Page 1

T

ECHNICAL INFORMATION

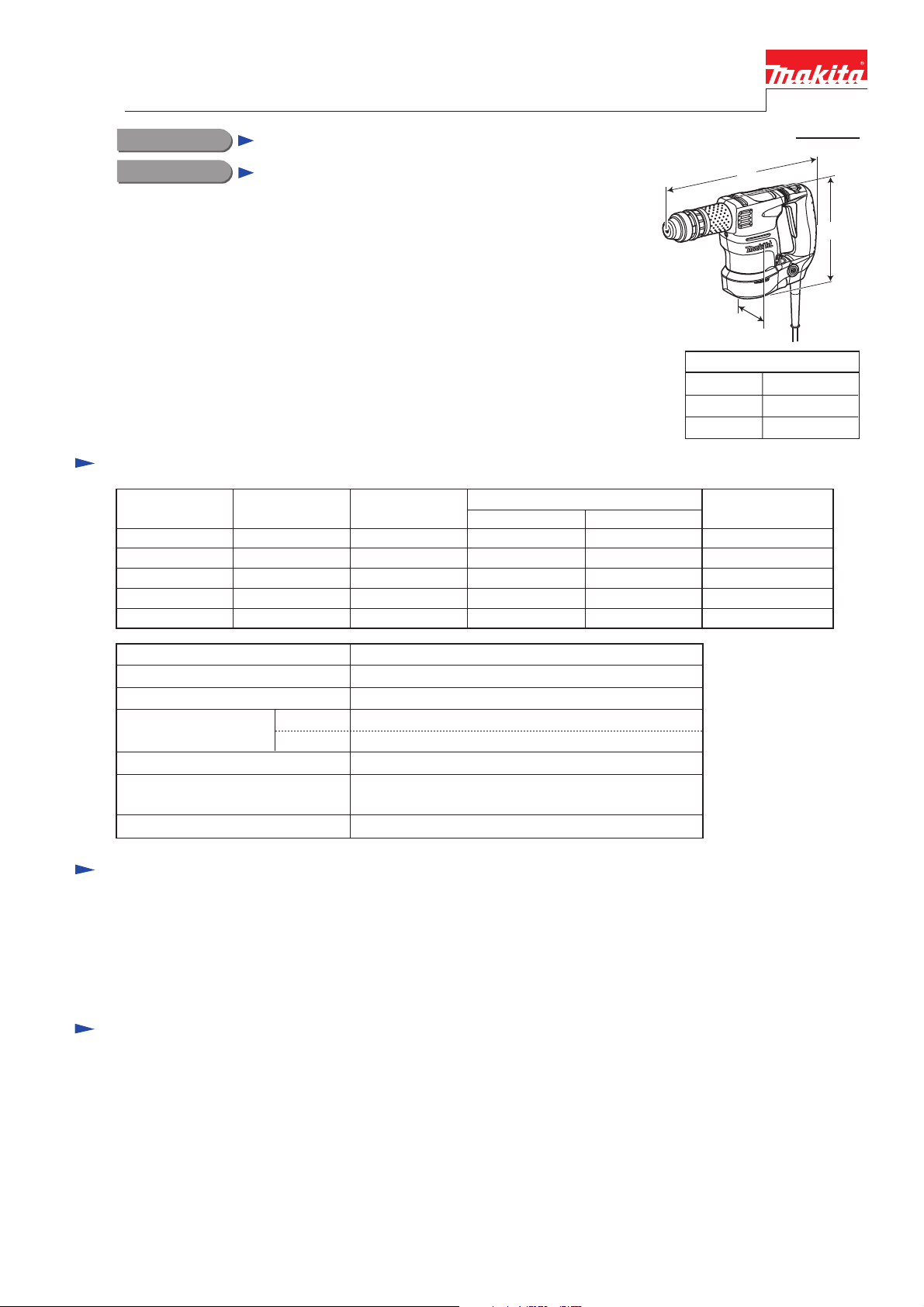

Models No.

HK1820

PRODUCT

P 1/17

Description

Power Scraper

CONCEPT AND MAIN APPLICATIONS

Model HK1820 has been developed as the successor model of HK1810,

featuring vibration absorbing handle additionally to the same compact

and lightweight design as the predecessor model.

Also features the chuck adapted for SDS-PLUS bits.

Specification

Voltage (V) Cycle (Hz)

110

120

220

230

240

Current (A)

5.3

5.0

2.6

2.5

2.4

50/60

50/60

50/60

50/60

50/60

Continuous Rating (W)

Input Output

550

---

550

550

550

260

260

260

260

260

L

W

Dimensions: mm (")

Length (L)

Width (W)

Height (H)

Max. Output (W)

351 (13-3/4)

390

390

390

390

390

H

102 (4)

203 (8)

Impacts per min: ipm=min-1

Shank type: mm (")

Impact energy [catalog value]: J 3.9

Variable speed control

Protection from electric shock

Power supply cord: m (ft)

Net weight: kg (lbs)

Chile, Brazil: 2m (6.6ft)

Other countries: 5m (16.4ft)

0 - 3,200

SDS-Plus

Yesby trigger

Yesby dial

Double insulation

3.3 (7.3)

Standard equipment

Bull point ................................. 1

Scaling chisel ........................... 1

Scaling chisel (for tile) ............. 1

Hook complete ......................... 1

Plastic carrying case ................. 1

Note: The standard equipment for the tool shown above may differ by country.

