Page 1

T

ECHNICAL INFORMATION

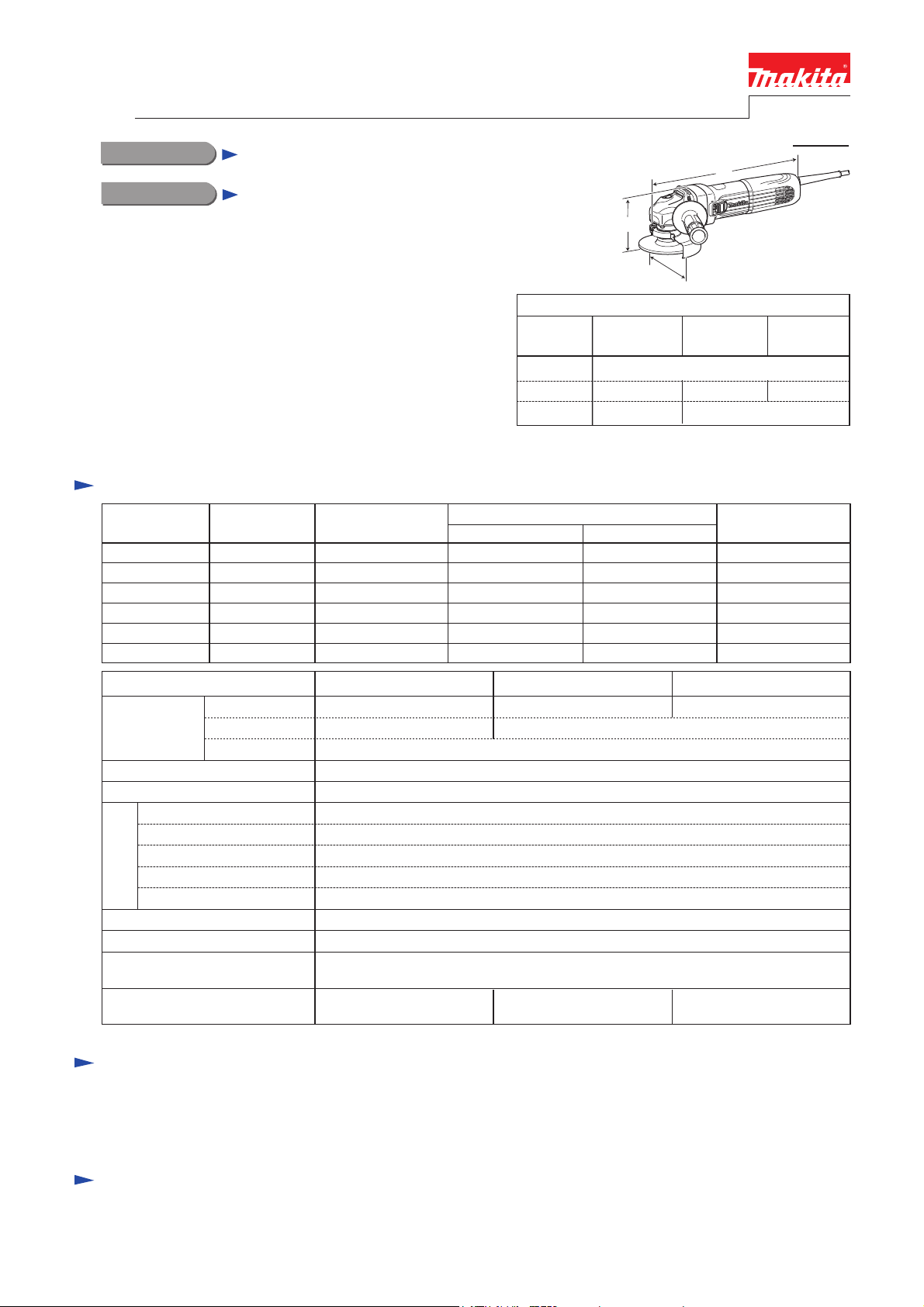

Model No.

GA4041C/GA4043C, GA4541C/GA4543C,

GA5041C/GA5043C

Description

Angle Grinders 100mm (4"), 115mm (4-1/2"),

125mm (5")

CONCEPT AND MAIN APPLICATIONS

1,400W Angle grinder series models; GA4041C/ GA4043C,

GA4541C/ GA4543C and GA5041C/ GA5043C are successor

models of 9560 series models, featuring:

• "Super Joint System II" developed for effective vibration

absorption

• Electronic current limiter, speed control and soft start

• Mechanical brake for powerful braking

• Anti-restart function*1

• Re-designed durable gear housing

• Ergonomically best possible barrel grip

1 Anti-restart function is for models, GA4041C, GA4541C, GA5041C only

*

Specification

Voltage (V) Cycle (Hz)

110

120

127 12

220

230

240

Current (A)

13

12

6.7

6.4

6.1

50/60

50/60

50/60

50/60

50/60

50/60

H

W

Dimensions: mm (")

Model No.

