Page 1

Flake & Nugget Ice Machines

RF / RFS / RNS Models

Installation, Operation and Maintenance Manual

This manual is updated as new information and models are released. Visit our website for the latest manual.

Part Number: 0000007644 8/14

Page 2

Section 1

General Information

Model Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

RF2300 Bin Adapter Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Section 2

Installation Instructions

Location of Ice Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Water and Drain Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Electrical Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Maximum Breaker Size & Minimum Circuit Amperage Chart . . . . . . . . . . . . . . . . 10

Refrigeration System Installation

Remote Condensing Unit Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Refrigeration Line Set Installation

Remote Condensing Unit Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installation Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Additional Checks for QuietQube Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table of Contents

UnderCounter Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Modular Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Clearance Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Potable Water Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Water Supply and Drain Line Sizing/Connections . . . . . . . . . . . . . . . . . . . . . . . 8

Drain Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Fuse/Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Ground Fault Circuit Interrupter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Minimum Power Cord Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

For United Kingdom Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

QuietQube Remote Condensing Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

A. Line Set Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

B. Line Set Rise or Drop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

C. Suction Line Oil Traps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Section 3

Operation

Evaporator Low Temperature Safety Thermostat and Bin Thermostat . . . . . . . . 19

RF0244/RF0266/RF0385/

RF0388/RF0399/RF0644 & RNS0244/RNS0385 Operation . . . . . . . . . . . . . . . . . . . 19

RFS0300 & RNS0300 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

RFS0650/RFS1200/RFS2300/RF1200/RF2300 Operation . . . . . . . . . . . . . . . . . . . . 20

2 Part Number 000007644 8/14

Page 3

Section 4

Maintenance

Section 5

Customer Support

Table of Contents (continued)

Interior Cleaning and Sanitizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Cleaning/Sanitizing Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Heavily Scaled Cleaning Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Exterior Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Cleaning/Sanitizing Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Procedure to Clean Heavily Scaled Flake Ice Machines . . . . . . . . . . . . . . . . . . . 22

Removal of Parts for Cleaning/Sanitizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Ice Chute Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Air-Cooled Condenser Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Arctic Pure Water Filter System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Manitowoc Cleaner and Sanitizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Commercial Ice Machine Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Residential Ice Machine Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Part Number 000007644 8/14 3

Page 4

Table of Contents (continued)

THIS PAGE INTENTIONALLY LEFT BLANK

4 Part Number 000007644 8/14

Page 5

Section 1

!

Warning

!

Warning

!

Caution

General Information

Model Numbers

This manual covers the following models:

FLAKE UNDERCOUNTER MODELS NUGGET UNDERCOUNTER MODELS

Self-Contained

Air-Cooled

RF0244A

RF0266A

RF0385A

RF0399A

RF0644A

NUGGET MODULAR MODELS

Self-Contained

Air-Cooled

RNS0308A --- --- --- --RNS0608A RNS0609W --- --- --RNS1008A RNS1009W --- RNS1078C RCU1098

FLAKE MODULAR MODELS

Self-Contained

Air-Cooled

RFS0300A --- --- --- --RFS0650A RFS0650W ---- --- --RFS1200A RFS1200W RFS1279R RFS1278C RCU1075

RF2300A RF2300W RFS2379R RFS2378C RCU2375

Self-Contained

Water-Cooled

Self-Contained

Water-Cooled

Rack Unit

Head Section

Rack Unit

Head Section

Self-Contained

Air-Cooled

RNS0244A

RNS0385A

QuietQube

Head Section

QuietQube

Head Section

Condensing Unit

Condensing Unit

RCU Remote

RCU Remote

Remove all ice machine panels before lifting and

installing.

PERSONAL INJURY POTENTIAL

Do not operate equipment that has been misused,

abused, neglected, damaged, or altered/modified

from that of original manufactured specifications.

This appliance is not intended for use by persons

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience and

knowledge, unless they have been given

supervision concerning use of the appliance by a

person responsible for their safety.

Part Number 000007644 8/14 5

Flake ice machines must be installed on a bin. Flake

ice machines cannot be installed on dispensers.

Page 6

General Information Section 1

!

Warning

Adapters

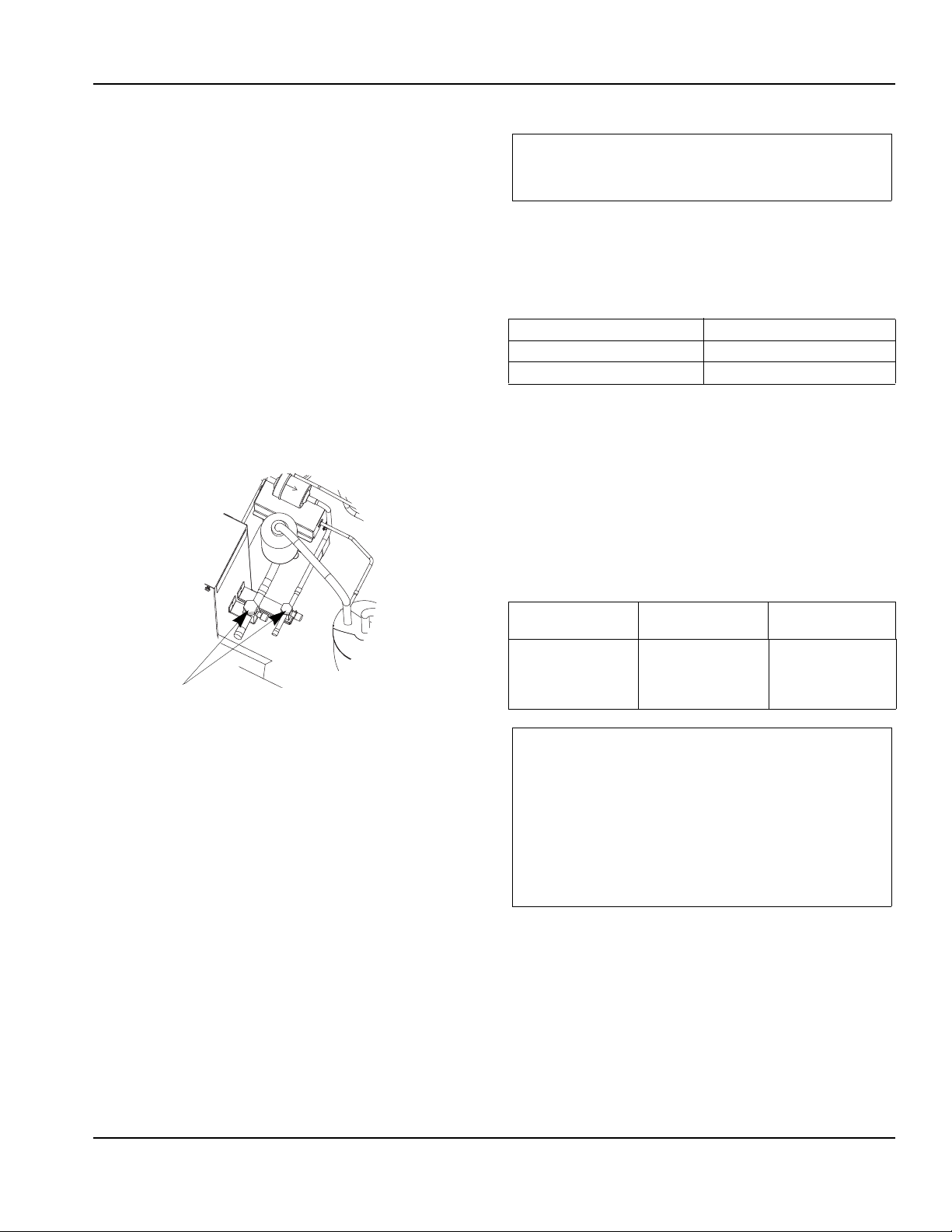

RF2300 BIN ADAPTER INSTALLATION

PERSONAL INJURY POTENTIAL

RF2300 ice machines are not approved for use on

B970 bins. RF2300 ice machines ship with a bracket

that must be used when installing on B1100 and

B1400 Series bins.

1. Refer to diagram. Place bracket on bin top and slide

back to engage.

2. Place ice machine on bin: ice machine must fit

between bracket and front ridge.

6

Part Number 000007644 8/14

Page 7

Section 2

Installation Instructions

Location of Ice Machine

The location selected for the ice machine must meet the

following criteria. If any of these criteria are not met,

select another location.

• The location must be free of airborne and other

contaminants.

• The air temperature must be at least 50°F (10°C), but

must not exceed 110°F (43°C).

• The water temperature must be at least 40°F (4°C),

but must not exceed 90°F (32°C).

• The location must not be near heat-generating

equipment or in direct sunlight.

