Page 1

Manitowoc

R Model

Flake & Nugget

Technician’s

Handbook

This manual is updated as new information and models

are released. Visit our website for the latest manual.

America’s #1 Selling Ice Machine

Part Number 000007661 7/10

www.manitowocice.com

Page 2

Read These Before Proceeding:

!

Caution

Important

! Warning

We reserve the right to make product

improvements at any time. S pecifications and

design are subject to change without notice.

Proper installation, care and maintenance are

essential for maximum performance and troublefree operation of your Manitowoc equipment. If

you encounter problems not covered by this

handbook, do not proceed, contact Manitowoc

Foodservice Group. We will be happy to provide

assistance.

Routine adjustments and maintenance

procedures outlined in this handbook are not

covered by the warranty.

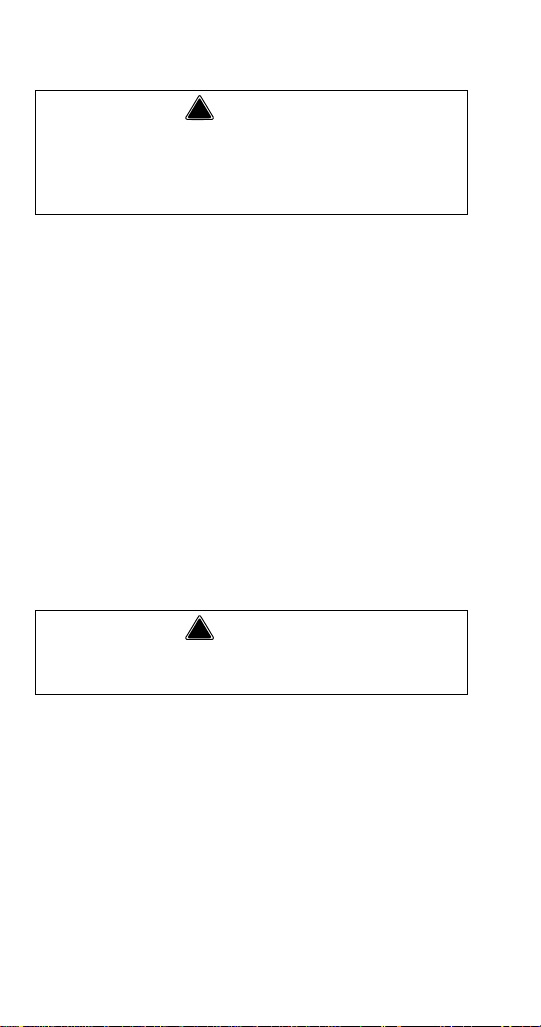

PERSONAL INJURY POTENTIAL

Do not operate equipment that has been

misused, abused, neglected, damaged, or

altered/modified from that of original

manufactured specifications.

This appliance is not intended for use by

persons (including children) with reduced

physical, sensory or mental capabilities, or

lack of experience and knowledge, unless

they have been given supervision

concerning use of the appliance by a person

responsible for their safety.

