Page 1

Original Instruction Manual

Instructions d’emploi d’origine

Originalbetriebsanleitung

Manuale di istruzioni originale

Originele gebruiksaanwijzing

Instrucciones de manejo originales

Instruções de serviço original

Original brugsanvisning

Πρωτότυπο εγχειρίδιο οδηγιών

Orijinal Kullanım Kılavuzu

Warning:

Read this instruction manual carefully before putting the Multi Function Power Head into operation and strictly observe the safety regulations!

Save instruction manual for future reference.

Avertissement :

Veuillez lire attentivement ce mode d’emploi avant d’utiliser l’outil multi-fonctions et respectez strictement les consignes de sécurité !

Conservez ce mode d’emploi pour vous y reporter ultérieurement.

Warnung:

Lesen Sie vor Verwendung des Multifunktions-Antriebes diese Bedienungsanleitung aufmerksam durch und halten Sie die

Sicherheitsregeln strikt ein!

Bewahren Sie die Anweisungen zum späteren Nachschlagen auf.

Avvertenza:

Leggere attentamente il presente manuale di istruzioni prima di mettere in funzione l’utensile multifunzione a benzina e rispettare

scrupolosamente le norme per la sicurezza.

Conservare il manuale di istruzioni per farvi riferimento in futuro.

Waarschuwing:

Lees deze gebruiksaanwijzing aandachtig door voordat u het multifunctionele aandrijfsysteem in gebruik neemt en houdt u te allen tijde

aan de veiligheidsinstructies!

Bewaar de gebruiksaanwijzing om deze in de toekomst te kunnen raadplegen.

Advertencia:

Lea atentamente este manual de instrucciones antes de utilizar el multifuncional y cumpla estrictamente la normativa de seguridad.

Guarde el manual de instrucciones para futuras consultas.

Aviso:

Leia cuidadosamente este manual de instruções antes de utilizar a Multifuncional a Gasolina e cumpra todas as normas de segurança!

Guarde o manual de instruções para referência futura.

Advarsel:

Læs denne brugsanvisning omhyggeligt igennem inden du anvender det multifunktionelle værktøjshoved og overhold

sikkerhedsbestemmelserne til mindste detalje!

Gem brugsanvisningen, så du har den til fremtidig brug.

Προειδοποιηση:

Πριν θέσετε σε λειτουργία τη Βενζινοκίνητη Κεφαλή Πολλαπλών Χρήσεων διαβάσετε προσεχτικά το εγχειρίδιο οδηγιών και εφαρμόσετε

αυστηρά τους κανονισμούς ασφαλείας!

Φυλάξτε το εγχειρίδιο οδηγιών για μελλοντική αναφορά.

Uyari:

Çok Fonksiyonlu Güç Başlığını kullanmaya başlamadan önce bu kullanım kılavuzunu dikkatli bir şekilde okuyun ve güvenlik talimatlarını

sıkı bir şekilde takip edin!

Kullanım kılavuzunu daha sonra başvurmak üzere saklayın.

EX2650LH

Page 2

English

(Original instructions)

Thank you very much for purchasing the MAKITA Multi Function Power Head.

We are pleased to recommend to you the MAKITA Multi Function Power Head

which is the result of a long development programme and many years of

knowledge and experience.

Please read this booklet which refers in detail to the various points that will

demonstrate its outstanding performance. This will assist you to obtain the best

possible result from your MAKITA Multi Function Power Head.

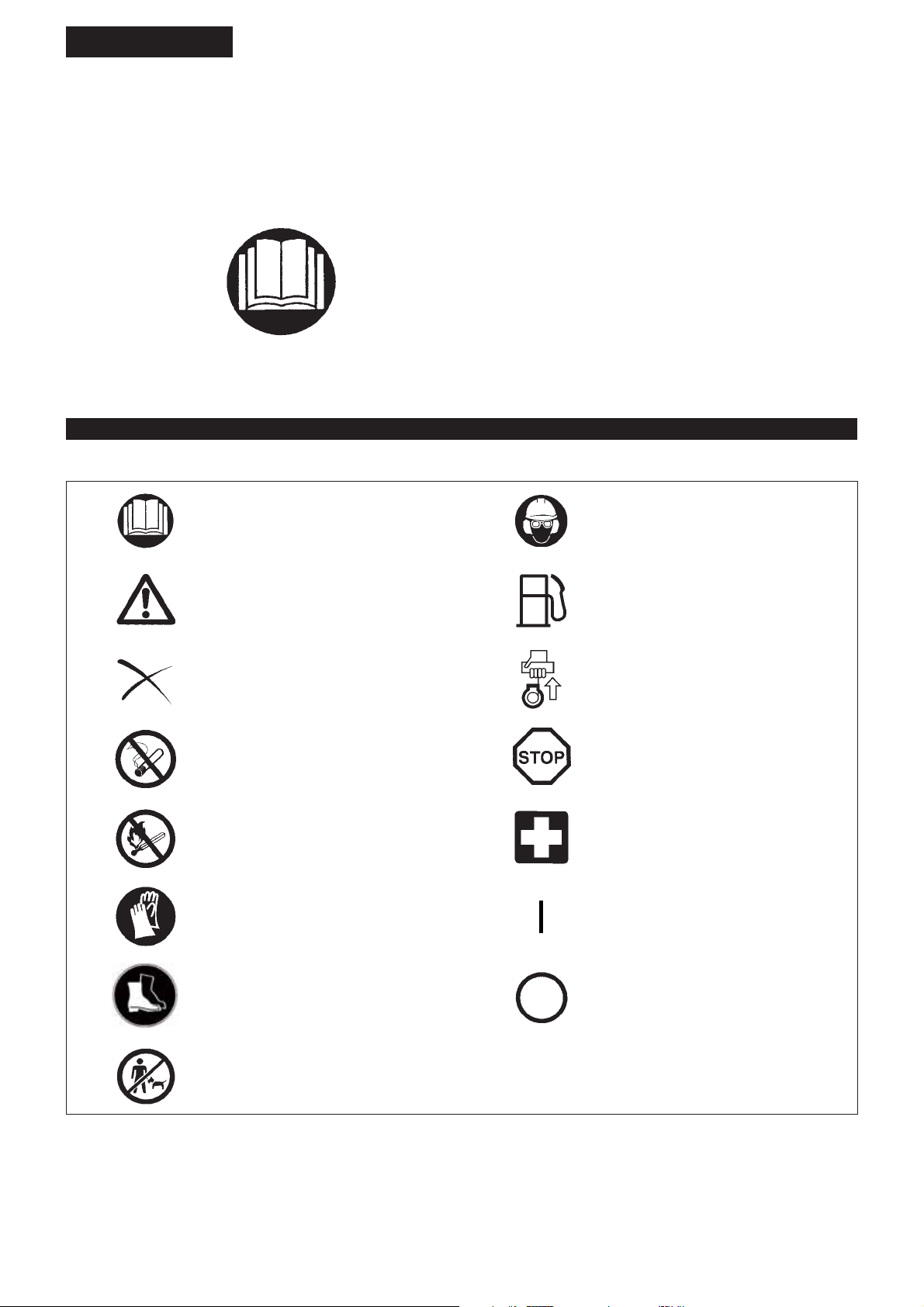

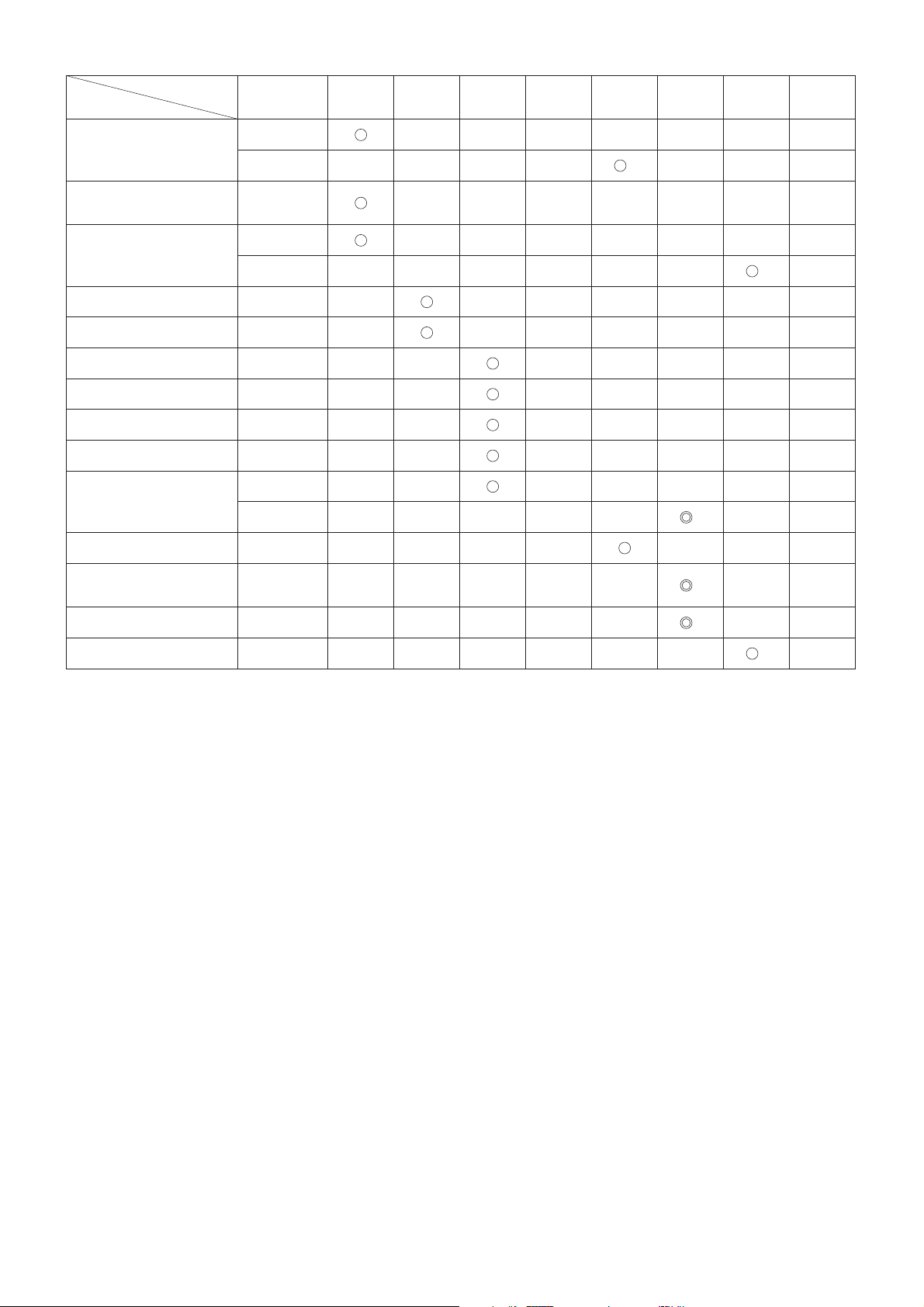

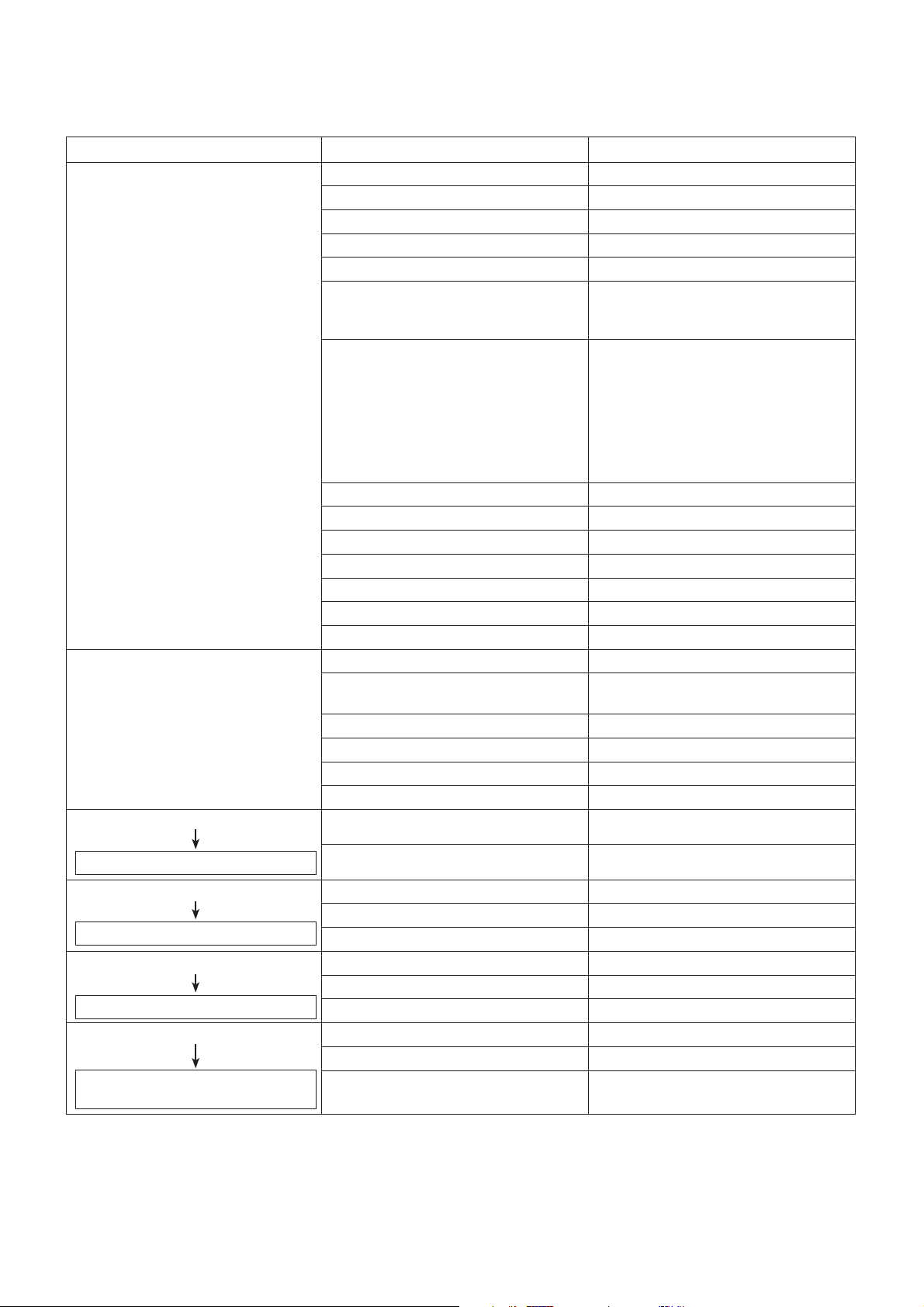

SYMBOLS

You will note the following symbols when reading the instructions manual.

Read instruction manual and follow the

warnings and safety precautions!

Table of Contents Page

Symbols .........................................................................2

Safety instructions .........................................................3

Technical data................................................................7

Approved attachments...................................................8

Designation of parts.......................................................9

Mounting of handle ......................................................10

Mounting attachment ...................................................10

Disassembling ............................................................. 11

Before start of operation ..............................................12

Correct handling of machine........................................14

Points in operation and how to stop ............................14

Servicing instructions...................................................17

Storage ........................................................................20

Wear protective helmet, eye and ear

protection!

Take particular care and attention! Fuel (Gasoline)

Forbidden! Engine-manual start

No smoking! Emergency stop

No open flame! First aid

Protective gloves must be worn! ON/START

Wear sturdy boots with nonslip soles.

Steeltoed safety boots are recommended!

OFF/STOP

Keep the area of operation clear of all

persons and pets!

2

Page 3

Intended use of the machine

This multi function power head is intended for driving an approved attachment

listed in this instruction manual. Never use the machine for the other purpose.

SAFETY INSTRUCTIONS

General instructions

To ensure correct operation, user has to read this instruction manual to make himself familiar with the handling of the Multi Function Power Head. Users

insufficiently informed will risk danger to themselves as well as others due to

improper handling.

It is recommended only to lend the Multi Function Power Head to people who have proven to be experienced with Multi Function Power Heads.

Always hand over the instruction manual.

First users should ask the dealer for basic instructions to familiarize oneself with the handling of an engine powered cutter.

Children and young persons aged under 18 years must not be allowed to operate the Multi Function Power Head. Persons over the age of 16 years

may however use the device for the purpose of being trained only whilst

under supervision of a qualified trainer.

Use Multi Function Power Heads with the utmost care and attention. Operate the Multi Function Power Head only if you are in good physical -

condition. Perform all work calmly and carefully. The user has to accept

liability for others.

Never use the Multi Function Power Head after consumption of alcohol or drugs, or if feeling tired or ill.