• The location must be capable of supporting the

weight of the ice machine and a full bin of ice.

• The location must allow enough clearance for water,

drain and electrical connections in the rear of the ice

machine.

• The location must not obstruct airflow through or

around the ice machine.

CLEARANCE REQUIREMENTS

Undercounter Units Air-Cooled Water-Cooled

Top 0” (0 cm) 0” (0 cm)

Sides 2” (5 cm) 2” (5 cm)

Back 8" (20 cm) 8" (20 cm)

NOTE: Allowance must be made for removal when the ice machine is built in.

Monthly removal of the top panel is required for cleaning & sanitizing.

Modular Units

Top/Sides 8" (20 cm) 8" (20 cm) 0" (0 cm)

Back 5" (13 cm) 5" (13 cm) 0" (0 cm)

RCU Units Remote Condensing Unit

Front/Back 24" (61 cm)

Sides/Top 6" (15.2 cm)

NOTE: Water-cooled/Remote condensing units only - there is no minimum

clearance required. This value is recommended for efficient operation and

servicing only.

Air-

Cooled

Water-

Cooled

QuietQube

Air-Cooled

Installation Requirements

• The ice machine and bin must be level.

• Vent the ice machine and bin drains separately.

• Bin drain termination must have an air gap.

• A backflow preventer is required on water inlet lines.

• The ice machine and bin must be sanitized after

installation.

• Local water conditions may require treatment of the

water to inhibit scale formation, filter sediment, and

remove chlorine odor and taste.

• Routine adjustments and maintenance procedures

outlined in this manual are not covered by the

warranty.

Ice Machine Heat of Rejection

Series

Ice Machine

RFS1279R 7850

RFS2379R 15700

B.T.U./Hour

Heat of Rejection

Ice machines, like other refrigeration equipment, reject

heat through the condenser. It is helpful to know the

amount of heat rejected by the ice machine when sizing

air conditioning equipment.

This information is also necessary when evaluating the

benefits of using water-cooled or remote condensers to

reduce air conditioning loads. The amount of heat added

to an air conditioned environment by an ice machine

using a water-cooled or remote condenser is negligible.

Knowing the amount of heat rejected is also important

when sizing a cooling tower for a water-cooled

condenser. Use the peak figure for sizing the cooling

tower.

Rack Unit Connection Size

Model Suction Line Liquid Line

RFS1279R

RFS2379R

5/8 inch

(15.9 mm)

3/4 inch

(19 mm)

3/8 inch

(9.5 mm)

1/2 inch

(12.7 mm)

Part Number 000007644 8/14 7

Page 8

Installation Instructions Section 2

!

Caution

Water and Drain Requirements

POTABLE WATER REQUIREMENTS

Follow these guidelines to install water inlet lines:

• Do not connect the ice machine to a hot water

supply. Be sure all hot water restrictors installed for

other equipment are working. (Check valves on sink

faucets, dishwashers, etc.)

• If water pressure exceeds the maximum of 80 psig

(552 kPA) recommended pressure, obtain a water

pressure regulator from your Manitowoc distributor.

• Install a water shut-off valve and unio n for both the

ice making and condenser water lines.

• Insulate water inlet lines to prevent condensation.

• Plumbing must conform to local codes.

Do not apply heat to water valve inlet fitting or over

tighten. This will damage plastic water inlet

connection.

COOLING TOWER APPLICATIONS

A water cooling tower installation does not require

modification of the ice machine. The water regulator

valve for the condenser continues to control the

refrigeration discharge pressure.

It is necessary to know the amount of heat rejectio n, and

pressure drop through the condenser and water valves

(inlet and outlet) when using a cooling tower on an ice

machine.

• Water entering the co ndenser must not be lower than

37°F (3°C) or exceed 90°F (32°C).

• Water flow through the con denser must not exceed 5

gal. (19 L) per minute.

• allow for a pressure drop of 7 psi (48 kPa) between

the condenser water inlet and the outlet of the ice

machine.

• Water exiting the condenser must not exceed 110°F

(43°C).

DRAIN CONNECTIONS

Follow these guidelines when installing drain lines to prevent

drain water from flowing back into the ice machine and storage

bin:

• Drain lines must have a 1.5 inch drop per 5 feet of run

(2.5 cm per meter), and must not create traps.

• The floor drain must be large enough to accommodate

drainage from all drains.

• Run separate bin and water-cooled condenser drain lines.

Insulate them to prevent condensation.

• Vent the bin and ice machine drain to the atmosphere. The

ice machine drain requires an 18" (46 cm) vent. Do not

vent the condenser drain on water-cooled models.

• Drains must have a union or other suitable means to allow

in place disconnection from the ice machine when

servicing is required.

8

Part Number 000007644 8/14

Page 9

Section 2 Installation Instructions

VENT TUBE

18" (46 CM)

LONG

ROUTE

DRAIN

TUBING TO

OPEN SITE

DRAIN

ICE MAKING

WATER INLET

TUBING 3/8" MIN.

I.D. (.95 CM)

VENT TUBE

18" (46 CM)

LONG

SEPERATE BIN AND ICE

MACHINE DRAINS ARE

REQUIRED

ROUTE DRAIN TUBING TO

OPEN SITE DRAIN

WATER SHUT-OFF VALVE

REQUIRED - ICE MAKING

WATER INLET TUBING 3/8"

MIN. I.D. (.95 CM)

MODULAR UNITS

UNDERCOUNTER UNITS

WATER SUPPLY AND DRAIN LINE SIZING/CONNECTIONS

Location

Potable

Water Inlet

Potable

Water Drain

Condenser

Water Inlet

Condenser

Water Drain

Water Temp

Min/Max

40°/90°F

(4°/32°C)

--- --- 1/2" MPT

40°/90°F

(4°/32°C)

--- --- 1/2" MPT

Water Pressure

Min/Max

14/80 psi

(100/552 kPA)

20/150 psi

(138/1034 kPA)

Fitting/Min Tubing Size

3/8" FPT

3/8” FPT

RF2300 only = 1/2" FPT

Bin Drain --- --- 3/4" FPT

Large Capacity Bin Drain --- --- 1" FPT

Typical Water Supply Drain Installation

Part Number 000007644 8/14 9

Page 10

Installation Instructions Section 2

!

Warning

!

Warning

Important

Electrical Service

GROUND FAULT CIRCUIT INTERRUPTER

All wiring must conform to local, state and national

codes.

VOLTAGE

The maximum allowable voltage variation is ±1 0% of the

rated voltage at ice machine star t-up (when the electrical

load is highest).

The ice machine must be grounded in accordance

with national and local electrical codes.

All electrical work, including wire routing and grounding,

must conform to local, state and national electrical

codes. The following precautions must be observed:

• The ice machine must be grounded.

• A separate fuse/circuit breaker must be provide d fo r

each ice machine.

• A qualified electrician must determine proper wire

size dependent upon location, materials used and

length of run (minimum circuit ampacity can be used

to help select the wire size).

• The maximum allowable voltage variation is +/-10 of

the rated voltage at ice machine start-up (when the

electrical load is highest).

• Check all ground screws in the control box and verify

they are tight before starting the ice machine.

We do not recommend the use of a GFCI/GFI circuit

protection with our equipment. If a GFCI/GFI is required

by code, use a GFCI/GFI breaker rather than outlet

which is more prone to intermittent nuisance trips than

panel circuit breakers.

MINIMUM POWER CORD SPECIFICATIONS

The wire size to the receptacle is dependent upon

location, materials used, length of run, etc., so it must be

determined by a qualified electrician. Local, state or

national requirements will supersede our minimum

requirements.

FOR UNITED KINGDOM ONLY

As the colors of the wires in the mains lead of the appliance may not

correspond with the colored markings identifying the terminals in your plug,

proceed as follows:

• The wire which is colored green and yellow must be connected to the

terminal in the plug which is marked with the letter E or by the earth

ground symbol or colored green or green and yellow.

• The wire colored blue

with the letter N or colored black.

• The wire colored brown

marked with the letter L or colored red.

must be connected to the terminal which is marked

must be connected to the terminal which is

Observe correct polarity of incoming line voltage.

Incorrect polarity can lead to erratic ice machine

operation.

FUSE/CIRCUIT BREAKER

A dedicated circuit and a separate fuse/circuit breaker

are required for each ice machine.

10

Part Number 000007644 8/14

Page 11

Section 2 Installation Instructions

Important

Maximum Breaker Size & Minimum Circuit Amperage Chart

Due to continuous improvements, this information is

for reference only. Please refer to the ice machine

serial number tag to verify electrical data. Serial tag

information overrides information listed on this page.

