Page 1

WINDOW

RPM ACTIVATED SWITCH

PART NO. 628

INSTALLATION INSTRUCTIONS

Parts Included in this kit:

1 RPM Activated Switch Part No.628

1 “U” shaped crimp-on wire ter minal

1 #6 x 1⁄4" sheet metal screw

2 #8 x 1⁄ 2" sheet metal screws

General Information...............................................................1

Mounting Procedure..............................................................2

Wiring Procedure...................................................................2

RPM and Cylinder Setting Procedure....................................3

Wiring Diagrams for the RPM Activated Switch

Connecting to a HYFIRE®IV.................................................5

Connecting to a HYFIRE®VII...............................................6

Connecting to relays with a HYFIRE®VII.............................7

CONTENTS

Connecting to a Timing Retard............................................8

Connecting to a Timing Control...........................................8

Connecting to a Light...........................................................8

Connecting to an Electric (Shifter) Solenoid.......................9

Connecting to a Nitrous System........................................10

Connecting to a Nitrous System and Timing Retard.........10

Shifnoid Wiring..................................................................11

The Mallory 628 Window RPM Switch is an RPM switch that is triggered from the tach terminal available on most

aftermarket performance ignitions. It will not only activate at a particular RPM, but can also be set to de-activate

at a second, higher, RPM. It can be used on 4, 6 (even-fire only), and 8 cylinder engines. NOTE: The Mallory 628

CANNOT be triggered from points or electronic distributor. It must be triggered from a tach output terminal.

The 628 features two independent sets of switch contacts that switch other devices on or off when the selected

RPM is reached. These contacts draw a maximum current of 5 amps. To switch more than 5 amps, you must use

the RPM Activated Switch output to drive a high current relay, such as a horn or headlight (see illustrations).

NOTE: The switch contacts are NOT connected electrically. This allows you to turn one circuit on and another off at the same RPM.

GENERAL INFORMATION

®

MOUNTING PROCEDURE

Step 1

Disconnect the battery (–) cable to cut power to the system.

Step 2

Mount the unit in an area away from hot engine components or extreme heat, such as exhaust manifolds, and

away from moving parts, such as fans, belts, and linkages.

Step 3

Mount the unit using supplied #8 x 1⁄2" sheet metal screws.

Page 2

2

WIRING PROCEDURE

Step 1

Connect the BLACK WIRE to engine or chassis ground. You can use the supplied “U” shaped terminal and #6 x

1⁄ 4" sheet metal screws to make this connection. If you are connecting the RPM Activated Switch to an aftermarket ignition system such as a Mallory HYFIRE®, use the same grounding location that the ignition uses. See

Figures 4-9, pages 7-12.

Step 2

Connect the RED WIRE to a 12-volt power supply, such as the ignition switch. You can use the same wire that

provides power for your ignition as long as a ballast resistor is not wired in series with it.

NOTE: Do NOT connect the RED WIRE to the coil (+) terminal. Connect it to the wire coming directly from the ignition switch. If

your vehicle is equipped with loom resistance wire, you must provide an alternate power connection to the

red wire.

Step 3

The GREEN WIRE must be connected to the ignition system tach output.

• When using a Mallory ignition system, connect the GREEN WIRE to the TACH terminal. See Figures 2, 3

and 4.

• When using an aftermarket ignition with a TACH output, connect the GREEN WIREto the TACH terminal.

Check manufacture’s ignition instructions to find this location.

• Other aftermarket ignitions - Connect the GREEN WIRE to the tachometer lead terminal. Check manufacturer’s ignition instructions to find this location.

Step 4

To connect a device that you want to switch ON at the RPM setting you’ve selected, such as a shift light, connect

one ORANGE WIRE to the device and the other ORANGE WIRE to a 12-volt power supply. Connect the remaining wire from the device to a ground. See Figure 5, page 8.

