Page 1

LS1440

Miter Saw

Instruction Manual

Gehrungssäge

Betriebsanleitung

Piła kątownica

Instrukcja obsługi

Торцовочная пила

Инструкция по эксплуатации

Page 2

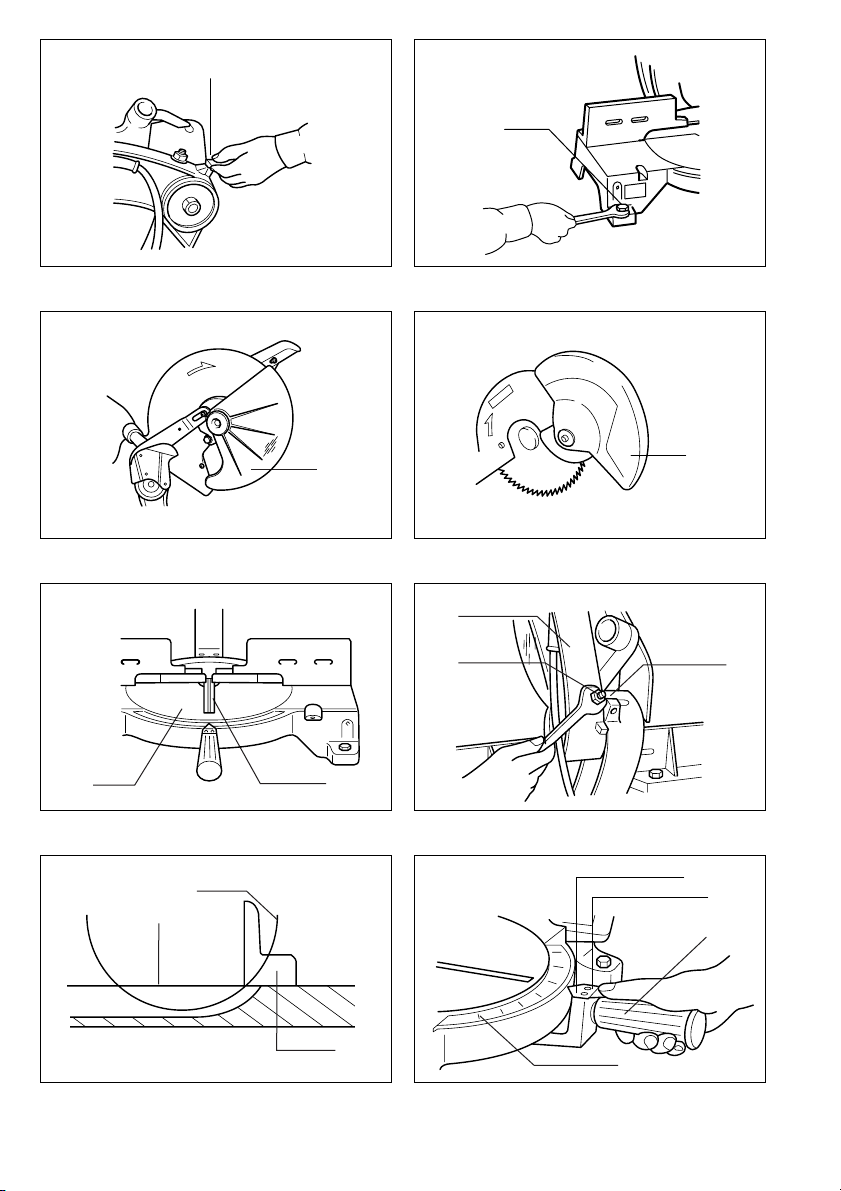

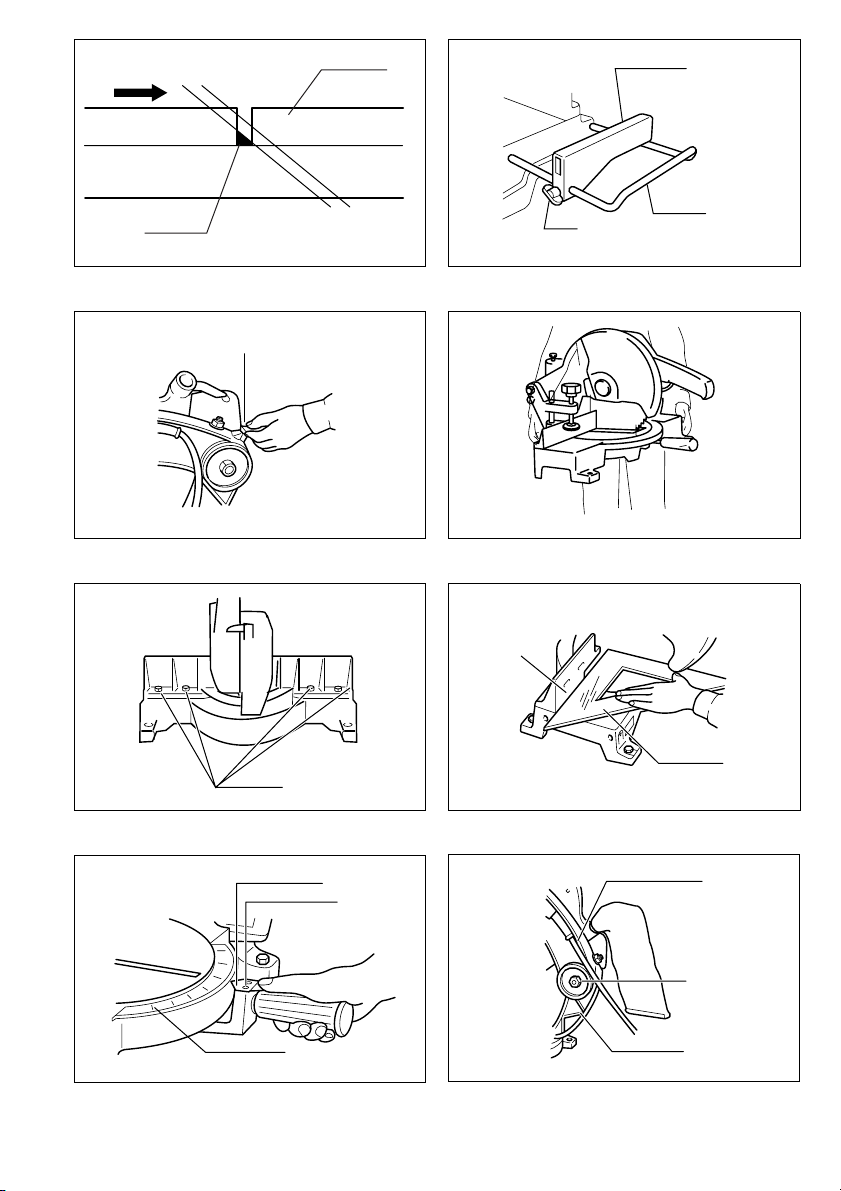

1

2

12

3

3

34

6

7

4

5

8

56

10

9

12

13

15

11

14

78

2

Page 3

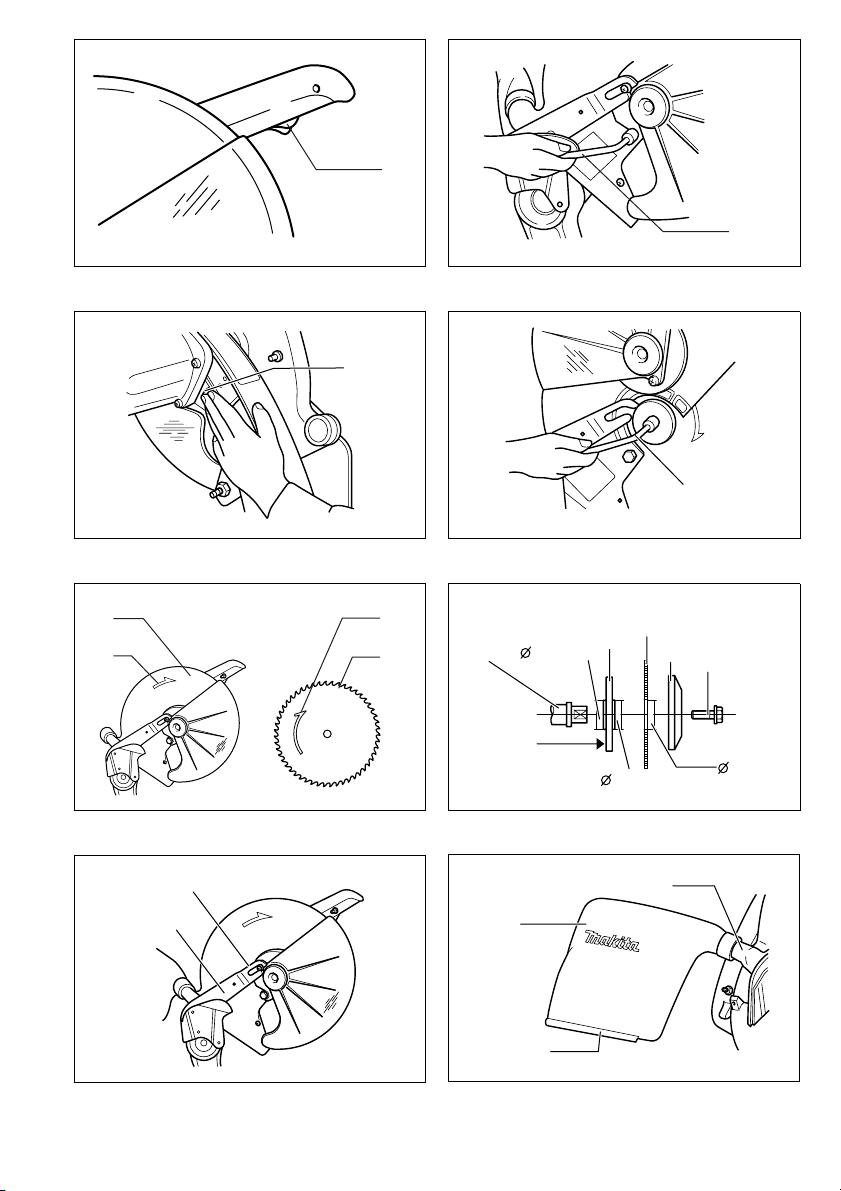

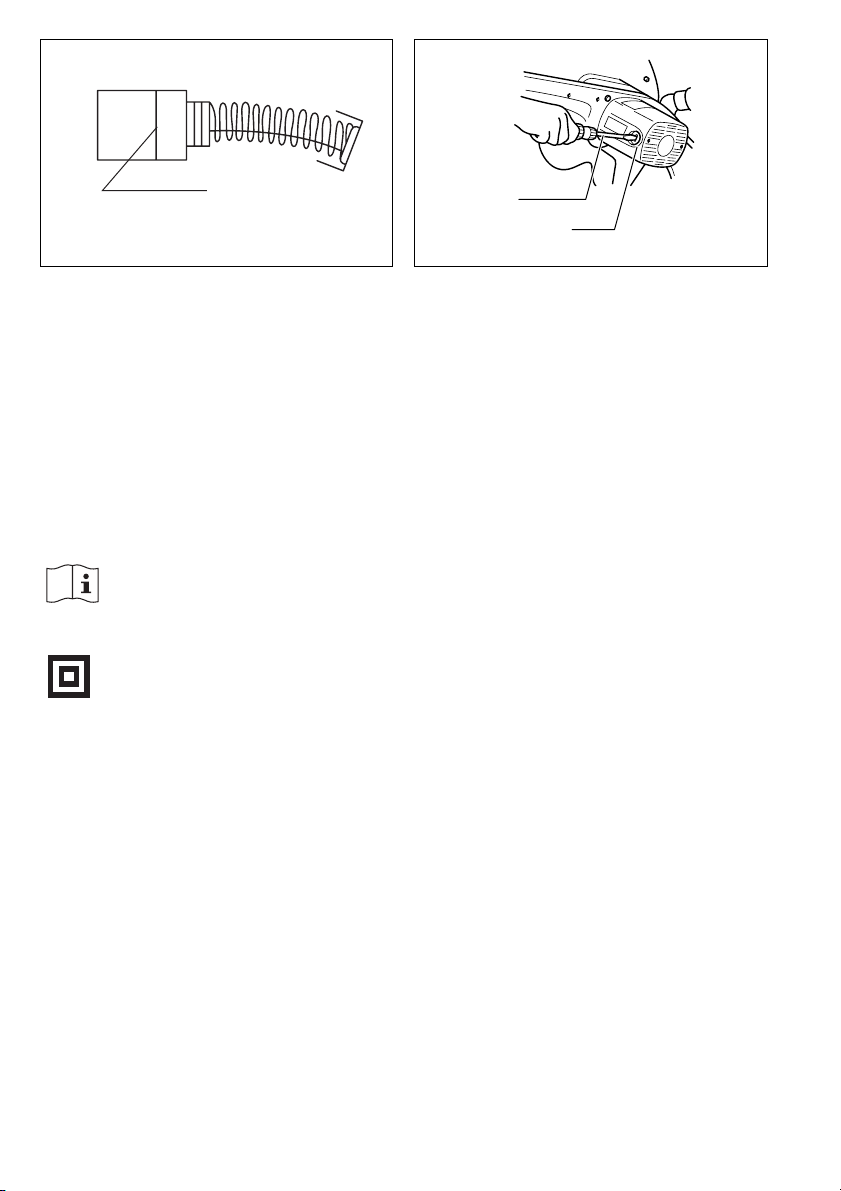

16

17

910

18

17

11 12

19

20

20

21

13 14

28

29

15 16

22

31

27

25.4mm

32

23

25mm

24

30

25

26

25mm

3

Page 4

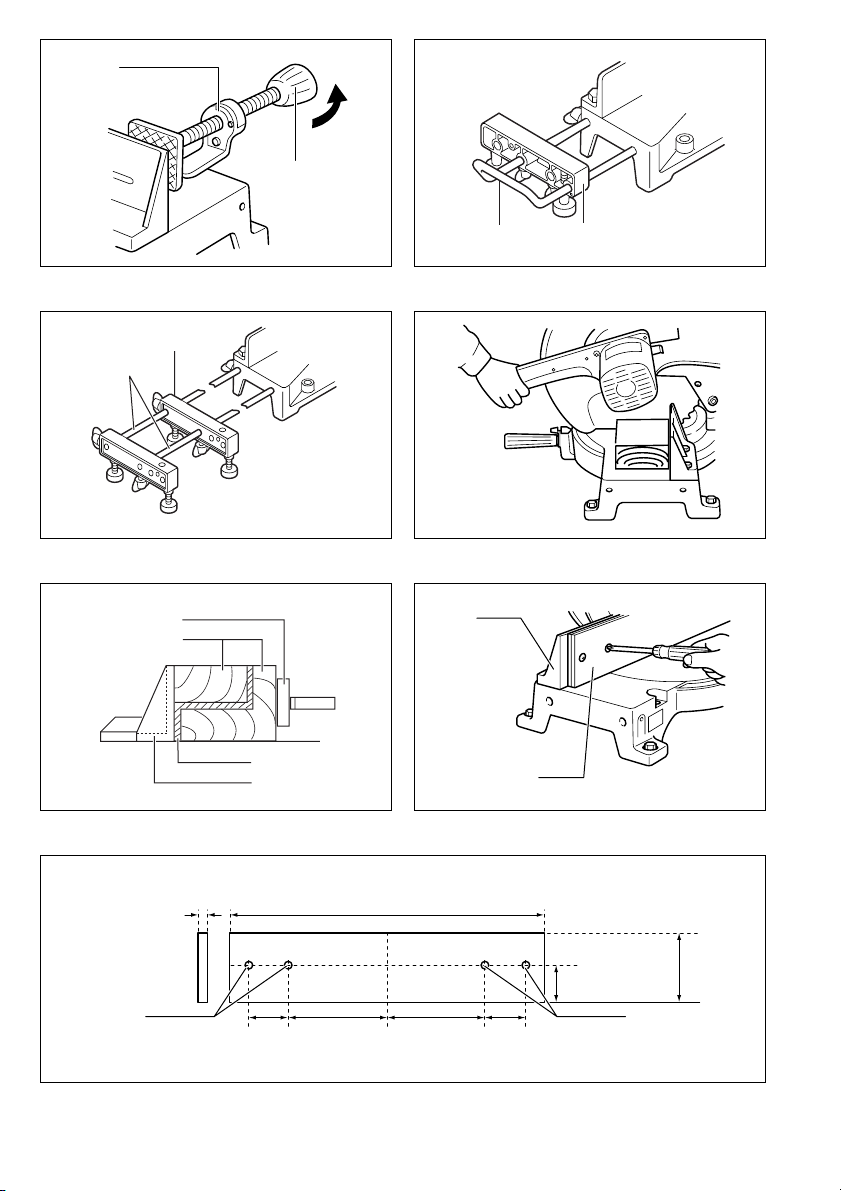

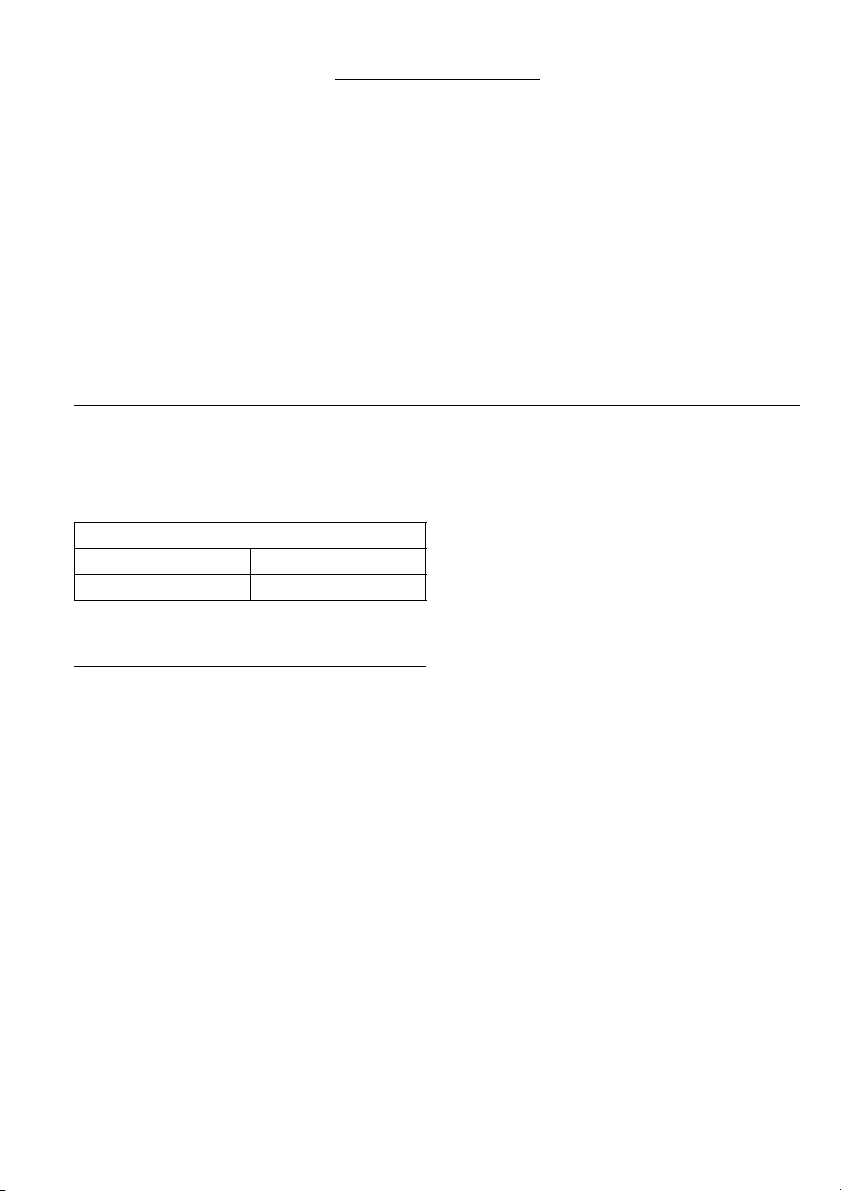

33

34

17 18

36

37

19 20

35 36

38

39

40

41

21 22

10 mm

(3/8")

Over 480 mm (18-1/32")

64 mm

(2-1/2")

154 mm

(6")

154 mm

(6")

23

4

11

41

90 mm (3-1/2")

45 mm (1-3/4")

4242

64 mm

(2-1/2")

Page 5

24

41

43

41

45

44

24 25

1

26 27

26

46

35

11

47

28 29

12

48

14

30 31

6

49

50

5

Page 6

51

52

53

32 33

Symbols

The followings show the symbols used for the tool. Be sure that you understand their meaning before use.

Symbole

Die folgenden Symbole werden für die Maschine verwendet. Machen Sie sich vor der Benutzung unbedingt mit ihrer

Bedeutung vertraut.

Symbole

Poniższe symbole używane są do opisu urządzenia. Przed użyciem należy upewnić się, że rozumie się ich znaczenie.

Символы

Следующие объяснения показывают символы, используемые для инструмента. Убедитесь перед

использованием, что Вы понимаете их значение.

❏ Read instruction manual.

❏ Bitte Betriebsanleitung lesen.

❏ Przeczytaj instrukcję obsługi.

❏ Прочитайте инструкцию по эксплуатации.

❏ DOUBLE INSULATION

❏ DOPPELT SCHUTZISOLIERT

❏ PODWÓJNA IZOLACJA

❏ ДВОЙНАЯ ИЗОЛЯЦИЯ

6

Page 7

ENGLISH

1 Handle latch

2Bolt

3 Blade guard

4 Turn base

5 Kerf board

6 Gear housing

7 Hex nut

8 Adjusting bolt

9 Top surface of turn base

10 Periphery of blade

11 Guide fence

12 Pointer

13 Latch spring

14 Miter scale

15 Grip

16 Switch trigger

17 Socket wrench

18 Shaft lock

19 Blade case

Explanation of general view

20 Arrow

21 Saw blade

22 Spindle

23 Inner flange

24 Blade

25 Onter flange

26 Hex bolt

27 25.4 mm marking

28 Pin

29 Guide arm

30 Dust nozzle

31 Dust bug

32 Fastener

33 Projection

34 Vise knob

35 Holder

36 Holder assembly

37 Rod 12

38 Horizontal vise

39 Spacer block

40 Aluminum extrusion

41 Wood facing

42 Hole

43 Workpiece

44 There should be no gap

between the blade, the wood

