Cordless Slide

Compound Saw

Equipped with Electric Blade Brake

190 mm (7-1/2”)

MODEL LS711D

INSTRUCTION MANUAL

WARNING:

For your personal safety, READ and UNDERSTAND before using.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

www.makitatools.com

SPECIFICATIONS

Blade diameter : ......................................................................................... 190 mm (7-1/2”)

Hole (arbor) diameter : ............................................................................... 15.88 mm (5/8”)

Max. Miter angle : ...................................................................................Left 47° , Right 57°

Max. Bevel angle : ....................................................................................................Left 45°

Max. Cutting capacities (H x W) with blade 190 mm (7-1/2”) in diameter.

Miter angle

0°

45° (left and right)

(Note)

The max. Cutting capacities may vary according to workpiece, blade and/or charging condition.

No load speed (RPM) : ........................................................................................ 2,000/min.

Dimensions (L x W x H) : ................550 mm x 430 mm x 454 mm (21-5/8” x 17” x 17-7/8”)

Net weight : ............................................................................................... 10.5 kg (23.1 lbs)

Battery Charger DC1804

Input A. C. only 50 Hz-60 Hz

Output D. C. 7.2 V-18 V

Battery Cartridge 1822 1833 1834 1835

Voltage 18 V

Charging time 45 min. 50 min. 60 min. 70 min.

• Manufacturer reserves the right to change specifications without notice.

• Specifications may differ from country to country.

0° 45° (left)

50 mm x 182 mm

(2” x 7-1/8”)

50 mm x 127 mm

(2” x 5”)

Bevel angle

35 mm x 182 mm

(1-3/8” x 7-1/8”)

35 mm x 127 mm

(1-3/8” x 5”)

For Your Own Safety Read Instruction Manual

Before Operating Tool

Save it for future reference

GENERAL SAFETY PRECAUTIONS

2

USA005-1

(For All TOOIS)

1. KNOW YOUR POWER TOOL. Read the

owner’s manual carefully. Learn the tool’s

applications and limitations, as well as the

specific potential hazards peculiar to it.

2. KEEP GUARDS IN PLACE and in working

order.

3. REMOVE ADJUSTING KEYS AND

WRENCHES. Form habit of checking to

see that keys and adjusting wrenches are

removed from tool before turning it on.

4. KEEP WORK AREA CLEAN. Cluttered

areas and benches invite accidents.

5. DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use power tools in damp or

wet locations, or expose them to rain.

Keep work area well lighted. Don’t use

tool in presence of flammable liquids or

gases.

6. KEEP CHILDREN AWAY. All visitors

should be kept safe distance from work

area.

7. MAKE WORKSHOP KID PROOF with padlocks, master switches, or by removing

starter keys.

8. DON’T FORCE TOOL. It will do the job better and safer at the rate for which it was

designed.

9. USE RIGHT TOOL. Don’t force tool or

attachment to do a job for which it was not

designed.

10. WEAR PROPER APPAREL. Do not wear

loose clothing, gloves, neckties, rings,

bracelets, or other jewelry which may get

caught in moving parts. Nonslip footwear

is recommended. Wear protective hair

covering to contain long hair.

11. ALWAYS USE SAFETY GLASSES. Also

use face or dust mask if cutting operation

is dusty. Everyday eyeglasses only have

impact resistant lenses, they are NOT

safety glasses.

12. SECURE WORK. Use clamps or a vise to

hold work when practical. It’s safer than

using your hand and it frees both hands

to operate tool.

13. DON’T OVERREACH. Keep proper footing

and balance at all times.

14. MAINTAIN TOOLS WITH CARE. Keep tools

sharp and clean for best and safest performance. Follow instructions for lubricating

and changing accessories.

15. DISCONNECT BATTERY FROM TOOL

before servicing; when changing accessories such as blades, bits, cutters, and

the like.

16. REDUCE THE RISK OF UNINTENTIONAL

STARTING. Make sure switch is in off

position before inserting battery.

