Page 1

Q Model

QuietQube Ice Machines

with CVD Technology

Model QDUALC

Installation

and

Owner/Operator

Use and Care Manual

Thank you for selecting a Manitowoc Ice Machine, the dependability leader in ice making equipment and related products.

With proper installation, care and maintenance, your new Manitowo c Ice Machine will provide you with many years of

reliable and economical performance.

Part Number 000001530

8/2006

Page 2

Safety Notices

Procedural Notices

As you work on a QuietQube®-Series Ice Machine, be

sure to pay close attention to the safety notices in this

manual. Disregarding the notices may lead to serious

injury and/or damage to the ice machine.

Throughout this manual, you will see the following types

of safety notices:

!

Warning

PERSONAL INJURY POTENTIAL

Do not operate equipment that has been misused,

abused, neglected, damaged, or altered/modified

from that of original manufactured specifications.

Warning

!

Text in a Warning box alerts you to a potential

personal injury situation. Be sure to read the

Warning statement before proceeding, and work

carefully.

Caution

!

Text in a Caution box alerts you to a situation in

which you could damage the ice machine. Be sure

to read the Caution statement before proceeding,

and work carefully.

As you work on a QuietQube®-Series Ice Machine, be

sure to read the procedural notices in this manual.

These notices supply helpful information which may

assist you as you work.

Throughout this manual, you will see the following types

of procedural notices:

Important

Text in an Important box provides you with

information that may help you perform a procedure

more efficiently. Disregarding this information will

not cause damage or injury, but it may slow you

down as you work.

NOTE: Text set off as a Note provides you with simple,

but useful, extra information about the procedure you

are performing.

Read These Before Proceeding:

Caution

!

Proper installation, care and maintenance are

essential for maximum ice production and troublefree operation of you Manitowoc Ice Machine.

Read and understand this manual. It contains

valuable care and maintenance information. If you

enounter problems not covered by this manual, do

not proceed, contact Manitowoc Ice, Inc. We will be

happy to provide assistance.

Important

Routine adjustments and maintenance procedures

outlined in this manual are not covered by the

warranty.

We reserve the right to make product improvements at any time.

Specifications and design are subject to change without notice.

Page 3

Section 1

General Information

Table of Contents

Model Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Ice Cube Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Bin Caster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Ice Bagger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Ice Deflector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Side By Side Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Manitowoc Cleaner and Sanitizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

AuCS Automatic Cleaning System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Guardianf Sachet Packets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Arctic Puref Water Filter System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Model/Serial Number Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Owner Warranty Registration Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Warranty Coverage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Labor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Exclusions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Authorized Warranty Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Service Calls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Section 2

Installation Instructions

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Ice Machine Installation Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Ice Machine Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Condensing Unit Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Location of Ice Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Ice Machine Head Section Clearance Requirements . . . . . . . . . . . . . . . . . . . 2-4

Stacking Two Ice Machines on a Single Storage Bin . . . . . . . . . . . . . . . . . . . 2-4

Location of CVD Condensing Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Condensing Unit Clearance Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Condensing Unit Heat of Rejection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Leveling the Ice Storage Bin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Air-Cooled Baffle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Head Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

QDUALC Ice Machines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

CVD1875/CVD2075 Air-Cooled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Ice Storage Bin Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

S970 Ice Storage Bin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Large Capacity Ice Storage Bin Dimensions . . . . . . . . . . . . . . . . . . . . . . . 2-3

30 Inch (76 cm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

48 Inch (122 cm) & 60 Inch (152 cm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Part Number 000001530 1

Page 4

Table of Contents (continued)

Electrical Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Fuse/Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Minimum Circuit Ampacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

QuietQube® Ice Machine Head Section . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

CVD® Condensing Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

QuietQube® Ice Machine Head Section Electrical Wiring Connections . . . . 2-8

115/1/60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

230/1/50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

For United Kingdom Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Condensing Unit Electrical Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . 2-9

208-230/1/60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

208-230/3/60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

230/1/50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Ice Machine Head Section Water Supply and Drains . . . . . . . . . . . . . . . . . . . 2-10

Potable Water Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Potable Water Inlet Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Drain Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Water Supply and Drain Line Sizing/Connections . . . . . . . . . . . . . . . . . . . . 2-11

Refrigeration System Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Usage With Non-Manitowoc

Condensing Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Refrigeration Line Set Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

A. Line Set Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

B. Line Set Rise or Drop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

C. Suction Line Oil Traps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

3 Phase Scroll Compressor Rotation CVD2075 Only. . . . . . . . . . . . . . . . . . . . 2-18

Installation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Before Starting the Ice Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

AuCS® Automatic Cleaning System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Section 3

Ice Machine Operation

Component Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Ice Machine Head Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

CVD Condensing Unit

CVD1875/CVD2075 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Ice Making Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Initial Start-Up or Start-Up After Automatic Shut-Off . . . . . . . . . . . . . . . . . . 3-2

Freeze Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Harvest Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Automatic Shut-Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Operational Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Water Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Ice Thickness Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

2 Part Number 000001530

Page 5

Section 4

Maintenance

Interior Cleaning and Sanitizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Ice Machine Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Exterior Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Cleaning the Condenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Removal from Service/Winterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Section 5

Before Calling For Service

Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Safety Limit Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Table of Contents (continued)

AlphaSan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Cleaning & Sanitizing Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Safety Limit Stand-By Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Safety Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Part Number 000001530 3

Page 6

Table of Contents (continued)

4 Part Number 000001530

Page 7

Section 1

General Information

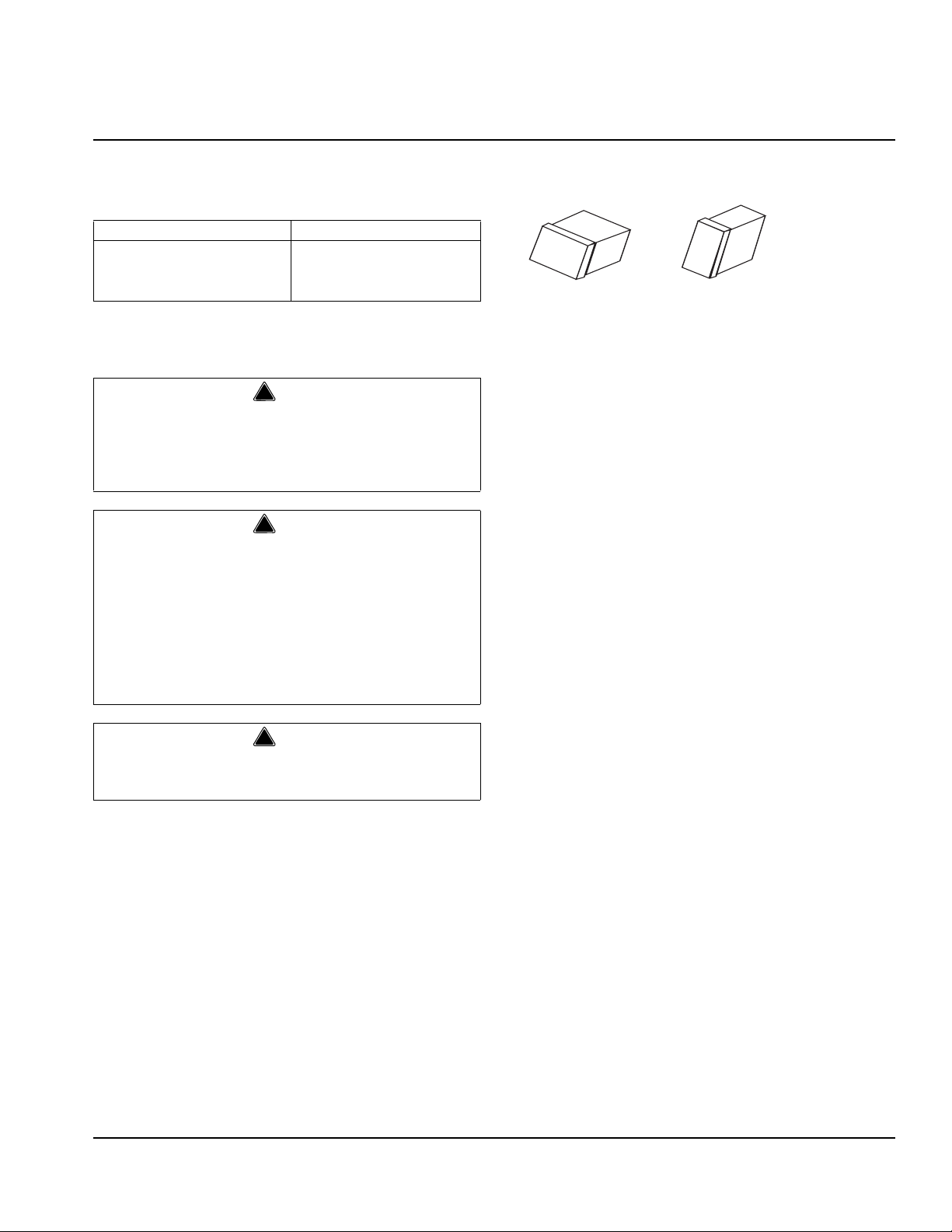

Model Numbers

This manual covers the following models:

Ice Machine Head Section CVD® Condensing Unit*

QRDUALC

QDDUALC

QYDUALC

For 3 phase electrical option: add the number “3” to the

end of model number (CVD18753).

Warning

!

PERSONAL INJURY POTENTIAL

Do not operate equipment that has been misused,

abused, neglected, damaged, or altered/modified

from that of original manufactured specifications.

Warning

!

When installing with non-Manitowoc ice storage

systems or Manitowoc F & B style bins. Manitowoc

QuietQube® ice machines require the ice storage

bin, to incorporate an ice deflector.

Prior to using a non-Manitowoc ice storage system

with Manitowoc ice machines, contact the

manufacturer to assure their ice deflector is

compatible with Manitowoc ice machines.

CVD1875

CVD2075

Ice Cube Sizes

Dice

7/8" x 7/8" x 7/8"

2.22 x 2.22 x 2.22 cm

SV3105

Half Dice

3/8" x 1-1/8" x 7/8"

0.95 x 2.86 x 2.22 cm

!

Warning

QDUALC ice machines are not approved for use on

Manitowoc S570 series bins.

Part Number 000001530 1-1

Page 8

General Information Section 1

Accessories

Contact your Manitowoc distributor for these optional accessories:

BIN CASTER

Replaces standard legs.

ICE BAGGER

Maximize profits from bagged ice sales with this

convenient accessory. This sturdy unit rests on the bin

door frame, and adapts for left or right side filling.

ICE DEFLECTOR

QDUALC ice machines mounted on an ice dispenser do

not require an ice deflector.

QDUALC ice machines mounted on an ice storage bin

(Manitowoc or non-Manitowoc) require the use of an ice

deflector. Refer to sales specification literature to

determine the proper deflector kit for your application.