Length (L)

Width (W)

Height (H)

Continuous Rating (W)

Input Output

1,400

--1,400

1,400

1,400

1,400

GA4041C

GA4043C

117 (4-5/8)

117 (4-5/8)

840

840

840

840

840

840

PRODUCT

P 1/ 14

L

GA4541C

GA4543C

325 (12-3/4)

130 (5-1/8) 140 (5-1/2)

Max. Output (W)

GA5041C

GA5043C

121 (4-3/4)

1,800

2,000

2,000

2,100

2,100

2,100

Model No.

Wheel size:

mm (")

No load speed: min.

Shock absorbing system

Constant speed control

Soft start

Electronic current limiter

control

Anti-restart function

Electronic

Variable speed control by dial

Mechanical brake

Protection against electric shock

Power supply cord: m (ft)

Weight according to

EPTA-Procedure 01/2003*2: kg (")

*2 With Side grip, Wheel cover, Inner flange, Lock nut

Diameter

Hole diameter

Max. thickness 6 (1/4)

ˉ¹=rpm

GA4041C/ GA4043C

100 (4) 115 (4-1/2)

GA4041C, GA4541C, GA5041C: Yes/ GA4043C, GA4543C, GA5043C: No

European countries except UK: 4.0 (13.2), Brazil, Australia: 2.0 (6.6)

2.6 (5.6) 2.7 (5.9)2.7 (5.9)

GA4541C/ GA4543C

22.23 (7/8)16 (5/8)

2,800 - 11,000

Super Joint System II

Yes

Yes

Yes

Yes

Yes

Double insulation

Other countries: 2.5 (8.2)

GA5041C/ GA5043C

125 (5)

Standard equipment

Side grip ...............................................1

Lock nut wrench ..................................1

Depressed center wheel ........................1 ( 100mm for GA4041C/ GA4043C, 115mm for GA4541C/ GA4543C,

125mm for GA5041C/ GA5043C)

Note: The standard equipment for the tool shown above may vary by country.

Optional accessories

Depressed center wheels

Rubber pads

Dust collection wheel guards

Abrasive discs

Wire cup brush sets

Wheel covers for wire cup brush sets

Wire bevel brush sets

Wheel covers for wire bevel brush sets

Diamond wheels

Dust collecting wheel guards

Abrasive cut off wheels

Wheel covers

Sanding lock nut

etc.

Page 2

P 2/ 14

Repair

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

[1] NECESSARY REPAIRING TOOLS

Code No. Description Use for

1R028 Bearing setting pipe 20-12.2 mounting Gear housing cover to Armature

1R045 Gear extractor (Large) separate Armature from Gear housing cover

1R232 Pipe 30 removing Coupling and Ball bearing 6903ZZ from large Spiral bevel gear

1R258 V block supporting Armature and Bearing box

1R268 Spring pin extractor M3 disassembling Shaft lock mechanism

1R269 Bearing extractor removing Ball bearings 627DDW/ 696ZZ from Armature

1R281 Round bar for Arbor 7-50 removing Switch knob from Switch lever

1R286 Round bar for Arbor 12-50 removing large Spiral bevel gear section from Bearing box