Page 3

Table of Contents

General Information

Model Numbers . . . . . . . . . . . . . . . . . . . . .7

Self Contained

Air & Water-Cooled Models . . . . . . . . .7

QuietQube Remote Air-cooled Models with

Remote Condensing Units . . . . . . . . .7

Model/Serial Number . . . . . . . . . . . . . . . .8

Manitowoc Cleaner and Sanitizer . . . . . .8

Ice Machine Warranty Information . . . . .8

Installation

Location of Ice Machine . . . . . . . . . . . . . .9

Installation Requirements . . . . . . . . . . . .9

Potable Water Requirements . . . . . . . . . .10

Drain Connections . . . . . . . . . . . . . . . . . .10

Ice Machine Clearance Requirements . .11

Cooling Tower Applications

(Water-Cooled Models Only) . . . . . . . . . .12

Heat of Rejection . . . . . . . . . . . . . . . . . . .13

RF Models . . . . . . . . . . . . . . . . . . . . . .13

RN Models . . . . . . . . . . . . . . . . . . . . .13

Electrical Service . . . . . . . . . . . . . . . . . . .13

Voltage . . . . . . . . . . . . . . . . . . . . . . . .13

Fuse/Circuit Breaker . . . . . . . . . . . . . . 14

Ground Fault Interrupter Circuit (GFIC) 14

Maintenance

Cleaning and Sanitizing . . . . . . . . . . . . . .15

Exterior Cleaning . . . . . . . . . . . . . . . . .15

RF Models Cleaning/

Sanitizing Procedures . . . . . . . . . . . . . 16

RN Models Cleaning/

Sanitizing Procedure . . . . . . . . . . . . . .22

Cleaning the Condenser . . . . . . . . . . .24

Removal from Service/Winterization . . .25

Part Number 000007661 7/10 3

Page 4

Operation

Ice Making Sequence of Operation . . . . 27

Self-Contained Air-Cooled

RF0244/RF0266/RF0385/

RF0388/RF0399 . . . . . . . . . . . . . . . . . 27

Self-Contained Air-Cooled

RF0300 . . . . . . . . . . . . . . . . . . . . . . . . 27

Self-Contained Air-Cooled

RF0650/RF1200/RF2300 . . . . . . . . . . 28

QuietQube Remote Air-cooled Models with

Remote Condensing Units

RF1200C/RF2300C . . . . . . . . . . . . . . 29

Self-Contained Air-cooled &

Water-Cooled RN0400 . . . . . . . . . . . . 30

Self-Contained Air-Cooled &

Water-Cooled RN1000/RN1400 . . . . . 31

QuietQube Remote Air-cooled Models with

Remote Condensing Units

RN1000C/RN1200C . . . . . . . . . . . . . . 32

Thermostat Settings . . . . . . . . . . . . . . . . 34

RF Models . . . . . . . . . . . . . . . . . . . . . 34

Troubleshooting

Electrical Flowcharts . . . . . . . . . . . . . . . . 37

RF0244/RF0266RF0385//RF00388/

RF0399 Air & Water . . . . . . . . . . . . . . 38

RF0300 Air & Water . . . . . . . . . . . . . . 43

RF0650/RF1200 Air & Water . . . . . . . 48

RF2300 Air & Water . . . . . . . . . . . . . . 53

RN1000/RN1400 Air & Water . . . . . . . 60

RN1000C/RN1200C QuietQube . . . . . 68

RF1200C QuietQube . . . . . . . . . . . . . 78

RF2300C QuietQube . . . . . . . . . . . . . 84

Capillary Tube Models . . . . . . . . . . . . . . . 91

Thermostatic Expansion Valve Models . 92

4 Part Number 000007661 7/10

Page 5

Component Specifications

Bin Thermostat . . . . . . . . . . . . . . . . . .93

Low Temperature Thermostat . . . . . . .93

High Pressure Cutout (HPCO) Control 93

Low Pressure Cutout (LPCO) Control . 94

Fan Cycle Control . . . . . . . . . . . . . . . .94

Filter-Driers . . . . . . . . . . . . . . . . . . . . .95

Suction Cleanup Filter-Drier . . . . . . . .95

Total System Refrigerant Charge . . . .96

Charts

Cycle Times/24-Hour Ice Production/

Refrigerant Pressure Charts . . . . . . . . . .97

RF0244A . . . . . . . . . . . . . . . . . . . . . . .98

RF0266A . . . . . . . . . . . . . . . . . . . . . . .99

RF0385A . . . . . . . . . . . . . . . . . . . . . . .100

RF0388A . . . . . . . . . . . . . . . . . . . . . . .101

RF0399A . . . . . . . . . . . . . . . . . . . . . . .102

RF0300A . . . . . . . . . . . . . . . . . . . . . . .103

RF0650A . . . . . . . . . . . . . . . . . . . . . . .104

RF1200A . . . . . . . . . . . . . . . . . . . . . . .105

RF1200W . . . . . . . . . . . . . . . . . . . . . .106

RF2300A . . . . . . . . . . . . . . . . . . . . . . .107

RF2300W . . . . . . . . . . . . . . . . . . . . . .108

RN1000A . . . . . . . . . . . . . . . . . . . . . . .109

RN1000W . . . . . . . . . . . . . . . . . . . . . .110

RN1400A . . . . . . . . . . . . . . . . . . . . . . .111

RN1400W . . . . . . . . . . . . . . . . . . . . . .112

RN1078C . . . . . . . . . . . . . . . . . . . . . .113

RN1278C . . . . . . . . . . . . . . . . . . . . . .114

RF1278C . . . . . . . . . . . . . . . . . . . . . . .115

RF2378C . . . . . . . . . . . . . . . . . . . . . . .116

Part Number 000007661 7/10 5

Page 6

Diagrams

Wiring Diagrams . . . . . . . . . . . . . . . . . . . 117

RF0244/RF0266/RF0385/

RF0388/RF0399 Air-Cooled . . . . . . . . 118

RF0300 Air-Cooled . . . . . . . . . . . . . . . 120

RF0650 - RF1200 Air-Cooled . . . . . . . 122

RF1200 Water-Cooled . . . . . . . . . . . . 124

RF2300 Air-Cooled & Water-cooled . . 126

RN1000/RN1400 Air & Water Cooled 128

RN1000C QuietQube Head Section . . 129

RN1200C QuietQube Head Section . . 130

RN2300C QuietQube Head Section . . 132

RCU Condensing Unit 1ph . . . . . . . . . 134

RCU Condensing Unit 3ph . . . . . . . . . 135

Refrigeration Tubing Schematics . . . . . 136

RF0244/RF0266/RF0388/RF0399

RF0300/RF0650 Air-cooled . . . . . . . . 136

RF1200 Air-cooled . . . . . . . . . . . . . . . 138

RF1200 Water-cooled . . . . . . . . . . . . 140

RF2300 Air-cooled . . . . . . . . . . . . . . . 142

RF2300 Water-cooled . . . . . . . . . . . . 144

RN1000/RN1400 Air & Water-cooled . 146

RN1000C QuietQube Head Section &

RCU1075 Condensing Unit . . . . . . . . 148

RN1200C QuietQube Head Section &

RCU1275 Condensing Unit . . . . . . . . 150

RN2300C QuietQube Head Section &

RCU2375 Condensing Unit . . . . . . . . 152

6 Part Number 000007661 7/10

Page 7

General Information

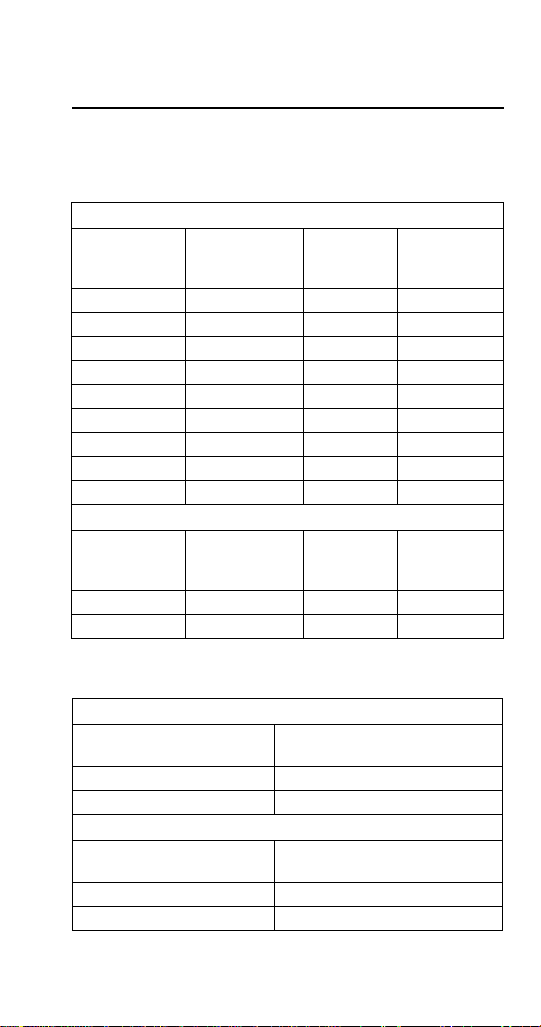

Model Numbers

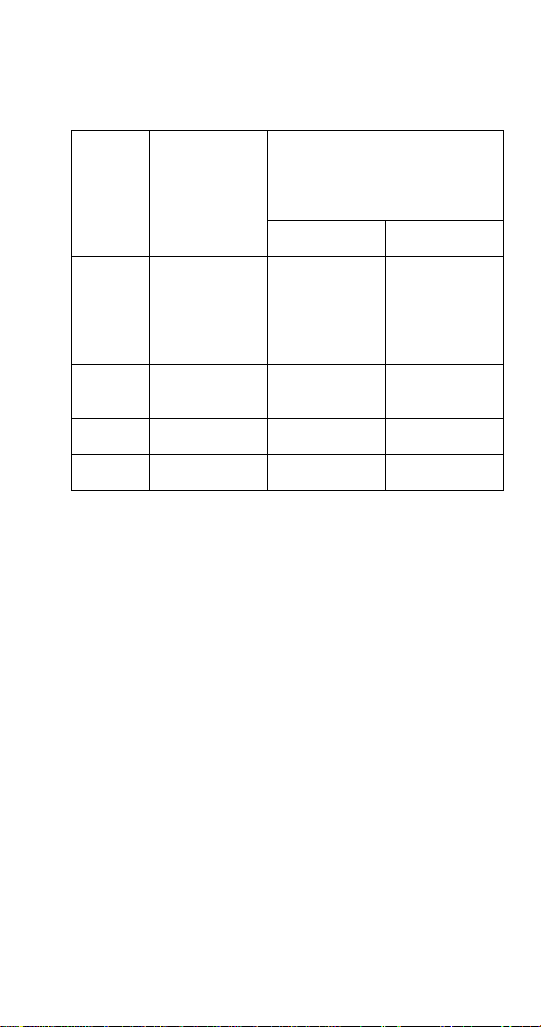

SELF CONTAINED AIR & WATER-COOLED MODELS

Flake Models

Self Storage

Air-Cooled

RF0244A – – –

RF0266A – – –

RF0385A – – –

RF0388A – – –

RF0399A – – –

– – RF0300A –

– – RF0650A –

– – RF1200A –

– – RF2300A –

Self Storage

Water-Cooled

Nugget Models

Self Storage

Air-Cooled

– – RN1008A RN1009W

– – RN1408A RN1409W

Self Storage

Water-Cooled

Modular

Air-Cooled

Modular

Air-Cooled

Modular

Water-

Cooled

Modular

Water-

Cooled

QUIETQUBE REMOTE AIR-COOLED MODELS WITH REMOTE CONDENSING UNITS

Flake Models

QuietQube Head

RF1278C RCU1275

RF2378C RCU2375

RCU Remote

Condensing Unit

Nugget Models

QuietQube Head

RN1078C RCU1075

RN1278C RCU1275

Part Number 000007661 7/10 7

RCU Remote

Condensing Unit

Page 8

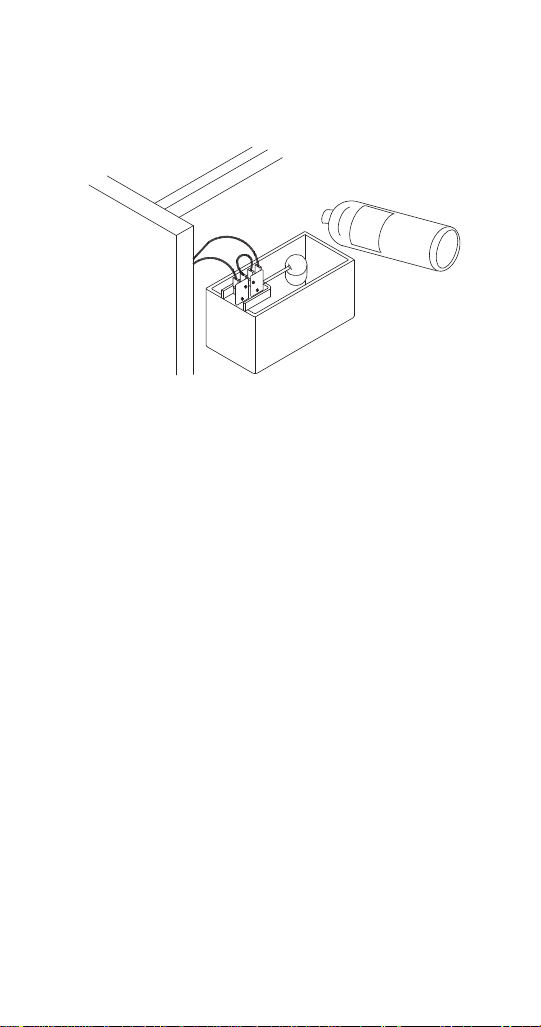

Model/Serial Number

These numbers are required when requesting

information from your local Manitowoc Distributor, or

Manitowoc Ice. The model and serial number are

listed on the MODEL/SERIAL NUMBER DECAL

affixed to the ice machine.

Manitowoc Cleaner and Sanitizer

Manitowoc Ice Machine Cleaner and Sanitizer are

available in 16 oz. (473 ml) bottles. These are the only

cleaners and sanitizers approved for use with

Manitowoc products.

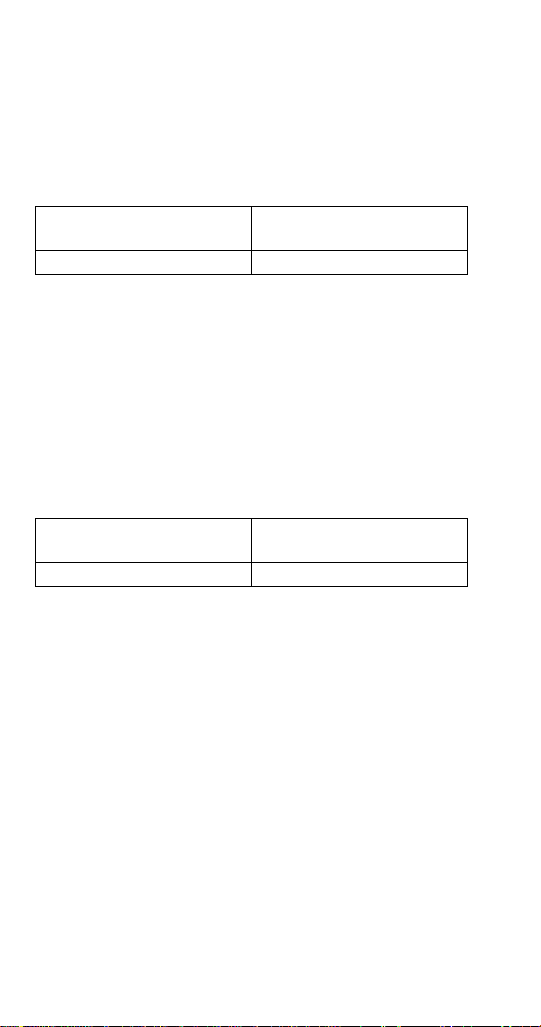

Cleaner Part Number Sanitizer Part Number

16 oz. 000000084 16 oz. 9405653

1 gal N/A 1 gal. 9405813

Ice Machine Warranty Information

Warranty information for all ice machine models is

available on our website at www.manitowocice.com.

8 Part Number 000007661 7/10

Page 9

Installation

Location of Ice Machine

The location selected for the ice machine must meet

the following criteria. If any of these criteria are not

met, select another location.

• The location must be free of airborne and other

contaminants.

• The location must not be near heat-generating

equipment or in direct sunlight.

• The location must be capable of supporting the

weight of the ice machine and a full bin of ice.

• The location must allow enough clearance for

water, drain and electrical connections in the rear

of the ice machine.

• The location must not obstruct airflow through or

around the ice machine.

Installation Requirements

• The air temperature must be at least 50°F (10°C),

but must not exceed 110°F (43°C).

• The water temperature must be at least 40°F

(4°C), but must not exceed 90°F (32°C).

• The ice machine and bin must be level.

• Vent the ice machine and bin drains separately.

• Bin drain termination must have an air gap.

• RF Models Only: A backflow preventer is required

on water inlet lines.

• Routine adjustments and maintenance procedures

outlined in this manual are not covered by the

warranty.

Part Number 000007661 7/10 9

Page 10

Potable Water Requirements

• Plumbing must conform to local codes.

• Do not connect the ice machine to a hot water

supply. Be sure all hot water restrictors installed for

other equipment are working. (Check valves on

sink faucets, dishwashers, etc.)

• If water pressure exceeds maximum pressure

(70 psig [483 kPa] RN1000; 80 psig [552 kPa] for

all other models) obtain a water pressure regulator

from your Manitowoc distributor.

• A water shut-off valve is required to clean the ice

machine.

• A union for both the ice making and condenser

water lines is required.

• Water inlet lines require insulation to prevent

condensation.

• RF Models: A backflow preventer is required on

water inlet lines.

Drain Connections

• Drain lines must have a 1.5 inch drop per 5 feet of

run (2.5 cm per meter), and must not create traps.

• The floor drain must be large enough to

accommodate drainage from all drains.

• Separate insulated bin and water-cooled

condenser drain lines are required.

• The bin and ice machine drains require a vent.

10 Part Number 000007661 7/10

Page 11

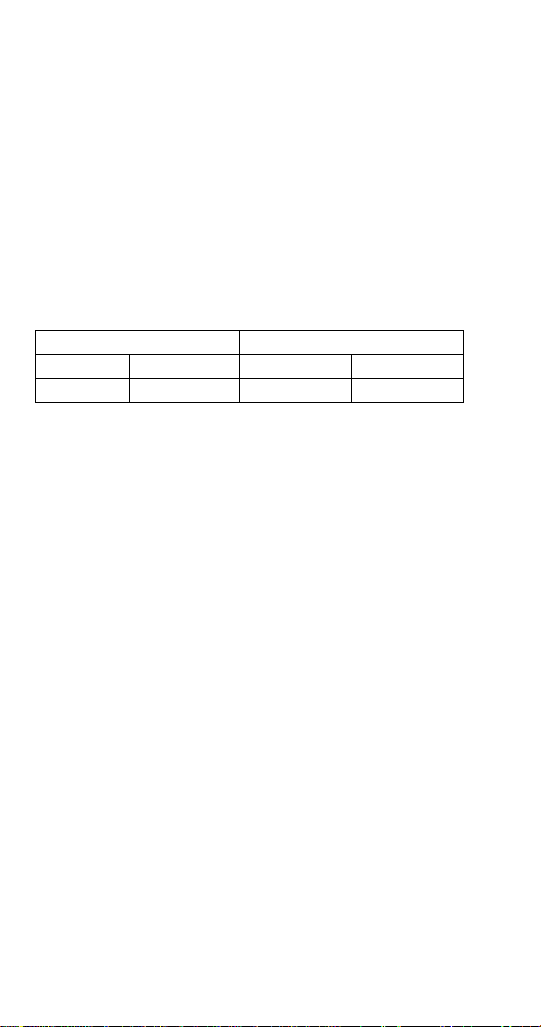

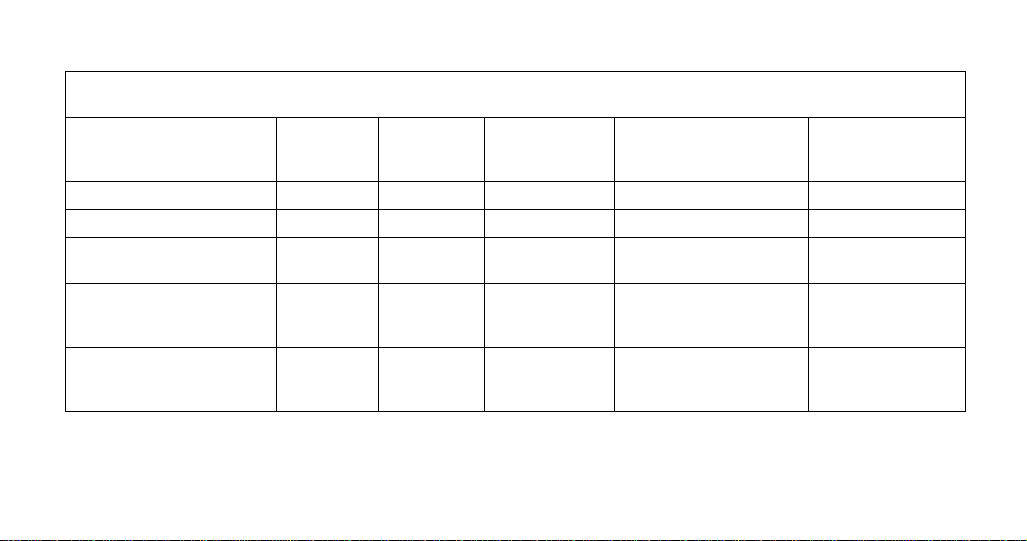

Ice Machine Clearance Requirements

Head

Sections

Back 5" (12.7 cm) 5" (12.7 cm) 0" (0 cm)

Sides/Top 8" (20.3 cm) 8" (20.3 cm) 0" (20 cm)

* Water-Cooled Only - There is no minimum clearan ce required. This

value is recommended for efficient operation and servicing only.

