Page 1

T

ECHNICAL INFORMATION

PRODUCT

P 1/ 8

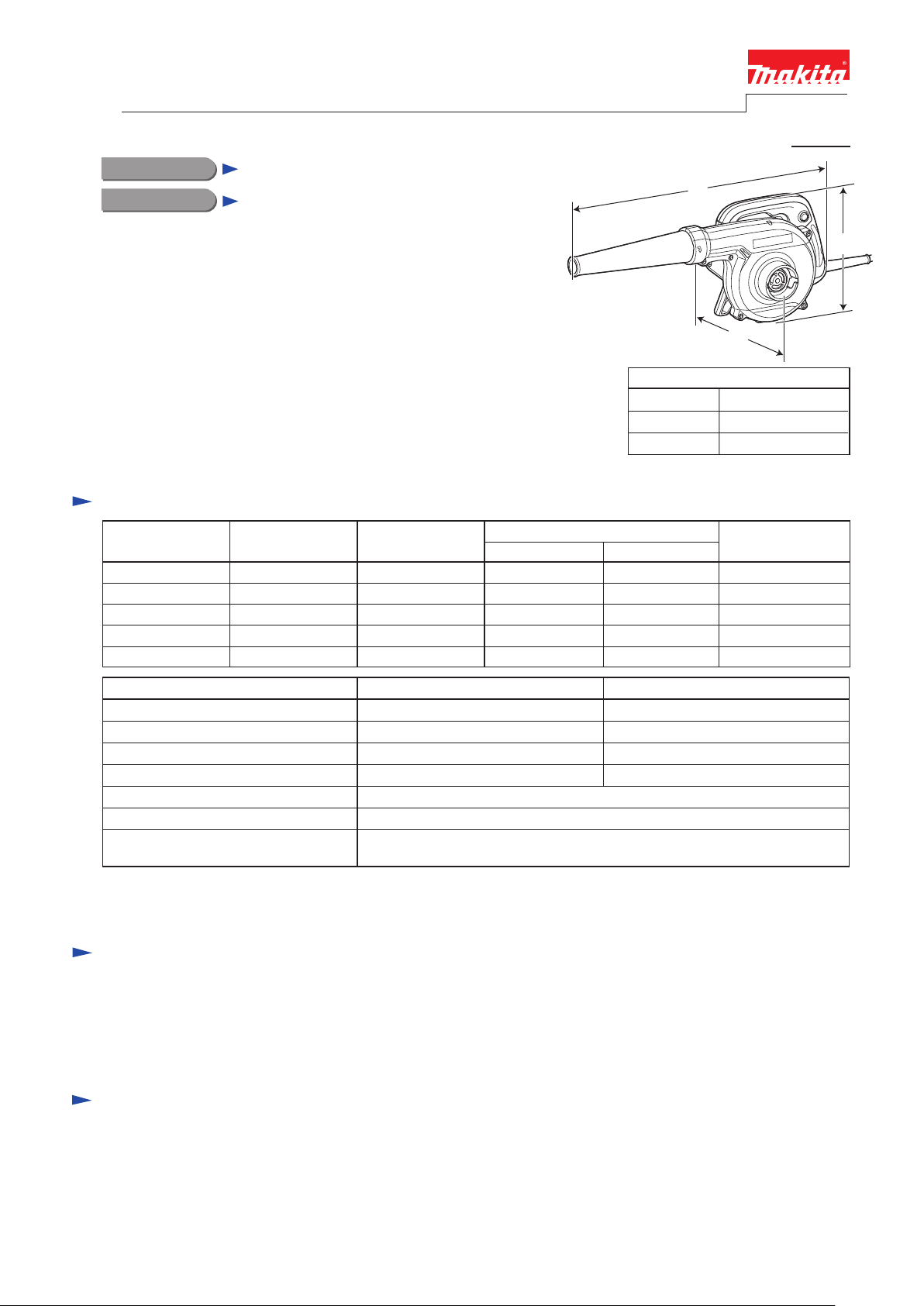

Model No.