Step 5

To connect a device that you want to switch OFF at the RPM setting you’ve selected, such as a nitrous solenoid,

connect one PURPLE WIRE to the device and the other PURPLE WIRE to a 12-volt power supply. Connect the

remaining wire from the device to a ground. See Figure 6, page 9.

Step 6

Secure all wires to prevent contact with extreme heat, sharp objects, or moving devices, such as fans, belts, and

linkages.

Step 7

Recheck all wires and connections to ensure that they are correct before applying power.

Step 8

Reconnect the battery (–) terminal cable. Start engine and check operation of the RPM Activated Switch.

Page 3

3

RPM AND CYLINDER SETTING PRODEDURE

The Mallory Window RPM switch has two RPM settings: a lower RPM to activate the switch, and a higher RPM

to de-activate the switch. For example, suppose you have a nitrous system installed. You might want the nitrous

to only come on above a certain RPM, but to protect the engine, you want to shut it off at an RPM just above your

shift point.

Step 1

Remove the four screws that hold the top cover in place, and remove the cover.

Step 2

If you want 4 or 6 cylinder operation, click the 4 or 6 cylinder switch on the left side to the "ON" position. For 8

cylinder operation, both switches should be off.

Step 3

Set the lower and upper RPM values by selecting an RPM value in the thousands (left-hand switch) and an RPM

value in the hundreds (right-hand switch). Note that on the switch for the RPM value in the thousands A=10,000;

B=11,000 and C=12,000. NOTE: For proper operation, the upper RPM switch should be set at least 200 RPM

higher than the lower RPM switch. The RPM range is 1000 to 12,700 RPM for the low side, and 12,900 RPM

for the high side. If you do not want to use the high-side deactivation feature, set the high-side switches to 12,900

(C9).

Step 4

Replace the top cover and re-attach the screws.

