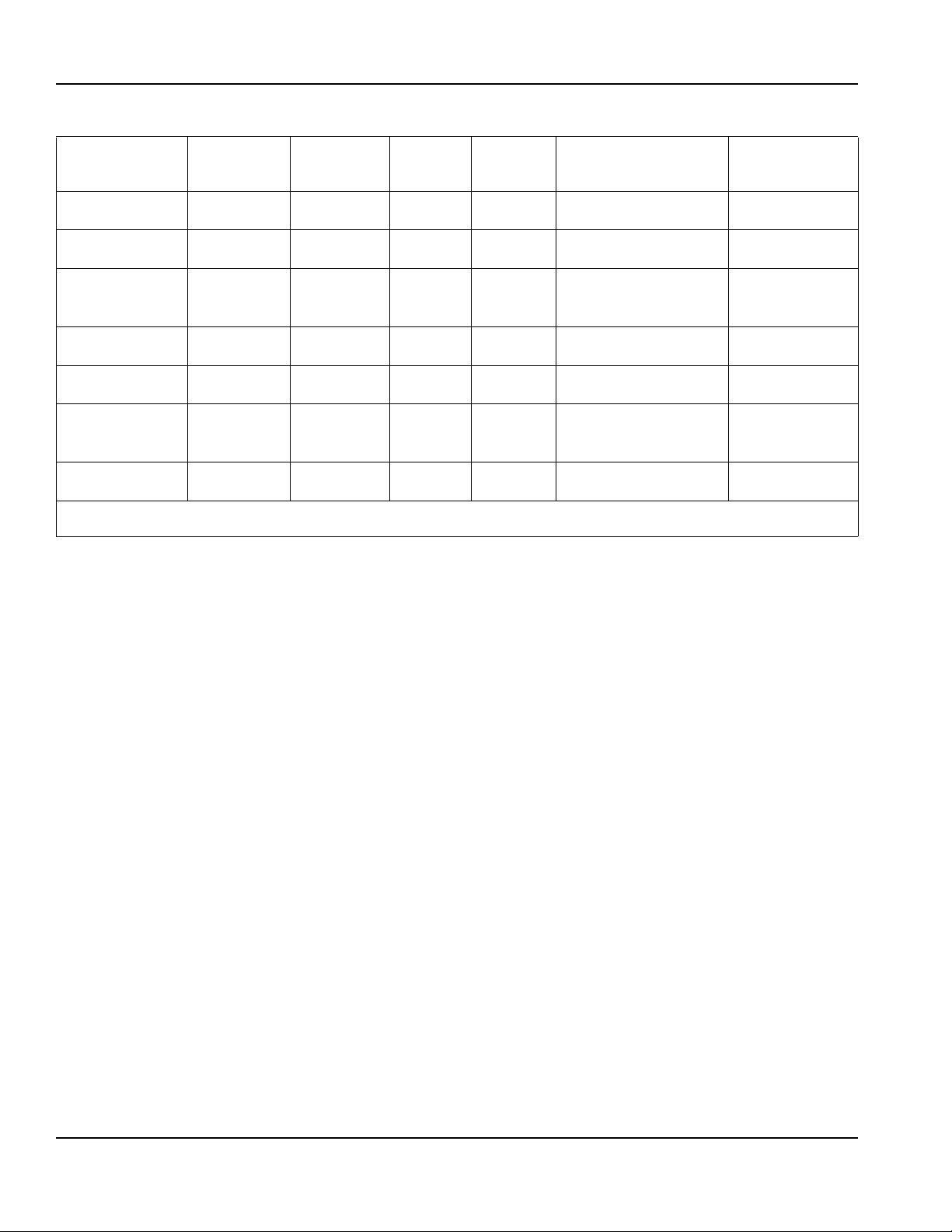

CVD CONDENSING UNITS

Condensing Unit Voltage/Phase/Cycle

208-230/1/60 15 amp 1 1.0 #12 Solid Copper Conductor

CVD0685

CVD0885

CVD1085

CVD1185

CVD1285

CVD1485

CVD1486

CVD1885

CVD2085*

CVD3085*

*CVD2085 & CVD3085 Only - Verify the direction of the rotation is correct on the 3ph scroll compressor. The ice machine will have high suction

pressure, low discharge pressure and will be noticeably loud. Reverse two incoming power leads to reverse rotation.

208-230/3/60 15 amp 7.5 #12 Solid Copper Conductor

230/1/50 15 amp NA #12 Solid Copper Conductor

208-230/1/60 20 amp 1 1.8 #10 Solid Copper Conductor

208-230/3/60 15 amp 9.1 #12 Solid Copper Conductor

230/1/50 20 amp 10.0 #10 Solid Copper Conductor

208-230/1/60 20 amp 12.5 #10 Solid Copper Conductor

208-230/3/60 15 amp 9.4 #12 Solid Copper Conductor

230/1/50 20 amp 10.9 #10 Solid Copper Conductor

208-230/1/60 25 amp 15.7 #10 Solid Copper Conductor

208-230/3/60 15 amp 10.8 #12 Solid Copper Conductor

230/1/50 20 amp 1 1.2 #10 Solid Copper Conductor

208-230/1/60 25 amp 14.7 #10 Solid Copper Conductor

208-230/3/60 20 amp 10.6 #10 Solid Copper Conductor

230/1/50 20 amp 1 1.7 #10 Solid Copper Conductor

208-230/1/60

208-230/3/60

230/1/50

208-230/1/60

208-230/3/60

230/1/50

208-230/1/60

208-230/3/60

230/1/50

208-230/1/60

208-230/3/60

208-230/3/60

380-415/3/50

Maximum Fuse/

Circuit Breaker

20 amp

15 amp

30 amp

20 amp

15 amp

20 amp

40 amp

25 amp

30 amp

40 amp

20 amp

35 amp

15 amp

Minimum Circuit

Amps

20.0

15.0

20.0

20.0

15.0

20.0

25.0

20.0

20.0

30.0

20.0

30.0

15.0

Minimum Wire Size Required

by Manitowoc

#10 Solid Copper Conductor

#12 Solid Copper Conductor

#10 Solid Copper Conductor

#10 Solid Copper Conductor

#12 Solid Copper Conductor

#10 Solid Copper Conductor

#8 Solid Copper Conductor

#10 Solid Copper Conductor

#40 Solid Copper Conductor

#6 Solid Copper Conductor

#8 Solid Copper Conductor

#8 Solid Copper Conductor

#12 Solid Copper Conductor

Part Number 000006505 11/10 9

Page 10

Installation Section 2

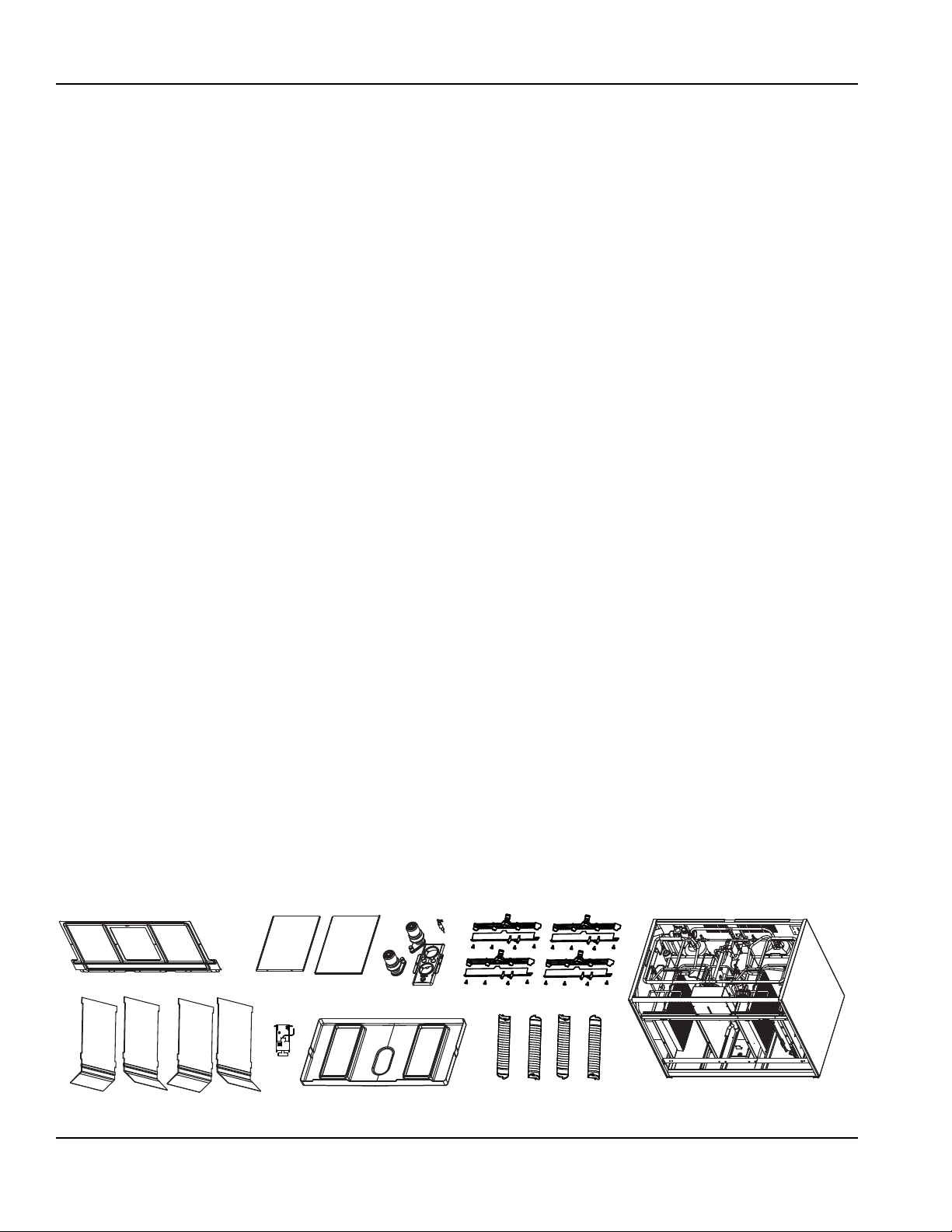

QUIETQUBE® ICE MACHINE HEAD SECTION

Voltage

Ice Machine

S0600C

S0800C

IB0600C

IB0800C

IB1000C

S1000C

S1200C

S1400C

S1800C

S2100C

S3000C

** All conductors must be solid copper wire

*** Indicates preliminary data

Phase

Cycle

1 15/1/60

230/1/50

1 15/1/60

230/1/50

1 15/1/60

230/1/50

1 15/1/60

230/1/50

1 15/1/60

230/1/50

1 15/1/60

208-230/1/60

230/1/50

1 15/1/60

***230/1/50

Fuse/Circuit

Maximum

Breaker

15 amp

15 amp

15 amp

15 amp

15 amp

15 amp

15 amp

15 amp

15 amp

15 amp

15 amp

15 amp

15 amp

15 amp

15 amp

Minimum

Circuit

Amps

1.1

0.6

1.1

1.5

N/A

2.5

1.5

2.5

1.5

1.1

0.6

0.6

2.0

2.0

Total

Circuit

Amps

N/A

N/A

1.4

0.8

N/A

N/A

N/A

N/A

**Minimum Wire Size

Required by Manitowoc

#14 Solid Copper

Conductor

#14 Solid Copper

Conductor

#14 Solid Copper

Conductor

#14 Solid Copper

Conductor

#14 Solid Copper

Conductor

#14 Solid Copper

Conductor

#14 Solid Copper

Conductor

Minimum Breaker

Size Required by

Manitowoc

15 amp

15 amp

15 amp

15 amp

15 amp

15 amp

15 amp

15 amp

15 amp

15 amp

15 amp

15 amp

15 amp

15 amp

10

Part Number 000006505 11/10

Page 11

Section 2 Installation

Important

!

Caution

!

Warning

!

