Page 1

Page 2

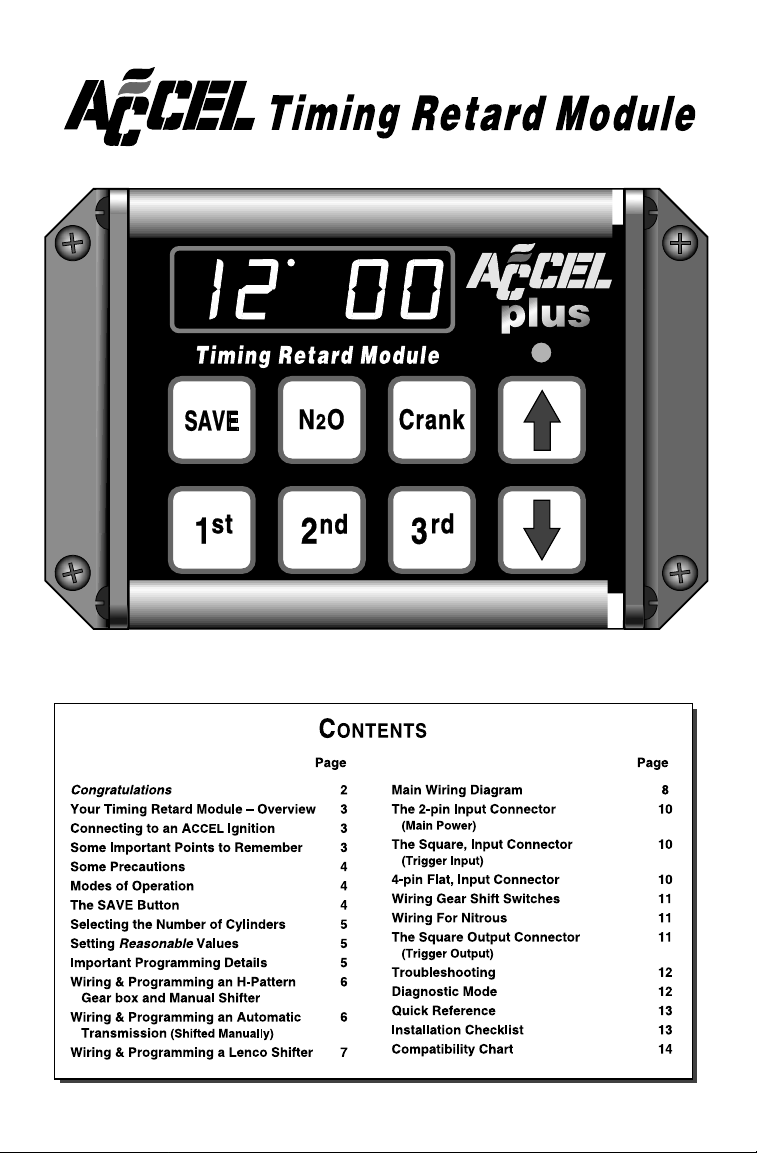

Congratulations! You have purchased the ACCEL TIMING RETARD MODULE.

This unit can be programmed to automatically retard your engine’s ignition timing

or four different inputs. When not being programmed, your ACCEL TIMING RETARD

MODULE functions as a digital retard meter.

CCEL 300+ RACE WIRE spark plug wires!

Use A

Solid-core spark plug wires emit RFI and EMI static,

which can disrupt On-board electronics.

Do not use your TIMING RETARD MODULE

with another timing control module.

They both may try to override each other.

Do not use your TIMING RETARD

MODULE

with more than 18 volts.

Your ACCEL TIMING RETARD MODULE, like

any electronic component, is sensitive to heat.

Keep it away from temperatures greater than 150°F (65°C)

.

Follow the installation instructions in this Owners Manual carefully.

Incorrect installation may damage your engine, this unit,

and may

VOID YOUR WARRANTY.

This unit cannot be returned to your

dealer for testing or for warranty.

It must be returned to

:

MR. GASKET PRODUCT REPAIR

8700 BROOKPARK ROAD

CLEVELAND, OH 44129

216-398-8300 Ext-310

Your warranty card must be on record at

ACCEL to insure warranty processing.

