Page 1

Page 2

Congratulations! You have purchased the ACCEL TIMING COMPUTER.

Your ACCEL TIMING COMPUTER allows you to pre-program timing curves, for engines

at use distributors, from 0 to 16,000

ressure with a MAP sensor it can adjust timing for vacuum advance and boost retard. It also

as inputs for Nitrous R

etard and two RPM-activated outputs.

RPM

in 500 RPM increments. When reading manifold

You must use your A

CCEL TIMING COMPUTER with an ACCEL+ ignition module.

Use ACCEL

RACE WIRE spark plug wires!

300+

Solid-core spark plug wires emit RFI and EMI static,

which can disrupt On-board electronics.

Do not use your TIMING COMPUTER with more than 18 volts.

Do not use your TIMING COMPUTER with another timing control module.

They both may try to override each other.

Your ACCEL TIMING COMPUTER, like any electronic component, is sensitive to heat.

Keep it away from temperatures greater than 150°F (65°C)

.

Follow the installation instructions in this Owners Manual carefully.

Incorrect installation can damage the Timing Computer, damage

your engine, and may

VOID YOUR W ARRANTY.

This unit cannot be returned to your

dealer for testing or for warranty.

It must be returned to:

MR. GASKET PRODUCT REPAIR

8700 BROOKPARK ROAD

CLEVELAND

216-398-8300 Ext-310

, OH 44129

Your warranty card must be on record at

A

CCEL to insure warranty processing.

(See your warranty card for details.)

his package provides everything you will need to install your ACCEL TIMING

COMPUTER. Wire lengths provided are enough for almost all vehicles. If you must splice

dditional wire use 16 gauge wire, or larger.

We

STRONGLY recommend you install an ACCEL

Crank Trigger with your Timing Computer.

With no crank trigger you will need a Locked

Distributor and a Rotor Phasing Kit.

To use the Vacuum Advance and Boost Retard

unctions you must install a 2-Bar MAP Sensor

A

CCEL/DFI Part# 74776). Install it either on

he intake manifold or the carburetor base.

(No need for a 3-Bar MAP Sensor)

ADDITIONAL HARDWARE

Page 3

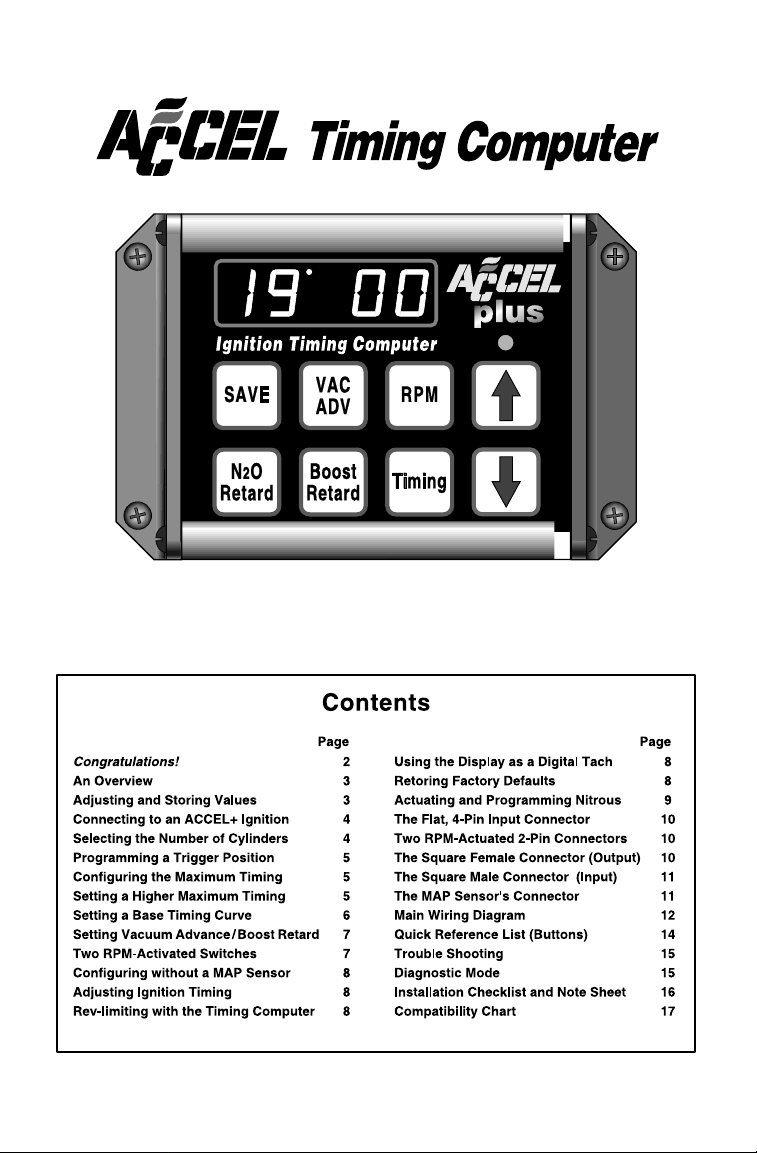

THE TIMING COMPUTER – AN OVERVIEW

our new ACCEL TIMING COMPUTER controls the signals that tell your ignition when to fire.

must be installed between your triggering device (distributor pickup, crank or magnetic

igger, etc.) and your ignition module.

our A

CCEL TIMING COMPUTER also has two

dditional inputs to further adjust timing

alues (from a MAP Sensor and a Nitrous

olenoid). It outputs timing values to your

CCEL+ ignition. It can also output, through

wo internally switched connectors, to two

PM-activated devices (either a Shift Light,

2O solenoid, or even an Air Shifter).

