Page 1

MSI 40

MSI 50

BP 249 Z. I.

44 158 ANCENIS CEDEX FRANCE

TEL : 02 40 09 10 11

YOUR DEALER

®

OPERATOR'S MANUAL

REF : 47974 EN (06 / 07 / 2000)

Page 2

Page 3

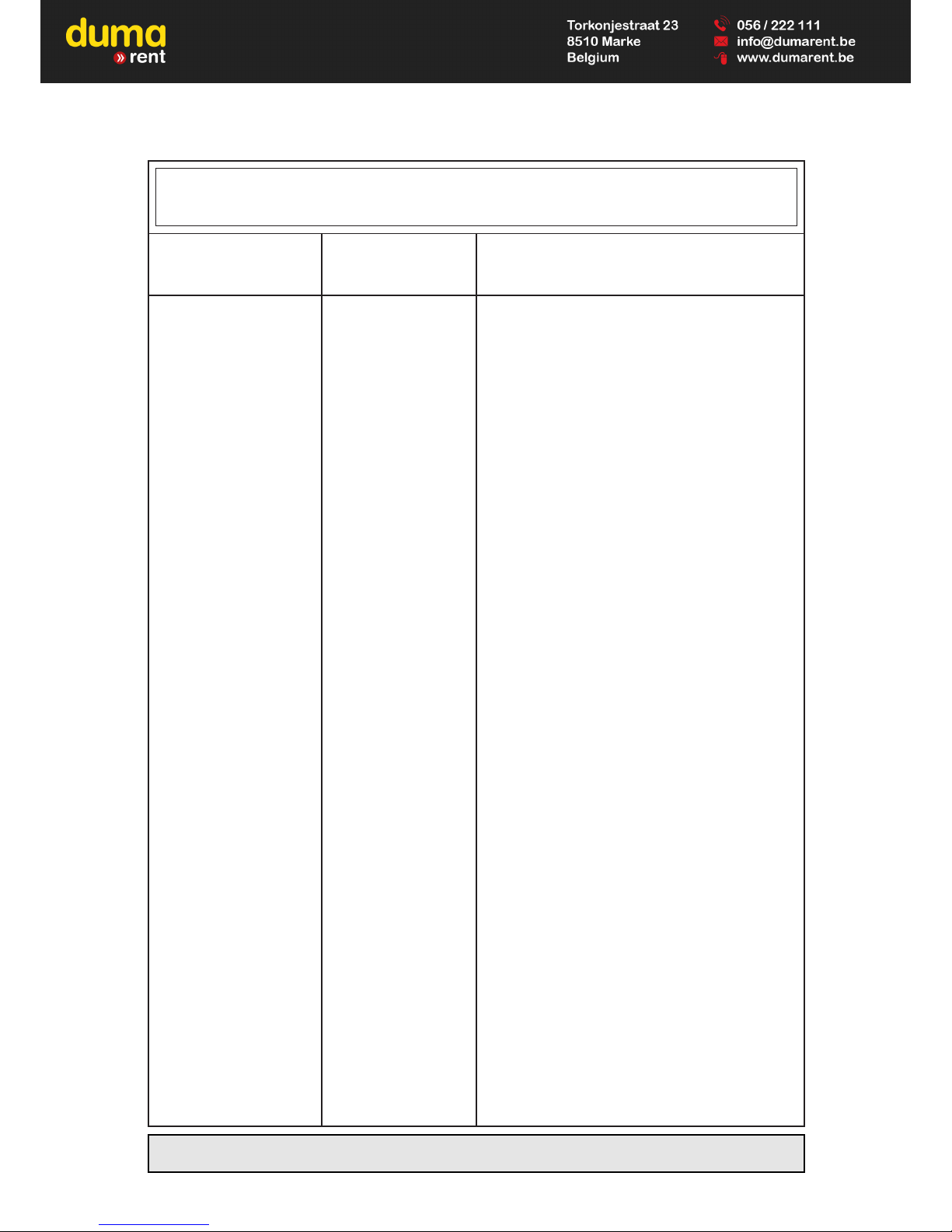

1st DATE OF ISSUE

CATALOGUE

INFORMATION

DATE OF ISSUE OBSERVATIONS

03 / 1993

09 / 1993

12 / 1993

05 / 1994

19 / 09 / 1997

06 / 07 / 2000

- 1stISSUE

- ADDING "REPAIRS NOTICE"

- UP DATING : LIFTING CAB

- UP DATING

- UP DATING : LIFTING CAB

- UP DATING : REVISION OF THE

OPERATOR'S MANUAL

- UP DATING

03 / 1993

THE TEXTS AND PICTURES IN THIS DOCUMENT CANNOT BE REPRODUCED EITHER TOTALLY OR

PARTLY.

Page 4

Page 5

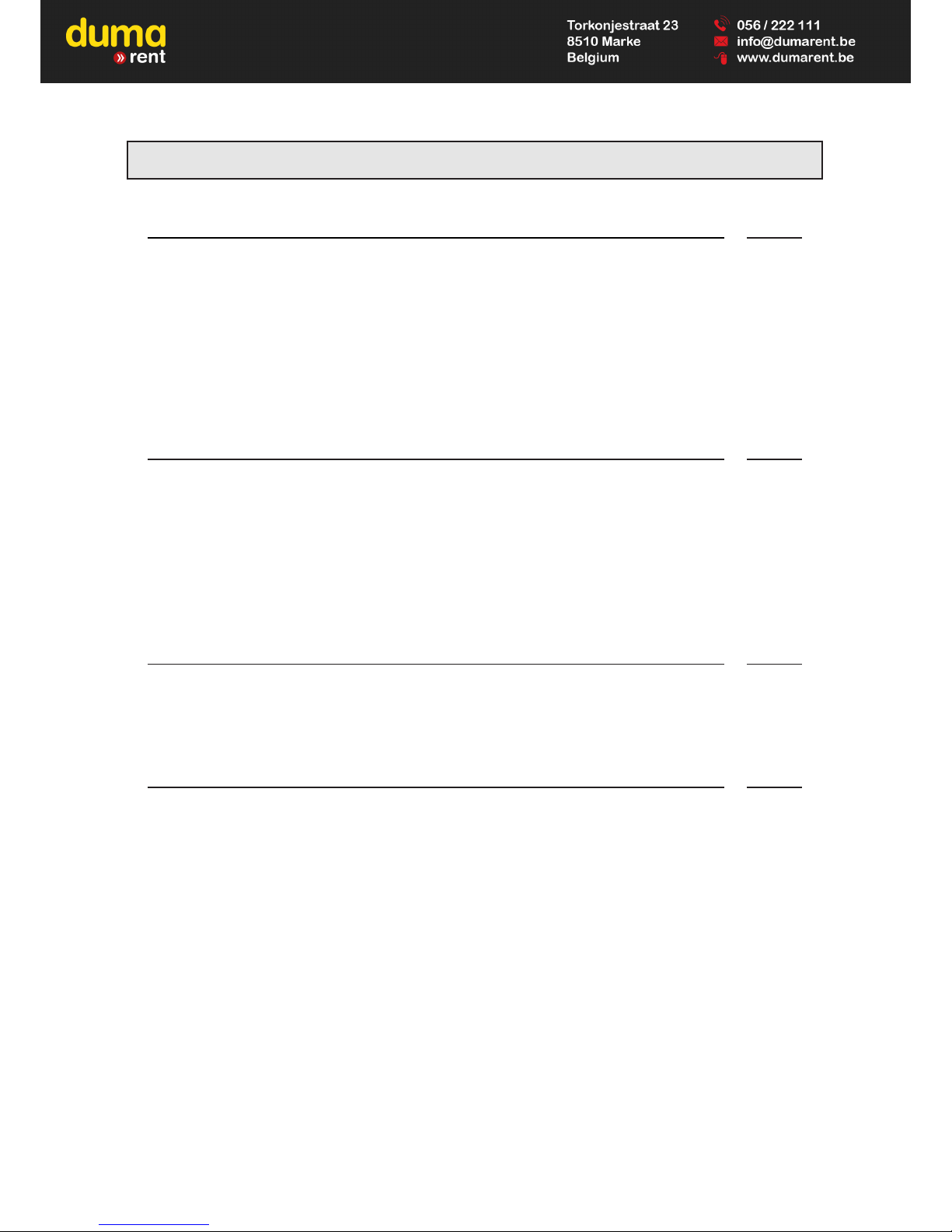

1 - OPERATING AND SAFETY INSTRUCTIONS

– ORIGINAL REPLACEMENT PARTS AND ATTACHMENTS

– DRIVER'S OPERATING INSTRUCTIONS

• CAUTION

• GENERAL INSTRUCTIONS

• OPERATING INSTRUCTIONS

• HANDLING INSTRUCTIONS

• LOAD HANDLING

– MAINTENANCE INSTRUCTIONS OF THE LIFT TRUCK

– BEFORE STARTING UP A NEW LIFT TRUCK

2 - DESCRIPTION

– IDENTIFICATION OF THE LIFT TRUCK

– CHARACTERISTICS

– MAST CHARACTERISTICS

– DIMENSIONS AND LOAD CHART

– INSTRUMENTS AND CONTROLS

Up to machine n° : 117 315

From machine n° : 117 316

– DESCRIPTION AND OPERATION OF ELECTRIC AND HYDRAULIC OPTIONS

3 - MAINTENANCE

– FILTERS CARTRIDGES AND BELTS

– LUBRICANTS AND FUEL

– SERVICING SCHEDULE

4 - ADAPTABLE ATTACHMENTS IN OPTION ON THE RANGE

– INTRODUCTION

– TECHNICAL SPECIFICATIONS OF ATTACHMENTS

– ATTACHMENT SHIELDS

TABLE OF CONTENTS

1 - 1

1 - 3

1 - 4

1 - 4

1 - 6

1 - 8

1 - 12

1 - 14

1 - 18

1 - 20

2 - 1

2 - 4

2 - 6

2 - 16

2 - 18

2 - 20

2 - 30

2 - 41

3 - 1

3 - 3

3 - 4

3 - 6

4 - 1

4 - 3

4 - 4

4 - 8

Page 6

Page 7

1 - 1

1 - OPERATING

AND SAFETY

INSTRUCTIONS

1 - OPERATING

AND SAFETY

INSTRUCTIONS

Page 8

1 - 2

Page 9

1 - 3

BY ALLOWING NON-ORIGINAL PARTS TO BE USED,

YOU RUN THE RISK - Legally, of being liable in the event of an accident.

- Technically, of causing breakdowns to occur or of reducing your lift truck's service life.

Using counterfeit parts or components not approved by the manufacturer may put an end to contract warranty terms

and lead the maker to withdraw the lift truck's certificate of compliance.

BY USING ORIGINAL PARTS DURING MAINTENANCE OPERATIONS,

YOU ARE LEGALLY

- Any user who procures parts from another quarter does so at his own risk.

COVERING

YOURSELF

- Any user who modifies his lift truck or has it modified by a service company, must consider

that a new item of equipment has been brought onto the market and therefore takes liability

for it.

- Any user who copies original parts or has them copied is taking a risk from the legal viewpoint.

- The certificate of compliance only binds the maker for parts chosen or produced under the

maker's control.

- The practicalities of maintenance terms are set out by the maker. The maker is in no way

liable in the event of the user not complying with such terms.

YOU GET THE THE MANUFACTURER BRINGS TO THE USER,

BENEFIT OF THE

MANUFACTURER'S - His know-how and skill.

KNOW-HOW

- Guaranteed quality work.

- Original replacement parts.

- Help with preventive maintenance.

- Effective help with diagnosing faults.

- Enhancements gained from feedback.

- Training for operating staff.

- Only the manufacturer knows the details of the lift truck design and therefore has the best

technological capability to carry out maintenance.

ALL MAINTENANCE ON OUR LIFT TRUCKS MUST BE CARRIED OUT USING ORIGINAL PARTS.

ORIGINAL REPLACEMENT PARTS ARE DISTRIBUTED EXCLUSIVELY

BY MANITOU AND ITS DEALER NETWORK.

You can obtain the list of dealers by phoning the spare parts department on :

TEL : 02 40 09 10 21

ORIGINAL REPLACEMENT PARTS AND ATTACHMENTS

Page 10

1 - 4

DRIVER'S OPERATING INSTRUCTIONS

CAUTION

WHENEVER YOU SEE THIS SYMBOL IT MEANS :

WARNING ! BE CAREFUL ! YOUR SAFETY OR THE SAFETY OF THE LIFT TRUCK IS AT RISK.

