Page 1

MAN B&W S 50ME-B9.3

199 02 51-4. 0

This Project Guide is intended to provide the information necessary for the layout of a marine propulsion

plant.

The information is to be considered as preliminary. It is intended for the project stage only and subject to

modification in the interest of technical progress. The Project Guide provides the general technical data

available at the date of issue.

It should be noted that all figures, values, measurements or information about performance stated in this

project guide are for guidance only and should not be used for detailed design purposes or as a substitute for specific drawings and instructions prepared for such purposes.

Data updates

Data not finally calculated at the time of issue is marked ‘Available on request’. Such data may be made

available at a later date, however, for a specific project the data can be requested. Pages and table entries

marked ‘Not applicable’ represent an option, function or selection which is not valid.

The latest, most current version of the individual Project Guide sections are available on the Internet at:

www.marine.man.eu → ’Two - Stroke’.

Extent of Delivery

The final and binding design and outlines are to be supplied by our licensee, the engine maker, see Chapter 20 of this Project Guide.

In order to facilitate negotiations between the yard, the engine maker and the customer, a set of ‘Extent of

Delivery’ forms is available in which the basic and the optional executions are specified.

Electronic versions

This Project Guide book and the ‘Extent of Delivery’ forms are available on the Internet at:

www.marine.man.eu → ’Two-Stroke’, where they can be downloaded.

Edition 0.5

May 2014

MAN B&W S50ME-B9.3-TII

Project Guide

Electronically Controlled

Two-stroke Engines

with Camshaft Controlled Exhaust Valves

Page 2

MAN B&W S 50ME-B9.3

199 02 51-4. 0

MAN Diesel & Turbo

Teglholmsgade 41

DK2450 Copenhagen SV

Denmark

Telephone +45 33 85 11 00

Telefax +45 33 85 10 30

mandiesel-cph@mandiesel.com

www.mandieselturbo.com

Copyright 2014 © MAN Diesel & Turbo, branch of MAN Diesel & Turbo SE, Germany, registered with the Danish

Commerce and Companies Agency under CVR Nr.: 31611792, (herein referred to as “MAN Diesel & Turbo”).

This document is the product and property of MAN Diesel & Turbo and is protected by applicable copyright laws.

Subject to modification in the interest of technical progress. Reproduction permitted provided source is given.

7020-0215-00ppr May 2014

All data provided in this document is non-binding. This data serves informational purposes only and is especially not guaranteed in any way.

Depending on the subsequent specic individual projects, the relevant data may be subject to changes and will

be assessed and determined individually for each project. This will depend on the particular characteristics of

each individual project, especially specic site and operational conditions.

If this document is delivered in another language than English and doubts arise concerning the translation, the

English text shall prevail.

Page 3

MAN B&W

MAN Diesel

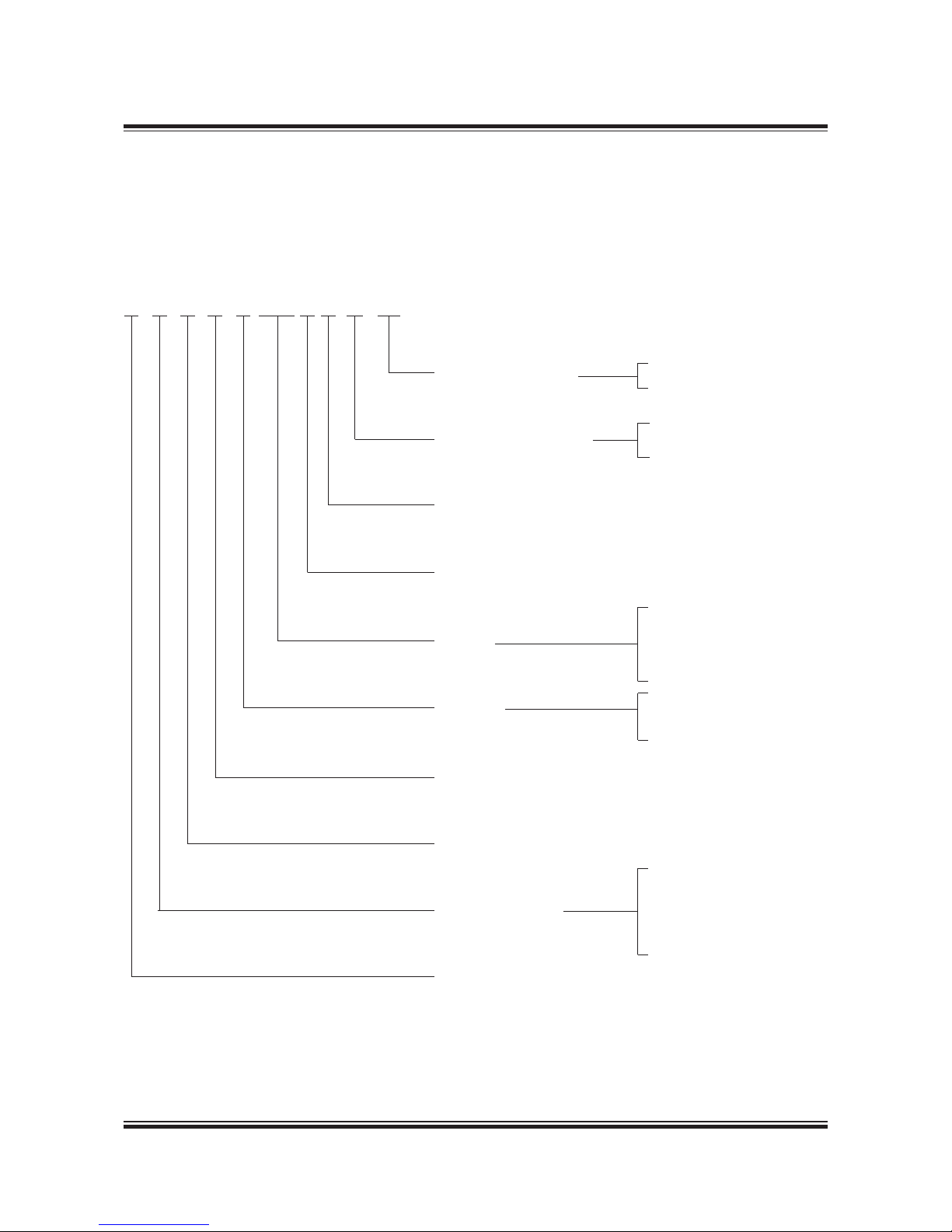

Engine Design ....................................................................... 1

Engine Layout and Load Diagrams, SFOC .............................. 2

Turbocharger Selection & Exhaust Gas By-pass .................... 3

Electricity Production ............................................................ 4

Installation Aspects ............................................................... 5

List of Capacities: Pumps, Coolers & Exhaust Gas ................. 6

Fuel ...................................................................................... 7

Lubricating Oil ...................................................................... 8

Cylinder Lubrication .............................................................. 9

Piston Rod Stuffing Box Drain Oil .......................................... 10

Central Cooling Water System ............................................... 11

Seawater Cooling System ..................................................... 12

Starting and Control Air ......................................................... 13

Scavenge Air ......................................................................... 14

Exhaust Gas .......................................................................... 15

Engine Control System .......................................................... 16

Vibration Aspects .................................................................. 17

Monitoring Systems and Instrumentation .............................. 18

Dispatch Pattern, Testing, Spares and Tools ........................... 19

Project Support and Documentation ...................................... 20

Appendix .............................................................................. A

Contents

Page 4

Page 5

MAN B&W Contents

Chapter Section

MAN Diesel

MAN B&W S 50ME-B9.3

1 Engine Design

The fuel optimised ME-B Tier II engine 1.01 1990113-7.0

Tier II fuel optimisation 1.01 1990112-5.0

Engine type designation 1.02 1983824-3.9

Power, speed, SFOC 1.03 1988502-3.1

Engine power range and fuel oil consumption 1.04 1984634-3.5

Performance curves 1.05 1985331-6.2

ME-B Mark 9 Engine description 1.06 1990120-8.0

Engine cross section 1.07 1988334-5.0

2 Engine Layout and Load Diagrams, SFOC

Engine layout and load diagrams 2.01 1983833-8.5

Propeller diameter and pitch, influence on optimum propeller speed 2.02 1983878-2.6