While the A

CCEL TIMING COMPUTER is not a complicated device, installation requires some

pecific knowledge. You will be better prepared for its initial and future configuration if

ou read this manual before installation and keep some important details in mind.

• Use caution when selecting values. Make small changes and then evaluate their effect.

• The rev-limit set in your A

CCEL+ ignition module is your engine’s maximum rev-limit.

Be sure it fits your engines needs and the needs of any additional control modules.

• Disconnect Nitrous, during installation and configuration.

• The A

CCEL TIMING

COMPUTER causes a small fixed timing retard in the trigger, due

to computational delay. Engine timing

MUST be adjusted during and after installation.

• The Timing Computer has three operating modes: Programming Mode, Control Mode, and

Diagnostics. Programming and Control modes overlap (ignition control is performed

while the Timing Computer is in Programming Mode).

Diagnostics Mode see Pg 17.

• It may take a few seconds for the Timing Computer to store saved values. Be sure

the LED display stabilizes, to show your current engine timing, before turning the

module off. Powering off during a save operation may corrupt the unit’s memory.

ADJUSTING AND STORING VALUES

The SAVE button tells the A

CCEL TIMING C

OMPUTER to store all newly adjusted values.

They will be remembered, until they have been re-programmed and then over-written with the

SAVE button.

You can adjust, and test, but not store values by turning

your

TIMING COMPUTER off, without pressing SAVE.

LED’s will display the current timing curve, or the

The

RPM of whatever function you are adjusting.

Page 4

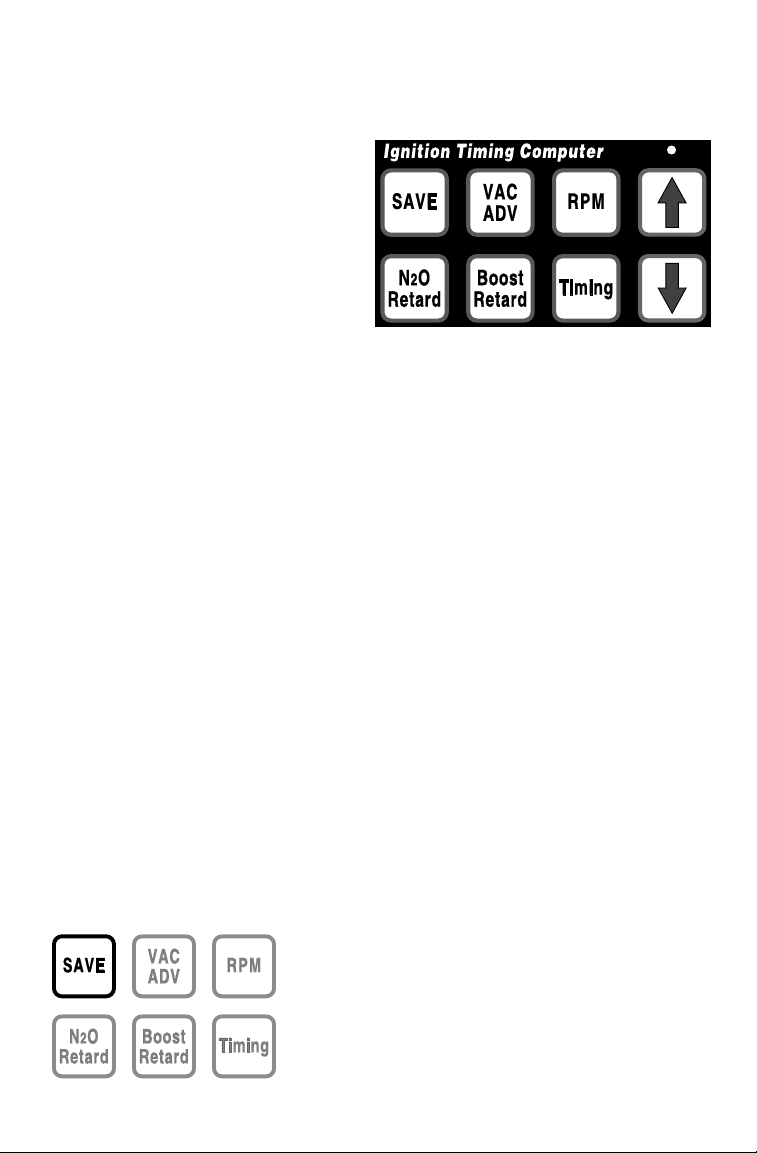

CONNECTING THE ACCEL TIMING COMPUTER

ACCEL IGNITION SYSTEM

TO AN

he ACCEL TIMING COMPUTER uses special signals to communicate with your ACCEL+

gnition, and

• Open the A

Unscrew the screws and swivel it out of the way to reveal the

• Using a small tool (A pencil is good) gently push up

DIP-Switch-4, inside your ACCEL+ ignition module, must be pushed UP.

