Page 1

GB Angle Grinder Instruction manual

F Meuleuse d'Angle Manuel d’instructions

D Winkelschleifer Betriebsanleitung

I Smerigliatrice angolare Istruzioni per l’uso

NL Haakse slijpmachine Gebruiksaanwijzing

E Amoladora Manual de instrucciones

P Rebarbadora Manual de instruções

DK Vinkelsliber Brugsanvisning

S Vinkelslipmaskin Bruksanvisning

N Vinkelsliper Bruksanvisning

FIN Kulmahiomakone Käyttöohje

GR Γωνιακς τροχς Οδηγίες χρήσης

GA7020/GA7020F

GA7020S/GA7020SF

GA9020/GA9020F

GA9020S/GA9020SF

Page 2

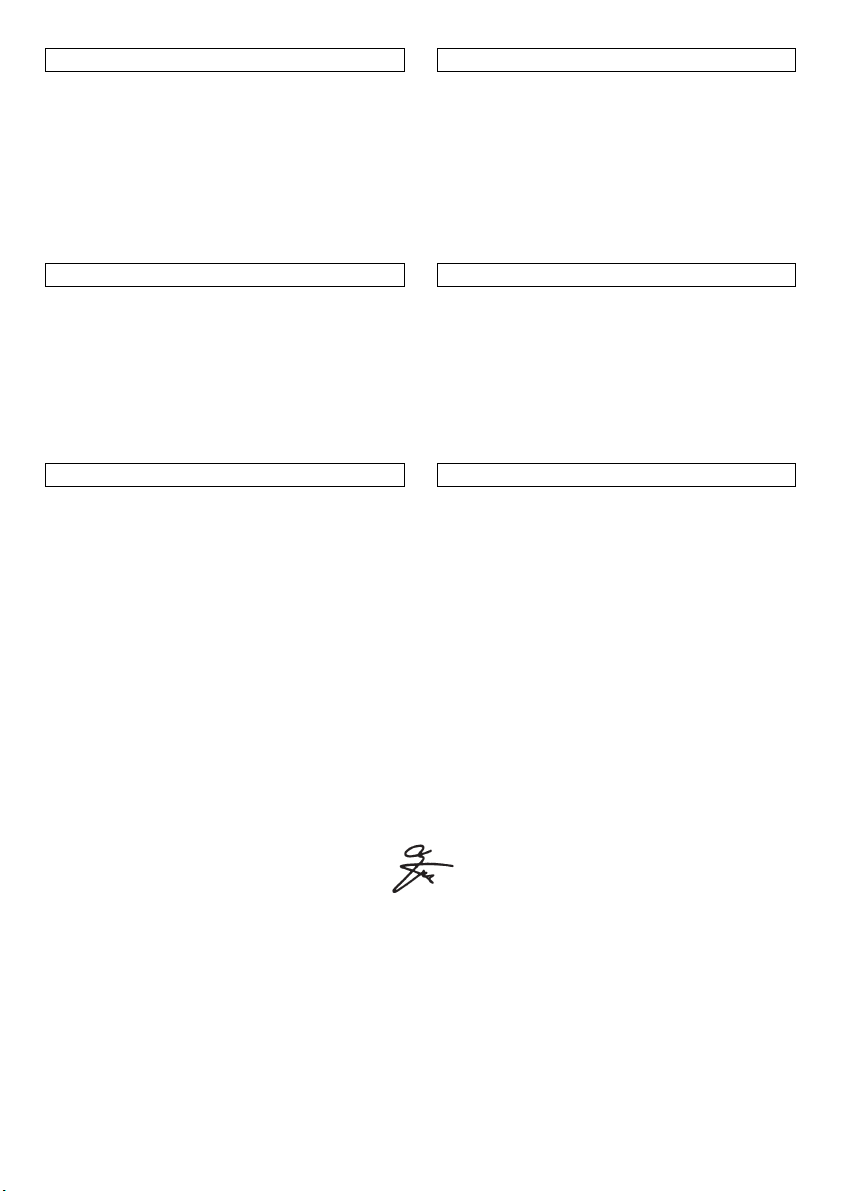

1

2

B

A

3

12

4

5

6

34

10

7

8

9

11

1

56

12

15

AB

13

78

2

Page 3

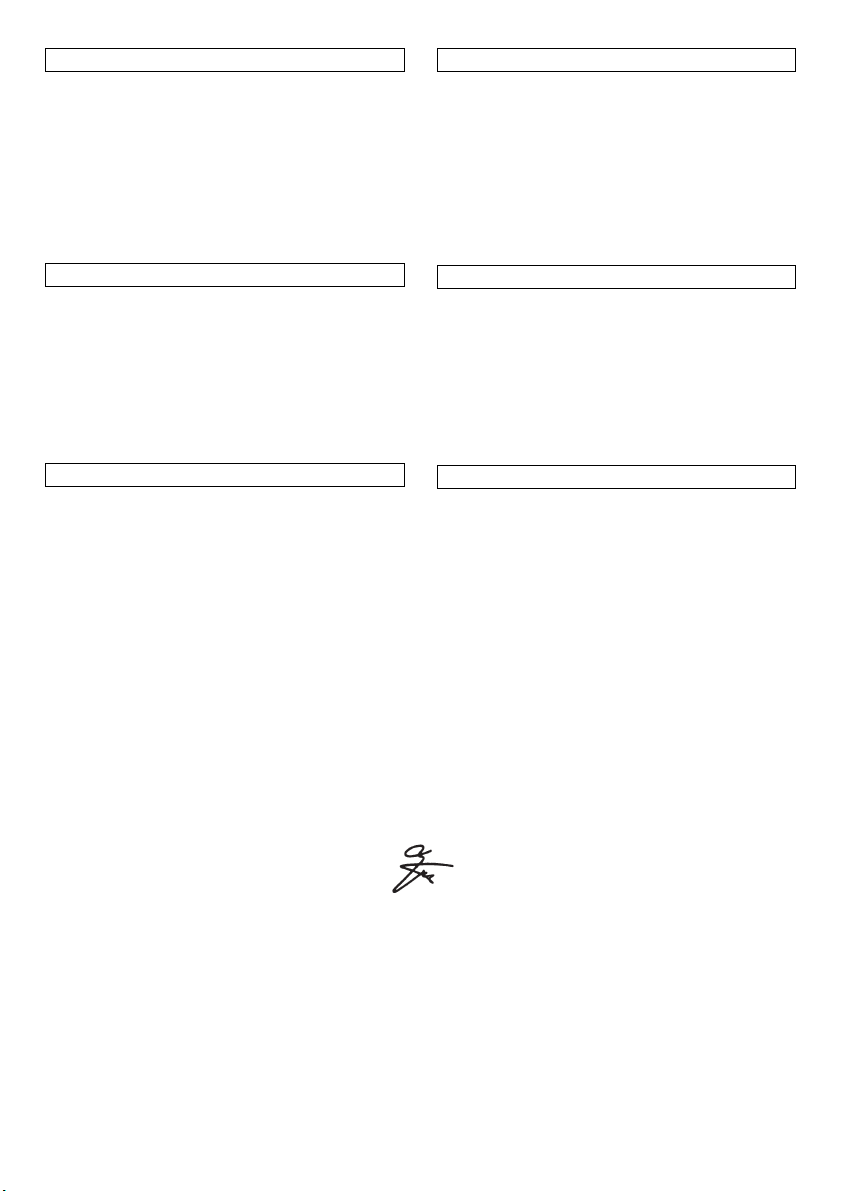

14

15

16

17

18

910

3

Page 4

ENGLISH

Explanation of general view

1. Shaft lock

2. Switch trigger

3. Lock lever

4. Wheel guard

5. Screw

6. Bearing box

7. Lock nut

8. Depressed center wheel

9. Super flange

10. Inner flange

11. Lock nut wrench

12. Exhaust vent

13. Inhalation vent

14. Commutator

15. Insulating tip

16. Carbon brush

17. Brush holder cap

18. Screwdriver

SPECIFICATIONS

Model

Depressed center wheel diameter 180 mm 230 mm

Spindle thread M14 M14

No load speed (min

Overall length 473 mm 473 mm

Net weight 4.7 kg 4.7 kg

Rated voltage /II

• Due to our continuing program of research and development, the specifications herein are subject to change without

notice.

• Note: Specifications may differ from country to country.

Symbols

The following show the symbols used for the tool. Be sure

that you understand their meaning before use.

............. Read instruction manual.

............. DOUBLE INSULATION

............. Wear safety glasses.

Intended use

The tool is intended for grinding, sanding and cutting of

metal and stone materials without the use of water.

Power supply

The tool should be connected only to a power supply of

the same voltage as indicated on the nameplate, and can

only be operated on single-phase AC supply. They are

double-insulated in accordance with European Standard

and can, therefore, also be used from sockets without

earth wire.

For public low-voltage distribution systems of

between 220 V and 250 V.

Switching operations of electric apparatus cause voltage

fluctuations. The operation of this device under unfavorable mains conditions can have adverse effects to the

operation of other equipment. With a mains impedance

equal or less than 0.27 Ohms it can be presumed that

there will be no negative effects. The mains socket used