Layout diagram sizes 2.03 1988277-0.7

Engine layout and load diagrams 2.04 1986993-5.3

Diagram for actual project 2.05 1988329-8.1

Specific fuel oil consumption, ME versus MC engines 2.06 1983836-3.4

SFOC for high efficiency turbochargers 2.07 1987016-5.2

SFOC reference conditions and guarantee 2.08 1988341-6.1

Examples of graphic calculation of SFOC 2.08 1988278-2.2

SFOC calculations (80%-85%) 2.09 1988790-8.0

SFOC calculations, example 2.10 1988782-5.0

Fuel consumption at an arbitrary load 2.11 1983843-4.5

3 Turbocharger Selection & Exhaust Gas Bypass

Turbocharger selection 3.01 1990172-3.0

Exhaust gas bypass 3.02 1984593-4.6

Emission control 3.03 1988447-2.2

4 Electricity Production

Electricity production 4.01 1984155-0.5

Designation of PTO 4.01 1985385-5.5

PTO/RCF 4.01 1984300-0.3

Space requirements for side mounted PTO/RCF 4.02 1987927-2.1

Engine preparations for PTO 4.03 1984315-6.3

PTO/BW GCR 4.04 1984316-8.8

Waste Heat Recovery Systems (WHRS) 4.05 1986647-4.1

L16/24-TII GenSet data 4.06 1988280-4.0

L21/31TII GenSet data 4.07 1988281-6.0

L23/30H-TII GenSet data 4.08 1988282-8.0

L27/38-TII GenSet data 4.09 1988284-1.0

L28/32H-TII GenSet data 4.10 1988285-3.0

Page 6

MAN B&W Contents

Chapter Section

MAN Diesel

MAN B&W S 50ME-B9.3

5 Installation Aspects

Space requirements and overhaul heights 5.01 1984375-4.7

Crane beam for overhaul of turbochargers 5.03 1988741-8.1

Crane beam for turbochargers 5.03 1987636-0.2

Engine room crane 5.04 1987936-7.0

Overhaul with Double-Jib crane 5.04 1984534-8.4

Double-Jib crane 5.04 1984541-9.2

Engine outline, galleries and pipe connections 5.05 1984715-8.3

Centre of gravity 5.07 1990161-5.0

Counterflanges, Connection D 5.10 1986670-0.6

Counterflanges, Connection E 5.10 1987027-3.4

Engine seating and holding down bolts 5.11 1984176-5.11

Engine seating profile 5.12 1987728-3.0

Engine top bracing 5.13 1984672-5.8

Mechanical top bracing 5.14 1987774-8.0

Components for Engine Control System 5.16 1988538-3.2

Shaftline earthing device 5.17 1984929-2.4

MAN Alpha Controllable Pitch (CP) propeller 5.18 1984695-3.6

Hydraulic Power Unit for MAN Alpha CP propeller 5.18 1985320-8.3

MAN Alphatronic 2000 Propulsion Control System 5.18 1985322-1.5

6 List of Capacities: Pumps, Coolers & Exhaust Gas

Calculation of capacities 6.01 1988291-2.0

List of capacities and cooling water systems 6.02 1987463-3.0

List of capacities, S50ME-B9.3 6.03 1988718-1.0

Auxiliary system capacities for derated engines 6.04 1987149-5.6

Pump capacities, pressures and flow velocities 6.04 1984385-0.3

Example 1, Pumps and Cooler Capacity 6.04 1989083-3.0

Freshwater Generator 6.04 1987145-8.1

Jacket cooling water temperature control 6.04 1987144-6.2

Example 2, Fresh Water Production 6.04 1989084-5.0

Calculation of exhaust gas amount and temperature 6.04 1984318-1.3

Diagram for change of exhaust gas amount 6.04 1986369-4.1

Exhaust gas correction formula 6.04 1987140-9.0

Example 3, Expected Exhaust Gas 6.04 1989085-7.0

7 Fuel

Pressurised fuel oil system 7.01 1984228-2.7

Fuel oil system 7.01 1987661-0.4

Fuel oils 7.02 1983880-4.7

Fuel oil pipes and drain pipes 7.03 1985052-4.3

Fuel oil pipe insulation 7.04 1984051-8.3

Fuel oil pipe heat tracing 7.04 1987662-2.0

Components for fuel oil system 7.05 1983951-2.8

Components for fuel oil system, venting box 7.05 1984735-0.3

Water in fuel emulsification 7.06 1983882-8.5

Page 7

MAN B&W Contents

Chapter Section

MAN Diesel

MAN B&W S 50ME-B9.3

8 Lubricating Oil

Lubricating and cooling oil system 8.01 1985317-4.3

Hydraulic Power Supply unit 8.02 1985318-6.2

Lubricating oil pipes for turbochargers 8.03 1984232-8.5

Lubricating oil consumption, centrifuges and list of lubricating oils 8.04 1983886-5.10

Components for lube oil system 8.05 1988891-5.0

Flushing of lubricating oil components and piping system 8.05 1988026-6.0

Lubricating oil outlet 8.05 1987034-4.1

Crankcase venting and bedplate drain pipes 8.07 1987837-3.1

Engine and tank venting to the outside air 8.07 1989181-5.0

Hydraulic oil back-flushing 8.08 1984829-7.3

Separate system for hydraulic control unit 8.09 1985315-0.1

9 Cylinder Lubrication

Cylinder lubricating oil system 9.01 1988559-8.2

List of cylinder oils 9.01 1988566-9.1

MAN B&W Alpha cylinder lubrication system 9.02 1987611-9.1

Alpha Adaptive Cylinder Oil Control (Alpha ACC) 9.02 1987614-4.1

Cylinder oil pipe heating 9.02 1987612-0.1

Cylinder lubricating oil pipes 9.02 1985328-2.2

Small heating box with filter, suggestion for 9.02 1987937-9.1

10 Piston Rod Stuffing Box Drain Oil

Stuffing box drain oil system 10.01 1983974-0.7

11 Central Cooling Water System

Central cooling 11.01 1984696-5.5

Central cooling water system 11.02 1984057-9.5

Components for central cooling water system 11.03 1983987-2.6

12 Seawater Cooling

Seawater systems 12.01 1983892-4.4

Seawater cooling system 12.02 1983893-6.5

Cooling water pipes 12.03 1983978-8.7

Components for seawater cooling system 12.04 1983981-1.3

Jacket cooling water system 12.05 1988576-5.3

Components for jacket cooling water system 12.07 1984056-7.3

Deaerating tank 12.07 1984063-8.3

Temperature at start of engine 12.08 1988346-5.0

13 Starting and Control Air

Starting and control air systems 13.01 1985329-4.2

Components for starting air system 13.02 1986057-8.1

Starting and control air pipes 13.03 1985330-4.4

Page 8

MAN B&W Contents

Chapter Section

MAN Diesel

MAN B&W S 50ME-B9.3

14 Scavenge Air

Scavenge air system 14.01 1984006-5.3

Auxiliary blowers 14.02 1986586-2.3

Operation panel for auxiliary blowers 14.02 1986587-4.0

Electric motor for auxiliary blower 14.04 1986677-3.2

Scavenge air cooler cleaning system 14.05 1987684-9.1

Air cooler cleaning unit 14.05 1987686-2.0

Scavenge air box drain system 14.06 1987693-3.2

Fire extinguishing system for scavenge air space 14.07 1984044-7.5

Fire extinguishing pipes in scavenge air space 14.07 1987681-3.2

15 Exhaust Gas

Exhaust gas system 15.01 1984045-9.5

Exhaust gas pipes 15.02 1984069-9.4

Cleaning systems, water and soft blast 15.02 1987916-4.0

Exhaust gas system for main engine 15.03 1984074-6.3

Components of the exhaust gas system 15.04 1984075-8.7

Exhaust gas silencer 15.04 1986396-8.0

Calculation of exhaust gas back-pressure 15.05 1984094-9.3

Forces and moments at turbocharger 15.06 1990055-0.0

Diameter of exhaust gas pipe 15.07 1985892-3.2

16 Engine Control System

Engine Control System ME-B 16.01 1985184-2.3

Pneumatic manoeuvring diagram 16.01 1987619-3.1

17 Vibration Aspects

2nd order moments on 4, 5 and 6-cylinder engines 17.01 1984140-5.3

1st order moments on 4-cylinder engines 17.02 1986884-5.4

Electrically driven moment compensator 17.02 1983925-0.5

Power Related Unbalance (PRU) 17.03 1986978-1.2

Guide force moments 17.04 1987680-1.1

Guide force moments, data 17.05 1984223-3.5

Vibration limits valid for single order harmonics 17.05 1987987-0.2

Axial vibrations 17.05 1988264-9.0

Critical running 17.06 1984224-5.4

External forces and moments in layout point 17.06 1984226-9.3

17.07 1989149-4.0

18 Monitoring Systems and Instrumentation

PMI Auto-tuning system 18.01 1988529-9.2

CoCoS-EDS systems 18.02 1988530-9.2

Alarm - slow down and shut down system 18.03 1984582-6.8

Class and MAN Diesel & Turbo requirements 18.04 1987040-3.4

Local instruments 18.04 1984583-8.10

Other alarm functions 18.05 1984586-3.9

Bearing monitoring systems 18.06 1984587-5.13

LDCL cooling water monitoring system 18.06 1986727-7.5

Control devices 18.06 1990197-5.0

Identification of instruments 18.06 1986728-9.4

18.07 1984585-1.6

Page 9

MAN B&W Contents

Chapter Section

MAN Diesel

MAN B&W S 50ME-B9.3

19 Dispatch Pattern, Testing, Spares and Tools

Specification for painting of main engine 19.01 1987620-3.2

Dispatch pattern, list of masses and dimensions 19.02 1984516-9.6

List of spare parts, unrestricted service 19.05 1984612-7.8

Additional spares 19.06 1985324-5.12

Wearing parts 19.07 1985323-3.4

Large spare parts, dimensions and masses 19.08 1988371-5.2

Rotor for turbocharger 19.09 1987832-4.1

20 Project Support and Documentation

Project support and documentation 20.01 1984588-7.5

Installation data application 20.02 1984590-9.3

Extent of Delivery 20.03 1984591-0.6

Installation documentation 20.04 1984592-2.5

A Appendix

Symbols for piping A 1983866-2.3

Page 10

Page 11

MAN B&W

MAN Diesel

Engine Design

1

Page 12

Page 13

MAN B&W 1.01

Page 1 of 2

MAN Diesel

MAN B&W M E-B-TII .5/.3 engine s 199 01 13-7.0

The Fuel Optimised ME-B Tier II Engine

The ever valid requirement of ship operators is

to obtain the lowest total operational costs, and

especially the lowest possible specific fuel oil

consumption at any load, and under the prevailing

operating conditions.

However, lowspeed twostroke main engines

of the MC-C type, with a chain driven camshaft,

have limited flexibility with regard to fuel injection

to match the prevailing operating conditions.

A system with electronically controlled hydraulic

activation provides the required flexibility, this

system form the core of the ME-B ‘Engine Control

System’, described later in detail in Chapter 16.

Concept of the ME-B engine

The ME-B engine concept consists of a hydraulic

mechanical system for activation of the fuel injection. The actuator is electronically controlled by a

number of control units forming the complete Engine Control System.

MAN Diesel & Turbo has specifically developed

both the hardware and the software inhouse, in

order to obtain an integrated solution for the Engine Control System.

The fuel pressure booster consists of a simple

plunger powered by a hydraulic piston activated

by oil pressure. The oil pressure is controlled by

an electronically controlled proportional valve.

The exhaust valve is activated by a light camshaft,

driven by a chain drive placed in the aft end of the

engine. The closing timing of the exhaust valve is

electronically controlled for lower fuel consumption at low load.

To have common spare parts, the exhaust valve

used for the ME-B is the same as the one used for

the MC-C. The exhaust valve is of the DuraSpindle type with a W-seat bottom piece.

In the hydraulic system, the normal lube oil is used

as the medium. It is filtered and pressurised by

an electrically driven Hydraulic Power Supply unit

mounted on the engine.

The starting valves are opened pneumatically by

the mechanically activated starting air distributor.

By electronic control of the above valve according

to the measured instantaneous crankshaft position, the Engine Control System fully controls the

combustion process.