Self-

Contained

Air-Cooled

RCU Units

Front/Back 24" (61.0 cm)

Sides/Top 6" (15.2 cm)*

Self-

Contained

Water-Cooled*

Remote Condensing Unit*

QuietQube

Air-Cooled

NOTE: Allowance must be made for removal when the

ice machine is built-in. Monthly removal of the top

panel is required for cleaning and sanitizing.

Part Number 000007661 7/10 11

Page 12

Cooling Tower Applications (Water-Cooled Models Only)

A water cooling tower installation does not require

modification of the ice machine. The water regulator

valve for the condenser continues to control the

refrigeration discharge pressure.

It is necessary to know the amount of heat rejection,

and pressure drop through the condenser and water

valves (inlet and outlet) when using a cooling tower on

an ice machine.

• Water entering the condenser must not be lower

than 37°F (3°C) or exceed 90°F (32°C).

• Water flow through the condenser must not

exceed 5 gal. (19 L) per minute.

• Allow for a pressure drop of 7 psi (48 kPa)

between the condenser water inlet and the outlet

of the ice machine.

• Water exiting the condenser must not exceed

110°F (43°C).

12 Part Number 000007661 7/10

Page 13

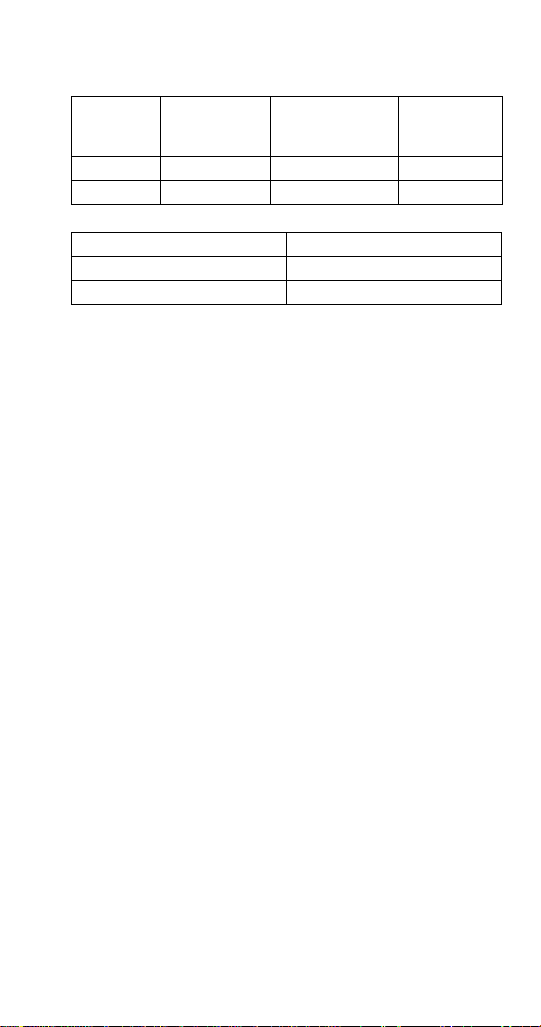

Heat of Rejection

!

Warning

RF MODELS

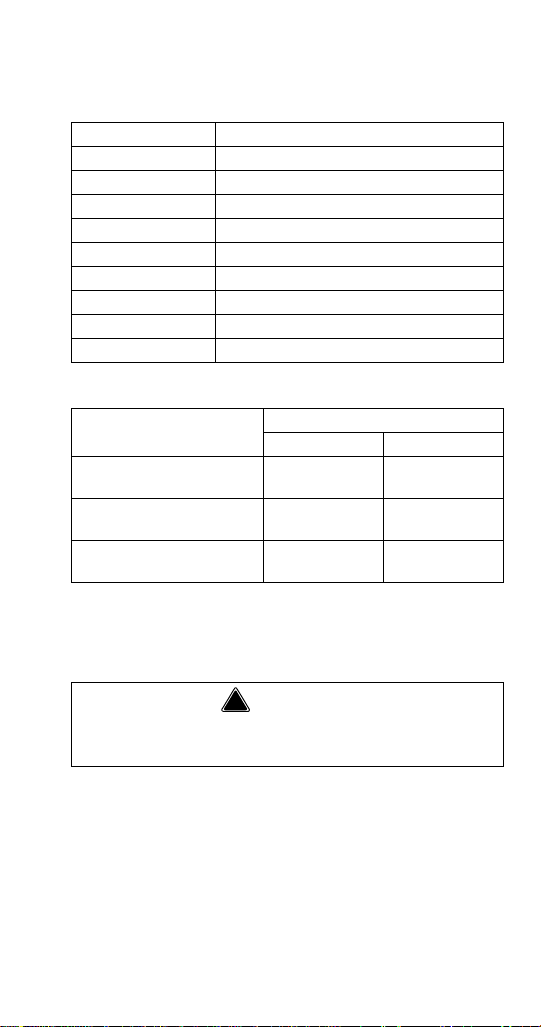

Model Heat of Rejection

RF0244 2,400 BTUH (605 Kcal/hr)

RF0266 2,400 BTUH (605 Kcal/hr)

RF0385 3,500 BTUH (882 Kcal/hr)

RF0388 3,500 BTUH (882 Kcal/hr)

RF0399 3,500 BTUH (882 Kcal/hr)

RF0300 3,500 BTUH (882 Kcal/hr)

RF0650 7,700 BTUH (1941 Kcal/hr)

RF1200 14,000 BTUH (3529 Kcal/hr)

RF2300 29,500 BTUH (7436 Kcal/hr)

RN MODELS

Series

Ice Machine

RN1000 - 50/60 Hz

RN1400 - 50 Hz

RN1400 - 60 Hz

1

The figure shown is an average.

Heat of Rejection

Air-Cooled Water-Cooled

11,300 BTU/hr

(2848 Kcal/hr)

16,000 BTU/hr

(4032 Kcal/hr)

15,500 BTU/hr

(3906 Kcal/hr)

1

1

12,800 BTU/hr

(3226 Kcal/hr)

16,400 BTU/hr

(4133 Kcal/hr)

15,500 BTU/hr

(3906 Kcal/hr)

Electrical Service

All wiring must conform to local, state and national

codes.

VOLTAGE

The maximum allowable voltage variation is ± 10% of

the rated voltage on the ice machine model/serial

number plate at compressor start-up.

Part Number 000007661 7/10 13

Page 14

FUSE/CIRCUIT BREAKER

!

Warning

A separate fuse/circuit breaker must be provided for

each ice machine. Circuit breakers must be H.A.C.R.

rated (does not apply in Canada).

The ice machine must be grounded in accordance

with national and local electrical codes.

GROUND FAULT INTERRUPTER CIRCUIT (GFIC)

A GFCI/GFI circuit protection is not recommended

with our equipment. If a GFCI/GFI is required by code

a GFCI/GFI breaker rather than outlet must be used to

avoid intermittent nuisance trips.

14 Part Number 000007661 7/10

Page 15

Maintenance

!

Caution

!

Warning

Cleaning and Sanitizing

Maintenance procedures covered in this manual are

not covered by the warranty.

Use only Manitowoc approved Ice Machine

Cleaner (part number 000000084) and Sanitizer

(part number 9405653). Do not mix Cleaner and

Sanitizer solutions together. It is a violation of

Federal law to use these solutions in a manner

inconsistent with their labeling. Read and

understand all labels printed on bottles before

use.

Wear rubber gloves and safety goggles (and/or

face shield) when handling ice machine Cleaner

or Sanitizer.

EXTERIOR CLEANING

Remove dust and dirt off exterior surfaces with mild

household dish-washing detergent and warm water.

Wipe dry with a clean, soft cloth.

Part Number 000007661 7/10 15

Page 16

RF MODELS CLEANING/SANITIZING PROCEDURES

Cleaning/Sanitizing Procedure

This procedure must be performed once every month.

• All ice must be removed from the bin

• The ice machine and bin must be disassembled

cleaned and sanitized

• The ice machine produces ice with the cleaner and

sanitizer solutions

• All ice produced during the cleaning and sanitizing

procedure must be discarded

Procedure to Clean/Sanitize

Use Ice Machine Cleaner part number 000000084.

Use Ice Machine Sanitizer part number 9405653.

Step 1 Remove front and top covers and set the

toggle switch to the OFF position.

Step 2 Remove all ice from the bin.

Step 3 Turn off the ice making water supply and drain

water from evaporator and reservoir.

Step 4 Remove the top cover from water reservoir.

Step 5 Follow the chart and premix cleaner and

water.

Amount of Water

1 gallon (4 Liters) 3 ounces (90 ml)

Amount of Cleaner

Part Number 000000084

16 Part Number 000007661 7/10

Page 17

Step 6 Fill the evaporator and reservoir with cleaning

Prop Float Up to Prevent Low

Water Level Shutdown

solution.

Step 7 Move the toggle switch to the ON position.

The ice machine will make ice with the cleaning

solution and deposit the ice in the bin. Add the

remaining cleaner/water solution as the water level in

the reservoir drops.

NOTE: Do not allow the cleaner/water level to drop

below the minimum water level. The ice machine will

discontinue the cleaning cycle if the water float switch

opens.

Step 8 After all of the cleaner/water solution has

been added turn on the ice making water supply.

Continue the freeze cycle for 10 minutes to remove

the cleaning solution from the water circuit.

Part Number 000007661 7/10 17

Page 18

Step 9 Place the toggle switch in the OFF position.

Step 10 Refer to disassembly for cleaning/sanitizing

and remove parts for hand cleaning/sanitizing.

• Hand clean all parts

• Rinse all parts with clear potable water

• Sanitize all parts - do not rinse after sanitizing

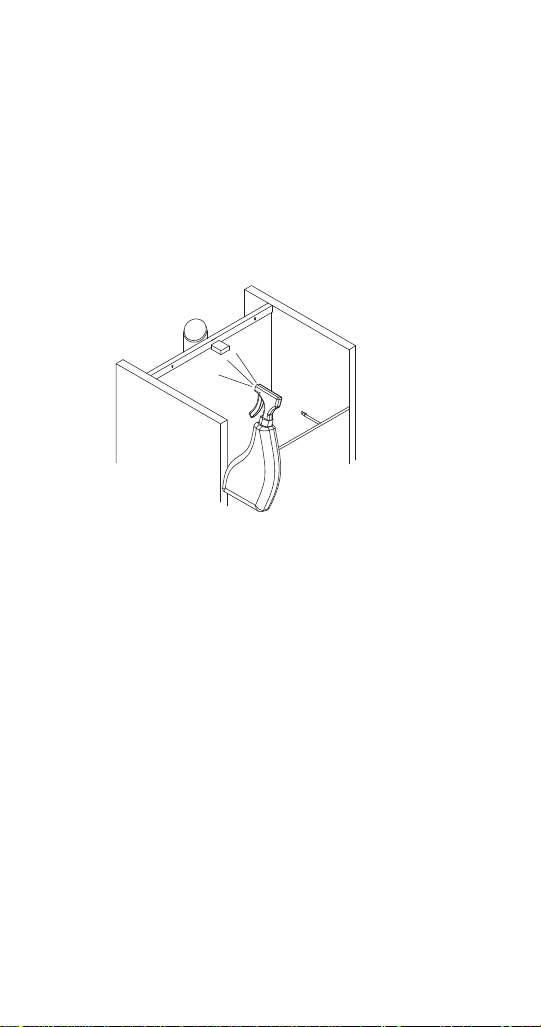

• Spray all interior bin surfaces with sanitizer (do not

rinse sanitized areas).