facing and the workpiece

45 Set plate

46 Screw

47 Triangular rule

48 Screws

49 Hex lock nut

50 Arm

51 Limit mark

52 Screwdriver

53 Brush holder cap

SPECIFICATIONS

Model LS1440

Blade diameter ................................................... 355 mm

Hole diameter ................................... 25 mm and 25.4 mm

Max. Miter angle ..................................Left 45°, Right 45°

Max. cutting capacities (H xW)

Miter angle

0° 45° (left and right)

122 mm x 152 mm 122 mm x 115 mm

–1

No load speed (min

Dimensions (L x W x H) .... 530 mm x 596 mm x 610 mm

Net weight ............................................................... 34 kg

• Due to our continuing program of research and development, the specifications herein are subject to change

without notice.

• Note: Specifications may differ from country to country.

Powe r supply

The tool should be connected only to a power supply of

the same voltage as indicated on the nameplate, and can

only be operated on single-phase AC supply. They are

double-insulated in accordance with European Standard

and can, therefore, also be used from sockets without

earth wire.

) ............................................ 3,200

SAFETY INSTRUCTIONS

Warning! When using electric tools, basic safety

precautions should always be followed to reduce

the risk of fire, electric shock and personal injury,

including the following. Read all these instructions before attempting to operate this product

and save these instructions.

For safe operation:

1. Keep work area clean

Cluttered areas and benches invite injuries.

2. Consider work area environment

Don’t expose power tools to rain. Don’t use

power tools in damp or wet locations. Keep work

area well lit. Don’t use power tools in presence of

flammable liquids or gases.

3. Guard against electric shock

Prevent body contact with grounded surfaces

(e.g. pipes, radiators, ranges, refrigerators).

4. Keep children away

Do not let visitors contact tool or extension cord.

All visitors should be kept away from work area.

5. Store idle tools

When not in use, tools should be stored in dry,

high, or locked-up place, out of the reach of children.

6. Don’t force tool

It will do the job better and safer at the rate for

which it was intended.

7. Use right tool

Don’t force small tools or attachments to do the

job of a heavy duty tool. Don’t use tools for purposes not intended; for example, don’t use circular saw for cutting tree limbs or logs.

