Page 1

FORM #1263M (REV. F) 01/01

®

INSTALLATION INSTRUCTIONS

UNILITE® BREAKERLESS IGNITION

CONVERSION KIT

1957-74 FORD/MOTORCRAFT 8-CYLINDER

SINGLE POINT DISTRIBUTORS

PART NO. 502

IMPORTANT: Before starting the installation of the UNILITE® Ignition System, make sure that the vehicle is equipped with an ignition

ballast resistor (or loom resistance wire) in the wire between the ignition switch and the coil (+) terminal. One easy way to find the

ignition ballast resistor is to check the service manual for your vehicle. You can test your stock ignition system voltage while the

engine is at idle at the coil (+) terminal. If the measured voltage is within 1 volt of battery voltage, an ignition ballast resistor must be

installed in the wire from the ignition switch. Example: Vehicles with a Ford TFI or Delco HEI require adding an ignition ballast resistor

in the wire from the ignition switch. If you find your vehicle is not equipped with an ignition ballast resistor, install a Mallory Ignition

Ballast Resistor Part No. 700 in series in the wire from the ignition switch. Failure to use an ignition ballast resistor will result in the

eventual destruction of the UNILITE® Ignition Module. Exception: If your vehicle is equipped with a HYFIRE® Electronic Ignition Control or

similar aftermarket ignition control, use ignition ballast resistors and wiring procedures as stated in the instructions for the particular

ignition control.

NOTE: This kit can be installed in the distributor without removing the distributor from the engine if the distributor is

easily accessible. However, removal of the distributor from the engine is recommended.

LIST OF PARTS:

1 UNILITE® Module Part No. 605

1 Rotor/Shutter Wheel Part No. 333

1 Distributor Wire Harness Part No. 29349

1 Female connector

1 Upper mounting plate

GENERAL INFORMATION

IGNITION COILS

The UNILITE® Ignition System is designed to work with most stock ignition coils

and aftermarket high performance ignition coils. For optimum performance,

use a Mallory PROMASTER® Coil Part No. 29440 or 29625, or Mallory

Chrome Electronic Ignition Coil Part No. 29216.

SPARK PLUG WIRES

To prevent false triggering and the possibility of premature ignition failures, use

suppression-type spark plug wire. We recommend spiral core ignition wire,

such as Mallory PRO SIDEWINDER® Ignition Wire.

1 Lower mounting plate

2 Screws, 6-32 x 3/16"

2 Flathead screws, 8-32 x 1/4"

1 Flathead screw, 8-32 x 3/8"

1 Capsule, white silicone grease

1 Grommet

ELECTRIC WIRING

Unplug the distributor wire harness before welding on the vehicle.

OPTIONAL ACTIVE POWER FILTER PART NO. 29351

Voltage spikes (voltage transients, power surges) are associated with noisy

electrical systems from electrical defects such as worn alternator brushes,

corroded or oxidized electrical connections and similar electrical problems.

This device protects the UNILITE® Ignition Module against voltage spikes.

SPARK PLUG GAPS

For street applications, use your engine manufacturers specifications. For

racing applications, start with your engine manufacturers specifications, then

experiment with and closely monitor various gaps to achieve maximum

performance.

1

Page 2

INSTALLATION PROCEDURE

Step 1

Disconnect the point trigger wire from the coil () terminal.

Step 2

Locate the #1 cylinders spark plug wire on the distributor cap. See a service

manual for these locations. Mark the distributor cap and the distributor

housing, in line with #1 cylinders spark plug wire position on the distributor

cap.

Step 3

Turn the engine crankshaft in the direction of rotation until the timing mark lines

up with the top dead center (TDC) mark on the timing tab. See a service

manual for these locations. NOTE: Removing the spark plugs may make it

easier to turn the crankshaft.

Step 4

Remove the distributor cap from the distributor and lay it aside. Do not remove

the spark plug wires or coil wire. The rotor blade should point to the mark

made on the distributor housing (from Step 2). If it is not, turn the engine

crankshaft in the direction of rotation one full turn (repeating Step 3) until the

timing mark lines up (again) with the TDC mark on the timing tab. NOTE: Once

you are finished with Step 4, DO-NOT turn the crankshaft until the UNILITE

Conversion Kit and distributor is installed (Step 12).

Step 5

Note the direction the rotor is pointing. Note the direction the vacuum chamber

is pointing. Remove the distributor hold down clamp and remove the

distributor from the engine.

Step 6

Remove the rotor. Disconnect the primary point wire. Remove the primary

wire and the grommet from the distributor. Remove the breaker point and the

condenser from the breaker plate. Install the ground wire to the breaker plate

using the condenser screw.

Step 7

Position the lower mounting plate (with one countersunk hole) against the

breaker plate. Align the countersunk hole over one existing breaker plate

threaded hole. Align one non-threaded hole with the other breaker plate

threaded hole. Install one 8-32 x 3/8" flathead screw through the nonthreaded hole (temporarily, do not tighten) to help in the alignment of the lower

mounting plate onto the breaker plate. Install one 8-32 x 1/4" flathead screw

through the countersunk hole and tighten firmly into the breaker plate.

