Page 1

T

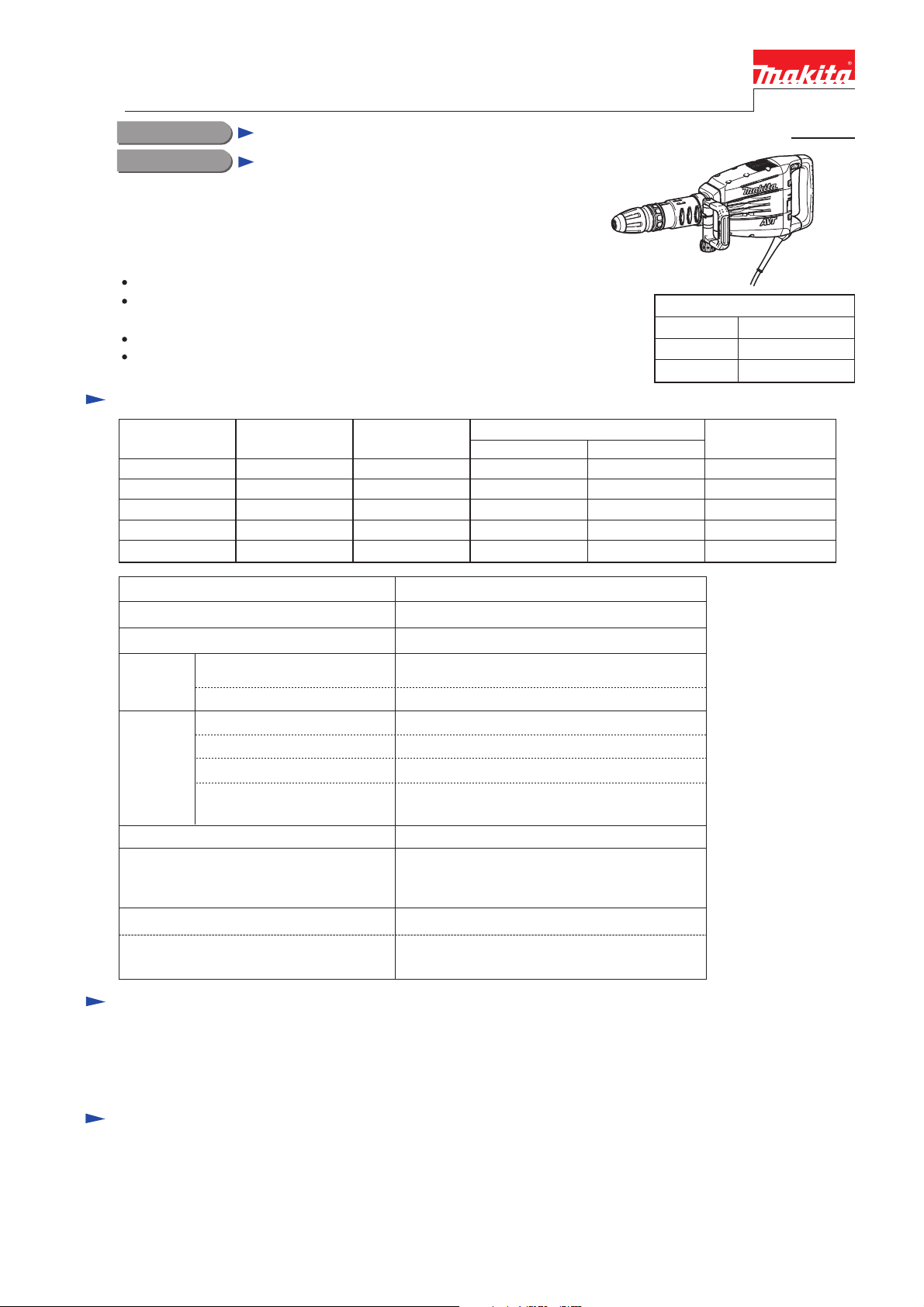

ECHNICAL INFORMATION

Model No.

Description

HM1214C

Demolition Hammer

CONCEPT AND MAIN APPLICATIONS

Model HM1214C is a 10kg-class demolition hammer adapted for

SDS-MAX bits.

The main features are as follows:

AVT (Active dynamic vibration absorber)

for reduced vibration during chipping

Suppression of motor speed during no-load

for reduced vibration when idling

In-line tool design optimum for downward vertical applications

High work efficiency

Specification

Dimensions: mm (")

Length (L)

Width (W)

Height (H)

PRODUCT

P 1/ 20

700 (27-1/2)

129 (5-1/8)

265 (10-3/8)

Voltage (V) Cycle (Hz)

110

120

220

230

240

Impacts per min: min-1=ipm

Shank type Adapted for SDS-MAX bits

Shank diameter: mm (")

Vibration

absorption

Electronic

control

Double insulation

Power supply cord: m (ft)

Net weight: kg (lbs)

AVT (Active dynamic

vibration absorber)

Vibration absorbing handle

Variable speed control by dial

Soft start

Constant speed control

Suppression of motor speed

during no-load

Current (A)

15

14

7.8

7.8

7.8

50/60

50/60

50/60

50/60

50/60

Europe, Korea, Cyprus: 4.0 (13.1)

Other countries: 5.0 (16.4)

Continuous Rating (W)

Input Output

1,510

--1,510

1,510

1,510

950 - 1,900

18 (11/16)

Yes

No

Yes

Yes

Yes

Yes

Yes

Brazil: 2.0 (6.6)

11.7 (25.8)

700

700

750

750

750

Max. Output (W)

1,600

1,600

1,800

1,800

1,800

Weight according to

EPTA-Procedure 01/2003: kg (lbs)

12.3 (27.1)

Standard equipment

Side handle (D-shaped) ........... 1

Bit grease .................................. 1

Bull point .................................. 1

Note: The standard equipment for the tool shown above may vary by country.

Plastic carrying ........................ 1

Cleaning cloth .......................... 1

Optional accessories

Bull points

Cold chisels

Scaling chisels

Scaling chisel (for Tile)

Grooving chisel

Clay spade

Bushing tool

Rammer

Grease vessel (containing 30g hammer grease)

Plastic carrying case

Safety goggles

Hammer service kit

Page 2

P 2/ 20

Repair

CAUTION: Remove the hammer bit from the machine and disconnect the Machine from

power source for safety before repair/ maintenance in accordance with the

instruction manual!