for this device must be protected with a fuse or protective

circuit breaker having slow tripping characteristics.

-1

) 8,500 6,600

GA7020/GA7020F/GA7020S/

GA7020SF

END202-2

ADDITIONAL SAFETY RULES

1. Always use eye and ear protection. Other personal

protective equipment such as dust mask, gloves,

helmet and apron should be worn.

2. Always be sure that the tool is switched off and

unplugged before carrying out any work on the

tool.

3. Keep guards in place.

4. Use only wheels with correct size and wheels having a maximum operating speed at least as high as

the highest No Load Speed marked on the tool’s

nameplate. When using depressed center wheels,

be sure to use only fiberglass reinforced wheels.

5. Check the wheel carefully for cracks or damage

before operation. Replace cracked or damaged

wheel immediately.

6. Observe the instructions of the manufacturer for

correct mounting and use of wheels. Handle and

store wheels with care.

7. Do not use separate reducing bushings or adaptors to adapt large hole abrasive wheels.

8. Use only flanges specified for this tool.

9. Do not damage the spindle, the flange (especially

the installing surface) or the lock nut. Damage to

these parts could result in wheel breakage.

10. For tools intended to be fitted with threaded hole

wheel, ensure that the thread in the wheel is long

enough to accept the spindle length.

11. Before using the tool on an actual workpiece, test

run the tool at the highest no load speed for at

least 30 seconds in a safe position. Stop immediately if there is any vibration or wobbling that

could indicate poor installation or a poorly bal-

GA9020/GA9020F/GA9020S/

GA9020SF

ENB031-6

4

Page 5

anced wheel. Check the tool to determine the

cause.

12. Check that the workpiece is properly supported.

13. Hold the tool firmly.

14. Keep hands away from rotating parts.

15. Make sure the wheel is not contacting the workpiece before the switch is turned on.

16. Use the specified surface of the wheel to perform

the grinding.

17. Do not use cutting off wheel for side grinding.

18. Watch out for flying sparks. Hold the tool so that

sparks fly away from you and other persons or

flammable materials.

19. Pay attention that the wheel continues to rotate

after the tool is switched off.

20. Do not touch the workpiece immediately after

operation; it may be extremely hot and could burn

your skin.

21. Position the tool so that the power cord always

stays behind the machine during operation.

