Page 1

1MALLORY TECHNICAL SUPPORT (775) 882-6600 www.malloryracing.com

E-SPARK™ BREAKERLESS CONVERSION KIT

FOR MALLORY POINT DISTRIBUTORS

NOTE: This product is legal in California only for racing vehicles which may never be operated upon a highway.

INSTALLATION INSTRUCTIONS

FORM 1673 1/07

APPLICATIONS

Part No. 61010M For Left-Hand Rotation 27 Series

Mallory 8 cylinder point automotive

vacuum advance equipped

distributors which use a standard

stack cap (Part no. 209).

Part No. 61011M For Right-Hand Rotation 27

Series Mallory 8 cylinder point

automotive vacuum advance

equipped distributors which use a

standard stack cap (Part no. 209).

Refer to the Mallory Catalog’s distributor application section

if you need a to determine your distributor’s rotation.

PARTS INCLUDE IN THIS KIT:

1 E-Spark™ Plate Assembly

1 Wire Harness

1 Rotor/Shutter Wheel Assembly (PN 322)

1 Wire Connector

1 Grommet

1 Rubber Plug

1 Thrust Button

WARNING

You must install the E-Spark™ Conversion Kit

exactly as shown in these instructions. After the

kit is installed—and before you start the engine—

check all wiring again. Mis-wiring will cause the

E-Spark™ Ignition to fail immediately.

INSTALLATION

Step 1

Rotate the engine to the #1 cylinder firing position.

Remove the distributor cap and note the position of

the rotor. You will need to reference this when you

reinstall the distributor. Remove the distributor from

the engine.