- Most accidents connected with the use, maintenance and repair of the lift truck are due to non application of the basic

safety instructions. By being aware of the risks to which you are exposed and by taking the necessary preventive

measures, you should be able to avoid accidents occurring.

- Any operation or manoeuvre not described in the instructions is prohibited a priori, however, any person who does use

another method must first ensure that he is not putting himself, another person or the lift truck in danger.

- The manufacturer is not able to anticipate all possible risk situations. Therefore the safety instructions and notices

given in the user manual and on the lift truck are not exhaustive.

Any bending of the rules in safety notices or the user, maintenance or repair instructions for your lift truck may result in

serious, or even fatal, accidents.

We would remind users of the risks in driving at excessive speed with regard to traffic conditions, particularly :

- Risk of loss of control on a poor-quality track.

- Increased stopping distance.

The user must remain in full control of his lift truck and should :

- Adapt his speed to each situation in order to be maintain his own safety, that of others and of his

equipment.

- Always be aware of his stopping distance.

On the basis of experience, there are a number of possible situations in which operating the lift truck is contra-indica-

ted. Such foreseeable abnormal uses, the main ones being listed below, are strictly forbidden.

- The foreseeable abnormal behaviour resulting from ordinary neglect, but does not result from any wish to put the

machinery to any improper use.

- The reflex reactions of a person in the event of a malfunction, incident, fault, etc. during operation of the lift truck.

- Behaviour resulting from application of the "principle of least action" when performing a task.

- For certain machines, the foreseeable behaviour of such persons as : apprentices, teenagers, handicapped persons

and trainees tempted to drive a lift truck. Truck drivers tempted to operate a truck to win a bet, in competition or for

their own personal experience.

The person in charge of the equipment must take these criteria into account when assessing whether or not a person

will make a suitable driver.

Page 11

1 - 5

Page 12

1 - 6

GENERAL INSTRUCTIONS

A - DRIVER’S OPERATING INSTRUCTIONS

- Read the operator's manual carefully, making sure you understand it.

- The operator’s manual must always be kept in the lift truck, in the place provided and in the language understood by

the operator.

- Respect the safety notices and instructions given on the lift truck.

- It is compulsory to replace all plates or stickers which are no longer legible or which have become worn or damaged.

B - AUTHORISATION TO OPERATE (LEGISLATION IN FORCE FOR FRANCE)

(Or refer to the legislation for each particular country)

- Only qualified personnel may use the lift truck. Its use is subject to authorisation to operate being given by the

appropriate manager in the user establishment.

- The user should always carry this authorisation to operate with him while he is using the lift truck.

- The driver is not competent to authorise the driving of the lift truck by another person.

- In addition, the vehicle should be used in accordance with good practice for the profession.

C - MAINTENANCE

- The user must immediately advise his superior if his lift truck is not in good working order or does not comply with the

safety notice.

- The operator is prohibited from carrying out any repairs or adjustments himself, unless he has been trained for this

purpose. He must keep the lift truck properly cleaned if this is among his responsibilities.

- Carry out daily maintenance (See chapter : A - DAILY OR EVERY 10 HOURS SERVICE in paragraph : 3 MAINTENANCE).

- Ensure tyres are adapted to the nature of the ground (See area of the contact surface of the tyres in the chapter :

CHARACTERISTICS in paragraph : 2 - DESCRIPTION).

. SAND tyres.

. LAND tyres.

. Snow chains.

There are optional solutions, consult your agent or dealer.

A worn or damaged tyre can result in the lift truck being temporarily out of service.

The fitting of foam inflated tyres is prohibited and is not guaranteed by the manufacturer, excepting prior authorisation.

- For your own and other people's safety, it is forbidden to modify the structure and settings of the various components of

your lift truck yourself (Hydraulic pressure, relief valve calibration, I.C. engine running speed, addition of extra

equipment etc.). The same holds with regard to any suppression or modification of the safety systems, in which case

the maker would no longer be liable.

Regular inspection of your lift truck is mandatory if it is to be kept in conforming condition. The frequency of such

checks are defined by the current legislation of the country in which the lift truck is being operated.

Maintenance or repairs other than those detailed in part : 3 - MAINTENANCE must be carried out by qualified person-

nel (Consult your agent or dealer) and under the necessary safety conditions to maintain the health of the operator and

any third party.

Page 13

1 - 7

D - ENVIRONMENT

- A lift truck operating in an area without fire extinguishing equipment must be equipped with an individual extinguisher.

There are optional solutions, consult your agent or dealer.

- Take into account climatic and atmospheric conditions of the site of utilisation.

For operation under average climatic conditions, i.e. : between -15 °C and + 35 °C, correct levels of lubricants in all the

circuits are checked in production. For operation under more severe climatic conditions, before starting up, it is necessa-

ry to drain all the circuits, then ensure correct levels of lubricants using lubricants properly suited to the relevant ambient

temperatures. It is the same for the cooling liquid.

. Protection against frost (See chapter : LUBRICANTS AND FUEL in paragraph : 3 - MAINTENANCE).

. Adaptation of lubricants (Ask your dealer for information).

. Engine filtration.

. Lighting (Working headlight).

Optional solutions exist, consult your dealer.

Use of a lift truck is prohibited in protected areas (e.g. refinery, explosive atmosphere). For use in these areas,

specific equipment is available as an option. Consult your dealer.

IF NECESSARY, CONSULT YOUR DEALER.

Page 14

1 - 8

OPERATING INSTRUCTIONS

A - DRIVER’S OPERATING INSTRUCTIONS

- Wear clothes suited for driving the lift truck, avoid loose clothes.

- Never operate the vehicle when hands or feet are wet or soiled with greasy substances.

- For increased comfort, adjust the driver’s seat to your requirements and adopt the correct position in the driver’s cab.

- The operator must always be in his normal position in the driver’s cab. It is prohibited to have arms or legs, or generally

any part of the body, protruding from the driver’s cab of the lift truck.

- Always remember to fasten your seat belt and adjust it to your requirements.

- The control units must never in any event be used for any other than their intended purposes (e.g. climbing onto or

down from the lift truck, portmanteau, etc.).

- If the control components are fitted with a forced operation (lever lock) device, it is forbidden to leave the cab without

first putting these controls in neutral.

- Never allow a passenger to travel on the lift truck in the driver’s cab.

B - BEFORE STARTING THE LIFT TRUCK

- If the lift truck is new, refer to chapter : BEFORE STARTING UP A NEW LIFT TRUCK in paragraph : 1 - OPERATING

AND SAFETY INSTRUCTIONS.

- Check the condition of the tyres and the tyre pressures (See chapter : CHARACTERISTICS in paragraph : 2 DESCRIPTION).

- Before starting the lift truck, check the different levels :

. Engine oil.

. Hydraulic reservoir oil.

. Cooling liquid.

. Braking oil.

- Also check for possible leakage of oil, fuel or liquid from the lift truck.

- Check the closing and locking of the hood.

- Whatever his experience as a truck driver is, the operator is advised to familiarize himself with the position and

operation of all the controls and instruments before operating the lift truck.

C - STARTING THE LIFT TRUCK

SAFETY NOTICE

The lift truck must only be started up or manoeuvred when the operator is sitting in the driver’s cab, with his seat belt

adjusted and fastened.

- Never try to start the lift truck by pushing or towing it.

Such operation may cause severe damage to the transmission. If necessary, to tow the lift truck in an emergency, the

transmission must be placed in the neutral position (See chapter : H - OCCASIONAL MAINTENANCE in paragraph : 3

- MAINTENANCE).

INSTRUCTIONS

- Open the LPG bottle.

- Make sure that the forward/reverse lever is in neutral.

- Turn the ignition key to the position I to activate the electrical system.

- Check the level on the fuel level gauge.

- Turn the ignition key to position II to preheat for 15 seconds.

Do not engage the starter motor for more than 15 seconds and carry out the preheating for 10 seconds between

unsuccessful attempts.

Page 15

1 - 9

- Press the accelerator pedal and turn the ignition key fully : the engine should then start. Release the ignition key and

let the engine run at idle.

- Check all control instruments immediately after starting up, when the engine is warm and at regular intervals during

use, so as to quickly detect any faults and to be able to correct them without any delay.

- If an instrument does not show the correct display, stop the engine and immediately carry out the necessary operations.

D - DRIVING THE LIFT TRUCK

SAFETY NOTICE

- Always drive the lift truck with the forks or attachment at approximately 300 mm from the ground, i.e. In the transport

position.

- Familiarise yourself with the lift truck on the terrain where it will be used.

- Ensure that the service brakes and the sound alarm are working properly.

- Drive according to, and at an appropriate speed for, the conditions and state of the terrain.

- Slow down before executing a turn.

- In all circumstances make sure you are in control of your speed.

- On damp, slippery or uneven terrain, drive slowly.

- Brake gently, never abruptly.

- Only use the lift truck’s forward/reverse lever from a stationary position and never do so abruptly.

- Do not drive with your foot on the brake pedal or with the parking brake on.

- Always remember that hydrostatic type steering is extremely sensitive to movement of the steering wheel, so turn it

gently and not jerkily.

- Never leave the engine on when the lift truck is unattended.

- Look in the direction you are travelling and always keep clear visibility of the road. Use the left and right rear view

mirrors frequently and ensure that they are kept in good condition, are clean and correctly adjusted.

- When working at night, ensure that your lift truck is fitted with full beam lights. There are optional solutions, consult your

agent or dealer.

- Drive round obstacles.

- Never move onto a loading platform without having first checked :

. That it is suitably positioned and made fast.

. That the unit to which it is connected (Wagon, lorry, etc.) will not shift.

. That this platform is prescribed for the total weight of the lift truck to be loaded.

. That this platform is prescribed for the width of the lift truck.

- Never move onto a foot bridge, floor or freight lift, without being certain that they are prescribed for the weight and size

of the lift truck to be loaded and without having checked that they are in sound working order.

Take extreme care with loading platforms, trenches, scaffolding, recently dug and/or backfilled ground.

- The loaded lift truck must not travel at speeds in excess of 12 km/h.

INSTRUCTIONS

- Raise the forks or attachment to the transport position approximately 300 mm from the ground.

- Shift the forward/reverse lever to the selected direction of travel.

- Release the parking brake and accelerate gradually until the lift truck moves off.

Page 16

1 - 10

E - STOPPING THE LIFT TRUCK

SAFETY NOTICE

- Before stopping the lift truck after a long working period, leave the I.C. engine idling for a few moments, to allow the

coolant liquid and oil to lower the temperature of the engine and transmission.

Do not forget this precaution, in the event of frequent stops of the engine, or else the temperature of certain parts will

rise significantly due to the stopping of the cooling system, with the risk of badly damaging such parts.

- Never leave the ignition key in the lift truck when the lift truck is unattended.

- When the lift truck is stationary, place the forks or attachment on the ground, apply the parking brake and put the

forward/reverse lever in neutral.

- If the driver has to leave his cab, even for a moment, it is essential apply the parking brake and put the forward/reverse

lever in neutral.

- Make sure that the lift truck is not stopped in any position that will interfere with the traffic flow and at less than one

meter from the track of a railway.

- In the event of prolonged parking on a site, protect the lift truck from bad weather, particularly from frost (Check the

level of antifreeze), close the rear windows, lock the cab doors and ensure that the hood is properly secured.

INSTRUCTIONS

- Park the lift truck on flat ground or on an incline lower than 15 %.

- Release the accelerator pedal and stop the lift truck.

- Place the forward/reverse lever in neutral.

- Apply the parking brake.

- Lower the forks or attachment to rest on the ground.

- Stop the engine with the ignition switch.

- Remove the pressure in the hydraulic circuits by using the hydraulic controls.

- Remove the ignition key.

- Check the closing and locking of doors, windows and hood.

Before leaving your driver's cabin, ensure that you have carried out all operations for stopping the lift truck, for your

safety and the safety of others.

F - DRIVING THE LIFT TRUCK ON THE PUBLIC HIGHWAY

SAFETY INSTRUCTIONS

- When driving a lift truck on roads open to public traffic, observe the provisions of the Highway Code.

- Lift truck drivers, driving on the public highway, must abide by the general provisions relative to highway traffic.

- The lift truck must conform to the provisions of the Highway Code. If necessary, optional solutions exist, consult your

dealer.

Transport of loads on the public highway is forbidden and attachments mounted on the lift truck must be fitted with

equipment in accordance with regulations or else dismounted.

Page 17

1 - 11

INSTRUCTIONS

- Ensure that the flashing light is in position and that it is working.

- Check the good working order and cleanness of lights, indicators and windscreen wiper.

- Check the adjustment of the rear view mirrors.

