Page 1

Concrete Planer

Instruction Manual

Betonschleifer

Betriebsanleitung

Szlifierka do betonu

Instrukcja obsługi

Бетонный продольно-строгальный станок

Инструкция по эксплуатации

PC1100

PC1100

PC1100PC1100

Page 2

1

2

3

5

7

4

6

8

2

Page 3

9

10

11

13

12

3

Page 4

Symbols

The following show the symbols used for the tool. Be sure that you understand their meaning before use.

Symbole

Die folgenden Symbole werden für die Maschine verwendet. Machen Sie sich vor der Benutzung unbedingt

mit ihrer Bedeutung vertraut.

Symbole

Poniższe symbole używane są do opisu piły. Przed użyciem należy upewnić się, że rozumie się ich znaczenie.

Символы

Следующие объяснения показывают символы, используемые для инструмента. Убедитесь перед

использованием, что Вы понимаете их значение.

❏ Read instruction manual.

❏ Bitte Betriebsanleitung lesen.

❏ Przeczytaj instrukcję obsługi.

❏ Прочитайте инструкцию по эксплуатации.

❏ DOUBLE INSULATION

❏ DOPPELT SCHUTZISOLIERT

❏ PODWÓJNA IZOLACJA

❏ ДВОЙНАЯ ИЗОЛЯЦИЯ

4

Page 5

ENGLISH

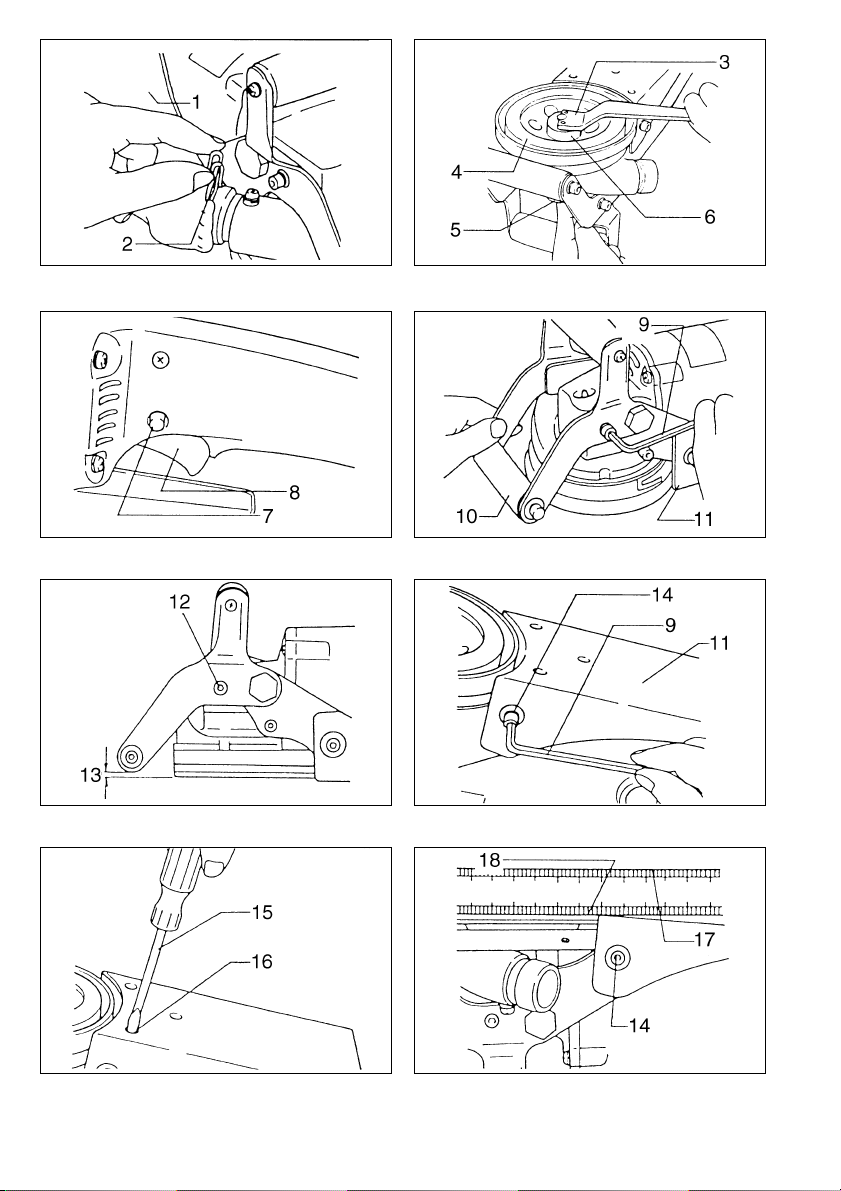

Explanation of general view

1 Dust bag

2Fitting

3 Lock nut wrench

4 Diamond wheel

5 Shaft lock

6 Lock nut

7 Lock button

8 Switch trigger

9 Hex wrench

10 Front roller

11 Base

12 Hex socket head bolt

13 Stock removal amount

14 Hex socket head bolt

15 Screwdriver

16 Screw

SPECIFICATIONS

Model PC1100

Wheel diameter ............................................. 110mm

Hole diameter ................................................. 15 mm

No load speed (min

–1

) ....................................10,000

Overall length ................................................ 418 mm

Net weight ........................................................ 4.3 kg

• Due to our continuing program of research and

development, the specifications herein are subject

to change without notice.

• Note: Specifications may differ from country to

country.

Power supply

The tool should be connected only to a power supply

of the same voltage as indicated on the nameplate,

and can only be operated on single-phase AC supply.

They are double-insulated in accordance with European Standard and can, therefore, also be used from

sockets without earth wire.

Safety hints

For your own safety, please refer to the enclosed

Safety instructions.

SAFETY INSTRUCTIONS

Warning! When using electric tools, basic safety

precautions should always be followed to reduce

the risk of fire, electric shock and personal injury,

including the following. Read all these instructions before attempting to operate this product

and save these instructions.

For safe operation:

1. Keep work area clean

Cluttered areas and benches invite injuries.

2. Consider work area environment

Don’t expose power tools to rain. Don’t use

power tools in damp or wet locations. Keep work

area well lit. Don’t use power tools in presence of

flammable liquids or gases.

3. Guard against electric shock

Prevent body contact with grounded surfaces

(e.g. pipes, radiators, ranges, refrigerators).

4. Keep children away

Do not let visitors contact tool or extension cord.

All visitors should be kept away from work area.

17 Square or ruler

18 Same level

19 Dust cover

20 Raise

21 Lower

22 Limit mark

23 Brush holder cap

5. Store idle tools

When not in use, tools should be stored in dry,

high, or locked-up place, out of the reach of children.

6. Don’t force tool

It will do the job better and safer at the rate for

which it was intended.

7. Use right tool

Don’t force small tools or attachments to do the

job of a heavy duty tool. Don’t use tools for purposes not intended; for example, don’t use circular saw for cutting tree limbs or logs.

8. Dress properly

Do not wear loose clothing or jewelry. They can

be caught in moving parts. Rubber gloves and

non-skid footwear are recommended when working outdoors. Wear protective hair covering to

contain long hair.

9. Use safety glasses and hearing protection

Also use face or dust mask if cutting operation is

dusty.

10. Connect dust extraction equipment

If devices are provided for the connection of dust

extraction and collection facilities, ensure these

are connected and properly used.

11. Don’t abuse cord

Never carry tool by cord or yank it to disconnect it

from receptacle. Keep cord from heat, oil and

sharp edges.

12. Secure work

Use clamps or a vise to hold work. It’s safer than

using your hand and it frees both hands to operate tool.

13. Don’t overreach

Keep proper footing and balance at all times.

14. Maintain tools with care

Keep tools sharp and clean for better and safer

performance. Follow instructions for lubricating

and changing accessories. Inspect tool cords

periodically and, if damaged, have repaired by

authorized service facility. Inspect extension

cords periodically and replace if damaged. Keep

handles dry, clean and free from oil and grease.

15. Disconnect tools

When not in use, before servicing, and when

changing accessories such as blades, bits and

cutters.

5

Page 6

16. Remove adjusting keys and wrenches

Form the habit of checking to see that keys and

adjusting wrenches are removed from tool before

turning it on.

17. Avoid unintentional starting

Don’t carry plugged-in tool with finger on switch.

Be sure switch is off when plugging in.

18. Outdoor use extension cords

When tool is used outdoors, use only extension

cords intended for use outdoors and so marked.

19. Stay alert

Watch what you are doing. Use common sense.

Do not operate tool when you are tired.

20. Check damaged parts

Before further use of the tool, a guard or other

part that is damaged should be carefully checked

to determine that it will operate properly and perform its intended function. Check for alignment of

moving parts, binding of moving parts, breakage

of parts, mounting, and any other conditions that

may affect its operation. A guard or other part

that is damaged should be properly repaired or

replaced by an authorized service center unless

otherwise indicated elsewhere in this instruction

manual. Have defective switches replaced by

and authorized service center. Do not use tool if

switch does not turn it on and off.