(See your warranty card for details.)

This package provides everything

you will need to install your

ACCEL TIMING RETARD MODULE

Wire lengths provided are enough for almost all vehicles.

If you must splice additional wire use 16 gauge wire, or larger.

Page 3

T

HE

Your new A

ACCEL TIMING

CCEL TIMING

RETARD MODULE is a computer module. It is meant to be installed

RETARD MODULE - AN OVERVIEW

etween your ignition triggering device (distributor pickup, crank trigger, etc.) and your

gnition module. It controls the signals that tell your ignition when to fire.

n addition to its trigger input, your A

CCEL

iming Retard Module uses four external

nputs to activate timing retard values.

he four inputs may be connected to any

ype of switch to activate selected retards.

Normally input switches are connected to

hree gear positions and an N

2O activation

nput. You can then select and adjust values

or these inputs with the key pad.

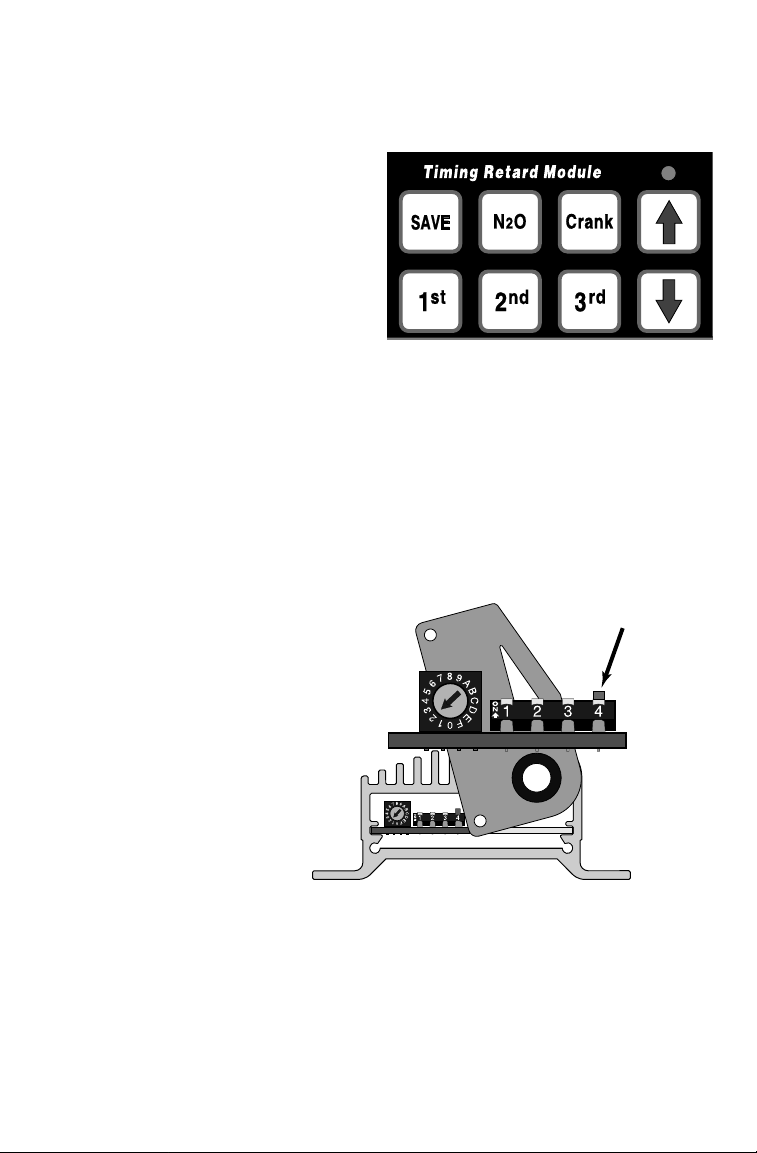

CONNECTING THE A

TO AN

CCEL TIMING RETARD MODULE

ACCEL IGNITION SYSTEM

he ACCEL Timing Retard Module uses special signals to communicate with your ACCEL

gnition module; and DIP-

• Open the A

CCEL ignition’s cover plate (the one with the wires coming through it).

