Page 1

EN

Router INSTRUCTION MANUAL 6

FR

DE

IT

NL

ES

PT

DA

EL

TR

Défonceuse MANUEL D’INSTRUCTIONS 11

Oberfräse BETRIEBSANLEITUNG 17

Fresatrice verticale ISTRUZIONI PER L’USO 23

Bovenfrees GEBRUIKSAANWIJZING 29

Rebajadora

Tupia MANUAL DE INSTRUÇÕES 41

Overfræser BRUGSANVISNING 47

Ρούτερ ΕΓΧΕΙΡΙΔΙΟ ΟΔΗΓΙΩΝ 52

Freze KULLANMA KILAVUZU 58

M3601

MANUAL DE

INSTRUCCIONES

35

Page 2

1

Fig.1

Fig.2

Fig.3

2

1

Fig.5

2

1

1

2

Fig.6

1

2

3

4

5

Fig.7

Fig.4

1

1

4

2

3

2

2

3

4

4

5

Fig.8

2

Page 3

1

23

12

Fig.9

Fig.10

Fig.11

4

1

3

Fig.13

Fig.14

2

Fig.15

A

Fig.12

R

Fig.16

3

Page 4

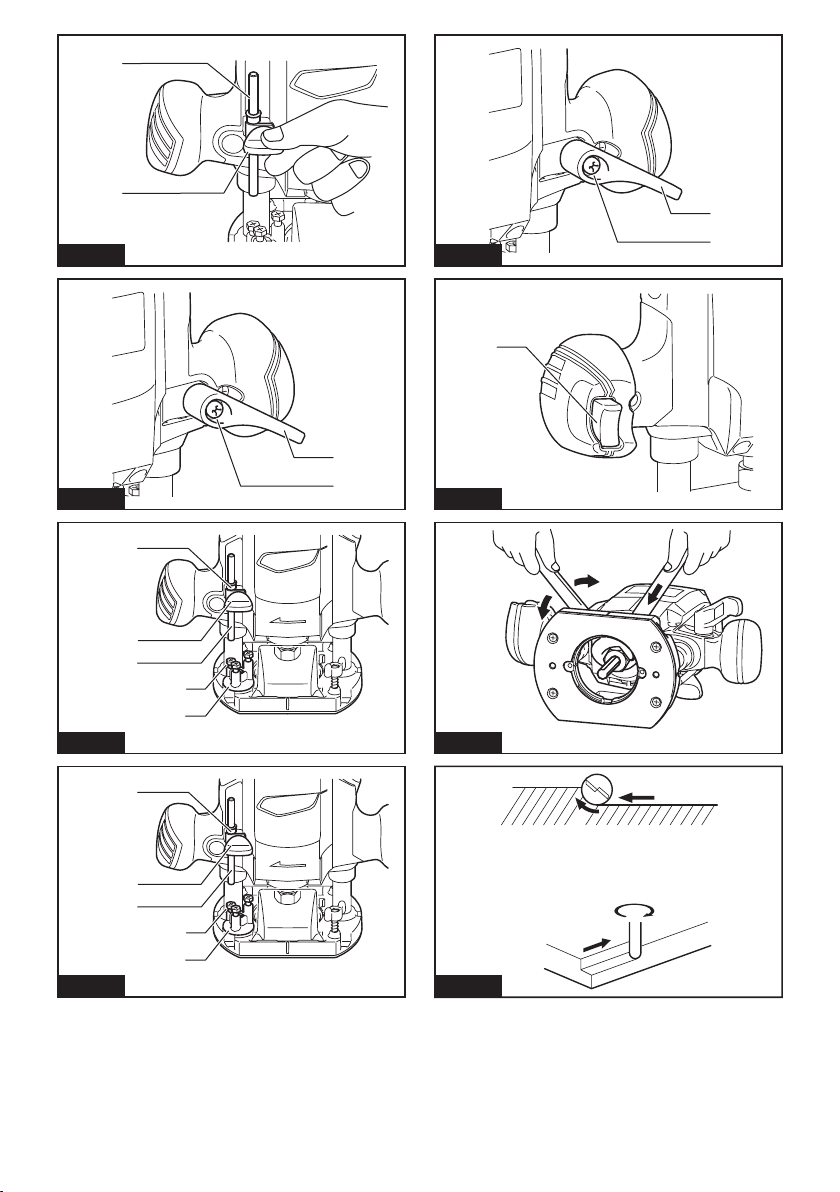

Fig.17

Fig.21

Fig.18

Fig.19

Fig.20

Fig.22

Fig.23

Fig.24

4

Page 5

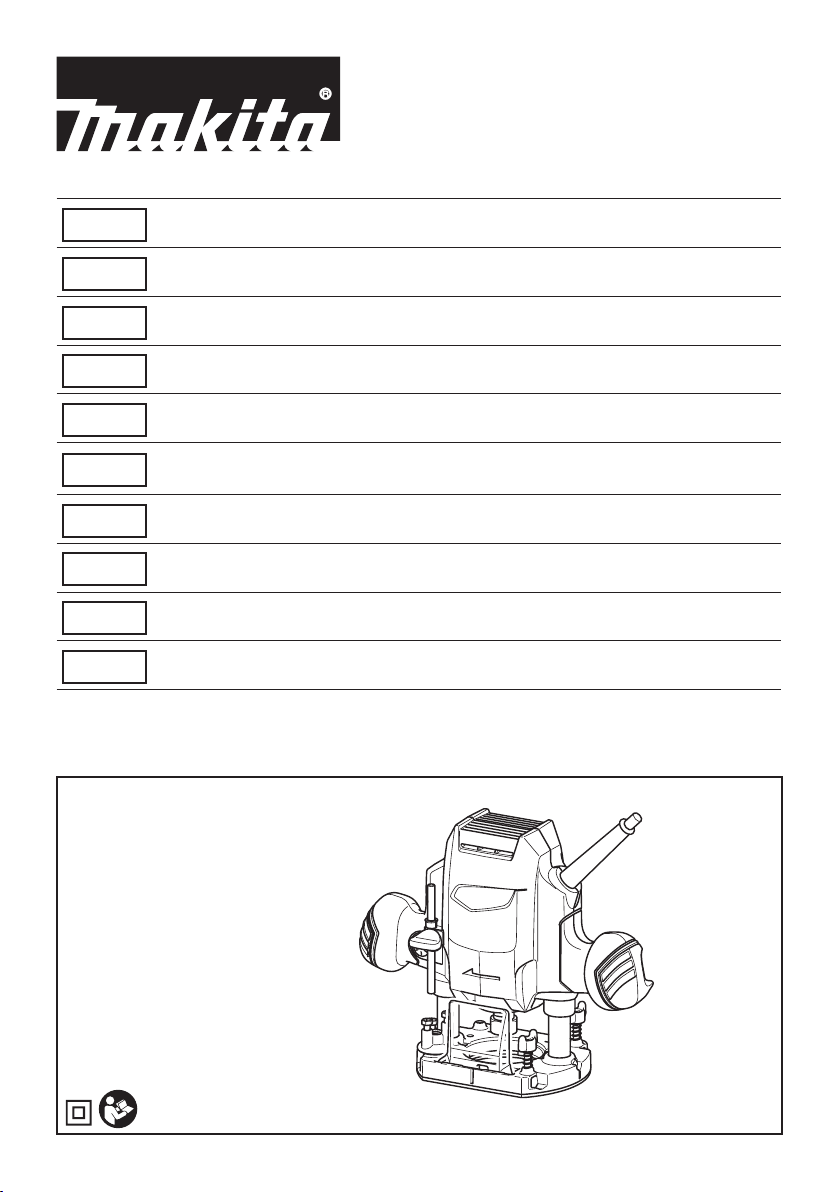

Fig.25

Fig.26

Fig.27

Fig.28

5

Page 6

ENGLISH (Original instructions)

SPECIFICATIONS

Model: M3601

Collet chuck capacity 6 mm, 1/4″ and/or 8 mm

Plunge capacity 0 - 35 mm

No load speed 27,000 min

Overall height 218 mm

Net weight 2.7 kg

Safety class

• Due to our continuing program of research and development, the specications herein are subject to change

without notice.

• Specications may differ from country to country.

• Weight according to EPTA-Procedure 01/2003

Intended use

The tool is intended for ush trimming and proling of

wood, plastic and similar materials.

Power supply

The tool should be connected only to a power supply of

the same voltage as indicated on the nameplate, and

can only be operated on single-phase AC supply. They

are double-insulated and can, therefore, also be used

from sockets without earth wire.

Noise

The typical A-weighted noise level determined according to EN60745:

Sound pressure level (LpA) : 91 dB(A)

Sound power level (LWA) : 102 dB (A)

Uncertainty (K) : 3 dB(A)

WARNING: Wear ear protection.