21. Warning

The use of any other accessory or attachment

other than recommended in this operating

instruction or the catalog may present a risk of

personal injury.

22. Have your tool repaired by an expert

This electric appliance is in accordance with the

relevant safety rules. Repairing of electric appliances may be carried out only by experts otherwise it may cause considerable danger for the

user.

ADDITIONAL SAFETY RULE

1. This is a dry-use tool. Never use water or

coolant. If water or coolant gets into the tool

or offset diamond wheel, damage to the tool

or a dangerous situation may occur.

2. Adequate ventilation of your work area is

very important when using this tool. Use a

dust mask or appropriate respirator.

3. Due to the dusty nature of this tool, be sure

to clean it often to remove dust accumulations. Carefully blow the dust out of the

motor, switch and dust cover areas frequently.

4. Always install the dust cover before operation.

5. Always use Makita offset diamond wheels

only. Never use ordinary diamond wheels

which may be available on the market. Never

use depressed center wheels, cut-off wheels,

or any other type of accessory on this tool.

Failure to do so may result in serious injury

or death to operator or anyone nearby.

6. Check the offset diamond wheel carefully for

cracks or damage before operation. Replace

cracked or damaged wheel immediately.

7. Before using the tool on an actual workpiece,

let it run for a while, keeping it away from

your body. Watch for vibration or wobbling

that could indicate poor installation, a poorly

balanced wheel, or a damaged wheel.

8. Hold the tool firmly with both hands during

operation.

9. Do not leave the tool running unattended.

Operate the tool only when handheld. Do not

fasten or mount the tool to a bench, table or

vise and then introduce workpieces to the

tool.

10. Do not touch the offset diamond wheel immediately after operation; it may be extremely

hot and could burn your skin.

SAVE THESE INSTRUCTIONS.

OPERATING INSTRUCTIONS

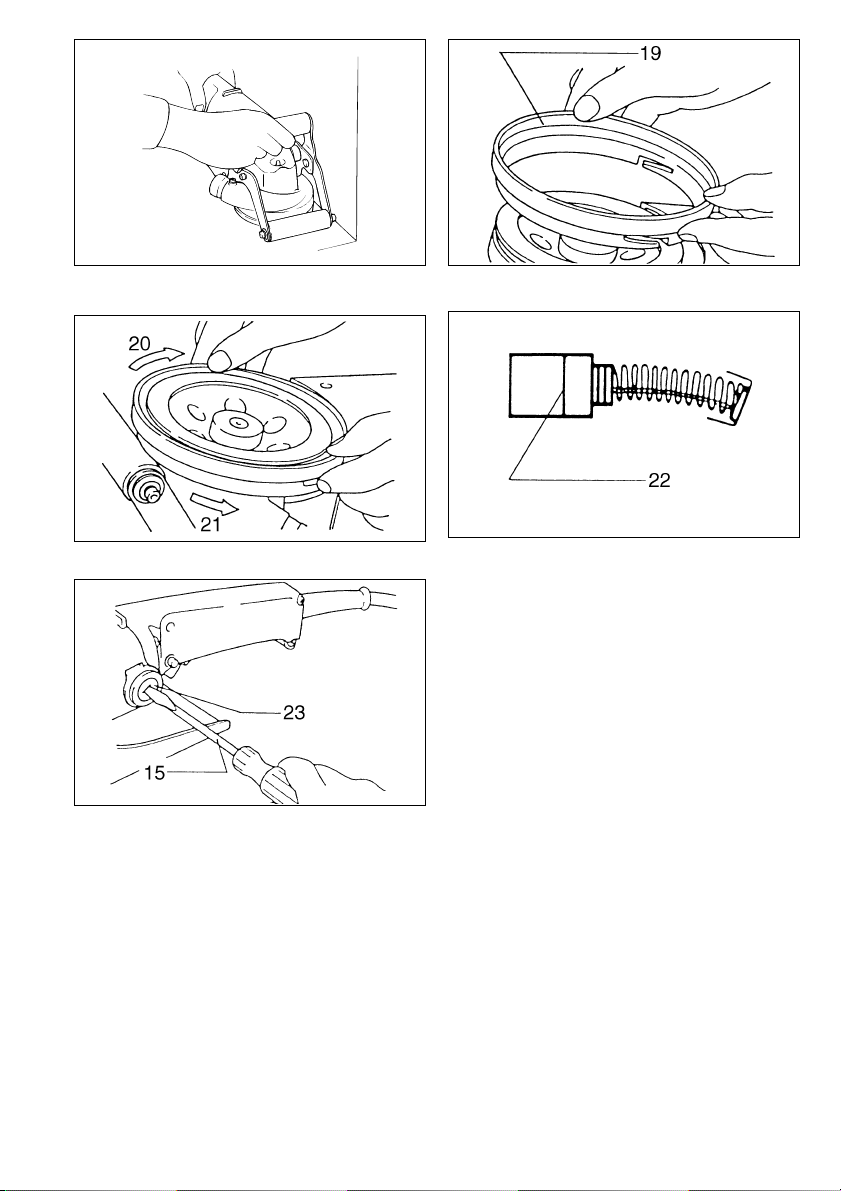

Dust bag installation (Fig.1)

To install dust bag, press bag fitting to inside, open

mouth of bag and slip onto dust port.

Remove dust bag when it begins to touch cutting surface. This is a sign that it is full. Failure to empty bag

will lead to poor suction/pickup.

Replacing diamond wheel (Fig. 2)

Important:

Always be sure that the tool is switched off and

unplugged before replacing the diamond wheel.

To replace a worn diamond wheel with a new one,

press in the shaft lock to hold the shaft steady, then

loosen the lock nut to the left with the lock nut wrench

provided.

NOTE:

The ordinary diamond wheels on the market have no

exhaust holes, so dust evacuation is poor. Also, if the

installing hole is not of the exact diameter, tool vibration occurs and accidents can occur. ALWAYS USE A

MAKITA OFFSET DIAMOND WHEEL.

Switch action (Fig. 3)

CAUTION:

Before plugging in the tool, always check to see that

the switch trigger actuates properly and returns to the

“OFF” position when released.

To start the tool, simply pull the trigger. Release the

trigger to stop. For continuous operation, pull the trigger and then push in the lock button. To stop the tool

from the locked position, pull the trigger fully, then

release it.

Level planing (Fig. 4 &5)

To level a surface, the base of the planer should be

aligned with the diamond wheel. The front roller

should be adjusted (use hex wrench) upward to the

level required for the desired stock removal amount.

6

Page 7

To change the amount of stock (concrete) removed,

loosen the hex socket head bolts on the grip holder

with the hex wrench. Raise or lower the front roller to

adjust the gap between it and the diamond wheel.

The difference is the stock removal amount. Then

secure the hex socket head bolts very carefully.

NOTE:

Maximum stock removal should be less than 2.5 mm.

Tilting base for smoother planing

For smooth removal of a given surface roughness or

texture, tilting the base is helpful. Use the hex wrench

to loosen the two hex socket head bolts securing the

base on either side. (Fig. 6)

Use a screwdriver to lower the three screws on the

base by turning rightward. (Fig. 7)

Use a square or ruler to obtain the desired base

angle in relation to the diamond wheel. Then secure

carefully the hex socket head bolts on either side of

the base. Adjust center of base near wheel so that it

is on the same level as the wheel. (Fig. 8)

NOTE:

After base adjustment, turn the three screws leftward

on base until the hands are flush with the back side

of the base. Turn gently or base adjustment will be

thrown off. (Fig. 7)

Base adjustment to compensate for wheel

wear (Fig. 6& 7)

With long use, the diamond wheel will wear and thus

create a gap with the planing surface so that performance becomes poor. Check the tool after every 4 or

5 hours of use. If the wheel and base surfaces are

not aligned, loosen the hex socket head bolts securing the base. Turn the screws on the base to the right

and adjust the base so as to be level with the wheel

surface. Retighten the bolts and then gently turn the

screws to the left until flush with the back side of the

base. The screws should not come loose during

operation.

Planing in corners (Fig. 9 & 10)

Flush planing of corners is possible after first removing the dust cover.

Turn dust cover rightward until it stops, light toward

you to remove.

Dust cover adjustment (Fig. 11)

The dust cover should be either flush with the diamond wheel surface or very slightly above (when tool

is inverted) 0.5mm. Suction/pickup will be poor if they

are not approximately on the same level.

To adjust the dust cover, grip it on the outside; turn

right to raise, left to lower.

MAINTENANCE

CAUTION:

Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

Replacement of carbon brushes (Fig. 12 &13)

Replace carbon brushes when they are worn down to

the limit mark. Both identical carbon brushes should

be replaced at the same time.