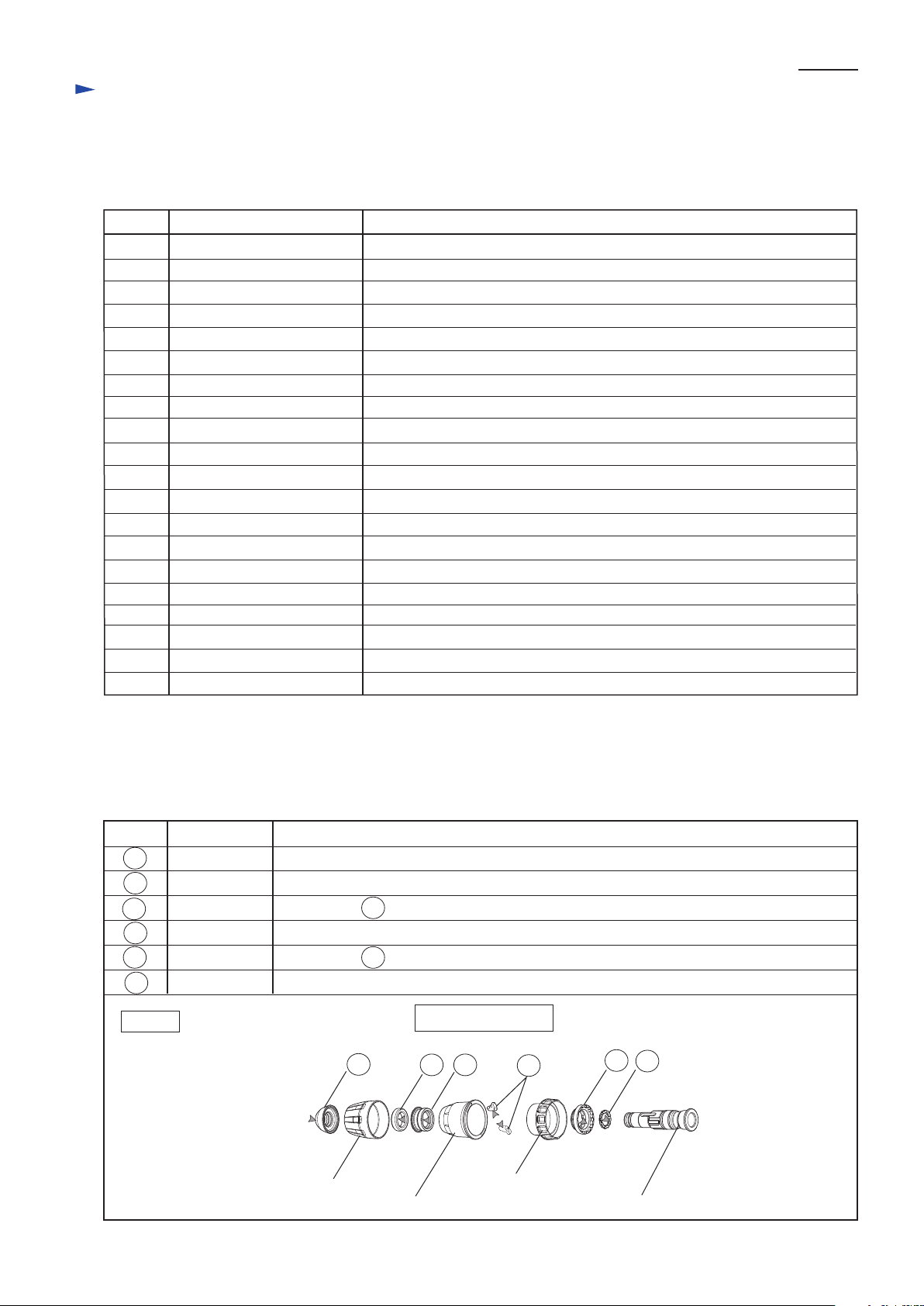

[1] NECESSARY REPAIRING TOOLS

[2] LUBRICATIONS

[2] - 1 Tool holder section

Fig. 1A

Code No. Description Use for

1R003 Retaining ring S pliers ST-2N Removing Ring spring 26

Pressing down Slide sleeve for easy removing of Ring spring 43

1R023

1R024

Pipe Ring (for Arbor press)

Press Tool (for Arbor press)

Assembling Helical gear 521R031

Bearing setting pipe 28-20.2

Removing Counter shaft1R045

Gear extractor (large)

Attaching to 1R045, when removing Counter shaft1R346

Center Attachment

Supporting Crank shaft for assembling Helical gear 521R165

Gear extractor (large)

Fitting Fluoride ring 28 on Impact bolt1R214

Taper sleeve

Removing / Assembling Crank shaft1R217

Ring 22

Removing M4 Hex socket head bolts1R228

1/4” Hex Shank bit for M4

Removing M6 Hex socket head bolts1R230

1/4” Hex Shank bit for M6

Removing M8 Hex socket head bolts1R231

1/4” Hex Shank bit for M8

Removing M8 Hex socket head bolts1R246

Round Bar for Arbor 18-100

Removing Retaining ring S-8 from Counter shaft1R291 Retaining ring S & R pliers

Disassembling AVT mechanism1R306

Ring spring removing Jig

Pressing down Flat washer 30 for easy removing Ring spring 261R363 Ring spring removing tool

Removing Ball bearing 6203LLB1R247

Round Bar for Arbor 20-100

Separating Cylinder 40 and Motor housing from Crank housing1R263

Bearing Extractor

Removing Ball bearing 6000DDW from Commutator end of Armature1R269

Bearing Extractor (small)

Removing Ball bearing

1R212 Tip for Retaining Ring Pliers Attaching to 1R003, when removing Ring spring 26

Item No.

Apply Makita grease N.No.2 to the following portions designated with the gray triangle to protect parts

and product from unusual abrasion.

Description Portion to lubricate

Chuck cover

Tool holder section

1

13

14

5

6

8

Release cover

Change ring cover

Tool holder

1 Tool holder cap

Rubber ring 30

Chuck ring

Change ring

Rock ring

Tool retainer

Rip portion

Inside where Tool holder contacts

Inside where 8 Tool retainers contact

Inside which 14 Lock ring accepts

Its inside where Tool holder contacts

The belly portion where Hammer bit contacts

5

6

8

13

14

Page 3

P 3/ 20

Repair

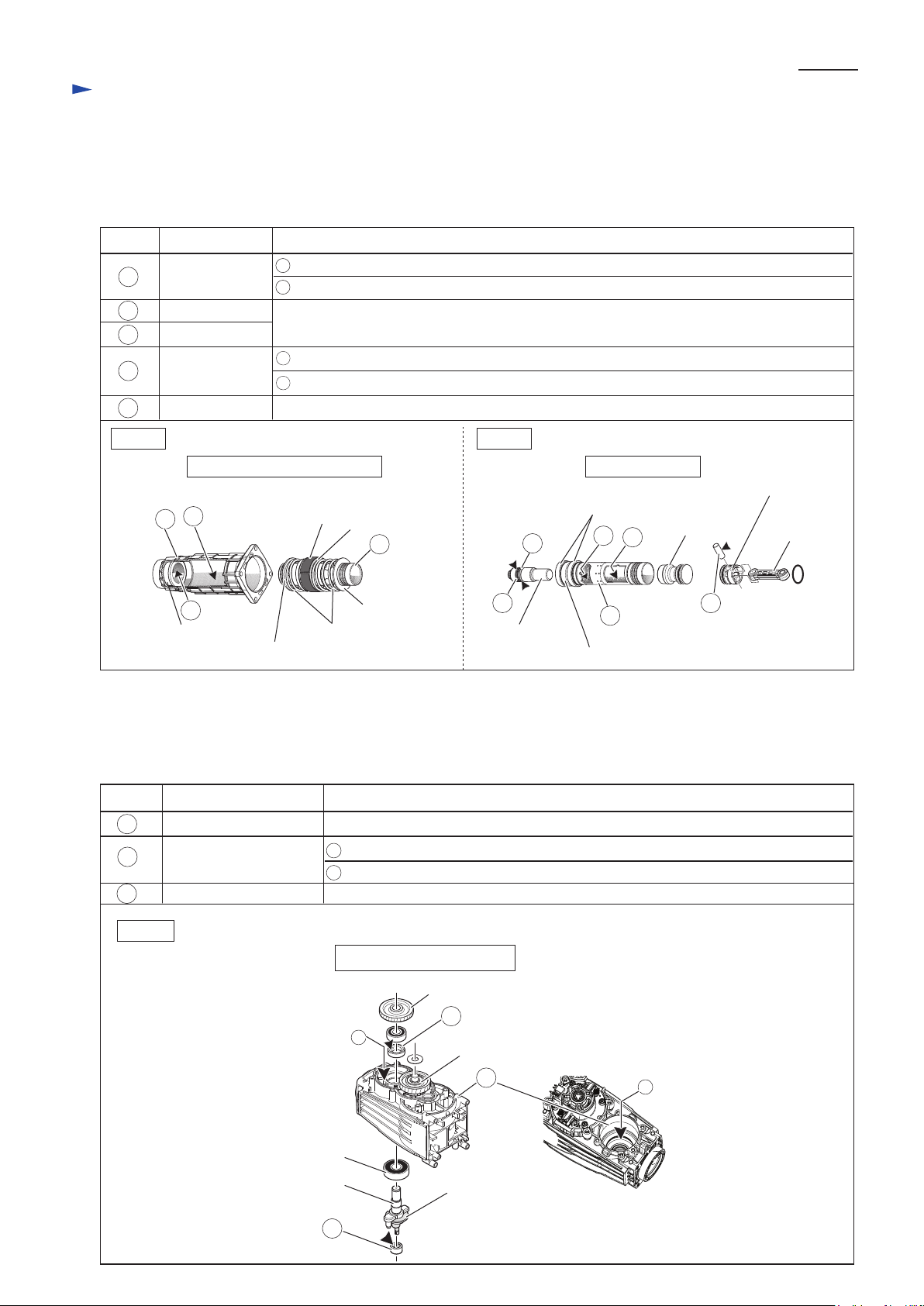

[2] LUBRICATIONS

[2]-2 Hammer section

Apply Makita grease R.No.00 to the following portions designated with the black triangle to protect parts

and product from unusual abrasion.

Apply Makita grease N.No.1 and Makita grease R.No.00 to the following portions designated with the black triangle to

protect parts and product from unusual abrasion.

Fig. 1C

Item No. Description Portion to lubricate

Rubber ring 24

Piston

Connecting

rod

Shoulder sleeve

Impact bolt

Cylinder section

Striker

24

25

35

25 Fluoride ring 28

35 Cylinder 40

24 X ring 21

Out side for smooth moving of Impact bolt in Tool holder

a

b Apply approx. 10g grease for smooth moving of Striker and Piston

a Apply approx. 10g grease for smooth moving of Striker and Impact bolt

b

44

44 Pin 12

Drum portion for smooth moving of Connecting rod

18

Barrel complete

a Inside of Tool holder guide which accepts Tool holder

b Inside of Barrel complete for smooth moving of Weight guide of AVT.