SIDE BY SIDE INSTALLATION

Two QDUALC ice machines can be mounted side by

side on a Manitowoc 60” F & B Style bins. This requires

an installation kit that is necessary to allow access to the

shut-off valves during installation and will improve

access during future service. Refer to sales literature to

determine the proper installation kit for your application.

Warning

!

Manitowoc QDUALC ice machines require the ice

storage bin to incorporate an ice deflector.

The deflector kit is not included with the ice machine

and must be ordered separately.

Prior to using a non-Manitowoc ice storage system

with Manitowoc ice machines, contact the

manufacturer to assure their ice deflector is

compatible with Manitowoc ice machines.

MANITOWOC CLEANER AND SANITIZER

Manitowoc Ice Machine Cleaner and Sanitizer are

available in convenient 16 oz. (473 ml) and 1 gal (3.78 l)

bottles. These are the only cleaner and sanitizer

approved for use with Manitowoc products.

Cleaner Part Number Sanitizer Part Number

16 oz. 94-0456-3 16 oz. 94-0565-3

1 Gallon 94-0580-3 1 Gallon 94-0581-3

AUCS AUTOMATIC CLEANING SYSTEM

This accessory reduces equipment cleaning expense.

The AuCS® accessory monitors ice making cycles and

initiates cleaning procedures automatically.

GUARDIAN SACHET PACKETS

Guardian sachet packets release chlorine dioxide on a

controlled basis to inhibit the growth of bacteria and

slime.

Guardian sachet packets are available through your

local Manitowoc Ice Machine dealer.

ARCTIC PURE WATER FILTER SYSTEM

Engineered specifically for Manitowoc ice machines,

This water filter is an efficient, dependable, and

affordable method of inhibiting scale formation, filtering

sediment, and removing chlorine taste and odor.

1-2

Part Number 000001530

Page 9

Section 1 General Information

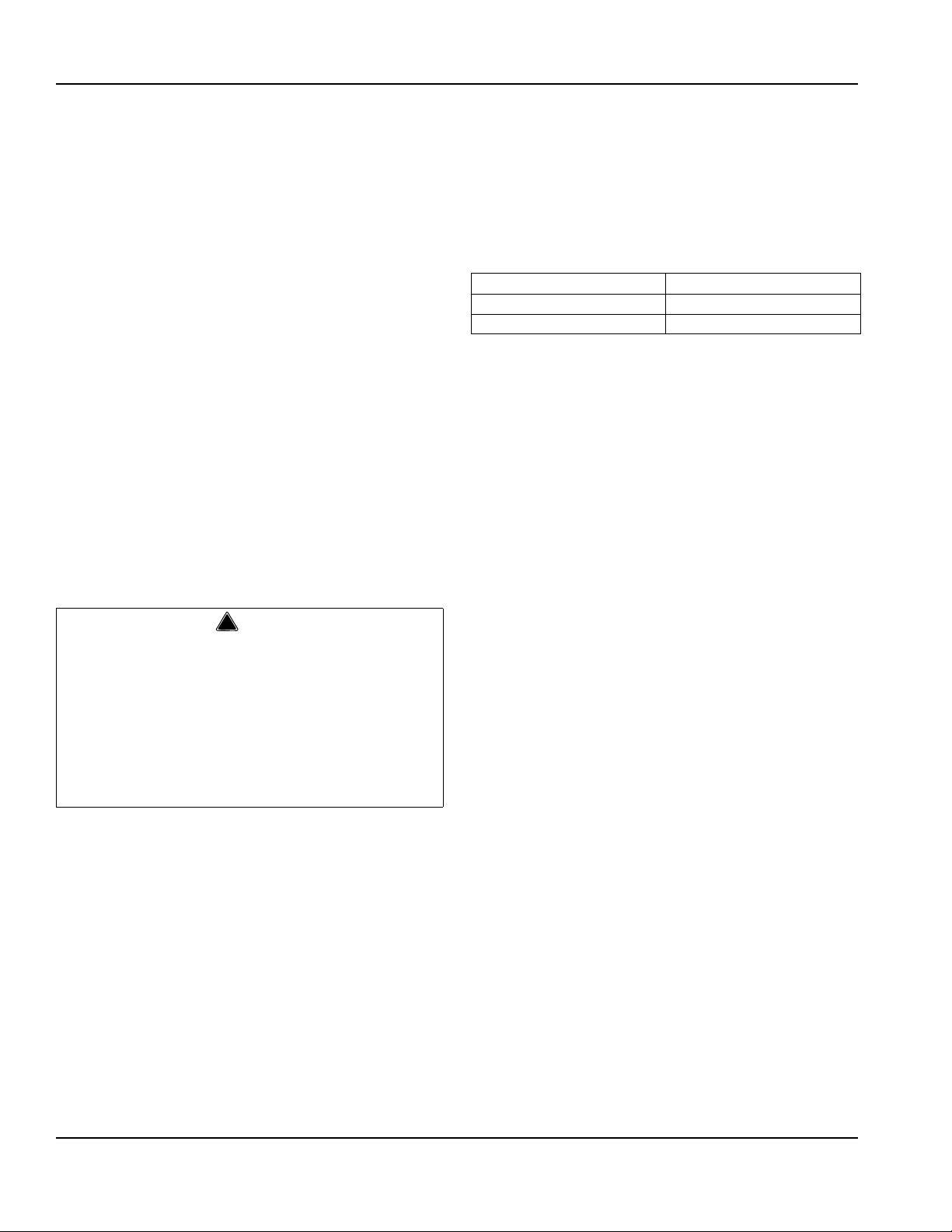

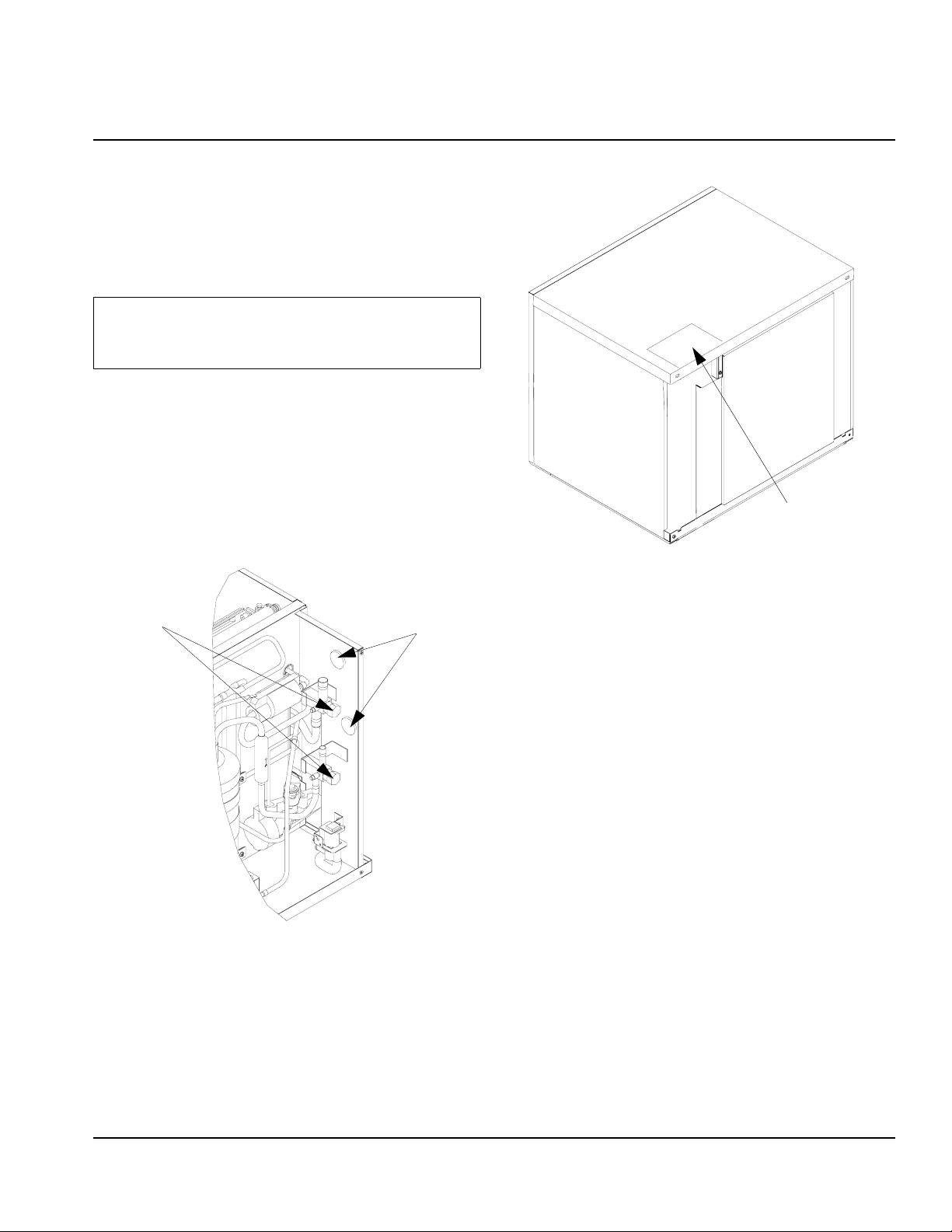

Model/Serial Number Location

Record the model and serial number of your ice machine

and bin or dispenser in the space provided below.

These numbers are required when requesting

information from your local Manitowoc distributor,

service representative, or Manitowoc Ice, Inc.

Condensing Unit

MODEL / SERIAL

NUMBERS DECAL

(CVD CONDENSING UNIT)

PT1306

The model and serial number are listed on the OWNER

WARRANTY REGISTRATION CARD. They are also

listed on the MODEL/SERIAL NUMBER DECAL affixed

to the ice machine head section and condensing unit.

Both model/serial numbers must be referenced to obt ain

warranty or service information.

Back of Ice Machine

MODEL /

SERIAL

NUMBERS

DECAL

(ICE

MACHINE)

MODEL /

SERIAL

NUMBERS

DECAL

(BIN)

SV1768A

MODEL / SERIAL

NUMBERS DECAL

(RIGHT SIDE OF

ICE MACHINE

ELECTRICAL

CONTROL BOX)

Model Number

Serial Number

QDUALC

SV1779RH

Model/Serial Number Location

Ice Machine Bin or Dispenser CVD Condensing Unit AuCS Accessory

Part Number 000001530 1-3

Page 10

General Information Section 1

Owner Warranty Registration Card

GENERAL

The packet containing this manual also includes

warranty information. Warranty coverage beg ins the day

the ice machine is installed.

Important

Complete and mail the OWNER WARRANTY

REGISTRATION CARD as soon as possible to

validate the installation date.