Vibration

The vibration total value (tri-axial vector sum) determined according to EN60745:

Work mode: cutting grooves in MDF

Vibration emission (a

Uncertainty (K) : 1.5 m/s

NOTE: The declared vibration emission value has

been measured in accordance with the standard test

method and may be used for comparing one tool with

another.

NOTE: The declared vibration emission value

may also be used in a preliminary assessment of

exposure.

) : 7.5 m/s

h

2

2

WARNING: The vibration emission during actual

use of the power tool can differ from the declared

emission value depending on the ways in which the

tool is used.

WARNING: Be sure to identify safety measures

to protect the operator that are based on an estimation of exposure in the actual conditions of use (taking

account of all parts of the operating cycle such as

the times when the tool is switched off and when it is

running idle in addition to the trigger time).

EC Declaration of Conformity

For European countries only

Makita declares that the following Machine(s):

Designation of Machine: Router

Model No./ Type: M3601

Conforms to the following European Directives:

2006/42/EC

They are manufactured in accordance with the following

standard or standardized documents: EN60745

The technical le in accordance with 2006/42/EC is

available from:

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgium

31.8.2015

Yasushi Fukaya

Director

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgium

General power tool safety warnings

WARNING: Read all safety warnings and

all instructions. Failure to follow the warnings and

instructions may result in electric shock, re and/or

serious injury.

-1

/II

6 ENGLISH

Page 7

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

Router safety warnings

1. Hold power tool by insulated gripping surfaces, because the cutter may contact its own

cord. Cutting a “live” wire may make exposed

metal parts of the power tool “live” and shock the

operator.

2. Use clamps or another practical way to secure

and support the workpiece to a stable platform. Holding the work by your hand or against

the body leaves it unstable and may lead to loss of

control.

3. Wear hearing protection during extended

period of operation.

4. Handle the router bits very carefully.

5. Check the router bit carefully for cracks or

damage before operation. Replace cracked or

damaged bit immediately.

6. Avoid cutting nails. Inspect for and remove all

nails from the workpiece before operation.

7. Hold the tool rmly with both hands.

8. Keep hands away from rotating parts.

9. Make sure the router bit is not contacting the

workpiece before the switch is turned on.

10. Before using the tool on an actual workpiece,

let it run for a while. Watch for vibration or

wobbling that could indicate improperly

installed bit.

11. Be careful of the router bit rotating direction

and the feed direction.

12. Do not leave the tool running. Operate the tool

only when hand-held.

13. Always switch off and wait for the router bit to

come to a complete stop before removing the

tool from workpiece.

14. Do not touch the router bit immediately after

operation; it may be extremely hot and could

burn your skin.

15. Do not smear the tool base carelessly with

thinner, gasoline, oil or the like. They may

cause cracks in the tool base.

16. Use router bits of the correct shank diameter

suitable for the speed of the tool.

17. Some material contains chemicals which may

be toxic. Take caution to prevent dust inhalation and skin contact. Follow material supplier

safety data.

18. Always use the correct dust mask/respirator

for the material and application you are working with.

SAVE THESE INSTRUCTIONS.

WARNING: DO NOT let comfort or familiarity

with product (gained from repeated use) replace

strict adherence to safety rules for the subject

product. MISUSE or failure to follow the safety

rules stated in this instruction manual may cause

serious personal injury.

FUNCTIONAL

DESCRIPTION

CAUTION: Always be sure that the tool is

switched off and unplugged before adjusting or

checking function on the tool.

Adjusting the depth of cut

1. Place the tool on a at surface. Loosen the screw

securing the stopper pole.

► Fig.1: 1. Stopper pole 2. Screw

2. Loosen the lock lever and lower the tool body until

the router bit just touches the at surface. Tighten the

lock lever to lock the tool body.

► Fig.2: 1. Lock lever 2. Screw

3. Lower the stopper pole until it makes contact with

the adjusting hex bolt. Align the depth pointer with the

"0" graduation.

► Fig.3: 1. Depth pointer 2. Screw 3. Stopper pole

4. Adjusting hex bolt 5. Stopper block

4. Raise the stopper pole until the desired depth

of cut is obtained. The depth of cut is indicated on the

scale (1 mm per graduation) by the depth pointer. Then

tighten the screw to secure the stopper pole.

5. Your predetermined depth of cut can be obtained

by loosening the lock lever and then lowering the tool

body until the stopper pole makes contact with the

adjusting hex bolt.

CAUTION: Since excessive cutting may cause

overload of the motor or difculty in controlling

the tool, the depth of cut should not be more than

15 mm (9/16″) at a pass when cutting grooves

with an 8 mm (5/16″) diameter bit.

CAUTION: When cutting grooves with a 20

mm (13/16″) diameter bit, the depth of cut should

not be more than 5 mm (3/16″) at a pass.

CAUTION: When you wish to cut grooves

more than 15 mm (9/16″) deep with an 8 mm

(5/16″) diameter bit or more than 5 mm (3/16″)

deep with a 20 mm (13/16″) diameter bit, make

several passes with progressively deeper bit

settings.

7 ENGLISH

Page 8

Stopper block

The stopper block has three adjusting hex bolts which

raise or lower 0.8 mm (approx. 1/32″) per turn. You can

easily obtain three different depths of cut using these

adjusting hex bolts without readjusting the stopper pole.

► Fig.4: 1. Depth pointer 2. Screw 3. Stopper pole

4. Adjusting hex bolt 5. Stopper block

1. Adjust the lowest hex bolt to obtain the deepest

depth of cut, following the method of "Adjusting the

depth of cut".

2. Adjust the two remaining hex bolts to obtain shal-

lower depths of cut. The differences in height of these

hex bolts are equal to the differences in depths of cut.

3. Turn the hex bolts to adjust the depth. The stopper

block is also convenient for making three passes with

progressively deeper bit settings when cutting deep

grooves.

NOTE: When using a bit having total length of 60 mm

(2-3/8″) or more, or edge length of 35 mm (1-3/8″) or

more, the depth of cut cannot be adjusted as previously mentioned. To adjust, proceed as follows:

1. Loosen the lock lever and carefully adjust bit

protrusion below the tool base to the desired

depth of cut by moving the tool body up or

down.

2. Retighten the lock lever to lock the tool body at

that depth of cut. Keep the tool body locked at

this position during use.

Since the bit always protrudes from the tool base, be

careful when handling the tool.

Adjusting the lock lever

The locked position of the lock lever is adjustable. To

adjust it, remove the screw securing the lock lever. The

lock lever will come off. Set the lock lever at the desired

angle. After adjustment, tighten the lock lever clockwise.

► Fig.5: 1. Lock lever 2. Screw

Switch action

CAUTION: Before plugging in the tool, always

check to see that the switch trigger actuates

properly and returns to the "OFF" position when

released.

To start the tool, simply pull the switch trigger. Release

the switch trigger to stop.

► Fig.6: 1. Switch trigger

Installing or removing the router bit

Insert the bit all the way into the collet cone and tighten

the collet nut securely with the two wrenches. An 8 mm

collet cone may be also provided as a standard equipment (depending on the country) besides the 6 mm or

1/4″ collet cone that is factory installed on the tool. Use

the correct size collet cone for the bit which you intend

to use.

► Fig.7

To remove the bit, follow the installation procedure in

reverse.

CAUTION: Install the router bit securely.

Always use only the wrench provided with the

tool. A loose or overtightened router bit can be

dangerous.

CAUTION: Do not tighten the collet nut with-

out inserting a bit. It can lead to breakage of the

collet cone.

OPERATION

Set the tool base on the workpiece to be cut without

the router bit making any contact. Then turn the tool on

and wait until the router bit attains full speed. Lower the

tool body and move the tool forward over the workpiece

surface, keeping the tool base ush and advancing

smoothly until the cutting is complete.

When doing edge cutting, the workpiece surface should

be on the left side of the router bit in the feed direction.

► Fig.8: 1. Workpiece 2. Bit revolving direction

3. View from the top of the tool 4. Feed

direction

NOTE: Moving the tool forward too fast may cause

a poor quality of cut, or damage to the router bit or

motor. Moving the tool forward too slowly may burn

and mar the cut. The proper feed rate will depend on

the router bit size, the kind of workpiece and depth

of cut.

Before beginning the cut on the actual workpiece, it

is advisable to make a sample cut on a piece of scrap

lumber. This will show exactly how the cut will look as

well as enable you to check dimensions.

NOTE: When using the straight guide or the trimmer

guide, be sure to install it on the right side in the feed

direction. This will help to keep it ush with the side of

the workpiece.