[2]-3 Gear and Crank section

Fig. 1B

Barrel and AVT mechanism

18

a

Tool holder guide

(factory-assembled)

b

Counter weight

Compression spring 58

Cylinder guide

Slide sleeve

Weight guide, covering

Counter weight

35

Gear complete 34-48

Ball bearing 6304LLU

Crank shaft

65 Needle bearing 1613 Needle portion where Counter shaft is accepted

Helical gear 52

55

61

Item No. Description Portion to lubricate

55 Oil seal 20 Lip portion

approx. 50g Makita grease N.No.1

a little of Makita grease R No. 00

a little of Makita grease R No. 00

approx. 60g Makita grease R No. 00

Crank housing complete

61

Counter shaft

65

a

b

a Gear room for smooth engaging of Gears

b Crank room

Gear and Crank section

Fig. 1D

Page 4

P 4/ 20

Repair

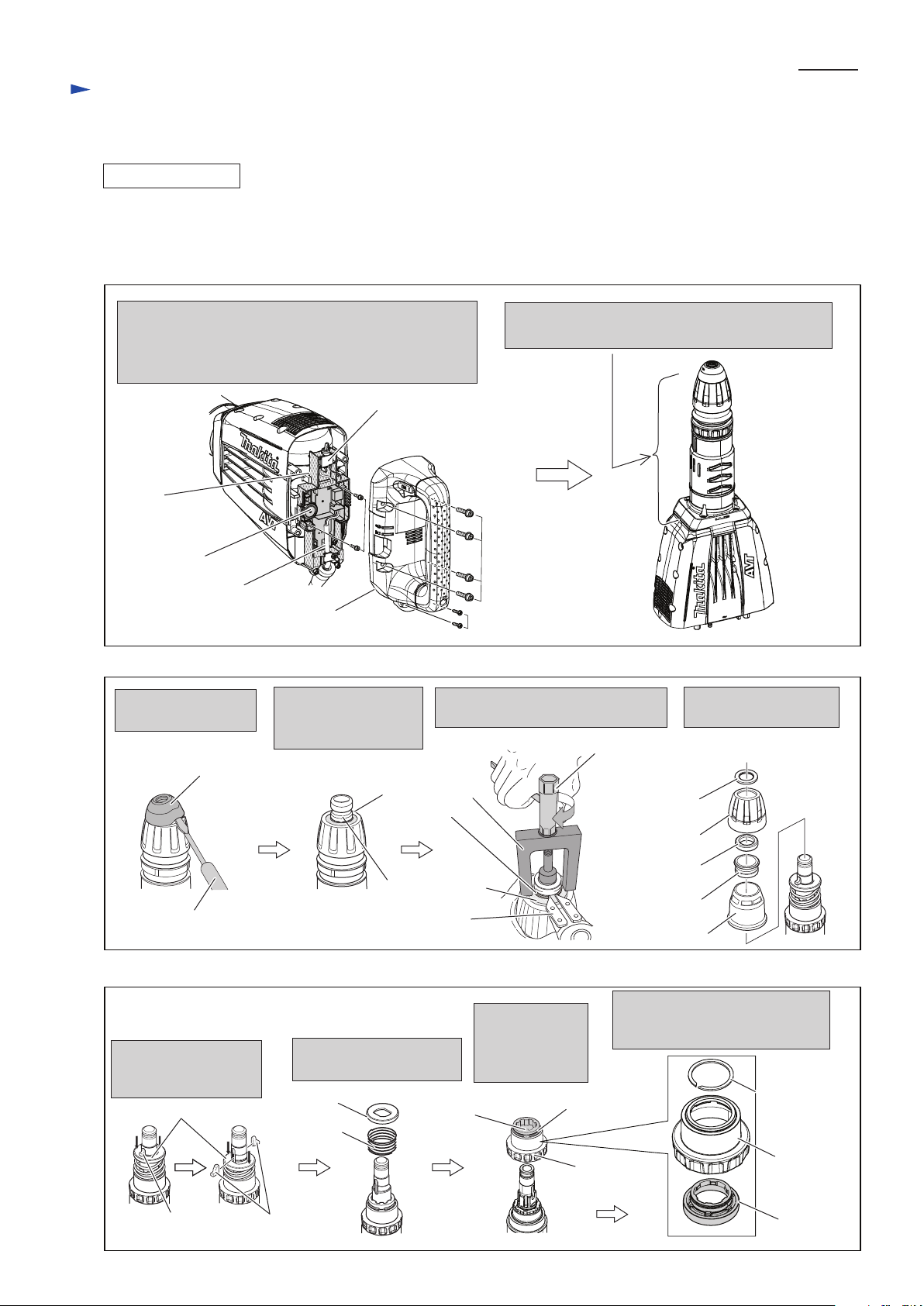

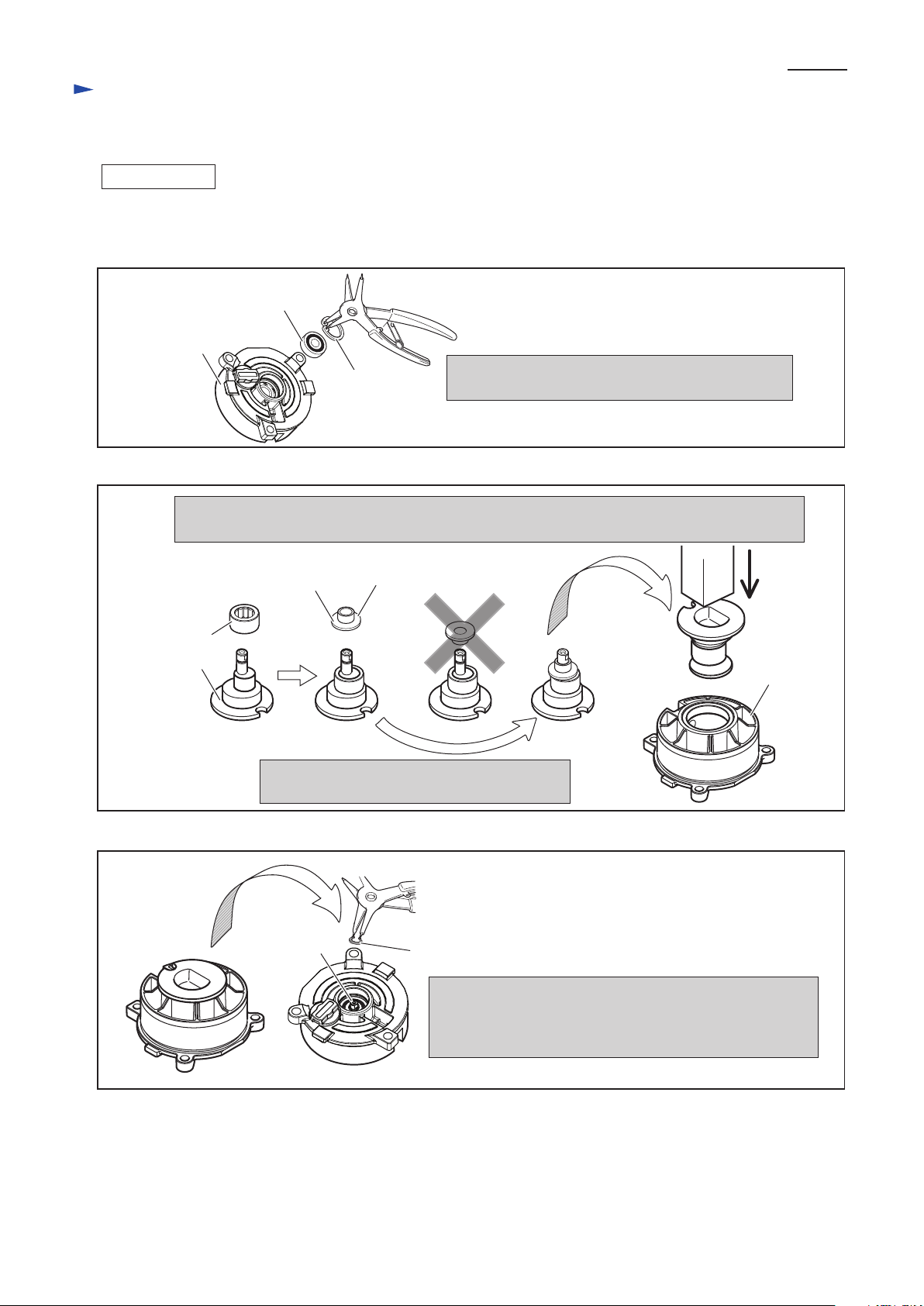

[3] DISASSEMBLY/ASSEMBLY

[3]-1. Chuck section

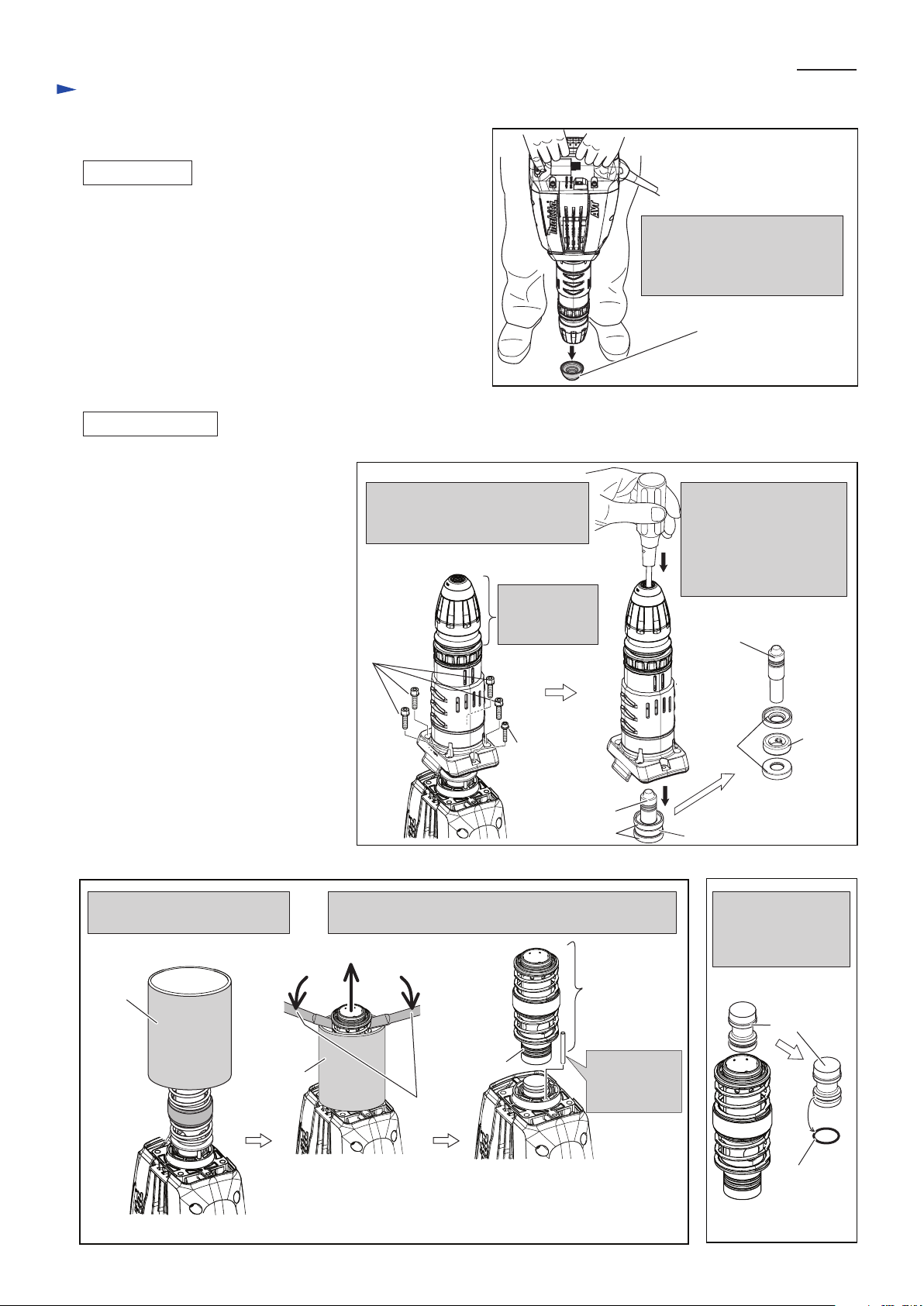

DISASSEMBLING

Controller

cover

Handle section

Tool holder cap

Ring

spring 26

Flat washer 30

Pressing down Flat Washer 30 with

1R363, remove Ring spring 26.

1R363

Socket

Wrench 13

Chuck cover

Release cover

slotted head screwdriver

You can stand the Machine for easy repairing

of these sections.

Remove Tool holder

cap.

Ring spring 26, Flat

washer 30 and Tool

holder come into sight.

Separating Handle section, remove Controller cover by

disconnecting Controller’s connector from Brush holder

unit. Electrical parts (Switch, Controller, Power supply