CCEL+ ignition’s cover plate (the one with the wires coming through it).

DIP-S

witches.

DIP-Switch-4.

This A

set to rev-limit an

engine at 5,000

When connected to any A

module,

DIP-Switch-4 must be pushed UP.

CCEL

300+ ig

nition box has been

8-cylinder

RPM.

CCEL control

DIP-Switch-4

When not connected to a module push

DIP-Switch-4 DOWN.

When not connected to an A

CCEL

control module your ACCEL+ will

not start with

DIP-S

witch-4 UP.

• After you have set dip-switch-4,

close the cover and retighten all

three of its screws.

you move your A

CCEL TIMING COMPUTER to a different car, or make significant changes

o your engine, you probably will also want to change most, if not all, of its stored values.

may be a good idea to treat any major engine change as a brand new installation, and

eprogram your Timing Computer from the ground up.

eep a good record of what values were used, when, and why! These records will be very

aluable, saving both time and parts, if and when you make more changes.

SELECTING THE NUMBER OF CYLINDERS

1. With the unit powered off press and hold

down both the SAVE and RPM buttons.

2. While holding both buttons down, apply power to the Timing Computer.

It will display a number that represents the number of cylinders in an

engine (

the factory default is 8).

3. Use the ⇑and ⇓keys to select the number of cylinders for your engine.

4. When finished, press SAVE. This stores this new information and puts

the module back into Control Mode operation.

If you do not make this selection your

Timing Computer uses the factory default.

Make this selection only once per installation.

Page 5

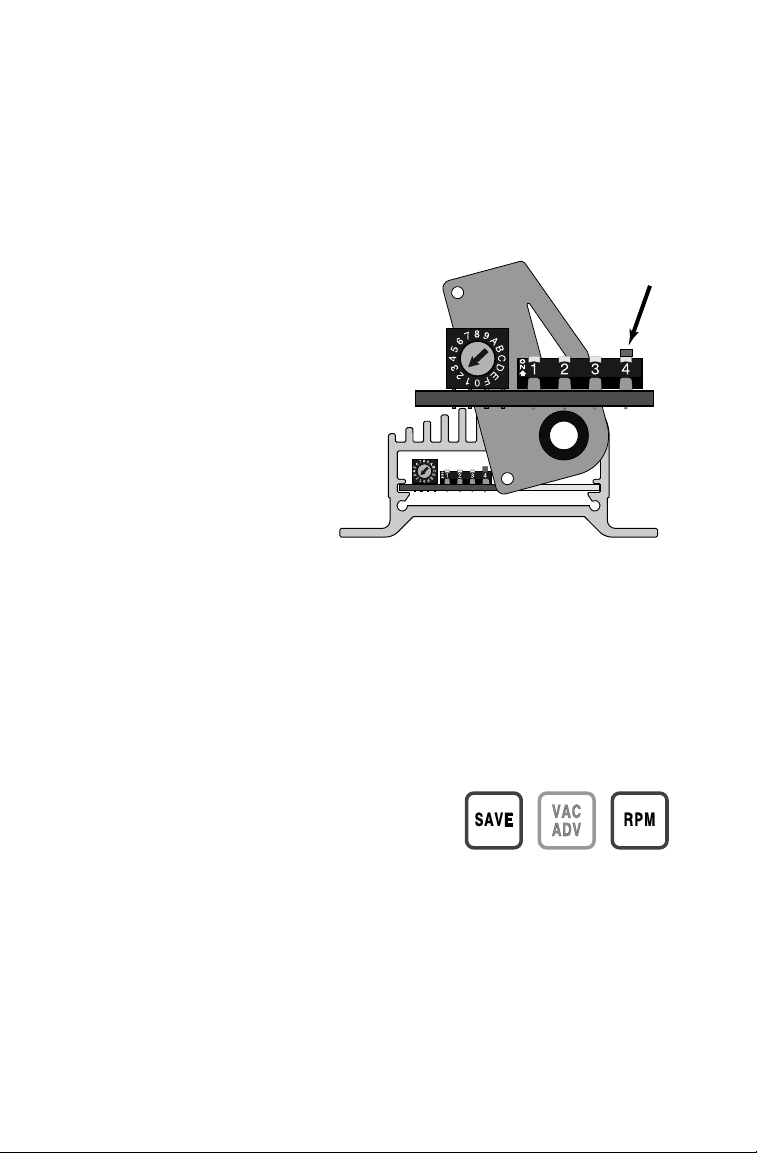

PROGRAMMING YOUR TRIGGER POSITION (Maximum Timing - 34°)

good choice to program for trigger position is the maximum timing you’ll ever use plus 2°.

1. With the engine stopped, and the Timing

Computer powered off, adjust the trigger

(distributor position, crank or mag trigger, etc.)

Programming

Dot

as close to 36° as possible.

