Page 1

HG 5010

HG 5011

HG 6010

HG 6020

HG 6300

i

110016930 02/2011 Subject to technical modifications.

Makita Corporation

Anjo, Aichi, Japan

www.makita.com

Page 2

HG 6300

1

2

3

6

10

8

HG 6010

HG 6020

HG 5011 HG 5010

5

8

9

1

2

3

6

10

7

5

1

2

3

6

10

5

1

2

6

5

7

9

4

4

1

2

6

5

4

4

4

- 3 -- 2 -

I

G

A B C

D

E

F

H

500 - 630 °C

250 - 300 °C

250 - 500 °C

500 - 630 °C

250 - 300 °C 630 °C

HG 5010 / HG 5011 / HG 6010 / HG 6020 / HG 6300

HG 6020 / HG 6300

250 - 400 °C

300 °C 300 - 400 °C

Page 3

Features - Getting started

- 5 -

HG 5010 / H G 5011

The tool is switched ON and OFF at the two-stage switch (6) on the back of the grip handle (HG 5011) or on

the front of the grip handle (HG 5010). Airflow and temperature can be adjusted to 2 settings. Stage 1 reaches

300 °C at an airflow of 240 l/min, stage 2 reaches 500 °C at 450 l/min.

HG 6300

The tool is switched ON and OFF at the three-stage switch (6) on the back of the grip handle. In addition to

three-stage speed/airflow control, temperature can be continuously adjusted over a range of 50 °C to 630 °C

by the pushbuttons (8). The target temperature can be increased in 10 °C steps by pressing the ”+” side of

the temperature pushbutton (8) or reduced by pressing the ”-” side of the temperature pushbutton (8).

Pressing the button briefly increases or reduces the target temperature by one 10 °C step. Keeping the button

pressed will continue to increase or reduce the temperature in steps of 10 °C until the button is released or the

minimum or maximum temperature is set.

Blower stage 1 delivers a temperature of 50 °C. The tool will take a short while to cool to 50 °C after switching

down to blower stage 1 when it has been operating at high temperatures on blower stage 2 or 3. While the

tool is cooling down, the LCD display (9) shows the actual temperature at the nozzle outlet. After switching off,

the tool stays in the last setting. The guard sleeve (3) detaches at a bayonet catch.

HG 6010

The tool is switched ON and OFF at the three-stage switch (6) on the back of the grip handle. Airflow

and temperature can be adjusted to 3 settings. Stage 1 is a cold-air stage at 50 °C with an airflow rate of

200 l/min. Stage 2 reaches 400 °C at an airflow of 300 l/min, stage 3 delivers 600 °C at 500 l/min. The

guard sleeve (3) detaches at a bayonet catch.

HG 6020

The tool is switched ON and OFF at the two-stage switch (6) on the back of the grip handle. In addition to

three-stage speed/airflow control (stage 1 is a cold-air stage at 50 °C ), temperature can be continuously

adjusted over a range of 50 °C – 600 °C at the thumbwheel (7). The numbers (1 to 9) on the thumbwheel

serve as a guide only. Whereas ”1” means 50 °C, the maximum temperature of 600 °C is attained at ”9”. Airflow

can be adjusted to the three stages of 150/300/500 l/min. The guard sleeve (3) detaches at a bayonet catch.

Please note: The distance from the object you are working on depends on material and intended method

of working. Always try out the airflow and temperature on a test piece first! Using the attachable accessory

nozzles (see accessories page on the cover) the flow of hot air can be controlled with maximum precision.

Take care when changing hot nozzles! When using the heat gun in the self-resting position, make sure

it is standing on a stable, non-slip and clean surface.