National regulation can restrict the use of the machine. -

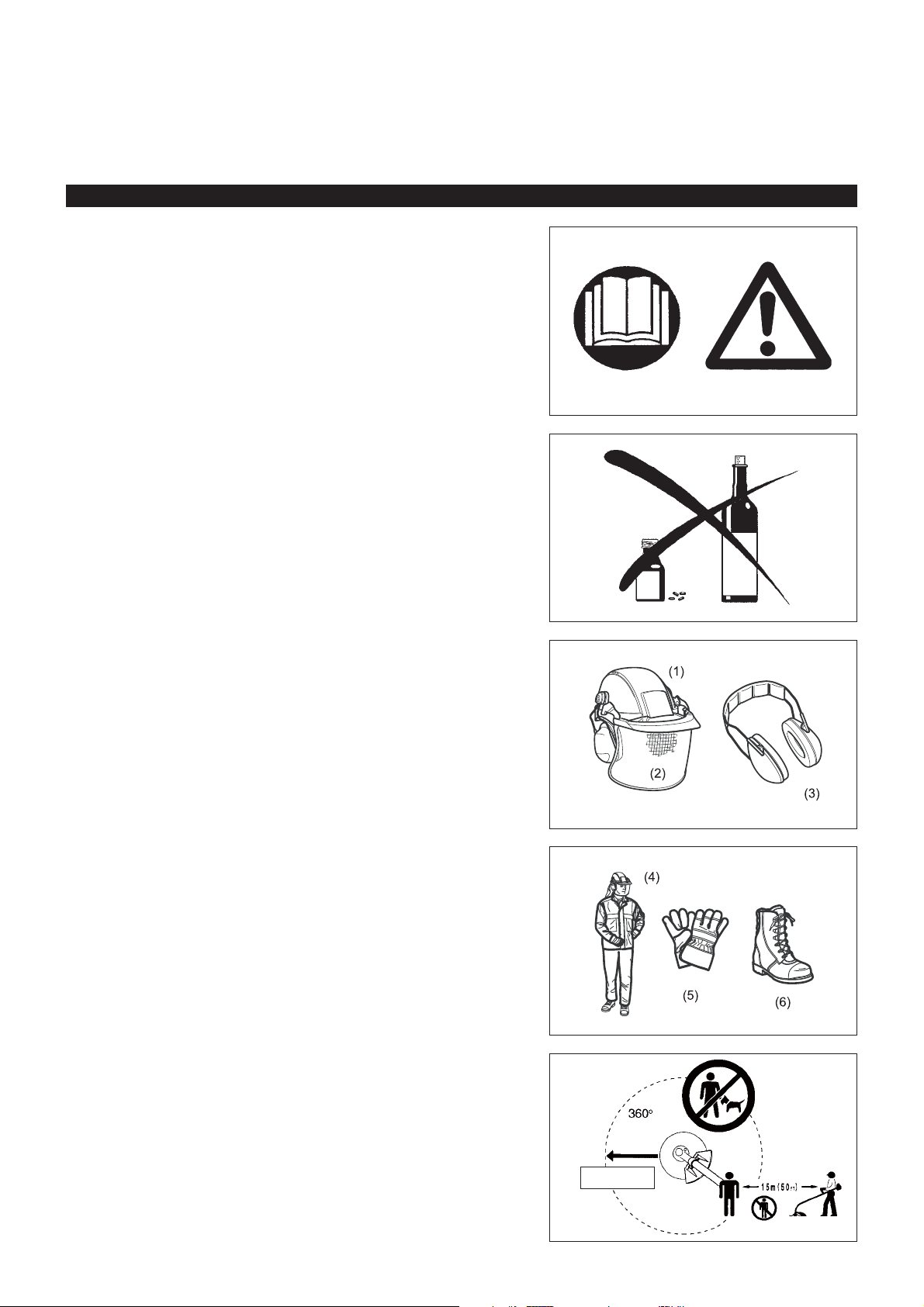

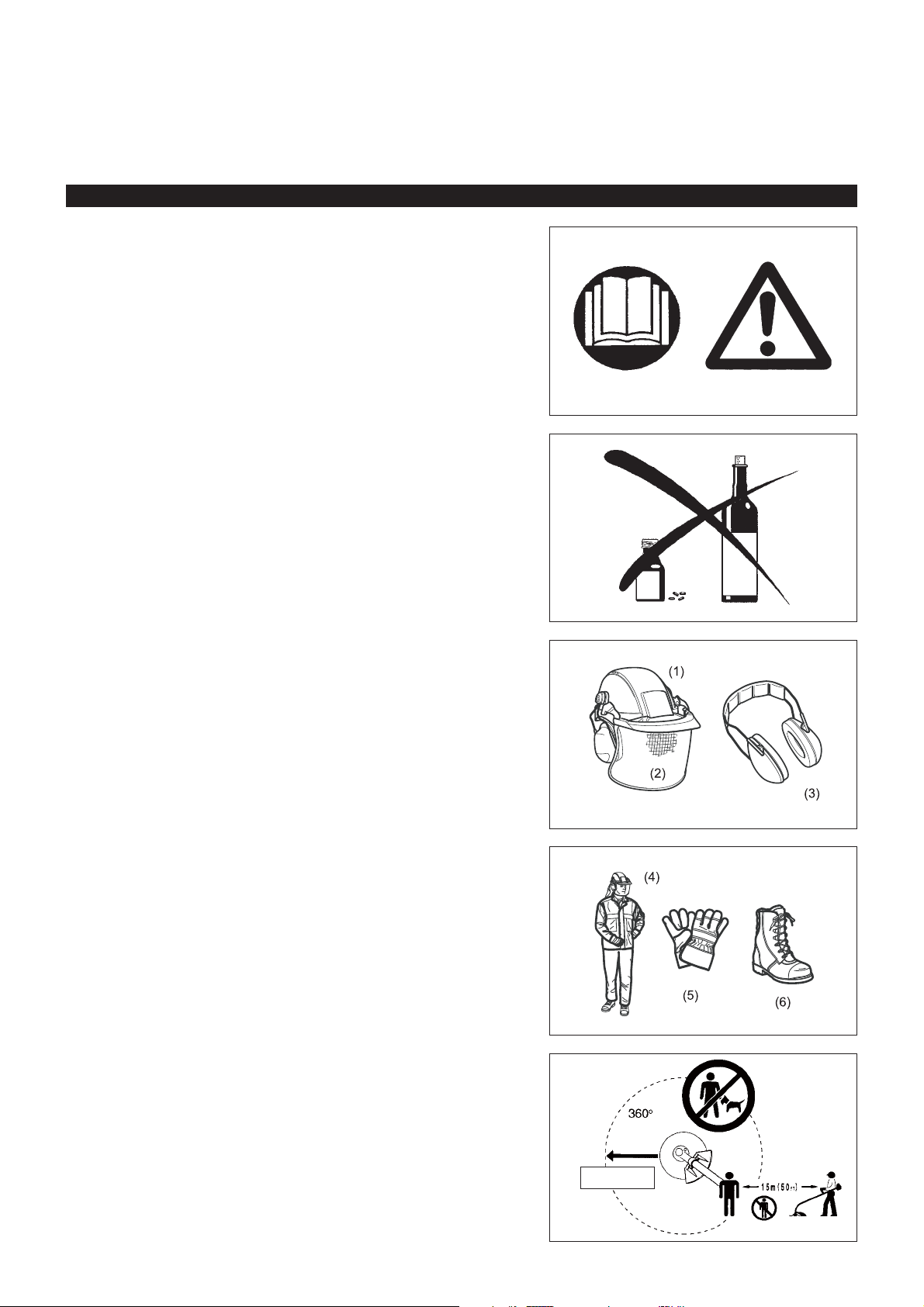

Personal protective equipment

The clothing worn should be functional and appropriate, i.e. it should be tight- fitting but not cause hindrance. Do not wear either jewelry or clothing which

could become entangled with bushes or shrubs.

In order to avoid either head-, eye-, hand-or foot injuries as well as to protect your hearing the following protective equipment and protective clothing must

be used during operation of the Multi Function Power Head.

Always wear a helmet where there is a risk of falling objects. The protective helmet (1) is to be checked at regular intervals for damage and is to be

replaced at the latest after 5 years. Use only approved protective helmets.

The visor (2) of the helmet (or alternatively goggles) protects the face from flying debris and stones. During operation of the Multi Function Power Head

always wear goggles, or a visor to prevent eye injuries.

Wear adequate noise protection equipment to avoid hearing impairment (ear muffs (3), ear plugs etc.).

The work overalls (4) protect against flying stones and debris. We strongly recommend that the user wears work overalls.

Special gloves (5) made of thick leather are part of the prescribed equipment and must always be worn during operation of the Multi Function Power Head.

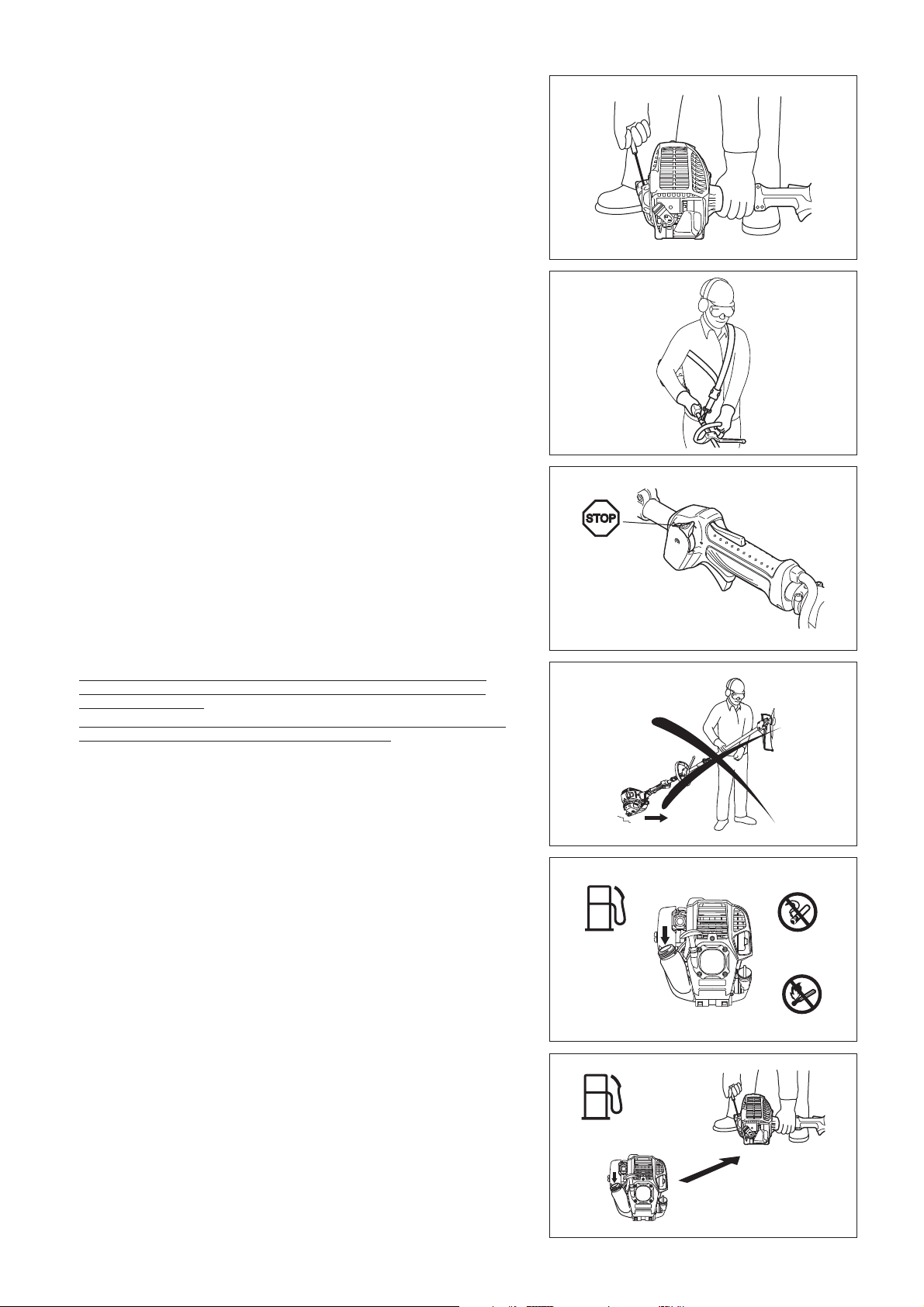

When using the Multi Function Power Head, always wear sturdy shoes (6) with a non-slip sole. This protects against injuries and ensures a good footing.

Starting up the Multi Function Power Head

Please make sure that there are no children or other people, also pay attention to any animals in the working vicinity.

Make sure that the attachment is attached in place, the control lever for easy action and check for proper functioning of the lock-off lever.

Motion of the attachment during idling speed is not allowed. Check with your dealer for adjustment if in doubt. Check for clean and dry handles and test

the function of the start/stop switch.

Diagrammatic figure

15 Meters

3

Page 4

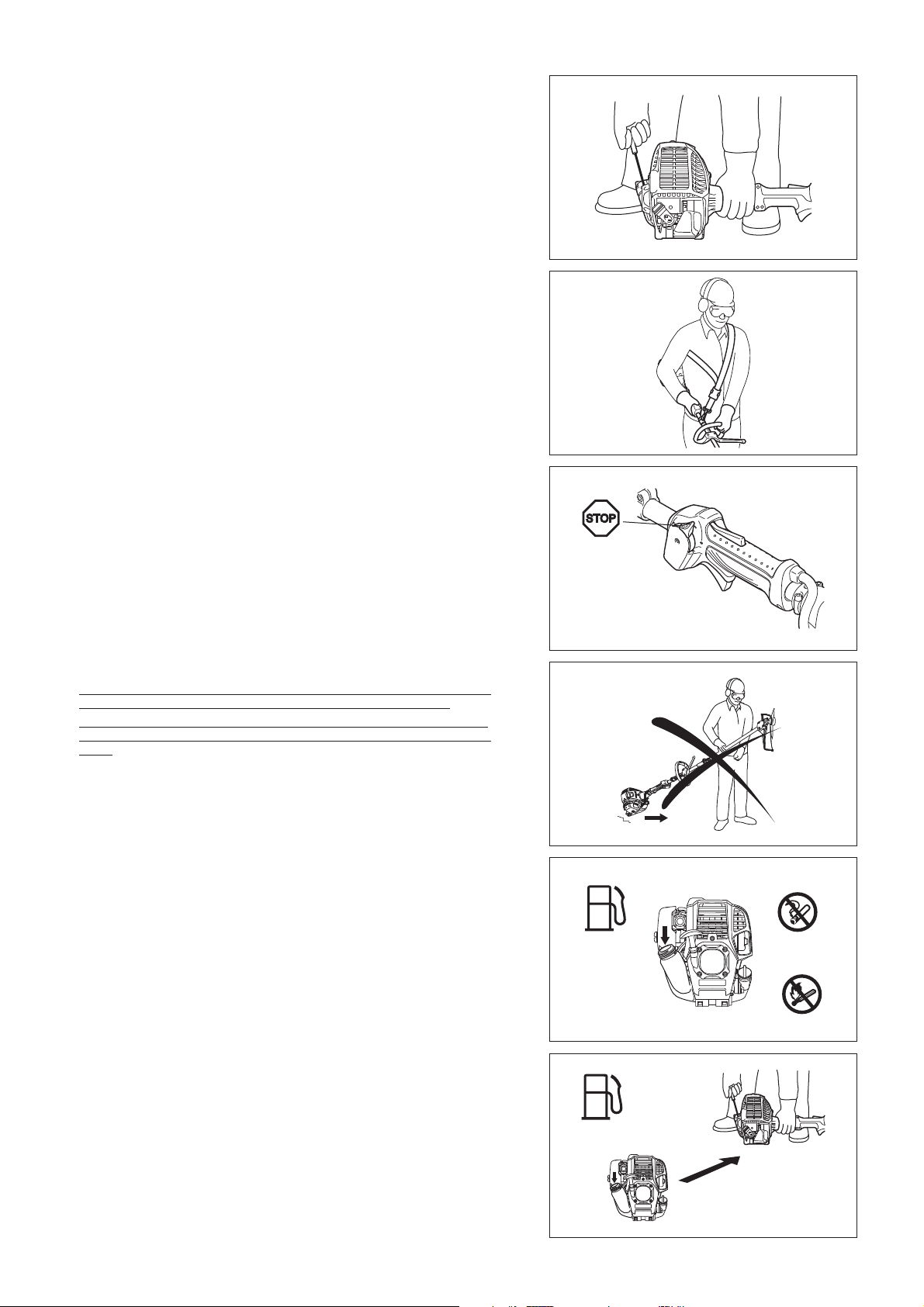

Start the Multi Function Power Head only in accordance with the instructions.

Do not use any other methods for starting the engine! Use the Multi Function Power Head and the tools only for such applications -

as specified.

Only start the Multi Function Power Head engine, after the entire assembly -

is done. Operation of the device is only permitted after all the appropriate

accessories are attached!

Before starting make sure that the attachment has no contact with hard objects such as branches, stones etc. as the attachment will revolve when

starting.

The engine is to be switched off immediately in case of any engine problems. Should the attachment hit stones or other hard objects, immediately switch off -

the engine and inspect the attachment.

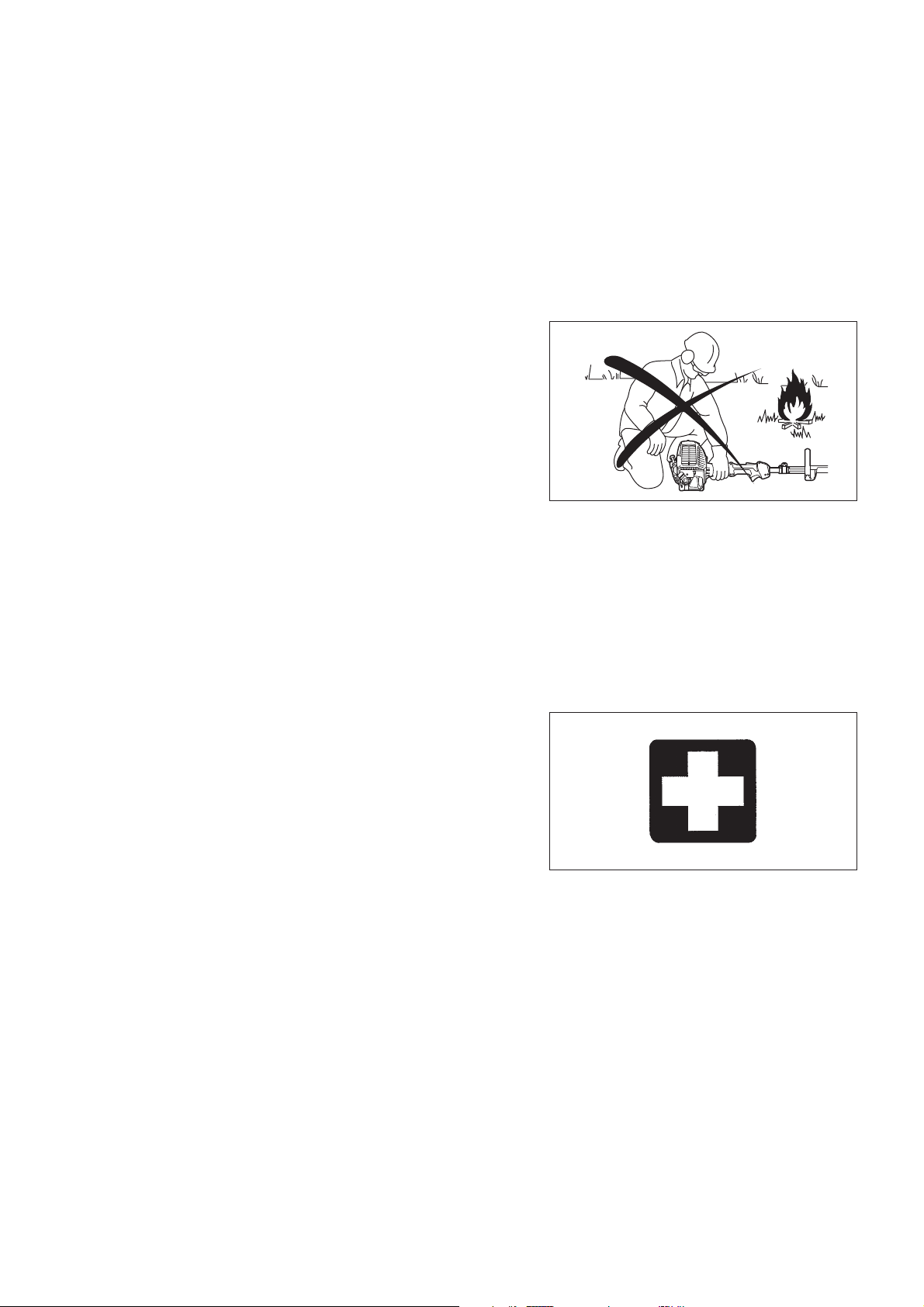

Operate the Multi Function Power Head only with the shoulder strap attached -

which is to be suitably adjusted before putting the Multi Function Power Head

into operation. It is essential to adjust the shoulder strap according to the user

size to prevent fatigue occurring during use. Never hold the cutter with one

hand during use.

During operation always hold the Multi Function Power Head with both hands. Always ensure a safe footing.

Operate the Multi Function Power Head in such a manner as to avoid inhalation of the exhaust gases. Never run the engine in enclosed rooms (risk

of gas poisoning). Carbon monoxide is an odorless gas.

Switch off the engine when resting and when leaving the Multi Function Power Head unattended, and place it in a safe location to prevent danger to

others or damage to the machine.

Never put the hot Multi Function Power Head onto dry grass or onto any combustible materials.

All protective installations and guards supplied with the machine must be used during operation.

Never operate the engine with faulty exhaust muffler. Shut off the engine during transport. During transport over long distances the tool protection included with the -

equipment must always be used.

Ensure safe position of the Multi Function Power Head during car -

transportation to avoid fuel leakage.

When transporting the Multi Function Power Head, ensure that the fuel tank -

is completely empty.

When unloading the Mul - ti Function Power Head from the truck, never drop

the engine to the ground or this may severely damage the fuel tank.

Except in case of emergency, never drop or cast the Multi Function Power -

Head to the ground or this may severely damage the Multi Function Power

Head.

Remember to lift the entire equipment from the ground when moving the equipment. Dragging the fuel tank is highly dangerous and will cause damage

and leakage of fuel, possibly causing fire.

If the equipment gets heavy impact or fall, check the condition before continuing work. Check the fuel system for fuel leakage and the controls

and safety devices for malfunction. If there is any damage or doubt, ask our

authorized service center for the inspection and repair.