To maintain product safety and reliability, repairs,

maintenance or adjustment should be carried out by

a Makita Authorized Service Center.

7

Page 8

The typical A-weighted noise levels are

The typical weighted root mean square acceleration

value is not more than 2.5 m/s

sound pressure level: 90 dB (A)

sound power level: 103 dB (A)

– Wear ear protection. –

2

.

EC-DECLARATION OF CONFORMITY

The undersigned, Yasuhiko Kanzaki, authorized by

Makita Corporation, 3-11-8 Sumiyoshi-Cho, Anjo,

Noise and Vibration

Aichi, 446-8502 Japan declares that this product

manufactured by Makita Corporation in Japan is in

compliance with the following standards or standardized documents,

in accordance with Council Directives, 73/23/EEC,

89/336/EEC and 98/37/EC.

(Serial No. : series production)

HD400, EN50144, EN55014, EN61000

Yasuhiko Kanzaki

Director

MAKITA INTERNATIONAL EUROPE LTD

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

CE94

.

8

Page 9

DEUTSCH

Übersicht

1Staubsack

2 Klemmverschluß

3 Stirnlochschlüssel

4 Diamantscheibe

5 Spindelarretierung

6 Flanschmutter

7 Einschaltarretierung

8 Schalter

9 Innensechskantschlüssel

10 Führungsrolle

11 Grundplatte

12 Innensechskantschraube

13 Schleiftiefe

14 Innensechskantschraube

15 Schraubendreher

16 Justierschraube

TECHNISCHE DATEN

Modell PC1100

Diamantscheibe .............................................110 mm

Diamantscheibenbohrung................................15 mm

Leerlaufdrehzahl .................................... 10 000 min

Gesamtlänge .................................................418 mm

Nettogewicht ..................................................... 4,3 kg

• Wir behalten uns vor, Änderungen im Zuge der Entwicklung und des technischen Fortschritts ohne

vorherige Ankündigung vorzunehmen.

• Hinweis: Die technischen Daten können von Land

zu Land abweichen.

Netzanschluß

Die Maschine darf nur an die auf dem Typenschild

angegebene Netzspannung angeschlossen werden

und arbeitet nur mit Einphasen-Wechselspannung.

Sie ist entsprechend den Europäischen Richtlinien

doppelt schutzisoliert und kann daher auch an Steckdosen ohne Erdanschluß betrieben werden.

Sicherheitshinweise

Lesen und beachten Sie diese Hinweise, bevor Sie

das Gerät benutzen.

SICHERHEITSHINWEISE

Achtung! Beim Gebrauch von Elektrowerkzeugen

sind zum Schutz gegen elektrischen Schlag. Verletzungsund Brandgefahr folgende grundsätzlichen Sicherheitsmaßnahmen zu geachten.

Lesen und beachten Sie diese Hinweise, bevor

Sie das Gerät benutzen.

1. Halten Sie Ihren Arbeitsbereich in Ordnung

Unordnung im Arbeitsbereich ergibt Unfallgefahr.

2. Berücksichtigen Sie Umgebungseinflüsse

Setzen sie Elektrowerkzeuge nicht dem Regen

aus. Benützen Sie Elektrowerkzeuge nicht in

feuchter oder nasser Umgebung. Sorgen Sie für

gute Beleuchtung. Benützen Sie Elektrowerkzeuge nicht in Nähe von brennbaren Flüssigkeiten oder Gasen.

3. Schützen Sie sich vor elektrischem Schlag

Vermeiden Sie Körperberührung mit geerdeten

Teilen, zum Beispiel Rohren, Heizkörpern, Herden, kühlschränken.

17 Anschlagwinkel

18 Plan

19 Staubführung

20 Heben

21 Senken

22 Verschleißgrenze

23 Bürstenhalterkappe

4. Halten Sie Kinder fern!

Lassen Sie andere Personen nicht das Werkzeug oder Kabel berühren, halten Sie sie von

Ihrem Arbeitsbereich fern.

5. Bewahren Sie Ihre Werkzeuge sicher auf

-1

Unbenutzte Werkzeuge sollten in trockenem,

verschlossenem Raum und für Kinder nicht

erreichbar aufbewahrt werden.

6. Überlasten Sie Ihr Werkzeug nicht

Sie arbeiten besser und sicherer im angegebenen Leistungsbereich.

7. Benützen Sie das richtige Werkzeug

Verwenden Sie keine zu schwachen Werkzeuge

oder Vorsatzgeräte für schwere Arbeiten.

Benützen Sie Werkzeuge nicht für Zwecke und

Arbeiten, Wofür sie nicht bestimmt sind; zum

Beispiel benützen Sie keine Handkreissäge, um

Bäume zu flällen oder Äste zu schneiden.

8. Tragen Sie geeignete Arbeitskleidung

Tragen Sie keine weite Kleidung oder Schmuck.

Sie können von beweglichen Teilen erfaßt werden. Bei Arbeiten im Freien sind Gummihandschuhe und rutschfestes Schuhwerk

empfehlenswert. Tragen Sie bei langen Haaren

ein Haarnetz.

9. Schutzbrille und Gehörschutz tragen

Verwenden Sie eine Atemmaske bei stauberzeugenden Arbeiten.

10. Schlleßen Sie eine Staubabsaugvorrichtung

an

Wenn Geräte für den Anschluß von Staubabsaug-und-sammelvorrichtungen ausgelegt sind,

sorgen Sie dafür, daß Jiese angeschlossen und

korrekt benutzi werden.

11. Zweckentfremden Sie nicht das Kabel

Tragen Sie das Werkzeug nicht am Kabel, und

benützen Sie es nicht, um den Stecker aus der

Steckdose zu ziehen. Schützen Sie das Kabel

vor Hitze, Öl und scharfen Kanten.

12. Sichern Sie das Werkstück

Benützen Sie Spannvorrichtungen oder einen

Schraubstock, um das Werkstück festzuhalten.

Es ist damit sicherer gehalten als mit Ihrer Hand

und ermöglicht die Bedienung der Maschine mit

beiden Händen.

13. Überdehnen Sie nicht Ihren Standbereich

Vermeiden Sie abnormale Körperhaltung. Sorgen Sie für sicheren Stand, und halten Sie jederzeit das Gleichgewicht.

9

Page 10

14. Pflegen Sie Ihre Werkzeuge mit Sorgtalt

Halten Sie Ihre Werkzeuge scharf und sauber,

um gut und sicher zu arbeiten. Befolgen Sie die

Wartungsvorschriften und die Hinweise für

Werkzeugwechsel. Kontrollieren Sie regelmäßig

den Stecker und das Kabel, und lassen Sie

diese bei Beschädigung von einem anerkannten

Fachmann erneuern.

Kontrollieren Sie Verlängerungskabel regelmäßig und ersetzen Sie beschädigte. Halten Sie

Handgriffe trocken und frei von Öl und Fett.

15. Ziehen Sie den Netzstecker

Bei Nichtgebrauch, vor der Wartung und beim

Werkzeugwechsel, wie zum Beispiel Sägeblatt,

Bohrer und Maschinenwerkzeugen aller Art.

16. Lassen Sie keine Werkzeugschlüssel stecken

Überprüfen Sie vor dem Einschalten, daß die

Schlüssel und Einstellwerkzeuge entfernt sind.

17. Vermeiden Sie unbeabsichtigten Anlauf

Tragen Sie keine an das Stromnetz angeschlossene Werkzeuge mit dem Finger am Schalter.

Vergewissern Sie sich, daß der Schalter beim

Anschluß an das Stromnetz ausgeschaltet ist.

18. Verlängerungskabel im Freien

Verwenden Sie im Freien nur dafür zugelassene

und entsprechend gekennzeichnete Varlängerungskabel.

19. Seien Sie stets aufmerksam

Beobachten Sie Ihre Arbeit. Gehen Sie vernünftig vor. Verwenden Sie das Werkzeug nicht,

wenn Sie unkonzentriert sind.

20. Kontrollieren Sie Ihr Gerät auf Beschädigungen

Vor weiterem Gebrauch des Werkzeugs die

Schutzeinrichtungen oder leicht beschädigte

Teile sorgfältig auf ihre einwandfreie und bestimmungsgemäße Funktion überprüfen. Überprüfen Sie, ob die Funktion beweglicher Teile in

Ordnung ist, ob sie nicht klemmen onder ob Teile

beschädigt sind. Sämtliche Teile müssen richtig

montiert sein und alle Bedingungen erfüllen, um

den einwandfreien Betrieb des Gerätes zu

gewährleisten.

Beschädigte Schutzvorrichtungen und Teile sollen sachgemäß durch eine Kundendienstwerkstatt repariert oder ausgewechselt werden,

soweit nichts anderes in den Betriebsanleitungen angegeben ist. Beschädigte Schalter müssen bei einer Kundendienstwerkstatt ersetzt

werden. Benutzen Sie keine Werkzeuge, bei

denen sich der Schalter nicht ein und ausschalten läßt.