Optional accessories

Bull points

Cold chisel

Grooving chisels

Scaling chisel

Scaling chisel (for tile)

Hook complete

Scraper assembly

Grease vessel (containing Hammer grease)

Bit grease

Safety goggles

Page 2

P 2/17

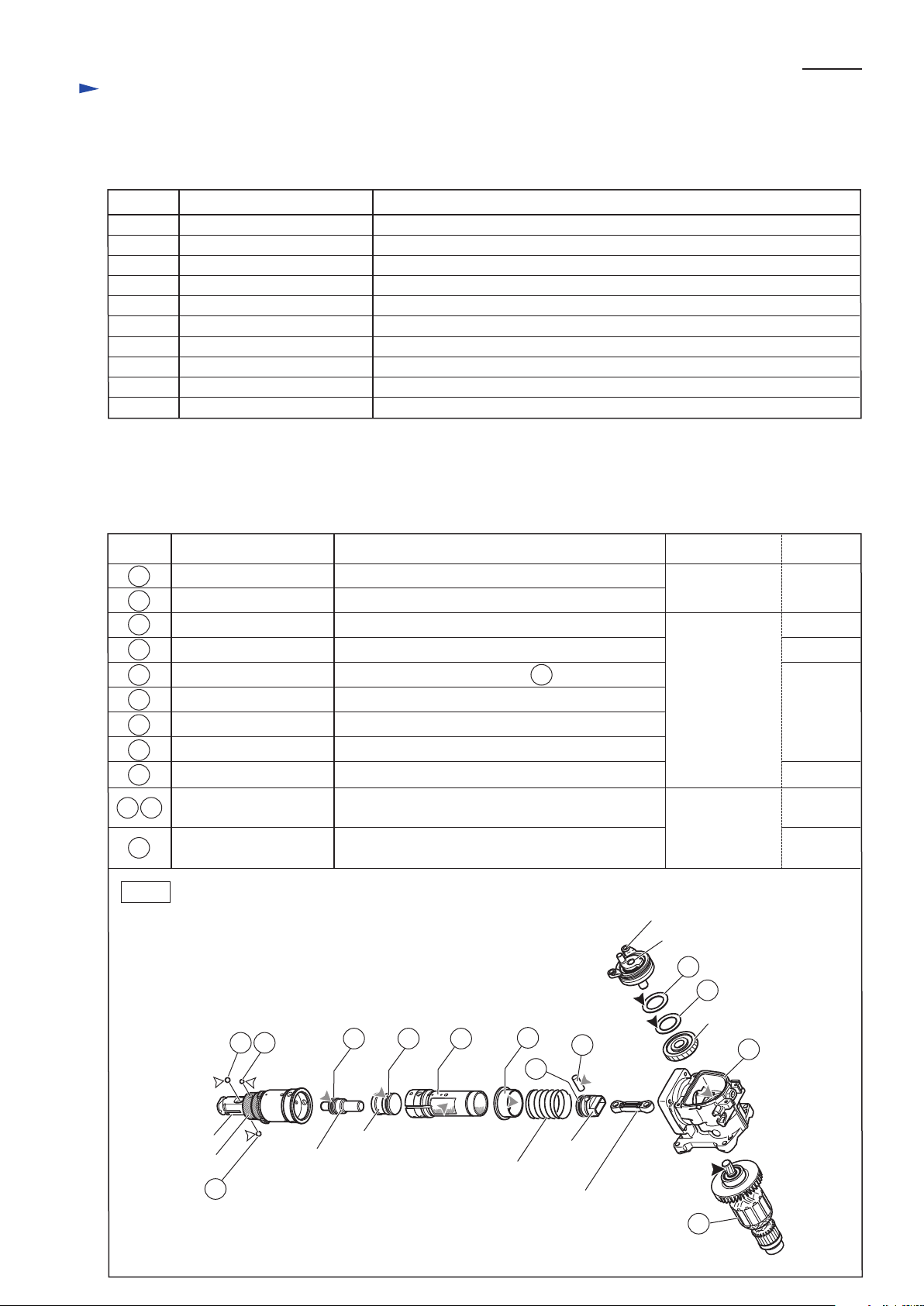

[2] LUBRICATION

Apply the following lubricants to protect parts and product from unusual abrasion:

*Makita grease N.No.1 to the portions designated with black triangle

*Makita grease R.No.00 to the portions designated with gray triangle

*Makita grease N.No.2 to the portions designated with white triangle

[1] NECESSARY REPAIRING TOOLS

CAUTION: Remove the bits from the machine for safety before repair/maintenance

in accordance with the instruction manual!

Fig. 1

Repair

DescriptionCode No. Use for

Item No. Description Portion to lubricate

1R003

1R022

1R023

1R029

1R212

1R228

1R229

1R258

1R288

Retaining ring pliers ST-2N

Bearing plate

Pipe ring

Bearing setting pipe 23-15.2

Tip for retaining ring pliers

1/4" Hex shank bit for M4

1/4" Hex shank bit for M5

V Block

Screwdriver magnetizer

Removing/mounting Ring spring

Stabilizing Bearing box when removing Ball bearing 6002LLU

Stabilizing Crank housing complete when removing Armature

Removing Oil seal 15 and Ball bearing 6002LLU from Bearing box

Removing/mounting Ring spring (for modular use with 1R003)

1R225 Bearing extractor Removing Armature and Ball bearing 6001DDW from Crank housing comp.