Warning

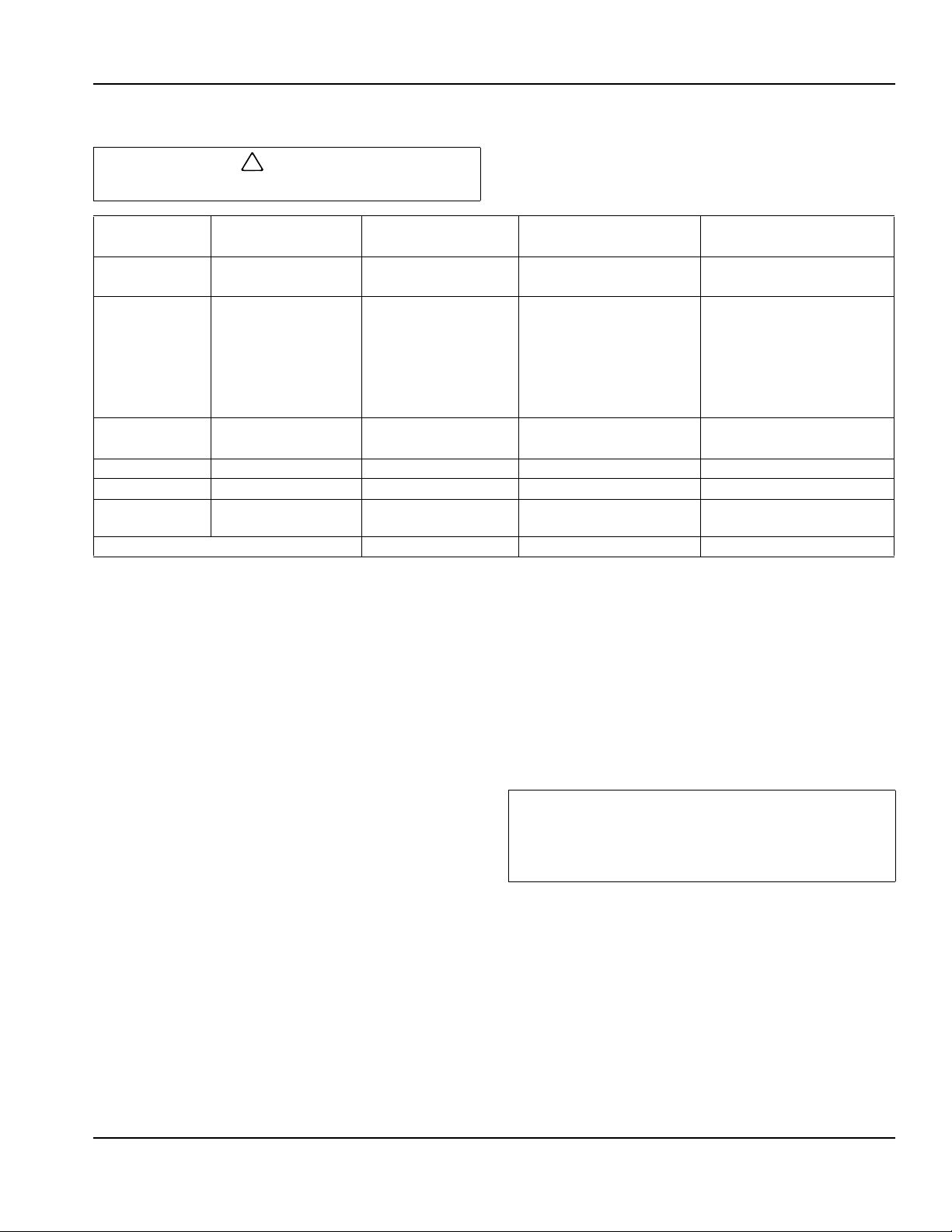

Refrigeration System Installation

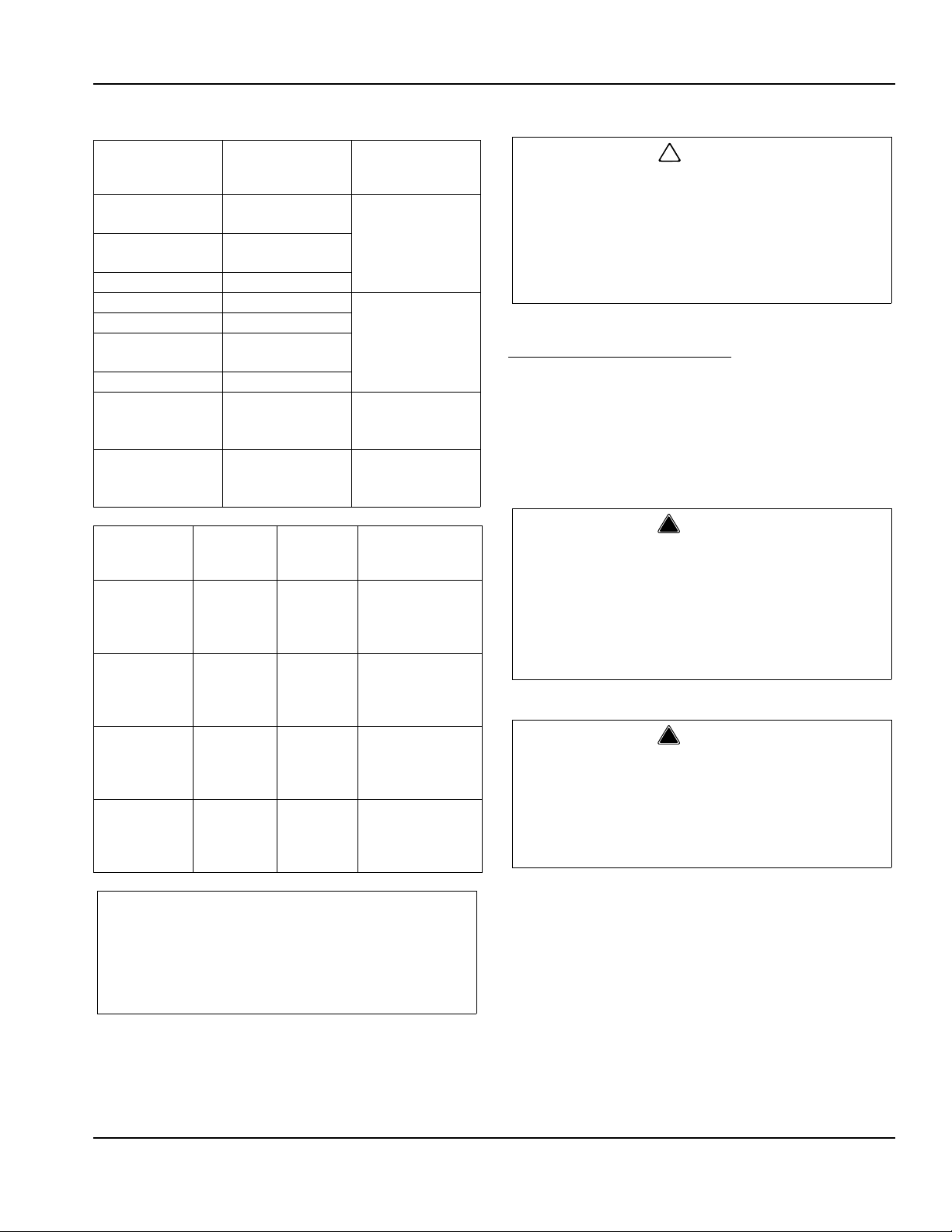

QuietQube®

Ice Machine

S0600C

IB600C

S0800C

IB800C

S1000C CVD1085

IB1000C CVD1185

S1200C CVD1285

S1470C

S1870C CVD1885

S2170C CVD2085

S3000C CVD3085

*Line Set

RC 21/31/51

RC 20/30/50

RC 23/33/53

RC 24/34/54

Remote Single

Condenser

Suction

Line

5/8 inch

(16 mm)

3/4 inch

(19 mm)

3/4 inch

(19 mm)

Two Lines -

3/4 inch

(19 mm)

Circuit

CVD685

CVD885

CVD1485

CVD1486

Liquid

Line

3/8 inch

(10 mm)

1/2 inch

(13 mm)

5/8 inch

(16 mm)

One Line -

5/8 inch

(16 mm)

Line Set*

RC-21

RC-31

RC-51

RC-20

RC-30

RC-50

RC-23

RC-33

RC-53

RC-24

RC-34

RC-54

Minimum

Insulation

Thickness

1/2" (13mm)

Suction Line

1/4" (7mm) Liquid

Line

1/2"(13mm)

Suction Line

1/4" (7mm) Liquid

Line

1/2"(13mm)

Suction Line

1/4" (7mm) Liquid

Line

3/4"(19mm)

Suction Line

1/4" (7mm) Liquid

Line

The refrigeration system warranty will not apply if

the Manitowoc Ice Machine and Manitowoc CVD

Condensing Unit are not installed according to

specifications. This warranty also will not apply if

the refrigeration system is modified with a

condenser, heat reclaim device, or other parts or

assemblies not manufactured by Manitowoc.

Ice Machine Refrigerant Amounts

ICE MACHINE HEAD SECTION

Each ice machine head section ships from the factory

with a R-404A refrigerant charge appropriate for the

entire system operation. The serial tag on the ice

machine indicates the refrigerant charge. The re frigerant

charge is sufficient to operate the ice machine at all

ambients with lineset lengths up to 100 feet (30 m).

Potential Personal Injury Situation

The ice machine head section contains the

refrigerant charge. Installation and brazing of the

line sets must be performed by a properly trained

and EPA certified refrigeration technician aware of

the dangers of dealing with refrigerant charged

equipment.

Installation of a QuietQube® Condensing Unit may

require the use of special equipment for placement.

Trained and qualified personnel are required for

proper rigging and lifting. Holes are provided on the

corners of the condensing unit to allow the use of

lifting shackles.

Manitowoc remote systems are only approved and

warranted as a complete new package. Warranty

on the refrigeration system will be void if a new ice

machine head section is connected to pre-existing

(used) tubing or condensing units or vice versa.

Part Number 000006505 11/10 11

Page 12

Installation Section 2

!

Warning

!