7

Page 8

8. Dress properly

Do not wear loose clothing or jewelry. They can

be caught in moving parts. Rubber gloves and

non-skid footwear are recommended when working outdoors. Wear protective hair covering to

contain long hair.

9. Use safety glasses and hearing protection

Also use face or dust mask if cutting operation is

dusty.

10. Connect dust extraction equipment

If devices are provided for the connection of dust

extraction and collection facilities, ensure these

are connected and properly used.

11. Don’t abuse cord

Never carry tool by cord or yank it to disconnect it

from receptacle. Keep cord from heat, oil and

sharp edges.

12. Secure work

Use clamps or a vise to hold work. It’s safer than

using your hand and it frees both hands to operate tool.

13. Don’t overreach

Keep proper footing and balance at all times.

14. Maintain tools with care

Keep tools sharp and clean for better and safer

performance. Follow instructions for lubricating

and changing accessories. Inspect tool cords

periodically and, if damaged, have repaired by

authorized service facility. Inspect extension

cords periodically and replace if damaged. Keep

handles dry, clean and free from oil and grease.

15. Disconnect tools

When not in use, before servicing, and when

changing accessories such as blades, bits and

cutters.

16. Remove adjusting keys and wrenches

Form the habit of checking to see that keys and

adjusting wrenches are removed from tool before

turning it on.

17. Avoid unintentional starting

Don’t carry plugged-in tool with finger on switch.

Be sure switch is off when plugging in.

18. Outdoor use extension cords

When tool is used outdoors, use only extension

cords intended for use outdoors and so marked.

19. Stay alert

Watch what you are doing. Use common sense.

Do not operate tool when you are tired.

20. Check damaged parts

Before further use of the tool, a guard or other

part that is damaged should be carefully checked

to determine that it will operate properly and perform its intended function. Check for alignment of

moving parts, binding of moving parts, breakage

of parts, mounting, and any other conditions that

may affect its operation. A guard or other part

that is damaged should be properly repaired or

replaced by an authorized service center unless

otherwise indicated elsewhere in this instruction

manual. Have defective switches replaced by

and authorized service center. Do not use tool if

switch does not turn it on and off.

21. Warning

The use of any other accessory or attachment

other than recommended in this operating

instruction or the catalog may present a risk of

personal injury.

22. Have your tool repaired by an expert

This electric appliance is in accordance with the relevant safety rules. Repairing of electric appliances

may be carried out only by experts otherwise it may

cause considerable danger for the user.

ADDITIONAL SAFETY RULES FOR TOOL

1. Wear eye protection.

2. Keep hands out of path of saw blade. Avoid con-

tact with any coasting blade. It can still cause severe

injury.

3. Do not operate saw without guards in place.

Check blade guard for proper closing before

each use. Do not operate saw if blade guard

does not move freely and close instantly. Never

clamp or tie the blade guard into the open position.

4. Do not perform any operation freehand.

5. Never reach around saw blade.

6. Turn off tool and wait for saw blade to stop

before moving workpiece or changing settings.

7. Unplug tool before changing blade or servicing.

8. Don’t use the tool in the presence of flammable liq-

uids or gases.

9. Check the blade carefully for cracks or damage

before operation.

Replace cracked or damaged blade immediately.

10. Use only flanges specified for this tool.

11. Be careful not to damage the arbor, flanges (espe-

cially the installing surface) or bolt. Damage to these

parts could result in blade breakage.

12. Make sure that the turn base is properly secured so

it will not move during operation.

13. For your safety, remove the chips, small pieces, etc.

from the table top before operation.

14. Avoid cutting nails. Inspect for and remove all nails

from the workpiece before operation.

15. Make sure the shaft lock is released before the

switch is turned on.

16. Be sure that the blade does not contact the turn

base in the lowest position.

17. Hold the handle firmly. Be aware that the saw moves

up or down slightly during start-up and stopping.

18. Make sure the blade is not contacting the workpiece

before the switch is turned on.

19. Before using the tool on an actual workpiece, let it

run for a while. Watch for vibration or wobbling that

could indicate poor installation or a poorly balanced

blade.

20. Wait until the blade attains full speed before cutting.

21. Stop operation immediately if you notice anything

abnormal.

22. Do not attempt to lock the trigger in the on position.

23. Be alert at all times, especially during repetitive,

monotonous operations. Don’t be lulled into a false

sense of security. Blades are extremely unforgiving.

24. Always use accessories recommended in this

manual. Use of improper accessories such as

abrasive wheels may cause an injury.

25. Do not use the saw to cut other than aluminum,

wood or similar materials.

ENB063-1

8

Page 9

26. Connect miter saws to a dust collecting device

when sawing.

27. Select saw blades in relation to the material to

be cut.

28. Take care when slotting.

29. Replace the kerf board when worn.

SAVE THESE INSTRUCTIONS

INSTALLATION

Bench mounting

When the tool is shipped, the handle is locked in the lowered position by the handle latch. Release the handle

latch by lowering the handle slightly and turn the handle

latch to the released position. (Fig. 1)

This tool should be bolted with four bolts to a level and

stable surface using the bolt holes provided in the tool’s

base. This will help prevent tipping and possible injury.

(Fig. 2)

FUNCTIONAL DESCRIPTION

CAUTION:

• Always be sure that the tool is switched off and

unplugged before adjusting or checking function on the

tool.

Blade guard

When lowering the handle, the blade guard rises automatically. The guard is spring loaded so it returns to its

original position when the cut is completed and the handle is raised. NEVER DEFEAT OR REMOVE THE

BLADE GUARD OR THE SPRING WHICH ATTACHES

TO THE GUARD.

In the interest of your personal safety, always maintain

the blade guard in good condition. Any irregular operation of the blade guard should be corrected immediately.

Check to assure spring loaded return action of guard.

NEVER USE THE TOOL IF THE BLADE GUARD OR

SPRING ARE DAMAGED, FAULTY OR REMOVED.

DOING SO IS HIGHLY DANGEROUS AND CAN CAUSE

SERIOUS PERSONAL INJURY.

If the see-through blade guard becomes dirty, or sawdust

adheres to it in such a way that the blade is no longer

easily visible, unplug the saw and clean the guard carefully with a damp cloth. Do not use solvents or any petroleum-based cleaners on the plastic guard.

If the blade guard is especially dirty and vision through

the guard is impaired, use the supplied socket wrench to

loosen the hex bolt holding the center cover.

Loosen the hex bolt by turning it counterclockwise and

raise the blade guard and center cover. With the blade

guard so positioned, cleaning can be more completely

and efficiently accomplished. When cleaning is complete,

reverse procedure above and secure bolt. Do not remove

spring holding blade guard. If guard becomes discolored

through age or UV light exposure, contact a Makita service center for a new guard. DO NOT DEFEAT OR

REMOVE GUARD.

(Fig. 3 & 4)

Kerf board

This tool is provided with the kerf board in the turn base

to minimize tearing on the exit side of a cut. If the kerf

groove has not yet been cut in the kerf board by the factory, you should cut the groove before actually using the

tool to cut a workpiece. Switch on the tool and lower the

blade gently to cut a groove in the kerf board.

Maintaining maximum cutting capacity

This tool is factory adjusted to provide the maximum cutting capacity for a 355 mm saw blade.

When installing a new blade, always check the lower limit

position of the blade and if necessary, adjust it as follows:

First, unplug the tool. Lower the handle completely.

Loosen the hex nut at the rear of the gear housing. Use a

screwdriver to turn the adjusting bolt until the periphery

of the blade extends slightly below the top surface of the

turn base at the point where the front face of the guide

fence meets the top surface of the turn base.

With the tool unplugged, rotate the blade by hand while

holding the handle all the way down to be sure that the

blade does not contact any part of the lower base. Readjust slightly, if necessary.

After adjusting, tighten the hex nut with the wrench while

carefully holding the adjusting bolt in position with the

screwdriver.

CAUTION:

• After installing a new blade, always be sure that the

blade does not contact any part of the lower base when

the handle is lowered completely. Always do this with

the tool unplugged.

Adjusting the miter angle

Loosen the grip by turning counterclockwise. Turn the

turn base while pressing down the lock lever. When you

have moved the grip to the position where the pointer

points to the desired angle on the miter scale, securely

tighten the grip clockwise.

CAUTION:

• When turning the turn base, be sure to raise the handle

fully.

• After changing the miter angle, always secure the turn

base by tightening the grip firmly.

Fence plate

The fence plate is designed to prevent smaller cutting

scraps from jamming inside the blade case. The fence

plate moves right or left automatically as the turn base is

rotated.

(Fig. 5)

(Fig. 6 & 7)

(Fig. 8)

Switch action (Fig. 9)

CAUTION:

• Before plugging in the tool, always check to see that

the switch trigger actuates properly and returns to the

“OFF” position when released.

To start the tool, simply pull the switch trigger. Release

the switch trigger to stop.

9

Page 10

Electric brake

This tool is equipped with an electric blade brake. If the

tool consistently fails to quickly stop blade after switch

trigger release, have tool serviced at a Makita service

center.

The blade brake system is not a substitute for blade

guard. NEVER USE TOOL WITHOUT A FUNCTIONING

BLADE GUARD. SERIOUS PERSONAL INJURY CAN

RESULT.

ASSEMBLY

CAUTION:

• Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

Installing or removing saw blade

CAUTION:

• Always be sure that the tool is switched off and

unplugged before installing or removing the blade.

• Use only the Makita socket wrench provided to install

or remove the blade. Failure to do so may result in

overtightening or insufficient tightening of the hex bolt.

This could cause a personal injury.

To remove the blade, use the socket wrench to loosen

the hex bolt holding the center cover by turning it counterclockwise. Raise the blade guard and center cover.

(Fig. 10)

Press the shaft lock to lock the spindle and use the

socket wrench to loosen the hex bolt clockwise. Then

remove the hex bolt, outer flange and blade. (Fig. 11 &

12)

To install the blade, mount it carefully onto the spindle,

making sure that the direction of the arrow on the surface

of the blade matches the direction of the arrow on the

blade case. Install the outer flange and hex bolt, and then

use the socket wrench to tighten the hex bolt (lefthanded) securely counterclockwise while pressing the

shaft lock. (Fig. 13 & 14)

CAUTION:

• The inner flange has a 25 mm diameter on one side

and a 25.4 mm diameter on the other. The side with

25.4 mm diameter is marked by “25.4”. Use the correct

side for the hole diameter of the blade you intend to

use. Mounting the blade on the wrong side can result in

dangerous vibration.

Slip the pin on the blade guard into the slot in the guide

arm while returning the blade guard to its original fully

closed position. Then tighten the hex bolt clockwise to

secure the center cover. Lower the handle to make sure

that the blade guard moves properly. Make sure shaft

lock has released spindle before making cut. (Fig. 15)

Dust bag

The use of the dust bag makes cutting operations clean

and dust collection easy. To attach the dust bag, fit it onto

the dust nozzle.

When the dust bag is about half full, remove the dust bag

from the tool and pull the fastener out. Empty the dust

bag of its contents, tapping it lightly so as to remove particles adhering to the insides which might hamper further

collection.

(Fig. 16)

NOTE:

• If you connect a Makita vacuum cleaner to your saw,

more efficient and cleaner operations can be performed.

Securing workpiece

Whenever possible, secure the workpiece with the

optional vise. If you must use your hand to hold the workpiece, then it must be done firmly and securely so as not

to lose control of the workpiece. Your hand and arm must

be kept well away from the blade area (100 mm minimum). Squeeze the workpiece firmly against the guide

fence with your fingers held over the top of the guide

fence. The workpiece must also rest steadily on the turn

base.

WARNING:

• Never use your hand to hold the workpiece that

requires your hand to be any closer than 100 mm from

the blade area. In this case, always use the optional

vise to secure the workpiece. After any cutting operation, raise the blade gently. Never raise the blade until it

has come to a complete stop. Serious injury may result.

Horizontal vise (optional accessory) (Fig. 17)

The horizontal vise can be installed on either the left or

right side of the base. When performing 30° or greater

miter cuts, install the horizontal vise on the side opposite

the direction in which the turn table is to be turned. By

turning the vise knob counterclockwise, the screw is

released and the vise shaft can be moved rapidly in and

out. By turning the vise knob clockwise, the screw

remains secured. To grip the workpiece, turn the vise

knob gently clockwise until the projection reaches its topmost position, then fasten securely. If the vise knob is

forced in or pulled out while being turned clockwise, the

projection may stop at an angle. In this case, turn the

vise knob back counterclockwise until the screw is

released, before turning again gently clockwise.