1R291 Retaining ring S & R pliers removing Retaining ring S-9

1R340 Bearing retainer wrench removing Bearing retainer 20-33 from Bearing box

1R350 Ring 60 supporting Gear housing when disassembling Shaft lock mechanism

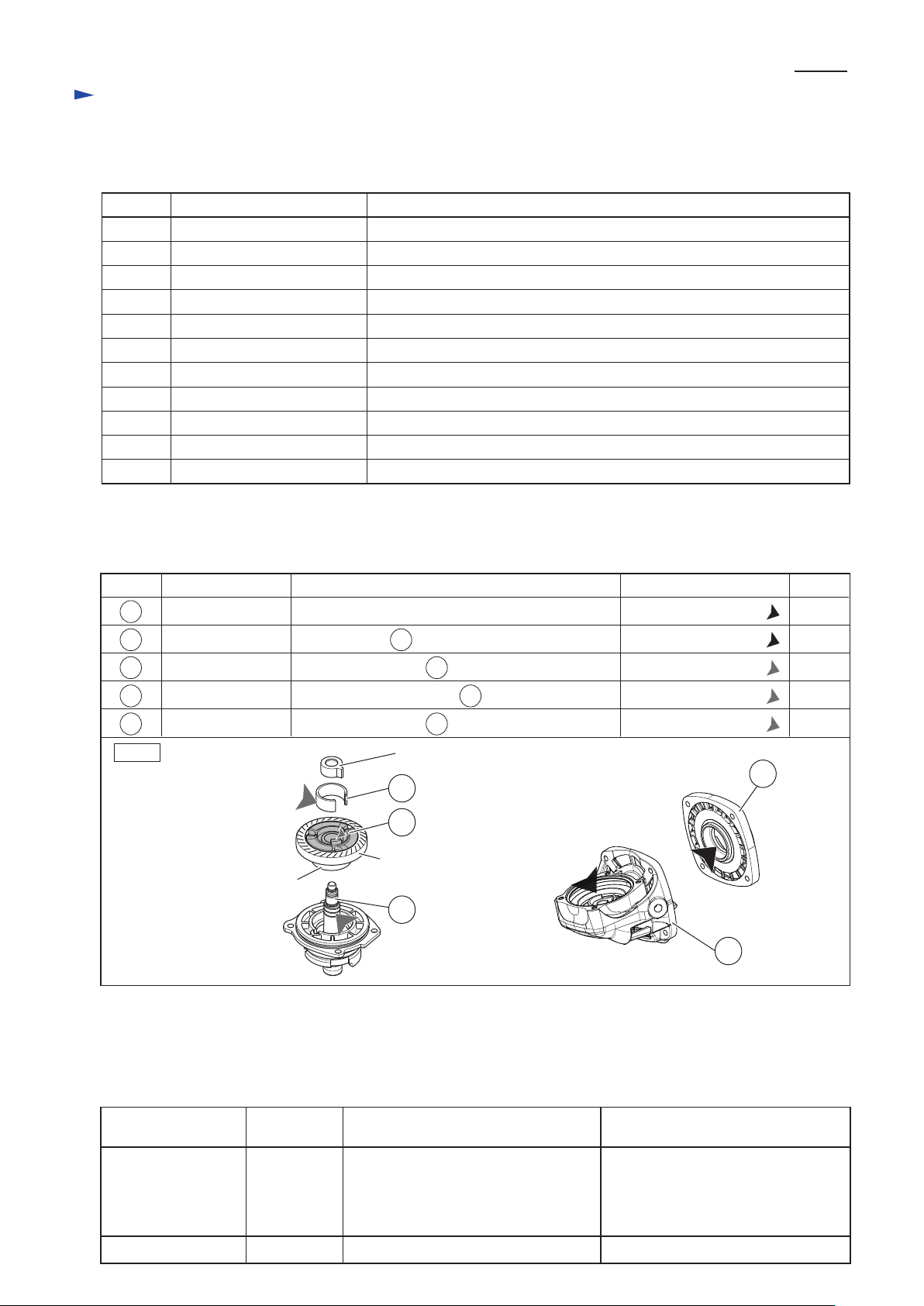

[2] LUBRICATION

Apply Makita grease to the following portions designated with the black triangle and the gray triangle to protect parts

and product from unusual abrasion.

Item No. Description

Gear housing

1

Gear housing cover

6

C-type plate a little56 Outer surface where 58 Coupling contacts

Coupling

58

Spindle

70

Fig. 1

Ball bearing 6903ZZ

Gear room 17g

O-ring 27.5 of 6 Gear housing cover

Cylindrical portion where 56 C-type plate contacts

Drum portion where 58 Coupling contacts

Joint sleeve

56

58

Spiral bevel gear (large)

70

Makita Grease SG No. 0:

Makita Grease SG No. 0:

Makita Grease FA No. 2:

Makita Grease FA No. 2:

Makita Grease FA No. 2:

Lubricant AmountPortion to lubricate

a little

a little

a little

6

1

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Note in Disassemble (general)

Note: As listed below, the grinders use different spiral bevel gears, and they are not interchangeable.

Referring to this list, therefore, be sure to use correct gears for replacement.

Model No.

GA4041 GA4541C

GA4541 GA5041C

GA5041 GA4543C

GA4041C GA5043C

GA4043C

GA6041

No load

speed: min.ˉ¹

11,000

9,000

Smaller spiral bevel gear

(on armature shaft)

Larger spiral bevel gear

10 teeth 38 teeth

9 teeth 41 teeth

(on spindle)