17. USE RECOMMENDED ACCESSORIES.

Consult the owner’s manual for recommended accessories. The use of improper

accessories may cause risk of injury to

persons.

18. NEVER STAND ON TOOL. Serious injury

could occur if the tool is tipped or if the

cutting tool is unintentionally contacted.

19. CHECK DAMAGED PARTS. Before further

use of the tool, a guard or other part that

is damaged should be carefully checked

to determine that it will operate properly

and perform its intended function - check

for alignment of moving parts, binding of

moving parts, breakage of parts, mounting, and any other conditions that may

affect its operation. A guard or other part

that is damaged should be properly

repaired or replaced.

20. DIRECTION OF FEED. Feed work into a

blade or cutter against the direction of

rotation of the blade or cutter only.

21. NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Don’t leave

tool until it comes to a complete stop.

3

ADDITIONAL SAFETY RULES USB033-2

DO NOT let comfort or familiarity with product (gained from

repeated use) replace strict adherence to slide compound saw

safety rules. If you use this tool unsafely or incorrectly, you can

suffer serious personal injury.

1. Wear eye protection.

2. Keep hands out of path of saw blade.

Avoid contact with any coasting blade. It

can still cause severe injury.

3. Do not operate saw without guards in

place. Check blade guard for proper closing before each use. Do not operate saw if

blade guard does not move freely and

close instantly. Never clamp or tie the

blade guard into the open position.

4. Do not perform any operation freehand.

The workpiece must be secured firmly

against the turn base and guide fence with

a vise during all operations. Never use

your hand to secure the workpiece.

5. Never reach around saw blade.

6. Turn off tool and wait for saw blade to

stop before moving workpiece or changing settings.

7. Remove battery from tool before changing

blade or servicing.

8. To reduce the risk of injury, return carriage to the full rear position after each

crosscut operation.

9. Always secure all moving portions before

carrying the tool.

10. Stopper pin which locks the cutter head

down is for carrying and storage purposes only and not for any cutting operations.

11. Be aware that this tool is always in an

operating condition, because it does not

have to be plugged into an electrical outlet.

12. Do not use the tool in the presence of

flammable liquids or gases.

13. Check the blade carefully for cracks or

damage before operation. Replace

cracked or damaged blade immediately.

Gum and wood pitch hardened on blades

slows saw and increases potential for

kickback. Keep blade clean by first removing it from tool, then cleaning it with gum

and pitch remover, hot water or kerosene.

Never use gasoline to clean blade.

14. While making a slide cut, KICKBACK can

occur. KICKBACK occurs when the blade

binds in the workpiece during a cutting

operation and the saw blade is driven

back rapidly towards the operator. Loss of

control and serious personal injury can

result. If blade begins to bind during a cutting operation, do not continue to cut and

release switch immediately.

15. Use only flanges specified for this tool.

16. Be careful not to damage the arbor,

flanges (especially the installing surface)

or bolt. Damage to these parts could

result in blade breakage.

17. Make sure that the turn base is properly

secured so it will not move during operation. Use the holes in the base to fasten

the saw to a stable work platform or

bench. NEVER use tool where operator

positioning would be awkward.

18. For your safety, remove the chips, small

pieces, etc. from the table top before operation.

4

19. Avoid cutting nails. Inspect for and

remove all nails from the workpiece

before operation.

20. Make sure the shaft lock is released

before the switch is turned on.

21. Be sure that the blade does not contact

the turn base in the lowest position.

22. Hold the handle firmly. Be aware that the

saw moves up or down slightly during

start-up and stopping.

23. Make sure the blade is not contacting the

workpiece before the switch is turned on.

24. Before using the tool on an actual workpiece, let it run for a while. Watch for

vibration or wobbling that could indicate

poor installation or a poorly balanced

blade.

25. Wait until the blade attains full speed

before cutting.

26. Stop operation immediately if you notice

anything abnormal.

27. Do not attempt to lock the trigger in the on

position.

28. Be alert at all times, especially during

repetitive, monotonous operations. Do

not be lulled into a false sense of security.

Blades are extremely unforgiving.