Unscrew the three screws and swivel it out of the way to reveal the

• Using a small tool (A pencil is good) gently push up

Switch-4, inside the ACCEL ignition module, must be re-set UP.

DIP-Switches.

DIP-Switch-4.

300+ ignition box has been

CCEL

This A

set to rev-limit an 8-cylinder

engine at 5,000 RPM.

DIP-Switch-4

The owner has installed

an A

CCEL Timing Retard

Module, and has also

set DIP-Switch-4 up.

• After you have set

DIP-Switch-4,

close the cover plate and retighten

all three of its screws.

IMPORTANT POINTS TO REMEMBER

you should remove your ACCEL Timing Retard Module from the car, remember to re-set

IP-Switch-4 inside the ACCEL ignition module DOWN.

• When connected to an ACCEL control module, the ignition module’s DIP- Switch-4 must be UP.

• When not connected to a control module the ignition will not start with DIP-Switch-4 U

P

The rev-limit set inside your ACCEL ignition module is the engine’s ultimate rev-limit.

Make sure that its chosen rev-limit fits your engine’s needs and

the needs of any additional control modules.

Page 4

PRECAUTIONS AND

W

ARNINGS

The ACCEL Timing Retard Module will cause a small, fixed timing retard in the trigger.

This is due to computational delay. Engine ignition timing must be checked, and

re-adjusted, to account for this delay after your timing retard module is installed.

This flexible product makes it easy to select values that can damage your engine.

Start by selecting safe values. Carefully evaluate their effect. Make small changes,

when changing values, and use caution.

MODES OF OPERATION

our new A

CCEL TIMING RETARD MODULE

has three different modes of operation.

1. Programming Programming and Control modes overlap in the sense

2. Control

that timing control is still performed in Programming Mode.

In Programming Mode the display shows the value you are

in the process of programming. In Control mode the LED’s display the

current timing retard from the trigger input.

3. Diagnostics Mode – See Pg. 12.

THE SAVE BUTTON

Pressing the SAVE button tells the Timing Retard Module to store all the values that

have been adjusted. They will be remembered until they have been re-programmed

and over-written with the SAVE button. Turning off the module does not erase any

values that have been stored with the SAVE button.

You can adjust, and test, different settings, without storing values, by turning your

Module off, before pressing SAVE. The unit remembers the last values stored with

he SAVE button, and restores them the next time it is used.

CAUTION: It may take a few seconds for the Timing Retard Module to SAVE values.

Be sure the display shows the current timing retard (default display) before turning

the module off. Powering off during a SAVE may cause you to lose stored values.

After you have completed the wiring (according to diagrams detailed later in this

ocument) you must do some basic configuration of your A

CCEL TimingRetard Module.

Page 5

1. With the unit powered off press, and hold

down, both the SAVE and CRANK buttons.

2. While holding those two buttons down, apply power to the module.

The module will enter its Programming Mode and display a number that

represents the number of cylinders in an engine (the factory default).

3. Use the ⇑and ⇓keys to select the number of cylinders for YOUR engine.

4. When finished, press SAVE. This stores this new information and puts

the module back into Control Mode operation.

Make this selection only once per installation.

If you do not make this selection your

TimingRetard Module uses the factory default.

SETTING S

REASONABLE TIMING R

OME

ETARD VALUES

Enter Programming Mode by pressing the key for the function you wish to modify.

Adjust the timing retard of that function to an appropriate value.

Exit Programming Mode by pressing that same key again.

i.e. To select a timing retard for starting your engine press the

CRANK button.

The display shows its current value and The Programming Dot will start to flash.

Use the ⇑and ⇓keys to adjust (in 1° increments) the value displayed.

When finished press

CRANK again.

The Programming Dot stops flashing and the current timing retard displays.

Do the same for all timing retard inputs. It is not necessary to exit Programming

Mode to select a new function, simply press the next value’s key.

i.e. Press 1

st

and select its value. Then press 2ndand select its value.

nd

Since 2

was the last value you programmed, you

exit Programming Mode by pressing 2

nd

again.

