Page 1

T

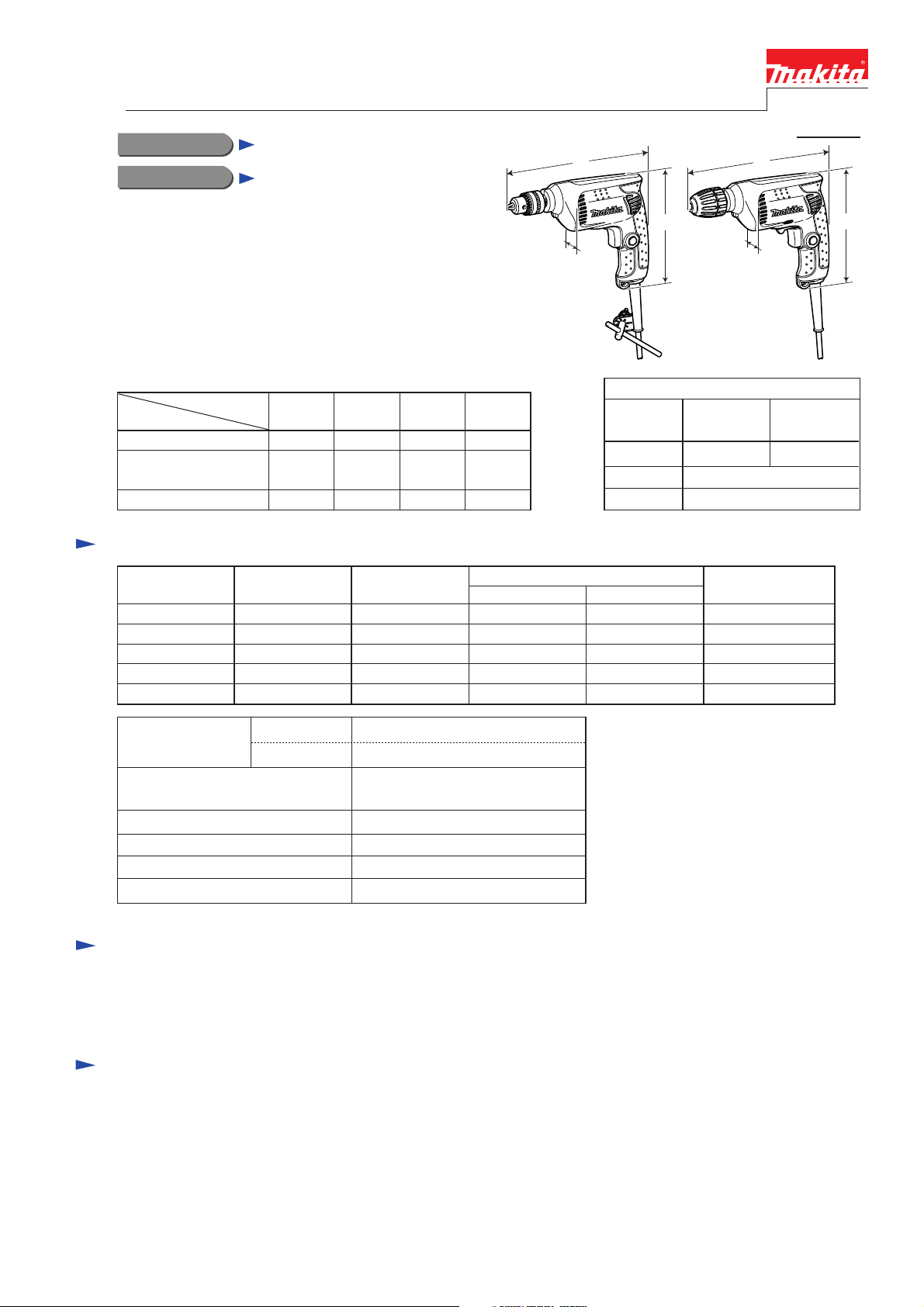

Description

ECHNICAL INFORMATION

Model No.

6411, 6412, 6413, M611

Drill 10mm (3/8")

PRODUCT

P 1 /12

L

L

CONCEPT AND MAIN APPLICATIONS

Models 6411, 6412, 6413 and M611 are cost-competitive

10mm Drills developed as the successor models of

6409, 6410, 6510SB and M610, featuring compact and

lightweight design yet with high durability.

