Page 1

HYFIRE® VII Series Electronic Ignition

Controls

Instruction Manual

Part#: 667C

Page 2

GENERAL INFORMATION

The RPM limiter in the HYFIRE®VIIC Ignition System is not recommended as

an engine speed governor. The use of the RPM limiters is not recommended

for applications equipped with a catalytic converter. Similarly, forcing engine

RPM past the RPM limiter continuously for long sustained intervals can cause

problems resulting from fuel build up in the exhaust system that may adversely affect the application.

Ignition Ballast Resistor / Loom Resistance Wire

The HYFIRE®VIIC Ignition Ignition’s performance is not affected by the presence of the factory ignition resistors or ignition ballast resistors in the wire

from the ignition switch. It is not necessary to install ignition ballast resistors

as specified by the instructions for the particular distributor.

Ignition Coils

The HYFIRE®VIIC Ignition Systems is designed to work with Mallory PROMASTER

®

Coil Part No. 28880. Avoid using any other type of ignition coil.

Spark Plug Wires

YOU MUST USE suppression type (carbon core, spiral core) spark plug wire.

We recommend spiral core ignition wire, such as Mallory PRO SIDEWINDER

®

Ignition Wire. Suppression type spark plug wires prevent false triggering and

the possibility of premature ignition or accessory failures.

DO NOT USE solid core (copper core; stainless steel core) spark plug wire

with any electronic ignition system or accessory. Solid core spark plug

wire is one cause of electro-magnetic interference (EMI; ignition noise).

EMI is one cause of false triggering (preignition; spark scatter) and premature ignition or accessory failures.

®

HYFIRE

®

VIIC PRO CD

IGNITION SYSTEM

Part No. 667C

4-12 Cylinder

6 Cylinder Odd-Fire

Notice: This product is legal to sell, distribute or install on vehicles in California. Executive Order D-70-6.

The HYFIRE®VII Pro CD Ignition Controls are not compatible with distributorless systems or positive ground applications.The HYFIRE®VII Ignition System is not designed for marine use.

Spark Plug Gaps

For street applications, use your engine manufacturer’s specifications. For

racing applications, start with your engine manufacturer’s specifications, then

experiment with and closely monitor various gaps to achieve maximum performance.

Electric Welding

Disconnect the HYFIRE®VIIC Ignition System and unplug any distributor harnesses (if possible) before any welding is done on the vehicle.

External RPM Limiters

Mallory RPM Limiter Part Nos. 641-4, 641-6, 641-8, 642, 643 and 644 WILL

NOT function with the HYFIRE

®

VII Ignition Systems.

Mallory PRO TACH®I, IV and IV

The tachometer and shift light will work with the HYFIRE®VII Ignition

Systems. However, the RPM limiter WILL NOT function with the HYFIRE

®

VII

Ignition Systems. Turn the LIMIT RPM knob slightly past 11,000 to prevent

the RPM limiter from interfering with the tachometer’s other functions.

Mounting to a flat surface with shock mounts

•Hold the unit in its mounting position and center punch the mounting pat-

tern on the mounting surface for drilling mounting holes. Drill mounting

holes using a 9/32" drill bit.

•Install the shock mounts into the bottom plate of the unit. Hold the unit in

position where it will be mounted.

• From the backside of the mounting surface, insert the washers and the

1/4-20 nylock nuts onto the shock mount studs. Tighten each nut until

snug.

FORM 1460 (REV. C) 5/00

INSTALLATION INSTRUCTIONS

Mallory-Ignition.com

1

MOUNTING PROCEDURE

Step 1

Disconnect the battery (–) cable to cut power to the system.

Step 2

Select a convenient location to mount the HYFIRE®VII Ignition System. Keep

the unit away from hot engine components or extreme heat such as the

exhaust system and manifolds. Keep the unit away from moving devices,

such as fans, belts and linkages. The location must be dry. Moisture will damage components inside the unit.