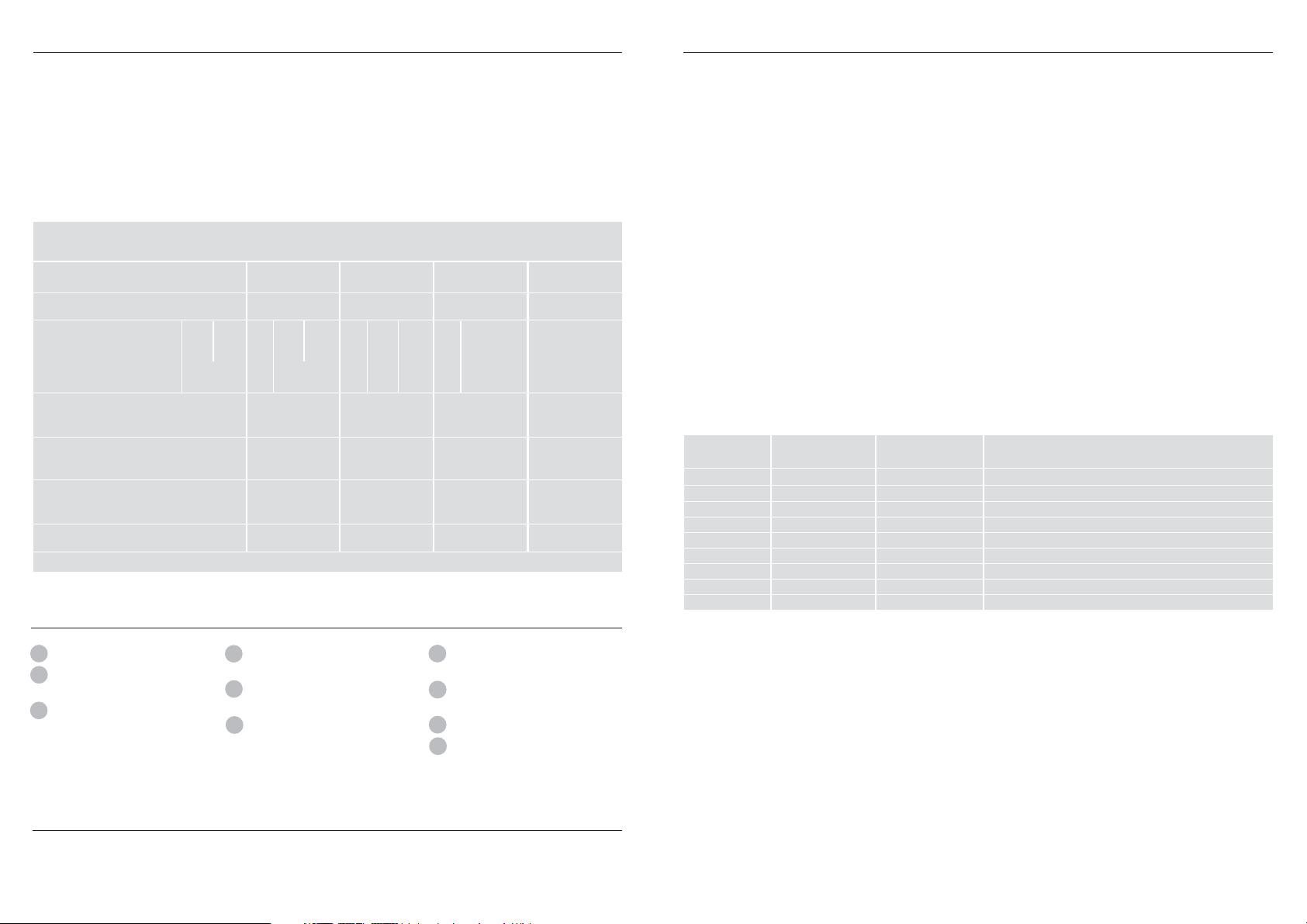

Temperature

Dial Setting

1

2

3

4

5

6

7

8

9

Temperature

Range °F

100 – 160 °F

200 –300°F

375 – 475 °F

475 – 57 5°F

600 –700°F

725 –825 °F

850 –950°F

975 –1075°F

1025 –1125°F

Temperature

Range °C

38 – 71 °C

93 –149 °C

191 – 246 °C

246 – 302 °C

316 – 371 °C

385 – 441 °C

454 – 510 °C

524 –579 °C

552 – 607 °C

Sample

Applications

cleaning surfaces

activating adhesives

shaping/removing flooring materials

welding PE, LDPE, PP, thawing pipes

welding ABS, PBT, PC; lap welding plastic sheeting

de-soldering circuit boards

stripping paint, loosening nuts/screws

de-soldering copper pipes

soldering

Mains voltage

Output

Stage

Airflow (l/min)

Temperature (°C)

Temperature

setting

Temperature

display

Protection class

(without earth terminal)

Overheating protection

230 – 240 V, 50 Hz

2000 W

123

150 300 500

50 50 – 630

continuous in

10 °C steps by

pushbutton controls

LCD display

II

yes

HG 5011

HG 6010

HG 6020

HG 6300

Technical specifications

CE Declaration of Conformity

This product complies with Low Voltage Directive 06/95/EC, EMC Directive 04/108/EC as well as

RoHS Directive 02/95/EC.

for deciding to choose a Makita

heat gun. This tool can be used

for completing a wide range of

jobs safely and reliably, such as

soldering, welding PVC, shaping,

drying, shrink-fitting, stripping paint

etc. All Makita tools are manufactured to the highest standards and

undergo a strict process of quality

control.

