Page 1

FORM 1085 (REV. F) 01/12

INSTALLATION INSTRUCTIONS

COMP PUMP® SERIES 110FI

ELECTRIC FUEL PUMP

PART NO. 5110FI

NOTE: DO NOT RUN THIS PUMP WITHOUT FUEL (EXCEPT FOR BRIEF PERIODS WHILE PRIMING).

PARTS INCLUDED IN THIS KIT

1 COMP PUMP® 110FI Series Electric Fuel Pump

2 Fittings, 3/4-16 x #8 AN Flare

2 O-rings, Nitrile 0.644ID x 0.087THK

SPECIFICATIONS

GENERAL INFORMATION

The COMP PUMP® 110FI Series Electric Fuel Pump is

a high pressure fuel pump designed for fuel injection

applications. In all cases, this fuel pump must be used

with a return style (bypass) fuel pressure regulator.

Using the pump with any other type of regulator (or

no regulator) will result in severe fuel pump damage.

We recommend the following return style fuel pressure

regulators:

4–25 PSI Part No. 4307M (gasoline or alcohol)

30–100 PSI Part No. 4305M (gasoline or alcohol)

As stated earlier, you must use a return style (bypass)

regulator with this fuel pump. You must install a fuel

return line between the fuel return port of the regulator

and the fuel tank. We recommend at minimum a #8

AN (1/2”) fuel return line.

An air bleed system is located at the bottom of the

fuel pump to assist in priming the fuel pump. The air

bleed line is plumbed to the fuel return line. If you are

running 10 PSI fuel pressure or less, install a 1/8” NPT

plug in the air bleed port, When installing the plug, use

a thread sealant compound on the fitting threads)

purchase 1/8” NPT fittings or plugs, as well as thread

sealant compound, at any hardware store). Do not use

thread sealing tape. Thread sealing tape can get into

the Gerotor and lock the pump. Also, do not overtighten

the fitting. This could damage the pump housing.

Maximum recommended operating pressure:

75 PSI continuous, 100 PSI intermittent

Fuel pump thread sizes: Inlet/outlet, 3/4-16 (#8AN)

Air bleed system, 1/8” NPT

Recommended fuel line size: 1/2” (or #8AN)

Current draw: 12 AMP Typical

Oil pressure switch rating: 25 AMP

Fuel pump over current protection: 25 AMP fuse

Fuel application: Gasoline

Use Seal/Repair Kit Part No. 3168 to convert the

COMP PUMP® SERIES 110FI Electric Fuel Pump to

alcohol/methanol.

Be sure to install a suitable fuel filter (max. 100 micron)

between the fuel tank and the fuel pump, such as the

Mallory COMP FILTER® Series Part Nos. 3140 or 3500.

This prevents debris from becoming wedged in the

fuel pump’s Gerotor and locking it.

An additional fuel filter (maximum 10 micron, such as

the COMP FILTER® 160 Series Part No. 3160) must be

installed between the fuel pump and the injectors. This

prevents debris from clogging the injectors.

SERVICE PARTS:

Part No. 3167 Seal/Repair Kit, Gasoline (may be used

to convert alcohol/methanol

fuel pumps to

gasoline)

Part No. 3168 Seal/Repair Kit, Alcohol/Methanol (may

be used to convert gasoline

fuel pumps to alcohol/methanol)