Listed below are the specification differences among

the four models.

Model No.

Specification

Reverse switch

Variable speed control

by trigger

Drill chuck type

Specification

Voltage (V) Cycle (Hz)

110 4.3 450 230 35050/ 60

120

220

230

240

6411

No

No

Current (A)

4.0 --- 230 35050/ 60

2.2 450 230 35050/ 60

2.1 450 230 35050/ 60

2.0 450 230 35050/ 60

6412 6413

Yes Yes

Yes

KeyedKeyed

Yes

Keyless

W

6411, 6412

M611

M611

Yes

Yes

Keyed

Continuous Rating (W)

Input Output

H

Model

Length (L)

Width (W)

Height (H)

W

6413

Dimensions: mm (")

6411, 6412

M611

228 (9)

Max. Output (W)

234 (9-1/4)

64 (2-1/2)

183 (7-1/4)

H

6413

Capacities: mm (")

Steel

Wood

No load speed: min-1=rpm

Chuck capacity: mm (")

Double insulation

Power supply cord: m (ft)

Net weight: kg (lbs)

6412, 6413, M611: 0 -3,000

10 (3/8)

25 (1)

6411: 3,000

1.5 - 10 (1/16 -3/8)

Yes

2.0 (6.6)

1.2 (2.6)

Standard equipment

Chuck key S10 ............ 1 (for 6411, 6412, M611)

Key holder 10 .............. 1 (for 6411, 6412, M611)

Note: The standard equipment for the tool shown above may differ by country.

Optional accessories

Drills bits

Page 2

Repair

CAUTION: Unplug the machine for safety before repair/ maintenance

in accordance with the instruction manual!