2. Press and hold the SAVE and VAC ADV buttons,

and apply power. The unit will display a value for

Trigger Position.

3. Use the ⇑or ⇓key to select 36° (For the example

we are using), and press SAVE to store this new

value and also return to Control Mode.

CONFIGURING MAXIMUM TIMING WITH A CRANK TRIGGER

et your ‘Rotor Phase’to 20° BTDC (most timing curves center around this arbitrary point).

1. Rotate the engine until Cylinder-1 is at 20°

BTDC.

2. Adjust the distributor so the rotor centers on Cylinder-1’s terminal.

The A

CCEL TIMING COMPUTER has a Computational Delay of 2°.

New Timing Computers come with a default trigger

configuration of 36°, for a “Maximum Timing” of 34°.

(Trigger minus 2° Computational Delay = Maximum Timing)

3. To use the factory default, adjust your crank trigger to 36°.

(36°Crank Trigger minus 2° Computational Delay = 34°Maximum Timing)

CONFIGURING MAXIMUM TIMING WITHOUT A CRANK TRIGGER

Instead of a crank trigger use a locked distributor and

a rotor phasing kit, or an A

et your ‘Rotor Phase’ to 20°

1. Rotate the engine until Cylinder-1 is at 20° BTDC.

2. Adjust the rotor (NOT the distributor body) to center on Cylinder-1’s terminal.

3. Adjust your distributor body to match the Timing Computer’s

BTDC (most timing curves center around this arbitrary point).

CCEL BILLETECH distributor.

trigger position (i.e. 36°).

CONFIGURING A HIGHER MAXIMUM TIMING (for example 50°)

1. With the power off, adjust your trigger to 52°.

(52° Trigger minus 2° Computational Delay = 50° Maximum Timing)

2. With the power still off, hold down the VAC ADV and SAVE buttons, and

power-up the unit (Do not start your engine yet).

The LED display will show the current trigger configuration.

3. Push the ⇑button until the display reads 52°

This tells the Timing Computer that the crank trigger is at 52°.

The actual Maximum Timing is 50° (52° minus Computational Delay).

4. Store this new value of 52° by pushing the SAVE button.

5. You can now power-off the unit or continue with further programming,

Page 6

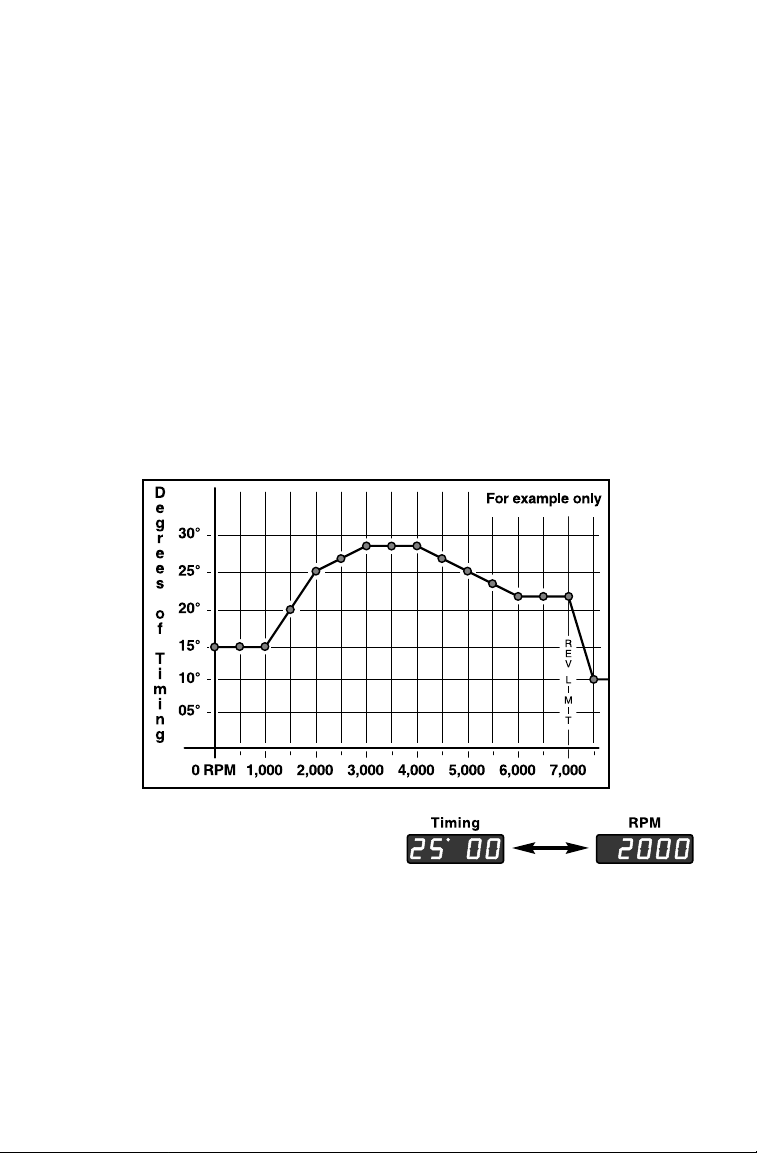

SETTING TIMING – ABASE CURVE

he ACCEL TIMING COMPUTER has been designed to automatically Advance or Retard your

gnition timing to meet changing conditions. You must program a Base Timing Curve

efore it can make any adjustments. The Base T iming Curve is the timing that takes effect

t specific RPM and atmospheric pressure

he Base Curve, and all future adjustments, are done in 1° per 500

1. Begin by pressing the

the

LED display reads the desired RPM value (start at 00000).