When you have finished programming press SAVE to store all new values.

IMPORTANT PROGRAMMING DETAILS

The initial values you program and save into your Timing Retard Module will get you

started. You will eventually want to modify them. Just select a function and change it.

Modifications take effect immediately. Press that function’s key again (displaying current timing retard), and the newly selected value takes effect.

st

The 1

, 2nd, and 3rdswitches do not represent gears, but rather switches. On a four

speed manual transmission the switches are normally installed on 2

Timing retard is additive. For example: you program 3° of retard for the 1

of retard for the 2

nd

key. The module will provide 3° of retard when switch #1 gets

activated, then adds 4° (7° total) when switch #2 is activated (while switch #1 remains

active). N

2O timing retard, when active, is also additive.

If your shifter and switches are designed so that only one switch can be activated at a

ime, the value programmed for each individual switch is not additive.

nd

, 3rd, and 4thgears.

st

key and 4°

Page 6

When connected to an H-Pattern, manual transmission, your Timing Retard Module’s 1st,

nd

, and 3rdkeys each program how much retard takes effect when one gear is selected.

nstall switches on the shifter that, when closed, signal the module that a gear is engaged.

When the A

CCEL Timing Retard Module receives its signal it adjusts timing retard to

e value you have programmed for that gear.

ypically the 3

rd

key, and its switch, is attached to

p gear. The next two highest gears are

en attached, by switches,

wires from the 4-Pin, Flat

onnector. When using your H-Pattern transmission, the values

rogrammed by the Module’s 1

st

, 2nd, or 3rdkeys take effect when their switches trip.

stall switches so one side is connected to +12volts and the other side is connected to the

iming Retard Module’s harness. Switches should be OPEN when their gear is not engaged

i.e. You have programmed, and stored 9° with the

nd

2

button, ⇓ and ⇑ keys, and the SAVE button.

When you shift into 3

by the

DK GREEN & WHITE wire (Connector Pin-C),

is tripped and ignition timing retards by 9°.

EMEMBER: the 2

R

nd

In this example the 2

button refers to the second switch, NOT 2ndgear!

rd

gear its switch, connected

nd

key, and its switch, is wired to 3rdgear.

W

IRING AND

PROGRAMMING AN

AUTOMATIC

TRANSMISSION (Shifted Manually)

Automatic transmissions and their shifters are programmed, and

wired, like manual H-Pattern systems, except the retard switches

are connected to the shifter in a straight line.

As you shift gears, the values programmed take effect; each gear

with its own programmed value.

i.e. You have programmed and stored

a value of 15° into the module

with the 3

rd

button.

When you shift into Top gear the

D

K BLUE & WHITE wire’s switch

trips

(Pin-D on the connector)

, and

timing retards by 15°.

ou may not want to use all three retard.

switches. Wire a manual switch to an unused

wire, and use it to program a conservative Timing Retard for your drive home.

Page 7

IRING AND PROGRAMMING A LENCO-TYPE SHIFTER

W

here are major differences between the Lenco gearbox and shifter, and an H-Pattern

manually shifted transmission:

• The Lenco box accumulates gear ratios.

Higher gear’s ratios are the total

of the lower gear shifts.

•The Lenco has a stick for each gear.

Before shifting into a high gear, all

lower gears must be engaged.

i.e. To be in

AND the 2

th

4

gear, the 3

nd

gear sticks

rd

must also be thrown.

st

•When you are moving forward 1

is always

engaged. Reverse is triggered off 1st.

Keep these differences in mind when installing, and

programming, your new A

CCEL

Timing Retard Module.

s with an H-Pattern or automatic shifter; wire the three

witches to your top three gear positions so that each

ear’s stick, as it is engaged, closes a switch contact.

When in Top gear all three switches will be closed.

ach stick’s switch should have one contact wired

VDC, and the other contact wired to the Timing

o +12

etard Module’s 4-pin flat connector (see Pg 8).

he Timing Retard Module senses when more than

ne switch is closed, and totals the values you have

rogrammed for all lower gear’s shifts.

