Mallory Ignition 585 User Manual

INSTALLATION INSTRUCTIONS

®

HYFIRE® V ELECTRONIC

IGNITION CONTROL

PARTS INCLUDED:

1 HYFIRE® V Ignition Control

4 #10 Sheet Metal Screws

2 Wire Ties

2 Ring Terminals, Insulated

1 1-amp/100 volt Diode

2 1/4" Tab Terminals

FORM 1051 (REV. A) 10/01

PART NO. 585

5 1/4" Male Disconnects

5 1/4" Female Disconnects

1 Rubber Grommet

2 Cable Clamps

1 Magnetic Pickup Extension

Battery

The HYFIRE® V Series Ignition Control operates on any negative

ground, 12 volt electrical system with a distributor. It will also work

with 16 volt batteries and can withstand a momentary spike of 24 volts

in case of jump starts. This system delivers full voltage with a supply

of 10-18 volts, and operates with a supply voltage as low as 8 volts.

If your application does not use an alternator, allow at least 15 amp/

hour for every half hour of operation. If you crank the engine with the

same battery or other accessories, such as an electric fuel or water

pump, increase the amp/hour rating

Coils

For optimum performance with your HYFIRE® V Ignition Control, we

recommend Mallorys PROMASTER® Coil P/N 29440. Mallorys

PROMASTER® Coil P/N 29625 can also be used, as well as most

stock coils or aftermarket coils designed as stock replacements.

NOTE: Do not use Mallorys PROMASTER® Coil P/N 28880.

Tachometers

The yellow wire on the HYFIRE® V Ignition Control provides a trigger

signal for tachometers, shift lights, or other add-on RPM activated

devices. This wire produces a 12 volts square wave signal with a 20%

duty cycle.

Some vehicles with factory tachometers may require a tach adapter

to work with the HYFIRE® V Ignition Control. If your GM vehicle uses

an inline filter, it may cause the tach to drop to zero on acceleration. If

this occurs, bypass the filter. For more information on tachometers,

see page 4.

Spark Plugs

Using the correct spark plug and heat range is important for optimum

performance. Because there are so many variables to consider, we

suggest starting with your engine manufacturers spark plug recommendation. From there, you can experiment with small changes in

plug gap and heat range to obtain the best performance from your

engine. We also recommend non-resistor spark plugs.

Spark Plug Wires

High quality, spiral wound wire and proper routing are essential to the

operation of the HYFIRE® V Ignition Control. This type of wire provides a good path for the spark to follow while minimizing electromagnetic interference (EMI).

NOTE: Do not use solid core spark plug wires with the HYFIRE®V

Ignition Control.

Routing

Wires should be routed away from sharp edges, moving objects, and

heat sources. Wires that are next to each other in the engines firing

order should be separated. For example, in a Chevy V8 with a firing

order of 1-8-4-3-6-5-7-2, the #5 and #7 cylinders are positioned next

to each other on the engine as well as in the firing order. Voltage from

the #5 wire could jump to the #7 wire. This could cause detonation

and engine damage.

For added protection against cross-fire, Mallory offers PRO SHIELD

insulated sleeving. PRO SHIELD is a glass woven, silicone coated

protective sleeve that slides over your plug wires. It also helps reduce

damage from heat and sharp objects.

Foreign Vehicles

Because of modern fuel injection systems, some foreign vehicles may

require a tachometer/fuel injection adapter to work with the HYFIRE

V Ignition Control.

NOTE: Do not install the HYFIRE® V Ignition Control in any vehicle that is originally equipped with a CD ignition control.

®

1MALLORY TECHNICAL SUPPORT (775) 882-6600 tech@mrgasket.com

MISCELLANEOUS INFORMATION

WIRE FUNCTIONS

Sealing

Do not attempt to seal the HYFIRE® V Ignition Control. All of the circuits of a HYFIRE® V receive a conformal coating of sealant that protects the electronics from moisture. Sealing the HYFIRE® V will not

allow any moisture that seeps in through the grommets to drain and

may result in corrosion.