If the OWNER WARRANTY REGISTRATION CARD is

not returned, Manitowoc will use the date of sale to the

Manitowoc Distributor as the first day of warranty

coverage for your new ice machine.

Warranty Coverage

GENERAL

The following Warranty outline is provided for your

convenience. For a detailed explanation, read the

warranty bond shipped with each product.

Contact your local Manitowoc Distributor or Manitowoc

Ice, Inc. if you need further warranty information.

Important

This product is intended exclusively for commercial

application. No warranty is extended for personal,

family, or household purposes.

PARTS

1. Manitowoc warrants the ice machine against defects

in materials and workmanship, under normal use

and service for three (3) years from the date of

original installation.

2. The evaporator and compressor are covered by an

additional two (2) year (five years total) warranty

beginning on the date of the original installation.

LABOR

1. Labor required to repair or replace defective

components is covered for three (3) years from the

date of original installation.

2. The evaporator is covered by an additional two (2)

year (five years total) labor warranty beginning on

the date of the original installation.

EXCLUSIONS

The following items are not included in the ice machine’s

warranty coverage:

1. Normal maintenance, adjustments and cleaning as

outlined in this manual.

2. Repairs due to unauthorized modifications to the ice

machine or use of non-standard parts without prior

written approval from Manitowoc Ice, Inc.

3. Damage caused by improper installation of the ice

machine, electrical supply , water supp ly or drainage,

or damage caused by floods, storms, or other acts of

God.

4. Premium labor rates due to holidays, overtime,

etc.; travel time; flat rate service call charges;

mileage and miscellaneous tools and material

charges not listed on the payment schedule.

Additional labor charges resulting from the

inaccessibility of equipment are also excluded.

5. Parts or assemblies subjected to misuse, abuse,

neglect or accidents.

6. Damage or problems caused by installation,

cleaning and/or maintenance procedures

inconsistent with the technical instructions provided

in this manual.

7. This product is intended exclusively for commercial

application. No warranty is extended for personal,

family, or household purposes.

AUTHORIZED WARRANTY SERVICE

To comply with the provisions of the warranty, a

refrigeration service company qualified and authorized

by a Manitowoc distributor, or a Contracted Service

Representative must perform the warranty repair.

NOTE: If the dealer you purchased the ice machine from

is not authorized to perform warranty service; contact

your Manitowoc distributor or Manitowoc Ice, Inc. for the

name of the nearest authorized service representative.

SERVICE CALLS

Normal maintenance, adjustments and cleaning as

outlined in this manual are not covered by the warranty.

If you have followed the procedures listed in this manual,

and the ice machine still does not perform properly, call

your Local Distributor or the Service Department at

Manitowoc Ice, Inc.

1-4

Part Number 000001530

Page 11

Section 2

Installation Instructions

General

These instructions are provided to assist the qualified

installer. Check your local Yellow Pages for the name of

the nearest Manitowoc distributor , or ca ll Manitowoc Ice,

Inc. for information regarding installation and start-up

services.

Important

Failure to follow these installation guidelines may

affect warranty coverage.

Ice Machine Installation Options

HEAD SECTION

The ice machine head can be installed with the electrical

inlet, water supply inlet and refrigeration tubing entering

from the back or top of the ice machine.

The ice machine water drain must exit the back of the

ice machine.

TRIM TOP COVER

IN THIS AREA

TUBING CAN BE

ROUTED OUT TOP

TUBING CAN BE

ROUTED OUT

BACK OF THE ICE

MACHINE WITH

PROVIDED 90

ELBOWS

°

SV1769A

SV1768B

Cut the top cover for top routing of electrical inlet, water

supply inlet or refrigeration lines.

1. Prior to cutting, mount top cover onto ice machine.

2. Locate the area that will need to be cut and mark the

top cover.

3. Using a tin snips, cut top cover as needed:

A. Do not cut out entire area! Cut up to 1/8 inch to

marked line.

B. Cut out only what is needed. (If routing only

refrigeration lines out the top, cut just enough to

route these lines.)

C. Do not cut out the entire corner area.

Part Number 000001530 2-1

Page 12

Installation Instructions Section 2

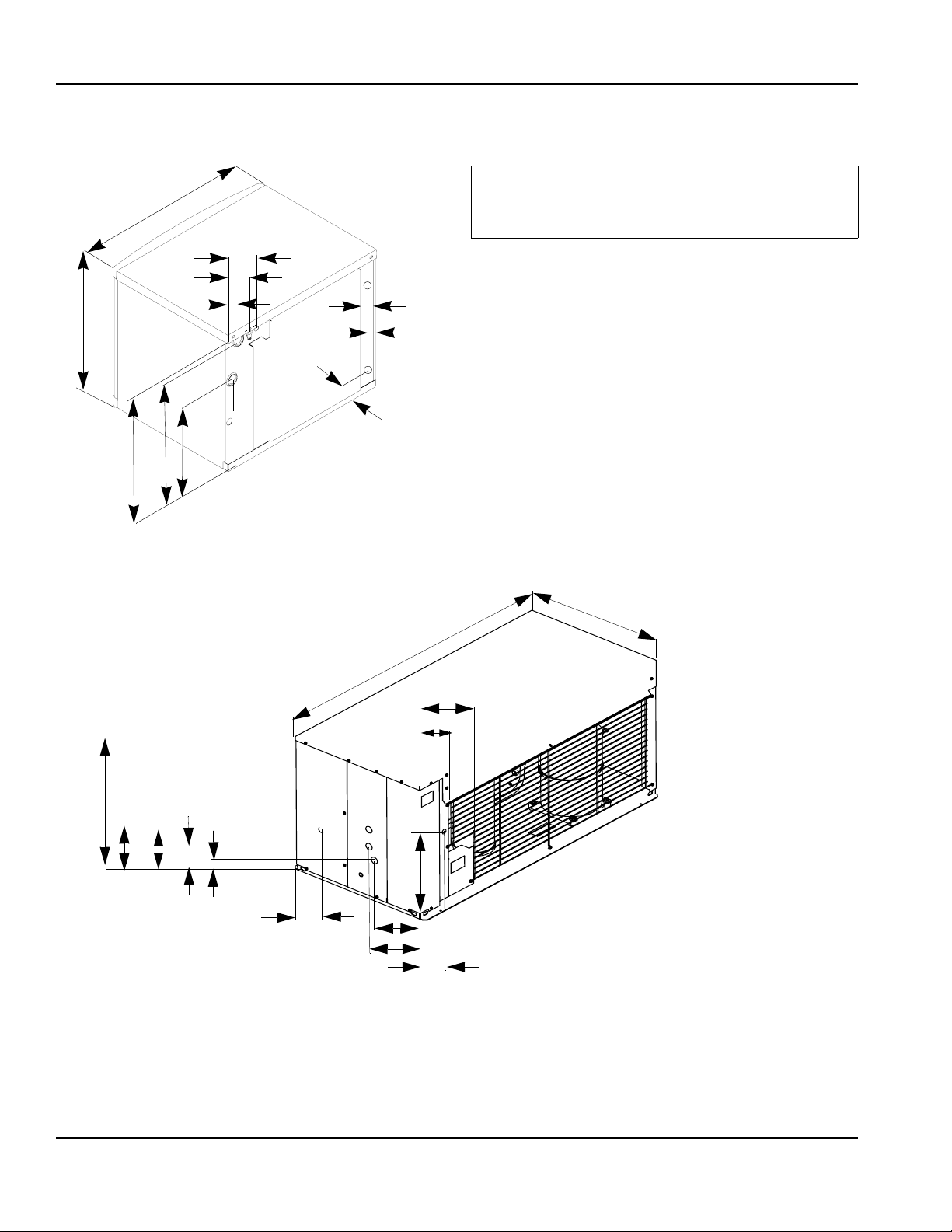

Ice Machine Dimensions

QDUALC ICE MACHINES

30”

(76.2 cm)

6.87”

29.5”

(74.93 cm)

26.76”

(67.97 cm)

(17.45 cm)

3.24”

(8.23 cm)

26.54”

(67.4 cm)

(50.22 cm)

(5.08 cm)

19.77”

(13.64 cm)

2”

5.37”

Condensing Unit Dimensions

CVD1875/CVD2075 Air-Cooled

(5.31 cm)

(4.27 cm)

2.02”

(5.14 cm)

SV1766

2.09”

1.68”

Important

Failure to follow these installation guidelines may

affect warranty coverage.

26”

(66.04 CM)

26”

(66.04 CM)

(26.04 CM)

13.5”

(34.3 CM)

10.25”

(25.4 CM)

10”

8”

(20.32 CM)

5”

(12.7 CM)

52.5”

(133.35 CM)

6.5”

(16.5 CM)

(36.8 CM)

9”

10”

(28.58 CM)

14.5”

11.5”

5.25”

(13.34 CM)