• Resting

• Transport

• Refuelling

• Maintenance

• Tool replacement

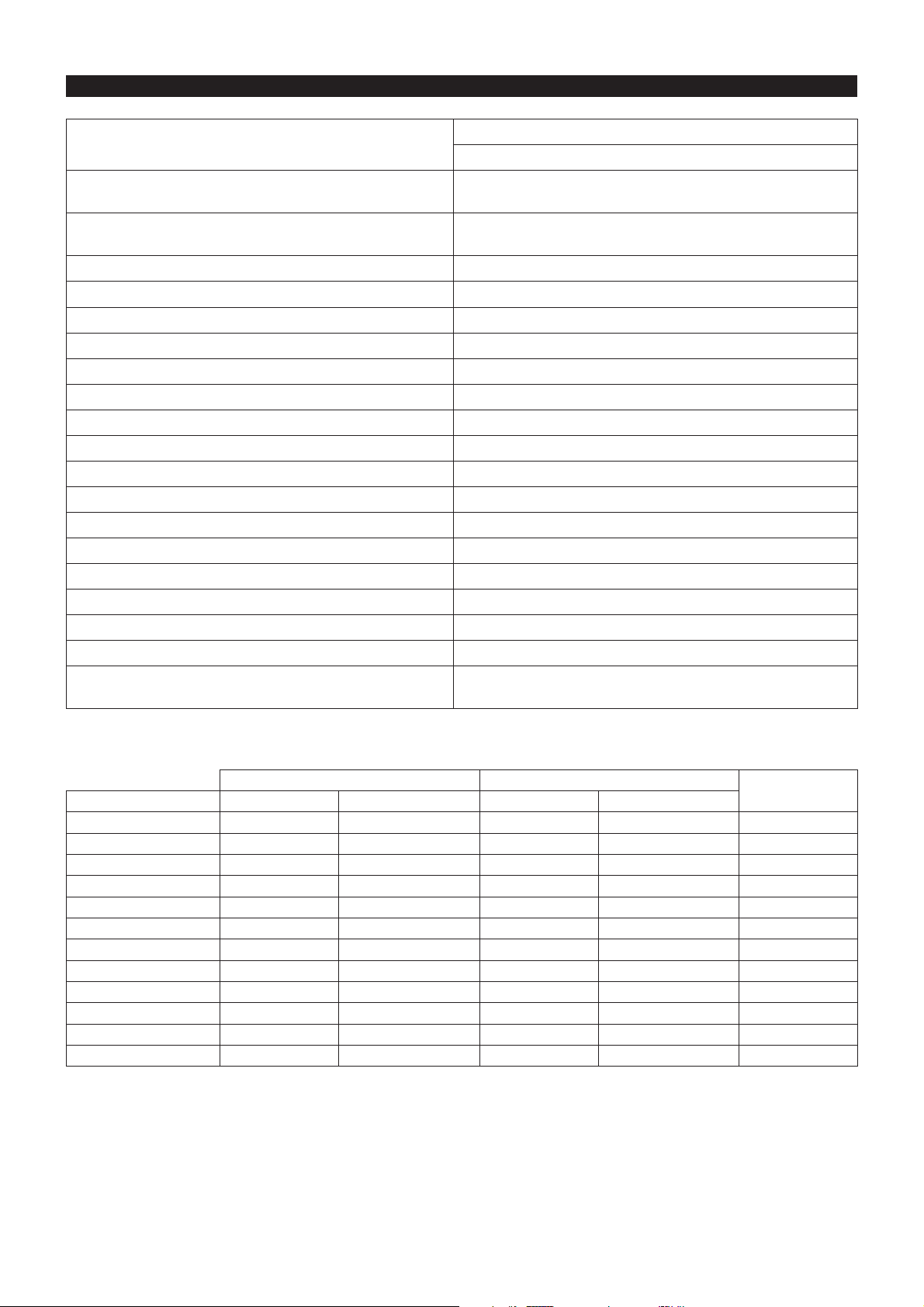

Refuelling

Shut off the engine during refuelling, keep away from open flames and do not smoke.

Avoid skin contact with mineral oil products. Do not inhale fuel vapor. Always wear protective gloves during refuelling. Change and clean protective clothing

at regular intervals.

Take care not to spill either fuel or oil in order to prevent soil contamination (environmental protection). Clean the Multi Function Power Head immediately

after fuel has been spilt.

Avoid any fuel contact with your clothing. Change your clothing instantly if fuel has been spilt on it (to prevent clothing catching fire).

Inspect the fuel cap at regular intervals making sure that it can be securely fastened and does not leak.

Carefully tighten the fuel tank cap. Change location to start the engine (at least 3 meters away from the place of refuelling).

Never refuel in closed rooms. Fuel vapors accumulate at ground lever (risk of explosions).

Only transport and store fuel in approved containers. Make sure the fuel stored is not accessible to children.

4

3 meters

Page 5

Method of operation

Only use the Multi Function Power Head in good light and visibility. During the winter season beware of slippery or wet areas, ice and snow (risk of slipping).

Always ensure a safe footing.

Never stand on a ladder and run the Multi Function Power Head. Never climb up into trees to perform cutting operation with the Multi Function -

Power Head.

Never work on unstable surfaces. Before using attachment, the attachment must have reached full working -

speed.

Take a rest to prevent loss of control caused by fatigue. We recommend to -

take a 10 to 20-minute rest every hour.

Maintenance instructions

Have your equipment serviced by our authorized service center, always using only genuine replacement parts. Incorrect repair and poor maintenance can

shorten the life of the equipment and increase the risk of accidents.

Operate the Multi Function Power Head with as little noise and contamination as possible. In particular check the correct setting of the carburetor.

Clean the Multi Function Power Head at regular intervals and check that all screws and nuts are well tightened.

Never service or store the Multi Function Power Head in the vicinity of naked flames.

Always store the Multi Function Power Head in locked rooms and with an emptied fuel tank.

Observe the relevant accident prevention instructions issued by the relevant trade associations and by the insurance companies.

Do not perform any modifications on the Multi Function Power Head as this will endanger your safety.

The performance of maintenance or repair work by the user is limited to those activities as described in the instruction manual. All other work is

to be done by an Authorized Service Agent. Use only genuine spare parts and accessories released and supplied by MAKITA.

Use of non-approved accessories and tools means increased risk of accidents.

MAKITA will not accept any liability for accidents or damage caused by the use of non-approved attachments and fixing devices of attachments,

or accessories.

First aid

In case of accident make sure that a first-aid box is available in the vicinity of

the cutting operations. Immediately replace any item taken from the first aid box.

When asking for help, please give the following

information:

Place of accident What happened Number of injured persons Kind of injuries Your name -

Vibration

People with poor circulation who are exposed to excessive vibration may experience injury to blood vessels or the nervous system. Vibration may cause the following symptoms to occur in the fingers, hands or wrists: “Falling asleep” (numbness), tingling, pain, stabbing sensation,

alteration of skin color or of the skin. If any of these symptoms occur, see a physician!

To reduce the risk of “white finger disease”, keep your hands warm during operation and well maintain the equipment and accessories. -

5

Page 6

EC DECLARATION OF CONFORMITY

We Makita Corporation as the responsible manufacturer declare that the following Makita Machines:

Designation of Machine: Multi Function Power Head

Model No./ Type: EX2650LH

Specifications: see “TECHNICAL DATA EX2650LH” table

are of series production and

Conforms to the following European Directives:

2000/14/EC, 2006/42/EC

And are manufactured in accordance with the following standards or standardised documents:

EN/ISO11806, EN709, EN/ISO10517, EN/ISO11680, EN/ISO12100

The technical documentation is kept by:

Makita International Europe Ltd., Technical Department,

Michigan Drive, Tongwell,

Milton Keynes, Bucks MK15 8JD, England

The conformity assessment procedure required by Directive 2000/14/EC was in accordance with annex V.

EX2650LH with EM400MP (Brushcutter Attachment)

EX2650LH with EM401MP (Brushcutter Attachment)

EX2650LH with ER400MP (String Trimmer Attachment)

EX2650LH with EN400MP (Hedge Trimmer Attachment)

EX2650LH with EN400MP (Hedge Trimmer Attachment) and LE400MP (Shaft Extension Attachment)

Measured Sound Power Level: 108.5 dB (A)

Guaranteed Sound Power Level: 113 dB (A)

Measured Sound Power Level: 102.7 dB (A)

Guaranteed Sound Power Level: 105 dB (A)

Measured Sound Power Level: 109.2 dB (A)

Guaranteed Sound Power Level: 116 dB (A)

Measured Sound Power Level: 103.8 dB (A)

Guaranteed Sound Power Level: 109 dB (A)

Measured Sound Power Level: 104.0 dB (A)

Guaranteed Sound Power Level: 106 dB (A)

The EC-Type Examination Certificate No. as a pole saw with EY400MP, EY401MP, LE400MP is:

4811004.11016

The EC-Type Examination per 2006/42/EC was performed by:

DEKRA Testing and Certification GmbH

Enderstraße 92b

01277 Dresden, Germany

Identification No. 2140

30. 1. 2012

Tomoyasu Kato

Director

Makita Corporation

3-11-8, Sumiyoshi-cho,

Anjo, Aichi, 446-8502, JAPAN

6

Page 7

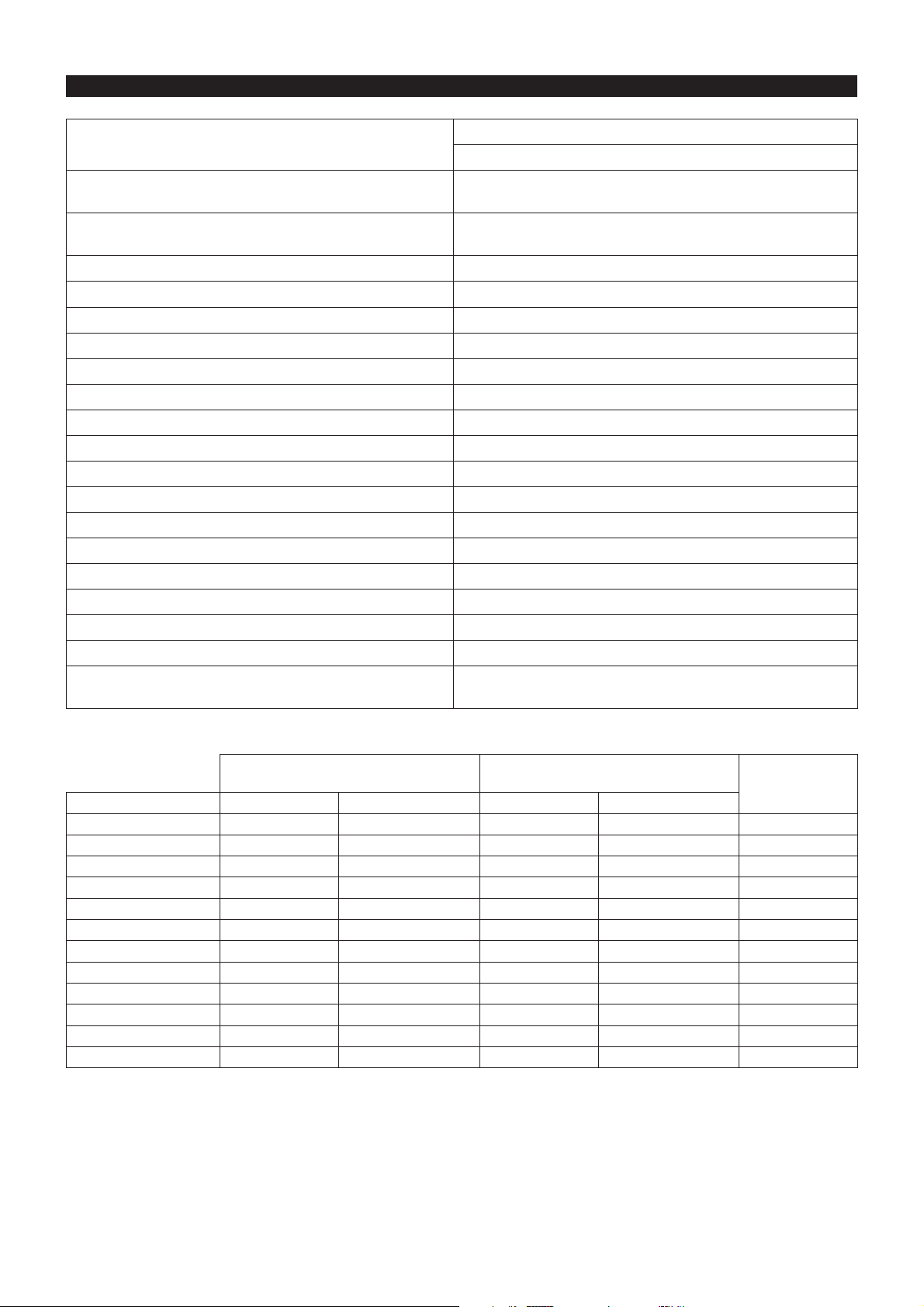

TECHNICAL DATA EX2650LH

Model

EX2650LH

Loop handle

Dimensions: length x width x height (without cutting blade)

with barrier

Dimensions: length x width x height (without cutting blade)

without barrier

mm 975 x 323 x 241

mm 975 x 242 x 241

Mass (without plastic guard and cutting blade) kg 4.6

Volume (fuel tank) L 0.6

Volume (oil reservoir) L 0.08

Engine displacement cm

3

25.4

Maximum engine performance kw 0.77 at 7,000 min

Engine speed at recommended max. spindle speed min

Maximum spindle speed (corresponding) min

-1

-1

8,500

6,500

Maximum fuel consumption kg/h 0.33

Maximum specific fuel consumption g/kwh 408

Idling speed min

Clutch engagement speed min

-1

-1

3,000

3,900

Carburetor type WALBRO WYL

Ignition system type Solid state ignition

Spark plug type NGK CMR4A

Electrode gap mm 0.7 - 0.8

Fuel Automobile gasoline

Engine oil

SAE 10W-30 oil of API Ciassification,

Class SF or higher (4-stroke engine for automobile)

-1

Vibration

Attachment a

Right handle

(Rear grip)

(m/s2) Uncertainty K (m/s2)a

hv eq

hv eq

Left handle

(Front grip)

(m/s2) Uncertainty K (m/s2)

