Manitowoc Ice K-0250 Owner’s Manual

Ice Machines

Installation and Maintenance Manual

Part Number 000012545 Rev01 9/15

Section 1

General Information

Section 2

Installation Instructions

Table of Contents

Model Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Ice Deflector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Bin Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Location of Ice Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Clearance Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Ice Machine Heat of Rejection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Removing Drain Plug and Leveling the Ice Storage Bin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Air Baffle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Electrical Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Minimum Circuit Ampacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Ground Fault Circuit Interrupter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Minimum Power Cord Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

For United Kingdom Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Maximum Breaker Size & Minimum Circuit Amperage Chart . . . . . . . . . . . . . . . . . . . . . . . . . 8

Water Supply and Drain Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Water Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Water Inlet Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Drain Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Water Supply and Drain Line Sizing/Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Water-Cooled Condenser Water Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Cooling Tower Applications (Water-Cooled Models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Remote Condenser/Line Set Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Remote Ice Machine Refrigerant Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Guidelines for Routing Line Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Calculating Remote Condenser Installation Distances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Route the Line Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Connect the Line Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Pressure Test and Evacuate Line Set and Condenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Open Line Set Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Installation Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Additional Checks for Remote Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Before Starting the Ice Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Part Number 000012545 Rev01 9/15 1

Table of Contents (continued)

Section 3

Operation

Ice Making Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Operational Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Section 4

Maintenance

Cleaning and Sanitizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Cleaning/Sanitizing Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Parts Removal for Cleaning/Sanitizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Preventative Maintenance Cleaning Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Door Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Cleaning the Condenser Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Cleaning the Condenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Removal from Service/Winterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Safety Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Ice Thickness Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Cleaning/Sanitizing Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Preventative Maintenance Cleaning Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Exterior Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Sanitizing Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Water-Cooled Ice Machines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Section 5

Customer Support

Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Safety Limit Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2 Part Number 000012545 Rev01 9/15

Section 1 General Information

!

Warning

!

Warning

Follow these precautions to prevent personal injury:

• Remove all panels before lifting and installing.

• Two or more people or a lifting device are required

to lift or move this appliance to avoid injury or

tipping.

• Do not damage the refrigeration circuit when

installing, maintaining or servicing the unit.

• Do not obstruct vents or openings or store gasoline

or other flammable vapors or liquids in the vicinity

of this or any other appliance.

• It is the responsibility of the equipment owner to

perform a Personal Protective Equipment Hazard

Assessment to ensure adequate protection during

maintenance procedures.

• Do not operate equipment that has been misused,

abused, neglected, damaged, or altered/modified

from that of original manufactured specifications.

This appliance is not intended for use by persons

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience and

knowledge, unless they have been given

supervision concerning use of the appliance by a

person responsible for their safety. Do not allow

children to play with this appliance.

• Ice machines require a deflector when installed on

an ice storage bin. Prior to using a storage system

with this ice machine, contact the manufacturer to

ensure their ice deflector is compatible with this ice

machine.

When using electric appliances, basic precautions must

always be followed, including the following:

• Read all the instructions before using the appliance.

• To reduce the risk of injury, close supervision is

necessary when an appliance is used near children.

• Do not contact moving parts.

• Do not use electrical appliances or accessories

other than those supplied by the manufacturer.

• Do not use outdoors.

• All covers and access panels must be in place and

properly secured, before operating this equipment.

• Connect to a properly grounded outlet only.

• For a cord-connected appliance, the following

precautions must be observed:

A. Do not unplug by pulling on cord. To unplug,

grasp the plug, not the cord.

B. Unplug from outlet when not in use and

before servicing or cleaning.

C. Do not operate any appliance with a damaged

cord or plug, or after the appliance

malfunctions or is dropped or damaged in any

manner. Contact the nearest authorized

service facility for examination, repair, or

electrical or mechanical adjustment.

• This equipment contains high voltage electricity

and refrigerant charge. Installation and repairs are

to be performed by properly trained technicians

aware of the dangers of dealing with high voltage

electricity and refrigerant under pressure. The

technician must also be certified in proper

refrigerant handling and servicing procedures. All

lock out and tag out procedures must be followed

when working on this equipment.

• Objects placed or dropped in the bin can affect

human health and safety. Locate and remove any

objects immediately.