Remove the 8-32 x 3/8" flathead screw.

Step 8

Position the upper mounting plate with its countersunk holes aligned with the

holes in the lower mounting plate. Install one 8-32 x 3/8" flathead screw

through the non-threaded hole in the lower mounting plate into the breaker

plate. Install one 8-32 x 1/4" flathead screw into the threaded hole in the lower

mounting plate. Make sure to tighten these screws firmly.

Step 9

Apply a thin coat of white silicone grease to the bottom of the UNILITE® Module.

Install the UNILITE® Module onto the upper mounting plate with two 6-32

screws. Make sure to tighten these screws firmly.

Step 10

The grommet has a flat on one flange. Install the grommet in the hole in the

distributor housing where the primary wire had previously fed through with the

flat on one flange facing out and up. Positioning the flat on one flange facing out

and up allows adequate distributor cap clearance. Slide the three wires from

the UNILITE® Module, through the grommet, to outside the distributor housing.

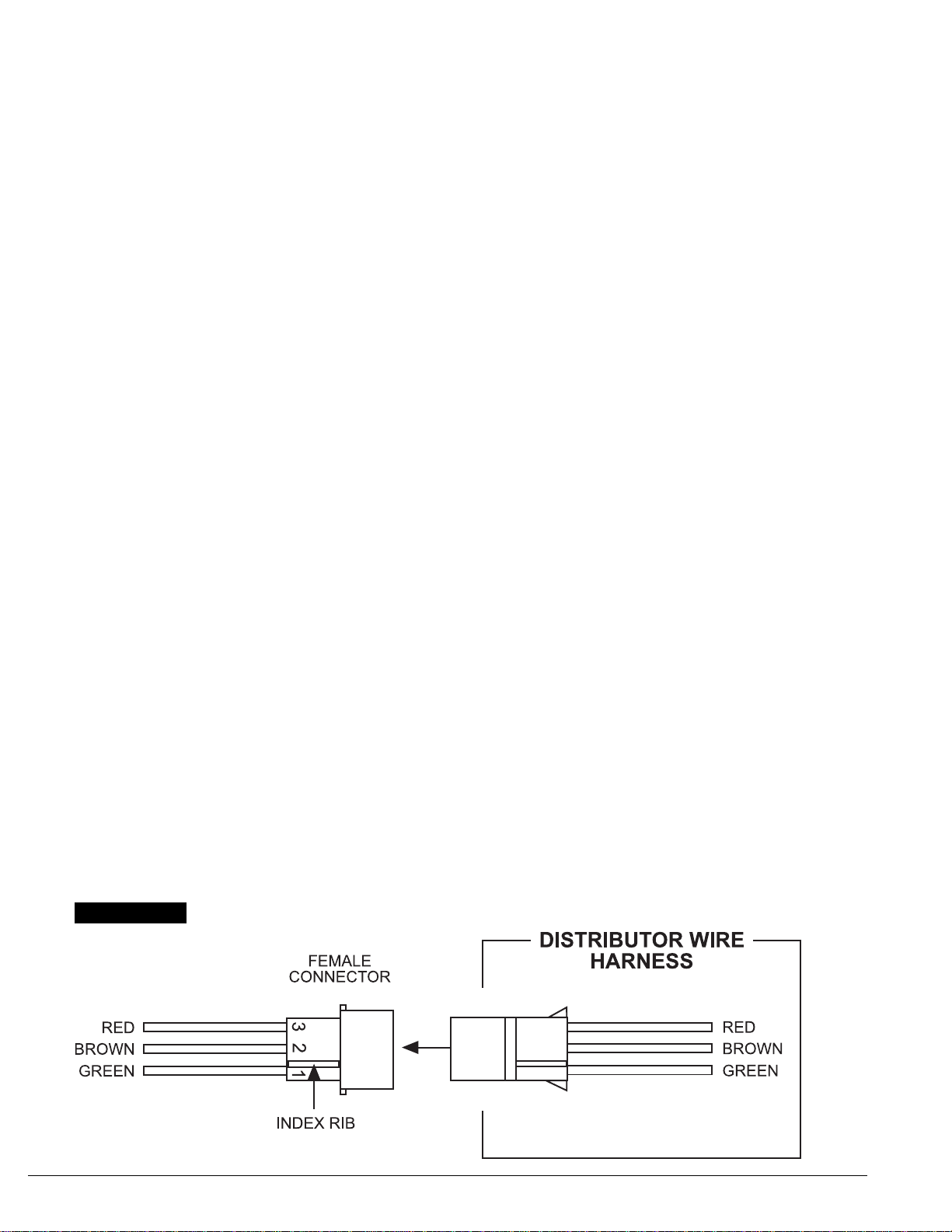

Step 11

Put the UNILITE® Modules three wires in the female connector:

GREEN WIRE in hole #1

BROWN WIRE in hole #2

®

RED WIRE in hole #3

Plug the female connector into the distributor wire harness. See Figure 1.