Welding

To avoid any damage to the HYFIRE® V Ignition Control when welding

on the vehicle, disconnect the positive (red) and negative (black) power

cables of the HYFIRE® V Ignition Control. It is also a good idea to

disconnect the tachometer ground wire as well.

Distributor Cap and Rotor

As with any high performance ignition system, we recommend installing a new distributor cap and rotor when installing the HYFIRE® V

Ignition Control. Be sure the cap is clean inside and out, especially the

terminals and rotor tip.

HYFIRE® V Diagnostic LED

On the end panel of your HYFIRE® V Ignition there is a small hole.

Behind this hole is a red LED indicator. The LED will flash when receiving a proper trigger signal from the vehicle. If, after a normal powerup, the LED doesnt flash when cranking the engine, you should check

your triggering circuit for problems. If the LED flashes when the engine is cranked, but there is still no spark, the problem lies somewhere else.

MOUNTING

The HYFIRE® V Ignition Control can be mounted in any position. If

you mount it in the engine compartment, keep it away from moving

objects and heat sources. Do not mount the unit in a closed area,

such as the glovebox.

When you find a suitable location to mount the unit, make sure all

wires of the ignition reach their connections. Hold the ignition in place

and mark the location of the mounting holes. Use a 1/8" drill bit to drill

the holes. Use the supplied self-tapping screws to mount the box.

WIRING

Wire Length

All of the wires of the HYFIRE® V Ignition Control may be shortened

as long as quality connectors are used or soldered in place. To lengthen

the wires, use one size larger gauge wire (12 gauge for power leads,

16 gauge for all others). Use the proper connectors to terminate all

wires. All connections must be soldered and sealed.

Power Leads

The two heavy gauge wires (14 gauge) that deliver battery voltage to

the ignition:

Heavy Red Connects directly to the battery positive (+) terminal

or to a positive battery junction. It could also be connected to the positive side of the starter solenoid.

NOTE: Never connect this wire to the alternator.

Heavy Black Connects to frame or chassis ground.

Trigger and Coil Leads

Small Red Connects to a switched 12 volt source, such as the

ignition key.

Orange Connects to the positive (+) terminal of the coil.

NOTE: This is the only wire that makes electrical contact with the coil positive (+) terminal.

Small Black Connects to the negative () terminal of the coil

NOTE: This is the only wire that makes electrical contact with the coil positive () terminal.

Trigger Wires Either of two circuits will trigger the HYFIRE® V Igni-

tion Control: a points circuit (white wire) or a magnetic pickup circuit (violet and green wires).

NOTE: The two circuits will never be used

together.

White Connects to points, electronic ignition amplifier out-

put or to the green wire of a Mallory timing accessory. When this wire is used, the magnetic pickup

connector is not used.

Violet/Green These wires are routed together in one harness to

form the magnetic pickup connector. The connector

plugs directly into a Mallory distributor or crank trigger. It will also connect to factory magnetic pickups

or other aftermarket pickups. The violet wire is positive (+) and the green is negative (). When these

wires are used, the white wire is not used. Consult

the chart that shows the polarity of other common

magnetic pickups

Yellow Connects to the tachometer pickup wire.

FIGURE 1

Grounds

A poor ground connection can cause many frustrating problems. When

a wire is specified to go to ground, connect it to the chassis. Always

connect a ground strap between the engine and chassis. Connect

any ground wires to a clean, paint-free metal surface.

Ballast Resistor

If your vehicle has a ballast resistor in line with the coil wiring, it is not

necessary to bypass it. This is because the HYFIRE® V Ignition Control receives its main power directly from the battery.

MALLORY IGNITION 550 MALLORY WAY, CARSON CITY, NV 897012

DIAGNOSTIC

LED

ROUTING WIRES

Route all wires away from heat sources, sharp edges, and moving

objects. Route the trigger wires separate from the other wires and

spark plug wires. If possible, route them along a ground plane, such

as the block or firewall, which creates an electrical shield. The magnetic pickup wires should be routed separately and twisted together to

help reduce extraneous interference.