CAUTION:

• Grip the workpiece only when the projection is at the

topmost position. Failure to do so may result in insufficient securing of the workpiece. This could cause the

workpiece to be thrown, cause damage to the blade or

cause the loss of control, which can result in PERSONAL INJURY.

Holders and holder assembly (optional accessories)

(Fig. 18)

The holders and the holder assembly can be installed on

either side as a convenient means of supporting workpieces horizontally. Install them as shown in Fig. 18.

Then tighten the screws firmly to secure the holders and

the holder assembly.

When cutting long workpieces, use the holder-rod

assembly (optional accessory). It consists of two holder

assemblies and two rods 12. (Fig. 19)

CAUTION:

• Always support long workpieces level with the top surface of the turn base for accurate cuts and to prevent

dangerous loss of control of the tool.

10

Page 11

OPERATION

CAUTION:

• Before use, be sure to release the handle from the lowered position by turning the handle latch to the

released position.

• Make sure the blade is not contacting the workpiece,

etc. before the switch is turned on.

• Do not apply excessive pressure on the handle when

cutting. Too much force may result in overload of the

motor and/or decreased cutting efficiency. Push down

handle with only as much force as is necessary for

smooth cutting and without significant decrease in

blade speed.

• Gently press down the handle to perform the cut. If the

handle is pressed down with force or if lateral force is

applied, the blade will vibrate and leave a mark (saw

mark) in the workpiece and the precision of the cut will

be impaired.

1. Press cutting (Fig. 20)

Secure the workpiece. Switch on the tool without the

blade making any contact and wait until the blade attains

full speed before lowering. Then gently lower the handle

to the fully lowered position to cut the workpiece. When

the cut is completed, switch off the tool and WAIT UNTIL

THE BLADE HAS COME TO A COMPLETE STOP

before returning the blade to its fully elevated position.

2. Miter cutting

Refer to the previously covered “Adjusting the miter

angle”.

3. Cutting aluminum extrusion (Fig. 21)

When securing aluminum extrusions, use spacer blocks

or pieces of scrap as shown in Fig. 21 to prevent deformation of the aluminum. Use a cutting lubricant when

cutting the aluminum extrusion to prevent buildup of the

aluminum material on the blade.

CAUTION:

• Never attempt to cut thick or round aluminum extrusions. Thick aluminum extrusions may come loose during operation and round aluminum extrusions cannot

be secured firmly with this tool.

4. Wood facing (Fig. 22, 23 & 24)

Use of wood facing helps to assure splinter-free cuts in

workpieces. Attach a wood facing to the guide fence

using the holes in the guide fence.

See Fig. 23 concerning the dimensions for a suggested

wood facing.

After changing the miter angle, cut the wood facing at

that selected angle. If there is a gap between the blade,

the wood facing and the workpiece, move the wood facing slightly in the direction of the arrow and cut it again.

CAUTION:

• Use straight wood of even thickness as the wood facing.

• Use screws to attach the wood facing to the guide

fence. The screws should be installed so that the screw

heads are below the surface of the wood facing.

• When the wood facing is attached, do not turn the turn

base with the handle lowered. The blade and/or the

wood facing will be damaged.

NOTE:

• When the wood facing is attached, the maximum cutting capacities in width will be reduced by thickness of

the wood facing.

5. Cutting repetitive lengths (Fig. 25)

When cutting several pieces of stock to the same length,

ranging from 300 mm to 400 mm, use of the set plate

(optional accessory) will facilitate more efficient operation. Install the set plate on the holder (optional accessory) as shown in Fig. 25.

Align the cutting line on your workpiece with either the

left or right side of the groove in the kerf board, and while

holding the workpiece from moving, move the set plate

flush against the end of the workpiece. Then secure the

set plate with the screw. When the set plate is not used,

loosen the screw and turn the set plate out of the way.

NOTE:

• Use of the holder-rod assembly (optional accessory)

allows cutting repetitive lengths up to 2,200 mm (7.2 ft.)

approximately.

Carrying tool

Make sure that the tool is unplugged. Secure the turn

base at right miter angle fully by means of the grip. Lower

the handle fully and lock it in the lowered position by turning the handle latch to the locked position. (Fig. 26)

Carry the tool by holding both sides of the tool base as

shown in the figure. If you remove the holders, dust bag,

etc., you can carry the tool more easily. (Fig. 27)

CAUTION:

• Always secure all moving portions before carrying the

tool.

• Handle latch is for carrying and storage purposes only

and not for any cutting operations.

MAINTENANCE

CAUTION:

• Always be sure that the tool is switched off and

unplugged before attempting to perform inspection or

maintenance.

WARNING:

• Always be sure that the blade is sharp and clean for the

best and safest performance.

Adjusting the cutting angle

This tool is carefully adjusted and aligned at the factory,

but rough handling may have affected the alignment. If

your tool is not aligned properly, perform the following:

Loosen the grip which secures the turn base. Turn the

turn base so that the pointer points to 0° on the miter

scale. Then turn the turn base slightly clockwise and

counterclockwise to seat the turn base in the 0° miter

notch. (Leave as it is if the pointer does not point to 0°.)

Loosen the hex bolts securing the guide fence using the

socket wrench. (Fig. 28)

Lower the handle fully and lock it in the lowered position

by turning the handle latch to the locked position. Square

the side of the blade with the face of the guide fence

using a triangular rule, try-square, etc. Then securely

tighten the hex bolts on the guide fence in the order from

the right side. (Fig. 29)

Make sure that the pointer on the indication plate points

to 0° on the miter scale. If the pointer does not point to

0°, loosen the screws which secure the indication plate

and adjust it so that the pointer will point to 0°. (Fig. 30)

11

Page 12

Adjusting for smooth handle action

The hex lock nut which holds the gear housing and the

arm has been factory adjusted to assure smooth handle

action up and down and to guarantee precise cutting. Do

not tamper with it. Should looseness develop at the gear

housing and arm connection, perform the following

adjustment. Work the handle up and down while tightening the hex lock nut; the best position to tighten the hex

lock nut is just before the motor body weight is obvious.

After adjusting the hex lock nut, be sure that the handle

returns automatically to the initial, raised position from

any position. If the hex lock nut is too loose, the cutting

accuracy will be affected; if it is too tight, it will be hard to

work the handle up and down. Note that this is a self

locking nut. It is a special type that does not loosen in

normal use. It should not be overtightened or replaced

with other types of nuts. (Fig. 31)

Replacing carbon brushes

Remove and check the carbon brushes regularly.

Replace when they wear down to the limit mark. Keep

the carbon brushes clean and free to slip in the holders.

Both carbon brushes should be replaced at the same

time. Use only identical carbon brushes. (Fig. 32)

Use a screwdriver to remove the brush holder caps. Take

out the worn carbon brushes, insert the new ones and

secure the brush holder caps. (Fig. 33)

After replacing brushes, plug in the tool and break in

brushes by running tool with no load for about 10 minutes. Then check the tool while running and electric

brake operation when releasing the switch trigger. If electric brake is not working well, ask your local Makita service center for repair.

After use

• After use, wipe off chips and dust adhering to the tool

with a cloth or the like. Keep the blade guard clean

according to the directions in the previously covered

section titled “Blade guard”. Lubricate the sliding portions with machine oil to prevent rust.

To maintain product SAFETY and RELIABILITY, repairs,

any other maintenance or adjustment should be performed by Makita Authorized Service Centers, always

using Makita replacement parts.

Noise and Vibration

ENG005-1

The typical A-weighted noise levels are

sound pressure level: 94 dB (A)

sound power level: 107 dB (A)

The typical weighted root mean square acceleration

value is not more than 2.5 m/s

– Wear ear protection. –

2

.

EC-DECLARATION OF CONFORMITY

We declare under our sole responsibility that this product

ENH003-1

is in compliance with the following standards of standardized documents,

EN61029, EN55014, EN61000

in accordance with Council Directives, 73/23/EEC,

89/336/EEC and 98/37/EC.

Yasuhiko Kanzaki

CE 2003

Director

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

12

Page 13

DEUTSCH

1Griffraste

2 Schraube

3 Schutzhaube

4 Drehteller

5 Schlitzplatte

6 Getriebegehäuse

7 Sechskantmutter

8 Einstellschraube

9 Drehteller-Oberfläche

10 Sägeblattumfang

11 Gehrungsanschlag

12 Zeiger

13 Rastenfeder

14 Gehrungswinkelskala

15 Griff

16 Ein-Aus-Schalter

17 Steckschlüssel

18 Spindelarretierung

19 Schutzhaube

Übersicht

20 Pfeil

21 Sägeblatt

22 Spindel

23 Innenflansch

24 Sägeblatt

25 Außenflansch

26 Sechskantschraube

27 25,4-mm-Markierung

28 Stift

29 Führungsarm

30 Absaugstutzen

31 Staubsack

32 Verschluss

33 Vorsprung

34 Schraubzwingenknopf

35 Halter

36 Auflageplatte

37 Stange 12

38 Horizontal-Schraubzwinge

39 Distanzblock

40 Aluminium-Werkstoff

41 Zwischenbrett

42 Loch

43 Werkstück

44 Es darf kein Spiel zwischen

Sägeblatt, Zwischenbrett und

Werkstück vorhanden sein.

45 Halteplatte

46 Schraube

47 Einstelldreieck

48 Schrauben

49 Sechskant-Sicherungsmutter

50 Arm

51 Verschleißgrenze

52 Schraubendreher

53 Bürstenhalterkappe

TECHNISCHE DATEN

Modell LS1440

Sägeblattdurchmesser......................................... 355 mm

Sägeblattbohrung ............................ 25 mm und 25,4 mm

Max. Gehrungswinkel .................... Links 45°, Rechts 45°

Max. Schnitttiefe (H × B)

Gehrungswinkel

0° 45° (links und rechts)

122 mm x 152 mm 122 mm x 115 mm

–1

Leerlaufdrehzahl (min

Abmessungen

(L × B × H) .........................530 mm × 596 mm × 610 mm

Nettogewicht............................................................ 34 kg

• Im Zuge unseres laufenden Forschungs- und Entwicklungsprogramms behalten wir uns das Recht vor,

Änderungen an den vorliegenden technischen Daten

ohne Vorankündigung vorzunehmen.

• Hinweis: Die technischen Daten können von Land zu

Land unterschiedlich sein.

Stromversorgung

Die Maschine darf nur an eine Einphasen-Wechselstromquelle angeschlossen werden, deren Spannung mit der

Angabe auf dem Typenschild übereinstimmt. Sie ist

gemäß der Europa-Norm doppelt schutzisoliert, und

kann daher auch mit Steckdosen ohne Erdleiter verwendet werden.

) ......................................... 3 200

SICHERHEITSHINWEISE

Achtung! Beim Gebrauch von Elektrowerkzeugen

sind zum Schutz gegen elektrischen Schlag. Verletzungsund Brandgefahr folgende grundsätzlichen Sicherheitsmaßnahmen zu geachten.

Lesen und beachten Sie diese Hinweise, bevor

Sie das Gerät benutzen.

1. Halten Sie Ihren Arbeitsbereich in Ordnung

Unordnung im Arbeitsbereich ergibt Unfallgefahr.

2. Berücksichtigen Sie Umgebungseinflüsse

Setzen sie Elektrowerkzeuge nicht dem Regen

aus. Benützen Sie Elektrowerkzeuge nicht in

feuchter oder nasser Umgebung. Sorgen Sie für

gute Beleuchtung. Benützen Sie Elektrowerkzeuge nicht in Nähe von brennbaren Flüssigkei-

ten oder Gasen.

3. Schützen Sie sich vor elektrischem Schlag

Vermeiden Sie Körperberührung mit geerdeten

Teilen, zum Beispiel Rohren, Heizkörpern, Her-

den, kühlschränken.

4. Halten Sie Kinder fern!

Lassen Sie andere Personen nicht das Werkzeug oder Kabel berühren, halten Sie sie von

Ihrem Arbeitsbereich fern.

5. Bewahren Sie Ihre Werkzeuge sicher auf

Unbenutzte Werkzeuge sollten in trockenem,

verschlossenem Raum und für Kinder nicht

erreichbar aufbewahrt werden.