Part Number 000012545 Rev01 9/15 3

General Information Section 1

Model Numbers

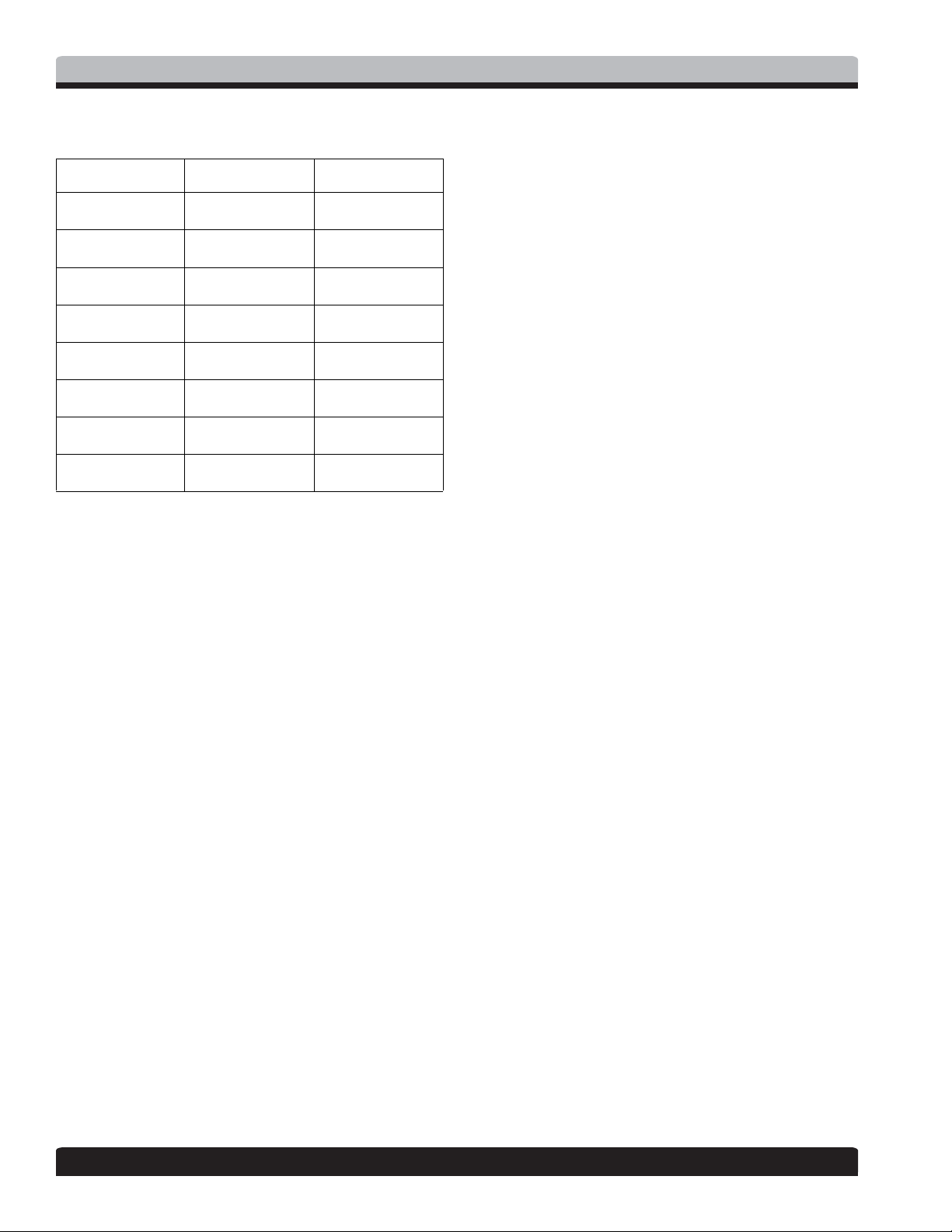

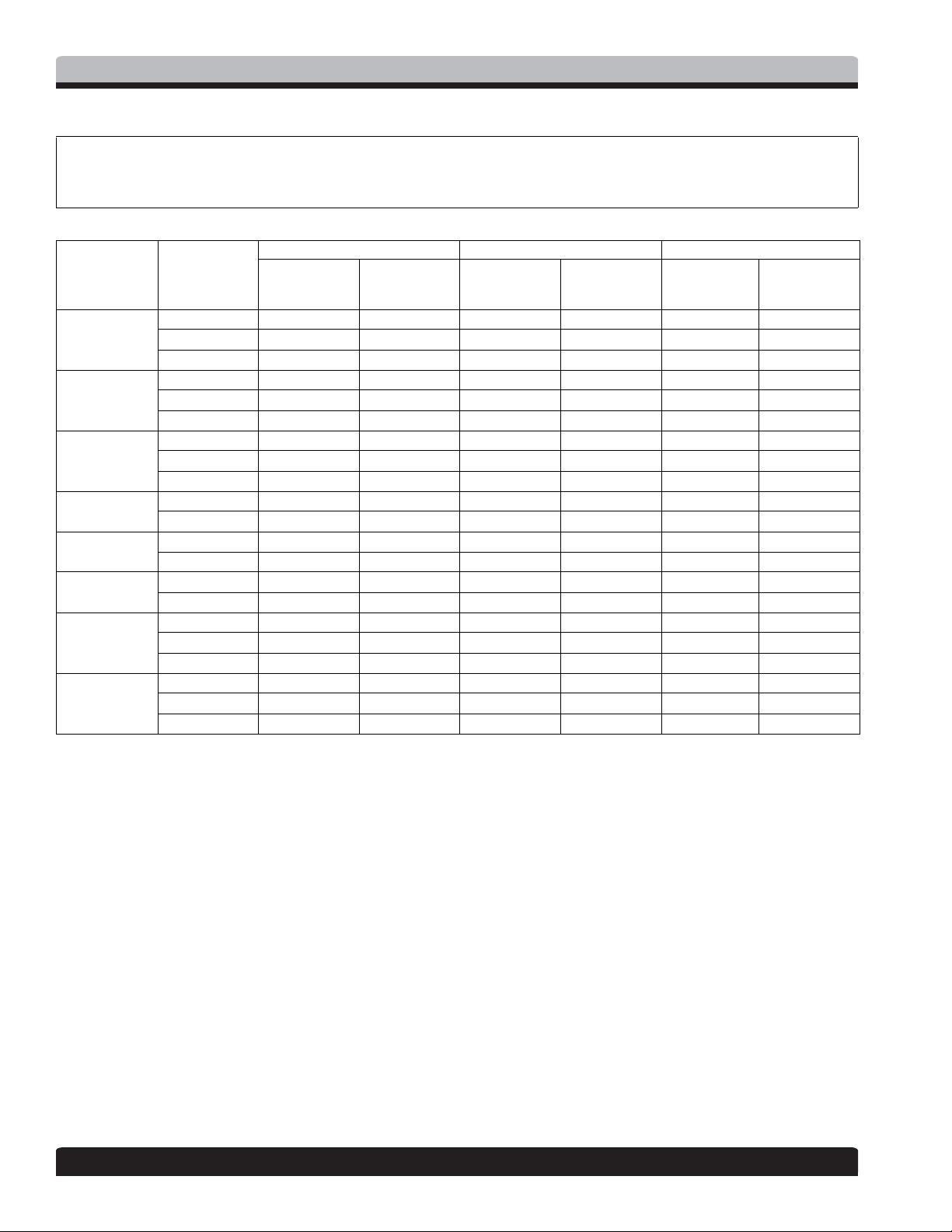

This manual covers the following models:

Self-Contained

Air-Cooled

KD0250A

KY0250A

KD0350A

KY0350A

KD0420A

KY0420A

KD0500A

KY0500A

KD0600A

KY0600A

KD1000A

KY1000A

KD1350A

KY1350A

KD1800A

KY1800A

Self-Contained

Water-Cooled

----

----

KD0350W

KY0350W

KD0420W

KY0420W

KD0500W

KY0500W

KD0600W

KY0600W

KD1000W

KY1000W

KD1350W

KY1350W

----

----

Remote

----

----

----

----

----

----

----

----

----

----

KD1000N

KY1000N

KD1350N

KY1350N

KD1800N

KY1800N

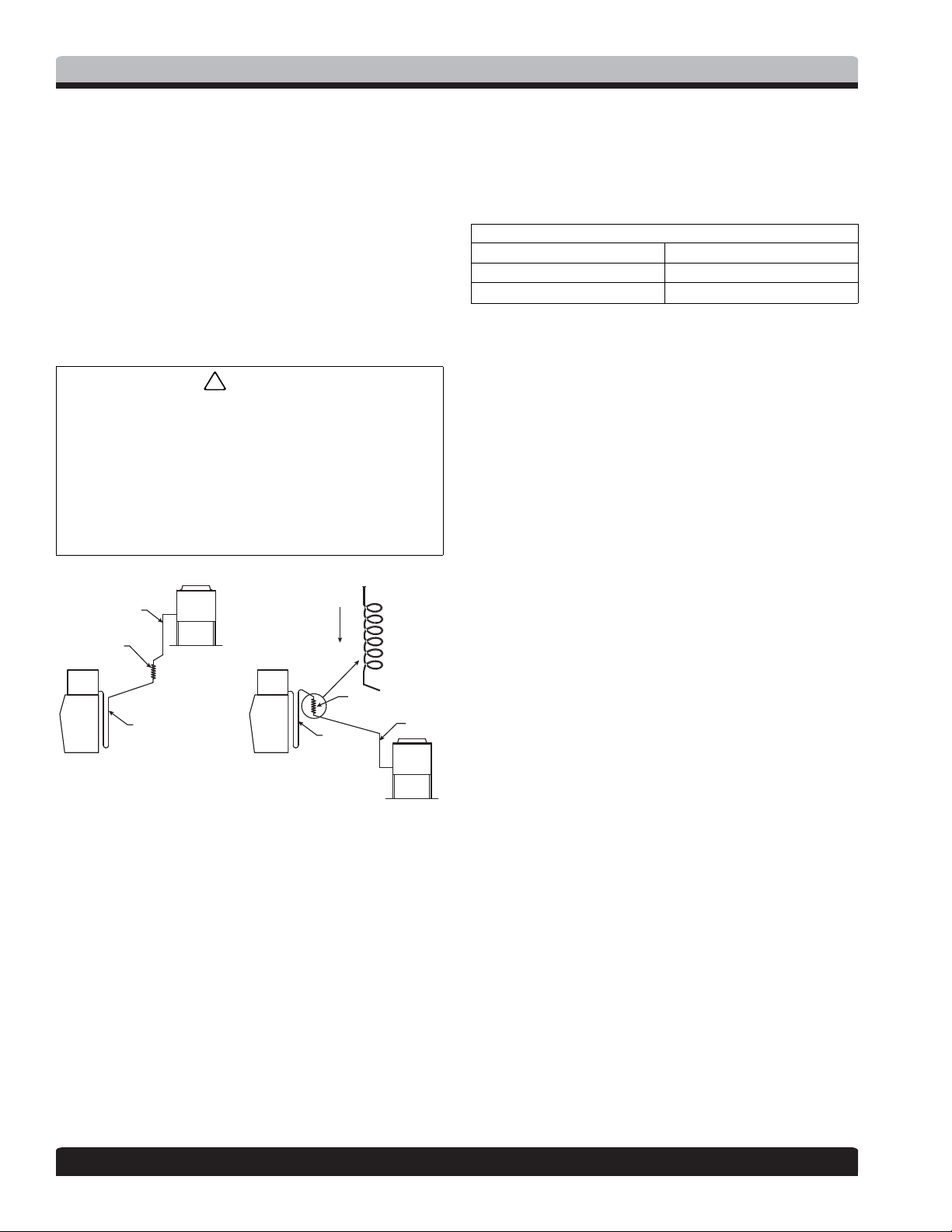

ICE DEFLECTOR

An ice deflector is required when the ice machine is installed

on a bin. An ice deflector is not required when the ice

machine is installed on a dispenser.

BIN INSTALLATION

• All ice machines installed on a bin require an ice

deflector.

• Koolaire bins have a deflector installed and require no

modifications when used with a forward facing

evaporator.

• Align sides and back of ice machine with sides and back

of bin, when placing ice machine on bin.

4 Part Number 000012545 Rev01 9/15

Section 2 Installation Instructions

!

Warning

!

Warning

!

Caution

Location of Ice Machine

The location selected for the ice machine must meet the

following criteria. If any of these criteria are not met, select

another location.

• The location must be free of airborne and other

contaminants.

• The air temperature must be at least 35°F (1.6°C), but

must not exceed 110°F (43.4°C).

NOTE: K1350 Minimum air temperature is 40°F (4.4°C).

• Remote air-cooled - The air temperature must be at least

-20°F (-29°C), but must not exceed 120°F (49°C).

• The location must not be near heat-generating (ovens,

dishwashers, etc) equipment or in direct sunlight and

must be protected from weather.

• The location must not obstruct airflow through or

around the ice machine. Refer to the clearance

requirements chart.

These ice machines are intended for use in applications such

as:

• Staff kitchen areas in shops, offices and other work

environments

• Clients in hotels, motels, farmhouses, bed and breakfast

and other residential type environments

• Catering and similar non-retail applications

Two or more people or a lifting device are required to

lift this appliance.

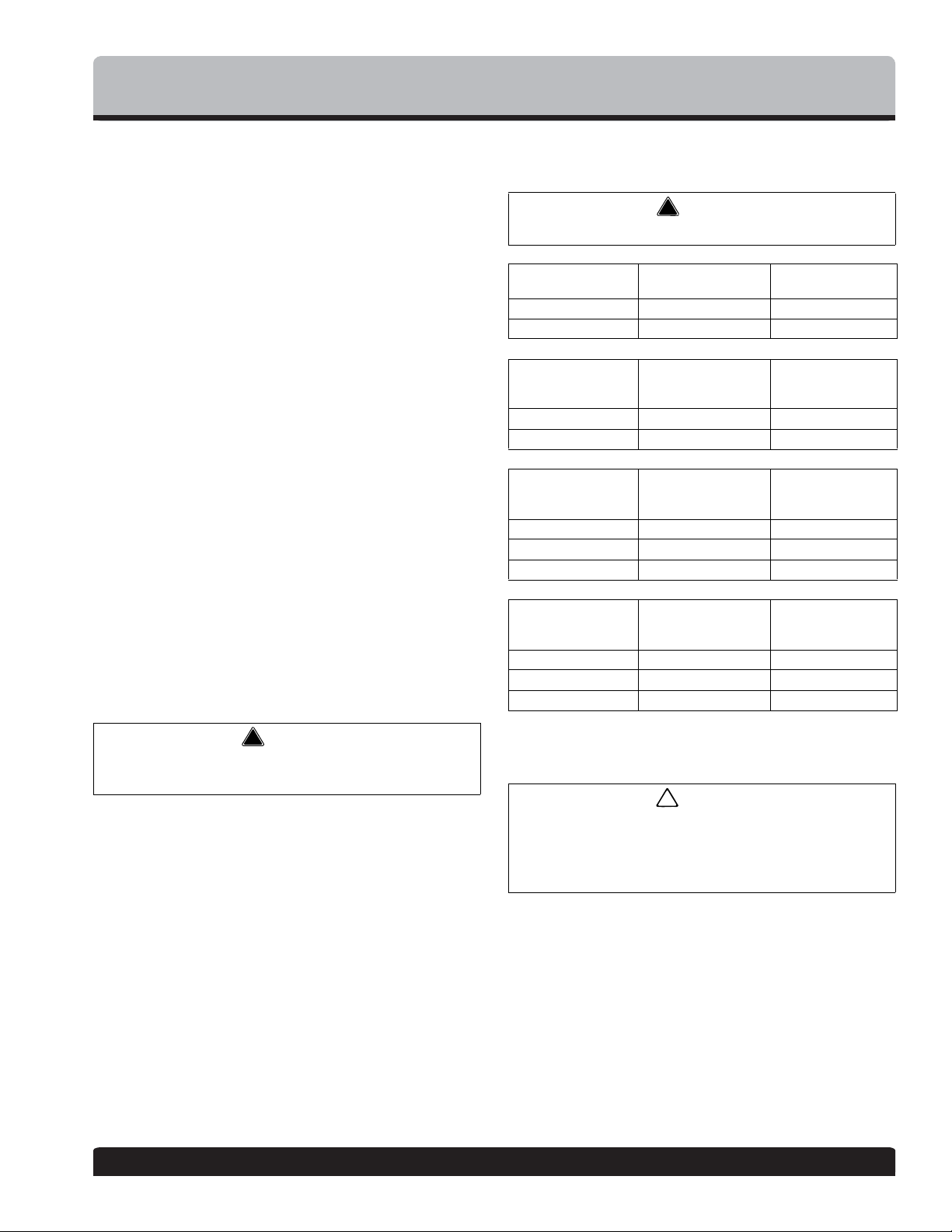

Clearance Requirements

Do not obstruct ice machine vents or openings.

K0250

To p/ Si de s 12" (30.5 cm)** N/A

Back 5" (12.7 cm)** N/A

K0350/K0420

K0500/K0600/

K1000/K1350/ K1800

To p/ Si de s 8" (20.3 cm)** 8" (20.3 cm)**

Back 5" (12.7 cm)** 5" (12.7 cm)**

K0420

Tropical Ra ting

50 Hz Only

Top 24" (61.0 cm)** 8" (20.3 cm)**

Sides 12" (30.5 cm)** 8" (20.3 cm)**

Back 5" (12.7 cm)** 5" (12.7 cm)**

K1000

Tropical Ra ting

50 Hz Only

Top 12" (30.5 cm)** 8" (20.3 cm)**

Sides 8" (20.3 cm)** 8" (20.3 cm)**

Back 5" (12.7 cm)** 5" (12.7 cm)**

* There is no minimum clearance required for water-cooled or remote ice

machines. This value is recommended for efficient operation and

servicing only.