21. Achtung!

Zu Ihrer eigenen Sicherheit, benützen Sie nur

Zubehör und Zusatzgeräte, die in der Bedienungsanleitung angegeben oder vom WerkzeugHersteller empfohlen oder angegeben werden.

Der Gebrauch anderer als der in der Bedienungsanleitung oder im Katalog empfohlenen

Einsatzwerkzeuge oder Zubehöre kann eine persönliche Verletzungsgefahr für Sie bedeuten.

22. Reparaturen nur vom Elektrofachmann.

Dieses Elektrowerkzeug entspricht den einschlägigen Sicherheitsbestimmungen. Reparaturen

dürfen nur von einer Elektrofachkraft ausgeführt

werden, andernfalls können Unfälle für den

Betreiber entstehen.

ZUSÄTZLICHE

SICHERHEITSBESTIMMUNGEN

1. Die Maschine ist nur für Trockenschliff zu

betnutzen. Wasser oder Kühlmittelzufuhr führen zu Maschinendefekten bzw. Diamantscheibenschäden und können die Sicherheit

durch Gefahr eines Stromschlages erheblich

beeinträchtigen.

2. Beim Arbeiten mit diesem Werkzeug muß auf

eine ausreichende Belüftung des Arbeitsplatzes geachtet werden. Tragen Sie eine Staubbzw. Atemmaske.

3. Die Maschine verursacht während des Bearbeitungsvorganges große Staubmengen. Um

Staubansammlungen zu vermeiden, sollte die

Maschine in kurzen Intervallen mit Druckluft

gereinigt werden, um Staubablagerungen im

Bereich des Motors, Schalters und der Staubführung zu entfernen.

4. Bringen Sie stets die Staubführung an, bevor

Sie mit der Maschine arbeiten.

5. Verwenden Sie ausschließlich Makita Diamantscheiben. Handelsübliche Diamantscheiben anderer Fabrikate dürfen nicht

verwendet werden. Benutzen Sie auf keinen

Fall kunstharzgebundene Schleifmittel,

Trennscheiben oder anderes Zubehör mit

dieser Maschine.

Bei Zuwiderhandlung besteht die Gefahr von

schweren Verletzungen mit möglicherweise

tödlichem Ausgang sowohl für den Bediener

als auch für umstehende Personen.

6. Überprüfen Sie die Diamantscheibe vor Inbetriebnahme der Maschine sorgfältig auf

Risse, Beschädigung oder Verformung.

Wechseln Sie rissige, beschädigte oder verformte Diamantscheiben unverzüglich aus.

7. Die Maschine vor der Bearbeitung eines

Werkstücks im Leerlauf auf Vibrationen und

Taumelbewegungen überprüfen. Diese können auf eine fehlerhafte Montage oder mangelhafte Auswuchtung der Scheibe

hinweisen.

8. Halten Sie die Maschine mit beiden Händen

fest.

9. Die Maschine nicht im eingeschalteten

Zustand aus der Hand legen. Die Benutzung

ist nur in handgehaltener Weise vorgesehen.

Die Maschine darf nicht stationär (z. B. im

Schraubstock) betrieben werden.

10

Page 11

10. Unmittelbar nach dem Betrieb der Maschine

die Diamantscheibe nicht berühren; sie kann

sehr heiß sein un Verbrennungen verursachen.

BEWAHREN SIE DIESE HINWEISE

SORGFÄLTIG AUF.

BEDIENUNGSHINWEISE

Montage des Staubsacks (Abb. 1)

Um den Staubsack zu montieren, drücken Sie den

Klemmverschluß des Staubsacks zusammen.

Der Staubsack muß rechtzeitig (spätestens bei

Berührung mit dem zu bearbeitenden Material)

geleert werden, um die Staubsammlung zu ermöglichen.

Diamantscheibenwechsel (Abb. 2)

Wichtig:

Vor der Montage bzw. Demontage der Diamantscheibe stets sicherstellen, daß der Betonschleifer

ausgeschaltet und der Netzstecker gezogen ist.

Zum Wechseln der Diamantscheibe die Spindel-Arretiertaste drücken, damit die Spindel sich nicht drehen

kann. Dann die Flanschmutter mit dem mitgelieferten

Stirnlochschlüssel lösen.

HINWEISE:

Bei Fremdzubehör-Diamantscheiben können die

Absaugbohrungen fehlen – der Staub kann nur unzureichend abgesaugt werden. Durch abweichende

Befestigungsbohrungen können Vibrationen oder

Unwucht auftreten – dies kann zu Unfällen führen.

Verwenden Sie ausschließlich Makita-Diamantscheiben.

Schalterfunktion (Abb. 3)

VORSICHT:

Vor dem Anschließen der Maschine an das Stromnetzstets überprüfen, ob der EIN-/AUS-Schalter ordnungsgemäß funktioniert und beim Loslassen in die

AUS-Stellung zurückkehrt.

Zum Einschalten den EIN-/AUS-Schalater drücken.

Zum Ausschalten den Schalter loslassen. Für Dauerbetrieb den EIN-/AUS-Schalter und gleichzeitig die

Einschaltarretierung drücken. Zum Entriegeln der

Einschaltarretierung den EIN-/AUS-Schalter drücken

und wieder loslassen.

Nivellier-Schleifen (Abb. 4 u. 5)

Zum Nivellieren muß die Grundplatte der Maschine

mit der Diamantscheibe auf einer Ebene liegen. Die

Höhendifferenz zwischen Führungsrolle und Grundplatte bestimmt die Schleiftiefe.

Zur Veränderung der Einstellung lösen Sie die Innensechskantschrauben am Zusatzhandgriff. Anschließend ziehen Sie die Innensechskantschrauben fest

an.

HINWEIS:

Die maximale Schleiftiefe beträgt 2,5 mm.

Feinschleifen

Die Maschine kann durch Neigung der Grundplatte

zur Nachbearbeitung von rauhen Oberflächen eingesetzt werden. Dazu lösen Sie die Innensechskantschrauben an den Seiten der Grundplatte.

Zur Einstellung die in der Grundplatte versenkten

Schrauben im Uhrzeigersinn eindrehen.

Mit einem Lineal o. ä. den gewünschten Winkel Zwischen Grundplatte und Diamantscheibe einstellen.

Die Vorderkante der Grundplatte sollte kurz vor der

Diamantscheibe und auf gleicher Höhe positioniert

(Abb. 8)

sein.

schrauben festziehen.

HINWEIS:

Nach der Grundplatten-Einstellung die Schrauben in

der Grundplatte durch Linksdrehung bis zum

Anschlag herausdrehen. (Abb. 7)

Anschließend die Innensechskant-

(Abb. 6)

(Abb. 7)

Einstellung bei Verschleiß (Abb. 6 u. 7)

Nach 4 – 5 Betriebsstunden wird durch Abnutzung

der Diamantscheibe die Arbeitsleistung spürbar

nachlassen. Die Einstellung der Grundplatte ist zu

überprüfen und ggf. zu korrigieren. Dazu lösen Sie

die Innensechskantschrauben der Grundplatte bündig mit der Diamantscheibe einstellen. Die Innensechskantschrauben wieder festziehen und die

Schrauben in der Grundplatte durch Linksdrehen bis

zum Anschlag herausdrehen.

Schleifen in Ecken (Abb. 9 u. 10)

Zum Schleifen in Ecken können Sie die Staubführung entfernen. Dazu drehen Sie die Staubführung

bis zum Anschlag nach rechts und ziehen sie von der

Maschine ab.

Einstellung der Staubführung (Abb. 11)

Die Staubführung ist entweder plan mit der Diamantschieber oder max. 0,5 mm oberhalb der Schleiffläche einzustellen, um maximale Absaugleistung zu

erzielen.

Zur Einstellung drehen Sie die Staubführung zum

Heben nach rechts bzw. zum Senken nach links.

WART UNG

VORSICHT:

Vor Arbeiten an der Maschine vergewissern Sie sich,

daß sich der Schalter in der “AUS-” Position befindet

und der Netzstecker gezogen ist.

Kohlebürsten wechseln (Abb. 12 u. 13)

Kohlebürsten ersetzen, wenn sie bis auf die Verschleißgrenze abgenutzt sind. Beide Kohlebürsten

nur paarweise ersetzen.

Um die Sicherheit und Zuverlässigkeit dieses Gerätes zu gewährleisten, sollten Reparatur-, Wartungs-,

und Einstellarbeiten nur von durch Makita autorisierten Werkstätten oder Kundendienstzentren unter

ausschließlicher Verwendung von Makita-Originalersatzteilen ausgeführt werden.