2. Press the

TIMING button and, also with the

RPM button. Use the

(no Vacuum, no Boost, no N20, open throttle).

RPM increments.

and ⇓buttons until

⇑

and ⇓buttons,

⇑

modify the value displayed to your pre-determined value.

3. Repeat Step

500

4. When you are satisfied with the values entered press the

-1 and Step-2, increasing the RPM value displayed by

rpm, and modify timing until you reach your Peak RPM.

(Do

NOT skip any of the 500 RPM increments!)

SAVE button,

storing all values currently in effect.

N ALTERNATE METHOD OF REV

A

go another 500

RPM increment and retard timing by 10°–15°.

-LIMITING

– When you reach Peak RPM.

The Timing Computer’s display at 2,000

when you toggle between T

IMING and RPM,

RPM,

or the chart, and timing curve shown above.

f the timing programmed for 1,000

Timing Computer will compute the correct timing for

RPM

is 15°, and the timing for 1,500

1,100, 1,200, 1,300, and 1,400RPM.

RPM is 20°, the

Timing will ramp up slowly from 15° to 20°. There will not be a sudden jump of 5°.

The maximum ignition advance and the trigger position are interdependent. Your A

CCEL

TIMING COMPUTER will not allow a maximum advance beyond trigger position minus 2°.

You cannot set a trigger position less than the timing curve’ s maximum advance plus2°.

Therefore - during installation some of the Timing Computer’s factory defaults may

ave to be modified to smaller values, before you can set the trigger position.

Page 7

SETTING VACUUM ADVANCE / BOOST RETARD

The A

CCEL Timing Computer can program Vacuum and Boost when Manifold Absolute

ressure is read with a 2-Bar MAP Sensor. When Vacuum Advance or Boost Retard takes

ffect, the whole Base Timing Curve either Advances or Retards.

(MAP Sensor info Pg 4)

When Retarding timing, the number displayed is subtracted from the Base Timing Curve.

When Advancing timing, the number displayed is added to the Base Timing Curve.

(Timing, however, can never exceed Maximum Timing.)

Decide how much timing to add for maximum vacuum, and how much to subtract for

maximum boost. Program both values into the Timing Computer by pressing

or

BOOST

RETARD

I.E. If you want 5° extra Advance for maximum vacuum (throttle closed) - press the

VAC ADV button, adjust the display to read 5°, then press the SAVE button.

Assume the Base Curve’s timing is set to 25° at 5,000 RPM - taking your foot

off the

As always; press the

buttons, and adjusting the number displayed with the ⇑or ⇓buttons.

throttle at that speed ramps timing up to 25° + 5° = 30°.

SAVE button and wait for the display to stabilize to store new values.

V AC ADV,

RPM-ACTIVATED SWITCHES

here are two RPM-Activated switches: one with RED &WHITE and BLACK&PINK wires, and

ne with

he other wire is switched to ground inside the Timing Computer. Connect any

BROWN and PINK wires. In each connector, one wire provides battery power and

RPM-

ctivated device (Shift Light, Air Shifter, N2O Actuator) to either one.

Setting the BROWN

and PINK Connector

1. Press RPM and BOOST RETARD

at the same time.

2. Adjust the value displayed with the

and ⇓buttons.

⇑

3. Store new value with the SAVE button.

Setting the RED & WHITE

and BLACK & PINK Connector

1. Press RPM and N2O RETARD

at the same time.

2. Adjust the value displayed with the

and ⇓buttons.

⇑

3. Store new value with the SAVE button.

Page 8

CONFIGURING WITHOUT A MAP SENSOR

lthough we do recommend a MAP Sensor, you can operate without one. For best results

se Magnetic Triggering, or a Points Distributor with mechanical advance locked out.

o not adjust or remove the Vacuum Advance mechanism on the distributor.

1. Program your Base Timing Curve as described on Pg 6.

2. Set VAC ADV and B

OOST RETARD both to 0°.

3. Press SAVE to store all new values.

ADJUSTING YOUR IGNITION TIMING TO PROPER SPECIFICATIONS

1. Start your engine and then press the TIMING and VAC ADV keys.

The Timing Computer displays the number of degrees BTDC ignition timing.

2. Use the

and ⇓keys to select one of the engine timing marks as a value.

⇑

Your Timing Computer will use this fixed ignition timing, regardless of

engine speed or other inputs.

3. Make fine adjustments to your trigger input, with a Timing Light,

so it matches the value on the Timing Computer’s display.