Step 3

Page 3

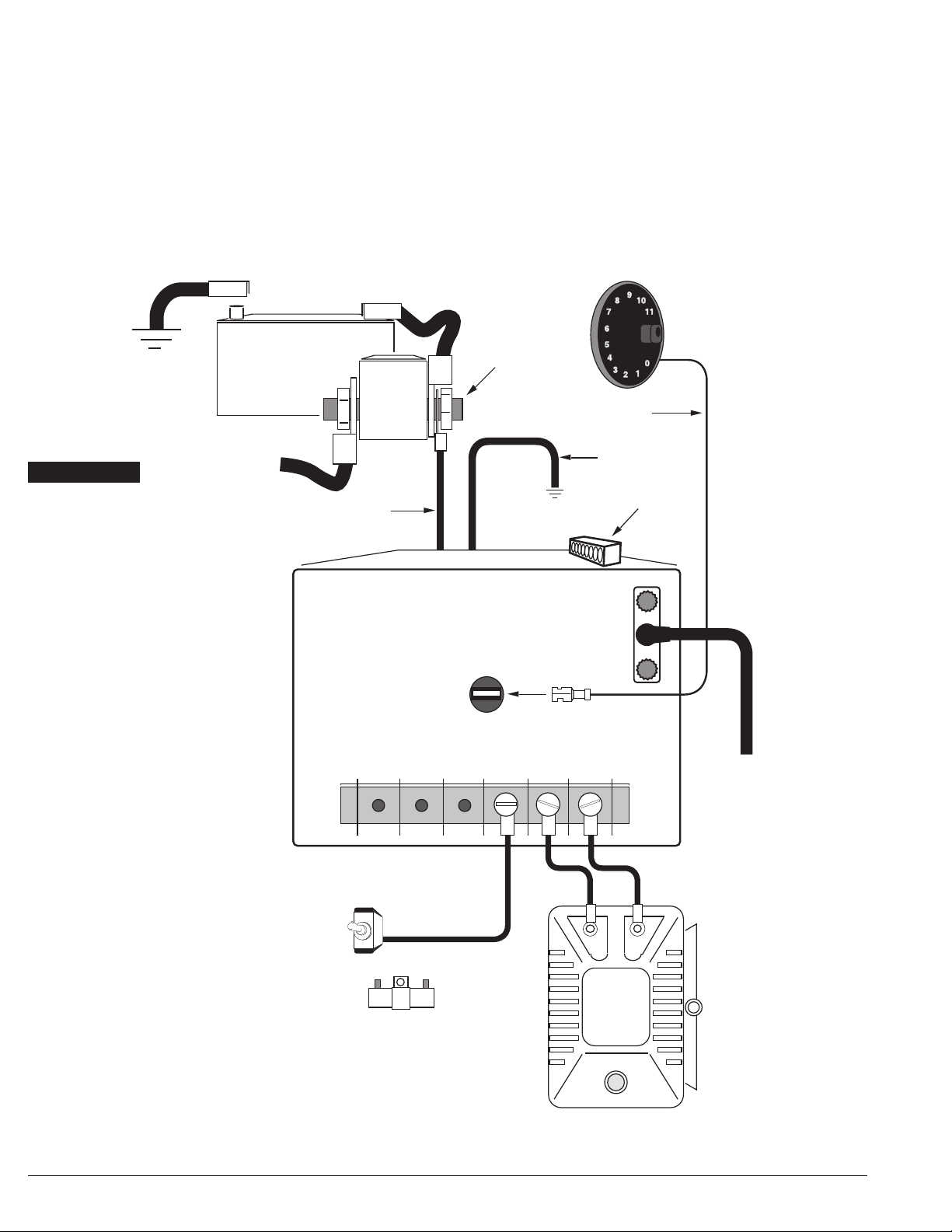

WIRING PROCEDURE

Step 1

Ensure that your vehicle is equipped with a ground cable between the engine

block and firewall (10 gauge or larger is required). Refer to Figure 1 while performing the following steps.

• Connect the HEAVY RED wire to the 12-volt battery (+) post or battery

(+) terminal on the starter solenoid.

• Connect the HEAVY BLACK wire to engine or chassis ground.

• Connect wires between the COIL (+) and (–) terminals.

• Connect 12-volts from ignition switch to the +12V terminal.

• Connect the tach/RPM sensing wire and optional external RPM control to

sockets.

Step 2

When wiring the HYFIRE®VIIC Pro CD Ignition System to an electronic ignition or magnetic pickup, refer to Figures 2 and 3, and trace wires for hookup.