► Fig.9: 1. Feed direction 2. Bit revolving direction

3. Workpiece 4. Straight guide

ASSEMBLY

CAUTION: Always be sure that the tool is

switched off and unplugged before carrying out

any work on the tool.

8 ENGLISH

Page 9

Straight guide

The straight guide is effectively used for straight cuts

when chamfering or grooving.

► Fig.10

To install the straight guide, insert the guide bars into

the holes in the tool base. Adjust the distance between

the bit and the straight guide. At the desired distance,

tighten the wing bolts to secure the straight guide in

place. When cutting, move the tool with the straight

guide ush with the side of the workpiece.

► Fig.11: 1. Guide bar 2. Clamp screw 3. Straight

guide

If the distance (A) between the side of the workpiece

and the cutting position is too wide for the straight

guide, or if the side of the workpiece is not straight, the

straight guide cannot be used. In this case, rmly clamp

a straight board to the workpiece and use it as a guide

against the trimmer base. Feed the tool in the direction

of the arrow.

► Fig.12

Dust nozzle set (For European

countries only)

Use the dust nozzle for dust extraction. Install the dust

nozzle on the tool base using the thumb screw so that

protrusion on the dust nozzle t to the notch in the

tool base. Then connect a vacuum cleaner to the dust

nozzle.

► Fig.13: 1. Dust nozzle 2. Thumb screw

► Fig.14

MAINTENANCE

CAUTION: Always be sure that the tool is

switched off and unplugged before attempting to

perform inspection or maintenance.

NOTICE: Never use gasoline, benzine, thinner,

alcohol or the like. Discoloration, deformation or

cracks may result.

To maintain product SAFETY and RELIABILITY,

repairs, any other maintenance or adjustment should

be performed by Makita Authorized or Factory Service

Centers, always using Makita replacement parts.

OPTIONAL

ACCESSORIES

If you need any assistance for more details regarding these accessories, ask your local Makita Service

Center.

• Straight & groove forming bits

• Edge forming bits

• Laminate trimming bits

NOTE: Some items in the list may be included in the

tool package as standard accessories. They may

differ from country to country.

Router bits

Straight bit

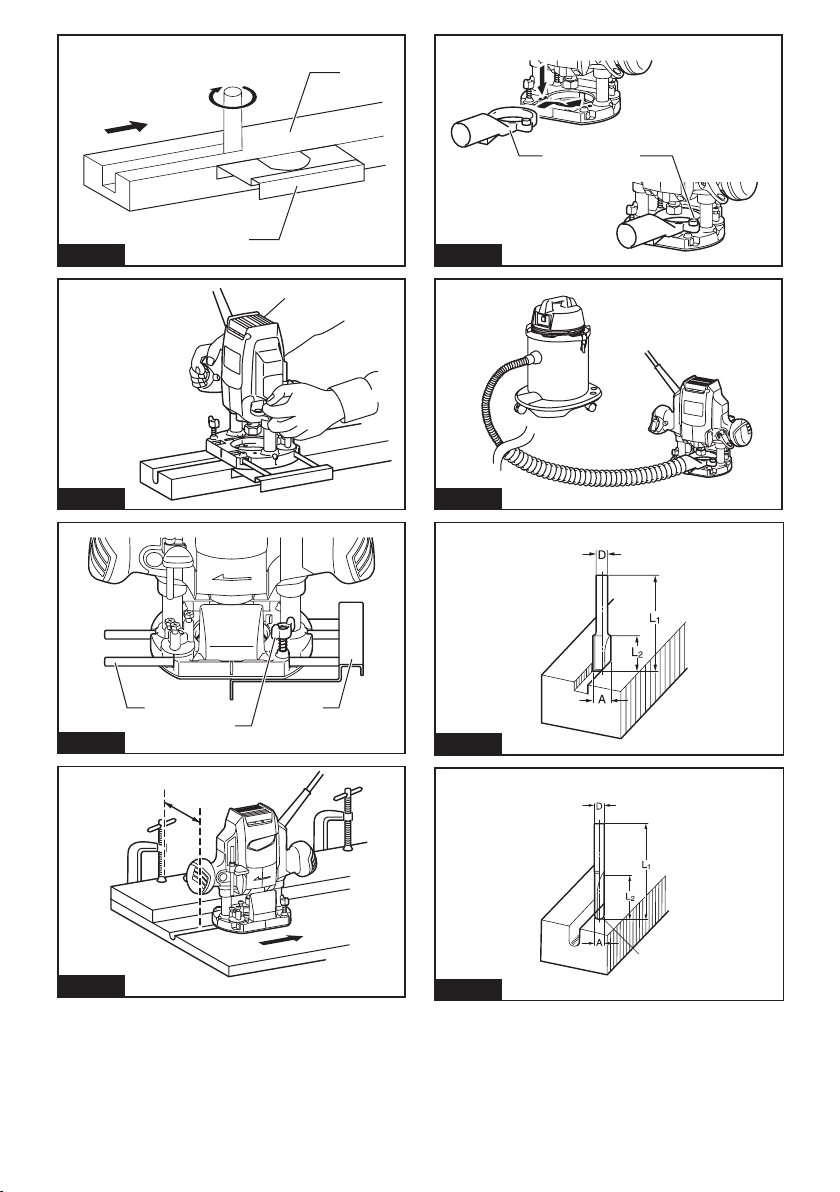

► Fig.15

Unit:mm

D A L1 L2

6 20 50 15

1/4″

8 8 60 25

6 8 50 18

1/4″

6 6 50 18

1/4″

“U”Grooving bit

► Fig.16

Unit:mm

D A L1 L2 R

6 6 50 18 3

“V”Grooving bit

► Fig.17

Unit:mm

D A L1 L2 θ

1/4″ 20 50 15 90°

Drill point ush trimming bit

► Fig.18

Unit:mm

D A L1 L2 L3

8 8 60 20 35

6 6 60 18 28

CAUTION: These accessories or attachments

are recommended for use with your Makita tool

specied in this manual. The use of any other

accessories or attachments might present a risk of

injury to persons. Only use accessory or attachment

for its stated purpose.

9 ENGLISH

Page 10

Drill point double ush trimming bit

► Fig.19

Unit:mm

D A L1 L2 L3 L4

8 8 80 55 20 25

6 6 70 40 12 14

Corner rounding bit

► Fig.20

Unit:mm

D A1 A2 L1 L2 L3 R

6 25 9 48 13 5 8

6 20 8 45 10 4 4

Chamfering bit

► Fig.21

Unit:mm

D A L1 L2 L3 θ

6 23 46 11 6 30°

6 20 50 13 5 45°

6 20 49 14 2 60°

Ball bearing chamfering bit

► Fig.25

Unit:mm

D A1 A2 L1 L2 θ

6 26 8 42 12 45°

1/4″

6 20 8 41 11 60°

Ball bearing beading bit

► Fig.26

Unit:mm

D A1 A2 A3 L1 L2 L3 R

6 20 12 8 40 10 5.5 4

6 26 12 8 42 12 4.5 7

Ball bearing cove beading bit

► Fig.27

Unit:mm

D A1 A2 A3 A4 L1 L2 L3 R

6 20 18 12 8 40 10 5.5 3

6 26 22 12 8 42 12 5 5

Cove beading bit

► Fig.22

D A L1 L2 R

6 20 43 8 4

6 25 48 13 8

Ball bearing ush trimming bit

► Fig.23

D A L1 L2

6 10 50 20

1/4″

Ball bearing corner rounding bit

► Fig.24

D A1 A2 L1 L2 L3 R

6 15 8 37 7 3.5 3

6 21 8 40 10 3.5 6

1/4″ 21 8 40 10 3.5 6

Unit:mm

Unit:mm

Unit:mm

Ball bearing roman ogee bit

► Fig.28

Unit:mm

D A1 A2 L1 L2 L3 R1 R2

6 20 8 40 10 4.5 2.5 4.5

6 26 8 42 12 4.5 3 6

10 ENGLISH

Page 11

FRANÇAIS (Instructions originales)

SPÉCIFICATIONS

Modèle : M3601

Capacité du mandrin à bague 6 mm, 1/4″ et/ou 8 mm

Capacité de plongée 0 à 35 mm

Vitesse à vide 27 000 min

Hauteur hors tout 218 mm

Poids net 2,7 kg

Catégorie de sécurité

• Étant donné l’évolution constante de notre programme de recherche et de développement, les spécications

contenues dans ce manuel sont sujettes à modication sans préavis.

• Les spécications peuvent varier suivant les pays.

• Poids selon la procédure EPTA 01/2003

Utilisations

L’outil est conçu pour l’afeurage au ras et le prolage

du bois, du plastique et de matériaux semblables.