4. Return the display to Control Mode by pressing the TIMING button twice.

REV-LIMITING WITH THE

TIMING COMPUTER

our ACCEL+ ignition has the final say in rev-limiting, but there are ways you can use

he Timing Computer to rev-limit at a lower engine speed than what has been set in the

gnition box. One way is to retard timing by 10° – 15° at your chosen engine speed, as

hown on Page 7. Another way is program a rev-limit with the Accel Timing Computer.

1. Press the RPM and VACADV keys to get into Programming Mode.

The current value for rev-limit will display.

2. Use the

(

Note: Your ACCEL+ ignition rev-limits in 250 RPM increments.)

3. Press the RPM button twice, to return to Control Mode, and then press SAVE.

and ⇓keys to adjust this value in 100 RPM increments.

⇑

USING THE DISPLAY AS A DIGITAL TACHOMETER

ou can make your Timing Computer display engine RPM by simultaneously pressing

oth the

RPM and TIMING keys. It will continue displaying as a digital tachometer until

ou enter Programming Mode. When you exit from Programming Mode the LED’s will

nce again display engine timing.

RESTORING THE FACTORY DEFAULT SETTING

ou may decide, for one reason or another (such as replacing a major engine component)

o restore the Timing Computer’s original Factory Defaults. To restore Factory Defaults:

1. Turn the power OFF.

2. Press and hold down SAVE and BOOST RETARD and apply the power.

When the display reads 12300 release both keys.

FACTORY SETTINGS: a default timing curve, no adjustment for additional inputs,

RPM Activated Switch-1 set at 4,500

RPM, Switch-2 set at 6,500 RPM,

no rev-limit, Cylinders = 8, Trigger Position set to 36° BTDC.

Page 9

ACTUATING N2O

Brown and

Pink wires

nstall all your N2O hardware according to the manufacturer’s instructions. If you are

sing an A

CCEL

3-STAGE REV -LIMITER to trigger N2O, follow the Rev-limiter’s instructions.

using a third party’s actuator, follow that manufacturer’s instructions.

our new A

CCEL TIMING COMPUTER

as two RPM-Activated switches connected to two 2-pin connectors.

Use one of them to actuate N

or consistency use the connector

ROWN and PINK wires.)

ith the B

2O.

ssemble it by splicing the N2O

olenoid’s Red (+) wire

o the Pink wire, and its Black wire to the Brown wire.

he N

2O solenoid is actuated through one of five possible connections: one of the two

-pin connectors coming from the Timing Computer,

oming from an A

CCEL 3-STAGE

REV-LIMITER

OR a third party actuator.

,

OR one of two 2-pin connectors

Both 2-pin, female output connectors are switched to Ground inside

he Timing Computer, and both connectors supply enough power to

rive multiple solenoids. Two solenoids, wired

n parallel, is common but different solenoids

may have different energy requirements.

he

ACCEL TIMING COMPUTER can drive up to three HURST solenoids (Roll Control solenoid

alve – Part# H566 7550) wired, in parallel, to either of these two 2-pin outputs.

N

2O makes more oxygen available for combustion and the air/fuel mixture burns very fast.

s a result, the mixture should be richened and the ignition timing Retarded.

PROGRAMMING NITROUS ACTUATION

he connector with the Red& White and Black & Pink wires is programmed by the RPM

nd N2

O RETARD

buttons. These buttons and this connector do not effect N

1. Decide at what

2. Press RPM and N2

3. Adjust the value with the

RPM you want N2

O RETARD

to display its current value.

and ⇓buttons.

⇑

O to be activated.

2

O retard.

4. Press SAVE to store the new value.

PROGRAMMING

NITROUS R

ETARD

(Through the Flat, 4-Pin Connector – See Pg 10)

o matter how N2O is triggered, the Timing Computer reads when it has been actuated

hrough its flat, 4-pin connector. The buttons and connectors do not affect N

When the N

2O solenoid is actuated the entire value set for N2O Retard is immediately

2O actuation.

ubtracted from the timing curve.

1. Decide exactly how much Retard you want.

2. Press the N2O RETARD button to display its current value.

3. Adjust with the

and ⇓buttons.

⇑

4. Press SAVE to store your adjustments.

Page 10

THE 4-PIN, FLAT, INPUT CONNECTOR

he 4-pin, flat connector is your ACCEL TIMING COMPUTER’s main power input.

It also inputs signals from the N

2O actuator

for Nitrous timing retard.

RED Connects to +12 volts.

B

LACK Connects to Ground.

G

RAY Connects to the Black ground

wire from the N

Y

ELLOW Connects to the Red +12 volt

power wire from the N

2O actuator.

2O actuator.

TWO RPM-ACTIVATED 2-PIN OUTPUT CONNECTORS

ince both connectors are powered and switched to ground inside the Timing Computer,

ither connector can be used for any

witch or power source. The RPM-1 Pink wire and the RPM-2 Red

ontinuos battery voltage. Both

RPM-Activated device. Neither needs an external

&White wire supply

RPM-Activated switches can drive multiple solenoids.

Please, be sure to wire the correct connectors to their correct solenoids and devices!!

THE SQUARE, FEMALE OUTPUT CONNECTOR

he square, female plug is the TIMING COMPUTER’s

main output connector.