Warning

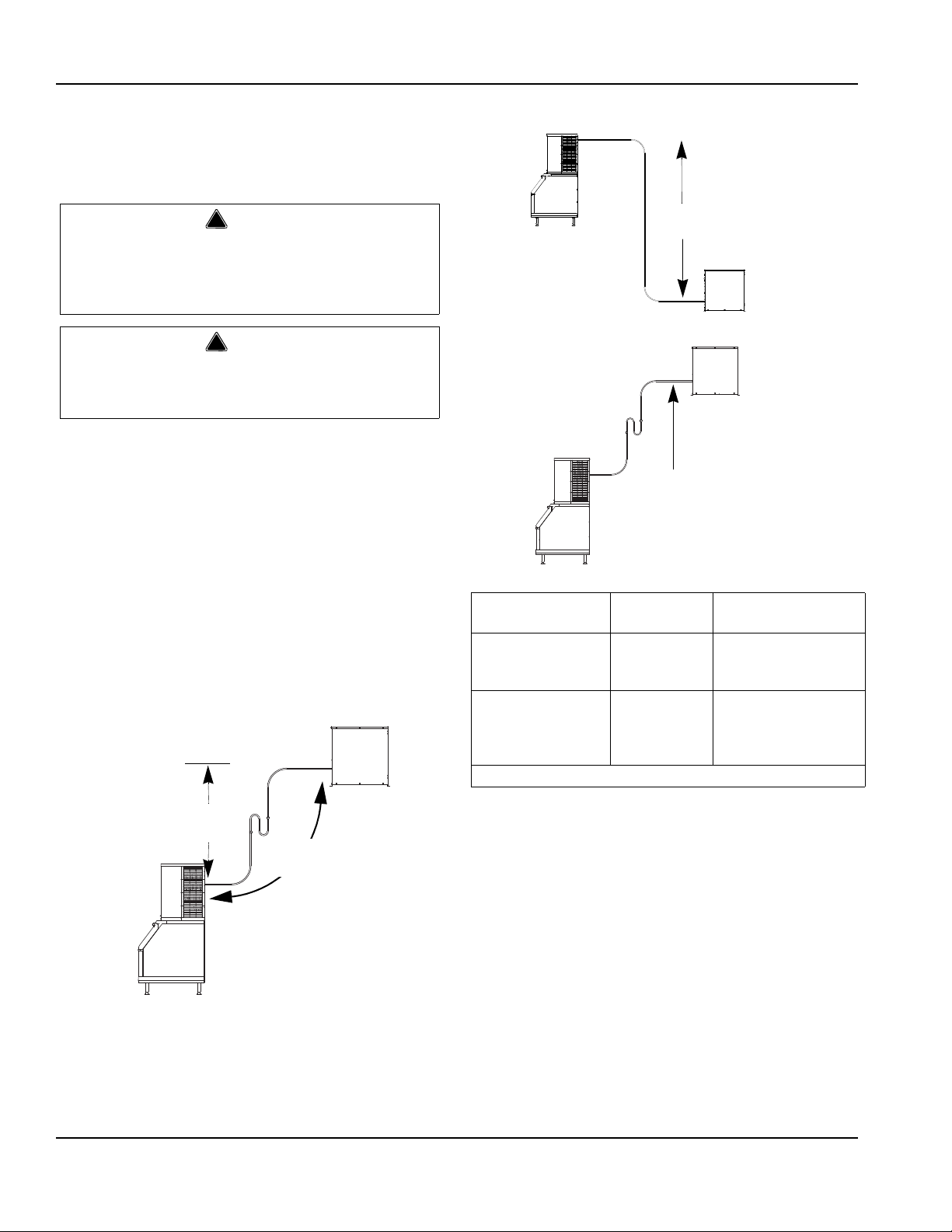

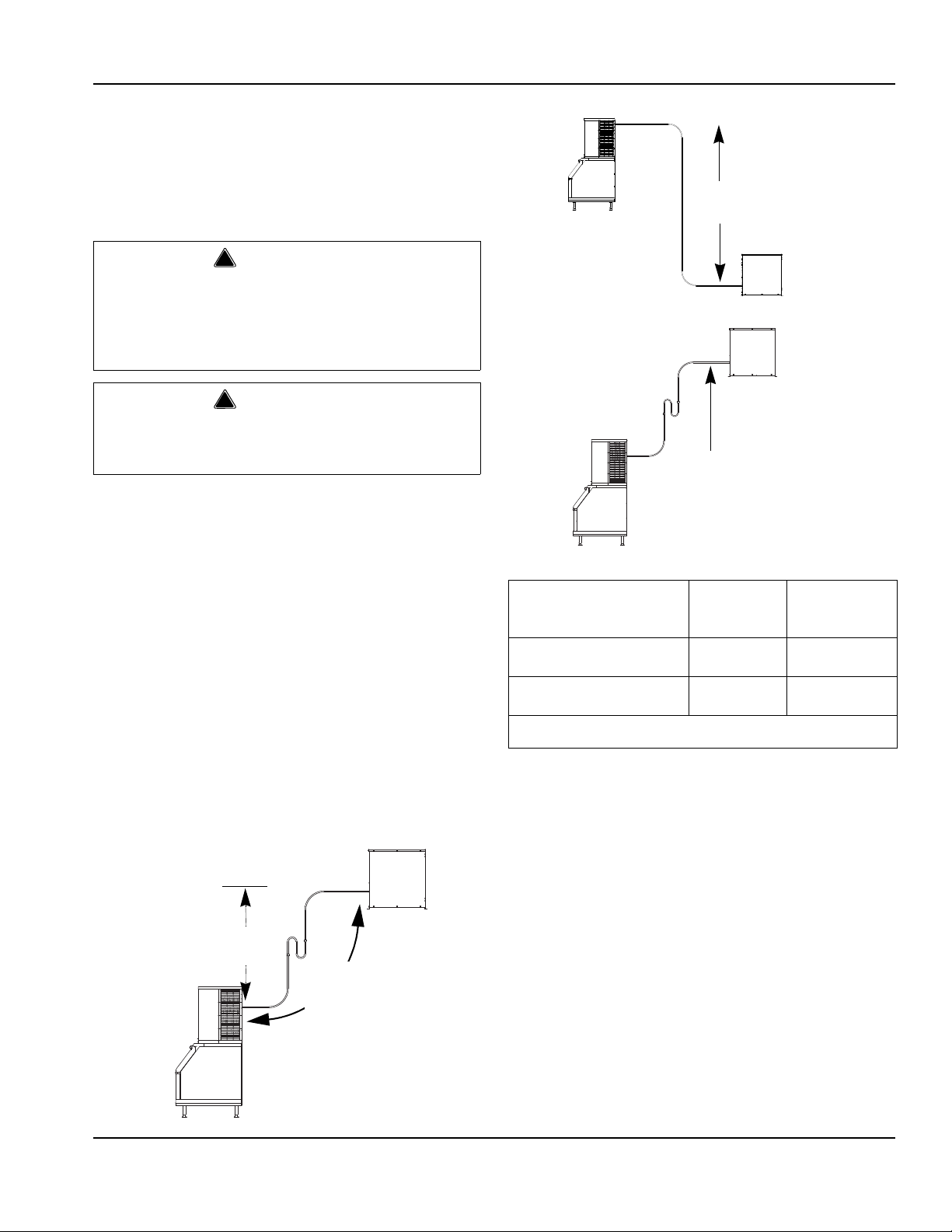

35' (10 M)

MAX.

DISTANCE

100' (30 M)

MAX LINESET

LENGTH

15' (4.5 M)

MAX.

DISTANCE

MORE THAN 20' (6 M) RISE

S-TRAP KIT REQUIRED

REFRIGERATION LINE SET INSTALLATION

The following requirements assure proper oil return.

The refrigeration line set installer must be certified/

licensed in refrigerant handling and servicing.

The ice machine head section contains refrigerant

charge. The ice machine head section contains

refrigeration valves that must remain closed until

proper installation of the line sets is completed.

.

Electrical power to the ice machine head section

and CVD® condensing unit must be disconnected

before proceeding.

Step 1 Lineset Requirements

• Maximum lineset length is 100' (30 m).

• Maximum rise is 35' (10 m).

• Maximum drop is 15' (4.5 m).

• A suction line oil trap is required when rise is more

than 20' (6 m).

• Maximum lineset exposed on rooftop is 25% of total

line set length.

• Only one trap is allowed in the lineset.

• Shorten the lineset as required, do not coil lineset.

• A qualified person must perform all roof penetrations

Manitowoc S-Trap Kit

Model

S0600C IB600C

S0800C IB800C

S1000C

IB1000C S1200C

S1470C S1870C

S2170C

S3000C*

*S3000C - requires two S-Trap kits, one for each suction line.

S-Trap Kit

Number

K00172

K00166

Tubing Size

5/8 inch

(15.9 mm)

3/4 inch

(19.1 mm)

12

Step 2 Secure Condenser

Through holes are provided to secure the condenser to

a curb, rack, or wooden timber.

Step 3 Route Refrigeration Tubing

Properly route refrigeration tubing between the ice

machine head section and the CVD® condensin g un it.

The line set can be routed for entry through the to p or

rear of the ice machine head section.

• Top routing requires the cover to be trimmed.

• Rear routing may require the use of 90° elbows.

Part Number 000006505 11/10

Page 13

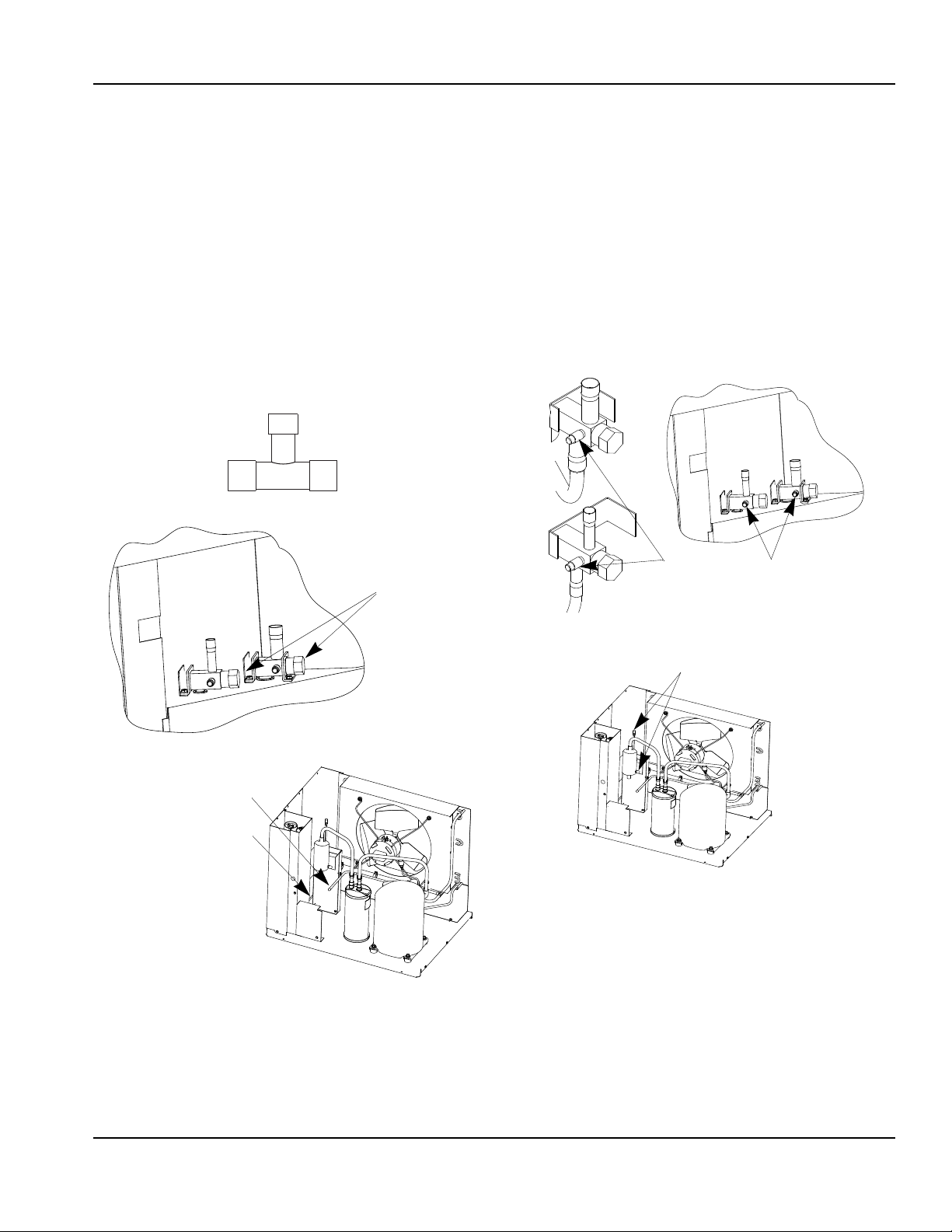

Section 2 Installation

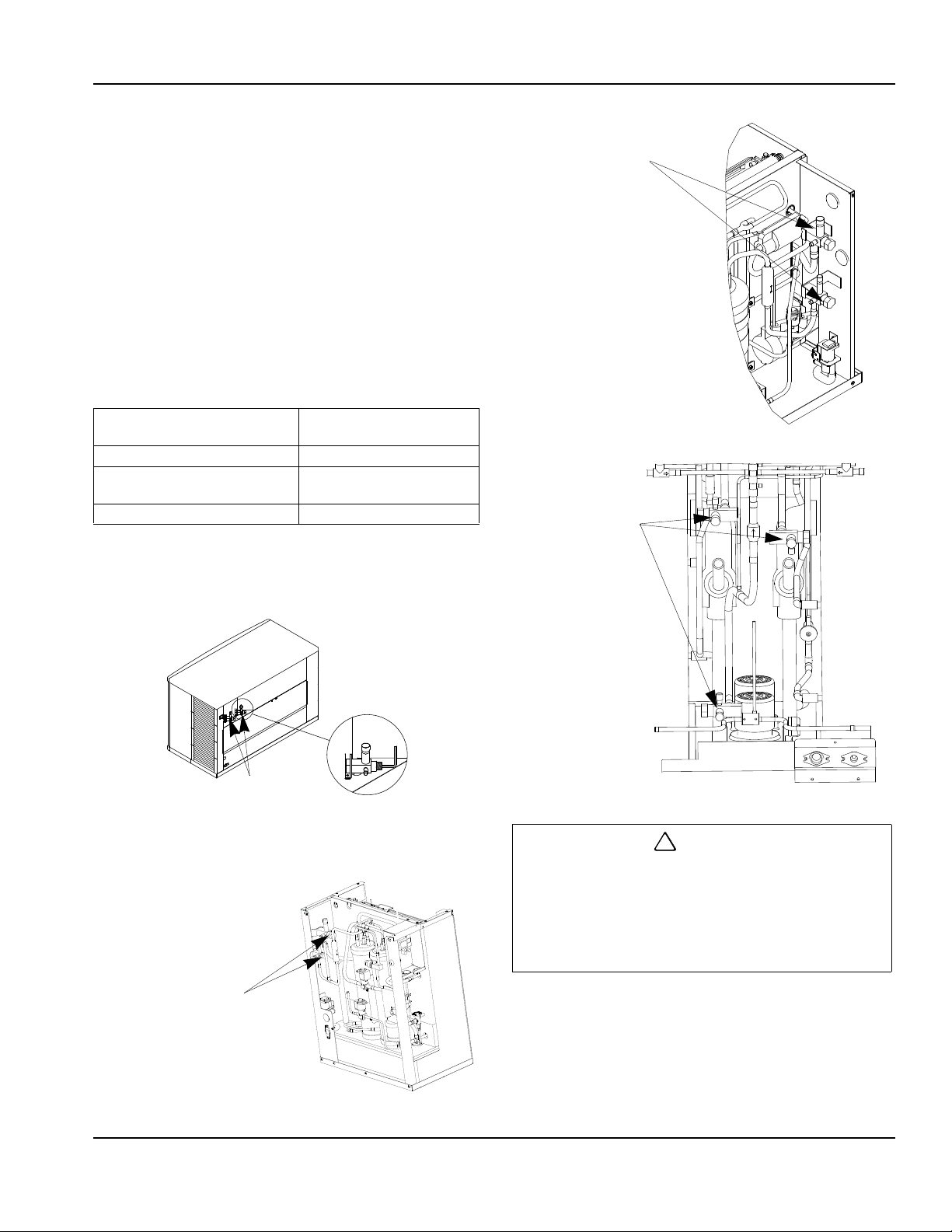

SUCTION LINE

FROM HEAD

SECTION

SUCTION LINE

FROM HEAD

SECTION

SUCTION LINE ON

CONDENSING UNIT

S3000C

TUBING MUST BE

CONNECTED TO

TEE AS SHOWN

VALVES MUST REMAIN

CLOSED AND BE

PROTECTED FROM

HEAT WHEN BRAZING

(WRAP WITH WET RAG)

MINIMIZE THE TIME THE

REFRIGERATION SYSTEM

IS EXPOSED TO THE

ATMOSPHERE (15

MINUTES MAXIMUM)

LIQUID

LINE

SUCTION

LINE

CONNECT VACUUM PUMP TO LINE SET

SHUT OFF VALVES

ALTERNATE CONNECTIONS AT

CONDENSING UNIT SCHRADER VALVES

Step 4 Connect the line set

• Maximum amount of time the refrigeration system

can be exposed to the atmosphere is 15 minutes

• Purge line set with dry nitrogen while brazing.

• Line set shut off valves on the ice machine must

remain closed and be protected from heat during

brazing.

• The condensing unit ships with a 50/50 mixture of

nitrogen/helium.

• S3000C has 2 suction lines and requires installation

of a tee at the condensing unit.

Step 5 Pressure Test and Evacuate Line Set and

CVD Condensing Unit

• Lineset shutoff valves must remain closed until

pressure testing and evacuation are complete.

• Schrader valve core removal tools that allow for

removal and installation of the valve cores without

removing manifold gauge set hoses are

recommended to decrease the evacuation time.

• Pressure test @ 150 psi (1000 kPa) for a minimum of

15 minutes.

• Minimum evacuation level is 500 microns.