Alimentation

L’outil ne devra être raccordé qu’à une alimentation

de la même tension que celle qui gure sur la plaque

signalétique, et il ne pourra fonctionner que sur un

courant secteur monophasé. Réalisé avec une double

isolation, il peut de ce fait être alimenté par une prise

sans mise à la terre.

Bruit

Niveau de bruit pondéré A typique, déterminé selon

EN60745 :

Niveau de pression sonore (LpA) : 91 dB (A)

Niveau de puissance sonore (L

Incertitude (K) : 3 dB (A)

) : 102 dB (A)

WA

AVERTISSEMENT : Portez un serre-tête

antibruit.

Vibrations

Valeur totale de vibrations (somme de vecteur triaxial)

déterminée selon EN60745 :

Mode de travail : coupe de rainures sur un panneau de

bres à densité moyenne

Émission de vibrations (ah) : 7,5 m/s

Incertitude (K) : 1,5 m/s

NOTE : La valeur d’émission de vibrations déclarée

a été mesurée conformément à la méthode de test

standard et peut être utilisée pour comparer les outils

entre eux.

NOTE : La valeur d’émission de vibrations déclarée

peut aussi être utilisée pour l’évaluation préliminaire

de l’exposition.

2

2

AVERTISSEMENT : L’émission de vibrations

lors de l’usage réel de l’outil électrique peut être

différente de la valeur d’émission déclarée, suivant la

façon dont l’outil est utilisé.

AVERTISSEMENT : Les mesures de sécurité à

prendre pour protéger l’utilisateur doivent être basées

sur une estimation de l’exposition dans des conditions réelles d’utilisation (en tenant compte de toutes

les composantes du cycle d’utilisation, comme par

exemple le moment de sa mise hors tension, lorsqu’il

tourne à vide et le moment de son déclenchement).

Déclaration de conformité CE

Pour les pays européens uniquement

Makita déclare que la ou les machines suivantes :

Désignation de la machine : Défonceuse

N° de modèle/Type : M3601

sont conformes aux Directives européennes suivantes :

2006/42/CE

et sont fabriquées conformément aux normes ou aux

documents normalisés suivants : EN60745

La documentation technique conforme à la norme

2006/42/CE est disponible auprès de :

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgique

31.8.2015

Yasushi Fukaya

Directeur

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgique

Consignes de sécurité générales

pour outils électriques

AVERTISSEMENT : Lisez toutes les

consignes de sécurité et toutes les instructions. Il

y a risque d’électrocution, d’incendie et/ou de graves

blessures si les mises en garde et les instructions ne

sont pas respectées.

-1

/II

11 FRANÇAIS

Page 12

Conservez toutes les mises en

garde et instructions pour référence ultérieure.

Le terme « outil électrique » dans les avertissements

fait référence à l’outil électrique alimenté par le secteur

(avec cordon d’alimentation) ou à l’outil électrique fonctionnant sur batterie (sans cordon d’alimentation).

Consignes de sécurité pour

défonceuse

1. Tenez l’outil électrique par une surface de

prise isolée, étant donné que l’outil de coupe

peut entrer en contact avec son cordon.

Couper un câble sous tension risque de mettre à

découvert les pièces métalliques de l’outil électrique sous tension et d’électrocuter l’utilisateur.

2. Utilisez des dispositifs de serrage ou un autre

moyen pratique pour xer et soutenir la pièce

sur une plateforme stable. La pièce sera instable et vous risquez d’en perdre la maîtrise si

vous la tenez dans vos mains ou l’appuyez contre

le corps.

3. Portez des protège-tympans si vous utilisez

l’outil pendant une période prolongée.

4. Manipulez les fraises de défonceuse avec

beaucoup de précaution.

5. Vériez soigneusement l’absence de ssures

ou de dommages sur les fraises de défonceuse avant l’utilisation. Remplacez immédia-

tement les fraises ssurées ou abîmées.

6. Prenez garde aux clous pendant la coupe.

Avant de travailler votre pièce, inspectez-la et

retirez-en tous les clous.

7. Tenez l’outil fermement à deux mains.

8. Gardez vos mains à l’écart des pièces en

rotation.

9. Assurez-vous que la fraise de défonceuse

n’est pas en contact avec la pièce avant de

mettre l’outil en marche.

10. Avant d’utiliser l’outil sur une pièce, faites-le

tourner un instant à vide. Soyez attentif aux

vibrations ou sautillements pouvant indiquer

que la fraise n’est pas bien installée ou est mal

équilibrée.

11. Faites attention au sens de rotation de la fraise

de défonceuse et au sens d’avance.

12. N’abandonnez pas l’outil alors qu’il tourne. Ne

faites fonctionner l’outil qu’une fois que vous

l’avez bien en main.

13. Avant de retirer l’outil de la pièce, mettez

toujours l’outil hors tension et attendez que

la fraise de défonceuse soit complètement

immobilisée.

14. Ne touchez pas la fraise de défonceuse immédiatement après avoir terminé le travail ; elle

peut être très chaude et vous brûler la peau.

15. Prenez garde de ne pas tacher le socle de

l’outil avec du diluant, de l’essence, de l’huile

ou toute substance similaire. Elles peuvent

entraîner des ssures sur le socle de l’outil.

16. Utilisez des fraises de défonceuse dont le diamètre de la tige convient à la vitesse de l’outil.

17. Certains matériaux contiennent des produits

chimiques qui peuvent être toxiques. Prenez

les précautions nécessaires pour ne pas

inhaler les poussières et pour éviter tout

contact avec la peau. Suivez les données de

sécurité du fournisseur du matériau.

18. Portez toujours un masque anti-poussières/un

masque ltrant adapté au matériau travaillé et

à l’application utilisée.

CONSERVEZ CES

INSTRUCTIONS.

AVERTISSEMENT : NE vous laissez PAS

tromper (au l d’une utilisation répétée) par un

sentiment d’aisance et de familiarité avec le

produit, en négligeant le respect rigoureux des

consignes de sécurité qui accompagnent le produit en question. La MAUVAISE UTILISATION de

l’outil ou l’ignorance des consignes de sécurité

indiquées dans ce mode d’emploi peut entraîner

de graves blessures.

DESCRIPTION DU

FONCTIONNEMENT

ATTENTION : Assurez-vous toujours que

l’outil est hors tension et débranché avant de

l’ajuster ou de vérier son fonctionnement.

Réglage de la profondeur de la

coupe

1. Placez l’outil sur une surface plane. Desserrez la

vis qui retient la tige d’arrêt.

► Fig.1: 1. Tige d’arrêt 2. Vis

2. Desserrez le levier de verrouillage et abaissez le

corps de l’outil jusqu’à ce que la fraise de défonceuse

entre légèrement en contact avec la surface plane.

Serrez le levier de verrouillage pour verrouiller le corps

de l’outil.

► Fig.2: 1. Levier de verrouillage 2. Vis

3. Abaissez la tige d’arrêt jusqu’à ce qu’elle entre en

contact avec le boulon hexagonal de réglage. Alignez

l’index de profondeur sur la graduation « 0 ».

► Fig.3: 1. Index de profondeur 2. Vis 3. Tige d’arrêt

4. Boulon hexagonal de réglage 5. Bloc

butoir

4. Soulevez la tige d’arrêt jusqu’à ce que vous obte-

niez la profondeur de coupe souhaitée. La profondeur

de coupe est indiquée sur l’échelle (1 mm par graduation) par l’index de profondeur. Puis serrez la vis pour

xer la tige d’arrêt.

5. La profondeur de coupe que vous avez prédé-

terminée peut être obtenue en desserrant le levier de

verrouillage, puis en abaissant le corps de l’outil jusqu’à

ce que la tige d’arrêt entre en contact avec le boulon

hexagonal de réglage.

12 FRANÇAIS

Page 13

ATTENTION : Comme une coupe trop pro-

fonde risquerait de surcharger le moteur et de

rendre difcile la maîtrise de l’outil, la profondeur

de coupe ne doit pas être supérieure à 15 mm

(9/16″) par passe lors du rainurage avec une

fraise de 8 mm (5/16″) de diamètre.

ATTENTION : Lors du rainurage avec une

fraise de 20 mm (13/16″) de diamètre, la profondeur de coupe ne doit pas être supérieure à 5 mm

(3/16″) par passe.

ATTENTION : Si vous souhaitez effectuer un

rainurage de plus de 15 mm (9/16″) de profondeur

avec une fraise de 8 mm (5/16″) de diamètre ou

de plus de 5 mm (3/16″) de profondeur avec une

fraise de 20 mm (13/16″) de diamètre, effectuez

plusieurs passes en augmentant progressivement

la profondeur de la fraise.