Applicable

standards

EM400MP 6.5 1.2 5.9 1.8 ISO 22867

EM401MP 5.6 2.1 4.8 1.0 ISO 22867

ER400MP 7.1 2.8 5.5 2.7 ISO 22867

EY400MP 9.4 2.0 4.2 2.0 ISO 22867

EY400MP + LE400MP 4.8 2.0 3.4 2.0 ISO 22867

EY401MP 6.5 2.0 3.8 2.0 ISO 22867

EY401MP + LE400MP 5.6 2.0 3.4 2.0 ISO 22867

EN400MP 8.4 1.8 5.0 0.7 ISO 10517

EN400MP + LE400MP 8.0 1.7 4.3 0.7 ISO 10517

KR400MP 5 1.1 4.4 2.3 ISO 22867

EJ400MP 7.1 1.5 4.9 1.5 ISO 22867

EJ400MP + LE400MP 6.4 0.6 4.0 0.7 ISO 22867

7

Page 8

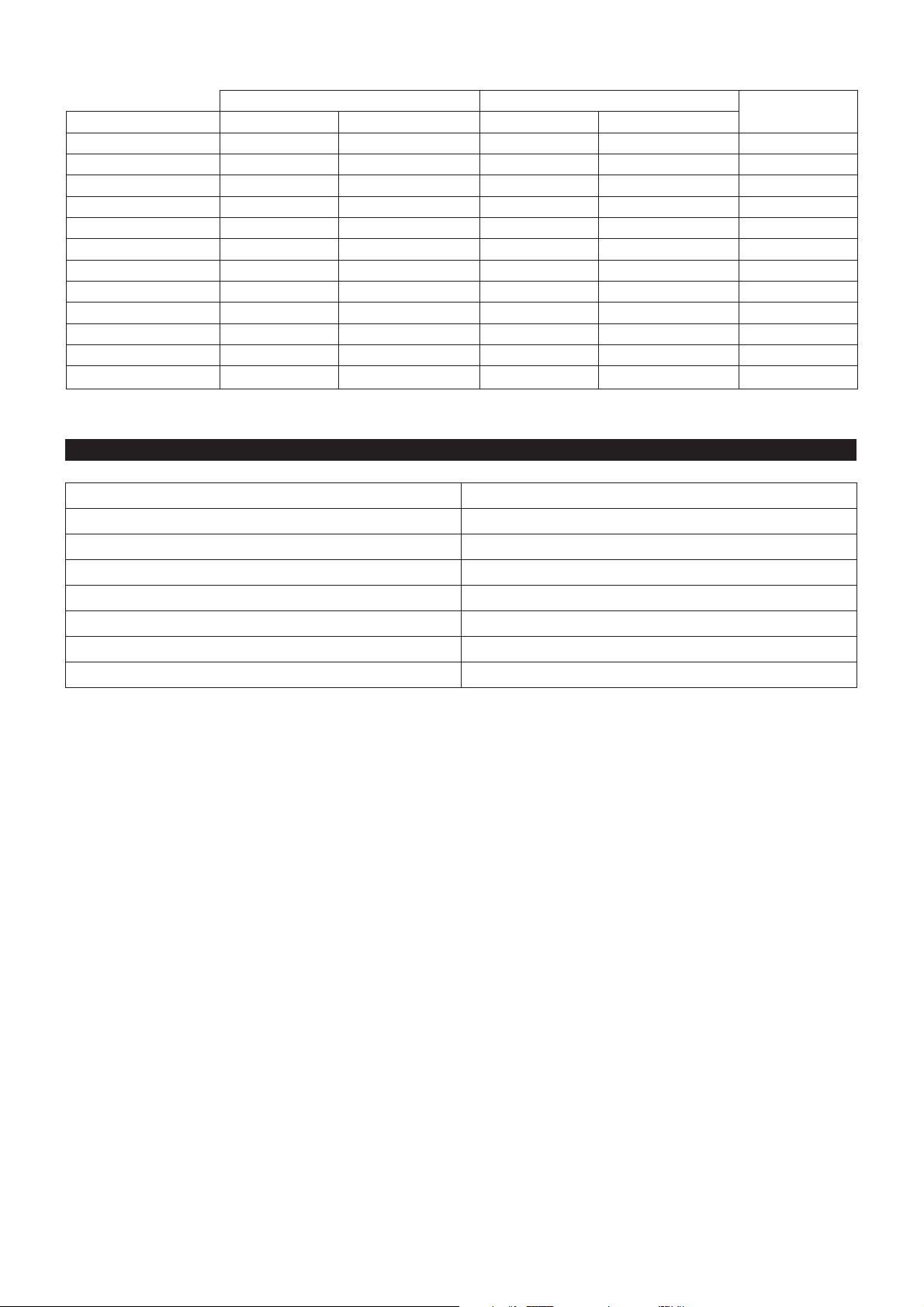

Noise

Attachment L

Sound pressure level average Sound power level average

PA eq

Uncertainty K L

WA eq

Uncertainty K

Applicable

standards

EM400MP 95.0 4.4 105.5 3.3 ISO 22868

EM401MP 89.9 3.6 99.7 2.7 ISO 22868

ER400MP 97.9 4.2 106.2 4.0 ISO 22868

EY400MP 93.0 2.5 104.5 2.5 ISO 22868

EY400MP + LE400MP 90.3 2.5 107.8 2.5 ISO 22868

EY401MP 92.6 2.5 104.7 2.5 ISO 22868

EY401MP + LE400MP 90.5 2.5 107.9 2.5 ISO 22868

EN400MP 93.1 4.4 102.9 4.8 ISO 10517

EN400MP + LE400MP 87.8 1.9 103.0 2.0 ISO 10517

KR400MP 93.7 2.6 99.7 1.2 ISO 22868

EJ400MP 89.0 2.3 99.8 1.1 ISO 22868

EJ400MP + LE400MP 88.1 2.2 100.8 2.3 ISO 22868

APPROVED ATTACHMENTS

ATTACHMENTS Models

Brushcutter Attachment EM400MP, EM401MP

String Trimmer Attachment ER400MP

Pole Saw Attachment EY400MP, EY401MP

Hedge Trimmer Attachment EN400MP

Cultivator Attachment KR400MP

Coffee Harvester Attachment EJ400MP

Shaft Extension Attachment LE400MP

8

Page 9

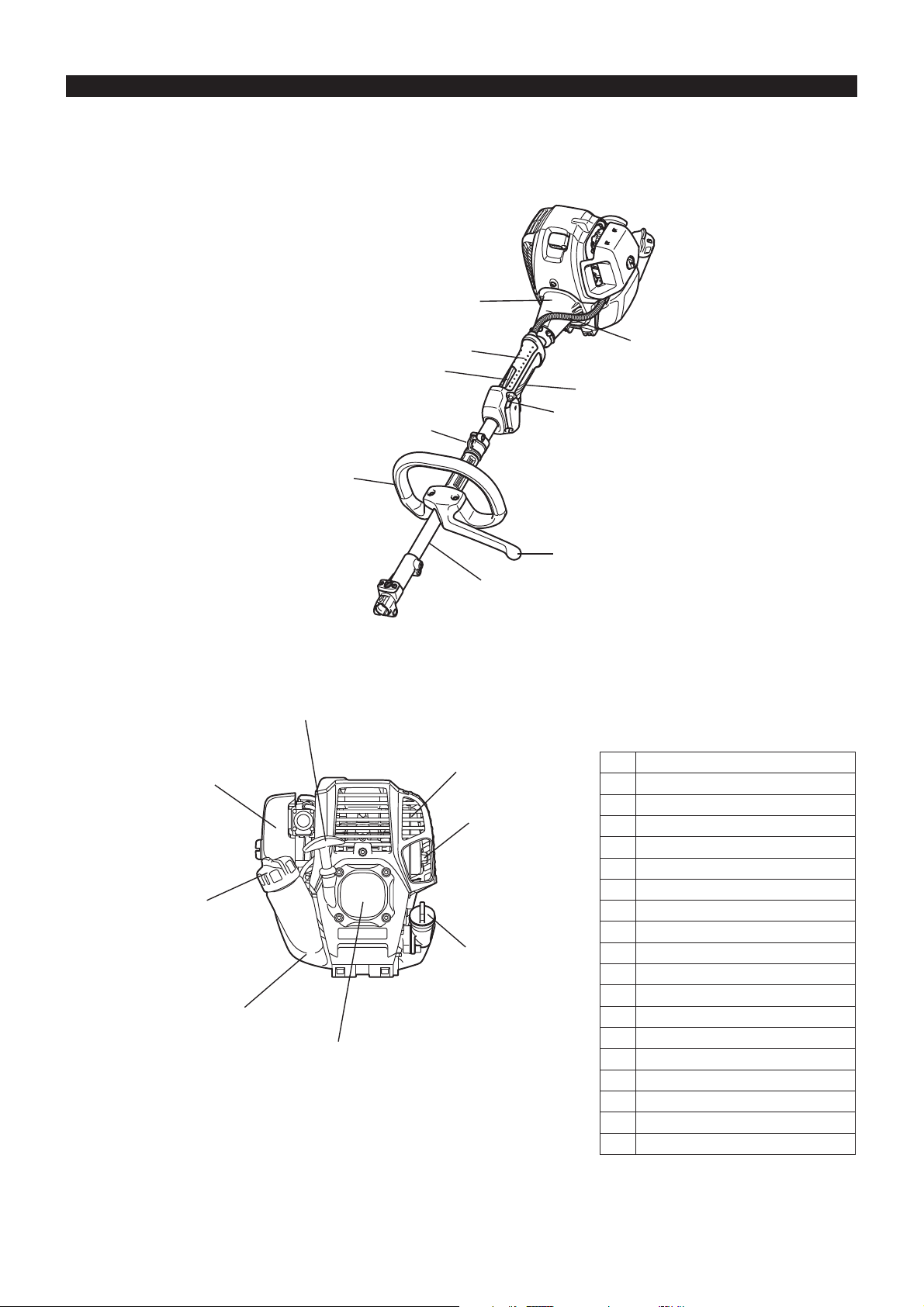

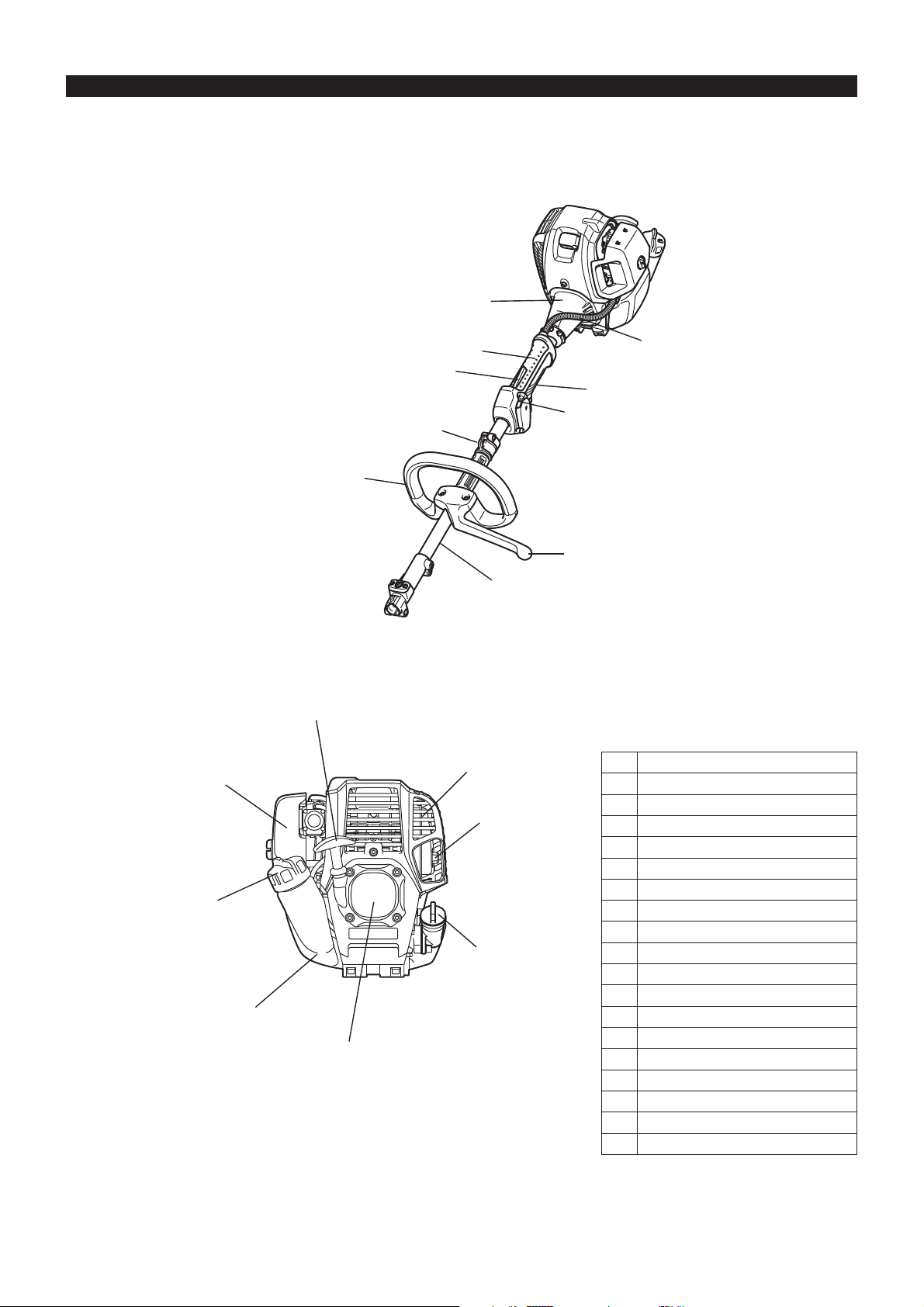

DESIGNATION OF PARTS

EX2650LH

6

14

7

12

11

10

4

8

9

18

13

15

3

5

16

17

1

2

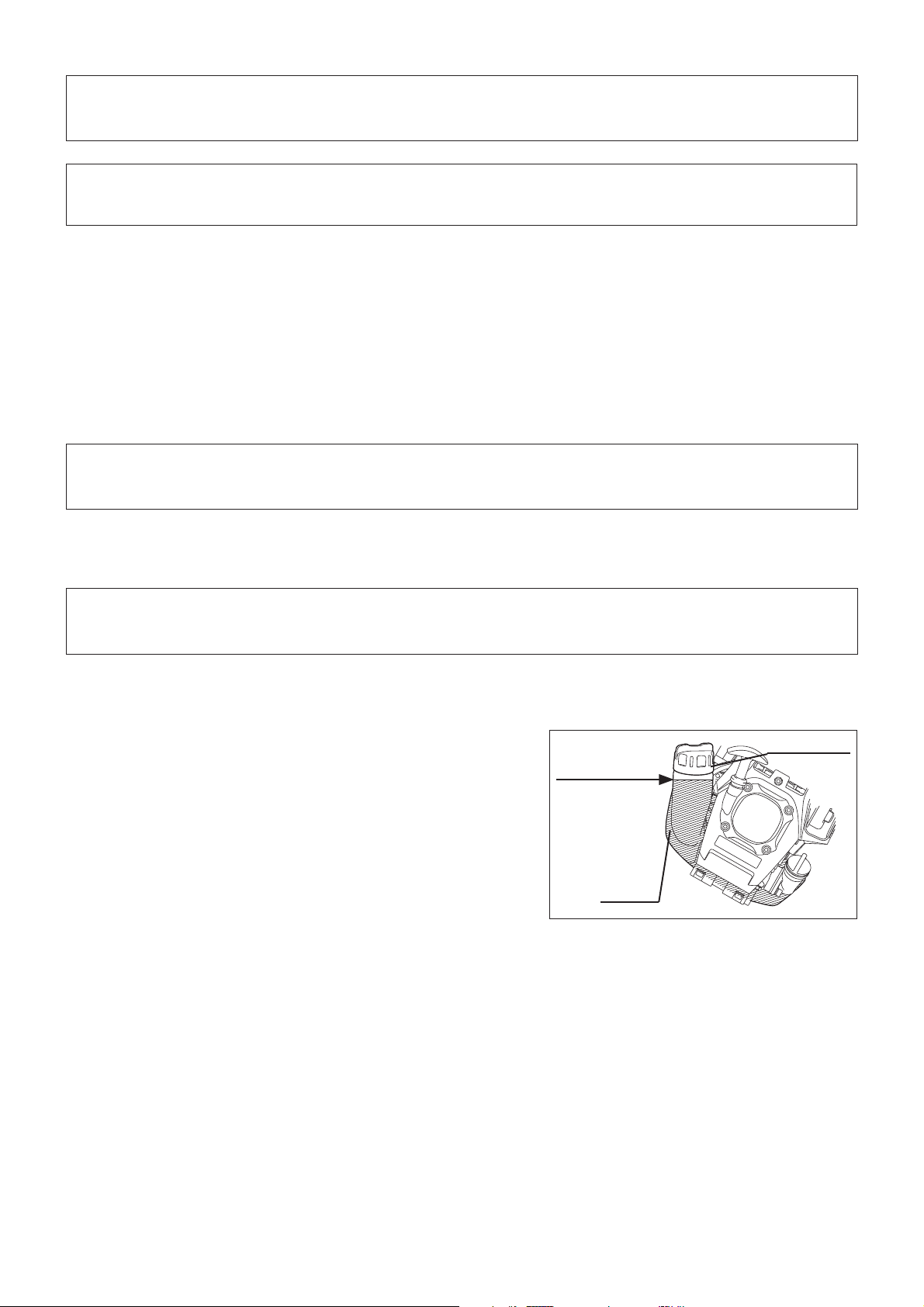

GB DESIGNATION OF PARTS

1 Fuel tank

2 Rewind starter

3 Air cleaner

4 I-O switch (on/off)

5 Exhaust muffler

6 Clutch case

7 Rear grip

8 Hanger

9 Handle

10 Throttle lever

11 Lock-off lever

12 Control cable

13 Shaft

14 Fuel filler cap

15 Starter knob

16 Exhaust pipe

17 Oil cap

18 Barrier*

Note: In some countries, the barrier is not

provided with the tool.

9

Page 10

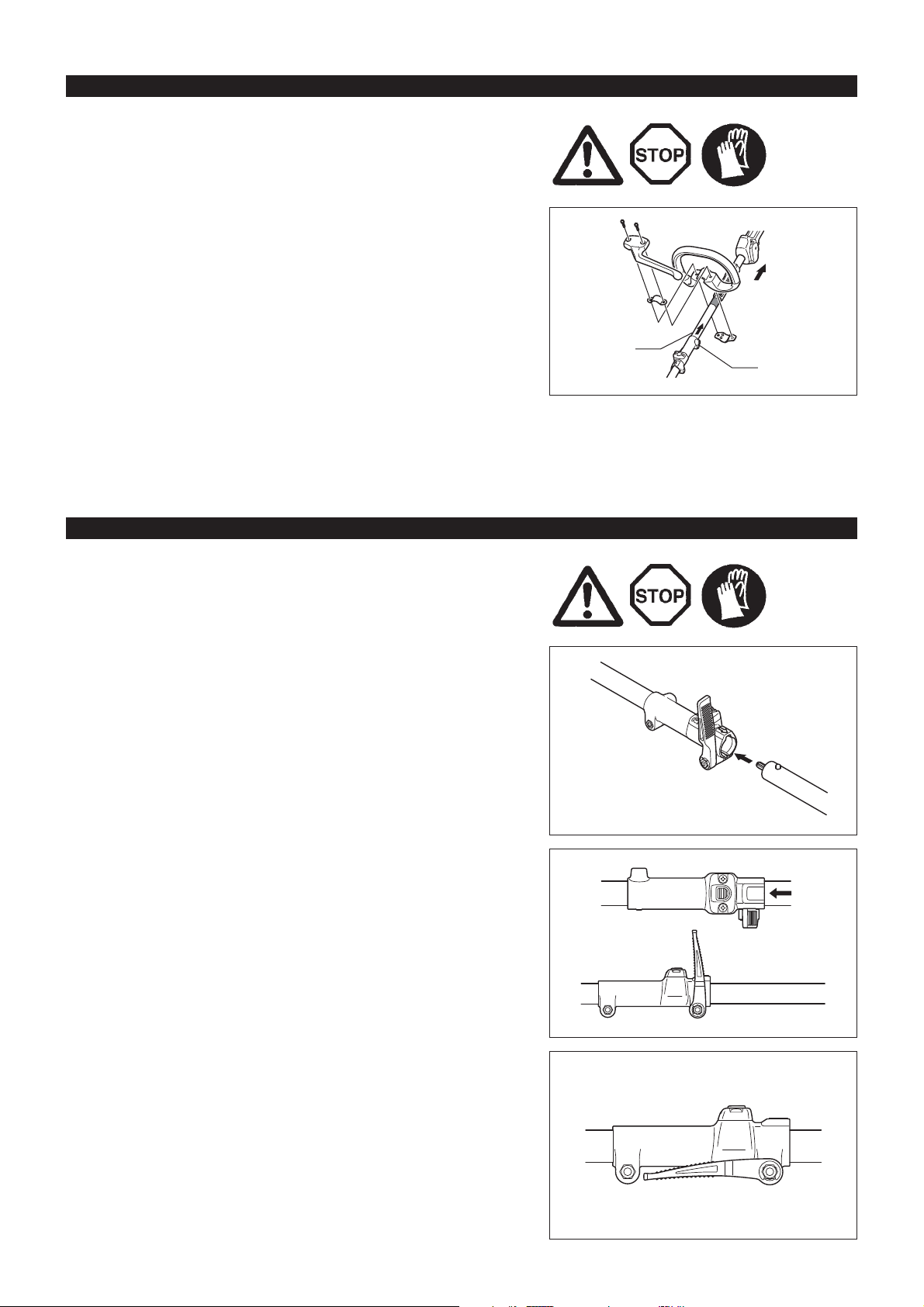

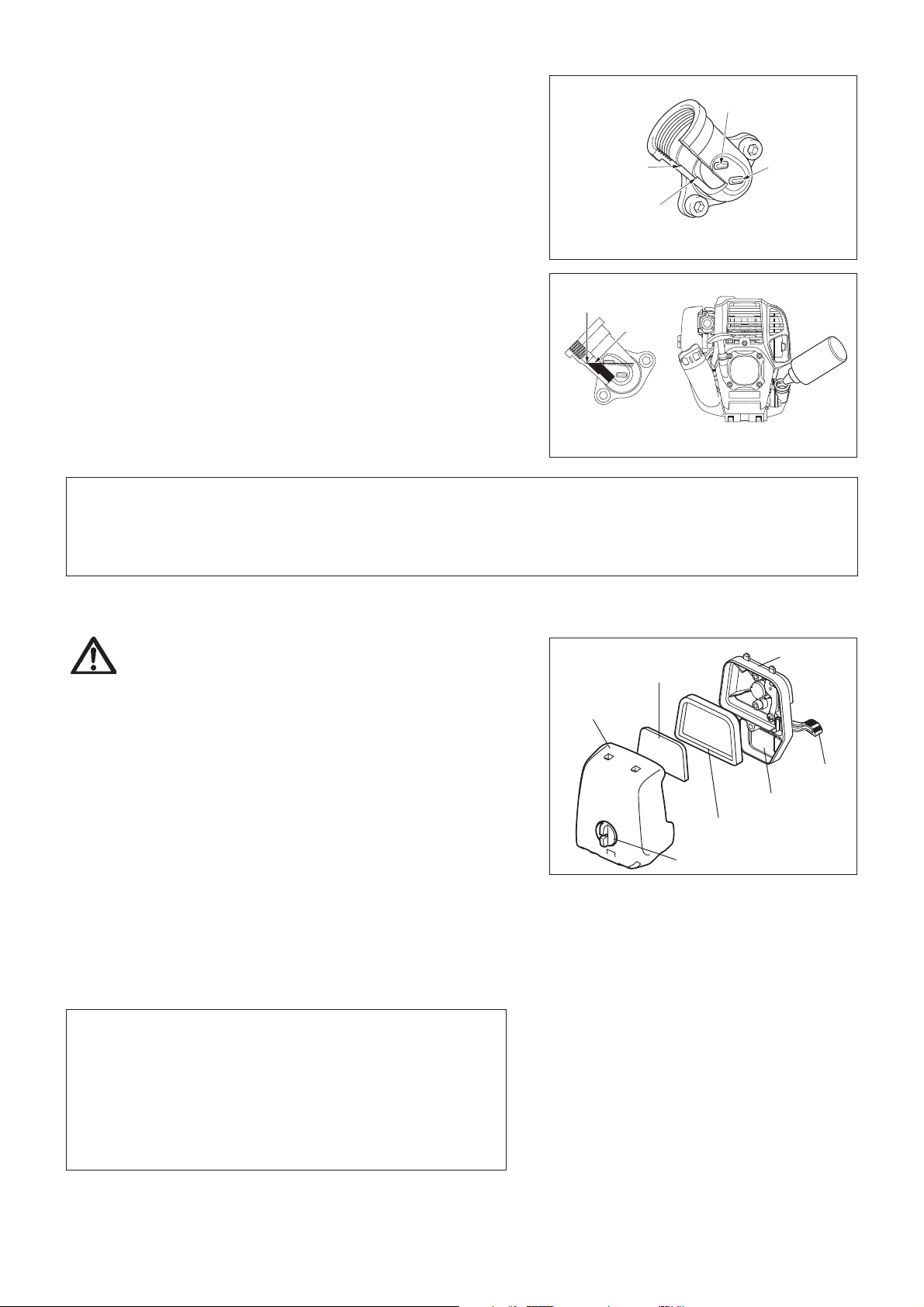

MOUNTING OF HANDLE

CAUTION: Before doing any work on the Multi Function Power Head, always

stop the engine and pull the spark plug connector off the spark plug.

Always wear protective gloves!

CAUTION: Start the Multi Function Power Head only after having assembled it

completely.

Assembling loop handle

Securely fit the barrier and grip onto the shaft pipe with two screws and clamps. At this time, put the barrier on the left side of the machine as

illustrated.

Make sure that the grip/barrier assembly is located between the spacer and the arrow mark. Do not remove or shrink the spacer.

Once assembled, do not remove the barrier. -

CAUTION: Never install the grip on the label or joint.

Note: In some countries, the barrier and arrow mark are not provided with the

tool.

MOUNTING ATTACHMENT

CAUTION: Before doing any work on the Multi Function Power Head, always

stop the engine and pull the spark plug connector off the spark plug.

Always wear protective gloves!

CAUTION: Start the Multi Function Power Head only after having assembled it

completely.

Engine

Arrow mark

Joint

Assembly

Loosen lever. Align the attachment’s pin with the joint’s groove and insert pin. Insert attachment up to the arrow position of attachment. -

And, check to see that button has risen.

Tighten lever. -

(See diagram on right for guideline.)