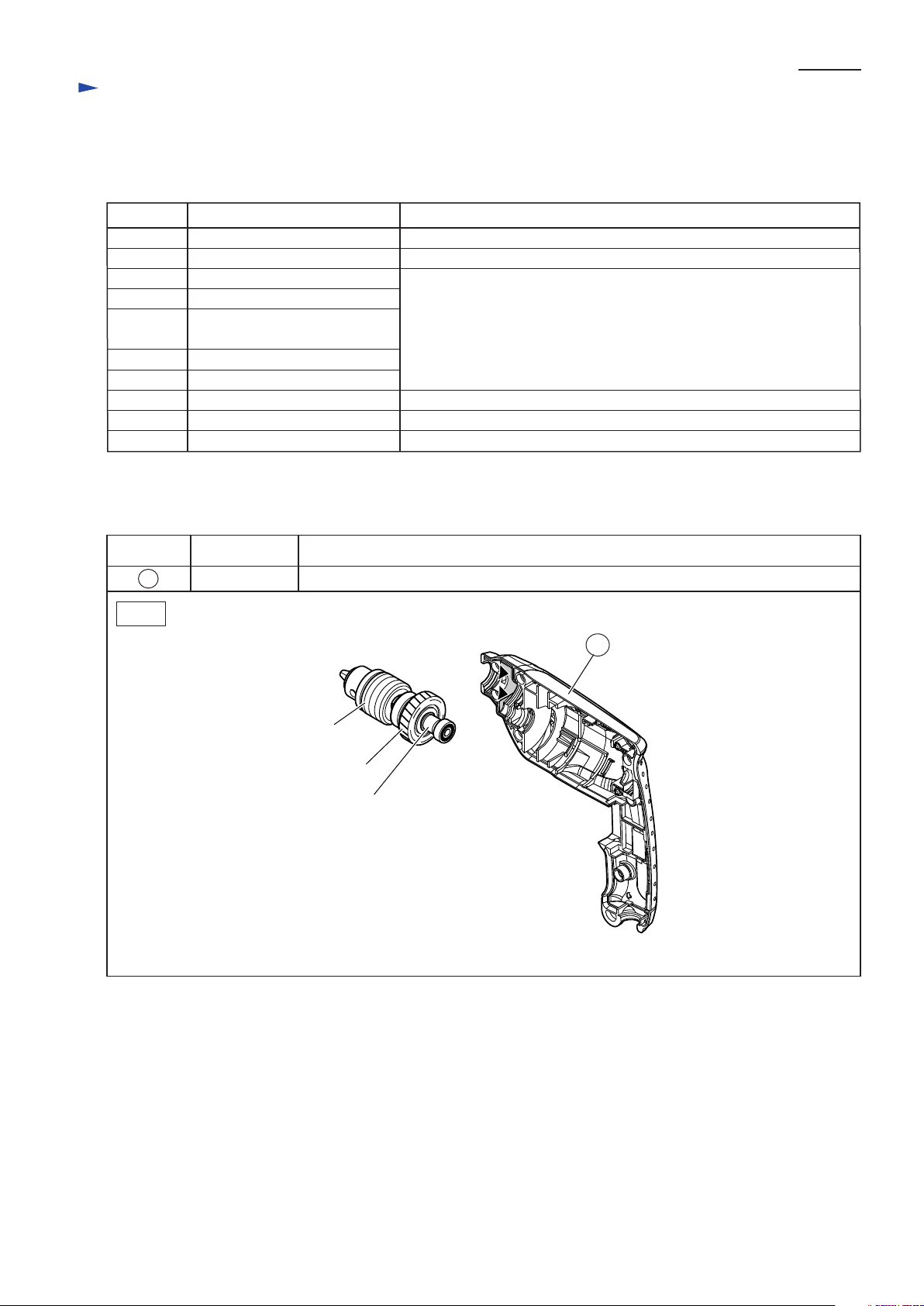

[1] NECESSARY REPAIRING TOOLS

DescriptionCode No. Use for

1R004 Removing/Installing Ring spring 13 from Spindle

1R139

1R220

1R222 Socket adapter

1R223

A-33750

1R231

1R269

1R273

1R031

[2] LUBRICATION

Apply Makita grease N. No.1 to the following portions designated with the black triangle to protect

parts and product from unusual abrasion.

Retaining ring pliers ST-2

Drill chuck extractor

Ratchet head 9.5

Torque wrench shaft 20- 90N.m

Bit Adaptor

1/4" Hex. shank bit for M8

Bearing extractor

Ring spring 26 setting tool B

Bearing setting pipe 28-20.2

Locking Spindle when removing Drill chuck from Spindle

Assembling Drill chuck to Spindle

Note: Preset the fastening torque of 1R223

to 25- 30 N.m (250- 300kgf.cm).

Removing Ball bearing 606ZZ

Removing/Installing Helical gear 35

Removing/Installing Ball bearing 6902ZZ

P 2 /12

Item No. Description Portion to lubricate

7

Fig. 1

Housing Gear room for Helical Gear 35 (Apply approx. 3g.)