Air-Cooled Water-Cooled QuietQube

Series Ice

Machine

RF0244

RNS0244

RF0266

RF0385

RNS0385

RF0388

RF0399

RF0644 115/1/60 25 Amp N/A 13.5 N/A N/A — —

RFS0300 115/1/60 20 Amp 12.8 — N/A N/A — —

RNS0300 115/1/60 20 Amp 12.8 — N/A N/A — —

RNS0600

RFS0650

RNS1000

RFS1200

RF2300

RFS2300

RFS1200R 208-230/1/60 15 Amp 1.4 — — — — —

RFS2300R 208-230/3/60 15 Amp 3.2 — — — — —

Maximum allowable voltage variation at compressor start-up is ±10% of voltage listed above and on the model/serial plate.

Voltage

Phase

Cycle

115/1/60 15 Amp N/A 7.5 N/A N/A — —

230/1/50 10 Amp N/A 2.7 N/A N/A — —

115/1/60 15 Amp N/A 7.5 N/A N/A — —

230/1/50 10 Amp N/A 2.7 N/A N/A — —

115/1/60 15 Amp N/A 7.5 N/A N/A — —

230/1/50 10 Amp N/A 2.7 N/A N/A — —

115/1/60 15 Amp N/A 10.0 N/A N/A — —

230/1/50 10 Amp N/A 3.3 N/A N/A — —

115/1/60 15 Amp N/A 10.0 N/A N/A — —

230/1/50 10 Amp N/A 3.3 N/A N/A — —

115/1/60 15 Amp N/A 10.0 N/A N/A — —

230/1/50 10 Amp N/A 3.3 N/A N/A — —

115/1/60 15 Amp N/A 10.0 N/A N/A — —

230/1/50 10 Amp N/A 3.3 N/A N/A — —

115/1/60 15 Amp 8.2 — 25 Amp 15.4 — —

208-230/1/60 15 Amp 8.7 — 25 Amp 16.3 — —

115/1/60 25 Amp 16.3 — 25 Amp 15.4 — —

208-230/1/60 15 Amp 8.7 — 15 Amp 8.2 — —

115/1/60 — — — — — 15 Amp 2.9

208-230/1/60 20 Amp 14.2 — 20 Amp 13.7 15 Amp 1.4

208-230/1/60 20 Amp 12.5 — 20 Amp 12.5 15 Amp 1.4

230/1/50 — — — — — 10 Amp 1.4

208-230/3/60 20 Amp 15.0 — 20 Amp 15.0 — —

400-415/3/50 16 Amp 13.9 — 16 Amp 13.9 — —

208-230/3/60 — — — — — 15 Amp 3.2

230/1/50 — — — — — 15 Amp 3.2

Max

Fuse/

Circuit

Breaker

Min

Circuit

Amps

Total

Circuit

Amps

Max

Fuse/

Circuit

Breaker

Min

Circuit

Amps

Max

Fuse/

Circuit

Breaker

Total

Circuit

Amps

Part Number 000007644 8/14 11

Page 12

Installation Instructions Section 2

QUIETQUBE REMOTE CONDENSING UNIT

Condensing Unit Voltage Phase Cycle Maximum Fuse/Circuit Breaker Minimum Circuit Amps

208-230/60/1 15 15

RCU1075

RCU1098

RCU2375

208-230/60/3

208-230/50/1

208-230/60/1 15 15

208-230/60/3

208-230/60/1 15 15

208-230/60/3

208-230/50/1

15 15

15 15

15 15

15 15

15 15

12

Part Number 000007644 8/14

Page 13

Section 2 Installation Instructions

Important

!

Caution

!

Warning

!

Caution

!

Warning

Refrigeration System Installation

Remote Condensing Unit Only

QuietQube®

Ice Machine

RNS1000C

RFS1200C

RFS2300C

*Line Set Suction Line Liquid Line

RC 21/31/51

Manitowoc remote systems are only approved and

warranted as a complete new package. Warranty on

the refrigeration system will be void if a new ice

machine head section is connected to pre-existing

(used) tubing or condensing units or vice versa.

USAGE WITH NON-MANITOWOC

CONDENSING UNITS

Manitowoc Remote Condensing Units are specifically

designed for usage with a QuietQube® Ice Machine

Head Section. Standard condensing units and NonManitowoc condensing units are not approved for use

with a QuietQube® Ice Machine Head Section.

Remote

Condensing Unit

RCU1098

RCU1075

RCU2375

5/8 inch

(15.9 mm)

Line Set*

RC-21

RC-31

RC-51

3/8 inch

(9.5 mm)

Factory Equipment Refrigeration Amounts

ICE MACHINE HEAD SECTION

Each ice machine condensing unit ships from the factory

with a R-404A refrigerant charge appropriate for the

entire system operation. The serial tag on the ice

machine indicates the refrigerant charge. The re frigerant

charge is sufficient to operate the ice machine in

ambient temperatures between -20°F (-28.9°C) and

120°F (48.9°C). With line set lengths of up to 100 feet

(30.5 m).

Potential Personal Injury Situation

The QuietQube Condensing Unit contains the

refrigerant charge. Installation and brazing of the line

sets must be performed by a properly trained and

EPA certified refrigeration technician aware of the

dangers of dealing with refrigerant charged

equipment.

Never add more than nameplate charge to the

refrigeration system for any application.

REFRIGERATION LINE SETS/TRAP KIT

Refrigeration Rated Tubing and Trap Kits are shipped

capped with atmospheric pressure.

The 60-month compressor warranty (including the 24month labor replacement warranty) will not apply if the

Manitowoc Ice Machine and Manitowoc Remote

Condensing Unit are not installed according to

specifications. This warranty also will not apply if the

refrigeration system is modified with a condenser,

heat reclaim device, or other parts or assemblies not

manufactured by Manitowoc Ice.

Installation of a QuietQube® Condensing Unit may

require the use of special equipment for placement.

Trained and qualified personnel are required for

proper rigging and lifting.

Part Number 000007644 8/14 13

Page 14

Installation Instructions Section 2

!

Warning

!

Warning

Important

35 ft. (10.7 m)

MAX.

DISTANCE

SV1751

15 ft. (4.5 m)

MAX.

DISTANCE

SV1750

Refrigeration Line Set Installation

Remote Condensing Unit Only

GENERAL

Refrigeration line set installations consist of vertical and

horizontal line set distances between the ice machine

and the condensing unit. The following guidelines,

drawings and calculation methods must be followed to

assure proper oil return and remote condensing unit/ice

machine operation.

The refrigeration line set installer must be USA

Government-Environmental Protection Agency (EPA)

certified in proper refrigerant handling and servicing

procedures.

The QuietQube Condensing unit contains refrigerant

charge. The two refrigeration valves must remain

closed until proper installation of the line sets is

completed.

Disconnect electrical power to the ice machine head

section and remote condensing unit before

proceeding.

A. LINE SET LENGTH

100 feet (30.5 m) Length: The maximum measured

length the line set can be.

The receiver is designed to hold a charge sufficient to

operate the ice machine in ambient temperatures

between -20°F (-28.9°C) and 120°F (48.9°C), with line

set lengths of up to 100 feet (30.5 m).The maximum

amount of line set which can be exposed on the rooftop

is 25% of the total length of the line set.

QuietQube® ice machines will not function with line

sets greater than 100 feet (30.5 m). Do not attempt to

go beyond this distance and add refrige rant ch ar ge to

compensate!

B. LINE SET RISE OR DROP

Step 1 Verify Ice Machine and Remote Condensing

Unit Locations Are Within Guidelines

Prior to installation of the ice machine head section and

remote condensing unit be sure that the distance

between them is within the line set routing guidelines

outlined in this manual.

Roof/Wall Penetration

If required, cut a 3-inch (76.2 mm) circular hole in the

wall or roof for routing of refrigeration tubing. A qualified

person must perform all roof penetra tio ns .

Step 2 Route Refrigeration Tubing

Properly route refrigeration tubing between the ice

machine head section and the remote condensing unit.

35 feet (10.7 m) Rise: The maximum distance the

remote condensing unit can be above the ice machine.

15 feet (4.5 m) Drop: The maximum distance the

remote condensing unit can be below the ice machine .

14

Part Number 000007644 8/14

Page 15

Section 2 Installation Instructions

!

Caution

21 ft. (6.4 m)

OR MORE RISE

ADDITIONAL

TRAP KIT

REQUIRED

!

Caution

!

Caution

C. SUCTION LINE OIL TRAPS

Do not form unwanted traps in refrigeration lines.

Never coil excess refrigeration tubing.

0 to 20 feet (0 to 6.1 m) Rise: No oil trap is required

when the condensing unit is located 20 feet (6.1 m) or

less above the ice machine head section.