** Indicates Preliminary Data

Self-Contained

Air-Cooled

Self-Contained

Air-Cooled

Self-Contained

Air-Cooled

Self-Contained

Air-Cooled

Self-Contained

Wate r-Coo led*

Water-Cooled

and

Remote*

Water-Cooled*

Water-Cooled

and

Remote*

The ice machine must be protected if it will be

subjected to temperatures below 32°F (0°C). Failure

caused by exposure to freezing temperatures is not

covered by the warranty.

Part Number 000012545 Rev01 9/15 5

Installation Instructions Section 2

!

Warning

!

Caution

AIR BAFFLE

Ice Machine Heat of Rejection

Series

Ice Machine

K0250 4600 5450

K0350 3800 6000

K0420 5400 6300

K0500 5300 6100

K0600 9000 13900

K1000 16250 18600

K1350 28300 34300

K1800 28800 34700

1 B.T.U./Hour

2 Because the heat of rejection varies during the ice making cycle, the

figure shown is an average.

Air Conditioning

Heat of Rejection

2

Ice machines, like other refrigeration equipment, reject heat

through the condenser. It is helpful to know the amount of

heat rejected by the ice machine when sizing air

conditioning equipment where self-contained air-cooled ice

machines are installed.

This information is also necessary when evaluating the

benefits of using water-cooled or remote condensers to

reduce air conditioning loads. The amount of heat added to

an air conditioned environment by an ice machine using a

water-cooled or remote condenser is negligible.

Knowing the amount of heat rejected is also important

when sizing a cooling tower for a water-cooled condenser.

Use the peak figure for sizing the cooling tower.

1

Peak

Removing Drain Plug and Leveling the Ice Storage Bin

To avoid instability, the bin/dispenser must be installed

in an area capable of supporting the weight of the bin/

dispenser, ice machine and a full bin of ice (48" models

1000 lbs [454 kg], 30" models 750 lbs [340 kg]). The bin/

dispenser must be level side-to-side and front-to-back

before installing the ice machine.

1. Remove threaded plug from drain fitting.

2. Screw the leveling legs onto the bottom of the bin.

3. Screw the foot of each leg in as far as possible.

The legs must be screwed in tightly to prevent them

from bending.

4. Move the bin into its final position.

5. Level the bin to assure that the bin door closes and seals

and the ice machine operates properly. Use a level on

top of the bin. Turn the base of each foot as necessary

to level the bin.

6. Inspect bin gasket prior to ice machine installation. (Our

bins come with a closed cell foam gasket installed along

the top surface of the bin.)

7. Remove all panels from ice machine before lifting and

installing on bin. Remove front panel, top cover, left and

right side panels.

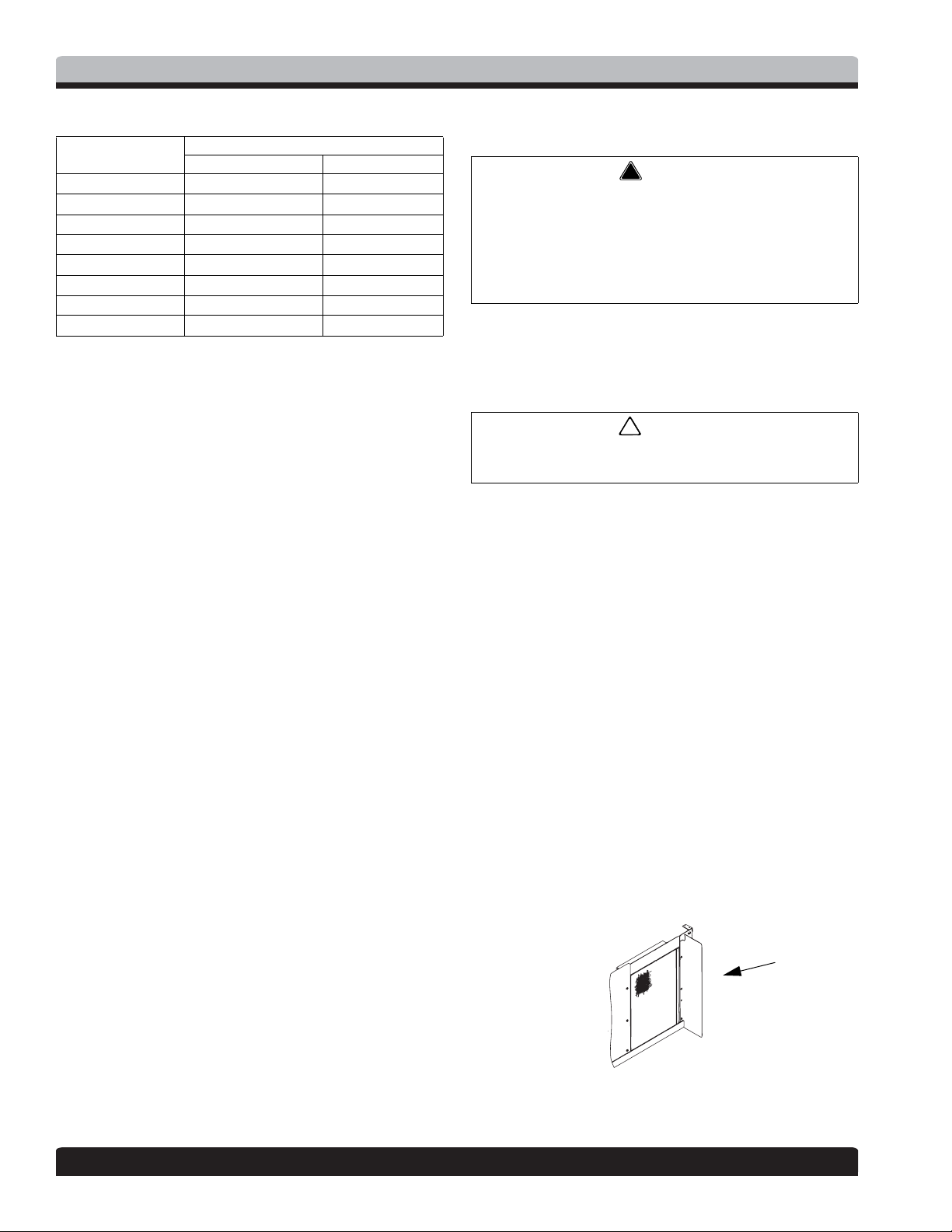

Air Baffle

Self-Contained Air-Cooled Only

The air-cooled baffle prevents condenser air from

recirculating. To install:

1. Loosen the back panel screws next to the condenser.

2. Align the keyhole slots in the air baffle with the screw

holes and slide the baffle down to lock in place.

6 Part Number 000012545 Rev01 9/15

Section 2 Installation Instructions

!

Warning

!

Caution

Electrical Service

All electrical work, including wire routing and

grounding must conform to all applicable national and

local electrical codes.

MINIMUM CIRCUIT AMPACITY

The minimum circuit ampacity is used to help select the

wire size of the electrical supply. (Minimum circuit ampacity

is not the ice machine’s running amp load.)

ELECTRICAL REQUIREMENTS

Refer to Ice Machine Model/Serial Plate for voltage/

amperage specifications.

• A separate fuse/circuit breaker must be provided for

each ice machine.

• The wire size (or gauge) is dependent upon location,

materials used, length of run, etc., so it must be

determined by a qualified electrician.