29. Always use accessories recommended in

this manual. Use of improper accessories

such as abrasive wheels may cause an

injury.

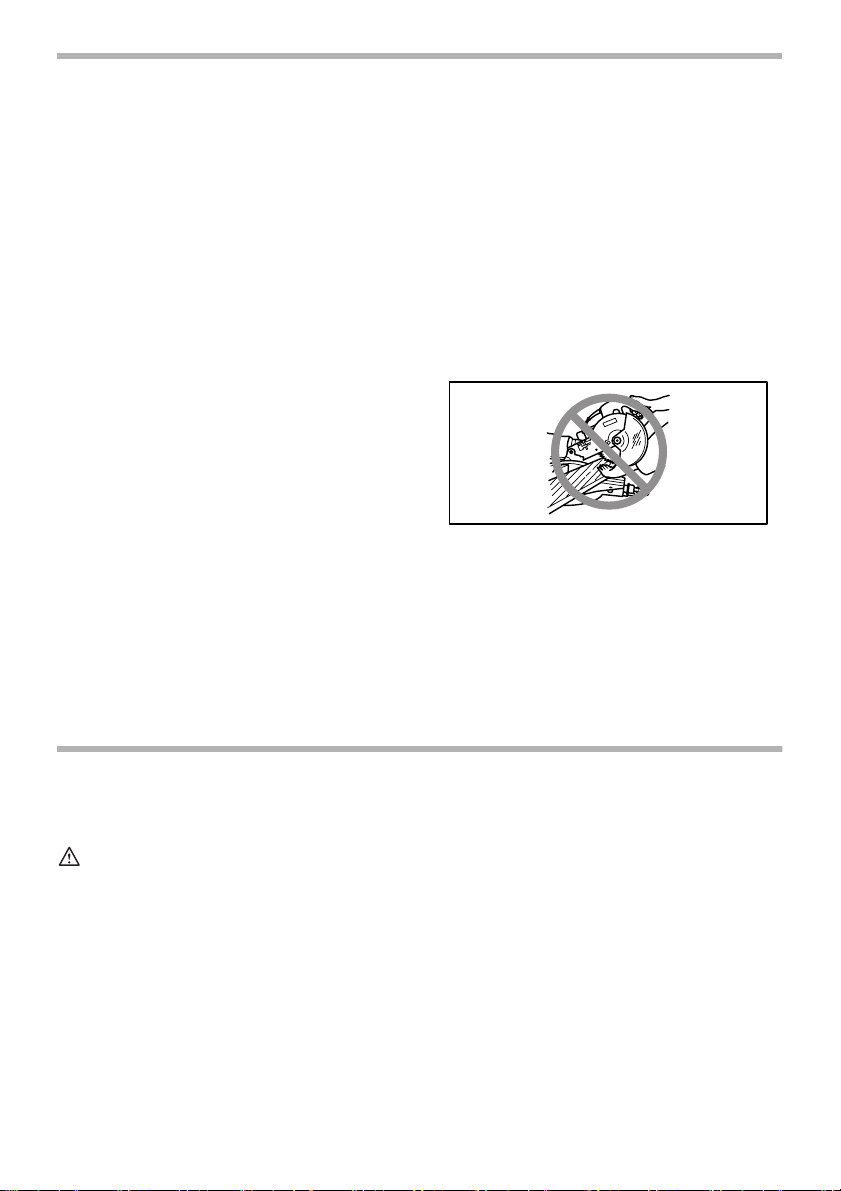

30. NEVER hold workpiece on right side of

blade with left hand or vice versa. This is

called cross-armed cutting and exposes

user to risk of SERIOUS PERSONAL

INJURY as shown in the figure. ALWAYS

use vise to secure workpiece.

31. NEVER stack workpieces on the table top

to speed cutting operations. Cut only one

piece at a time.

32. Some material contains chemicals which

may be toxic. Take caution to prevent dust

inhalation and skin contact. Follow material supplier safety data.

SAVE THESE INSTRUCTIONS

WARNING:

MISUSE or failure to follow the safety rules stated in this

instruction manual may cause serious personal injury.