Description

UB1102, UB1103

Blower

CONCEPT AND MAIN APPLICATIONS

Models UB1102, UB1103 Blowers are successors of UB1100, UB1101.

Their output air volume is 4.1m³/min. over the predecessors 2.8m³/min.

The other features are as follows:

• Ergonomic designed handle with elastomer for more comfortable

and controlled operation

• Self-standing design enables stationary use, easy storage and upside-down

standing

The specification difference between UB1102 and UB1103 is;

UB1102: Single speed

UB1103: Variable speed control by dial and trigger

Specification

Voltage (V) Cycle (Hz)

110

220

230

240

Current (A)

5.7

2.9

2.8

2.7

50/60

50/60

50/60

50/60

Length (L)

Width (W)

Height (H)

Continuous Rating (W)

Input Output

600

600

--- ---

--- ---120 6.8 50/60 ---

--- ---

--- ---600

--- ---600

L

H

W

Dimensions: mm (")

479 (18-7/8)

185 (7-1/4)

178 (7)

Max. Output (W)

Model No. UB1102

No load speed: min.

Max. air volume*

Max. sealed suction: kPa

Variable speed control

Protection against electric shock

Power supply cord: m (ft)

Weight according to

EPTA-Procedure 01/2003*2: kg (lbs)

*1 Without Nozzle, Joint

*2 With Nozzle, Joint

ˉ¹=rpm

1: m³/min.

16,000

4.1

5.7

No

Double insulation

Australia: 0.5 (1.64), Others: 2.5 (8.2)

Standard equipment

Nozzle .....................................1

Joint .........................................1

Dust bag (capacity of 2L) .......1 (for some countries)

Note: The standard equipment for the tool shown above may vary by country.

Optional accessories

Dust bag assembly

Nozzle assembly

Long nozzle assembly

Flexible hose set

Anchor nozzle set (for vacuum function only)

Bending long nozzle set

UB1103

0 - 16,000

0 - 4.1

0 - 5.7

Yes

2.0 (4.3)

Page 2

P 2/ 8

Repair

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

[1] NECESSARY REPAIRING TOOLS

Code No. Description Use for

1R370 connecting Ring terminals to Brush holderRing Terminal Setting Jig

1R063 assembling Field to Motor housing completeGuide Bar for fitting Field

[2] LUBRICATION

It is not required to lubricate, because the product has no gear mechanism to be lubricated.