COMMON COLORS FOR MAG PICKUP WIRES

Distributor Mag + Mag

Mallory Crank Trigger Purple Green

Mallory Billet Competition Distributor,

Series Nos. 81 and 84 Orange Purple

Mallory COMP

Mallory Harness P/N 29040 Red Black

MSD Orange/Black Violet/Black

MSD Crank Trigger Orange/Black Violet/Black

Ford Orange Purple

Accel 46/48000 Series Orange/Black Violet/Black

Accel 51/61000 Series Red Black

Chrysler Orange/White Black

®

9000 Series Nos. 96-99 Orange Purple

PRESTART CHECKLIST

The only wires connected to the coil terminals should be the or-

ange connected to coil positive (+) and black connected to coil

negative ().

The small red wire is connected to a switched 12 volts source,

such as the ignition key.

Power leads are connected directly to the battery positive and nega-

tive terminals.

If youre not using an alternator, the battery should be connected

and fully charged.

The engine is equipped with at least one ground strap to the

chassis.

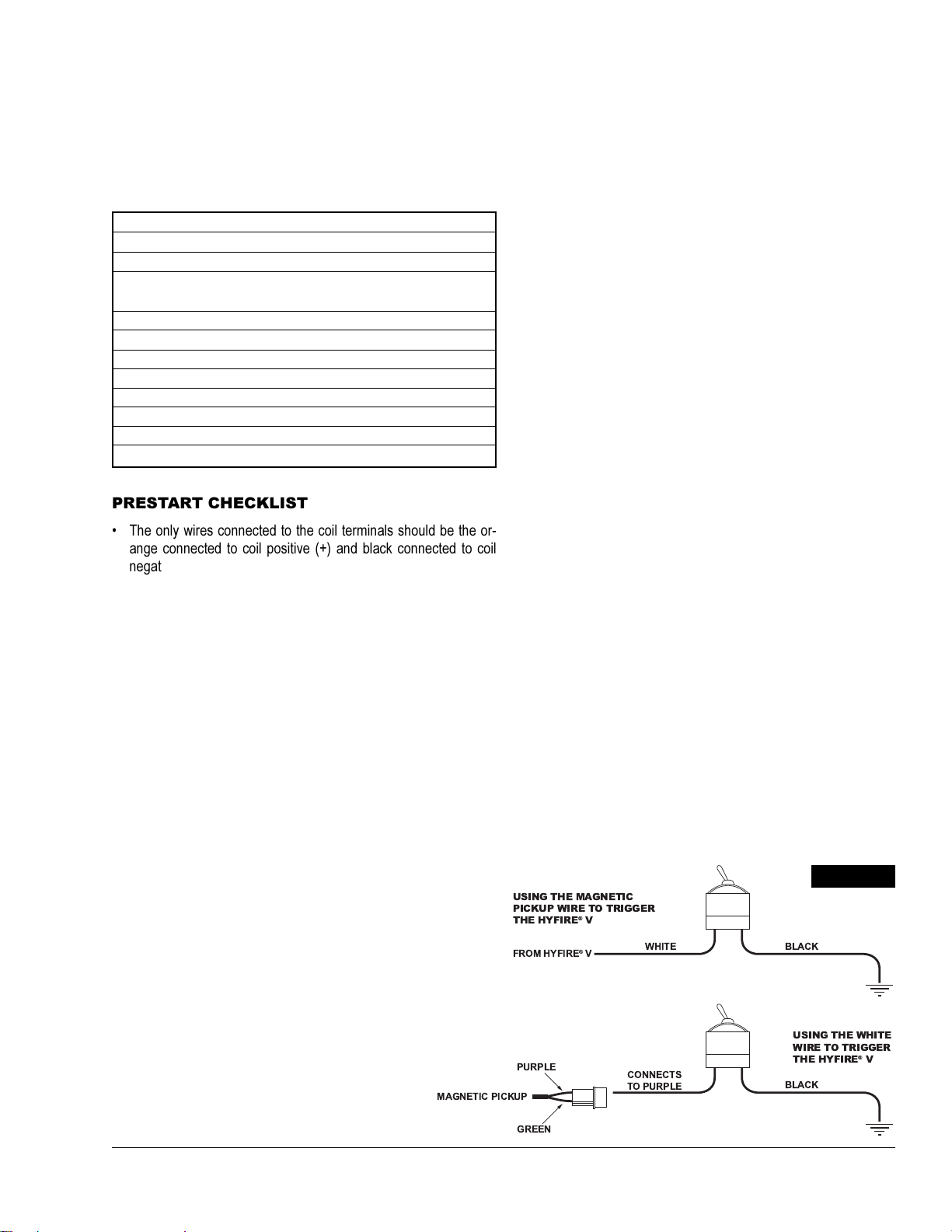

THEFT DETERRENT

The HYFIRE® V Ignition Control provides an easy way to install a theft

deterrent kill switch. See Figure 2.

TROUBLESHOOTING

This section offers several tests and checks you can perform to ensure proper installation and operation of the HYFIRE® V Ignition Control. If you experience a problem with your HYFIRE® V, first check for

proper installation and poor connections. You can eliminate many problems by checking these items. If you have any questions concerning