System flexibility is obtained by means of different

‘Engine running modes’, which are selected either

automatically, depending on the operating conditions, or manually by the operator to meet specific

goals. The basic running mode is ‘Fuel economy

mode’ to comply with IMO NOx emission limitation.

The market is always moving, and requirements

for more competitive engines, i.e. the lowest possible propeller speed, lower fuel consumption,

lower lube oil consumption and more flexibility

regarding emission and easy adjustment of the

engine parameters, call for a re-evaluation of the

design parameters, engine control and layout.

Engine design and IMO regulation compliance

For MAN B&W ME-B-TII designated engines, the

design and performance parameters have been

upgraded and optimised to comply with the International Maritime Organisation (IMO) Tier II emission regulations.

The potential derating and part load SFOC figures

for the Tier II engines have also been updated.

For engines built to comply with IMO Tier I emission regulations, please refer to the Marine Engine

IMO Tier I Project Guide.

Page 14

MAN B&W 1.01

Page 2 of 2

MAN Diesel

199 01 12-5.0

MAN B&W M E-C/ME-B-TII .5 /.3 engin es

Tier II fuel optimisation

NOx regulations place a limit on the SFOC on

two-stroke engines. In general, NOx emissions will

increase if SFOC is decreased and vice versa. In

the standard configuration, MAN B&W engines are

optimised close to the IMO NOx limit and, therefore, NOx emissions may not be further increased.

The IMO NOx limit is given as a weighted average

of the NOx emission at 25, 50, 75 and 100% load.

This relationship can be utilised to tilt the SFOC

profile over the load range. This means that SFOC

can be reduced at part load or low load at the

expense of a higher SFOC in the high-load range

without exceeding the IMO NOx limit.

Optimisation of SFOC in the part-load (50-85%)

or low-load (25-70%) range requires selection of a

tuning method:

• ECT: Engine Control Tuning

• VT: Variable Turbine Area

• EGB: Exhaust Gas Bypass

• HPT: High Pressure Tuning (only for ME-C)

Each tuning method makes it possible to optimise

the fuel consumption when normally operating at

low loads, while maintaining the possibility of operating at high load when needed.

The tuning methods are available for all SMCR in

the specific engine layout diagram but they cannot be combined. The specific SFOC reduction

potential of each tuning method together with

full rated (L

1/L3

) and maximum derated (L2/L4) is

shown in Section 1.03.

For engine types 40 and smaller, as well as for

larger types with conventional turbochargers, only

high-load optimisation is applicable.

In general, data in this project guide is based on

high-load optimisation unless explicitly noted. For

part- and low-load optimisation, calculations can

be made in the CEAS application described in

Section 20.02.

Page 15

MAN B&W M C/MC-C, ME/ MEC/MEB/-G I engines 198 38 24 3.9

MAN B&W 1.02

Page 1 of 1

MAN Diesel

Engine Type Designation

6 S 90 M E C 9 .2 -GI -TII

Engine programme

Diameter of piston in cm

G ‘Green’ Ultra long stroke

S Super long stroke

L Long stroke

K Short stroke

Stroke/bore ratio

Number of cylinders

Concept

E Electronically controlled

C Camshaft controlled

Fuel injection concept

(blank) Fuel oil only

GI Gas injection

Emission regulation

TII IMO Tier level

Design

C Compact engine

B Exhaust valve controlled

by camshaft

Mark number

Version number

Page 16

MAN B&W 1.03

Page 1 of 1

MAN Diesel

198 85 02- 3.1MAN B&W S 50ME-B9.3 -TII

Power, Speed and Fuel Oil

MAN B&W S50ME-B9.3-TII

Fig 1.03.01: Power, speed and fuel oil

MAN B&W S50ME-B9

Cyl. L1 kW Stroke: 2,214 mm

5 8,900

6 10,680

7 12,460

8 14,240

9 16,020

SFOC for engines with layout on L1 - L3 line [g/kWh]

L1/L3 MEP: 21.0 bar

SFOC optimised load range Tuning 50% 75% 100%

High load (85%-100%) - 167.5 165.0 168.0

Part load (50%-85%)

ECT 166.5 164.0 171.0

VT 164.5 163.5 168.5

EGB 164.5 163.5 169.5

Low load (25%-70%)

ECT 165.0 164.5 169.5

VT 162.5 164.5 168.5

EGB 162.5 164.5 169.5

SFOC for engines with layout on L2 - L4 line [g/kWh]

L2/L4 MEP: 16.8 bar

SFOC optimised load range Tuning 50% 75% 100%

High load (85%-100%) - 163.5 159.5 162.0

Part load (50%-85%)

ECT 162.5 158.5 165.0

VT 160.5 158.0 162.5

EGB 160.5 158.0 163.5

Low load (25%-70%)

ECT 161.0 159.0 163.5

VT 158.5 159.0 162.5

EGB 158.5 159.0 163.5

The SFOC excludes 1 g/kWh for the consumption of the electric HPS

kW/cyl.

r/min

L

1

L

2

1,780

1,510

1,420

1,210

99 117

L

3

L

4

Page 17

MAN B&W 1.04

Page 1 of 1

MAN Diesel

MAN B&W M C/MC-C, ME/ ME-C/MEB en gines 198 4 6 343.5

Engine Power Range and Fuel Oil Consumption

Power

Speed

L

3

L

4

L

2

L

1

Specific Fuel Oil Consumption (SFOC)

The figures given in this folder represent the values obtained when the engine and turbocharger

are matched with a view to obtaining the lowest

possible SFOC values while also fulfilling the IMO

NOX Tier II emission limitations.

Stricter emission limits can be met on request, using proven technologies.

The SFOC figures are given in g/kWh with a tolerance of 5% (at 100% SMCR) and are based

on the use of fuel with a lower calorific value of

42,700 kJ/kg (~10,200 kcal/kg) at ISO conditions:

Ambient air pressure .............................1,000 mbar

Ambient air temperature ................................25 °C

Cooling water temperature ............................ 25 °C

Although the engine will develop the power specified up to tropical ambient conditions, specific

fuel oil consumption varies with ambient conditions and fuel oil lower calorific value. For calculation of these changes, see Chapter 2.

Lubricating oil data

The cylinder oil consumption figures stated in the

tables are valid under normal conditions.

During runningin periods and under special conditions, feed rates of up to 1.5 times the stated

values should be used.

Engine Power

The following tables contain data regarding the

power, speed and specific fuel oil consumption of

the engine.

Engine power is specified in kW for each cylinder

number and layout points L1, L2, L3 and L4.

Discrepancies between kW and metric horsepower (1 BHP = 75 kpm/s = 0.7355 kW) are a consequence of the rounding off of the BHP values.

L1 designates nominal maximum continuous rating

(nominal MCR), at 100% engine power and 100%

engine speed.

L2, L3 and L4 designate layout points at the other

three corners of the layout area, chosen for easy

reference.

Fig. 1.04.01: Layout diagram for engine power and speed

Overload corresponds to 110% of the power at

MCR, and may be permitted for a limited period of

one hour every 12 hours.

The engine power figures given in the tables remain valid up to tropical conditions at sea level as

stated in IACS M28 (1978), i.e.:

Blower inlet temperature ................................45 °C

Blower inlet pressure ............................1,000 mbar

Seawater temperature .................................... 32 °C

Relative humidity ..............................................60%

178 51 489.0

Page 18

MAN B&W

Page 1 of 1

MAN Diesel

198 53 31-6 .2MAN B&W MC/MC -C, ME/ME-C /MEB/ GI engines

Performance Curves

1.0 5

Updated engine and capacities data is available

from the CEAS program on www.marine.man.eu

→ ’Two-Stroke’ → ’CEAS Engine Calculations’.

Page 19

MAN B&W 1.06

Page 1 of 7

MAN Diesel

MAN B&W M E-B9.5/.3 engin es 199 01 20 -8.0

Please note that engines built by our licensees are

in accordance with MAN Diesel & Turbo drawings

and standards but, in certain cases, some local standards may be applied; however, all spare

parts are interchangeable with MAN Diesel &

Turbo designed parts.

Some components may differ from MAN Diesel &

Turbo’s design because of local production facilities

or the application of local standard components.

In the following, reference is made to the item

numbers specified in the ‘Extent of Delivery’ (EoD)

forms, both for the ‘Basic’ delivery extent and for

some ‘Options’.

Bedplate and Main Bearing

The bedplate is made with the thrust bearing in

the aft end of the engine. The bedplate is of the

welded design and the normally cast part for the

main bearing girders is made from either rolled

steel plates or cast steel.

For fitting to the engine seating in the ship, long,

elastic holdingdown bolts and hydraulic tightening tools are used.

The bedplate is made without taper for engines

mounted on epoxy chocks.

The oil pan, which is made of steel plate and is

welded to the bedplate, collects the return oil from

the forced lubricating and cooling oil system. The

oil outlets from the oil pan are normally vertical

and are provided with gratings.

Horizontal outlets at both ends can be arranged

for some cylinder numbers, however this must be

confirmed by the engine builder.

The main bearings consist of thin walled steel

shells lined with bearing metal. The main bearing

bottom shell can be rotated out and in by means

of special tools in combination with hydraulic tools

for lifting the crankshaft. The shells are kept in position by a bearing cap.

Frame Box

The frame box is of welded design. On the exhaust side, it is provided with relief valves for each

cylinder while, on the manoeuvring side, it is provided with a large hinged door for each cylinder.

The framebox is of the well-proven triangular

guide-plane design with twin staybolts giving excellent support for the guide shoe forces.

Cylinder Frame and Stuffing Box

For the cylinder frame, two possibilities are available.

• Nodular cast iron

• Welded design with integrated scavenge air receiver.

The cylinder frame is provided with access covers

for cleaning the scavenge air space, if required,

and for inspection of scavenge ports and piston

rings from the manoeuvring side. Together with

the cylinder liner it forms the scavenge air space.

The cylinder frame is fitted with pipes for the piston cooling oil inlet. The scavenge air receiver, turbocharger, air cooler box and gallery brackets are

located on the cylinder frame. At the bottom of the

cylinder frame there is a piston rod stuffing box,

provided with sealing rings for scavenge air, and

with oil scraper rings which prevent crankcase oil

from coming up into the scavenge air space.

Drains from the scavenge air space and the piston

rod stuffing box are located at the bottom of the

cylinder frame.