YOU MUST USE suppression type

spark plug wire (carbon core, spiral

core) to help prevent false

triggering and premature ignition

or accessory failures. DO NOT USE

solid core (copper core, stainless

steel core) spark plug wire.

YOU MUST USE Mallory

PROMASTER

®

Coil Part

No. 28880 with this

ignition system.

12V / IGNITION SWITCH

+

-

MALLORY

PROMASTER®

COIL

PART NO. 28880

STARTER

SOLENOID

(–) 12V/BATTERY (+)

ENGINE OR

CHASSIS

GROUND

TO THE STARTER

(TYPICAL)

ENGINE OR

CHASSIS

GROUND

HEAVY RED

IGNITION BALLAST

RESISTOR

AN IGNITION BALLAST RESISTOR

IS NOT REQUIRED FOR PROPER

OPERATION OF THE HYFIRE

®

VIIC.

IF ONE IS ALREADY INSTALLED,

DO NOT REMOVE IT. IF A BALLAST

RESISTOR IS NOT INSTALLED, DO

NOT ADD ONE.

DISCONNECT UNTIL INSTALLATION IS FINISHED

TACH / RPM

SENSING WIRE

12V / BATTERY OR

BATTERY TERMINAL

AT STARTER

SOLENOID

– + – +

HYFIRE® VIIC PR O CD

IGNITION CONTROL

MAGNETIC PICKUP

POINTS

+12V COIL

(REAR PANEL)

TACH

TO HYFIRE® VIIC

IGNITION CONTROL

HEAVY BLACK

ACTIVATION/RELAY

PLUG

FIGURE 1

SEE PAGE 4 FOR

INSTRUCTIONS

ON WIRING THE

RELAY PLUG

NOTE:The Ignition

Control

MUST

be

connected for the

ignition to work.

Mallory-Ignition.com

2

Page 4

– + – +

HYFIRE® VIIC PRO CD

IGNITION CONTROL

MAGNETIC PICKUP

POINTS

+12V COIL

(REAR PANEL)

TACH

JUMPER

WIRE

12V / IGNITION

SWITCH

ENGINE OR

CHASSIS GROUND

BROWN

RED

IGNITION

MODULE

FEMALE

CONNECTOR

GREEN

DISTRIBUTOR WIRE HARNESS

PART NO. 29349

ENGINE OR

CHASSIS

GROUND

ENGINE OR

CHASSIS

GROUND

HEAVY BLACK

(REAR

PANEL)

HEAVY RED

+

-

MALLORY

PROMASTER®

COIL

PART NO. 28880

(-) (+)

12V/BATTERY

HOOKUP HOOKUP TTO A MALLORO A MALLORY UNILITE® IGNITION,Y UNILITE® IGNITION, MA MAGNETIC BREAKERLESS IGNITION OR ELECTRGNETIC BREAKERLESS IGNITION OR ELECTRONICONIC

ADADVVANCE IGNITION (THREE ANCE IGNITION (THREE WIRE:WIRE: RED RED,, BR BROOWN,WN, GREEN) GREEN)

Figure 2Figure 2

YOU MUST USE Mallory

PROMASTER® Coil Part No.

28880 with this ignition system

YOU MUST USE suppression type

spark plug wire (carbon core, spiral

core) to help prevent false

triggering and premature ignition

or accessory failures. DO NOT USE

solid core (copper core, stainless

steel core) spark plug wire.

IGNITION BALLAST RESISTOR

AN IGNITION BALLAST RESISTOR IS NOT

REQUIRED FOR PROPER OPERATION OF THE

HYFIRE

®

VIIC. IF ONE IS ALREADY INSTALLED,

DO NOT REMOVE IT. IF A BALLAST RESISTOR

IS NOT INSTALLED, DO NOT ADD ONE.