Used in the proper manner

(please read the information on

p. 8), this heat gun will give you

lasting satisfaction.

230 – 240 V, 50 Hz

2000 W

123

150 300 500

50 50 – 600

continuous in

9 steps by

thumbwheel

–

II

thermal cut-out

only

230 – 240 V, 50 Hz

1800 W

123

200 300 500

50 400 600

–

–

II

yes

230 – 240 V, 50 Hz

1600 W

12

240 450

300 500

–

–

II

yes

HG 5010

230 – 240 V, 50 Hz

1400 W

12

240 450

300 500

–

–

II

thermal cut-out

only

Thank you

Subject to technical modifications

- 4 -

7

Tool elements

Stainless steel outlet

Air intake with lattice guard to

keep out foreign matter

Detachable guard sleeve

(for poorly accessible places)

Soft stand for stable,

non-slip stationary work

Heavy-duty rubber-sheathed

cord

Air flow switch

(2-stage/3-stage)

8

9

6

Thumbwheel for setting

temperature

Pushbutton for setting

temperature

Temperature monitor LCD

Soft grip handle for com-

fortable operation

2

3

1

5

4

10

Page 4

Applications

F Soft soldering: First, clean

metal parts you want to join.

Then, using hot air, heat the point

you want to solder and offer up

the soldering wire. Use flux or a

soldering wire with a flux core to

prevent oxide forming.

G Welding and joining plastic:

All parts being welded must be of

the same plastic material. Use an

appropriate welding rod.

Here are some of the applications

you can use Makita heat guns for.

This selection is by no means

exhaustive – no doubt you can

immediately think of other examples.

A Stripping paint: Paint is softened and can be removed with a

stripping knife and paint scraper

to leave a clean surface.

B Shrinking tubing on cables:

The shrink tubing is slipped over

the section you want to insulate

and heated with hot air. The tubing shrinks by approx. 50% in

diameter to give a sealed union.

Shrinking is particularly fast and

even using reflector nozzles.

Sealing and stabilising cable

breaks, insulating soldered joints,

gathering cable runs, sheathing

terminal blocks.

C Forming PVC: Sheeting, piping or ski boots can be softened

and formed with hot air.

D Lighting the barbecue:

Gets charcoal glowing in next to

no time; no more waiting.

E Thawing: Water pipes, frozen

door locks, steps. Gently thaws

and dries all in one go.

H Electronic components

from damaged circuit boards

can be desoldered using hot

air (approx. 400 °C) and the

reduction nozzle.

I Joining sheeting: The sheets

are overlapped and welded

together. A slit nozzle is used to

direct hot air under the overlap,

then the two sheets are firmly

pressed together with a feed

roller. Also possible: Repairing

PVC tarpaulins by overlap welding with a slit nozzle.

Rigid PVC

Plasticised

PVC

Soft PE

(LDPE)

Polyethylene

Hard PE

(HDPE)

Polyethylene

PP

Polypropylene

ABS

Pipes, fittings, sheets, building profiles, technical mouldings

Welding temperature 300 °C

Floor coverings, wallpapers,

hoses, sheets, toys

Welding temperature 400 °C

Domestic and electrotechnical

articles, toys

Welding temperature 250 °C

Baths, baskets, canisters, insulating material, pipes

Welding temperature 300 °C

HT drainage pipes, moulded

seats, packaging, car components

Welding temperature 250 °C

Car components, equipment

housings, cases

Welding temperature 350 °Cr

Carbonises in the flame, pungent odour;

crashing sound

Smoking, yellowish-green flame,

pungent odour; silent

Light yellow flame, drips continue to

burn, smells of a candle being extinguished; dull sound

Light yellow flame, drips continue to

burn, smells of a candle being extinguished; crashing sound

bright flame with a blue core,

drips continue to burn, pungent odour;

crashing sound

black, fluffy smoke, sweet odour;

crashing sound

- 7 -

Material Application types Distinguishing characteristics

Read and observe this information before using the tool.

