Page 1

English / French / German

Italian / Dutch / Spanish / Português

Backpack BrushCutter

Débroussailleuse à dos

Rücken tragbare Benzin Motorsense

Decespugliatore a Zaino

Op de rug braagbare Bosmaaier

Desbrozadora de mochila

Cortador de Grama Tipo Mochila

EBH341R

INSTRUCTION MANUAL

MANUEL D’INSTRUCTIONS

BETRIEBSANLEITUNG

ISTRUZIONI D’USO

GEBRUIKSAANWIJZING

MANUAL DE INSTRUCCIONES

EBH341R

Warning

Read this instruction manual carefully before putting the Brush Cutter into operation and strictly observe the safety regulations!

Preserve instruction manual carefully!

Avertissement

Lire attentivement ce manuel d’instruction avant d’utiliser la Débroussailleuse et observer rigoureusement les règles de sécurité!

Conserver ce manuel dans un endroit sûr!

Waarschuwing

Lesen Sie diese Betriebsanleitung vor der lnbetriebnahme der Montorsense sufmerksam durch und halten Sie die

Sicherheitsvorschriften genau ein!

Bewahren Sie diese Betriebsanleitung sorgfältig auf!

Attenzione

Leggete attentamente questo manuale di istruzioni prima di far funzionare il Decespugliatore, ed osservate rigorosamente le regole

sulla sicurezza!

Conservate con cura questo manuale di instruzioni!

MANUAL DE INSTRUÇÕES

Waarschuwing

Lees deze gebruiksaanwijzing zorgvuldig alvorens de Bosmaaier in gebruik te nemen en neem de veiligheidsvoorschriften strict in

acht!

Bewaar deze gebruiksaanwijzing zorgvuldig!

Advertencia

Lea atentamente este manual de instrucciones antes de poner en funcionamiento el Desbrozadora y cumpla estrictamente los

reglamentos de seguridad.

Guarde cuidadosamente este manual de instrucciones.

Advertência

Leia este manual cuidadosamente antes de pôr o Cortador de Grama Tipo Mochila em funcionamento e observe rigorosamente as

normas de segurança.

Conserve este manual de instruções com cuidado.

Page 2

English

Thank you very much for selecting the MAKITA Brush Cutter. We

are pleased to be able to you the MAKITA Brush Cutter which is

the result of a long development programme and many years of

knowledge and experience.

Please read, understand and follow this booklet which refers in

detail to the various points that will demonstrate its outstanding

performance. This will assist you to safely obtain the best

possible result from your MAKITA Brush Cutter.