Removing M4x25 Hex socket head bolt from Crank housing cover

Removing M5x25 Hex socket head bolt from Barrel

Stabilizing Bearing box when removing Helical gear 36

Magnetizing Screwdriver when removing Steel balls and Pins

Ring 25

Impact bolt

Tool holder

Compression spring 32

23277

Striker

30

Piston

Connecting rod

38

68

37

27 O Ring 12 Whole portion

Cylinder Inside surface that Piston and Striker contacts

Whole portion

30

7 Steel ball 4.8 (3 pcs) Whole portion

23 Steel Ball 7.0 (2 pcs) Whole portion

37 O Ring 18 on Striker

O Ring 18 on Piston Whole portion

38

32

32 Ring 29

Inside periphery that contacts 30 Cylinder

3g

17g

4g

39 Pin 7 Cylindrical surface that contacts Connecting rod

Flat washer 22

Crank housing complete Crank room

Whole portion for smooth rotation

of Helical gear 36

58 59

61

68 Armature

Gear portion for smooth rotation

of Helical gear 36

39

AmountLubricant

Makita grease

N.No.2

Makita grease

N.No.1

Makita grease

R.No.00

a little

a little

a little

Crank shaft

Bearing box

Helical gear 36

58

59

61

23

a little

Page 3

Motor housing

P 3/17

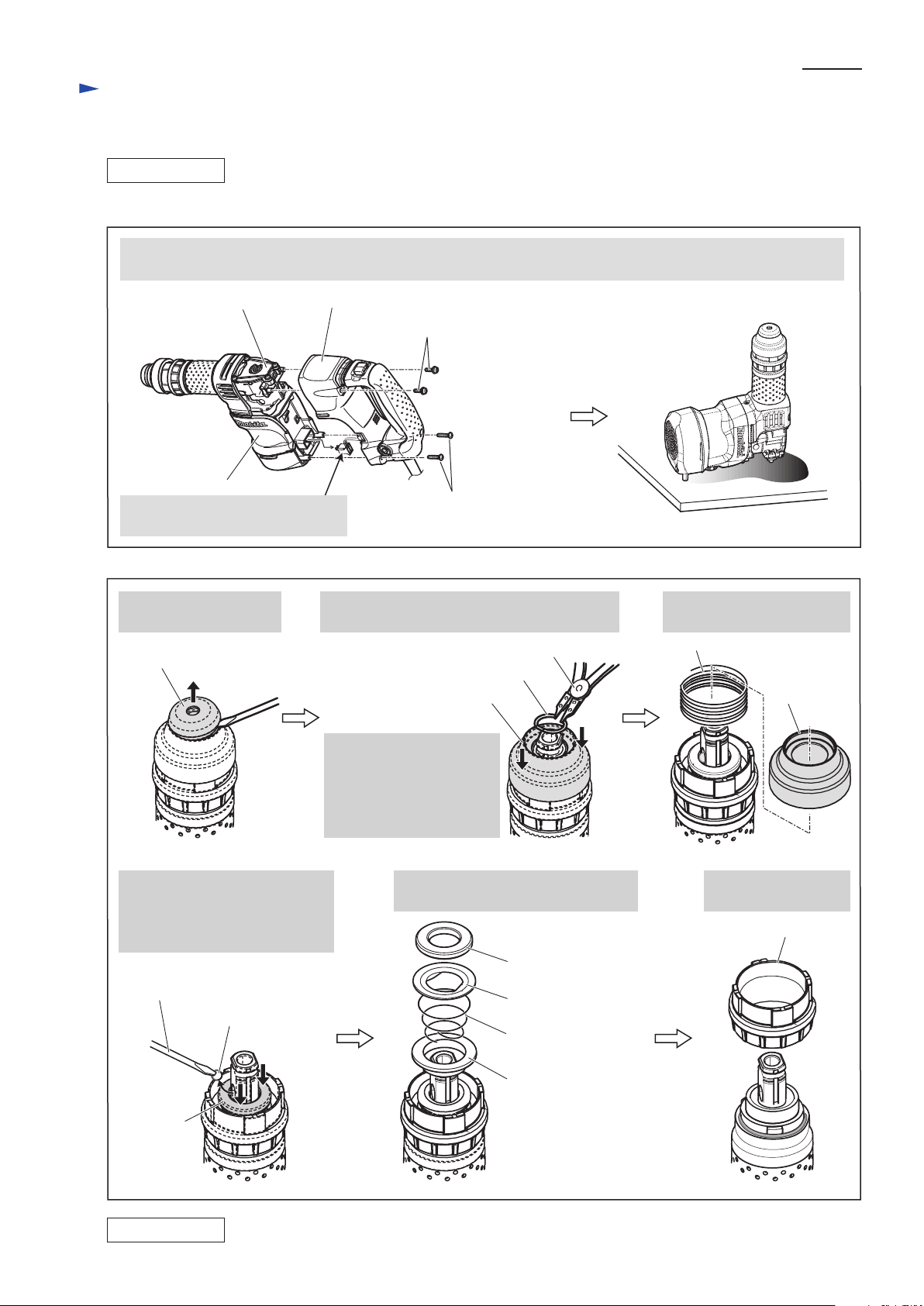

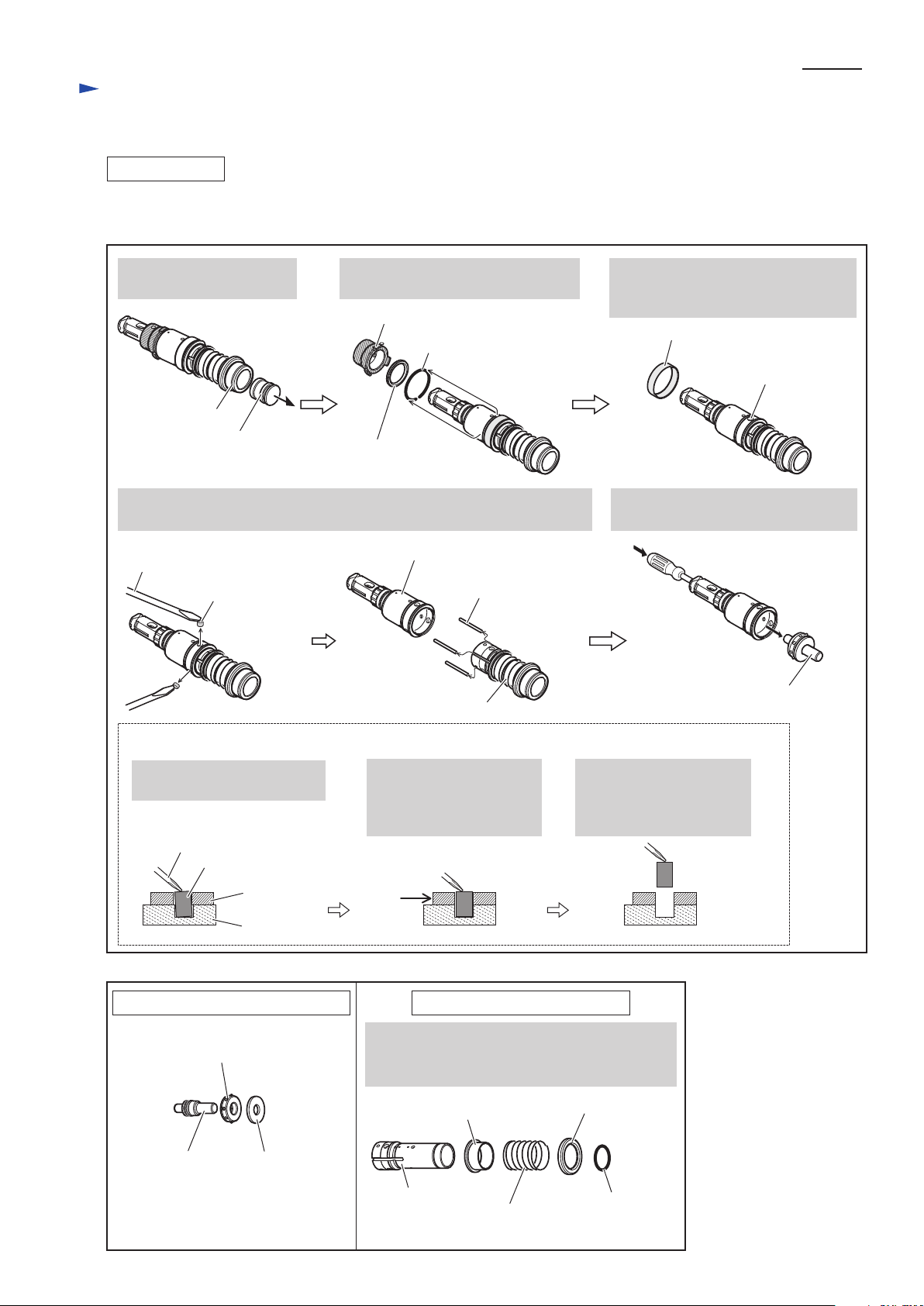

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Chuck Section

Repair

DISASSEMBLY