Page 3

Repair

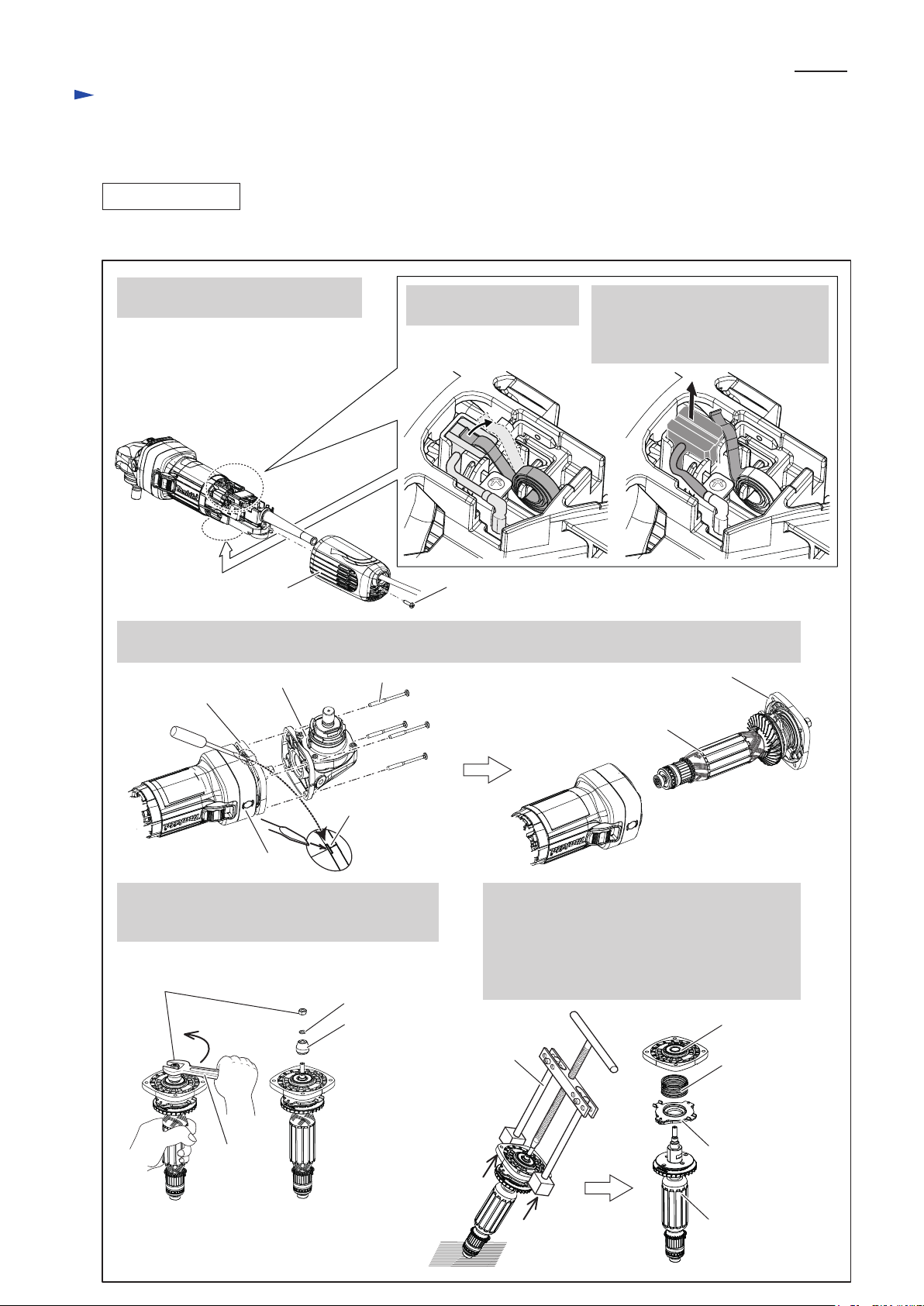

[3] DISASSEMBLY/ASSEMBLY

[3] -2. Armature, Spiral bevel gear [small one]

DISASSEMBLING

(1) Remove Spiral bevel gear (small) from the drive end of Armature as drawn in Fig. 2.

Fig. 2

P 3/ 14

1. Remove Rear cover by unscrewing

one 4x18 Tapping screw.

Rear cover

4. Unscrew four Tapping screws. Then separate Gear housing cover from Spacer while applying a slotted

screwdriver to the notch on Gear housing cover on belly side.

Gear housing cover

Gear housing

4x50 Tapping screw

2. Shift Spiral spring from

Carbon brush top.

4x18 Tapping screw

3. Disconnect Carbon brush from

commutator by pulling up.

Note: No need to remove Carbon

brush in this step.

Gear housing cover

Armature

Notch on

Gear housing cover

Spacer

5. Remove M6 Hex nut to turn it with Wrench 10

counterclockwise. Then, remove Flat washer 6

and small Spiral bevel gear from Armature.

M6 Hex nut

Flat washer 6

Spiral bevel

gear (small)

Wrench 10

6. Remove Gear housing cover with 1R045.

Then, remove Compression spring 33 and

Brake shoe holder complete.

Caution: Be careful that the cover and the spring

may jump out from Armature side

due to recoil force by the spring.

Gear housing

1R045

cover

Compression

spring 33

Brake shoe

holder complete

Armature

Page 4

P 4/ 14

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -2. Armature, Spiral bevel gear [small one] (cont.)

DISASSEMBLING

(2) Disassemble the commutator end of Armature as drawn in Fig. 3.

Note: This step is required for the models with electronic control system of GA4041C, GA4043C, GA4541C,

GA4543C, GA5041C, GA5043C.

Fig. 3

1. Pick up three tabs of

Self lock 6 with tweezers

to remove it from Armature.

3. Remove Ball bearing 627DDW with 1R269. 4. Remove Flat washer 7 and

1R269

Ball bearing 627DDW

ASSEMBLING

Tabs

Self lock 6

Tweezers

2. Remove Magnet sleeve,

Wave washer 6 and

Labyrinth rubber ring 22.