Step 2

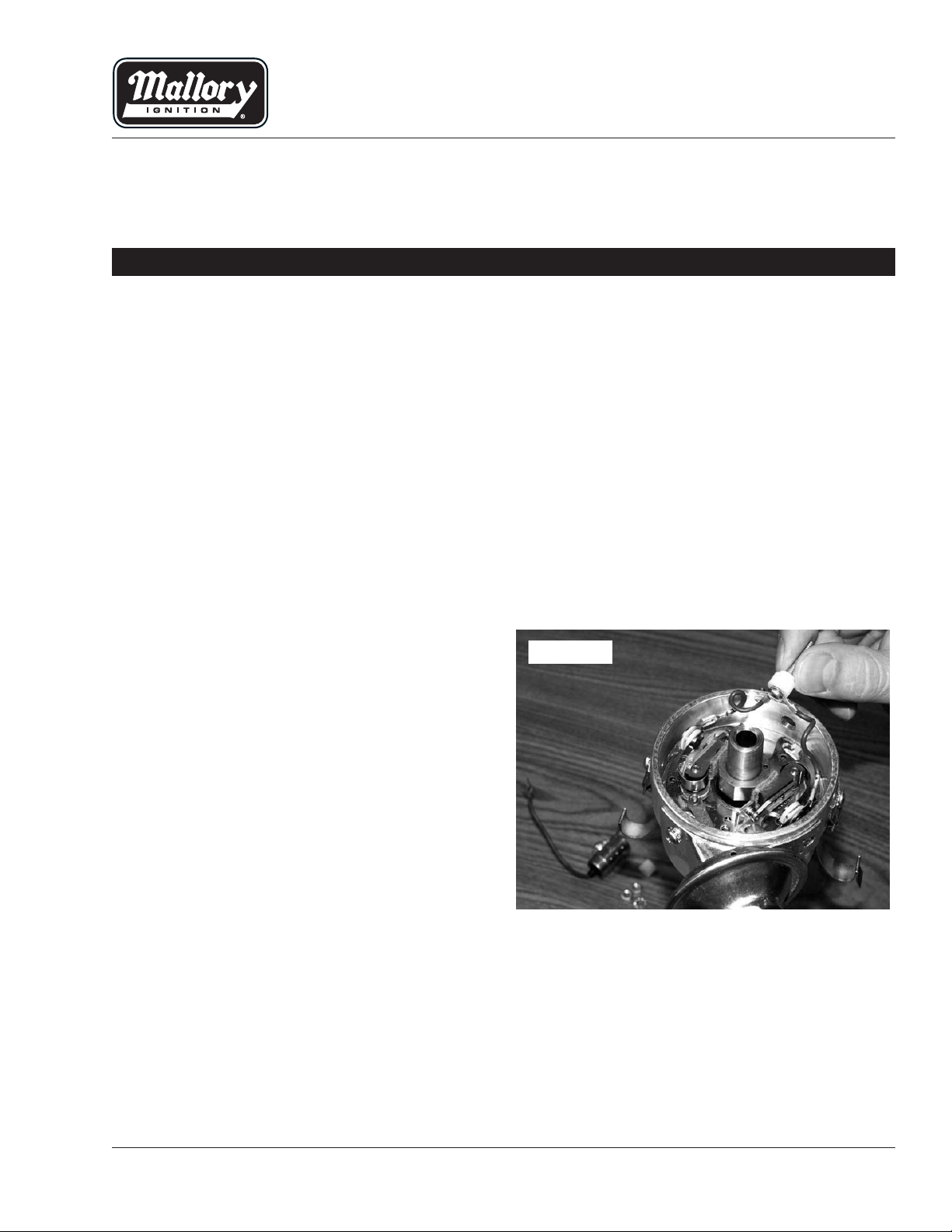

Remove the rotor, and then remove the condenser

and bracket. Remove the insulators (Figure 1).

IMPORTANT

All kits listed below must be used with an ignition ballast resistor (or loom resistance wire) to prevent

module failure. If your vehicle is not equipped with a ballast resistor or loom resistance wire, Mallory

Ballast Resistor (Part No. 700) or Mallory Coils 29219, 29450 or 30450 (which are internally ballasted)

may be used.