5

IMPORTANT SAFETY INSTRUCTIONS FOR

CHARGER & BATTERY CARTRIDGE

1. SAVE THESE INSTRUCTIONS - This manual contains important safety and operating instructions for battery charger.

2. Before using battery charger, read all

instructions and cautionary markings on

(1) battery charger, (2) battery, and (3)

product using battery.

3. CAUTION - To reduce risk of injury, charge

only MAKITA rechargeable batteries

marked on the charger label. Other types

of batteries may burst causing personal

injury and damage.

4. Do not expose charger to rain or snow.

5. Use of an attachment not recommended

or sold by the battery charger manufacturer may result in a risk of fire, electric

shock, or injury to persons.

Table 1: RECOMMENDED MINIMUM AWG SIZE FOR EXTENSION CORDS FOR BATTERY CHARGERS

Length of Cord (Feet) 25 50 100 150

AWG Size of Cord 18 18 18 16

9. Do not operate charger with damaged

cord or plug - replace them immediately.

10. Do not operate charger if it has received a

sharp blow, been dropped, or otherwise

damaged in any way; take it to a qualified

serviceman.

11. Do not disassemble charger or battery

cartridge; take it to a qualified serviceman

when service or repair is required, Incorrect reassembly may result in a risk of

electric shock or fire.

12. To reduce risk of electric shock, unplug

charger from outlet before attempting any

maintenance or cleaning. Turning off controls will not reduce this risk.

6. To reduce risk of damage to electric plug

and cord, pull by plug rather than cord

when disconnecting charger.

7. Make sure cord is located so that it will

not be stepped on, tripped over, or otherwise subjected to damage or stress.

8. An extension cord should not be used

unless absolutely necessary. Use of

improper extension cord could result in a

risk of fire and electric shock. If extension

cord must be used, make sure:

a. That pins on plug of extension cord

are the same number, size, and shape

as those of plug on charger;

b. That extension cord is properly wired

and in good electrical condition;

c. That wire size is at least as large as

the one specified in the table below.

13. The battery charger is not intended for

use by young children or infirm persons

without supervision.

14. Young children should be supervised to

ensure that they do not play with the battery charger.

15. If operating time has become excessively

shorter, stop operating immediately. It

may result in a risk of overheating, possible burns and even an explosion.

16. If electrolyte gets into your eyes, rinse

them out with clear water and seek medical attention right away. It may result in

loss of your eyesight.

USC001-3

6

ADDITIONAL SAFETY RULES FOR CHARGER &

BATTERY CARTRIDGE

1. Do not charge Battery Cartridge when

temperature is BELOW 10°C (50°F) or

ABOVE 40°C (104°F).

2. Do not attempt to use a step-up transformer, an engine generator or DC power

receptacle.

3. Do not allow anything to cover or clog the

charger vents.

4. Always cover the battery terminals with

the battery cover when the battery cartridge is not used.

5. Do not short the battery cartridge:

(1) Do not touch the terminals with any

conductive material.

(2) Avoid storing battery cartridge in a

container with other metal objects

such as nails, coins, etc.

(3) Do not expose battery cartridge to

A battery short can cause a large current

flow, overheating, possible burns and

even a breakdown.

6. Do not store the tool and Battery Cartridge in locations where the temperature

may reach or exceed 50°C (122°F).

7. Do not incinerate the Battery Cartridge

even if it is severely damaged or is completely worn out. The battery cartridge can

explode in a fire.

8. Be careful not to drop, shake or strike battery.

9. Do not charge inside a box or container of

any kind. The battery must be placed in a

well ventilated area during charging.

SAVE THESE INSTRUCTIONS

water or rain.