11

Page 12

Geräusch- und Vibrationsentwicklung

Die typischen A-bewerteten Geräuschpegel betragen:

Schalldruckpegel: 90 dB (A)

Schalleistungspegel: 103 dB (A)

– Gehörschutz tragen. –

Der gewichtete Effektivwert der Beschleunigung beträgt nicht

mehr als 2,5 m/s

2

.

CE-KONFORMITÄTSERKLÄRUNG

Hiermit erklärt der Unterzeichnete, Yasuhiko Kanzaki, Bevollmächtigter von Makita Corporation, 3-11-8 Sumiyoshi-Cho,

Anjo, Aichi, 446-8502 Japan, daß dieses von der Firma

Makita Corporation in Japan hergestellte Produkt

(Serien-Nr.: Serienproduktion)

gemäß den Ratsdirektiven 73/23/EWG, 89/336/EWG und

98/37/EG mit den folgenden Normen bzw. Normendokumenten übereinstimmen:

HD400, EN50144, EN55014, EN61000.

12

Yasuhiko Kanzaki

CE94

Direktor

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

Page 13

POLSKI

Wyjaśnienia dotyczące urządzenia i jego użycia

1 Worek na pył

2Łącznik

3 Klucz do nakrętki blokady

4 Tarcza diamentowa

5 Blokada wałka

6 Nakrętka blokady

7 Przycisk blokady

8Język włącznika

9Klucz inbus

10 Rolka przednia

11 Baza

12 Śruba z łbem gniazdowym

sześciokątnym

13 Ilość usuwanego materiału

14 Śruba z łbem gniazdowym

sześciokątnym

15 Śrubokręt

16 Śruba

DANE TECHNICZNE

Model PC1100

Średnica tarczy .............................................110 mm

Średnica otworu ............................................. 15 mm

Prędkość bez obciążenia (min

–1

) ....................10.000

Całkowita długość ........................................ 418mm

Ciężar netto ..................................................... 4.3 kg

• Ze względu na prowadzony program udoskonaleń i

badań, podane dane techniczne mogą zostać

zmienione bez uprzedzenia.

• Uwaga: Dane techniczne mogą się różnić w

zależności od kraju.

Zasilanie

Urządzenie to, powinno być podłączone tylko do

źródła zasilania o takim samym napięciu jak

pokazano na tabliczce znamionowej i może być

używane tylko dla zmiennego prądu jednofazowego.

Zgodnie ze standardami Unii Europejskiej

zastosowano podwójną izolację i dlatego też

możliwe jest zasilanie z gniazda bez uziemienia.

Wskazówki dotyczące bezpieczeństwa.

Dla własnego bezpieczeństwa prosimy o zapoznanie

się zamieszczonymi instrukcjami bezpieczeństwa.

INSTRUKCJE BEZPIECZEŃSTWA

Ostrzeżenie! Używając urządzeń elektrycznych

podstawowe środki ostrożności muszą być

zawsze zachowane, aby zmniejszyć ryzyko

ognia, porażenia prądem i uszkodzenia ciała,

włączając poniższe. Przeczytaj wszystkie podane

instrukcje przed próbą użycia tego produktu i

zachowaj je do wglądu.

Dla bezpiecznego użycia:

1. Utrzymuj miejsce pracy w czystości

Zabałaganione miejsca i stoły warsztatowe

sprzyjają wypadkom.

2. Zastanów się nad warunkami pracy

Nie wystawiaj urządzeń elektrycznych na

deszcz. Nie używaj urządzeń elektrycznych w

wilgotnych lub mokrych miejscach. Utrzymuj

miejsce pracy dobrze oświetlone. Nie używaj

urządzeń elektrycznych w obecności

łatwopalnych płynów lub gazów.

17 Ekierka lub linijka

18 Ten sam poziom

19 Osłona od pyłu

20 Podnoszenie

21 Opuszczanie

22 Znak limitu

23 Nasadka szczoteczki

3. Chroń się przed porażeniem prądu.

Zapobiegaj kontaktom ciała z uziemionymi

powierzchniami (np. rurami, grzejnikami,

kuchenkami, lodówkami).

4. Nie pozwalaj zbliżać się dzieciom

Nie pozwalaj wizytującym osobom dotykać

urządzenia lub przedłużacza. Wszystkie

wizytujące osoby nie powinny zbliżać się do

miejsca pracy.

5. Zachowaj nieczynne urządzenia.

Nieużywane urządzenia powinny być

przechowywane w suchych, wysokich lub

zamykanych miejscach tak, aby były

niedostępne dla dzieci.

6. Nie przeciążaj urządzenia.

Wykona ono pracę lepiej i bezpieczniej, pracując

w sposób, dla którego zostało ono

zaprojektowane.

7. Używaj poprawnego urządzenia.

Nie nadużywaj małych lub dodatkowych

urządzeń do wykonania pracy urządzeń do

dużej pracy. Nie używaj urządzeń do celów, do

których nie zostały przeznaczone; na przykład,

nie używaj piły tarczowej do przecinania gałęzi

lub kłód drzew.

8. Ubierz się odpowiednio

Nie noś luźnych ubrań lub biżuterii. Mogą one

zostać zahaczone o ruchome części. Gumowe

rękawiczki i przeciwpoślizgowe buty są

wskazane przy pracy na dworze. Zaleca się

noszenie ochrony na głowę przytrzymującej

długie włosy.

9. Użyj okularów ochronnych i ochraniaczy

uszu.

Użyj masek na twarz lub masek

przeciwpyłowych jeżeli czynność cięcia

wytwarza pyły.

10. Podłącz urządzenie usuwające pył.

Jeżeli urządzenia posiadają podłączenia do

urządzeń do usuwania i składowania pyłu,

upewnij się, że są one poprawnie podłączone i

użyte.

11. Uważaj na przewód sieciowy

Nigdy nie noś urządzenia trzymając za przewód i

nie odłączaj go od gniazda przez pociągnięcie

przewodu. Chroń przewód przed ciepłem,

olejem i ostrymi krawędziami.

1313

Page 14

12. Pewnie mocuj cięte elementy.

Użyj ścisków lub imadła do zamocowania

ciętych elementów. Jest to bezpieczniejsze niż

używanie rąk, a dodatkowo zwalnia obie ręce do

obsługiwania piły.

13. Używając piłę, nie oddalaj jej zbytnio od

siebie.

Cały czas trzymaj dobrze ustawione nogi i

równowagę.

14. Pamiętaj o dobrej konserwacji urządzenia.

Utrzymuj urządzenie ostre i czyste dla jego

lepszego i bezpieczniejszego działania. Wykonaj

podane instrukcje w celu smarowania lub

wymiany elementów wyposażenia. Regularnie

sprawdzaj przewody urządzenia, i jeżeli są

uszkodzone, oddaj je do naprawy do

autoryzowanego serwisu. Regularnie sprawdzaj

przewody przedłużające i wymień je, jeżeli są

uszkodzone. Utrzymuj uchwyty suche, czyste i

nie zabrudzone olejem lub smarem.

15. Odłącz urządzenia

Przed konserwacją urządzenia lub zmianą

wyposażenia takiego jak tarcze, noże do struga i

noże do frezowania, gdy nie jest ono używane.

16. Wyjmij klucze regulacyjne

Nabierz zwyczaju sprawdzania czy klucze

regulacyjne są usunięte z urządzenia przed jego

użyciem.

17. Unikaj przypadkowych uruchomień.

Nie noś podłączonego urządzenia z palcem na

włączniku. Upewnij się, że urządzenie jest

wyłączone, gdy je podłączasz do zasilania.

18. Zastosuj przedłużacz używając urządzenia

na dworze.

Gdy urządzenie używane jest na dworze, stosuj

tylko przedłużacze przeznaczone i oznaczone

do pracy na dworze.

19. Bądź uważny

Patrz co robisz. Bądź rozsądny. Nie używaj

urządzenia, gdy jesteś zmęczony.

20. Sprawdzaj uszkodzone części.

Przed dalszym użyciem urządzenia, osłona lub

inne części, które są uszkodzone, muszą być

uważnie sprawdzone, aby upewnić się, że będą

poprawnie działać i wykonywać przeznaczone

im funkcje. Sprawdzaj ustawienia ruchomych

części, oprawy ruchomych części, pęknięcia

części, zamocowania, i jakiekolwiek inne

warunki, które mogą wpływać na działanie.

Osłona lub inne części, które są uszkodzone,

powinny być naprawione lub wymienione przez

autoryzowany serwis, jeżeli w instrukcji nie

podano inaczej. Uszkodzone przełączniki

powinny być wymienione przez autoryzowany

serwis. Nie używaj urządzenia, jeżeli włącznik

nie może go włączyć lub wyłączyć.

21. Ostrzeżenie

Użycie jakiegokolwiek innego wyposażenia lub

części dodatkowych innych niż zalecane w tej

instrukcji obsługi lub katalogu, może stworzyć

ryzyko uszkodzenia ciała.

