Page 1

T

ECHNICAL INFORMATION

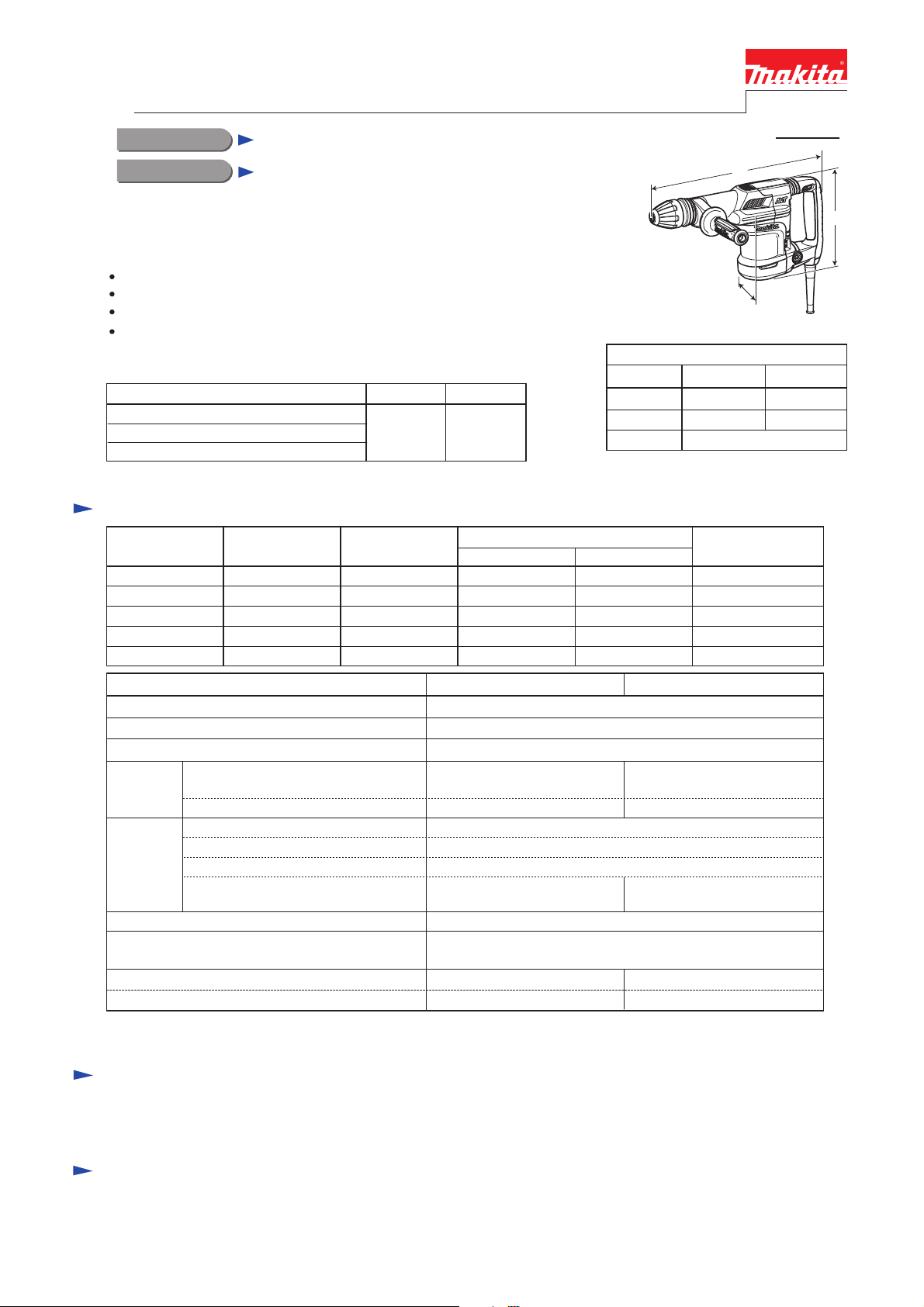

Models No.

HM0871C, HM0870C

PRODUCT

P 1/ 17

Description

Demolition Hammers

CONCEPT AND MAIN APPLICATIONS

Models HM0871C and HM0870C are 5kg-class demolition hammers

adapted for SDS-MAX bits, and developed from HM0860C, featuring:

Same high work efficiency as HM0860C

Higher durability achieved by using ball bearing for crank section

AVT* for reduced vibration during chipping (HM0871C only)

Suppression of motor speed during no-load for reduced vibration

when idling

Listed below are the specification differences between the two models.

Model No.

AVT*

Vibration absorbing handle

Suppression of motor speed during no-load

*Anti-Vibration Technology using Active dynamic vibration absorber

Yes No

Specification

Voltage (V) Cycle (Hz)

110

120

220

230

240

Current (A)

12

10

5.8

5.8

5.8

50/60

50/60

50/60

50/60

50/60

HM0870CHM0871C

[The image above is HM0871C.]

Model No.

Length (L)

Width (W)

Height (H)

Continuous Rating (W)

Input Output

1,100

---

1,100

1,100

1,100

450

450

500

500

500

L

H

W

Dimensions: mm (")

HM0870CHM0871C

466 (18-3/8) 449 (17-3/4)

116 (4-9/16) 109 (4-1/4)

230 (9)

Max. Output (W)

1,200

1,200

1,200

1,200

1,200

Model No.

Impacts per min: min-1= ipm

Shank type Adapted for SDS-MAX bits

Shank diameter: mm (")

Vibration

absorption

Electronic

control

Double insulation

Power supply cord: m (ft)

Net weight*1: kg (lbs)

Net weight*2: kg (lbs)

*1 Weight according to EPTA-Procedure 01/2003, with bar-shaped Side handle.

*2 Weight according to EPTA-Procedure 01/2003, with D-shaped Side handle.

AVT (Anti-Vibration Technology using

Active dynamic vibration absorber)

Vibration absorbing handle

Variable speed control by dial

Soft start

Constant speed control

Suppression of motor speed

during no-load

Yes No

Yes No

Yes No

Europe, Hong Kong, Korea: 4.0 (13.1);

Brazil: 2.0 (6.6); Other countries: 5.0 (16.4)

5.6 (12.4) 5.1 (11.1)

5.8 (12.8) 5.3 (11.6)

1,100 - 2,650

18 (11/16)

Yes

Yes

Yes

Yes

Standard equipment

Side handle (Bar- or D-shaped) ........... 1

Bit grease .............................................. 1

Note: The standard equipment for the tool shown above may vary by country.

Plastic carrying case ........................ 1

Cleaning cloth .................................. 1

HM0870CHM0871C

Optional accessories

Bull points

Cold chisels

Scaling chisels

Scaling chisel (for Tile)

Grooving chisel

Clay spade

Bushing tool

Rammer

Shank (for Bushing tool and Rammer)

Grease vessel (containing 30g hammer grease)

Side handle (Bar-shaped/ D-shaped)