Failure to observe the operating instructions may result in

the tool becoming a source of

danger.

When using electric power tools,

observe the following basic safety

precautions to avoid electric shock

and the risk of injury and fire. Fire

may be caused if the tool is not

used with care.

This appliance is not intended

for use by persons (including

children) with reduced physical,

sensory or mental capabilities,

or lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the appliance by a

person responsible for their safety.

Childeren should be supervised to

ensure that they do not play with

the appliance.

Take ambient conditions

into account.

Do not expose electric power tools

to rain.

Do not use electric power tools

when they are damp or in a damp

or wet environment.

Exercise care when using the tool in

the proximity of flammable materials.

Do not direct hot air onto the same

spot for any prolonged period.

Do not use in the presence of an

explosive atmosphere.

Heat may be conducted to flammable materials that are out of

sight.

Protect yourself from

electric shock.

Avoid touching earthed objects,

such as pipes, radiators, cookers

or refrigerators. Do not leave the

tool unattended while in operation.

Store your tools in

a safe place.

Always store tool upwards resting

on its back after use so that

remaining heat in the unit can

extract. Allow to cool down before

putting tool away.

Tools that are not in use should be

stored in a dry, locked room and

out of the reach of children.

Do not overload your

tools.

Work results and safety will be

enhanced if you stay within the

specified output range.

After using the tool for a prolonged

period at maximum temperature,

you should reduce the temperature before switching the tool off.

This will prolong the life of the

heating element.

Do not carry the tool by the power

cord. Do not unplug the tool by

pulling on the power cord. Protect

the power cord from heat, oil and

sharp edges.

Beware of toxic gases

and fire hazards.

Toxic gases may occur when

working on plastics, paints,

varnishes or similar materials.

Beware of fire and ignition

hazards.

For your own safety, use only

accessories and attachments that

are specified in the operating

instructions or recommended or

specified by the tool manufacturer.

Using attachments or accessories

other than those recommended

in the operating instructions or

catalogue may result in personal

injury.

Repairs must only be

carried out by a

qualified electrician.

This electric power tool complies

with the relevant safety regulations.

Repairs must only be performed

by a qualified electrician, otherwise the user may run the risk of

accidents.

Keep these safety warnings in

a safe place.

Safety warnings

!

- 6 -

For your safety

These heat guns are doubly protected from overheating:

1. A thermal control switches the heating element off when the discharge of air from the outlet nozzle

is blocked (heat accumulation). The fan continues to run however. Once the outlet nozzle is free again,

the heating element switches on again automatically after a short period. The thermal control may also

respond after the device has been switched off. It may therefore take longer than usual until the temperature

at the outlet nozzle is reached after switching on again. *

2. The thermal cut-out completely shuts down the tool if it is overloaded.

*does not apply to HG 6020, HG 5010

Page 5

- 9 -

J Accessories

- 8 -

Nozzle for lighting

barbecues

Lights charcoal quickly

and safely without using

chemicals.

Wide-slit nozzle

*

For welding tarpaulin,

groundsheets etc.

Can be fitted to a

14 mm reduction nozzle.

Slit nozzle

*

For welding tarpaulin,

groundsheets etc.

Can be fitted to a

9 mm reduction nozzle.

Welding nozzle

*

For working with plastic

welding rod up to

6 mm in dia.

Can be fitted to a

9 mm reduction nozzle.

Soldering reflector

Nozzle

*

For soldering and

shrink-fitting soldering

sleeves and heat

shrinkable sleeves.

Reduction nozzle

*

9 mm

Focused source of

hot air for desoldering

and welding PVC.

Reduction nozzle

*

14 mm

Focused source of

hot air for desoldering

and welding PVC.

Reduction nozzle

*

20 mm

Focused jet of heat,

e.g. for edgebanding.

Surface nozzle

75 mm

Spreads air over

wider area for drying,

paint stripping etc.

Surface nozzle

50 mm

Spreads air over

smaller areas,

e.g. for waxing skis.

Paint scraper set

Complete kit for stripping

paint, including replacement blade holder,

replacement blades

and paint scraper.

Plastic welding rod

For securely welding

plasticised PVC

Plastic welding rod

For securly welding

LDPE plastics

Reflector nozzle

For soldering pipes

and fitting shrink-fit

sleeves.