Bloc butoir

Le bloc butoir est pourvu de trois boulons hexagonaux

de réglage se soulevant ou s’abaissant de 0,8 mm

(environ 1/32″) par tour. Vous pouvez facilement obtenir

trois profondeurs de coupe différentes à l’aide de ces

boulons hexagonaux de réglage sans avoir à régler à

nouveau la tige d’arrêt.

► Fig.4: 1. Index de profondeur 2. Vis 3. Tige d’arrêt

4. Boulon hexagonal de réglage 5. Bloc

butoir

1. Réglez le boulon hexagonal le plus bas pour obtenir la profondeur de coupe la plus profonde en suivant

la méthode indiquée dans « Réglage de la profondeur

de la coupe ».

2. Réglez les deux boulons hexagonaux restants

pour obtenir des profondeurs de coupe moins profondes. Les différences de hauteur entre ces boulons

hexagonaux sont égales aux différences entre les

profondeurs de coupe.

3. Tournez les boulons hexagonaux pour régler la

profondeur. Le bloc butoir est également pratique pour

effectuer trois passes en augmentant progressivement

la profondeur de la fraise pour obtenir des rainures

profondes.

NOTE : Lorsque vous utilisez une fraise d’une

longueur totale de 60 mm (2-3/8″) ou plus, ou une

longueur d’arête de 35 mm (1-3/8″) ou plus, la profondeur de coupe ne peut pas être réglée comme

indiqué précédemment. Procédez comme suit pour

la régler :

1. Desserrez le levier de verrouillage et réglez

soigneusement la partie saillante de la fraise

sous le socle de l’outil à la profondeur de coupe

souhaitée en déplaçant le corps de l’outil en

haut ou en bas.

2. Resserrez le levier de verrouillage pour verrouiller le corps de l’outil à la profondeur de coupe.

Maintenez le corps de l’outil verrouillé sur cette

position pendant l’utilisation.

Étant donné que la fraise dépasse toujours du socle

de l’outil, soyez prudent lorsque vous manipulez

l’outil.

Réglage du levier de verrouillage

La position verrouillée du levier de verrouillage est

réglable. Pour la régler, retirez la vis qui retient le levier

de verrouillage. Le levier de verrouillage se libérera.

Réglez le levier de verrouillage à l’angle souhaité.

Après le réglage, serrez le levier de verrouillage dans le

sens des aiguilles d’une montre.

► Fig.5: 1. Levier de verrouillage 2. Vis

Fonctionnement de l’interrupteur

ATTENTION : Avant de brancher l’outil,

assurez-vous toujours que la gâchette fonctionne

correctement et revient en position d’arrêt une

fois relâchée.

Il suft d’enclencher la gâchette pour démarrer l’outil.

Pour arrêter l’outil, relâchez la gâchette.

► Fig.6: 1. Gâchette

ASSEMBLAGE

ATTENTION : Avant d’effectuer toute inter-

vention sur l’outil, assurez-vous toujours qu’il est

hors tension et débranché.

Pose ou dépose de la fraise de

défonceuse

Insérez la fraise à fond dans le cône de serrage et serrez solidement l’écrou de serrage avec les deux clés.

Un cône de serrage de 8 mm peut également être fourni

comme accessoire standard (selon le pays) en plus

du cône de serrage de 6 mm ou 1/4″ xé sur l’outil en

usine. Utilisez un cône de serrage dont la taille correspond à celle de la fraise que vous prévoyez d’utiliser.

► Fig.7

Pour retirer la fraise, effectuez la procédure de pose

dans l’ordre inverse.

ATTENTION : Installez solidement la fraise de

défonceuse. Veillez toujours à utiliser uniquement

la clé fournie avec l’outil. Une fraise de défonceuse

pas assez ou trop serrée représente un danger.

ATTENTION : Ne serrez pas l’écrou de ser-

rage sans insérer de fraise. Vous risqueriez de

casser le cône de serrage.

UTILISATION

Placez le socle de l’outil sur la pièce à couper sans que la

fraise de défonceuse touche quoi que ce soit. Mettez ensuite

l’outil sous tension et attendez que la fraise de défonceuse

ait atteint sa pleine vitesse. Abaissez le corps de l’outil et

faites avancer l’outil sur la surface de la pièce, en maintenant le socle de l’outil au ras de la pièce et en progressant

régulièrement jusqu’à ce que la coupe soit terminée.

13 FRANÇAIS

Page 14

Lorsque vous faites des coupes sur des bords, la surface de la pièce doit être du côté gauche de la fraise de

défonceuse dans le sens d’avance.

► Fig.8: 1. Pièce 2. Sens de rotation de la fraise

3. Vue du haut de l’outil 4. Sens d’avance

NOTE : Si vous déplacez votre outil trop vite vers

l’avant, vous risquez d’obtenir une coupe de qualité

médiocre et d’endommager la fraise de défonceuse

ou le moteur. Si vous déplacez l’outil trop lentement

vers l’avant, vous risquez de brûler la pièce et de

gâcher la coupe. La vitesse d’avance adéquate

dépend du calibre de la fraise de défonceuse, de la

nature de la pièce et de la profondeur de coupe.

Avant de commencer votre coupe sur la pièce, nous

vous conseillons de faire un essai sur un morceau de

chute de bois. Cela vous montrera exactement l’allure

qu’aura votre coupe et vous permettra de vérier les

dimensions.

NOTE : Lorsque vous utilisez le guide de coupe rectiligne ou le guide d’afeurage, veillez à l’installer sur le

côté droit dans le sens d’avance. Cela vous aidera à

le garder bien en contact avec le côté de la pièce.

► Fig.9: 1. Sens d’avance 2. Sens de rotation de la

fraise 3. Pièce 4. Guide de coupe rectiligne

Guide de coupe rectiligne

Le guide de coupe rectiligne est efcace pour obtenir des coupes droites lors du chanfreinage ou du

rainurage.

► Fig.10

Pour xer le guide de coupe rectiligne, insérez les

barres de guidage dans les orices sur le socle de l’outil.

Réglez la distance entre la fraise et le guide de coupe

rectiligne. À la distance souhaitée, serrez les boulons à

oreille pour xer le guide de coupe rectiligne en position.

Lors de la coupe, déplacez l’outil avec le guide de coupe

rectiligne bien en contact avec le côté de la pièce.

► Fig.11: 1. Barre de guidage 2. Vis de serrage

3. Guide de coupe rectiligne

Si la distance (A) entre le côté de la pièce et la position

de coupe est trop importante pour le guide de coupe

rectiligne ou si le côté de la pièce n’est pas droit, le

guide de coupe rectiligne ne peut pas être utilisé. Le

cas échéant, xez fermement une planche droite sur

la pièce et utilisez-la comme guide contre le socle de

l’afeureuse. Faites avancer l’outil dans le sens de la

èche.

► Fig.12

Ensemble du raccord à poussière

(Pour les pays européens

uniquement)

Utilisez le raccord à poussière pour aspirer la poussière. Installez le raccord à poussière sur le socle de

l’outil au moyen de la vis à oreilles de sorte que la partie

saillante sur le raccord à poussière s’insère dans l’entaille du socle de l’outil. Puis, raccordez un aspirateur

au raccord à poussière.

► Fig.13: 1. Raccord à poussière 2. Vis à oreilles

► Fig.14

ENTRETIEN

ATTENTION : Assurez-vous toujours que

l’outil est hors tension et débranché avant d’y

effectuer tout travail d’inspection ou d’entretien.

REMARQUE : N’utilisez jamais d’essence, ben-

zine, diluant, alcool ou autre produit similaire.

Cela risquerait de provoquer la décoloration, la

déformation ou la ssuration de l’outil.

Pour assurer la SÉCURITÉ et la FIABILITÉ du produit,

toute réparation, tout travail d’entretien ou de réglage

doivent être effectués par un centre d’entretien Makita

agréé, avec des pièces de rechange Makita.

ACCESSOIRES EN

OPTION

ATTENTION : Ces accessoires ou pièces

complémentaires sont recommandés pour l’utili-

sation avec l’outil Makita spécié dans ce mode

d’emploi. L’utilisation de tout autre accessoire ou

pièce complémentaire peut comporter un risque de

blessure. N’utilisez les accessoires ou pièces complémentaires qu’aux ns auxquelles ils ont été conçus.

Pour obtenir plus de détails sur ces accessoires,

contactez votre centre d’entretien local Makita.

• Fraises droites et fraises pour rainure

• Fraises pour usiner les bords

• Fraises pour découpe de stratié

NOTE : Il se peut que certains éléments de la liste

soient compris dans l’emballage de l’outil en tant

qu’accessoires standard. Ils peuvent varier d’un pays

à l’autre.