FRONT VIEW

PT1307

2-2

Part Number 000001530

Page 13

Section 2 Installation Instructions

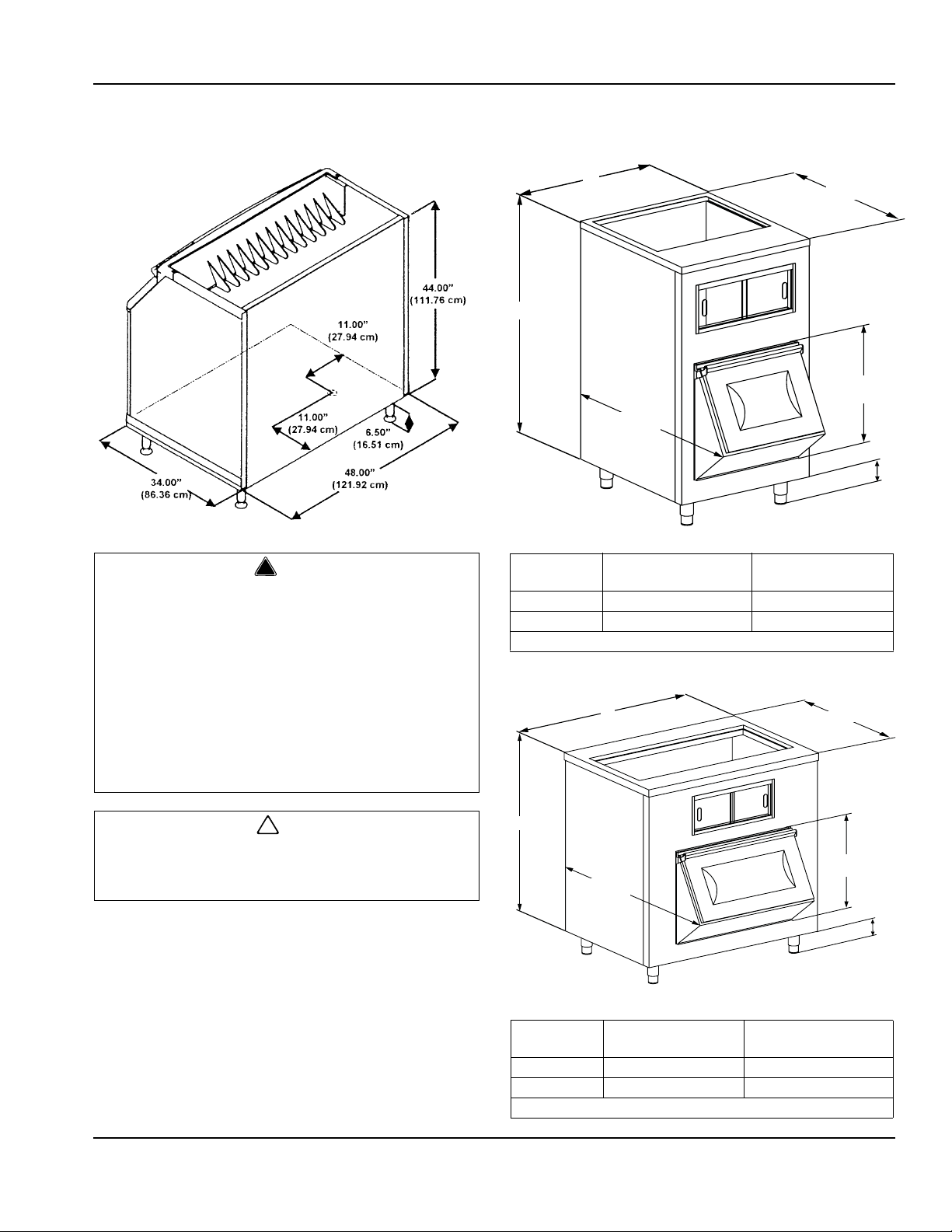

Ice Storage Bin Dimensions

S970 ICE STORAGE BIN

Warning

!

All Manitowoc ice machines require the ice storage

system (bin, dispenser, etc.) to incorporate an ice

deflector.

The Manitowoc QDUALC ice machines require

adding Manitowoc Ice Deflector Kit when installing

with non-Manitowoc ice storage systems or 60”

Manitowoc F & B style bins.

Prior to using a non-Manitowoc ice storage system

with other Manitowoc ice machines, contact the

manufacturer to assure their ice deflector is

compatible with Manitowoc ice machines.

SV1610

Large Capacity Ice Storage Bin Dimensions

30 INCH (76 CM)

A

B

43.6”

(110.81 cm)

Bin Model Dimension A (Width)

Dimension B

B700 30 in. (76.2 cm.) 58 in. (147.3 cm.)

B1050 30 in. (76.2 cm.) 78 in. (198.1 cm.)

The bin drain is exactly in the center of the bin.

48 INCH (122 CM) & 60 INCH (152 CM)

A

34” (86.4 cm)

(Height)

34” (86.4 cm)

25.25”

(64.1 cm)

(15.2 cm)

6”

Caution

!

30” large capacity ice storage bins must be

attached to the wall with the bracket provided with

the bin.

B

Bin Model

43.6”

(110.81 cm)

Dimension A

(Width)

25.25”

(64.1 cm)

Dimension B

(Height)

6”

(15.2 cm)

B1100 48 in. (121.9 cm.) 55.0 in. (139.7 cm.)

B1400 60 in. (152.4 cm.) 55.0 in. (139.7 cm.)

The bin drain is exactly in the center of the bin.

Part Number 000001530 2-3

Page 14

Installation Instructions Section 2

Location of Ice Machine

The location selected for the ice machine must meet the

following criteria. If any of these criteria are not met,

select another location.

• The location must be free of airborne and other

contaminants.

• The air temperature must be at least 35°F (1.6°C),

but must not exceed 110°F (43.4°C).

• The location must not be near heat-generating

equipment or in direct sunlight.

• The location must not obstruct airflow through or

around the ice machine. Refer to the chart below for

clearance requirements.

Ice Machine Head Section Clearance

Requirements

QDUALC:

Top/Sides 5” (127 mm) is recommended for efficient

operation and servicing. There is no minimum clearance

required.

Back 1” (25.4 mm) required when routing electrical inlet,

water inlet and refrigeration tubing out of the top of the

unit.

5” (127 mm) required when routing all connections out

the back.

Caution

!

The ice machine head section must be protected if it

will be subjected to temperatures below 32°F (0°C).

Failure caused by exposure to freezing

temperatures is not covered by the warranty. See

“Removal from Service/Winterization”.

Stacking Two Ice Machines on a Single

Storage Bin

QDUALC ice machines cannot be stacked. However an

adapter is available that allows two QDUALC ice

machines to be placed side by side on a 60” Manitowoc

F & B style bins.

Location of CVD Condensing Unit

The location selected for the CVD Condensing Unit must

meet the following criteria. If any of these criteria are not

met, select another location.

• The air temperature must be at least -20°F (-28.9°C)

but must not exceed 120°F (48.8°C).

• The location must not allow exhaust fan heat and/or

grease to enter the condenser.

• The location must not obstruct airflow through or

around the condensing unit. Refer to the chart below

for clearance requirements.

Condensing Unit Clearance Requirements

Top/Sides

There is no minimum clearance required, although 6”

(13 cm) is recommended for efficient operation and

servicing only.,

Front/Back

48” (122 cm)

Condensing Unit Heat of Rejection

Series

Condensing Unit

CVD1875 28,000 42,000

CVD2075 39,000 53,000

B.T.U./Hour

Because the heat of rejection varies during the ice making cycle,

the figure shown is an average.

Ice machines, like other refrigeration equipment, reject

heat through the condenser. It is helpful to know the

amount of heat rejected by the ice machine when sizing

air conditioning equipment where self-contained aircooled ice machines are installed.

This information is also necessary when evaluating the

benefits of using water-cooled or CVD® Condensing

Units to reduce air conditioning loads. The amount of

heat added to an air-conditioned environment by a

QuietQube® ice machine head section is negligible.

Air Conditioning**

Heat of Rejection*

Peak

2-4

Part Number 000001530

Page 15

Section 2 Installation Instructions

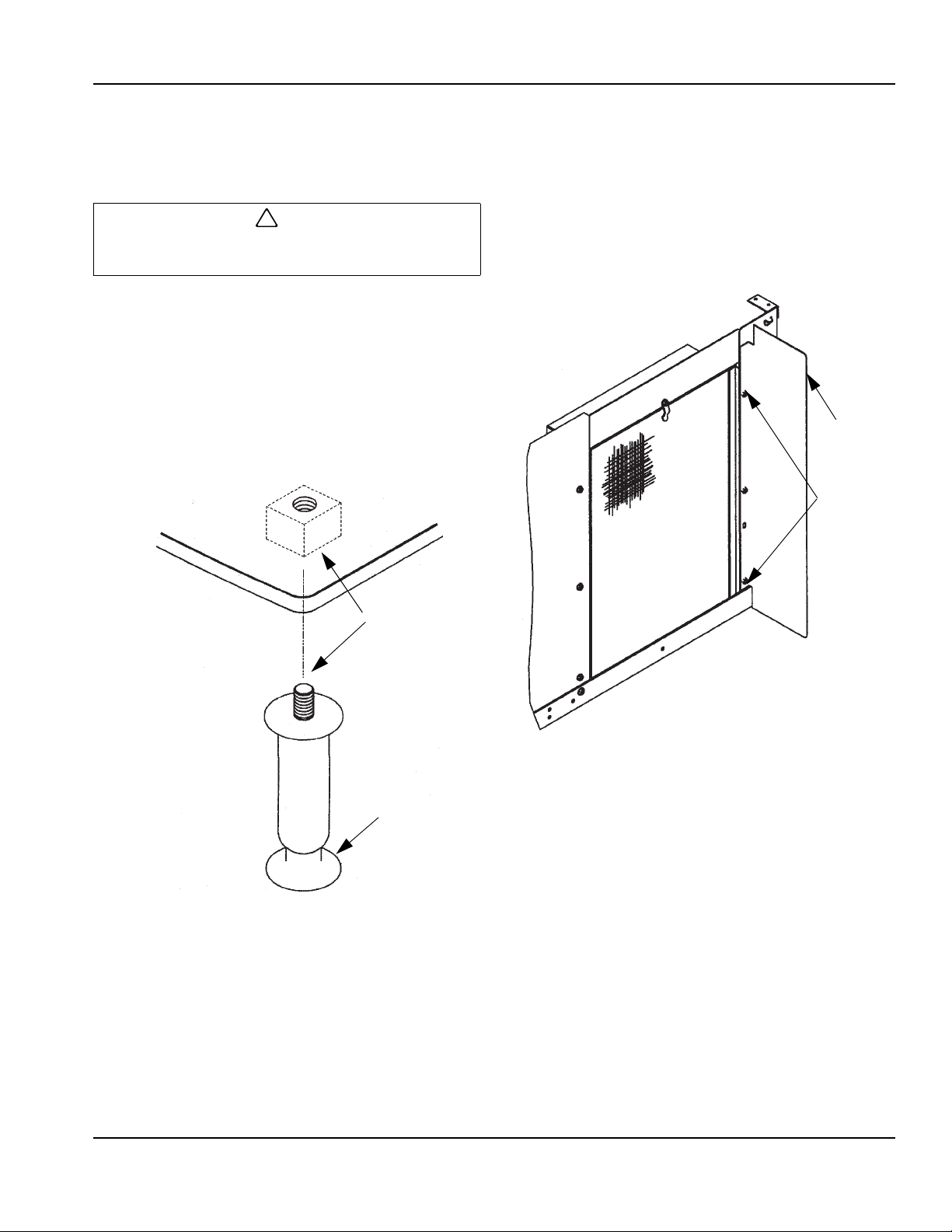

Leveling the Ice Storage Bin

1. Screw the leveling legs onto the bottom of the bin.

2. Screw the foot of each leg in as far as possible.

Caution

!

The legs must be screwed in tightly to prevent them

from bending.

3. Move the bin into its final position.

4. Level the bin to assure that the bin door closes and

seals properly. Use a level on top of the bin. Turn

each foot as necessary to level the bin.

NOTE: An optional caster assembly is available for use

in place of the legs. Installation instructions are supplied

with the casters.

Air-Cooled Baffle

The air-cooled baffle prevents condenser air from

recirculating. To install:

1. Remove the back panel screws next to the

condenser.

2. Align the mounting holes in the air baffle with the

screw holes and reinstall the screws.

SCREWS

AIR

BAFFLE

THREAD ‘FOOT’ IN AS

FAR AS POSSIBLE

Leveling Leg and Foot

THREAD LEVELING

LEG INTO BASE OF

CABINET

SV1606

SV1607

Air Baffle

Part Number 000001530 2-5

Page 16

Installation Instructions Section 2

Electrical Service

GENERAL

Warning

!