HIGH RPM

LOW RPM

1000's 100's

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

ON

ON

4 CYL

6 CYL

FIGURE 1

Page 4

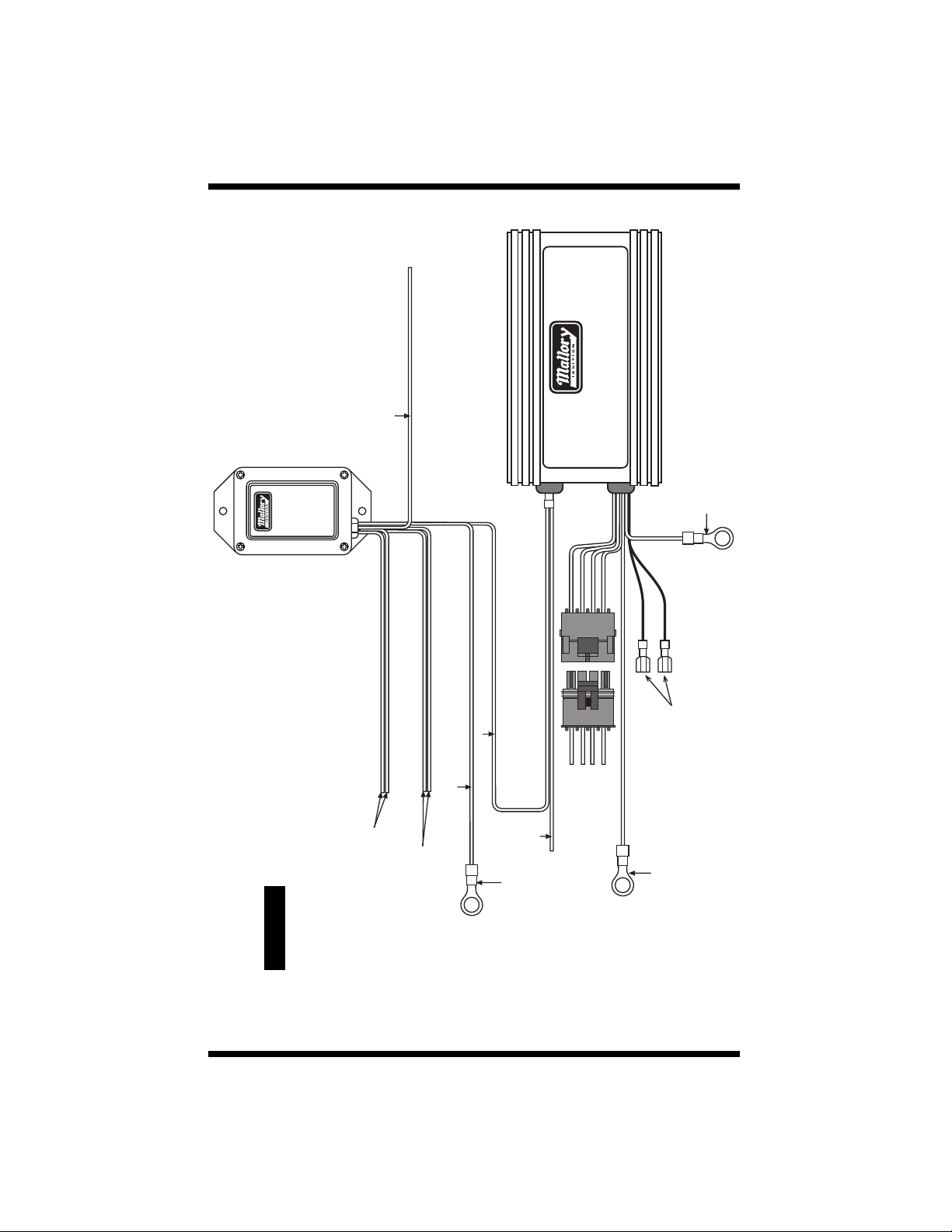

CONNECT THESE ORANGE WIRES TO A

DEVICE TO BE TURNED ON

AT A SELECTED RPM

CONNECT THESE PURPLE WIRES TO A

DEVICE TO BE TURNED OFF AT A SELECTED

RPM

RED

TO 12 VOLT SOURCE DO NOT

CONNECT TO COIL +

BLACK

TO ENGINE BLOCK

OR CHASSIS GROUND

TO TACH

CONNECT THIS HARNESS ACCORDING TO

THE HYFIRE

®

INSTRUCTIONS APPLICABLE

TO THE HYFIRE

®

, DISTRIBUTOR AND COIL

BEING USED

TO BATTERY +

TERMINAL

USED FOR MAGNETIC

PICKUP DISTRIBUTOR

OR CRANK TRIGGER

TO ENGINE BLOCK

OR CHASSIS GROUND

HYFIRE

®

IV

IGNITION SYSTEM

®

GREEN

PART NO. 628

WINDOW

RPM

ACTIVATED

SWITCH

®

RPM ACTIVATED SWITCH WITH HYFIRE

®

IV

4

FIGURE 2

Page 5

5

0 7 5

GREEN

BLACK

ORANGE

PURPLE

RED

TO ENGINE BLOCK

OR CHASSIS GROUND

DO NOT CONNECT TO

COIL + TERMINAL

TO TACH

CONNECT IGNITION COIL AND DISTRIBUTOR/TRIGGER WIRES ACCORDING TO THE

HYFIRE VII INSTRUCTIONS APPLICABLE TO THE DISTRIBUTOR/TRIGGER BEING USED

®

DO NOT CONNECT TO COIL +

CONNECT THIS WIRE TO A

SWITCHED 12 VOLT SOURCE.

SWITCH MUST BE CAPABLE

OF SWITCHING ALL OF THE

CURRENT FROM THE IGNITION

AND DEVICE(S).

THE IGNITION MAY DRAW UP

TO 1/2 AMP. MINIMUM OF 18 GA

WIRE SHOULD BE USED.