Magnet sleeve

Wave washer 6

Labyrinth rubber ring 22

Insulation washer.

Flat washer 7

Insulation washer

(1) Assemble the commutator end of Armature as drawn in Fig. 4.

Note: This step is required for the models with electronic control system of GA4041C, GA4043C, GA4541C,

GA4543C, GA5041C, GA5043C.

Fig. 4

1. Return tabs of Self lock 6 to their

normal shape before assembling.

Then, mount Wave washer 6 to

the commutator end of Armature.

Note: Be careful of their directions.

Refer to the drawings in Fig. 4.

Self lock 6

Magnet sleeve

Wave washer 6

2. Press down Self lock 6 until

Wave washer 6 gets flat.

3. Magnet sleeve is stabilized

between Self lock 6 and

Wave washer 6 by the reaction

force of Wave washer 6.

Self lock 6

Magnet sleeve

Wave washer 6

Page 5

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -2. Armature, Spiral bevel gear [small one] (cont.)

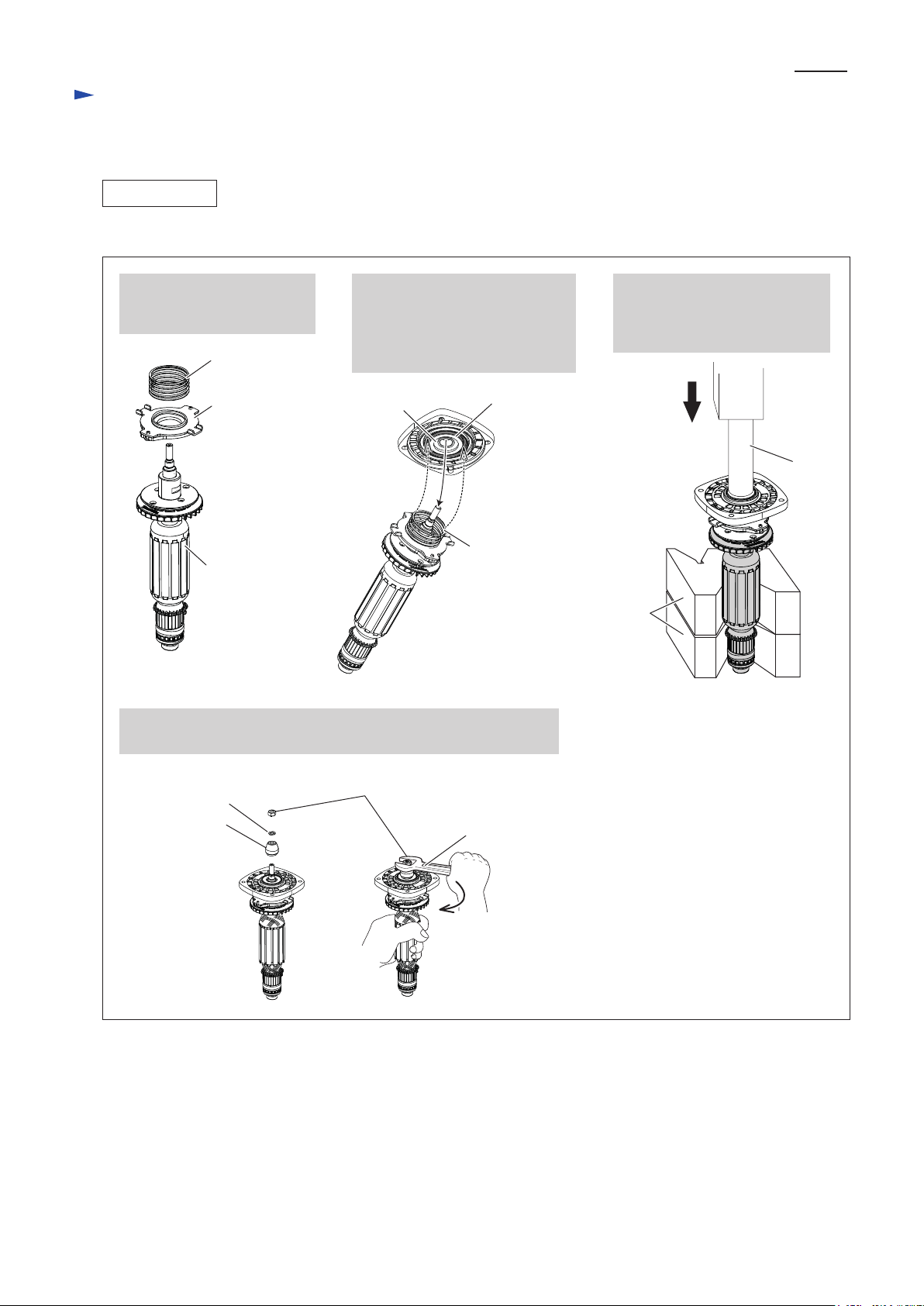

ASSEMBLING

(2) Assemble the drive end of Armature as drawn in Fig. 5.