7

Drill chuck S-10

Helical gear 35

Spindle

Page 3

P 3 /12

Repair

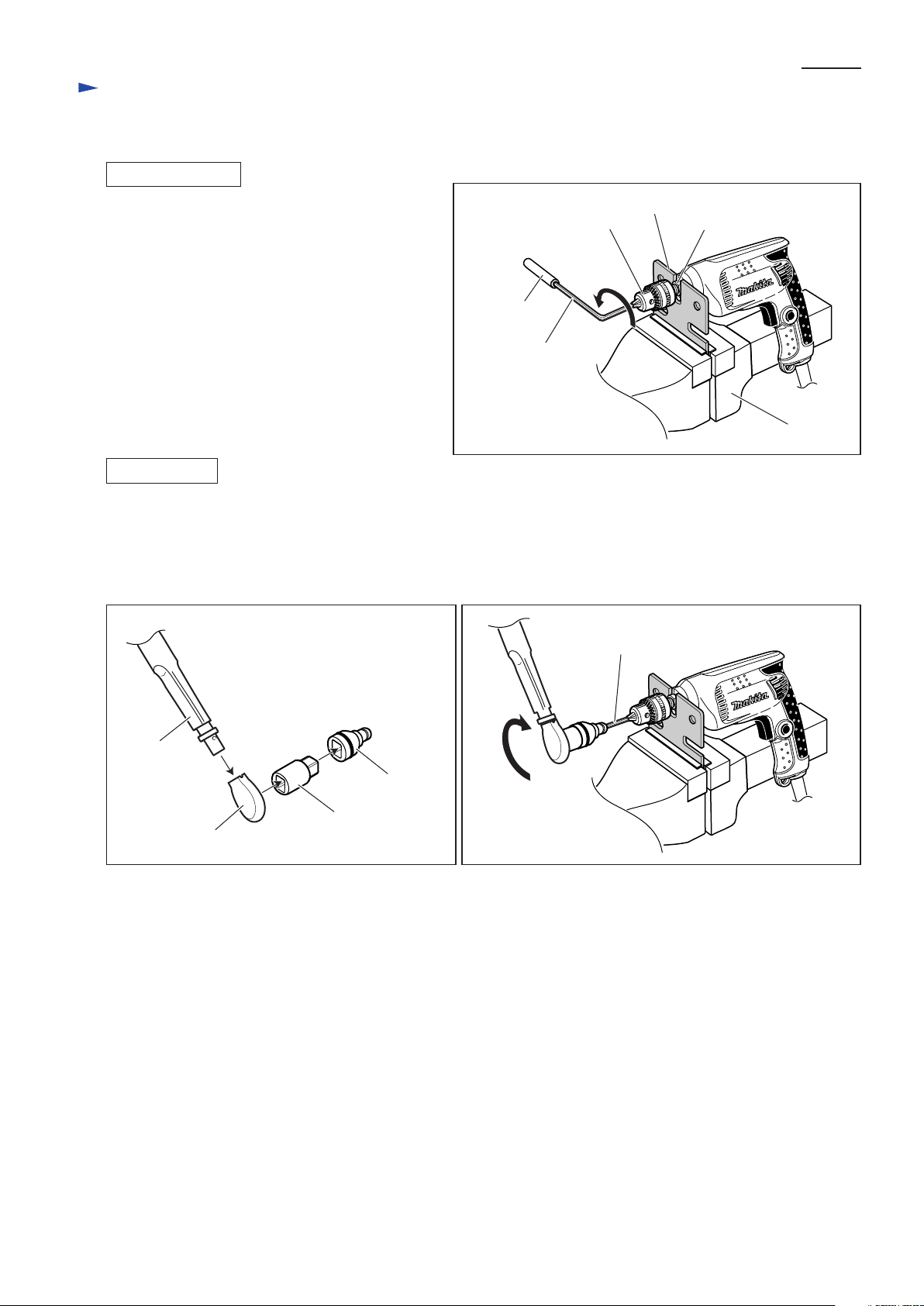

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Drill Chuck

DISASSEMBLING

See Fig. 2.

1) Fix 1R139 securely in vise, then lock Spindle

by putting it in the U-shaped notch of 1R139.

2) Fix Hex wrench 10 securely in Drill chuck.

Attach an appropriate steel pipe to Hex wrench 10

as extension bar.

3) Remove Drill chuck from Spindle by turning

Drill chuck counterclockwise using Hex wrench 10

and steel pipe.

ASSEMBLING

1) Assemble 1R220, 1R222, 1R223 and A-33750 as illustrated in Fig. 3.

Note: Preset the fastening torque of 1R223 to 25- 30N.m (250- 300 kgf.cm).

2) Lock Spindle as you did in step 1) of DISASSEMBLING, then fix 1R231 securely in Drill chuck. (Fig. 4)

3) Assemble Drill chuck to Spindle by turning 1R231 and Drill chuck clockwise using the repairing tools described in

step 1) of ASSEMBLING. (Fig. 4)