Connect it to an A

CCEL+ ignition, OR

Connect it through your ACCEL 3-STAGE

REV-

LIMITER to an ACCEL

+ ignition.

In either case the square, male (input)

connector should already be in place.

If it has not yet been wired,

see the A

Remember: when using an A

miter, you must use an A

CCEL+ Ignition’s manual.

CCEL 3-Stage Rev-

CCEL+ ignition system,

with DIP-Switch-4 pushed up).

using your A

CCEL TIMING COMPUTER with any

xternal rev-limiter, the rev-limiter is placed

etween the Timing Computer and the A

CCEL+.

To an A

CCEL 3-STAGE

REV-LIMITER

The Square, output

connector plugs into

+ ignition or

CCEL

an A

CCEL 3-STAGE

an A

REV-LIMITER.

To an ACCEL+

Ignition

Page 11

THE SQUARE, 4-PIN, MALE INPUT CONNECTOR

he ACCEL TIMING

COMPUTER

inputs from all kinds of trigger types, except distributor-less,

nd its digital, micro-processor controlled, rev-limiter will be as sensitive as your trigger.

We recommend an

re read through the square male connector:

Your ACCEL+ ignition system should already have this connector in place.

he W

HITE wire’ s input is in the form of

Square Wave. It gets this input from

ACCEL Billetech Distributor or ACCEL Crank Trigger. Triggering inputs

WHITE

wire, or the PURPLE and ORANGE wires.

:

• All points ignitions

• Most fuel injections

HEI modules

• Some

PURPLE and ORANGE wires get their

he

nputs from magnetic pickup or crank-

iggered systems

PURPLE wire is a positive (+) input

he

ORANGE is a negative (–) input.

nd the

(See chart for various connections.)

your system uses the WHITE wire you

ust isolate and insulate the

PURPLE

nd ORANGE wires. If your system uses

PURPLE and ORANGE wires you must

he

olate and insulate the

CCEL Crank triggers may connect WHITE to PURPLE and BLACK to ORANGE.

Older A

*

WHITE wire.

THE MAP (MANIFOLD ABSOLUTE /AIR PRESSURE) SENSOR CONNECTOR

he MAP Sensor’s signal to the Timing Computer is through the flat, 3-pin connector.

BAR

nstall a 2-

MAP Sensor, according to its own instructions and plug the Timing

Computer’s male connector into the sensor’s 3-pin female port.

he MAP Sensor reads intake manifold pressure. This makes it possible for the Timing

Computer to adjust to a predetermined timing curve under Vacuum or Boost conditions.

Use an A

(No need for a 3-Bar MAP Sensor, even with high boost.)

CCEL / DFI 2-BAR MAP Sensor, Part# 74776

he MAP Sensor measures pressure. Manifold Absolute Pressure is near 0 BAR at high

acuum, near 1

BAR at wide open throttle, and up to 2 BAR at about 14 PSI of Boost.

Vacuum sensing provides a linear advance of the Base Timing Curve from 0° to full

dvance during high vacuum conditions.

I.E. You have set Maximum vacuum advance

t 10°. At wide open throttle there is little intake manifold vacuum and ignition timing

ollows the

dds 5° (

RPM curve. At light load (.5 BAR, about 15 inches of Hg) the Timing Computer

half the 10° Maximum Timing) to the Base Timing Curve.

Boost retard works the same but in the opposite direction: Suppose you program a Boost

Retard value of 6° at the maximum sensing boost of 1

about 7 PSI) boost the Timing Computer retards ignition 3° from the Base Timing Curve.

BAR (about 14 PSI). At 0.5 BAR

Page 12

Page 13

Page 14

QUICK REFERENCE

When setting Timing this button will show a value for RPM.

This button is also used, with other buttons, for other functions.

Shows Timing at a selected RPM.

It is also used with other buttons for other functions.

These buttons

increase or decrease

the displayed values.

Adjusts the entire Timing Curve up, for Vacuum Advance, in 1° increments.

Can only be used with an A

Adjusts your entire Timing Curve down, for Boost Retard, in 1° increments.

Can only be used with a MAP Sensor.

CCEL 2-Bar MAP Sensor (Part# 74776).

Adjusts the entire Timing Curve down, for N

Do not confuse Programming N

2O Retard with Actuating a N2O solenoid.

2O Retard, in 1° increments.

Toggles the display between a digital tachometer and ignition timing.

Fixes ignition timing, regardless of engine speed or other inputs. Use

arrow keys to modify. This mode is used to set ignition timing with a

timing light and by moving the trigger point to match that value.

Sets the Maximum RPM rev-limit. Use the arrow keys to set this

value in 100 RPM increments. Cannot exceed the rev-limit set by

your A

CCEL+ ignition box.

Controls output to RPM-Activated Switches.

These buttons control RPM Switch-1. If actuating a N

2O solenoid,

use the connector controlled by these two buttons.

The other RPM-Activated function.

These buttons control Switch-2.

When the

SAVE button is pushed, alone or with another button, all current

values are stored. You can adjust values and not store them by turning off the

ignition before pushing

SAVE. Previously stored values will be remembered.