• The ice machine must be grounded. Check all green

ground screws in the control box and verify they are

tight before starting the ice machine.

• The maximum allowable voltage variation is ±10% of the

rated voltage at ice machine start-up (when the

electrical load is highest).

Observe correct polarity of incoming line voltage.

Incorrect polarity can lead to erratic ice machine

operation. Operate equipment only on the type of

electricity indicated on the specification plate.

GROUND FAULT CIRCUIT INTERRUPTER

Ground Fault Circuit Interrupter (GFCI/GFI) protection is a

system that shuts down the electric circuit (opens it) when it

senses an unexpected loss of power, presumably to ground.

GFCI/GFI circuit protection is not recommended with our

equipment. If code requires the use of a GFCI/GFI, then you

must follow the local code. The circuit must be dedicated,

sized properly and there must be a panel GFCI/GFI breaker.

We do not recommend GFCI/GFI outlets as they are known

for more intermittent nuisance trips than panel breakers.

MINIMUM POWER CORD SPECIFICATIONS

Maximum

Breaker Size

15 amp

20 amp

30 amp

40 amp

Minimum Wire

Size

14 gauge 6 feet (1.83 m)

12 gauge 6 feet (1.83 m)

10 gauge 6 feet (1.83 m)

8 gauge 6 feet (1.83 m)

Maximum Length of Power

Cord

If a power cord is used, the wire size to the receptacle is

dependent upon location, materials used, length of run, etc.,

so it must be determined by a qualified electrician. Local,

state or national requirements will supersede our minimum

requirements.

FOR UNITED KINGDOM ONLY

As the colors of the wires in the mains lead of the appliance may not

correspond with the colored markings identifying the terminals in your

plug, proceed as follows:

• The wire which is colored green and yellow must be connected to

the terminal in the plug which is marked with the letter E or by the

earth ground symbol

• The wire colored blue must be connected to the terminal which is

marked with the letter N or colored black.

• The wire colored brown must be connected to the terminal which is

marked with the letter L or colored red.

or colored green or green and yellow.

Part Number 000012545 Rev01 9/15 7

Installation Instructions Section 2

Important

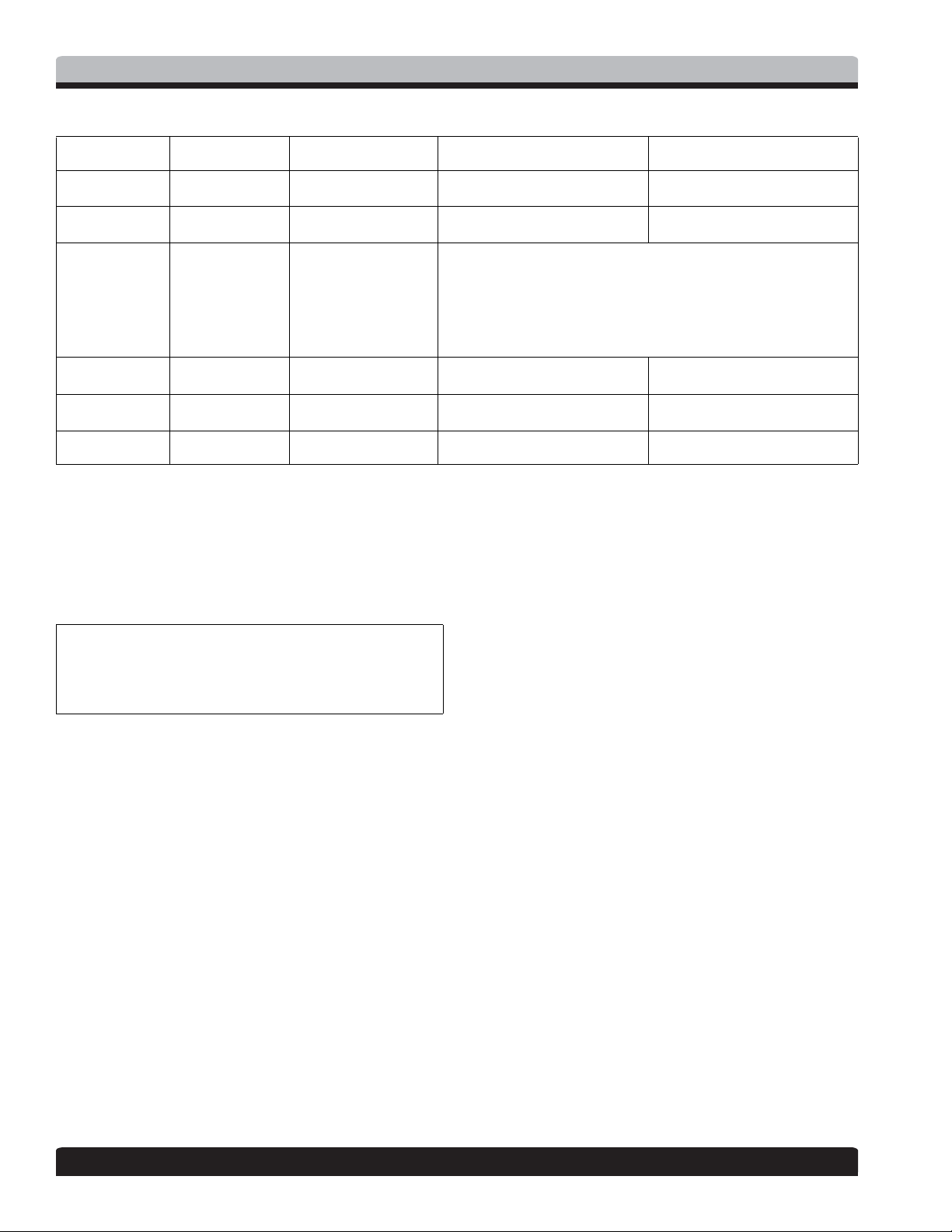

Maximum Breaker Size & Minimum Circuit Amperage Chart

Due to continuous improvements, this information is for reference only. Please refer to the ice machine serial number tag

to verify electrical data. Serial tag information overrides information listed on this page.

Air-Cooled Water-Cooled Remote

Ice Machine

K0250

K0350

K0420

K0500

K0600

K1000

K1350

K1800

Voltage/Phase/

Cycle

Maximum Fuse/

Circuit Breaker

Minimum

Circuit Amps

Maximum Fuse/

Circuit Breaker

Minimum

Circuit Amps

115/1/60 15 9.44 N/A N/A N/A N/A

230/1/50 15 4.5 N/A N/A N/A N/A

230/1/60 15 4.7 N/A N/A N/A N/A

115/1/60 15 12.1 15 11.4 N/A N/A

230/1/50 15 6.3 15 5.9 N/A N/A

230/1/60 15 6.2 15 5.8 N/A N/A

115/1/60 15 11.3 15 10.6 N/A N/A

230/1/50 15 6.2 15 5.8 N/A N/A

230/1/60 15 6.2 15 5.8 N/A N/A

115/1/60 20 12.7 20 12.0 N/A N/A

230/1/50 15 6.3 15 5.9 N/A N/A

208-230/1/60 20 9.2 20 8.8 N/A N/A

230/1/50 20 8.6 20 8.2 N/A N/A

208-230/1/60 20 13.9 20 13.2 20 12.8

230/1/50 20 13.8 20 13.1 20 14.1

208-230/1/60 30 18.2 30 16.8 30 17.8

208-230/3/60 20 13.6 20 12.2 20 13.2

230/1/50 30 18.2 30 16.8 30 17.8

208-230/1/60 30 19.6 N/A N/A 30 19.6

208-230/60/3 20 13.3 N/A N/A 20 12.9

230/1/50 30 19.6 N/A N/A 30 19.6

Maximum

Fuse/Circuit

Breaker

Minimum

Circuit Amps

8 Part Number 000012545 Rev01 9/15

Section 2 Installation Instructions

!