7

INSTALLATION

1

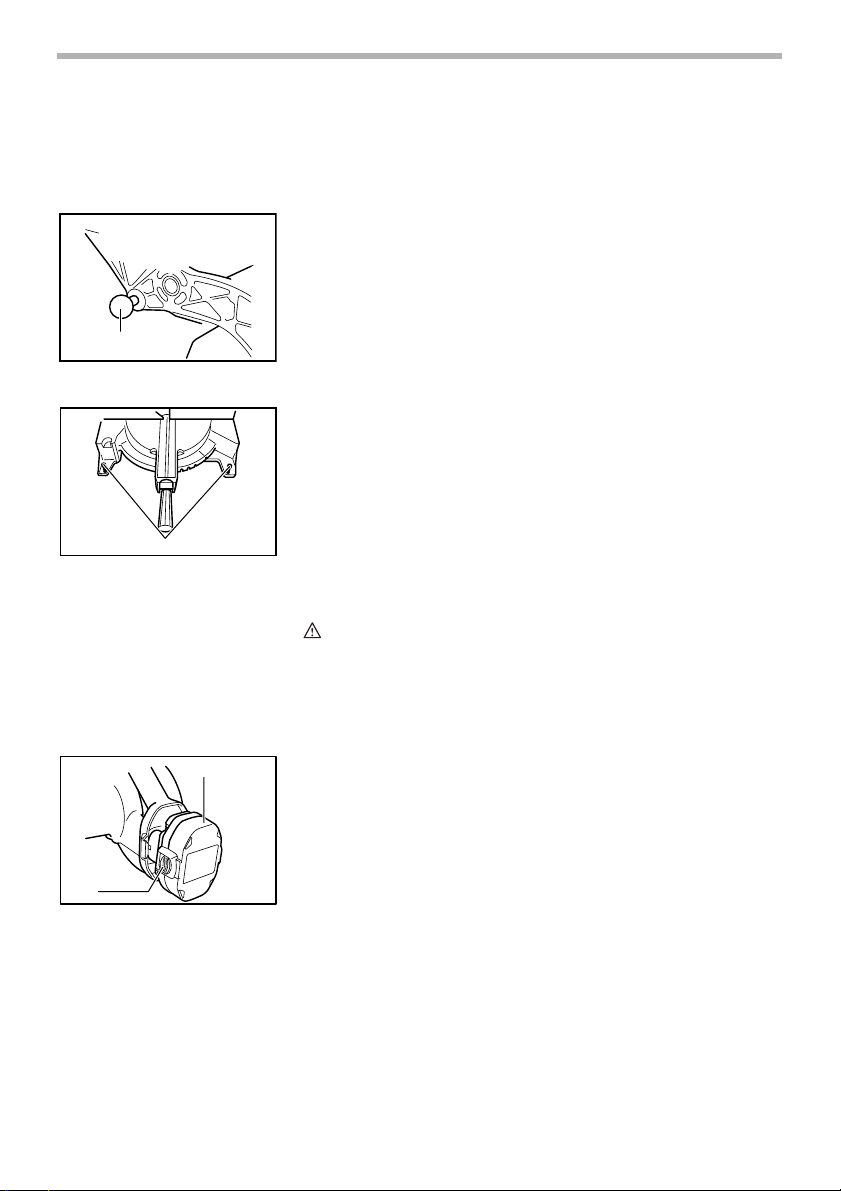

1. Stopper Pin

Bench mounting

002193

When the tool is shipped, the handle is locked in the lowered

position by the stopper pin. Release the stopper pin by lowering the handle slightly and pulling the stopper pin.

002194

This tool should be bolted with two bolts to a level and stable

surface using the bolt holes provided in the tool’s base. This

will help prevent tipping and possible injury.