DISASSEMBLY

M5x20 Pan head screw (2 pcs)

Handle section

Cap 38

Do the reverse of the disassembling steps.

2) Remove Cap 38 with

slotted screwdriver.

4) Remove Chuck cover and

Compression spring 42.

Steel ball guide

1) For easy repairing, separate Handle section and stand the machine on a workbench as illustrated below on right.

Note: Remove Compression spring 14 before standing the machine if it is left on Crank housing complete.

Disassemble the Chuck section as described in Figs. 2 and 3.

5x25 Tapping screw (2 pcs)

Fig. 2

Fig. 3

Change ring

Guide washer

Conical compression

spring 21-29

Ring 21

Crank housing complete

Disconnect Connector housing

of Controller from Motor housing.

Compression spring 42

Chuck cover

3) Remove Ring spring 19 with 1R212 and

1R003 while pressing down Chuck cover.

5) Remove Steel ball 7 (2 pcs)

using screwdriver magnetized

with 1R288 while pressing

down Ring 21.

7) Change ring can

now be removed.

6) The parts inside Change ring can

be removed.

Ring 21

Steel ball 7 (2 pcs)

Screwdriver magnetized

with 1R288

Chuck cover

Ring spring 19

1R212 and 1R003

Note:

Be sure to press down

Chuck cover or it will

pop off due to the pressure

of Compression spring 42.

Page 4

Remove Barrel cover support

and Barrel cover.