Warning

!

Caution

Water Supply and Drain Requirements

WATER SUPPLY

Local water conditions may require treatment of the water

to inhibit scale formation, filter sediment, and remove

chlorine odor and taste.

Connect to a potable water supply only. Plumbing must

conform to state, local and national codes.

WATER INLET LINES

Follow these guidelines to install water inlet lines:

• If you are installing a water filter system, refer to the

installation instructions supplied with the filter system

for ice making water inlet connections.

• Do not connect the ice machine to a hot water supply.

Be sure all hot water restrictors installed for other

equipment are working. (Check valves on sink faucets,

dishwashers, etc.)

• If water pressure exceeds the maximum recommended

pressure of 80 psi (552 kPa), obtain a water pressure

regulator from your local distributor.

DRAIN CONNECTIONS

Follow these guidelines when installing drain lines to

prevent drain water from flowing back into the ice machine

and storage bin:

• Drain lines must have a 1.5 inch drop per 5 feet of run

(2.5 cm per meter), and must not create traps.

• The floor drain must be large enough to accommodate

drainage from all drains.

• Run separate bin and ice machine drain lines. Insulate

them to prevent condensation.

• Vent the bin and ice machine drain to the atmosphere.

Do not vent the condenser drain on water-cooled

models.

• A separate auxiliary drain is located in the ice machine

base to remove moisture in high humidity areas. The

drain fitting is a female socket for 1/2" CPVC pipe. The

drain is sealed and the seal must be removed before

attaching the drain fitting/tubing. Tap the seal out with a

wooden dowel or similar tool. Seal the CPVC pipe to the

ice machine socket with silicone sealant to allow future

removal.

• Install a water shut-off valve for both the ice making and

condenser water lines.

• Insulate water inlet lines to prevent condensation.

Do not apply heat to water valve inlet fitting. This will

damage plastic water inlet connection.

Part Number 000012545 Rev01 9/15 9

Installation Instructions Section 2

Important

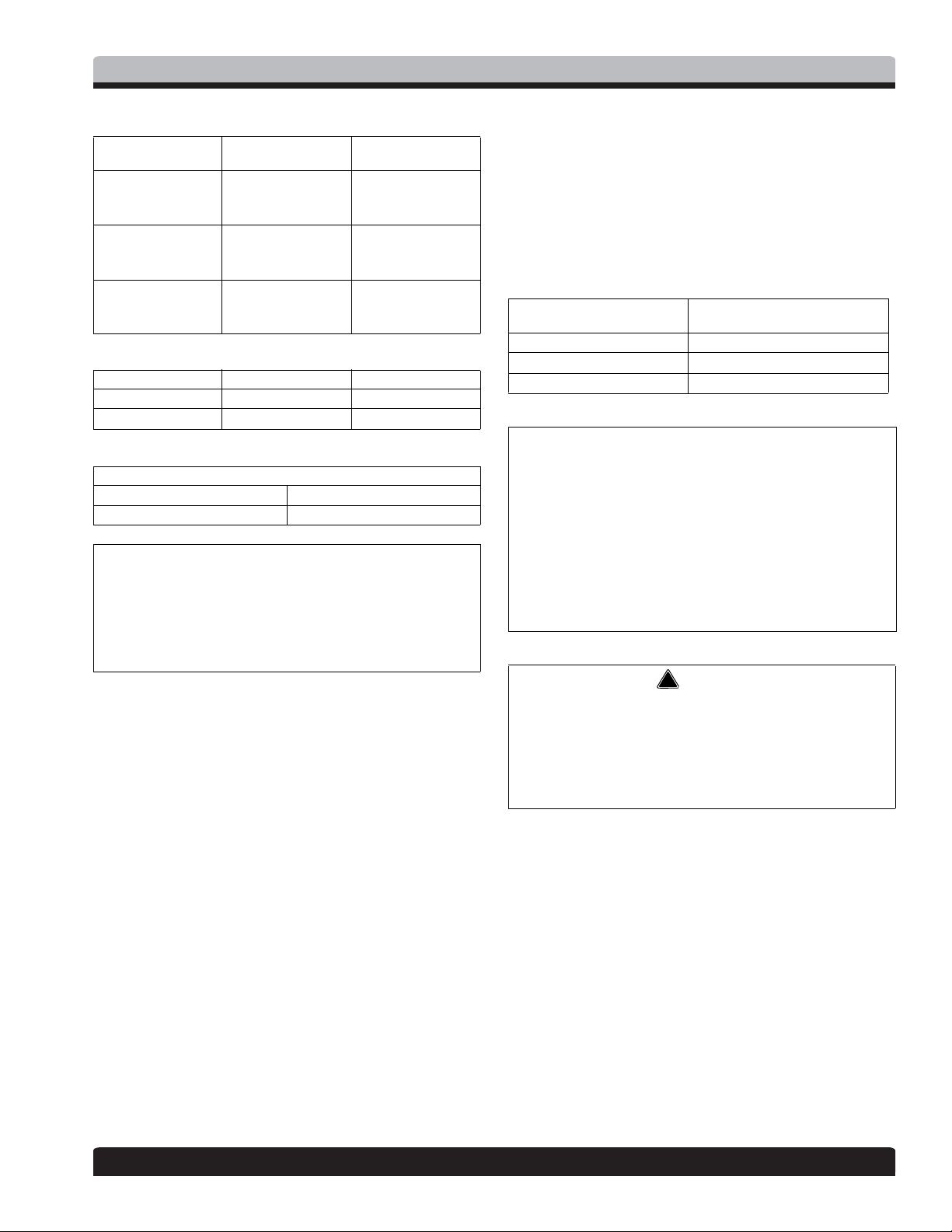

Water Supply and Drain Line Sizing/Connections

Location Water Temperature Water Pressure Ice Machine Fitting

Ice Making Water

Inlet

Ice Making Water

Drain

Condenser Water

Inlet

Condenser Water

Drain

Bin Drain

Large Capacity

Bin Drain

35°F (2°C) Min.

90°F (32°C) Max.

– – 1/2" (1.27 cm) Female Pipe Thread 1/2" (1.27 cm) min. inside

90°F (32°C) Max. Standard

– – 1/2" (1.27 cm) Female Pipe Thread 1/2" (1.27 cm) min. inside

– – 3/4" (1.91 cm) Female Pipe Thread 3/4" (1.91 cm) min. inside

– – 1" (2.54 cm) Male Pipe Thread 1" (2.54 cm) min. inside diameter

20 psi (140 kPa) Min.

80 psi (552 kPa) Max.

20 psi (140 kPa) Min.

150 psi (1034 kPa) Max.

High Pressure Option

20 psi (140 kPa) Min.

350 psi (2410 kPa) Max.

3/8" (.95 cm) Female Pipe Thread 3/8" (.95 cm) min. inside diameter

3/8" Female Pipe Thread

Tubing Size Up to Ice Machine

Fitting

diameter

diameter

diameter

WATER-COOLED CONDENSER WATER PRESSURE

Water pressure at the condenser cannot exceed 150 psig

(1034 kPa) with the standard water-regulating valve.