Fraises de défonceuse

Fraise droite

► Fig.15

Unité : mm

D A L1 L2

6 20 50 15

1/4″

8 8 60 25

6 8 50 18

1/4″

6 6 50 18

1/4″

14 FRANÇAIS

Page 15

Fraise à rainurer en « U »

► Fig.16

Unité : mm

D A L1 L2 R

6 6 50 18 3

Fraise à rainurer en « V »

► Fig.17

Unité : mm

D A L1 L2 θ

1/4″ 20 50 15 90°

Fraise à afeurer à pointe de foret

► Fig.18

Unité : mm

D A L1 L2 L3

8 8 60 20 35

6 6 60 18 28

Fraise à afeurer à pointe de foret

combinaison double

► Fig.19

Unité : mm

D A L1 L2 L3 L4

8 8 80 55 20 25

6 6 70 40 12 14

Fraise quart de rond

► Fig.20

Unité : mm

D A1 A2 L1 L2 L3 R

6 25 9 48 13 5 8

6 20 8 45 10 4 4

Fraise à chanfreiner

► Fig.21

Unité : mm

D A L1 L2 L3 θ

6 23 46 11 6 30°

6 20 50 13 5 45°

6 20 49 14 2 60°

Fraise pour panneau mouluré en

cavet

► Fig.22

Unité : mm

D A L1 L2 R

6 20 43 8 4

6 25 48 13 8

Fraise à afeurer à roulement

► Fig.23

Unité : mm

D A L1 L2

6 10 50 20

1/4″

Fraise quart de rond à roulement

► Fig.24

Unité : mm

D A1 A2 L1 L2 L3 R

6 15 8 37 7 3,5 3

6 21 8 40 10 3,5 6

1/4″ 21 8 40 10 3,5 6

Fraise à chanfreiner à roulement

► Fig.25

Unité : mm

D A1 A2 L1 L2 θ

6 26 8 42 12 45°

1/4″

6 20 8 41 11 60°

Fraise à moulurer à roulement

► Fig.26

Unité : mm

D A1 A2 A3 L1 L2 L3 R

6 20 12 8 40 10 5,5 4

6 26 12 8 42 12 4,5 7

Fraise pour panneau mouluré en

cavet à roulement

► Fig.27

Unité : mm

D A1 A2 A3 A4 L1 L2 L3 R

6 20 18 12 8 40 10 5,5 3

6 26 22 12 8 42 12 5 5

15 FRANÇAIS

Page 16

Fraise à doucine à roulement

► Fig.28

D A1 A2 L1 L2 L3 R1 R2

6 20 8 40 10 4,5 2,5 4,5

6 26 8 42 12 4,5 3 6

Unité : mm

16 FRANÇAIS

Page 17

DEUTSCH (Original-Anleitung)

TECHNISCHE DATEN

Modell: M3601

Spannzangenfutterkapazität 6 mm, 1/4″ und/oder 8 mm

Hubhöhe 0 - 35 mm

Leerlaufdrehzahl 27.000 min

Gesamthöhe 218 mm

Nettogewicht 2,7 kg

Sicherheitsklasse

• Wir behalten uns vor, Änderungen der technischen Daten im Zuge der Entwicklung und des technischen

Fortschritts ohne vorherige Ankündigung vorzunehmen.

• Die technischen Daten können von Land zu Land unterschiedlich sein.

• Gewicht nach EPTA-Verfahren 01/2003

Vorgesehene Verwendung

Das Werkzeug ist zum Bündigfräsen und Proldrehen

von Holz, Kunststoff und ähnlichen Materialien

vorgesehen.

Stromversorgung

Das Werkzeug sollte nur an eine Stromquelle angeschlossen werden, deren Spannung mit der Angabe

auf dem Typenschild übereinstimmt, und kann nur mit

Einphasen-Wechselstrom betrieben werden. Diese

sind doppelt schutzisoliert und können daher auch an

Steckdosen ohne Erdleiter verwendet werden.

Geräusch

Typischer A-bewerteter Geräuschpegel ermittelt gemäß

EN60745:

Schalldruckpegel (LpA): 91 dB (A)

Schallleistungspegel (LWA): 102 dB (A)

Messunsicherheit (K): 3 dB (A)

WARNUNG: Einen Gehörschutz tragen.

Schwingungen

Schwingungsgesamtwert (Drei-Achsen-Vektorsumme)

ermittelt gemäß EN60745:

Arbeitsmodus: Nutenfräsen in MDF

Schwingungsemission (ah): 7,5 m/s

Messunsicherheit (K): 1,5 m/s

HINWEIS: Der angegebene

Schwingungsemissionswert wurde im Einklang mit

der Standardprüfmethode gemessen und kann für

den Vergleich zwischen Werkzeugen herangezogen

werden.

HINWEIS: Der angegebene

Schwingungsemissionswert kann auch für eine

Vorbewertung des Gefährdungsgrads verwendet

werden.

2

2

WARNUNG: Die Schwingungsemission während

der tatsächlichen Benutzung des Elektrowerkzeugs

kann je nach der Benutzungsweise des Werkzeugs

vom angegebenen Emissionswert abweichen.

WARNUNG: Identizieren Sie

Sicherheitsmaßnahmen zum Schutz des Benutzers

anhand einer Schätzung des Gefährdungsgrads unter

den tatsächlichen Benutzungsbedingungen (unter

Berücksichtigung aller Phasen des Arbeitszyklus, wie

z. B. Ausschalt- und Leerlaufzeiten des Werkzeugs

zusätzlich zur Betriebszeit).

EG-Konformitätserklärung

Nur für europäische Länder

Makita erklärt, dass die folgende(n) Maschine(n):

Bezeichnung der Maschine: Oberfräse

Modell-Nr./Typ: M3601

Entspricht den folgenden europäischen Richtlinien:

2006/42/EG

Sie werden gemäß den folgenden Standards oder standardisierten Dokumenten hergestellt: EN60745

Die technische Akte in Übereinstimmung mit 2006/42/

EG ist erhältlich von:

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgien

31.8.2015

Yasushi Fukaya

Direktor

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgien

Allgemeine Sicherheitswarnungen

für Elektrowerkzeuge

WARNUNG: Lesen Sie alle

Sicherheitswarnungen und Anweisungen durch.

Eine Missachtung der unten aufgeführten Warnungen

und Anweisungen kann zu einem elektrischen

Schlag, Brand und/oder schweren Verletzungen

führen.

-1

/II

17 DEUTSCH

Page 18

Bewahren Sie alle Warnungen

und Anweisungen für spätere

Bezugnahme auf.

Der Ausdruck „Elektrowerkzeug“ in den Warnhinweisen

bezieht sich auf Ihr mit Netzstrom (mit Kabel) oder Akku

(ohne Kabel) betriebenes Elektrowerkzeug.

Sicherheitswarnungen für Oberfräse

1.

Halten Sie das Elektrowerkzeug an den isolierten

Griffächen, weil der Fräser das eigene Kabel

berühren kann. Bei Kontakt mit einem Strom führenden Kabel werden die freiliegenden Metallteile des

Elektrowerkzeugs ebenfalls Strom führend, so dass

der Benutzer einen elektrischen Schlag erleiden kann.

2.

Verwenden Sie Klemmen oder eine andere praktische Methode, um das Werkstück auf einer stabilen Unterlage zu sichern und abzustützen. Wenn

Sie das Werkstück nur mit der Hand oder gegen Ihren

Körper halten, bendet es sich in einer instabilen

Lage, die zum Verlust der Kontrolle führen kann.

3. Tragen Sie bei längeren Betriebszeitspannen

einen Gehörschutz.

4. Behandeln Sie die Oberfräseneinsätze mit

größter Sorgfalt.

5. Überprüfen Sie den Oberfräseneinsatz

vor dem Betrieb sorgfältig auf Risse oder

Beschädigung. Wechseln Sie einen gerissenen

oder beschädigten Einsatz unverzüglich aus.

6. Vermeiden Sie das Schneiden von Nägeln.

Untersuchen Sie das Werkstück sorgfältig

auf Nägel, und entfernen Sie diese vor der

Bearbeitung.

7. Halten Sie das Werkzeug mit beiden Händen

fest.

8. Halten Sie Ihre Hände von rotierenden Teilen

fern.

9. Vergewissern Sie sich vor dem Einschalten

des Werkzeugs, dass der Oberfräseneinsatz

nicht das Werkstück berührt.

10. Lassen Sie das Werkzeug vor der eigentlichen Bearbeitung eines Werkstücks eine

Weile laufen. Achten Sie auf Vibrationen oder

Taumelbewegungen, die auf einen falsch montierten Einsatz hindeuten können.

11. Achten Sie sorgfältig auf die Drehrichtung

und die Vorschubrichtung des

Oberfräseneinsatzes.