• Spray evaporator discharge spout

Step 11 Reassemble ice machine.

Step 12 Turn off the ice making water supply.

18 Part Number 000007661 7/10

Page 19

Step 13 Refer to chart and premix water and

sanitizer.

Amount of Water Amount of Sanitizer

1 Gallons (4 L) Water 1/2 ounce (15 ml)

Step 14 Fill the evaporator and reservoir with

sanitizer/water solution.

Step 15 Move the toggle switch to the ON position.

The ice machine will make ice with the sanitizer/water

solution and deposit the ice in the bin. Add the

remaining sanitizer/water solution when the water

level in the reservoir drops.

NOTE: Do not allow the sanitizer/water level to drop

below the minimum water level. The ice machine will

discontinue the cleaning cycle if the water float switch

opens.

Step 16 After all of the sanitizer/water solution has

been added to the reservoir, turn on the ice making

water supply.

Step 17 Continue the freeze cycle for 30 minutes and

then discard all ice produced.

Part Number 000007661 7/10 19

Page 20

Heavily Scaled Cleaning Procedure

Perform this procedure if you have some or all of these

symptoms.

• Excessive grinding, popping or squealing noises

from the evaporator

• Grinding noise from gearbox

• Ice machine trips speed sensor

NOTE: A Cleaning/Sanitizing Procedu re mu st be

performed after this procedure.

Procedure to Clean Heavily Scaled Flake Ice

Machines

Step 1 Remove front and top covers and set the

toggle switch to the OFF position.

Step 2 Remove all ice from the bin.

Step 3 Turn off the ice making water supply.

Step 4 Remove the top cover from water reservoir.

20 Part Number 000007661 7/10

Page 21

Step 5 Refer to chart below:

Premix cleaner with lukewarm water in a

non-metallic container.

Mix Cleaner and Water

Use Ice machine nickel safe

cleaner, part number

000000084 only

Cleaner Water

Model

RF0244

RF0266

RF0385

RF0388

RF0399

Water

Reservoir

Capacity

14 oz (400 ml) 9 oz (266 ml) 5 oz (148 ml)

RF0300

RF0650

RF1200 34 oz (1 L) 23 oz (680 ml) 11 oz (325 ml)

RF2300 68 oz (2 L) 46 oz (1.3 L) 22 oz (650 ml)

17 oz (500 ml) 11 oz (325 ml) 6 oz (177 ml)

Step 6 Remove all water from the evaporator and

water reservoir. Add the entire cleaner/water solution

and re-install the reservoir cover.

Leave the cleaner/water solution in the evaporator

for a minimum of 4 hours.

Step 7 Remove all cleaner/water from the evaporator

and water reservoir.

Step 8 Follow the standard cleaning and sanitizing

procedures.

Part Number 000007661 7/10 21

Page 22

RN MODELS CLEANING/SANITIZING PROCEDURE

Use Ice Machine Cleaner part number 000000084.

Use Ice Machine Sanitizer part number 94-0565-3.

Step 1 Remove all ice from the bin/dispenser.

Step 2 Remove front and top covers.

Step 3 Mix a solution of cleaner and water.

Amount of

Luke Warm Water

1 gallon (4 Liters) 4 ounces (120 ml)

Amount of Cleaner

Part Number 000000084

Step 4 To start a cleaning cycle, depress the CLEAN

switch to drain the water from the evaporator. Wait for

the LOW WATER light to energize.

Step 5 Remove cover from the cleaning cup and add

cleaner/water solution until the HI WATER light

energizes, then replace cleaning cup cover. The

machine will clean and then flush three times in

approximately twelve minutes.

Step 6 While the ice machine is in the clean cycle,

prepare for the sanitizing cycle by mixing a solution of

sanitizer and water.

Amount of

Luke Warm Water

1 gallon (4 L) Water 1/2 ounce (15 ml)

Amount of Sanitizer

Part Number 94-0565-3

Step 7 To start a sanitize cycle, depress the clean

switch to drain the water from the evaporator. Wait for

the LOW WATER light to energize.

Step 8 Remove cover from the cleaning cup and add

sanitizer/water solution until the HI WATER light

energizes, then replace cleaning cup cover. The

machine will sanitize and then flush three times in

approximately twelve minutes.

22 Part Number 000007661 7/10

Page 23

Step 9 Press the OFF switch, then unscrew the ice

chute connector.

Step 10 Using disposable food service grade gloves

insert one dry sponge into the transport tube going to

the evaporator (NOT the tube going to the bin), then

insert one sponge soaked in the sanitizer water

solution. With the pusher tube supplied with the

sponge kit, push sponges all the way down the

transport tube 16 inches (41 cm) or the length of the

pusher tube.

Step 11 Reconnect chute connector and press the

ON switch. Allow the ice machine to run for 10

minutes, then press the OFF switch. Catch and

remove all sponges and ice from the bin/dispenser.

Step 12 Clean and sanitize the bin/dispenser:

• Disconnect power to the dispenser to prevent

injury.

• Use the cleaner and sanitizer ratios from the

charts on the previous page.

• Heavy accumulations of scale will require removal

of components for cleaning and sanitizing.

• Rinse parts with clear water after cleaning - do not

rinse parts after sanitizing.

Step 13 Spray all interior bin/dispenser surfaces with

sanitizer (do not rinse sanitized areas).

Step 14 Place rocker switch in the ON position and

reinstall all removed panels.

1. Lift out ice damper.

2. Remove ice deflector.

A. Remove the two thumbscrews.

Part Number 000007661 7/10 23

Page 24

CLEANING THE CONDENSER

!

Warning

!

Warning

Disconnect electric power to the ice machine at the

electric service switch before cleaning the

condenser. The condenser fins are sharp. Use care

when cleaning them.

Air-Cooled Condenser

Clean the condenser at least every six months. Follow

the steps below.

1. Some models have a washable aluminum filter.

Clean the filter with a mild soap and water

solution.

2. Shine a flashlight through the condenser to check

for dirt between the fins. Blow compressed air

through the condenser fins from the inside or use

a commercial condenser coil cleaner. Follow the

directions and cautions supplied with the cleaner.

3. Straighten any bent condenser fins with a fin

comb.

4. Carefully wipe off the fan blades and motor with a

soft cloth. Do not bend the fan blades. If the fan

blades are excessively dirty, wash with warm,

soapy water and rinse thoroughly.

If you are cleaning the condenser fan blades with

water, cover the fan motor to prevent water damage.

24 Part Number 000007661 7/10

Page 25

Removal from Service/Winterization

!

Caution

If water is allowed to remain in the ice machine in

freezing temperatures, severe damage to some

components could result. Damage of this nature is

not covered by the warranty.

Follow the procedure below.

1. Disconnect the electric power at the circuit

breaker or the electric service switch.

2. Turn off the water supply.

3. Disconnect and drain the incoming ice-making

water line at the rear of the ice machine.

4. Disconnect drain tubing and drain water into

container and discard.

5. Make sure water is not trapped in any of the water

or drain lines.

6. Water cooled - Use compressed air to remove all

water from the condenser.

Part Number 000007661 7/10 25

Page 26

26 Part Number 000007661 7/10

This Page Intentionally Left Blan k

Page 27

Operation

Ice Making Sequence of Operation

NOTE: Flake ice machines use an auger to remove

ice from the evaporator. Occasional noises (creaks,

groans, squeaks, or pops) are a normal part of the ice

making process.

SELF-CONTAINED AIR-COOLED RF0244/RF0266/RF0385/RF0388/RF0399

When the toggle switch is placed in the “ON” position

the following controls must be in the closed position

before the ice machine will start:

A. Bin Thermostat

B. Low Evaporator Temperature Thermostat

C. Low Water Level Switch

Placing the toggle switch in the ON position starts the

gear motor and refrigeration system. The float valve

controls the water inlet valve and water level. The

freeze cycle ends when ice contacts the bin

thermostat. The ice machine w ill restart when ice no

longer contacts the bin thermostat.

SELF-CONTAINED AIR-COOLED RF0300

When the toggle switch is placed in the “ON” position

the following controls must be in the closed position

before the ice machine will start:

A. Bin Thermostat

B. Low Evaporator Temperature Thermostat

C. Ice Chute Safety Switch

D. Low Water Level Switch

Placing the toggle switch in the ON position starts the

gear motor and a 10 minute compressor time delay.

The compressor starts and the float valve controls the

water inlet valve and water level. The freeze cycle

ends when ice contacts the bin thermostat. The ice

machine remains off until ice no longer contacts the

bin thermostat.

Part Number 000007661 7/10 27

Page 28

SELF-CONTAINED AIR-COOLED RF0650/RF1200/RF2300

When the toggle switch is placed in the ON position

the following controls must be in the closed position

before the ice machine will start:

A. Bin Thermostat

B. High Pressure Cut-out Switch

C. Ice Chute Safety Switch

D. Low Pressure Switch

E. Low Water Level Switch

Placing the toggle switch in the ON position starts the

gear motor. After the rotation speed sensor verifies

10 minutes of correct rotation the time delay ends and

the compressor starts.The ice machine will continue to

make ice until ice contacts the bin thermostat. The ice

machine remains off until ice no longer contacts the

bin thermostat.

28 Part Number 000007661 7/10

Page 29

QUIETQUBE REMOTE AIR-COOLED MODELS WITH REMOTE CONDENSING UNITS RF1200C/RF2300C

Part Number 000007661 7/10 29

Page 30

SELF-CONTAINED AIR-COOLED & WATER-COOLED RN0400

NOTE: Ice machines use an auger to remove ice from

the evaporator. Occasional noises (creaks, groans,

squeaks, or pops) are a normal part of the ice making

process.

Operation

The ice machine will not start until:

A. The compressor rocker switch is moved to

“ON”.

B. Ice does not contact the bin thermostat bulb.

C. The water reservoir is full of water.

With power supplied and the compressor rocker

switch in the ON position, the gear motor and

refrigeration system start. The float valve controls the

water inlet valve and water level. The freeze cycle

ends when ice contacts the bin thermostat. A

20 minute delay period initiates. The ice machine will

restart when ice no longer contacts the bin thermostat

and the 20 minute delay period expires.

30 Part Number 000007661 7/10

Page 31

SELF-CONTAINED AIR-COOLED & WATER-COOLED RN1000/RN1400

NOTE: Ice machines use an auger to remove ice from

the evaporator. Occasional noises (creaks, groans,

squeaks, or pops) are a normal part of the ice making

process.

Operation

The ice machine will not start until:

A. The rocker switch is moved to ON.

B. The transport tube shuttle switch is closed.

C. The water reservoir is full of water.

Placing the toggle switch in the ON position starts the

gear motor and refrigeration system. The water level

sensor controls the water inlet valve and water level.

The freeze cycle ends when ice contact opens the

transport tube switch. A 60 minute time delay period

initiates. The ice machine will restart when the ice

transport tube switch closes and the 60 minute time

delay period expires.

Flush Cycle

The ice machine will automatically flush the

evaporator.

The refrigeration system will shut down and the gear

motor will continue to run. After the flush is complete,

the machine will refill and start the refrigeration system

without a time delay.

Part Number 000007661 7/10 31

Page 32

QUIETQUBE REMOTE AIR-COOLED MODELS WITH REMOTE CONDENSING UNITS RN1000C/RN1200C

NOTE: Ice machines use an auger to remove ice from

the evaporator. Occasional noises (creaks, groans,

squeaks, or pops) are a normal part of the ice making

process.

Operation

The ice machine will not start until:

A. The rocker switch is moved to ON.

B. The transport tube switch is closed.

C. The water reservoir is full of water.

Placing the toggle switch in the ON position starts the

gear motor and energizes the liquid line solenoid

valve. The refrigerant pressure at the condensing unit

increases and the low pressure switch closes and

starts the refrigeration system. The water level sensor

controls the water inlet valve and water level. The

freeze cycle ends when ice contact opens the

transport tube switch. The liquid line solenoid valve

closes and the refrigerant pressure at the condensing

unit drops. The low pressure switch opens and turns

off the refrigeration system. A 60 minute time delay

period initiates. The ice machine will restart when the

ice transport tube switch closes and the 60 minute

time delay period expires.