Feed roller

For edgebands and

welding PVC sheets.

Plastic welding rod

For securly welding

HDPE plastics

Plastic welding rod

For securly welding

rigid PVC

Your dealer has a wide range of accessories for you to choose from. (*For HG 6020 and HG6300 only)

Tensión de red

Salida

Posición

Flujo de aire (l/min)

Temperatura (°C)

Ajuste de

temperatura

Indicación de

temperatura

Clase de protección

(sin conexión de

puesta a tierra)

Protección contra

sobrecalentamiento

230 – 240 V, 50 Hz

2000 W

123

150 300 500

50 50 – 630

continuo en pasos de

10 °C por medio de

botones de control

pantalla LCD

II

sí

HG 5011

HG 6010

HG 6020

HG 6300

Especificaciones técnicas

CE Declaración de conformidad

Este producto cumple con la Directiva de Baja Tensión 06/95/CE, Directiva CEM 04/108/CE así como la

Directiva de limitación del uso de ciertas sustancias peligrosas 02/95/CE.

Por haber adquirido una pistola

de calor marca Makita. Esta herramienta puede utilizarse para llevar

a cabo una amplia gama de trabajos de forma segura y fiable,

como por ejemplo, soldar, termo-

fusión de PVC, conformar, secar,

acoplar por contracción, eliminar

pintura, etc. Todas las herramientas Makita se fabrican de acuerdo

con los más altos niveles de control y se someten a un estricto

proceso de control de calidad.

Usado de manera adecuada (por

favor, lea la información de la pág.

8), esta pistola de calor le proporcionará una satisfacción duradera.

120 V~ 50-60 Hz

1500 W

123

150 l/min 300 l/min 500 l/min

50 °C 50 °C – 600 °C

continuo en

9 pasos con

rueda de mando

–

II

sólo interruptor

termostático

230 – 240 V, 50 Hz

1800 W

123

200 300 500

50 400 600

–

–

II

sí

230 – 240 V, 50 Hz

1600 W

12

240 450

300 500

–

–

II

sí

HG 5010

230 – 240 V, 50 Hz

1400 W

12

240 450

300 500

–

–

II

sólo interruptor

termostático

Gracias

Sujeto a modificaciones técnicas

7

Elementos de herramientas

Salida de acero inoxidable

Entrada de aire con protec-

ción de rejilla para evitar la

entrada de partículas extrañas

Manguito de protección separable (para lugares de difícil

acceso)

Soporte blando para un

trabajo estacionario estable,

antideslizante

Cable recubierto de caucho

de alto rendimiento

Interruptor de flujo de aire

(2 posiciones/3 posiciones)

8

9

6

Rueda de control para ajustar

la temperatura

Botón para ajustar la

temperatura

LCD de control de temperatura

Empuñadura suave para

trabajar cómodamente

2

3

1

5

4

10

Page 6

- 11 -

- 10 -

Características - Primeros pasos

HG 5010 / H G 5011

La herramienta se conecta y desconecta con el interruptor de dos posiciones (6) que hay en la parte trasera de la

empuñadura (HG 5011) o en la parte frontal de la misma (HG 5010). El flujo de aire y la temperatura pueden ajustarse en 2 posiciones. En la posición 1 se alcanzan 300 °C con un flujo de aire de 240 l/min, en la posición 2 se

alcanzan 500 °C con 450 l/min.

HG 6300

La herramienta se conecta (ON) y desconecta (OFF) con el interruptor de tres posiciones (6) en la parte

trasera de la empuñadura. Además del control de tres posiciones de velocidad/flujo de aire, la temperatura

puede ajustarse continuamente en un rango de 50 °C a 630 °C con los botones (8). La temperatura objetivo

puede aumentarse en pasos de 10 °C pulsando el lado ”+” del botón de temperatura (8) o reducirse pulsando el lado ”-” del botón de temperatura (8). Pulsando el botón brevemente se aumenta o reduce la temperatura objetivo en un paso de 10 °C. Manteniendo pulsado el botón seguirá aumentándose o reduciéndose la

temperatura en pasos de 10 °C hasta que se suelte el botón o se ajuste la temperatura mínima o máxima.