FIGURE 1

Page 2

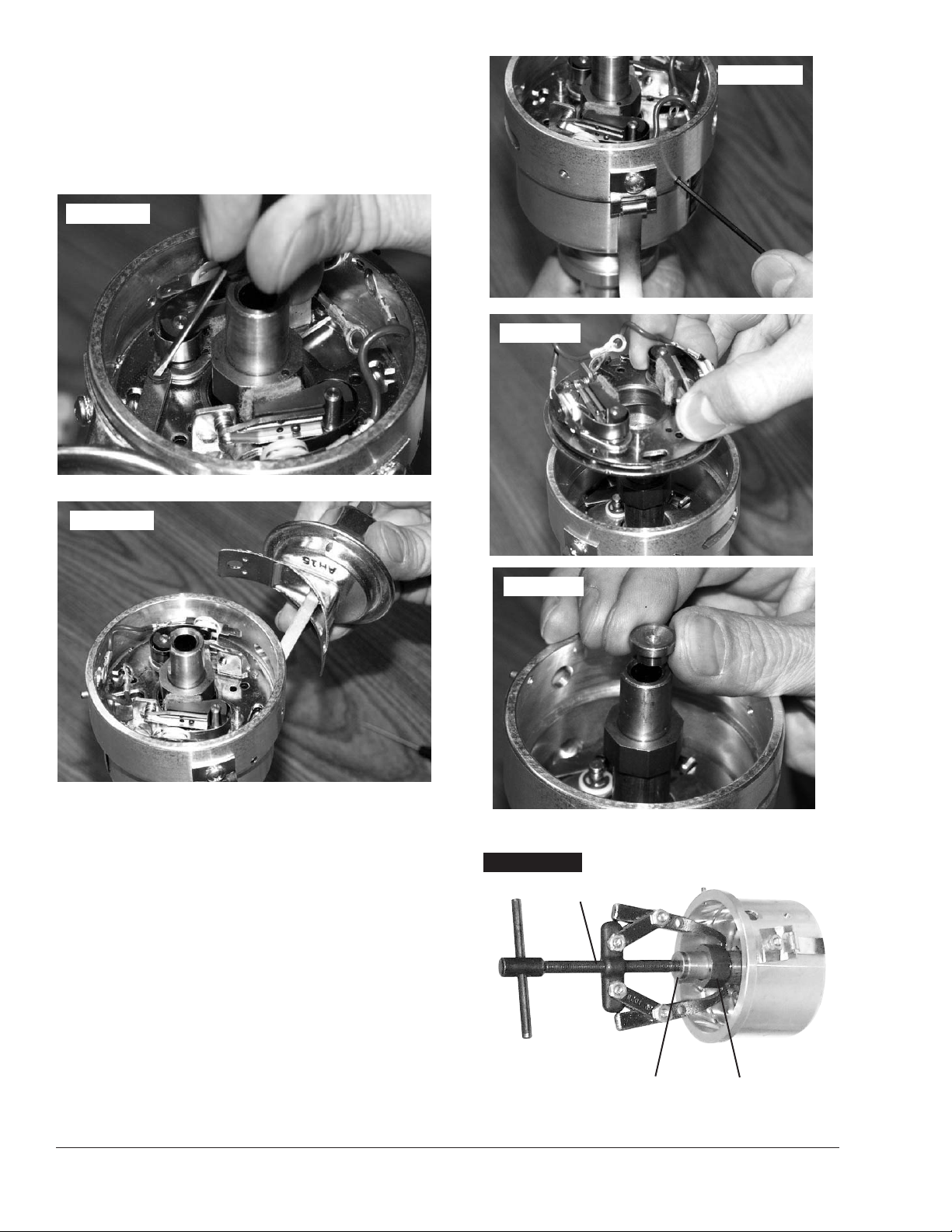

Step 3

Remove the e-clip from the vacuum advance arm

(Figure 2). Remove the 2 screws holding the vacuum

advance chamber from the outside of the distributor

housing and remove the vacuum chamber (Figure 3).

You will re-install it later so do not discard it.

Step 4

Using a 5/64” Allen wrench, loosen the 2 set screws

that hold the point plate assembly into the distributor

housing (Figure 4). You do not need to remove them

completely. Lift the point plate assembly out of the

housing (Figure 5).

Step 5

Place the thrust button into the end of the distributor

shaft (Figure 6). Using a 2 or 3 arm puller and

remove the point cam from the rotor sleeve (Figure 7).

WARNING - Do not try to remove the cam by

prying on it with a screwdriver(s). This will

damage the advance assembly.

MALLORY IGNITION 550 MALLORY WAY, CARSON CITY, NV 89701

2

FIGURE 4

FIGURE 5

FIGURE 6

FIGURE 7

Puller

Thrust Button

Remove button

after cam has

been removed

Cam

FIGURE 3

FIGURE 2

Page 3

Step 6

This step requires you to drill a 3/8” hole in the

distributor housing to accommodate the new wiring

harness. Measure 1” from the existing insulator hole

and the same distance down from the top of the

housing and mark the distributor housing. You will be

slightly offset from the cap locating pin. With a paper

towel inside the housing for shavings, drill the 3/8”

hole now (Figure 8).

Step 7

Clean out any remaining metal shavings left from the

drilling operation using a vacuum, brush, etc. Do not

wash out the housing with the shaft assembly in

place or you will wash the lubrication out of the

centrifugal advance and cause it to fail. If necessary,

you can remove the shaft as an assembly then clean

out the housing.

Step 8

Lower the new plate assembly into the housing

(Figure 9). Use the vacuum advance arm to

determine the position. Tighten the 2 set screws,

reinstall the vacuum advance with the 2 external

screws. Reinstall the e-clip. Use Figure 10 for reference.

Step 9

Install the supplied grommet into the new hole you

drilled (Figure 11) and route the wiring as shown

in Figure 10.

3MALLORY TECHNICAL SUPPORT (775) 882-6600 www.malloryracing.com

FIGURE 8

FIGURE 9

FIGURE 10

Page 4

MALLORY IGNITION 550 MALLORY WAY, CARSON CITY, NV 897014

Step 10

Insert the rubber plug into the existing grommet hole

(Figure 12). This is a tight fit and you may need to pull

it through. Once it is in position, cut the bushing off

flush on the inside (Figure 13).

Step 11

Install the wire grommet. Lubricate the wires with light

oil. Run the wires through the grommet and out of the

distributor housing (see Figure 14).

FIGURE 11

FIGURE 12

FIGURE 13

FIGURE 14

Grommet

E-SPARK Plate

Assembly

Connector

Page 5

5MALLORY TECHNICAL SUPPORT (775) 882-6600 www.malloryracing.com

Step 12

Install the connector onto the wires. Be sure the wires

are in the correct positions (see Figure 15).

Step 13

Install the rotor shutter assembly. Make sure the

rotor/shutter does not rub on the module or wires.

Step 14

Reinstall the distributor using the rotor for a reference.

Reinstall the cap.

Step 15

Connect the wire harness to the connector. Connect

the 3 wires to the correct locations, as shown in

Figures 16 and 17.

Step 16

Set the ignition timing. Start the engine and

recheck timing.

FIGURE 15

Red

Brown

Green

Female Connector

Index Rib

Distributor Wire Harness

Red

Brown

Green

▼

+

COIL

–

FIGURE 16

12V/Ignition

Switch

Distributor Wire Harness

Part No. 29349

Ignition Ballast

Resistor

All other wires originally connected

to the coil (+) terminal

Ignition Module

Female Connector

Engine

Ground

Brown

Green

Red

NOTE: The purpose of an ignition ballast

resistor between the ignition switch (12V)

and the ignition coil positive terminal is to

restrict current flow through the ignition

coil. Failure to use an ignition ballast

resistor will eventually destroy the Ignition

Module.