- Ensure that the fuel level is sufficient.

- Put the attachment at 300 mm from the ground.

G - OPERATING THE LIFT TRUCK WITH A TRAILER ON A PUBLIC HIGHWAY

- For using a trailer, consult the regulations in force in your country (Maximum travel speed, braking, maximum weight of

trailer, etc.).

- Do not forget to connect the lift truck’s electrical equipment to that of the trailer.

- Do not use a non-braked trailer if the unit weight of a load exceeds that imposed by the highway code.

- Do not use a non-braked trailer without braking equipment for the trailer on the lift truck.

- Do not forget to connect the lift truck’s braking equipment to that of the trailer.

- The maximum vertical pull on the trailer hook must not exceed 1500 daN.

- The authorised total towed weight (A.T.T.W.) must not exceed the maximum weight authorised by the manufacturer

(Consult the manufacturer’s plate on your lift truck).

H - OPERATING THE LIFT TRUCK WITH A FRONT-END ATTACHMENT ON A PUBLIC HIGHWAY

- For driving with an attachment, check the regulations currently applicable in your country.

- The attachment must not exceed the overall width of the lift truck.

- The length of the entire unit must not exceed the overall length by 6 metres.

- Do not mask the lighting range of the front headlamps.

- Set the attachments shields in place (See chapter : ATTACHMENT SHIELDS in paragraph : 4 - ADAPTABLE

ATTACHMENTS IN OPTION ON THE RANGE) or disassemble the attachment.

IF NECESSARY, CONSULT YOUR DEALER.

Page 18

HANDLING INSTRUCTIONS

A - GENERAL

- Ensure the correct functioning of your lift truck’s attachments.

- Do not attempt to carry out operations which exceed the capacities of your lift truck or attachments.

- It is prohibited to increase the counterweight value in any way.

- It is strictly prohibited to carry or to lift up persons using the lift truck, unless the vehicle is specially equipped for this

purpose and has the corresponding certificate of conformance for lifting people.

- Avoid travelling for a long distance in reverse.

B - ATTACHMENTS

- Ensure that the attachment is correctly fitted and locked to its frame.

- Conform to the limits on the load chart for the lift truck and/or attachment.

- Ensure that palettes, cases, etc, are in good order and suitable for the load to be lifted.

- Position the forks perpendicular to the load to be lifted, taking account of the load’s centre of gravity.

- Never lift a load with a single fork.

- Never lift a sling load with a single fork or with the carriage. Optional solutions exist, consult your dealer.

- Ensure that rapid hydraulic connections on the attachment system are clean and protected.

Before each change of an attachment with hydraulic function, in order to avoid damaging the rapid hydraulic

connections :

- Place the attachment in the closed position, flat on the ground (For unstable attachments, ensure they are secured

using wedges).

- Switch off the I.C. engine.

- Remove pressure from the attachment hydraulic system using the hydraulic controls.

C - ENVIRONMENT

- Take care when raising the load that no object or person is in the way of movement and do not make any incorrect

manoeuvres.

- In the case of work near aerial lines, ensure that the safety distance is sufficient between the working area of the lift

truck and the aerial line.

You must consult your local electrical agency.

You could be electrocuted or seriously injured if you operate or park the lift truck too close to power cables. You are

strongly advised to ensure that the safety rules on the site conform to the local regulations in force regarding all types

of work carried out close to power cables.

- Do not allow anybody to come near the working area of the lift truck or pass beneath an elevated load.

- When using the lift truck on a slope, before raising the mast, ensure that the ground is horizontal (See paragraph : F HORIZONTAL POSITION OF THE LIFT TRUCK in the chapter : LOAD HANDLING).

- Travelling on a longitudinal slope :

• Drive and brake gently.

• Moving without load : Forks or attachment facing downhill.

• Moving with load : Forks or attachment facing uphill.

- Ensure that scaffolding, loading platform or pile is capable of bearing

the weight.

- Ensure the stability and solidity of the ground before depositing a load.

1 - 12

Page 19

1 - 13

D - HANDLING

- Always consider safety and only transport balanced and correctly secured loads to avoid any risk of tipping.

- Fully engage forks under the load and move it in the transport position (The forks 300 mm from the ground and the

mast sloping backwards).

- For obvious reasons regarding the lift truck’s stability and clear visibility of the surrounding environment, only move the

lift truck when the mast is in the transport position.

- Do not manoeuvre the lift truck with the mast in the raised position unless under exceptional circumstances and then

with extreme caution, at very low speed and using gentle braking. Ensure that visibility is adequate and get another

person to guide you along if necessary.

- Never shift the position of the load while the lift truck is in motion.

- The simultaneous use of two lift trucks to handle heavy or bulky loads is a dangerous manoeuvre, requiring specific

precautions to be taken. This should only be done in exceptional circumstances and in the presence of a handling

manager.

- Never drive too fast or brake abruptly when carrying a load.

- During handling, drive at low speed.

- Check the load, particularly when turning corners and especially if it is very bulky.

- Secure unstable loads.

- Handle loads with caution, at slow speed, without sudden jerks when moving them at significant heights and jib

extention.

In the event of high winds or storms, do not carry out handling work that jeopardizes the stability of the lift truck and its

load, particularly if the load catches the wind badly.

- Do not change direction sharply and at high speed.

In the event of the lift truck overturning, do not try to leave the cabin during the incident.

YOUR BEST PROTECTION IS TO STAY FASTENED IN THE CABIN.

- Apply the parking brake when lifting or depositing a difficult load or when on an incline.

- Do not stop the lift truck with the load in an elevated position.

- Do not leave a laden lift truck with the parking brake applied on an incline which exceeds 15 %.

E - VISIBILITY

- Constantly keep clear visibility of the road, either direct view (looking backwards when reversing) or indirect view using

the panoramic rear view mirrors to check for people, animals, holes, obstacles, change of slope, etc.

- If the visibility in forward motion is not sufficient because of the bulkiness of the load, drive in reverse motion. This

manoeuvre must remain exceptional and for short distances.

- Ensure you have good visibility (Clean windows, adequate lighting, correctly adjusted rear view mirror, etc.).

- Signalling and lighting on the lift truck must take account of the conditions of use. In addition to series equipment

mounted on your lift truck, a certain number of options are available, such as : road lighting, stop lights, flashing light,

reverse lights, reverse buzzer alarm, front light, rear light, etc. Consult your agent or dealer.

IF NECESSARY, CONSULT YOUR DEALER.

Page 20

1 - 14

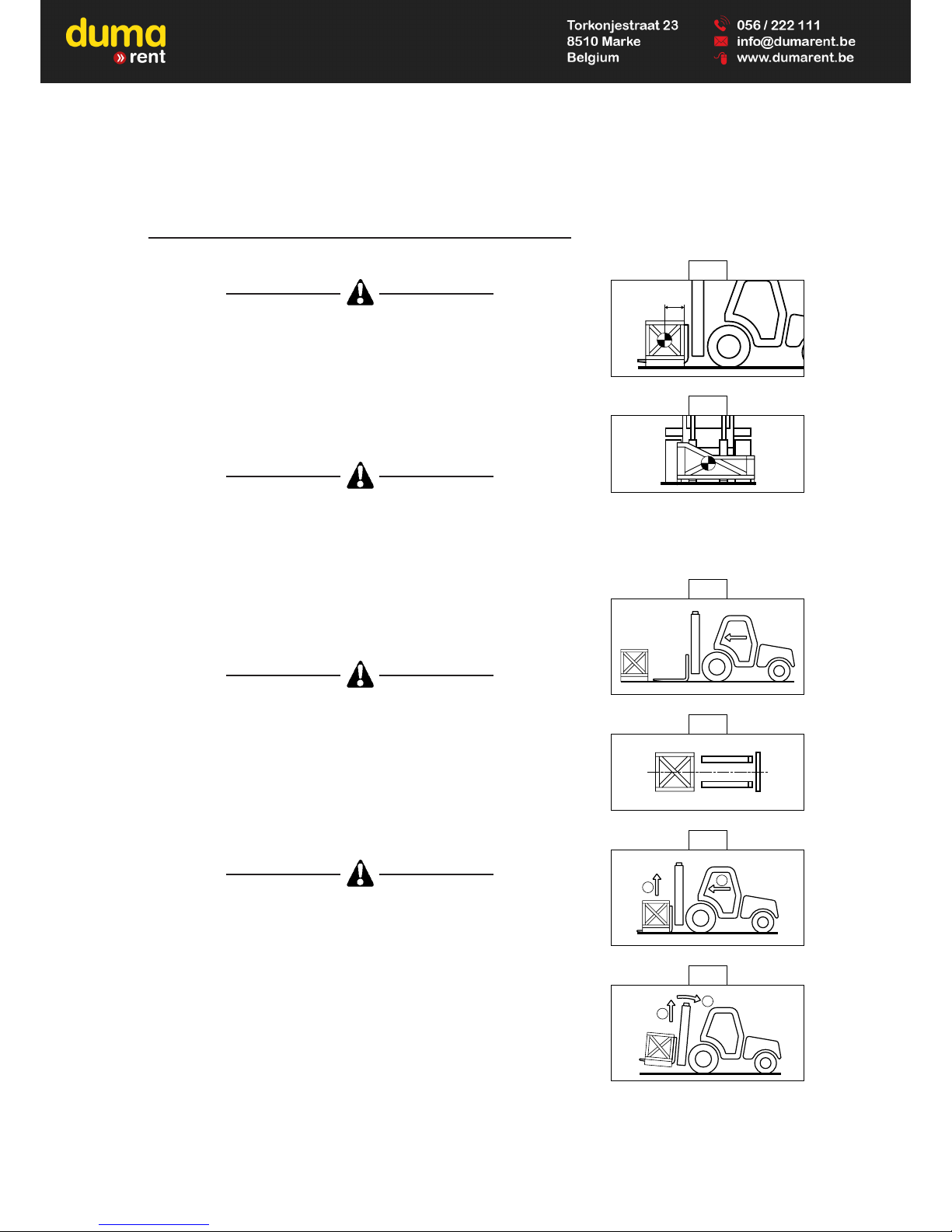

LOAD HANDLING

A - WEIGHT OF LOAD AND CENTRE OF GRAVITY

Carrying a load greater than the rated capacity for the lift truck or for the

attachment is prohibited.

- Before taking up a load, you must know its weight and its centre of gravity.

- The load chart relating to your lift truck is valid for a weight with its centre of

gravity 500 or 600 mm from the heel of the forks (As model of lift truck) (Fig.

A). For a higher centre of gravity, consult your agent or dealer.

- For irregular loads, determine the centre of gravity in the transverse

direction before handling (Fig. B).

For loads with a moving centre of gravity (e.g. liquids), take account of the

variations in the centre of gravity in order to determine the load to be hand-

led (Consult your agent or dealer) and be vigilant and take extra care to limit

these variations as far as possible.