cord) can be removed as a unit.

M6x30 Hex

socket head

bolt (4pcs.)

4x18 Tapping

Screw (2pcs.)

Controller

Switch

Remove Handle section and Controller cover so that you can stand the machine for easy repairing of the section except

Motor and Crank section. See Fig. 2.

Chuck section can be disassembled as illustrated in Figs. 3 and 4.

Power supply cord

Fig. 2

Fig. 3

Fig. 4

Flat washer 30

Rubber ring 30

Chuck ring

1R212

The following parts can

be removed.

Tool retainer

Spring guide

Tool retainer

Remove Tool retainer,

pressing down Spring

guide.

Remove Spring guide and

Compression spring 56.

Remove Change

ring cover.

Change ring will

come with it.

Spring guide

Compression

spring 56

Change

ring

Retaining ring

WR-45

Retaining ring

WR-45

Change

ring cover

Change

ring cover

Change

ring

Remove Retaining ring WR-45.

Change ring can be separated

from Change ring cover.

Page 5

P 5/ 20

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-1. Chuck section

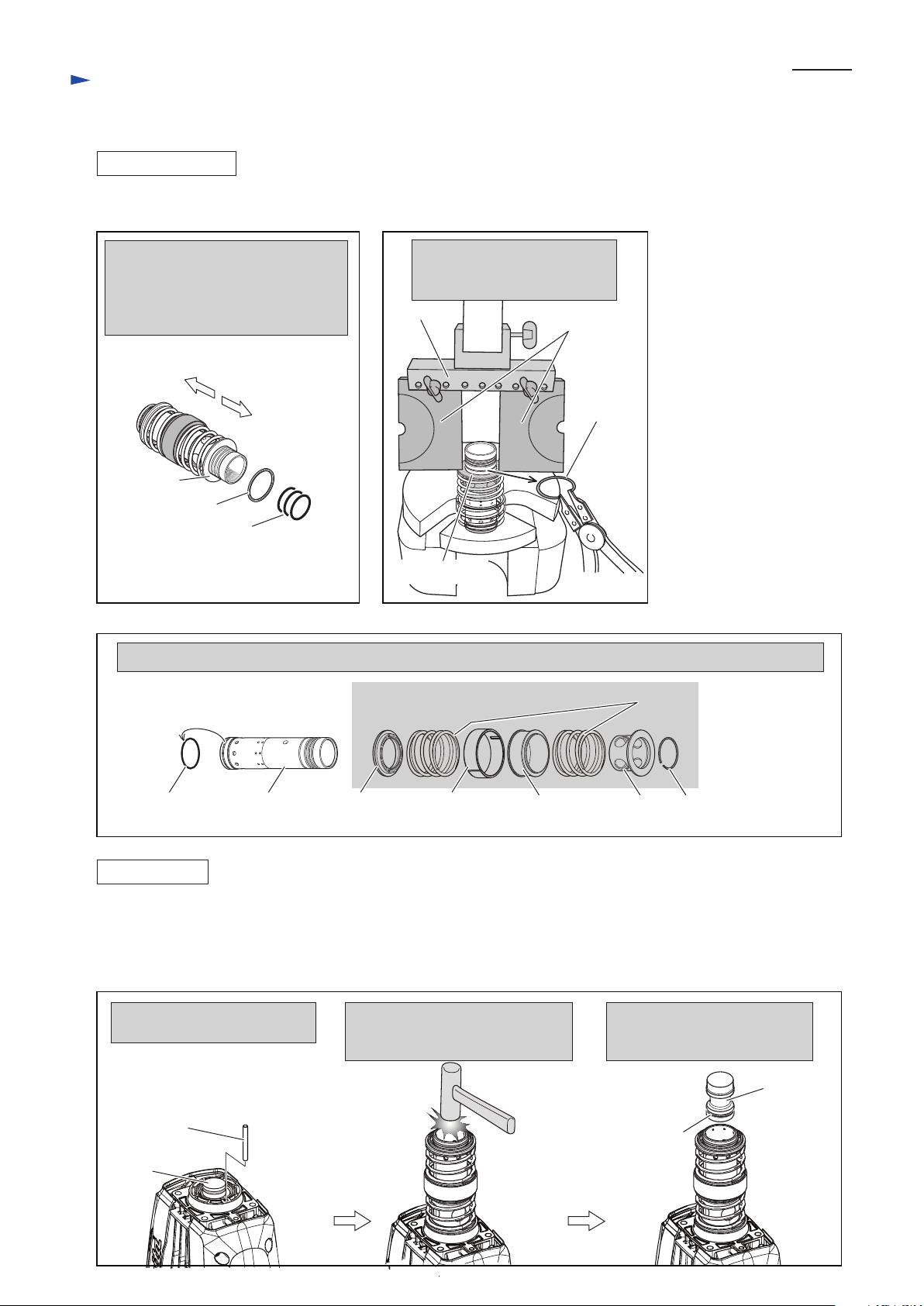

[3]-2. Barrel section

DISASSEMBLING

ASSEMBLING

Fig. 5

Fig. 6

(1) Do the reverse step of Disassembly. Refer to Figs. 4and 3.

However, assemble Handle section before mounting

Tool holder cap.

(2) Assemble Tool holder cap as illustrated in Fig.5.

Put Tool holder cap on ground,

and push Tool holder to

Tool holder cap while making

use of the machine weight.

Tool holder cap

(1) Remove Handle section and Controller

cover to hold the machine upright.