La posición de soplador 1 proporciona una temperatura de 50 °C. La herramienta tardará un poco hasta que se

enfríe a 50 °C después de reducirse a la posición de soplador 1 cuando se haya estado utilizando a altas

temperaturas en la posición de soplador 2 ó 3. Mientras se enfría la herramienta, la pantalla LCD (9) indica la

temperatura real en la salida de la boquilla. Después de desconectar, la herramienta permanece en el último

ajuste. El manguito de protección (3) se separa con un cierre de bayoneta.

HG 6010

La herramienta se conecta (ON) y desconecta (OFF) con el interruptor de tres posiciones (6) en la parte trasera

de la empuñadura. El flujo de aire y la temperatura pueden ajustarse en 3 posiciones. La posición 1 es una posición de aire frío a 50 °C con un caudal de aire de 200 l/min. En la posición de 2 se alcanzan 400 °C con un flujo

de aire de 300 l/min, en la posición 3 se proporcionan 600 °C con 500 l/min. El manguito de protección (3) se

desacopla con cierre de bayoneta.

HG 6020

La herramienta se conecta (ON) y desconecta (OFF) con el interruptor de dos posiciones (6) en la parte trasera

de la empuñadura. Además del control de tres posiciones de velocidad/flujo de aire (la posición 1 es de aire frío

a 50 °C ), la temperatura puede ajustarse continuamente en un rango de 50 °C – 600 °C con la rueda de control

(7). Los números (1 a 9) de la rueda de mando sólo sirven como guía. Mientras que ”1” significa 50 °C, la temperatura máxima de 600 °C se alcanza con ”9”. El flujo de aire puede ajustarse en las tres posiciones de

150/300/500 l/min. El manguito de protección (3) se separa con un cierre de bayoneta.

Debe tenerse en cuenta: La distancia al objeto en que está trabajando depende del material y del método de

trabajo previsto. ¡Pruebe siempre primero el flujo de aire y la temperatura en una pieza de prueba! Usando las

boquillas accesorias separables (véase la página de accesorios en la cubierta), el flujo de aire caliente puede

controlarse con la máxima precisión. ¡Tenga precaución al cambiar las boquillas, ya que están calientes!

Al usar el decapador de aire caliente en la posición de autorreposo, asegúrese de que se encuentre sobre una

superficie estable, antideslizante y limpia.

Temperatura

ajuste del disco

1

2

3

4

5

6

7

8

9

Temperatura

Rango °F

100 – 16 0 °F

200 – 300 °F

375 – 475 °F

475 – 575 °F

600 – 700 °F

725 – 825 °F

850 – 950 °F

975 – 1075 °F

10 25 – 112 5 ° F

Temperatura

Rango °C

38 – 71 °C

93 – 149 °C

191 – 246 °C

246 – 302 °C

316 – 371 °C

385 – 441 °C

454 – 510 °C

524 – 579 °C

552 – 607 °C

Ejemplos de

aplicaciones

limpieza de superficies

activación de adhesivos

conformación/eliminación de materiales de pavimentos

termofusión de PE, LDPE, PP, tubos de descongelación

termofusión de ABS, PBT, PC; soldadura a solape de hojas plásticas

desoldeo de placas de circuitos

eliminar pintura, aflojar tuercas/tornillos

desoldeo de tubos de cobre

soldar

Lea y siga estrictamente esta información antes de usar la herramienta. Si no se siguen las instrucciones de funcionamiento, la herramienta puede ser una fuente de

peligro.

Cuando utilice herramientas eléctricas, siga las precauciones básicas

de seguridad siguientes para evitar

descargas eléctricas y el riesgo de

daños personales e incendio. Si la

herramienta no se usa con cuidado,

puede producirse un incendio.

Este aparato no está pensado para

ser usado por personas (incluidos

niños) con facultades físicas, sensoriales o mentales reducidas, o falta

de experiencia y conocimiento, a

menos que se proporcione supervisión o instrucción en relación con

el uso del aparato por parte de

una persona responsable de su

seguridad.

Es necesario vigilar que los niños no

jueguen con el aparato.

Deben tenerse en cuenta las

condiciones ambientales.

No exponer las herramientas eléctricas a la lluvia.

No usar las herramientas eléctricas

cuando estén húmedas o en un

entorno húmedo o mojado.

Debe tenerse cuidado al usar la

herramienta cerca de materiales inflamables. No dirigir aire caliente directamente sobre el mismo punto

durante un periodo prolongado.

No usar en una atmósfera explosiva.

El calor puede conducirse hacia

materiales inflamables que no estén

a la vista.

Protéjase contra descargas

eléctricas.

