Page 1

FORM 1552M 04/05

INSTALLATION INSTRUCTIONS

COMP PUMP®SERIES 160FI ELECTRIC

FUEL PUMP PART NO. 5160FI

DO NOT RUN THIS PUMP WITHOUT FUEL

(EXCEPT FOR BRIEF PERIODS WHILE PRIMING).

Parts Included in this kit

1 COMP PUMP® 160FI Series Electric Fuel Pump

2 Fittings, 3/4-16 x #8 AN Flare

2 O-rings, Nitrile 0.644ID x 0.087THK

GENERAL INFORMATION

The COMP PUMP® 160FI Series Electric Fuel Pump is a

high pressure fuel pump designed for fuel injection applications. In all cases, this fuel pump must be used with a

return style (bypass) fuel pressure regulator. Using the pump

with any other type of regulator (or no regulator) will result in

severe fuel pump damage. We recommend the following

return style fuel pressure regulators:

4–25 PSI Part No. 4307M (gasoline or alcohol)

30–100 PSI Part No. 4305M (gasoline or alcohol)

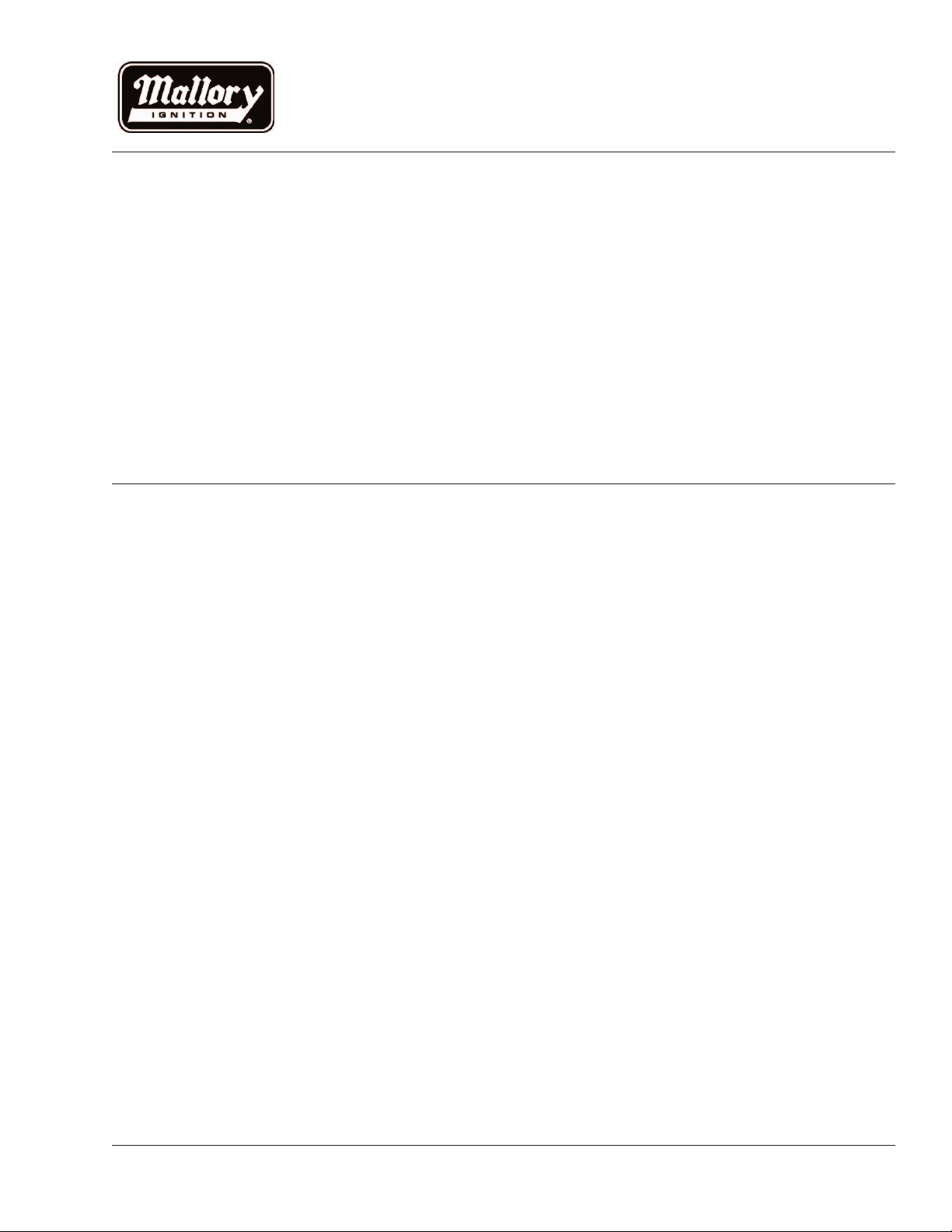

You must install a fuel return line between the fuel return

port of the regulator and the fuel tank. We recommend at

minimum a #8 AN (1/2”) fuel return line.

Be sure to install a suitable fuel filter (max. 100 micron)

between the fuel tank and the fuel pump, such as the

Mallory COMP FILTER® Series Part Nos. 3140, 3500, or

3175. This prevents debris from becoming wedged in the

fuel pump’s gears and locking it.

An additional fuel filter (maximum 10 micron, such as the

COMP FILTER® 160 Series Part No. 3160) must be installed

between the fuel pump and the injectors. This prevents

debris from clogging the injectors.