Contact your distributor if your water pressure is greater

than 150 psig (1034 kPa). A special order condenser/waterregulating valve is available that allows water pressure up to

350 psig (2413 kPa).

The Commonwealth of Massachusetts requires that all

water-cooled models must be connected only to a

closed loop, cooling tower system.

COOLING TOWER APPLICATIONS (WATER-COOLED MODELS)

A water cooling tower installation does not require

modification of the ice machine. The water regulator valve

for the condenser continues to control the refrigeration

discharge pressure.

It is necessary to know the amount of heat rejection and the

pressure drop through the condenser and water valves

(inlet and outlet) when using a cooling tower on an ice

machine.

• Water entering the condenser must not exceed

90°F

(32°C).

• Water flow through the condenser must not exceed

5

gallons (19 liters) per minute.

• Allow for a pressure drop of 7 psi (50 kPa) between the

condenser water inlet and the outlet of the ice machine.

• Water exiting the condenser must not exceed

110°F

(43°C).

10 Part Number 000012545 Rev01 9/15

Section 2 Installation Instructions

Important

Important

!

Warning

Remote Condenser/Line Set Installation

Ice Machine

K1000 KC1000

K1350 KC1350

K1800 KC1350

*Line Set Discharge Line Liquid Line

RTK 1/2" (1.27 cm) 5/16" (.79 cm)

RLK 1/2" (1.27 cm) 3/8" (.95 cm)

Air Temperature Around the Condenser

Minimum Maximum

-20°F (-29°C) 120°F (49°C)

Remote systems are only approved and warranted as a

complete new package. Warranty on the refrigeration

system will be void if a new ice machine head section is

connected to pre-existing (used) tubing or remote

condensers.

Remote Single

Circuit Condenser

Line Set*

RTK-20-R410A

RTK-35-R410A

RTK-50-R410A

RLK-20-R410A

RLK-35-R410A

RLK-50-R410A

RLK-20-R410A

RLK-35-R410A

RLK-50-R410A

REMOTE ICE MACHINE REFRIGERANT CHARGE

Each remote ice machine ships from the factory with a

refrigerant charge appropriate for installation with line sets

of up to 50' (15 m). The serial tag on the ice machine

indicates the refrigerant charge.

Additional refrigerant may be required for installations

using line sets between 50' and 100' (15-30 m) long. If

additional refrigerant is required, refer to the chart below for

the correct amount to be added.

Ice Machine

K1000 2 lbs (907g)

K1350 2 lbs (907g)

K1800 2 lbs (907g)

Refrigerant to be added for

50'-100' Line Sets

EPA CERTIFIED TECHNICIANS

If remote line set length is between 50' and 100' (15 and

30 m), add additional refrigerant to the nameplate

charge. Refer to the table below for the model being

worked on.

Tubing length: ______________________________________

Refrigerant added to nameplate: _______________________

New total refrigerant charge: __________________________

Potential Personal Injury Situation

The ice machine contains refrigerant charge.

Installation of the line sets must be performed by a

properly trained and EPA certified refrigeration

technician aware of the dangers of dealing with

refrigerant charged equipment.

Part Number 000012545 Rev01 9/15 11

Installation Instructions Section 2

!

Caution

DOWNWARD

HORIZONTAL

SPIRAL

GENERAL

Condensers must be mounted horizontally with the fan

motor on top with nothing obstructing it. There must be at

least a 16" (41 cm) clearance from the bottom for air intake.

The front coupling panel and one other panel (back or side)

must also be unobstructed.

Remote condenser installations consist of vertical and

horizontal line sets between the ice machine and the

condenser. When combined, they must fit within approved

specifications. The following guidelines, drawings and

calculation methods must be followed to verify a proper

remote condenser installation.

The compressor warranty (including the labor

replacement warranty) will not apply if the remote ice

machine is not installed according to specifications.

The warranty also will not apply if the refrigeration

system is modified with a condenser, heat reclaim

device, or other parts or assemblies not manufactured

by us unless we specifically approved the component in

writing.

3

2

1

DOWNWARD

HORIZONTAL

SPIRAL

1

2

3

WIRING

Interconnecting line voltage wiring is used to energize and

de-energize the condenser fan motor.

• The remote condenser voltage matches the ice machine

head section voltage.

Interconnecting Wire Connections

Ice Machine Head Section Remote Condenser

F1 L1

F2 L2

GUIDELINES FOR ROUTING LINE SETS

First, cut a 2.5" (6.35 cm) circular hole in the wall or roof for

tubing routing. The line set end with the 90° bend will

connect to the ice machine. The straight end will connect to

the remote condenser.

Follow these guidelines when routing the refrigerant lines.

This will help ensure proper performance and service

accessibility.

1. Optional - Make the service loop in the line sets (as

shown in Routing Line Sets graphic). This permits easy

access to the ice machine for cleaning and service. Do

not use hard rigid copper at this location.

2. Required - Do not form traps in the refrigeration lines

(except the service loop). Refrigerant oil must be free to

drain toward the ice machine or the condenser. Route

excess tubing in a supported downward horizontal

spiral (as shown below). Do not coil tubing vertically.

3. Required - Keep outdoor refrigerant line runs as short as

possible.

Routing Line Sets

12 Part Number 000012545 Rev01 9/15

Section 2 Installation Instructions

!