P 4/17

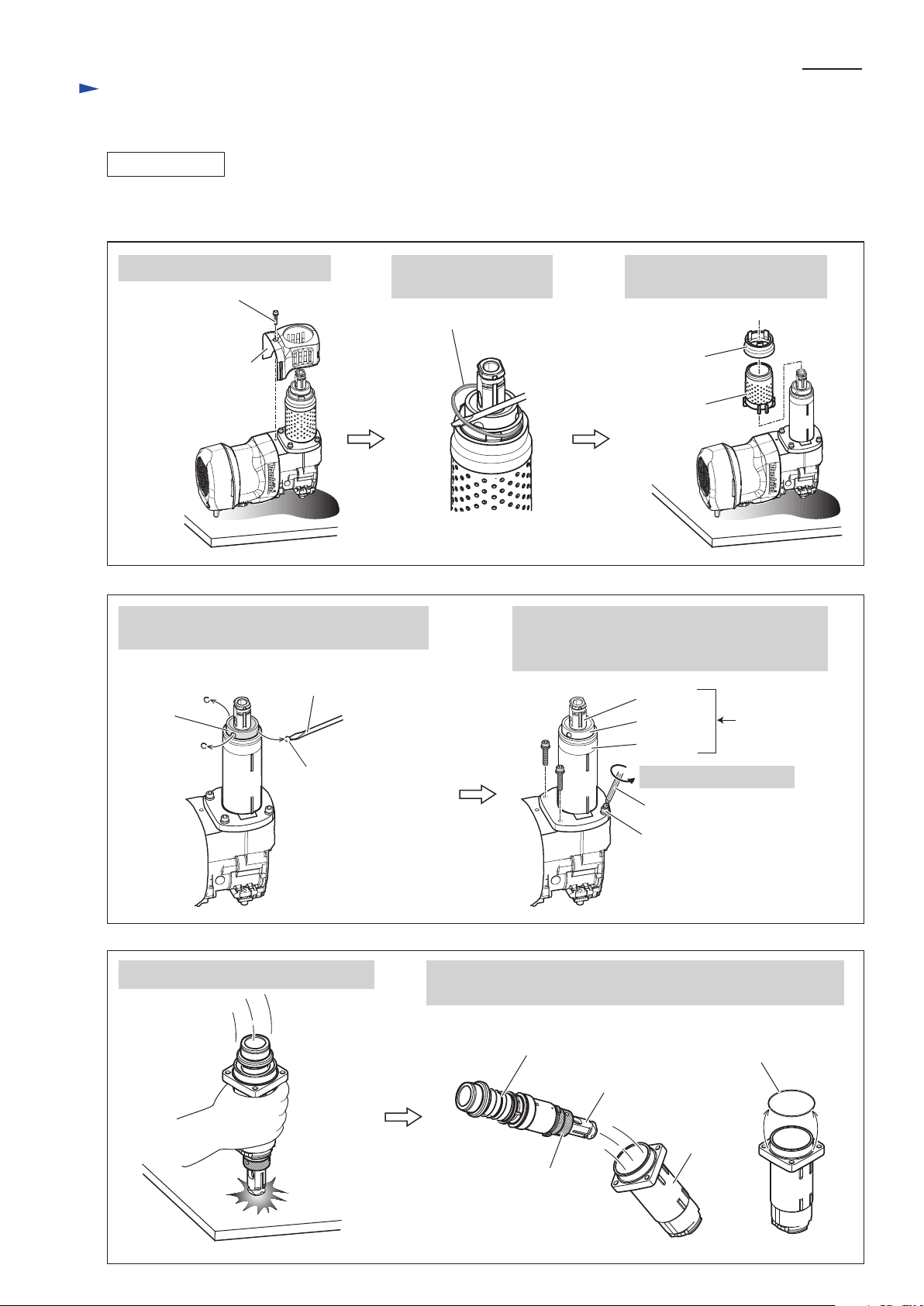

[3] DISASSEMBLY/ASSEMBLY

[3] -2. Barrel, Tool Holder, Cylinder Section

Repair

DISASSEMBLY

1) Disassemble the Chuck section as described in Figs. 2, 3.

2) Disassemble Tool holder, Ring 25 and Cylinder section from Barrel as described in Figs. 4, 5, 6.

Crank housing cover

Ring spring 43

M4x25 Hex socket

head bolt (1 pc)

Steel ball 4.8 (3 pcs)

Remove Crank housing cover. Remove Ring spring 43

with slotted screwdriver.

Remove Steel ball 4.8 (3 pcs) from each hole

of Ring 25 with slotted screwdriver.

Strike Tool holder against work bench. Tool holder, Ring 25 and Cylinder section can now be removed

from Barrel. Remove O ring 48 from Barrel.

Barrel section can now be separated from

Crank housing complete by unscrewing

four M5x25 Hex socket head bolts with 1R229.

Ring 25

Ring 25

Barrel

1R229

Tool holder

Cylinder section

O Ring 48

Fig. 4

Fig. 5

Fig. 6

Screwdriver magnetized

with 1R288

Barrel cover

support

Barrel cover

M5x25 Hex socket

head bolt (4 pcs)

Barrel section

Turn counterclockwise.

Ring 25

Barrel

Tool holder

Page 5

P 5/17

[3] DISASSEMBLY/ASSEMBLY

[3] -2. Barrel, Tool Holder, Cylinder Section

Repair

DISASSEMBLY

Ring 39

1. Pull out Striker from

Cylinder section.

2. Remove ring 25, Urethane ring 26

and Ring spring 37 from Cylinder.

3. By removing Ring 39, you can see

Pin 6 (3 pcs) that join Tool holder

with Cylinder.

Ring 25

Urethane ring 26

Ring spring 37

Rod 2.5 (3 pcs)

Tool holder

Impact bolt section

Pin 6 (3 pcs)

Cylinder section

Fig. 7

4. By removing Pin 6, Tool holder can be separated from Cylinder section.

Remove Rod 2.5 (3 pcs) from the grooves of Cylinder.

5. Push out Impact bolt section from

Cylinder section using screwdriver.