(Fig. 2)

(2) Separate Barrel section from Crank

housing complete, and remove Impact

bolt from Barrel section. (Fig. 6)

(3) Disassemble Cylinder and Striker as

illustrated in Figs. 7 and 8.

M8x30 Hex

socket head

bolt (4pcs.)

No need to

disassemble

Chuck section.

Push the removed Barrel

section with screwdriver

inserted from Tool holder

cap. Impact bolt can be

removed from Barrel

section.

Separate Barrel, Barrel cover and

Chuck section from Crank housing

complete as illustrated below.

M6x30 H.S

head bolt

with GM

Impact bolt

Rubber ring 24

Impact bolt

Shoulder

sleeve

Rubber

ring 24

Shoulder sleeve

1R023

Note: Even after removing Cylinder 40, do not lay Crank housing

complete,

Pin 6 (a component of AVT) can easily fall out of Crank

housing complete.

1R023

Striker

Take out Striker from

Cylinder 40, and

Remove O ring 31.5

from Striker.

O ring 31.5

1R263

Cylinder 40

Pull off Pin 6

after removing

Cylinder.

Put 1R023 onto Crank housing

as illustrated below.

Remove Cylinder 40 and Pin 6, as illustrated below.

The component parts of AVT come with Cylinder 40.

Fig. 7

Fig. 8

Components

of AVT

Page 6

P 6/ 20

Repair

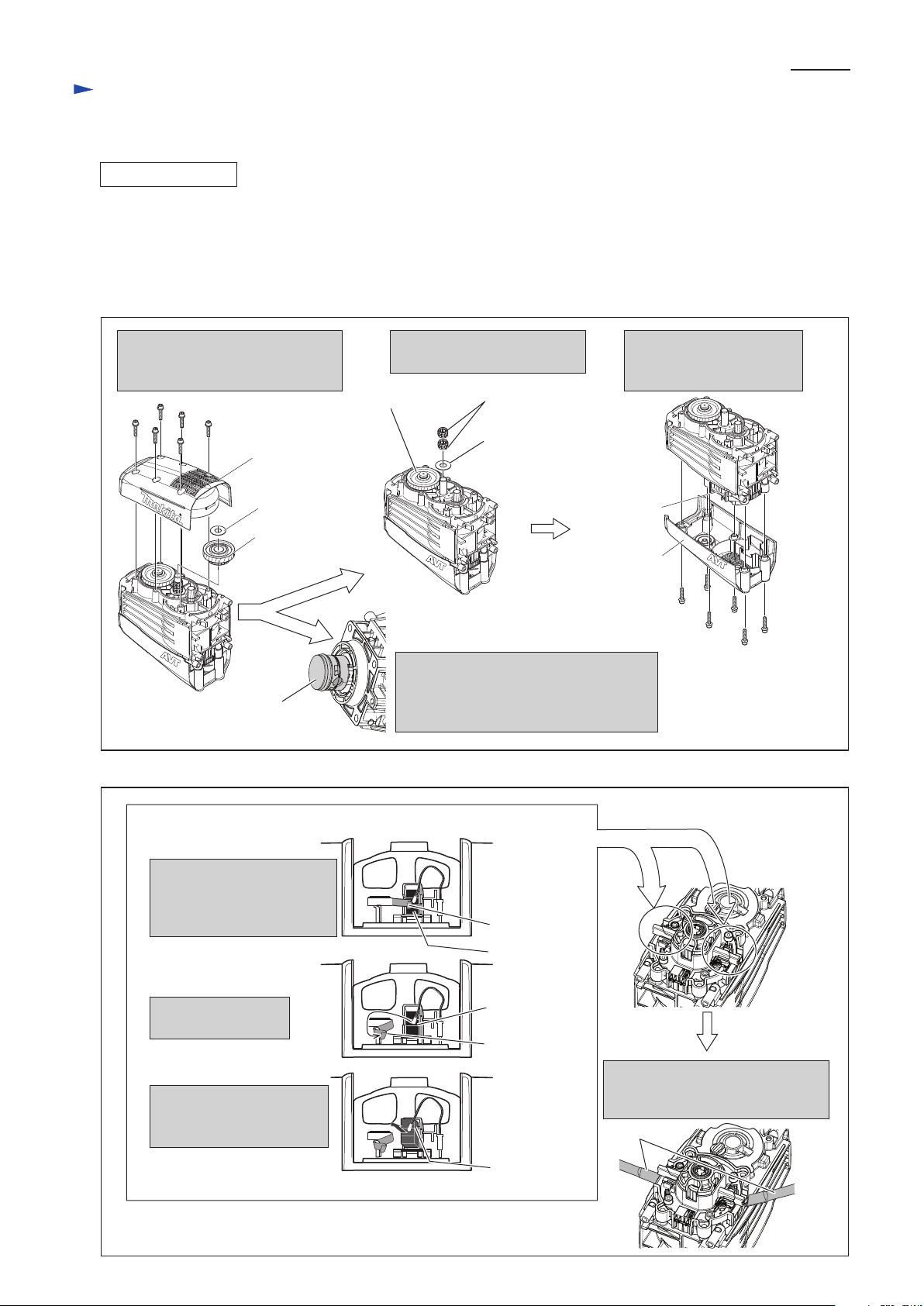

[3] DISASSEMBLY/ASSEMBLY

[3]-2. Barrel section (cont.)

DISASSEMBLING

ASSEMBLING

Crank housing side

Ring 45

O ring 36 (3pcs.)

Slide sleeve

Compression spring 58

Tool holder side

Remove O ring 36 and Ring 45 from

Crank housing side of Cylinder 40 as

illustrated below.

Ring spring 43 still remains on the

Cylinder as a stopper for Slide sleeve.

1R024

or

1R356

Fig. 9 Fig. 10

Fig. 11

O Ring 41

After removing Ring spring 43, the component parts of AVT are removed from Cylinder 40 as illustrated below.

Cylinder 40 Cylinder

guide

Weight

guide

Counter

weight

1R306

Pressing down Slide sleeve as

illustrated below, remove Ring

spring 43.

Ring

spring 43

Slide

sleeve

Ring spring 43

Component parts of AVT

Slide sleeve

(4) The components of AVT can be removed from Cylinder 40 (Figs. 9

(1) Assemble O ring 41 to Cylinder 40. And assemble the component parts of AVT. (Fig. 11)

(2) Secure the component parts of AVT with Ring spring 43. (Fig. 10)

(3) Assemble Ring 45 and 3 pcs. of O ring 36 to Cylinder 40. (Fig. 9) The assembling of Cylinder section is finished.

And mount it to Crank housing as illustrated in Fig. 12.

Pin 6

Piston

Do not forget to assemble Pin 6

for AVT mechanism.

Aligning Cylinder hole to Piston,

insert Cylinder into Crank housing

complete by striking.

O ring 31.5

Facing O Ring 31.5 assembled

side to Crank housing complete,

insert Striker into Cylinder 40.

Striker

Fig. 12

Page 7

P 7/ 20

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-2. Barrel Section (cont.)

ASSEMBLING

X ring 21

O ring 23

Fluoride ring 28

(the worn one)

Impact bolt

In the following cases all the Rings on

Impact bolt have to be replaced.

* When carbon brush is replaced.

* O ring 23 (orange) shows hrough

the worn Fluoride ring 28.

Taper sleeve

(No.1R214)

Correction

Insert Impact bolt from

the HR5001C side of

the Taper sleeve. And

keep it aprox. 60 sec. in

the Taper sleeve.

Impact bolt

Assemble of Rings to Impact bolt

Before Correction:

Rings' edges are protruding from the top edge

of the groove on Impact bolt.

groove on Impact bolt

Fluoride ring 28

X ring 21

O ring 23

After Correction:

Rings' edges are positioned under the top

edge of the groove on Impact bolt.

Corrected

Fig. 13

(4) If the wearing away on Fluoride ring 28 is recognized in the step of Fig. 6, all the Rings on Impact bolt have to be

replaced as illustrated in Fig. 13.

1. Insert Impact bolt into

Tool holder mounted

in Barrel complete

2. Put Shoulder sleeves and

Rubber ring 24 onto the

Cylinder 40.

Shoulder sleeve

Cylinder 40 fits to this Concave.

3. Assemble Barrel complete

to Cylinder 40 while fitting

Tool holder to Shoulder

sleeve’s concave.

Tool holder in Barrel complete,

fits to this Concave.

The tail of Impact bolt is

passed through these holes.

Rubber ring 24

Shoulder sleeve

Cylinder 40

Fig. 14

(4) Assemble Barrel complete to Cylinder 40 as illustrated in Fig. 14.

Impact bolt

Barrel

complete

(5) Secure the Barrel complete with four M8x30 Hex socket head bolts and one M6x30 Hex socket head bolt

together with Barrel cover. Refer to the left illustration in Fig. 6.

Tool holder

Cylinder 40

Page 8

P 8/ 20

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-3. Tool holder section

DISASSEMBLING

ASSEMBLING

(1) Disassemble Chuck section as illustrated in Figs. 3 and 4.