Fig. 5

P 5/ 14

1. Set Brake shoe holder

complete and Compression

spring 33 to Armature.

Compression

spring 33

Brake shoe

holder complete

Armature

4. Set Spiral bevel gear (small) and Flat washer 6 to Armature shaft.

Then, secure them with M6 Hex nut.

2. Mount Gear housing cover to

Armature to fit the groove of

the cover to Compression

spring 33 and Armature shaft

through Ball bearing 6001LLB.

Ball bearing

6001LLB

Groove of Gear

housing cover

Compression

spring 33

3. Supporting Armature section

with 2 pcs. of 1R258, press

Gear housing cover to

Armature section with 1R028.

1R028

1R258

Flat washer 6

Spiral bevel

gear (small)

M6 Hex nut

Wrench 10

Page 6

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -2. Armature, Spiral bevel gear [small one] (cont.)

ASSEMBLING

(3) Assemble Spacer, Armature section and Gear housing to Motor housing as drawn in Fig. 6.

Fig. 6

1. Set Switch knob to “Lock ON” position so that Switch plate is pushed toward Spacer.

Then, mount Spacer while fitting its groove to Switch plate.

And then, return Switch knob to “OFF” position.

P 6/ 14

Spacer

2. Assemble Armature section to Motor housing

while fitting the wings of Brake shoe complete

to the grooves of Spacer.

Wing of

Brake shoe complete

Wing of

Brake shoe complete

Switch plate Switch knob

groove

Groove of Spacer

3. Face the notch to the same side as Name plate

by twisting Gear housing cover.

Gear housing cover

Name plate

Spacer

Notch on

Gear housing cover

4. Assemble Gear housing while facing Spindle to the same side

as the notch and Name plate.

Spindle

Notch on

Gear housing cover

Name plate

Gear housing

Page 7

P 7/ 14

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -3. Spiral bevel gear [large one], Ball bearings 696ZZ/ 6201DDW

DISASSEMBLING

Note: The gear and the ball bearings can be replaced without disassembling the motor section.

(1) Remove Ball bearing 696ZZ, Retaining ring S-9, Flat washer 10 and C-type plate from Spindle as drawn in Fig. 7.

Fig. 7

1. Remove four M4x16 Hex socket head bolts, then separate Bearing box section from Gear housing.

M4x16 Hex socket head bolt

Bearing box

section

2. Remove Ball bearing 696ZZ

with 1R269.

1R269

Ball bearing

696ZZ

5. Receive Bearing box with 1R258

and remove Spindle by pressing it

with Arbor press.

Arbor press

3. Remove Retaining ring S-9

with 1R291.

1R291

Retaining

ring S-9

6. Joint sleeve can be removed.

Joint sleeve

4. Remove Flat washer 10.

Then, remove C-type plate.

C-type plate.

Flat washer 10

7. Using 1R291, remove Retaining

ring R-26 from the inside of

Lead flange.

Then, separate Lead flange

from Spindle .

1R258

1R258

1R258 1R258

Spindle

Retaining

ring R-26

Spindle

Lead flange

Page 8

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -3. Spiral bevel gear [large one], Ball bearings 696ZZ/ 6201DDW (cont.)

DISASSEMBLING

(2) Disassemble large Gear section from Bearing box as drawn in Fig. 8.

Fig. 8

P 8/ 14

1. Tap Bearing box to shift Flat washer 12

so that the surface is revealed as large as

possible.

Then, put Bearing box on 1R258.

Bearing box

Bearing retainer

3. Put large Spiral bevel gear section

on 1R258. Then, apply 1R232 to

Coupling of the gear section.

Flat washer 12

Flat washer 12

2. While applying 1R286 to Flat washer 12 through Bearing

retainer, press it carefully to remove large Spiral bevel gear

section (including Coupling and Ball bearing 6903ZZ)

from Bearing box.

1R286

Ball bearing

6903ZZ

Coupling

1R258

4. Remove Coupling together with Ball bearing 6903ZZ

from large Spiral bevel gear by pressing 1R232 with Arbor

press. And then, disassemble the bearing from Coupling.

Note: Do not re-use the removed Ball bearing 6903ZZ

because it is damaged in the step of removing Spindle.

large

Spiral bevel gear

Flat washer 12

large Spiral bevel gear

1R232

1R232

1R2581R258 1R2581R258

Coupling

Ball bearing 6903ZZ

Arbor press

Page 9

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -3. Spiral bevel gear [large one], Ball bearings 696ZZ/ 6201DDW (cont.)