12. Lassen Sie das Werkzeug nicht unbeaufsichtigt laufen. Benutzen Sie das Werkzeug nur im

handgeführten Einsatz.

13. Schalten Sie das Werkzeug stets aus, und

warten Sie, bis der Oberfräseneinsatz zum

vollständigen Stillstand kommt, bevor Sie ihn

aus dem Werkstück herausnehmen.

14. Vermeiden Sie eine Berührung des

Oberfräseneinsatzes unmittelbar nach der

Bearbeitung, weil er dann noch sehr heiß ist

und Hautverbrennungen verursachen kann.

15. Beschmieren Sie die Grundplatte nicht achtlos

mit Verdünner, Benzin, Öl oder dergleichen.

Diese Stoffe können Risse in der Grundplatte

verursachen.

16. Verwenden Sie Oberfräseneinsätze mit korrektem Schaftdurchmesser, die für die Drehzahl

des Werkzeugs geeignet sind.

17. Manche Materialien können giftige

Chemikalien enthalten. Treffen Sie

Vorsichtsmaßnahmen, um das Einatmen

von Arbeitsstaub und Hautkontakt zu verhüten. Befolgen Sie die Sicherheitsdaten des

Materiallieferanten.

18. Verwenden Sie stets die korrekte

Staubschutz-/Atemmaske für das jeweilige

Material und die Anwendung.

DIESE ANWEISUNGEN

AUFBEWAHREN.

WARNUNG: Lassen Sie sich NICHT durch

Bequemlichkeit oder Vertrautheit mit dem Produkt

(durch wiederholten Gebrauch erworben) von der

strikten Einhaltung der Sicherheitsregeln für das

vorliegende Produkt abhalten. MISSBRAUCH oder

Missachtung der Sicherheitsvorschriften in dieser

Anleitung können schwere Personenschäden

verursachen.

FUNKTIONSBESCHREIBUNG

VORSICHT: Vergewissern Sie sich vor

jeder Einstellung oder Funktionsprüfung des

Werkzeugs stets, dass es ausgeschaltet und vom

Stromnetz getrennt ist.

Einstellen der Frästiefe

1. Stellen Sie das Werkzeug auf eine ebene Fläche.

Lösen Sie die Schraube, mit der die Anschlagstange

befestigt ist.

► Abb.1: 1. Anschlagstange 2. Schraube

2. Lösen Sie den Verriegelungshebel, und sen-

ken Sie den Fräskorb ab, bis der Oberfräseneinsatz

die ebene Fläche leicht berührt. Ziehen Sie den

Verriegelungshebel an, um den Fräskorb zu verriegeln.

► Abb.2: 1. Verriegelungshebel 2. Schraube

3. Senken Sie die Anschlagstange ab, bis sie die

Sechskant-Einstellschraube berührt. Richten Sie den

Tiefenzeiger auf den Teilstrich „0“ aus.

► Abb.3: 1. Tiefenzeiger 2. Schraube

3. Anschlagstange 4. Sechskant-

Einstellschraube 5. Anschlagblock

4. Heben Sie die Anschlagstange an, bis die

gewünschte Frästiefe erreicht ist. Die Frästiefe wird

durch den Tiefenzeiger auf der Skala (1 mm pro

Teilstrich) angezeigt. Ziehen Sie dann die Schraube

fest, um die Anschlagstange zu sichern.

5. Sie können die vorbestimmte Frästiefe erhalten,

indem Sie den Verriegelungshebel lösen und dann

den Fräskorb absenken, bis die Anschlagstange die

Sechskant-Einstellschraube berührt.

18 DEUTSCH

Page 19

VORSICHT: Da übermäßiges Fräsen eine

Überlastung des Motors oder schwierige

Kontrolle des Werkzeugs verursachen kann,

sollte die Frästiefe nicht mehr als 15 mm (9/16″)

pro Durchgang betragen, wenn Nuten mit einem

Einsatz von 8 mm (5/16″) Durchmesser gefräst

werden.

VORSICHT: Beim Fräsen von Nuten mit

einem Einsatz von 20 mm (13/16″) Durchmesser

sollte die Frästiefe nicht mehr als 5 mm (3/16″)

pro Durchgang betragen.

VORSICHT: Wenn Sie Nuten von mehr als

15 mm (9/16″) Tiefe mit einem Einsatz von 8

mm (5/16″) Durchmesser oder mehr als 5 mm

(3/16″) Tiefe mit einem Einsatz von 20 mm

(13/16″) Durchmesser fräsen wollen, führen Sie

mehrere Durchgänge mit fortschreitend tieferen

Fräsereinstellungen durch.

Anschlagblock

Der Anschlagblock weist drei SechskantEinstellschrauben auf, die sich um 0,8 mm (ca. 1/32″)

pro Umdrehung heben oder senken. Mithilfe dieser

Sechskant-Einstellschrauben können Sie bequem

drei unterschiedliche Schnitttiefen erhalten, ohne die

Anschlagstange neu einstellen zu müssen.

► Abb.4: 1. Tiefenzeiger 2. Schraube

3. Anschlagstange 4. Sechskant-

Einstellschraube 5. Anschlagblock

1. Stellen Sie die unterste Sechskantschraube nach

der Methode „Einstellen der Frästiefe“ ein, um die

größte Frästiefe zu erhalten.

2. Stellen Sie die beiden übrigen

Sechskantschrauben ein, um achere Frästiefen

zu erhalten. Die Höhenunterschiede dieser Sechskantschrauben entsprechen den

Frästiefenunterschieden.

3. Drehen Sie die Sechskantschrauben zum

Einstellen der Tiefe. Der Anschlagblock ist auch praktisch, um drei Durchgänge mit fortschreitend tieferen

Fräsereinstellungen durchzuführen, wenn tiefe Nuten

gefräst werden.

HINWEIS: Wenn Sie einen Einsatz verwenden, der

eine Gesamtlänge von 60 mm (2-3/8″) oder mehr,

oder eine Kantenlänge von 35 mm (1-3/8″) oder mehr

besitzt, kann die Frästiefe nicht so eingestellt werden,

wie vorher beschrieben. Gehen Sie zum Einstellen

folgendermaßen vor:

1. Lösen Sie den Verriegelungshebel, und stellen

Sie den Fräserüberstand unter der Grundplatte

auf die gewünschte Frästiefe ein, indem Sie den

Fräskorb anheben oder absenken.

2. Ziehen Sie den Verriegelungshebel wieder an,

um den Fräskorb auf dieser Frästiefe zu verriegeln. Halten Sie den Fräskorb während der

Benutzung auf dieser Position verriegelt.

Da der Einsatz immer von der Grundplatte übersteht,

lassen Sie bei der Handhabung des Werkzeugs

Vorsicht walten.

Einstellen des Verriegelungshebels

Die verriegelte Position des Verriegelungshebels ist

einstellbar. Um sie einzustellen, entfernen Sie die

Befestigungsschraube des Verriegelungshebels.

Der Verriegelungshebel löst sich. Stellen Sie den

Verriegelungshebel auf den gewünschten Winkel

ein. Ziehen Sie den Verriegelungshebel nach der

Einstellung im Uhrzeigersinn fest.

► Abb.5: 1. Verriegelungshebel 2. Schraube

Schalterfunktion

VORSICHT: Vergewissern Sie sich vor dem

Anschließen des Werkzeugs an das Stromnetz

stets, dass der Ein-Aus-Schalter ordnungsgemäß

funktioniert und beim Loslassen in die AUSStellung zurückkehrt.

Zum Einschalten des Werkzeugs betätigen Sie einfach

den Ein-Aus-Schalter. Zum Ausschalten lassen Sie den

Ein-Aus-Schalter los.

► Abb.6: 1. Ein-Aus-Schalter

MONTAGE

VORSICHT: Vergewissern Sie sich vor der

Ausführung von Arbeiten am Werkzeug stets,

dass es ausgeschaltet und vom Stromnetz

getrennt ist.

Montage und Demontage des

Oberfräseneinsatzes

Führen Sie den Einsatz bis zum Anschlag in

den Spannzangenkonus ein, und ziehen Sie die

Spannzangenmutter mit den zwei Schraubenschlüsseln

fest. Ein Spannzangenkonus von 8 mm kann

neben dem werkseitig am Werkzeug montierten

Spannzangenkonus von 6 mm bzw. 1/4″ ebenfalls in

der Standardausstattung enthalten sein (abhängig vom

Land). Verwenden Sie einen Spannzangenkonus der

korrekten Größe für den zu benutzenden Einsatz.

► Abb.7

Zum Abnehmen des Einsatzes wenden Sie das

Montageverfahren umgekehrt an.

VORSICHT: Installieren Sie den

Oberfräseneinsatz sicher. Verwenden Sie

stets nur den mit dem Werkzeug gelieferten

Schraubenschlüssel. Ein loser oder zu fest angezo-

gener Oberfräseneinsatz kann gefährlich sein.