6. Überlasten Sie Ihr Werkzeug nicht

Sie arbeiten besser und sicherer im angegebenen Leistungsbereich.

7. Benützen Sie das richtige Werkzeug

Verwenden Sie keine zu schwachen Werkzeuge

oder Vorsatzgeräte für schwere Arbeiten.

Benützen Sie Werkzeuge nicht für Zwecke und

Arbeiten, Wofür sie nicht bestimmt sind; zum

Beispiel benützen Sie keine Handkreissäge, um

Bäume zu flällen oder Äste zu schneiden.

13

Page 14

8. Tragen Sie geeignete Arbeitskleidung

Tragen Sie keine weite Kleidung oder Schmuck.

Sie können von beweglichen Teilen erfaßt werden. Bei Arbeiten im Freien sind Gummihandschuhe und rutschfestes Schuhwerk

empfehlenswert. Tragen Sie bei langen Haaren

ein Haarnetz.

9. Schutzbrille und Gehörschutz tragen

Verwenden Sie eine Atemmaske bei stauberzeugenden Arbeiten.

10. Schlleßen Sie eine Staubabsaugvorrichtung

an

Wenn Geräte für den Anschluß von Staubabsaug-und-sammelvorrichtungen ausgelegt sind,

sorgen Sie dafür, daß Jiese angeschlossen und

korrekt benutzi werden.

11. Zweckentfremden Sie nicht das Kabel

Tragen Sie das Werkzeug nicht am Kabel, und

benützen Sie es nicht, um den Stecker aus der

Steckdose zu ziehen. Schützen Sie das Kabel

vor Hitze, Öl und scharfen Kanten.

12. Sichern Sie das Werkstück

Benützen Sie Spannvorrichtungen oder einen

Schraubstock, um das Werkstück festzuhalten.

Es ist damit sicherer gehalten als mit Ihrer Hand

und ermöglicht die Bedienung der Maschine mit

beiden Händen.

13. Überdehnen Sie nicht Ihren Standbereich

Vermeiden Sie abnormale Körperhaltung. Sorgen Sie für sicheren Stand, und halten Sie jederzeit das Gleichgewicht.

14. Pflegen Sie Ihre Werkzeuge mit Sorgtalt

Halten Sie Ihre Werkzeuge scharf und sauber,

um gut und sicher zu arbeiten. Befolgen Sie die

Wartungsvorschriften und die Hinweise für

Werkzeugwechsel. Kontrollieren Sie regelmäßig

den Stecker und das Kabel, und lassen Sie

diese bei Beschädigung von einem anerkannten

Fachmann erneuern.

Kontrollieren Sie Verlängerungskabel regelmä-

ßig und ersetzen Sie beschädigte. Halten Sie

Handgriffe trocken und frei von Öl und Fett.

15. Ziehen Sie den Netzstecker

Bei Nichtgebrauch, vor der Wartung und beim

Werkzeugwechsel, wie zum Beispiel Sägeblatt,

Bohrer und Maschinenwerkzeugen aller Art.

16. Lassen Sie keine Werkzeugschlüssel stecken

Überprüfen Sie vor dem Einschalten, daß die

Schlüssel und Einstellwerkzeuge entfernt sind.

17. Vermeiden Sie unbeabsichtigten Anlauf

Tragen Sie keine an das Stromnetz angeschlossene Werkzeuge mit dem Finger am Schalter.

Vergewissern Sie sich, daß der Schalter beim

Anschluß an das Stromnetz ausgeschaltet ist.

18. Verlängerungskabel im Freien

Verwenden Sie im Freien nur dafür zugelassene

und entsprechend gekennzeichnete Varlänge-

rungskabel.

19. Seien Sie stets aufmerksam

Beobachten Sie Ihre Arbeit. Gehen Sie vernünf-

tig vor. Verwenden Sie das Werkzeug nicht,

wenn Sie unkonzentriert sind.

20. Kontrollieren Sie Ihr Gerät auf Beschädigungen

Vor weiterem Gebrauch des Werkzeugs die

Schutzeinrichtungen oder leicht beschädigte

Teile sorgfältig auf ihre einwandfreie und bestimmungsgemäße Funktion überprüfen. Überprü-

fen Sie, ob die Funktion beweglicher Teile in

Ordnung ist, ob sie nicht klemmen onder ob Teile

beschädigt sind. Sämtliche Teile müssen richtig

montiert sein und alle Bedingungen erfüllen, um

den einwandfreien Betrieb des Gerätes zu

gewährleisten.

Beschädigte Schutzvorrichtungen und Teile sollen sachgemäß durch eine Kundendienstwerkstatt repariert oder ausgewechselt werden,

soweit nichts anderes in den Betriebsanleitungen angegeben ist. Beschädigte Schalter müs-

sen bei einer Kundendienstwerkstatt ersetzt

werden. Benutzen Sie keine Werkzeuge, bei

denen sich der Schalter nicht ein und ausschalten läßt.

21. Achtung!

Zu Ihrer eigenen Sicherheit, benützen Sie nur

Zubehör und Zusatzgeräte, die in der Bedienungsanleitung angegeben oder vom WerkzeugHersteller empfohlen oder angegeben werden.

Der Gebrauch anderer als der in der Bedienungsanleitung oder im Katalog empfohlenen

Einsatzwerkzeuge oder Zubehöre kann eine persönliche Verletzungsgefahr für Sie bedeuten.

22. Reparaturen nur vom Elektrofachmann.

Dieses Elektrowerkzeug entspricht den einschlä-

gigen Sicherheitsbestimmungen. Reparaturen

dürfen nur von einer Elektrofachkraft ausgeführt

werden, andernfalls können Unfälle für den

Betreiber entstehen.

ZUSÄTZLICHE SICHERHEITSREGELN FÜR

DIE MASCHINE

1. Tragen Sie stets eine Schutzbrille.

2. Halten Sie Ihre Hände von der Schnittlinie des

Sägeblatts fern. Vermeiden Sie die Berührung

eines auslaufenden Sägeblatts. Es kann auch in diesem Zustand noch schwere Verletzungen verursachen.

3. Betreiben Sie die Säge nicht ohne Schutzvorrichtungen. Überprüfen Sie die Schutzhaube vor

jeder Benutzung auf einwandfreies Schließen.

Betreiben Sie die Säge nicht, wenn sich die

Schutzhaube nicht ungehindert bewegt und sich

nicht sofort schließt. Die Schutzhaube darf auf

keinen Fall in der geöffneten Stellung festgeklemmt oder festgebunden werden.

4. Führen Sie keine freihändigen Arbeiten aus.

5. Fassen Sie niemals um das Sägeblatt.

6. Schalten Sie die Maschine aus und lassen Sie

das Sägeblatt zum Stillstand kommen, bevor Sie

das Werkstück bewegen oder Einstellungen

ändern.

7. Trennen Sie die Maschine vom Stromnetz, bevor

Sie das Sägeblatt wechseln oder die Maschine

warten.

14

Page 15

8. Betreiben Sie die Maschine nicht in Gegenwart von

brennbaren Flüssigkeiten oder Gasen.

9. Überprüfen Sie das Sägeblatt vor dem Betrieb sorg-

fältig auf Risse oder Beschädigung.

Wechseln Sie ein gerissenes oder beschädigtes

Sägeblatt unverzüglich aus.

10. Verwenden Sie nur die für diese Maschine vorge-

schriebenen Flansche.

11. Achten Sie sorgfältig darauf, dass Achse, Flansche

(insbesondere die Ansatzfläche) und Schraube nicht

beschädigt werden. Eine Beschädigung dieser Teile

kann zu einem Sägeblattbruch führen.

12. Vergewissern Sie sich, dass der Drehteller einwand-

frei gesichert ist, damit er sich während des Betriebs

nicht bewegt.

13. Zur Sicherheit sollte die Tischplatte vor dem Betrieb

von Spänen, Kleinteilen usw. gesäubert werden.

14. Schneiden Sie keine Nägel durch. Untersuchen Sie

das Werkstück sorgfältig auf Nägel, und entfernen

Sie diese vor der Bearbeitung.

15. Vergewissern Sie sich vor dem Einschalten der

Maschine, dass die Spindelarretierung freigegeben

ist.

16. Vergewissern Sie sich, dass das Sägeblatt in der

Tiefstellung nicht mit dem Drehteller in Berührung

kommt.

17. Halten Sie den Handgriff sicher fest. Beachten Sie,

dass sich die Säge beim Anlaufen und Abstellen

geringfügig nach oben oder unten bewegt.

18. Vergewissern Sie sich vor dem Einschalten der

Maschine, dass das Sägeblatt nicht das Werkstück

berührt.

19. Lassen Sie die Maschine vor dem eigentlichen

Schneiden eines Werkstücks eine Weile laufen.

Achten Sie auf Vibrationen oder Taumelbewegungen, die Anzeichen für schlechte Montage oder ein

schlecht ausgewuchtetes Sägeblatt sein können.

20. Warten Sie, bis das Sägeblatt die volle Drehzahl

erreicht hat, bevor Sie mit dem Schneiden beginnen.

21. Brechen Sie sofort den Betrieb ab, wenn Sie irgend-

etwas Ungewöhnliches bemerken.

22. Versuchen Sie nicht, den Schalter in der Einschalt-

stellung zu arretieren.

23. Seien Sie stets wachsam, besonders bei sich dau-

ernd wiederholenden, eintönigen Arbeiten. Lassen

Sie sich nicht in trügerische Sicherheit wiegen.

Sägeblätter kennen kein Erbarmen.

24. Verwenden Sie stets das in dieser Anleitung

empfohlene Zubehör. Der Gebrauch ungeeigneten Zubehörs, wie z.B. Schleifscheiben, kann

Verletzungen zur Folge haben.

25. Benutzen Sie die Säge nur zum Schneiden von

Aluminium, Holz oder ähnlichem Material.

26. Schließen Sie Gehrungs- und Kappsägen beim

Betrieb an eine Staubsammelvorrichtung an.

27. Wählen Sie die Sägeblätter unter Berücksichtigung des zu schneidenden Materials aus.

28. Lassen Sie beim Nutenschneiden Vorsicht walten.

29. Wechseln Sie die Schlitzplatte bei Verschleiß

aus.

BEWAHREN SIE DIESE HINWEISE

SORGFÄLTIG AUF.

MONTAGE

Befestigung der Säge auf einer Werkbank

Der Handgriff wurde werksseitig vor dem Versand mit der

Griffraste in der Tiefstellung verriegelt. Lösen Sie die

Griffraste, indem Sie den Handgriff leicht nach unten

drücken und die Griffraste auf die Freigabestellung drehen. (Abb. 1)

Diese Maschine sollte unter Verwendung der Schraubenbohrungen in der Grundplatte mit vier Schrauben auf

einer ebenen und stabilen Oberfläche befestigt werden.

Dadurch werden Umkippen und mögliche Verletzungen

vermieden. (Abb. 2)

FUNKTIONSBESCHREIBUNG

VORSICHT:

• Vergewissern Sie sich vor jeder Einstellung oder Funktionsprüfung der Maschine stets, dass sie ausgeschaltet und vom Stromnetz getrennt ist.

Schutzhaube (Abb. 3 u. 4)

Wird der Handgriff abgesenkt, hebt sich die Schutzhaube

automatisch. Die Schutzhaube ist gefedert, so dass sie

in ihre Ausgangsstellung zurückkehrt, wenn der Schnitt

vollendet ist und der Handgriff angehoben wird. NIEMALS DIE SCHUTZHAUBE ODER DIE DARAN ANGEBRACHTE FEDER FUNKTIONSUNFÄHIG MACHEN

ODER ENTFERNEN.

Im Interesse Ihrer eigenen Sicherheit sollten Sie die

Schutzhaube stets in ordnungsgemäßem Zustand halten. Funktionsstörungen der Schutzhaube müssen sofort

behoben werden. Überprüfen Sie die gefederte Rückkehrbewegung der Schutzhaube. BENUTZEN SIE DIE

MASCHINE NIEMALS MIT BESCHÄDIGTER, DEFEKTER ODER FEHLENDER SCHUTZHAUBE ODER

FEDER, WEIL DIES SEHR GEFÄHRLICH IST UND ZU

SCHWEREN VERLETZUNGEN FÜHREN KANN.