Safety goggles

Hammer service kit

Page 2

P 2/ 17

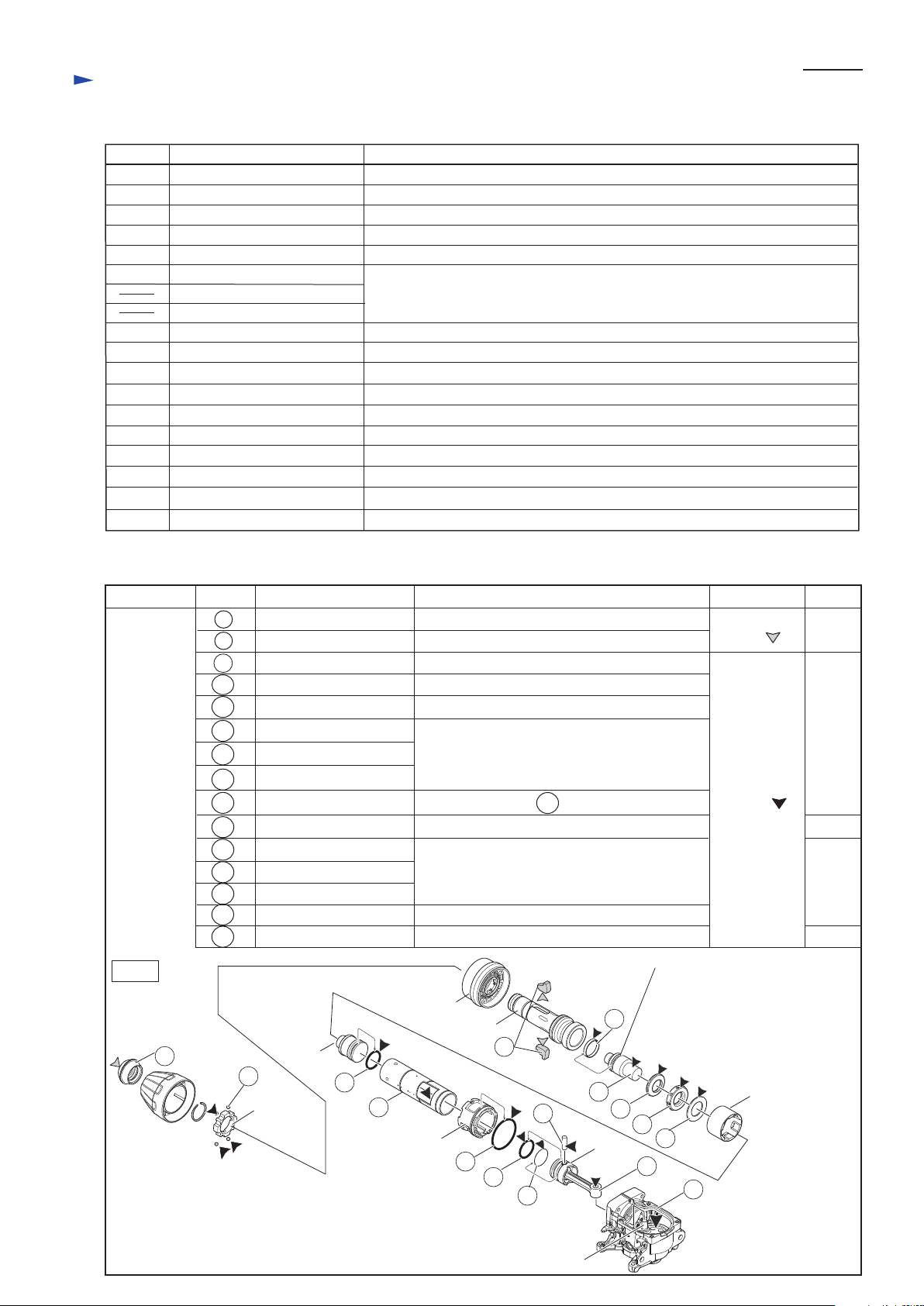

Repair

[1] NECESSARY REPAIRING TOOLS

[2] LUBRICATIONS

Fig. 1

Code No.

1R003 Retaining ring S pliers ST-2N

1R212 Tip for Retaining ring pliers

1R005 Retaining ring R pliers RT-2N

1R089 Bearing extractor

1R023 When it is difficult to remove Armature from Crank housing complete.

When it is difficult to remove Ball bearing 6203LLU.

Pipe ring ( for Arbor press)

1R132 Nose 15-20 Attachment for 1R089 to remove Ball bearing 6203LLU

1R139 Drill chuck extractor

M8x40 Hex socket head bolt

Flat washer 8

Removing Crank shaft

Attachment for 1R003 to remove Ring springs

1R214 Taper sleeve Fitting Fluoride ring on Impact bolt

1R229 1/4” Hex shank bit for M5

Unscrewing/ screwing M5 size Hex socket head bolt

1R230 1/4” Hex shank bit for M6

Unscrewing/ screwing M6 size Hex socket head bolt

1R239 Round bar for Arbor 10-100 When it is difficult to remove Armature from Crank housing complete.

1R269 Bearing extractor Removing Ball bearing 608DDW from Armature’s commutator end

1R288 Screwdriver magnetizer

Magnetizing screwdriver when removing Steel balls

1R291 Retaining ring S and R pliers

Removing Ring spring 34 when disassembling Barrel section

1R306 Ring spring removing jig When it is difficult to remove Armature from Crank housing complete.

1R363 Ring spring removing tool

Removing Ring spring 25

Removing Ring springs

Removing Retaining ring (INT) round R-42

Description Use for

Item No.

Apply the following lubricants to the portions to protect the parts and product from unusual abrasion.

Description Portion to lubricate Lubricant Amount

a little

a little

a little

1 Tool holder cap

7

7

Tool retainer

Steel ball 4.8 (4pcs.)

Lip portion

Belly portion where Hammer bit contacts

Whole portion

1

Lock ring

Striker

Change ring

Tool holder

16

16

Makita grease

N.No.2

Makita grease

R.No.00

19

21

22

23

27

31

Cylinder guide

Guide ring

O ring 23 between Fluoride ring

28 and Impact bolt

Note: Do not apply any grease

to O ring 23 attached to

Fluoride ring 28.

32

38

50

Piston

Pin of Crank shaft

51

53

58

19

21

22

23

27

31

32

38

49

51

53

58

Fluoride ring 28

Impact bolt

Ring 20

Rubber ring 20

Flat washer 23

O ring 24

Cylinder 32

O ring 46

Pin 8

O ring 26

Connecting rod

Crank housing complete

The surface where Tool holder contacts

Cylindrical portion of Striker side

Whole portion

The surface where 32 Cylinder contacts.

Inside between Striker and Piston.