Fig. 3 Fig. 4

Fig. 2

steel pipe

Hex wrench 10

Drill chuck

1R139

Spindle

Vise

1R223

1R231

A-33750

1R222

1R220

Page 4

Repair

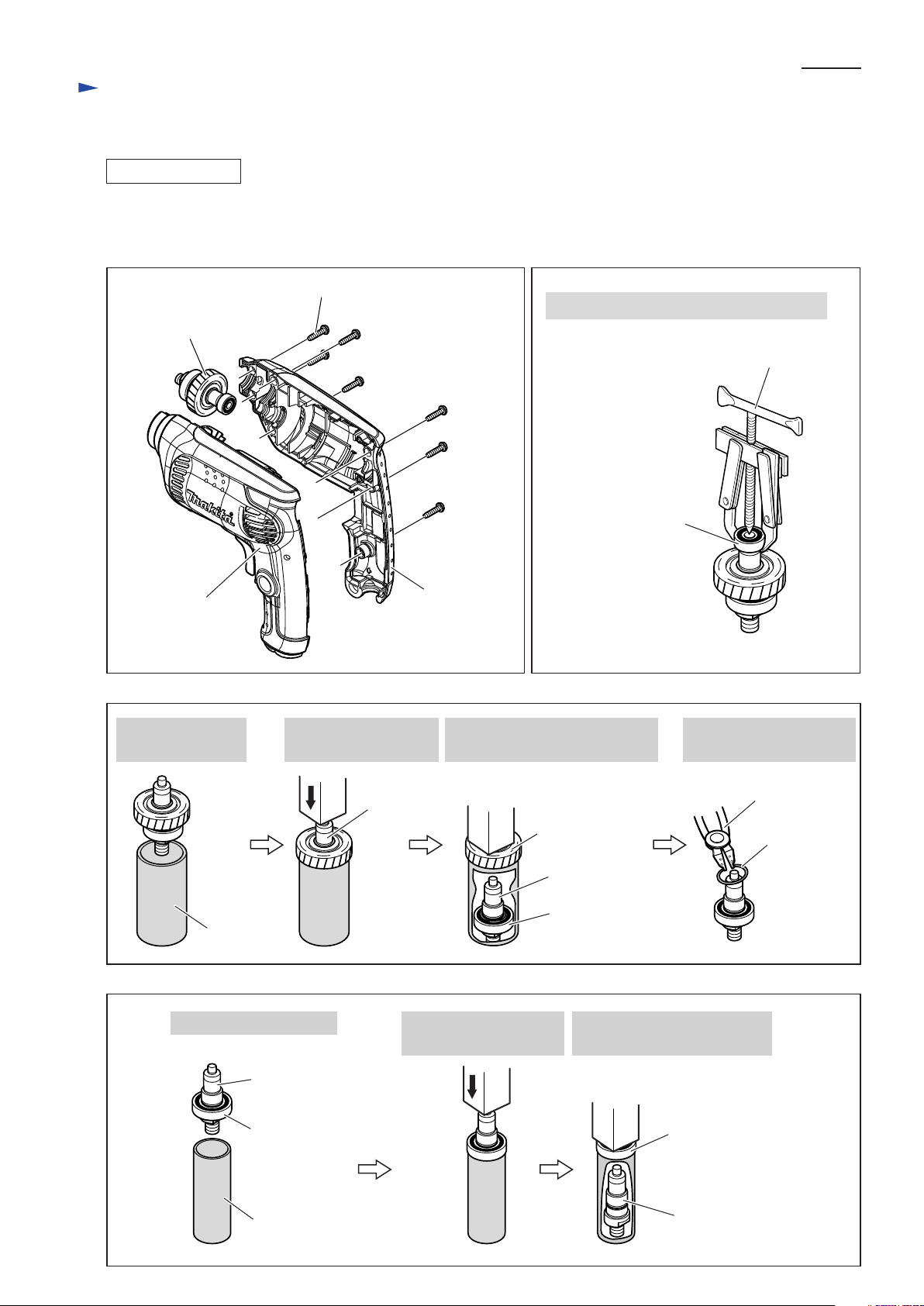

[3] DISASSEMBLY/ASSEMBLY

[3] -2. Gear Section

DISASSEMBLING

1) After disassembling Drill chuck as illustrated in Fig. 2, separate Housing (R) from Housing (L).

Remove Gear section from Housing (L). (Fig. 5)

2) Disassemble Gear section as illustrated in Figs. 6, 7, 8.

Fig. 5 Fig. 6

Tapping screw 4x18 (7 pcs)

1) Remove Ball bearing 606ZZ with 1R269.

Gear section

P 4 /12

1R269

Housing (L)

Fig. 7

2) Put Gear section

on 1R273.

1R273

3) By pressing Spindle

using arbor press,

Spindle

Ball bearing 606ZZ

Housing (R)

Spindle can be removed together

with Ball bearing 6902ZZ.

Helical gear 35

Spindle

Ball bearing

6902ZZ

4) Remove Ring spring 13

using 1R004.