22. If working place is extremely hot and humid, or

badly polluted by conductive dust, use a short-circuit breaker (30 mA) to assure operator safety.

23. Do not use the tool on any materials containing

asbestos.

24. Do not use water or grinding lubricant.

25. Ensure that ventilation openings are kept clear

when working in dusty conditions. If it should

become necessary to clear dust, first disconnect

the tool from the mains supply (use non metallic

objects) and avoid damaging internal parts.

26. When use cut-off wheel, always work with the dust

collecting wheel guard required by domestic regulation.

27. Cutting discs must not be subjected to any lateral

pressure

SAVE THESE INSTRUCTIONS

FUNCTIONAL DESCRIPTION

CAUTION:

• Always be sure that the tool is switched off and

unplugged before adjusting or checking function on the

tool.

Shaft lock (Fig. 1)

CAUTION:

• Never actuate the shaft lock when the spindle is mov-

ing. The tool may be damaged.

Press the shaft lock to prevent spindle rotation when

installing or removing accessories.

Switch action (Fig. 2)

CAUTION:

• Before plugging in the tool, always check to see that

the switch trigger actuates properly and returns to the

“OFF” position when released.

For tool with the lock-on switch

To start the tool, simply pull the switch trigger (in the B

direction). Release the switch trigger to stop. For continuous operation, pull the switch trigger (in the B direction)

and then push in the lock lever (in the A direction). To stop

the tool from the locked position, pull the switch trigger

fully (in the B direction), then release it.

For tool with the lock-off switch

To prevent the switch trigger from accidentally pulled, a

lock lever is provided.

To start the tool, push in the lock lever (in the A direction)

and then pull the switch trigger (in the B direction).

Release the switch trigger to stop.

For tool with the lock on and lock-off switch

To prevent the switch trigger from accidentally pulled, a

lock lever is provided.

To start the tool, push in the lock lever (in the A direction)

and then pull the switch trigger (in the B direction).

Release the switch trigger to stop.

For continuous operation, push in the lock lever (in the A

direction), pull the switch trigger (in the B direction) and

then push the lock lever (in the A direction) further in.

To stop the tool from the locked position, pull the switch

trigger fully (in the B direction), then release it.

NOTE:

Models GA7020S, GA9020S, GA7020SF and GA9020SF

begin to run slowly when they are turned on. This soft

start feature assures smoother operation and less operator fatigue.

ASSEMBLY

CAUTION:

• Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

Installing side grip (handle) (Fig. 3)

CAUTION:

• Always be sure that the side grip is installed securely

before operation.

Screw the side grip securely on the position of the tool as

shown in the figure.

Installing or removing wheel guard

(Fig. 4)

CAUTION:

• The wheel guard must be fitted on the tool so that the

closed side of the guard always points toward the operator.

Mount the wheel guard with the protrusion on the wheel

guard band aligned with the notch on the bearing box.

Then rotate the wheel guard around 180 degrees counterclockwise. Be sure to tighten the screw securely.

To remove wheel guard, follow the installation procedure

in reverse.

5

Page 6

Installing or removing depressed center

grinding wheel/Multi-disc (accessory)

(Fig. 5)

Mount the inner flange onto the spindle. Fit the wheel/disc

on the inner flange and screw the lock nut onto the spindle.

Super flange (Fig. 6)

Models GA7020F,GA7020SF,GA9020F and 9020SF are

standard-equipped with a super flange. Only 1/3 of efforts

needed to undo lock nut, compared with conventional

type.

To tighten the lock nut, press the shaft lock firmly so that

the spindle cannot revolve, then use the lock nut wrench

and securely tighten clockwise.

To remove the wheel, follow the installation procedure in

reverse.

OPERATION

WARNING:

• It should never be necessary to force the tool. The

weight of the tool applies adequate pressure. Forcing

and excessive pressure could cause dangerous wheel

breakage.

• ALWAYS replace wheel if tool is dropped while grinding.

• NEVER bang or hit grinding disc or wheel onto work.

• Avoid bouncing and snagging the wheel, especially

when working corners, sharp edges etc. This can

cause loss of control and kickback.

• NEVER use tool with wood cutting blades and other

sawblades. Such blades when used on a grinder frequently kick and cause loss of control leading to personal injury.

CAUTION:

• Never switch on the tool when it is in contact with the

workpiece, it may cause an injury to operator.

• Always wear safety goggles or a face shield during

operation.

• After operation, always switch off the tool and wait until

the wheel has come to a complete stop before putting

the tool down.

Grinding and sanding operation (Fig. 7)

ALWAYS hold the tool firmly with one hand on rear handle

and the other on the side handle. Turn the tool on and

then apply the wheel or disc to the workpiece.

In general, keep the edge of the wheel or disc at an angle

of about 15 degrees to the workpiece surface.

During the break-in period with a new wheel, do not work

the grinder in the B direction or it will cut into the workpiece. Once the edge of the wheel has been rounded off

by use, the wheel may be worked in both A and B direction.

MAINTENANCE

CAUTION:

• Always be sure that the tool is switched off and

unplugged before attempting to perform inspection or

maintenance.

The tool and its air vents have to be kept clean. Regularly

clean the tool's air vents or whenever the vents start to

become obstructed. (Fig. 8)

Replacing carbon brushes

When the resin insulating tip inside the carbon brush is

exposed to contact the commutator, it will automatically

shut off the motor. When this occurs, both carbon brushes

should be replaced. Keep the carbon brushes clean and

free to slip in the holders. Both carbon brushes should be

replaced at the same time. Use only identical carbon

brushes. (Fig. 9)

Use a screwdriver to remove the brush holder caps. Take

out the worn carbon brushes, insert the new ones and

secure the brush holder caps. (Fig. 10)

To maintain product SAFETY and RELIABILITY, repairs,

any other maintenance or adjustment should be performed by Makita Authorized Service Centers, always

using Makita replacement parts.