ME-B Mark 9 Engine Description

Page 20

MAN B&W 1.06

Page 2 of 7

MAN Diesel

MAN B&W M E-B9.5/.3 engin es 199 01 20 -8.0

Cylinder Liner

The cylinder liner is made of alloyed cast iron

and is suspended in the cylinder frame with a

lowsituated flange. The top of the cylinder liner

is fitted with a cooling jacket. The cylinder liner

has scavenge ports and drilled holes for cylinder

lubrication.

The Piston Cleaning ring (PC-ring) is installed between the liner and the cylinder cover, scraping

off excessive ash and carbon formations from the

piston topland.

Cylinder Cover

The cylinder cover is of forged steel, made in one

piece, and has bores for cooling water. It has a

central bore for the exhaust valve, and bores for

the fuel valves, a starting valve and an indicator

valve.

The cylinder cover is attached to the cylinder

frame with studs and nuts tightened with hydraulic

jacks.

Crankshaft

The crankshaft is of the semi-built design, in one

piece, and made from forged steel.

At the aft end, the crankshaft is provided with the

collar for the thrust bearing, and the flange for the

turning wheel and for the coupling bolts to an intermediate shaft.

At the front end, the crankshaft is fitted with the

collar for the axial vibration damper and a flange

for the fitting of a tuning wheel. The flange can

also be used for a Power Take Off, if so desired.

Coupling bolts and nuts for joining the crankshaft

together with the intermediate shaft are not normally supplied.

Thrust Bearing

The propeller thrust is transferred through the

thrust collar, the segments, and the bedplate, to

the end chocks and engine seating, and thus to

the ship’s hull.

The thrust bearing is located in the aft end of the

engine. The thrust bearing is of the B&WMichell

type, and consists primarily of a thrust collar on

the crankshaft, a bearing support, and segments

of steel lined with white metal. The thrust shaft is

an integrated part of the crankshaft and it is lubricated by the engine’s lubricating oil system.

As the propeller thrust is increasing due to the

higher engine power, a flexible thrust cam has

been introduced to obtain a more even force distribution on the pads.

Turning Gear and Turning Wheel

The turning wheel is fitted to the thrust shaft, and

it is driven by a pinion on the terminal shaft of the

turning gear, which is mounted on the bedplate.

The turning gear is driven by an electric motor.

A blocking device prevents the main engine from

starting when the turning gear is engaged. Engagement and disengagement of the turning gear

is effected manually by an axial movement of the

pinion.

The control device for the turning gear, consisting

of starter and manual control box, can be ordered

as an option.

Axial Vibration Damper

The engine is fitted with an axial vibration damper,

mounted on the fore end of the crankshaft. The

damper consists of a piston and a splittype housing located forward of the foremost main bearing.

The piston is made as an integrated collar on the

main journal, and the housing is fixed to the main

bearing support.

Page 21

MAN B&W 1.06

Page 3 of 7

MAN Diesel

MAN B&W M E-B9.5/.3 engin es 199 01 20 -8.0

Tuning Wheel / Torsional Vibration Damper

A tuning wheel or torsional vibration damper may

have to be ordered separately, depending on the

final torsional vibration calculations.

Connecting Rod

The connecting rod is made of forged and provided with bearing caps for the crosshead and

crankpin bearings.

The crosshead and crankpin bearing caps are secured to the connecting rod with studs and nuts

tightened by means of hydraulic jacks.

The crosshead bearing consists of a set of

thinwalled steel shells, lined with bearing metal.

The crosshead bearing cap is in one piece, with

an angular cutout for the piston rod.

The crankpin bearing is provided with thinwalled

steel shells, lined with bearing metal. Lube oil is

supplied through ducts in the crosshead and connecting rod.

Piston

The piston consists of a piston crown and piston

skirt. The piston crown is made of heatresistant

steel and has four ring grooves which are

hardchrome plated on both the upper and lower

surfaces of the grooves.

The piston is bore-cooled and with a high topland.

The piston ring pack is No. 1 piston ring, high CPR

(Controlled Pressure Relief), Nos. 2 to 4, piston

rings with angle cut. All rings are with Alu-coat on

the running surface for safe running-in of the piston ring.

The uppermost piston ring is higher than the others. The piston skirt is of cast iron with a bronze

band.

Piston Rod

The piston rod is of forged steel and is surface

hardened on the running surface for the stuffing

box. The piston rod is connected to the crosshead

with four bolts. The piston rod has a central bore

which, in conjunction with a cooling oil pipe, forms

the inlet and outlet for cooling oil.

Crosshead

The crosshead is of forged steel and is provided

with cast steel guide shoes with white metal on

the running surface.

The guide shoe is of the low friction design.

The telescopic pipe for oil inlet and the pipe for oil

outlet are mounted on the guide shoes.

Scavenge Air System

The air intake to the turbocharger takes place

directly from the engine room through the turbocharger intake silencer. From the turbocharger,

the air is led via the charging air pipe, air cooler

and scavenge air receiver to the scavenge ports

of the cylinder liners, see Chapter 14.

Scavenge Air Cooler

For each turbocharger is fitted a scavenge air

cooler of the monoblock type designed for seawater cooling at up to 2.0 2.5 bar working pressure, alternatively, a central cooling system can be

chosen with freshwater of maximum 4.5 bar working pressure.

The scavenge air cooler is so designed that the

difference between the scavenge air temperature

and the water inlet temperature at specified MCR

can be kept at about 12 °C.

Page 22

MAN B&W 1.06

Page 4 of 7

MAN Diesel

MAN B&W M E-B9.5/.3 engin es 199 01 20 -8.0

Auxiliary Blower

The engine is provided with electricallydriven

scavenge air blowers. The suction side of the

blowers is connected to the scavenge air space

after the air cooler.

Between the air cooler and the scavenge air receiver, nonreturn valves are fitted which automatically close when the auxiliary blowers supply

the air.

The auxiliary blowers will start operating consecutively before the engine is started in order to

ensure sufficient scavenge air pressure to obtain a

safe start.

The auxiliary blower design is of the integrated

type.

Further information is given in Chapter 14.

Exhaust Gas System

From the exhaust valves, exhaust gas is led to the

exhaust gas receiver where the fluctuating pressure from the individual cylinders is equalised,

and the total volume of gas is led further on to the

turbocharger(s). After the turbocharger(s), the gas

is led to the external exhaust pipe system.

Compensators are fitted between the exhaust

valves and the receiver, and between the receiver

and the turbocharger(s).

The exhaust gas receiver and exhaust pipes are

provided with insulation, covered by galvanised

steel plating.

A protective grating is installed between the exhaust gas receiver and the turbocharger.

Exhaust Turbocharger

Three turbocharger makes are available for the

ME-B engines, i.e. MAN, ABB and MHI. As an option, MAN TCA turbochargers can be delivered

with variable nozzle area technology that reduce

the fuel consumption at part load by controlling

the scavenge air pressure.

The turbocharger selection is described in Chapter 3, and the exhaust gas system in Chapter 15.

Camshaft and Cams

The camshaft is made in one piece with exhaust

cams.

The exhaust cams are made of steel, with a hardened roller race, and are shrunk onto the shaft.

They can be adjusted and dismantled hydraulica lly.

The camshaft bearings consist of one lower halfshell fitted in a bearing support. The camshaft is

lubricated by the main lubricating oil system.

Chain Drive

The camshaft is driven from the crankshaft by a

chain drive, which is kept running tight by a manually adjusted chain tightener. The long free lengths

of chain are supported by rubber-clad guidebars

and the chain is lubricated through oil spray pipes

fitted at the chain wheels and guidebars.

2nd Order Moment Compensators

The 2nd order moment compensators are relevant only for 5 or 6-cylinder engines, and can be

mounted either on the aft end or on both fore and

aft end. The aft-end compensator consists of balance weights built into the camshaft chain drive.

The fore-end compensator consists of balance

weights driven from the fore end of the crankshaft.

The 2nd order moment compensators as well as

the basic design and options are described in

Section 17.02.

Page 23

MAN B&W 1.06

Page 5 of 7

MAN Diesel

MAN B&W M E-B9.5/.3 engin es 199 01 20 -8.0

Hydraulic Cylinder Unit

The hydraulic cylinder unit (HCU) consists of a

base plate on which a distributor block is mounted. The distributor block is fitted with one accumulator to ensure that the necessary hydraulic oil

peak flow is available for the Electronic Fuel Injection.

The distributor block serves as a mechanical support for the hydraulically activated fuel pressure

booster.

There is one Hydraulic Cylinder Unit per two cylinders. The HCU is equipped with two pressure

boosters, two ELFI valves and two Alpha Lubricators. Thereby, one HCU is operating two cylinders.

The Hydraulic Power Supply

The Hydraulic Power Supply (HPS) is installed in

the front end of the engine. The HPS is electrically

driven and consists of two electric motors each

driving a hydraulic pump.

The pressure for the hydraulic oil is 300 bar. Each

of the pumps has a capacity corresponding to

min. 55% of the engine power. In case of malfunction of one of the pumps, it is still possible to operate the engine with 55% engine power, enabling

around 80% ship speed.

Fuel Oil Pressure Booster and

Fuel Oil High Pressure Pipes

The engine is provided with one hydraulically activated fuel oil pressure booster for each cylinder.

Fuel injection is activated by a proportional valve,

which is electronically controlled by the Cylinder

Control Unit.

The fuel oil highpressure pipes are double-walled

and insulated but not heated.

Further information is given in Section 7.01.

Fuel Valves and Starting Air Valve

Each cylinder cover is equipped with two fuel

valves, starting valve, and indicator cock.

The opening of the fuel valves is controlled by

the high pressure fuel oil created by the fuel oil

pressure booster, and the valves are closed by a

spring.

An automatic vent slide allows circulation of fuel

oil through the valve and high pressure pipes

when the engine is stopped. The vent slide also

prevents the compression chamber from being

filled up with fuel oil in the event that the valve

spindle sticks. Oil from the vent slide and other

drains is led away in a closed system.

The mechanically driven starting air distributor is

the same as the one used on the MC-C engines.

The starting air system is described in detail in

Section 13.01.

Engine Control System

The ME-B Engine Control System (ECS) controls

the hydraulic fuel booster system, the fuel injection, governor function and cylinder lubrication.

The ECS consists of a number of computer-based

control units, operating panels and auxiliary

equipment located in the engine room and the engine control room.