EXCEPTION: If your vehicle is equipped

with a HYFIRE

®

Electronic Ignition Control

or similar aftermarket ignition control, use

the wiring procedures stated in the instructions

included with the ignition control.

To prevent false triggering and possible

premature ignition failure, you must use

suppression type (carbon core, spiral

core, or radio suppression core) spark

plug wire.

DO NOT USE SOLID CORE (COPPER

CORE OR STAINLESS STEEL CORE)

SPARK PLUG WIRE WITH ANY

ELECTRONIC IGNITION SYSTEM.

EQUIPPED WITH EXTERNAL BALLAST RESISTOR

Page 6

MALLORY IGNITION 550 MALLORY WAY, CARSON CITY, NV 897016

COIL

–

+

EQUIPPED WITH LOOM RESISTANCE WIRE

12V/Ignition

Switch

Engine

Ground

Brown

Green

All other wires originally connected

to the coil (+) terminal

Loom Resistance

Wire

Red

Distributor Wire Harness

Part No. 29349

Ignition Module

Female Connector

FIGURE 17

NOTE: The purpose of loom resistance

wire between the ignition switch (12V) and

the ignition coil positive terminal is to

restrict current flow through the ignition

coil. Failure to use an ignition ballast

resistor will eventually destroy the Ignition

Module.

EXCEPTION: If your vehicle is equipped

with a HYFIRE

®

Electronic Ignition Control

or similar aftermarket ignition control, use

the wiring procedures stated in the instructions included with the ignition control.

To prevent false triggering and possible

premature ignition failure, you must use

suppression type (carbon core, spiral

core, or radio suppression core) spark

plug wire.

DO NOT USE SOLID CORE (COPPER

CORE OR STAINLESS STEEL CORE)

SPARK PLUG WIRE WITH ANY

ELECTRONIC IGNITION SYSTEM.

Page 7

7MALLORY TECHNICAL SUPPORT (775) 882-6600 www.malloryracing.com7

COIL

–

+

12V/Ignition

Switch

Engine

Ground

Brown

Green

All other wires originally connected

to the coil (+) terminal

Red

Distributor Wire Harness

Part No. 29349

Ignition Module

Female Connector

FIGURE 18

EQUIPPED WITH 29219, 29450, OR 30450 COILS ONLY

To prevent false triggering and possible

premature ignition failure, you must use

suppression type (carbon core, spiral core,

or radio suppression core) spark plug wire.

DO NOT USE SOLID CORE (COPPER

CORE OR STAINLESS STEEL CORE)

SPARK PLUG WIRE WITH ANY

ELECTRONIC IGNITION SYSTEM

Page 8

8 www.malloryracing.com

MALLORY IS A DIVISION OF THE MR. GASKET PERFORMANCE GROUP

10601 MEMPHIS AVE. #12, CLEVELAND, OH 44144

216.688.8300 FAX 216.688.8306

FORM 1673

Made in U.S.A.

Printed in U.S.A.

FROM COIL (–) TERMINAL

SOLDER AND INSULATE

SOLDER AND INSULATE

2 EA. 400V 3A DIODES IN SERIES

(RADIO SHACK PART NO. 276-1144)

NOTE POSITION OF BANDS ON DIODES

2 EA. 4.7K, 1/2W RESISTORS IN PARALLEL

(RADIO SHACK PART NO. 271-1124

GRAY WIRE

TO SHIFT BOX

TO ENGINE

GROUND

FIGURE 19

FOR MARINE USE ONLY

After installing your Mallory Electronic

Distributor, the Electronic Shift Assist

(ESA) circuit in your boat must be function

tested.Shifting into or out of gear can be

difficult or impossible if the ESA circuit is

malfunctioning or missing. If you

encounter shifter related problems with

your boat after installing any Mallory distributor, contact the Mallory Technical

Service Department at 216.688.8300.

All Mallory Marine Electronic Ignition Systems in

Outboard Marine Corp (OMC) applications with a shift

box require the gray wire from the coil to the shift box

be modified as follows:

The gray wire from the coil (–) terminal triggers the

shift box. The gray wire should be cut or disconnected at the coil terminal so that the components

shown here can be inserted. Solder all connections

and confirm correct operation, then insulate well,

especially if the boat is being used in salt water.

Loading...

Loading...