your HYFIRE® V Ignition Control contact the Mallory Technical Service Department at 775-882-6600, Monday through Friday, 8:00 am

to 5:00 pm Pacific time.

Tach/Fuel Adapters

If your tachometer does not operate correctly, you probably need a

Mallory tach adapter. Consult the Tachometer Compatibility List at

right for common tachometers and compatible tach adapters.

No-Run on Foreign Vehicles

Some foreign vehicles with fuel injection systems may require a tachometer/fuel injection adapter to run with the HYFIRE® V Ignition

Control. Often, the same trigger source is used to operate an ignition,

tachometer, and fuel injection. This results in a voltage signal that is

too low to trigger the fuel injection. A tach/fuel injection adapter will

usually solve this problem.

Inoperative Tachometers

If your tachometer fails to operate with the HYFIRE® V installed, you

may need a Mallory tach adapter. Before purchasing a tach adapter,

try connecting your tachometer trigger wire to the yellow wire of the

HYFIRE® V Ignition Control. This output produces a 12 volt, square

wave. If the tach still does not operate, you will need a tach adapter.

Two different tach adapters are available:

PN 29078 If you are using the magnetic pickup connector (green

and violet wires) to trigger the HYFIRE® V, you will need

this adapter.

PN 29074 If your tach was triggered from the coil negative termi-

nal (voltage trigger) and you are using the white wire

to trigger the HYFIRE® V, you will need this adapter.