10

Page 11

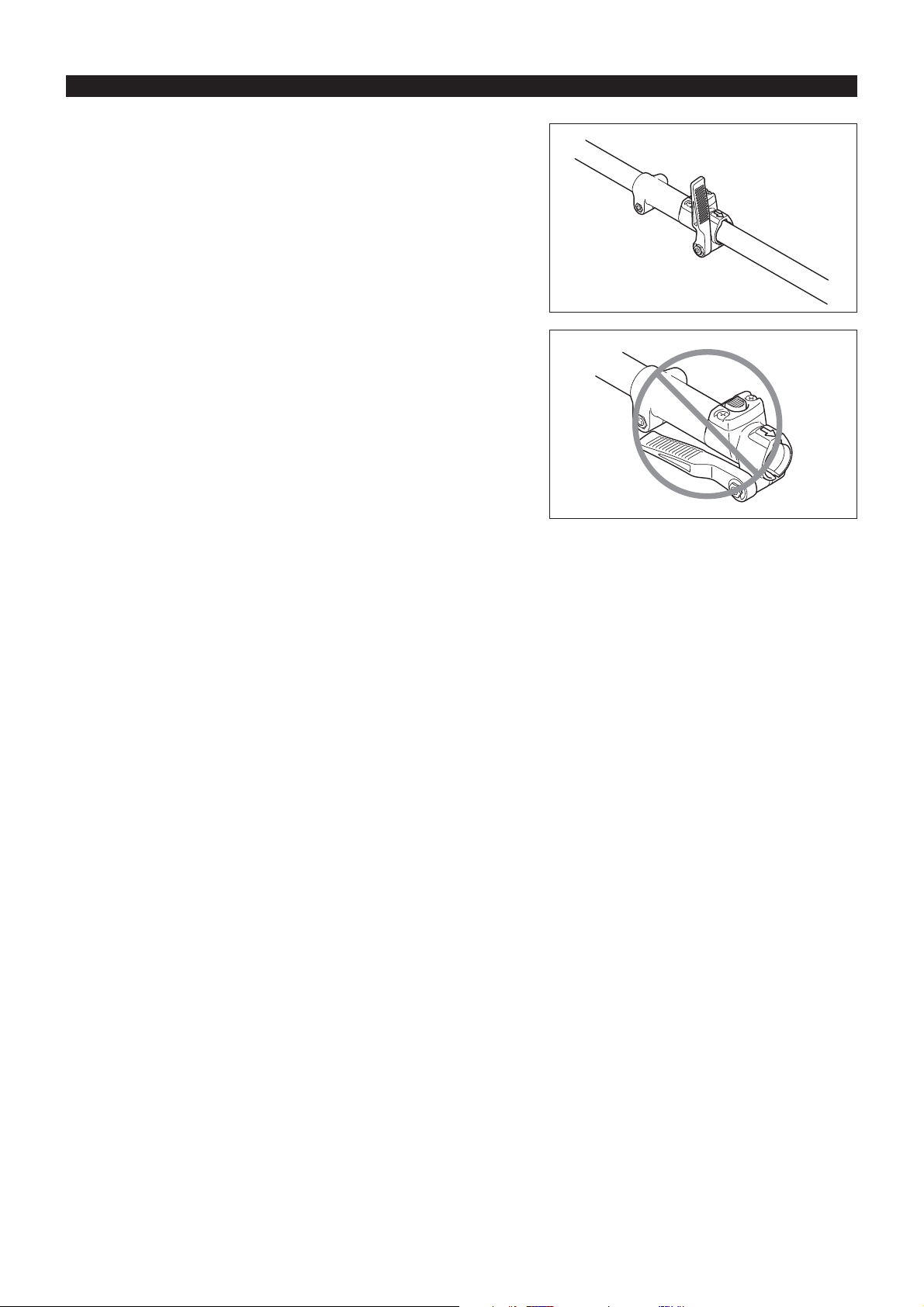

DISASSEMBLING

Loosen lever. Press button and extract attachment. -

(As much as possible, try to extract the attachment in a straight line.)

Note:

Do not leave the lever in a tightened state when attachment is not attached. -

11

Page 12

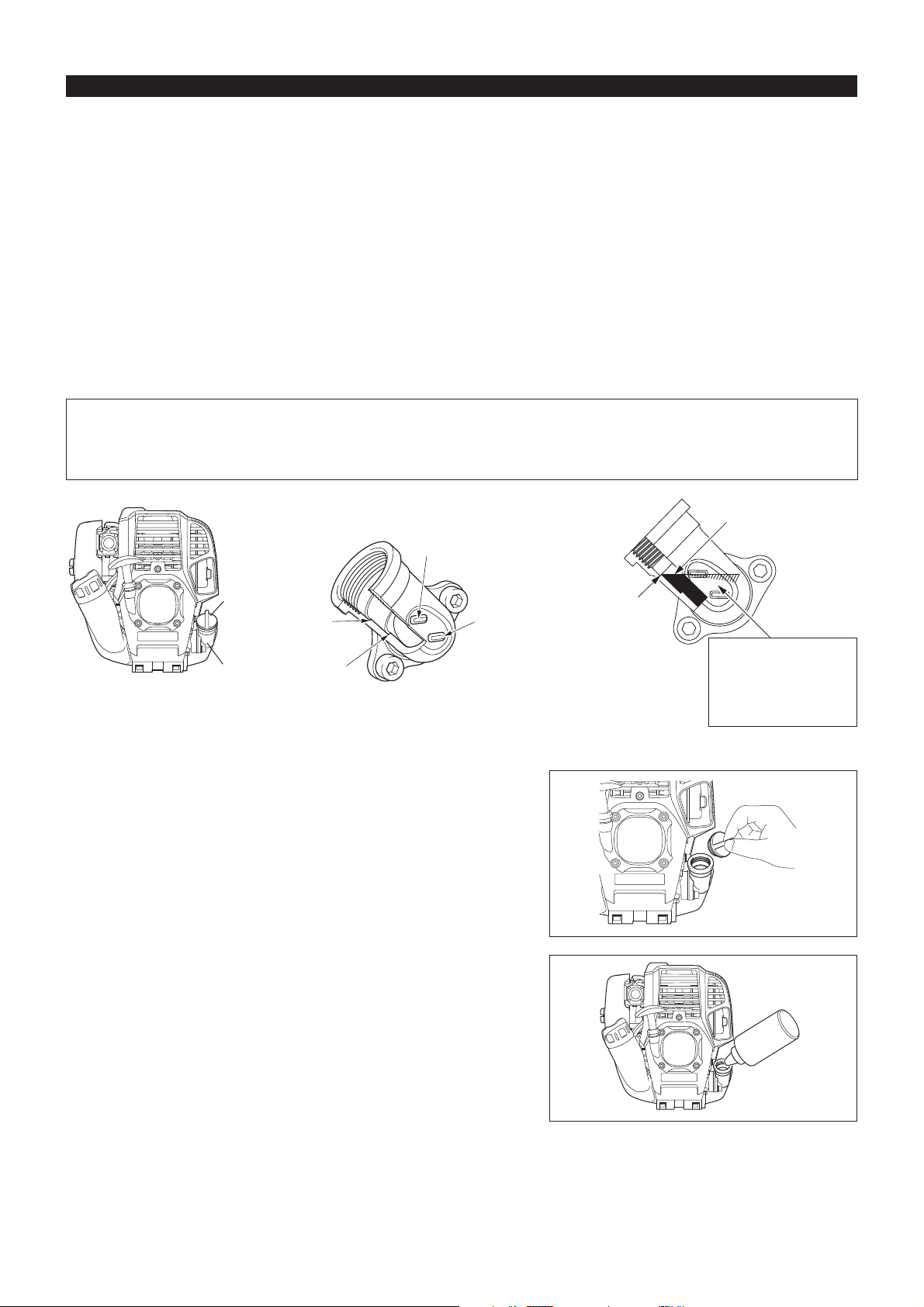

BEFORE START OF OPERATION

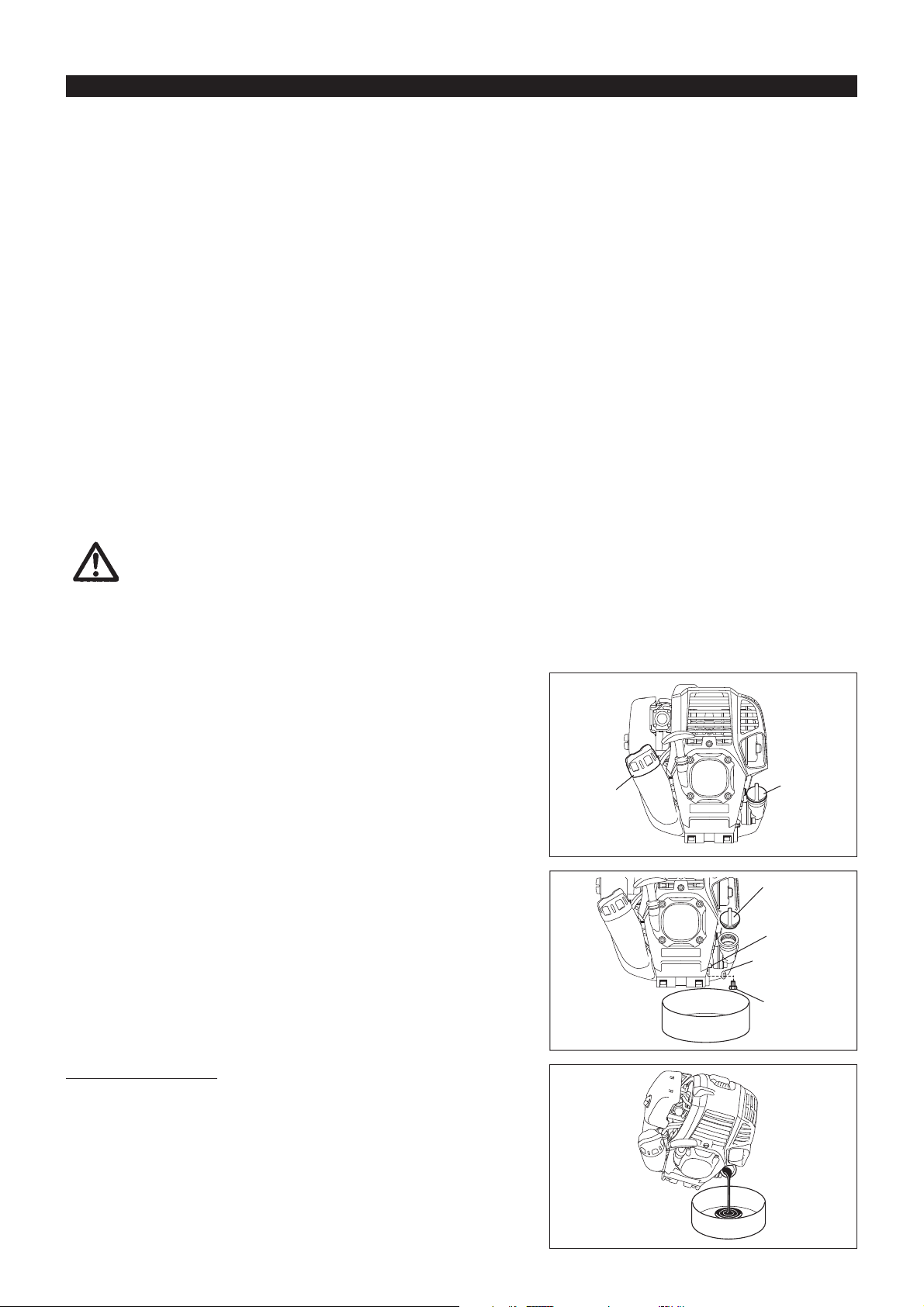

Inspection and refill of engine oil

Perform the following procedure, with the engine cooled down. Set the engine level, remove oil cap (Fig. 1), and check to see whether or not there is oil in the range between the upper limit and lower limit -

marks of the oil pipe (Fig. 2).

Top up with oil to upper limit mark if oil is insufficient (oil level is close to lower limit mark) (Fig. 3). The area surrounding the external marks is transparent, so the amount of oil inside can be checked without having to remove the oil cap. -

However, if oil pipe becomes extremely dirty, visibility may be lost, and oil level will have to be checked against stepped section on inside of

oil pipe.

For reference, the oil refill time is about 10h (every 10 refuellings). If the oil changes in color or mixes with dirt, replace it with new one. (For the interval and method of replacement, refer to P 17)

Recommended oil: SAE 10W-30 oil of API Classification, Class SF or higher (4-stroke engine for automobile)

Oil volume: Approx. 0.08L

Note: If the engine is not kept upright, oil may go into around the engine, and may be refilled excessively.

If the oil is filled above the limit, the oil may be contaminated or may catch fire with white smoke.

Point 1 in Replacement of oil: “Oil cap”

Remove dust or dirt near the oil refill port, and detach the oil cap. Keep the detached oil cap free of sand or dust. Otherwise, any sand or dust adhering to the oil cap may cause irregular oil circulation or -

wear on the engine parts, which will result in troubles.

Oil cap

Internal stepped

section (upper

limit)

Oil pipe

Fig. 1

(1) Keep the engine level, and detach the oil cap.

(2) Fill with oil to upper limit mark. (see Fig. 3)

Use oil bottle when filling.

Internal stepped

section (lower

limit)

External mark

(upper limit)

External mark

(lower limit)

Fig. 2 Oil pipe Fig. 3

Top up with oil until

oil level reaches

internal stepped

section (upper

limit).

Oil

The area between the

external upper and lower

limits is transparent, so

oil level can be checked

externally against these

marks.

(3) Securely tighten the oil cap. Insufficient tightening may cause oil leakage.

12

Page 13

Note

Do not replace oil with the engine in a tilted position.•

Filling with oil while engine is tilted leads to overfilling which causes oil contamination and/or white smoke.•

Point 2 in Replacement of oil: “If oil spills out”

If oil spills out between the fuel tank and engine main unit, the oil is sucked into through the cooling air intake port, which will contaminate the engine. Be sure to wipe out spilt oil before start of operation.

REFUELING

Handling of fuel

It is necessary to handle fuel with utmost care. Fuel may contain substances similar to solvents. Refueling must be performed in a sufficiently

ventilated room or in the open air. Never inhale fuel vapor, and keep fuel away from you. If you touch fuel repeatedly or for a long time, the

skin becomes dry, which may cause skin disease or allergy. If fuel enters into the eye, clean the eye with fresh water. If your eye remains still

irritated, consult your doctor.

Storage period of fuel

Fuel should be used up within a period of 4 weeks, even if it is kept in a special container in a well-ventilated shade.

If a special container is not used or if the container is not covered, fuel may deteriorate in one day.

STORAGE OF MACHINE AND REFILL TANK

Keep the machine and tank at a cool place free from direct sunshine. Never keep the fuel in the cabin or trunk. -

Fuel

The engine is a four-stroke engine. Be sure to use an automobile gasoline (regular gasoline or premium gasoline).

Points for fuel

Never use a gasoline mixture which contains engine oil. Otherwise, it will cause excessive carbon accumulation or mechanical troubles. Use of deteriorated oil will cause irregular startup. -

Refueling

WARNING: INFLAMMABLES STRICTLY PROHIBITED

Gasoline used: Automobile gasoline (unleaded gasoline)

Loosen the tank cap a little so that there will be no difference in atmospheric pressure.

Detach the tank cap, and refuel, discharging air by tilting the fuel tank so that the refuel port will be oriented upward. (Never refill fuel full to the oil refill

port.)

Wipe well the periphery of the tank cap to prevent foreign matter from entering into the fuel tank.

After refueling, securely tighten the tank cap. -

If there is any flaw or damage on the tank cap, replace it.•

The tank cap is consumable, and therefore should be renewed every two to •

three years.

Fuel upper limit

Fuel tank

Fuel tank cap

13

Page 14

CORRECT HANDLING OF MACHINE

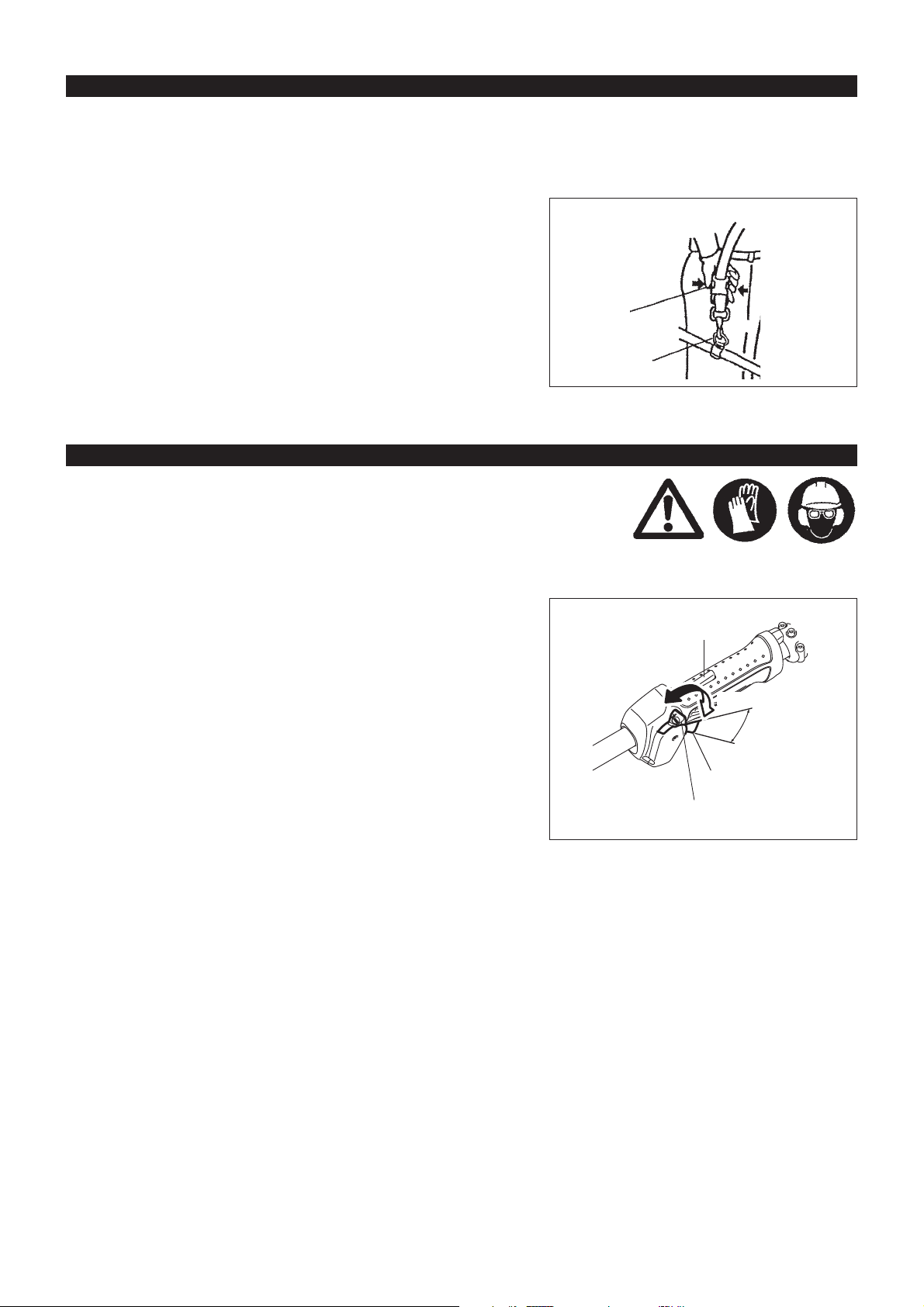

Attachment of shoulder strap

Adjust the strap to the suitable length for your operation. -

Detachment

In an emergency, push the notches (1) at both sides, and you can detach the machine from you.

Be extremely careful to maintain control of the machine at this time. Do not

allow the machine to be deflected toward you or anyone in the work vicinity.

WARNING: Failure to maintain complete control of the machine at all could

result in serious bodily injury or DEATH.

POINTS IN OPERATION AND HOW TO STOP

Observe the applicable accident prevention regulations!