32 Part Number 000007661 7/10

Page 33

Ice Production/Quality Check

QUALITY CHECK

Ice quality varies with ambient and water

temperatures, and is measured by the amount of

water in the ice. Generally speaking, higher incoming

water temperature results in lower ice quality. Lower

water temperature results in higher ice quality.

ICE PRODUCTION CHECK

NOTE: Ice production checks that are within 10% of

the charted capacity are considered normal due to

variances in air and water temperatures. Actual

temperatures will seldom match the chart exactly.

1. Run the ice machine a minimum of 10 minutes to

allow the system to stabilize.

2. Catch the ice in a non-perforated container for

7 minutes and 12 seconds or for more accuracy

14 minutes and 24 seconds.

3. Weigh the container and ice, then deduct the

weight of the container.

4. Convert ounces to pounds.

5. Example: 3 lbs. 12 oz. converts to 3.75 lbs.

6. (12 oz. ÷ 16 oz. =.75 lb.)

7. Determine the 24-hour ice production capacity.

A. 7 minutes 12 seconds = Multiply the total ice

weight by 200.

B. 14 minutes 24 seconds = Multiply the total ice

weight by 100.

Part Number 000007661 7/10 33

Page 34

Thermostat Settings

1

2

3

4

5

6

7

1

2

3

4

5

6

7

Bin Thermostat

Small Numbers = Less ice in bin

Large Numbers = More ice in bin

Start at Chart Setting, then adjust as

required

Evaporator Low Temperature

Safety Thermostat

Refer to chart for setting

Incorrect settings will cause ice machine to

shut off prematurely

RF MODELS

Bin Thermostat:

The bin thermostat sensing bulb is located in the ice

chute on modular models and in the bin thermostat

holder on the right side of the bin on self storage

models. The bin thermostat turns the ice machine on

and off as the level of ice in the bin changes. Use the

initial setting from the chart and adjust as required.

Evaporator Low Temperature Safety Thermostat:

The evaporator low temperature safety thermostat

protects the ice machine if the evaporator temperature

is too cold. Refer to chart for correct setting.

34 Part Number 000007661 7/10

Page 35

Thermostat Setting Chart

Model

RF0244 5 5

RF0266 5 5

RF0388 5 7

RF0399 5 7

RF0300 4 7

RF0650 4 N/A

RF1200 5 N/A

RF2300 5 N/A

Bin Thermostat

Setting

Evaporator

Thermostat Setting

Part Number 000007661 7/10 35

Page 36

36 Part Number 000007661 7/10

Page 37

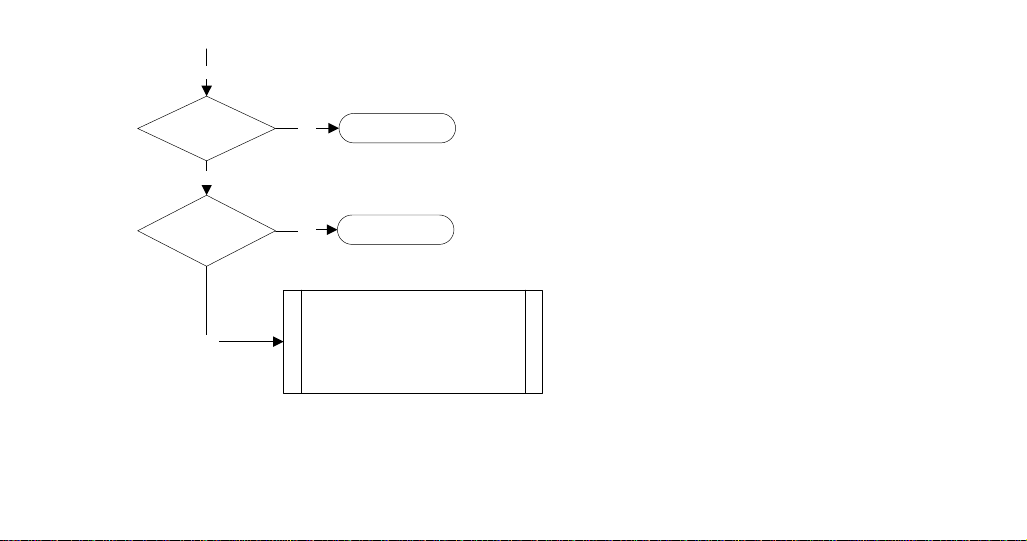

Troubleshooting

Electrical Flowcharts

Diagnostic troubleshooting for the ice machine

involves following flowcharts that are dependant on

symptoms of the failed machine.

Follow the flowcharts for the failure symptom and

model you are working on.

NOTE: Refer to the sequence of operation to

determine where in the sequence the ice machine has

failed. An example would be an ice machine that

energizes the gear motor, but the compressor does

not energize. Following the electrical flowchart will

quickly and easily eliminate non issues.

Part Number 000007661 7/10 37

Page 38

38 Part Number 000007661 7/10

Power Supplied to Ice

Machine?

Toggle Switch In ON

Position?

Move Switch To ON Position

Plug In Ice Machine, Reset BreakerNO

YES

NO

YES

Electrical Flowchar t – RF0244/RF0266/5)RF0388/RF0399 Air & Water

Switch Illuminated?

NO

YES

Replace Switch

RF0244/RF0266RF0385//RF00388/RF0399 AIR & WATER

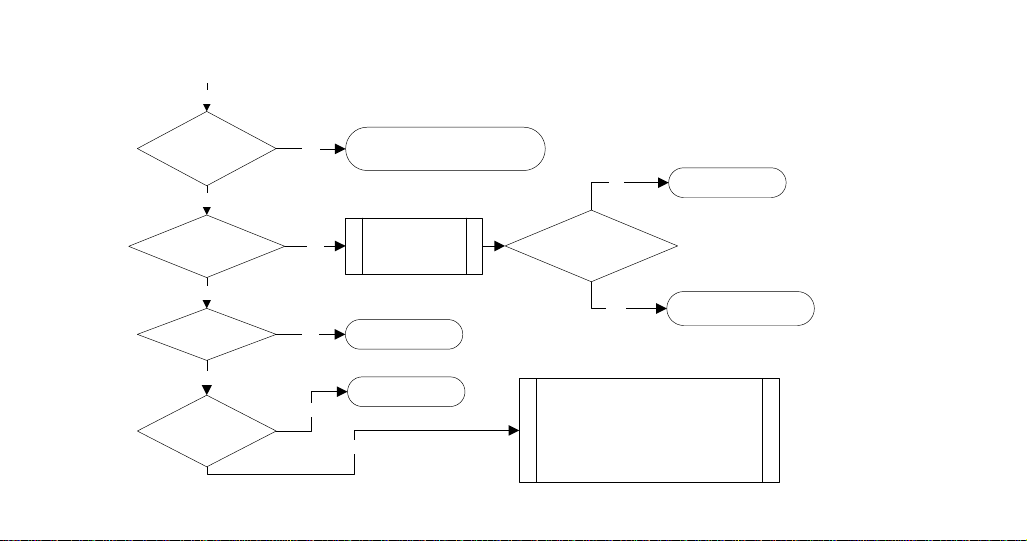

Page 39

Part Number 000007661 7/10 39

YES

Bin Thermostat

Closed?

NO

Replace Thermostat

Ice Contacting

Thermostat?

Remove Ice - Allow

To Warm And Retest

Adjusting Closes

Thermostat?

Verify New Setting Cycles

Machine On/Off

Yes

No No

Yes

Evaporator Safety

Thermostat Closed?

NO

Evaporator Cold?

Replace Thermostat

Allow Evaporator To

Warm And Retest

Adjusting Closes

Thermostat?

Verify New Setting Cycles

Machine On/Off

Yes

No

No

Yes

YES

YES

Page 40

40 Part Number 000007661 7/10

Low Water Level

Switch Closed?

YES

YES

NO

Reservoir Full Of

Water?

NO

Restore Water Supply / Replace Water Inlet Valve

Power To Water

Inlet Valve?

Yes

Water Level

Switch Closed?

No

No

Repair WiringYes

YES

Replace Switch or Float Assembly

Replace Switch or Float Assembly

Page 41

Part Number 000007661 7/10 41

Wiring From

Gearmotor Intact?

Line Voltage To

Compressor Relay

Coil?

Gear Motor Runs? NO

YES

NO

YES

Line Voltage To

Gear motor?

Repair WiringNo

Remove Auger

From Evaporator

Ice In Evaporator?

Gear Motor Runs?

Replace Gear Motor

Yes

No

Rebuild

Evaporator

Thaw Evaporator

Yes

Yes

No

Replace Gear Motor

Repair Wiring

Yes

No

Page 42

42 Part Number 000007661 7/10

Relay Closed?

Line Voltage To

Compressor?

YES

YES

NO

YES

NO

Verify:

Compressor Overload is Closed

Start Components Function

Fan Cycling Control Functions

Condenser Fan Motor Functions

Water cooled only:

Water Regulating Valve Functions

Repair Wiring

Replace Relay

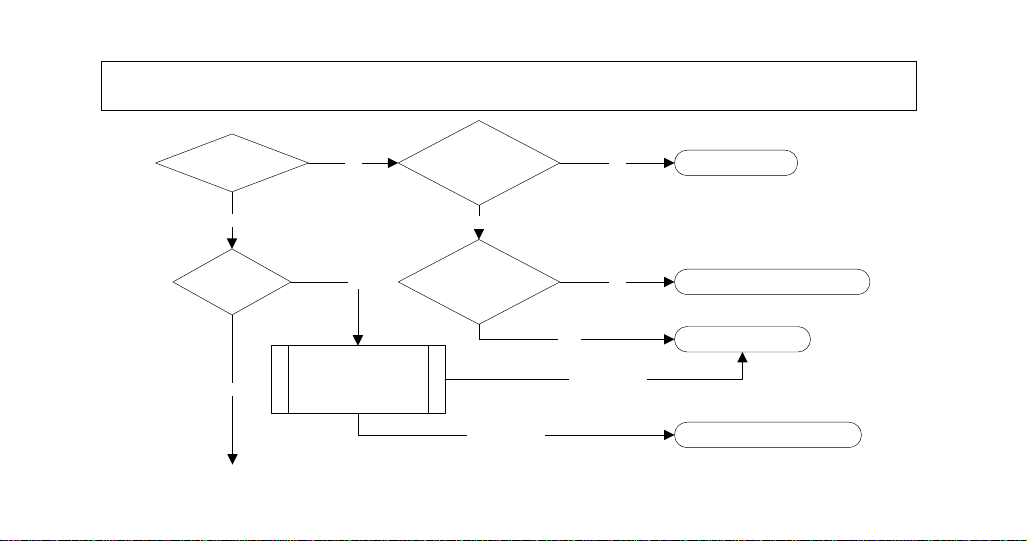

Page 43

Part Number 000007661 7/10 43

Power Supplied to Ice

Machine?

Toggle Switch In ON

Position?

Move Switch To ON Position

Plug In Ice Machine, Reset Breaker

NO

YES

NO

YES

Electrical Flowchart – RF0300 Air & Water

Switch Illuminated?

NO

YES

Replace Switch

RF0300 AIR & WATER

Page 44

44 Part Number 000007661 7/10

Bin Thermostat

Closed?

NO

Replace Thermostat

YES

Evaporator Safety

Thermostat Closed?

NO

Chute Switch

Closed?

NO

YES

Ice Contacting

Thermostat?

Remove Ice - Allow

To Warm And Retest

Adjusting Closes

Thermostat?

Verify New Setting Cycles

Machine On/Off

Yes

No No

Yes

Evaporator Cold?

Replace Thermostat

Allow Evaporator To

Warm And Retest

Adjusting Closes

Thermostat?

Verify New Setting Cycles

Machine On/Off

Yes

No

No

Yes

Adjust Or Replace

Actuator

Ice Contacting

Actuator?

Remove Ice And

Retest

Actuator Functions?

Replace Switch

Yes

No No

Yes

Yes

Yes

Page 45

Part Number 000007661 7/10 45

Low Water Level

Switch Closed?

YES

YES

NO

Reservoir Full Of

Water?