.e. Assume you are running a four-

speed Lenco transmission, and

you have programmed your new

CCEL Timing Retard Module so

A

that the 1

st

button’s value is 4°, the 2ndbutton is 5,° and the 3rdbutton is 6°.

Remember: A button’s label refers to its switch, NOT to which gear it is wired.

• Usually you will not be adjusting Timing Retard for First gear.

The ACCEL Timing Retard Module has been designed to adjust

Retard for three forward gears, and for Nitrous

(see Pg-11)

.

• When you shift into 2ndgear you will get 4° of Retard,

since the 1stbutton has been programmed 4° for

nd

gear.

2

• When you shift into 3rdgear you will have 9° of Retard.

The 1stbutton’s 4° is added to the 2ndbutton’s 5°,

making a total of 9° when you are in

rd

3

.

• Shift into 4th(Top) gear and you will get 15° of Retard.

st

1

and 2ndvalues are added to the 3rdbutton’s value;

4° + 5° + 6° totals 15° of Retard, for

th

4

gear.

Page 8

Page 9

Page 10

HE 2-P

IN, INPUT CONNECTOR

(Main Power)

This is the main power input for

CCEL Timing Retard Module.

your A

Its

B

wire is Grounded and

LACK

R

wire inputs +12

its

ED

VDC

from the battery.

(not more than +

or less than +

18 VDC

8 VDC)

In general, the best place

to Ground the

RED wire

The

connects to the battery

through the power or

key switch.

HE SQUARE, INPUT CONNECTOR (Trigger Input)

T

CCEL Timing Retard Module takes all kinds of triggering, except Distributor-less.

he A

is on the engine.

Make sure that rubber

mounted engines are

well Grounded.

BLACK wire

s digital micro-processor controls are as sensitive as your trigger, and we recommend you

CCEL Crank Trigger or Billetech Distributor. The triggering inputs are read either

se an A

hrough the Square, Male connector’s P

he W

HITE

wire typically gets its

URPLE and O

RANGE wires, or the WHITE wire.

quare wave input from:

• All Points ignitions

• Some

HEI modules

• Most Fuel Injections

he P

URPLE and ORANGE wires get

heir inputs from either Magnetic

ickup or Crank-triggered systems.

URPLE wire is the Positive

he P

+)

(

nput and the Orange wire is the

(–). See chart at right.

egative

your system uses the WHITE wire,

ou must isolate and insulate both

URPLE and ORANGE wires.

he P

your system uses both the P

URPLE

nd ORANGE wires, you will isolate

nd insulate the W

he L

IGHT GREEN wire connects

irectly to the Tach’s signal lead.

HITE wire.

* Older ACCEL Crank Triggers may connect

W

HITE

to PURPLE and BLACK to ORANGE

THE 4-PIN, FLAT CONNECTOR (Input from Switches)

his connector receives signals from switches telling the module when to adjust Timing

etard. You do not have to connect all four switches. (See Wiring Diagram on Pg, 8)

Page 11

WIRING

GEAR SHIFT SWITCHES

lthough programming may be different for Automatic, H-Pattern, or Lenco type trans-

missions, the way you place and connect their switches will probably be similar.

nfortunately gear shifts come in many different shapes, and we cannot tell you which

ind of switch you should use. You’ll have to choose and attach your own switch.

SOME GUIDELINES FOR

ATTACHING SWITCHES

A momentary or a toggle switch is

•

probably best: one that stays in its

tripped position until the shifter is

put into another gear.

Place your switch so that only the

•

selected gear shift can trip it.

Make sure all switches are firmly

•

fixed in place, and that nothing can

tangle their wires.

WIRING F

Ground the same way

that you Grounded the

2-Pin Connector.

OR NITROUS

Connect the G

REY wire to the Nitrous

system by splicing it to the wire running

between the Nitrous solenoid and the

Nitrous activation switch.

Timing Retard for Nitrous is added on top of whatever Timing Retard is already active.

i.e. You have programmed Top gear to retard timing by 15° with the

rd

3

button, and Nitrous to retard by an additional 5° with the N2O key.