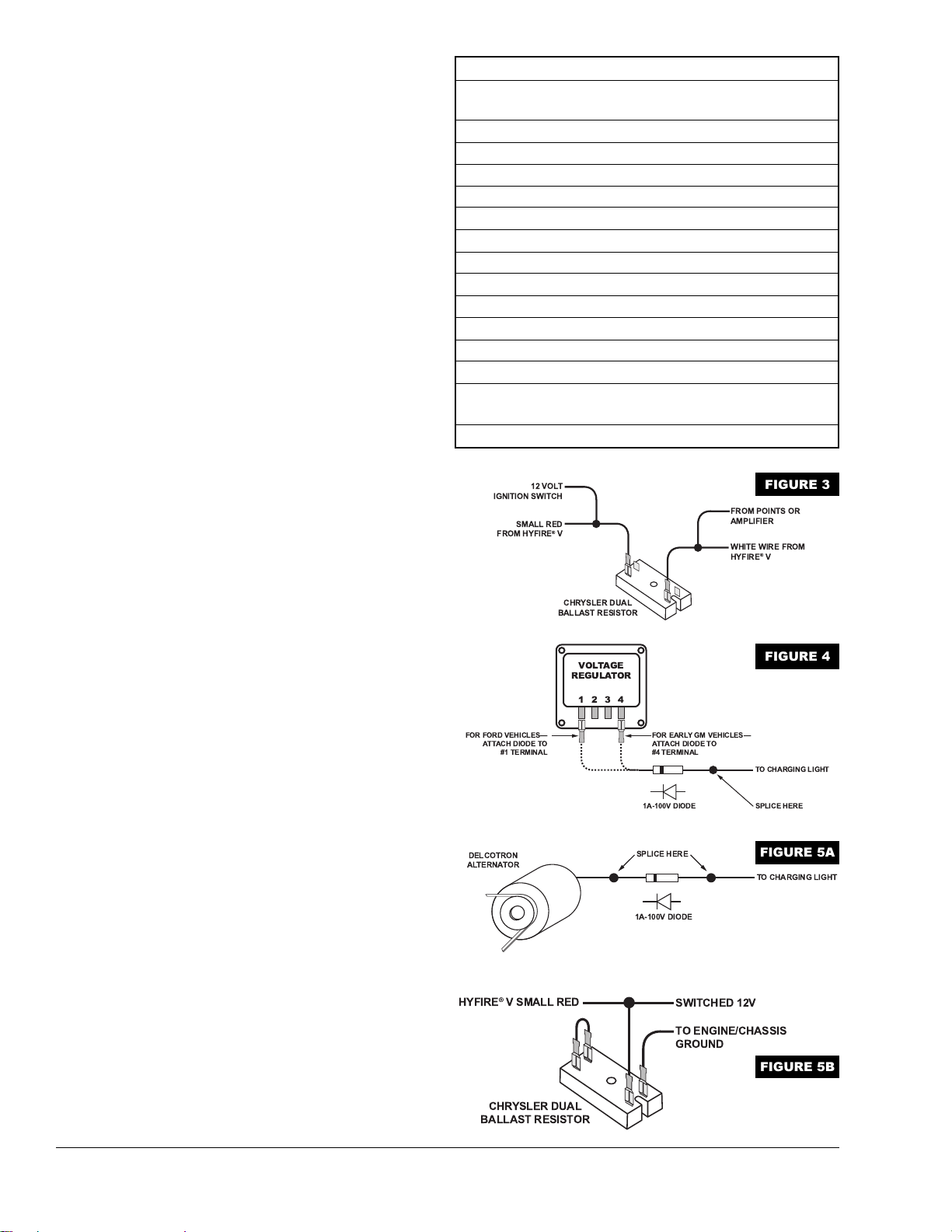

Ballast Resistor

If you have a current trigger tach (originally connected to coil (+) positive) and use the white wire of the HYFIRE® V for triggering, you can

purchase a Chrysler Dual Ballast Resistor (1973-76 applications). Wire

it as shown in Figure 3.

White Wire Trigger

When using the white wire to trigger the HYFIRE® V Ignition Control,

install a switch across the magnetic pickup violet wire to ground. When

the violet wire is grounded, the vehicle will crank but will not start.

Magnetic Pickup Trigger

When using the mag pickup to trigger the HYFIRE® V Ignition Control,

install a switch to the white wire and the other side to ground. When the

white wire is grounded, the vehicle will crank but will not start.

MAGNETIC PICKUP

USING THE MAGNETIC

PICKUP WIRE TO TRIGGER

THE HYFIRE

FROM HYFIRE®V

PURPLE

GREEN

®

V

CONNECTS

TO PURPLE

WHITE

FIGURE 2

BLACK

USING THE WHITE

WIRE TO TRIGGER

THE HYFIRE

BLACK

®

V

3MALLORY TECHNICAL SUPPORT (775) 882-6600 tech@mrgasket.com

Engine Run-On

If your engine continues to run even when the ignition is turned off,

you are experiencing engine run-on. Usually, older vehicles with an

external voltage regulator are susceptible to this condition. Because

the HYFIRE® V Ignition Control receives power directly from the battery, it does not require much current to keep the unit energized. If you

are experiencing run-on, it is due to a small amount of voltage going

through the charging lamp indicator and feeding the small red wire

(even if the key is turned off).