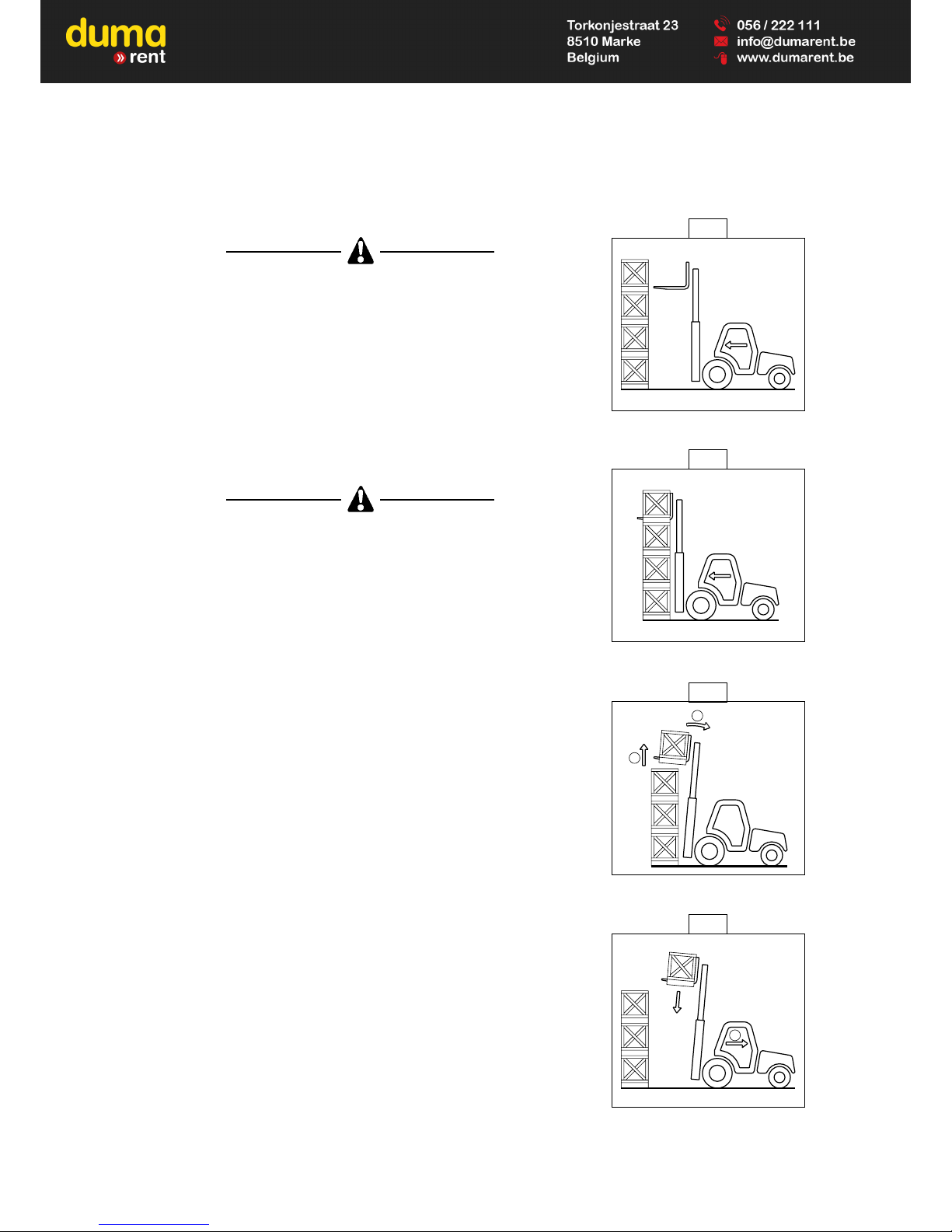

B - TAKING UP A LOAD ON THE GROUND

- Approach the lift truck perpendicular to the load, with the forks in a

horizontal position (Fig. C).

- Adjust the fork spread and centering in connection with the load (Fig. D)

(Optional solutions exist, consult your dealer).

Beware of the risks of trapping or squashing limbs when manually adjusting

the forks. Always maintain an equal distance between the forks and the

centre of the carriage in order to keep the load completely stable.

- Move the lift truck forward slowly (1) and bring the forks to stop in front of

the load (Fig. E), if necessary, slightly lift the mast (2) while taking up the

load.

- Apply the parking brake and place the forward/reverse lever in neutral.

- Slightly lift the load (1), incline the mast (2) backwards in the transport

position (Fig. F).

Tilt the load sufficiently backwards to ensure its stability (loss of load on bra-

king) without upsetting the balance of the load in so doing.

500 mm

A

B

C

D

1

2

E

2

1

F

Page 21

1 - 15

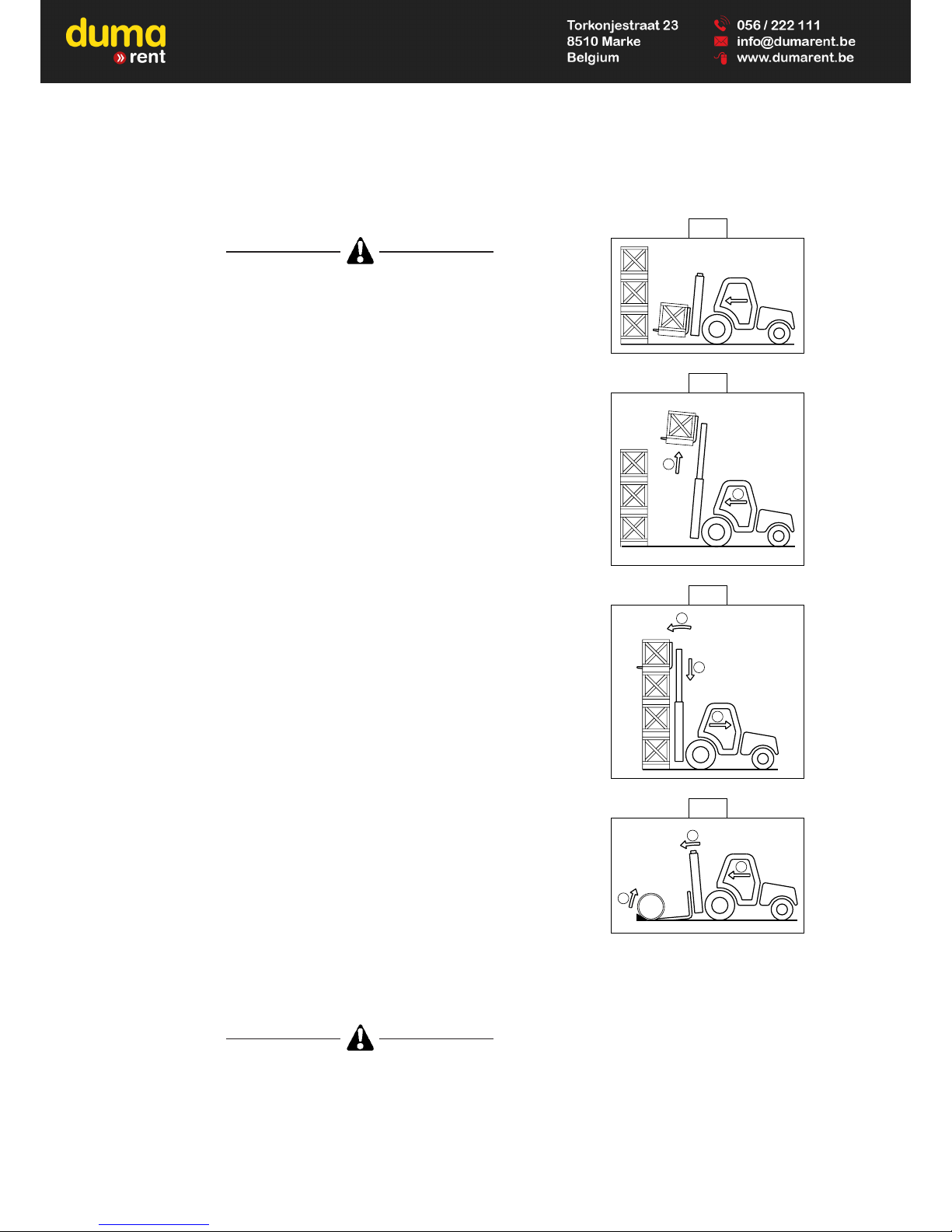

C - TAKING UP A HIGH LOAD ON TYRES

Under no circumstances should you pick up a load if the lift truck is not a

horizontal position. (See paragraph : F - HORIZONTAL POSITION OF THE

LIFT TRUCK in the chapter : LOAD HANDLING).

- Ensure that the forks will easily pass under the load.

- Approach the lift truck perpendicular to the load and with the forks in a

horizontal position (Fig. G) manoeuvring gently and carefully (See

paragraph : E - VISIBILITY in the chapter : HANDLING INSTRUCTIONS for

visibility of the road).

- Bring the forks to stop in front of the load (Fig. H). Apply the parking brake

and place the forward/reverse lever in neutral.

- Slightly lift the load (1) and incline the mast (2) backwards to stabilize the

load (Fig. I).

Tilt the load sufficiently backwards to ensure its stability (loss of load on bra-

king) without upsetting the balance of the load in so doing.

- Manoeuvring very gently and carefully (See paragraph : E - VISIBILITY in the

chapter : HANDLING INSTRUCTIONS for visibility of the road), back up the

lift truck (1) to release the load, and bring the load into the transport position

(Fig. J).

G

H

2

1

I

1

J

Page 22

1 - 16

D - LAYING A HIGH LOAD ON TYRES

Under no circumstances should you lay down a load if the lift truck is not a

horizontal position. (See paragraph : F - HORIZONTAL POSITION OF THE

LIFT TRUCK in the chapter : LOAD HANDLING).

- Approach the load in the transport position in front of the pile (Fig. K).

- Lift the mast (1) until the load is above the pile, and move the lift truck

forward (2) (Fig. L) manoeuvring very gently and carefully (See paragraph :

E - VISIBILITY in the chapter : HANDLING INSTRUCTIONS for visibility of

the road). Apply the parking brake and place the forward/reverse lever in

neutral.

- Place the load in a horizontal position by tilting the mast forwards (1) and lay

it down on the pile (2) while checking the correct positioning of the load (Fig.

M).

- To drive very gently and carefully.

- Free the forks by reversing the lift truck (3) (Fig. M) (See paragraph : E VISIBILITY in the chapter : HANDLING INSTRUCTIONS for visibility of the

road). Then bring the forks into the transport position.

E - TAKING UP A NON PALLETISED LOAD

- Tilt the carriage (1) forwards and move the lift truck forward (2) while

simultaneously crowding the carriage backwards to slip the forks under the

load (Fig. N). If necessary, wedge the load.

F - HORIZONTAL POSITION OF THE LIFT TRUCK

Apart from the transverse slope of the ground, several parameters can upset

the horizontal position of the lift truck.

• The tyre pressure.

• The stability of the ground.

• The balance of the load.

• Strong wind or stormy conditions.

Before any handling work, check the points above and ensure that the lift

truck is completely horizontal.

2

1

3

N

3

2

1

M

1

2

L

K

Page 23

1 - 17

Page 24

1 - 18

MAINTENANCE INSTRUCTIONS

A - GENERAL

- Read the operator's manual carefully and ensure you understand it.

- Stop the I.C. engine, when an intervention is necessary.

- Wear clothes suitable for the maintenance of the lift truck, avoid wearing jewellery and loose clothes. Tie and protect

your hair, if necessary.

- Ensure the area is sufficiently ventilated before starting the lift truck.

Make sure that the disposal of process materials and of spare parts is carried out in total safety

and in a ecological way.

- Carry out all repairs immediately, even if the repairs concerned are minor.

- Repair all leaks immediately, even if the leak concerned is minor.

- Do not attempt to loosen unions, hoses or any hydraulic component with the circuit under pressure.

The handling and removal of the balancing valves or safety valves which may be fitted to the cylinders of your lift truck

can be dangerous. A balancing valve must only be removed when the cylinder concerned is at rest and the hydraulic

circuit is depressurised.

This operation can only be carried out by authorised staff.

- Do not smoke or approach the lift truck with a flame, when the fuel tank is open or is being filled.

- Take care not to burn yourself (Exhaust, radiator, I.C. engine, etc.).

- Disconnect the negative cable terminal (-) from the top of the battery before working on the electrical circuit or on the lift

truck (e.g. : Welding).

- Do not drop metallic items on the battery.

- When carrying out electric welding work on the lift truck, connect the negative cable from the equipment directly to the

part being welded, so as to avoid high tension current passing through the alternator.

B - MAINTENANCE

- The maintenance and the keeping in compliance of the lift truck are compulsory.

- Carry out daily maintenance (See chapter : A - DAILY OR EVERY 10 HOURS SERVICE in paragraph : 3 MAINTENANCE).

- Do not run the engine without air filter, or with oil, water or fuel leaks.

Wait for the I. C engine to cool before removing the radiator cap or expansion pan (Pressurised system).

- Change the filter cartridges (See servicing schedules in chapter : FILTERS CARTRIDGES AND BELTS in

paragraph : 3 - MAINTENANCE).

C - LEVELS

- Use the recommended lubricants (Never use contaminated lubricants).

- Do not fill the fuel tank when the I.C. engine is running.

- Only fill up the fuel tank in areas specified for this purpose.

- Do not fill the fuel tank to the maximum level.

MAINTENANCE INSTRUCTIONS OF THE LIFT TRUCK

Page 25

1 - 19

D - WASHING

- Clean the lift truck or at least the area concerned before any intervention.

- Remember to close the doors and the windows of the cab.

- During washing, avoid the articulations and electrical components and connections.

If necessary, protect against penetration of water, steam or cleaning agents, components susceptible of being dama-

ged, particularly electrical components and connections and the injection pump.

- Clean the lift truck of any fuel, oil or grease trace.

FOR ANY INTERVENTION OTHER THAN REGULAR MAINTENANCE, CONSULT YOUR DEALER.

Page 26

1 - 20

INTRODUCTION

- Our lift trucks have been designed for easy handling by the operator and maximum ease of maintenance for the

mechanic.

- However, before commencing to operate the lift truck, the user should carefully read and understand the various

chapters of this manual which has been provided to solve driving and maintenance problems. By following these

instructions the user will be able to take full advantage of the versatility of this lift truck.