You are in Top gear when your A

CCEL 3-Stage Rev-limiter activates

the Nitrous system. Total Timing Retard instantly becomes 20°.

With Multi-stage Nitrous use any unused switch to sense when the system is activated.

Wire the unused switch to the negative terminal of any Nitrous solenoid. (See Pg 8.)

T

HE SQUARE, OUTPUT CONNECTOR (Trigger Output)

utputs the triggering signals received, through the 4-Pin Square Input connector, to your

gnition. If you are using an A

CCEL+ ignition, its input connector is already in place.

using a third party’s CD ignition, build a mating connector , with the connector supplied.

The BLACK& WHITE wire connects to the

Points terminal of a CD ignition.

IGHT GREEN & BLACK wire connects

The L

to a CD ignition’s Tach input.

Connect wires according the instructions

that come with your CD ignition system.

Connect the

the White

wire (Pin-C) to the

CD’s Points input.

& BLACK

Connect the

T GREEN & BLACK

L

(Pin-D) to the

CD’s Tach input.

Page 12

LED’s do The Timing Retard Module is not getting power.

not display Check the 2-Pin connectors’s Red and Black wires. See Pg 10.

A timing light The engine was not retimed when the Timing Retard Module was

does not show originally installed, or the wrong number of cylinders was selected

he programmed Time the engine again. See Pg 3.

value Check the number of cylinders (4, 6, or 8). See Pg 5.

Tachometer Any one of the Tachometer wires throughout the system may

does not be disconnected or shorted, or the Tach itself may be broken.

work Check the square, input connector first. See Pg 10.

Your A

CCEL+ DIP-Switch-4 inside your ACCEL+ ignition is down.

sparks randomly See Pg 3.

Status Light on The ignition is not firing, or the Timing Retard Module is unplugged

CCEL+ from the ignition. The battery may be low.

Your A

is Dim If the 2-Pin connector and battery are OK, pull a spark plug, lean it

against the engine. It should spark as you crank the starter. See Pg 10.

Status Light on The unit is not sending a trigger signal, probably because

Your A

+ it is not receiving a trigger signal. Check the trigger device

CCEL

is O

FF and the square, input connector. See Pg 11.

Timing doesn’t The unit does not have a value programmed for that gear, or

hange when car it is not getting a signal from that gear shift.

is in a new gear Check the switch and its wires. See Pg 11.

DIAGNOSTIC MODE

our A

CCEL Timing Retard Module has features that test functions through your key pad.

iagnostic Mode does not perform any Control Mode engine functions.

you enter Diagnostic Mode with the engine running, your engine will stall.

(Read this whole section before entering Diagnostic Mode)

ISPLAY, PROCESSOR, and MEMORY test

Enter Diagnostic Mode by simultaneously pressing and releasing three keys:

1ST, 2ND, and 3

RD

. The display will show 00000.

About every two seconds the display will increment: 11100, 22200, up to 99900.

The ‘degree dot’ will appear with the odd numbered (

EY PAD

test

When

99900 appears the ‘programming dot’will start flashing. From now on you must

33300

, 55500) displays.

press the proper key within eight seconds or the module will return to Control Mode.

Keys must be pressed in order:

DISPLAY PRESS

99900 1

11100 2

22200 3

33300

44400

55500 CRANK

66600 SAVE

77700 N

ST

ND

RD

(UP A

⇑

(DOWN Arrow)

⇓

2O

rrow)

After each key is pressed the display will update.

It starts at

11100 and increments to 77700 as

each key is pressed, in order. If the proper key

is not pressed within eight seconds Diagnostic

Mode ends and returns you to Control Mode.

If you press the correct key and the display does

not update (and the unit exits Diagnostics), the

test has found a key pad failure.

When the last key (

N2O) is pressed and released

the unit returns to Control Mode operation.

Page 13

Q

UICK

REFERENCE

Adjusts how much Retard takes effect when you first start your engine.

Press the C

Cranking Retard only takes effect below 600

Sets how much Timing Retard will take effect when Switch #1 is ON.

Press the 1

The Module senses through the

shifter, is

Sets how much Timing Retard will take effect when Switch #2 is ON.