NO

Restore Water Supply / Replace Water Inlet Valve

Replace Switch or Float Assembly

Power To Water

Inlet Valve?

Yes

Water Level

Switch Closed?

No

No

Repair WiringYes

YES

Replace Switch or Float Assembly

Page 46

46 Part Number 000007661 7/10

Gear Motor Runs? NO

YES

Line Voltage To

Gear motor?

Repair WiringNo

Disconnect

Evaporator From

Gear Motor

Ice In Evaporator?

Gear Motor Runs?

Replace Gear Motor

Yes

No

Rebuild

Or

Replace Evaporator

Thaw Evaporator

Yes

Yes

No

Yes

Gear Motor

Centrifugal Switch

Closed?

Line Voltage To

Compressor Time

Delay?

NO

Repair Wiring

Replace Gear Motor

Yes

No

YES

Page 47

Part Number 000007661 7/10 47

Contactor Closed?

Line Voltage To

Compressor?

YES

YES

NO

YES

NO

Verify:

Compressor Overload is Closed

Start Components Function

Fan Cycling Control Functions

Condenser Fan Motor Functions

Water cooled only:

Water Regulating Valve Functions

Repair Wiring

Replace Contactor

Line Voltage To

Compressor Contactor

Coil?

NO

Repair Wiring

Replace Time Delay Relay

No

10 Minute Time

Delay Expired?

NO

Wait 10 Minutes - Do Not Install

Compressor Time Delay Jumper

Yes

Power To Contactor Coil?

Yes

Install

Compressor Time

Delay Jumper

Yes

Page 48

48 Part Number 000007661 7/10

Power Supplied to Ice

Machine?

Toggle Switch In ON

Position?

Move Switch To ON Position

Plug In Ice Machine, Reset Breaker

NO

YES

NO

YES

Electrical Flowchart - RF0650/RF1200 Air & Water

Switch Illuminated?

NO

YES

Replace Switch

RF0650/RF1200 AIR & WATER

Page 49

Part Number 000007661 7/10 49

Bin Thermostat

Closed?

NO

Replace Thermostat

YES

Low Pressure

Control Closed?

NO

YES

Ice Contacting

Thermostat?

Remove Ice - Allow

To Warm And Retest

Adjusting Closes

Thermostat?

Verify New Setting Cycles

Machine On/Off

Yes

No No

Yes

Evaporator Cold?

Replace LPCO

Allow Evaporator To

Warm And Retest

Refrigerant Pressure

Below Cut-out?

Repair Refrigerant Leak,

Evacuate, Recharge

Yes

No

No

Yes

Yes

High Pressure

Control Closed?

NO

YES

Resets?

Replace HPCO

Clean Condenser,

Check Fan Motor

Check Fan Cycle Control

Refrigerant Pressure

Above Cut-out?

Clean Condenser,

Check Fan Motor,

Check FCC & Refrigeration System

Resets

&

Trips

No

No

Yes

Page 50

50 Part Number 000007661 7/10

Low Water Level

Switch Closed?

YES

NO

Reservoir Full Of

Water?

NO

Restore Water Supply / Replace Water Inlet Valve

Replace Switch or Float Assembly

Power To Water

Inlet Valve?

Yes

Water Level

Switch Closed?

No No

Repair WiringYes

YES

Replace Switch or Float Assembly

Chute Switch

Closed?

NO

Adjust Or Replace

Actuator

Ice Contacting

Actuator?

Remove Ice And

Retest

Actuator Functions?

Replace Switch

Yes

No No

Yes

Yes

YES

Page 51

Part Number 000007661 7/10 51

Gear Motor Runs? NO

YES

Line Voltage To

Gear motor?

Repair Wiring

No

Disconnect

Evaporator From

Gear Motor

Ice In Evaporator?

Gear Motor Runs?

Replace Gear Motor

Yes

No

Rebuild

Or

Replace Evaporator

Thaw Evaporator

Yes

Yes

No

Yes

YES

10 Minute Time

Delay Expired?

NO

Wait 10 Minutes - Do Not Install

Compressor Time Delay Jumper

Page 52

52 Part Number 000007661 7/10

Contactor Closed?

Line Voltage To

Compressor?

YES

YES

NO

YES

NO

Verify:

Compressor Overload is Closed

Start Components Function

Fan Cycling Control Functions

Condenser Fan Motor Functions

Water cooled only:

Water Regulating Valve Functions

Repair Wiring

Replace Contactor

Line Voltage To

Compressor Contactor

Coil?

NO

Repair Wiring

Replace Rotation Sensor/Time Delay Relay

No

Yes

Power To Contactor Coil?

Yes

Install

Compressor Time

Delay Jumper

Page 53

Part Number 000007661 7/10 53

Power Supplied

to Ice Machine?

Toggle Switch In

ON Position?

Move Switch To ON Position

Restore Power, Reset BreakerNO

NO

YES

Electrical Flowchart – RF2300 Air & Water

Switch

Illuminated?

NO

YES

Replace Switch

Immediately

Trips?

Yes

Ohm Compressor

Crankcase Heater

And Toggle Switch

Yes

No

Toggle Switch In

Off Position?

Isolate And Ohm Each

Component - Then Each

Wire If Required

Yes

No

Trips

RF-2300 AIR & WATER

Page 54

54 Part Number 000007661 7/10

Bin Thermostat

Closed?

NO

Replace Thermostat

YES

YES

Ice Contacting

Thermostat?

Remove Ice - Allow

To Warm And Retest

Adjusting Closes

Thermostat?

Verify New Setting Cycles

Machine On/Off

Yes

No No

Yes

Yes

High Pressure

Control Closed?

NO Resets?

Replace HPCO

Clean Condenser,

Check Fan Motor

Check Fan Cycle Control

Refrigerant Pressure

Above Cut-out?

Clean Condenser,

Check Fan Motor,

Check FCC & Refrigeration System

Resets

&

Trips

No

No

Yes

Left Side Chute

Switch Closed?

NO

Adjust Or Replace

Actuator

Ice Contacting

Actuator?

Remove Ice And

Retest

Actuator Functions?

Replace Switch

Yes

No No

Yes

Yes

Page 55

Part Number 000007661 7/10 55

Low Pressure

Control Closed?

NO

Evaporator Cold?

Replace LPCO

Allow Evaporator To

Warm And Retest

Refrigerant Pressure

Below Cut-out?

Repair Refrigerant Leak,

Evacuate, Recharge

Yes

No

No

Yes

Right Side Chute

Switch Closed?

NO

Adjust Or Replace

Actuator

Ice Contacting

Actuator?

Remove Ice And

Retest

Actuator Functions?

Replace Switch

Yes

No No

Yes

YES

YES

Reservoir Full Of

Water?

NO

Restore Water Supply / Replace Water Inlet Valve

Power To Water

Inlet Valve?

Yes

Water Level

Switch Closed?

No No

Repair WiringYes

Replace Switch or Float Assembly

Yes

Page 56

56 Part Number 000007661 7/10

Gear Motor Runs? NO

YES

Line Voltage To

Gear motor?

Repair WiringNo

Disconnect

Evaporator From

Gear Motor

Ice In Evaporator?

Gear Motor Runs?

Replace Gear Motor

Yes

No

Rebuild

Or

Replace Evaporator

Thaw Evaporator

Yes

Yes

No

YES

10 Minute Time

Delay Expired?

NO

Wait 10 Minutes - Do Not Install

Compressor Time Delay Jumper

Low Water Level

Switch Closed?

NO

Replace Switch or Float Assembly

YES

Yes

Page 57

Part Number 000007661 7/10 57

YES

NO

Replace Relay

Line Voltage To

Left Delay Relay Coil?

NO

Repair Wiring

Replace Left Rotation

Sensor/Time Delay

No

Power To Left Time

Delay Relay Coil?

Install

Compressor Time

Delay Jumper On

Left Evaporator

Left Delay Relay

Contacts Closed?

Left Delay Relay

Contacts Closed?

Yes

No Yes

YES

NO

Replace Relay

Line Voltage To

Right Delay Relay Coil?

NO

Repair Wiring

Replace Right Rotation

Sensor/Time Delay

No

Power To Right Time

Delay Relay Coil?

Install

Compressor Time

Delay Jumper On

Right Evaporator

Right Delay Relay

Contacts Closed?

Right Delay Relay

Contacts Closed?

Yes

No Yes

YES

YES

YES

Page 58

58 Part Number 000007661 7/10

Contactor Closed?

Line Voltage To

Compressor?

YES

YES

NO

YES

NO

Verify:

Compressor Overload is Closed

Start Components Function

Fan Cycling Control Functions

Condenser Fan Motor Functions

Water cooled only:

Water Regulating Valve Functions

Repair Wiring

Replace Contactor

Line Voltage To

Compressor Contactor

Coil?

NO Repair Wiring

Yes

Page 59

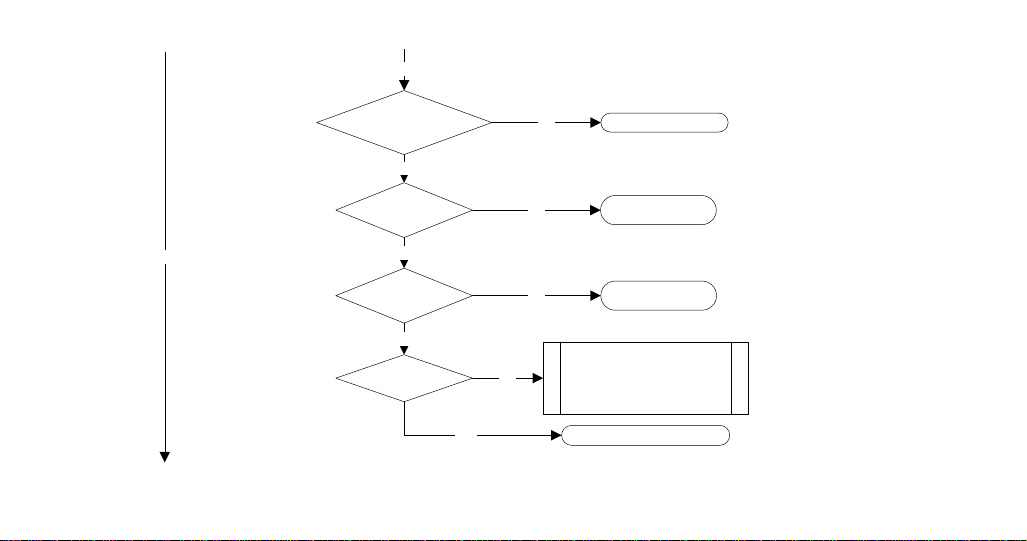

Part Number 000007661 7/10 59

Page 60

60 Part Number 000007661 7/10

YES

Electrical Flowchart – RN100051 Air & Water

YES

Control Board

PWR Light On?

Replace Control Board

NO

Power Supplied to Ice

Machine Control board?

Turn On Switch

NO

YES

NO

Control Board CPU

Light Flashing?

Rocker Switch in ON

position?

NO

Plug In Ice Machine, Reset Breaker

YES

Remove & Restore Line

Voltage, Then Depress

Reset Button On Control

Board

Power Light Off

Test Run & Verify OperationPower Light On

RN1000/RN1400 AIR & WATER

Page 61

Part Number 000007661 7/10 61

YES

Low Bin Light On?

YES

Ice Holding

Shuttle Open?

Check Wiring, Repair Or Replace

Repair Or Replace Shuttle

Yes

Time Delay Light OFF?

Time Delay

Period Expired?

Wait For Delay To ExpireNO

Clear Ice

Shuttle in up

position?

NO

NO

YES

YES

NO

NO

YES

Light On Sensor

Illuminated?

NO

Depress Reset Button On Control Board

Replace Control Board If Required

YES

Page 62

62 Part Number 000007661 7/10

Purge Light Off? NO

Purge Rocker Switch

In Off Position?

YES

NO

YES

YES

Move Switch To Off Position

Clear Drain Or Replace Drain Solenoid

YES

No

Water Drains From

Evaporator?

Replace Control Board

Level Ice Machine To Allow Complete Drainage

Line Voltage At

Drain Solenoid?

Ice Machine Level?