Step 12

Install the rotor/shutter. Place the distributor in the engine with the rotor pointing

in the same general direction as during removal of the distributor (from Step 5).

NOTE: The distributor must be fully seated into the engine. It may be

necessary to turn the oil pump drive, or turn the engine crankshaft in the

direction of rotation two full turns until the timing mark lines up (again) with the

TDC mark on the timing tab to allow the distributor to seat fully.

Step 13

Rotate the distributor housing until the rotor points to the mark on the distributor

housing (from Step 2) and the nearest slot on the rotors shutter wheel is

approximately in the center of the optics of the UNILITE® Module. This will

generally put timing close enough for starting purposes. Put the distributor hold

down clamp in place and tighten slightly, leaving it loose enough to turn the

distributor housing.

Step 14

Install the distributor cap. NOTE: The grommet was installed during step 10.

The grommet has a flat on one flange. When installed, the flat on the flange of

the grommet must face out and up to allow adequate distributor cap clearance.

The distributor cap may not sit properly on the distributor housing unless these

details are followed exactly.

FIGURE 1

2

Page 3

WIRING PROCEDURE

SEE FIGURES 3 AND 4

IMPORTANT: Make sure that your vehicle is equipped with an

ignition ballast resistor (or loom resistance wire) in the wire

between the ignition switch and the coil (+) terminal. One easy

way to find the ignition ballast resistor is to check the service

manual for your vehicle. In general, all vehicles equipped with

the Ford/Motorcraft point ignition were equipped with an ignition

ballast resistor. If you find your vehicle is not equipped with an

ignition ballast resistor, install a Mallory Ignition Ballast Resistor

Part No. 700 in series in the wire from the ignition switch. Failure

to use an ignition ballast resistor will result in the eventual

destruction of the UNILITE

®

Ignition Module. Exception: If your

vehicle is equipped with a HYFIRE® Electronic Ignition Control

or similar aftermarket ignition control, use ignition ballast resistors and wiring procedures as stated in the instructions for the

particular ignition control.

NOTE: If your vehicle is equipped with a HYFIRE® Electronic

Ignition Control or similar aftermarket ignition control, use ignition

ballast resistors and wiring procedures as stated in the instructions for the particular ignition control.

ADDITIONAL CONNECTIONS

Tachometer operation: Connect tachometer wire or wires as

recommended by the actual tachometer manufacturer.

FIGURE 2

STARTING ENGINE

CAUTION: Be sure all tools, wires and miscellaneous objects

are clear of moving engine parts and extreme heat before

starting the engine.

Step 1

Recheck all wires and connections to make sure they are

correct. Check and clean, or replace, spark plugs. If replacing

spark plugs, use types recommended by the engine manufacturer.

Step 2

Connect a timing light. Find the area with the best view of the

timing marks.

Step 3

Start the engine. If it fails to start, rotate the distributor housing in

small increments clockwise or counterclockwise until engine

starts. Do not exceed more than 10 degrees of distributor

housing rotation in either direction.

Step 4

Set timing as recommended by engine manufacturer, then

tighten distributor hold down clamp. Make sure timing is still

correct. If timing has moved, repeat this procedure.

DISTRIBUTOR TUNE-UP PARTS

DESCRIPTION PART NO.

DISTRIBUTOR CAP 217

ROTOR/SHUTTER WHEEL 333

UNILITE® MODULE 605

3

Page 4

FIGURE 3

You must use suppressor coil wire

NOTE: When using the UNILITE® distributor with a HYFIRE® or other

aftermarket amplifier box, connect the distributor according to the

amplifier box instructions.

A PROMASTER

®

coil is shown for illustration purposes. When using

a stock coil, connect it in the same manner shown.

COIL

DISTRIBUTOR

(TYPICAL)

FIGURE 4

DISTRIBUTOR

WIRE HARNESS

TO IGNITION SWITCH

OEM PRIMARY

RED

BROWN GREEN

GROUND TO

ENGINE BLOCK

RESISTANCE WIRE

You must use suppressor coil wire

NOTE: When using the UNILITE® distributor with a HYFIRE® or other

aftermarket amplifier box, connect the distributor according to the

amplifier box instructions.

A PROMASTER

®

coil is shown for illustration purposes. When using

a stock coil, connect it in the same manner shown.

+

–

COIL

DISTRIBUTOR

(TYPICAL)

4

TO IGNITION SWITCH

MALLORY BALLAST

RESISTOR PN 700

RED

BROWN

DISTRIBUTOR

WIRE HARNESS

GROUND TO

ENGINE BLOCK

MALLORY IS A DIVISION OF THE MR. GASKET PERFORMANCE GROUP

550 MALLORY WAY, CARSON CITY, NEVADA 89701

(775) 882-6600 FAX (775) 887-4326

www.mrgasket.com

OR OEM BALLAST

GREEN

+

–

FORM #1263M

(REV. F) 01/01

Made in U.S.A.

Printed in U.S.A.

Loading...

Loading...