Wenn die transparente Schutzhaube schmutzig wird

oder soviel Sägemehl an ihr haftet, dass das Sägeblatt

nicht mehr ohne weiteres sichtbar ist, sollten Sie die

Maschine vom Stromnetz trennen und die Schutzhaube

mit einem feuchten Tuch sorgfältig reinigen. Verwenden

Sie keine Lösungsmittel oder Reinigungsmittel auf Petroleumbasis zum Reinigen der Kunststoff-Schutzhaube.

Wenn bei besonders starker Verschmutzung der Schutzhaube die Sicht durch die Schutzhaube behindert ist,

lösen Sie die Sechskantschraube, mit der die Mittenabdeckung befestigt ist, mit dem mitgelieferten Steckschlüssel.

Lösen Sie die Sechskantschraube durch Drehen entgegen dem Uhrzeigersinn, und heben Sie die Schutzhaube

und die Mittenabdeckung an. In dieser Stellung der

Schutzhaube kann die Reinigung gründlicher und effizienter durchgeführt werden. Wenden Sie nach der Reinigung das obige Demontageverfahren umgekehrt an, und

ziehen Sie die Schraube an. Entfernen Sie nicht die

Feder, welche die Schutzhaube hält. Falls sich die

Schutzhaube durch Alterung oder UV-Strahlung verfärbt,

bestellen Sie eine neue Schutzhaube bei einer MakitaKundendienststelle. DIE SCHUTZHAUBE DARF NICHT

FUNKTIONSUNFÄHIG GEMACHT ODER ENTFERNT

WERDEN.

15

Page 16

Schlitzplatte (Abb.5)

Diese Maschine ist mit einer Schlitzplatte im Drehteller

versehen, um Reißen am Austrittsende eines Schnitts

auf ein Minimum zu reduzieren. Falls der Einschnitt nicht

bereits werkseitig ausgeführt wurde, müssen Sie den

Schlitz schneiden, bevor Sie die Maschine zum tatsächli-

chen Sägen eines Werkstücks verwenden. Schalten Sie

die Maschine ein, und senken Sie das Sägeblatt vorsichtig ab, um einen Schlitz in die Schlitzplatte zu schneiden.

Aufrechterhaltung der maximalen Schnittleistung

(Abb. 6 u. 7)

Diese Maschine wurde werkseitig so eingestellt, dass die

maximale Schnittleistung mit einem Sägeblatt von

355 mm Durchmesser erreicht wird.

Wenn Sie ein neues Sägeblatt montieren, überprüfen Sie

immer die untere Grenzposition des Sägeblatts, und nehmen Sie nötigenfalls eine Einstellung vor, wie folgt:

Ziehen Sie zuerst den Netzstecker ab. Senken Sie den

Handgriff völlig ab. Lösen Sie die Sechskantmutter auf

der Rückseite des Getriebegehäuses. Drehen Sie die

Einstellschraube mit einem Schraubenzieher, bis der

Sägeblattumfang am Berührungspunkt von Gehrungsanschlag-Vorderseite und Drehteller-Oberfläche geringfü-

gig unterhalb der Drehteller-Oberfläche liegt.

Drehen Sie das Sägeblatt bei vom Stromnetz getrennter

Maschine von Hand, während Sie den Handgriff in der

Tiefstellung halten, um sicherzugehen, dass das Säge-

blatt keinen Teil des Auflagetisches berührt. Nötigenfalls

ist eine Nachjustierung vorzunehmen.

Ziehen Sie die Sechskantmutter nach der Einstellung mit

dem Steckschlüssel an, während Sie die Einstellschraube mit dem Schraubenzieher einwandfrei festhalten.

VORSICHT:

• Vergewissern Sie sich nach der Montage eines neuen

Sägeblatts stets, dass das Sägeblatt in der Tiefstellung

des Handgriffs keinen Teil des Auflagetisches berührt.

Führen Sie diese Überprüfung immer bei abgezogenem Netzstecker durch.

Einstellung des Gehrungswinkels (Abb. 8)

Lösen Sie den Griff durch Linksdrehung. Drehen Sie den

Drehteller, während Sie den Arretierhebel niederdrücken.

Bewegen Sie den Griff, bis der Zeiger auf den gewünsch-

ten Winkel der Gehrungswinkelskala zeigt, und ziehen

Sie dann den Griff durch Rechtsdrehung fest.

VORSICHT:

• Bringen Sie den Handgriff in die Hochstellung, bevor

Sie den Drehteller drehen.

• Sichern Sie den Drehteller nach jeder Änderung des

Gehrungswinkels stets durch Anziehen des Griffs

gegen Verdrehen.

Anschlagplatte

Die Anschlagplatte soll verhindern, dass sich kleine

Späne in der Schutzhaube ansammeln. Die Anschlagplatte bewegt sich automatisch nach rechts oder links,

wenn der Drehteller gedreht wird.

Schalterfunktion (Abb. 9)

VORSICHT:

• Vergewissern Sie sich vor dem Anschließen der

Maschine an das Stromnetz stets, dass der Ein-AusSchalter ordnungsgemäß funktioniert und beim Loslassen in die AUS-Stellung zurückkehrt.

Zum Einschalten der Maschine einfach den Ein-AusSchalter drücken. Zum Ausschalten den Ein-Aus-Schalter loslassen.

Elektrische Bremse

Diese Maschine ist mit einer elektrischen Sägeblatt-

bremse ausgestattet. Falls die Maschine nach dem Loslassen des Ein-Aus-Schalters nicht sofort anhält, lassen

Sie sie von einer Makita-Kundendienststelle warten.

Das Sägeblatt-Bremssystem ist kein Ersatz für die

Schutzhaube. BENUTZEN SIE DIE MASCHINE NIEMALS OHNE EINE FUNKTIONSFÄHIGE SCHUTZHAUBE, WEIL ES SONST ZU SCHWEREN

VERLETZUNGEN KOMMEN KANN.

MONTAGE

VORSICHT:

• Vergewissern Sie sich vor der Ausführung von Arbeiten

an der Maschine stets, dass sie ausgeschaltet und vom

Stromnetz getrennt ist.

Montage und Demontage des Sägeblatts

VORSICHT:

• Vergewissern Sie sich vor der Montage bzw. Demontage des Sägeblatts stets, dass die Maschine ausgeschaltet und vom Stromnetz getrennt ist.

• Verwenden Sie nur den mitgelieferten Makita-Steckschlüssel zum Demontieren oder Montieren des Sägeblatts. Anderenfalls besteht die Gefahr, dass die

Sechskantschraube zu stark oder zu schwach angezogen wird. Dies könnte zu einer Verletzung führen.

Zum Demontieren des Sägeblatts lösen Sie zunächst die

Sechskantschraube, mit der die Mittenabdeckung befestigt ist, durch Linksdrehung mit dem Steckschlüssel.

Heben Sie die Schutzhaube und die Mittenabdeckung

an. (Abb.10)

Blockieren Sie die Spindel durch Drücken der Spindelarretierung, und lösen Sie die Sechskantschraube (linksgängig) durch Rechtsdrehung des Steckschlüssels.

Nehmen Sie dann Sechskantschraube, Außenflansch

und Sägeblatt ab. (Abb.11 u. 12)

Zum Montieren schieben Sie das Sägeblatt vorsichtig auf

die Spindel, wobei Sie darauf achten, dass der Pfeil auf

dem Sägeblatt in dieselbe Richtung zeigt wie der Pfeil

auf dem Sägeblattgehäuse. Bringen Sie Außenflansch

und Sechskantschraube an, und ziehen Sie dann die

Sechskantschraube (linksgängig) bei gedrückter Spindelarretierung durch Linksdrehung des Steckschlüssels

fest. (Abb.13 u. 14)

VORSICHT:

• Der Innenflansch hat einen Durchmesser von 25 mm

auf der einen, und von 25,4 mm auf der anderen Seite.

Die Seite mit 25,4 mm Durchmesser ist mit “25.4” markiert. Verwenden Sie die für die Bohrung des zu benutzenden Sägeblatts passende Seite. Die Montage des

Sägeblatts auf der falschen Seite kann zu gefährlichen

Vibrationen führen.

16

Page 17

Schieben Sie den Stift an der Schutzhaube in den Schlitz

am Führungsarm, während Sie die Schutzhaube auf die

völlig geschlossene Stellung zurückführen. Ziehen Sie

dann die Sechskantschraube zur Sicherung der Mittenabdeckung im Uhrzeigersinn an. Senken Sie den Handgriff ab, um zu prüfen, ob sich die Schutzhaube

einwandfrei bewegt. Vergewissern Sie sich vor der

Benutzung der Maschine, dass die Spindelarretierung

gelöst ist. (Abb. 15)

Staubsack (Abb.16)

Der Staubsack ermöglicht sauberes Arbeiten und einfaches Staubsammeln. Zum Anbringen wird der Staubsack

auf den Absaugstutzen geschoben.

Wenn der Staubsack etwa halb voll ist, nehmen Sie ihn

von der Maschine ab und ziehen den Verschluss heraus.

Entleeren Sie den Staubsack, indem Sie ihn leicht

abklopfen, um die an den Innenflächen haftenden Staubpartikel, die den Durchlass behindern können, zu lösen.

HINWEIS:

• Wenn Sie einen Makita-Staubsauger an Ihre Säge

anschließen, können Sie noch effizienter und sauberer

arbeiten.

Sicherung von Werkstücken

Spannen Sie das Werkstück nach Möglichkeit in die

optionale Schraubzwinge ein. Wenn Sie das Werkstück

mit der Hand halten müssen, halten Sie es mit festem

Griff, damit Sie nicht die Kontrolle über das Werkstück

verlieren. Halten Sie Hand und Arm vom Sägeblattbe-

reich fern (mindestens 100 mm). Drücken Sie das Werkstück fest gegen den Gehrungsanschlag, indem Sie mit

Ihren Fingern über den Gehrungsanschlag greifen. Das

Werkstück muss auch fest auf dem Drehteller aufliegen.

WARNUNG:

• Halten Sie ein Werkstück, bei dem Ihre Hand näher als

100 mm an den Sägeblattbereich herankommt, niemals mit der Hand. Sichern Sie das Werkstück in diesem Fall immer mit der optionalen Schraubzwinge.

Heben Sie das Sägeblatt nach jedem Schneidvorgang

sachte an. Heben Sie das Sägeblatt erst an, nachdem

es zum völligen Stillstand gekommen ist. Anderenfalls

kann es zu schweren Verletzungen kommen.

Horizontal-Schraubzwinge (Sonderzubehör)

(Abb. 17)

Die Horizontal-Schraubzwinge kann entweder auf der linken oder rechten Seite des Auflagetisches montiert werden. Wenn Gehrungsschnitte in einem Winkel von 30°

oder mehr ausgeführt werden, ist die HorizontalSchraubzwinge auf der entgegengesetzten Seite der

Drehteller-Drehrichtung zu montieren. Durch Linksdrehung des Schraubzwingenknopfes wird die Schraube

gelöst, so dass der Schraubzwingenschaft schnell vorund zurückgeschoben werden kann. Durch Rechtsdrehen des Schraubzwingenknopfes bleibt die Schraube

gesichert. Drehen Sie den Schraubzwingenknopf zum

Einspannen von Werkstücken sachte im Uhrzeigersinn,

bis der Vorsprung seine Höchstposition erreicht, und ziehen Sie ihn dann fest. Wird der Schraubzwingenknopf

während der Rechtsdrehung hineingedrückt oder herausgezogen, bleibt der Vorsprung eventuell schräg stehen. Drehen Sie den Schraubzwingenknopf in diesem

Fall entgegen dem Uhrzeigersinn zurück, bis sich die

Schraube löst, bevor Sie ihn wieder sachte im Uhrzeigersinn drehen.

VORSICHT:

• Spannen Sie das Werkstück nur ein, wenn sich der

Vorsprung an der obersten Position befindet. Anderenfalls wird das Werkstück möglicherweise nicht ausreichend gesichert, so dass die Gefahr besteht, dass es

herausgeschleudert, das Sägeblatt beschädigt oder

Verlust der Kontrolle verursacht wird, was zu VERLETZUNGEN führen kann.