Early Ford and GM: To solve the run-on problem, a diode is supplied

with the HYFIRE® V Ignition Control. By installing this diode in-line of

the wire that goes to the charging indicator, the voltage is blocked

from entering the HYFIRE® V Ignition Control. Figure 4 shows the

proper diode installation for early Ford and GM vehicles.

NOTE: Diodes are used to allow voltage to flow only one way.

Make sure the diode is installed facing the proper direction, as

shown in Figure 4.

Ford: Install the diode inline to the wire going to the #1 terminal.

GM: Install the diode inline to the wire going to the #4 terminal.

GM 1973-83 with Delcotron Alternators

GM Delcotron alternators use an internal voltage regulator. Install the

diode inline on the smallest wire exiting the alternator (see Figure 5A).

It is usually a brown wire.

Most other applications: To eliminate run-on, connect a Chrysler dual

ballas resistor as shown in Figure 5B.

Misses and Intermittent Problems

Experience has shown that if your engine is misfiring or hesitating at

higher RPM, it is usually not a HYFIRE® problem. Most common causes

include a coil or plug wire failure, arcing from the cap or boot plug to

ground or spark ionization inside the cap. Perform the following checks:

Inspect the plug wires at the cap and at the spark plug for a tight

connection. Visually inspect for cuts, abrasions, or burns.

Inspect the primary coil wire connections. Because the HYFIRE® V

Ignition Control receives a direct 12 volt source from the battery,

there will not be any voltage at the coil positive (+) terminal, even

with the key turned on. During cranking, or while the engine is running, very high voltage will be present and no test equipment should

be connected.

WARNING: Do not touch the coil terminals during cranking or

while the engine is running.

Make sure that the battery is fully charged and the connections are

clean and tight, especially if you are not running an alternator. If the

battery voltage drops below 10 volts during a race, the HYFIRE® V

Ignition Control output voltage will drop.

TACHOMETER COMPATIBILITY LIST

Aftermarket White Wire Magnetic Trigger

Tachometer Trigger Connector

Autogage 29074 29078

Autometer

Ford Motorsport

Moroso

Stewart 29074 29078

S.W. & Bi Torx

Sun 29074 29078

VDO 8910 29078

AMC (Jeep) 29074 29078

Chrysler 29074 29078

Ford (Before 1976) 29074 29078

Ford (After 1976) 29074 29078

GM Bypass in-lin Bypass in-line

filter filter

Imports 29074 29078

12 VOLT

IGNITION SWITCH

SMALL RED

FROM HYFIRE

FOR FORD VEHICLES

ATTACH DIODE TO

#1 TERMINAL

DELCOTRON

ALTERNATOR

®

V

CHRYSLER DUAL

BALLAST RESISTOR

VOLTAGE

REGULATOR

1 2 3 4

FOR EARLY GM VEHICLES

ATTACH DIODE TO

#4 TERMINAL

1A-100V DIODE

SPLICE HERE

1A-100V DIODE

FIGURE 3

FROM POINTS OR

AMPLIFIER

WHITE WIRE FROM

®

HYFIRE

V

FIGURE 4

TO CHARGING LIGHT

SPLICE HERE

FIGURE 5A

TO CHARGING LIGHT

Is the engine running lean? Inspect the spark plugs and the entire

fuel system.

Check all wiring connections for corrosion or damage. Remember

to use proper connections followed by soldering, then seal the connections completely.

If the items above are ok, use the procedure on Page 5 to test the

ignition for spark. Mallory also offers an Ignition Tester (PN 28357)

that allows you to check the entire ignition system while it is installed

in the vehicle. This tool can also be used to check RPM limiters, RPM

activated switches, and shift lights.

MALLORY IGNITION 550 MALLORY WAY, CARSON CITY, NV 897014

HYFIRE®V SMALL RED

CHRYSLER DUAL

BALLAST RESISTOR

SWITCHED 12V

TO ENGINE/CHASSIS

GROUND

FIGURE 5B

Loading...

Loading...