Whole portion

The hole in which Crank shaft’s pin is inserted

Crank room

49

7g

20g

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

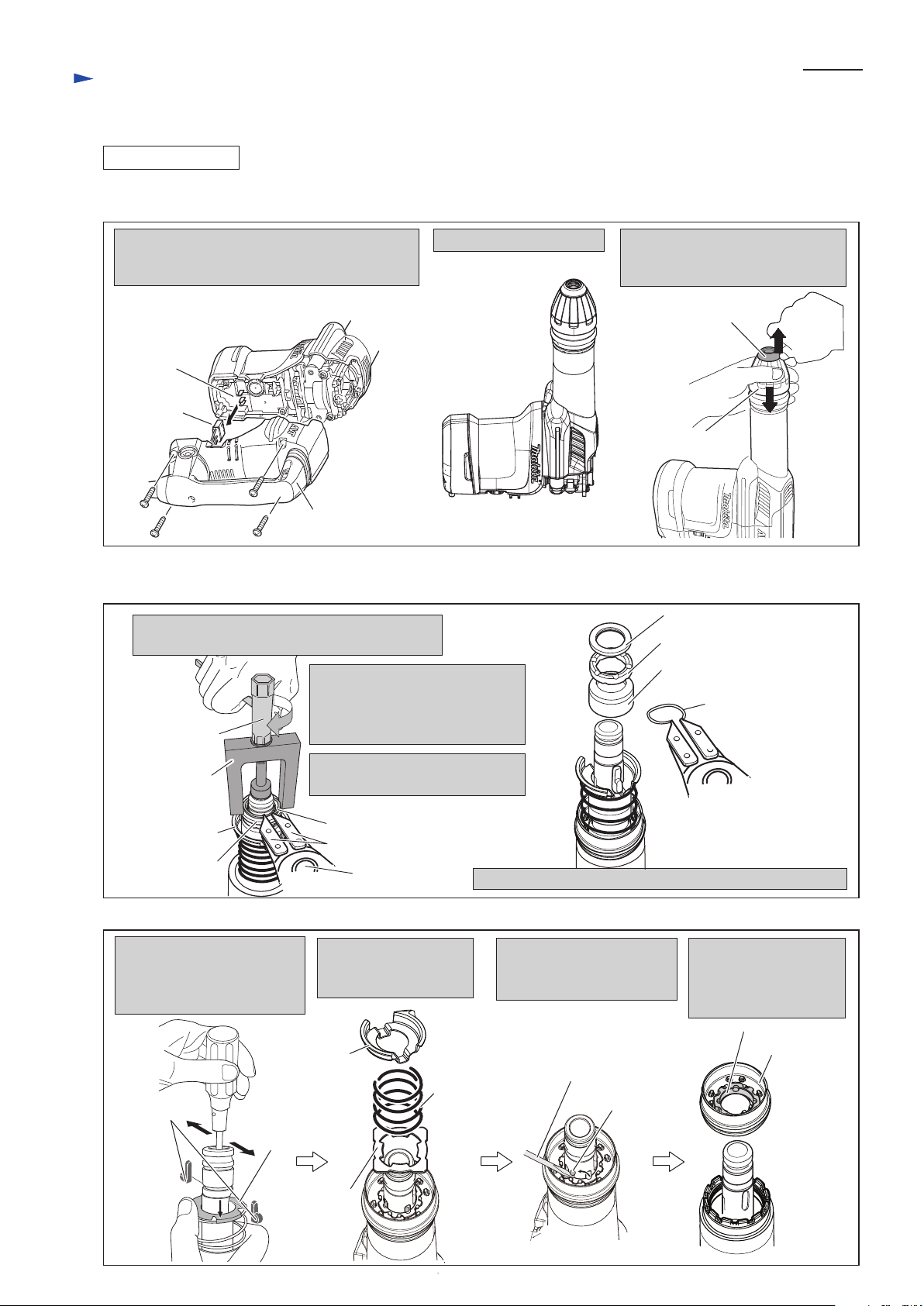

Page 3

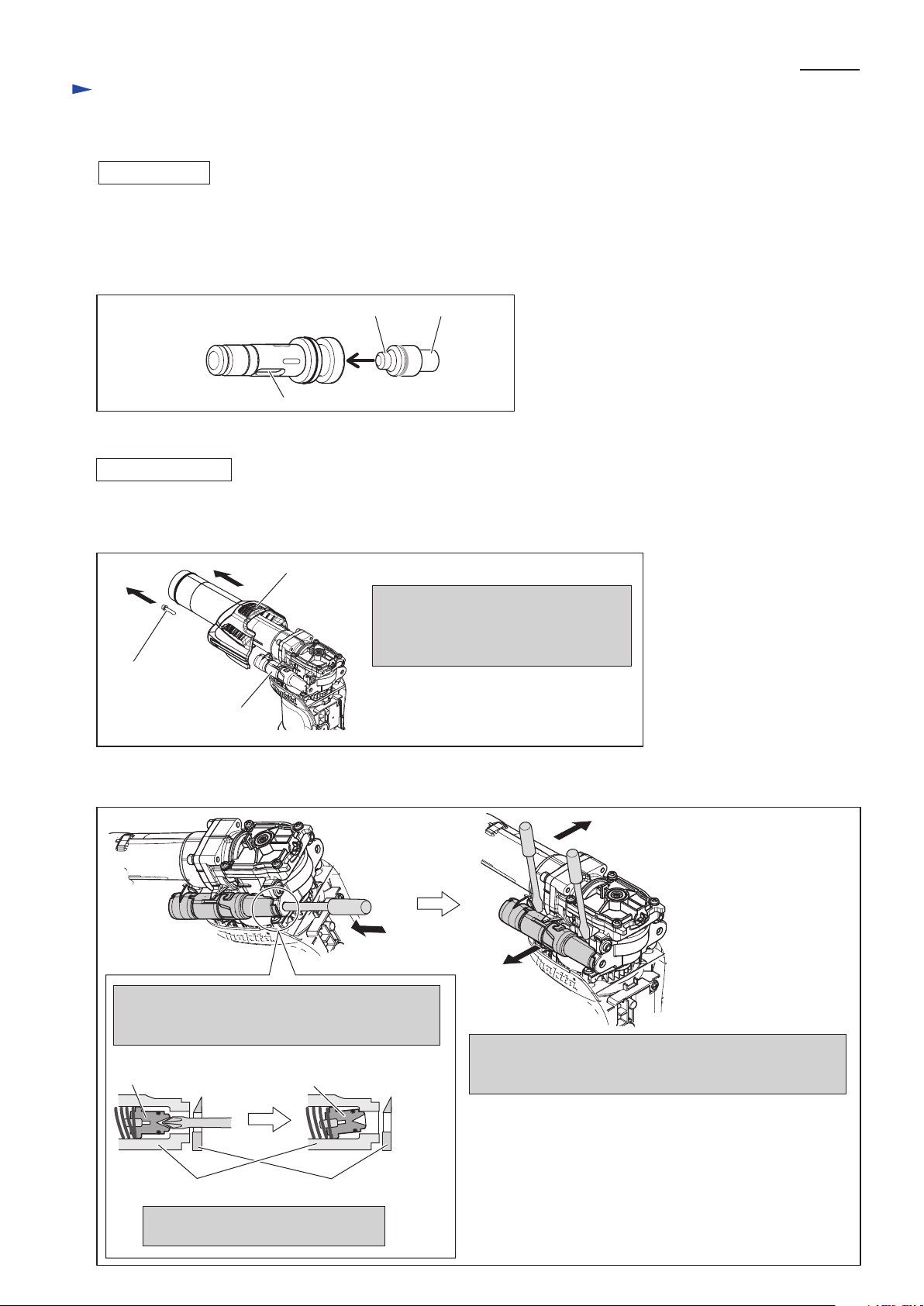

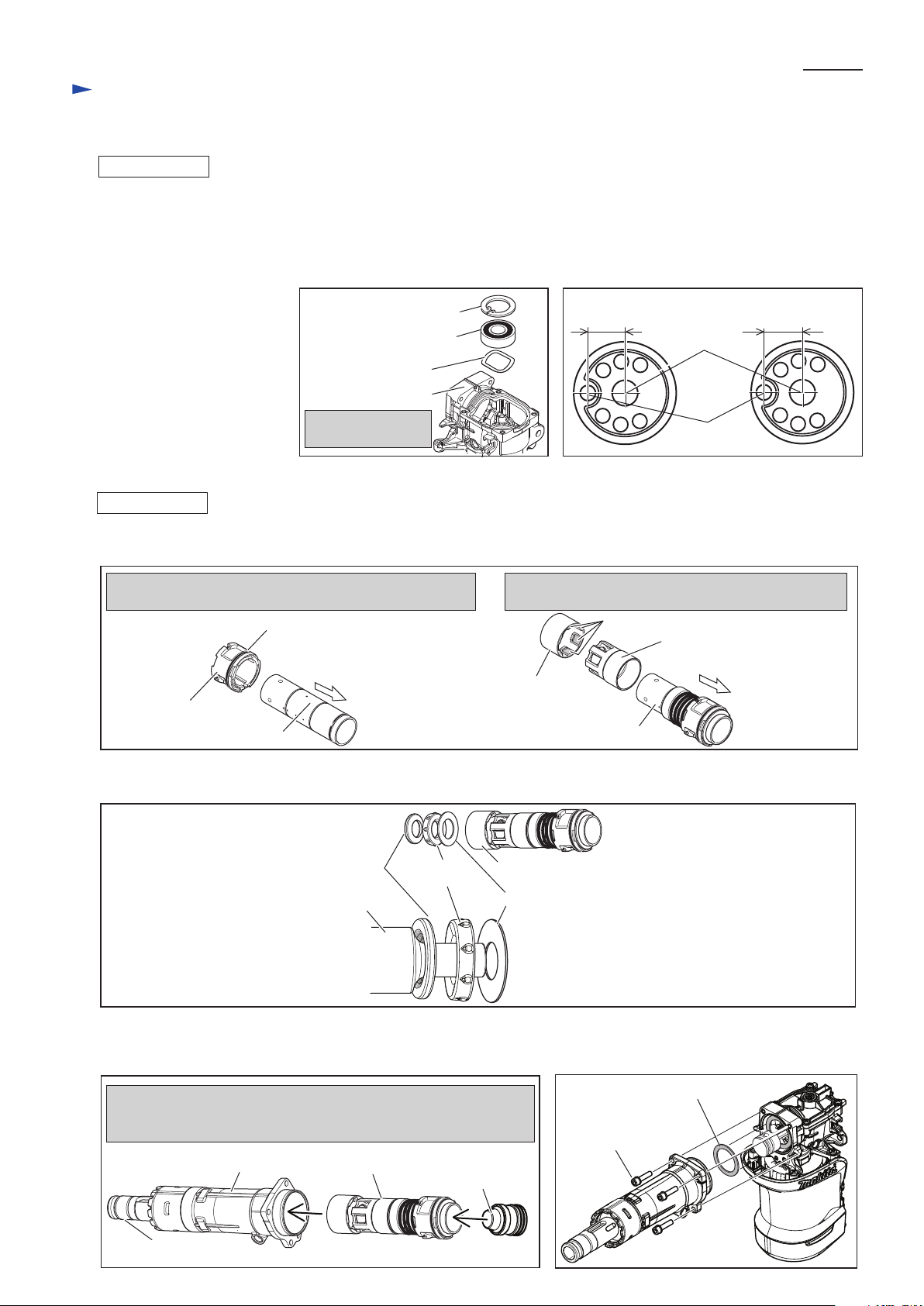

DISASSEMBLING

(1) Remove Tool holder cap as illustrated in Fig. 2.

Remove Handle section by loosening four 5x25

Tapping screws, and then disconnect Lead unit

from Controller.

Stand the machine upright. While pressing down Chuck cover,

remove Tool holder cap.

And then, remove Chuck cover.

Fig. 2

Handle section

Lead unit

Controller

Note: It is not necessary to disconnect Switch and

Power supply cord.

Chuck cover

Tool holder cap

P 3/ 17

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-1. Chuck section

(2) Disassemble Chuck section as illustrated in Figs. 3 and 4.

2. Press down Flat washer 28 by

turning Socket wrench to make

Ring spring 25 free from the

pressure by Flat washer 28.

3. Remove Ring spring 25 using

1R003 with 1R212.

4. Remove Flat washer 28, Rubber ring 28 and Chuck ring.

Remove Spring guide,

Compression spring 52

and Plate.

Remove four Steel balls 4.8

with Slotted screwdriver

magnetized by 1R288.

Remove Change ring

together with Lock ring.

And separate Lock ring

from Change ring.

While pressing down Spring

guide, push out Tool retainers

by screwdriver inserted from

Tool holder.

Fig. 3

Fig. 4

Flat washer 28

1R003

Flat washer 28

1R363

1. Pulling down Chuck cover, install 1R363

in the same way of SDS-MAX bit installation.

Socket wrench

Spring guide

Ring spring 25

Ring spring 25

Rubber ring 28

Chuck ring

Tool retainer

Spring

guide

Spring

guide

Plate

Compression

spring 52

Steel ball 4.8

(4pcs.)

Screwdriver magnetized

by 1R288

Lock ring

Change ring

5x25 Tapping screw (4pcs.)