Auflagebügel und Auflageplatte (Sonderzubehör)

(Abb.18)

Die Auflagebügel und Auflageplatten können zur zusätz-

lichen Abstützung von Werkstücken auf beiden Seiten

montiert werden. Montieren Sie die Teile, wie in Abb. 18

gezeigt. Ziehen Sie dann die Schrauben fest, um Auflagebügel und Auflageplatte zu sichern.

Wenn Sie lange Werkstücke sägen, verwenden Sie den

Auflageverlängerungssatz (Sonderzubehör). Dieser best

eht aus zwei Auflageplatten und zwei Stangen 12.

(Abb. 19)

VORSICHT:

• Lange Werkstücke müssen stets auf gleicher Höhe mit

der Drehteller-Oberfläche abgestützt werden, um

genaue Schnitte auszuführen und gefährlichen Verlust

der Kontrolle über die Maschine zu vermeiden.

BETRIEB

VORSICHT:

• Lösen Sie den Handgriff vor der Benutzung aus der

Tiefstellung, indem Sie die Griffraste auf die Freigabestellung drehen.

• Vergewissern Sie sich vor dem Einschalten der

Maschine, dass das Sägeblatt nicht das Werkstück

usw. berührt.

•Üben Sie beim Schneiden keinen übermäßigen Druck

auf den Handgriff aus. Zu starker Druck kann zu Über-

lastung des Motors und/oder verminderter Schnittleistung führen. Drücken Sie den Handgriff nur mit soviel

Kraft nieder, wie für reibungslosen Sägebetrieb notwendig ist, ohne einen beträchtlichen Abfall der Säge-

blattdrehzahl zu verursachen.

• Drücken Sie den Handgriff zur Ausführung des Schnitts

sachte nieder. Bei zu großer oder seitlicher Kraftausübung kann das Sägeblatt in Schwingung versetzt werden, wodurch zusätzliche Sägespuren im Werkstück

erzeugt werden und die Schnittgenauigkeit beeinträch-

tigt wird.

1. Kappschnitt (Abb.20)

Sichern Sie das Werkstück. Schalten Sie die Maschine

ein, ohne dass das Sägeblatt Kontakt hat, und warten

Sie, bis es seine volle Drehzahl erreicht, bevor Sie es

absenken. Senken Sie dann den Handgriff zum Schneiden des Werkstücks sachte bis auf die Tiefstellung ab.

Sobald der Schnitt beendet ist, schalten Sie die

Maschine aus und WARTEN, BIS DAS SÄGEBLATT

ZUM VÖLLIGEN STILLSTAND GEKOMMEN IST, bevor

Sie den Sägekopf wieder ganz anheben.

2. Gehrungsschnitt

Siehe den vorhergehenden Abschnitt “Einstellung des

Gehrungswinkels”.

17

Page 18

3. Schneiden von Aluminium-Strangpressprofilen

(Abb.21)

Verwenden Sie zum Einspannen von Aluminium-Strangpressprofilen Distanzblöcke oder Abfallholzstücke, wie in

Abb. 21 gezeigt, um eine Verformung des Aluminiums zu

vermeiden. Verwenden Sie Schneidflüssigkeit zum

Schneiden von Aluminium-Strangpressprofilen, um die

Ablagerung von Aluminium-Rückständen am Sägeblatt

zu verhüten.

VORSICHT:

• Versuchen Sie niemals, dicke oder runde Aluminium-

Strangpressprofile zu schneiden. Dicke AluminiumStrangpressprofile können sich während der Arbeit

lösen, und runde Aluminium-Strangpressprofile lassen

sich mit dieser Maschine nicht einwandfrei einspannen.

4. Zwischenbrett (Abb. 22, 23 u. 24)

Durch die Verwendung eines Zwischenbretts lassen sich

Werkstücke splitterfrei sägen. Die Bohrungen im Gehrungsanschlag dienen als Befestigungshilfe für ein Zwischenbrett.

Die Maße für ein vorgeschlagenes Zwischenbrett sind

aus Abb. 23 ersichtlich.

Schneiden Sie das Holz nach einer Änderung des Gehrungswinkels so, dass es auf den gewählten Winkel ausgerichtet ist. Falls eine Lücke zwischen Sägeblatt,

Zwischenbrett und Werkstück vorhanden ist, verschieben

Sie das Zwischenbrett geringfügig in Pfeilrichtung, bevor

Sie einen erneuten Schnitt ausführen.

VORSICHT:

• Verwenden Sie glatt gehobeltes Holz von gleichmäßi-

ger Dicke als Zwischenbrett.

• Befestigen Sie das Zwischenbrett mit Schrauben am

Gehrungsanschlag. Die Schrauben sind so zu installieren, dass die Schraubenköpfe im Zwischenbrett versenkt sind.

• Drehen Sie den Drehteller bei montiertem Zwischen-

brett nicht mit abgesenktem Handgriff. Anderenfalls

kommt es zu einer Beschädigung des Sägeblatts und/

oder des Zwischenbretts.

HINWEIS:

• Wenn ein Zwischenbrett eingespannt wird, verringert

sich die maximale Schnittkapazität um die Dicke des

Zwischenbretts.

5. Wiederholtes Schneiden auf gleiche Länge

(Abb.25)

Wenn Sie mehrere Werkstücke innerhalb des Bereichs

von 300 bis 400 mm auf die gleiche Länge schneiden, ist

die Verwendung der Anschlagplatte (Sonderzubehör) zu

empfehlen, um rationeller zu arbeiten. Montieren Sie die

Anschlagplatte am Auflagebügel (Sonderzubehör), wie in

Abb. 25 gezeigt.

Richten Sie die Schnittlinie des Werkstücks entweder auf

die linke oder rechte Kante der Nut in der Schlitzplatte

aus, und schieben Sie die Anschlagplatte bündig gegen

das Ende des Werkstücks, während Sie das Werkstück

am Verrutschen hindern. Sichern Sie dann die Anschlagplatte mit der Flügelschraube. Wenn Sie die Anschlagplatte nicht benutzen, lösen Sie die Flügelschraube, um

die Anschlagplatte zur Seite zu schieben.

HINWEIS:

• Der Auflageverlängerungssatz (Sonderzubehör) ermög-

licht das wiederholte Schneiden auf gleiche Längen von

bis zu etwa 2 200 mm.

Tragen der Maschine

Vergewissern Sie sich, dass der Netzstecker abgezogen

ist. Sichern Sie den Drehteller mit dem Griff im rechten

Gehrungswinkel. Senken Sie den Handgriff völlig ab, und

sichern Sie ihn in der Tiefstellung, indem Sie die

Griffraste auf die Verriegelungsstellung drehen. (Abb.

26)

Tragen Sie die Maschine, indem Sie die Grundplatte auf

beiden Seiten halten, wie in der Abbildung gezeigt. Die

Maschine lässt sich bequemer tragen, wenn Auflagebü-

gel, Staubsack usw. entfernt werden. (Abb. 27)

VORSICHT:

• Sichern Sie stets alle beweglichen Teile, bevor Sie die

Maschine tragen.

• Die Griffraste ist nur zum Tragen und zur Lagerung,

nicht für irgendwelche Schneidarbeiten, vorgesehen.

WARTUNG

VORSICHT:

• Denken Sie vor der Durchführung von Überprüfungen

oder Wartungsarbeiten stets daran, die Maschine auszuschalten und vom Stromnetz zu trennen.

WARNUNG:

• Achten Sie stets darauf, dass das Sägeblatt scharf und

sauber ist, um die bestmögliche und sicherste Leistung

zu erzielen.

Einstellen des Schnittwinkels

Diese Maschine wurde werkseitig sorgfältig eingestellt

und justiert, doch grobe Behandlung kann die Justierung

beeinträchtigen. Sollte Ihre Maschine einer Nachjustierung bedürfen, gehen Sie folgendermaßen vor: Lösen

Sie den Spanngriff, mit dem der Drehteller gesicher t

wird. Drehen Sie dann den Drehteller, so dass der Zeiger

auf 0° auf der Gehrungswinkelskala zeigt. Bewegen Sie

dann den Drehteller geringfügig nach links und rechts,

bis er einwandfrei in der 0°-Gehrungswinkelraste sitzt.

(Lassen Sie den Drehteller unverändert, falls der Zeiger

nicht auf 0° zeigt.) Lösen Sie die Sechskantschrauben,

die den Gehrungsanschlag halten, mit dem Steckschlüs-

sel. (Abb. 28)

Senken Sie den Handgriff völlig ab, und sichern Sie ihn in

der Tiefstellung, indem Sie die Griffraste auf die Verriegelungsstellung drehen. Bringen Sie die Seitenfläche

des Sägeblatts mit Hilfe eines Einstelldreiecks, Anschlagwinkels usw. in den rechten Winkel mit der Fläche des

Gehrungsanschlags. Ziehen Sie dann die Sechskantschrauben des Gehrungsanschlags von rechts der Reihe

nach fest. (Abb. 29)

Vergewissern Sie sich, dass der Zeiger an der Anzeigeplatte auf 0° der Gehrungswinkelskala zeigt. Falls der

Zeiger nicht auf 0° zeigt, lösen Sie die Halteschrauben

der Anzeigeplatte, und stellen Sie diese so ein, dass der

Zeiger auf 0° zeigt. (Abb. 30)

18

Page 19

Einstellung für reibungslose Griffbewegung

Die Sechskant-Sicherungsmutter, die das Getriebegehäuse und den Arm hält, wurde werksseitig so eingestellt, dass eine reibungslose Bewegung des Griffs nach

oben und unten gewährleistet ist, um präzises Schneiden

zu garantieren. Lassen Sie diese Mutter unverändert.

Sollte sich die Verbindung von Getriebegehäuse und

Arm lockern, führen Sie die folgende Einstellung durch.

Bewegen Sie den Handgriff nach oben und unten, wäh-

rend Sie die Sechskant-Sicherungsmutter anziehen. Am

besten zieht man die Sechskant-Sicherungsmutter an

dem Punkt an, an dem sich das Gewicht des Motors

bemerkbar macht. Vergewissern Sie sich vor dem Anziehen der Sechskant-Sicherungsmutter, dass der Handgriff

aus jeder Stellung wieder automatisch auf die anfängli-

che Hochstellung zurückkehrt. Falls die SechskantSicherungsmutter zu locker ist, wird die Schnittgenauigkeit beeinträchtigt, und falls sie zu fest ist, lässt sich der

Handgriff nur schwer anheben und absenken. Beachten

Sie, dass es sich um eine selbstsichernde Mutter handelt. Dies ist ein spezieller Typ, der sich bei normalem

Gebrauch nicht lockert. Diese Mutter darf nicht überdreht

oder durch andere Muttertypen ersetzt werden.

(Abb. 31)

Auswechseln der Kohlebürsten

Die Kohlebürsten müssen regelmäßig entfernt und über-

prüft werden. Wenn sie bis zur Verschleißgrenze abgenutzt sind, müssen sie erneuert werden. Halten Sie die

Kohlebürsten stets sauber, damit sie ungehindert in den

Haltern gleiten können. Beide Kohlebürsten sollten

gleichzeitig erneuert werden. Verwenden Sie nur identische Kohlebürsten. (Fig. 32)

Drehen Sie die Bürstenhalterkappen mit einem Schraubendreher heraus. Nehmen Sie die abgenutzten Kohlebürsten heraus, setzen Sie die neuen ein, und drehen

Sie dann die Bürstenhalterkappen wieder ein. (Abb. 33)

Schalten Sie die Maschine nach dem Auswechseln der

Bürsten ein, um die Bürsten bei im Leerlauf laufender

Maschine etwa 10 Minuten lang einzuschleifen. Überprü-

fen Sie dann die Maschine im Betrieb und die Funktion

der elektrischen Bremse, wenn Sie den Ein-Aus-Schalter

loslassen. Falls die elektrische Bremse nicht einwandfrei

funktioniert, lassen Sie sie von Ihrer Makita-Kundendienststelle reparieren.

Nach dem Gebrauch

• Wischen Sie nach dem Gebrauch an der Maschine haftende Späne und Staub mit einem Tuch oder dergleichen ab. Halten Sie die Schutzhaube gemäß den

Anweisungen im vorhergehenden Abschnitt “Schutz-

haube” sauber. Schmieren Sie die Gleitteile der

Maschine mit Öl, um Rostbildung zu verhüten.