1. Bolt

1

FUNCTIONAL

DESCRIPTION

1

2

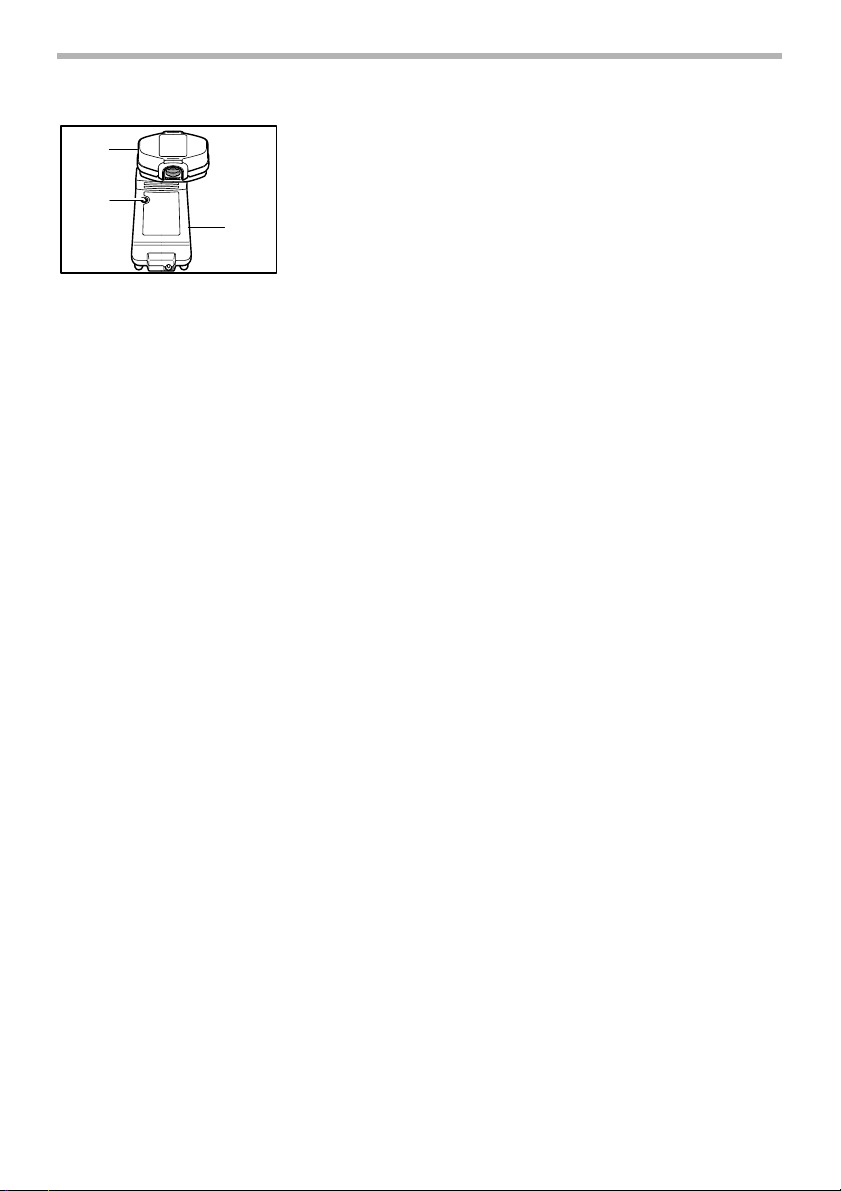

1. Battery cartridge

2. Button

8

CAUTION:

• Always be sure that the tool is switched off and the

battery cartridge is removed before adjusting or

checking function on the tool.

002240

Installing or removing battery cartridge

• Always switch off the tool before insertion or removal of

the battery cartridge.

• To remove the battery cartridge, withdraw it from the tool

while pressing the buttons on both sides of the cartridge.

• To insert the battery cartridge, align the tongue on the

battery cartridge with the groove in the housing and slip

it into place. Always insert it all the way until it locks in

place with a little click. If not, it may accidentally fall out

of the tool, causing injury to you or someone around you.

• Do not use force when inserting the battery cartridge. If

the cartridge does not slide in easily, it is not being

inserted correctly.