Part Number 000006505 11/10 13

Page 14

Installation Section 2

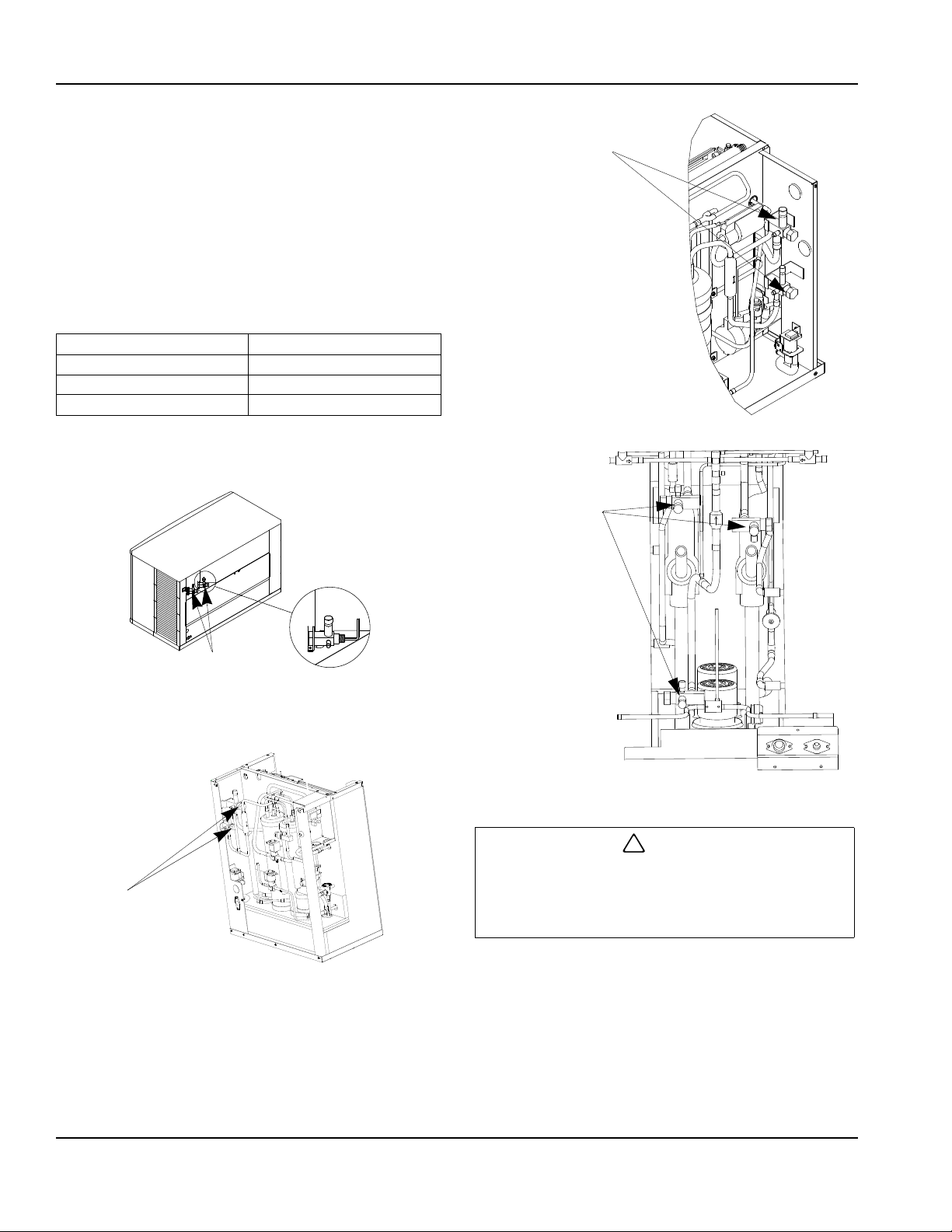

USE ALLEN WRENCH TO OPEN

(TURN COUNTERCLOCKWISE)

LIQUID AND SUCTION LINE

SHUT OFF VALVES

USE ALLEN WRENCH

TO OPEN (TURN

COUNTERCLOCKWISE)

LIQUID AND SUCTION

LINE SHUT OFF

VALVES

!

Caution

USE ALLEN WRENCH

TO OPEN (TURN

COUNTERCLOCKWISE)

LIQUID AND SUCTION

LINE SHUT OFF

VALVES

USE ALLEN WRENCH

TO OPEN (TURN

COUNTERCLOCKWISE)

LIQUID AND SUCTION

LINE SHUT OFF

VALVES

Step 6 Open Lineset and Receiver Valves

You will not hear refrigerant flow when the valves are

opened. Refrigerant will not flow until the toggle switch is

placed in the ice position and the solenoid valve opens.

• All valve caps must be reinstalled, tigh tened and leak

checked to assure no refrigerant leakage exists.

• Counterclockwise opens all valves:

A. Refer to chart and open the suction and liquid

line shut off valves the correct number of 360

turns.

Valve Tubing Size Number of Tu rns To Open

3/8" 6

1/2" 5/8" 3/4" 10

7/8" 14

B. Open the receiver service valve until

backseated (two valves on the S3000C).

.

°

S1470C/S1870C/S2170C

14

S0600C/S0800C/S1000C/S1200C

.

IB0600C/IB0800C/IB1000C

S3000C

After opening suction, discharge and receiver

service valves, refrigerant pressure will not be

detected until the toggle switch is placed in the ice

position and the solenoid valves energize.

Part Number 000006505 11/10

Page 15

Section 2 Installation

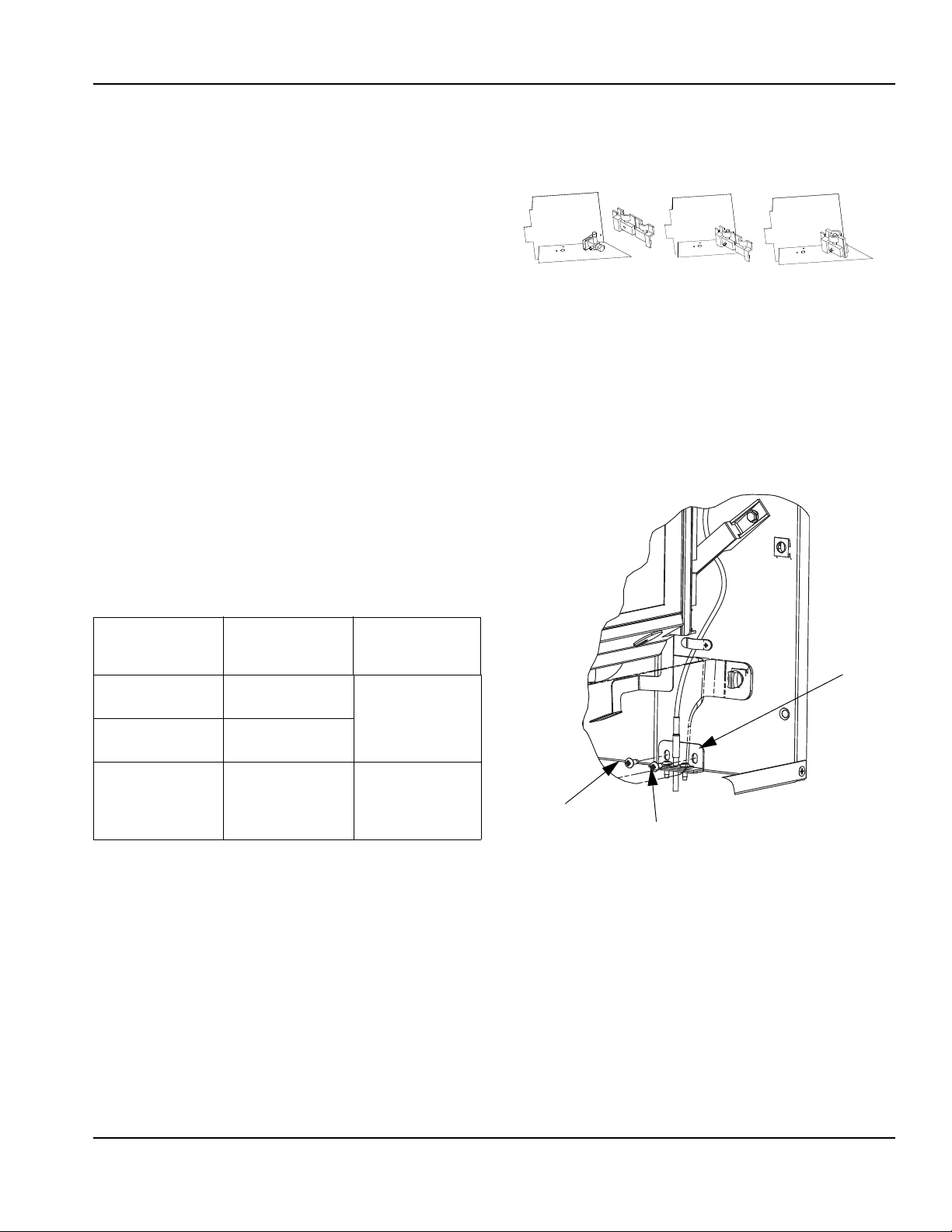

FINAL

POSITION

A. REMOVE

REAR SCREW

B. LOOSEN FRONT SCREW &

ROTATE PROBE/BRACKET.

REINSTALL & TIGHTEN ALL

SCREWS

Step 7 Leak Check The Refrigeration System

A. Connect power to the ice machine head section -

Do not connect power to the CVD condensing

unit.

B. Place the ICE/OFF/CLEAN toggle switch in the

ICE position for 60 seconds to equalize

pressures, then move to OFF position.

C. Disconnect power to the ice machine head

section.

D. Leak check lineset connections, S trap and all

factory joints in head section and condensing

unit.

E. Connect power to the CVD condensing unit and

allow system to pump down.

Step 8 Insulation Requirements

• To prevent condensation the entire suction line

including the shut-off valve must be insulated.

• All insulation must be airtight and sealed at both

ends.

The following insulation requirements prevent

condensation at 90°F (32.2°C) ambient 90% Relative

Humidity. If higher humidity is expected, increase

insulation thickness:

Suction Shut Off Valve Insulation

The pre-formed suction shut-off valve insulation is

located in the plastic bag taped to the water curtain.

.

ELECTRONIC BIN THERMOSTAT INSTRUCTIONS IB600C/IB800C/IB1000C ON LY

• The bin thermostat probe must be rotated down to

enable ice contact and proper operation.

• Verify probe wire does not interfere with the water

curtain.

• The control is preset and does not require

programming.

Suction Line Liquid Line

3/4 inch

(19.1 mm)

5/8 inch

(15.9 mm)

3/4 inch

(19.1 mm)

1/2 inch

(12.7 mm)

3/8 inch

(9.5 mm)

5/8 inch

(15.9 mm)

Min.

Insulation

Thickness

1/2" (13 mm)

Suction Line

1/4" (7 mm)

Liquid Line

3/4" (19 mm)

Suction Line

1/4" (7 mm)

Liquid Line

Part Number 000006505 11/10 15

Page 16

Ice Making Sequence of Operation

Section 3

Operation

Water Purge Cycle

The ice machine purges any remaining water from the

water trough down the drain.

Freeze Cycle

Water flows across the eva porator and the refrigeration

system chills the evaporator. Ice builds on the

evaporator until water contacts the ice thickness probe.

Harvest Cycle

Any remaining water is purged down the drain as

refrigerant gas warms the evaporator. When the

evaporator warms, the sheet of cubes slides off the

evaporator and into the storage bin. If all cubes fall clear

of the water curtain (or ice damper) the ice machine

starts another freeze cycle.

Off Cycle

If the water curtain or ice damper are held open by ice

cubes the ice machine shuts off. When the water cur t ain

or ice damper closes the ice machine starts a new cycle

at the water purge.

Control Board Timers

The control board has the following non-adjustable

timers:

• The ice machine is locked into the freeze cycle for 6

minutes before a harvest cycle can be initiated.

Freeze lock is bypassed after moving the toggle

switch from OFF to ICE position for the first cycle

only .

• The maximum freeze time is 60 minutes at which

time the control board automatically initiates a

harvest sequence.

• The maximum harvest time is 3.5 minutes for single

evaporators and 7 minutes for multiple evaporator

model. The control board automatically initiates a

freeze sequence when these times are exceeded.

SAFETY LIMITS

Safety limits are stored and indicated by the control

board after three cycles. The number of cycles required

to stop the ice machine varies for each safety limit.

• Safety Limit 1 all models - If the freeze time reaches

60 minutes, the control board automatically initiates a

harvest cycle. If 6 consecutive 60-minute freeze

cycles occur, the ice machine stops.

• Safety Limit 2 single & twin evaporator models - If the

harvest time reaches 3.5 minutes, the control board

automatically returns the ice machine to the freeze

cycle. If 500 consecutive 3.5 minute harvest cycles

occur, the ice machine stops.

• Safety Limit 2 S3000C - If the harvest time reaches 7

minutes, the control board automatically returns the

ice machine to the freeze cycle. If 500 consecutive 7

minute harvest cycles occur, the ice machine stops.

• Safety Limit 3 S3000C - If the low refrigerant

pressure control opens, the ice machine shuts off

and starts a 5 minute delay period. If 3 consecutive

low pressure events occur the ice machine stops and

flashes the harvest light.

Use the following procedures to determine if the control

board contains a safety limit indication.

1. Move the toggle switch to OFF.

2. Move the toggle switch back to ICE. Watch the

safety limit lights/harvest light on the control board. If

a safety limit has been recorded, the corresponding

light will blink once, twice or three times to indicate

which safety limit stopped the ice machine.