(1)

Hanger

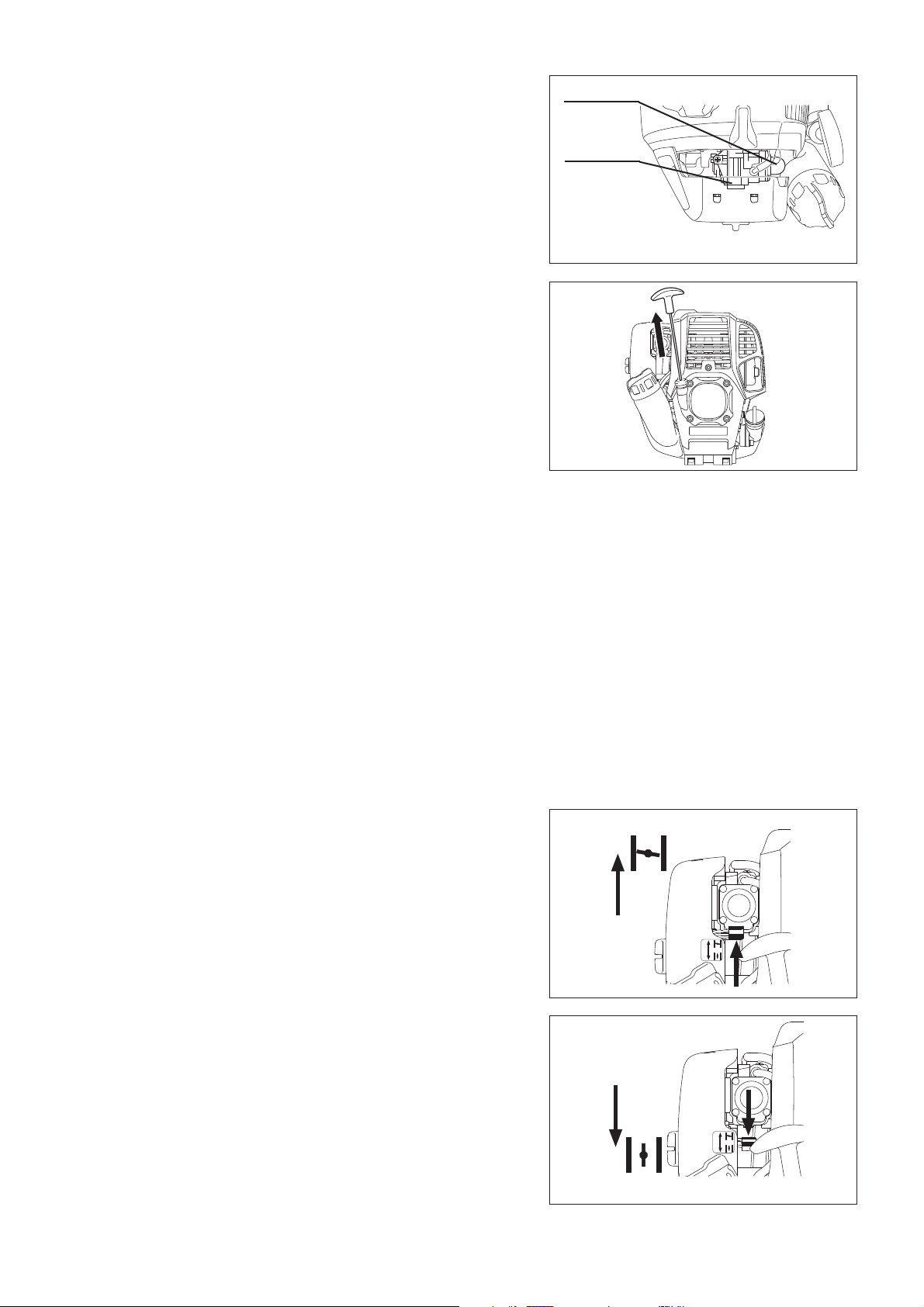

STARTING

Move at least 3 m away from the place of refuelling. Place the Multi Function Power Head on a clean piece of ground taking care that the

attachment does not come into contact with the ground or any other objects.

A: Cold start

1) Set this machine on a flat space.

2) Set the I-O switch (1) to OPERATION.

OPERATION

Lock-off lever

STOP

Throttle lever

(1)

High speed

Low speed

14

Page 15

3) Primer pump

Continue to push the primer pump until fuel enters into the primer pump.

(In general, fuel enters into the primer pump by 7 to 10 pushes.)

If the primer pump is pushed excessively, an excess of gasoline returns to

the fuel tank.

4) Recoil starter

Pull the start knob gently until it is hard to pull (compression point). Then,

return the start knob, and pull it strongly.

Never pull the rope to the full. Once the start knob is pulled, never release

your hand immediately. Hold the start knob until it returns to its original

point.

5) Warm-up operation

Continue warm-up operation for 2 to 3 minutes.

Note: In case of excessive fuel intake, remove the spark plug and pull the starter handle slowly to remove excess fuel. Also, dry the electrode

section of the spark plug.

Primer pump

Carburetor

Caution during operation:

If the throttle lever is opened fully in a no-load operation, the engine rotation is increased to 10,000 min-1 or more. Never operate the engine at a

higher speed than required and at an approximate speed of 6,000 - 8,500 min

-1

.

B: Startup after warm-up operation

1) Push the primer pump repeatedly.

2) Keep the throttle lever at the idling position.

3) Pull the recoil starter strongly.

4) If it is difficult to start the engine, open the throttle by about 1/3.

Pay attention to the attachment which may rotate.

At times, such as winter, when starting the engine

CLOSE

is difficult

Operate choke lever with the following procedure when starting engine.

After implementing startup steps 1) to 3), set choke lever to the CLOSE •

position.

Implement startup step 4) and start engine.•

Once engine starts, set choke lever to the OPEN position.•

Implement startup step 5) and complete warm up.•

CAUTION: If a bang (explosive sound) is heard and the engine stops, or the

CAUTION: If the choke lever is left in the CLOSE position, and the starter knob

just-started engine stalls before the choke lever is operated, return

the choke lever to the OPEN position, and pull the starter knob a

few times again to start the engine.

merely pulled repeatedly, too much fuel will be sucked in, and the

engine will become difficult to start.

15

OPEN

Page 16

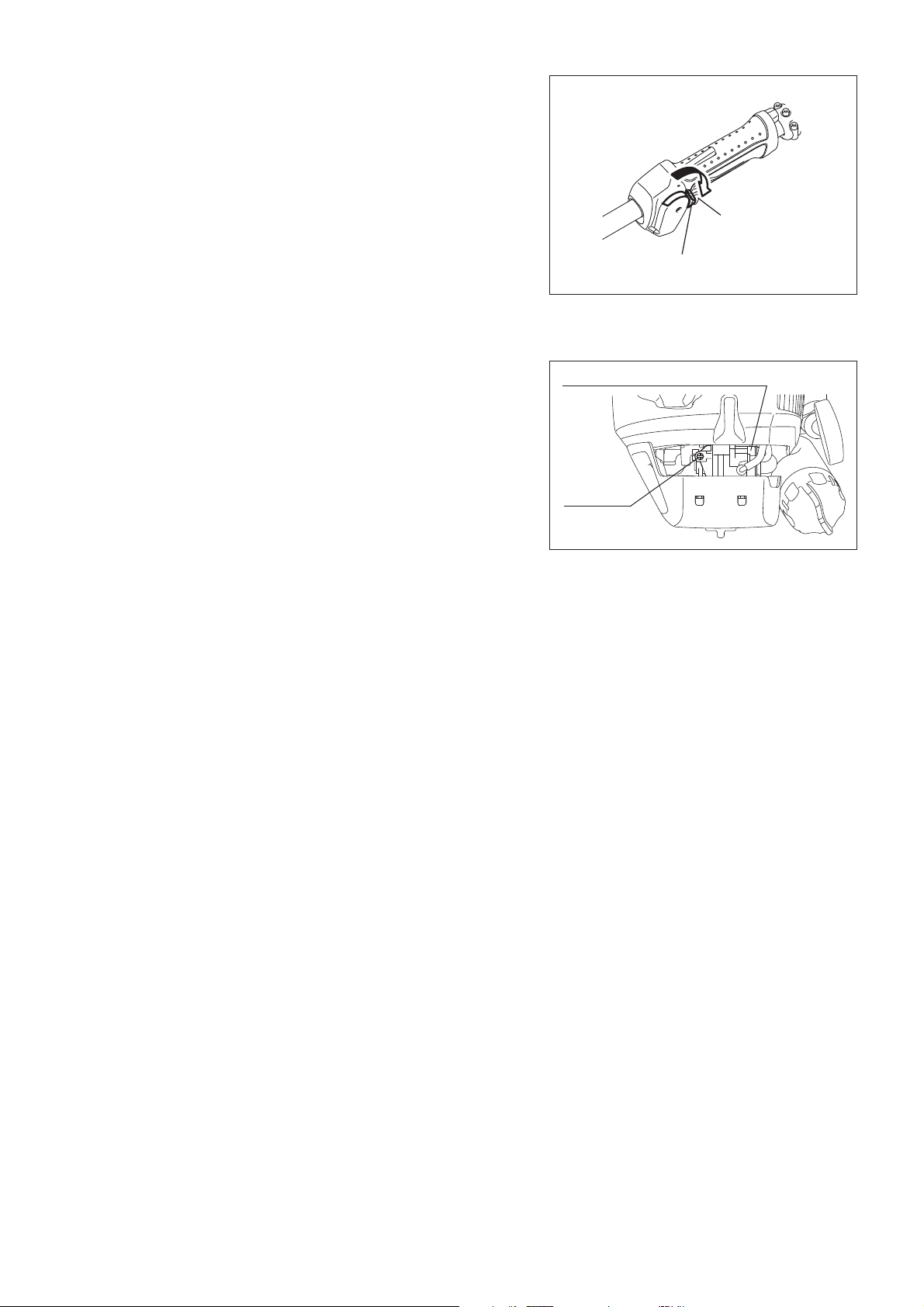

STOPPING

1) Release the throttle lever (2) fully, and when the engine rpm has lowered,

set the I-O switch to STOP the engine will now stop.

2) Be aware that the attachment may not stop immediately and allow it to slow

down fully.

ADJUSTMENT OF LOW-SPEED ROTATION (IDLING)

When it is necessary to adjust the low-speed rotation (idling), perform it by the carburetor adjusting screw.

STOP

(2)

(1)

CHECKUP OF LOW-SPEED ROTATION

Set the low-speed rotation to 3,000 min If it is necessary to change the rotation speed, regulate the adjusting screw

(illustrated on the right), with Phillips screwdriver.

Turn the adjusting screw to the right, and the engine rotation will increase. Turn the adjusting screw to the left, and the engine rotation will drop.

The carburetor is generally adjusted before shipment. If it is necessary to readjust it, please contact Authorized Service Agent.

-1

.

Carburetor

Adjusting

screw

16

Page 17

SERVICING INSTRUCTIONS

CAUTION: Before doing any work on the Multi Function Power Head, always stop the engine and pull the plug cap off the spark plug (see

To ensure a long service life and to avoid any damage to the equipment, the following servicing operations should be performed at regular

intervals.

“checking the spark plug”).

Always wear protective gloves!

Never use gasoline, benzine, thinner, alcohol or the like. Discoloration, deformation or cracks may result.

Daily checkup and maintenance

Before operation, check the machine for loose screws or missing parts. Pay particular attention to a specified attachment for mounting in place securely.

Before operation, always check for clogging of the cooling air passage and the cylinder fins. Clean them if necessary.

Perform the following work daily after use: -

• Clean the Multi Function Power Head externally and inspect for damage.

• Clean the air filter. When working under extremely dusty conditions, clean the filter several times a day.

• Check that there is sufficient difference between idling and engagement speed to ensure that the attachment is at a standstill while the

engine is idling (if necessary reduce idling speed).

If under idling conditions the tool should still continue to run, consult your nearest Authorized Service Agent.

Check the functioning of the I-O switch, the lock-off lever and the control lever. -

REPLACEMENT OF ENGINE OIL

Deteriorated engine oil will shorten the life of the sliding and rotating parts to a great extent. Be sure to check the period and quantity of

replacement.

ATTENTION: In general, the engine main unit and engine oil still remain hot just after the engine is stopped. In replacement of oil,

confirm that the engine main unit and engine oil are sufficiently cooled down. Otherwise, there may remain a risk of

scald.

Note: If the oil filled above the limit, it may be contaminated or may catch fire with white smoke.

Interval of replacement: Initially, every 20 operating hours, and subsequently every 50 operating hours

Recommended oil: SAE10W-30 oil of API Classification SF Class or higher (4-stroke engine oil for automobile)

In replacement, perform the following procedure.

1) Confirm that the fuel tank cap is tightened securely.

2) Place large container (pan, etc.) under drain hole.

Fuel tank cap

3) Remove drain bolt and then remove oil cap to drain out oil from drain hole.

At this time, be sure not to mislay drain bolt’s gasket, or to make dirty any of

the removed components.

4) Once all the oil has been drained, combine gasket and drain bolt, and tightly

secure drain bolt, so that it will not loosen and cause leaks.

* Use cloth to fully wipe off any oil attached to bolt and equipment.

Oil cap

Oil cap

Drain hole

Gasket

Drain bolt

Alternative draining method

Remove oil cap, tilt Multi Function Power Head toward oil filler hole, and drain

out oil.

Collect oil in container.

17

Page 18

5) Set the engine level, and gradually fill up to upper limit mark with new oil.

6) After filling, tightly secure oil cap, so that it will not loosen and cause leaks.

If oil cap is not tightly secured, it may leak.

External mark

(upper limit)

Internal stepped

section (upper

limit)

Internal stepped

section (lower

limit)

Upper limit mark

POINTS ON OIL

Never discard replaced engine oil in garbage, earth or sewage ditch. Disposal of oil is regulated by law. In disposal, always follow the relevant laws and regulations. For any points remaining unknown, contact Authorized Service Agent.

Oil will deteriorate even when it is kept unused. Perform inspection and replacement at regular intervals (replace with new oil every 6 months).

External mark

(lower limit)

Oil

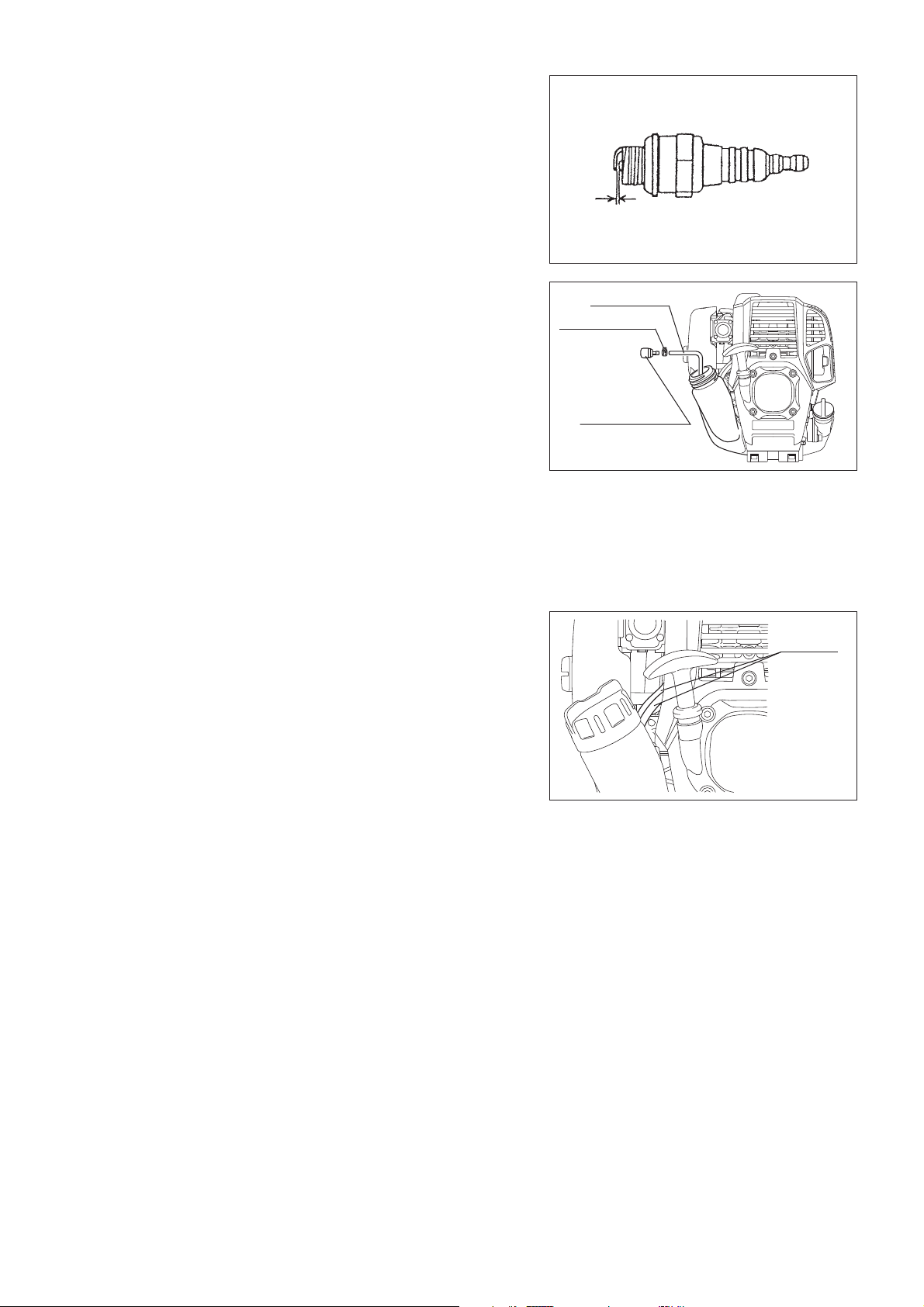

CLEANING OF AIR CLEANER

DANGER: INFLAMMABLES STRICTLY PROHIBITED

Interval of cleaning and inspection: Daily (every 10 operating hours)

Turn the choke lever to the full close side, and keep the carburetor off from dust or dirt.

Loosen the fixing bolt. Remove the air cleaner cover by pulling its bottom side. Remove the elements and tap them to remove dirt. If the elements are heavily contaminated: -

Remove the elements, immerse them in warm water or in water-diluted

neutral detergent, and dry them completely. Do not squeeze or rub them

when washing.

Before attaching the elements, be sure to dry them completely. Insufficient drying of the elements may lead to difficult startup.

Wipe out oil adhering around the air cleaner cover and the breather part with waste cloth.

Fit the element (sponge) into the element (felt). Fit the elements into the plate so that the sponge faces the air cleaner cover.

Immediately attach the cleaner cover and tighten it with fixing bolts. (In remounting, first place the upper claw, and then the lower claw.)

NOTICE:

Clean the elements several times a day, if excessive dust adheres to it. Dirty elements reduce engine power and make starting engine difficult.

Remove oil on the elements. If operation continues with the elements remaining not cleared of oil, oil in the air cleaner may fall outside, resulting

in contamination of the environment.

Do not put the elements on the ground or dirty place. Otherwise they pick up dirt or debris and it may damage the engine.