Note: Pin 6 can be removed as described below if it is difficult to remove.

1. Apply magnetized

screwdriver to Pin 6.

Cylinder

Pin 6

Tool holder

3. Remove Pin 6 using

magnetized screwdriver

when the two holes are

aligned.

Rubber ring 13

Disassembling Impact Bolt Section Disassembling Cylinder Section

Flat washer 12

After removing O Ring 26, the following parts

can be removed from Cylinder:

Cup washer 29, Compression Spring 32, Ring 29

Impact bolt

Fig. 8

Ring 29

Compression Spring 32

Cylinder

Cup washer 29

O Ring 26

3) Separate Tool holder from Cylinder section as described in Fig. 7.

4) Disassemble Impact bolt and Cylinder section as described in Fig. 8.

Striker

Cylinder section

Pin 6 (3 pcs)

Screwdriver,

magnetized with 1R288

2. Align the through hole

of Tool holder with that

of Cylinder by pushing

Tool holder.

Screwdriver,

magnetized with 1R288

Page 6

P 6/17

[3] DISASSEMBLY/ASSEMBLY

[3] -2. Barrel, Tool Holder, Cylinder Section

Repair

ASSEMBLY

Fig. 9

Do the reverse of the disassembling steps.

Note: Rubber ring 13 is directional when assembled to Impact bolt.

Be sure to assemble as illustrated to left in Fig. 9.

ASSEMBLY

Do the reverse of the disassembling steps.

DISASSEMBLY

[3] -3. Electrical Parts in Handle Section

Correct Wrong

Rubber ring 13

Impact bolt Flat washer 12

Rubber portion

Metal portion

Rubber portion

Metal portion

Rubber ring 13

Impact bolt Flat washer 12

1) Disassemble Handle section as described in Fig. 2

2) The electrical Parts can be replaced as described in Fig. 10.

1. Disassemble Handle cover from Handle

by unscrewing 4x18 tapping screw.

2. Disconnect all the Lead wires from Switch.

Controller, Switch and Power supply cord can now be replaced.

Fig. 10

Handle cover

Handle base

4x18 Tapping screw (1 pc)

Handle

Controller

Switch

4x18 Tapping

screw (1 pc)

Power supply cord

Strain relief

Page 7

P 7/17

[3] DISASSEMBLY/ASSEMBLY

[3] -4. Motor Section

Repair

1) Disassemble Handle section as illustrated in Fig. 2

2) Separate the contact of Carbon brushes from Commutator as described in Fig. 11.

3) Disassemble Crank housing complete from Motor housing as illustrated in Fig. 12.

4) Remove Piston from Crank shaft as illustrated in Fig. 13.

DISASSEMBLY

1. Disconnect Crank housing cover

from Crank housing complete

by unscrewing M4x25 Hex socket

head bolt; no need to remove the

cover in this step.

2. Lifting up Crank housing cover,

remove Barrel section from

Crank housing by unscrewing

four M5x25 Hex socket head

bolts.

3. Disassemble Crank housing

complete from Motor housing

by unscrewing four 5x25

Tapping screws.

1. Remove Rear cover from Motor housing.

Fig. 11

Fig. 12

Crank housing cover

M4x25 Hex socket

head bolt (1 pc)

5x25 Tapping

Screw (4 pcs)

M5x25 Hex socket

head bolt (4 pcs)

Motor housing

Crank housing complete

Rear cover

4x18 Tapping screw

(2 pcs)

Motor housing

2. Remove the end of Spiral spring

from Carbon brush because

Carbon brush is pressed with

Spiral spring to maintain secure

contact with Commutator.

3. By pulling Carbon brush,

separate the contact of

Carbon brushes from

Commutator.

[Spiral spring and Carbon brush

viewed from A]

Carbon brush

Spiral spring

M4x18 Pan head

screw (4 pcs)

Crank cap

Crank housing

complete

Crank chamber,

viewed from Crank cap side

1. Remove Crank cap by unscrewing

four M4x18 Pan head screws.

Piston

Fig. 13

2. For easy removal of Piston,

move it to the front dead center.

PistonM4x16 Hex socket

head bolt (2 pcs)

3. Remove Piston, then unscrew

two M4x16 Hex socket head

bolts that fasten Crank section

to Crank housing complete.

A

Page 8

P 8/17

[3] DISASSEMBLY/ASSEMBLY

[3] -4. Motor Section

Repair

5) Remove Crank section from Crank housing complete by tapping

Crank housing complete with plastic hammer. (Fig. 14)

6) Remove Armature from crank housing complete using 1R023,

1R225 and arbor press as described in Fig. 15.

DISASSEMBLY

1. Set Crank housing complete

on 1R023, and apply the thin

end of 1R225 to Armature shaft.

Then press down 1R225 using

arbor press until it stops.

2. Turn over 1R225, and fit the pin on the thick end of 1R225

in the inner race of Ball bearing 6001DDW.

Armature can now be removed by pressing down 1R225

using arbor press.

Fig. 15

Ball bearing

6001DDW

1R023

Armature shaft

thin end

of 1R225

thick end

of 1R225

Fig. 14

Crank section

O Ring 39

thin end

of 1R225

thick end

of 1R225

Note:

1R225 of old specification cannot

be set in place due to the height A

of 20mm. If your 1R225 is old one,

grind down the height A to 15mm

or less using power grinder.

[Cross-sectional view] [Cross-sectional view]

pin

height A

1R225

ASSEMBLY

Do the reverse of the disassembling steps.