VORSICHT: Ziehen Sie die

Spannzangenmutter nicht ohne eingefügten

Einsatz an. Dies kann dazu führen, dass der

Spannzangenkonus bricht.

19 DEUTSCH

Page 20

BETRIEB

Setzen Sie die Grundplatte auf das zu bearbeitende

Werkstück auf, ohne dass der Oberfräseneinsatz

mit dem Werkstück in Berührung kommt. Schalten

Sie dann das Werkzeug ein, und warten Sie, bis der

Oberfräseneinsatz die volle Drehzahl erreicht hat.

Senken Sie den Fräskorb ab, und schieben Sie das

Werkzeug bei ach auiegender Grundplatte gleichmäßig über die Werkstückoberäche vor, bis der Schnitt

ausgeführt ist.

Beim Kantenfräsen sollte die Werkstückoberäche

auf der linken Seite des Oberfräseneinsatzes in

Vorschubrichtung liegen.

► Abb.8: 1. Werkstück 2. Einsatz-Drehrichtung

3. Ansicht von der Oberseite des Werkzeugs

4. Vorschubrichtung

HINWEIS: Zu schnelles Vorschieben des

Werkzeugs kann schlechte Schnittqualität oder

Beschädigung des Oberfräseneinsatzes oder Motors

zur Folge haben. Zu langsames Vorschieben des

Werkzeugs kann Verbrennung oder Beschädigung

des Schnitts zur Folge haben. Die korrekte

Vorschubgeschwindigkeit hängt von der Größe des

Oberfräseneinsatzes, der Art des Werkstücks und der

Frästiefe ab.

Bevor Sie den Schnitt am tatsächlichen Werkstück

ausführen, ist es ratsam, einen Probeschnitt in

einem Stück Abfallholz zu machen. Dies gibt Ihnen

die Möglichkeit, das genaue Aussehen des Schnitts

festzustellen und die Abmessungen zu überprüfen.

HINWEIS: Wenn Sie die Geradführung oder die

Fräsenführung verwenden, halten Sie die Vorrichtung

auf der rechten Seite in Vorschubrichtung. Dies trägt

dazu bei, sie bündig mit der Seite des Werkstücks zu

halten.

► Abb.9: 1. Vorschubrichtung 2. Einsatz-Drehrichtung

3. Werkstück 4. Geradführung

Geradführung

Die Geradführung ist effektiv, um gerade Schnitte beim

Anfasen oder Rillenfräsen auszuführen.

► Abb.10

Zum Montieren der Geradführung führen Sie die

Führungsstangen in die Löcher der Grundplatte

ein. Stellen Sie den Abstand zwischen Einsatz und

Geradführung ein. Ziehen Sie die Flügelschrauben

am gewünschten Abstand fest, um die Geradführung

zu sichern. Schieben Sie das Werkzeug beim Fräsen

so vor, dass die Geradführung an der Seite des

Werkstücks anliegt.

► Abb.11: 1. Führungsstange 2. Klemmschraube

3. Geradführung

Falls der Abstand (A) zwischen der Seite des

Werkstücks und der Fräsposition zu breit für die

Geradführung ist, oder die Seite des Werkstücks nicht

gerade ist, kann die Geradführung nicht benutzt werden. Klemmen Sie in diesem Fall ein gerades Brett am

Werkstück fest, und benutzen Sie dieses als Führung

gegen den Frästisch. Schieben Sie das Werkzeug in

Pfeilrichtung vor.

► Abb.12

Absaugstutzensatz (nur für

europäische Länder)

Benutzen Sie den Absaugstutzen für Staubabsaugung.

Befestigen Sie den Absaugstutzen mit der

Rändelschraube so an der Grundplatte, dass der

Vorsprung des Absaugstutzens in der Aussparung der

Grundplatte sitzt. Schließen Sie dann ein Sauggerät an

den Absaugstutzen an.

► Abb.13: 1. Absaugstutzen 2. Flügelschraube

► Abb.14

WARTUNG

VORSICHT: Vergewissern Sie sich vor

der Durchführung von Überprüfungen oder

Wartungsarbeiten des Werkzeugs stets, dass es

ausgeschaltet und vom Stromnetz getrennt ist.

ANMERKUNG: Verwenden Sie auf keinen Fall

Benzin, Waschbenzin, Verdünner, Alkohol oder

dergleichen. Solche Mittel können Verfärbung,

Verformung oder Rissbildung verursachen.

Um die SICHERHEIT und ZUVERLÄSSIGKEIT dieses

Produkts zu gewährleisten, sollten Reparaturen und

andere Wartungs- oder Einstellarbeiten nur von MakitaVertragswerkstätten oder Makita-Kundendienstzentren

unter ausschließlicher Verwendung von MakitaOriginalersatzteilen ausgeführt werden.

SONDERZUBEHÖR

VORSICHT: Die folgenden Zubehörteile oder

Vorrichtungen werden für den Einsatz mit dem in

dieser Anleitung beschriebenen Makita-Werkzeug

empfohlen. Die Verwendung anderer Zubehörteile

oder Vorrichtungen kann eine Verletzungsgefahr

darstellen. Verwenden Sie Zubehörteile oder

Vorrichtungen nur für ihren vorgesehenen Zweck.

Wenn Sie weitere Einzelheiten bezüglich dieser

Zubehörteile benötigen, wenden Sie sich bitte an Ihre

Makita-Kundendienststelle.

• Gerad- und Nutenfräser

• Kantenfräser

• Laminatfräser

HINWEIS: Manche Teile in der Liste können als

Standardzubehör im Werkzeugsatz enthalten sein.

Sie können von Land zu Land unterschiedlich sein.

20 DEUTSCH

Page 21

Oberfräseneinsätze

Geradfräser

► Abb.15

Einheit: mm

D A L1 L2

6 20 50 15

1/4″

8 8 60 25

6 8 50 18

1/4″

6 6 50 18

1/4″

„U“-Nutenfräser

► Abb.16

Einheit: mm

D A L1 L2 R

6 6 50 18 3

„V“-Nutenfräser

► Abb.17

Einheit: mm

D A L1 L2 θ

1/4″ 20 50 15 90°

Bohrspitzen-Bündigfräser

► Abb.18

Einheit: mm

D A L1 L2 L3

8 8 60 20 35

6 6 60 18 28

Bohrspitzen-Doppelbündigfräser

► Abb.19

Einheit: mm

D A L1 L2 L3 L4

8 8 80 55 20 25

6 6 70 40 12 14

Eckenrundungsfräser

► Abb.20

Einheit: mm

D A1 A2 L1 L2 L3 R

6 25 9 48 13 5 8

6 20 8 45 10 4 4

Fasenfräser

► Abb.21

Einheit: mm

D A L1 L2 L3 θ

6 23 46 11 6 30°

6 20 50 13 5 45°

6 20 49 14 2 60°

Hohlkehlen-Abrundfräser

► Abb.22

Einheit: mm

D A L1 L2 R

6 20 43 8 4

6 25 48 13 8

Kugellager-Bündigfräser

► Abb.23

Einheit: mm

D A L1 L2

6 10 50 20

1/4″

Kugellager-Eckenrundungsfräser

► Abb.24

Einheit: mm

D A1 A2 L1 L2 L3 R

6 15 8 37 7 3,5 3

6 21 8 40 10 3,5 6

1/4″ 21 8 40 10 3,5 6

Kugellager-Fasenfräser

► Abb.25

Einheit: mm

D A1 A2 L1 L2 θ

6 26 8 42 12 45°

1/4″

6 20 8 41 11 60°

21 DEUTSCH

Page 22

Kugellager-Abrundfräser

► Abb.26

Einheit: mm

D A1 A2 A3 L1 L2 L3 R

6 20 12 8 40 10 5,5 4

6 26 12 8 42 12 4,5 7

Kugellager-Hohlkehlen-Abrundfräser

► Abb.27

Einheit: mm

D A1 A2 A3 A4 L1 L2 L3 R

6 20 18 12 8 40 10 5,5 3

6 26 22 12 8 42 12 5 5

Kugellager-Kamies-Prolfräser

► Abb.28

Einheit: mm

D A1 A2 L1 L2 L3 R1 R2

6 20 8 40 10 4,5 2,5 4,5

6 26 8 42 12 4,5 3 6

22 DEUTSCH

Page 23

Makita

Jan-Baptist Vinkstraat 2, 3070, Belgium

Makita Corporation Anjo, Aichi, Japan

www.makita.com

885486-994

EN, FR, DE, IT,

NL, ES, PT, DA,

EL, TR

20151111

Loading...

Loading...