21 to 35 feet (6.4 to 10.7 m) Rise: The suction line

requires an additional Oil Trap (“S” type) to be installed.

Install the trap as close as possible to midpoint between

the ice machine head section and remote cond en sin g

unit. S-Trap Kits are available from Manitowoc.

Service Loop

A service loop in the line set permits easy access to the

ice machine for cleaning and service.

• A service loop is not considered an oil trap.

• The service loop is not included when calculating

length, rise or drop of the tubing run.

• Do not use hard rigid copper for the service loop.

If a line set has a rise followed by a drop, another rise

cannot be made. Likewise, if a line set has a drop

followed by a rise, another drop cannot be made.

Step 3 Lengthening or Reducing Line Set Lengths

Do not form unwanted traps in refrigeration lines.

Never coil excess refrigeration tubing.

When the line set requires shortening or lengthenin g, do

so before connecting the line set to the ice machine

head section or the remote condensing unit.

Part Number 000007644 8/14 15

Page 16

Installation Instructions Section 2

!

Warning

!

Warning

MINIMIZE THE TIME THE

REFRIGERATION SYSTEM IS

EXPOSED TO THE A TMOSPHERE

(15 MINUTES MAXIMUM)

SUCTION LINE

LIQUID LINE

Suction and liquid line shut-off valves

must remain closed until evacuation and

pressure testing are complete.

Step 4 Connecting the line set

To prevent oxidation of the copper, purge line set and

condensing unit with dry nitrogen while brazing.

A. Connect the Line Set to the Remote Condensing

Unit

The QuietQube Condensing unit contains refrigerant

charge. The two refrigeration valves must remain

closed until proper installation of the line sets is

completed.

The line set shut-off valves must remain closed and be

protected from heat during the braz ing pro ce ss. Wrap

the valves in a wet rag or other type of heat sink prior to

brazing. Cool braze joint with water immediately after

brazing to prevent heat migration to the valve.

Step 5 Pressure Test and Evacuate Line Set and

Ice Machine Head Section

• Suction and liquid line set shutoff valves must remain

closed until pressure testing and evacuation are

complete.

• Pressure testing and evacuation can be performed

from the ice machine head section or CVD

condensing unit shut-off valves.

• Schrader valve core removal tools that allow for

removal and installation of the valve cores without

removing manifold gauge set hoses are

recommended to decrease the evacuation time.

• Pressure test @ 150 psi (1000 kPa) for a minimum of

15 minutes.

• Minimum evacuation level is 500 microns.

B. Connect the Line Set to the Ice Machine Head

Section

The ice machine head section ships from the factory

pressurized with R404A refrigerant. Recover the

refrigerant from both suction and liquid line access

ports prior to cutting into refrigeration lines.

• Cut the suction and liquid tubing with a tubing cutter,

leaving enough tubing to easily braze.

• Connect the line set.

• Cool braze joint with water immediately after brazing

to prevent heat migration.

16

Part Number 000007644 8/14

Page 17

Section 2 Installation Instructions

Open suction and liquid line

shut-off valves

Important

Important

Step 6 Leak Check The Refrigeration System

Leak check the new line set connections at the ice

machine head section, condensing unit and S trap as

well as all factory joints throughout the entire system.

Disconnect power to the remote condensing unit. Place

the rocker switch into the ON position. This allows the

low side and high side pressures to equalize for leak

checking. Place the rocker switch in the OFF position.

Connect power to the remote condensing unit and allow

system to pump down after leak checking is complete.

Step 7 Open The Valves Prior To Starting The Ice

Machine

A. Slowly backseat (open-turn counterclockwise)

the suction line shutoff valve.

B. Slowly backseat (open-turn counterclockwise)

the liquid line shutoff valve.

All refrigeration valve caps must be reinstalled to

prevent future refrigeration leaks.

Verify O-ring in schrader valve caps are intact and

reinstall on shutoff valves to prevent re frigerant leakage .

Replace shutoff valve access caps and torque to the

following specifications.

Torque Values

Stem 18-20 ft. lbs. (24.4-27.1 Nm)

Caps 12-15 ft. lbs. (16.3-20.3 Nm)

Schrader Core 1.5-3 in. lbs. (0.17-0.34 Nm)

Step 8 Insulation Requirements

To prevent condensation the entire suction line must be

insulated. All insulation must be airtight and sealed at

both ends.

The following insulation requirements prevent

condensation at 90°F (32.2°C) ambient 90% Relative

Humidity. If higher humidity is expected, increase

insulation thickness.

The entire suction line set requires:

Open Valves

Suction Line Liquid Line

5/8 in. (16 mm) 3/8 in. (10 mm)

Min. Insulation

Thickness

1/2 in. (13 mm)

Suction Line

1/4 in. (7 mm)

Liquid Line

To prevent condensation the entire suction line must

be insulated. All insulation must be airtight and

sealed at both ends.

The minimum requirements are for conditions at or

below 90% humidity and 90°F (32°C) ambient. When

higher humidity will be experienced, or local code

requires, insulation wall thickness will need to be

increased.

Part Number 000007644 8/14 17

Page 18

Installation Instructions Section 2

Installation Check List

All Manitowoc ice machines are factory-operated and adjusted before shipment. Adjustments and maintenance

procedures outlined in this manual are the responsibility of the owner/operator and are not covered by the warranty.

Is the Ice Machine level?

Is the ice machine and adapter (when used)

secured to the dispenser?

Have all of the electrical and water

connections been made?

Has the supply voltage been tested and

checked against the rating on the nameplate?

Is there proper clearance around the ice

machine for air circulation?

Is the ice machine grounded and polarity

correct?

Has the ice machine been installed where

ambient temperatures will remain in the range

of 50° - 100°F (14.4° - 37.8°C)?

Is there a separate drain for the water-cooled

condenser?

‘

Is there a separate drain for the dispenser?

Is the ice making water turned on?

Are all electrical leads free from contact with

refrigeration lines and moving equipment?

Has the owner/operator been instructed

regarding maintenance and the use of

Manitowoc Cleaner and Sanitizer?

Has the owner/operator comp leted the

warranty registration card?

Has the ice machine and bin been sanitized?

Is the rocker switch set to ON?

Has the ice machine been installed where the

incoming water temperature will remain in the

range of 50° - 90°F (14.4° - 32.2°C)?

18

Part Number 000007644 8/14

Page 19

Section 2 Installation Instructions

Additional Checks for QuietQube Models

Is the lineset length, rise and drop within the

guidelines?

Are the suction and liquid line shut-off valves

open?

Is the line set routed properly?

Are both refrigeration lines to remote

condensing unit run so they do not lay in water

and are properly insulated?

Does the condenser fan motor(s) operate

properly after start-up?

Have all the refrigeration fittings and joints

been leak checked?

Has the condenser/condensing unit been

installed to prevent any roofing damage?

Have the refrigeration lines been insulated and

secured properly to prevent vibration?

Has the RCU remote condensing unit been

located where ambient temperatures will

remain in the range of -20° to 120°F (-29° to

48.9°C)?

Is a refrigeration oil trap (S-trap) inst alled if the

condenser is installed 21 to 35 fe et (6 to 11 m)

above the ice machine head?

Part Number 000007644 8/14 19

Page 20

Installation Instructions Section 2

THIS PAGE INTENTIONALLY LEFT BLANK

20

Part Number 000007644 8/14

Page 21

Section 3

1

2

3

4

5

6

7

1

2

3

4

5

6

7

BIN THERMOSTAT

SMALL NUMBERS = LESS ICE IN BIN

LARGE NUMBERS = MORE ICE IN BIN

EVAPORATOR LOW TEMPERATURE

SAFETY THERMOSTAT

INCORRECT SETTINGS WILL CAUSE ICE

MACHINE TO SHUT OFF

SENSING BULB IS

LOCATED IN BIN

BIN THERMOSTAT

LOCATION

EVAPORATOR LOW

TEMPERATURE SAFETY

THERMOSTAT LOCATION

Operation

NOTE: Flake ice machines use an auger to remove ice from the evaporator. Occasional noises (creaks, groans,

squeaks, or pops) are a normal part of the ice making process.

Evaporator Low Temperature Safety Thermostat and Bin Thermostat

The bin thermostat sensing bulb is located in the ice

chute or bin and turns the ice machine on and off as the

level of ice in the ice chute or bin changes.