Note: Make sure that O Ring 39 is mounted to Bearing box of Crank section before assembling Crank section

to Crank housing complete. (Fig. 14)

Crank housing complete

Crank housing

complete

Page 9

P 9/17

[3] DISASSEMBLY/ASSEMBLY

[3] -5. Gear (Crank) Section

Repair

DISASSEMBLY

Fig. 16

ASSEMBLY

Do the reverse of the disassembling steps.

Note: Make sure that O Ring 39 is mounted to Bearing box of Crank section before assembling Crank section

to Crank housing complete. (Fig. 14)

1) Disassemble Gear (Crank) section from Crank housing complete as described in Figs. 11 - 14.

2) Gear (Crank) section can now be disassembled as described in Fig. 16.

Ball bearing 6002LLU

1R029

1R022

Bearing box

Crank shaft

1R258

Oil seal 15

1. Stabilizing Bearing box

of Gear section on 1R258,

remove Crank shaft using

arbor press.

2. Remove Helical gear 36

and Flat washer 22 (2 pcs)

from Bearing box.

3. Put 1R022 under Bearing box to make

Bearing box parallel to arbor press,

then apply 1R029 to Oil seal 15.

By pressing down 1R029 with arbor press,

Oil seal 15 and Ball bearing 6002LLB

can be removed from Bearing box.

Flat washer 22

(2 pcs)

Helical gear 36

Page 10

P 10/17

[3] DISASSEMBLY/ASSEMBLY

[3] -6. Handle Section

Repair

DISASSEMBLY

M5x20 Pan head

screw (2 pcs)

5x25 Tapping

screw (2 pcs)

Handle section

Handle section consists of the following main parts: Handle base, Handle, Handle cover

And it can be disassembled as illustrated in Figs. 17 - 20.

Handle base

Handle

Lock-on button

Stop ring E-4

Switch Lever

Compression spring 8

Dust cover

Dust cover support

Spring guide

Handle cover

Handle base

3. Separate Handle from Handle base.

Note: See Fig. 10 for disassembling the electrical parts

in Handle section.

4. Remove Switch lever and Stop ring E-4

from Handle. Compression spring 8 and

Lock-on button can now be removed.

Handle

Shoulder sleeve 6 (2 pcs)

Fig. 17 Fig. 18

Fig. 19 Fig. 20

4x18 Tapping screw (2 pcs)

4x18 Tapping screw (1 pc)

1. Separate Handle section from the machine first by removing the four

screws illustrated below, then by disconnecting Connector housing of

Controller from Motor housing; Compression spring 14 can be

removed from Crank housing in this step.

2. Remove Handle cover and

Spring guide from Handle base.

Connector housing

of Controller

Compression spring 14

5x25 Tapping screw (2 pcs)

ASSEMBLY

Do the reverse of the disassembling steps.

Page 11

P 11/17

[3] DISASSEMBLY/ASSEMBLY

[3] -7. Recommended Fastening Torque of Screws and Bolts

Repair

Tighten the bolt to the recommended torque described in Fig. 21.

Fig. 21

Fig. 22

[4] MAINTENANCE PROGRAM

When replacing carbon brush, it is recommended to do the following maintenance at the same time

for longer service life of the machine.

1) Replace the parts described in Fig. 22 with new ones.

2) Wash out or wipe off old grease in Crank housing complete, and lubricate the parts

in accordance with the instructions in [2] LUBRICATION. (Refer to Fig. 1.)

Chuck cover Guide washer Change ring

Impact boltTool holder

Steel ball 4.8

Ring 21 Striker Cylinder Piston

Connecting rod

Ring 29

1

23

Cap 38

Item No. Description

Urethane Ring 26

Steel ball 7.0 (2 pcs)

O Ring 12

Rubber Ring 13

O Ring 18 (thick one)

27

28

37 38

9

Barrel

Crank housing

complete

19

19

Item No.

Fastening Torque

Q'ty

Description

4

7.8 - 11.8 N.m

M5 x 25 Hex socket head bolt

1

239 27 28 3837

Page 12

P 12/17

Circuit diagram

White

Red

Orange

Blue

Brown

Color index of lead wires' sheath

Black Clear

Fig. D-1A

Connector housing A

Polyolefin tube (Protective tube)

Connector housing B

Switch

Connector

Power supply cord

Controller

High Voltage Areas where Radio Interference Suppression Is Required

Fig. D-1B

Fig. D-1C

Low Voltage Areas where Radio Interference Suppression Is Required

Other Areas where Radio Interference Suppression Is Not Required

Connector housing A

Switch

Controller

Noise

suppressor

Connector housing A

Grounding (Earth) terminal

Switch

Controller

Power supply cord

Power supply cord

Connector

Connector

Polyolefin tube (Protective tube)

Polyolefin tube (Protective tube)

Choke coil

Noise

suppressor

Page 13

Wiring diagram

P 13/17

Handle base,

viewed from

Controller side

Handle

Through hole for

passing Lead wires

from Controller and

Connector housing

to the opposite side

Handle cover

Handle,

viewed from Handle cover side

Handle base

Controller

Be careful not to pinch the Lead wires with the ribs. (Figs. D-2, D-3)

[1] Routing Wires Through Handle Base and Handle

Fig. D-2

Fig. D-3

Do not put the Lead wires on this rib

or they will be pinched between the rib

and Handle.

Do not to put the Lead wires on these ribs

or they will be pinched between the ribs

and Motor housing.

Through hole for

passing Grounding

(Earth) wire from

the opposite side

Through hole for

passing Lead wires

to the opposite side

Do not to put the Lead wires on this rib

or they will be pinched between the rib

and Handle cover.