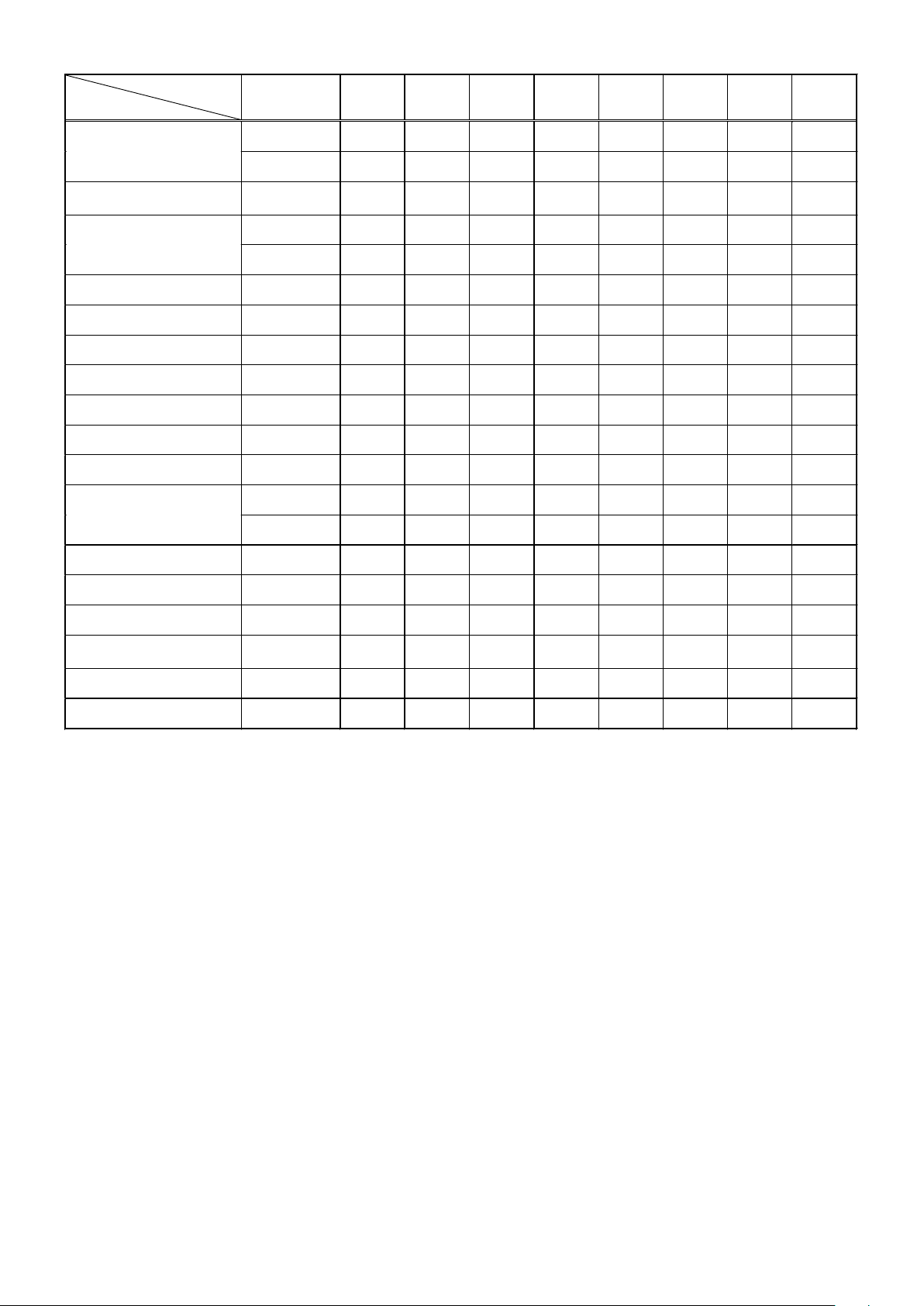

Table of Contents Page

Symbols ......................................................................................... 2

Safety instructions ..................................................................... 3-6

Technical data ............................................................................... 8

Designation of parts ...................................................................... 9

Assembly of engine and drive shaft ...................................... 10-11

Mounting of handle ...................................................................... 12

Mounting of protector .................................................................. 12

Mounting of cutter blade .............................................................. 12

Before start of operation ........................................................ 13-14

Point in operation and how to stop ......................................... 15-16

Resharpening the cutter blade .................................................... 16

Servicing instructions .............................................................17-19

Storage ................................................................................... 20-21

Troubleshooting procedures ....................................................... 22