1R212

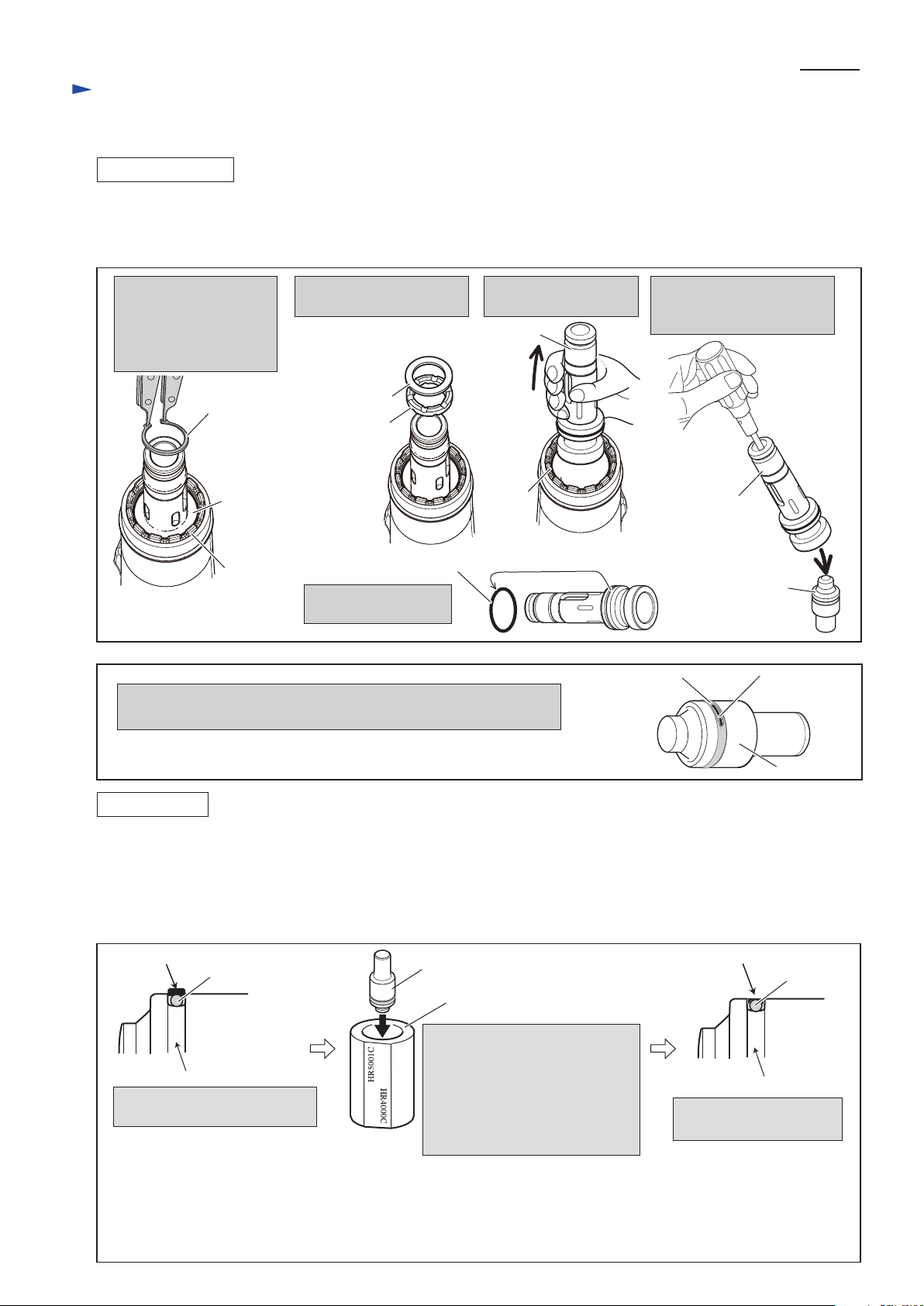

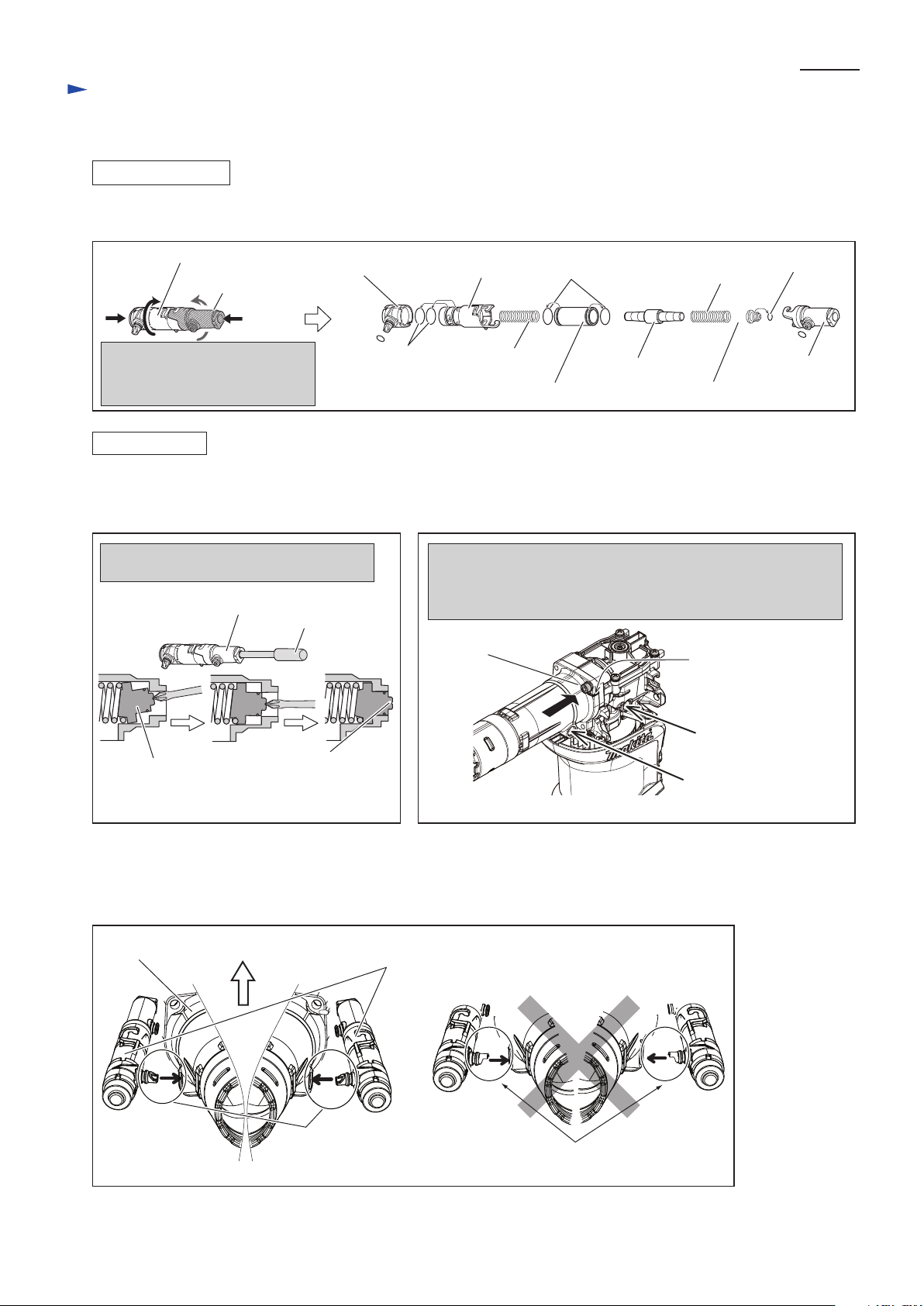

Page 4

P 4/ 17

Repair

DISASSEMBLING

(1) Disassemble Chuck section. (Figs. 2, 3 and 4)

(2) Removing Retaining ring R-42, disassemble Tool holder section and take out Impact bolt. (Fig. 5)

(3) Remove Fluoride ring 28 and O ring 23 from Impact bolt when Fluoride ring 28 is worn out as illustrated in Fig. 6.

2. Remove Flat washer 29

and Rubber ring 28.

3. Pull off Tool retainer

from Barrel.

Fig. 5

Fig. 6

[3] DISASSEMBLY/ASSEMBLY

[3]-2 Tool holder section

1. Tool holder is fixed to

Barrel with Retaining

ring R-42.

Remove the Retaining

ring R-42 with 1R005.

Barrel

Tool holder

Impact bolt

O ring 38

5. Remove O ring 38

from Tool holder.

4. Remove Impact bolt from

Tool holder by pushing

out with Screwdriver.