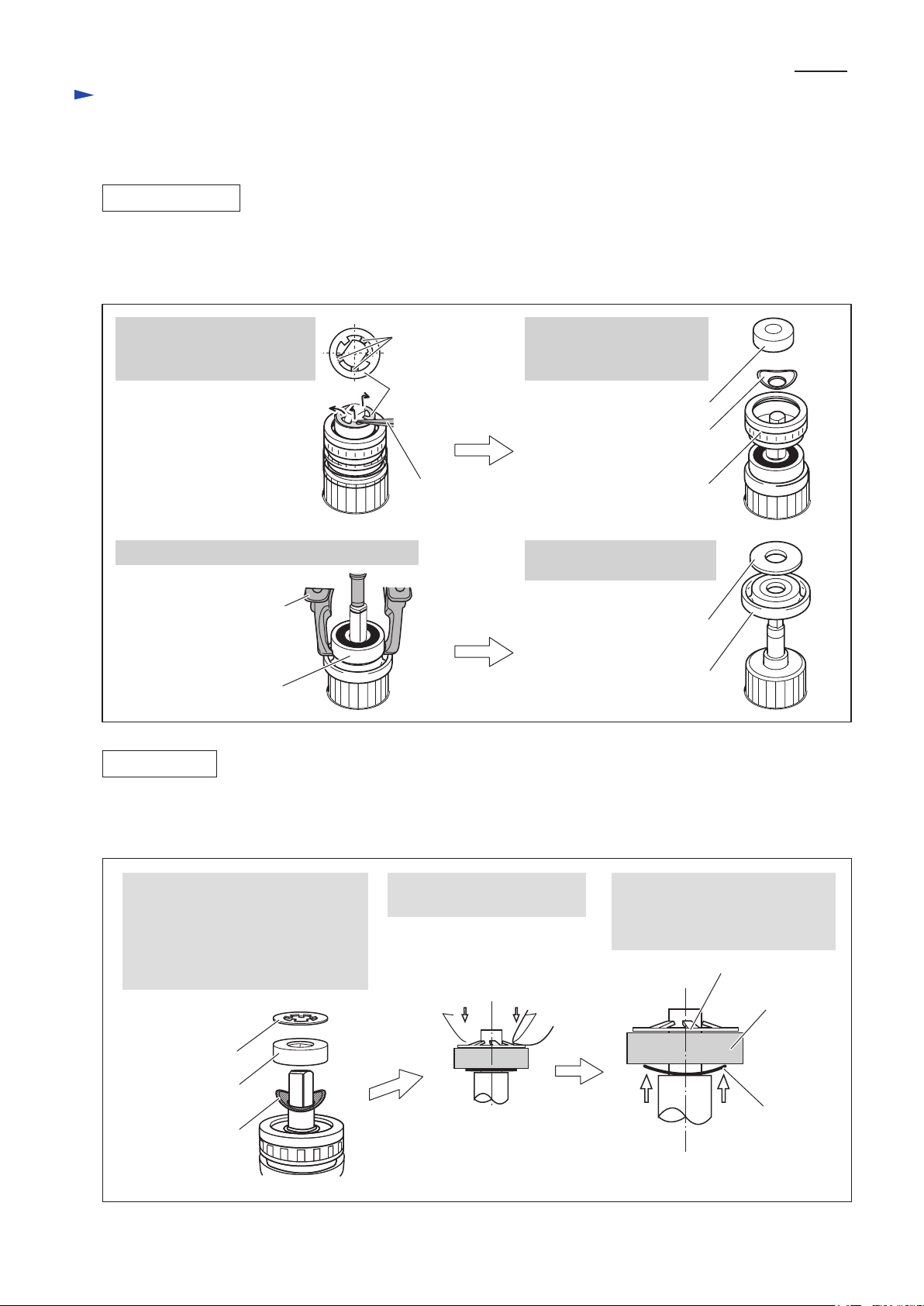

DISASSEMBLING

(3) Disassemble Ball bearing 6201DDW from Bearing box as drawn in Fig. 9.

Fig. 9

1. Clamp Bearing box with Vise. Then, while fitting the claw of 1R340 to the notch of Bearing retainer 20-33,

turn 1R340 clockwise to remove the retainer.

Bearing

1R340

retainer 20-33

P 9/ 14

Bearing

retainer 20-33

2. Take out Felt ring 17 and Flat washer 21

from Lead flange side of Bearing box.

Felt ring 17

Flat washer 21

Ball bearing

6201DDW

Felt ring 17

3. Remove Ball bearing 6201DDW with Arbor press.

Arbor press

Ball bearing

6201DDW

ASSEMBLING

Assemble by reversing the disassembly procedure. (Refer to Figs. 9, 8 and 7)

Note: • Do not re-use the removed Joint sleeve. New Joint sleeve has to be mounted.

(Refer to the bottom center illustration in Fig. 7)

• Apply the following thread locker to the thread of M4x16 Hex socket head bolts if the unscrewed bolts are used.

* Three Bond 1342

* Loctite 242

(Refer to the upper left illustration in Fig. 7)

• Coupling, large Spiral bevel gear, Ball bearing 6903ZZ have to be assembled tightly that there is any gaps

among them. See the left illustration in Fig. 10.

Fig. 10

Incomplete assembling causes gaps.