TO HYFIRE® VIIC

IGNITION CONTROL

TO HYFIRE® VIIC

IGNITION CONTROL

12V / IGNITION

SWITCH

+

-

MALLORY

PROMASTER®

COIL

PART NO. 28880

MAGNETIC PICKUP DISTRIBUTOR OR CRANK TRIGGER IGNITION

MAMAG+G+

MALLORY BILLET COMPETITION DISTRIBUTOR SERIES NOS. 81 AND 84 ORANGE PURPLE

MALLORY C0MP 9000® SERIES NOS. 96-99 ORANGE PURPLE

MALLORY CRANK TRIGGER OR WIRE HARNESS PART NO. 29787 PURPLE GREEN

MALLORY DISTRIBUTOR WIRE HARNESS PART NO. 29788 ORANGE PURPLE

MALLORY HARNESS PART NO. 29040 RED BLACK

MSD™ CRANK TRIGGER OR WIRE HARNESS PART NOS. 8859 OR 8860 PURPLE GREEN

MSD™ CRANK TRIGGER (OLD STYLE) ORANGE BLACK

MSD™ DISTRIBUTOR ORANGE PURPLE

MOROSO™ CRANK TRIGGER BLACK WHITE

MOROSO™ DISTRIBUTOR ORANGE PURPLE

ACCEL® CRANK TRIGGER BLACK WHITE

CHRYSLER ELECTRONIC DISTRIBUTOR (NON-COMPUTER) ORANGE BLACK

FORD DURASPARK DISTRIBUTOR (NON-COMPUTER) ORANGE PURPLE

GM/DELCO HEI DISTRIBUTOR (NON-COMPUTER) WHITE GREEN

HOOKUP HOOKUP TTO A MAO A MAGNETIC PICKUP DISTRIBGNETIC PICKUP DISTRIBUTUTOR OR CRANK OR OR CRANK TRIGGERTRIGGER

Figure 3Figure 3

MAMAG–G–

MAMAGNETIC PICKUP DISTRIBGNETIC PICKUP DISTRIBUTUTOR OROR OR

CRANK CRANK TRIGGER TRIGGER WIRE COLORSWIRE COLORS

YOU MUST USE Mallory

PROMASTER® Coil Part

No. 28880 with this

ignition system

TWIST WIRES

TOGETHER TO

REDUCE EMI

IGNITION BALLAST RESISTOR

AN IGNITION BALLAST RESISTOR IS

NOT REQUIRED FOR PROPER

OPERATION OF THE HYFIRE

®

VIIC.

IF ONE IS ALREADY INST ALLED, DO

NOT REMOVE IT. IF A BALLAST

RESISTOR IS NOT INSTALLED, DO

NOT ADD ONE.

ENGINE OR

CHASSIS

GROUND

ENGINE OR

CHASSIS

GROUND

HEAVY BLACK

(REAR

PANEL)

HEAVY RED

(-) (+)

12V/BATTERY

– + – +

HYFIRE® VIIC PRO CD

IGNITION CONTROL

MAGNETIC PICKUP

POINTS

+12V COIL

(REAR PANEL)

TACH

NOTE: The Ignition

MUST

MUST

Mallory-Ignition.com

3

Control

connected for the

be

ignition to work.

NOTE: The Ignition

Control

connected for the

ignition to work.

be

Page 5

NOTE: When you apply 12 volts to RPM2, RPM3, RET1, RET2, or RET3 the

display will switch to show that function. If you have both an auxiliary

RPM limit AND a retard selected, the display will show the retard value.

NOTE: When activating Modes 2, 3, 4, 5, or 6, the display will change to

show the active mode. If more than one mode is activated, the higher

mode number will be displayed.

USING THE HYFIRE VIIC FEATURES

Push this button to change the mode

FIGURE 4

Push either of these

buttons to change

the value of the

selected mode.

NOTE: If any button is held down for more than 1/2 second,

the displayed value will change automatically.

Mallory-Ignition.com

4

®

Your Mallory HYFIRE

667C has a number of built-in features that make it

easier to use. This instruction addition tells how to use these built-in features.

First, take a look at the top of the main unit. You'll see that there is an 8-pin

connector beneath the surface, Supplied in the plastic bag that came with

your Hyfire is an 8-pin plug that fits this connector. It has screw clamp terminals that accept up to 14 gauge wire. For best results, use stranded , insulated copper wire, rather than solid wire. The

plug is made so that it will only

fit one way, and has hold down screws at each end.

The connector and mode descriptions are listed below:

RPM switch:

The built-in RPM switch can either turn an electrical load off or on at a selected RPM. See below for more detail.