This pump is assembled with the inlet port on the right and

the outlet on the left. However, by loosening the bolt on the

clamp portion of the coupler housing, the lower pump

housing can be rotated so that the inlet is on the opposite

side (see Figure 4).

SPECIFICATIONS

Maximum recommended operating pressure:

60 PSI continuous, 100 PSI intermittent

Fuel pump thread sizes: Inlet/outlet, 3/4-16 (#8AN)

Recommended fuel line size: 1/2” (or #8AN)

Current draw: 14 AMP Typical

Oil pressure switch rating: 25 AMP

Fuel pump over current protection: 25 AMP fuse

Fuel application: Gasoline or Alcohol

MOUNTING PROCEDURE

Step 1

Mount the pump as close as possible to the fuel tank (at or

below the level of the fuel tank pickup) in a well ventilated

area with minimal exposure to road debris. Avoid exposing

the pump and fuel lines to moving parts and hot surfaces,

such as the exhaust system.

Step 2

Using the pump mounting bracket as a template, locate

mounting holes on a solid member, such as the vehicle

chassis. Drill clearance holes for 5/16” bolts. NOTE: Pump

may be mounted at any angle.

Step 3

Connect 1/2” (or –8AN) or larger fuel lines as shown in

Figure 1.

Step 4

Your system must have a Return Style Fuel Pressure

Regulator near the injection system. For maximum

efficiency, mount the pressure regulator as close as possible

to the injection system. See instructions packaged with the

regulator. The regulator may be installed just before or just

after the fuel injection.