(2) Disassemble Tool holder as illustrated in Fig. 15.

M8x30 Hex

socket head

bolt

Separate Barrel section from Crank housing complete.

And pull off Barrel section from Barrel cover.

Removing Ring spring 35, disassemble Tool holder

by striking it with plastic hammer.

M8x30 Hex

socket head

bolt

Barrel cover

Ring spring 35

M6x30 H.

s head bolt

with GM

Fig. 15

Tool holder

O ring 35.5

Barrel complete has to be assembled so that the notch is located on the opposite side of M6 bolt hole. (Fig. 16)

Rubber ring 39

Flat washer 39

Fig. 16

Hole for M6 Bolt bored on

Crank housing complete

Crank housing complete

Barrel complete

Notch of Barrel

complete

Page 9

P 9/ 20

Repair

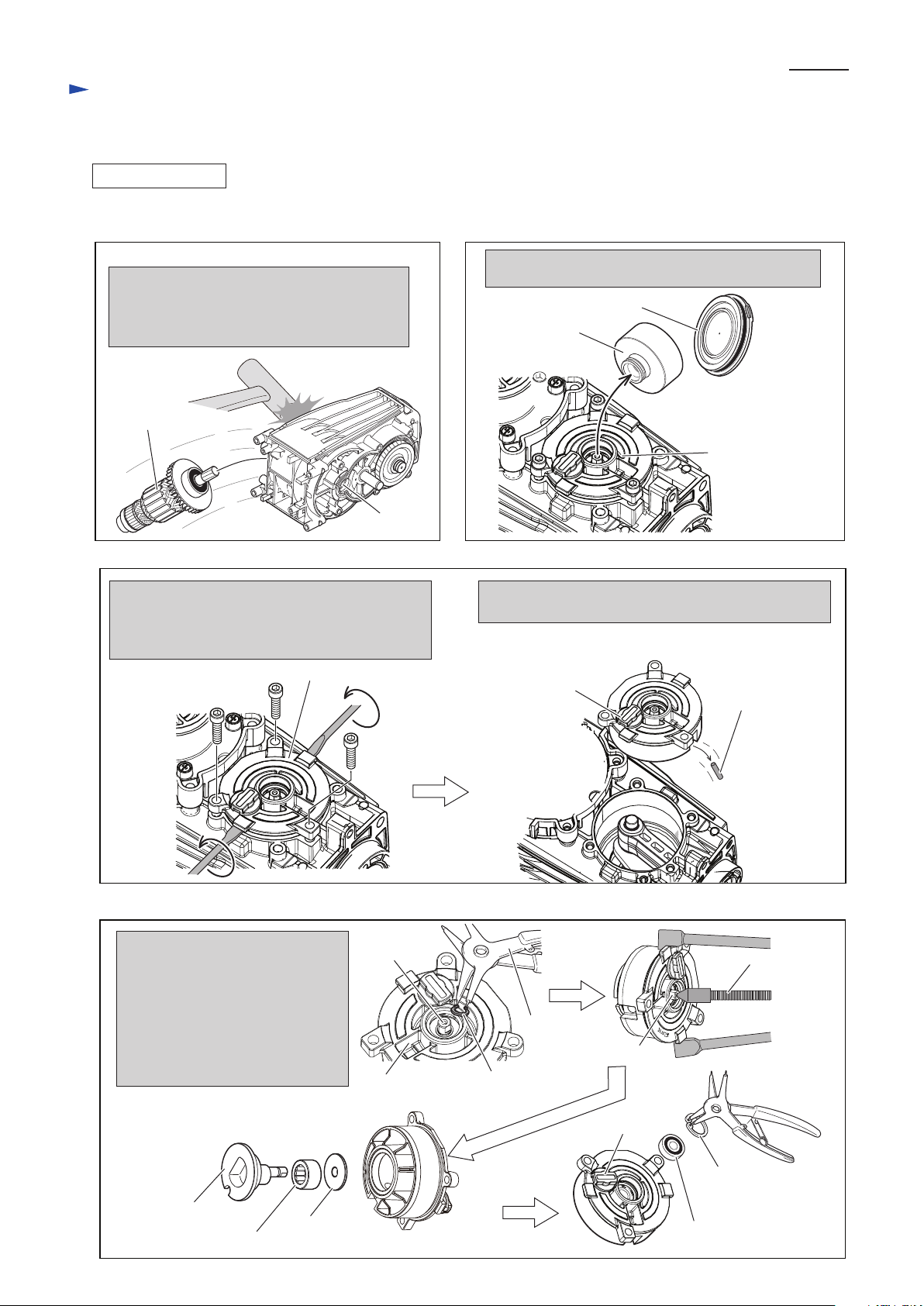

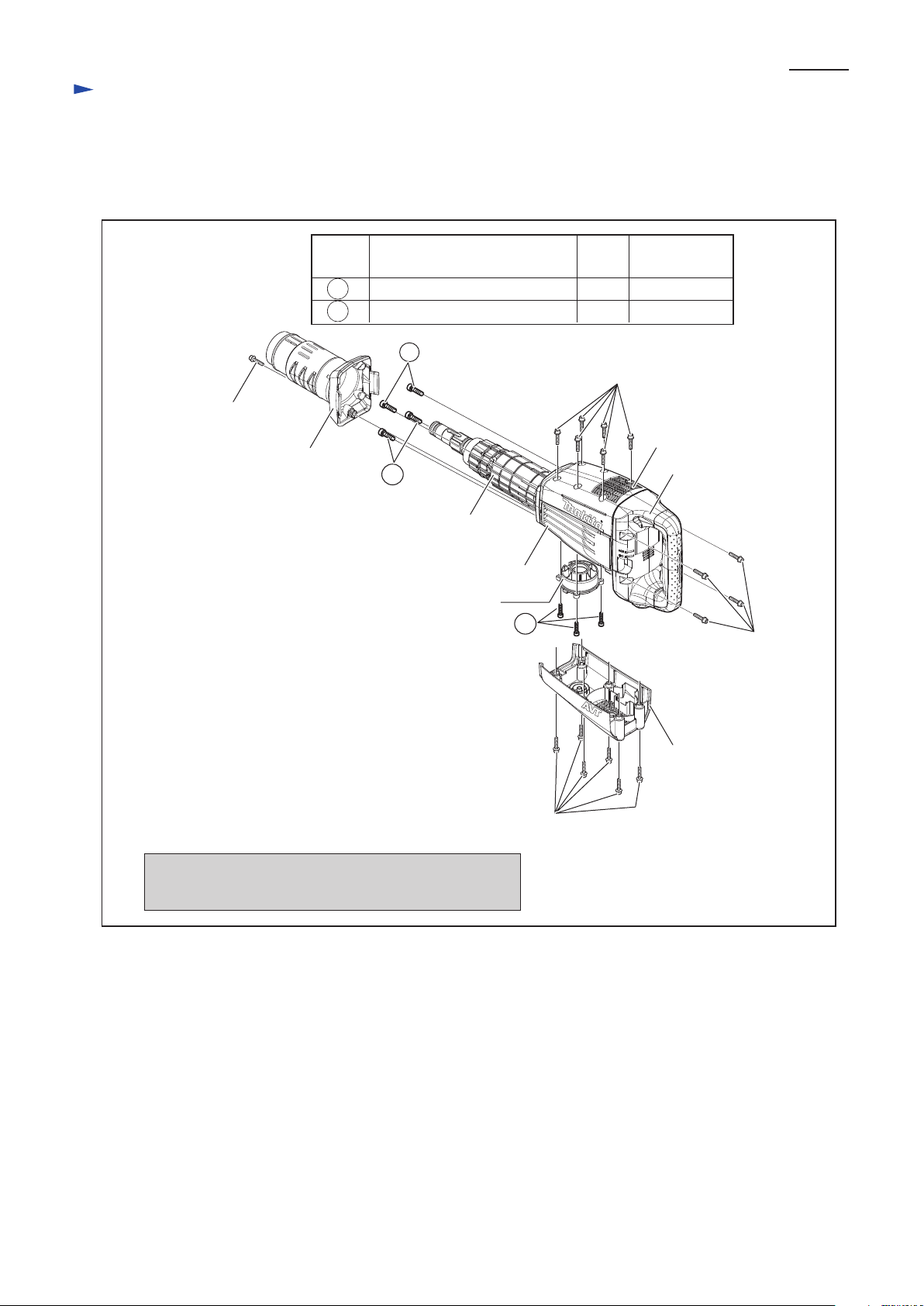

[3] DISASSEMBLY/ASSEMBLY

[3]-4. Bearing box section, Piston, Crank section

DISASSEMBLING

(1) Remove Handle section and Controller cover to hold the machine upright. (Fig. 2)

(2) Separate Barrel section from Crank housing complete (the left illustration in Fig. 6)

(3) Disassemble Cylinder section (Fig. 7)

(4) For repairing Piston & Crank section, Motor section has to be separated from Crank housing complete.