NC This is the RPM switch (mode 7) relay contact that is normally closed.

In other words, as long as you haven't reached the point where the

RPM switch is active, this contact remains connected to the "common" or "C" terminal. You would use this connection if

, for example,

you wanted to turn something OFF (such as a nitrous system) when

you reached the RPM switch point. See example 1.

C This is the common terminal for the RPM switch (mode 7) relay in the

main unit. It is connected to the RPM switch, where it will switch the

accessory connected to the "NC" terminal OFF, and the accessory connected to the "NO" terminal ON when the RPM switch value is

reached. The "C" terminal can be used to switch either to power or

ground.

NO This is the RPM switch (mode 7) relay contact that is normally

open.

In other words, as long as you haven't reached the point where the

RPM switch is active, this contact isn't connected to the "C" contact.

You would use this contact to turn something ON (such as a shift light

or an air shifter) at a specific RPM. See example 2 and example 3.

RPM Limiters:

The HYFIRE

®

667C has three built-in RPM limiters. Each one has a range of

1000 to 12,800 RPM in 50 RPM steps. On the main display, there is a decimal point on the mode digit. When that decimal point is lit up, the RPM limit

is increased by 50

RPM.

RPM1 (Mode 1) This is the RPM limit that is always active if you haven't

selected any other RPM limit.

RPM2 (Mode 2) This is an auxiliary RPM limiter that is activated when you

apply 12 volts to the "RPM2" terminal on the top-side connector. This

could be a burnout limiter. When selected, it over-rides RPM1 (the

main engine protection RPM limiter). See example 4.

RPM3 (Mode 3) This is the other auxiliary RPM limiter. It also is activated by

12 volts on the "RPM3" terminal on the top-side connector, and overrides both RPM2 and RPM1.

Use this limit as a staging (starting-line)

RPM limiter. See example 5.

High-Speed Timing Retards:

RET1, RET2, RET3 (Modes 4,5,6) These are all high-speed timing retard

functions that are activated by 12 volts on the appropriate top-side connector

terminal. Each higher stage over-rides the lower stages, which means that

you set each stage for exactly the amount of retard you want, rather than

adding up each stage to get the actual retard. See example 6.

See the accompanying illustrations for some examples of how to use the

RPM limiters, the RPM switch, and the timing retard functions.

®

Page 6

NC

C

NO

RPM2

RPM3

RET1

RET2

RET3

COIL

COIL

CONTACT

CONTACT

To Ground

To +12 Volts

To Nitrous System

From Nitrous

Activation Switch

RELAY

Use a relay if you are

switching more than 3-5 amps.

EXAMPLE 1: Using the RPM switch (Mode 7) to turn OFF

a nitrous system at a particular RPM.

NC

C

NO

RPM2

RPM3

RET1

RET2

RET3

To +12 Volts

To Ground

EXAMPLE 2: Using the RPM switch (Mode 7)

to turn on a shift light.

Additional Functions:

The HYFIRE

®

667C has two more functions that can make the ignition installation and setup work better. One of these is the high-speed advance function.

This lets you put small amounts of timing in the engine after the torque peak

to pick up a bit of horsepower. There are three things that need to be set up

for this: the cut-in RPM (mode 9), the maximum advance (mode A), and the

slope (mode 8). The cut-in RPM is the RPM where you want the curve to start

working. The slope is how much the timing will advance every 1000 RPM

after the cut-in RPM. The maximum advance is the highest amount of

advance you want the system to reach.

For example, say that your engine has the torque peak at 6500 RPM, and you

want to add some timing after this. You might want to start adding timing

after 7000 RPM, so this becomes your cut-in speed. If you then want 2

degrees additional timing at 8000 RPM, then the slope would be set for 2

degrees per 1000 RPM. However, let's say that you don't want more than 2

degrees of advance, so you would set the maximum advance at 2 degrees.

See example 7 for more detail.

The other additional function available is trigger compensation, which is set

when the mode indicator is "b". This lets you compensate for the various

delays in ignition timing caused by both electronic and mechanical changes.