Page 15

TROUBLE SHOOTING THE ACCEL TIMING COMPUTER

LED’s do The Timing Computer is not getting power.

not display Check the 4-Pin connectors’s Red and Black wires. See Pg 10.

Timing light does The engine was not retimed when the Timing Computer was

not show the originally installed, or the wrong number of cylinders was selected

programmed value Re-time the engine. Check the number of cylinders (4, 6, or 8).

(Incorrect cylinder selection can also cause incorrect tach readings.)

LED’s The Timing Computer is not getting a trigger.

Display Check the square input (male) connector,and check all its wires.

0 RPM timing See wiring diagram on Pg 12, and the Triggering chart on Pg 11.

Your A

CCEL+ DIP-Switch-4 inside your ACCEL+ ignition is down.

sparks randomly See Pg 4.

Status Light on The ignition is not firing, or the Timing Computer has unplugged

Your A

CCEL+ from the ignition. The battery may be low.

is Dim If the connectors and battery are OK, pull a spark plug, lean it

against the engine. It should spark as you crank the starter. See Pg 12.

Status Light on The unit is not sending a trigger signal, probably because

Your A

CCEL+ it is not receiving a trigger signal. Check the trigger device

is O

FF and the square, input connector. See Pg 10.

DIAGNOSTIC MODE

our ACCEL TIMING COMPUTER has features that test functions through your key pad.

iagnostic Mode does not perform any Control Mode engine functions, and if you enter

iagnostic Mode with the engine running, your engine will stall.

(Read this whole section before entering Diagnostic Mode)

ISPLAY, PROCESSOR, and MEMORY test

Enter Diagnostic Mode by simultaneously pressing and releasing three keys:

N2O RETARD, BOOST RETARD, and TIMING. The display will show 00000.

About every two seconds the display will increment: 11100, 22200, up to 99900.

The ‘degree dot’ will appear with the odd numbered (

EY PAD test

When

99900

appears the ‘programming dot’will start flashing. From now on you must

33300, 55500) displays.

press the proper key within eight seconds or the module will return to Control Mode.

Keys must be pressed in order:

DISPLAY PRESS

99900 N2O RETARD

11100 BOOST

22200 TIMING

33300

44400

55500 RPM

66600 SAVE

77700 VAC ADV

RETARD

(DOWN Arrow)

⇓

(UP A

⇑

rrow)

After each key is pressed the display will update.

It starts at

11100 and increments to 77700 as

each key is pressed, in order. If the proper key

is not pressed within eight seconds Diagnostic

Mode ends and returns you to Control Mode.

If you press the correct key and the display does

not update (and the unit exits Diagnostics), the

test has found a key pad failure.

When the last key (

VAC ADV) is released the unit

returns to Control Mode operation.

Page 16

INSTALLATION

C

HECKLIST

Disconnect the battery’s negative (ground) connections.

If Nitrous has been installed, disconnect the Nitrous solenoid. (Pg 9)

Install the your A

Connect to the MAP sensor, and N

Connect your A

CCEL ignition module and set its DIP-Switches. (Pg 4)

2O Retard, Shift Light, Trigger Input.

CCEL Timing Computer to your ACCEL+ ignition module.

Reconnect the battery.

Set and save the number of Cylinders in the Timing Computer. (Pg 4)

Program and Save the Trigger Position. (Pg 5)

Decide on a Base Timing Curve and enter all the values. Save them. (Pg 6)

Program and save reasonable values for the N

2O and Shift Light.

Decide on a rev-limit for the Timing Computer. Set and save it. (Pg 8)

If any values are not yet saved, press SAVE now.

Start the engine, adjust, and verify engine timing.

Verify N

2O activation with the Shift Light, then connect the N2O solenoid.

INSTALLATION NOTES

Date Installed: Serial Number: ACCEL+ Rev-limit: Cylinders:

Other Engine Control Modules?

Trigger Position:

Base Timing Curve (enter all values to maximum RPM):

Vacuum Advance: Boost Retard:

Nitrous actuation: Nitrous retard:

RPM-Activated Switch #1: RPM-Activated Switch #2:

gnition Timing: Timing Computer Rev-limit:

Other:

Page 17

A

CCEL

DRAG RACE COIL

PART # 140010

ACCEL TIMING COMPUTER

COMPATIBILITY CHART

Any of the ACCEL+ family

of ignition systems, in

this case an

CCEL 300+.

A

ACCEL SUPER COIL

PART # 140009

ACCEL

3-STAGE

REV-LIMITER PART # 49345

ILLETECH

B

DISTRIBUTOR

Your ACCEL TIMING COMPUTER

connects directly to any of the ACCEL

Capacitive Discharge ignition systems.

If it is connected through an

A

CCEL 3-STAGE

REV

-LIMITER,

and it outputs to the ignition

through the Rev-limiter.

The A

CCEL TIMING COM

PUTER accepts input from

any Accel distributor, Crank

Trigger, Nitrous system, or

A

CCEL DFI system.

Do not connect with an

A

CCEL

TIMING R

ETARD

MODULE.

ACCEL CRANK

TRIGGER

-

Loading...

Loading...