2

3

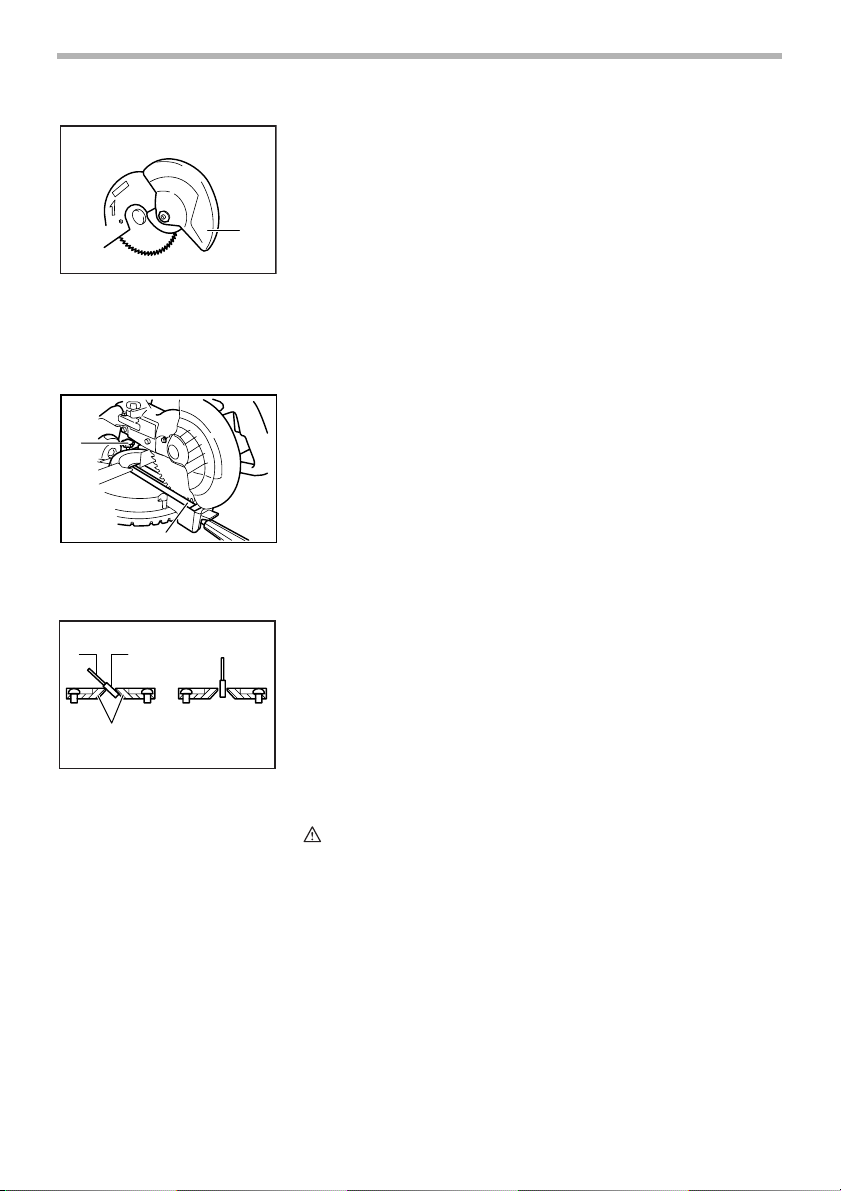

1. Battery charger

2. Battery cartridge

3. Charging light

004513

Charging

1. Plug the battery charger into the proper AC voltage

source. The charging light will flash in green color.

2. Insert the battery cartridge so that the plus and minus

1

terminals on the battery cartridge are on the same sides

as their respective markings on the charger. Insert the

cartridge fully into the port so that it rests on the charger

port floor.

3. When the battery cartridge is inserted, the charging light

color will change from green to red and charging will

begin. The charging light will remain lit steadily during

charging.

4. When the charging light color changes from red to

green, the charging cycle is complete.

5. If you leave the battery cartridge in the charger after the

charging cycle is complete, the charger will switch into

its “trickle charge (maintenance charge)” mode.

6. After charging, unplug the charger from the power

source.

NOTE:

• The battery charger is for charging Makita battery

cartridge. Never use it for other purposes or for other

manufacturer’s batteries.

• When you charge a new battery cartridge or a battery

cartridge which has not been used for a long period of

time, it may not accept a full charge. This is a normal

condition and does not indicate a problem. You can

recharge the battery cartridge fully after discharging it

completely and recharging a couple of times.