1R004

Ring spring 13

Fig. 8

5) Put Spindle on 1R031. 6) By pressing Spindle

using arbor press,

Spindle

Ball bearing

6902ZZ

1R031

Spindle can be removed from

Ball bearing 6902ZZ.

Ball bearing

6902ZZ

Spindle

Page 5

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -2. Gear Section (cont.)

ASSEMBLING

1) Assemble Gear section as illustrated in Fig. 9 to Fig. 12.

2) Assemble Gear section to Housing (L). (Fig. 5 in page 4)

Fig. 9 Fig. 10

P 5/12

Fig. 11

Ball bearing

6902ZZ

1) Assemble Ball bearing to Spindle

using 1R031 and arbor press.

Spindle

Ball bearing 6902ZZ

1R031

3) Assemble Helical gear 35 to Spindle using 1R273

and arbor press.

Note:

Helical gear 35 is not reversible when assembled

to Spindle. The flat side of the gear must face

towards Ball bearing 6902ZZ.

flat side

Helical gear 35

grooved side

2) Fix Ball bearing 6902ZZ by assembling

Ring spring 13 to Spindle using 1R004.

Note:

If Ring spring 13 is deformed or damaged

when removed from Spindle, be sure to

replace it with new one.

Ring spring 13

Fig. 12

4) Assemble Ball bearing 606ZZ

to Spindle using arbor press.

Ball bearing 606ZZ

1R273

flat side

[3] -3. Motor Section

DISASSEMBLING

1) After separating Housing (R) from Housing (L), disconnect Carbon brushes from Armature commutator by pulling off

Brush holders from Housing (L). Disassemble Motor section from Housing (L). (Fig. 13)

2) Pull out Armature from Field. (Fig. 14)

Fig. 13 Fig. 14

Motor section

Brush holder

Carbon brush

Armature commutator

Leaf spring

Housing (L)

Carbon brush

Brush holder

Armature

Field

Page 6

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -3. Motor Section (cont.)

ASSEMBLING

Do the reverse of the disassembling steps.

Note:

Leaf spring is not reversible when assembled

to Housing (L). The concave side must face towards

Ball bearing 627ZZ on Armature. (Fig. 15)

P 6/12

Fig. 15

Housing (L)

Ball bearing 627ZZ

Leaf spring

concave side

Page 7

Circuit diagram

Model 6411 (without Variable speed control and Reverse switch)

Machines Without Choke Coil and Noise Suppressor

Fig. D-1

Color index of lead wires' sheath

Black

White

P 7/12

Brush holder

Field

Switch

Power supply cord

Page 8

Wiring diagram

Model 6411 (without Variable speed control and Reverse switch)

Machines Without Choke Coil

Important: Do not put slack portion of any Lead wire in the space surrounded by Field and Brush holders.

Otherwise Lead wires will be broken by rotating Armature.

Fig. D-2

P 8/12

Put slack portion of Field lead wire (black)

in the space between Brush holder and

inside wall of Housing (L).

boss A

boss B

See "Connecting Lead wire to Brush holder".

Route the following two Lead wires

between the ribs:

*Field lead wire (white)

*Lead wire (black)

from No.2a Terminal of Switch

to Brush holder

Power supply cord

See "Connecting Lead wire to Brush holder".

Brush holder

Field

Switch

Route Field lead wire (white)

under Brush holder.

Connecting Lead wire to Brush holder

1) Brush holders are not reversible

when assembled to Housing (L).

Terminal insertion hole of each

Brush holder must be positioned

outside boss A/boss B.

2) Do not route each Lead wire

inside boss A/boss B.

boss A

boss B

Field lead wire (black)

Terminal

Lead wire (black)

from No.2a Terminal of Switch

Brush holder

Page 9

Circuit diagram

Model 6411 (without Variable speed control and Reverse switch)

Machines With Choke Coil

Fig. D-3

P 9/12

Color index of lead wires' sheath

Black

White

Orange

Purple

Brush holder

*Note: Some countries do not use Noise suppressor.

Choke coil

(with purple Lead wires)

Field

Choke coil

(with orange Lead wires)

*Noise suppressor

[if used]

Switch

Power supply cord

Page 10

Wiring diagram

Model 6411 (without Variable speed control and Reverse switch)

Machines With Choke Coil

Important: Do not put slack portion of any Lead wire in the space surrounded by Field and Brush holders.