1MALLORY IGNITION www.malloryracing.com

Page 2

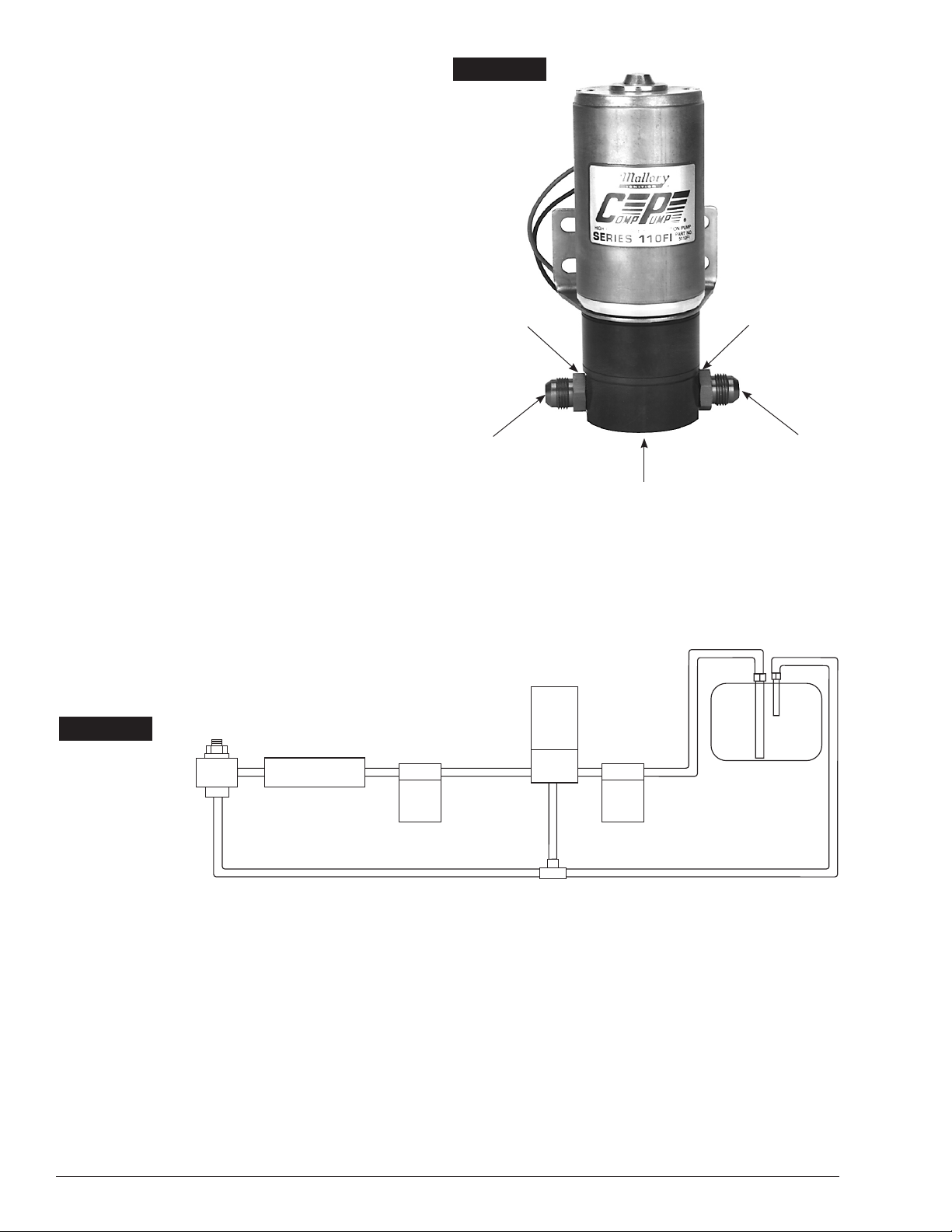

FUEL INJECTION

FUEL

FILTER

FUEL

FILTER

REGULATOR

FUEL

PUMP

FUEL RETURN AIR BLEED

FUEL

TANK

COMP�

FILTER

P/N 3160

COMP�

FILTER

P/N 3140

or 3500

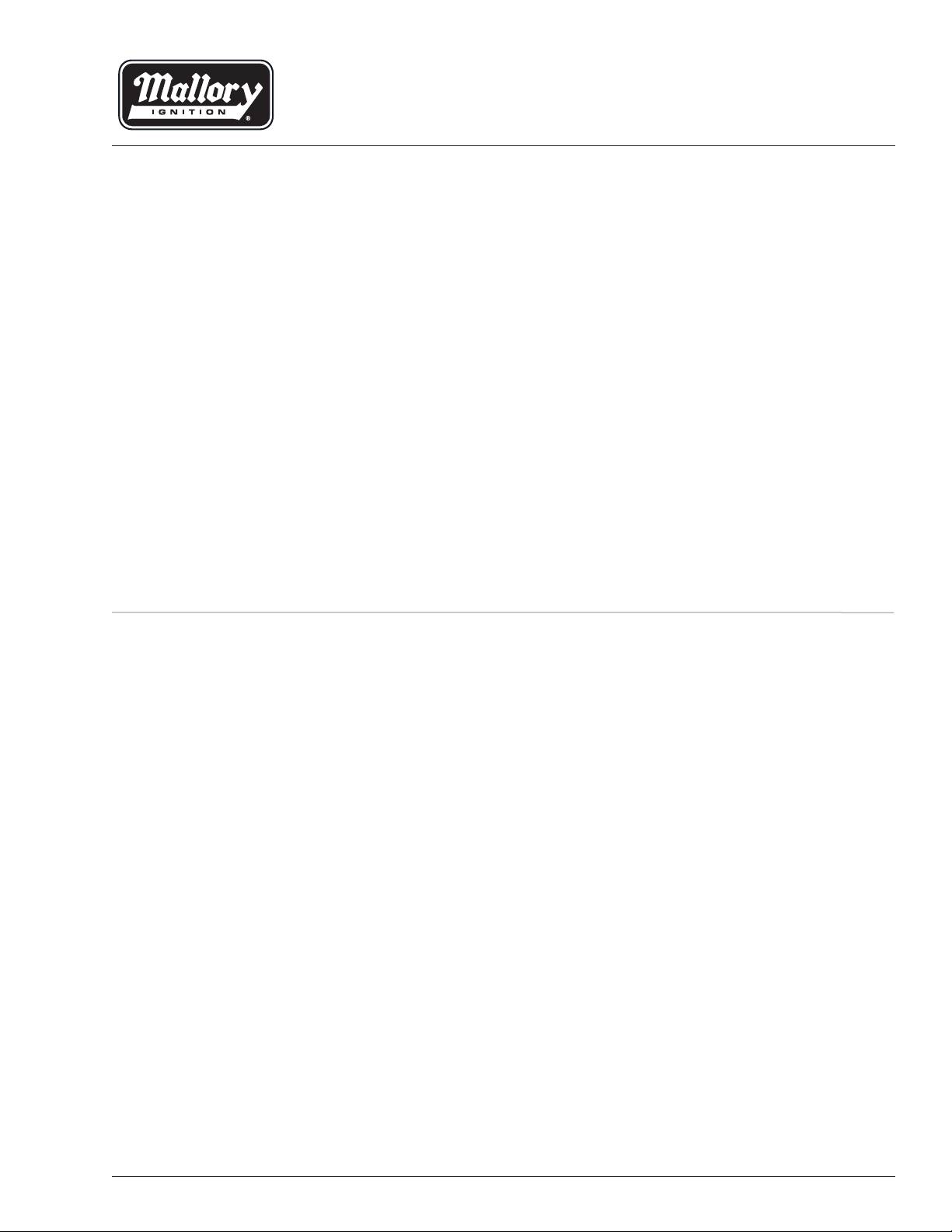

MOUNTING PROCEDURE

Step 1

Mount the pump as close as possible to the fuel tank

(at or below the level of the fuel tank pickup) in a well

ventilated area with minimal exposure to road debris.

Avoid exposing the pump and fuel lines to moving parts

and hot surfaces, such as the exhaust system. NOTE:

Increasing distance between the pump and tank will

decrease pump efficiency.

Step 2

Using the pump mounting bracket as a template, locate

mounting holes on a solid member, such as the vehicle

chassis. Drill clearance holes for 5/16” bolts. See

Figure 1.

Step 3

Connect 1/2” or larger fuel lines as shown in Figure 2.

The 1/8” NPT outlet on the bottom of the pump is for

an air bleed line to assist pump priming. This air bleed

line is not necessary if the regulated pressure of your

system is less than 10 psi. NOTE: Use a thread sealant

compound on the fitting threads. Don’t use thread

sealing tape because it could get into the Gerotor

and lock the pump.

Step 4

Your system must have a Return Style Fuel Pressure

Regulator near the injection system. See the General

Information section on page 1 for recommendations.

For maximum efficiency, mount the pressure regulator

as close as possible to the injection system. See instructions packaged with the regulator. The regulator may be

installed just before or just after the fuel injection.