ACCESSORIES

CAUTION:

• These accessories or attachments are recommended

for use with your Makita tool specified in this manual.

The use of any other accessories or attachments might

present a risk of injury to persons. Only use accessory

or attachment for its stated purpose.

If you need any assistance for more details regarding

these accessories, ask your local Makita Service Center.

• Wheel guard (Wheel cover)

• Inner flange

• Depressed center wheels

• Lock nut (For depressed center wheel)

• Rubber pad

• Abrasive discs

• Lock nut (For abrasive disc)

• Lock nut wrench

• Cut-off wheels

• Inner flange (For cut-off wheel)

• Outer flange (For cut-off wheel)

• Wire cup brush

• Side grip

• Dust collecting wheel guard

6

Page 7

NEDERLANDS

Verklaring van het onderdelenoverzicht

1. Asvergrendeling

2. Aan/uit-schakelaar

3. Vergrendelhendel

4. Beschermkap

5. Schroef

6. Kussenblokkast

7. Borgmoer

8. Schijf met een verzonken

middengat

9. Superflens

10. Binnenflens

11. Borgmoersleutel

12. Luchtuitlaatopening

13. Luchtinlaatopening

14. Collector

15. Isolerend uiteinde

16. Koolborstel

17. Koolborsteldop

18. Schroevendraaier

TECHNISCHE GEGEVENS

Model

Diameter van schijf met een verzonken

• Als gevolg van ons doorlopende onderzoeks- en ontwikkelingsprogramma, zijn de technische gegevens van dit

gereedschap onderhevig aan veranderingen zonder voorafgaande kennisgeving.

• Opmerking: De technische gegevens kunnen van land tot land verschillen.

Symbolen

Hieronder staan de symbolen die voor dit gereedschap

worden gebruikt. Zorg ervoor dat u weet wat ze

betekenen alvorens het gereedschap te gebruiken.

Gebruiksdoeleinden

Dit gereedschap is bedoeld voor het slijpen, schuren en

snijden van

metaal en steen zonder gebruik van water.

Voe din g

Het gereedschap mag uitsluitend worden aangesloten op

een voeding met dezelfde spanning als aangegeven op

het identificatieplaatje en werkt alleen op enkele-fase

wisselstroom. Het gereedschap is dubbel geïsoleerd

volgens de Europese norm en mag derhalve ook op een

niet-geaard stopcontact worden aangesloten.

Voor het openbare laagspanningnet van 220 V t/m

250 V.

Het in- en uitschakelen van elektrische apparatuur

veroorzaakt spanningsfluctuaties. Het gebruik van dit

gereedschap terwijl het elektriciteitsnet in een slechte

toestand verkeert, kan de werking van andere apparatuur

nadelig beïnvloeden. Als de netweerstand lager is dan

0,27 ohm, mag u ervan uitgaan dat geen nadelige

effecten optreden. Het stopcontact waarop dit

middengat

Asschroefdraad M14 M14

Onbelaste snelheid (min

Totale lengte 473 mm 473 mm

Netto gewicht 4,7 kg 4,7 kg

Nominale spanning /II

............. Lees de gebruiksaanwijzing.

............. DUBBEL GEÏSOLEERD

............. Draag een veiligheidsbril.

-1

) 8500 6600

GA7020/GA7020F/GA7020S/

GA7020SF

180 mm 230 mm

END202-2

gereedschap is aangesloten moet zijn beveiligd met een

zekering of veiligheidsstroomonderbreker met trage

uitschakeling.

AANVULLENDE

VEILIGHEIDSVOORSCHRIFTEN

1. Draag altijd oog- en oorbescherming. Ook andere

persoonlijke-veiligheidsmiddelen, zoals een

stofmasker, handschoenen, helm en schort,

dienen te worden gedragen.

2. Controleer altijd of het gereedschap is

uitgeschakeld en de stekker uit het stopcontact is

getrokken alvorens enige werk aan het

gereedschap uit te voeren.

3. Laat de beschermkappen op hun plaats zitten.

4. Gebruik uitsluitend schijven met de juiste

diameter en met een maximale draaisnelheid van

minstens de hoogste onbelaste snelheid zoals

aangegeven op het typeplaatje op het

gereedschap. Bij gebruik van een schijf met een

verzonken middengat, mag u uitsluitend met

glasvezel versterkte schijven gebruiken.

5. Controleer vóór het gebruik de schijf zorgvuldig

op barsten of beschadiging. Vervang een

gebarsten of beschadigd schijf meteen.

6. Houd u aan de instructies van de fabrikant voor

juiste montage en gebruik van de schijven.

Behandel en bewaar de schijven zorgvuldig.

7. Gebruik niet afzonderlijke verkleinbussen of

adapterringen om slijpschijven met een groot

middengat te kunnen monteren.

GA9020/GA9020F/GA9020S/

GA9020SF

ENB031-6

19

Page 8

8. Gebruik uitsluitend flenzen die geschikt zijn voor

dit gereedschap.

9. Beschadig de as, de flens (met name de

montagekant) en de borgmoer niet. Als deze

onderdelen beschadigd raken, kan de schijf

breken.

10. Voor gereedschappen waarop schijven met

schroefdraad in het middengat kunnen worden

gemonteerd, controleert u dat de schroefdraad

van de schijf lang genoeg is voor de lengte van de

as.

11. Alvorens het gereedschap te gebruiken op een

werkstuk, draait u het gereedschap proef op

maximale onbelaste snelheid gedurende minstens

30 seconden in een veilige houding. Stop het

gereedschap onmiddellijk als u trillingen of

schommelingen waarneemt, die een teken kunnen

zijn van een verkeerd gemonteerde of slecht

uitgebalanceerde schijf. Controleer het

gereedschap om de oorzaak op te sporen.