22. Naprawy urządzenia powinny być

wykonywane tylko przez specjalistę.

To urządzenie jest wykonane zgodnie z

odpowiednimi zasadami bezpieczeństwa.

Naprawa urządzeń elektrycznych może być

wykonana wyłącznie przez specjalistę, gdyż w

przeciwnym wypadku może ono stanowić

zagrożenie dla użytkownika.

DODATKOWE INSTRUKCJE

BEZPIECZEŃSTWA

1. To urządzenie przeznaczone jest do pracy na

sucho. Nigdy nie używaj wody lub płynu

chłodzącego. Jeżeli woda lub płyn chłodzący

dostanie się do urządzenia lub odgiętej

tarczy diamentowej, wówczas urządzenie

może zostać uszkodzone lub może zaistnieć

niebezpieczna sytuacja.

2. Bardzo ważne jest, aby miejsce pracy było

dobrze wentylowane w tracie pracy z

urządzeniem. Używaj maski przeciwpyłowej

lub odpowiedniego respiratora.

3. Ze względu na pyłową pracę urządzenia,

pamiętaj o częstym czyszczeniu zbierającego

się na nim pyłu. Często i uważnie zdmuchuj

pył z silnika, włącznika i osłony od pyłu.

4. Przed użyciem zawsze instaluj osłonę od

pyłu.

5. Używaj wyłącznie odgiętej tarczy

diamentowej Makita. Nigdy nie używaj

zwykłych tarcz diamentowych dostępnych na

rynku. Nigdy nie używaj tarcz z obniżonym

środkiem, tarcz do cięcia lub innych

akcesoriów z tym urządzeniem. Nie

zastosowanie się do tego wymogu może

spowodować poważne uszkodzenia ciała,

śmierć operatora lub osoby w pobliżu.

6. Przed użyciem sprawdź uważnie, czy odgięta

tarcza diamentowa nie jest popękana lub

uszkodzona. Natychmiast wymień popękaną

lub uszkodzoną tarczę.

7. Przed użyciem urządzenia na właściwym

elemencie, uruchom je na chwilę z dala od

siebie. Zwróć uwagę na drgania lub bicie

osiowe, które sugerują złą instalację, źle

wyważoną tarczę lub jej uszkodzenie.

8. W trakcie pracy trzymaj urządzenie mocno

obiema rękami.

9. Nie pozostawiaj urządzenia włączonego bez

dozoru. Używaj urządzenia tylko, gdy jest

trzymane rękami. Nie mocuj, ani nie instaluj

urządzenia do ławki, stołu lub imadła z

intencją przemieszczania po urządzeniu

szlifowanym elementem.

10. Nie dotykaj odgiętej tarczy diamentowej

zaraz po pracy; może być bardzo gorąca i

może poparzyć skórę.

ZACHOWAJ TĘ INSTRUKCJĘ.

1414

Page 15

INSTRUKCJA OBSŁUGI

Zakładanie worka na pył (Rys.1)

Aby założyć worek na pył, wciśnij łącznik worka do

środka, następnie otwórz wylot worka i wsuń na

otwór.

Zdejmij worek na pył, gdy zacznie dotykać ciętej

powierzchni. Oznacza to, że worek jest pełen. Nie

wymienienie pełnego worka osłabia ssanie i

zbieranie pyłu.

Wymiana tarczy diamentowej (Rys.2)

Ważne:

Zawsze upewnij się, że urządzenie jest wyłączone i

odłączone od zasilania przed wymianą tarczy

diamentowej.

Aby wymienić zużytą tarczę diamentową na nową

naciśnij blokadę wałka, aby przytrzymać go w

miejscu, a następnie poluzuj nakrętkę blokady

przekręcając ją w lewo przy pomocy dostarczonego

klucza do nakrętki blokady.

UWAGA:

Normalne tarcze diamentowe dostępne na rynku nie

mają otworów wydechowych, co uniemożliwia dobre

odprowadzanie pyłów. Również wtedy, kiedy otwór

instalacyjny nie posiada dokładnie żądanej średnicy,

mogą pojawić się drgania, co może spowodować

wypadek. ZAWSZE UŻYWAJ ODGIĘTEJ TARCZY

DIAMENTOWEJ MAKITA.

Funkcje włącznika (Rys.3)

OSTRZEŻENIE:

Przed podłączeniem urządzenia do zasilania,

zawsze sprawdź, czy język włącznika działa

poprawnie i czy powraca do pozycji OFF (Wył.) po

zwolnieniu.

Aby uruchomić urządzenie, naciśnij język. Zwolnij

język, aby zatrzymać urządzenie. Dla ciągłej pracy

naciśnij język, a następnie naciśnij przycisk blokady.

Aby zatrzymać urządzenie w pozycji zablokowanej,

naciśnij język do końca, a następnie zwolnij go.

Szlifowanie płaszczyzn (Rys. 4 i 5)

Aby wyrównywać płaszczyznę, baza szlifierki

powinna być zrównana z tarczą diamentową. Rolka

przednia powinna być ustawiona ku górze (używając

klucza inbus), do poziomu wymaganego żądaną

ilością usuwanego materiału.

Aby zmienić ilość usuwanego materiału (betonu)

poluzuj śruby z łbem gniazdowym sześciokątnym na

uchwycie, używając klucza inbus. Podnieś lub opuść

rolkę przednią, aby wyregulować szczelinę

pomiędzy tarczą diamentową i rolką. Różnica

określa ilość usuwanego materiału. Następnie

bardzo ostrożnie dokręć śruby z łbem gniazdowym

sześciokątnym.

UWAGA:

Maksymalna ilość usuwanego materiału powinna

być mniejsza niż 2.5 mm.

Przechylanie bazy w celu gładkiego

szlifowania.

W celu gładkiego szlifowania powierzchni o

określonej szorstkości lub teksturze, pomocne jest

przechylenie bazy. Użyj klucza inbus, aby poluzować

dwie śruby z łbem gniazdowym sześciokątnym

przytrzymujące bazę z każdej strony. (Rys. 6)

Użyj śrubokręta, aby obniżyć trzy śruby znajdujące

się na bazie, przekręć je w prawo. (Rys. 7)

Użyj ekierki lub linijki, aby otrzymać żądany kąt

nachylenia bazy do tarczy diamentowej. Następnie

uważnie dokręć śruby z łbem gniazdowym

sześciokątnym. znajdujące się na bokach bazy.

Wyreguluj środek bazy w pobliżu tarczy tak, aby

znajdował się na tym samym poziomie co tarcza.

(Rys.8)

UWAGA:

Po regulacji bazy, przekręć w lewo trzy śruby na

bazie, dopóki wskazówki nie zrównają się z tylną

stroną bazy. Przekręcaj je delikatnie tak, aby

wykonana regulacja bazy nie zmieniła się. (Rys. 7)

Regulacja bazy w celu wyrównania starcia się

tarczy. (Rys. 6 i 7)

Przy długim użyciu tarcza diamentowa zetrze się i

utworzy się szczelina pomiędzy nią a szlifowaną

płaszczyzną, co obniża wydajność pracy urządzenia.

Sprawdzaj urządzenie po każdych 4 lub 5 godzinach

użycia. Jeżeli tarcza i powierzchnia bazy nie są

zrównane, poluzuj śruby z łbem gniazdowym

sześciokątnym przytrzymujące bazę. Przekręć w

prawo śruby na bazie i wyreguluj bazę tak, aby

znajdowała się na tym samym poziomie, co

powierzchnia tarczy. Dokręć ponownie śruby z łbem

gniazdowym sześciokątnym, a następnie delikatnie

przekręć śruby w lewo dopóki nie dopasują się do

tylnej strony bazy. Śruby nie powinny poluzować się

w czasie działania.

Szlifowanie narożników (Rys. 9 i10)

Szlifowanie narożników jest możliwe po

wcześniejszym wyjęciu osłony od pyłu.

Przekręć osłonę od pyłu w prawo, dopóki się nie

zatrzyma i podnieś ją w swoim kierunku, aby ją

wyjąć.

Regulacja osłony od pyłu (Rys. 11)

Osłona od pyłu powinna być albo dopasowana do

powierzchni tarczy diamentowej albo minimalnie

powyżej (gdy urządzenie jest odwrócone) 0,5 mm.

Jeśli nie będą w przybliżeniu na tym samym

poziomie, słabe będzie ssanie/zbieranie pyłu.Aby

wyregulować osłonę od pyłu, chwyć ją na

zewnętrznej stronie i przekręć w prawo, aby ją

podnieść lub w lewo, aby ją opuścić.

1515

Page 16

KONSERWACJA

OSTRZEŻENIE:

Zawsze upewnij się, że urządzenie jest wyłączone i

odłączone od zasilania przed wykonywaniem

jakichkolwiek prac nad urządzeniem.