Remove & Restore Line

Voltage, Then Depress

Reset Button On Control

Board

No Power @ Solenoid

YES

Power @ Solenoid

NO

Test Run To Verify OperationYES

NO

Page 63

Part Number 000007661 7/10 63

Drain Clog

Light Off?

NO Water In Drain Trough? YES

YES

YES

Replace Sensor

High Pressure

Light Off?

Clean and Dry

Drain Sensor

Light On

Light Off

Clear Drain

Test Run To Verify Operation

NO

YES

Verify:

Clearances & Ambient Are OK

Filter & Condenser Are Clean

Condenser Fan Motor Functions

Replace High Pressure Cut Out

Water cooled Models:

Water Regulating Valve Functions

NO

Press Control Board Reset

Button To Clear Error

YES

Disconnect

Sensor From

Control Board

Replace Control BoardLight On

Light Off

Page 64

64 Part Number 000007661 7/10

YES

HI AMPS Light Off?

Yes

Reset Breaker - Press Control Board

Reset Button To Clear Error

Circuit Breaker On

Control Box Tripped?

YES

NO

Line Voltage To

Gear Motor?

NO

NO

Press Control

Board Reset Button To

Clear Error

Replace Control

Board

NO

Gear Motor Runs?

YES

Clean Ice Machine - Install Water Filter - Increase

Cleaning Frequency -Verify Shuttle Shuts Off Ice

Machine – Test Run

Check Wires & Connections

Replace Gear Motor

NO

YES

Page 65

Part Number 000007661 7/10 65

Low Water

Light Off?

NO

YES

Yes

Sensor Wires

Connected?

Reservoir Full

Of Water?

Connect Sensor Wires

Clean and

Dry Water

Level Probes

Water is Supplied?

Voltage @ Water

Inlet Valve?

NO

YES

YES

NO

Restore Water SupplyNO

YES

Replace Water Inlet ValveYESNO

Voltage @ Water

Inlet Valve?

YES

Reservoir Full

Of Water?

YES NO

Replace Control BoardNO

Press Control Board Reset Button

To Clear Error

YES

Page 66

66 Part Number 000007661 7/10

High Water

Light Off?

NO

YES

Yes

Control Board

Sending Line Voltage To

Water Valve?

Press Control Board Reset Button

Replace Control Board

Clean, Dry &

Reinsert Water

Level Probes

Voltage @ Water

Inlet Valve?

YES

NO

Replace Water Inlet ValveNO

YES

Replace Sensor – Control Board if RequiredWater Flows

Water Flow Stops Press Control Board Reset Button To Clear Error

Gear Motor

Running?

YES

See Step

HI AMPS LIGHT OFF

NO

Page 67

Part Number 000007661 7/10 67

Compressor

Running?

NO

YES

Yes

Ice Has Excessive

Water Content?

YES

NO

Verify Water Inlet Valve Closes 100% & Water Level Probe Functions

Replace Control BoardNO

YES

Line Voltage At

Compressor?

YES

NO

Verify:

Compressor Overload is Closed

Start Components Function

Compressor Windings Are OK

Repair Wiring

Compressor

Running?

NO

Test Run To Verify Operation

YES

Line Voltage @

Control Board Compressor

Terminals

Page 68

68 Part Number 000007661 7/10

YES

YES

Control Board

PWR Light On?

Replace Control Board

NO

Power Supplied to Ice

Machine Control board?

Turn On Switch

NO

YES

NO

Control Board CPU

Light Flashing?

Rocker Switch in ON

position?

NO

Plug In Ice Machine, Reset Breaker

YES

Remove & Restore Line

Voltage, Then Depress

Reset Button On Control

Board

Power Light Off

Test Run & Verify OperationPower Light On

Electrical Flowcart – RN1000&51& QuietQube Remote

RN1000C/RN1200C QUIETQUBE REMOTE CONDENSING

Page 69

Part Number 000007661 7/10 69

YES

Low Bin Light On?

YES

Ice Holding

Shuttle Open?

Check Wiring, Repair Or Replace

Repair Or Replace Shuttle

Yes

Time Delay Light OFF?

Time Delay

Period Expired?

Wait For Delay To ExpireNO

Clear Ice

Shuttle in up

position?

NO

NO

YES

YES

NO

NO

YES

Light On Sensor

Illuminated?

NO

Depress Reset Button On Control Board

Replace Control Board If Required

YES

Page 70

70 Part Number 000007661 7/10

Purge Light Off? NO

Purge Rocker Switch

In Off Position?

YES

NO

YES

YES

Move Switch To Off Position

Clear Drain Or Replace Drain Solenoid

YES

No

Water Drains From

Evaporator?

Replace Control Board

Level Ice Machine To Allow Complete Drainage

Line Voltage At

Drain Solenoid?

Ice Machine Level?

Remove & Restore Line

Voltage, Then Depress

Reset Button On Control

Board

No Power @ Solenoid

YES

Power @ Solenoid

NO

Test Run To Verify OperationYES

NO

Page 71

Part Number 000007661 7/10 71

Drain Clog

Light Off?

NO Water In Drain Trough? YES

YES

YES

Replace Sensor

High Pressure

Light Off?

Clean and Dry

Drain Sensor

Light On

Light Off

Clear Drain

Test Run To Verify Operation

NO

YES

Verify:

Clearances & Ambient Are OK

Condenser Is Clean

Condenser Fan Motor Functions

Replace High Pressure Cut Out

NO

Press Control Board Reset

Button To Clear Error

YES

Disconnect

Sensor From

Control Board

Replace Control BoardLight On

Light Off

Page 72

72 Part Number 000007661 7/10

YES

HI AMPS Light Off?

YES

Reset Breaker - Press Control Board

Reset Button To Clear Error

Circuit Breaker On

Control Box Tripped?

YES

NO

Line Voltage To

Gear Motor?

NO

NO

Press Control

Board Reset Button To

Clear Error

Replace Control

Board

NO

Gear Motor Runs?

YES

Clean Ice Machine - Install Water Filter - Increase

Cleaning Frequency -Verify Shuttle Shuts Off Ice

Machine – Test Run

Check Wires & Connections

Replace Gear Motor

NO

YES

Page 73

Part Number 000007661 7/10 73

Low Water

Light Off?

NO

YES

YES

Sensor Wires

Connected?

Reservoir Full

Of Water?

Connect Sensor Wires

Clean and

Dry Water

Level Probes

Water is Supplied?

Voltage @ Water

Inlet Valve?

NO

YES

YES

NO

Restore Water SupplyNO

YES

Replace Water Inlet ValveYESNO

Voltage @ Water

Inlet Valve?

YES

Reservoir Full

Of Water?

YES NO

Replace Control BoardNO

Press Control Board Reset Button

To Clear Error

YES

Page 74

74 Part Number 000007661 7/10

High Water

Light Off?

NO

YES

YES

Control Board

Sending Line Voltage To

Water Valve?

Press Control Board Reset Button

Replace Control Board

Clean, Dry &

Reinsert Water

Level Probes

Voltage @ Water

Inlet Valve?

YES

NO

Replace Water Inlet ValveNO

YES

Replace Sensor – Control Board if RequiredWater Flows

Water Flow Stops Press Control Board Reset Button To Clear Error

Gear Motor

Running?

YES

See Step

HI AMPS LIGHT OFF

NO

Page 75

Part Number 000007661 7/10 75

Compressor

Running?

NO

YES

YES

Replace Control BoardNO

YES

Line Voltage At

Liquid Line Solenoid

Valve?

YES

NO

Verify:

Refrigerant Pressure is Higher Than LPCO Cut-in

Both Shut-off Valves are Open

Repair/Replace Liquid Line Solenoid

Locate and Repair Refrige rant Leak

Replace LPCO Switch

Repair Wiring

Low Pressure

Control Closed?

NO

YES

Line Voltage @

Control Board Compressor

Terminals

Page 76

76 Part Number 000007661 7/10

YES

YES

Repair WiringNO

YES

Line Voltage At

Compressor?

YES

NO

Verify:

Compressor Overload is Closed

Start Components Function

Compressor Windings Are OK

Repair Wiring

Compressor

Running?

NO

Test Run To Verify OperationYES

Contactor Coil Has Line

Voltage?

Contactor Closed?

YES

Replace ContactorNO

Page 77

Part Number 000007661 7/10 77

Ice Has Excessive

Water Content?

YES

NO

Verify Water Inlet Valve Closes 100% & Water Level Probe Functions

Test Run To Verify Operation

ELECTRILOWCHART - /

Page 78

78 Part Number 000007661 7/10

Power Supplied

to Ice Machine?

Toggle Switch In

ON Position?

Move Switch To ON Position

Restore Power, Reset BreakerNO

NO

YES

Electrical Flowchart - RF-1200C QuietQube

Switch

Illuminated?

NO

YES

Replace Switch

Immediately

Trips?

YES

YES

NO

Toggle Switch In

Off Position?

Isolate And Ohm Each

Component - Then Each

Wire If Required

NO

TRIPS

YES

Isolate And Ohm Switch

Check Wiring From Panel

Test Run

YES

RF1200C QUIETQUBE

Page 79

Part Number 000007661 7/10 79

Bin Thermostat

Closed?

NO

Replace Thermostat

YES

Ice Contacting

Thermostat?

Remove Ice - Allow

To Warm And Retest

Adjusting Closes

Thermostat?

Verify New Setting Cycles

Machine On/Off

YES

NO NO

YES

YES

Chute Switch

Closed?

NO

Adjust Or Replace

Actuator

Ice Contacting

Actuator?

Remove Ice And

Retest

Actuator Functions?

Replace SwitchYES

NO NO

YES

Yes

YES

Reservoir Full Of

Water?

NO

Restore Water Supply / Replace Water Inlet Valve

Power To Water

Inlet Valve?

YES

Water Level

Switch Closed?

NO NO

Repair Wiring

Replace Switch or

Float Assembly

YES

Page 80

80 Part Number 000007661 7/10

Low Water Level

Switch Closed?

NO

Replace Switch or

Float Assembly

Gear Motor Runs? NO

Line Voltage To

Gear motor?

Repair WiringNO

Disconnect

Evaporator From

Gear Motor

Gear Motor

Runs?

Replace Gear Motor

YES

NO

YES

YES

Ice In

Evaporator?

Rebuild

Or

Replace Evaporator

Thaw EvaporatorYES

NO

YES

YES

YES

10 Minute Time

Delay Expired?

NO

Wait 10 Minutes - Do Not Install

Compressor Time Delay Jumper

Page 81

Part Number 000007661 7/10 81

YES

NO

Replace Relay

NO

Repair Wiring

Replace Rotation

Sensor/Time Delay

NO

Power To Left Time

Delay Relay Coil?

Install

Compressor Time

Delay Jumper On

Left Evaporator

Delay Relay Contacts

Closed?

Delay Relay Contacts

Closed?

Yes

NO

YES

YES

Line Voltage To

Left Delay Relay Coil?

YES

Replace Relay

Page 82

82 Part Number 000007661 7/10

Low Pressure

Control Closed?

Line Voltage At

Liquid Line Solenoid

Valve?

NO

NO

YES

Verify:

Refrigerant Pressure is Higher Than

LPCO Cut-in

Both Shut-off Valves are Open

Repair/Replace Liquid Line Solenoid

Locate and Repair Refrigerant Leak

Replace LPCO Switch

Replace Relay

YES

High Pressure

Control Closed?

NO Resets?

Replace HPCO

Clean Condenser,

Check Fan Motor

Check Fan Cycle Control

Refrigerant Pressure

Above Cut-out?

Clean Condenser,

Check Fan Motor,

Check Fan Cycle Control &

Refrigeration System

Resets

&

Trips

NO NO

YES

NO

Line Voltage To

Compressor

Contactor Coil?

YES

YES

YES

Repair Wiring

Page 83

Part Number 000007661 7/10 83

Contactor

Closed?

NO

Replace Contactor

Line Voltage To

Compressor?

YES

YES

NO

Verify:

Compressor Overload is Closed

Start Components Function

Fan Cycling Control Functions

Condenser Fan Motor Functions

Repair Wiring

YES

Page 84

84 Part Number 000007661 7/10

Power Supplied

to Ice Machine?

Toggle Switch In

ON Position?

Move Switch To ON Position

Restore Power, Reset BreakerNO

NO

YES

Electrical Flowchart - RF-2300C QuietQube

Switch

Illuminated?