- The operator must familiarize himself with the positions and functions of all the controls and instruments before

operating the lift truck.

Do not attempt to start a new lift truck before the following checks have been carried out :

LUBRICATION

- Check that all the correct grades of oils and greases that are required are available ; see chapter : SERVICING

SCHEDULE in paragraph : 3 - MAINTENANCE and top up if necessary.

For operation under average climatic conditions, i.e. : between -15 °C and + 35 °C, correct levels of lubricants in all the

circuits are checked in production. For operation under more severe climatic conditions, before starting up, it is necessa-

ry to drain all the circuits, then ensure correct levels of lubricants using lubricants properly suited to the relevant ambient

temperatures. It is the same for the cooling liquid (Contact your dealer for information, if necessary).

DRY AIR FILTER

- Ensure that the air filter is undamaged and not blocked.

- Tighten the fastening devices if necessary.

Never run the engine with the air filter removed or damaged.

COOLING SYSTEM

- Do not start the lift truck without checking the radiator coolant level or if the fan belt is damaged or broken.

HYDRAULIC SYSTEM

- Check by a visual examination that there are no leaks or oil oozing in the hoses, connections and unions. If necessary,

tighten or repair the defective connections.

- Also check that the tank oil level is correct.

BRAKING SYSTEM

- Check by a visual examination that there are no leaks or oil oozing in the hoses, connections and unions. If necessary,

tighten or repair the defective connections.

- Also check the oil level in the tank.

Ensure that the recommended oil is used, in order to avoid serious damage to the braking system.

TYRES

- Make sure that the wheel nuts are correctly tightened (See chapter : A - DAILY OR EVERY 10 HOURS SERVICE in

paragraph : 3 - MAINTENANCE) and that the tyre pressures are correct (See chapter : CHARACTERISTICS in

paragraph : 2 - DESCRIPTION).

FUEL SYSTEM

- Check that all fuel lines are secured.

- If necessary drain the fuel filter and bleed the fuel system of air.

BEFORE STARTING UP A NEW LIFT TRUCK

Page 27

1 - 21

ELECTRICAL CIRCUIT

- Check the level and the density of the electrolyte in the battery (See chapter : B - EVERY 50 HOURS SERVICE in

paragraph : 3 - MAINTENANCE).

- Check the components of the electrical system, the connections and fastening devices.

IF NECESSARY, CONSULT YOUR DEALER.

Page 28

1 - 22

Page 29

2 - 1

2 - DESCRIPTION

2 - DESCRIPTION

Page 30

2 - 2

Page 31

2 - 3

Page 32

2 - 4

IDENTIFICATION OF THE LIFT TRUCK

D

As our policy is to promote a constant improvement of our products, our

range of telescopic lift trucks may undergo certain modifications, without

obligation for us to advise our customers.

When you order parts, or when you require any technical information, always

specify :

NOTE : For the owner's convenience, it is recommended that a note of these

numbers is made in the spaces provided, at the time of the delivery of

the lift truck.

PLATE MANUFACTURER OF THE LIFT TRUCK (FIG. A)

- Model

- Series

- Serial Nr

- Chassis Nr

- Year of manufacture

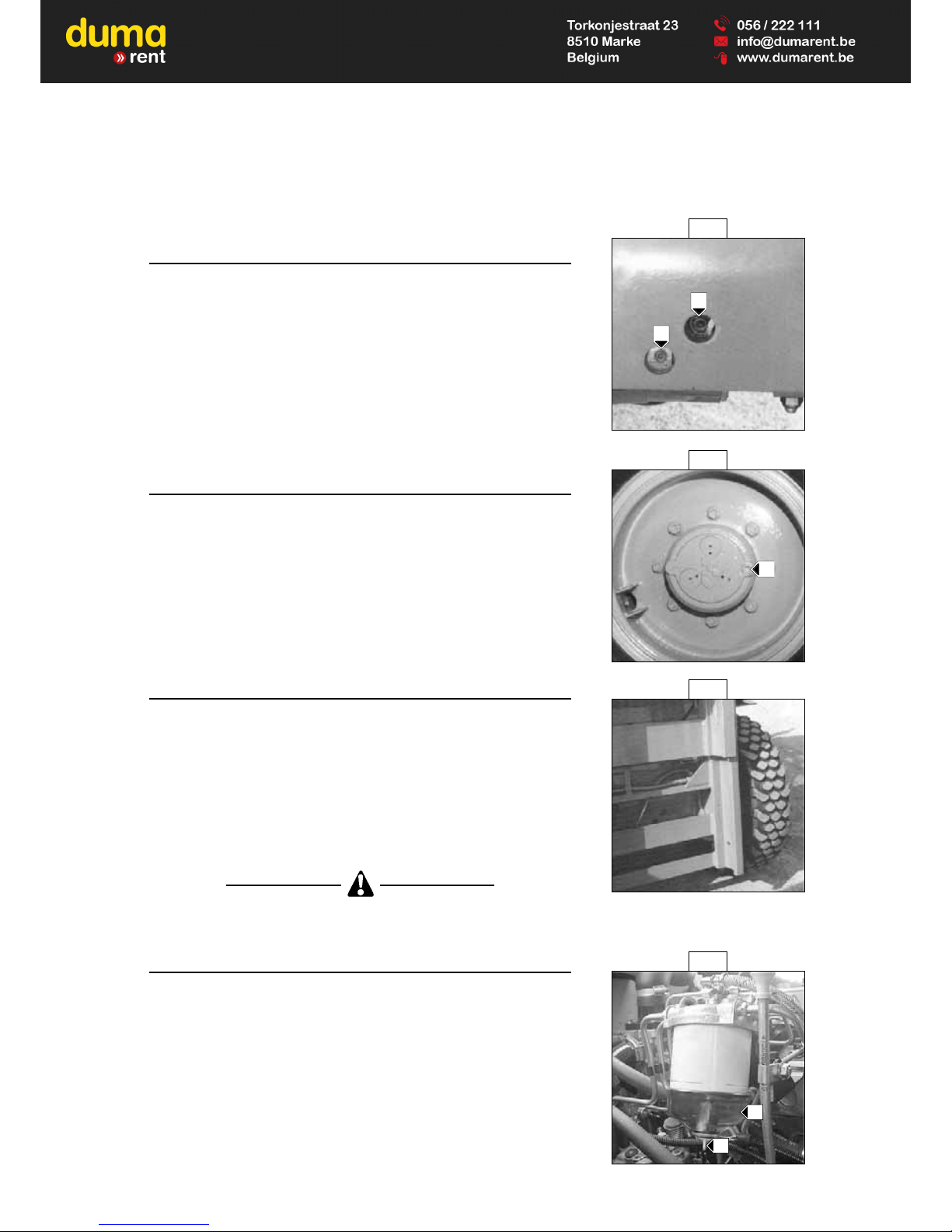

I.C. ENGINE (FIG. B)

- Engine Nr

HYDROSTATIC PUMP (FIG. C)

- Pump Nr

- Codification type

- Manufacturer’s Nr

- Year of manufacture

HYDROSTATIC MOTOR (FIG. D)

- Pump Nr

- Codification type

- Manufacturer’s Nr

- Year of manufacture

A

B

C

Page 33

2 - 5

TRANSFER BOX-FRONT (FIG. E)

- Type

- MANITOU reference

CAB (FIG. F)

- Type

- Serial Nr

MAST (FIG. G)

- Mast identification Nr

PLATE MANUFACTURER OF THE ATTACHMENT (FIG. H)

- Model

- Serial Nr

- Year of manufacture

E

F

G

MANITOU BF

44158 ANCENIS CEDEX

FRANCE

TELEX : 710 521

FAX : 40.83.36.88

MODELE

N° dans la série

Année fabrication

Masse à vide

C d G / Tablier

A vide / En charge : mm

/

kg

250 bar maxi.

Cap. Nominale

Pression de service

AVERTISSEMENT : RESPECTEZ

LA CAPACITE DE L'ENSEMBLE

"CHARIOT ET EQUIPEMENT"

N°207701

H

Page 34

2 - 6

PERKINS 1004-4

4

4

Direct

1.3.4.2

0,20 mm

0,45 mm

3990 cm

3

100 mm

127 mm

16.5 : 1

2300 tr/mn

850 tr/mn

2500 tr/mn

82 cv 60,5 kw

80,5 cv 59,3 kw

85,2 cv 62,9 kw

82,1 cv 60,5 kw

289 Nm to 1425 rpm

dry 3 microns

By water

Puller

6

457 mm

77 °C to 85 °C

92 °C to 98 °C

Negative

12 V - 105 Ah

14 V - 35 A (1stAssembly)

12 V - 55 A (2ndAssembly)

Incorporated into the alternator

12 V - 2,2 kw

A4VG56DA With variable cubic capacity and

with automatic power governor.

Electromagnetic 12V.

Hydraulic by valve TH7

56 cm

3

0 cm

3

141,68 L/min

ENGINE

- Type

- Number of cylinders

- Number of strokes

- Injection system

- Ignition sequence

- Clearance of rocker valve (Cold)

. Inlet

. Exhaust

- Capacity

- Bore

- Stroke

- Volumetric ratio

- Nominal running speed

- Idle speed

- Full speed

- Power DIN 70.020

- Power DIN 6270 B

- Power SAE

- Power BS.AU 141 a 1971

- Maximum torque

- Air cleaner

COOLING CIRCUIT

- Type

- Fan

. Number of blades

. Diameter

- Thermostat

. Start opening

. Full opening

ELECTRIC CIRCUIT

- Earth

- Battery

- Alternator

- Tension regulator

- Starter

HYDROSTATIC TRANSMISSION

HYDROSTATIC PUMP

- Type

- Gear reverser

- Inching control

- Main pump

. Capacity MAXI

. Capacity MINI

. MAX. flow rate

CHARACTERISTICS

UP TO MACHINE N° 142 126

Page 35

2 - 7

420 Bar

380 Bar

11,1 cm

3

27,19 L/min.

25 Bar (Transmission in neutral).

A6VM107DA variable displacement

107 cm3

26 cm3

HURTH Coupled with front axle.

1

1

HURTH

Epicyclic

Foot pedal. Mechanical

Multidisc brake immersed in oil.

Foot pedal. Hydraulic brake acting on front

wheels.

Mechanical hand lever applied on the front

wheels.

. Working pressure

(Up to pump N° : 3890010)

(From pump N° : 3890011)

- Boost pump

. Cubic capacity

. MAX. flow rate

. Boost pressure MAX. r.p.m.

HYDROSTATIC MOTOR

- Type

. Capacity MAXI

. Capacity MINI

TRANSFER BOX

- Type

- Number of forward speeds

- Number of reverse speeds

FRONT AXLE

- Type

- Hub reducers

- Differential lock

BRAKE

- Type

- Service brake

- Parking brake

Page 36

2 - 8

PERKINS 1004-42 AR 81155

4

4

Direct

1.3.4.2

0,20 mm

0,45 mm

4233 cm

3

103 mm

127 mm

18.5 / 1

2300 tr/mn

825 tr/mn

2500 tr/mn

83 cv 61,5 kw

85 cv 63 kw

89 cv 65,5 kw

298 Nm to 1400 tr/mn

300 Nm to 1400 tr/mn

dry 3 microns

By water

Puller

6

457 mm

77° C to 85° C

92° C to 98° C

Negative

12 V - 105 Ah - 680 A EN

12 V - 65 A

Magneti Marelli A127

Incorporated into the alternator

12 V

Magneti Marelli M127

A4VG56DA With variable cubic capacity and

with automatic power governor.

Electromagnetic 12V.

Hydraulic by valve TH7

56 cm

3

0 cm

3

141,68 L/mn

380 Bar

ENGINE

- Type

- Number of cylinders

- Number of strokes

- Injection system

- Ignition sequence

- Rocker arm clearance (Hot)

. Inlet

. Exhaust

- Capacity

- Bore

- Stroke

- Volumetric ratio

- Nominal running speed

- Idle speed

- Full speed

- Power ISO 3046-1

- Power ISO/TR 14396

- Power SAE

- Maximum torque ISO 3046-1

- Maximum torque ISO/TR 14396

- Air cleaner

COOLING CIRCUIT

- Type

- Fan

. Number of blades

. Diameter

- Thermostat

. Start opening

. Full opening

ELECTRIC CIRCUIT

- Earth

- Battery

- Alternator

. Type

. Tension regulator

- Starter

. Type

HYDROSTATIC TRANSMISSION

HYDROSTATIC PUMP

- Type

- Gear reverser

- Inching control

- Main pump

. Capacity MAXI

. Capacity MINI

. MAX. flow rate

. Working pressure

FROM MACHINE N° 142 127

Page 37

2 - 9

11,1 cm

3

27,19 L/min.