Wymiana szczoteczek węglowych

(Rys. 12 i 13)

Wymień szczoteczki węglowe, gdy są one starte do

znaku limitu. Dwie identyczne szczoteczki węglowe

powinny być wymienione w tym samym czasie.

Aby zapewnić bezpieczeństwo i niezawodność

produktu, naprawy i konserwacje lub ustawianie

powinny być wykonywane przez autoryzowany

serwis Makita.

1616

Page 17

Typowe A-ważone poziomy szumów

Szumy i Drgania

poziom ciśnienia dźwięku: 90 dB (A).

poziom dźwięku w trakcie pracy: 103 dB (A).

- Noś ochraniacze uszu. -

Typowa wartość ważonej średniej kwadratowej

przyspieszenia nie jest większa niż 2,5 m/s

UE-DEKLARACJA ZGODNOŚCI

Niżej podpisany, Yasuhiko Kanzaki,

autoryzowany przez Korporację Makita, 3-11-8

Sumiyoshi-Cho, Anjo, Aichi, 446-8502 Japan,

deklaruje, iż niniejszy produkt

(Nr seryjny: seria produkcyjna)

wyprodukowany przez Korporację Makita w

Japonii jest zgodny z następującymi

standardami lub dokumentami standaryzacji,

HD400, EN50144, EN55014, EN61000

w zgodzie z Dyrektywami Rady 73/23/EEC,

89/336/EEC i 98/37/EC.

2

.

Yasuhiko Kanzaki

Dyrektor

MAKITA INTERNATIONAL EUROPE LTD

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

CE94

.

1717

Page 18

РУССКИЙ ЯЗЫК

Объяснения общего плана

1 Мешок для пыли

2Фитинг

3 Фиксирующий гаечный

ключ

4 Алмазный диск

5 Рукоятка

6 Фиксирующая гайка

7 Кнопка фиксации

8 Пусковой механизм

9 Торцевый гаечный ключ

10 Передний ролик

11 Основа

12 Болт с шестигранной

головкой

13 Толщина снимаего

материала

14 Болт с шестигранной

головкой

15 Отвертка

16 Винт

17 Угломер или линейка

18 Одинаковый уровень

ТЕХНИЧЕСКИЕ ХАРАКТЕРИСТИКИ

Модель PC1100

Диаметр диска ............................................. 110 мм

Диаметр отверстия ........................................ 15 мм

Скорость в незагруженном состоянии (мин

......................................................................... 10000

Общая длина ................................................ 418 мм

Вес нетто ........................................................ 4,3 кг

• Вследствие нашей продолжающейся программы

поиска и разработок технические характеристики

могут быть изменены без уведомления.

• Примечание: Технические характеристики могут

различаться в зависимости от страны.

Источник питания

Инструмент должен быть подсоединен только к

источнику питания с напряжением, указанным в

табличке номиналов, и может функционировать

только от однофазного источника питания

переменного тока. В соответствии с Европейским

стандартом имеется двойная изоляция,

следовательно, возможно использование с

розетками без провода заземления.

Советы по мерам безопасности

С целью Вашей личной безопасности прочитайте,

пожалуйста, приведенные инструкции по мерам

безопасности.

–1

)

ИНСТРУКЦИИ ПО МЕРАМ

БЕЗОПАСНОСТИ

Предостережение! При использовании

электрических инструментов следует всегда

соблюдать основные меры безопасности для

уменьшения опасности пожара, поражения

электрическим током и персональных травм,

включая следующие.

Прочитайте эти инструкции перед тем, как

пытаться управлять этим изделием, и

сохраните эти инструкции.

19 Пылесобирающая крышка

20 Повысьте

21 Понизьте

22 Ограничительная метка

23 Крышка держателя щеток

Для безопасного функционирования:

1. Поддерживайте чистоту на рабочем месте

Захламленные места и подставки могут

привести к травмам.

2. Учитывайте рабочую окружающую среду

Не подвергайте инструменты с

электроприводом воздействию дождя. Не

используйте инструменты с электроприводом в

сырых или влажных местах. Поддерживайте

хорошее освещение на рабочем месте. Не

используйте инструменты с электроприводом в

присутствии возгараемы жидкостей или газов.

3. Предохраняйтесь от поражения

электрическим током

Предотвращайте контакт тела с заземленными

поверхностями (например, трубами,

радиаторами, батареями, холодильниками).

4. Держитесь подальше от детей

Не позволяйте посетителям прикасаться к

инструменту или шнуру-удлинителю. Все

посетители должны находиться подальше от

рабочей области.

5. Правильно храните неработающие

инструменты

Если инструменты не используются, они

должны храниться в сухом, высоком или

закрытом месте, вне достижения детей.

6. Не прилагайте усилие к инструменту

Он будет выполнять работу лучше и

безопаснее при скорости, для которой он

предназначен.

7. Используйте правильный инструмент

Не пытайтесь прилагать усилие к маленьким

инструментам или присоединениям для

выполнения работы инструмента тяжелого

назначения. Не используйте инструменты

для непредназначенных целей; например, не

используйте дисковую пилу для резки веток

или корней деревьев.

8. Одевайтесь правильно

Не одевайте свисающую одежду или

украшения. Они могут попасть в движущиеся

части. При работе на улице рекомендуется

одевать резиновые перчатки и нескользящую

обувь. Одевайте предохранительный головной

убор для убирания длинных волос.

18

Page 19

9. Используйте защитные очки и

предохранительные приборы для слуха.

Если работа по резке является пыльной,

используйте также маску для лица или

пылезащитную маску

10. Подсоедините пылевсасывающее

оборудование

Если имеются подсоединения чстройств для

всасывания и сбора пыли, убедитесь в том,

что они подсоединены и используются

правильно.

11. Не прилагайте усилие к шнуру

Никогда не носите инструмент за шнур и не

дергайте за него для отсоединения его из

розетки. Держите шнур подальше от жарких

мест, масла и острых краев.

12. Закрепите рабочее изделие

Используйте зажимы или тиски для

крепления рабочего изделия. Это является

более безопасным, чем использование

Вашей руки, и при этом освобождаются две

руки для управления инструментом.

13. Не заходите слишком далеко

Сохраняйте правильную стойку и баланс все

время.

14. Осторожно обращайтесь с инструментами

Держите инструменты острыми и чистыми для

более лучшей и безопасной работы. Следуйте

инструкциям для смазки и смены

принадлежностей. Периодически проверяйте

шнуры инструмента, и, если они повреждены,

обращайтесь относительно ремонта в

уполномоченный центр по техобслуживанию.

Периодически проверяйте шнуры-удлинители

и заменяйте, если они повреждены. Держите

ручки сухими чистыми и свободными от масла

или смазки.

15. Отсоединяйте инструменты

Если не используются, перед техобслуживанием,

и при смене принадлежностей, таких, как

лезвия, резцы и резаки.

16. Убирайте регулировочные ключи и

гаечные ключи

Сформируйте привычку проверять, что

регулировочные ключи и гаечные ключи

убраны с инструмента перед его включением.

17. Избегайте случайных запусков

Не носите подсоединенный к сети инструмент

с пальцем, находящемся на переключателе.

Перед подсоединением инструмента к сети

убедитесь, что переключатель находится в

положении “выкл”.

18. Шнуры-удлинители для использования на

улице

Когда инструмент используется на улице,

используйте только шнуры-удлинители,

предназначенные для использования на

улице с указанием этого.

19. Будьте бдительны

Наблюдайте за тем, что Вы делаете.

Используйте разумный подход. Не управляйте

инструментом, если Вы устали.

20. Проверяйте поврежденные части

Перед дальнейшим использованием

инструмента, предохранитель или другая

часть должны быть тщательно проверены

для определения того, что они будут

функционировать правильно и выполнять

предназначенную функцию. Проверьте на

предмет совмещения движущихся частей,

соединения движущихся частей, поломки

частей, монтажа и других условий, которые

могут повлиять не их функционирование.

Предохранитель или другая часть должны

быть правильно отремонтированы или

заменены в уполномоченном центре по

техобслуживанию, если только не указано

другое в этой инструкции по эксплуатации.

Дефектные переключатели должны быть

заменены в уполномоченном центре по

техобслуживанию. Не используйте

инструмент, если невозможно его включение

и выключение с помощью переключателя.

21. Предостережение

Использование любой другой принадлежности

или присоединения, отличного от

рекомендуемого в этой инструкции по

эксплуатации или каталоге, может привести к

опасности персональной травмы.

22. Используйте для ремонта услуги

специалиста

Это электрическое оборудование

соответствует относящимся к нему правилам

безопасности. Ремонт электрического

оборудования может проводиться только

специалистами, в противном случае, он

может вызвать существенную опасность для

пользователя.