CONNECT THESE PURPLE WIRES TO A DEVICE

TO BE TURNED OFF AT A SELECTED RPM.

NOTE:

RELAYS ARE REQUIRED IF THE DEVICE

BEINGSWITCHED DRAWS MORE THAN 5 AMPS.

CONNECT THESE ORANGE WIRES TO A DEVICE

TO BE TURNED ON AT A SELECTED RPM.

PART NO. 628

WINDOW

RPM

ACTIVATED

SWITCH

®

RPM ACTIVATED SWITCH WITH HYFIRE

®

VII

FIGURE 3

Page 6

0 7 5

STANDARD

STANDARD

GREEN

BLACK

ORANGE

PURPLE

RED

TO ENGINE BLOCK

OR CHASSIS GROUND

TO ENGINE BLOCK

OR CHASSIS GROUND

DO NOT CONNECT TO

COIL + TERMINAL

TO TACH

CONNECT IGNITION COIL AND DISTRIBUTOR/TRIGGER WIRES ACCORDING TO THE

HYFIRE VII INSTRUCTIONS APPLICABLE TO THE DISTRIBUTOR/TRIGGER BEING USED

®

DO NOT CONNECT TO COIL +

CONNECT THESE WIRES TO A

SWITCHED 12 VOLT SOURCE.

SWITCH MUST BE CAPABLE

OF SWITCHING ALL OF THE

CURRENT FROM THE IGNITION

AND DEVICE(S).

THE IGNITION MAY DRAW UP

TO 1/2 AMP. MINIMUM OF 18 GA

WIRE SHOULD BE USED.

CONNECT THIS WIRE TO THE DEVICE

TO BE TURNED ON AT A SELECTED

RPM. CONNECT THE OTHER WIRE

FROM THE DEVICE TO THE GROUND.

CONNECT THIS WIRE TO THE DEVICE

TO BE TURNED ON AT A SELECTED

RPM. CONNECT THE OTHER WIRE

FROM THE DEVICE TO THE GROUND.

NOTE:

RELAYS ARE REQUIRED IF THE DEVICE

BEINGSWITCHED DRAWS MORE THAN 5 AMPS.

THES RELAYS ARE SHOWN AS EXAMPLES

ONLY. OTHER RELAYS MAY BE USED SUCH AS

BLUE STREAK PART NO. RY-48.

PART NO. 628

WINDOW

RPM

ACTIVATED

SWITCH

®

RPM ACTIVATED SWITCH AND RELAYS WITH HYFIRE

®

VII

6

FIGURE 4

Page 7

7

PURPLE WIRES

(NOT USED)

ORANGE WIRES (NORMALLY OPEN CLOSES/“ON” AT THE RPM SETTING)

TO 12V SOURCE

ORANGE 18AWG

WIRE

PART NO. 618-1

HIGH SPEED RETARD

PART NO. 628

PART NO. 628

PART NO. 628

PURPLE

WIRES

(NOT

USED)

RED, GREEN AND BLACK

WIRES: SEE PAGES 5-12

ORANGE WIRES (NORMALLY OPEN CLOSES/“ON” AT THE RPM SETTING)

TO 12V SOURCE

ORANGE 18AWG

WIRE

(#21)

REMOTE TIMING CONTROL

IGNITION SYSTEM

PART NO. 631

PURPLE WIRES

(NOT USED)

RED, GREEN AND

BLACK WIRES: SEE

TO 12V SOURCE

ORANGE WIRES

TO 12V SOURCE

ORANGE WIRES

ORANGE WIRES:

OR

NOTE: TO TURN LIGHTS “OFF” AT RPM SETTING - EXCHANGE THE ORANGE WIRES AND THE PURPLE WIRES.