Retaining

ring R-42

Flat washer 29

Flat

washer 29

Rubber ring 28

Barrel

Tool holder

O ring 23

(color: orange)

Fluoride ring 28

(the worn one)

Impact bolt

Fig. 7

ASSEMBLING

Taper sleeve (No.1R214)

Impact bolt

Fluoride ring 28 is protruded

from the groove on Impact bolt.

groove on Impact bolt

Fluoride ring 28

O ring 23

groove on Impact bolt

O ring 23

Fluoride ring 28 is fit into

the groove on Impact bolt.

Outer surface of Fluoride ring 28

(1) When particles and dust are in the inside of Barrel and Crank housing, be sure to clean them up.

(2) Fit O ring 23 into the groove of Impact bolt, and then put Fluoride ring 28 on O ring 23 as illustrated in Fig. 7.

(3) Assemble Tool holder and Chuck section by taking the reverse step of Figs. 5, 4, 3 and 2.

Note: Do not apply any grease to O ring 23, or the Fluoride ring will not shrink even using Taper sleeve.

Be sure to apply Makita grease R.No.00 to the outer surface of Fluoride ring 28 after fitting into Impact bolt.

When orange colored O ring 23 can be seen through Fluoride ring 28,

Fluoride ring 28 and O ring 23 have to be replaced with new ones.

1) Insert Impact bolt securely into

Taper Sleeve from HR5001C

marking side.

2) Hold the Impact bolt for at least

60 seconds.

3) Then pull Impact bolt out of

Taper sleeve.

Note: Once Fluoride ring is expanded,

it does not shrink by itself.

If you insert Impact bolt into Tool

holder without shrinking Fluoride

ring, Fluoride ring will be pinched

and broken, or Impact bolt will

loose smooth sliding action.

Note: If it is hard to pull out Impact bolt,

insert a round bar from the opposite

side and hit it slightly.

Note: If it is hard to pull out

Impact bolt, insert a round

bar from the opposite side

and hit it slightly.

Page 5

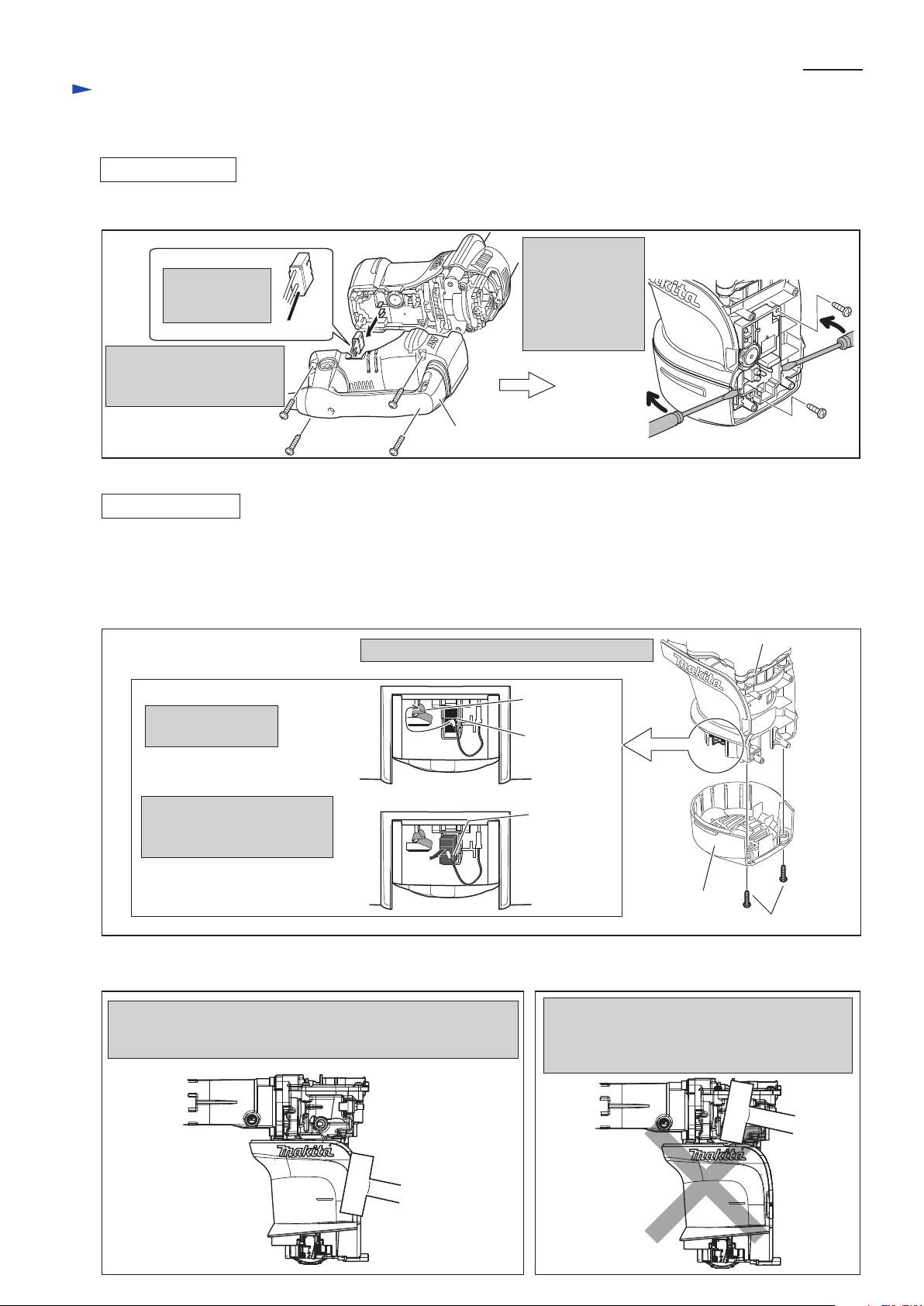

(1) First, disassemble Chuck section as illustrated in Fig. 2, 3 and 4.

(2) Remove Housing cover as illustrated in Fig. 9.

Fig. 9

Fig. 10

[3] DISASSEMBLY/ASSEMBLY

[3]-2 Tool holder section (cont.)

Housing cover

Remove Housing cover by unscrewing

M5x25 Hex socket Head bolt.

Active dynamic vibration absorber

comes into sight.

Insert Screwdriver into the hole of Handle side,

and push Spring guide in Active dynamic vibration

absorber to be stuck as follows:

M5x25 Hex

socket head bolt

Active dynamic vibration

absorber

Spring guide has to be removed from

Crank housing prior to the next step.

Spring guide

Spring guide tilted and stuck

in Pipe holder A

Crank housing

Insert two slotted screwdrivers between Crank housing and

Active dynamic vibration absorber, and then lever up

Active dynamic vibration absorber from Crank housing.

(3) Remove Active dynamic vibration absorbers from the both side of the machine as illustrated in Fig. 10.

[3]-3 Active dynamic vibration absorber (exclusively for HM0871C)

DISASSEMBLING

ASSEMBLING

Short end Long end

Impact bolt

(2) Assemble Tool holder section by taking the reverse step of Fig. 5.

Insert Impact bolt into Tool holder.

Note: Face the short end of Impact bolt to Hammer bit insertion side. See Fig. 8.

(3) Assemble Chuck section by taking reverse step of disassembly. Refer to Figs. 4, 3 and 2.