All wiring must conform to local, state and national

codes.

VOLTAGE

For both the Ice Machine Head Section and the CVD®

Condensing Unit, the maximum allowable voltage

variation is ±10% of the rated voltage at ice machine

start-up (when the electrical load is highest).

Warning

!

The ice machine and condensing unit must be

grounded in accordance with national and local

electrical codes.

FUSE/CIRCUIT BREAKER

The ice machine head section and condensing unit are

wired independently from each other.

Ice Machine Head Section

The ice machine head section does not require a

dedicated circuit breaker.

CVD® Condensing Unit

A separate fuse/circuit breaker must be provided for

each condensing unit. Circuit breakers must be H.A.C.R.

rated (does not apply in Canada).

MINIMUM CIRCUIT AMPACITY

The minimum circuit ampacity is used to help select the

wire size of the electrical supply. (Minimum circuit

ampacity is not the ice machine’s running amp load.)

The wire size (or gauge) is also dependent upon

location, materials used, length of run, etc., so it must be

determined by a qualified electrician.

GROUND FAULT CIRCUIT INTERUPTER

Ground Fault Circuit Interupter (GFCI/GFI) protection is

a system that shuts down the electric circuit (opens it)

when it senses an unexpected loss of power,

presumably to ground. Manitowoc Ice, Inc. does not

recommend the use of a GFCI/GFI circuit protection with

our equipment. If code requires the us e of a GF CI /G FI

then you must follow the local code. The circuit must be

dedicated, sized properly and there must be a panel

GFCI/GFI breaker. We do not recommend GFCI/GFI

outlets as they are known for more intermittent n uisance

trips than panel breakers.

2-6

Part Number 000001530

Page 17

Section 2 Installation Instructions

Electrical Requirements

QUIETQUBE® ICE MACHINE HEAD SECTION

Voltage

Ice Machine

Phase

Cycle

Maximum Fuse/

Circuit Breaker

Total Amps

QDUALC

115/1/60

208-230/1/60

230/1/50

15 amp

15 amp

15 amp

Important

The QuietQube® Ice Machine Head Section and

CVD Condensing Unit are wired independently from

each other.

CVD® CONDENSING UNIT

CONNECT POWER SUPPLY WIRING DIRECTLY TO L1 & L2 ON THE CONTACTOR.

TORQUE SCREWS TO THE TORQUE VALUE SPECIFICATION ON THE CONTACTOR LABEL.

FOLLOW ALL LOCAL, STATE AND NATIONAL ELECTRICAL CODES.

Condensing Unit

CVD1875

CVD2075

Vo ltage Phase

Cycle

208-230/1/60

208-230/3/60

230/1/50 40 23.2 8 AWG

208-230/1/60 50 27.1 8 AWG

208-230/3/60 40 19.9 8 AWG

230/1/50 50 29.9 8 AWG

Maximum Fuse/

Circuit Breaker

40 24.3 8 AWG

30 16.1 8 AWG

Minimum Circuit

Amps

1.1

0.6

0.6

Minimum Wire Size T o

Condensing Unit

Part Number 000001530 2-7

Page 18

Installation Instructions Section 2

QuietQube® Ice Machine Head Section Electrical Wiring Connections

!

Warning

These diagrams are not intended to show proper

wire routing, wire sizing, disconnects, etc., only the

correct wire connections.

All electrical work, including wire routing and

grounding, must conform to local, state and national

electrical codes.

Though wire nuts are shown in the drawin gs, th e ice

machine field wiring connections may use either

wire nuts or screw terminals.

115/1/60

L

1

N=115V

OR

L2=208-230V

GROUND

ICE MACHINE

CONNECTIONS

GROUND

L

1

SV1258

230/1/50

L

N

GROUND

1

ICE MACHINE

CONNECTIONS

L

1

N

GROUND

TO SEPARATE

FUSE/BREAKER.

DISCONNECT ALL

POLES.

SV1191

For United Kingdom Only

As the colours of the wires in the mains lead of the appliance may not correspond with the coloured markings

identifying the terminals in your plug, proceed as follows:

• The wire which is coloured green and yellow

the letter E or by the earth ground symbol or coloured green or green and yellow.

• The wire coloured blue

• The wire coloured brown

must be connected to the terminal which is marked with the letter N or coloured black.

must be connected to the terminal which is marked with the letter L or coloured red.

2-8

must be connected to the terminal in the plug which is ma rked with

Part Number 000001530

Page 19

Section 2 Installation Instructions

Condensing Unit Electrical Wiring

Connections

!

Warning

These diagrams are not intended to show proper

wire routing, wire sizing, disconnects, etc., only the

correct wire connections.

All electrical work, including wire routing and

grounding, must conform to local, state and national

electrical codes.

Though wire nuts are shown in the drawin gs, th e ice

machine field wiring connections may use either

wire nuts or screw terminals.

208-230/1/60

L

1

L

L2

208-230/3/60

L

L

L

GROUND

SV1190

1

2

3

GROUND

CONDENSING

CONNECTIONS

L

1

L

L

UNIT

2

3

TO SEPARATE

FUSE/BREAKER

230/1/50

1

L

1

L

1

GROUND

CONDENSING UNIT

CONNECTIONS

GROUND

TO SEPARATE

FUSE/BREAKER

SV1258

N

GROUND

CONDENSING UNIT

CONNECTIONS

N

GROUND

TO SEPARATE

FUSE/BREAKER.

DISCONNECT ALL

POLES.

SV1191

Part Number 000001530 2-9

Page 20

Installation Instructions Section 2

Ice Machine Head Section Water Supply and Drains

POTABLE WATER SUPPLY

Local water conditions may require treatment of the

water to inhibit scale formation, filter sediment, and

remove chlorine odor and taste.

Important

If you are installing a Manitowoc water filter system,

refer to the Installation Instructions supplied with the

filter system for ice making water inlet connections.

POTABLE WATER INLET LINES

Follow these guidelines to install water inlet lines:

• Do not connect the ice machine to a hot water

supply. Be sure all hot water restrictors installed for

other equipment are working. (Check valves on sink

faucets, dishwashers, etc.)

• If water pressure exceeds the maximum

recommended pressure 80 psig (551.5 kPA), obtain

a water pressure regulator from your Manitowoc

distributor.

• Install a water shut-off valve for ice making potable

water.

• Insulate water inlet lines to prevent condensation.

DRAIN CONNECTIONS

Follow these guidelines when installing drain lines to

prevent drain water from flowing back into the ice

machine and storage bin:

• Drain lines must have a 1.5 inch drop per 5 feet of

run (2.5 cm per meter), and must not create traps.

• The floor drain must be large enough to

accommodate drainage from all drains.

• Run separate bin and ice machine drain lines.

Insulate them to prevent condensatio n.

• Vent the bin and ice machine drain to the

atmosphere. The ice machine drain requires an 18”

vent.

2-10

Part Number 000001530

Page 21

Section 2 Installation Instructions

WATER SUPPLY AND DRAIN LINE SIZING/CONNECTIONS

Caution

!

Plumbing must conform to state and local codes.

Location Water Temperature Water Pressure Ice Machine Fitting

Ice Making

Water Inlet

Ice Making

Water Drain

Bin Drain

Large Capacity

Bin Drain

°F (0.6°C) Min.

33

90°F (32.2°C) Max.

--- --- 1/2” Female Pipe

--- --- 3/4” Female Pipe

--- ---

20 psi (137.9 kPA) Min.

80 psi (551.5 kPA) Max.

3/8” Female Pipe

Thread

Thread

Thread

1” Female Pipe Thread

T ubing Size Up to Ice

Machine Fitting

3/8” (9.5 mm) min. inside

diameter

1/2” (12.7 mm) min. inside

diameter

3/4” (19.1 mm) min. inside

diameter

1” (25.4 mm) min. inside

diameter

ICE MAKING WATER

INLET FITTING

3/8” F.P.T. (0.95 cm)

18.00” VENT

(45.70 cm)

DRAIN CONNECTION

1/2” N.P.T. (1.27 cm)

DO NOT TRAP

MUST HAVE

AIR-GAP

INCORRECT

Typical Water Supply and Drain Installation

ICE MAKING WATER

DRAIN TUBING

1/2” MIN. I.D. (1.27 cm)

AIR GAP

REQUIRED

OPEN, TRAPPED OR

VENTED DRAIN

SV1783

Part Number 000001530 2-11

Page 22

Installation Instructions Section 2

Refrigeration System Installation

QuietQube®

Ice Machine

QDUALC

Line Set Suction Line Liquid Line

RC 20/30/50

USAGE WITH NON-MANITOWOC

CONDENSING UNITS

Manitowoc CVD® Condensing Units are specifically

designed for usage with a QuietQube® Ice Machine

Head Section. Standard condensing units and NonManitowoc condensing units will not operate a

QuietQube® Ice Machine Head Section.

Remote Single

Condenser

CVD1875

CVD2075

7/8 inch

(22.2 mm)

Circuit

5/8 inch

(15.9 mm)

Line Set*

RC-22

RC-32

RC-52

Insulation

Thickness

3/4”(19mm)

Suction Line

1/4” (7mm)

Liquid Line

Factory Equipment Refrigeration Amounts

ICE MACHINE HEAD SECTION

Each ice machine head section ships from the factory

with a R-404A refrigerant charge appropriate for the

installations with up to 50’ of refrigeration tubing. The

serial tag on the ice machine indicates the refrigerant

charge. For line set runs longer than 50’ 1 lb. of

additional refrigerant must be added for each 10’ of line

set run. The receiver is designed to hold a charge

sufficient to operate the ice machine in ambient

temperatures between -20°F (-28.9°C) and 120°F

(49°C), with line set lengths of up to 100 feet (30.5 m).

Warning

!

The ice machine head section contains the refrigerant

charge. Installation and brazing of the line sets must be

performed by a properly trained and EPA certified

refrigeration technician aware of the dangers of dealing

with refrigerant charged equipment.

Caution

!

Never add more than nameplate charge to the

refrigeration system for any application.

Caution

!

The 60-month compressor warranty (including the

36-month labor replacement warranty) will not apply if

the Manitowoc Ice Machine and Manitowoc CVD

Condensing Unit are not installed according to

specifications. This warranty also will not apply if the

refrigeration system is modified with a condenser,

heat reclaim device, or other parts or assemblies not

manufactured by Manitowoc Ice, Inc.

CVD

® CONDENSING UNIT

Each condensing unit ships from the factory pressurized

with 50/50 nitrogen helium mixture that must be

removed during the installation process (approximately

20 psig).