RED, GREEN AND BLACK

WIRES: SEE PAGES 5-12

TIMING RETARD “ON”AT RPM SETTING

TIMING CONTROL

“ON”AT RPM SETTING

LIGHT

“ON”AT RPM SETTING

FIGURE 5

Page 8

MANUAL SHIFTING: TURN

SWITCH “OFF”

TOGGLE SWITCH

PART NO. 26074

PART NO. 628

PAR T NO . 628

PAR T NO . 628

TO 12V SOURCE

ORANGE OR PURPLE WIRES

RED, GREEN AND BLACK

WIRES: SEE PAGES 5-12

RED, GREEN AND BLACK

WIRES: SEE PAGES 5-12

RED, GREEN AND BLACK

WIRES: SEE PAGES 5-12

MANUAL SHIFTING: TURN SWITCH “OFF”

TOGGLE SWITCH

PART NO. 26074

TO 12V SOURCE

ORANGE OR PURPLE WIRES

MANUAL SHIFTING: TURN SWITCH “OFF”

TOGGLE SWITCH

TO 12V SOURCE

ORANGE OR PURPLE WIRES

HR - 106

1 3 5

USE ORANGE WIRES TO TURN

“ON” AT LOW RPM SETTING.

USE PURPLE WIRES TO TURN

“OFF” AT LOW RPM SETTING.

USE ORANGE WIRES TO TURN

“ON” AT LOW RPM SETTING.

USE PURPLE WIRES TO TURN

“OFF” AT LOW RPM SETTING.

USE ORANGE WIRES TO TURN

“ON” AT LOW RPM SETTING.

USE PURPLE WIRES TO TURN

“OFF” AT LOW RPM SETTING.

ELECTRIC (SHIFTER) SOLENOID

8

FIGURE 6

Page 9

PART NO. 628

RED, GREEN AND BLACK

WIRES: SEE PAGES 5-12

NOTE: THE NITROUS SYSTEM WILL TURN “OFF” AT UPPER RPM SETTING.

PURPLE WIRES

(NOT USED)

ORANGE WIRES

TO 12V SOURCE:

“ON” ONLY WITH THE NITROUS

ARMING SYSTEM

HR - 106

GAS

SOLENOID

NITROUS

SOLENOID

PART NO. 628

TO 12V SOURCE:

“ON” ONLY WITH THE NITROUS

ARMING SYSTEM

RED, GREEN AND BLACK

WIRES: SEE PAGES 4-11

PURPLE WIRES

(NOT USED)

NOTE: THE NITROUS SYSTEM WILL TURN “OFF” AT UPPER RPM SETTING.

HR - 106

GAS

SOLENOID

NITROUS

SOLENOID

ORANGE

18AWG WIRE

PART NO. 618-1

HIGH SPEED RETARD

ORANGE WIRES

9

NITROUS SYSTEM “ON” AT RPM SETTING

NITROUS SYSTEM AND TIMING RETARD

“ON” AT RPM SETTING

FIGURE 7

FIGURE 8

Page 10

10

PURPLE WIRES

NOT USED

PART NO. 628

BLACK WIRE

GROUND

GREEN WIRE

TACH TERMINAL

RED WIRE

12V IGN. SWITCH

ORANGE WIRES

OPTIONAL

SWITCH

B&M PRO

RATCHET SHIFTER

NEUTRAL SAFETY

TO 12V

TO STARTER

SWITCH

TO 12V

SHIFNOID

INTERFACE RELAY

COMMON

NORMALLY OPEN

NORMALLY CLOSED

87A

87

(NOT USED)

86 85

30

SHIFNOID WIRING

FOR A B & M RATCHET SHIFTER

W/SN5070 SOLENOID

FIGURE 9

Page 11

11

Page 12

MALLORY IS A DIVISION OF THE MR. GASKET PERFORMANCE GROUP

550 MALLORY WAY, CARSON CITY, NV 89701

(775) 882-6600 FAX (775) 887-4326

www.mrgasket.com

FORM #1471

(REV. A) 7/99

MADE IN U.S.A.

PRINTED IN U.S.A.

Loading...

Loading...