Noise suppressor

(if used)

Do not to put the Lead wire (clear)

of Noise suppressor on these ribs.

Page 14

Wiring diagram

P 14/17

Fig. D-4A

Fig. D-5A

Handle base,

viewed from Controller side

Handle base,

viewed from Handle side

Handle, viewed from Handle cover side

red

blue

Lead wires covered with

Polyolefin tube (black)

Controller

Connector housing A

Connector housing B

Choke coil

Controller

Noise suppressor

Switch

Switch holder

Pass the following Lead wires

through this hole:

*Noise suppressor's Lead

wires (black)

*Controller’s Lead wires covered

with Polyolefin tube (black)

*Lead wire (red) from

Connector housing A

*Controller's Lead wire (white)

Pass Controller’s Lead wires covered

with Polyolefin tube (black) between

Switch and Switch holder's wall.

[2] Wiring in Handle Base and Handle

High Voltage Areas where Radio Interference Suppression Is Required

boss

rib

Put the slack portion of

Lead wires in this space.

Route all of the Controller's

Lead wires through this slit.

Fix the following Lead wires of

Controller with this Lead wire holder:

*Lead wire (orange) to Choke coil

*Lead wires (black, red) to Connector

housing A

Pass these Lead wires from Controller

and Connector housing A through

the hole illustrated to right in Fig. D-2.

The Lead wires to Connector

housings must be tight between

Controller and Lead wire holder.

Route all of the Lead wires

to Switch through between

the boss and the rib.

Fix all of the Lead wires to Switch

with this Lead wire holder of

Switch holder complete.

Page 15

Wiring diagram

P 15/17

Fig. D-4B

Fig. D-5B

[2] Wiring in Handle Base and Handle

Low Voltage Areas where Radio Interference Suppression Is Required

The Lead wires to Connector

housing A must be tight between

Controller and Lead wire holder.

Terminal of Grounding wire

Grounding wire (clear)

Controller

Put the slack portion of

Lead wires in this space.

Route all of the Lead wires

to Switch through between

the boss and the rib.

Fix all of the Lead wires to Switch

with this Lead wire holder of

Switch holder complete.

Handle Base,

viewed from Handle side

Handle, viewed from Handle cover side

Noise suppressor

Switch

Switch holder

Pass Controller’s Lead wires covered

with Polyolefin tube (black) between

Switch and Switch holder's wall.

boss

rib

Handle base,

viewed from Controller side

Pass the following Lead wires

through this hole:

*Noise suppressor's Lead

wires (black)

*Controller’s Lead wires covered

with Polyolefin tube (black)

*Lead wire (red) from

Connector housing A

*Controller's Lead wire (white)

Pass Grounding wire (clear)

through the hole illustrated

to right in Fig. D-2.

red

white

Route all of the Controller's

Lead wires and grounding

wire (clear) through this slit.

Fix the following Lead wires of

Controller with this Lead wire holder:

*Grounding wire (clear)

*Lead wires (black, red) to Connector

housing A

Controller

Connector housing A

Lead wires covered with

Polyolefin tube (black)

Pass these Lead wires from Controller

and Connector housing A through

the hole illustrated to right in Fig. D-2.

Grounding wire (clear)

Fix Grounding wire (clear)

with this Lead wire holder.

Put the slack portion of

Grounding wire in this space.

Fix Grounding wire (clear)

with this Lead wire holder.

Page 16

Wiring diagram

P 16/17

Fig. D-4C

Fig. D-5C

[2] Wiring in Handle Base and Handle

Other Areas where Radio Interference Suppression Is Not Required

Put the slack portion of

Lead wires in this space.

Route all of the Lead wires

to Switch through between

the boss and the rib.

Fix all of the Lead wires to Switch

with this Lead wire holder of

Switch holder complete.

Handle base,

viewed from Handle side

Handle, viewed from Handle cover side

Switch

Switch holder

Pass Controller’s Lead wires covered

with Polyolefin tube (black) between

Switch and Switch holder's wall.

boss

rib

Handle base,

viewed from Controller side

Pass the following Lead wires

through this hole:

*Controller’s Lead wires covered

with Polyolefin tube (black)

*Lead wire (red) from

Connector housing A

*Controller's Lead wire (blue)

The Lead wires to Connector

housing A must be tight between

Controller and Lead wire holder.

Controller

red

blue

Connector housing A

Lead wires covered with

Polyolefin tube (black)

Pass these Lead wires from Controller

and Connector housing A through

the hole illustrated to right in Fig. D-2.

Controller

Route all of the Controller's

Lead wires through this slit.

Fix the following Lead wires of

Controller with this Lead wire holder:

*Lead wires (black, red) to Connector

housing A

Page 17

Wiring diagram

P 17/17

Fig. D-6

[3] Connecting Connector Housing with Brush Holder Unit

Rear cover

The side where Lead wires are drawn out must be placed on Rear cover side as illustrated blow.

to Controller

on Handle base

Connector housing A

Connector housing B

(if used)

Motor housing

Choke coil

(if used)

Connector housing is directional when connected with Brush holder complete in Motor housing.

Be sure to connect as described in Fig. D-6.

2. Do not put Lead wires on Connector

housing(s) or Lead wires will be

pinched between Handle base and

Motor housing.

[DO NOTs]

1. The side where Lead wires are drawn out

must not be placed on the opposite side to

Rear cover.

side where Lead wires

are drawn out

Loading...

Loading...