REFRIGERATION LINE SETS/TRAP KIT

Refrigeration Rated Tubing and Trap Kits are shipped

capped with atmospheric pressure.

!

Warning

Installation of a QuietQube® Condensing Unit may require

the use of special equipment for placement. Trained and

qualified personnel are required for proper rigging and

lifting. Holes are provided on the corners of the condensing

unit to allow the use of lifting shackles.

2-12

Part Number 000001530

Page 23

Section 2 Installation Instructions

Refrigeration Line Set Installation

GENERAL

Refrigeration line set installations consist of vertical and

horizontal line set distances between the ice machine

and the condensing unit. The following guidelines,

drawings and calculation methods must be followed to

assure proper oil return and CVD® condensing unit/ice

machine operation.

The refrigeration line set installer must be USA

Government-Environmental Protection Agency (EPA)

certified in proper refrigerant handling and servicing

procedures.

!

Warning

The ice machine head section contains refrigerant

charge. The ice machine he ad sectio n contains thre e

(3) refrigeration valves that must remain closed until

proper installation of the line sets is completed.

Warning

!

Disconnect electrical power to the ice machine head

section and CVD® condensing unit before

proceeding.

A. LINE SET LENGTH

100 feet (30.5 m) Length: The maximum measured

length the line set can be.

The receiver is designed to hold a charge sufficient to

operate the ice machine in ambient temperatures

between -20°F (-28.9°C) and 120°F (4 9° C) , with line set

lengths of up to 100 feet (30.5 m).

Important

QuietQube® ice machines will not function with line

sets greater than 100 feet (30.5 m). Do not attempt to

go beyond this distance and add refr igera nt ch ar ge to

compensate! Refer to factory equipment refrigerant

amounts on previous page for details.

B. LINE SET RISE OR DROP

35’ (10.7 M)

MAX.

DISTANCE

Step 1 Verify Ice Machine and CVD® Condensing

Unit Locations Are Within Guidelines.

Prior to installation of the ice machine head section and

CVD® condensing unit be sure that the distance

between then is within the line set routing guidelines

outlined in this manual.

Roof/Wall Penetration

If required, cut a 3-inch (76.2 mm) circular hole in the

wall or roof for routing of refrigeration tubing. A qualified

person must perform all roof penetrations.

Step 2 Route Refrigeration Tubing

Properly route refrigeration tubing between the ice

machine head section and the CVD® condensing unit.

SV1751

35 feet (10.7 m) Rise: The maximum distance the

CVD® condensing unit can be above the ice machine.

15’ (4.5 M)

MAX.

DISTANCE

SV1750

15 feet (4.5 m) Drop: The maximum distance the CVD®

condensing unit can be below the ice machine.

Part Number 000001530 2-13

Page 24

Installation Instructions Section 2

C. SUCTION LINE OIL TRAPS

Caution

!

Do not form unwanted traps in refrigeration lines.

Never coil excess refrigeration tubing.

0 to 20 feet (0 to 6.1 m) Rise: The ice machine head

section has one oil trap built in which allows for a

maximum condenser rise of 20 feet (6.1 m) without

additional traps in the suction line.

21 to 35 feet (6.4 to 10.7 m) Rise: The suction line

requires an additional Oil Trap (“S” type) to be installed.

Install the trap as close as possible to midpoint between

the ice machine head section and CVD condensing unit.

S-Trap Kits are a vailable from Manitowoc (refer to chart).

21’ OR MORE

RISE

ADDITIONAL

TRAP KIT

REQUIRED

Service Loop

A service loop in the line set permits easy access to the

ice machine for cleaning and service.

• The supplied service loop is an installation

requirement. Excess tubing length must be

sufficient to allow 180° rotation of the ice

machine.

• A service loop is not considered an oil trap.

• The service loop is not included when calculating

length, rise or drop of the tubing run.

• Do not use hard rigid copper for the service loop.

Caution

!

If a line set has a rise followed by a drop, another rise

cannot be made. Likewise, if a line set has a drop

followed by a rise, another drop cannot be made.

Step 3 Lengthening or Reducing Line Set Lengths

Caution

!

Do not form unwanted traps in refrigeration lines.

Never coil excess refrigeration tubing.

Manitowoc S-Trap Kit

Model S-Trap Kit

QDUALC K00164

When the line set required shortening or lengthening, do

so before connecting the line set to the ice machine

head section or the CVD condensing unit.

SV1751

SV1760

Tubing Size

Number

7/8 inch

(22.2 mm)

2-14

Part Number 000001530

Page 25

Section 2 Installation Instructions

A

Step 4 Connecting the line set.

To prevent oxidation of the copper, purge line set and

condensing unit with dry nitrogen while brazing.

Connect The Line Set To The Ice Machine Head

Section

!

Warning

The ice machine head section contains refrigerant

charge. The ice machine he ad sectio n contains thre e

(3) refrigeration valves that must remain closed until

proper installation of the line sets is completed.

The line set can be routed for entry through the top or

rear of the ice machine head section.

• Top routing requires the cover to be trimmed.

• Rear routing requires the use of the supplies 90°

elbows.

Nitrogen purge is recommended while brazing the line

set to the ice machine head section. The line set shut off

valves at the back of the ice machine must remain

closed and be protected from heat during the brazing

process. Wrap the valves in a wet rag or other type of

heat sink prior to brazing. Cool braze joint with water

immediately after brazing to prevent heat migration to

the valve.

Connect The Line Set To The CVD Condensing Unit

!

Warning

The condensing unit ships from the factory

pressurized with a 50/50 mixture of nitrogen/helium.

Bleed off pressure from both suction and liquid line

access ports prior to cutting into refrigeration lines.

The compressor oil rapidly absorbs moisture. Be

prepared to complete line set installation and start your

evacuation process in order to minimize the time the

compressor is exposed to the atmosphere. (Maximum

amount of time the system can be exposed to the

atmosphere is 15 minutes).

The line set can be routed for entry through the rear or

left side of the condensing unit.

• Remove knockout for preferred location.

• Insert supplied plastic bushings in knockout holes to

prevent tubing from contacting sheet metal.

• Use the supplied 90° elbows to route tubing.

• Cut the tubing ends of the suction and liquid lines

and braze the line sets to the condensing unit.

SUCTION

LINE

LIQUID

LINE

VALVES MUST REMAIN

CLOSED AND BE

PROTECTED FROM

HEAT WHEN BRAZING

(WRAP WITH WET RAG)

Warning

!

SV1757

MINIMIZE THE TIME THE REFRIGERATION

SYSTEM IS EXPOSED TO THE ATMOSPHERE

(15 MINUTES MAXIMUM)

PT1306

The condensing unit ships from the factory

pressurized with a 50/50 mixture of nitrogen/helium.

Bleed off pressure from both suction and liquid line

access ports prior to cutting into refrigeration lines.

Part Number 000001530 2-15

Page 26

Installation Instructions Section 2

Step 5 Pressure Test and Evacuate The Line Set

and CVD Condensing Unit

Schrader valve core removal tools that allow for removal

and installation of the valve cores without removing

manifold gauge set hoses are recommended to

decrease the evacuation time.

Leave the line set shut off valves closed (front seated).

Pressure test the line sets and CVD condensing unit

with 150 psig of dry nitrogen. Add nitrogen at the line set

shut off valves located at the back of the ice machine.

Complete the pressure test, verify no leaks are present

and remove the nitrogen from the system before

connecting the vacuum pump. Connect a vacuum pump

to both of the line set shut off valves located at the back

of the ice machine head section. Evacuate to 500

microns minimum. To completely evacuate the CVD

condensing unit, continue the evacuation for 30 minutes

after reaching the 500 micron point.

If required, the line set and condensing unit can be

evacuated from the schrader valves located in the CVD

condensing unit. Schrader valve core removal tools (that

allow for putting the cores back in without removing

vacuum pump hoses) must be used if evacuating from

the condensing unit side.

Pressure test the condensing unit and line set with 150

psig of dry nitrogen. Add nitrogen at the conden sing unit

Schrader valves. Complete the pressure test, verify no

leaks are present and remove the nitrogen from the

system before connecting a vacuum pump. Connect the

vacuum pump to both the Schrader valves and evacuate

to 500 microns minimum.

Disconnect the vacuum pump from the condensing unit

access ports prior to proceeding. Open refrigeration

system shut off valves.

The suction line, liquid line and receiver service valves

are closed during shipment and installation.

CONDENSING UNIT

SCHRADER VALVES

CONNECT

VACUUM PUMP TO

LINE SET SHUT

OFF VALVES

SV1769b

SV1306A

2-16

Part Number 000001530

Page 27

Section 2 Installation Instructions

Step 6 Open The Valves Prior To Starting The Ice

Machine.

The suction line, liquid line and receiver service valves

are closed during shipment and installation. Open the

valves prior to starting the ice machine.

All refrigeration valve caps must be reinstalled to

prevent future refrigeration leaks.

Important

A. Slowly backseat (open-turn counterclockwise)

the suction line shut off valve.

B. Slowly backseat (open-turn counterclockwise)

the liquid line shut off valve.

C. Slowly backseat (open-turn counterclockwise)

the receiver service valve.

NOTE: You will not hear refriger ant flow when the valves

are opened. Refrigerant will not flow until the toggle

switch is placed in the ice position and the liquid line

solenoid valve opens.

USE ALLEN WRENCH TO OPEN

(TURN COUNTERCLOCKWISE)

LIQUID AND SUCTION LINE SHUT

OPEN SUCTION AND LIQUID LINE SHUT OFF VALVES

OFF VALVES

SV1769C

Verify O-ring in schrader valve caps are intact and

reinstall on shut off valves to prevent refrigerant leakage.

Replace shut off valve access caps and torque to the

following specifications.

Torque Value’s

Stem 18-20 ft. lbs.

Caps 12-15 ft. lbs.

Schrader Core 1.5-3 in. lbs.

Replace cap on receiver service valve and tighten.

TURN

COUNTERCLOCKWISE

RECEIVER SERVICE V ALVE CAP

(TURN COUNTERCLOCKWISE

TO REMOVE)

SV1756

Open Receiver Service Valve

Caution

!

After opening suction, discharge and receiver service

valves, refrigerant pressure will not be detected until

the toggle switch is placed in the ice position and the

cool vapor solenoid valve energizes.

There is a liquid line solenoid valve at the outlet of the

receiver; refrigerant will not flow to the condensing unit

until the ice machine head section is started. Connect

power to both the ice machine head section and the

CVD condensing unit. Place the ICE/OFF/CLEAN toggle

switch into the ICE position, this will allow refrigerant to

enter the line set and condensing unit.

Part Number 000001530 2-17

Page 28

Installation Instructions Section 2

Step 7 Leak Check The Refrigeration System

Leak check the new line set connections at the ice

machine head section, condensing unit and S trap as

well as all factory joints throughout the entire system.