25 Bar (Transmission in neutral).

A6VM107DA variable displacement

107 cm3

26 cm3

HURTH Coupled with front axle.

1

1

HURTH

Epicyclic

Foot pedal. Mechanical

Multidisc brake immersed in oil.

Foot pedal. Hydraulic brake acting on front

wheels.

Mechanical hand lever applied on the front

wheels.

- Boost pump

. Cubic capacity

. MAX. flow rate

. Boost pressure MAX. r.p.m.

HYDROSTATIC MOTOR

- Type

. Capacity MAXI

. Capacity MINI

TRANSFER BOX

- Type

- Number of forward speeds

- Number of reverse speeds

FRONT AXLE

- Type

- Hub reducers

- Differential lock

BRAKE

- Type

- Service brake

- Parking brake

Page 38

2 - 10

FRONT TYRES

STANDARD

OPTION

REAR TYRES

STANDARD

OPTION

HYDRAULIC CIRCUIT

UP TO MACHINE N° : 109 832 EXCEPT FOR N° : 107 781

- Lifting, tilting, attachment circuit

. Type of pump

. Flow rate at full speed

. Pressure

. Capacity

- Steering direction

. Type of pump

. Flow rate at full speed

. Pressure

. Capacity

- Filtration

. Return

- Hydraulic shock absorber

. Capacities

. Pressure

Gear pump

71,3 L/min.

200 Bar

31 cm

3

Gear pump

27,6 L/min.

140 Bar

12 cm

3

10 Microns

1,4 L

120 Bar

MSI 40

DIMENSIONS PRESSURE

TYRE LOAD

PRESSURE ON THE CONTACT SURFACE

AERA OF THE CONTACT SURFACE

UNLADEN LOADED UNLADEN LOADED UNLADEN LOADED

315/70 R22,5 G391 6,75 Bar

2000 Kg 5200 Kg 6,7 Kg/cm26,7 Kg/cm2300 cm

2

780 cm

2

GOOD YEAR

DIMENSIONS PRESSURE

TYRE LOAD

PRESSURE ON THE CONTACT SURFACE

AERA OF THE CONTACT SURFACE

UNLADEN LOADED UNLADEN LOADED UNLADEN LOADED

225/75 R15 XZM 149 A5 5 Bar

1850 Kg 650 Kg 5,4 Kg/cm23,1 Kg/cm2345 cm

2

210 cm

2

MICHELIN

DIMENSIONS PRESSURE

TYRE LOAD

PRESSURE ON THE CONTACT SURFACE

AERA OF THE CONTACT SURFACE

UNLADEN LOADED UNLADEN LOADED UNLADEN LOADED

PPS 28-9x15 CSESC10

1850 Kg 650 Kg 7,2 Kg/cm24,4 Kg/cm2260 cm

2

150 cm

2

CONTINENTAL (Solid)

DIMENSIONS PRESSURE

TYRE LOAD

PRESSURE ON THE CONTACT SURFACE

AERA OF THE CONTACT SURFACE

UNLADEN LOADED UNLADEN LOADED UNLADEN LOADED

12-5 R20 16PR MPT80 5 Bar

2000 Kg 5200 Kg 3,6 Kg/cm24,2 Kg/cm2560 cm

2

1250 cm

2

CONTINENTAL

445/65 R19,5 Tubeless XZY 165K 6,3 Bar

2000 Kg 5200 Kg 4,3 Kg/cm25,7 Kg/cm2470 cm

2

905 cm

2

MICHELIN

16/70-20 14PR E91-2 4,5 Bar

2000 Kg 5200 Kg 7,2 Kg/cm28,8 Kg/cm2280 cm

2

595 cm

2

DUNLOP

10.00-20 CSE SC10

2000 Kg 5200 Kg 5,5 Kg/cm28,4 Kg/cm2365 cm

2

620 cm

2

CONTINENTAL (Solid)

Page 39

2 - 11

Gear pump

37 cm

3

85,1 L/mn

200 Bar

Load control system

140 Bar

10 Microns

100 Microns

1,4 L

120 Bar

Gear pump

37 cm

3

92,5 L/mn

200 Bar

Load control system

145 Bar

10 Microns

100 Microns

1,4 L

120 Bar

80,5 dBA

24 km/h

24 km/h

3700 mm (DUPLEX mast)

4000 kg

500 mm

100 kg

HYDRAULIC CIRCUIT

UP TO MACHINE N° : 109 833 AND FOR N° : 107 781

UP TO MACHINE N° 130 517

- Type of pump

. Capacity

- Lifting, tilting, attachment circuit

. Flow rate at full speed

. Pressure

- Steering direction

. Flow rate at full speed

. Pressure

- Filtration

. Return

. Suction (Up to machine N° : 115 593)

- Hydraulic shock absorber

. Capacities

. Pressure

HYDRAULIC CIRCUIT

FROM MACHINE N° 130 518

- Type of pump

. Capacity

- Lifting, tilting, attachment circuit

. Flow rate at full speed

. Pressure

- Steering direction

. Flow rate at full speed

. Pressure

- Filtration

. Return

. Suction

- Hydraulic shock absorber

. Capacities

. Pressure

SPECIFICATIONS

- Level of sound pressure in the driver's cabin

(According to norm prEN 12053 : 1995)

. Cab model

- Travel speed of the lift truck

. Forward unladen

. Reverse unladen

- Standard lift height

- Rated capacity with standard mast

- Load center

- Weight of forks (Each)

Page 40

2 - 12

0,525 m/s

0,518 m/s

0,424 m/s

0,542 m/s

6975 kg

10975 kg

3425 kg

9740 kg

3550 kg

1235 kg

2050 daN

3600 daN

26 % to 1 km/h

30 % to 1 km/h

daN

- Lifting movement (With standard mast)

. Unladen lifting

. Rated load lifting

. Unladen lowering

. Rated load lowering

- Weight of lift truck with standard mast

. Unladen

. Rated load

- Weight per axle with standard mast (Transport position)

. Front unladen

rated load

. Rear unladen

rated load

- Drawbar pull

. Unladen

. Rated load

- Maximum ramp negotiable in forward motion

. Unladen

. Rated load

- Break out force at bucket teeth

Page 41

2 - 13

FRONT TYRES

STANDARD

OPTION

REAR TYRES

STANDARD

OPTION

HYDRAULIC CIRCUIT

UP TO MACHINE N° : 109 832 EXCEPT FOR N° : 107 781

- Lifting, tilting, attachment circuit

. Type of pump

. Flow rate at full speed

. Pressure

. Capacity

- Steering direction

. Type of pump

. Flow rate at full speed

. Pressure

. Capacity

- Filtration

. Return

- Hydraulic shock absorber

. Capacities

. Pressure

Gear pump

71,3 L/mn

210 Bar

31 cm

3

Gear pump

27,6 L/mn

140 Bar

12 cm

3

10 Microns

1,4 L

120 Bar

MSI 50

DIMENSIONS PRESSURE

TYRE LOAD

PRESSURE ON THE CONTACT SURFACE

AERA OF THE CONTACT SURFACE

UNLADEN LOADED UNLADEN LOADED UNLADEN LOADED

315/70 R22,5 G391 7,75 Bar

2050 Kg 6000 Kg 7,6 Kg/cm27,6 Kg/cm2270 cm

2

790 cm

2

GOOD YEAR

DIMENSIONS PRESSURE

TYRE LOAD

PRESSURE ON THE CONTACT SURFACE

AERA OF THE CONTACT SURFACE

UNLADEN LOADED UNLADEN LOADED UNLADEN LOADED

225/75 R15 XZM 149 A5 6 Bar

2300 Kg 800 Kg 6,3 Kg/cm23,8 Kg/cm2370 cm

2

210 cm

2

MICHELIN

DIMENSIONS PRESSURE

TYRE LOAD

PRESSURE ON THE CONTACT SURFACE

AERA OF THE CONTACT SURFACE

UNLADEN LOADED UNLADEN LOADED UNLADEN LOADED

PPS 28-9x15 CSE SC10

2300 Kg 800 Kg 8 Kg/cm24,7 Kg/cm2290 cm

2

170 cm

2

CONTINENTAL (Solid)

DIMENSIONS PRESSURE

TYRE LOAD

PRESSURE ON THE CONTACT SURFACE

AERA OF THE CONTACT SURFACE

UNLADEN LOADED UNLADEN LOADED UNLADEN LOADED

12-5 R20 22PR MPT80 7 Bar

2050 Kg 6000 Kg 4,1 Kg/cm25 Kg/cm

2

500 cm

2

1210 cm

2

CONTINENTAL

445/65 R19,5 Tubeless XZY 165K 7,5 Bar

2050 Kg 6000 Kg 4,8 Kg/cm26,7 Kg/cm2430 cm

2

895 cm

2

MICHELIN

16/70-20 14PR E91-2 5,5 Bar

2050 Kg 6000 Kg 7,1 Kg/cm29,5 Kg/cm2290 cm

2

635 cm

2

DUNLOP

10.00-20 CSE SC10

2050 Kg 6000 Kg 5,6 Kg/cm29,5 Kg/cm2370 cm

2

635 cm

2

CONTINENTAL (Solid)

Page 42

2 - 14

Gear pump

37 cm

3

85,1 L/mn

200 Bar

Load control system

140 Bar

10 Microns

100 Microns

1,4 L

120 Bar

Gear pump

37 cm

3

92,5 L/mn

200 Bar

Load control system

145 Bar

10 Microns

100 Microns

1,4 L

120 Bar

80,5 dBA

24 km/h

24 km/h

3700 mm (DUPLEX mast)

5000 kg

600 mm

130 kg

HYDRAULIC CIRCUIT

FROM MACHINE N° : 109 833 AND FOR N° : 107 781

UP TO MACHINE N° 130 517

- Type of pump

. Capacity

- Lifting, tilting, attachment circuit

. Flow rate at full speed

. Pressure

- Steering direction

. Flow rate at full speed

. Pressure

- Filtration

. Return

. Suction (From machine N° : 115 593)

- Hydraulic shock absorber

. Capacities

. Pressure

HYDRAULIC CIRCUIT

FROM MACHINE N° 130 518

- Type of pump

. Capacity

- Lifting, tilting, attachment circuit

. Flow rate at full speed

. Pressure

- Steering direction

. Flow rate at full speed

. Pressure

- Filtration

. Return

. Suction

- Hydraulic shock absorber

. Capacities

. Pressure

SPECIFICATIONS

- Level of sound pressure in the driver's cabin

(According to norm prEN 12053 : 1995)

. Cab model

- Travel speed of the lift truck

. Forward unladen

. Reverse unladen

- Standard lift height

- Rated capacity with standard mast

- Load center

- Weight of forks (Each)

Page 43

2 - 15

0,451 m/s

0,435 m/s

0,348 m/s

0,451 m/s

7900 kg

12900 kg

3450 kg

11345 kg

4450 kg

1555 kg

2050 daN

3600 daN

24 % to 1 km/h

25 % to 1 km/h

daN

- Lifting movement (With standard mast)

. Unladen lifting

. Rated load lifting

. Unladen lowering

. Rated load lowering

- Weight of lift truck with standard mast

. Unladen

. Rated load

- Weight per axle with standard mast (Transport position)