ДОПОЛНИТЕЛЬНЫЕ ПРАВИЛА

БЕЗОПАСНОСТИ

1. Это инструмент для сухого

использования. Никогда не используйте

воду или охладитель. Если вода или

охладитель попадут внутрь инструмента

или на офсетный алмазный диск,

возможно повреждение инструмента или

опасная ситуация.

2. При использовании этого инструмента

адекватная вентиляция Вашего рабочего

места является очень важной.

Используйте пылезащитную маску или

подходящий респиратор.

3. Вследствие пылевой природы этого

инструмента следует часто прочищать его

для удаления накоплений пыли.

Осторожно и часто выдувайте пыль из

областей двигателя, переключателя и

пылесобирающей крышки.

191919

Page 20

4. Перед эксплуатацией всегда

устанавливайте пылесобирающую

крышку.

5. Всегда используйте только офсетные

алмазные диски фирмы Makita. Никогда не

используйте обычные алмазные диски,

которые могут иметься в продаже.

Никогда не используйте диски с выжатым

центром, резущие диски или

принадлежности любого другого типа на

этом инструменте. Невыполнение этого

условия может привести к серьезной

травме или смерти оператора, или

близкостоящего человека.

6. Перед эксплуатацией проверьте

офсетный алмазныый диск на предмет

трещин или повреждений. Немедленно

замените треснутые или поврежденные

диски.

7. Перед использованием инструмента на

действительном рабочем изделии дайте

ему поработать некоторое время, держа

его подальше от Вашего тела. Обращайте

внимание на вибрацию или колебания,

которые могут указывать на

неправильную установку, плохо

сбалансированный диск или

поврежденный диск.

8. Держите инструмент крепко обеими

руками во время эксплуатации.

9. Не оставляйте инструмент работающим

без оператора. Управляйте инструментом

только удерживая его руками. Не

привязывайте и не монтируйте

инструмент на скамью, стол или в тиски,

а затем не вставляйте рабочие изделия в

инструмент.

10. Не прикасайтесь к офсетному алмазному

диску сразу же после эксплуатации; он

может быть очень горячим и обжечь Вашу

кожу.

СОХРАНИТЕ ЭТИ ИНСТРУКЦИИ.

ИНСТРУКЦИЯ ПО ЭКСПЛУАТАЦИИ

Установка мешка для пыли (Рис. 1)

Для установки мешка для пыли нажмите фитинг

мешка внутрь, откройте верх мешка и засуньте

его в отверстие для пыли.

Удалите мешок для пыли, когда он начнет

касаться поверхности резки. Это показывает то,

что он заполнен. Невыбрасывание мешка

приведет к неудовлетворительному всасыванию/

собиранию.

Замена алмазного диска (Рис. 2)

Важно:

Следует всегда быть уверенным, что инструмент

выключен и отсоединен от сети перед

установкой или удалением алмазного диска.

Для замены изношенного алмазного диска новым

нажмите на рукоятку для удерживания рукоятки

в устойчивом положении, затем отвинтите

фиксирующую гайку налево с помощью

поставляемого фиксирующего гаечного ключа.

ПРИМЕЧАНИЕ:

Обычные алмазные диски, имеющиеся в

продаже, не имеют выхлопных отверстий,

поэтому удаление пыли является

неудовлетворительным. К тому же, если

установочное отверстие не имеет точный

диаметр, наблюдаются вибрация инструмента и

могут случиться несчастные случаи. ВСЕГДА

ИСПОЛЬЗУЙТЕ ОФСЕТНЫЕ АЛМАЗНЫЕ ДИСКИ

МAKITA.

Действия при переключении (Рис. 3)

ПРЕДУПРЕЖДЕНИЕ:

Перед подсоединением инструмента всегда

проверяйте, чтобы видеть, что пусковой

механизм действует правильно и возвращается в

положение “OFF” (выкл.) при высвобождении.

Для запуска инструмента просто нажмите

пусковой механизм. Для остановки высвободите

пусковой механизм. Для непрерывного

функционирования нажмите пусковой механизм,

а затем нажмите кнопку фиксации. Для

остановки инструмента из фиксированного

положения полностью нажмите пусковой

механизм, затем высободите его.

Ровное строгание (Рис. 4 и 5)

Для выравнивания поверхности основа

продольно-строгального станка должна быть

совмещена с алмазным диском. Следует

подрегулировать передний ролик (используйте

торцовый гаечный ключ) вверх до требуемого

уровня для желаемой толщины снимаего

материала.

Для изменения толщины снятого материала

(бетона) отвинтите болты с шестиугольной

головкой на захватывающем держателе с

помощью гаечного ключа. Опустите или

поднимите передний ролик для регулировки

зазора между ним и алмазным диском. Разницей

является толщина снимаего материала. Затем

зафиксируйте болты с шестиугольной головкой

очень плотно.

ПРИМЕЧАНИЕ:

Максимальная толщина снимаего материала

должен быть менее 2,5 мм.

202020

Page 21

Наклонная основа для гладкого строгания

Для гладкого снятия данной поверхностной

шероховатости или текстуры полезной является

наклонная основа. Используйте торцовый

гаечный ключ для отвинчивания двух болтов с

шестиугольной головкой, фиксирующих основу с

каждой стороны. (Рис. 6)

Используйте отвертку для опускания трех

винтов на основе путем их поворота вправо.

(Рис. 7)

Используйте угломер или линейку для получения

желаемого угла, под которым основа

расположена к алмазному диску. Затем

зафиксируйте болты с шестиугольной головкой

надежно с каждой сторон основы.

Подрегулируйте центр основы возле диска так,

чтобы он был на том же уровне, что и диск.

(Рис. 8)

ПРИМЕЧАНИЕ:

После регулировки основы поверните три винта

влево на основе до тех пор, пока ручки не станут

вровень с задней стороной основы.

Поворачивайте осторожно, либо регулировка

основы будет неудачной. (Рис.7)

Регулировка основы для компенсации

износа диска (Рис. 6 и 7)

При продолжительном использовании алмазный

диск будет изнашиваться, и это создаст зазор с

поверхностью строгания так, что

функционирование станет

неудовлетворительным. Проверяйте инструмент

через каждые 4 или 5 часов использования. Если

диск и поверхности основы не совмещен,

отвинтите болты с шестиугольной головкой,

фиксирующие основу. Поверните болты на

основе вправо и подрегулируйте основу так, чтоб

она была вровень с поверхностью диска.

Повторно завинтите болты, а затем поверните

винты влево до тех пор, пока не будут вровень с

задней стороной Винты не должны быть

развинчены во время эксплуатации.

Строгание в углах (Рис. 9 и 10)

Строгание углов вровень возможно после

первого удаления пылесобирающей крышки.

Поверните пылесобирающую крышку вправо до

её остановки, поднимите по направлению к Вам

для удаления.

Регулировка пылесобирающей крышки

(Рис. 11)

Пылесобирающая крышка должна быть либо

вровень с поверхностью алмазного диска, либо

слегка над ним (когда инструмент перевернут)

0,5 мм. Всасывание/собирание будет

неудовлетворительным, если они не находятся

на приблизительно одном уровне.

Для регулировки пылесобирающей крышки

захватите её снаружи; поверните вправо для

подъема, влево для опускания.

ОБСЛУЖИВАНИЕ

ПРЕДУПРЕЖДЕНИЕ:

Всегда проверяйте, что инструмент выключен и

отсоединен перед выполнением любой работы с

инструментом.

Замена угольных щеток (Рис.12и 13)

Заменяйте угольные щетки, когда они износятся

до предельного значка. Обе одинаковые

угольные щетки следует заменять

одновременно.

Для поддержания безопасности и долговечности

изделия, ремонт, уход и регулировка должна

проводиться в уполномоченном центре по

техобслуживанию Makita.

212121

Page 22

Типичные А-взвешенные уровни шума составляют

уровень звукового давления 90 дБ (А).

уровень звуковой мощности 103 дБ (А).

Типичная взвешенное значение квадратного корня

ускорения составляет не более чем 2,5 м/с

– Надевайте защиту для слуха. –

2

.

ЕС ДЕКЛАРАЦИЯ СООТВЕТСТВИЯ

Подписавшийся ниже Ясухико Канзаки,

умолномоченнй корпорацией Makita, 3-11-8 Sumiyoshi-

Cho, Anjo, Aichi, 446-8502 Japan, декларирует, что это

изделие

(Серийный №: серия производства)

изготовленное в корпорации Makita в Японии

находится в соответствии со следующими

стандартами и документами по стандартизации,

HD400, EN50144, EN55014, EN61000

в соответствии со сборником директив 73/23/EEC,

89/336/EEC и 98/37/EC.

Шум и вибрация

222222

Ясухико Канзаки

Директор

MAKITA INTERNATIONAL EUROPE LTD

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

CE94

.

Page 23

Page 24

Makita Corporation

Anjo, Aichi Japan

Made in Japan

883308-207

Loading...

Loading...