Disconnect power to the CVD condensing unit. Place the

ICE/OFF/CLEAN toggle switch into the ICE position.

This allows the low side and high side pressures to

equalize. Place the ICE/OFF/CLEAN toggle switch in the

OFF position. Connect power to the CVD condensing

unit and allow system to pump down.

Step 8 Insulation Requirements

To prevent condensation the entire suction line including

the shut-off valve must be insulated. All insulation must

be airtight and sealed at both ends. Insulate shut-off

valves with the supplied preformed insulation.

The following insulation requirements prevent

condensation at 90°F (32.2°C) ambient 90% Relative

Humidity. If higher humidity is expected, increase

insulation thickness.

The entire suction line set, including the suction service

valve located on the back of the ice machine requires:

Suction Line Liquid Line Min. Insulation

Thickness

3/4”(19mm)

3/4 inch

(19 mm)

1/4 inch

(7 mm)

Suction Line

1/4” (7mm)

Liquid Line

3 Phase Scroll Compressor Rotation

CVD2075 Only

A trained and qualified technician must verify

compressor rotation at equipment st artup o r compressor

warranty will be void. Incorrect rotation of a scroll

compressor can be identified by:

• Noisy compressor operation

• Elevated suction pressure

• Low discharge pressure

• Compressor trips on overload protector

To change compressor rotation, reverse (exchange

locations) any two incoming power supply leads.

Te st run ice machine in the freeze and harvest cycles,

then place toggle switch in OFF position and verify

condensing unit cycles off.

Important

To prevent condensation the entire suction line

including the shut off valve must be insulated. All

insulation must be airtight and sealed at both ends.

The minimum requirements are for conditions at or

below 90% humidity and 90°F (32.2°C) ambient.

When higher humidity will be experienced, insulation

wall thickness will need to be increased.

2-18

Part Number 000001530

Page 29

Section 2 Installation Instructions

CVD CONDENSING

UNIT

ELECTRICAL

DISCONNECT

SUCTION

LIQUID

LINE

LINE

ICE MACHINE

HEAD SECTION

BIN

BIN DRAIN LINE

SHUT-OFF

VALVES

ICE MACHINE DRAIN

LINE

SV1768D

Typical QuietQube System Installation

Part Number 000001530 2-19

Page 30

Installation Instructions Section 2

Installation Checklist

Is the Ice Machine level?

Has all of the internal packing been removed?

Have all of the electrical and water connections

been made?

Has the supply voltage been tested and checked

against the rating on the nameplate?

Is there proper clearance around the ice machine

for air circulation?

Has the ice machine been installed where

ambient temperatures will remain in the range of

35° - 110°F (1.7° - 43.3°C)?

Has the ice machine receiver service valve been

opened 100%?

Are the ice machine line set shut-of f valves ope n

100%?

Does the condenser fan motor(s) operate

properly after start-up?

Have all the refrigeration fittings and joints been

leak checked?

Is the line set routed properly?

Is a refrigeration oil trap (S-trap) installed if the

condenser is installed 21 to 35 feet (6.1 to 10.7m)

above the ice machine head?

Has the ice machine been installed where the

incoming water temperature will remain in the

range of 33° - 90°F (0.6° - 32.2°C)?

Are the ice machine and bin drains separately

vented?

Are all electrical leads free from contact with

refrigeration lines and moving equipment?

Has the owner/operator been instructed rega rding

maintenance and the use of Manitowo c Cleane r

and Sanitizer?

Has the warranty registration card been sent to

the factory?

Has the ice machine and bin been sanitized?

Has the CVD® condensing unit been installed to

prevent any roofing damage?

Have the refrigeration lines been insulated and

secured properly to prevent vibration?

Has the remote condensing unit been located

where ambient temperatures will remain in the

range of -20° to 120°F (-28.9° to 49°C)?

Is the toggle switch set to ice?

Is the ice thickness control set correctly?

Is the water trough drain plug installed? (The

drain plug is taped to the top of the water pump)

Does the condenser fan motor(s) operate

properly after start-up?

2-20

Is the direction of rotation correct on a CVD2075

3ph scroll compressor?

Part Number 000001530

Page 31

Section 2 Installation Instructions

Before Starting the Ice Machine

All Manitowoc ice machines are factory-operated and

adjusted before shipment. Normally, new installations do

not require any adjustment.

To ensure proper operation, follow the Operational

Checks in Section 3 of this manual. Starting the ice

machine and completing the Operational Checks are the

responsibilities of the owner/operator.

Adjustments and maintenance procedures outlined in

this manual are not covered by the warranty.

!

Warning

Do not operate equipment that has been misused.

abused, neglected, damaged, or altered/modified

from that of original manufactured specifications.

AuCS® Automatic Cleaning System

This optional accessory monitors ice making cycles and

initiates cleaning procedures automatically. The AuCS®

accessory can be set to automatically clean or sanitize

the ice machine every 2, 4 or 12 weeks. Refer to the

AuCS® Installation and Owner/Operator Use and Care

Guide for details.

SV1601

Part Number 000001530 2-21

Page 32

Installation Instructions Section 2

THIS PAGE INTENTIONALLY LEFT BLANK

2-22

Part Number 000001530

Page 33

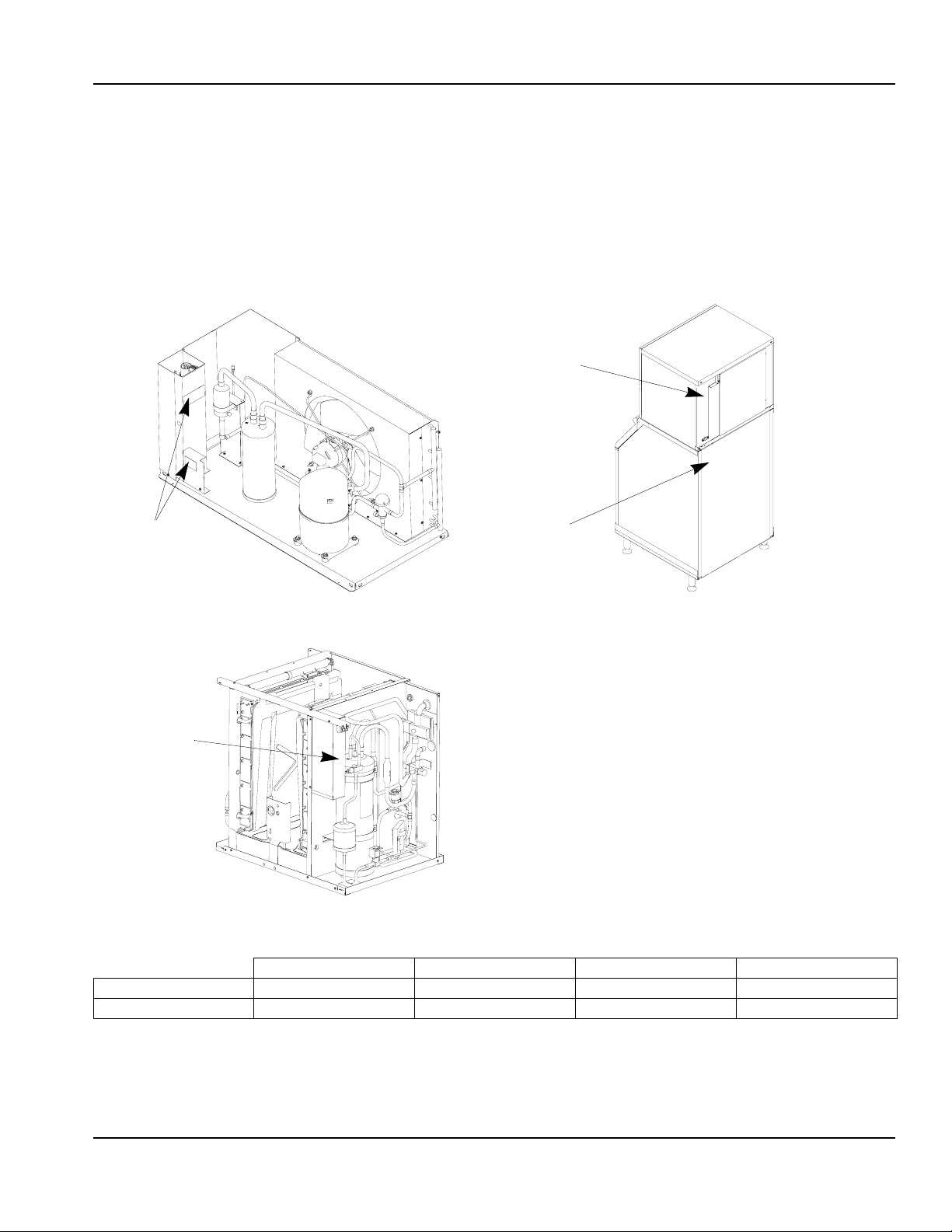

Component Identification

ICE MACHINE HEAD SECTION

QDUALC

EVAPORATOR

WATER

PUMP

Section 3

Ice Machine Operation

DISTRIBUTION

TUBE

SUCTION LINE

SHUT-OFF

VALVE

LIQUID LINE

SHUT-OFF

VALVE

WATER

CURTAIN

WATER INLET

VALVE

WATER

DUMP

VALVE

WATER

TROUGH

ICE

THICKNESS

PROBE

SV1780

RECEIVER

SERVICE

VALVE

RECEIVER

CVD CONDENSING UNIT

CVD1875/CVD2075

ACCESS

VALVES

ELECTRICAL

COMPARTMENT

CONDENSER

FAN MOTOR

LIQUID LINE

SOLENOID

VALVE

AIR

CONDENSER

COOL

VAPOR

VALVE

SV1779RH

HEAD PRESSURE

CONTROL VALVE

ICE/OFF/CLEAN

COOL VAPOR

VALVE

WATER INLET

FITTING

BRACKET

TOGGLE

WITCH

SV1779LH

LIQUID LINE

AND

SUCTION LINE

CONNECTION

POINTS

SUCTION

ACCUMULATOR

COMPRESSOR

PT1306A

Part Number 000001530 3-1

Page 34

Ice Machine Operation Section 3

Ice Making Sequence of Operation

INITIAL START-UP OR START-UP AFTER

AUTOMATIC SHUT-OFF

1. Water Purge

Before the refrigeration system starts, the water pump

and water dump solenoid are energized for 45 seconds,

to completely purge the ice machine of old water. This

feature ensures that the ice making cycle starts with

fresh water. The harvest solenoid valves are also

energized during the water purge, although they stay on

for an additional 5 seconds (50 seconds total on time)

then shuts off.

2. Refrigeration System Start-Up

Ice Machine Head Section: The liquid line solenoid

valve energizes after the 45 second water purge and

remains on throughout the entire Freeze and Harvest

Sequences. The harvest solenoid valves remains on for

5 seconds during initial compressor start-up and then

shuts off.