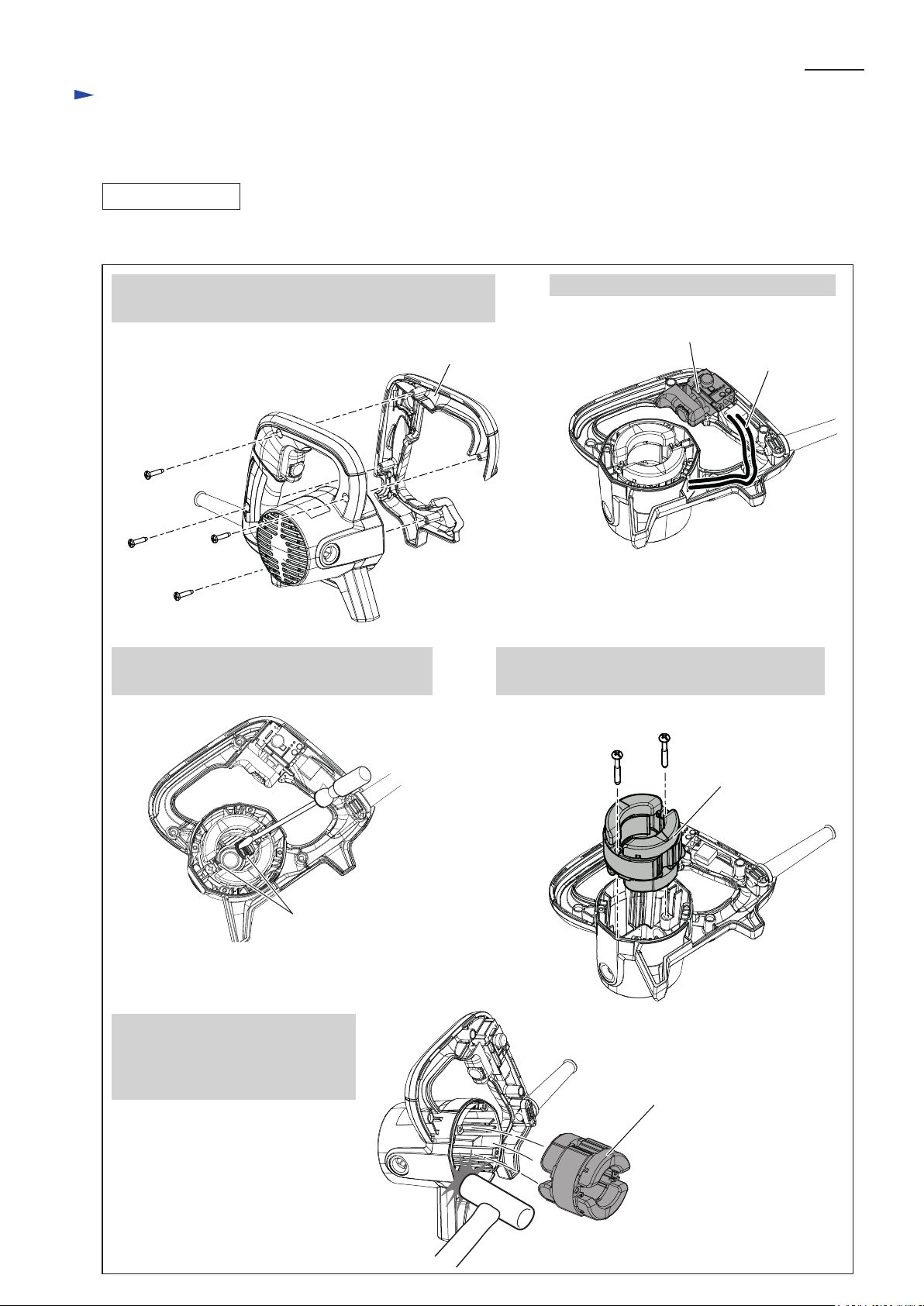

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Switch

DISASSEMBLING

1. Switch can be disassembled without separating Fan housing complete section. See Fig. 1.

Fig. 1

1. Remove four 4x18 Tapping screws

that secure Handle cover to Motor

housing.

Handle cover

4. Remove Switch from Handle section

of Motor housing complete.

Switch

2. Separate Handle cover, pulling toward Fan housing complete side

(pulling toward the direction designated with arrow No.1.)

3. Disassemble Handle cover by broadening Handle cover (pulling

its ends toward the direction designated with arrow No. 2).

Now, Handle cover is removed.

Handle cover

Fan housing

complete

No.1

No.2

ASSEMBLING

Assemble Switch by reversing the disassembly procedure. Refer to Fig. 1.

Note: When mounting Handle cover, be careful of the following.

• Switch and Lead wire are not pinched with Handle cover.

Refer to Fig. D-2 and Fig. D-3.

• There are no gaps between Handle cover and Fan housing complete.

Page 3

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -2. Fan Section

DISASSEMBLING

Disassemble Fan 110 as drawn in Fig. 2.

Fig. 2

P 3/ 8

1. Remove Nozzle.

3. Unscrew five 4x18 Tapping screws

and remove Fan cover.

Fan cover

Nozzle

2. Remove Set plate by prying it off with

a small slotted screwdriver.

Set plate

Fan cover

4. Remove M5-8 Hex nut by turning it

counterclockwise with an impact driver while

holding Fan 110 firmly with a gloved hand.

5. Remove Flat washer 5, Fan 110 and Flat washer 8.

M5-8 Hex nut

Fan 110

Flat washer 5

Flat washer 8

ASSEMBLING

Assemble Fan Section by reversing the disassembly procedure. Refer to Fig. 2.