Never use fuel for cleaning the elements. Fuel may damage them. -

Plate

Element (sponge)

Air cleaner

cover

Choke

lever

Breather part

Element (felt)

Fixing bolt

18

Page 19

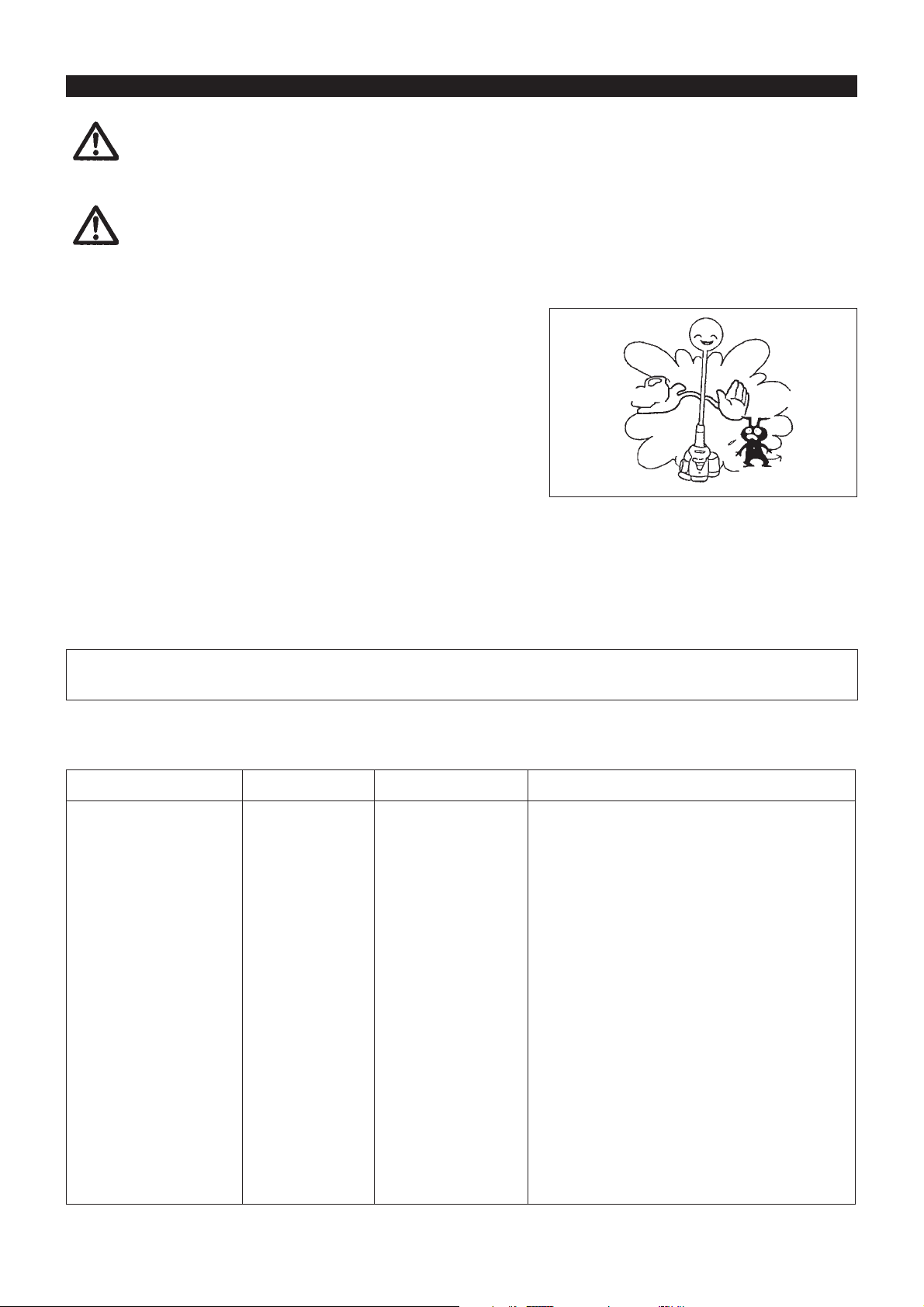

CHECKING THE SPARK PLUG

Only use the supplied universal wrench to remove or to install the spark plug. The gap between the two electrodes of the spark plug should be 0.7 - 0.8 mm -

(0.028” - 0.032”). If the gap is too wide or too narrow, adjust it. If the spark

plug is clogged or contaminated, clean it thoroughly or replace it.

CAUTION: Never touch the spark plug connector while the engine is running

(danger of high voltage electric shock).

CLEANING OF FUEL FILTER

WARNING: INFLAMMABLES STRICTLY PROHIBITED

Interval of cleaning and inspection: Monthly (every 50 operating hours)

Suction head in the fuel tank

Check the fuel filter periodically. To check the fuel filter, follow the steps below.

(1) Remove the fuel tank cap, drain the fuel to empty the tank. Check the tank

inside for any foreign materials. If any, remove them.

(2) Pull out the suction head by using a wire hook through the tank opening.

(3) If the fuel filter clogged slightly, clean it. To clean it, gently shake and tap

it in fuel. To avoid damage, do not squeeze or rub it. The fuel used for the

cleaning must be disposed in accordance with the method specified by

regulations in your country.

If the fuel filter became hard or heavily clogged up, replace it.

(4) After checking, cleaning or replacing, push the fuel filter in all the way to the

bottom of the fuel tank.

Clogged or damaged fuel filter can cause insufficient fuel supply and reduce

engine power. Replace the fuel filter at least quarterly to ensure satisfactory fuel

supply to the carburetor.

REPLACEMENT OF FUEL PIPE

CAUTION: INFLAMMABLES STRICTLY PROHIBITED

Interval of cleaning and inspection: Daily (every 10 operating hours)

Replacement: Annually (every 200 operating hours)

Replace the fuel pipe every year, regardless of operating frequency. Fuel

leakage may lead to fire.

If any leakage is detected during inspection, replace the fuel pipe immediately.

0.7 mm - 0.8 mm

(0.028” - 0.032”)

Fuel pipe

Hose clamp

Fuel filter

Fuel pipe

INSPECTION OF BOLTS, NUTS AND SCREWS

Retighten loose bolts, nuts, etc. Check for fuel and oil leakage. Replace damaged parts with new ones for safety operation. -

CLEANING OF PARTS

Keep the engine always clean. Keep the cylinder fins free of dust or dirt. Dust or dirt adhering to the fins will -

cause piston seizure.

REPLACEMENT OF GASKETS AND PACKINGS

In reassembling after the engine is dismounted, be sure to replace the gaskets and packings with new ones.

Any maintenance of adjustment work that is not included and described in this manual is only to be performed by Authorized Service Agents.

19

Page 20

STORAGE

WARNING: When draining the fuel, be sure to stop the engine and confirm that the engine cools

down.

Just after stopping the engine, it may still hot with possibility of burns, inflammability

and fire.

ATTENTION: When the machine is kept out of operation for a long time, drain up all fuel from the

fuel tank and carburetor, and keep it at a dry and clean place.

Drain up fuel from the fuel tank and carburetor according to the following procedure:

1) Remove the fuel tank cap, and drain fuel completely.

If there is any foreign matter remaining in the fuel tank, remove it

completely.

2) Pull out the fuel filter from the refill port using a wire.

3) Push the primer pump until fuel is drained from there, and drain fuel

coming into the fuel tank.

4) Reset the filter to the fuel tank, and securely tighten the fuel tank cap.

5) Then, continue to operate the engine until it stops.

Remove the spark plug, and drip several drops of engine oil through the spark plug hole.

Gently pull the starter handle so that engine oil will spread over the engine, and attach the spark plug.

Do not move the lever in the lock position while not mounting the attachment. The lever in the lock position without the attachment being mounted does not

allow the pole shaft of the attachment to be mounted.

During storage, keep the rod horizontal or keep the machine upright with the joint edge oriented upward. (In this case, pay full attention to prevent the

machine from falling.)

Never store the machine with the joint oriented downward. Lubricating oil may

spill out.

Keep the drained fuel in a special container in a well-ventilated shade. -

Drain fuel

Humidity

Attention after long-time storage

Before startup after long-time shutdown, be sure to replace oil (refer to P 17). Oil will deteriorate while the machine is kept out of operation. -

Fault location

Fault System Observation Cause

Engine not starting or with

difficulty

Warm start problems Tank filled ignition spark

Engine starts but dies Fuel supply Tank filled Incorrect idling adjustment, carburetor contaminated

Ignition system Ignition spark O.K. Fault in fuel supply or compression system, mechanical

defect

No ignition spark STOP-switch operated, wiring fault or short circuit, spark

plug or connector defective, ignition module faulty

Fuel supply Fuel tank filled Incorrect choke position, carburetor defective, fuel supply

line bent or blocked, fuel dirty

Compression No compression when

pulled over

Mechanical fault Starter not engaging Broken starter spring, broken parts inside of the engine

existing

Cylinder bottom gasket defective, crankshaft seals

damaged, cylinder or piston rings defective or improper

sealing of spark plug

Carburetor contaminated, have it cleaned

Fuel tank vent defective, fuel supply line interrupted,

cable or STOP-switch faulty

Insufficient performance Several systems may

simultaneously be

affected

Engine idling poor Air filter contaminated, carburetor contaminated, muffler

clogged, exhaust duct in the cylinder clogged

20

Page 21

Item

Operating time

Before

operation

After

lubrication

Daily

(10h)

30h 50h 200h

Shutdown/

rest

Corres-

ponding P

Engine oil

Inspect/clean

Replace

Tightening parts

(bolt, nut)

Inspect

Clean/inspect

Fuel tank

Drain fuel

Throttle lever Check function

Stop switch Check function

Low-speed rotation Inspect/adjust

Air cleaner Clean

Ignition plug Inspect

Cooling air duct Clean/inspect

Inspect

Fuel pipe

Replace

Fuel filter Clean/replace

Clearance between air intake

valve and air discharge valve

Adjust

Engine overhaul

Carburetor Drain fuel

13

1

*

17

19

—

3

*

20

—

16

16

18

19

19

19

2

*

—

19

2

*

2

*

3

*

—

—

20

*1 Perform initial replacement after 20h operation.

*2 For the 200 operating hour inspection, request Authorized Service Agent or a machine shop.

*3 After emptying the fuel tank, continue to run the engine and drain fuel in the carburetor.

Check instruction manuals for each attachment, and carry out maintenance on them when they are being used.

21

Page 22

TROUBLESHOOTING

Before making a request for repairs, check a trouble for yourself. If any abnormality is found, control your machine according to the description

of this manual. Never tamper or dismount any part contrary to the description. For repairs, contact Authorized Service Agent or local dealership.

State of abnormality Probable cause (malfunction) Remedy

Failure to operate primer pump Push 7 to 10 times

Low pulling speed of starter rope Pull strongly

Lack of fuel Feed fuel

Clogged fuel filter Clean

Broken fuel tube Straighten fuel tube

Deteriorated fuel Deteriorated fuel makes starting more difficult.

Replace with new one. (Recommended

replacement: 1 month)

Excessive suction of fuel Set throttle lever from medium speed to high

speed, and pull starter handle until engine

starts. Once engine starts, attachment

Engine does not start

Engine stops soon

Engine speed does not increase

Attachment does not rotate or move

Detached plug cap Attach securely

Contaminated spark plug Clean

Abnormal clearance of spark plug Adjust clearance

Other abnormality of spark plug Replace

Abnormal carburetor Make request for inspection and maintenance.

Starter rope cannot be pulled Make request for inspection and maintenance.

Abnormal drive system Make request for inspection and maintenance.

Insufficient warm-up Perform warm-up operation

Choke lever is set to “CLOSE” although

engine is warmed up.

Clogged fuel filter Clean or replace

Contaminated or clogged air cleaner Clean

Abnormal carburetor Make request for inspection and maintenance.

Abnormal drive system Make request for inspection and maintenance.

Attachment not inserted to the specified point. Insert as instructed.

starts rotating or moving. Pay full attention

to attachment.

If engine will not start still, remove spark plug,

make electrode dry, and reassemble them as

they originally are. Then, start as specified.

Set to “OPEN”

Stop engine immediately

Main unit vibrates abnormally Attachment not inserted to the specified point. Insert as instructed.

Stop engine immediately

Attachment does not stop immediately High idling rotation Adjust

Stop engine immediately

Engine does not stop Detached connector Attach securely

Run engine at idling, and set choke lever

to CLOSE

When the engine does not start after warm-up operation:

If there is no abnormality found for the check items, open the throttle by about 1/3 and start the engine.

Abnormal drive system Make request for inspection and maintenance.

Loosened lever Tighten securely.

Abnormal drive system Make request for inspection and maintenance.

Detached throttle wire Attach securely

Abnormal drive system Make request for inspection and maintenance.

Abnormal electric system Make request for inspection and maintenance.

22

Page 23

Français

(Instructions d’origine)

Merci beaucoup d’avoir choisi cet outil multi-fonctions MAKITA. Nous sommes

ravis de vous recommander l’outil multi-fonctions de MAKITA, résultat d’un long

programme de développement et de nombreuses années d’expérience et de

connaissances.

Veuillez lire ce livret qui explique en détails les nombreuses caractéristiques qui

en font un outil d’une performance exceptionnelle. Elles vous aideront à obtenir

les meilleurs résultats possibles de votre outil multi-fonctions MAKITA.

SYMBOLES

Le mode d’emploi contient les symboles suivants.

Lisez le mode d’emploi et suivez les

avertissements et les précautions de

sécurité !

Table des matières Page

Symboles .....................................................................23

Consignes de sécurité .................................................24

Données techniques ....................................................28

Pièces de fixation agréées ..........................................29

Nomenclature des pièces ............................................30

Montage de la poignée ................................................31

Montage de la pièce de fixation ...................................31

Démontage ..................................................................32

Avant de commencer ................................................... 33

Maniement correct de la machine ...............................35

Avertissement de fonctionnement et comment

l’arrêter ........................................................................35

Instructions d’entretien ................................................38

Entreposage ................................................................41

Portez un casque protecteur, des lunettes

de protection et des protège-oreilles !

Faites preuve de prudence et de

vigilance !

Interdit ! Démarrage manuel du moteur

Ne fumez pas ! Arrêt d’urgence

Pas de flammes nues ! Premiers secours

Portez des gants de protection ! SOUS TENSION/DÉMARRAGE

Portez des bottes de sécurité avec des

semelles antidérapantes.

Les bottes de sécurité à doigts de pieds

métalliques sont recommandées !

Carburant (Essence)

HORS TENSION/ARRÊT

Éloignez les personnes et les animaux du

lieu de travail !

23

Page 24

Utilisation prévue de l’outil

Cet outil multi-fonctions est destiné à insérer un accessoire approuvé indiqué

dans ce mode d’emploi. N’utilisez jamais l’appareil à d’autres fins.

CONSIGNES DE SÉCURITÉ

Instructions générales

Pour une utilisation correcte, lisez ce mode d’emploi afin de vous familiariser avec le fonctionnement de l’outil multi-fonctions. Sans ces informations, vous

risquez de vous mettre en danger ou de blesser d’autres personnes à cause

d’une utilisation incorrecte.

Il est recommandé de prêter l’outil multi-fonctions uniquement à des personnes ayant déjà utilisé des outils multi-fonctions.

Transmettez-leur toujours ce mode d’emploi.

Les personnes utilisant l’outil pour la première fois doivent demander au revendeur de leur fournir des instructions de base afin de se familiariser avec

le maniement d’une découpeuse thermique.

Les enfants et jeunes gens âgés de moins de 18 ans ne doivent pas utiliser l’outil multi-fonctions. Toutefois, les personnes âgées de plus de 16 ans

peuvent utiliser l’appareil à des fins de formation uniquement sous la

supervision d’un formateur qualifié.

Utilisez les outils multi-fonctions avec la plus grande prudence et vigilance. Faites fonctionner l’outil multi-fonctions uniquement si vous êtes en bonne -

forme physique. Effectuez tout le travail avec calme et prudence. Vous êtes

responsable des autres personnes.

N’utilisez jamais l’outil multi-fonctions après avoir consommé de l’alcool ou des médicaments, ou bien si vous vous sentez fatigué (e) ou malade.

Les réglementations nationales peuvent limiter l’utilisation de l’appareil. -

Dispositif de protection individuelle

Les vêtements que vous portez doivent être fonctionnels et adaptés, c’est-à-dire qu’ils doivent être près du corps, sans pour autant gêner vos

mouvements. Ne portez pas de bijoux ou de vêtements qui pourraient

s’emmêler dans les taillis ou les petits arbustes.

Pour éviter de vous blesser à la tête, aux yeux, aux mains ou aux pieds et pour protéger votre ouïe pendant l’utilisation de l’outil multi-fonctions, portez

l’équipement et les vêtements de protection suivants.

Portez toujours un casque en cas de risque de chute d’objets. Le casque de protection (1) doit être vérifié à intervalles réguliers pour parer à d’éventuels

dommages et il doit être remplacé au plus tard tous les 5 ans. N’utilisez que

des casques de protection agréés.

La visière (2) du casque (ou alternativement les lunettes) protège le visage des débris et des pierres qui volent. Pendant l’utilisation de l’outil multifonctions, portez toujours des lunettes de protection ou une visière pour

protéger vos yeux des blessures.

Portez un équipement de protection antibruit adéquat afin d’éviter toute perte auditive (coquilles antibruit (3), bouchons d’oreille etc.).

Les combinaisons de travail (4) protègent contre les pierres et débris qui volent.

Il est fortement recommandé de porter une combinaison de travail.

Les gants spéciaux (5) en cuir épais font partie de l’équipement prescrit et doivent être portés lors de l’utilisation de l’outil multi-fonctions.

Portez également toujours des chaussures de sécurité (6) dotées d’une semelle antidérapante. Elles vous protègerons des blessures éventuelles et

vous assureront une bonne stabilité.

Démarrage de l’outil multi-fonctions

Assurez-vous qu’aucun enfant ou adulte ne se trouve à proximité et faites attention aux animaux situés dans la zone de travail.

Assurez-vous que la pièce de fixation est bien en place, que le levier de commande peut être actionné aisément et que le levier de verrouillage

fonctionne correctement.

Il est interdit de faire bouger la pièce de fixation pendant le ralenti. En cas de doute, vérifiez le réglage avec votre revendeur. Vérifiez que les poignées sont

propres et sèches et que l’interrupteur marche/arrêt fonctionne correctement.

Illustration

15 mètres

24

Page 25

Démarrez l’outil multi-fonctions uniquement conformément aux instructions.

Ne démarrez pas le moteur selon une autre méthode ! Utilisez l’outil multi-fonctions et les au tres outils uniquement pour les -

applications indiquées.

Ne démarrez le moteur de l’outil multi-fonctions qu’après avoir procédé au -

montage complet. Le fonctionnement de l’outil n’est autorisé qu’une fois

l’ensemble des accessoires fixés !

Avant de démarrer, assurez-vous que la pièce de fixation n’est pas en contact avec des objets durs, tels que des branches, des pierres, etc., car

elle tournera au démarrage.

En cas de problème avec le moteur, éteignez-le immédiatement. Si l’outil de coupe frappe des pierres ou d’autres objets durs, coupez -

immédiatement le moteur et examinez la pièce de fixation.

N’utilisez l’outil multi-fonctions qu’après avoir fixé et réglé correctement le -

harnais. Il est très important de régler le harnais selon votre taille, afin d’éviter

toute fatigue supplémentaire pendant l’utilisation. Ne tenez jamais l’outil

d’une seule main pendant l’utilisation.

Pendant l’utilisation, tenez toujours l’outil multi-fonctions avec les deux mains. Assurez-vous toujours d’avoir une bonne stabilité.

Faites fonctionner l’outil multi-fonctions de manière à éviter d’inhaler les gaz d’échappement. Ne faites jamais tourner le moteur dans une pièce confinée

(risque d’intoxication aux gaz). Le monoxyde de carbone est un gaz inodore.

Éteignez le moteur avant de faire une pause ou de laisser l’outil multi- fonctions sans surveillance. Placez-le également en lieu sûr pour éviter que

d’autres personnes se blessent ou endommagent l’appareil.

Ne posez jamais l’outil multi-fonctions dans l’herbe sèche ou sur des matériaux combustibles lorsqu’il est chaud.

Vous devez utiliser tous les carters et installations de protection fournis avec l’appareil pendant son fonctionnement.

Ne faites jamais tourner le moteur si le pot d’échappement est défectueux. Éteignez le moteur pendant le transport. En cas de transport sur de longues distances, utilisez toujours le dispositif de -

protection d’outil fourni.

Veillez à placer l’outil multi-fonctions de manière sécurisée pendant le -

transport en voiture afin d’éviter toute fuite de carburant.

Lors du transport de l’outil multi-fonctions, assurez-vous que le réservoir de -

carburant est complètement vide.

Lors du déchargement de - l’outil multi-fonctions depuis un véhicule, veillez

à ne pas laisser tomber le moteur au risque d’endommager grièvement le

réservoir de carburant.

Sauf en cas d’urgence, ne laissez jamais tomber l’outil multi-fonctions et ne le jetez pas au sol, au risque de l’endommager grièvement.