Otherwise Lead wires will be broken by rotating Armature.

Note: 1) Some countries do not use Noise suppressor.

2) Put Choke coils and Noise suppressor (if used) in place as illustrated in Fig. D-4.

Fig. D-4

Lead wires

Choke coil lead wire (purple) to Brush holder

Choke coil lead wire (purple) to No.1a Terminal of Switch

Choke coil lead wire (orange) to Brush holder

Choke coil lead wire (orange) to Field

Field lead wire (black) to No.2a Terminal of Switch

See "Connecting Lead wire to Brush holder".

Brush holder

Put slack portion of Lead wire

in the space between Brush holder

and inside wall of Housing (L).

Otherwise the Lead wire will touch

rotating Armature.

Fix two Lead wires

with this Lead wire holder.

Choke coil

(with purple Lead wires)

P 10/12

boss A

boss B

See "Connecting Lead wire to Brush holder".

Route Lead wires

between these ribs.

Choke coil

(with orange Lead wires)

Field

Switch

Route Lead wires

under Brush holder.

Noise suppressor

[if used]

Power supply cord

Connecting Lead wire to Brush holder

1) Brush holders are not reversible

when assembled to Housing (L).

Terminal insertion hole of each

Brush holder must be positioned

outside boss A/boss B.

2) Do not route each Lead wire

inside boss A/boss B.

boss A

boss B

Terminal

Brush holder

Page 11

Circuit diagram

Models 6412, 6413, M611 (with Variable speed control and Reverse switch)

Fig. D-5

Color index of lead wires' sheath

Black

White

Orange

Blue

Purple

Note:

*Choke coil (with blue Lead wire and black Lead wire)

is reversible when connected to Switch.

**Some countries do not use Noise suppressor or Choke coils.

*Choke coil

(with purple Lead wires)

[if used]

P 11/12

Brush holder

*Choke coil

(with orange Lead wires)

[if used]

*Choke coil

(with blue Lead wire

and black Lead wire)

[if used]

**Noise suppressor

[if used]

Field

Switch

Power supply cord

Page 12

Wiring diagram

Models 6412, 6413, M611 (with Variable speed control and Reverse switch)

Important: Do not put slack portion of any Lead wire in the space surrounded by Field and Brush holders.

Otherwise Lead wires will be broken by rotating Armature.

Note: 1) Some countries do not use Noise suppressor or Choke coils.

2) Put Choke coils and Noise suppressor (if used) in place as illustrated in Fig. D-6.

3) Choke coil (with blue Lead wire and black Lead wire) is reversible when connected to Switch.

Fig. D-6

Lead wires

Choke coil lead wire (purple) to Brush holder

Choke coil lead wire (purple) to No.4 Terminal of Switch

Choke coil lead wire (orange) to Brush holder

Choke coil lead wire (orange) to No.3 Terminal of Switch

Field lead wire (black) to No.2a Terminal of Switch

Field lead wire (white) to No.5 Terminal of Switch

Choke coil lead wire (blue or black) to No.6 Terminal of Switch

Brush holder

See "Connecting Lead wire to Brush holder".

Fix two Lead wires

with this Lead wire holder.

Choke coil

(with purple Lead wires)

[if used]

P 12/12

Put slack portion of Lead wire

in the space between Brush holder

and inside wall of Housing (L).

Otherwise the Lead wire will touch

rotating Armature.

Put slack portion of Lead wires

in this space.

See "Connecting Lead wire to Brush holder".

Route Lead wires

between these ribs.

Choke coil

(with orange Lead wires)

[if used]

Choke coil

(with blue Lead wire

and black Lead wire)

[if used]

boss A

boss B

Field

Switch

Route Lead wires

under Brush holder.

Noise suppressor

[if used]

Power supply cord

Connecting Lead wire to Brush holder

1) Brush holders are not reversible

when assembled to Housing (L).

Terminal insertion hole of each

Brush holder must be positioned

outside boss A/boss B.

2) Do not route each Lead wire

inside boss A/boss B.

boss A

boss B

Terminal

Brush holder

Loading...

Loading...