16 Part Number 000006505 11/10

Page 17

Section 3 Operation

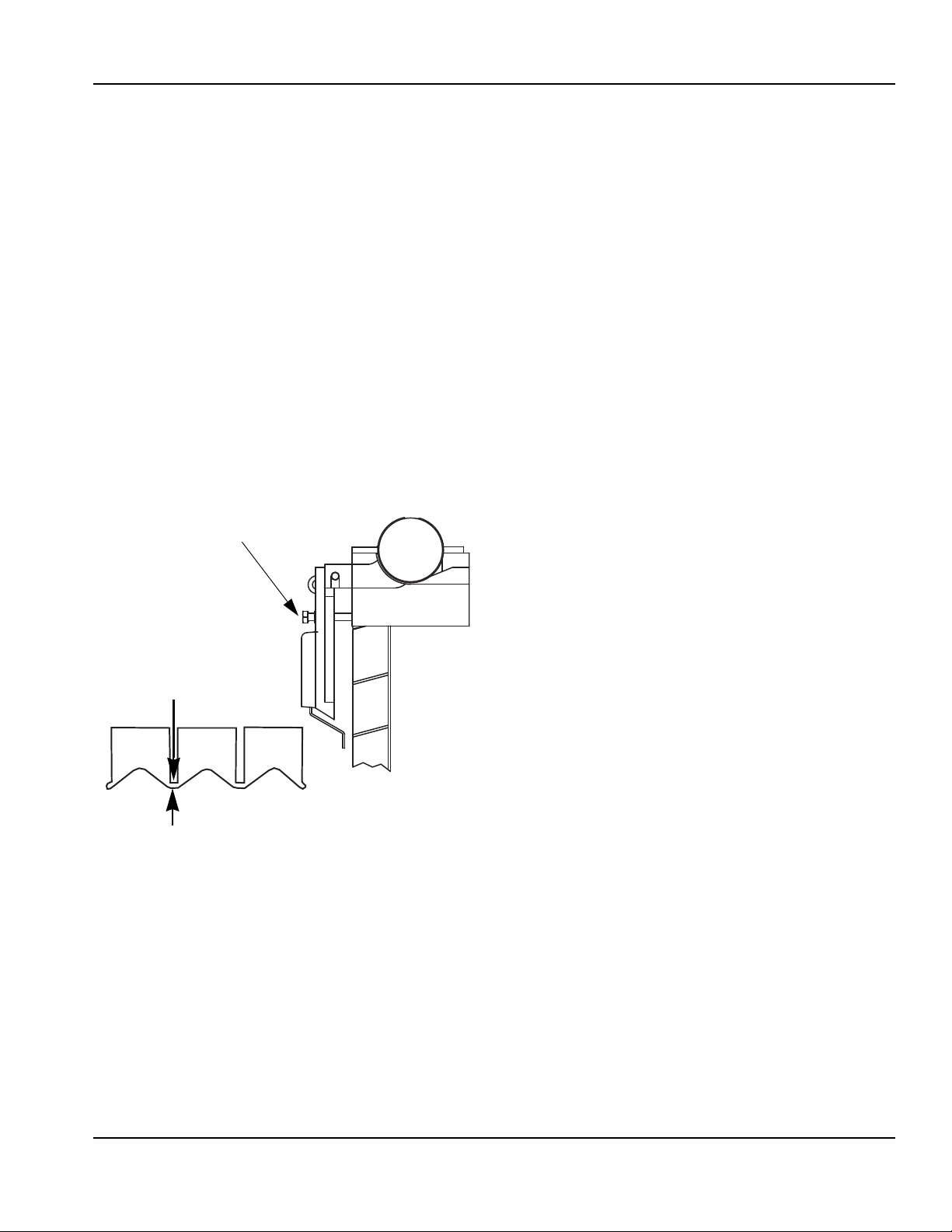

ADJUSTING SCREW

1/8" ICE BRIDGE THICKNESS

Operational Checks

ICE THICKNESS CHECK

After a harvest cycle, inspect the ice cubes in the ice

storage bin. The ice thickness probe is factory-set to

maintain the ice bridge thickness at 1/8" (3 mm).

NOTE: Make sure the water curtain is in place when

performing this check. It prevents water from splashing

out of the water trough.

1. Inspect the bridge connecting the cubes. It should

be about 1/8" (3 mm) thick.

2. If adjustment is necessary, turn the ice thickness

probe adjustment screw clockwise to increase

bridge thickness, counterclockwise to decrease

bridge thickness. Set at 1/4" gap between ice

machine and evaporator as starting point, then

adjust to achieve a 1/8" bridge thickness.

NOTE: Turning the adjustment 1/3 of a turn will change

the ice thickness about 1/16" (1.5 mm).

3. Make sure the ice thickness probe wire and the

bracket do not restrict movement of the probe.

Part Number 000006505 11/10 17

Ice Thickness Check

Page 18

Section 4

!

Caution

!

Caution

!

Warning

Maintenance

Cleaning and Sanitizing

You are responsible for maintaining the ice machine in

accordance with the instructions in this manual.

Maintenance procedures are not covered by the

warranty.

Clean and sanitize the ice machine every six months for

efficient operation. If the ice machine requires more

frequent cleaning and sanitizing, consult a qualified

service company to test the water quality and

recommend appropriate water treatment. An extremely

dirty ice machine must be taken apart for cleaning and

sanitizing.

Manitowoc Ice Machine Cleaner and Sanitizer are the

only products approved for use in Manitowoc ice

machines.

Use only Manitowoc approved Ice Machine Cleaner

and Sanitizer for this application (Manitowoc

Cleaner part number 94-0546-3 and Manitowoc

Sanitizer part number 94-0565-3). It is a violation of

Federal law to use these solutions in a manner

inconsistent with their labeling. Read and

understand all labels printed on bottles before use.

Do not mix Cleaner and Sanitizer solutions together.

It is a violation of Federal law to use these solutions

in a manner inconsistent with their labeling.

Wear rubber gloves and safety goggles (and/or face

shield) when handling ice machine Cleaner or

Sanitizer.

CLEANING/SANITIZING PROCEDURE DIFFERENCES

This Manitowoc Ice Machine has two separate cleaning

procedures.

Cleaning/Sanitizing Procedure

This procedure must be performed a minimum of once

every six months.

• The ice machine and bin must be disassembled

cleaned and sanitized

• The ice machine produces ice with the cleaner and

sanitizer solutions

• Removes mineral deposits from areas or su rfaces

that are in direct contact with water

Heavily Scaled Cleaning Procedure

Perform this procedure if you have some or all of these

symptoms.

• An IB600C/IB800C/IB1000C

• Ice machine stops on Safety Shutdown

• Your water has a high concentration of minerals

• The ice machine has not been on a regular

maintenance schedule

EXTERIOR CLEANING

Clean the area around the ice machine as often as

necessary to maintain cleanliness and efficient

operation. Use cleaners designed for use with stainless

steel products.

Sponge any dust and dirt off the outside of the ice

machine with mild soap and water. Wipe dry with a

clean, soft cloth.

Heavy stains should be removed with stainless steel

wool. Never use plain steel wool or abrasive pads. They

will scratch the panels.

18 Part Number 000006505 11/10

Page 19

Section 4 Maintenance

!

Caution

!

Caution

!

Warning

!

Caution

!

Warning

Cleaning / Sanitizing Procedure

Use only Manitowoc approved Ice Machine Cleaner

and Sanitizer for this application (Manitowoc

Cleaner part number 94-0546-3 and Manitowoc

Sanitizer part number 94-0565-3). It is a violation of

Federal law to use these solutions in a manner

inconsistent with their labeling. Read and

understand all labels printed on bottles before use.

CLEANING PROCEDURE

Do not mix Cleaner and Sanitizer solutions together.

Wear rubber gloves and safety goggles (and/or face

shield) when handling ice machine Cleaner or

Sanitizer.

Ice machine cleaner is used to remove lime scale and

mineral deposits. Ice machine sanitizer disinfects and

removes algae and slime.

NOTE: IB Models must be cleaned using the procedure

on Page 21.

Step 1 Remove front door and top cover. This will allow

easiest access for adding cleaning and sanitizing

solutions.

Step 2 Set the toggle switch to the OFF position after

ice falls from the evaporator at the end of a Harvest

cycle. Or, set the switch to the OFF position and allow

the ice to melt off the evaporator.

Never use anything to force ice from the evaporator.

Damage may result.

Step 3 Remove all ice from the bin/dispenser.

Step 4 Place the toggle switch in the CLEAN position.

The water will flow through the water dump valve and

down the drain. Wait until the water trough refills and

water flows over the evaporator, then add the proper

amount of ice machine cleaner.

Model Amount of Cleaner

S0600C/S0800C

S1000C/S1200C

S1470C/S1870C/S2170C 9 ounces (270 ml)

S3000C 16 ounces (475 ml)

Step 5 Wait until the clean cycle is complete

(approximately *35 minutes) then place the toggle switch

in the OFF position and disconnect power to the ice

machine (and dispenser when used).

NOTE: *S3000C Only - 80 minutes.

Disconnect the electric power to the ice machine at

the electric service switch box.

Step 6 Remove parts for cleaning.

Please refer to the proper parts removal for your

ice machine. Continue with step 7 when the parts

have been removed.

S0600C/S0800C/S1000C/S1200C - Page 24.

Remove the water curtain, Ice thickness probe and

water trough - parts A, B & C in the graphic.

S1470C/S1870C/S2170C - Page 26.

Remove the splash shields, Ice thickness probe, water

trough shield and water trough - parts A, B, C & D in the

graphic.

S3000C - Page 27.

Remove the front evaporator shield, evaporator covers,

splash shields, Ice thickness probe, water pump

assembly & water trough - parts A, B, C, D, E & F in the

graphic.

5 ounces (150 ml)

Part Number 000006505 11/10 19

Page 20

Maintenance Section 4

Step 7 Mix a solution of cleaner and warm water.

Depending upon the amount of mineral buildup, a larger

quantity of solution may be required. Use the ratio in the

table below to mix enough solution to thoroughly clean

all parts.

Solution Type Water Mixed With

Cleaner 1 gal. (4 l) 16 oz (500 ml) cleaner

Step 8 Use 1/2 of the cleaner/water mixture to clean all

components. The cleaner solution will foam when it

contacts lime scale and mineral deposits; once the

foaming stops use a soft-bristle nylon brush, sponge or

cloth (NOT a wire brush) to carefully clean the parts.

Soak parts for 5 minutes (15 - 20 minutes for heavily

scaled parts). Rinse all components with clean water.

Step 9 While components are soaking, use 1/2 of the

cleaner/water solution to clean all foodzone surfaces of

the ice machine and bin (or dispenser). Use a nylon

brush or cloth to thoroughly clean the following ice

machine areas:

• Side walls

• Base (area above water trough)

• Evaporator plastic parts - including top, bottom, and

sides

• Bin or dispenser

Rinse all areas thoroughly with clean water.

SANITIZING PROCEDURE

Step 10 Mix a solution of sanitizer and warm water.

Solution Type Water Mixed With

Sanitizer 6 gal. (23 l) 4 oz (120 ml) sanitizer

Step 11 Use 1/2 of the sa nit izer /wa te r so lut ion to

sanitize all removed components. Use a spray bottle to

liberally apply the solution to all surfaces of the removed

parts or soak the removed parts in the sanitizer/water

solution. Do not rinse parts after sanitizing.

Step 12 Use 1/2 of the sanitizer/water solution to

sanitize all foodzone surfaces of the ice machine and bin

(or dispenser). Use a spray bottle to liberally apply the

solution. When sanitizing, pay particular attention to the

following areas:

• Side walls

• Base (area above water trough)

• Evaporator plastic parts - including top, bottom and

sides

• Bin or dispenser

Do not rinse the sanitized areas.

Step 13 Replace all removed components.

Step 14 Wait 30 minutes.

Step 15 Reapply power to the ice machine and place

the toggle switch in the CLEAN position.

Step 16 Wait until the water trough refills and water

flows over the evaporator (approximately 3 minutes).

Add the proper amount of Manitowoc Ice Machine

Sanitizer to the water trough by pouring betwee n the

water curtain and evaporator.

Model Amount of Sanitizer

S0600C/S0800C

S1000C/S1200C

S1470C/S1870C/S2170C 12 ounces (355 ml)

S3000C 25 ounces (740 ml)

3 ounces (90 ml)

Step 17 Move the toggle switch to the ICE position and

replace the front panel. The ice machine will

automatically start ice making after the sanitize cycle is

complete (approximately 35 minutes, S3000C - 80

minutes).

20

Part Number 000006505 11/10

Page 21

Section 4 Maintenance

!

Caution

!

Caution

!

Warning

!

Caution

!

Warning

Procedure to Clean Heavily Scaled Ice Machines

IB models and ice machines that are heavily scaled or

have not been cleaned on a regular basis will need to

run this procedure.

Use only Manitowoc approved Ice Machine Cleaner

and Sanitizer for this application (Manitowoc

Cleaner part number 94-0546-3 and Manitowoc

Sanitizer part number 94-0565-3). It is a violation of

Federal law to use these solutions in a manner

inconsistent with their labeling. Read and

understand all labels printed on bottles before use.

CLEANING PROCEDURE

Do not mix Cleaner and Sanitizer solutions together.

Wear rubber gloves and safety goggles (and/or face

shield) when handling ice machine Cleaner or

Sanitizer.

Ice machine cleaner is used to remove lime scale and

mineral deposits. Ice machine sanitizer disinfects and

removes algae and slime.

Step 3 Remove all ice from the bin/dispenser.

Step 4 Place the toggle switch in the CLEAN position.