• If you charge a battery cartridge from a just operated

tool or a battery cartridge which has been left in a

location exposed to direct sunlight or heat for a long

time, the charging light may flash in red color. If this

occurs, wait for a while. Charging will begin after the

battery cartridge cools. The battery cartridge will cool

faster if you remove the battery cartridge from the

battery charger.

• If the charging light flashes alternately in green and red

color, charging is not possible. The terminals on the

charger or battery cartridge are clogged with dust or the

battery cartridge is worn out or damaged.

Trickle charge (Maintenance charge)

9

1. Blade guard

If you leave the battery cartridge in the charger to prevent

spontaneous discharging after full charge, the charger will

switch into its “trickle charge (maintenance charge)” mode

and keep the battery cartridge fresh and fully charged.

Tips for maintaining maximum battery life

1. Charge the battery cartridge before completely discharged.

Always stop tool operation and charge the battery cartridge when you notice less tool power.

2. Never recharge a fully charged battery cartridge.

Overcharging shortens the battery service life.

3. Charge the battery cartridge with room temperature at

10°C - 40°C (50°F - 104°F).

Let a hot battery cartridge cool down before charging it.

4. Charge the Nickel Metal Hydride battery cartridge when

you do not use it for more than six months.

002245

Blade guard

When lowering the handle, the blade guard rises automatically. The guard is spring loaded so it returns to its original

position when the cut is completed and the handle is raised.

NEVER DEFEAT OR REMOVE THE BLADE GUARD OR

1

THE SPRING WHICH ATTACHES TO THE GUARD.

In the interest of your personal safety, always maintain the

blade guard in good condition. Any irregular operation of the

blade guard should be corrected immediately. Check to

assure spring loaded return action of guard. NEVER USE

THE TOOL IF THE BLADE GUARD OR SPRING ARE DAMAGED, FAULTY OR REMOVED. DOING SO IS HIGHLY

DANGEROUS AND CAN CAUSE SERIOUS PERSONAL

INJURY.

If the see-through blade guard becomes dirty, or sawdust

adheres to it in such a way that the blade is no longer easily

visible, remove the battery cartridge and clean the guard

carefully with a damp cloth. Do not use solvents or any petroleum-based cleaners on the plastic guard.

10

1. Blade guard

1

2

1. Clamp screw

2. Kerf board

12

3

45

1. Saw blade

2. Blade teeth

3. Kerf board

4. Left bevel cut

5. Straight cut

001782

If the blade guard is especially dirty and vision through the

guard is impaired, use the supplied socket wrench to loosen

the hex bolt holding the center cover. Loosen the hex bolt by

turning it counterclockwise and raise the blade guard and

center cover. With the blade guard so positioned, cleaning

can be more completely and efficiently accomplished. When

1

cleaning is complete, reverse procedure above and secure

bolt. Do not remove spring holding blade guard. If guard

becomes discolored through age or UV light exposure, contact a Makita service center for a new guard. DO NOT

DEFEAT OR REMOVE GUARD.

002195

Positioning kerf board

This tool is provided with the kerf boards in the turn base to

minimize tearing on the exit side of a cut. The kerf boards are

factory adjusted so that the saw blade does not contact the

kerf boards. Before use, adjust the kerf boards as follows:

First, remove the battery cartridge. Loosen all the screws (2

each on left and right) securing the kerf boards. Re-tighten

them only to the extent that the kerf boards can still be easily

moved by hand. Lower the handle fully and push in the stopper pin to lock the handle in the lowered position. Loosen the

001800

clamp screw which secures the slide poles. Pull the carriage

toward you fully. Adjust the kerf boards so that the kerf

boards just contact the sides of the blade teeth. Tighten the

front screws (do not tighten firmly). Push the carriage toward

the guide fence fully and adjust the kerf boards so that the

kerf boards just contact the sides of blade teeth. Tighten the

rear screws (do not tighten firmly).

After adjusting the kerf boards, release the stopper pin and

raise the handle. Then tighten all the screws securely.

CAUTION:

• Before and after changing the bevel angle, always adjust

the kerf boards as described above.

11

Loading...

Loading...