Page 1

FORM 1532 (REV. A) 8/01

®

HIGH VOLUME FUEL RAILS

FOR GM TPI

Part No. 4311M

APPLICATIONS: Small Block Chevy V8 with TPI or Accel Super Ram

Electronic Fuel Injection.

PARTS LIST:

INSTALLATION INSTRUCTIONS

1 Drivers side fuel rail

1 Passenger side fuel rail

1 Hose, -6AN braided 90°

1 Hose, -6AN braided 90°/45°

1 Pressure regulator

1 Regulator bracket

2 Regulator bracket screws

GENERAL INFORMATION

A factory repair manual should be referred to during installation.

Mallory fuel rails can be used on stock engines. However, the

adjustable, high flow, remote mount regulator makes this kit ideal

for high performance engines using high flow fuel pumps.

Adapter fittings and 6AN lines are supplied which allow Mallory

fuel rails to be connected to the stock fuel line and return line.

However, applications over 500 horsepower should use largerthan-stock lines. Mallory fuel rails and regulator accept 8AN for

those applications over 500 hp. Recommended line and pump

sizes are listed after the installation portion of this form.

NOTE: These instructions show installation on an F-body

(Camaro/Firebird). Installation on a Corvette is similar, however, the routing of the fuel lines and the mounting location of

the regulator may be different.

ASSEMBLE THE FUEL RAILS AND REGULATOR

See Photos 1 and 2

1) Make sure to install the supplied o-rings on all -8AN port

fittings before installing the fittings into the rails and regulator.

2) The supplied -8AN port plugs may be hex or button head.

3) Engines equipped with a cold start injector will use the

-8AN port to cold start adapter in the end of the drivers side

rail. If a cold start injector is not used, install a -8AN port plug

in the end of the rail.

4) O-rings are supplied for the crossover tubes. Be sure to lubricate o-rings with oil before pressing the tubes into the rails.

5) Connect the hoses to the rails and regulator, but leave the

fittings loose until the rails are installed on the engine. This

makes it easier to route the hoses around obstructions.

6) The extra ports on the regulator can be plugged with supplied

plugs or used for gauge ports or used to supply fuel for a

nitrous system. Be sure to use thread sealer on any tapered

NPT fittings.

INSTALL RAIL ASSEMBLY ON THE ENGINE

See Photo 3 and Photo 4

1) Remove the upper manifold, runners, and stock fuel rails

(consult a repair manual for more information).

2 Crossover tubes

2 O-rings for crossover tubes

3 Fittings, -8AN port to 6AN male

2 Fittings, -8AN port plug

1 Fitting, -8AN port to 6AN female

1 Fitting, -8AN port to cold start adapter

6 O-rings, for 8AN ports

2) Remove the injectors from the stock fuel rails by removing the

small metal clips near the top of each injector. Save these

clips they must be re-used.

3) Re-install the metal clips onto the injectors. Lubricate injector

o-rings with oil. Press the injectors into the Mallory rails.

NOTE: The clips must be on the injectors to prevent the

injectors from extending too deep into the rails and damaging the o-rings.

4) Install the rail assembly (with injectors) onto the lower manifold. Oil on the lower o-rings will help the injectors press into

the mainfold easier. The stock bolts can be re-used to hold

the rails to the lower manifold.

5) Connect the cold start injector (if applicable).

6) Using the nut and washer supplied, mount the regulator to

the stud on the shock tower (see photo).

7) Connect the factory fuel line to the Mallory hose with the -6AN

to 3/8 Saginaw fitting. Connect the factory return line to the

return port on the bottom of the regulator.

8) Use one of the extra ports on the regulator to connect a pressure gauge (if desired).

9) Find the vacuum hose that was originally connected to the

stock fuel pressure regulator. Connect this hose to the small

barb on the Mallory regulator. Because the regulator is mounted

remotely, an additional length of vacuum hose will be needed.

10) Turn the pump on and check for leaks.

NOTE: If the system will not prime properly, remove the adjustment screw from the regulator until the system is primed.

11) Reinstall the upper manifold, runner, and any other components that were removed earlier.

12) Set the fuel pressure. Loosen the jam nut on the regulator

and turn the adjustment screw while the pump is running to

adjust fuel pressure. Clockwise increases pressure. The best

fuel pressure depends on many variables. However, a starting point of about 45 psi (with the vacuum line disconnected)

is usually close.