Separate Motor housing from Crank housing complete in order of Figs. 17 and 18.

M6x30 Hex socket

head bolt (6pcs.)

M6x30 Hex socket

head bolt (6pcs.)

Gear cover

Disassemble Gear cover, and then,

remove Flat washer 14 and Gear

complete 34-48.

Disassemble Rear cover.

So, Motor housing comes

into your sight.

And then, remove two Needle

gauges and Flat washer 14.

Rear cover

Helical gear 52

Motor

housing

Flat washer 14

Gear

complete 34-48

Needle gauge

1412 (2pcs.)

Flat washer 14

Turn Helical gear 52 until Piston comes

out from Crank housing complete.

O rings on Piston can be replaced in this

step.

Remove Motor housing by levering

it up with 2 pcs. of 1R263 as

illustrated below.

Carbon brush is pressed with

Spiral spring to maintain its

contact with Armature's

commutator.

Carbon brush

Disconnection of the Contact of Carbon brush with Commutator

Spiral spring

Carbon brush

Carbon brush

Spiral spring

Detach Spiral spring

from Carbon brush.

By pulling Carbon brush,

disconnect the contact with

Armature's commutator.

Fig. 17

Fig. 18

1R263

Piston

Page 10

P 10/ 20

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-4. Bearing box section, Crank housing section (cont.)

DISASSEMBLING

Fig. 19

Even after removing Motor housing, Armature

still remains in Crank housing complete.

Disassemble Armature by striking the edge of

Crank housing complete as illustrated below.

Fig. 20

Fig. 21

Fig. 22

Armature

(5) Disassemble Bearing box section in order of Figs. 19 to 24.

M6x25 Hex socket

head bolt (3pcs.)

After unscrewing M6x25 Hex Socket head bolts,

remove Bearing box by twisting two slotted head

screwdrivers inserted between Crank housing

complete and Bearing box complete.

Remove Retaining ring S-8, and

push out Counter shaft with 1R045.

Shoulder washer 8 and Needle

bearing 1613 can be removed from

Bearing box complete together

with Counter shaft.

Remove Retaining ring R-25, Ball

bearing 608ZZ and Grease cap.

Bearing box

complete

Filter case

Filter case cover

Pull off Filter case from Bearing box after removing

Filter case cover.

Bearing box complete

Bearing box

complete

Bearing box

complete

Counter

shaft

Counter shaft

Counter shaft

1R291

Retaining ring S-8

Shoulder

washer 8

Remove Pin 8 that functions for AVT in combination

with Pin 6. Pay attention not to lose Pin 8.

Pin 8

Pin 8

Grease cap

1R045

Needle bearing 1613

Ball bearing 608ZZ

Retaining

ring R-25

Page 11

Piston

Connecting rod

P 11/ 20

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-4. Bearing box section, Crank housing section

DISASSEMBLING

Fig. 23 Fig. 24

Filter case cover and Filter case (Re: Fig. 20)

can be disassembled.

O ring 72 and O ring 14 can be removed from

Bearing box complete and Grease cap

Filter case

Filter

Filter case cover

O ring 18

O ring 45

O ring 71

Grease cap

Bearing box complete

O ring 14

(6) In the step of Fig. 21 (after removing Bearing box complete), Piston can be disassembled from Crank housing

complete as illustrated in Fig. 25.

(7) Crank shaft section can be disassembled as illustrated in Fig. 26.

Align Piston, Connecting rod and Crank shaft

on their center line by turning Crank shaft, .

Piston can be removed from Crank housing

complete together with Connecting rod.

Piston

Connecting rod

To stabilize Crank housing during

disassembly, put it onto 1R217.

And apply 1R246 to Crank shaft

and press down Crank shaft.

Apply 1R247 to Ball bearing

6203LLU from Bearing box

complete side, and press down

Ball bearing 6203LLU.

Helical gear 52 and Crank

shaft section are disassembled

as illustrated below.

Crank shaft

Crank Shaft

1R246

Crank housing

complete

Fig. 25

Fig. 26

1R247

Helical gear 52

Crank Shaft

Ball bearing

6304LLU

Ball bearing

6203LLB

Ball bearing 6203LLB

Oil seal 20

1R217

Crank housing complete

Page 12

P 12/ 20

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-4. Bearing box section, Crank housing section

ASSEMBLING

Lip portion

of Oil seal 20

Facing the lip portion to the side of box for Ball bearing

6304LLU (large Bearing), assemble Oil seal 20 by

pressing down until they stop.

Side of box for Ball bearing

6304LLU (large bearing)

Assemble Ball bearing 6304LLU

to Crank shaft as illustrated below.

Oil seal 20

(1) Assemble Crank shaft with Ball bearing 6304LLU to Crank housing complete as illustrated in Figs. 27 and 28.

Crank shaft

Crank shaft

Ball bearing

6304LLU

1R217

1R217

Setting Crank housing complete on 1R217,

assemble the Crank shaft with arbor press as

illustrated below. And then turn Crank housing

complete.

Put it onto 1R165 while aligning the assembled

Crank shaft to the 1R165.

Assemble Ball bearing 6203LLB. And then, assemble

Helical gear 52 as illustrated below.

Crank housing

complete

1R165

Crank shaft

Helical gear 52

Helical Gear 52 has to be assembled so that Crank shaft protrudes

approx. by 3 - 4 mm from the Helical gear 52.

The protruding portion of Crank shaft is accepted by the boss of

Gear housing.

Crank shaft

1R031

Helical

gear 52

Ball bearing

6203LLB

Crank shaft

3 - 4 mm

1R031

Note in Assembly

1R031

Gear

housing

Boss

Fig. 27

Fig. 28

Page 13

P 13/ 20

R

epair

[3] DISASSEMBLY/ASSEMBLY

[3]-4. Bearing box section, Crank housing section (cont.)

ASSEMBLING

(2) Assemble Piston together with Connecting rod to Crank shaft. Refer to the right illustration in Fig. 25.

(3) Assemble Bearing box complete as illustrated in Figs. 29 to 31.

Insert Needle bearing 1613 and Shoulder washer 8 over Counter shaft. Assemble Counter shaft

to Bearing box complete by pressing down with arbor press.

Assemble Ball bearing 608ZZ to Bearing box.

And secure the Ball bearing with Retaining ring R-25.

Needle

bearing 1613

Brim portion

Shoulder washer 8

Counter shaft

When assembling Shoulder washer 8,

face the brim portion to Needle bearing side.

Turning Bearing box complete, mount Retaining ring S-8 to

Counter shaft.

The assembled Bearing box complete is ready to be mounted

to Crank housing complete in the next step.

Retaining

ring R-25

Ball bearing 608ZZ

Bearing box

complete

Counter shaft

Retaining

ring S-8

Fig. 29

Fig. 30

Fig. 31

Bearing box

Complete

Page 14

P 14/ 20

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-4. Bearing box section, Crank housing section (cont.)

ASSEMBLING

Fit the Notch of Counter shaft to the pin portion of Crank shaft by turning Counter shaft with Wrench 7.

(Unless the notch of Counter shaft fits to the pin portion of Crank shaft, approx. 5mm gap arises between

Bearing box complete and Crank housing complete.)

Pin portion of Crank shaft

When assembling Gear complete 34-48 and Needle gauge 112,

do not forget to mount two Flat washers as illustrated below.

The notch of Counter shaft fits to the pin portion

of Crank shaft. Bearing box complete can be exactly

mounted to Crank housing complete without any gap.

The notch of Counter shaft does

not fit to the pin portion of Crank

shaft in this step.

Notch of Counter shaft

Gap between Bearing box

complete and Crank housing

complete

Bearing box

complete

Counter shaft

Condition under Bearing box complete

Wrench 7

Crank housing

complete

Wrench 7

Fig. 32

Fig. 33

Needle gauge 1412

(2pcs.)

Flat washer 14

(6) As for the further steps, do the reverse step of Disassembly.

Flat washer 14

Gear complete 34-48

4) Mount Bearing box complete to Crank housing complete as illustrated in Figs. 32.

5) Mount Gear complete 34-48 to Crank housing complete as illustrated in Figs. 33.

Page 15

1R023

1R024

P 15/ 20

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-5. Motor section

DISASSEMBLING

ASSEMBLING

(1) Remove Rear cover (with “AVT” mark) from Crank housing complete (Re: the right illustration in Fig. 17)

(2) Disconnecting Carbon brush from Armature’s commutator, separate Motor housing from Crank housing complete. (Fig. 18)

(3) Disassemble Armature, by striking the edge of Crank housing complete. (Fig. 19)

(4) Ball bearings on Armature can be removed as illustrated in Fig. 34.

Ball bearing

6000DDW

Remove Ball bearing 6000DDW,

and Insulation washer from the

Commutator end,

Insulation

washer

Ball bearing 6302LLU

Sealing screw

Sealing screw and Ball bearing 6302LLU

are removed in one process by pressing

down with arbor press.

1R023

Do the reverse step of Disassembly.