Page 10

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -4. Switch Lever

DISASSEMBLING

(1) Remove Rear cover from Motor housing by removing 4x18 Tapping screw. (Fig. 2)

(2) Disassemble Switch lever and Switch knob from the machine as drawn in Fig. 11.

Fig. 11

P 10/ 14

1. While locking Switch knob

with 1R281, strongly push

Switch lever in a direction

designated with black arrow.

1R281

Switch lever

ASSEMBLING

(1) Insert Switch lever into Motor housing. And push it until the loop portion comes into sight through Switch knob

assembling hole on Motor housing. Refer to the right and center illustration in Fig. 11.

(2) Assemble Switch knob to Switch lever as drawn in Fig. 12.

Fig. 12

1. Make sure that Compression spring 4 is assembled

to Switch lever in advance.

2. Switch lever is disconnected from

the locking claw of Switch knob.

Then, remove Switch knob.

Switch knob

2. Fitting Switch knob to the loop portion of Switch

lever and the claw portion of Switch plate, hold

Switch knob. And then, release Switch lever.

(The hook of Switch knob interlocks with the hole

of Switch lever when Switch lever is pushed back

to OFF position by Compression spring 4.)

Switch lever

Switch plate

3. Bending Switch lever, pull out

Switch lever from Motor housing.

Switch lever

Switch knob

Compression spring 4

Switch lever

Page 11

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -5. Switch Block

DISASSEMBLING

After removing Switch lever (Refer to Fig. 11), separate Switch block from Motor housing as drawn in Fig. 13.

Fig. 13

Insert Slotted screwdriver into the gap between Switch

block and Motor housing, remove Switch block from

Motor housing by twisting the screwdriver.

Slotted screwdriver

[3] -6. Switch

DISASSEMBLING

Switch block

Controller

P 11/ 14

After removing Switch lever (Refer to Fig. 11), remove Switch from Switch block as drawn in Fig. 14.

Fig. 14

Insert Slotted screwdriver into the gap between Switch and Switch block.

While fitting the tip of the screwdriver to the side groove of Switch,

remove Switch by prying it off.

Switch

Slotted screwdriver

[3] -7. Brush Holder

DISASSEMBLING

Brush holders can be disassembled as drawn in Fig. 15.

Fig. 15

Remove 3x10 Tapping screw. Then, insert Slotted screwdrivers into the gap between Motor housing

and Brush holder’s plastic portion. And then, disassemble Brush holder by prying them off.

Brush holder

Slotted screwdrivers

Page 12

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -8. Shaft Lock

DISASSEMBLING

(1) Disassemble Bearing box section as drawn in the upper two illustrations in Fig. 7.

(2) Disassemble Shaft lock mechanism as drawn in Figs. 16 and 17.

Fig. 16 Fig. 17

P 12/ 14

While applying 1R268 to Shoulder pin 6 through the small hole

on Pin cap, tap 1R268 with a hammer.

Now, Shoulder pin 6 comes out from Gear housing complete.

1R268

Pin cap

Pin cap

1R350

ASSEMBLING

(1) Be sure to use a new Pin cap for replacement and to remove all the plastic dust on Shoulder pin 6. (Fig. 18)

(2) Assemble the Parts for Shaft lock mechanism as drawn in Fig. 19.

Shoulder pin 6

Release 1R268 from Pin cap carefully

so that Pin cap will not pop out by

Compression spring 8.

Pin cap

Compression

spring 8

Note: Do not re-use removed Pin cap

because removal one damages

the inside surface of the cap,

producing plastic dust.

Fig. 18 Fig. 19

1. Insert Shoulder pin 6 through

the hole of Gear housing

complete.

Plastic dust

Shoulder pin 5

O Ring 4

Shoulder

pin 6

2. Assemble new Pin cap by pressing

it to Shoulder pin 6.

Note: Do not forget to assemble

Compression spring 8.

Pin cap

Compression

spring 8

Page 13

Circuit diagram

GA4041C, GA4043C, GA4541C, GA4543C, GA5041C, GA5043C

Fig. D-1A

with Controller

Color index of lead wires' sheath

Blue

Brown

P 13/ 14

Black lead wire is used

for some countries.

White lead wire is used

for some countries.

Noise suppressor* is installed

in Switch block.

*Noise suppressor is not used

for some countries.

GA4041, GA4541, GA5041, GA6041

Fig. D-1B

Switch

1

2

Switch block

Noise

suppressor

3

Controller

6

Field

7

45

8

Brush holder

Blue Brown

Black lead wire is used

for some countries.

White lead wire is used

for some countries.

Noise suppressor* is installed

in Switch block.

*Noise suppressor is not used

for some countries.

without Controller

Color index of lead wires' sheath

Switch

1

Switch block

Noise

suppressor

2

3

6

Field

4

8

Brush holder

57

Page 14

Wiring diagram

Fig. D-2

P 14/ 14

Wiring of Lead wires of Power supply cord

Put Lead wires of Power supply cord

into this place designated with gray color.

Loading...

Loading...