The ME-B Engine Control System is described in

Chapter 16.

Page 24

MAN B&W 1.06

Page 6 of 7

MAN Diesel

MAN B&W M E-B9.5/.3 engin es 199 01 20 -8.0

Exhaust Valve

The exhaust valve consists of the valve housing

and the valve spindle. The valve housing is made

of cast iron and is arranged for water cooling. The

housing is provided with a water cooled bottom

piece of steel with a flame hardened seat of the

W-seat design.

The exhaust valve spindle is a DuraSpindle, a

spindle made of Nimonic is available as an option.

The housing is provided with a spindle guide in

any case.

The exhaust valve is tightened to the cylinder cover with studs and nuts. It is opened hydraulically

and closed by means of air pressure. The hydraulic system consists of a piston actuator placed on

the roller guide housing, a highpressure pipe, and

a working cylinder on the exhaust valve.

The piston actuator is activated by a cam on the

camshaft, a built-in timing piston and a control

valve enables control of the closing time of the exhaust valve.

In operation, the valve spindle slowly rotates, driven by the exhaust gas acting on small vanes fixed

to the spindle.

Sealing of the exhaust valve spindle guide is provided by means of Controlled Oil Level (COL), an

oil bath in the bottom of the air cylinder, above the

sealing ring. This oil bath lubricates the exhaust

valve spindle guide and sealing ring as well.

Reversing

On reversible engines (with Fixed Pitch Propellers

mainly), reversing of the engine is performed in

the Engine Control System by letting the starting

air distributor supply air to the cylinders in order of

the desired direction of rotation and by timing the

fuel injection accordingly.

The exhaust valve gear is not to be reversed.

Indicator Cock

The engine is fitted with an indicator cock to

which the PMI pressure transducer is connected.

The PMI system, a pressure analyser system, is

described in Section 18.02.

MAN B&W Alpha Cylinder Lubrication

The electronically controlled MAN B&W Alpha

cylinder lubrication system is applied to the ME-B

engines.

The main advantages of the MAN B&W Alpha cylinder lubrication system, compared with the conventional mechanical lubricator, are:

• Improved injection timing

• Increased dosage flexibility

• Constant injection pressure

• Improved oil distribution in the cylinder liner

• Possibility for prelubrication before starting.

More details about the cylinder lubrication system

can be found in Chapter 9.

Manoeuvring System

The engine is provided with a pneumatic/electric

manoeuvring system. The system transmits orders

from the Engine Control System to the engine.

The manoeuvring system makes it possible to

start, stop, reverse the engine and control the engine speed.

The engine is provided with an engine side console and instrument panel.

Page 25

MAN B&W 1.06

Page 7 of 7

MAN Diesel

MAN B&W M E-B9.5/.3 engin es 199 01 20 -8.0

Gallery Arrangement

The engine is provided with gallery brackets,

stanchions, railings and platforms (exclusive of

ladders). The brackets are placed at such a height

as to provide the best possible overhauling and

inspection conditions.

Some main pipes of the engine are suspended

from the gallery brackets, and the topmost gallery

platform on the manoeuvring side is provided with

overhauling holes for the pistons.

The engine is prepared for top bracings on the exhaust side, or on the manoeuvring side.

Piping Arrangements

The engine is delivered with piping arrangements

for:

• Fuel oil

• Heating of fuel oil pipes

• Lubricating oil, piston cooling oil and

hydraulic oil pipes

• Cylinder lubricating oil

• Cooling water to scavenge air cooler

• Jacket and turbocharger cooling water

• Cleaning of turbocharger

• Fire extinguishing in scavenge air space

• Starting air

• Control air

• Oil mist detector

• Various drain pipes.

All piping arrangements are made of steel piping,

except the control air and steam heating of fuel

pipes, which are made of copper.

The pipes are provided with sockets for local

instruments, alarm and safety equipment and,

furthermore, with a number of sockets for supplementary signal equipment. Chapter 18 deals with

the instrumentation.

Page 26

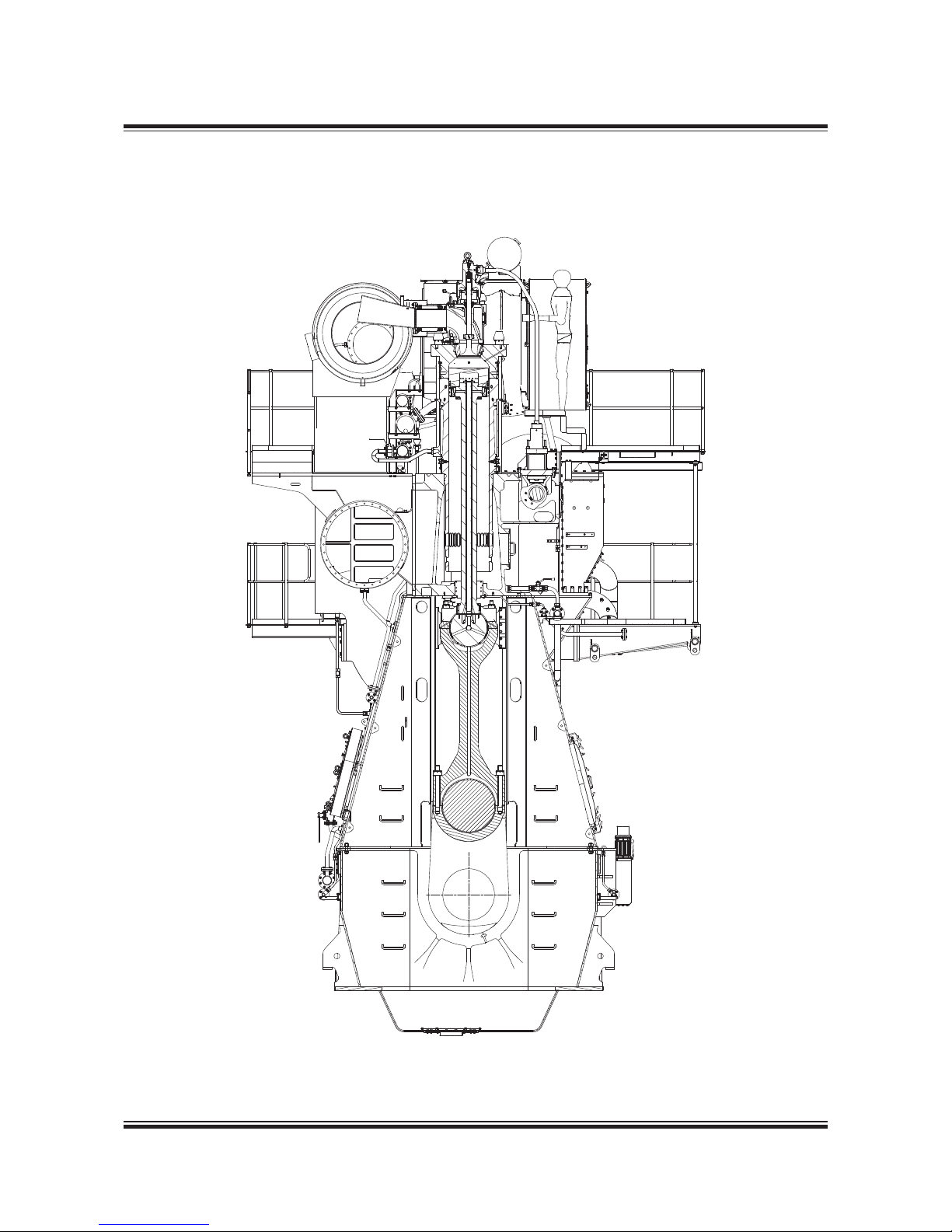

MAN B&W 1.07

Page 1 of 1

MAN Diesel

198 83 34 -5 .0MAN B&W S50 ME-B9

Engine Cross Section of S50ME-B9

526 56 24-2.0.0

Fig.: 1.07.01: Engine cross section

Page 27

MAN B&W

MAN Diesel

Engine Layout and Load

Diagrams, SFOC

2

Page 28

Page 29

MAN B&W 2.01

Page 1 of 2

MAN Diesel

198 38 33 8.5MAN B&W MC/ MCC, ME/ME GI/ME-B eng ines

Engine Layout and Load Diagrams

Introduction

The effective power ‘P’ of a diesel engine is proportional to the mean effective pressure pe and

engine speed ‘n’, i.e. when using ‘c’ as a constant:

P = c × pe × n

so, for constant mep, the power is proportional to

the speed:

P = c × n1 (for constant mep)

When running with a Fixed Pitch Propeller (FPP),

the power may be expressed according to the

propeller law as:

P = c × n3 (propeller law)

Thus, for the above examples, the power P may

be expressed as a power function of the speed ‘n’

to the power of ‘i’, i.e.:

P = c × n

i

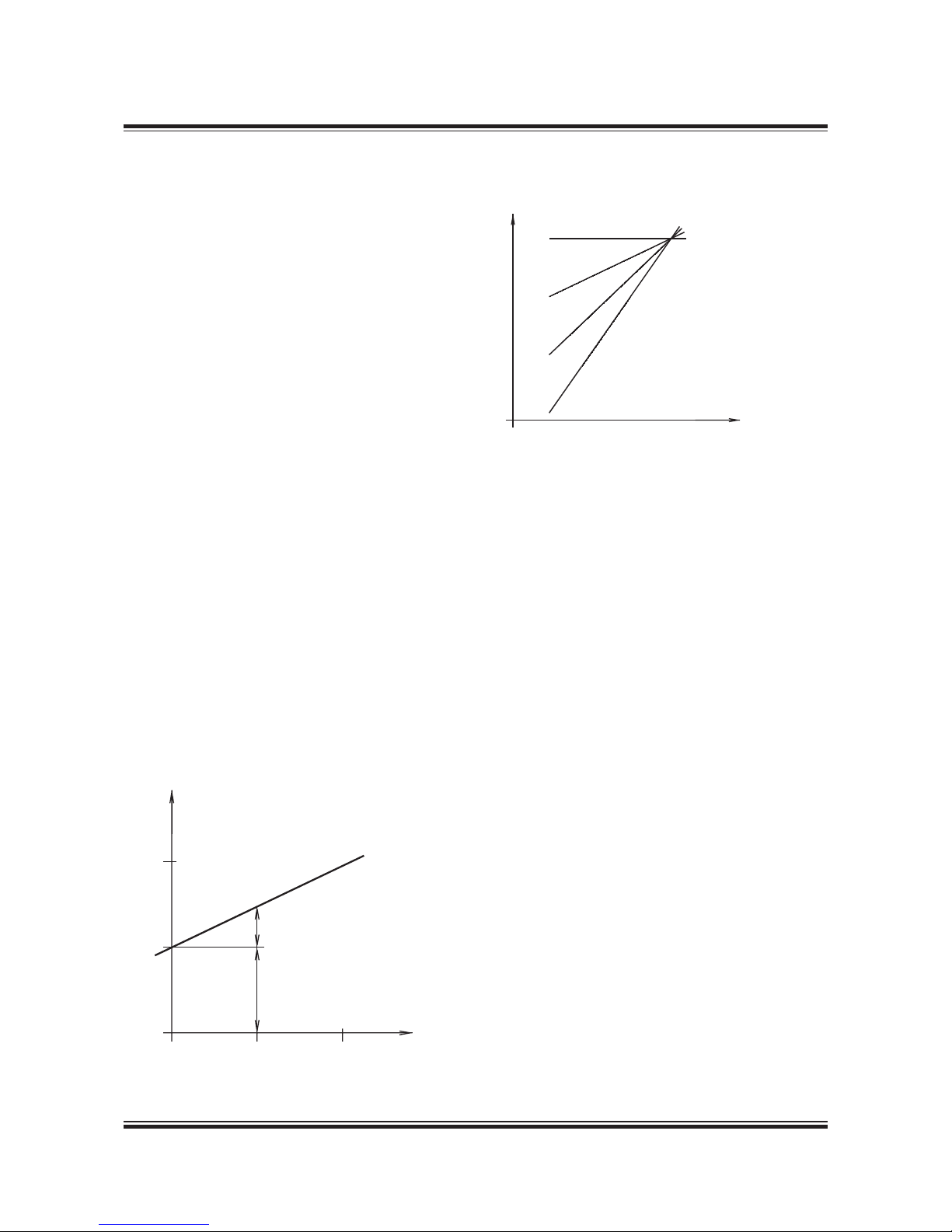

Fig. 2.01.01 shows the relationship for the linear

functions, y = ax + b, using linear scales.

The power functions P = c × ni will be linear functions when using logarithmic scales:

log (P) = i × log (n) + log (c)

Fig. 2.01.01: Straight lines in linear scales

Fig. 2.01.02: Power function curves in logarithmic scales

Thus, propeller curves will be parallel to lines having the inclination i = 3, and lines with constant

mep will be parallel to lines with the inclination i = 1.

Therefore, in the Layout Diagrams and Load Diagrams for diesel engines, logarithmic scales are

used, giving simple diagrams with straight lines.

Propulsion and Engine Running Points

Propeller curve

The relation between power and propeller speed

for a fixed pitch propeller is as mentioned above

described by means of the propeller law, i.e. the

third power curve:

P = c × n3, in which:

P = engine power for propulsion

n = propeller speed

c = constant

Propeller design point

Normally, estimates of the necessary propeller

power and speed are based on theoretical calculations for loaded ship, and often experimental

tank tests, both assuming optimum operating

conditions, i.e. a clean hull and good weather. The

combination of speed and power obtained may

be called the ship’s propeller design point (PD),

178 05 403.0

178 05 403.1

y

2

1

0

0

12

b

a

y=ax+b

x

y=log(P)

i = 0

i = 1

i = 2

i = 3

P = n x c

i

log (P) = i x log (n) + log (c)

x = log (n)

Page 30

MAN B&W 2.01

Page 2 of 2

MAN Diesel

198 38 33 8.5MAN B&W MC/ MCC, ME/ME GI/ME-B eng ines

placed on the light running propeller curve 6. See

below figure. On the other hand, some shipyards,

and/or propeller manufacturers sometimes use a

propeller design point (PD) that incorporates all or

part of the socalled sea margin described below.

the socalled sea margin, which is traditionally

about 15% of the propeller design (PD) power.

Engine layout (heavy propeller)

When determining the necessary engine layout

speed that considers the influence of a heavy running propeller for operating at high extra ship resistance, it is (compared to line 6) recommended to

choose a heavier propeller line 2. The propeller

curve for clean hull and calm weather line 6 may

then be said to represent a ‘light running’ (LR)

propeller.

Compared to the heavy engine layout line 2, we

recommend using a light running of 3.07.0% for

design of the propeller.

Engine margin

Besides the sea margin, a socalled ‘engine margin’ of some 10% or 15% is frequently added. The

corresponding point is called the ‘specified MCR

for propulsion’ (MP), and refers to the fact that the

power for point SP is 10% or 15% lower than for

point MP.

Point MP is identical to the engine’s specified

MCR point (M) unless a main engine driven shaft

generator is installed. In such a case, the extra

power demand of the shaft generator must also

be considered.

Constant ship speed lines

The constant ship speed lines ∝, are shown at

the very top of the figure. They indicate the power

required at various propeller speeds in order to

keep the same ship speed. It is assumed that, for

each ship speed, the optimum propeller diameter

is used, taking into consideration the total propulsion efficiency. See definition of ∝ in Section 2.02.

Note:

Light/heavy running, fouling and sea margin are

overlapping terms. Light/heavy running of the

propeller refers to hull and propeller deterioration

and heavy weather, whereas sea margin i.e. extra

power to the propeller, refers to the influence of

the wind and the sea. However, the degree of light

running must be decided upon experience from

the actual trade and hull design of the vessel.

Fig. 2.01.03: Ship propulsion running points and engine

layout

Power, % af L

1

100%

= 0,15

= 0,20

= 0,25 = 0,30

L

3

100%

L

4

L

2

Engine margin

(SP=90% of MP)

Sea margin

(15% of PD)

Engine speed, % of L

1

L

1

MP

SP

PD

HR

LR

2 6

PD

Line 2 Propulsion curve, fouled hull and heavy weather

(heavy running), recommended for engine layout

Line 6 Propulsion curve, clean hull and calm weather (light

running), for propeller layout

MP Specified MCR for propulsion

SP Continuous service rating for propulsion

PD Propeller design point

HR Heavy running

LR Light running

Fouled hull

When the ship has sailed for some time, the hull

and propeller become fouled and the hull’s resistance will increase. Consequently, the ship’s

speed will be reduced unless the engine delivers

more power to the propeller, i.e. the propeller will

be further loaded and will be heavy running (HR).

As modern vessels with a relatively high service

speed are prepared with very smooth propeller

and hull surfaces, the gradual fouling after sea

trial will increase the hull’s resistance and make

the propeller heavier running.

Sea margin and heavy weather

If, at the same time the weather is bad, with head

winds, the ship’s resistance may increase compared to operating in calm weather conditions.

When determining the necessary engine power, it

is normal practice to add an extra power margin,

178 05 415.3

Page 31

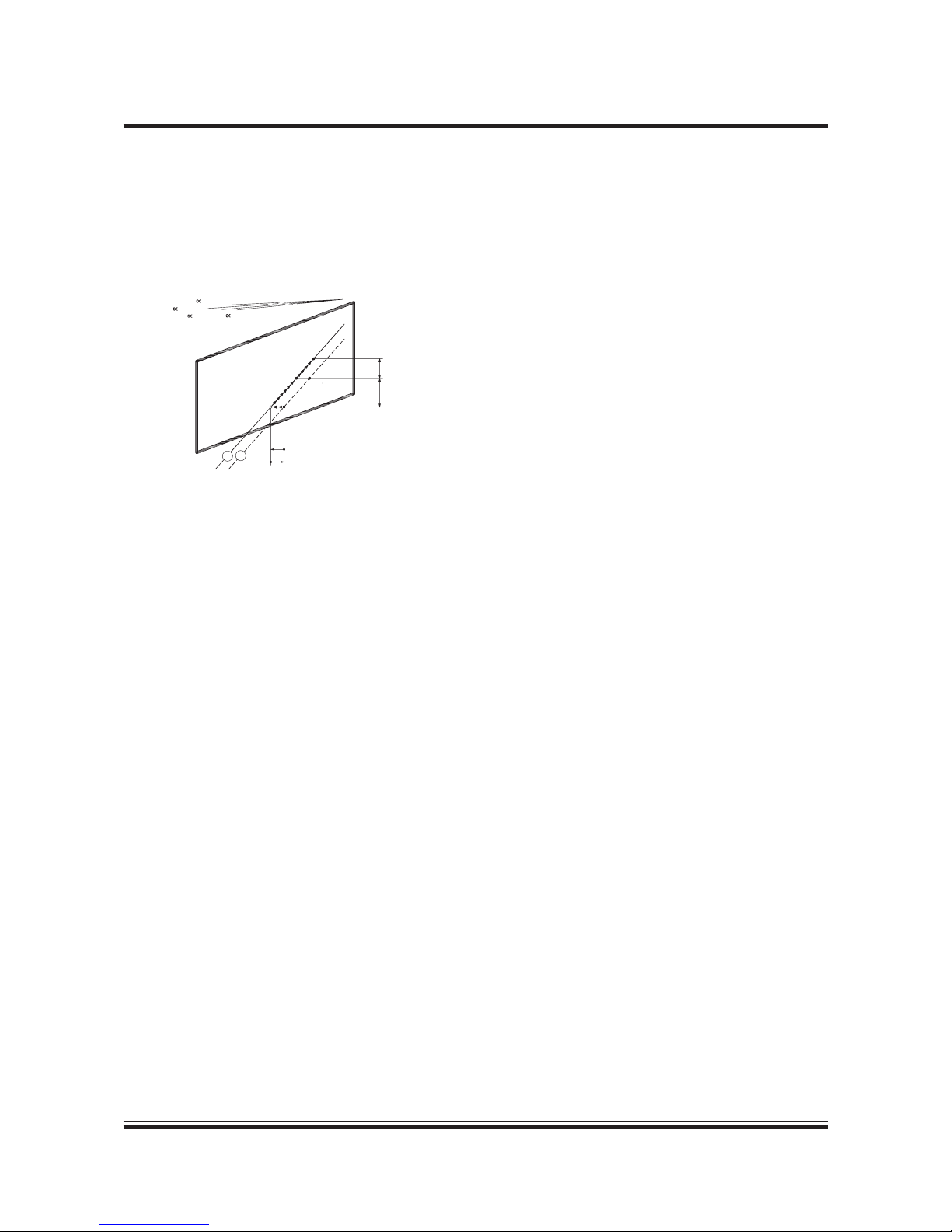

MAN B&W 2.02

Page 1 of 2

MAN Diesel

198 38 78 2.6MAN B&W MC/M C-C, ME/ME- C/ME -B/GI eng ines

D = Optimum propeller diameters

P/D = Pitch/diameter ratio

Shaft power

kW

8.500

8.600

8.700

8.800

8.900

9.000

9.100

9.200

9.300

9.400

9.500

70

80

90

100

110

120

130

r/min

Propeller

speed

P/D

1.00

0.95

0.90

0.85

0.80

D

7.4m

0.75

7.2m

7.0m

6.8m

6.6m

0.70

0.65

0.60

0.55

D

P/D

0.50

Fig. 2.02.01: Influence of diameter and pitch on propeller design

Propeller diameter and pitch, influence on the optimum propeller speed

In general, the larger the propeller diameter D,

the lower is the optimum propeller speed and the

kW required for a certain design draught and ship

speed, see curve D in the figure below.