Bin

Model

Thermostat

Setting

RF0244 5 5

RFS0244 5 6

RNS0244 5 5

RF0266 5 5

RF0300 4 7

RFS0300 3 ---

RNS0300 3 6

RF0385 5 7

RNS0385 5 7

RF0388 5 7

RF0399 5 7

RF0644 5 ---

RNS0600 3 ---

RF0650 3 ---

RFS0650 3 ---

RNS1000 3 ---

RF1200 4 ---

RFS1200 3 ---

RF2300 3 ---

RFS2300 3 ---

Evaporator

Thermostat

Setting

RF0244/RF0266/RF0385/

RF0388/RF0399/RF0644 & RNS0244/

RNS0385 Operation

The ice machine will not start until:

A. The rocker switch is moved to “ ON”.

B. Ice does not contact the bin thermostat bulb.

C. The water reservoir is full of water.

Placing the toggle switch in the ON position starts the

gear motor and refrigeration system. The float valve

controls the water inlet valve and water level. The freeze

cycle ends when ice contacts th e bin thermosta t. The ice

machine will restart when ice no longer contacts the bin

thermostat.

Part Number 000007644 8/14 21

Page 22

Operation Section 3

BIN THERMOSTAT

EVAPORATOR

THERMOSTAT

BIN THERMOSTAT IS

LOCATED ON SIDE OF

CONTROL BOX

RFS0300 & RNS0300 Operation

The ice machine will not start until:

A. The rocker switch is moved to “ON”.

B. Ice does not contact the bin thermostat bulb.

C. The water reservoir is full of water.

Placing the toggle switch in the ON position starts the

gear motor and a 10 minute compressor time delay. The

compressor starts and the float valve controls the water

inlet valve and water level. The freeze cycle ends when

ice contacts the bin thermostat. The ice machine remains

off until ice no longer contacts the bin thermostat.

RNS0600/RFS0650/RNS1000/RFS1200/ RFS2300 & RF1200/RF2300 Operation

The ice machine will not start until:

A. The rocker switch is moved to “ ON”.

B. Ice does not contact the bin thermostat bulb.

C. The water reservoir is full of water.

Placing the toggle switch in the ON position start s the

gear motor. After the rotation speed sensor verifies

10

minutes of correct rotation, the time delay ends and

the compressor starts. The ice machine will continue to

make ice until ice contacts the bin thermostat. The ice

machine remains off until ice no longer contacts the bin

thermostat.

22

Part Number 000007644 8/14

Page 23

Section 4

!

Caution

!

Warning

Maintenance

Interior Cleaning and Sanitizing

Maintenance procedures covered in this manual are not

covered by the warranty.

Use only Manitowoc approved Metal Safe Ice

Machine Cleaner (part number 000000084) and

Sanitizer (part number 9405653). Do not mix

Cleaner and Sanitizer solutions together. It is a

violation of Federal law to use thes e solutions in a

manner inconsistent with their labeling. Read and

understand all labels printed on bottles before use.

Wear rubber gloves and safety goggles (and/or face

shield) when handling Ice Machine Cleaner or

Sanitizer.

CLEANING/SANITIZING PROCEDURE

This procedure must be performed once every six

months.

• All ice must be removed from the bin.

• The ice machine and bin must be disassembled

cleaned and sanitized.

Cleaning/Sanitizing Procedure

Use Metal Safe Ice Machine Cleaner, part number

000000084.

Use Ice Machine Sanitizer part number 94056 53.

Step 1 Remove front and top covers and set the toggle

switch to the OFF position.

Step 2 Remove all ice from the bin.

Step 3 Turn off the ice making water supply and drain

water from evaporator and reservoir.

Step 4 Remove the top cover from water reservoir.

Step 5 Follow the chart and premix cleaner and water.

Amount of Metal Safe

Amount of Water

1 gallon (4 Liters) 3 ounces (90 ml)

Step 6 Fill the evaporator and reservoir with cleaning

solution.

Cleaner - Part Number

000000084

• The ice machine produces ice with the cleaner and

sanitizer solutions.

• All ice produced during the cleaning and sanitizing

procedure must be discarded.

HEAVILY SCALED CLEANING PROCEDURE

Perform this procedure if you have some or all of these

symptoms.

• Grinding, popping or squealing noises from the

evaporator.

• Grinding noise from gearbox.

• Ice machine trips speed sensor.

NOTE: A Cleaning/Sanitizing Procedure must be

performed after this procedure.

Exterior Cleaning

Remove dust and dirt off exterior surfaces with mild

household dishwashing detergent and warm water . Wipe

dry with a clean, soft cloth.

Step 7 Move the toggle switch to the ON position. The

ice machine will make ice with the cleaning solution and

deposit the ice in the bin. Add the remaining cleaner/

water solution as the water level in the reservoir drops.

NOTE: Do not allow the cleaner/water level to drop

below the minimum water level. The ice machine will

discontinue the cleaning cycle if the water float switch

opens.

Step 8 After all of the cleaner/water solution has been

added, turn on the ice making water supply. Continue

the freeze cycle for 10 minutes to remove the cleaning

solution from the water circuit.

Step 9 Place the toggle switch in the OFF position.

Part Number 000007644 8/14 23

Page 24

Maintenance Section 4

Step 10 Refer to disassembly for cleaning/sanitizing

and remove parts for hand cleaning/sani tizing.

• Hand clean all parts.

• Rinse all parts with clear potable water.

• Sanitize all parts — do not rinse after sanitizing.

• Spray all interior bin surfa ces with sa nitizer (do not

rinse sanitized areas).

• Spray evapor ator discharge spout.

Step 11 Reassemble ice machine.

Step 12 Turn off the ice making water supply.

Step 13 Refer to chart and premix water and sanitizer.

Amount of Water Amount of Sanitizer

1 Gallons (4 L) Water 0.5 ounce (15 ml)

Procedure to Clean Heavily Scaled Flake Ice Machines

Step 1 Remove front and top covers and set the toggle

switch to the OFF position.

Step 2 Remove all ice from the bin.

Step 3 Turn off the ice making water supply.

Step 4 Remove the top cover from water reservoir.

Step 5 Refer to chart below:

Premix cleaner with lukewarm water in a non-

metallic container.

Mix Cleaner and Water

Use Ice machine metal safe

cleaner, part number

000000084 only

Cleaner Water

Model

RF0244

RNS0244

RF0266

RF0385

RNS0385

RF0388

RF0399

RF0644

Water

Reservoir

Capacity

14 oz (400 ml) 9 oz (266 ml) 5 oz (148 ml)

Step 14 Fill the evaporator and reservoir with sanitizer/

water solution.

Step 15 Move the toggle switch to the ON position. The

ice machine will make ice with the sanitizer/water

solution and deposit the ice in the bin. Add the remainin g

sanitizer/water solution when the water level in the

reservoir drops.

NOTE: Do not allow the sanitizer/water level to drop

below the minimum water level. The ice machine will

discontinue the cleaning cycle if the water float switch

opens.

Step 16 After all of the sanitizer/water solution has

been added to the reservoir, turn on the ice making

water supply.

Step 17 Continue the freeze cycle for 30 minutes and

then discard all ice produced.

RFS0300

RNS0300

RNS0600

RFS0650

RNS1000

RFS1200

RF1200

RFS2300

RF2300

17 oz (500 ml) 11 oz (325 ml) 6 oz (177 ml)

34 oz (1 L) 23 oz (680 ml) 11 oz (325 ml)

68 oz (2 L) 46 oz (1.3 L) 22 oz (650 ml)

Step 6 Remove all water from the evaporator and water

reservoir. Add the entire cleaner/water solution and reinstall the reservoir cover.

Leave the cleaner/water sol ut io n in th e ev ap o r at o r

for a minimum of 4 hours.

Step 7 Remove all cleaner/water from the evaporator

and water reservoir.

Step 8 Follow the standard cleaning and sanitizing

procedures.

24

Part Number 000007644 8/14

Page 25

Section 4 Maintenance

!

Warning

!

Caution

Removal of Parts for Cleaning/Sanitizing

Disconnect electric power to the ice machine at the

electric switch box and wear rubber gloves and

safety goggles (or face shield) while handling

cleaner or sanitizer.

Do not mix Cleaner and Sanitizer solutions together.

It is a violation of Federal law to use these solutions

in a manner inconsistent with their labeling.

1. Turn off the water supply to the ice machine at the

water service valve.

2. Remove the components listed on the following

pages for cleaning and sanitizing.

3. Soak the removed part(s) in a properly mixed

solution of cleaner and water.

Solution Type Water Mixed With

Cleaner 1 gal. (4 L)

16 oz (500 ml) cleaner

Part Number 000000084

ICE CHUTE REMOVAL

RFS0300/RNS0300/RNS0600/RFS0650/RNS1000/

RFS1200/RFS2300/ & RF1200/RF2300 Only

1. Place the toggle switch in the OFF position, turn off

the water supply and disconnect electrical power to

the ice machine.