Note: Align the hole on Set plate with the protrusion on Fan cover, and insert Set plate by hand, then push it

with a small screwdriver until it stops.

Refer to the drawing on the top right in Fig. 2.

Page 4

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -3. Motor Section

DISASSEMBLING

(1) Remove Carbon brush as drawn in Fig. 3.

Fig. 3

Carbon brush

(2) Disassemble Fan section as drawn in Fig. 2.

(3) Disassemble Armature as drawn in Fig. 4.

P 4/ 8

Fig. 4

1. Unscrew four 4x35 Tapping

screws and disassemble Fan

housing complete.

Fan housing

complete

2. Remove Flat washer 8 from

Armature shaft.

Flat washer 8

3. Remove Armature from

Motor housing.

Armature

Page 5

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -3. Motor Section (cont.)

DISASSEMBLING

(4) Disassemble Field as drawn in Fig. 5.

Fig. 5

P 5/ 8

1. Unscrew four 4x18 Tapping screws and remove Handle

cover.

Handle cover

3. Disconnect Ring terminals from Brush holders

with a Slotted screwdriver.

2. Disconnect Field lead wires from Switch.

Switch

Field lead wire

4. Unscrew two 5x40 Tapping screws and remove

Field from Motor housing.

Ring terminal

Note:

Tapping the edge of Motor housing

with a plastic hammer enables Field

to be removed easily.

Field

Field

Page 6

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -3. Motor Section (cont.)

ASSEMBLING

(1) Assemble Field to Motor housing. Refer to the drawing on the middle right in Fig. 5.

Also see Fig. D-2 about the wiring of Field lead wires.

Note: Using 1R063 enables Field to be assembled easily than by hand. See Fig. 6.

Fig. 6

Field

P 6/ 8

1R063

Fig. 7

(2) Connect Ring terminal to Brush holder using 1R370. See

Fig. 7

1R370

Ring terminal

(3) Connect field lead wires to Switch and mount Handle cover to Motor housing with four 4x18 Tapping screws.

Refer to the drawings on the top left and right in Fig. 5.

(4) Insert Armature into Motor housing. Refer to the drawing on the right in Fig. 4.

(5) Mount Flat washer 8 to the drive end of Armature's shaft. Refer to the drawing on the center in Fig. 4.

(6) Assemble Fan housing complete with four 4x35 Tapping screws. Refer to the drawing on the left in Fig. 4.

(7) Assemble Fan 110 and Fan cover. Refer to Fig. 2.

And then, set Carbon brush. Refer to Fig. 3.

.

Page 7

Circuit diagram

Fig. D-1

Lead wire (white or blue) of Power supply

cord connected to P2 terminal

Lead wire (black or brown) of Power supply

cord connected to P1 terminal

Note: Noise suppressor and Line filter are not

used for some countries.

Color index of lead wires' sheath

Black Blue

White

Brown

P 7/ 8

Switch

viewed from Commutator side

Brush

holder A

Field

Brush

holder B

Wiring diagram

Fig. D-2

Wiring of Field lead wires

1. Mount Filed to Motor housing complete as shown below.

Field

connected to

Switch

Line filter

Noise

suppressor

Power supply cord

2. Route Field lead wires through the slit

and Lead wire holder as shown below.

connected to

Switch

Motor housing

complete

Slit

Lead wire

holder

Field lead wires

Page 8

Wiring diagram

Fig. D-3

P 8/ 8

Switch

Motor housing

complete

Field

See the drawing

on the right in Fig. D-2.

1. Pass Field lead wires through Line filter

and wind them one turn and pass them

again as shown below.

Noise suppressor

(if used)

Lead wire

holder

Power supply

cord

Line filter (if used)

Set Line filter with Field lead wires

between Lead wire holders.

2. Winded Filed lead wires have to be located on

the Motor housing complete side.

Field lead wires

Line filter

Motor housing complete

Winded Field

lead wires

Field side

Handle cover

Loading...

Loading...