1R022

1R024

1R269

Fig. 34

Page 16

P 16/ 20

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-6. Electrical parts in Handle section

DISASSEMBLING

(1) Remove Handle section from Crank housing and Motor housing. The following electrical Parts can be replaced as

illustrated in Fig. 2.

* Switch

* Controller

* Power supply cord

(2) Separate Handle cover from Handle. The parts for switching mechanism are disassembled as illustrated in Fig. 35.

ASSEMBLING

Disassemble Switch lever from Side lever by unscrewing

4x18 Tapping screw. And Remove Slide lever from Handle.

Pay attention not to lose Leaf spring in this step.

Switch lever

Switch

lever

Slide lever

Unscrew 4x18 Tapping screw,

and remove Handle cover.

Leaf

spring

Handle cover

Handle

4x18 Tapping screw

4x18 Tapping screw

4x18 Tapping screw

Fig. 35

(1) When replacing Switch in the step of Fig. 2, do not forget to assemble Rubber pin 4 to the illustrated position in Fig. 36.

Switch

Tumbler of Switch is controlled by the pronged portion of

Switch lever that is joined to Slide lever with 4x18 Tapping screw.

Fitting the Prong of Switch lever to Tumbler of Switch, assemble

Handle section to Crank housing complete.

Rubber Pin 4

(green color)

Fig. 36

Fig. 37

Tumbler of

Switch

Prong of

Switch Lever

(2) Mount Leaf spring to Slide lever, and assemble Slide lever to Handle. Fasten Switch lever to the Slide lever with

4x18 Tapping screw. And mount Handle cover to Handle. Refer to the illustrations in Fig. 35.

(3) Assemble the Handle section to Crank housing as illustrated in Fig. 37.

Handle section

Slide Lever

Page 17

P 17/ 20

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-7. Fastening torque

19

M6x30 Hex socket

head bolt (1 pc.)

<Note in Assembling>

Applying ThreeBond 1342 or Loctite 242 to their thread,

tighten Hex socket head bolts illustrated above.

Barrel complete

Barrel cover

Gear cover

Handle

Rear cover

Bearing box complete

Crank housing complete

M6x30 Hex socket

head bolt (6pcs.)

M6x30 Hex socket

head bolt (6pcs.)

M6x30 Hex socket

head bolt (4pcs.)

72

19

Position

No.

Fastening

Torque

Used

Q’ty

Size of Hex Socket

Head Bolt

19 4 30 - 40 N.mM8 x 35

72 3 13 - 16 N.m

M6 x 25

Fasten the Bolts and Screws to the fastening torque listed in Fig. 38.

Fig. 38

Page 18

P 18/ 20

Repair

[4] MAINTENANCE PROGRAM

20

22

Flat washer 39

Flat washer 30

Chuck cover

Ring spring 26

Tool holder

Impact bolt

Cylinder 40

1

24

25

26

29

Shoulder

sleeve

32

Striker

Piston

45

47

When replacing carbon brush, it is recommended to replace the following parts at the same time for longer service life

of the machine. Refer to Fig. 39.

Removing old grease, apply the new grease to the portions in Figs. 1A to 1D of the clause of [2] LUBRICATIONS.

Fig. 39

Item No. Item No.Descriptions Descriptions

1

20

22

24

25

Tool Holder Cap

Rubber Ring 39

O Ring 35.5 on Tool holder

X Ring 21 on Impact bolt

Fluoride Ring 28 on Impact bolt

26

29

32

45

47

O Ring 23 on Impact bolt

Rubber Ring 24

O Ring 31.5 on Striker

O Ring 31.5 on Piston

O Ring 35 on Piston

Page 19

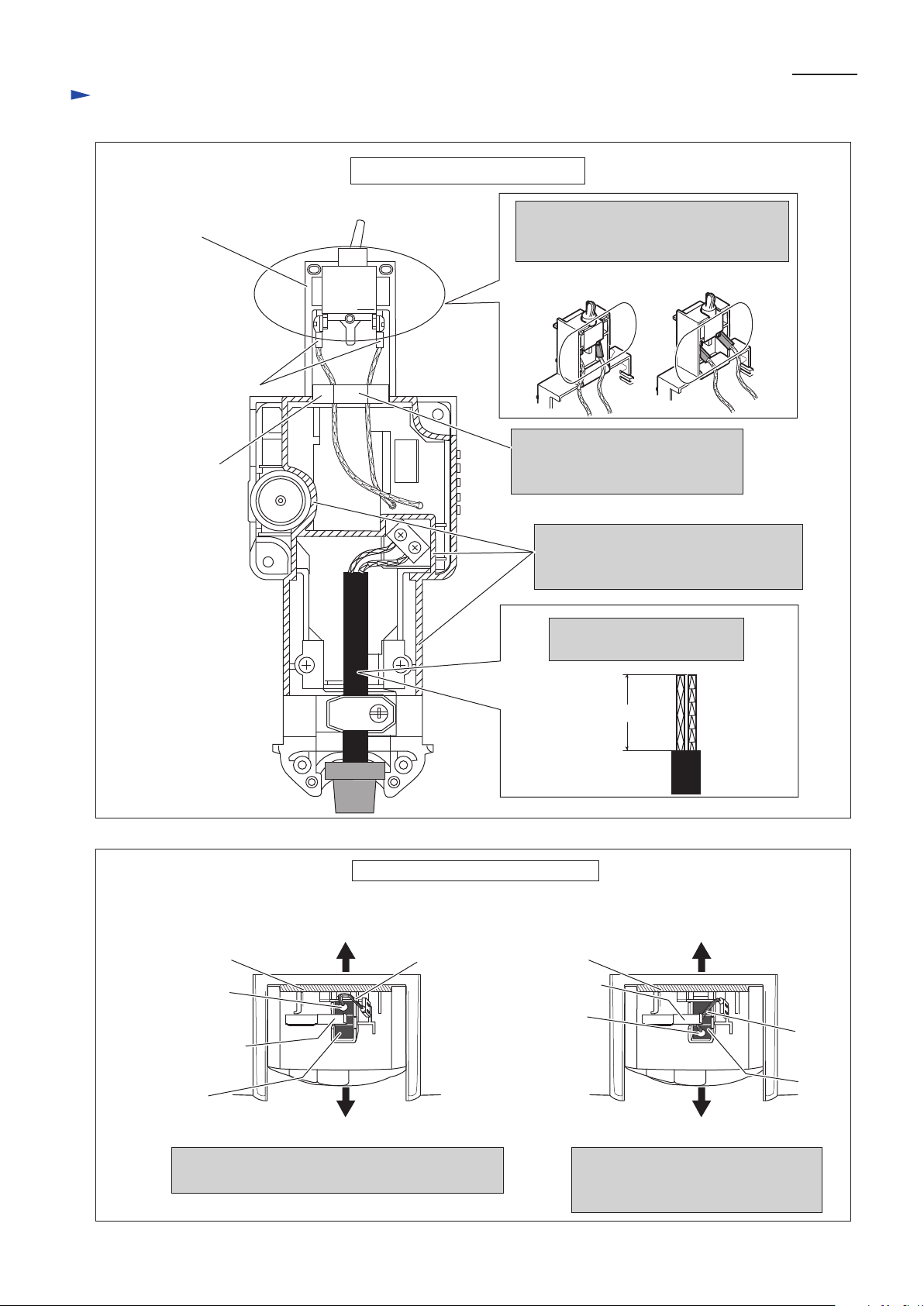

Circuit diagram

P 19/ 20

Color index of lead wires' sheath

Blue

Brown

3 1

T2

T1

Controller

Fig. D-1

This Lead wire is white for

some countries.

This Lead wire is black for

some countries.

This Lead wire is white for

some countries.

This Lead wire is black for

some countries.

Switch

Terminal Block

built in Controller

Page 20

Brim side

Brim of Brush

Holder Unit

Wiring diagram

wiring on Controller Cover

P 20/ 20

Do not protrude Terminals from the edge

of Controller cover when connecting them

to Switch.

Controller

Cover

Sponge

Pay attention not to pinch the Lead wires

with the edge of Controller or Controller

cover (designated with hatching).

Put Controller’s Lead wires for

connecting to Switch into the slit of

Sponge.

Switch

Terminal

approx. 30mm

Cut the Power supply cord as

illustrated below.

Fig. D-2

Fig. D-3

Correct Wrong

Correct

Wiring of Carbon Brush’s Pig Tail

Wrong

Pig tail’s Root on the brim side of Spiral spring

does not pinch Pig tail by mistake when assembling.

Pig Tail’s Root on the Rear cover side

Spiral spring easily pinches Pig tail by

mistake when assembling.

Brim of Brush

holder unit

Rear Cover Side

Brim side

Rear Cover Side

Spiral Spring, correctly

pressing Carbon Brush

Spiral spring,

pinching Pig tail

Pig Tails

Root

Pig Tail

Pig Tail’s

Root

Carbon

Brush

Carbon

Brush

Pig Tail

Loading...

Loading...