Evite tocar objetos puestos a tierra

como tuberías, radiadores, cocinas o

frigoríficos. No deje la herramienta

desatendida cuando esté en funcionamiento.

Guarde sus herramientas en

un lugar seguro.

Guarde siempre las herramientas en

posición vertical descansando sobre

su parte posterior después de usarlas,

de modo que pueda salir el calor que

quede en ellas. Antes de guardar la

herramienta tiene que dejarse enfriar.

Las herramientas que no se utilicen

deben guardarse en una estancia

seca y cerrada bajo llave y fuera del

alcance de los niños.

No sobrecargue sus

herramientas.

Si se mantiene dentro del rango de

salida especificado, se mejorarán los

resultados del trabajo y la seguridad.

Después de usar la herramienta

durante un periodo prolongado a la

máxima temperatura, debe reducir la

temperatura antes de desconectar la

herramienta. Esto prolongará la duración del elemento de calentamiento.

No sujete la herramienta por el cable

de alimentación. No desenchufe la

herramienta tirando del cable de alimentación. Proteja el cable de alimentación del calor, el aceite y los bordes

afilados.

Tenga precaución con los

gases tóxicos y peligros

de incendio.

Pueden generarse gases tóxicos

cuando se trabaje en plásticos, pinturas, barnices o materiales similares.

Tenga precaución con los peligros de

incendio e ignición.

Para su seguridad, use sólo accesorios y anexos especificados en las

instrucciones de funcionamiento o

recomendados o especificados por el

fabricante de la herramienta. El uso

de anexos o accesorios no recomendados en las instrucciones de funcionamiento o el catálogo puede causar

daños personales.

Las reparaciones deben

ser realizadas exclusivamente por un electricista

cualificado.

Esta herramienta eléctrica cumple

con las regulaciones de seguridad

relevantes. Las reparaciones deben

ser realizadas exclusivamente por un

electricista cualificado, de lo contrario

existe riesgo de accidente para el

usuario.

Guarde estas advertencias de

seguridad en un lugar seguro.

Si el cordón de alimentación es

dañado este debe de ser reemplazado por un cordón especial o ensamble disponible por parte del fabricante

o su agente de servicio.

Advertencias de seguridad

!

Para su seguridad

Estos decapadores de aire caliente tienen protección doble contra sobrecalentamiento:

1. Un control térmico desconecta el elemento de calentamiento cuando la descarga de aire de la boquilla de

salida está bloqueada (acumulación de calor). Sin embargo, el ventilador sigue funcionando. Una vez que

la boquilla de salida esté libre de nuevo, el elemento de calentamiento se conecta de nuevo automáticamente después de un breve periodo. El control térmico puede responder también después de que el dispositivo se haya desconectado. Por lo tanto, puede tardar más de lo normal hasta que se alcance la temperatura en la boquilla de salida después de conectar de nuevo. *

2. El interruptor termostático desconecta totalmente la herramienta si se ha sobrecargado.

*no aplicable a HG 6020, HG 5010

Page 7

- 13 -- 12 -

Aplicaciones

F Soldado suave: En primer

lugar, limpie las piezas metálicas

que desee unir. Seguidamente,

usando aire caliente, caliente el

punto que desee soldar y aplique el

hilo de soldeo. Use fundente o un

hilo de soldeo con un núcleo de

fundente para evitar la formación de

óxido.

G Termofusión y unión de

plástico: Todas las piezas a soldar

deben ser del mismo material plástico. Use un alambre de soldadura

apropiado.

Éstas son algunas de las aplicaciones que puede usar para los decapadores de aire caliente Makita. Esta

selección no pretende ser exhaustiva – sin duda se le ocurrirán inmediatamente otros ejemplos.

A Eliminar pintura: La pintura se

ablanda y puede eliminarse con

una cuchilla decapante y un rascador de pintura para dejar una superficie limpia.

B Contracción de tubos aislantes

en cables: El tubo retráctil se desliza

sobre la sección que desea aislar y

se calienta con aire caliente. El tubo

se contrae aprox. un 50% de su diámetro para proporcionar una unión

sellada. La contracción es especialmente rápida y uniforme usando toberas reflectoras. Sellado y estabilización de roturas de cables, aislamiento de juntas soldadas, agrupamiento de tendidos de cables, envainado de bloques de terminales.