12. Controleer dat het werkstuk goed wordt

ondersteund.

13. Houd het gereedschap stevig vast.

14. Houd uw handen uit de buurt van draaiende delen.

15. Zorg ervoor dat de schijf niet in aanraking is met

het werkstuk voordat u het gereedschap hebt

ingeschakeld.

16. Gebruik de aangegeven kant van de schijf om mee

te slijpen.

17. Gebruik nooit een doorslijpschijf om zijdelings

mee te slijpen.

18. Wees alert op rondvliegende vonken. Houd het

gereedschap zodanig vast dat de vonken

wegvliegen van u en andere personen of

brandbare materialen.

19. Wees erop bedacht dat de schijf blijft doordraaien

nadat het gereedschap is uitgeschakeld.

20. Raak de schijf niet onmiddellijk na gebruik aan.

Deze kan bijzonder heet zijn en brandwonden op

uw huid veroorzaken.

21. Houd het gereedschap zodanig vast dat tijdens

gebruik het netsnoer zich altijd achter het

gereedschap bevindt.

22. Als de werkruimte bijzonder heet en vochtig is, of

sterk vervuild door geleidend stof, gebruik dan

een kortsluitonderbreker (30 mA) om de veiligheid

van de gebruiker te garanderen.

23. Gebruik het gereedschap niet op materiaal dat

asbest bevat.

24. Gebruik geen water of slijpsmeermiddel.

25. Zorg ervoor dat de ventilatie-openingen niet

verstopt raken bij gebruik in een stoffige

omgeving. Als het noodzakelijk is het stof te

verwijderen, moet u het gereedschap eerst

loskoppelen van de netvoeding (gebruik hiervoor

niet-metalen voorwerpen) en wees voorzichtig

geen inwendige onderdelen te beschadigen.

26. Bij gebruik van een doorslijpschijf, gebruikt u

altijd de stofbeschermkap, zoals vereist door

plaatselijke regelgeving.

27. Doorslijpschijven mogen niet worden blootgesteld

aan enige laterale druk.

BEWAAR DEZE

VOORSCHRIFTEN

BESCHRIJVING VAN DE

FUNCTIES

LET OP:

• Controleer altijd of het gereedschap is uitgeschakeld

en de stekker uit het stopcontact is getrokken alvorens

de functies van het gereedschap te controleren of af te

stellen.

Asvergrendeling (zie afb. 1)

LET OP:

• Bedien de asvergrendeling nooit terwijl de as nog

draait. Het gereedschap kan hierdoor worden

beschadigd.

Druk op de asvergrendeling om te voorkomen dat de as

kan draaien tijdens het monteren of verwijderen van

schijven of accessoires.

In- en uitschakelen (zie afb. 2)

LET OP:

• Controleer altijd, voordat u de stekker in het

stopcontact steekt, of de aan/uit-schakelaar op de

juiste manier schakelt en weer terugkeert naar de uitstand nadat deze is losgelaten.

Voor gereedschappen met een aan-vergrendeling

Om het gereedschap in te schakelen, knijpt u gewoon de

aan/uit-schakelaar in (in de richting van pijl B). Laat de

aan/uit-schakelaar los om het gereedschap te stoppen

Voor continue werking knijpt u de aan/uit-schakelaar in (in

de richting van pijl B) en duwt u vervolgens tegen de

vergrendelhendel (in de richting van pijl A). Om vanuit de

vergrendelde werking het gereedschap te stoppen, knijpt

u de aan/uit-schakelaar helemaal in (in de richting van pijl

B) en laat u deze vervolgens weer los.

Voor gereedschappen met een uit-vergrendeling

Om te voorkomen dat de aan/uit-schakelaar per ongeluk

wordt bediend, is een vergrendelhendel aangebracht.

Om het gereedschap te starten, duwt u tegen de uitvergrendelhendel (in de richting van pijl A) en knijpt u

vervolgens de aan/uit-schakelaar in (in de richting van pijl

B). Laat de aan/uit-schakelaar los om het gereedschap te

stoppen

Voor gereedschappen met een aan-vergrendeling en

een uit-vergrendeling

Om te voorkomen dat de aan/uit-schakelaar per ongeluk

wordt bediend, is een vergrendelhendel aangebracht.

Om het gereedschap te starten, duwt u tegen de uitvergrendelhendel (in de richting van pijl A) en knijpt u

vervolgens de aan/uit-schakelaar in (in de richting van pijl

B). Laat de aan/uit-schakelaar los om het gereedschap te

stoppen

20

Page 9

Voor continue werking, duwt u tegen de vergrendelhendel

(in de richting van pijl A), knijpt u de aan/uit-schakelaar in

(in de richting van pijl B), en duwt u vervolgens de

vergrendelhendel (in de richting van pijl A) nog verder.

Om vanuit de vergrendelde werking het gereedschap te

stoppen, knijpt u de aan/uit-schakelaar helemaal in (in de

richting van pijl B) en laat u deze vervolgens weer los.

OPMERKING:

De modellen GA7020S, GA9020S, GA7020SF en

GA9020SF beginnen langzaam te draaien nadat ze zijn

ingeschakeld. Deze langzame-opstartfunctie zorgt voor

een geleidelijkere werking en minder vermoeidheid voor

de gebruiker.

ONDERDELEN AANBRENGEN/

VERWIJDEREN

LET OP:

• Controleer altijd of het gereedschap is uitgeschakeld

en de stekker uit het stopcontact is getrokken alvorens

enige werk aan het gereedschap uit te voeren.

De zijhandgreep monteren (handvat)

(zie afb. 3)

LET OP:

• Controleer altijd voor gebruik dat de zijhandgreep

stevig vastzit.