The water fill valve is energized at the same time as the

liquid line solenoid valve.

CVD Condensing Unit: When the refrigerant pressure

is high enough to close the low pressure control, (after

the cool vapor valves energize in step 1) the contactor

coil is energized and the compressor starts. The

compressor and fan cycling control are supplied with

power throughout the entire Freeze and Harvest

Sequences. When the refrigerant pressure is high

enough to close the fan cycling pressure control the

condenser fan motor starts.

FREEZE SEQUENCE

3. Prechill

The liquid line solenoid is energized for 30 seconds prior

to water flow. This allows the refrigeration system to start

up and prechill the evaporator. The water fill valve

remains energized until the water level sensor is

satisfied.

4. Freeze

The water pump restarts after the 30 second Prechill. An

even flow of water is directed across the evaporator and

into each cube cell, where it freezes. The water fill valve

will cycle on one more time to refill the water trough as

needed.

When sufficient ice has formed, the water flow (not the

ice) contacts the ice thickness probe. After

approximately 10 seconds of continual water contact,

the Harvest Sequence is initiated. The ice machine

cannot initiate a Harvest Sequence until a 6-minute

freeze lock has been surpassed.

HARVEST SEQUENCE

5. Water Purge

The water pump continues to run, and the water dump

valve energizes for 45 seconds to purge the water in the

sump trough. The water fill valve energizes for the last

15 seconds of the 45 second water purge. After the

45 second water purge, the water pump and dump

solenoid valve de-energize. The harvest solenoids open

at the beginning of water purge.

6. Harvest

The harvest solenoid valves remain open and the

refrigerant warms each evaporator causing the cube s to

slide as a sheet, off the evaporator and into the storage

bin. The ice may fall first from either the right or the left

evaporator, or both at the same time. The sliding sheet

of cubes swings the water curtain out, opening the

corresponding bin switch, which causes relay #5 or #6 to

open. Opening relay #5 or #6 de-energizes the

corresponding harvest solenoid valve for the remainder

of the Harvest Sequence. The momentary opening and

re-closing of both bin switches terminates the Harvest

Sequence and returns the ice machine to the Freeze

Sequence (steps 3-4).

6a. Water Assist Harvest Feature

Typical duration of a harvest sequence is less than 2.5

minutes when the harvest sequence time reaches 4

minutes the following occurs:

4 minutes into a Harvest Sequence. The water fill valve

will energize to fill the trough with water.

5 minutes into a Harvest Sequence. The water pump will

energize and flow water over the evaporators.

The water fill valve and water pump remain on until all

bin switches have been activated, or until the 7 minute

Harvest Sequence time limit is reached.

3-2

Part Number 000001530

Page 35

Section 3 Ice Machine Operation

AUTOMATIC SHUT-OFF

7. Automatic Shut-Off

Ice Machine Head Section: When the storage bin is full

at the end of a harvest sequence, the sheet of cubes

fails to clear either one or both water curtains. After one

or both water curtains are held open for 7 seconds the

ice machine shuts off.

CVD Condensing Unit: When the refrigerant pressure

is low enough to open the low-pressure switch, the

contactor coil is de-energized and the compressor and

condenser fan motor stop.

The ice machine remains off until enough ice has been

removed from the storage bin to allow the ice to fall clear

of the water curtain(s). As the water curtain(s) swing

back to the operating position, the bin switch re-closes

and the ice machine restart s (steps 1 - 2) provided the 3

minute delay period is complete. Both curtains must be

closed to start an ice making sequence.

Part Number 000001530 3-3

Page 36

Ice Machine Operation Section 3

Operational Checks

GENERAL

Manitowoc ice machines are factory-operated and

adjusted before shipment. Normally , a newly inst alled ice

machine does not require any adjustment.

To ensure proper operation, always follow the

Operational Checks:

• when starting the ice machine for the first time

• after a prolonged out of service period

• after cleaning and sanitizing

NOTE: Routine adjustments and maintenanc e

procedures outlined in this manual are not covered by

the warranty.

Important

CVD2075 Condensing Units

A scroll compressor must be operated for a

minimum break in period of 72 hours before full ice

production capacity will be reached.

WATER LEVEL

ICE THICKNESS CHECK

After a harvest cycle, inspect the ice cubes in the ice

storage bin. The ice thickness probe is factory-set to

maintain the ice bridge thickness at 1/8" (3.2 mm).

NOTE: Make sure the water curtain is in place when

performing this check. It prevents water from splashing

out of the water trough.

1. Inspect the bridge connecting the cubes. It should

be about 1/8" (3.2 mm) thick.

2. If adjustment is necessary, turn the ice thickness

probe adjustment screw clockwise to increase

bridge thickness, counterclockwise to decrease

bridge thickness.

NOTE: Turning the adjustment 1/3 of a turn will change

the ice thickness about 1/16" (1.5 mm).

ADJUSTING SCREW

The water level sensor is set to maintain the proper

water level above the water pump housing. The water

level is not adjustable.

If the water level is incorrect, check the water level probe

for damage (probe bent, etc.). Repair or replace the

probe as necessary.

SV1616A

1/8” ICE BRIDGE THICKNESS

SV1208

Ice Thickness Check

3. Make sure the ice thickness probe wire and the

bracket do not restrict movement of the probe.

3-4

Water Level Probe

Part Number 000001530

Page 37

Section 4 Maintenance

Section 4

Maintenance

Interior Cleaning and Sanitizing

GENERAL

Clean and sanitize the ice machine every six months for

efficient operation. If the ice machine requires more

frequent cleaning and sanitizing, consult a qualified

service company to test the water quality and

recommend appropriate water treatment. The ice

machine must be taken apart for cleanin g and sanitizing.

Caution

!

Use only Manitowoc approved Ice Machine Cleaner

and Sanitizer for this application (Manitowoc

Cleaner part number 94-0546-3 and Manitowoc

Sanitizer part number 94-0565-3). It is a violation of

Federal law to use these solutions in a manner

inconsistent with their labeling. Read and

understand all labels printed on bottles before use.

CLEANING PROCEDURE

Caution

!

Do not mix Cleaner and Sanitizer solutions together.

It is a violation of Federal law to use these solutions

in a manner inconsistent with their labeling.

Step 3 Remove all ice from the bin.

Step 4 Place the toggle switch in the CLEAN position.

The water will flow through the water dump valve and

down the drain. Wait until the water trough refills and

water flows over the evaporator, then add the proper

amount of ice machine cleaner.

Model Amount of Cleaner

QDUALC 9 ounces (270 ml)

Step 5 Wait until the clean cycle is complete

(approximately 30 minutes) then place the toggle switch

in the OFF position and disconnect power to the ice

machine (and dispenser when used).

Warning

!

Disconnect the electric power to the ice machine at

the electric service switch box..

Warning

!

Wear rubber gloves and safety goggles ( an d/or face

shield) when handling ice machine Cleaner or

Sanitizer.

Ice machine cleaner is used to remove lime scale and

mineral deposits. Ice machine sanitizer disinfects and

removes algae and slime.

Step 1 Set the toggle switch to the OFF position after

ice falls from the evaporator at the end of a Harvest

cycle. Or, set the switch to the OFF position and allow

the ice to melt off the evaporator.

Caution

!

Never use anything to force ice from the evaporator.

Damage may result.

Step 2 Remove front cover.

Part Number 000001530 4-1

Page 38

Maintenance Section 4

Step 6 Remove parts for cleaning.

!

Warning

Disconnect the electric power to the ice machine at

the electric service switch box..

A. Remove the splash shield

• Pull forward on left and right nylatch connectors until

disengaged from ice machine (connectors remain

attached to splash shield).

• Remove panel from front of ice machine by lifting

forward and up.

B. Remove the water curtain

• Gently flex the curtain in the center and remove it

from the right side.

• Slide the left pin out.

Water Curtain Removal

C. Remove the ice thickness probe

• Compress the hinge pin on the top of the ice

thickness probe.

NYLATCH CONNECTORS

PULL FORWARD TO

DISENGAGE

SV1771A

Important

Splash Shield must be reinstalled to prevent water

leakage.

COMPRESS

HINGE PIN TO

REMOVE

SV3135

Ice Thickness Probe Removal

• Pivot the ice thickness probe to disengage one pin

then the other. The ice thickness probe can be

cleaned at this point without complete removal. If

complete removal is desired, disconnect the ice

thickness control wiring from the control board.

4-2

Part Number 000001530

Page 39

Section 4 Maintenance

21-Jan-99

D. Remove the water distribution tube

• Remove the clamp from the vinyl water hose on the

right side of the distribution tube.

1. LIFT UP

2. SLIDE BACK

3. SLIDE TO RIGHT

DISTRIBUTION

TUBE

3

THUMBSCREW

2

1

THUMBSCREW

LOCATING

PIN

SV1620

Water Distribution Tube Removal

• Loosen the two thumbscrews which secure the

distribution tube.

SU1024YC - Loosen the three thumbscrews, which

secure the distribution tube.

• Lift the right side of the distribution tube up, and then

rotate it backward and to the right until the left side of

the distribution tube disengages the thumbscrew.

E. Remove the water level probe

• Pull the water level probe straight down to

disengage.

• Disconnect the wire lead from the water level probe.

• Remove the water level probe from the ice machine.

WATER LEVEL

PROBE

LOCATION

21-Jan-99

Caution

!

Do not force this removal. Be sure the locating tab is

clear before rotating the distribution tube back.

• Pull the vinyl hose off the distribution tube.

Disassemble for cleaning:

• Twist both of the inner tube ends until the tabs line up

with the keyways.

• Pull the inner tube ends outward.

Part Number 000001530 4-3

Page 40

Maintenance Section 4

F. Remove the water pump.

• Disconnect the water pump power cord.

LOOSEN

SCREWS

POWER

CORD

WATER

PUMP

OUTLET

PUMP

SV1456B

• Disconnect the hose from the pump outlet.

• Loosen the screws securing the pump mounting

bracket to the bulkhead.

• Lift the pump and bracket assembly off the screws.

• Remove water pump assembly from ice machine.Do

not soak the water pump motor in cleaner or sanitizer

solution

G. Remove the water trough

• Remove the quarter turn fasteners (turn

counterclockwise) securing the trough in place.

• Lift up and forward on the front of the water trough

while allowing the rear of the water trough to drop.

• Remove the water trough from the ice machine.

REMOVE THE TWO

1/4 TURN FASTENERS

BY TURNING

COUNTERCLOCKWISE

SV1771B

4-4

DO NOT SOAK

WATER PUMP

MOTOR IN

CLEANER OR

SANITIZER

SOLUTIONS

Part Number 000001530