The water will flow through the water dump valve and

down the drain. Wait until the water trough refills and

water flows over the evaporator, then add the proper

amount of ice machine cleaner.

Model Amount of Cleaner

S0600C/S0800C

S1000C/S1200C

IB600C/IB800C/IB1000C 5 ounces (150 ml)

S1470C/S1870C/S2170C 9 ounces (270 ml)

S3000C 16 ounces (475 ml)

Step 5 Wait until the clean cycle is complete

(approximately *35 minutes) then place the toggle switch

in the OFF position and disconnect power to the ice

machine (and dispenser when used).

NOTE: *S3000C Only - 80 minutes.

Disconnect the electric power to the ice machine at

the electric service switch box.

Step 6 Remove parts for cleaning.

5 ounces (150 ml)

Step 1 Remove front door and top cover. This will allow

easiest access for adding cleaning and sanitizing

solutions.

Step 2 Set the toggle switch to the OFF position after

ice falls from the evaporator at the end of a Harvest

cycle. Or, set the switch to the OFF position and allow

the ice to melt off the evaporator.

Never use anything to force ice from the evaporator.

Damage may result.

Please refer to the proper parts removal for your ice

machine. Continue with step 7 when the parts have

been removed.

S0600C/S0800C/S1000C/S1200C - Page 24.

IB600C/IB800C/IB1000C - Page 25.

S1470C/S1870C/S2170C - Page 26.

S3000C - Page 27.

Part Number 000006505 11/10 21

Page 22

Maintenance Section 4

!

Warning

Step 7 Mix a solution of cleaner and warm water.

Depending upon the amount of mineral buildup, a larger

quantity of solution may be required. Use the ratio in the

table below to mix enough solution to thoroughly clean

all parts.

Solution Type Water Mixed With

Cleaner 1 gal. (4 l) 16 oz (500 ml) cleaner

Step 8 Use 1/2 of the cleaner/water mixture to clean all

components. The cleaner solution will foam when it

contacts lime scale and mineral deposits; once the

foaming stops use a soft-bristle nylon brush, sponge or

cloth (NOT a wire brush) to carefully clean the parts.

Soak parts for 5 minutes (15 - 20 minutes for heavily

scaled parts). Rinse all components with clean water.

Step 9 While components are soaking, use 1/2 of the

cleaner/water solution to clean all foodzone surfaces of

the ice machine and bin (or dispenser). Use a nylon

brush or cloth to thoroughly clean the following ice

machine areas:

• Side walls

Step 12 Use 1/2 of the sanitizer/water solution to

sanitize all foodzone surfaces of the ice machine and bin

(or dispenser). Use a cloth or sponge to liberally apply

the solution. When sanitizing, pay particular attention to

the following areas:

• Side walls

• Base (area above water trough)

• Evaporator plastic parts - including top, bottom and

sides

• Bin or dispenser

Do not rinse the sanitized areas.

Step 13 Replace all removed components.

Step 14 Reapply power to the ice machine and place

the toggle switch in the CLEAN position.

Step 15 Wait about two minutes or until water starts to

flow over the evaporator. Add the proper amount of

Manitowoc Ice Machine Sanitizer to the water trough by

pouring between the water curtain and evaporator .

• Base (area above water trough)

• Evaporator plastic parts - including top, bottom, and

sides

• Bin or dispenser

Rinse all areas thoroughly with clean water.

SANITIZING PROCEDURE

Step 10 Mix a solution of sanitizer and warm water.

Solution Type Water Mixed With

Sanitizer 6 gal. (23 l) 4 oz (120 ml) sanitizer

Step 11 Use 1/2 of the sa nit izer /wa te r so lut ion to

sanitize all removed components. Use a cloth or sponge

to liberally apply the solution to all surfaces of the

removed parts or soak the removed parts in the

sanitizer/water solution. Do not rinse parts after

sanitizing.

Model Amount of Sanitizer

S0600C/S0800C

S1000C/S1200C

IB600C/IB800C 3 ounces (90 ml)

IB1000C 3.5 ounces (104 ml)

S1470C/S1870C/S2170C 12 ounces (355 ml)

S3000C 25 ounces (740 ml)

3 ounces (90 ml)

Step 16 The ice machine will stop after the sanitize

cycle (approximately *35 minutes). Place the toggle

switch in the OFF position and disconnect power to the

ice machine.

NOTE: *S3000C Only - 80 minutes.

Disconnect the electric power to the ice machine at

the electric service switch box.

22

Part Number 000006505 11/10

Page 23

Section 4 Maintenance

Step 17 Refer to step 6 and disassemble components.

After dissembling proceed to step 18.

Step 18 Mix a solution of sanitizer and warm water.

Solution Type Water Mixed With

Sanitizer 6 gal. (23 l) 4 oz (120 ml) sanitizer

Step 19 Use 1/2 of the sanitizer/water solution to

sanitize all removed components. Use a cloth or sponge

to liberally apply the solution to all surfaces of the

removed parts or soak the removed parts in the

sanitizer/water solution. Do not rinse parts after

sanitizing.

Step 20 Use 1/2 of the sanitizer/water solution to

sanitize all foodzone surfaces of the ice machine and bin

(or dispenser). Use a cloth or sponge to liberally apply

the solution. When sanitizing, pay particular attention to

the following areas:

• Side walls

• Base (area above water trough)

• Evaporator plastic parts - including top, bottom and

sides

• Bin or dispenser

Do not rinse the sanitized areas.

Step 21 Install the removed parts, restore power and

place the toggle switch in the ICE position.

Part Number 000006505 11/10 23

Page 24

Maintenance Section 4

G

A

B

E

C

D

F

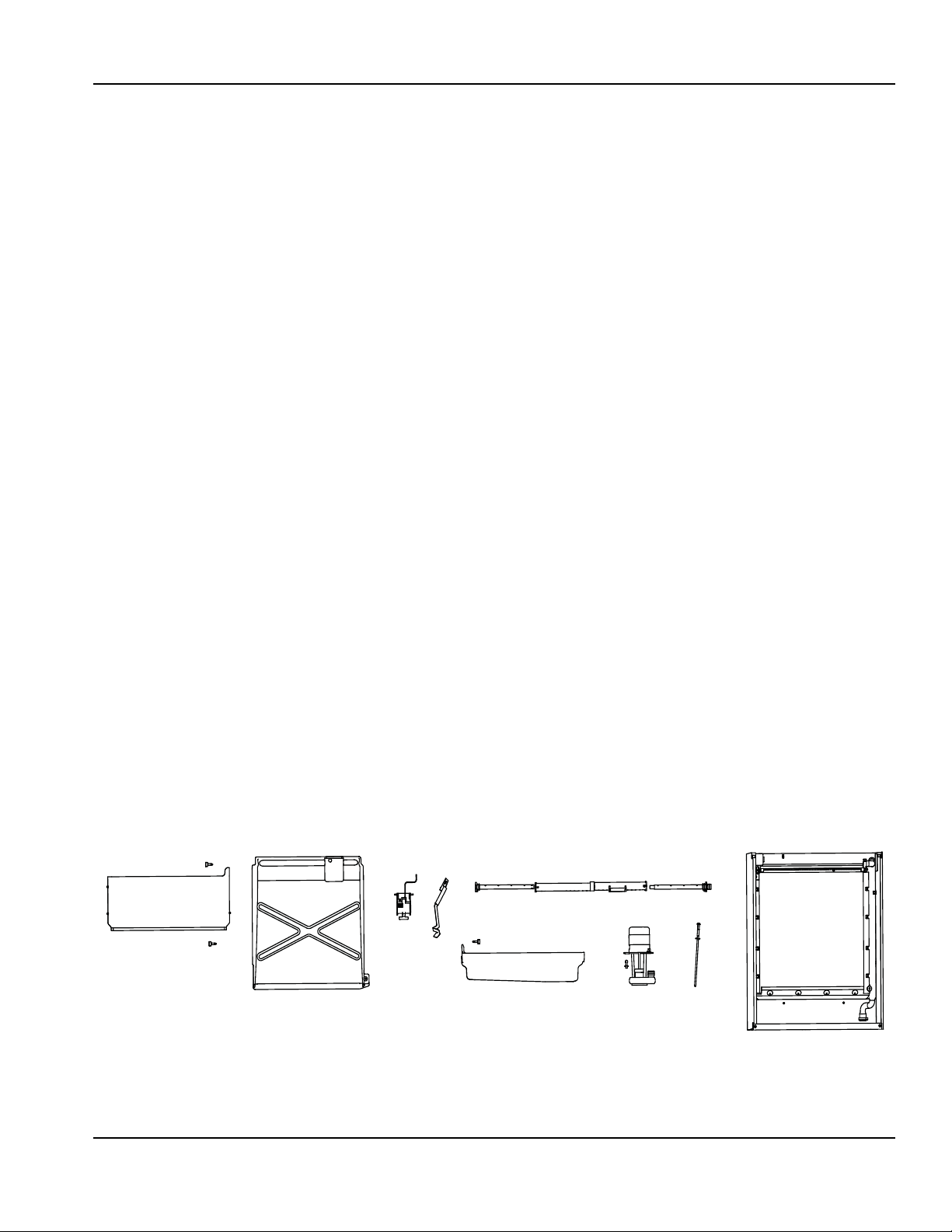

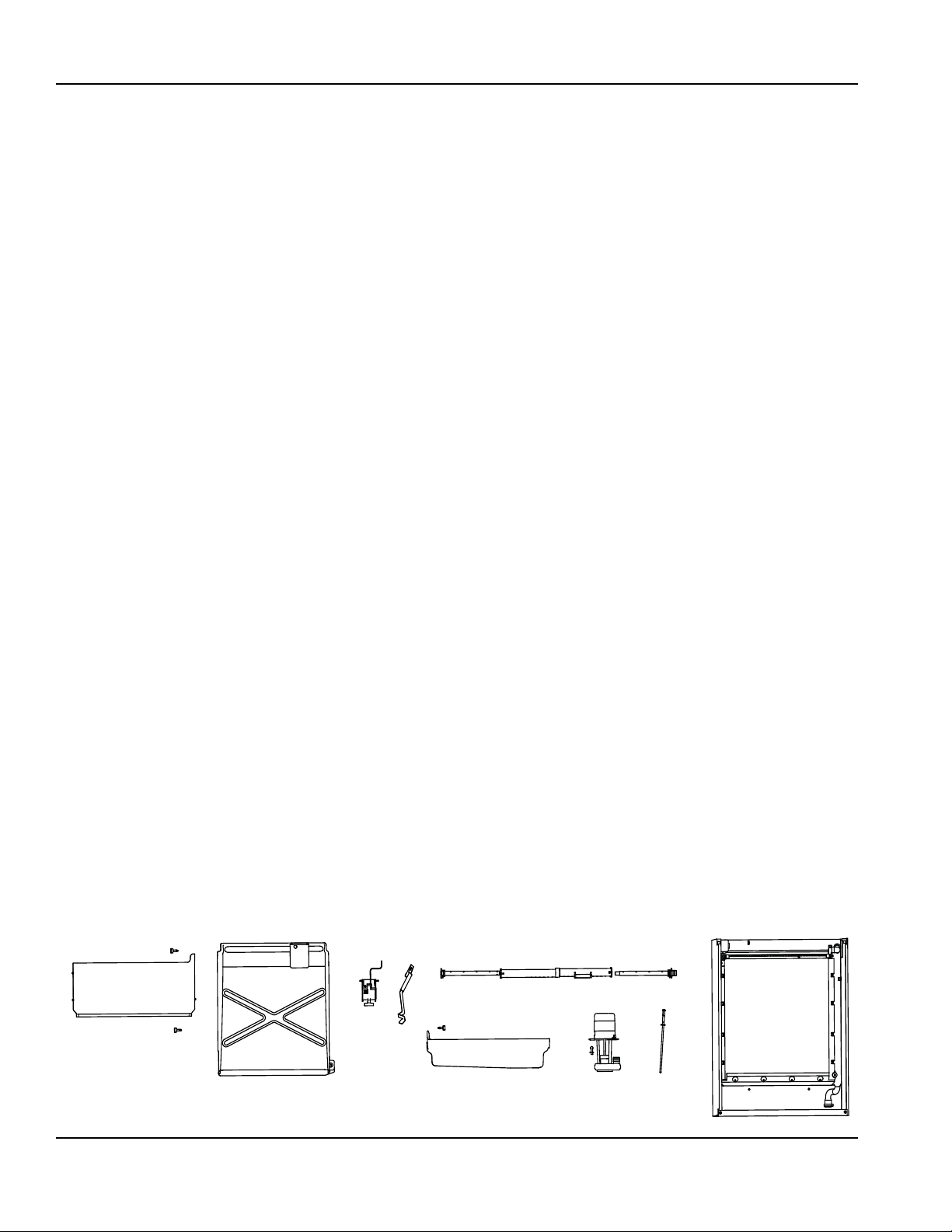

PARTS REMOVAL FOR CLEANING/SANITIZING

S0600C/S0800C/S1000C/S1200C

A. Remove the water curtain

• Gently flex the curtain in the center and remove it

from the right side.

• Slide the left pin out.

B. Remove the ice thickness probe

• Compress the hinge pin on the top of the ice

thickness probe.

• Pivot the ice thickness probe to disengage one pin

then the other. The ice thickness probe can be

cleaned at this point without complete removal. If

complete removal is desired, disconnect the ice

thickness control wiring from the control board.

C. Remove the evaporator tray or water diverter

from the bottom of the evaporator

• Loosen thumbscrew on left side of tray.