Caution

H

R

Combination of a Rise and a

Horizontal Run

Combination of a Drop and a

Horizontal Run

Combination of a Rise, a Drop and a

Horizontal Run

SV1196 SV1195 SV1194

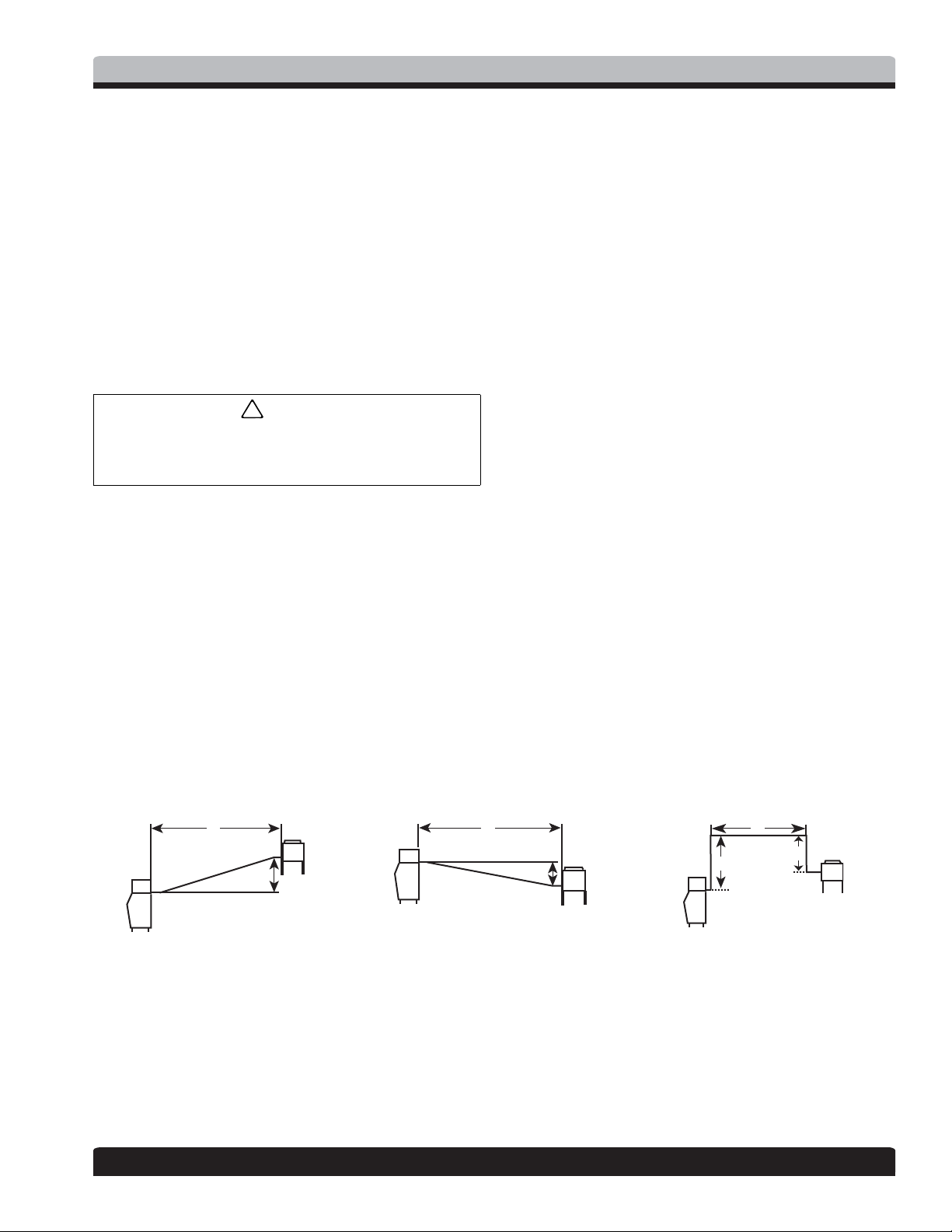

CALCULATING REMOTE CONDENSER INSTALLATION DISTANCES

Line Set Length

The maximum length is 100' (30 m).

The ice machine compressor must have the proper oil

return. The receiver is designed to hold a charge sufficient to

operate the ice machine in ambient temperatures between

-20°F (-29°C) and 120°F (49°C), with line set lengths of up to

100' (30 m).

Line Set Rise/Drop

The maximum rise is 35' (10.7 m).

The maximum drop is 15' (4.5 m).

If a line set has a rise followed by a drop, another rise

cannot be made. Likewise, if a line set has a drop

followed by a rise, another drop cannot be made.

Calculated Line Set Distance

The maximum calculated distance is 150' (45 m).

Line set rises, drops, horizontal runs (or combinations of

these) in excess of the stated maximums will exceed

compressor start-up and design limits. This will cause poor

oil return to the compressor.

Make the following calculations to make sure the line set

layout is within specifications.

1. Insert the measured rise into the formula below.

Multiply by 1.7 to get the calculated rise.

(Example: A condenser located 10 feet above the ice

machine has a calculated rise of 17 feet.)

2. Insert the measured drop into the formula below.

Multiply by 6.6 to get the calculated drop.

(Example. A condenser located 10 feet below the ice

machine has a calculated drop of 66 feet.)

3. Insert the measured horizontal distance into the

formula below. No calculation is necessary.

4. Add together the calculated rise, calculated drop, and

horizontal distance to get the total calculated

distance. If this total exceeds 150' (45 m), move the

condenser to a new location and perform the

calculations again.

Maximum Line Set Distance Formula

Step 1. Measured Rise (35' [10.7 m] Maximum) ______ x 1.7 = _______ Calculated Rise

Step 2. Measured Drop (15' [4.5 m] Maximum) ______ x 6.6 = _______ Calculated Drop

Step 3. Measured Horizontal Distance (100' [30 m] Maximum) _______ Horizontal Distance

Step 4. Total Calculated Distance 150' (45 m) _______ Total Calculated Distance

H

D

H

R

D

Part Number 000012545 Rev01 9/15 13

Installation Instructions Section 2

ROUTE THE LINE SET

• Route the line set to avoid traps and kinks.

• Minimize the amount of line set exposed on the roof.

CONNECT THE LINE SET

• Cut the line set to the correct length.

• Purge line set with dry nitrogen while brazing.

• Line set shutoff valves on the ice machine must remain

closed and be protected from heat during brazing.

PRESSURE TEST AND EVACUATE LINE SET AND CONDENSER

• Lineset shutoff valves must remain closed until pressure

testing and evacuation are complete.

• Pressure test @ 150 psi (1000 kPa) for a minimum of 15

minutes.

• Minimum evacuation level is 500 microns.

• Pressure test the line set and condenser with 150 psig of

dry nitrogen. Add nitrogen at the line set shutoff valves

located at the back of the ice machine head section.

Complete the pressure test, verify no leaks are present

and remove the nitrogen from the system before

connecting the vacuum pump.

OPEN LINE SET VALVES

You will not hear refrigerant flow when the valves are

opened. Refrigerant will not flow until the ice machine is

started and the solenoid valve opens.

• All valve caps must be reinstalled, tightened and leakchecked to assure no refrigerant leakage exists.

• Counterclockwise opens all valves.

14 Part Number 000012545 Rev01 9/15

Section 2 Installation Instructions

!

Warning

Installation Check List

Is the Ice Machine level?

Have all of the electrical and water connections

been made?

Has the supply voltage been tested and checked

against the rating on the nameplate?

Is there proper clearance around the ice

machine for air circulation?

Is the ice machine grounded and polarity

correct?

Has the ice machine been installed where

ambient temperatures will remain in the range

of 35° - 110°F (1.6° - 43.3°C)?

Has the ice machine been installed where the

incoming water temperature will remain in the

range of 35° - 90°F (1.6° - 32.2°C)?

Is there a separate drain for the potable water,

bin and water-cooled condenser?

Are the ice machine and bin drains vented?

Additional Checks for Remote Models

Does the remote condenser fan operate

properly after start-up?

Has the remote condenser been located where

ambient temperatures will remain in the range

of -20° - 120°F (-29 - 49°C).

Is the line set routed properly?

Are both refrigeration lines to remote condenser

run so they do not lay in water and are properly

insulated?

Before Starting the Ice Machine

All ice machines are factory-operated and adjusted before

shipment. Normally, new installations do not require any

adjustment.

To ensure proper operation, follow the Operational Checks

in Section 3 of this manual. Starting the ice machine and

completing the Operational Checks are the responsibilities

of the owner/operator.

Adjustments and maintenance procedures outlined in this

manual are not covered by the warranty.

Are all refrigerant lines free from contact with

other components?

Are all electrical leads free from contact with

refrigeration lines and moving equipment?

Has the owner/operator been instructed

regarding maintenance and the use of our

Cleaner and Sanitizer?

Has the owner/operator completed the

warranty registration card?

Has the ice machine and bin been sanitized?

Is the ice thickness set correctly? (Refer to

Operational Checks to check/set the correct ice

bridge thickness).

Potential Personal Injury Situation

Do not operate equipment that has been misused.

abused, neglected, damaged, or altered/modified from

that of original manufactured specifications.

Part Number 000012545 Rev01 9/15 15

Installation Instructions Section 2

THIS PAGE INTENTIONALLY LEFT BLANK

16 Part Number 000012545 Rev01 9/15

Loading...

Loading...