FIGURE 1

BLACK WIRE (–)

NITRILE

O-RING

FUEL OUTLET

3/4-16 x #8AN FLARE

(TOP)

RED WIRE (+)

NITRILE

O-RING

FUEL INLET

3/4-16 x #8AN FLARE

AIRBLEED PORT

1/8” NPT

(BOTTOM)

FIGURE 2

2 www.malloryracing.com MALLORY IGNITION

Page 3

IGNITION SWITCH

OIL PRESSURE SWITCH

TO ACCESSORIES

TO COIL (+)

GROUND

GROUND

COMMON

FUSE (25 AMP)

NORMALLY

OPEN

NORMALLY

CLOSED

FROM

VEHICLE

BATTERY

STARTER

VEHICLE

BATTERY

FUEL

PUMP

RED

BLACK

12 VOLT OUTPUT

TERMINAL ON

STARTER THAT

HAS 12 VOLT ONLY

Y

WHILE STARTER

IS CRANKING

WIRING PROCEDURE

IGNITION SWITCH

TO ACCESSORIES

TO COIL (+)

GROUND

FUSE (25 AMP)

FROM

VEHICLE

BATTERY

FUEL

PUMP

RED

BLACK

Wiring a pump to an oil pressure switch will provide

power only when the ignition switch is on and the engine

is running. This will prevent the pump from running if

your engine stalls. Use 12 gauge wire or larger and be

sure to disconnect the battery ground cable before wiring the pump. Refer to Figure 3 when connecting the

pump to an oil pressure switch.

FIGURE 3

FIGURE 4

The pump may also be wired directly to the ignition “ON” terminal and grounded

to the frame or battery. Refer to Figure 4 when connecting the pump to the

ignition switch “ON” terminal.

3MALLORY IGNITION www.malloryracing.com

Page 4

FIGURE 5

2

1

5

4

3

6

7

8

9

10

11

12

13

14

15

16

17

ITEM NO. DESCRIPTION

*1. Screw, Fuel Chamber (2)

2. Fuel Chamber

3. Spring, Air Bleed

4. Ball, Air Bleed

*5. Gasket, Fuel Chamber

6. Port Plate

7. Gerotor

*8. O-Ring

9. Pump Housing

*10. Seal

*11. Gasket, Bracket Vibration

12. Bracket

13. Nut, Motor Housing (2)

14. Adapter, Motor

15. Washer, Spring

16. Screw, Motor Adapter (2)

17. Motor

*Parts included in Seal Kit

SERVICE PARTS

Seal and Repair Kit PN 3167

COMP PUMP Series 110FI Gasoline

Seal and Repair Kit PN 3168

COMP PUMP Series 110FI Alcohol

MAINTENANCE—PUMP DISASSEMBLY

If your pump fails to produce adequate pressure or

volume, it may require cleaning. Follow the steps below to

disassemble and clean your Mallory Electric Fuel Pump.

Refer to Figure 5 while performing the following steps.

Step 1

Remove the pump from the vehicle and clean pump

exterior. Place the pump on its side on a clean work

surface. Scribe or draw a line across the pump housing,

port plate and fuel chamber so that you can reassemble

the pump correctly.

Step 2

Remove the two fuel chamber screws from the bottom

of the pump. Remove the fuel chamber and port plate.

NOTE: Do not drop the Gerotor from the pump cavity.

Step 3

Separate the port plate from the fuel chamber.

NOTE: Do not drop the air bleed check ball and spring

from the fuel chamber.

Step 4

Place your hand beneath the Gerotor and hold the pump

in an upright position. The gerotor should slide out of the

pump and into your hand. NOTE: Observe the position

of the Gerotor and be careful not to reverse it when

you reassemble the pump. Inspect the gerotor housing

and port plate for wear. If the gerotor has worn through

the plating, return pump to Mallory for repair.

Step 5

Inspect the O-ring and gasket. Replace them if necessary.

Reinstall the air bleed spring and check ball in the fuel

chamber. Place the gasket and port plate on the fuel

chamber. Install the fuel chamber assembly on the pump

housing. Torque the fuel chamber screws.

NOTE: DO NOT OPERATE THE PUMP WITHOUT

FUEL. (Except for brief periods while priming).

IMPORTANT: Turn fuel chamber screws by hand

until they contact the chamber. Then torque to

24 inch/pounds

MALLORY IS A TRADEMARK OF PRESTOLITE PERFORMANCE

10601 MEMPHIS AVE. #12, CLEVELAND, OH 44144

4 www.malloryracing.com

216.688.8300 FAX 216.688.8306

Made and Printed in U.S.A.

FORM 1085

(REV. F) 01/12

Loading...

Loading...