Fig. 8

Tool holder

Hammer bit

insertion side

P 5/ 17

Repair

Pipe holder A

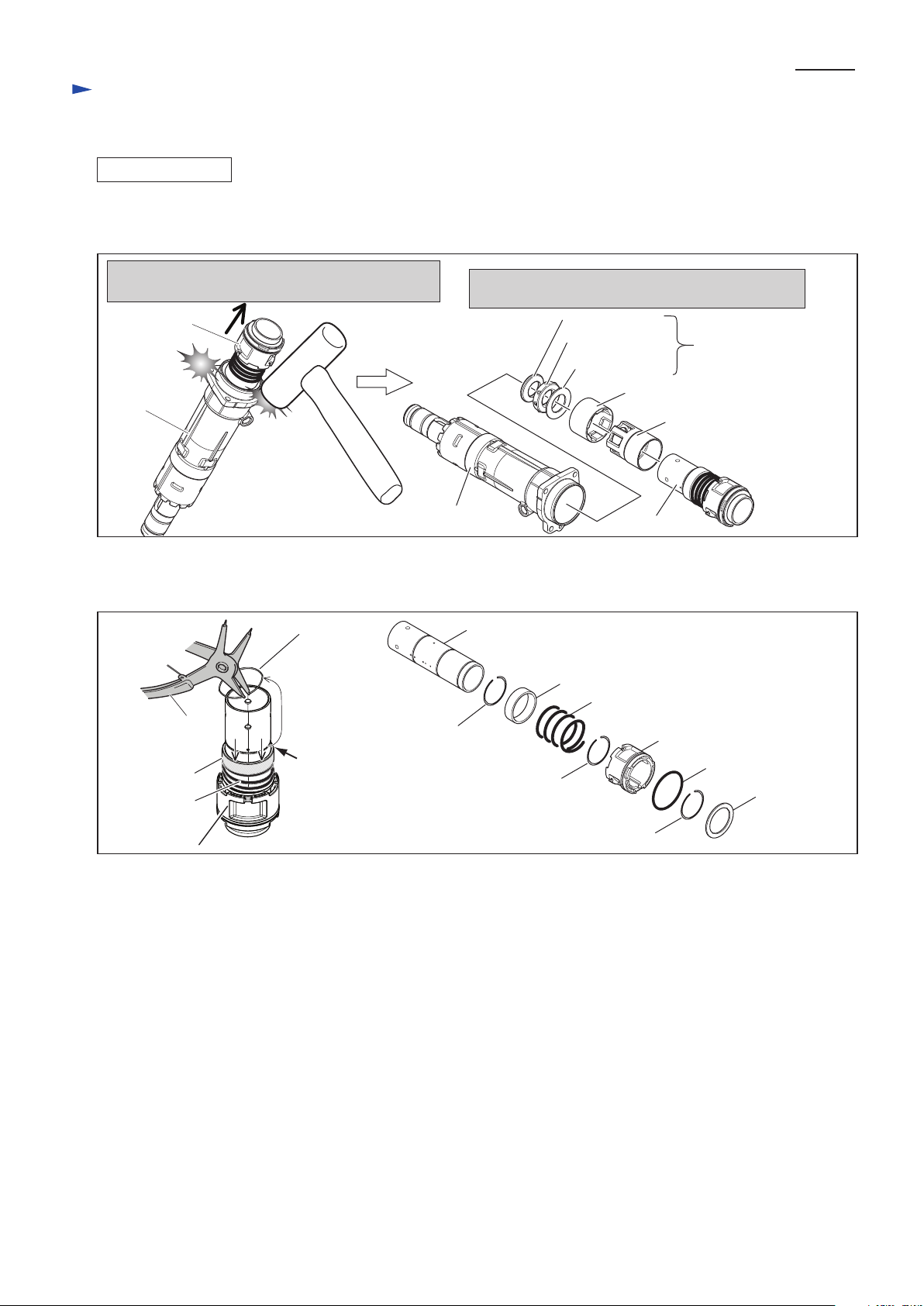

Page 6

P 6/ 17

Repair

Fig. 11

Fig. 12 Fig. 13

Fig. 14

DISASSEMBLING

ASSEMBLING

[3] DISASSEMBLY/ASSEMBLY

[3]-3 Active dynamic vibration absorber (exclusively for HM0871C) (cont.)

(4) The removed Active dynamic vibration absorber can be disassembled as illustrated in Fig. 11.

(1) Assemble a pair of Active dynamic vibration absorber. (Fig. 11)

(2) Before fitting Active dynamic vibration absorber to the machine, take the steps in Figs. 12 and 13.

Pipe holders can be separated by

turning and pushing Pipe holders

each other illustrated above.

Pipe holder B

Pipe holder A

Pipe holder A

Pipe 16

Counter weight

Compression

spring 12

Pipe holder support

O ring 18

O ring 18

Pipe holder B

Compression spring 12

Spring guide

O ring 8

Crank cap side

Spring guide

Spring guide to be

protruded from

Pipe holder A

Protrude Spring guide from Pipe holder A

with Screwdriver

Tighten M6x25 Hex socket head bolt designated with black

arrow in order to align Insertion hole for Pipe holder support with

Insertion hole for Pipe holder A. Then tighten the other M6x25

M6x25 Hex socket head bolts (3pcs.).

Pipe holder A

Screwdriver

Insertion hole

for Pipe holder A

Protrusion as distinction

of the direction of Barrel.

Insertion hole

for Pipe holder

support

Connector of

Pipe holder support

Note: Do not insert Pipe holder supports

as illustrated above.

Barrel

(3) Insert Pipe holder supports of Active dynamic vibration absorbers to holes on Barrel and Crank housing. (Fig. 14.)

And push Active dynamic vibration absorbers parallel to the machine so as to pass the protrusion of Spring guides

through the holes of Crank housing. (Refer to Figs. 12 and 10.)