2 Fittings, brass 3/8NPT plug

1 Fitting, -6AN to 3/8 Saginaw

1 Fitting, -6AN to 5/16 Saginaw

1 Nut, 8mm x 1.25

1 Lockwasher, 8mm

www.mrgasket.com 1

Page 2

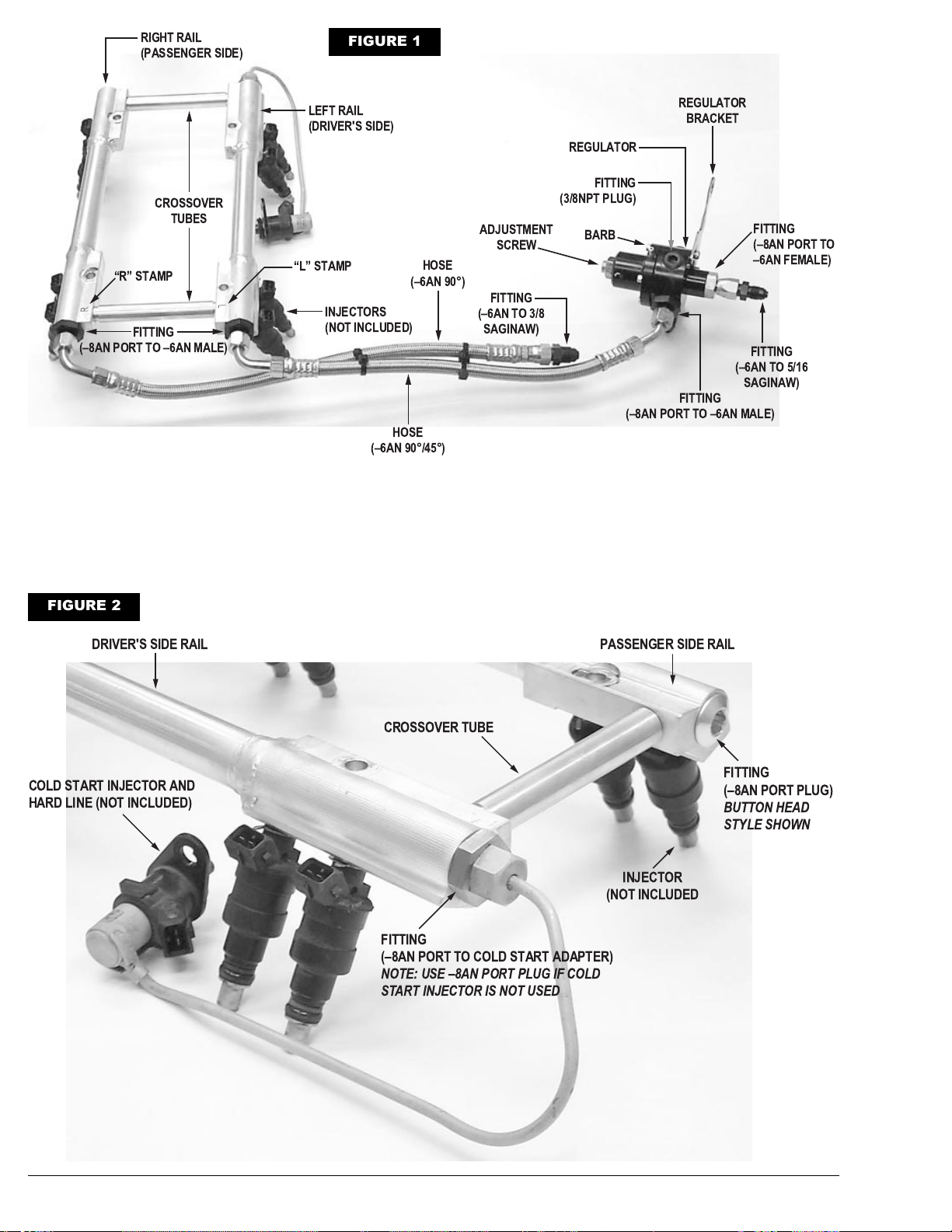

RIGHT RAIL

(PASSENGER SIDE)

FIGURE 1

CROSSOVER

TUBES

R STAMP

R

FITTING

(8AN PORT TO 6AN MALE)

LEFT RAIL

(DRIVER'S SIDE)

REGULATOR

FITTING

(3/8NPT PLUG)

ADJUSTMENT

SCREW

L STAMP

L

INJECTORS

(NOT INCLUDED)

(6AN 90°/45°)

HOSE

(6AN 90°)

FITTING

(6AN TO 3/8

SAGINAW)

HOSE

BARB

(8AN PORT TO 6AN MALE)

REGULATOR

BRACKET

FITTING

(8AN PORT TO

6AN FEMALE)

FITTING

(6AN TO 5/16

SAGINAW)

FITTING

FIGURE 2

DRIVER'S SIDE RAIL

COLD START INJECTOR AND

HARD LINE (NOT INCLUDED)

PASSENGER SIDE RAIL

CROSSOVER TUBE

FITTING

(8AN PORT PLUG)

BUTTON HEAD

STYLE SHOWN

INJECTOR

(NOT INCLUDED

FITTING

(8AN PORT TO COLD START ADAPTER)

NOTE: USE 8AN PORT PLUG IF COLD

START INJECTOR IS NOT USED

www.mrgasket.com2

Page 3

METAL INJECTOR

CLIPS MUST BE IN

PLACE BEFORE

INSERTING

INJECTORS INTO

MALLORY RAILS.

FIGURE 3

GAUGE LINE

(IF DESIRED)

FIGURE 4

SHOCK

TOWER

VACUUM HOSE

RETURN LINE

FUEL LINE

www.mrgasket.com 3

Page 4

FUEL LINE SIZE

Fuel line size is determined by the horsepower of the engine.

Up to 350 HP 5/16" or 4AN

Up to 500 HP 3/8" or 6AN

Up to 700 HP 1/2" or 8AN

Up to 1200 HP 5/8" or 10AN

RETURN LINE SIZE

Return line size is determined by the output of the fuel pump.

Up to *29 gal/hr (110 liters/hr) 1/4" or 3AN

Up to *45 gal/hr (170 liters/hr) 5/16" or 4AN

Up to *90 gal/hr (340 liters/hr) 3/8" or 6AN

Up to *180 gal/hr (680 liters/hr) 1/2" or 8AN

*Pump output @ 45psi

PUMP SIZE

Pump size is determined by the horsepower of the engine.

Horsepower x .083 = gallons per hour @ 45 psi

Example: 500hp x .083 = 42 gal/hr

or

Horsepower x .314 = liters per hour @ 45 psi

Example: 500hp x .314 = 157 liters/hr

NOTE: add 25% to pump size for supercharged applications.

MALLORY IS A DIVISION OF THE MR. GASKET PERFORMANCE GROUP

550 MALLORY WAY, CARSON CITY, NEVADA 89701

(775) 882-6600 FAX (775) 887-4326

www.mrgasket.com4

FORM 1532 (REV. A) 8/01

Made in U.S.A.

Printed in U.S.A.

Loading...

Loading...