• Allow left side of tray to drop as you pull the tray to

the left side. Continue until the outlet tube

disengages from the right side.

D. Remove the water trough

• Depress tabs on right and left side of the water

trough.

• Allow front of water trough to drop as you pull forward

to disengage the rear pins.

E. Remove the water level probe

• Pull the water level probe straight down to

disengage.

• Lower the water level probe until the wiring connector

is visible.

• Disconnect the wire lead from the water level probe.

• Remove the water level probe from the ice machine.

F. Remove the water pump

• Grasp pump and pull straight down on pump

assembly until water pump disengages and electrical

connector is visible.

• Disconnect the electrical connector.

• Remove the water pump assembly from ice machine.

• Do not soak the water pump motor in cleaner or

sanitizer solution.

G. Remove the water distribution tube

NOTE: Distribution tube thumbscrews ar e re tained to

prevent loss. Loosen thumbscrews but do not pull

thumbscrews out of distribution tube.

• Loosen the two outer screws (do not remove scre ws

completely they are retained to prevent loss) a nd pull

forward on the distribution tube to release from slip

joint.

• Disassemble distribution tube by loosening the two

(2) middle thumbscrews and dividing the distribution

tube into two pieces.

24

Part Number 000006505 11/10

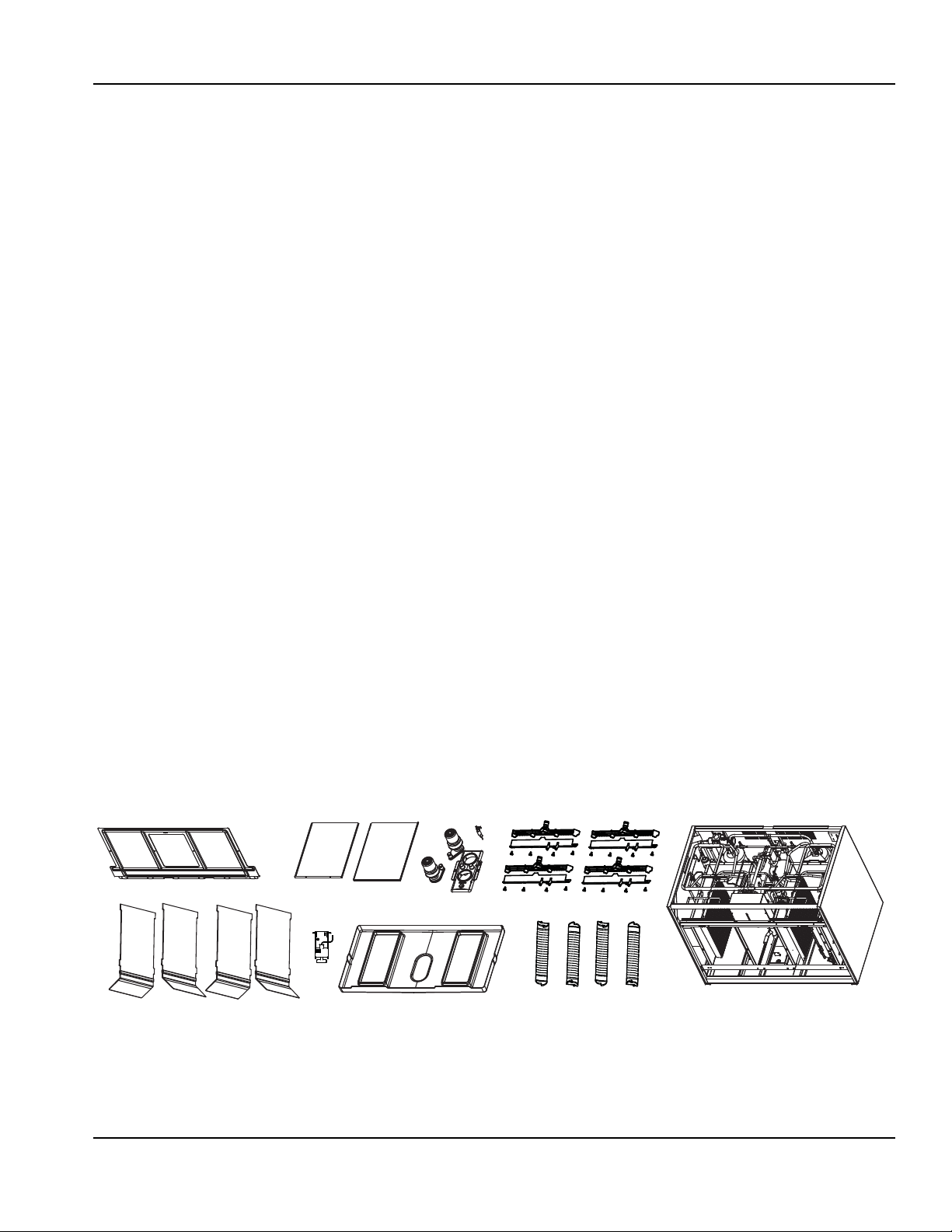

Page 25

Section 4 Maintenance

A

B

C

D

E

F

G

H

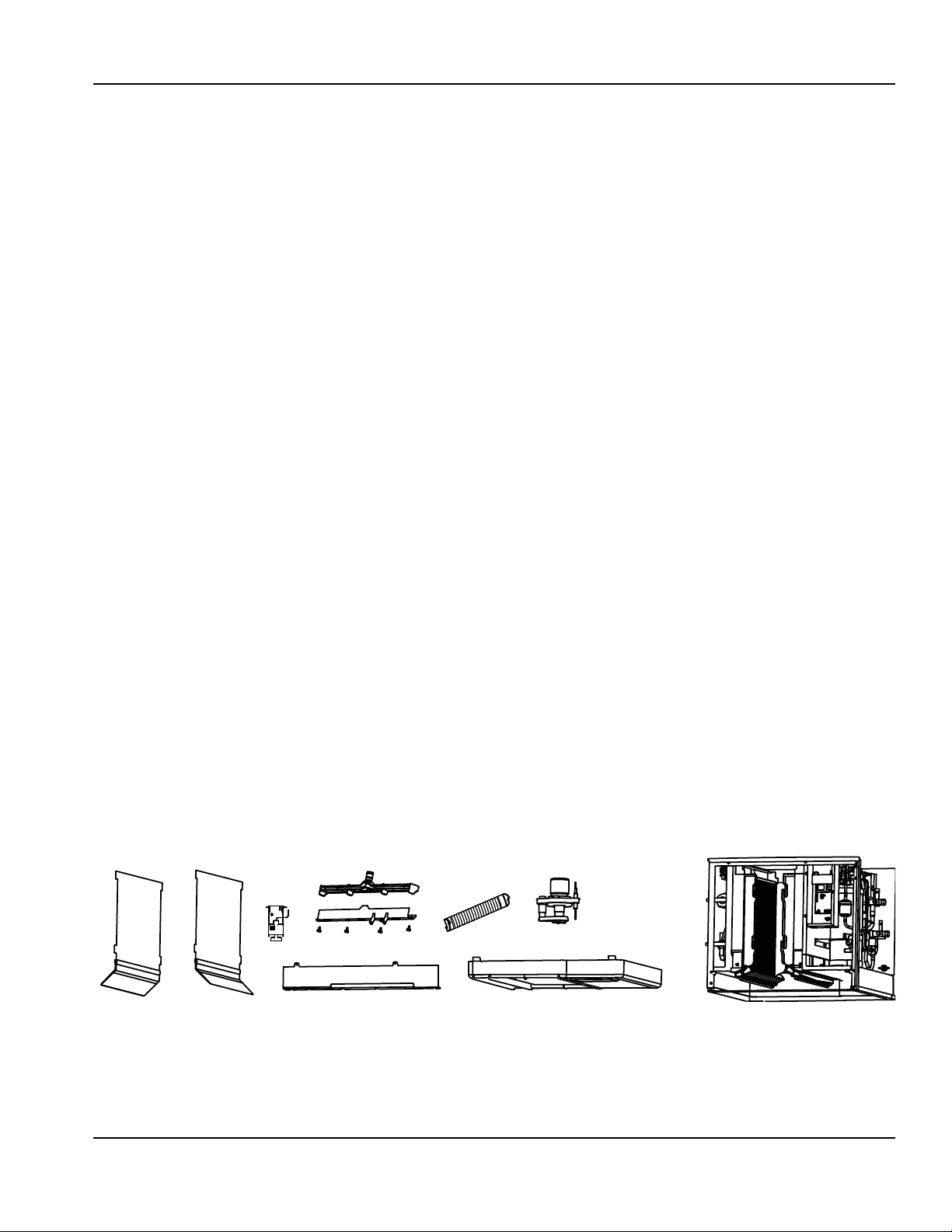

IB600C/IB800C/IB1000C

A. Remove the splash shield

F. Remove the water distribution tube

• Remove quarter turn connector from the right side of

splash shield, then gently bow the center of the

splash shield and lift up and forward to remove.

B. Remove the water curtain

• Gently flex the curtain in the center and remove one

side then the other.

C. Remove the ice thickness probe

• Compress the hinge pin on the top of the ice

thickness probe.

• Pivot the ice thickness probe to disengage one pin

then the other. The ice thickness probe can be

cleaned at this point without complete removal. If

complete removal is desired, disconnect the ice

thickness control wiring from the control board.

D. Remove the water level probe

• Remove the screw that holds the water level probe in

place. The probe can easily be cleaned at this point

without complete removal. If complete removal is

desired, remove the top cover, left and right side

panels and control box cover. Disconnect the wire

lead from the control board inside the electrical

control box.

E. Remove the water trough

• Remove the quarter turn fasteners.

• Pull forward on the water trough until the rear pins

disengage from the water trough.

• Lift up and forward on the front of the water trough

while allowing the rear of the water trough to drop.

• Loosen the two distribution tube thumbsc re ws.

• Lift the right side of the distribution tube up, and then

rotate it backward and to the right until the left side of

the distribution tube disengages the thumbscrew.

• Remove the clamp/hose from the distribution tube.

Disassemble for cleaning:

• Twist both of the inner tube ends until the tabs line up

with the keyways.

• Pull the inner tube ends outward.

G. Remove the water pump

• Note position of water pump outlet, and then

disconnect vinyl hose from the pump outlet.

• Rotate the thumbscrew that secures the pump to the

bulkhead 1/4 turn clockwise.

• Rotate the water pump assembly 1/4 turn

counterclockwise.

• Lower the pump assembly into the evaporator

compartment.

• Disconnect the water pump power cord.

• Remove water pump assembly from ice machine.Do

not soak the water pump motor in cleaner or sanitizer

solution

H. Remove the bin thermostat probe

• Loosen the 2 screws that holds the probe in place .

The probe can easily be cleaned at this point without

complete removal.

Part Number 000006505 11/10 25

Page 26

Maintenance Section 4

A

B

E

C

F

G

D

S1470C/S1870C/S2170C

A. Remove splash shields

E. Remove distribution tubes

• Grasp the top center of splash shields.

• Lift up and then out.

B. Remove ice thickness probe

• Compress the hinge pin on the top of the ice

thickness probe.

• Pivot the ice thickness probe to disengage one pin

then the other. The ice thickness probe can be

cleaned at this point without complete removal. If

complete removal is desired, disconnect the ice

thickness control wiring from the control board.

C. Remove the water trough shield

• Grasp the water trough shield in the center and the

left end.

• Flex the water trough shield in the center and pull the

left end forward until clear of the side wall. Repeat for

the right end.

• Pull water trough shield forward to remove.

D. Remove the water trough

• Depress the two tabs on the top of the water trough.

• Turn left and right ice dampers down to clear water

trough.

• Pull forward on the water trough to remove.

• Distribution tubes thumbscrews are retained to

prevent loss. Loosen thumbscrews but do not pull

thumbscrews out of distribution tube.

• Loosen the two outer screws and pull forward on the

distribution tube to release from slip joint.

• Disassemble distribution tube by loosening the two

(2) middle thumbscrews and dividing the distribution

tube into two pieces.

F. Remove ice dampers

• Grasp ice damper and apply pressure toward the

back mounting bracket.

• Apply pressure to the front mounting bracket with

thumb.

• Pull ice damper downward when the front ice damper

pin disengages.

G. Remove the water pump assembly

• Disconnect the vinyl distribution tube from the water

pump.

• Disconnect the water pump and water level probe

electrical connections.

• After the wires are disconnected squeeze the two

tabs and lift the water pump assembly out of the ice

machine.

• Do not immerse the water pump motor in cleaner or

sanitizer solutions.