Draai de zijhandgreep vast op het gereedschap in een

van de standen aangegeven in de afbeelding.

De beschermkap aanbrengen en

verwijderen (zie afb. 4)

LET OP:

• De beschermkap moet zodanig op het gereedschap

worden gemonteerd dat de gesloten zijde van de kap

altijd naar de gebruiker is gekeerd.

Monteer de beschermkap met het uitsteeksel op de

beschermkap-band uitgelijnd met de inkeping in de

kussenblokkast. Draai vervolgens de beschermkap 180

graden linksom. Draai tenslotte de schroef stevig vast.

Om de beschermkap te verwijderen, volgt u de procedure

in omgekeerde volgorde.

Een slijpschijf/multischijf met een

verzonken middengat (accessoire)

aanbrengen of verwijderen (zie afb. 5)

Breng de binnenflens aan op de as. Monteer de schijf op

de binnenflens en schroef de borgmoer op de as.

Superflens (zie afb. 6)

De modellen GA7020F,GA7020SF,GA9020F en 9020SF

zijn standaard uitgerust met een superflens. In

vergelijking met een conventionele flens, is hierbij slechts

1/3 van de kracht nodig om de borgmoer los te draaien.

Om de borgmoer vast te draaien, drukt u de

asvergrendeling stevig in zodat de as niet kan draaien, en

gebruikt u vervolgens de borgmoersleutel om de

borgmoer stevig rechtsom vast te draaien.

Om de schijf te verwijderen, volgt u de procedure in

omgekeerde volgorde.

BEDIENING

WAARSCHUWING:

• Het moet nooit nodig zijn om grote kracht uit te oefenen

op het gereedschap. Het gewicht van het gereedschap

zorgt al voor voldoende druk op het werkstuk. Grote

kracht en hoge druk uitoefenen kunnen ertoe leiden dat

de schijf breekt. Dit is zeer gevaarlijk.

• Vervang de schijf ALTIJD als het gereedschap tijdens

het slijpen is gevallen.

• Stoot of sla NOOIT met de slijpschijf tegen het

werkstuk.

• Voorkom dat de schijf over het werkstuk huppelt of

bekneld raakt tijdens het werken in hoeken, op scherpe

randen, enz. Hierdoor kunt u de controle over het

gereedschap verliezen of terugslag worden

veroorzaakt.

• Gebruik het gereedschap NOOIT met zaagbladen en

dergelijke. Als dergelijke zaagbladen op een

slijpmachine worden gebruikt, springen ze veelal

waardoor u de controle over het gereedschap verliest

en persoonlijk letsel kan ontstaan.

LET OP:

• Schakel het gereedschap nooit in terwijl deze het

werkstuk raakt omdat hierdoor de gebruiker kan

worden verwond.

• Draag tijdens het gebruik altijd een veiligheidsbril of

gezichtsbescherming.

• Schakel na gebruik altijd het gereedschap uit en wacht

totdat de schijf volledig tot stilstand is gekomen

alvorens het gereedschap neer te leggen.

Gebruik als slijpmachine of

schuurmachine (zie afb. 7)

Houd het gereedschap ALTIJD stevig vast met een hand

aan de achterhandgreep en de andere hand aan de

zijhandgreep. Schakel het gereedschap in en breng

daarna de schijf in aanraking met het werkstuk.

In het algemeen geldt: houd de rand van de schijf onder

een hoek van ongeveer 15 graden op het oppervlak van

het werkstuk.

Tijdens de inloopperiode van een nieuwe schijf, mag u de

slijpmachine niet in de richting van pijl B gebruiken omdat

de schijf dan in het werkstuk zal snijden. Nadat de rand

van de schijf is afgerond door gebruik, kunt u de schijf in

de richting van zowel pijl A als B gebruiken.

ONDERHOUD

LET OP:

• Zorg er altijd voor dat de machine is uitgeschakeld en

de stekker uit het stopcontact is getrokken, voordat u

een inspectie of onderhoud uitvoert.

Het gereedschap en de ventilatieopeningen moeten

schoon gehouden worden. Maak de ventilatieopeningen

van het gereedschap regelmatig schoon of zodra de

ventilatieopeningen verstopt dreigen te raken (zie afb. 8).

21

Page 10

De koolborstels vervangen

Wanneer de isolatiepunt binnenin de koolborstel bloot ligt

en de collector raakt, schakelt deze automatisch de motor

uit. Wanneer dit gebeurt, moeten beide koolborstels

worden vervangen. Houd de koolborstels schoon en zorg

ervoor dat ze vrij kunnen bewegen in de houders. Beide

koolborstels dienen tegelijkertijd te worden vervangen.

Gebruik alleen identieke koolborstels (zie afb. 9).

Gebruik een schroevendraaier om de koolborsteldoppen

te verwijderen. Haal de versleten koolborstels eruit, plaats

de nieuwe erin, en zet de koolborsteldoppen goed vast

(zie afb. 10).

Om de VEILIGHEID en BETROUWBAARHEID van het

gereedschap te handhaven, dienen alle reparaties,

onderhoud en afstellingen te worden uitgevoerd door een

erkend Makita-servicecentrum, en altijd met

gebruikmaking van originele Makitavervangingsonderdelen.

ACCESSOIRES

LET OP:

• Deze accessoires of hulpstukken worden aanbevolen

voor gebruik met het Makita-gereedschap dat in deze

gebruiksaanwijzing wordt beschreven. Het gebruik van

andere accessoires of hulpstukken kan gevaar voor

persoonlijk letsel opleveren. Gebruik de accessoires of

hulpstukken uitsluitend voor de aangegeven

gebruiksdoeleinden.