Press the 2

The Timing Retard Module senses, through the

RANK button and adjust the value with the

RPM. (See Pg 5)

st

button and adjust the value with the ⇓or ⇑buttons.

YELLOW wire when Switch #1, on the

CLOSED, and Retards by the amount designated. (See Pg 6)

nd

button and adjust the value with the ⇓or ⇑buttons.

DARK G

or ⇑buttons.

⇓

REEN & WHITE

wire, if Switch #2, is CLOSED and Retards by the set amount.

Sets how much Timing Retard will be in effect when Switch #3 is ON.

Press the 3rdbutton and adjust the value with the ⇓or ⇑buttons.

The module senses, through the

on the shifter, is

CLOSED and Retards by that designated amount.

DARK BLUE &

WHITE wire, if Switch #3,

Switch #3 is typically attached to the tallest gear.

Sets how much Timing Retard takes effect when Nitrous is activated.

Press the N

2O button and adjust the value with the

Nitrous activation is sensed through the Grey wire

spliced to the Black wire between the N

2O Solenoid activates Nitrous Retard. (See Pgs 8& 11)

The N

NSTALLATION CHECKLIST

I

2O Solenoid and the N2O Switch.

and ⇑keys.

⇓

(4-pin, flat connector),

Disconnect the battery’s negative (ground) connections.

Install the your A

Install and connect the 1

Install and connect the N

CCEL ignition module and set its DIP-Switches. (Pg 3)

st

, 2nd, and 3rdswitches. (Pgs 6-11)

2O input. (Pg 11)

Install the trigger input. (Pg 11)

Connect your A

CCEL Timing Retard Module to your ACCEL ignition module. (Pg 3)

Reconnect the battery.

Program your Timing Retard Module for the proper number of cylinders. (Pg 5)

Program reasonable values for 1

Save these initial values into memory with the

st

, 2nd, 3rd, N2O, and Crank. (Pg 5)

SAVE button. (Pg 5)

Adjust and verify the correct engine timing. (Pg 4)

Fine tune any values that need re-adjustment and save the new values.

Page 14

CCEL

A

DRAG RACE COIL

PART # 140010

ACCEL TIMING RETARD MODULE

COMPATIBILITY CHART

ACCEL SUPER COIL

PART # 140009

CCEL 3-STAGE R

ART

# 49345

EV-LIMITER

ACCEL TIMING RETARD MODULE

PART NUMBER - 49355

Any of the A

ignition systems,

in this case an

CCEL 300+.

A

Your ACCEL

CCEL+

TIMING RET ARD

MODULE connects directly to any

Capacitive Discharge ignition system.

If it is connected through an

A

CCEL 3-STAGE REV-LIMITER,

it outputs to the ignition

through the Rev-limiter.

The A

CCEL TIMING RETARD

MODULE accepts input from

any Accel distributor, Crank

Trigger, Nitrous system,

or fuel injection.

Do not connect with

an A

CCEL TIMING

COMPUTER.

ACCEL CRANK

TRIGGER

B

ILLETECH

DISTRIBUTOR

Fuel Injection

and/or

Nitrous system.

Page 15

ACCEL+ TIMING RETARD MODULE

rag Racers must be able to launch off the line hard, with MAXIMUM TIMING ADVANCE.

eat, caused by combustion, can cause engine damaging “Detonation”. Retarding ignition

ming can prevent detonation. The A

esigned for this purpose. Your new A

gnition timing retard for single or multi-stage Nitrous.

When using the A

CCEL+ TIMING RETARD MODULE you have four possible adjustments for

etarding ignition timing, based on four different specific inputs: three gear switches, and

ne Nitrous switch. These four switches do not have to be wired only to the various gears,

r Nitrous, that their control panel keys suggest. If you wish, you can wire the retard

nputs to whichever switch or device you like. You may even want to rig a manual switch

or specific situations, such as driving to or from the race track.

CCEL+ TIMING RETARD MODULE has been specifically

CCEL+ TIMING RETARD MODULE can also adjust

For installation questions call

216-398-8300 Ext-310

Loading...

Loading...