26

Part Number 000006505 11/10

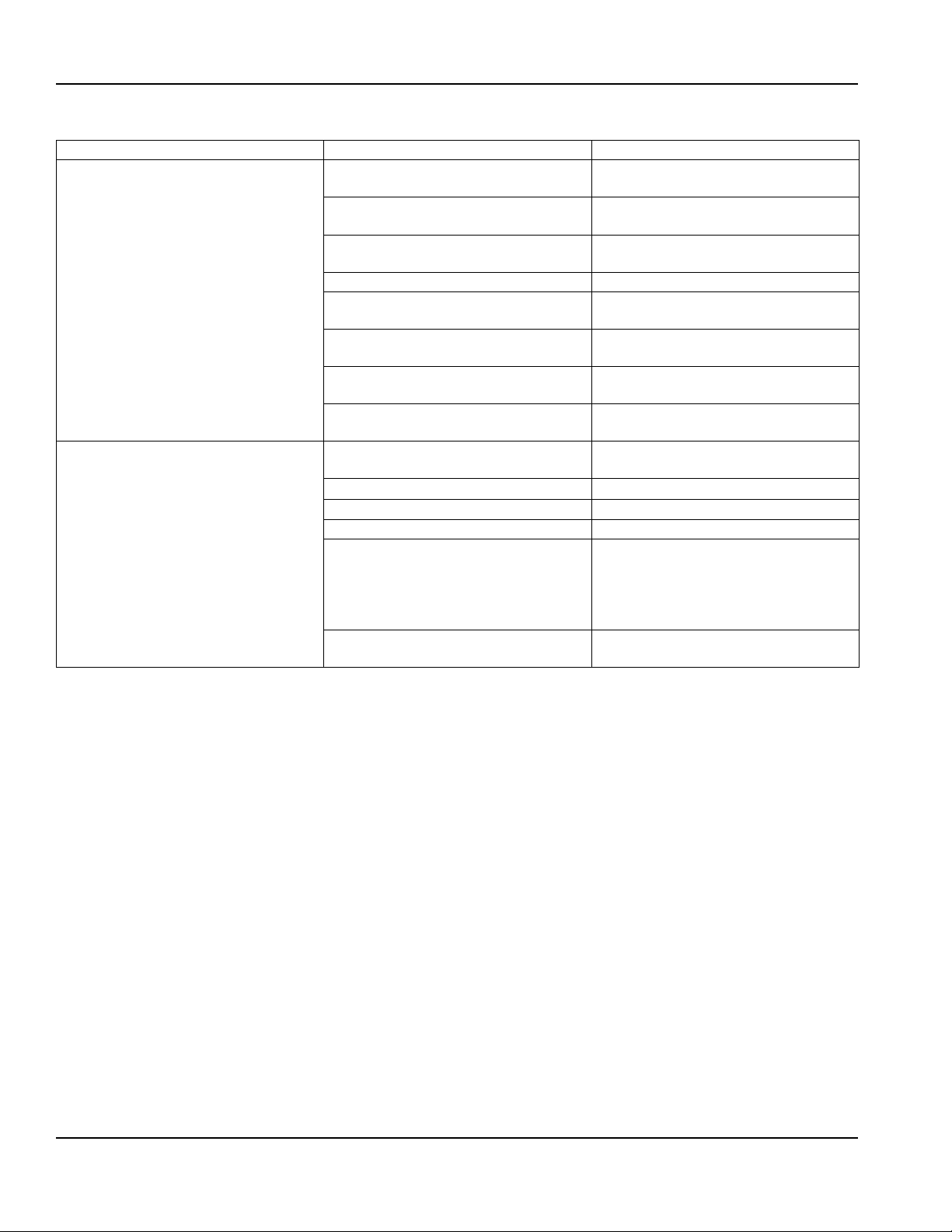

Page 27

Section 4 Maintenance

A

B

C

D

E

F

G

H

S3000C

A. Remove front evaporator shield

• Remove four quarter turn connectors.

• Remove splash shield.

B. Remove left and right evaporator top covers

• Remove two thumbscrews from the front of each

evaporator top cover.

• Lift front of cover, pull forward to remove.

C. Remove splash shields

NOTE: Each evaporator has a splash shield that must

be removed - total of four splash shields.

• Grasp the top center of splash shields.

• Lift up and then out.

D. Remove ice thickness probe

• Compress the hinge pin on the top of the ice

thickness probe.

• Pivot the ice thickness probe to disengage one pin

then the other. The ice thickness probe can be

cleaned at this point without complete removal. If

complete removal is desired, disconnect the ice

thickness control wiring from the control board.

E. Remove the water pump assembly

• Disconnect the vinyl distribution tube from both water

pumps.

• Disconnect the water pump and water level probe

electrical connections.

• After the wires are disconnected remove the two

thumbscrews and lift the water pump assembly out of

the ice machine.

• Remove the thumbscrews securing the water pumps

(2 each pump) and remove water pumps. Do not

immerse the water pump motor in cleaner or sanitize r

solutions.

• Remove the water level probe from the assembly

housing.

F. Remove the water trough

• Pull forward on the water trough to remove.

G. Remove distribution tubes

NOTE: Each evaporator has a distribution that must be

removed - total of four distribution tubes.

• Distribution tube thumbscrews are retained to

prevent loss. Loosen thumbscrews but do not pull

thumbscrews out of distribution tube.

• Loosen the two outer screws and pull forward on the

distribution tube to release from slip joint.

• Disassemble distribution tube by loosening the two

(2) middle thumbscrews and dividing the distribution

tube into two pieces.

H. Remove ice dampers

NOTE: Each evaporator has an ice damper that must be

removed - total of four ice dampers.

• Grasp ice damper and apply pressure toward the

back mounting bracket.

• Apply pressure to the front mounting bracket with

thumb.

• Pull ice damper downward when the front ice damper

pin disengages.

Part Number 000006505 11/10 27

Page 28

Maintenance Section 4

2

1

4

!

Warning

!

Warning

Door Removal

1. Use a phillips screwdriver to loosen the two screws

securing the left and right doors. Do no t remove they

are secured to prevent loss.

2. 30 Inch and 48 Inch Models: To remove right front

door lift up and remove (22 inch ice machines have

a single door, lift to remove entire door).

3. Open left front door to 45 degrees.

4. Support with right hand, depress top pin, tilt top of

door forward and lift out of bottom pin to remove.

Exterior Cleaning

Clean the area around the ice machine as often as

necessary to maintain cleanliness and efficient

operation. Use cleaners designed for use with stainless

steel products.

Sponge any dust and dirt off the outside of the ice

machine with mild soap and water. Wipe dry with a

clean, soft cloth.

Heavy stains should be removed with stainless steel

wool. Never use plain steel wool or abrasive pads. They

will scratch the panels.

Cleaning the Condenser

Disconnect electric power to the ice m achine head

section and the remote condensing unit at the

electric service switches before cleaning the

condenser.

A dirty condenser restricts airflow, resulting in

excessively high operating temperatures. This reduces

ice production and shortens component life.

• Clean the condenser at least every six month.

The condenser fins are sharp. Use care when

cleaning them.

• Shine a flashlight through the condenser to check for

dirt between the fins.

• Blow compressed air or rinse with water from the

inside out (opposite direction of airflow).

• If dirt still remains call a service agent to clean the

condenser.

Removal from Service/Winterization

1. Clean and sanitize the ice machin e.

2. Move the ICE/OFF/CLEAN switch to OFF.

3. Turn off the water supply, disconnect and drain the

incoming ice-making water line at the rear of the ice

machine and drain the water trough.

4. Energize the ice machine, wait on e minut e fo r the

water inlet valve to open and blow compressed air in

both the incoming water and the drain openings in

the rear of the ice machine to remove all water.

5. Move ICE/OFF/CLEAN switch to OFF & disconnect

the electric power at the circuit breaker or the

electric service switch.

28

6. Fill spray bottle with sanitizer and spray all interior

food zone surfaces. Do not rinse and allow to air dry.

7. Replace all panels.

Part Number 000006505 11/10

Page 29

Section 5

Customer Support

Before Calling for Service Checklist

If a problem arises during operation of your ice machine, follow the checklist below before calling service. Routine

adjustments and maintenance procedures are not covered by the warranty.

Problem Possible Cause To Correct

Ice machine does not operate. No electrical power to the ice machine and/or

condensing unit.

High pressure cutout tripping. Clean condenser coil. (See Section 4)

ICE/OFF/CLEAN toggle switch set

improperly.

Water curtain stuck open. Water curtain or ice damper must be installed

Remote receiver service valve and/or Liquid/

suction line shut off valves are closed.

IB Only - Dispenser level thermostat open. Adjust thermostat to maintain correct

Ice machine stops, and can be

restarted by moving the toggle

switch to OFF and back to ICE.

Ice machine does not release

ice or is slow to harvest.

Ice machine does not cycle into

harvest mode.

Ice quality is poor (soft or not

clear).

Safety limit feature stopping the ice machine. Refer to “Safety Limit Feature” on the next

Ice machine is dirty. Clean and sanitize the ice machine.

Ice machine is not level. Level the ice machine. (See Section 2)

Low air temperature around ice machine

head section.

Fan cycling control does not de-energize

condenser fan motor.

CVD1486 - Water regulating valve incorrectly

adjusted or will not close.

The six-minute freeze time lock-in has not

expired yet.

Ice thickness probe is dirty. Clean and sanitize the ice machine.

Ice thickness probe is disconnected. Connect the wire.

Ice thickness probe is out of adjustment. Adjust the ice thickness probe.

Uneven ice fill (thin at the top of evaporator). Verify sufficient water level in sump trough.

Poor incoming water quality. Contact a qualified service company to test the

Water filtration is poor. Replace the filter.

Ice machine is dirty. Clean and sanitize the ice machine.

Water dump valve is not working. Disassemble and clean the water dump valve.

Water softener is working improperly (if

applicable).

Replace the fuse/reset the breaker/turn on the

main switch.

Move the toggle switch to the ICE position.

and swinging freely. (See Section 4)

Open the valve(s). (See Section 2)

dispenser level.

page.

(See Section 4)

Air temperature must be at least 35°F (1.6°C).

Verify pressure is below cut-out setpoint,

replace fan cycling control.

Check for water at condenser water drain

outlet. Contact a qualified service company to

adjust/replace valve.

Wait for the freeze lock-in to expire.

(See Section 4)

(See Section 3)

Contact a qualified service company to check

refrigeration system.

quality of the incoming water and make

appropriate filter recommendations.

(See Section 4)

(See Section 4)

Repair the water softener.

Part Number 000006505 11/10 29

Page 30

Customer Support Section 5

Problem Possible Cause To Correct

Ice machine produces shallow or

incomplete cubes, or the ice fill p attern on

the evaporator is incomplete.

Low ice capacity. Water inlet valve filter screen is dirty. Remove the water inlet valve and clean

Ice thickness probe is out of adjustment. Adjust the ice thickness probe.

(See Section 3)

Water trough level is too high or too low. Check the water level probe for damage.

(See Section 3)

Water inlet valve filter screen is dirty. Remove the water inlet valve and clean

the filter screen. (See Section 4)

Water filtration is poor. Replace the filter.

Hot incoming water. Connect the ice machine to a cold water

supply. (See Section 2)

Water inlet valve is not working. Clean or replace the water inlet valve.

(See Section 4)

Incorrect incoming water pressure. Water pressure must be 20-80 psi

(137.9 - 551.5 kPA).

Ice machine head section is not level. Level the ice machin e head section.

(See Section 2)

the filter screen. (See Section 4)

Incoming water supply is shut off. Open the water service valve.

Water inlet valve stuck open or leaking. Replace the water inlet valve.

The condenser is dirty. Clean the condenser. (See Section 4)

High air temperature entering condenser. Air temperature must not exceed 130°F

(54°C)

CVD685/CVD1185/CVD2085/CVD3085 -

120°F (49°C)

CVD1486 - 110°F (43°C)

The harvest assist air compressor is not

functioning.

Call for service.

SAFETY LIMIT FEATURE

In addition to the standard safety controls, such as the

high pressure cutout, your Manitowoc ice machine

features built-in safety limits which will stop the ice

machine if conditions arise which could cause a major

component failure.

Before calling for service, re-start the ice machine using

the following procedure:

1. Move the ICE/OFF/CLEAN switch to OFF and then

back to ICE.

A. If the safety limit feature has stopped the ice

machine, it will restart after a short delay.

Proceed to step 2.

B. If the ice machine does not restart, see “Ice

machine does not operate” on the previous

page.

2. Allow the ice machine to run to determine if the

condition repeats.

A. If the ice machine stops again, the condition has

repeated. Call for service.

B. If the ice machine continues to run, the condition

has corrected itself. Allow the ice machine to

continue running.

30

Part Number 000006505 11/10

Page 31

Section 5 Customer Support

Commercial Ice Machine Warranty

Manitowoc Ice, Inc. (hereinafter referred to as the “COMPANY”) warrants for a period of thirty-six months from the installation date

(except as limited below) that new ice machines manufactured by the COMPANY shall be free of defects in material or

workmanship under normal and proper use and maintenance as specified by the COMPANY and upon proper installation and

start-up in accordance with the instruction manual supplied with the ice machine. The COMPANY’S warranty hereunder with

respect to the compressor shall apply for an additional twenty-four months, excluding all labor cha rges, and with respect to the

evaporator for an additional twenty-four months, including labor charges.

The obligation of the COMPANY under this warranty is limited to the repair or replacement of parts, components, or assemblies

that in the opinion of the COMPANY are defective. This warranty is further limited to the cost of parts, components or assemblies

and standard straight time labor charges at the servicing location.

Time and hourly rate schedules, as published from time to time by the COMPANY, apply to all service procedures. Additional

expenses including without limitation, travel time, overtime premium, material cost, accessing or removal of the ice machine, or

shipping are the responsibility of the owner, along with all maintenance, adjustments, cleaning, and ice purchases. Labor covered

under this warranty must be performed by a COMPANY Contracted Service Representative or a refrigeration service agency as

qualified and authorized by the COMPANY'S local Distributor. The COMPANY'S liability under this warranty shall in no event be

greater than the actual purchase price paid by customer for the ice machine.

The foregoing warranty shall not apply to (1) any part or assembly that has been altered, modified, or changed; (2) any part or

assembly that has been subjected to misuse, abuse, neglect, or accidents; (3) any ice machine that has been installed and/or

maintained inconsistent with the technical instructions provided by the COMPANY; or (4) any ice machine initially installed more