Veillez à soulever l’ensemble du matériel du sol lorsque vous le déplacez. Il est très dangereux de traîner le réservoir de carburant : cela risque de créer

des fuites de carburant, voir un incendie.

En cas de chute ou d’impact de l’appareil, vérifiez qu’il est en bon état avant de poursuivre le travail. Vérifiez qu’il n’y a pas de fuite de carburant dans

le circuit d’alimentation, et que les commandes et dispositifs de sécurité

fonctionnent correctement. En cas de dommage ou de doute, demandez à un

centre d’entretien agréé d’examiner et de réparer l’outil.

• Au repos

• Transport

• Ravitaillement en carburant

• Entretien

• Remplacement d’outil

Ravitaillement en carburant

Lors du ravitaillement en carburant, coupez le moteur, éloignez-le des flammes nues et ne fumez pas.

Évitez tout contact entre la peau et l’essence. N’inhalez pas les vapeurs de carburant. Portez toujours des gants de protection durant le ravitaillement en

carburant. Changez et nettoyez régulièrement les vêtements de protection.

Veillez à ne pas renverser de carburant ou d’huile, afin d’éviter toute contamination du sol (protection environnementale). Si vous avez renversé

du carburant, nettoyez immédiatement l’outil multi-fonctions.

Évitez tout contact entre vos vêtements et le carburant. Si vous renversez du carburant sur vos vêtements, changez-en immédiatement (pour éviter que

vos vêtements ne prennent feu).

Vérifiez régulièrement le bouchon du réservoir pour vous assurer qu’il est bien fermé et ne fuit pas.

Serrez soigneusement le bouchon du réservoir de carburant. Déplacez-vous pour démarrer le moteur (à au moins 3 mètres de l’endroit où vous avez fait

le plein).

Ne faites jamais le plein dans une pièce confinée. Les vapeurs de carburant s’accumulent au niveau du sol (risques d’explosions).

Transportez et stockez le carburant uniquement dans des conteneurs agréés. Assurez-vous que les enfants ne peuvent pas accéder au carburant.

25

3 mètres

Page 26

Mode d’emploi

Utilisez l’outil multi-fonctions uniquement lorsque l’éclairage est correct et la visibilité satisfaisante. Pendant l’hiver, soyez attentif aux zones glissantes

ou mouillées, au verglas et à la neige (risques de glissade). Assurez-vous

toujours d’avoir une bonne stabilité.

N’utilisez jamais l’outil multi-fonctions lorsque vous vous trouvez sur une échelle.

N’utilisez jamais l’outil multi-fonctions lorsque vous trouvez dans un arbre. Ne travaillez jamais sur des surfaces instables. Avant d’utiliser la pièce de fixation, veillez à ce que celle-ci ait atteint sa -

vitesse maximale.

Reposez-vous pour éviter toute perte de contrôle due à la fatigue. Il est -

recommandé de faire une pause de 10 à 20 minutes toutes les heures.

Instructions d’entretien

L’entretien de votre appareil doit être effectué par l’un de nos centres d’entretien agréés et seules des pièces de rechange authentiques doivent

être utilisées. Une réparation incorrecte et un entretien défectueux peuvent

réduire la durée de vie de l’appareil et accroître le risque d’accidents.

Veillez à faire le moins de bruit possible et à limiter la contamination lors de l’utilisation de l’outil multi-fonctions. Vérifiez notamment le bon réglage du

carburateur.

Nettoyez régulièrement l’outil multi-fonctions et vérifiez que toutes les vis ainsi que les écrous sont bien serrés.

Ne procédez jamais à l’entretien de l’outil multi-fonctions et ne le stockez pas à proximité de flammes nues.

Toujours rangez l’outil multi-fonctions dans des pièces fermées, après avoir vidé le réservoir de carburant.

Observez les instructions de prévention d’accident pertinentes publiées par les associations commerciales et les compagnies d’assurance.

N’effectuez aucune modification sur l’outil multi-fonctions, au risque de compromettre votre sécurité.

L’exécution de l’entretien ou des réparations par l’utilisateur est limitée aux activités décrites dans le mode d’emploi. Toute autre tâche doit être

réalisée par un agent d’entretien agréé. N’utilisez que des pièces de rechange et des accessoires d’origine fournis par MAKITA.

L’utilisation d’accessoires ou d’outils non approuvés augmente les risques d’accident.

MAKITA n’acceptera aucune responsabilité pour des accidents ou des dommages causés par l’utilisation de pièces de fixation et de dispositifs

de fixation de pièces de fixation ou d’accessoires non agréés.

Premiers secours

En cas d’accident, assurez-vous qu’une mallette de premier secours se trouve

à proximité des opérations de coupe. Remplacez immédiatement tout article

pris dans la mallette de premier secours.

Lorsque vous demandez de l’aide, veuillez fournir les

renseignements suivants :

Lieu de l’accident Que s’est-il passé ? Nombre de personnes blessées Types de blessures Votre nom -

Vibrations

Les personnes souffrant de troubles circulatoires peuvent subir des blessures au niveau des vaisseaux sanguins ou du système nerveux si elles sont exposées à des vibrations excessives. Les vibrations peuvent entraîner les symptômes suivants aux doigts, mains ou poignets :

engourdissement, picotements, douleur, sensation lancinante, altération de la couleur ou de l’aspect de la peau. Si l’un ou l’autre de ces

symptômes apparaît, consultez un médecin !

Afin de réduire le risque de syndrome des vibrations du système main-bras, gardez vos mains au chaud et maintenez correctement l’appareil et ses accessoires.

26

Page 27

DÉCLARATION DE CONFORMITÉ CE

Nous, Makita Corporation, en tant que fabricant responsable, déclarons que les machines Makita suivantes :

Nom de la machine : Outil Multi-Fonctions

N° de modèle/Type : EX2650LH

Spécifications : voir le tableau « DONNÉES TECHNIQUES EX2650LH »

sont fabriquées en série et

sont conformes aux directives européennes suivantes :

2000/14/CE, 2006/42/CE

et sont produites conformément aux normes ou documents de normalisation suivants :

EN/ISO11806, EN709, EN/ISO10517, EN/ISO11680, EN/ISO12100

La documentation technique est disponible auprès de :

Makita International Europe Ltd., Technical Department,

Michigan Drive, Tongwell,

Milton Keynes, Bucks MK15 8JD, Angleterre

La procédure d’évaluation de la conformité requise par la directive 2000/14/CE est conforme à l’annexe V.

EX2650LH avec EM400MP (Tête Débroussailleuse)

EX2650LH avec EM401MP (Tête Débroussailleuse)

EX2650LH avec ER400MP (Tête Coupe Herbe)

EX2650LH avec EN400MP (Tête Taille-Haie à Perche)

EX2650LH avec EN400MP (Tête Taille-Haie à Perche) et LE400MP (Rallonge d’Arbre)

Niveau de puissance sonore mesurée : 108,5 dB (A)

Niveau de puissance sonore garantie : 113 dB (A)

Niveau de puissance sonore mesurée : 102,7 dB (A)

Niveau de puissance sonore garantie : 105 dB (A)

Niveau de puissance sonore mesurée : 109,2 dB (A)

Niveau de puissance sonore garantie : 116 dB (A)

Niveau de puissance sonore mesurée : 103,8 dB (A)

Niveau de puissance sonore garantie : 109 dB (A)

Niveau de puissance sonore mesurée : 104,0 dB (A)

Niveau de puissance sonore garantie : 106 dB (A)

Le numéro du certificat d’inspection de type CE comme une scie à long manche avec EY400MP, EY401MP, LE400MP est :

4811004.11016

L’inspection de type CE pour la norme 2006/42/CE a été réalisée par :

DEKRA Testing and Certification GmbH

Enderstraße 92b

01277 Dresden, Allemagne

N° d’identification 2140

30. 1. 2012

Tomoyasu Kato

Directeur

Makita Corporation

3-11-8, Sumiyoshi-cho,

Anjo, Aichi, 446-8502, JAPAN

27

Page 28

DONNÉES TECHNIQUES EX2650LH

Modèle

EX2650LH

Poignée fermée

Dimensions : longueur x largeur x hauteur (sans la lame de

coupe) avec garde-fou

Dimensions : longueur x largeur x hauteur (sans la lame de

coupe) sans garde-fou

mm 975 x 323 x 241

mm 975 x 242 x 241

Masse (sans la protection plastique et la lame de coupe) kg 4,6

Volume (réservoir de carburant) L 0,6

Volume (réservoir d’huile) L 0,08

Déplacement du moteur cm

3

Performance maximale du moteur kw 0,77 à 7 000 min

Vitesse du moteur à la vitesse max. recommandée de l’axe min

Vitesse maximale de l’axe (correspondant) min

-1

-1

25,4

-1

8 500

6 500

Consommation maximale de carburant kg/h 0,33

Consommation maximale spécifique de carburant g/kwh 408

Ralenti min

Vitesse d’engagement de l’embrayage min

-1

-1

3 000

3 900

Carburateur type WALBRO WYL

Système d’allumage type Allumage à semi-conducteur

Bougie d’allumage type NGK CMR4A

Distance entre les électrodes mm 0,7 - 0,8

Carburant Essence automobile

Huile moteur

Classe SF ou supérieure (moteur 4 temps pour automobile)

Huile SAE 10W-30 de classe API,

Vibrations

Tête a

Poignée droite (prise arrière) Poignée gauche (prise avant)

(m/s2) Incertitude K (m/s2)a

hv eq

(m/s2) Incertitude K (m/s2)

hv eq

Normes

applicables

EM400MP 6,5 1,2 5,9 1,8 ISO 22867

EM401MP 5,6 2,1 4,8 1,0 ISO 22867

ER400MP 7,1 2,8 5,5 2,7 ISO 22867

EY400MP 9,4 2,0 4,2 2,0 ISO 22867

EY400MP + LE400MP 4,8 2,0 3,4 2,0 ISO 22867

EY401MP 6,5 2,0 3,8 2,0 ISO 22867

EY401MP + LE400MP 5,6 2,0 3,4 2,0 ISO 22867

EN400MP 8,4 1,8 5,0 0,7 ISO 10517

EN400MP + LE400MP 8,0 1,7 4,3 0,7 ISO 10517

KR400MP 5 1,1 4,4 2,3 ISO 22867

EJ400MP 7,1 1,5 4,9 1,5 ISO 22867

EJ400MP + LE400MP 6,4 0,6 4,0 0,7 ISO 22867

28

Page 29

Bruit

Moyenne du niveau de pression sonore Moyenne du niveau de puissance sonore

Tête L

PA eq

Incertitude K L

WA eq

Incertitude K

Normes

applicables

EM400MP 95,0 4,4 105,5 3,3 ISO 22868

EM401MP 89,9 3,6 99,7 2,7 ISO 22868

ER400MP 97,9 4,2 106,2 4,0 ISO 22868

EY400MP 93,0 2,5 104,5 2,5 ISO 22868

EY400MP + LE400MP 90,3 2,5 107,8 2,5 ISO 22868

EY401MP 92,6 2,5 104,7 2,5 ISO 22868

EY401MP + LE400MP 90,5 2,5 107,9 2,5 ISO 22868

EN400MP 93,1 4,4 102,9 4,8 ISO 10517

EN400MP + LE400MP 87,8 1,9 103,0 2,0 ISO 10517

KR400MP 93,7 2,6 99,7 1,2 ISO 22868

EJ400MP 89,0 2,3 99,8 1,1 ISO 22868

EJ400MP + LE400MP 88,1 2,2 100,8 2,3 ISO 22868

PIÈCES DE FIXATION AGRÉÉES

PIÈCES DE FIXATION Modèles

Tête Débroussailleuse EM400MP, EM401MP

Tête Coupe Herbe ER400MP

Tête Élagueuse à Perche EY400MP, EY401MP

Tête Taille-Haie à Perche EN400MP

Tête Moto-Bineuse KR400MP

Tête Peigne Vibreur Pour Café EJ400MP

Rallonge d’Arbre LE400MP

29

Page 30

NOMENCLATURE DES PIÈCES

EX2650LH

6

14

7

12

11

10

4

8

9

18

13

15

3

5

16

17

1

2

F NOMENCLATURE DES PIÈCES

1 Réservoir de carburant

2 Démarreur à rappel

3 Filtre à air

4 Interrupteur I-O (marche/arrêt)

5 Pot d’échappement

6 Carter d’embrayage

7 Prise arrière

8 Crochet de suspension

9 Poignée

10 Levier d’accélération

11 Levier de verrouillage

12 Câble de contrôle

13 Arbre

14 Bouchon de réservoir de carburant

15 Bouton de démarrage

16 Tuyau d’échappement

17 Bouchon d’huile

18 Garde-fou*

Remarque : Dans certains pays, le garde-fou

n’est pas fourni avec l’outil.

30

Page 31

MONTAGE DE LA POIGNÉE

ATTENTION : Avant tout travail sur l’outil multi-fonctions, coupez toujours le

moteur et débranchez le connecteur des bougies.

Portez toujours des gants de protection !

ATTENTION : Démarrez l’outil multi-fonctions uniquement après l’avoir

entièrement monté.

Montage de la poignée fermée

Installez solidement le garde-fou et la commande sur le tuyau de l’arbre à l’aide de deux vis et colliers. À ce stade, placez le garde-fou sur le côté

gauche de l’appareil, comme illustré.

Assurez-vous que l’ensemble commande/garde-fou ne se trouve pas entre l’entretoise et le repère flèche. Ne retirez pas et ne contractez pas

l’entretoise.

Une fois le montage terminé, ne retirez pas le garde-fou. -

ATTENTION : N’installez jamais la commande sur l’étiquette ou le joint.

Remarque : Dans certains pays, le garde-fou et le repère flèche ne sont pas

fournis avec l’outil.

MONTAGE DE LA PIÈCE DE FIXATION

ATTENTION : Avant tout travail sur l’outil multi-fonctions, coupez toujours le

moteur et débranchez le connecteur des bougies.

Portez toujours des gants de protection !

ATTENTION : Démarrez l’outil multi-fonctions uniquement après l’avoir

entièrement monté.

Montage

Dévissez le levier. Alignez l’axe de la pièce de fixation sur la rainure du joint et insérez l’axe. Insérez la pièce de fixation jusqu’à la position de la pièce de fixation -

représentée par une flèche.

Vérifiez également que le bouton est monté.

Serrez le levier. (pour obtenir des instructions de montage, voir le schéma à droite.)

Repère

flèche

Moteur

Joint

31

Page 32

DÉMONTAGE

Dévissez le levier. Appuyez sur le bouton et sortez la pièce de fixation de la porte. -

(Dans la mesure du possible, essayez de sortir la pièce de fixation en ligne

droite.)

Remarque :

Ne laissez pas le levier serré lorsque la pièce de fixation est retirée. -

32

Page 33

AVANT DE COMMENCER

Inspection et remplissage de l’huile moteur

Procédez comme suit, lorsque le moteur est froid. Réglez le niveau du moteur, retirez le bouchon d’huile (Fig. 1) et vérifiez l’absence d’huile dans la plage comprise entre les repères des -

limites supérieure et inférieure du tuyau d’huile (Fig. 2).

Si la quantité d’huile est insuffisante (le niveau d’huile est proche du repère de limite intérieure) (Fig. 3), remplissez d’huile jusqu’au repère de -

limite supérieure.

La zone proche des repères externes est transparente, dont la quantité d’huile à l’intérieur peut être vérifiée sans qu’il soit nécessaire de -

retirer le bouchon d’huile. Toutefois, si le tuyau d’huile devient extrêmement encrassé, vous risquez d’avoir une mauvaise visibilité et de

devoir vérifier le niveau d’huile par rapport à la section décrochée sur l’intérieur du tuyau d’huile.

À titre d’information, la durée de remplissage de l’huile est de 10 heures environ (tous les 10 remplissages). Si l’huile change de couleur ou contient de la saleté, remplacez-la. (Pour la fréquence et la méthode de vidange, référez-vous à la page 38)

Huile recommandée : Huile SAE 10W-30 de classe API Classification, Classe SF ou supérieure (moteur 4 temps pour automobile)

Volume d’huile : Environ 0,08 L

Remarque : Si le moteur n’est pas maintenu en position verticale, la quantité d’huile versée risque d’être trop importante et l’huile risque de

pénétrer à l’intérieur du moteur.

Si l’huile est ajoutée au-delà de la limite, elle risque d’être contaminée ou de déclencher un incendie avec de la fumée blanche.

Point n°1 du remplacement de l’huile : « bouchon d’huile »

Retirez la poussière ou les saletés entourant l’orifice du réservoir d’huile, puis retirez le bouchon d’huile. Veillez à ce que le bouchon d’huile n’entre pas en contact avec du sable ou de la poussière. Dans le cas contraire, les impuretés -

adhérant au bouchon d’huile pourraient empêcher la bonne circulation de l’huile ou abimer des pièces du moteur, ce qui provoquerait des

problèmes.

Huile

Repère externe

(limite supérieure)

Bouchon d’huile

Section interne

décrochée (limite

supérieure)

Tuyau

d’huile

Fig. 1

(1) Gardez le moteur à plat et enlevez le bouchon d’huile.

Section interne

décrochée

(limite inférieure)

Fig. 2 Tuyau d’huile Fig. 3

Repère

externe

(limite

inférieure)

Remplissez d’huile

jusqu’à ce que

le niveau d’huile

atteigne la section

décrochée (limite

supérieure).

La zone située entre

les limites externes

supérieure et inférieure

est transparente, donc le

niveau d’huile peut être

vérifié à l’extérieur par

rapport à ces repères.

(2) Remplissez d’huile jusqu’au repère de limite supérieure. (voir Fig. 3)

Utilisez la bouteille d’huile lors du remplissage.

(3) Serrez à fond le bouchon d’huile. Un vissage insuffisant pourrait provoquer

une fuite d’huile.

33

Page 34

Remarque

Ne remplacez pas l’huile lorsque le moteur est en position inclinée.•

Le remplissage d’huile avec le moteur incliné risque de provoquer un remplissage trop important, entraînant la contamination de l’huile et/•

ou de la fumée blanche.

Point n°2 du remplacement de l’huile : « En cas de débordement d’huile »

Si de l’huile se répand entre le réservoir de carburant et le bloc principal du moteur, elle risque d’être aspirée dans le port d’entrée de l’air de refroidissement, contaminant le moteur. Veillez à nettoyer l’huile qui a débordé avant toute utilisation.

RAVITAILLEMENT EN CARBURANT

Maniement du carburant

Veillez à manipuler le carburant avec la plus grande prudence. Il peut contenir des substances similaires aux solvants. Pour faire le plein,

placez-vous dans une pièce suffisamment ventilée ou à l’extérieur. N’inhalez jamais les vapeurs de carburant et restez à distance du carburant.

En cas de contact répété ou prolongé de votre peau avec du carburant, elle peut se dessécher et causer des maladies de peau ou des

allergies. En cas de contact du carburant avec un œil, rincez celui-ci à l’eau claire. Si votre œil reste irrité, consultez votre médecin.

Durée de stockage du carburant

Le carburant doit être utilisé dans les 4 semaines, même s’il est conservée dans un bidon spécial dans un endroit ombragé et bien ventilé.

Si vous n’utilisez pas de bidon spécial ou qu’il n’est pas fermé, le carburant peut se détériorer en une journée.

STOCKAGE DE LA MACHINE ET REMPLISSAGE DU RÉSERVOIR

Conservez la machine et le réservoir dans un endroit frais et abrité de la lumière directe du soleil. Ne conservez jamais le carburant dans un bungalow ou un coffre. -

Carburant

Le moteur est un moteur à quatre temps. Assurez-vous d’utiliser de l’essence pour automobile (super ou premium).

Avertissements concernant le carburant

N’utilisez jamais de mélange de carburant contenant de l’huile moteur. Cela pourrait créer une accumulation excessive de carbone ou des pannes mécaniques.

L’utilisation d’huile détériorée peut provoquer des démarrages irréguliers du moteur. -

Ravitaillement en carburant

AVERTISSEMENT : PRODUITS INFLAMMABLES STRICTEMENT

INTERDITS

Essence utilisée : Essence pour automobile (super sans plomb)

Dévissez légèrement le bouchon du réservoir afin qu’il n’y ait pas de différence de pression.