The maximum possible propeller diameter depends on the given design draught of the ship,

and the clearance needed between the propeller

and the aft body hull and the keel.

The example shown in the figure is an 80,000 dwt

crude oil tanker with a design draught of 12.2 m

and a design speed of 14.5 knots.

When the optimum propeller diameter D is increased from 6.6 m to 7.2. m, the power demand

is reduced from about 9,290 kW to 8,820 kW, and

the optimum propeller speed is reduced from 120

r/min to 100 r/min, corresponding to the constant

ship speed coefficient ∝ = 0.28 (see definition of

∝ in Section 2.02, page 2).

Once an optimum propeller diameter of maximum

7.2 m has been chosen, the corresponding optimum pitch in this point is given for the design

speed of 14.5 knots, i.e. P/D = 0.70.

However, if the optimum propeller speed of 100

r/min does not suit the preferred / selected main

engine speed, a change of pitch away from optimum will only cause a relatively small extra power

demand, keeping the same maximum propeller

diameter:

• going from 100 to 110 r/min (P/D = 0.62) requires

8,900 kW i.e. an extra power demand of 80 kW.

• going from 100 to 91 r/min (P/D = 0.81) requires

8,900 kW i.e. an extra power demand of 80 kW.

In both cases the extra power demand is only

of 0.9%, and the corresponding ‘equal speed

curves’ are ∝ =+0.1 and ∝ =0.1, respectively, so

there is a certain interval of propeller speeds in

which the ‘power penalty’ is very limited.

178 47 032.0

Page 32

MAN B&W 2.02

Page 2 of 2

MAN Diesel

198 38 78 2.6MAN B&W MC/M C-C, ME/ME- C/ME -B/GI eng ines

Constant ship speed lines

The constant ship speed lines ∝, are shown at

the very top of Fig. 2.02.02. These lines indicate

the power required at various propeller speeds to

keep the same ship speed provided that the optimum propeller diameter with an optimum pitch

diameter ratio is used at any given speed, taking

into consideration the total propulsion efficiency.

Normally, the following relation between necessary power and propeller speed can be assumed:

P2 = P1 × (n2/n1)

∝

where:

P = Propulsion power

n = Propeller speed, and

∝= the constant ship speed coefficient.

For any combination of power and speed, each

point on lines parallel to the ship speed lines gives

the same ship speed.

When such a constant ship speed line is drawn

into the layout diagram through a specified propulsion MCR point ‘MP1’, selected in the layout

area and parallel to one of the ∝lines, another

specified propulsion MCR point ‘MP2’ upon this

line can be chosen to give the ship the same

speed for the new combination of engine power

and speed.

Fig. 2.02.02 shows an example of the required

power speed point MP1, through which a constant

ship speed curve ∝= 0.25 is drawn, obtaining

point MP2 with a lower engine power and a lower

engine speed but achieving the same ship speed.

Provided the optimum pitch/diameter ratio is used

for a given propeller diameter the following data

applies when changing the propeller diameter:

for general cargo, bulk carriers and tankers

∝= 0.25 0.30

and for reefers and container vessels

∝= 0.15 0.25

When changing the propeller speed by changing

the pitch diameter ratio, the ∝ constant will be different, see above.

Fig. 2.02.02: Layout diagram and constant ship speed lines

178 05 667.0

=0,15

=0,20

=0,25

=0,30

C

o

ns

ta

nt s

h

ip

s

p

e

e

d

lin

e

s

MP

2

MP

1

=0,25

1

2

3

4

m

ep

1

0

0

%

9

5

%

9

0

%

8

5

%

8

0

%

7

5

%

7

0

%

Nominal propeller curve

75% 80%85% 90% 95% 100% 105%

Engine speed

Power

110%

100%

90%

80%

70%

60%

50%

40%

Page 33

MAN B&W 2.03

Page 1 of 1

MAN Diesel

198 82 77-0 .7MAN B&W M C/MC-C, ME/ ME-C/ME-B/-G I.2-TII engines

L

4

L

2

L

1

L

3

Power

Speed

L

4

L

2

L

1

L

3

Power

Speed

Power

Speed

L

4

L

2

L

1

L

3

Power

Speed

L

4

L

2

L

1

L

3

Power

Speed

L

4

L

2

L

1

L

3

L

4

L

2

L

1

L

3

Power

Speed

L

4

L

2

L

1

L

3

Power

Speed

L

4

L

2

L

1

L

3

Speed

L

4

L

2

L

1

L

3

Power

Speed

L

4

L

2

L

1

L

3

Power

Speed

L

4

L

2

L

1

L

3

Power

Speed

L

4

L

2

L

1

L

3

Power

Speed

L

4

L

2

L

1

L

3

Power

Speed

L

4

L

2

L

1

L

3

Speed

100 80% power and

100 85% speed range

valid for the types:

G80ME-C9.2-Basic

S70/65MC-C/ME-C8.2

S60MC-C/ME-C/ME-B8.3

L60MC-C/ME-C8.2

G/S50ME-B9.3

S50MC-C/ME-C8.2/ME-B8.3

S46MC-C/ME-B8.3

G45ME-B9.3

G/S40ME-B9.3, S40MC-C

S35MC-C/ME-B9.3

S30ME-B9.3

100 80% power and

100 87.5% speed range

valid for the types:

G95ME-C9.2

100 80% power and

100 90% speed range

valid for the types:

K80ME-C9.2

100 80% power and

100 85.7% speed range

valid for the types:

S90ME-C10.2

S90ME-C9.2

S80ME-C8.2

Fig. 2.03.01 Layout diagram sizes

Layout Diagram Sizes

178 62 22-5.3

See also Section 2.05 for actual project.

100 80% power and

100 79% speed range

valid for the types:

G70ME-C9. 2

G60ME-C9.2

100 80% power and

100 84% speed range

valid for the types:

L70MC-C/ME-C8.2

100 80% power and

100 92% speed range

valid for the types:

S80ME-C9.2/4

S90ME-C8.2

100 80% power and

100 93% speed range

valid for the types:

K98ME/ME-C7.1

100 80% power and

100 81% speed range

valid for the types:

G80ME-C9.2-Extended

Page 34

MAN B&W 2.04

Page 1 of 9

MAN Diesel

198 69 93 -5.3 MAN B&W MC/MC-C/ME/ME-C/ME-B/-GI-TII engines

Engine Layout and Load Diagram

Engine Layout Diagram

An engine’s layout diagram is limited by two constant mean effective pressure (mep) lines L1– L3

and L2– L4, and by two constant engine speed

lines L1– L2 and L3– L4. The L1 point refers to the

engine’s nominal maximum continuous rating, see

Fig. 2.04.01.

Within the layout area there is full freedom to select the engine’s specified SMCR point M which

suits the demand for propeller power and speed

for the ship.

On the horizontal axis the engine speed and on

the vertical axis the engine power are shown on

percentage scales. The scales are logarithmic

which means that, in this diagram, power function

curves like propeller curves (3rd power), constant

mean effective pressure curves (1st power) and

constant ship speed curves (0.15 to 0.30 power)

are straight lines.

Specified maximum continuous rating (M)

Based on the propulsion and engine running

points, as previously found, the layout diagram

of a relevant main engine may be drawnin. The

SMCR point (M) must be inside the limitation lines

of the layout diagram; if it is not, the propeller

speed will have to be changed or another main

engine type must be chosen. The selected SMCR

has an influence on the turbocharger and its

matching and the compression ratio.

For ME and ME-C/-GI engines, the timing of the

fuel injection and the exhaust valve activation are

electronically optimised over a wide operating

range of the engine.

For ME-B engines, only the fuel injection (and not

the exhaust valve activation) is electronically controlled over a wide operating range of the engine.

178 60 85-8.1

Fig. 2.04.01: Engine layout diagram

L

1

L

2

L

3

L

4

Speed

Power

M

S

1

For a standard high-load optimised engine,

the lowest specific fuel oil consumption for

the ME and ME-C engines is optained at 70%

and for MC/MC-C/ME-B engines at 80% of the

SMCR point (M).

For ME-C-GI engines operating on LNG, a further

SFOC reduction can be obtained.

Continuous service rating (S)

The continuous service rating is the power needed in service – including the specified sea margin

and heavy/light running factor of the propeller

– at which the engine is to operate, and point S

is identical to the service propulsion point (SP)

unless a main engine driven shaft generator is installed.

Page 35

MAN B&W 2.04

Page 2 of 9

MAN Diesel

198 69 93 -5.3MAN B&W MC/MC-C/ME/ME-C/ME-B/-GI-TII engines

Engine shaft power, % of A

40

45

50

55

60

65

70

75

80

85

90

95

100

105

110

7

5

4

1 2

6

7

8

4

1

2

6

5

M

3

9

Engine speed, % of A

60

65

70

75

80

85 90 95 100 105 110

Definitions

The engine’s load diagram, see Fig. 2.04.02, defines the power and speed limits for continuous as

well as overload operation of an installed engine

having a specified MCR point M that confirms the

ship’s specification.

The service points of the installed engine incorporate the engine power required for ship propulsion

and shaft generator, if installed.