M6x25 Hex socket

head bolt

Active dynamic

vibration absorbers

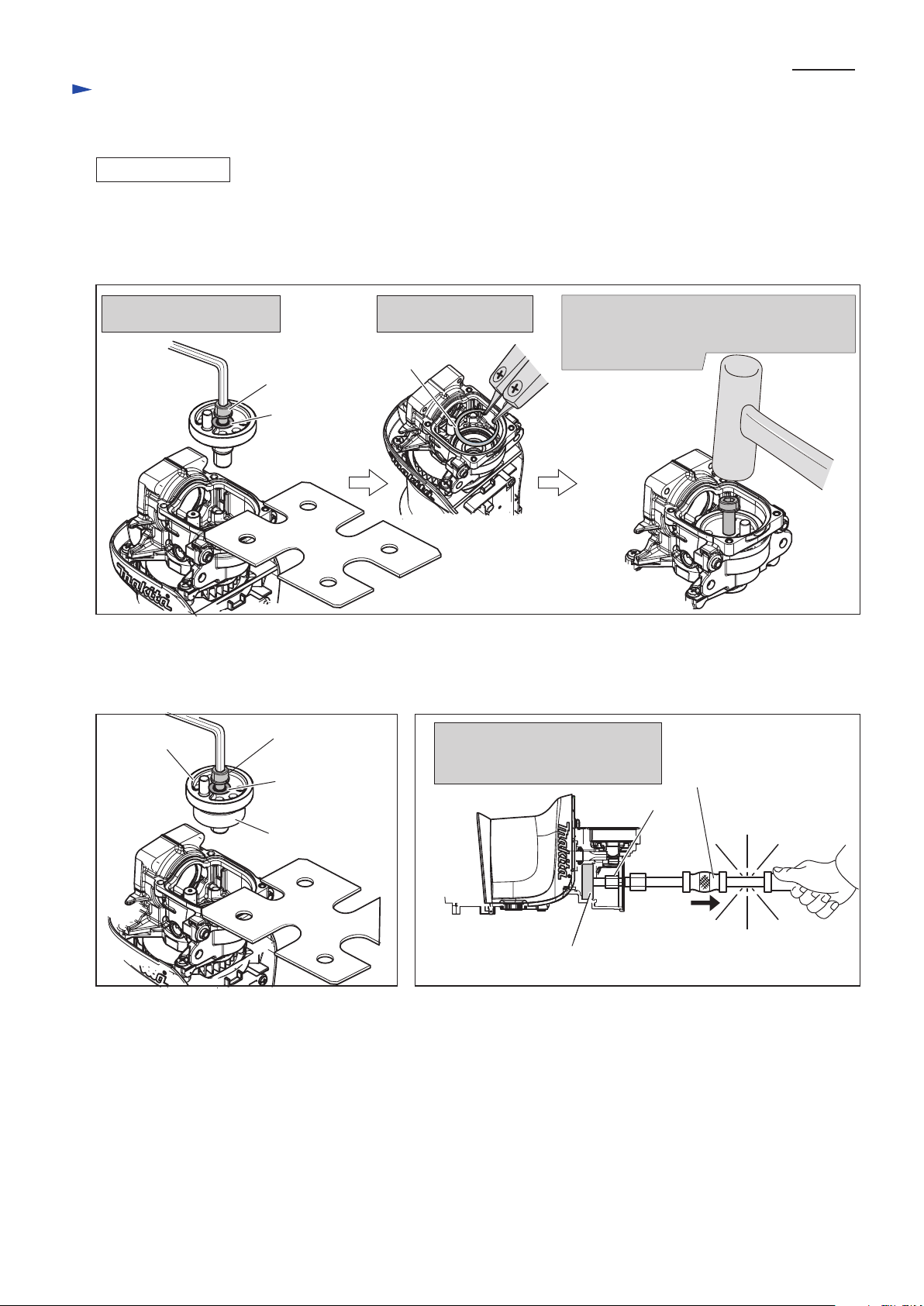

Page 7

P 7/ 17

Repair

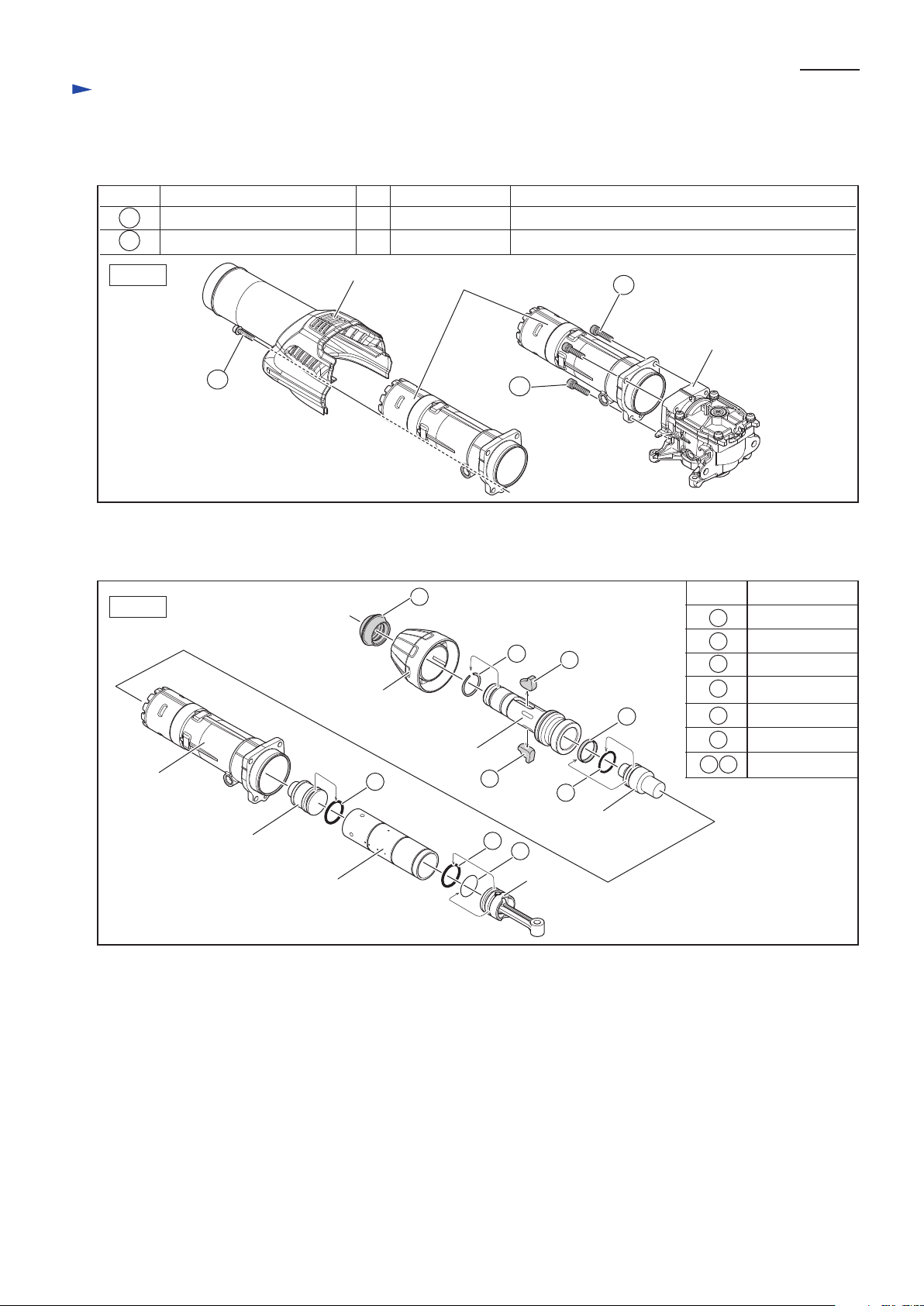

Fig. 15

Fig. 16

DISASSEMBLING

[3] DISASSEMBLY/ASSEMBLY

[3]-4 Piston, Striker, Cylinder

Remove Barrel from Crank housing

M6x25 Hex socket

head bolt (4pcs.)

(1) Disassemble Chuck section as illustrated in Figs 2, 3 and 4.

(2) Remove Housing cover as illustrated in Fig. 9. In case of HM0871C, disassemble Active dynamic vibration absorber as

illustrated Figs. 9 and 10.

(3) Striker and Piston can be disassembled as illustrated in Figs. 15 and 16.

Note: It is not necessay to remove Tool holder from Barrel.

Barrel

Crank cap

Remove Crank cap, Seal ring, Air pipe

and Flat washer 34 from Crank housing.

O rings on Piston can be

replaced .

Seal ring

Flat washer 34

Air pipe

Turning Crank shaft,

set Piston to the closest

position to Barrel side.

Barrel

Striker

O ring 24

Striker

Separate Striker from Barrel, and then

remove O ring 24 from Striker.

M4x18 Pan

head screw (4pcs.)

Crank housing

O ring 24

Piston

Piston

Pin 8

O ring 26

Connecting rod

Connecting rod

Crank

shaft

And remove Piston together

with Connecting rod.

Barrel

side

Piston

Crank shaft

Note: Do not lose Flat washer 34 between

Crank housing and Barrel.

Page 8

P 8/ 17

Fig. 17

Fig. 18

DISASSEMBLING

[3] DISASSEMBLY/ASSEMBLY

[3]-4 Piston, Striker, Cylinder (cont.)

Remove Cylinder section by tapping Barrel using

plastic hammer. Pay attention to the tapped position.

Ring 20, Rubber ring 20, Flat washer 23, Guide ring,

Slide sleeve are removed from Cylinder section.

(4) Separate Cylinder section from Barrel. The parts on Tool holder side can be removed from Cylinder 32 as per the right

illustration in Fig. 17.

(5) Pressing down Ring 36, remove Ring spring 34 (A) from Groove (A) on Cylinder 32 with 1R291.

The components of Cylinder section can be separated by removing Ring spring 34 (B) and (C). (Fig. 18.)

Barrel

Barrel

Ring 20

fit to the long drum side

of Impact bolt

Guide ring

Slide sleeve

Cylinder 32

Rubber ring 20

Flat washer 23

Cylinder Section

Ring 36

Groove (A)

on Cylinder 32

Ring spring 34

1R291

Compression

spring 37

Cylinder guide

Repair

Cylinder 32

Ring spring 34 (A)

groove(A)

groove(B)

groove(C)

Ring spring 34 (B)

Ring spring 34 (C)

Ring 36

Compression

spring 37

Cylinder guide

O ring 46

Ring washer 34

(See Fig. 15.)

Page 9

1. Keeping Crank shaft in the condition Crank pin is at the closest position to Barrel side,

hold Armature by inserting a bar into Armature fan.

P 9/ 17

Fig. 19

Fig. 20

DISASSEMBLING

[3] DISASSEMBLY/ASSEMBLY

[3]-5 Crank shaft

4. Tighten the M8x40 Hex socket head bolt using

Hex wrench until Crank shaft is pulled off from

Ball bearing 6203LLU in Crank housing.

(1) Separate Barrel from Crank housing. (Fig. 15)

(2) Remove Crank cap, Seal ring, Air pipe and Flat washer 34 from Crank housing. (the left illustration in Fig. 16)

(3) Remove Piston together with Connecting rod ( the right illustrations in Fig. 16)

Note: Turn Crank shaft so that the crank pin is at the closest position to Barrel side for easy removal of Connecting rod.

(4) remove Crank shaft as illustrated in Figs. 19 and 20.

Bar to hold Armature fan

2. Put 1R139 on Crank housing,

facing 13mm notch to Barrel side.

Crank pin at the closest position

to Barrel side

Barrel

side

Bar to hold

Armature fan

Bar to hold

Armature fan

M8x40 Hex

socket head bolt

Flat washer 8

Crank pin is locked

by 1R139.

3. Putting Flat washer 8 on 1R139, drive M8x40

Hex socket head bolt to the center hole of

Crank housing through Flat washer 8.

Hex wrench

Repair

Page 10

Crank shaft can be removed

as illustrated below.

Remove Retaining ring

R-40 with 1R005.

Loosening M8x40 Hex socket head bolt

halfway, insert Crank shaft into the remaining

Ball bearing 6203LLU by tapping the M8x40

Hex socket head bolt.

P 10/ 17

Fig. 21

Fig. 22

Fig. 22A

DISASSEMBLING

[3] DISASSEMBLY/ASSEMBLY

[3]-5 Crank shaft

Setting 1R132 into the inner ring

of Ball bearing 6203LLU, pull off

Ball bearing 6203LLUwith 1R089.

(1) Separate Barrel from Crank housing as per the left illustration in Fig. 15.

(2) Remove Crank cap, Seal ring Air pipe and Flat washer 34 from Crank housing as per the left illustration in Fig. 16.

(3) Remove Piston together with Connecting rod as per the center and right illustrations in Fig. 16.

(4) remove Crank shaft as illustrated in Figs. 19 and 20.

M8x40 Hex

Socket head bolt

(5) Lock Armature, and set 1R139, Flat washer 8 and M8x40 Hex socket head bolt as illustrated in Fig. 20 again,

tighten the M8x40 Hex socket head bolt with Hex wrench. So Ball bearing 6203LLU are removed as illustrated

in Fig. 22. If it is difficult to remove as illustrated in Fig. 22, remove Ball bearing 6203LLU as illustrated in Fig. 22A.

Flat washer 8

Retaining ring R-40

M8x40 Hex

socket head bolt

Flat washer 8

Crank shaft

Ball bearing 6203LLU

1R132

1R089

Ball bearing 6203LLU

Repair

Page 11

P 11/ 17

Assemble Cylinder guide to Cylinder 32 so that O ring 46

side of Cylinder guide faces Crank housing side.

(1) Cylinder section can be assembled as illustrated in Fig. 25.

Cylinder guide

Cylinder 32

O ring 46

Crank housing

Side

Crank housing

side

Align the six protrusions of Guide ring to Slide sleeve

and assemble Guide ring to Slide sleeve.