Um die SICHERHEIT und ZUVERLÄSSIGKEIT dieses

Produkts zu gewährleisten, sollten Reparaturen und

andere Wartungs- oder Einstellarbeiten nur von MakitaVer tr ag swe rk stätten oder Makita-Kundendienstzentren

unter ausschließlicher Verwendung von Makita-Originalersatzteilen ausgeführ t werden.

Geräusch- und Vibrationsentwicklung

ENG005-1

Die typischen A-bewerteten Geräuschpegel betragen:

Der gewichtete Effektivwert der Beschleunigung beträgt

nicht mehr als 2,5 m/s

Schalldruckpegel: 94 dB (A)

Schalleistungspegel: 107 dB (A)

– Gehörschutz tragen. –

2

.

CE-KONFORMITÄTSERKLÄRUNG

Hiermit erklärt wir unter unserer alleinigen Verantwortung, daß dieses Produkt gemäß den Ratsdirektiven 73/

23/EWG, 89/336/EWG und 98/37/EG mit den folgenden

Normen von Normendokumenten übereinstimmen:

EN61029, EN55014, EN61000.

Yasuhiko Kanzaki

CE 2003

Direktor

ENH003-1

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

19

Page 20

POLSKI

Wyjaśnienia dotyczące urządzenia i jego użycia

1 Zatrzask uchwytu

2Śruba

3 Osłona brzeszczotu

4Podstawa obrotowa

5 Podstawa z nacięciem

6 Obudowa przekładni

7 Nakrętka sześciokątna

8 Śruba regulacyjna

9 Powierzchnia górna podstawy

obrotowej

10 Obwód brzeszczotu

11 Osłona prowadnicy

12 Wskaźnik

13 Sprężyna zatrzasku

14 Podziałka kąta poziomego

15 Uchwyt

16 Spust włacznika

17 Klucz nasadkowy

18 Blokada wałka

19 Obudowa brzeszczotu

20 Strzałka

21 Brzeszczot

22 Wrzeciono

23 Kołnierz wewnętrzny

24 Brzeszczot

25 Kołnierz zewnętrzny

26 Śruba sześciokątna

27 Oznaczenie 25,4 mm

28 Przetyczka

29 Ramię prowadzące

30 Dysza pyłu

31 Torba na pył

32 Zamocowanie

33 Występ

34 Pokrętło imadła

35 Uchwyt

36 Zespół uchwytu

37 Pręt o srednicy 12 mm

38 Imadło poziome

39 Klocek dystansowy

DANE TECHNICZNE

Model LS1440

Średnica tarczy ................................................... 355 mm

Średnica otworu ................................... 25 mm i 25,4 mm

Maks. kąt cięcia w poziomie ...........................................

Maks. wydajność cięcia (wys. x szer.)

0˚ 45˚ (w lewo i w prawo)

122 mmx 152 mm 122 mm x115 mm

Prędkość bez obciążenia (min

Wymiary

(dług. x szer. x wys.) ......... 530 mm x 596 mm x 610 mm

Ciężar netto ............................................................. 34 kg

• Ze względu na ciągle prowadzone prace badawczo-

rozwojowe podane tu dane techniczne mogą ulec

zmianie bez powiadomienia.

• Uwaga: W różnych krajach parametry techniczne

urządzenia mogą różnić się między sobą.

Zasilanie

Urządzenie należy podłączać tylko do źródeł zasilania o

napięciu zgodnym z napięciem podanym na tabliczce

znamionowej. Można je zasilać wyłącznie jednofazowym

prądem zmiennym. Posiada ono podwójną izolację

zgodną z Normą Europejską i dlatego może być również

podłączane do gniazdek bez uziemienia.

W lewo

Kąt cięcia w poziomie

45˚, w prawo — 45˚

—

–

1

) ............................. 3200

40 Aluminiowy kształtownik

41 Drewniana osłona

42 Otwór

43 Obrabiany przedmiot

44 Pomiedzy brzeszczotem,

drewniana osłoną i obrabianym

przedmiotem nie powinno być

przerwy

45 Płytka sprężynująca

46 Śruba

47 Ekierka

48 Śruby

49 Sześciokątna nakrętka

blokująca

50 Ramią

51 Znak limitu

52 Śrubokręt

53 Pokrywa pojemnika na

szczoteczkę

INSTRUKCJE BEZPIECZEŃSTWA

Ostrzeżenie! Używając urządzeń elektrycznych

podstawowe środki ostrożności muszą być zawsze

zachowane, aby zmniejszyć ryzyko ognia, porażenia

prądem i uszkodzenia ciała, włączając poniższe.

Przeczytaj wszystkie podane instrukcje przed próbą

użycia tego produktu i zachowaj je do wglądu.

Dla bezpiecznego użycia:

1. Utrzymuj miejsce pracy w czystości

Zabałaganione miejsca i stoły warsztatowe

sprzyjają wypadkom.

2. Zastanów się nad warunkami pracy

Nie wystawiaj urządzeń elektrycznych na deszcz.

Nie używaj urządzeń elektrycznych w wilgotnych

lub mokrych miejscach. Utrzymuj miejsce pracy

dobrze oświetlone. Nie używaj urządzeń

elektrycznych w obecności łatwopalnych płynów

lub gazów.

3. Chroń się przed porażeniem prądem

Zapobiegaj kontaktom ciała z uziemionymi

powierzchniami (np. rurami, grzejnikami,

kuchenkami, lodówkami).

4. Nie pozwalaj zbliżać się dzieciom

Nie pozwalaj wizytującym osobom dotykać

urządzenia lub przedłużacza. Wszystkie wizytujące

osoby nie powinny zbliżać się do miejsca pracy.

5. Zachowaj nieczynne urządzenia

Nieużywane urządzenia powinny być

przechowywane w suchych, wysokich lub

zamykanych miejscach tak, aby były niedostępne

dla dzieci.

6. Nie przeciążaj urządzenia

Wykona ono pracę lepiej i bezpieczniej, pracując w

sposób, dla którego zostało ono zaprojektowane.

7. Używaj poprawnego urządzenia

Nie nadużywaj małych lub dodatkowych urządzeń

do wykonania pracy urządzeń do dużej pracy. Nie

używaj urządzeń do celów, do których nie zostały

przeznaczone; na przykład, nie używaj piły

tarczowej do przecinania gałęzi lub kłód drzew.

20

Page 21

8. Ubierz się odpowiednio

Nie noś luźnych ubrań lub biżuterii. Mogą one

zostać zahaczone o ruchome części. Gumowe

rękawiczki i przeciwpoślizgowe buty są wskazane

przy pracy na dworze. Zaleca się noszenie ochrony

na głowę przytrzymującej długie włosy.

9. Użyj okularów ochronnych i ochraniaczy uszu

Użyj masek na twarz lub masek przeciwpyłowych

jeżeli czynność cięcia wytwarza pyły.

10. Podłącz urządzenie usuwające pył

Jeżeli urządzenia posiadają podłączenia do

urządzeń do usuwania i składowania pyłu, upewnij

się, że są one poprawnie podłączone i użyte.

11. Uważaj na przewód sieciowy

Nigdy nie noś urządzenia trzymając za przewód i

nie odłączaj go od gniazda przez pociągnięcie

przewodu. Chroń przewód przed ciepłem, olejem i

ostrymi krawędziami.

12. Pewnie mocuj obrabiane elementy

Użyj ścisków lub imadła do zamocowania

obrabianych elementów. Jest to bezpieczniejsze niż

używanie rąk, a dodatkowo zwalnia obie ręce do

obsługiwania urządzenia.

13. Używając urządzenie, nie oddalaj go zbytnio od

siebie

Cały czas trzymaj dobrze ustawione nogi i

równowagę.

14. Pamiętaj o dobrej konserwacji urządzenia

Utrzymuj urządzenie ostre i czyste dla jego lepszego

i bezpieczniejszego działania. Wykonaj podane

instrukcje w celu smarowania lub wymiany

elementów wyposażenia. Regularnie sprawdzaj

przewody urządzenia, i jeżeli są uszkodzone, oddaj

je do naprawy do autoryzowanego serwisu.

Regularnie sprawdzaj przewody przedłużające i

wymień je, jeżeli są uszkodzone. Utrzymuj uchwyty

suche, czyste i nie zabrudzone olejem lub smarem.

15. Odłącz urządzenia

Przed konserwacją urządzenia lub zmianą

wyposażenia takiego jak tarcze, końcówki robocze i

noże, gdy nie jest ono używane.

16. Wyjmij klucze regulacyjne

Nabierz zwyczaju sprawdzania czy klucze

regulacyjne są usunięte z urządzenia przed jego

użyciem.

17. Unikaj przypadkowych uruchomień

Nie noś podłączonego urządzenia z palcem na

włączniku. Upewnij się, że urządzenie jest

wyłączone, gdy je podłączasz do zasilania.

18. Zastosuj przedłużacz używając urządzenia na

dworze

Gdy urządzenie używane jest na dworze, stosuj

tylko przedłużacze przeznaczone i oznaczone do

pracy na dworze.

19. Bądź uważny

Patrz co robisz. Bądź rozsądny. Nie używaj

urządzenia, gdy jesteś zmęczony.

20. Sprawdzaj uszkodzone części

Przed dalszym użyciem urządzenia, osłona lub inne

części, które są uszkodzone, muszą być uważnie

sprawdzone, aby upewnić się, że będą poprawnie

działać i wykonywać przeznaczone im funkcje.

Sprawdzaj ustawienia ruchomych części, oprawy

ruchomych części, pęknięcia części, zamocowania,

i jakiekolwiek inne warunki, które mogą wpływać na

działanie. Osłona lub inne części, które są

uszkodzone, powinny być naprawione lub

wymienione przez autoryzowany serwis, jeżeli w

instrukcji nie podano inaczej. Uszkodzone

przełączniki powinny być wymienione przez

autoryzowany serwis. Nie używaj urządzenia, jeżeli

włącznik nie może go włączyć lub wyłączyć.

21. Ostrzeżenie

Użycie jakiegokolwiek innego wyposażenia lub

części dodatkowych innych niż zalecane w tej

instrukcji obsługi lub katalogu, może stworzyć

ryzyko uszkodzenia ciała.

22. Naprawy urządzenia powinny być wykonywane

tylko przez specjalistę

To urządzenie jest wykonane zgodnie z

odpowiednimi zasadami bezpieczeństwa. Naprawa

urządzeń elektrycznych może być wykonana

wyłącznie przez specjalistę, gdyż w przeciwnym

wypadku może ono stanowić zagrożenie dla

użytkownika.

DODATKOWE ZASADY BEZPIECZEŃSTWA

DOTYCZĄCE NARZĘDZIA

1. Zakładaj okulary ochronne.

2. Nie zbliżaj rąk do obracającej się tarczy. Staraj

się nie dotykać ostrzy na krawędzi tarczy. Można się

bowiem poważnie skaleczyć.

3. Nie uruchamiaj piły bez zamocowanych osłon.

Każdorazowo przed użyciem sprawdź, czy

osłona prawidłowo się zamyka. Nie uruchamiaj

pilarki, jeżeli osłona nie przesuwa się swobodnie

i zamyka się z opóźnieniem. Nie wolno w

żadnym wypadku przywiązywać osłony lub w

inny sposób unieruchamiać jej w pozycji

otwartej.

4. Nie wykonuj żadnych operacji, trzymając

obrabiany element w ręce.

5. Nie zbliżaj rąk do tarczy.

6. Przed usunięciem przeciętego elementu lub

zmianą ustawień wyłącz narzędzie i odczekaj, aż

tarcza zatrzyma się.

7. Przed przystąpieniem do wymiany tarczy lub

czynności serwisowych wyciągnij wtyczkę z

gniazdka

8. Nie używaj narzędzia w obecności palnych cieczy

lub gazów.

9. Przed przystąpieniem do pracy sprawdź dokładnie,

czy tarcza nie jest popękana lub uszkodzona.

Natychmiast wymień popękaną lub uszkodzoną

tarczę.

10. Używaj wyłącznie kołnierzy przeznaczonych do

tego urządzenia.

11. Uważaj, aby nie uszkodzić wałka, kołnierzy

(szczególnie powierzchni mocujących) ani śruby.

Uszkodzenie tych części może być przyczyną

pękania tarczy.

12. Upewnij się, czy podstawa obrotowa jest dobrze

zabezpieczona i nie będzie przesuwać podczas

pracy.

21

Page 22

13. Dla swojego bezpieczeństwa, przed przystąpieniem