NO

YES

Replace Switch

Immediately

Trips?

YES

YES

Toggle Switch In

Off Position?

Isolate And Ohm Each

Component - Then Each

Wire If Required

NO

TRIPS

YES

Isolate And Ohm Switch

Check Wiring From Panel

YES

NO

Test Run

RF2300C QUIETQUBE

Page 85

Part Number 000007661 7/10 85

Bin Thermostat

Closed?

NO

Replace Thermostat

YES

Ice Contacting

Thermostat?

Remove Ice - Allow

To Warm And Retest

Adjusting Closes

Thermostat?

Verify New Setting Cycles

Machine On/Off

YES

NO NO

YES

YES

Left Side Chute

Switch Closed?

NO

Adjust Or Replace

Actuator

Ice Contacting

Actuator?

Remove Ice And

Retest

Actuator Functions?

Replace Switch

YES

NO NO

YES

YES

Right Side Chute

Switch Closed?

NO

Adjust Or Replace

Actuator

Ice Contacting

Actuator?

Remove Ice And

Retest

Actuator Functions?

Replace Switch

YES

NO NO

YES

YES

Page 86

86 Part Number 000007661 7/10

YES

Reservoir Full Of

Water?

NO

Restore Water

Supply / Replace

Water Inlet Valve

Power To Water

Inlet Valve?

YES

Water Level

Switch Closed?

NO NO

Repair WiringYES

Replace Switch or Float Assembly

Low Water Level

Switch Closed?

NO Replace Switch or Float Assembly

YES

Do Both Gear

Motors Run?

NO

Line Voltage To

Gear motors?

Repair WiringNO

Disconnect

Evaporator From

Gear Motor

Gear Motor

Runs?

Replace Gear Motor

YES

NO

YES

YES

Ice In

Evaporator?

Rebuild

Or

Replace Evaporator

Thaw Evaporator

YES

NO

YES

Page 87

Part Number 000007661 7/10 87

YES

10 Minute Time

Delay Expired?

NO

Wait 10 Minutes - Do Not Install

Compressor Time Delay Jumper

Yes

YES

NO

Replace Relay

NO

Repair Wiring

Replace Left Rotation

Sensor/Time Delay

No

Power To Left Time

Delay Relay Coil?

Install

Compressor Time

Delay Jumper On

Left Evaporator

Left Delay Relay

Contacts Closed?

Left Delay Relay

Contacts Closed?

Yes

No Yes

YES

Line Voltage To

Left Delay Relay Coil?

Page 88

88 Part Number 000007661 7/10

NO

Replace Relay

Replace Right Rotation

Sensor/Time Delay

Right Delay Relay

Contacts Closed?

Right Delay Relay

Contacts Closed?

YES

Line Voltage To

Right Delay Relay Coil?

NO

Repair Wiring

NO

Power To Right Time

Delay Relay Coil?

Install

Compressor Time

Delay Jumper On

Right Evaporator

YES

YES

YES

YES

Replace Relay

NO

Page 89

Part Number 000007661 7/10 89

Replace Relay

Line Voltage To

Compressor

Contactor Coil?

YES

Low Pressure

Control Closed?

Line Voltage At

Liquid Line Solenoid

Valve?

NO

NO

YES

Verify:

Refrigerant Pressure is Higher Than LPCO

Cut-in Both Shut-off Valves are Open

Repair/Replace Liquid Line Solenoid Locate

and Repair Refrigerant Leak

Replace LPCO Switch

YES

High Pressure

Control Closed?

Resets?

Replace HPCO

Clean Condenser,

Check Fan Motor

Check Fan Cycle Control

Refrigerant Pressure

Above Cut-out?

Resets

&

Trips

NO NO

YES

NO

NO

Clean Condenser,

Check Fan Motor,

Check Fan Cycle Control &

Refrigeration System

YES

YES

Repair Wiring

Page 90

90 Part Number 000007661 7/10

Contactor

Closed?

NO

Replace Contactor

Line Voltage To

Compressor?

YES

YES

NO

Verify:

Compressor Overload is Closed

Start Components Function

Fan Cycling Control Functions

Condenser Fan Motor Functions

Repair Wiring

YES

Page 91

Part Number 000007661 7/10 91

Capillary Tube Models

If the gear motor and/or compressor are not energized refer to Electrical Troubleshooting

Refer to Operational Pressure Charts for normal pressures and temperatures

Discharge Pressure Low High High Low

Suction Pressure Low High High Low

Evaporator Inlet Temperature Normal Low High Low

Evaporator Outlet Temperature High Normal High Low

Compressor Discharge Line Temperature

Normal Range =

> 165° @ 70° - 210° @ 110°

> 74°C @ 21°C - 99°C @ 43°C)

Low on

Refrigerant

High

Increases with

run time

Overcharge of

Refrigerant

Normal

Non Condensable

in System

High

Increases with

run time

Restricted Capillary

Tube

High

Increases with

run time

Page 92

92 Part Number 000007661 7/10

Thermostatic Expansion Valve Models

If the gear motor and/or compressor are not energized refer to Electrical Troubleshooting

Refer to Operational Pressure Charts for normal pressures and temperatures

Low on

Refrigerant

Discharge Pressure Low High High Low High

Suction Pressure Low High High Low High

Evaporator Inlet

Temperature

Evaporator Outlet

Temperature

Discharge Line

Temperature

Normal

High Normal High

High Normal

Overcharge

of

Refrigerant

Normal or

Low

Non

Condensable In

System

High Normal Normal or High

High

Increases With

Run Time

Liquid Line Restriction,

Suction Line Restriction,

Or TXV Starving

High > 12° Differential

between Inlet and Outlet

High

Increases With

Run Time

Flooding TXV or

Loose Sensing

< 10° Differential

between Inlet and

Decreases With

Bulb

Outlet

Low

Run Time

Page 93

Component Specifications

BIN THERMOSTAT

Setting Cut-Out Cut-In

5

37°F ±1

6°C ±.1

LOW TEMPERATURE THERMOSTAT

(Evaporator safety thermostat)

(RF0244/RF0266/RF0385/RF0388/RF0399/RF0300

ONLY)

Setting Cut-Out Cut-In

5

37°F ±1

6°C ±.1

HIGH PRESSURE CUTOUT (HPCO) CONTROL

Model Cut-Out Cut-In

RF0650/

RF1200/RF2300

RN1000/RN1400

RN1000C/RCU1075

RN1200C/RCU1275

RF1200C/RCU1275

RF2300C/RCU2375

435 psig ±10

(3000 kPa ±69)

30 bar ±.69

425 psig ±10

(2930 kPa ±69)

29 bar ±.69

450 psig ±10

(3100 kPa ±69)

31 bar ±.69

450 psig ±10

(3100 kPa ±69)

31 bar ±.69

43°F ±1

3°C ±.1

43°F ±1

3°C ±.1

Manual Reset

287 psig ±10

(1979 kPa ±69)

19.79bar ±.69

Auto Reset

295 psig ±10

(2034 kPa ±69)

20 bar ±.69

Auto Reset

Manual Reset

Part Number 000007661 7/10 93

Page 94

LOW PRESSURE CUTOUT (LPCO) CONTROL

Model Cut-Out Cut-In

R0F650/

RF1200

RF2300

RN1000C/RCU1075

RN1200C/RCU1275

RF1200C/RCU1275

RF2300C/RCU2375

7 psig ±2

(.5 bar ±.2)

12 psig ±2

(.8 bar ±.2)

12 psig ±3

(.8 bar ±.2)

36 psig ±2

(2.5 bar ±.2)

Manual Reset

35 psig ±5

(2.4 bar ±.4)

FAN CYCLE CONTROL

Model Cut-Out (Open) Cut-In (Close)

RF0244

RF0266

RF0385

RF0388

RF0399

RF0300 60 hz

RF0300 50 hz

RF0650 60 hz

RF0650 50 hz

RF1200 60 hz

RF1200 50 hz

RF2300

230±5

(16 bar ±.34)

230±5

(16 bar ±.34)

260 ±5

(18.1 bar ±.34)

260 ±5

(18.1 bar ±.34)

260 ±5

(18.1 bar ±.34)

260 ±5

(17.8 bar ±.34)

260 ±5

(17.8 bar ±.34)

230 ±5

(16 bar ±.34)

215 ±5

(14.8 bar ±.34)

260 ±5

(17.8 bar ±.34)

240 ±5

(16.6 bar ±.34)

250 ±5

(17.2 bar ±.34)

250 ±5

(17.2 bar ±.34)

250 ±5

(17.2 bar ±.34)

280 ±5

(19.3 bar ±.34)

280 ±5

(19.3 bar ±.34)

280 ±5

(19.3 bar ±.34)

275 ±5

(16.6 bar ±.34)

280 ±5

(19 bar ±.34)

250 ±5

(17.2 bar ±.34)

230 ±5

(16 bar ±.34)

275 ±5

(19 bar ±.34)

260 ±5

(17.8 bar ±.34)

265 ±5

(18.4 bar ±.34)

94 Part Number 000007661 7/10

Page 95

FILTER-DRIERS

Important

The size of the filter-drier is important. The refrigerant

charge is critical. Using an improperly sized filter-drier

will cause the ice machine to be improperly charged

with refrigerant.

Driers are covered as a warranty part. The drier

must be replaced any time the system is opened for

repairs.

SUCTION CLEANUP FILTER-DRIER

Contaminated systems must have a suction line filterdrier installed to remove contamination. An access

valve must be installed on the inlet side of the suction

filter to allow pressure drop readings to be obtained.

Suction Line Clean-Up Filter

Model Drier Size

All Models UK-165S 5/8 in.

End

Connection

Size

Part Number 000007661 7/10 95

Page 96

T OTAL SYSTEM REFRIGERANT CHARGE

Important

This information is for reference only. Refer to the

ice machine serial number tag to verify the system

charge. Serial plate information overrides

information listed on this page.

Model Refrigerant Charge

RF0244A 7.5 oz / 210 g

RF0266A 7.5 oz / 210 g

RF0385A 11.25 oz / 320 g

RF0388A 11.25 oz / 320 g

RF0399A 11.25 oz / 320 g

RF0300A 11.25 oz / 320 g

RF0650A 19.5 oz / 550 g

RF1200A 24.75 oz / 700 g

RF1200W 16.25 oz / 460 g

RF1200C 156 oz / 4.42 kg

RF2300C 240 oz / 6.08 kg

RF2300A 63.5 oz / 1800 g

RF2300W 38.75 oz / 1100 g

RN1000A 24 oz / 680 g

RN1000W 15 oz / 426 g

RN1000C 156 oz / 4.42 kg

RN1200C 156 oz / 4.42 kg

RN1400A 34 oz / 652 g

RN1400W 21 oz / 426 g

NOTE: All ice machines are charged using R-404A

refrigerant.

96 Part Number 000007661 7/10

Page 97

Charts

Cycle Times/24-Hour Ice Production/ Refrigerant Pressure Charts

These charts are used as guidelines to verify correct

ice machine operation.

Accurate collection of data is essential to obtain the

correct diagnosis.

• Zero out manifold gauge set before obtaining

pressure readings to avoid misdiagnosis.

• Discharge and suction pressure are highest at the

beginning of the cycle. Allow system to stabilize for

a minimum of 10 minutes, then verify the

pressures are within the range indicated.

• Water temperature will affect suction and

discharge pressure - 50°F (10°C) water

temperature will result in pressures on the lower

end of the ranges specified. 90°F (32°C) water

temperatures will result in pressures on the upper

end of the range specified.

Part Number 000007661 7/10 97

Page 98

RF0244A

SELF STORAGE AIR-COOLED

Characteristics will vary depending on operating

conditions.

ICE PRODUCTION

Air Temperature/

Water Temperature

70°F/50°F 182lbs 7.86

90°F/70°F 150 lbs 7.86

21°C/10°C 83 kgs 7.86

32°C/21°C 68 kgs 7.86

OPERATING PRESSURES PSIG & kPa

Air Temperature

Entering

Condenser

70°F PSIG

21°C kPa

90°F PSIG

32°C kPa

110°F PSIG

43°C kPa

24 hour

Ice Production

Freeze Cycle

Discharge

Pressure

220-250