2. Disconnect water supply.

3. Remove water reservoir cover.

4. Remove microswitch and bin thermostat from the ice

chute.

5. Remove retainer, ice chute elbow and ice chute.

4. Use a soft-bristle brush or sponge (NOT a wire

brush) to carefully clean the parts.

5. Use the solutio n an d a br us h or spon g e to clean all

disassembled components and the inside of the bin.

6. Rinse all cleaned parts with clear water.

7. Mix a solution of sanitizer and water.

Solution Type Water Mixed With

Sanitizer 3 gal. (11 L)

2 oz (60 ml) sanitizer

Part Number 9405653

8. Soak the parts in the sanitizer/water solution for

10 minutes. Use the sanitizer/water solution and a

sponge to sanitize all removed components and the

inside of the bin. Do not rinse the sanitized parts.

9. Continue with step 11 of the cleaning/sanitizing

procedure.

Part Number 000007644 8/14 25

Page 26

Maintenance Section 4

!

Warning

!

Caution

Air-Cooled Condenser Cleaning

Disconnect electric power to the ice machine and

the remote condenser at the electric service switch

before cleaning the condenser.

A dirty condenser restricts airflow, resulting in

excessively high operating temperatures and reduced

ice production. Clean the condenser at least every six

months.

The condenser fins are sharp. Use care when

cleaning them.

1. Clean the outside of the condenser with a soft brush

or a vacuum with a brush attachment. Shine a

flashlight through the condenser to check for dirt

between the fins. If dirt remains, a method suitable

to remove the contamination must be used to ensure

air flow.

2. Modular Units Only: Clean the washable filter with a

mild soap and water solution.

Arctic Pure Water Filter System

Engineered specifically for Manitowoc ice machines.

This water filter is an efficient, dependable, and

affordable method of inhibiting scale formation, filtering

sediment, and removing chlorine taste and odor.

Manitowoc Cleaner and Sanitizer

Manitowoc Ice Machine Metal Safe Cleaner is available

in convenient 16 oz. (473 ml) bottles. Manitowoc Ice

Machine Sanitizer is available in 16 oz. (473 ml) and

1

gal (3.78 L) bottles.

Cleaner Part Number Sanitizer Part Number

16 oz. 000000084 16 oz. 9405653

1 Gallon 94-05813

Removal from Service/Winterization

1. Clean and san itize the ice machine.

2. Press the power button and turn off the ice machine.

3. Turn off the water supply, disconnect and drain the

incoming ice-making water line at the rear of the ice

machine and drain the water trough.

4. Energiz e the ic e mach in e, wa it on e minut e fo r the

water inlet valve to open and blow compressed air in

both the incoming water and the drain openings in

the rear of the ice machine to remove all water.

5. Press the power button and turn off the ice machine.

Disconnect the electric power at the circuit breaker

or the electric service switch.

6. Fill spray bottle with sanitizer/water solution and

spray all interior food zone surfaces. Do not rinse

and allow to air dry.

26

7. Replace all panels.

WATER-COOLED ICE MACHINES

1. Perform steps 1-6.

2. Disconnect the incoming water and drain line from

the water-cooled condenser.

3. Energize the ice machine in the freeze cycle. The

increasing refrigerant pressure will open the water

regulating valve.

4. Blow compressed air through the condenser until no

water remains.

5. Replace all panels.

Part Number 000007644 8/14

Page 27

Section 5

Customer Support

Checklist

If a problem arises during operation of your ice machine, follow the checklist below before calling service. Routine

adjustments and maintenance procedures are not covered by the warranty.

Problem Possible Cause To Correct

Ice machine does not operate. No electrical power to the ice machine

and/or condensing unit.

High pressure cutout tripping. Clean condenser coil. (See Section 4)

Power switch set improperly. Move the switch to the ON position.

Bin Thermostat Open or Ice touching

thermostat probe.

No water in reservoir No water to ice machine, plugged filter,

Evaporator safety thermostat open Adjust thermostat

Ice chute switch open Check for ice or binding and close switch

Low air temperature around ice machine Air temperature must be at least 35°F

Gearmotor runs and no ice is produced Time delay has not expired Wait 10 minutes for time delay to expire

High pressure cutout tripping Clean condenser coil and reset

Low pressure control open Thaw evaporator and retest - Call for

Replace the fuse/reset the breaker/turn

on the main switch.

Adjust thermostat or remove ice

float valve defective

(2°C)

service

Part Number 000007644 8/14 27

Page 28

Customer Support Section 5

THIS PAGE INTENTIONALLY LEFT BLANK

28

Part Number 000007644 8/14

Page 29

Section 5 Customer Support

Commercial Ice Machine Warranty

LIMITED WARRANTY

Manitowoc Ice a division of Manitowoc FSG Services, LLC,

(“Company”) warrants that new RF Flake Ice Machines sold by

Company shall be free of defects in material or workmanship under

normal and proper use and maintenance as specified by the Company

and upon proper installation and start-up in accordance with the

instruction manual supplied.

WHAT IS COVERED

• Parts for a period of three (3) years.

• Labor for a period of two (2) years.

• Compressor parts for five (5) years and labor for two (2) years.

The RF Flake Ice Machine warranty begins on the date of the original

installation. This warranty shall not apply to any ice machine initially

installed more than five (5) years from the serial number production

date.

The obligation of the Company under this warranty is limited to the

repair or replacement of parts, components, or assemblies that in the

sole opinion of the Company are defective. This warranty is further

limited to the cost of parts, components or assemblies and standard

straight time labor charges (excluding the compressor warranty) at the

servicing location.

Time and hourly rate schedules, as published from time to time by the

Company, apply to all service procedures. Additional expenses

including without limitation, travel time, overtime premium, material

cost, accessing or removal of the RF Flake Ice Machine, or shipping

are the responsibility of the purchaser, along with all maintenance,

adjustments, cleaning, and ice purchases. Labor covered under this

warranty must be performed by an approved Company contracted

Service Representative or a refrigeration service agency as qualified

and authorized by the Company’s local Distributor. The Company's

liability under this warranty shall in no event be greater than the actual

purchase price paid by purchaser for the RF Flake Ice Machine.

EXCLUSIONS FROM COVERAGE

• Repair or replacement of parts required because of misuse,

improper care or storage, negligence, alteration, use of

incompatible supplies or lack of specified maintenance shall be

excluded.

• Normal maintenance items.

• Failures caused by improper or erratic voltages, adverse

environmental or water conditions, improper drainage, interruption

in electrical or water supply.

• Improper or unauthorized repair.

• Any RF Flake Ice Machine that has been installed and/or

maintained inconsistent with the instructions provided by the

Company.

• Parts subject to damage beyond the control of Company, or to RF

Flake Ice Machine’s which have been subject to accidents,

damage in shipment, fire, floods, other hazards or acts of God that

are beyond the control of the Company.

• This Limited Warranty shall not apply if the RF Flake Ice Machine's

refrigeration system is modified with a condenser, heat reclaim

device, or parts and assemblies other than those manufactured by

the Company, unless the Company approves these modifications

for specific locations in writing prior to the commencement of such

modification.

LIMITATIONS OF LIABILITY

The preceding paragraphs set forth the exclusive remedy for all claims

based on failure of, or defect in, RF Flake Ice Machines sold

hereunder, whether the failure or defect arises before or during the

warranty period, and whether a claim, however instituted, is based on

contract, indemnity, warranty, tort (including negligence), strict liability,

implied by statute, common-law or otherwise, and Company and

agents shall not be liable for any claims for personal injuries or

consequential damages or loss, howsoever caused. Upon the

expiration of the warranty period, all such liability shall terminate. THE

FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL

OTHER WARRANTIES, WHETHER WRITTEN, ORAL, IMPLIED OR

STATUTORY NO IMPLIED WARRANTY OF MERCHANTABILITY OR

FITNESS FOR PARTICULAR PURPOSE SHALL APPLY, COMPANY

DOES NOT WARRANT ANY PRODUCTS OR SERVICES OF

OTHERS

REMEDIES

The liability of Company for breach of any warranty obligation

hereunder is limited to: (i) the repair or replacement of the RF Flake Ice

Machine on which the liability is based, or with respect to services, reperformance of the services; or (ii) at Company’s option, the refund of

the amount paid for said equipment or services. Any breach by

Company with respect to any item or unit of equipment or services

shall be deemed a breach with respect to that item or unit or service

only.

WARRANTY CLAIM PROCEDURE

Customer shall be responsible to:

• Complete and return warranty registration card or register on line

within five (5) days from the installation date.

• All warranty service must be preformed by an approved

Manitowoc contracted or authorized Service Representative.