1MALLORY IGNITION www.malloryracing.com

Page 2

FIGURE 1

12V

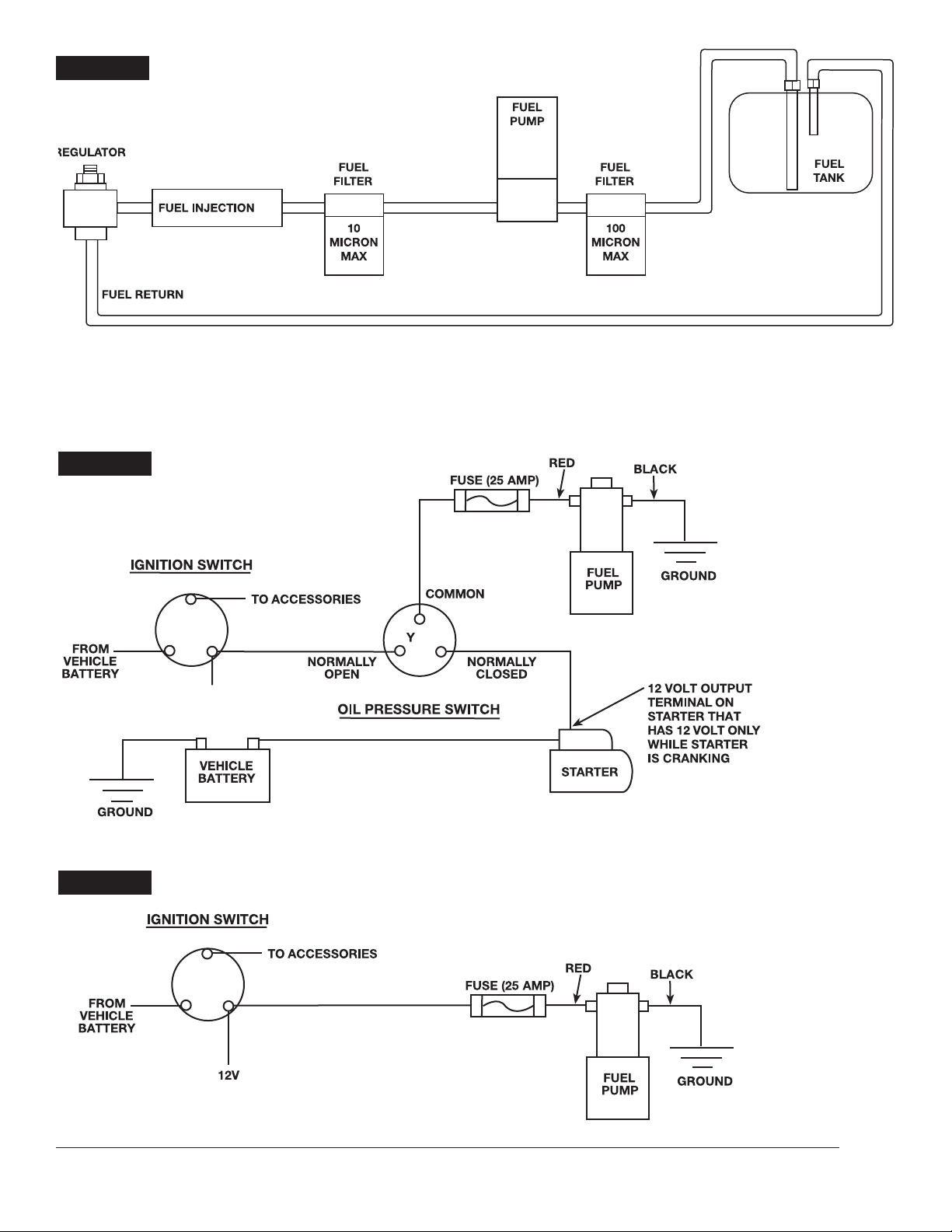

WIRING PROCEDURE

Wiring a pump to an oil pressure switch will provide power only when the ignition switch is on and the engine is running.

This will prevent the pump from running if your engine stalls. Use 12 gauge wire or larger and be sure to disconnect the battery

ground cable before wiring the pump. Refer to Figure 3 when connecting the pump to an oil pressure switch.

FIGURE 2

FIGURE 3

2 www.malloryracing.com MALLORY IGNITION

The pump may also be wired directly to the ignition “ON” terminal and grounded to the frame or battery.

Refer to Figure 4 when connecting the pump to the ignition switch “ON” terminal.

Page 3

FIGURE 4

ITEM NO. DESCRIPTION

1. Lower Pump Housing

2. Clamp Bolt

3. Coupler Housing

4. Coupler

5. Gasket, Bracket Vibration

6. Bracket

7. Nut, Motor Housing (2)

8. Adapter, Motor

9. Washer, Spring

10. Screw, Motor Adapter (2)

11. Motor

3MALLORY IGNITION www.malloryracing.com

Page 4

MALLORY IS A DIVISION OF THE MR. GASKET PERFORMANCE GROUP

10601 MEMPHIS AVE. #12, CLEVELAND, OH 44144

216.688.8300 FAX 216.688.8306

www.malloryracing.com

FORM 1552M

04/05

Made in U.S.A.

Printed in U.S.A.

4MALLORY IGNITION www.malloryracing.com

Loading...

Loading...