. Front unladen

rated load

. Rear unladen

rated load

- Drawbar pull

. Unladen

. Rated load

- Maximum ramp negotiable in forward motion

. Unladen

. Rated load

- Break out force at bucket teeth

Page 44

2 - 16

MAST CHARACTERISTICS

DOUBLE MAST WITH ALL-ROUND VISION

MSI 40 MSI 50

MAST HL Z Y LL H H1 H2 HL Z Y LL H H1 H2

3m00 3050 10° 12° – 2425 3977 54 3060 10° 12° – 2425 3972 44

3m30 3350 10° 12° – 2575 4277 54 3360 10° 12° – 2575 4272 44

3m50 3550 10° 12° – 2675 4477 54 3560 10° 12° – 2675 4472 44

3m70 3750 10° 12° – 2775 4677 54 3760 10° 12° – 2775 4672 44

4m00 4050 10° 12° – 2925 4977 54 4060 10° 12° – 2925 4972 44

4m50 4550 10° 12° – 3175 5477 54 4560 10° 12° – 3175 5472 44

5m00 5050 10° 12° – 3425 5977 54 5060 10° 12° – 3425 5972 44

TRIPLE MAST WITH TOTAL FREE-ACTING LIFT

MSI 40 MSI 50

MAST HL Z Y LL H H1 H2 HL Z Y LL H H1 H2

3m70 3750 10° 12° 1258 2175 4667 44 3760 10° 12° 1263 2175 4672 44

4m00 4050 10° 12° 1358 2275 4967 44 4060 10° 12° 1363 2275 4972 44

4m30 4350 10° 12° 1458 2375 5267 44 4360 10° 12° 1463 2375 5272 44

4m50 4550 10° 12° 1533 2450 5467 19 4560 10° 12° 1538 2450 5472 19

4m70 4750 10° 12° 1593 2510 5667 39 4760 10° 12° 1598 2510 5672 39

5m00 5050 10° 12° 1708 2625 5967 14 5060 10° 12° 1713 2625 5972 14

5m50 5550 10° 12° 1858 2775 6467 44 5560 10° 12° 1863 2775 6472 44

6m00 6050 10° 12° 2033 2950 6967 19 6060 10° 12° 2038 2950 6972 19

DOUBLE MAST WITH TOTAL FREE-ACTING LIFT

MSI 40 MSI 50

MAST HL Z Y LL H H1 H2 HL Z Y LL H H1 H2

3m00 3050 10° 12° 1532 2450 3968 32 3060 10° 12° 1541 2450 3969 32

3m30 3350 10° 12° 1682 2600 4268 32 3360 10° 12° 1691 2600 4269 32

3m50 3550 10° 12° 1782 2700 4468 32 3560 10° 12° 1791 2700 4469 32

3m70 3750 10° 12° 1882 2800 4668 32 3760 10° 12° 1891 2800 4669 32

4m00 4050 10° 12° 2032 2950 4968 32 4060 10° 12° 2041 2950 4969 32

HL : Lift height in mm

Z : Forward tilting

Y : Backward tilting

LL : Free-acting lift in mm

H : Overall height with folded mast in mm

H1 : Overall height with spreaded out mast in mm

H2 : Carriage overshooting

Page 45

2 - 17

Page 46

2 - 18

DIMENSIONS AND LOAD CHART

MSI 40 MSI 50

Page 47

2 - 19

MSI 40 MSI 50

A 1200 mm 1200 mm

B 2075 mm 2075 mm

C 692 mm 702 mm

D 3312 mm 3322 mm

E 4512 mm 4522 mm

F 1391 mm 1391 mm

F1 1135 mm 1135 mm

G 185 mm 185 mm

G1 220 mm 220 mm

G2 225 mm 225 mm

G3 210 mm 210 mm

H 2775 mm 2775 mm

H* 2575 mm 2575 mm

H1 4677 mm 4672 mm

H1* 4277 mm 4272 mm

I 545 mm 545 mm

J 1300 mm 1300 mm

K 1670 mm 1670 mm

L 50 mm 60 mm

N 1710 to 1775 mm 1710 to 1775 mm

O 150 mm 150 mm

P1 30 ° 58 % 30 ° 58 %

P2 27 ° 51 % 27 ° 51 %

P3 58 ° 160 % 58 ° 160 %

R 2700 mm 2700 mm

S 2760 mm 2760 mm

T 4992 mm 5002 mm

U 2370 mm 2370 mm

V 2900 mm 2900 mm

V1 200 mm 200 mm

W 1735 mm 1735 mm

Y 12 ° 12 °

Z 10 ° 10 °

H - H1 = Standard mast DUPLEX 3M70

H* - H1* = Option mast DUPLEX 3M30

Page 48

2 - 20

INSTRUMENTS AND CONTROLS

UP TO MACHINE N° : 117 315

1

2

3

4

5

6

7

8

9

10

11

12

13

13

13

14

15

19

20

20

21

21

22

22

17

23

23

24

24

25

16

18

28

26

27

30

Page 49

2 - 21

DESCRIPTION

1 - DRIVER’S SEAT

2 - TILTING HANDLE OF WHEEL

3 - INSTRUMENT PANEL

4 - SWITCH'S AND LAMP'S PANEL

5 - LIGHT SWITCH , HORN AND INDICATOR SWITCH

6 - IGNITION SWITCH

7 - FUSES BOX

8 - ACCELERATOR PEDAL

9 - INCHING AND SERVICE BRAKE PEDAL

10 - DIFFERENTIAL LOCK PEDAL

11 - FORWARD/REVERSE LEVER

12 - PARKING BRAKE LEVER

13 - HYDRAULIC CONTROL DISTRIBUTOR LEVERS

14 - BRAKING OIL TANK SLUDGE DOOR

15 - ENGINE SLUDGE DOOR

LIFTING CAB

16 - UNLOCKING HANDLE FOR CAB

17 - LIFTING CAB SWITCH (OPTION)

18 - SAFETY SHORE FOR LIFTING CAB

19 - CAB HEATER CONTROL

20 - HEATING VENTILATORS

21 - DOOR LOCKS

22 - CLOSING HANDLES FOR DOOR

23 - UNLOCKING HANDLES FOR OPEN DOOR

24 - ACCES HANDLES DRIVER'S CAB

25 - HANDLES FOR L.H. SIDE WINDOW OPENING

26 -OUTSIDE REARVIEW MIRROR

27 - WINDSCREEN WASHER TANK

28 - ROOF LIGHT

29 - TOWING PIN

30 - DOCUMENT HOLDER NET

31 - REAR LIGHTS AND INDICATORS

NOTA : All the terms such as : RIGHT, LEFT, FRONT, REAR are meant for an observer seated on driver's seat and

looking in front of him.

Page 50

2 - 222 - 22

1 - DRIVER’S SEAT

1stASSEMBLY

FOR OPTIMAL COMFORT, THIS SEAT CAN BE ADJUSTED IN

DIFFERENT WAYS.

LONGITUDINAL ADJUSTMENT

- Pull the locking lever 1 upwards.

- Slide the seat to the required position.

- Release the lever and ensure it returns to the lock position.

SEAT SUSPENSION ADJUSTMENT

- Refer to the seat's graduation.

- Turn handle 2 depending on the driver's weight.

2ndASSEMBLY

FOR OPTIMAL COMFORT, THIS SEAT CAN BE ADJUSTED IN

DIFFERENT WAYS.

LONGITUDINAL ADJUSTMENT

- Pull the locking lever 1 upwards.

- Slide the seat to the required position.

- Release the lever and ensure it returns to the lock position.

SEAT SUSPENSION ADJUSTMENT

- Pull and lift up the locking lever 2 so as to place it into one of these five

positions.

Position A : Light-weight driver (50 kg).

Position B : Intermediate.

Position C : Middle-weight driver.

Position D : Intermediate.

Position E : Heavy-weight driver (120 kg).

ANGLE ADJUSTMENT OF THE BACK-REST

- Pull the locking lever 3 backwards.

- Tilt the back-rest into one of the three possible positions.

- Release the locking lever and ensure it returns to the lock position.

ANGLE ADJUSTMENT OF THE WHOLE SEAT

- Lift up the locking lever 4.

- Tilt the seat forwards or backwards.

- Release the lever and ensure it returns to the lock position.

2 - TILTING HANDLE OF WHEEL

- Turn the lever 1 towards A for loosening.

- Tilt the steering wheel into the required position.

- Turn the lever 1 towards B for blocking.

2

1

1

1

2

3

4

A

B

C

D

E

A

B

Page 51

2 - 23

3 - INSTUMENT PANEL

A - Fuel level gauge.

B - Hourmeter.

C - Water temperature gauge.

D - Green indicator lamp.

E - Red engine oil pressure lamp.

F - Red alternator charge lamp.

G - Blue main beam lamp.

H - Red air filter clog lamp.

I - Red hydrostatic transmission oil filter clog lamp.

J - Fuses box.

A - FUEL LEVEL GAUGE

B - HOURMETER

It shows the number of hours the fork lift truck has run. The hours are shown on the dial up to a multiple of thousand.

The moving tell-tale shows the good working order of the apparatus.

C - WATER TEMPERATURE GAUGE

When the truck works in normal conditions the needle of the indicator should indicate 80° to 90° C.

If the needle indicates an abnormally high temperature (100° C maximum) , stop the engine immediately and investigate

the cooling system for the cause of the malfunction.

D - GREEN INDICATOR LAMP

It is illuminated when the indicators are on and indicates that they are functioning properly.

E - RED ENGINE OIL PRESSURE LAMP

This lamp is illuminated when the ignition switch is in the ON position and should go out as soon as the fork lift truck

starts. If this lamp stays on when the engine is running, stop the fork lift truck immediately and look for the cause (see oil

level in engine crankcase).

F - RED ALTERNATOR CHARGE LAMP

This lamp is illuminated when the ignition switch is in the ON position and should go out as soon as the fork lift truck

starts. If this lamp stays on when the engine is running, stop the fork lift truck immediately and check the electrical circuit

as well as the alternator belt.

G - BLUE MAIN BEAM LAMP (OPTION)

The lamp is illuminated when lights are on main beam.

H - RED AIR FILTER CLOG LAMP

This lamp provides the operator with information about the condition of the filter cartridge. If this cartridge is clogged the

lamp comes on (See cleaning and replacement requirements in chapter : FILTERS CARTRIDGES AND BELTS in

paragraph : 3 - MAINTENANCE).

I - RED HYDROSTATIC TRANSMISSION OIL FILTER CLOG LAMP

This lamp provides the operator with information about the condition of the filter cartridge. If this cartridge is clogged the

lamp comes on (See cleaning and replacement requirements in chapter : FILTERS CARTRIDGES AND BELTS in

paragraph : 3 - MAINTENANCE).

NOTE : This lamp comes on by cold weather or when starting the fork lift truck, it goes off when the hydraulic oil reach

the temperature of functionning.

Page 52

2 - 24

J - FUSES BOX

Remove the cover to replace a fuse.The using is described herewith from L.H. to R.H. :

1 : fuse hand the left : Indicators (7,5A).

2 : Horn. + Stop swith (7,5A).

3 : OPTION R.H sidelight. + R.H rear light (7,5A).

4 : OPTION L.H sidelight + L.H rear light (7,5A).

5 : OPTION Dipped headlights (7,5A).

6 : Forward / Reverse (7,5A).

7 : Heating.+ 2nd heating OPTION (7,5A).

8 : Front windscreen wiper and windscreen washer + Brake oil level lamp (7,5A).

9 : OPTION Warning light (7,5A).

10 : OPTION (7,5A).

11 : OPTION (7,5A).

12 : OPTION Main beam (7,5A).

NOTE : Replace a used fuse with a new fuse of the same quality and capacity. Never reuse a repaired fuse.

4 - SWITCH'S AND LAMP'S PANEL

A - Front windscreen wiper switch and windscreen washer.

B - OPTION heater fan switch.

C - R ear windscreen washer switch.

E - OPTION warning light switch.

D - Brake oil level lamp.

F - OPTION working head light switch.

or

OPTION left working head light switch.

G - OPTION flashing alarm light switch.

H - OPTION working tail light switch.

or

OPTION left working tail light switch.

A - FRONT WINDSCREEN WIPER SWITCH AND WINDSCREEN WASHER

This two position switch, when set on the "down" position and simultaneously pressed, allows the windscreen-washer and the

windscreen wiper to be operated, and when set on the "up" position, the windscreen wiper to be operated.

B - HEATER FAN SWITCH

This two speed switch allows warm or cold air to pass through the heating ventilators.

C - REAR WINDSCREEN WASHER SWITCH

D - BRAKE OIL LEVEL LAMP

This lamp comes on when the brake oil level is insufficient. If an abnormally low level is noted consult your dealer.

G AE F

B CD H

Page 53

2 - 25

5 - LIGHT SWITCH, HORN AND INDICATOR SWITCH

The switch controls the road lights and horn.

A - All lights are off, the rear direction indicators do not flash.

B - The right rear hand direction indicator flash.

C - The left rear hand direction indicator flash.

D - The sidelights (OPTION) and the rear lights are on.

E - The dipped headlights (OPTION) and the rear lights are on.

F - The main beam headlights (OPTION) and the rear lights are on.

G - Headlight signal (OPTION).

To operate the horn, press the switch.

NOTE : The positions D - E - F - G can be carried out without the ignition being on.

6 - IGNITION SWITCH

The key switch has five positions :

P - Ignition off, parking position.

O - Ignition switched off and engine stopped.

I - Ignition on.

II - Heating.

III - The engine starts, return to position I as soon as the key is released

7 - FUSES BOX

Remove the cover to replace a fuse, which is to be used as per the following

numbers :

1 - OPTION Working tail lights (10A).