Mocht u meer informatie willen hebben over deze

accessoires, dan kunt u contact opnemen met uw

plaatselijke Makita-servicecentrum.

• Beschermkap (schijfkap)

• Binnenflens

• Schijf met een verzonken middengat

• Borgmoer (voor schijf met een verzonken middengat)

• Rubberblok

• Slijpschijven

• Borgmoer (voor slijpschijven)

• Borgmoersleutel

• Doorslijpschijven

• Binnenflens (voor doorslijpschijf)

• Buitenflens (voor doorslijpschijven)

• Komstaaldraadborstel

• Zijhandgreep

• Stofbeschermkap

22

Page 11

ENGLISH

For European countries only

Noise and Vibration

The typical A-weighted noise levels are

sound pressure level: 90 dB (A)

sound power level: 103 dB (A)

- Wear ear protection. -

The typical weighted root mean square acceleration value is

not more than 2.5 m/s

These values have been obtained according to EN50144.

2

.

ITALIANO

Modello per l’Europa soltanto

Rumore e vibrazione

I tipici livelli di rumore ponderati "A" sono

livello di pressione sonora: 90 dB (A)

livello di potenza sonora: 103 dB (A)

– Indossare la protezione per gli occhi. –

In genere, il valore efficace ponderato dell'accelerazione non

supera i 2,5 m/s

Questi valori sono stati ottenuti in conformità con la norma

EN50144.

2

.

FRANÇAIS

Pour les pays d’Europe uniquement

Bruit et vibrations

Les niveaux de bruit pondéré A typiques sont les suivants :

niveau de pression sonore = 90 dB (A)

niveau de puissance sonore = 103 dB (A)

– Portez des protections d’oreilles. –

La valeur d’accélération quadratique pondérée typique ne

dépasse pas 2,5 m/s

Ces valeurs ont été obtenues selon EN50144.

2

.

DEUTSCH

Nur für europäische Länder

Geräusch- und Vibrationsentwicklung

Die typischen effektiven Geräuschpegel betragen für

Schalldruck: 90 dB (A)

Schallleistungspegel: 103 dB (A)

– Tragen Sie einen Gehörschutz. –

Der typische effektive Beschleunigungswert beträgt höchstens

2

2,5 m/s

.

Diese Werte wurden entsprechend der Norm EN50144

gewonnen.

Yasuhiko Kanzaki CE 2006

NEDERLANDS

Alleen voor Europese landen

Geluidsniveau en trilling

De typischa, A-gewogen geluidsniveaus zijn

geluidsdrukniveau: 90 dB (A)

geluidsvermogenniveau: 103 dB (A)

– Draag gehoorbescherming. –

De typisch, gewogen, kwadratisch-gemiddelde

versnellingswaarde is niet hoger dan 2,5 m/s

Deze waarden zijn verkregen volgens EN50144.

2

.

ESPAÑOL

Para países europeos solamente

Ruido y vibración

Los niveles típicos de ruido ponderado A son

nivel de presión sonora: 90 dB (A)

nivel de potencia sonora: 103 dB (A)

– Utilice protección para los oídos. –

El valor ponderado de aceleración no es superior a 2,5 m/s2.

Estos valores se han obtenido conforme a EN50144.

Director Amministratore

Directeur Directeur

Direktor Director

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

Responsible manufacturer: Produttore responsabile:

Fabricant responsable : Verantwoordelijke fabrikant:

Verantwortlicher Hersteller: Fabricante responsable:

Makita Corporation Anjo Aichi Japan

47

Page 12

PORTUGUÊS

Só para países Europeus

Ruído e vibração

Os níveis acústicos ponderados A típicos são

nível de pressão sonora: 90 dB (A)

nível de potência sonora: 103 dB (A)

– Use protecção para os ouvidos. –

A do valor médio quadrático ponderado da variação da

aceleração não é superior a 2,5 m/s

Estes valores foram obtidos segundo a norma EN50144.

2

.

NORSK

Gjelder bare land i Europa

Støy og vibrasjon

Disse verdiene er fremkommet i samsvar med EN60745.

Typisk A-vektede lydtrykknivåer er

Lydtrykknivå: 90 dB (A)

Lydeffektnivå: 103 dB (A)

– Bruk hørselvern. –

Typisk vektet kvadratisk middelverdi av akselerasjonen er ikke

mer enn 2,5 m/s

Disse verdiene er fremkommet i samsvar med EN50144.

2

.

DANSK

Kun for lande i Europa

Lyd og vibration

De typiske A-vægtede støjniveauer er

lydtryksniveau: 90 dB (A)

lydkraftniveau: 103 dB (A)

– Bær høreværn. –

Den typiske vægtede effektive accelerationsværdi er ikke over

2

2,5 m/s

.

Disse værdier er målt i overensstemmelse med EN50144.

SVENSKA

Endast för Europa

Buller och vibration

Normala bullernivåer är

ljudtrycksnivå: 90 dB (A)

ljudeffektsnivå: 103 dB (A)

– Bär öronskydd. –

Kvadratiska medelvärdet för accelerationen är inte mer än

2

2,5 m/s

.

Dessa värden är inhämtade enligt EN50144.

Yasuhiko Kanzaki CE 2006

SUOMI

Vain Euroopan maat

Melutaso ja tärinä

Tyypilliset A-painotetut äänenpainetasot ovat

äänenpainetaso: 90 dB (A)

äänitehotaso: 103 dB (A)

– Käytä kuulosuojaimia. –

Tyypillinen painotettu tehollisarvo on enintään 2,5 m/s

Nämä arvot on saatu standardin EN50144 mukaisesti.

2

.