GOVERNING LAW

This Limited Warranty shall be governed by the laws of the state of

Wisconsin, USA, excluding their conflicts of law principles. The United

Nations Convention on Contracts for the International Sale of Goods is

hereby excluded in its entirety from application to this Limited

Warranty.

To secure prompt and continuing warranty service, the warranty

registration card must be completed and sent to the COMPANY within

five (5) days from the installation date.

Complete the following and retain for your record:

Distributor/Dealer ______________________________________________________________________________________________________

Model Number ____________________________________________ Serial Number ______________________________________________

Installation Date _______________________________________________________________________________________________________

MANITOWOC ICE, INC. 2110 So. 26th St., P.O. Box 1720, Manitowoc, WI 54221-1720

Telephone: 920-682-0161 Fax: 920-683-7585 Web Site - www.manitowocice.com Form 80-0375-3 Rev. 01-02

Part Number 000007644 8/14 29

Page 30

Customer Support Section 5

Residential Ice Machine Limited Warranty

WHAT DOES THIS LIMITED WARRANTY COVER?

Subject to the exclusions and limitations below, Manitowoc

Foodservice (“Manitowoc”) warrants to the original consumer

that any new ice machine manufactured by Manitowoc (the

“Product”) shall be free of defects in material or workmanship

for the warranty period outlined below under normal use and

maintenance, and upon proper installation and start-up in

accordance with the instruction manual supplied with the

Product.

HOW LONG DOES THIS LIMITED WARRANTY LAST?

Product Covered Warranty Period

Ice Machine Twelve (12) months

from the sale date

WHO IS COVERED BY THIS LIMITED WARRANTY?

This limited warranty only applies to the original consumer of

the Product and is not transferable.

WHAT ARE MANITOWOC ICE’S OBLIGA T IO NS UNDER

THIS LIMITED WARRANTY?

If a defect arises and Manitowoc receives a valid warranty

claim prior to the expiration of the warranty period, Manitowoc

shall, at its option: (1) repair the Product at Manitowoc’s cost,

including standard straight time labor charges, (2) replace the

Product with one that is new or at least as functionally

equivalent as the original, or (3) refund the purchase price for

the Product. Replacement parts are warranted for 90 days or

the balance of the original warranty period, whichever is

longer. The foregoing constitutes Manitowoc’s sole obligation

and the consumer’s exclusive remedy for any breach of this

limited warranty. Manitowoc’s liability under this limited

warranty is limited to the purchase price of Product. Additional

expenses including, without limitation, service travel time,

overtime or premium labor charges, accessing or removing

the Product, or shipping are the responsibility of the

consumer.

HOW TO OBTAIN WARRANTY SERVICE

To obtain warranty service or information regarding your

Product, please contact us at:

MANITOWOC FOODSERVICE

2110 So. 26th St.

P.O. Box 1720,

Manitowoc, WI 54221-1720

Telephone: 920-682-0161 Fax: 920-683-7585

www.manitowocice.com

WHAT IS NOT COVERED?

This limited warranty does not cover, and you are solely

responsible for the costs of: (1) periodic or routine

maintenance, (2) repair or replacement of the Product or parts

due to normal wear and tear, (3) defects or damage to the

Product or parts resulting from misuse, abuse, neglect, or

accidents, (4) defects or damage to the Product or parts

resulting from improper or unauthorized alterations,

modifications, or changes; and (5) defects or damage to any

Product that has not been installed and/or maintained in

accordance with the instruction manual or technical

instructions provided by Manitowoc. To the extent that

warranty exclusions are not permitted under some state laws,

these exclusions may not apply to you.

EXCEPT AS STATED IN THE FOLLOWING SENTENCE, THIS LIMITED

WARRANTY IS THE SOLE AND EXCLUSIVE WARRANTY OF

MANITOWOC WITH REGARD TO THE PRODUCT. ALL IMPLIED

ARRANTIES ARE STRICTLY LIMITED TO THE DURATION OF THE

W

LIMITED WARRANTY APPLICABLE TO THE PRODUCTS AS STATED

ABOVE, INCLUDING BUT NOT LIMITED TO, ANY WARRANTY OF

ERCHANTABILITY OR OF FITNESS FOR A PARTICULAR

M

PURPOSE.

Some states do not allow limitations on how long an implied

warranty lasts, so the above limitation may not apply to you.

IN NO EVENT SHALL MANITOWOC OR ANY OF ITS AFFILIATES BE

IABLE TO THE CONSUMER OR ANY OTHER PERSON FOR ANY

L

INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES OF ANY

KIND (INCLUDING, WITHOUT LIMITATION, LOSS PROFITS,

EVENUE OR BUSINESS) ARISING FROM OR IN ANY MANNER

R

CONNECTED WITH THE PRODUCT, ANY BREACH OF THIS LIMITED

WARRANTY, OR ANY OTHER CAUSE WHATSOEVER, WHETHER

ASED ON CONTRACT, TORT OR ANY OTHER THEORY OF

B

LIABILITY.

Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation

or exclusion may not apply to you.

HOW STATE LAW APPLIES

This limited warranty gives you specific legal rights, and you

may also have rights that vary from state to state or from one

jurisdiction to another.

REGISTRA TION CARD

To secure prompt and continuing warranty service, this

warranty registration card must be completed and sent to

Manitowoc within thirty (30) days from the sale date. Complete

the following registration card and send it to Manitowoc.

30

Part Number 000007644 8/14

Page 31

Section 1

Généralités

Références des modèles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

RF2300 Installation de l’adaptateur de bac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Section 2

Instructions d’installation

Emplacement de la machine à glaçons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Conditions requises d’installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Conditions requises en eau et évacuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Conditions électriques requises . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Installation du système de réfrigération

Condenseur à distance uniquement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Installation des conduites de réfrigération

Condenseur à distance uniquement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Liste de vérification d’installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Contrôles additionnels pour modèles QuietQube . . . . . . . . . . . . . . . . . . . . . . . . 45

Table des matières

Integre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Modulaires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Conditions d’espace requises . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Conditions requises pour l’eau potable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Dimensionnement/Raccordement des conduites d’alimentation

en eau et d’évacuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Raccordements d’évacuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Fusible/Disjoncteur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Différentiel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Généralités . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

A. Longueur des conduites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

B. Montée ou descente de conduites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

C. Siphons d’huile de conduite d’aspiration . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Section 3

Fonctionnement

Thermostat de sécurité de basse température d’évaporateur et thermostat

de bac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

RF0244/RF0266/RF0385/

RF0388/RF0399/RF0644 & RNS0244/RNS0385 Fonctionnement . . . . . . . . . . . . . 47

RFS0300 & RNS0300 Fonctionnement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

RFS0650/RFS1200/RFS2300/RF1200/RF2300 Fonctionnement . . . . . . . . . . . . . . 48

Part Number 000007644 8/14 31

Page 32

Section 4

Entretien

Section 5

Service clientèle

Table des matières (suite)

Nettoyage et désinfection intérieurs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Procédure de nettoyage et de désinfection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Nettoyage extérieur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Procédure de nettoyage et de désinfection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Procédure de nettoyage des machines à glace en écailles fortement entartrées 50

Retrait des pièces pour le nettoyage/la désinfection . . . . . . . . . . . . . . . . . . . . . . 51

Dépose de la goulotte à glaçons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Dépose de l’actionneur d’interrupteur de goulotte à glaçons . . . . . . . . . . . . . . . 52

Nettoyage du condenseur refroidi à l’air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Système de filtration d’eau Arctic Pure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Nettoyant et désinfectant Manitowoc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Liste de vérification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Garantie commerciale de la machine à glaçons . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Garantie limitée résidentielle de la machine à glaçons . . . . . . . . . . . . . . . . . . . . 56

32 Part Number 000007644 8/14

Page 33

Références des modèles

!

Avertissement

! Avertissement

Section 1

Généralités

Le présent manuel s’applique aux modèles suivants :

INTEGRE

Autonomes

refroidis à l’air

RF0244A

RF0266A

RF0385A

RF0388A

RF0399A

RF0644A

MODULAIRES

Autonomes

refroidis à l’air

RNS0308A --- --- --- --RNS0608A RNS0609W --- --- --RNS1008A RNS1009W --- RNS1078C RCU1098

RFS0300A --- --- --- --RFS0650A RFS0650W ---- --- --RFS1200A RFS1200W RFS1279R RFS1278C RCU1075

RF2300A RF2300W RFS2379R RFS2378C RCU2375

Autonomes

refroidis à l’eau

À distance Tête QuietQube

INTEGRE

Autonomes

refroidis à l’air

RNS0244A

RNS0385A

Unité de

condensation à

distance RCU

Retirer tous les panneaux de la machine à glaçons

avant de la soulever ou l’installer.