OPTION Left working tail light (10A).

2 - OPTION Working head lights (10A).

OPTION Left working head light (10A).

3 - OPTION Flashing alarm light (7,5A).

4 - OPTION.Cabin lifting (10A).

5 - OPTION (10A).

6 - Rear windscreen wiper (7,5A).

NOTE : Replace a worn fuse by a new fuse of equal quality and capacity. Do not re-use a repaired fuse.

8 - ACCELERATOR PEDAL

9 - INCHING AND SERVICE BRAKE PEDAL

This pedal acts in two stages :

In the first stage during the braking clearance stroke, it acts progressively the hydrostatic transmission to do a slow

approach with all the power of the engine.

In the second stage it acts both on front wheels through a brake hydraulic system, and allows to slow down and stop the

fork lift truck.

F

D

G

C

B

A

E

1

3

5

6

4

2

Page 54

2 - 26

10 - DIFFERENTIAL LOCK PEDAL

The differential lock enables the drive wheels to turn at the same speed

irrespective of the state of the ground.

- Press the pedal and hold it in that position for the time during which locking

is required.

- To release the differential lock simply release the pedal, which should

automatically return to its initial position.

When the differential lock is on, the truck should always be driven in a

straight line and at low speed.

11 - FORWARD/REVERSE LEVER

When operating this control the truck should be travelling at slow speed and

not accelerating.

FORWARD : Push the lever forwards (Position A).

REVERSE : Pull the lever backwards (Position B).

NEUTRAL : To start the truck, the lever must be in neutral

(Position C).

12 - PARKING BRAKE LEVER

The parking brake acts on the two front wheels.

- To tighten the parking brake, pull the lever backwards (Position A).

- To untighten the parking brake, push the lever forwards (Position B).

13 - HYDRAULIC CONTROL DISTRIBUTOR LEVERS

LEVER A : Single acting section, controle the raising and lowering of the mast.

- Pull the lever backwards when raising of the mast.

- Push the lever forwards when lowering of the mast.

NOTE : The engine r.p.m. automatically increases when lifting the load.

LEVER B : Double acting section, controle the tilting of the mast.

- Pull the lever backwards when reverse tilt of the mast.

- Push the lever forwards when forward tilt of the mast.

LEVER C : Double acting section, intented for the control of additional

equipment.

Do not attempt to alter the hydraulic system pressure by interfering with the

pressure regulating valve. In the event of suspected malfunction, contact

your dealer.

ANY ALTERATION MAY RENDER THE WARRANTY NULL AND VOID.

A B C

C

A

B

A

B

Page 55

2 - 27

14 - BRAKING OIL TANK SLUDGE DOOR

15 - ENGINE SLUDGE DOOR

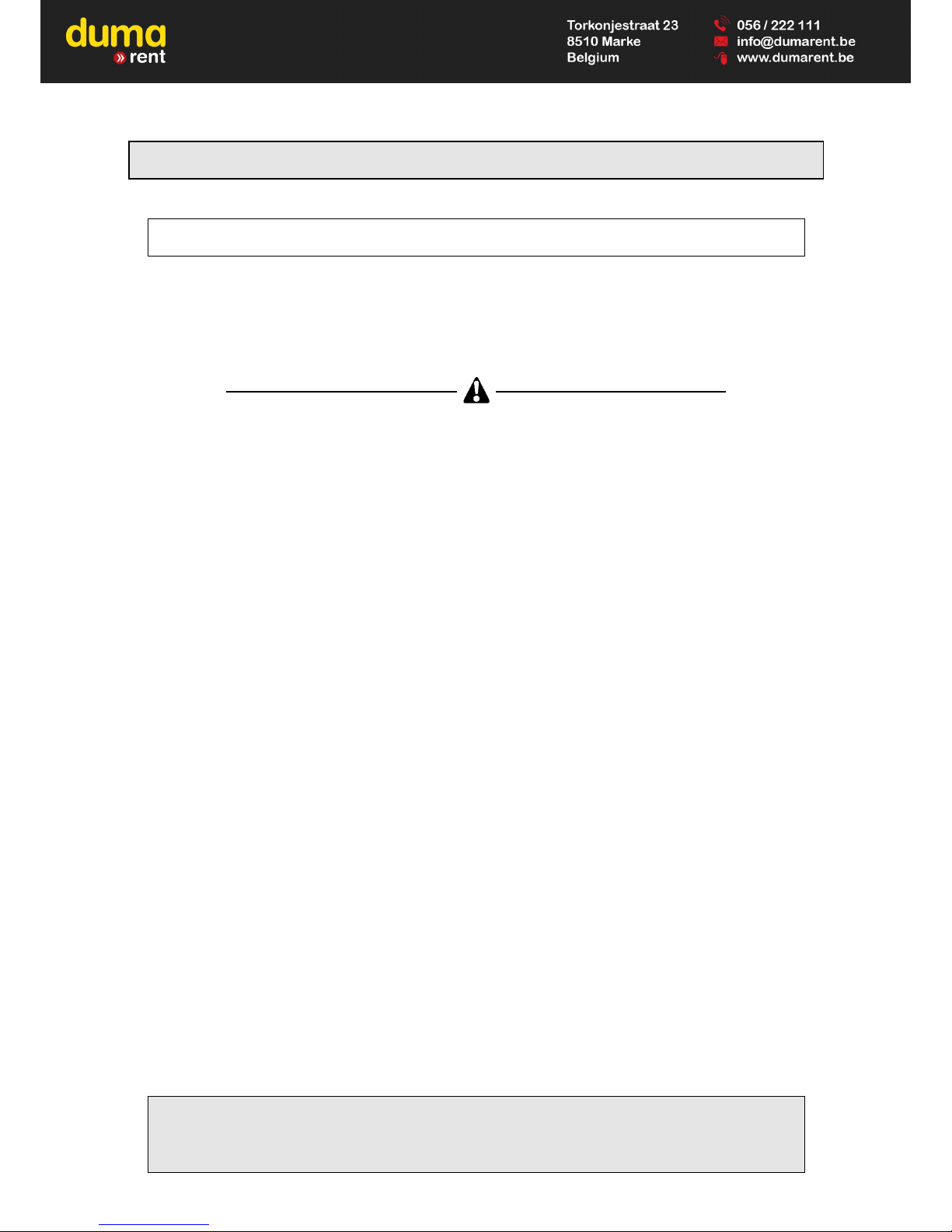

LIFTING CAB

MANUAL LIFTING WITH AIR SPRING IN STANDARD

Be sure that the mast is tilted forward to the maximum and that the engine is

stopped before lifting the cab.

UNLOCKING OF THE CAB :

- Close the L.H. door.

- Open the R.H. door.

- Open the engine sludge door 15 (Fig. A).

- Push the lever 16 (Fig. B) forward (position A ) to unlock the lifting cab

- Close the engine sludge door 15 (Fig. A).

- Close the R.H. door.

LIFTING OF THE CAB :

- Lift the cab (Fig. C) and incline to the maximum forward.

- Bring back the lever 16 (Fig. B).initial position (position B).

- Engage the safety shore 18 (Fig. D) in its clip ; vertically under the cab.

LOWERING OF THE CAB :

- Re-position the safety shore 18 (Fig. D).

- To decrease the necessary effort to tilt the cab backward, open the R.H.

door and lock it in open position.

- Lower the cab by pulling on the door handle and be sure of its lock.

- Re-close the R.H. door.

ELECTRICAL LIFTING IN OPTION

Be sure that the mast is tilted forward to the maximum and that the engine is

stopped before lifting the cab.

UNLOCKING OF THE CAB :

- Close the L.H. door.

- Open the R.H. door.

- Open the engine sludge door 15 (Fig. A).

- Push the lever 16 (Fig. B) forward (position A ) to unlock the lifting cab.

- Close the engine sludge door 15 (Fig. A).

- Put the ignition on in the lift truck.

15

16

B

A

B

A

C

D

18

Page 56

2 - 28

LIFTING OF THE CAB :

- Let the R.H. door of the cab to be half open and press on the top of the

switch 17 (Fig. E) to incline the cab forward to the maximum.

- Bring back the lever 16 (Fig. B).initial position (position B).

- Close the R.H. door.

- Engage the safety shore 18 (Fig. D) in its clip vertically under the cab.

Check that any object left in the driver’s stand cannot impede the operation.

LOWERING OF THE CAB :

- Re-position the safety shore 18 (Fig. D).

- Half open the R.H. door of the cab, press on the bottom of the switch 17

(Fig. E) to lower the cab in its initial position and be sure of the locking.

- Re-close the R.H. door.

Check that nothing or nobody can impede the lowering of the cabin.

19 - CAB HEATER CONTROL

Allows the temperature inside the cab to be adjusted.

A - With the valve closed, the blower delivers fresh air.

B - With the valve opened completely, the blower delivers warm air.

The intermediate positions allow the temperature inside the cab to be adjusted.

20 - HEATING VENTILATORS

These heating ventilators allow air ventilation to be directed inside the cab.

21 - DOOR LOOCKS

22 - CLOSING HANDLES FOR DOOR

23 - UNLOCKING HANDELS FOR OPEN DOOR

24 - ACCES HANDELS DRIVER'S CAB

E

17

A

B

Page 57

2 - 29

25 - HANDLES FOR L.H. SIDE WINDOW OPENING

26 - OUTSIDE REARVIEW MIRROR

27 - WINDSCREEN WASHER TANK

Check the level in the windscreen washer tank regularly, and top up, if necessary,

with water plus a product for windscreen washers and antifreeze in winter, via the

filler port 1.

28 - ROOF LIGHT

The switch is integral with the roof light.

29 - TOWING PIN

Located at the back of the truck, this pin makes it possible to couple a trailer.

The capacity is limited for each lift truck by the Permissible Total Moveable

Weight (P. T. M. W.), the drawbar pull and the maximum vertical drawbar pull

on the towing pin. This information is indicated on the manufacturer's plate on

each lift truck (See chapter : IDENTIFICATION OF THE LIFT TRUCK in

paragraph : 2 - DESCRIPTION).

NOTE : For towing, optional solutions exist, consult your dealer.

Before towing trailers, ensure that the clip is fully engaged in the towing pin.

30 - DOCUMENT HOLDER NET

Make sure that the operator’s manual is in the right place, i.e. in the

document holder net.

31 - REAR LIGHTS AND INDICATORS

A - Left rear indicator.

B - Left rear stoplight.

C - Left tail light.

D - Right tail light.

E - Right rear stoplight.

F - Right rear indicator.

1

A B C D E F

Page 58

2 - 30

INSTRUMENTS AND CONTROLS

FROM MACHINE N° : 117 316

1

2

3

4

7

9

10

12

14

15

19

20

22

24

26

30

1

5

6

7

8

9

10

11

13

14

17

19

20

21

22

24

25

26

28

16

18

23

27

32

1

Page 59

2 - 31

DESCRIPTION

1 - DRIVER’S SEAT

2 - TILTING HANDLE OF WHEEL

3 - INSTRUMENT PANEL

4 - SWITCH'S AND LAMP'S PANEL

5 - LIGHT SWITCH , HORN AND INDICATOR SWITCH

6 - IGNITION SWITCH

7 - KEY-OPERATED BATTERY DISCONNECTING DEVICE

8 - FUSES BOX

9 - ACCELERATOR PEDAL

10 - INCHING AND SERVICE BRAKE PEDAL

11 - DIFFERENTIAL LOCK PEDAL

12 - FORWARD/REVERSE LEVER

3 - PARKING BRAKE LEVER

14 - HYDRAULIC CONTROL DISTRIBUTOR LEVERS

15 - BRAKING OIL TANK SLUDGE DOOR

LIFTING CAB

16 - UNLOCKING HANDLE FOR CAB

17 - LIFTING CAB SWITCH

18 - SAFETY SHORE FOR LIFTING CAB

19 - CAB HEATER CONTROL

20 - HEATING VENTILATORS

21 - DOOR LOCKS

22 - CLOSING HANDLES FOR DOOR

23 - UNLOCKING HANDLES FOR OPEN DOOR

24 - ACCES HANDLES DRIVER'S CAB

25 - HANDLES FOR L.H. SIDE WINDOW OPENING

26 - OUTSIDE REARVIEW MIRROR

27 - WINDSCREEN WASHER TANK

28 - ROOF LIGHT

29 - TOWING PIN

30 - DOCUMENT HOLDER NET

31 - REAR LIGHTS AND INDICATORS

32 - SAFETY BELT

NOTA : All the terms such as : RIGHT, LEFT, FRONT, REAR are meant for an observer seated on driver's seat and

looking in front of him.