ΕΛΛΗΝΙΚΑ

Μνο για χώρες της Ευρώπης

Θρυβος και κραδασKς

Το σύνηθες σταθμισμένο επίπεδο ηχητικής πίεσης είναι:

επίπεδο ηχητικής πίεσης: 90 dB (A)

επίπεδο ηχητικής ισχύς: 103 dB (A)

– Να φοράτε ωτοασπίδες. –

Η συνήθης σταθμισμένη μέση τετραγωνική ρίζα της τιμής

επιτάχυνσης δεν υπερβαίνει τα 2,5 m/s

Οι τιμές αυτές έχουν ληφθεί σύμφωνα με το EN50144.

2

.

Director Direktor

Direktør Johtaja

Direktör Διευθυντής

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

Fabricante responsável: Ansvarlig produsent:

Ansvarlig fabrikant: Vastaava valmistaja:

Ansvarig tillverkare: Yπεύθυνος κατασκευαστής:

Makita Corporation Anjo Aichi Japan

48

Page 13

ENGLISH

EC-DECLARATION OF CONFORMITY

We declare under our sole responsibility that this product is in

compliance with the following standards of standardized

documents, EN50144, EN55014, EN61000 in accordance with

Council Directives, 89/336/EEC, 98/37/

EC.

FRANÇAIS

DÉCLARATION DE CONFORMITÉ CE

Nous déclarons sous notre entière responsabilité que ce

produit est conforme aux normes des documents standardisés

suivants, EN50144, EN55014, EN61000 conformément aux

Directives du Conseil, 89/336/CEE et 98/37/EG.

ITALIANO

LE NORME DELLA COMUNITÀ EUROPEA

Dichiariamo sotto la nostra sola responsabilità che questo

prodotto è conforme agli standard di documenti standardizzati

seguenti: EN50144, EN55014, EN61000 secondo le direttive

del Consiglio 89/336/CEE e 98/37/CE.

NEDERLANDS

EG-VERKLARING VAN CONFORMITEIT

Wij verklaren hierbij uitsluitend op eigen verantwoordelijkheid

dat dit produkt voldoet aan de volgende normen van

genormaliseerde documenten, EN50144, EN55014, EN61000

in overeenstemming met de richtlijnen van de Raad

89/336/EEC en 98/37/EC.

DEUTSCH

Hiermit erklärt wir unter unserer alleinigen Verantwortung, daß

dieses Produkt gemäß den Ratsdirektiven 89/336/EWG und

98/37/EG mit den folgenden Normen von Normendokumenten

übereinstimmen: EN50144, EN55014, EN61000

CE-KONFORMITÄTSERKLÄRUNG

Yasuhiko Kanzaki CE 2006

ESPAÑOL

DECLARACIÓN DE CONFORMIDAD DE LA CE

Declaramos bajo nuestra sola responsabilidad que este

producto cumple con las siguientes normas de documentos

normalizados, EN50144, EN55014, EN61000 de acuerdo con

las directivas comunitarias, 89/336/EEC y 98/37/CE.

Director Amministratore

Directeur Directeur

Direktor Director

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

Responsible manufacturer: Produttore responsabile:

Fabricant responsable : Verantwoordelijke fabrikant:

Verantwortlicher Hersteller: Fabricante responsable:

Makita Corporation Anjo Aichi Japan

49

Page 14

PORTUGUÊS

DECLARAÇÃO DE CONFORMIDADE DA CE

Declaramos sob inteira responsabilidade que este produto

obedece às seguintes normas de documentos normalizados,

EN50144, EN55014, EN61000 de acordo com as directivas

89/336/CEE e 98/37/CE do Conselho.

NORSK

Vi erklærer på eget ansvar at dette produktet er i

overensstemmelse med følgende standard i de standardiserte

dokumenter: EN50144, EN55014, EN61000, i samsvar med

Råds-direktivene, 89/336/EEC og 98/37/EC.

EUs SAMSVARS-ERKLÆRING

DANSK

EU-DEKLARATION OM KONFORMITET

Vi erklærer hermed på eget ansvar, at dette produkt er i

overensstemmelse med de følgende standarder i de

normsættende dokumenter, EN50144, EN55014, EN61000 i

overensstemmelse med Rådets Direktiver, 89/336/EEC og

98/37/EC.

SVENSKA

EG-DEKLARATION OM ÖVERENSSTÄMMELSE

Under eget ansvar deklarerar vi härmed att denna produkt

överensstämmer med följande standardiseringar för

standardiserade dokument, EN50144, EN55014, EN61000 i

enlighet med EG-direktiven 89/336/EEC och 98/37/EC.

SUOMI

Yksinomaisesti vastuullisina ilmoitamme, että tämä tuote on

seuraavien standardoitujen dokumenttien standardien

mukainen, EN50144, EN55014, EN61000 neuvoston

direktiivien 89/336/EEC ja 98/37/EC mukaisesti.

VAKUUTUS EC-VASTAAVUUDESTA

ΕΛΛΗΝΙΚΑ

Δηλώνουμε υπ την μοναδική μας ευθύνη τι αυτ το

προϊν βρίσκεται σε Συμφωνία με τα ακλουθα πρτυπα

τυποποιημένων εγγράφων, EN50144, EN55014, EN61000

σύμφωνα με τις Οδηγίες του Συμβουλίου, 89/336/EEC και

98/37/EC.

ΔΗΛΩΣΗ ΣΥΜΜΟΡΦΩΣΗΣ ΕΚ

Yasuhiko Kanzaki CE 2006

Director Direktor

Direktør Johtaja

Direktör Διευθυντής

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

Fabricante responsável: Ansvarlig produsent:

Ansvarlig fabrikant: Vastaava valmistaja:

Ansvarig tillverkare: Yπεύθυνος κατασκευαστής:

Makita Corporation Anjo Aichi Japan

50

Page 15

51

Page 16

Makita Corporation

Anjo, Aichi, Japan

884635A990

Loading...

Loading...