RISQUE DE BLESSURES CORPORELLES

Ne pas utiliser un équipement qui aura été mal

utilisé, abusé, négligé, endommagé ou dont les

spécifications originales de fabrication auront été

altérées/modifiées.

Le présent appareil ne doit pas être utilisé par des

personnes (enfants y compris) ayant des capacités

physiques, sensorielles ou mentales diminuées, ou

ayant un manque d’expérience et de connaissance,

à moins que celles-ci n’aient reçu un e formation sur

l’utilisation de l’appareil par une personne

responsable de leur sécurité.

Part Number 000007644 8/14 33

Page 34

Généralités Section 1

!

Avertissement

RF2300 Installation de l’adaptateur de bac

RISQUE DE BLESSURES CORPORELLES

Les machines à glaçons RF2300 ne sont pas

approuvées pour être utilisées avec les bacs B970.

Les machines à glaçons RF2300 sont expédiées

avec un support qui doit être utilisé lors de

l’installation sur les bacs de Séries B1100 et B1400.

1. Consulter le schéma. Placer le support sur le

dessus du bac et le faire glisser en arrière pour

l’enclencher.

2. Placer la machine à glaçons sur le bac : la machine

à glaçons doit rentrer entre le support et la ne rv ur e

avant.

34

Part Number 000007644 8/14

Page 35

Section 2

Instructions d’installation

Emplacement de la machine à glaçons

Le choix de l’emplacement pour la machine à glaçons

doit respecter les critères suivants. Si l’un de ces critères

n’est pas respecté, choisir un autre emplacement.

• L’emplaceme nt doit être exempt d’agent s aéroportés

et de toute autre substance contaminante.

• La température de l’air doit être au moins de 10°C

(50 °F) sans toutefois excéder 43°C (110°F).

• La température de l’eau doit être au moins de 4°C

(40 °F) sans toutefois excéder 32°C (90°F).

• L’emplacement ne doit pas se trouver à proximité

d’appareils générateurs de chaleur ou à la lumière

directe du soleil.

• L’emplacement doit pouvoir supporter le poids de la

machine à glaçons et un bac plein de glaçons.

• L’emplaceme nt doit prévoir suffisamment de

dégagement pour les prises d’eau, raccordements

de vidange et raccordements électriques à l’arrière

de la machine à glaçons.

• L’emplaceme nt ne doit pas obstruer l’écoulement

d’air dans la machine ou autour de celle-ci.

Conditions requises d’installation

• La machine à glaçons et le bac doivent être nivelés.

• Ventiler les lignes d’évacuation de la machine à

glaçons et du bac séparément.

• Le raccordement de la ligne d’évacuation du bac doit

comporter un espace d’air.

• Un dispositif anti-refoulement est exigé sur les

conduites d’arrivée d’eau.

• La machine à glaçons et le bac doivent être

aseptisés après l’installation.

• En fonction des conditions d’eau locales, il peut

s’avérer nécessaire de traiter l’eau pour e mpêcher la

formation de tartre, filtrer les sédiments et éliminer le

goût et l’odeur du chlore.

• Les réglages de routine et les procédures de

maintenance périodique indiqués dans ce manuel n e

sont pas couverts par la garantie.

CONDITIONS D’ESPACE REQUISES

INTEGRE

Haut 0 cm (0") 0 cm (0"

Côtés 5 cm (2") 5 cm (2")

Arrière 20 cm (8") 20 cm (8")

REMARQUE : Prévoir un espace pour le retrait de la machine à glaçons

lorsqu’elle est encastrée. Il faut déposer le panneau supérieur une fois par

mois pour le nettoyage et la désinfection.

MODULAIRES

Haut/Côtés 20 cm (8") 20 cm (8")

Arrière 13 cm (5") 13 cm (5")

Refroidissement

à l’air

Refroidissement

à l’air

Refroidissement

à l’eau

Refroidissement

à l’eau

Machine à glaçons Chaleur de rejet

Series Machine à

glaçons

RFS1279R 7850

RFS2379R 15700

B.T.U./Heure

Chaleur de rejet

Les machines à glaçons, tout comme tout autre

équipement de réfrigération, rejet ten t la ch ale ur par le

condenseur. Il est utile de connaître la quantité de

chaleur rejetée par la machine à glaçons lors du

dimensionnement du matériel de conditionnement d’air

où sont installées les machines à glaçons autonomes

refroidies par l’air.

Cette information est également nécessaire pour

évaluer les avantages d’utiliser des condenseurs

refroidis par eau ou à distance afin de réduire les

charges de conditionnement d’air. La quantité de

chaleur ajoutée à un environnement climatisé par une

machine à glaçons utilisant un condenseur refroidi par

eau ou à distance est négligeable.

Connaître la quantité de chaleur rejetée est également

important lors du dimensionnement d’une tour de

refroidissement pour un condenseur refroidi par eau.

Utiliser le chiffre de crête pour dimensionner la tour de

refroidissement.

Part Number 000007644 8/14 35

Page 36

Instructions d’installation Section 2

!

Attention

Important

Conditions requises en eau et évacuation

CONDITIONS REQUISES POUR L’EAU POTABLE

Suivre ces directives pour l’installation des lignes

d’arrivée d’eau :

• Ne pas raccorder la machine à glaçons à une

alimentation en eau chaude. S’assurer que tous les

restricteurs d’eau chaude installés pour les autres

appareils fonctionnent (clapets de non-retour sur

robinets d’éviers, lave-vaisselle, etc.)

• Si la pression de l’eau dépasse la pression maximale

recommandée de 552 kPa (80 psig), se procurer un

régulateur de pression d’eau auprès d’un distributeur

Manitowoc.

• Installer un robinet d’arrêt de l’eau et un raccord pour

les lignes d’eau de fabrication de glaçons et d’eau du

condenseur.

• Isoler les lignes d’arrivée d’eau pour éviter les

problèmes de condensation.

• La tuyauterie doit être conforme aux codes locaux.

Ne pas appliquer de chaleur au raccord d’arrivée du

robinet d’eau et ce, pour ne pas endommager

la connexion d’arrivée d’eau en plastique.

RACCORDEMENTS D’ÉVACUATION

Suivre ces directives lors de l’installation des conduites

d’évacuation pour empêcher l’eau de retourner s’écouler

dans la machine à glaçons et dans le bac de stockage :

• Les lignes d’évacuation doivent avoir une inclinaison

de 2,5 cm par mètre (1,5 pouce par 5 pieds) et ne

doivent pas créer de siphons.

• Le siphon de sol doit être suffisamment grand pour

recevoir l’eau provenant de toutes les évacuations.

• Faire fonctionner séparément les lignes d’évacuation

du bac et du condenseur refroidi à l’eau. Les isoler

pour prévenir la condensation.

• Ventiler le bac e t la ligne d’é vacuation d e la ma chine

à glaçons dans l’atmosphère. L’évacuation de la

machine à glaçons requiert une ventilation de 46 cm

(18 po). Ne pas ventiler l’évacuation du condenseur

sur les modèles refroidis par eau.

• Les évacuations doivent être équipées d’un raccordunion ou de tout autre moyen adapté permettant de

déconnecter la machine à glaçons pour des raisons

de maintenance.

APPLICATIONS AVEC TOUR DE

REFROIDISSEMENT (MODÈLES REFROIDIS PAR

EAU UNIQUEMENT)

Une installation avec tour de refroidissement à eau ne

requiert pas de modification de la machine à glaçons. Le

régulateur d’eau du condenseur continue de contrô ler la

pression de refoulement de réfrigération. Il est

nécessaire de connaître la quantité de chaleur rejetée

ainsi que la chute de pression dans le condenseur et les

robinets d’eau (entrée et sortie) lors de l’utilisation d’une

tour de refroidissement sur une machine à glaçons.

• La température de l’eau arrivant dans le condenseur

ne doit pas être inférieure à 3 °C (37 °F) ni être

supérieure à 32 °C (90 °F).

36

• La quantité d’eau traversant le condenseur ne doit

pas dépasser 19 litres (5 gallons) par minute.

• Prévoir une chute de pression de 48 kPa (7 psi) entre

l’arrivée d’eau du condenseur et la sortie de la

machine à glaçons.

• La température de l’eau sortant dans le condenseur

ne doit pas dépasser 43 °C (110 °F).

L’État du Massachusetts exige que tous les

modèles refroidis à l’eau soient raccordés

uniquement à un système de tour de

refroidissement à boucle fermée.

Part Number 000007644 8/14

Page 37

Section 2 Instructions d’installation

TUBE

D’AÉRATION