Guide ring

Slide sleeve

Cylinder 32

Six protrusions

[3]-6 Cylinder section

Fig. 25

Repair

(2) When assembling the parts which accept Impact bolt, put them into Guide ring as illustrated in Fig. 26.

(3) Assemble Cylinder section to Barrel as illustrated in Fig. 27.

(4) Assemble Flat washer 34 into Crank housing, and then assemble Barrel to Crank housing as illustrated in Fig. 28.

Fig. 26

Fig. 27 Fig. 28

Impact bolt

Ring 20

Note: Ring 20 has to be assembled

so that its inner side can be fit to

Impact bolt as illustrated right.

Note: Rubber ring 20 has to be

assembled so as to contact closely

to Ring 20 without any gap.

Rubber

ring 20

Flat washer 23

Tool holder

Insert Cylinder section into Barrel.

Insert Striker into the Cylinder so that the protrusion of Striker faces

Tool holder side.

Flat washer 34

Guide ring

M6x25 Hex socket

head bolt (4pcs.)

ASSEMBLING

ASSEMBLING

(1) Assemble Crank housing section as illustrated in Fig.s 23.

Be careful that Crank shaft of HM0870C is different from that of HM0871Cas illustrated in Fig. 24.

(2) Assemble Piston to Crank pin while referring to the right illustration in Fig. 16.

(3) Assemble Air pipe, Seal ring and Crank cap. And secure them with M4x18 Pan head screws. Refer to the left illustration

in Fig. 16.

Retaining ring R-40

Set the above parts

in place.

Ball bearing 6203LLU

Wave washer 30

Crank housing

Fig. 23

Fig. 24

HM0871CHM0870C

17.5mm

Center of

Crank shaft

Center of

Crank pin

17mm

[3] DISASSEMBLY/ASSEMBLY

[3]-5 Crank shaft (cont.)

Protrusion

of Striker

Cylinder sectionBarrel

Page 12

P 12/ 17

DISASSEMBLING

DISASSEMBLING

[3] DISASSEMBLY/ASSEMBLY

[3]-7 Controller

Controller can be removed as illustrated in Fig. 29.

Fig. 29

Fig. 30

Disconnect

Connector

From Controller.

Disassemble Handle section

by unscrewing four 5x25

Tapping screws.

Unscrewing 4x12

Tapping screws,

remove Controller

by levering up

with two Slotted

screwdrivers.

Handle section

[3]-8 Armature

(1) Disassemble Chuck section as illustrated in Fig. 2, Fig. 3, Fig. 4. However, no need to remove Tool holder.

(2) Disassemble Housing cover as illustrated in Fig. 9.

(3) In case of HM0871C, remove Active dynamic vibration abosorber after removing Housing cover. See Fig. 10.

(4) Disconnect Carbon brush from Armature’s commutator as illustrated in Fig. 30.

Carbon brush

Carbon brush

Spiral spring

Detach Spiral spring

from Carbon brush.

Note: It is not necessary to remove

Carbon brush completely from

Brush holder set.

By pulling Carbon brush,

disconnect its contact with

Armature's commutator.

Disassemble Rear cover from Motor housing.

Rear cover

4x18 Tapping screw(2pcs.)

Motor housing

Repair

(5) Separate Motor housing by tapping with Plastic hammer as illustrated in Fig. 31R.

Fig. 31R Fig. 31F

Tap Motor housing at the illustrated portion with Plastic hammer.

Armature can be removed together with Crank housing from

Motor housing.

Do not tap Motor housing at the edge portion

illustrated below.

The edge of Motor housing is so thin that it may

be broken.

Page 13

P 13/ 17

Repair

DISASSEMBLING

[3] DISASSEMBLY/ASSEMBLY

[3]-8 Armature (cont.)

Fig. 32

Fig. 33

Fig. 32A

(6) Disassemble Armature from Crank housing as illustrated in Fig. 32.

If it is difficult to remove as illustrated in Fig. 32, Crank shaft has to be removed in the following process.

1. Disassemble Barrel, Cylinder section as illustrated in Fig. 15.

2. Disassemble Crank cap, Seal ring, Air pipe and Piston as illustrated in Fig. 16.

3. Remove Crank shaft from Crank housing as illustrated in Figs. 19 and 20.

4. Remove Armature using 1R306, 1R239, 1R023 and arbor press as illustrated in Fig. 32A.

Crank housing

Armature can be removed by striking Crank

housing with plastic hammer.

Crank housing

Put Crank housing on 1R023.

Set 1R306 to ram of Arbor press.

Press down Armature using 1R239.

Armature

1R239

1R306

Armature

1R023

(7) Armature can be disassembled as illustrated in Fig. 33.

Flat washer 12

Ball bearing 6203LLB

Fan 76

Insulation washer

Ball bearing 608DDW

Page 14

P 14/ 17

Fig. 34

[3]-9 Handle section

(1) Disassemble Handle section as per the left illustration in Fig. 29.

(2) Remove Handle cover by unscrewing 4x18 Tapping screw to replace the electrical parts in Handle. See Fig. 34.

Power supply cord

Remove 4x18 Tapping screw and Handle cover.

Switch and Power supply cord can be replaced.

Rubber pin 4 comes out after removing Switch.

4x18 Tapping

screw

Switch

Rubber pin 4

Handle cover

Repair

ASSEMBLING

Fig. 35

Fig. 36

Unscrew 5x25 Tapping screws. So Vibration absorbing handle can be disassembled in five parts as illustrated below.

(3) In case of HM0871C, the Vibration absorbing handle section can be disassembled as illustrated in Fig. 35.

Assemble Handle section as illustrated in Fig. 36.

Dust Cover

Support

Dust cover support

Assemble Dust cover support to Handle base, facing its Triangle mark to Back side.

When assembling Dust cover to Dust cover support, face the >NBS< mark to

Triangle mark on Dust cover support.

Dust cover

Dust cover

Handle

Handle

cover

5x25 Tapping

screw (2pcs.)

Flat washer 5 (2pcs.)

Handle base

Compression

spring 11

“>NBS<” Mark

Triangle mark

Back side

Page 15

P 15/ 17

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-10. Fastening torque

[4] MAINTENANCE PROGRAM

Replacing the following parts is recommended when Carbon brush is replaced.

Wipe off the old grease in the machine, and then apply the fresh grease in accordance with [2] LUBRICATIONS.

Fig. B

Fig. A

Item No.

1

3

Barrel

Description

Fasten the following bolts to the specific fastening torque.

7.8 - 11.7 N.m

M6 x 25 Hex socket head bolt

Barrel

Crank housing complete

Housing cover

4 Fastening Barrel to Crank housing complete

2.9 - 3.4 N.m

M5 x 25 Hex socket head bolt 1 Fastening Housing cover to Barrel

Item No. Fastening torqueQ’tyDescription Use for

25

42

42

25

25

Striker

Cylinder 32

Piston

Impact bolt

Tool holder

Chuck cover

7

19

20

7

31

50

51

1 Tool holder cap

3 Ring spring 25

7

19 Fluoride ring 28

20 O ring 23

O ring 24

31 50

51 O ring 26

Tool retainer

Page 16

Circuit diagram

Wiring diagram

P 16/ 17

Blue Lead wire is used

for some countries.

Brown Lead wire is used

for some countries.

Terminal block

Power supply cord

Polyethylene tube

White

Color index of lead wires' sheath

Black

Fig. D-2

Fig. D-1

HM0870C

without No Load Speed

Suppression

Note in wiring

6 3 1 9 2 9 - 5

LOT No.

LOW

6 3 1 9 3 0 - 0

LOT No.

HIGH

HM0871C

with No Load Speed

Suppression

6 3 1 9 3 1 - 8

100 - 130V

220 - 240V

LOT No.

LOW

6 3 1 9 3 2 - 6

LOT No.

HIGH

Indication for 110V-127V area

Indication for 220V-240V area

HM0870C

without No Load Speed

Suppression

HM0871C

with No Load Speed

Suppression

Controller for HM0870C is different from that for HM0871C.

Controller

Page 17

Wiring diagram

P 17/ 17

Fig. D-3

Handle

Lead Unit

Fig. D-4

Polyethylene Tube Ø8-30

Connector

for connecting to Switch

for connecting to Terminal block

Pass the Lead wires of Lead unit through Polyethylene tube illustrated below.

Lead unit’s Lead wires

Lead unit’s Lead wires have to

be put on both side of Boss,

And connect them to Switch

and Terminal.

Lead unit’s Lead wires bundled

with Polyethylene tube has to put

under Terminal block.

Boss

Terminal block

Sponge sheet

Connector of

Lead unit

Put the following Lead wires

of Lead unit into Sponge sheet.

* Lead wire (black) for connecting to Switch

* Lead wire (black) for connecting to Terminal

block

* Lead wire (white) for connecting to Switch

The Lead wires have

to be tightened in this

area.

Polyethylene

tube

Loading...

Loading...