C Conformación de PVC: Las

hojas, tuberías o las botas de esquí

pueden ablandarse y conformarse

con aire caliente.

D Encender la barbacoa:

Enciende el carbón en un momento; sin esperas.

E Descongelación: Tuberías de

agua, cerraduras de puerta, congelados, escalones. Descongela y seca

suavemente, todo a la vez.

H Los componentes electrónicos

de placas de circuitos dañadas

pueden desoldarse usando aire

caliente (aprox. 400 °C) y la boquilla reductora.

I Unión de hojas: Las hojas se

solapan y se sueldan entre sí. Se

usa una boquilla ranurada para

dirigir el aire caliente debajo del

solapamiento, después las dos

hojas se presionan firmemente

uniéndolas con un rodillo de avance. También es posible:

Reparación de lonas de PVC

solapando la termofusión con una

boquilla ranurada.

PVC rígido

PVC plastificado

PE blando

(LDPE)

Polietileno

PE duro

(HDPE)

Polietileno

PP

Polipropileno

ABS

Tubos, accesorios, hojas, perfiles de

edificios, piezas moldeadas técnicas

Temperatura de termofusión 300 °C

Revestimientos para suelos, papeles

pintados, mangueras, hojas, juguetes

Temperatura de termofusión 400 °C

Artículos domésticos y electrotécnicos,

juguetes

Temperatura de termofusión 250 °C

Cubetas, cestos, botes,

material aislante, tubos

Temperatura de termofusión 300 °C

Tubos de drenaje de tratamiento

térmico, asientos moldeados,

embalajes, componentes para coches

Temperatura de termofusión 250 °C

Componentes para coches,

alojamientos de equipos, cajas

Temperatura de termofusión 350 °C

Carboniza en la llama, olor irritante;

sonido de choque

Humo, llama verde amarillenta,

olor irritante; silencioso

Llama amarillo claro, las gotas siguen

quemando, huele a vela apagada;

sonido apagado

Llama amarillo claro, las gotas siguen

quemando, huele a vela apagada;

sonido de choque

llama brillante con núcleo azul, las

gotas siguen quemando, olor irritante;

sonido de choque

humo negro, oscilante, olor dulce;

sonido de choque

Material Tipos de aplicación Características distintivas

J Accesorios

Boquilla para encender

barbacoas

Enciende el carbón rápidamente y con seguridad sin

usar productos químicos.

Boquilla de ranura ancha

*

Para termofundir lonas, hojas

de suelo, etc. Puede montarse en una boquilla reductora

de 14 mm.

Boquilla ranurada

*

Para termofundir lonas,

hojas de suelo, etc. Puede

montarse en una boquilla

reductora de 9 mm.

Soldadura de tobera

reflectora

*

Para soldar y acoplar por

contracción manguitos de

soldadura y manguitos

termorretráctiles.

Boquilla reductora

* 9 mm

Fuente enfocada de aire

caliente para desoldar y

termofundir PVC.

Boquilla reductora *

14 mm

Fuente enfocada de aire

caliente para desoldar y

termofundir PVC.

Boquilla reductora

*

20 mm

Chorro de calor enfocado,

p. ej. para bandado de

bordes.

Boquilla superficial

de 75 mm

Difunde el aire en un área

más amplia para secado,

eliminación de pintura, etc.

Boquilla superficial

de 50 mm

Difunde el aire sobre áreas

menores, p. ej. para encerar

esquíes.

Juego de rascadores

de pintura

Kit completo para eliminar

pintura, incluido portacuchillas de recambio,

cuchillas de recambio y

rascador de pintura.

Alambre de soldadura

de plástico

Para termofundir con seguridad PVC plastificado.

Alambre de soldadura

de plástico

Para termofundir con

seguridad plásticos

LDPE

Boquilla reflectora

Para soldar tubos y

montar manguitos de

ajuste en caliente.

Rodillo de avance

Para bandas de bordes

y termofundir hojas de

PVC.

Alambre de soldadura

de plástico

Para termofundir con

seguridad plásticos

HDPE

Alambre de soldadura

de plástico

Para termofundir con

seguridad

PVC rígido

Su distribuidor tiene una amplia gama de accesorios para escoger. (*Sólo para HG 6020 y HG6300)

Boquilla de termofusión *

Para trabajar con alambre

de soldadura de plástico

de hasta 6 mm de diámetro. Puede montarse en

una boquilla reductora de

9 mm.

Loading...

Loading...