Operating curves and limits for continuous

operation

The continuous service range is limited by four

lines: 4, 5, 7 and 3 (9), see Fig. 2.04.02. The propeller curves, line 1, 2 and 6 in the load diagram

are also described below.

Line 1:

Propeller curve through specified MCR (M), engine layout curve.

Line 2:

Propeller curve, fouled hull and heavy weather

– heavy running.

Line 3 and line 9:

Line 3 represents the maximum acceptable speed

for continuous operation, i.e. 105% of M.

During trial conditions the maximum speed may

be extended to 107% of M, see line 9.

The above limits may in general be extended to

105% and during trial conditions to 107% of the

nominal L1 speed of the engine, provided the torsional vibration conditions permit.

The overspeed setpoint is 109% of the speed

in M, however, it may be moved to 109% of the

nominal speed in L1, provided that torsional vibra-

tion conditions permit.

Running at low load above 100% of the nominal L1

speed of the engine is, however, to be avoided for

extended periods. Only plants with controllable

pitch propellers can reach this light running area.

Line 4:

Represents the limit at which an ample air supply

is available for combustion and imposes a limitation on the maximum combination of torque and

speed.

Regarding ‘i’ in the power function P = c x ni, see page 2.01.

M Specified MCR point

Line 1 Propeller curve through point M (i = 3)

(engine layout curve)

Line 2 Propeller curve, fouled hull and heavy weather

– heavy running (i = 3)

Line 3 Speed limit

Line 4 Torque/speed limit (i = 2)

Line 5 Mean effective pressure limit (i = 1)

Line 6 Propeller curve, clean hull and calm weather

– light running (i = 3), for propeller layout

Line 7 Power limit for continuous running (i = 0)

Line 8 Overload limit

Line 9 Speed limit at sea trial

178 05 427.6

Fig. 2.04.02: Standard engine load diagram

Engine Load Diagram

Page 36

MAN B&W 2.04

Page 3 of 9

MAN Diesel

198 69 93 -5.3 MAN B&W MC/MC-C/ME/ME-C/ME-B/-GI-TII engines

Recommendation

Continuous operation without limitations is allowed only within the area limited by lines 4, 5,

7 and 3 of the load diagram, except on low load

operation for CP propeller plants mentioned in the

previous section.

The area between lines 4 and 1 is available for

operation in shallow waters, heavy weather and

during acceleration, i.e. for nonsteady operation

without any strict time limitation.

After some time in operation, the ship’s hull and

propeller will be fouled, resulting in heavier running of the propeller, i.e. the propeller curve will

move to the left from line 6 towards line 2, and

extra power is required for propulsion in order to

keep the ship’s speed.

In calm weather conditions, the extent of heavy

running of the propeller will indicate the need for

cleaning the hull and possibly polishing the propeller.

Once the specified MCR has been chosen, the

capacities of the auxiliary equipment will be

adapted to the specified MCR, and the turbocharger specification and the compression ratio

will be selected.

If the specified MCR is to be increased later on,

this may involve a change of the pump and cooler

capacities, change of the fuel valve nozzles, adjusting of the cylinder liner cooling, as well as

rematching of the turbocharger or even a change

to a larger size of turbocharger. In some cases it

can also require larger dimensions of the piping

systems.

It is therefore of utmost importance to consider,

already at the project stage, if the specification

should be prepared for a later power increase.

This is to be indicated in the Extent of Delivery.

Line 5:

Represents the maximum mean effective pressure level (mep), which can be accepted for continuous operation.

Line 6:

Propeller curve, clean hull and calm weather – light

running, used for propeller layout/design.

Line 7:

Represents the maximum power for continuous

operation.

Limits for overload operation

The overload service range is limited as follows:

Line 8:

Represents the overload operation limitations.

The area between lines 4, 5, 7 and the heavy

dashed line 8 is available for overload running for

limited periods only (1 hour per 12 hours).

Line 9:

Speed limit at sea trial.

Limits for low load running

As the fuel injection for ME engines is automatically controlled over the entire power range, the

engine is able to operate down to around 15-20%

of the nominal L1 speed, whereas for MC/MC-C

engines it is around 20-25% (electronic governor).

Page 37

MAN B&W 2.04

Page 4 of 9

MAN Diesel

198 69 93 -5.3MAN B&W MC/MC-C/ME/ME-C/ME-B/-GI-TII engines

Extended load diagram for ships operating in extreme heavy running conditions

When a ship with fixed pitch propeller is operating in normal sea service, it will in general be

operating in the hatched area around the design

propeller curve 6, as shown on the standard load

diagram in Fig. 2.04.02.

Sometimes, when operating in heavy weather, the

fixed pitch propeller performance will be more

heavy running, i.e. for equal power absorption of

the propeller, the propeller speed will be lower

and the propeller curve will move to the left.

As the low speed main engines are directly coupled to the propeller, the engine has to follow the

propeller performance, i.e. also in heavy running

propeller situations. For this type of operation,

there is normally enough margin in the load area

between line 6 and the normal torque/speed limitation line 4, see Fig. 2.04.02. To the left of line 4

in torquerich operation, the engine will lack air

from the turbocharger to the combustion process,

i.e. the heat load limits may be exceeded and

bearing loads might also become too high.

For some special ships and operating conditions,

it would be an advantage when occasionally

needed to be able to operate the propeller/main

engine as much as possible to the left of line 6,

but inside the torque/speed limit, line 4.

Such cases could be for:

• ships sailing in areas with very heavy weather

• ships operating in ice

• ships with two fixed pitch propellers/two main

engines, where one propeller/one engine is declutched for one or the other reason.

The increase of the operating speed range between line 6 and line 4 of the standard load diagram, see Fig. 2.04.02, may be carried out as

shown for the following engine Example with an

extended load diagram for speed derated engine

with increased light running.

Extended load diagram for speed derated engines with increased light running

The maximum speed limit (line 3) of the engines is

105% of the SMCR (Specified Maximum Continuous Rating) speed, as shown in Fig. 2.04.02.

However, for speed and, thereby, power derated

engines it is possible to extend the maximum

speed limit to 105% of the engine’s nominal MCR

speed, line 3’, but only provided that the torsional

vibration conditions permit this. Thus, the shafting, with regard to torsional vibrations, has to be

approved by the classification society in question,

based on the extended maximum speed limit.

When choosing an increased light running to be

used for the design of the propeller, the load diagram area may be extended from line 3 to line 3’,

as shown in Fig. 2.04.03, and the propeller/main

engine operating curve 6 may have a correspondingly increased heavy running margin before exceeding the torque/speed limit, line 4.

A corresponding slight reduction of the propeller efficiency may be the result, due to the higher

propeller design speed used.

Page 38

MAN B&W 2.04

Page 5 of 9

MAN Diesel

198 69 93 -5.3 MAN B&W MC/MC-C/ME/ME-C/ME-B/-GI-TII engines

Examples of the use of the Load Diagram

In the following are some examples illustrating the

flexibility of the layout and load diagrams.

• Example 1 shows how to place the load diagram

for an engine without shaft generator coupled to

a fixed pitch propeller.

• Example 2 shows the same layout for an engine

with fixed pitch propeller (example 1), but with a

shaft generator.

• Example 3 is a special case of example 2, where

the specified MCR is placed near the top of the

layout diagram.

In this case the shaft generator is cut off,

and the GenSets used when the engine runs

at specified MCR. This makes it possible to

choose a smaller engine with a lower power output, and with changed specified MCR.

• Example 4 shows diagrams for an engine

coupled to a controllable pitch propeller, with

or without a shaft generator, constant speed or

combinator curve operation.

For a specific project, the layout diagram for actual project shown later in this chapter may be used

for construction of the actual load diagram.

80 100 1058555 90 9560

Engine speed, % A

M Specified engine MCR

Engine shaft power, % A

Heavy

running

operation

Normal

operation

50

70

80

90

100

40

110

60

110 115120

L

1

M

L

2

5%

L

3

L

4

70 7565

Normal load

diagram area

Extended light

running area

2

1

5

7

6

3

3

4

Line 1: Propeller curve through SMCR point (M)

layout curve for engine

Line 2: Heavy propeller curve

fouled hull and heavy seas

Line 3: Speed limit

Line 3’: Extended speed limit, provided torsional vibration

conditions permit

Line 4: Torque/speed limit

Line 5: Mean effective pressure limit

Line 6: Increased light running propeller curve

clean hull and calm weather

layout curve for propeller

Line 7: Power limit for continuous running

178 60 79-9.1

Fig. 2.04.03: Extended load diagram for speed derated

engine with increased light running

Page 39

MAN B&W 2.04

Page 6 of 9

MAN Diesel

198 69 93 -5.3MAN B&W MC/MC-C/ME/ME-C/ME-B/-GI-TII engines

Example 1: Normal running conditions.

Engine coupled to fixed pitch propeller (FPP) and without shaft generator

Propulsion and engine

service curve for fouled

hull and heavy weather

Engine speed, % of L

1

100%

Power, % of L

1

100%

7

5

4

1

2 6

1

2

6

7

M=MP

S=SP

Engine speed, % of L

1

100%

Power, % of L

1

100%

Propulsion and engine

service curve for fouled

hull and heavy weather

7

5

4

1

2

6

3 3

5%L

1

S

M

3.3%M

5%M

L

1

L

2

L

3

L

4

L

1

L

2

L

3

L

4

M Specified MCR of engine

S Continuous service rating of engine

MP Specified MCR for propulsion

SP Continuous ser vice rating of propulsion

178 05 440.9

The specified MCR (M) and its propeller curve 1 will normally be selected on the engine ser vice curve 2.

Once point M has been selected in the layout diagram, the load diagram can be drawn, as shown in the figure, and hence the actual

load limitation lines of the diesel engine may be found by using the inclinations from the construction lines and the %figures stated.

Layout diagram Load diagram

Fig. 2.04.04: Normal running conditions. Engine coupled to a fixed pitch propeller (FPP) and without a shaft generator

Page 40

MAN B&W 2.04

Page 7 of 9

MAN Diesel

198 69 93 -5.3 MAN B&W MC/MC-C/ME/ME-C/ME-B/-GI-TII engines

Example 2: Normal running conditions.

Engine coupled to fixed pitch propeller (FPP) and with shaft generator

M Specified MCR of engine

S Continuous service rating of engine

MP Specified MCR for propulsion