To set the trigger compensation, set mode 9 to 5000 RPM, and mode 8 to

zero. What this does is tell the system to start the high-speed advance at 5000

RPM, but with a slope of zero, there should be no advance. Once the system

is set up this way, watch the timing as the engine revs past 5000 RPM. If the

timing does not stay at a steady value (once the 5000 RPM point is reached)

then adjust the compensation value until it is as flat as possible. For example,

if the timing retards slightly as the RPM goes up, increase the compensation

value. If the timing advances slightly as the RPM goes up, decrease the compensation value. NOTE: This function is only valid for RPM above the high-

speed advance cut-in RPM. If you have the high-speed advance cut-in set

above the normal operational range of the motor, the compensation function does nothing.

Once the compensation is set, then the high speed advance settings will be

accurate. The factory setting should be correct for most types of flying magnet type crank trigger systems, and should not normally need to be adjusted

unless you are using a different trigger type.

Number of cylinders selection

The final mode that can be set is mode "C". This allows you to select 4 through

12 cylinder operation. This ensures that the RPML and the timing are proper for

the engine. Mode 6F is special - this is for odd-fire V6 engines ONLY! The cylinder firing spacing should be 45/75 (at the distributor) or 90/150 at the crank.

Mallory-Ignition.com

5

Page 7

NC

C

NO

RPM2

RPM3

RET1

RET2

RET3

To +12 Volts

EXAMPLE 3: Using the RPM switch to activate a

retard stage at a particular RPM.

To roll control switch that supplies

+12 volts when active.

NC

C

NO

RPM2

RPM3

RET1

RET2

RET3

EXAMPLE 4: Burnout RPM Limiter (Mode 2).

To clutch pedal or transbrake switch

that supplies +12 volts when active.

NC

C

NO

RPM2

RPM3

RET1

RET2

RET3

EXAMPLE 5: Staging RPM Limiter.

Mallory-Ignition.com

6

Page 8

To nitrous stage 3 (+12 volts when active)

To nitrous stage 1 (+12 volts when active)

To nitrous stage 2 (+12 volts when active)

NC

C

NO

RPM2

RPM3

RET1

RET2

RET3

EXAMPLE 6: Using the High-Speed timing retard function

with a 3-stage nitrous system.

8

6

4

2

0

ADVANCE

RPM

0

10k8000600040002000

EXAMPLE 7: High Speed Advance Curve (Modes 8 and 9)

SLOPE (Mode 8)

This is how much the timing advances for

every 1000 RPM. This example shows a

slope of 2.0 (2 degrees per 1000 RPM).

CUT-IN (Mode 9)

THIS IS THE RPM WHERE THE TIMING

STARTS TO ADVANCE. THIS EXAMPLE

SHOWS A CUT-IN OF 7.0 (7000 RPM)

MAXIMUM ADVANCE (Mode A)

This example shows a maximum of 2

degrees advance.

Mallory-Ignition.com

7

Page 9

TECHNICAL BULLETIN

Mallory-Ignition.com

8

®

HYFIRE® VIIC AND VIIS

IGNITION SYSTEMS

Part One: Start Retard

The Mallory HYFIRE® VIIC AND VIIS Ignition Systems both have a built-in start retard feature. This retard is

20 degrees at 100 RPM, and decreases to 0 degrees at 500 RPM. This is a very useful feature which

eases the load on the starter motor when used with vehicles that have crank triggered ignition systems or

distributors with locked advances and 30 or more degrees of timing. However, there are applications

where the start retard is either not needed or not wanted. For example, motors with radical camshaft

profiles, large carbs and timing in the 15 to 25 degree BTDC range (Pro Mod motors, for example) may

experience lean-mixture backfiring during startup if the retard feature is active, especially if the temperature is colder than usual.

Current production versions of the HYFIRE® VIIC AND VIIS have a yellow wire loop which comes out of the

back of the ignition box. Cutting this loop eliminates the start retard. Earlier versions of the ignition dont

have this feature, but the start retard can still be shut off. You must either send your ignition in to our service

department for modification, or, if you are attending an NHRA National event, you can bring your ignition to

our race support trailer and have it modified.

CUT YELLOW WIRE LOOP TO

ELIMINATE START RETARD

AFTER CUTTING YELLOW WIRE,

USE SHRINK TUBING TO INSULATE

EXPOSED ENDS

Loading...

Loading...