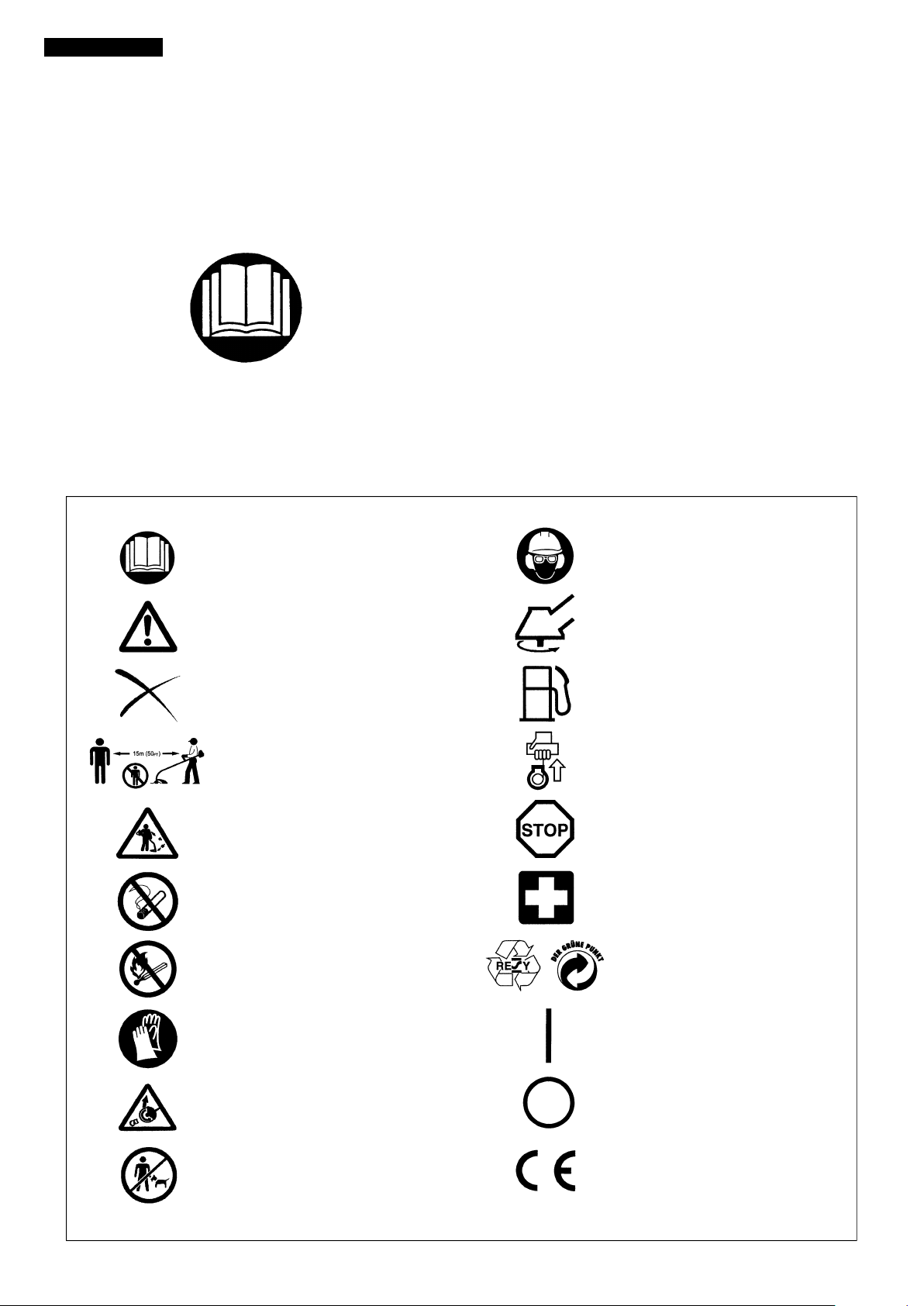

SYMBOLS

It is very important to undestand the following symbols when reading this instructions manual.

Read instruction Manual

WARNING/DANGER/CAUTION

Forbidden

Keep distance

Flying object hazard

No Smoking

No open flame

Wear protective helmet, eye and ear

protection

Top pemissible tool speed

Fuel (Gasoline)

Engine-Manual start

Emergency stop

First Aid

Recycling

Protective gloves must be worn

Kickback (for Brush Cutter only)

Keep the area of operation clear of all

persons and pets

ON/START

OFF/STOP

CE mark

2

Page 3

SAFETY INSTRUCTIONS

General Instructions

– To ensure correct and safe operation, the user must read,

understand and follow this instruction manual to assure

familiarity with the handling of the brush cutter. Users insufficiently informed will risk danger to themselves as well as others

due to improper handling.

– It is recommended only to loan the brush cutter to people who

have proven to be experienced with brush cutters.

Always hand over the instruction manual.

– Use brush cutters with the utmost care and attention.

– First-time users should ask the dealer for basic instructions to

familiarize oneself with the handling of an engine powered

cutter.

– Children and young persons aged under 18 years must not be

allowed to operate the brush cutter. Persons over the age of

16 years may however use the tool for the purpose of being

trained only while under the direct supervision of a qualified

trainer.

– Use brush cutters with the utmost care and attention.

– Operate the brush cutter only if you are in good physical

condition. Perform all work conscientiously and carefully. The

user has to accept responsibility for others.

– Never use the brush cutter while under the influence of alcohol

or drugs.

– Do not use the unit when you are tired.

– Save these instructions for future referral.

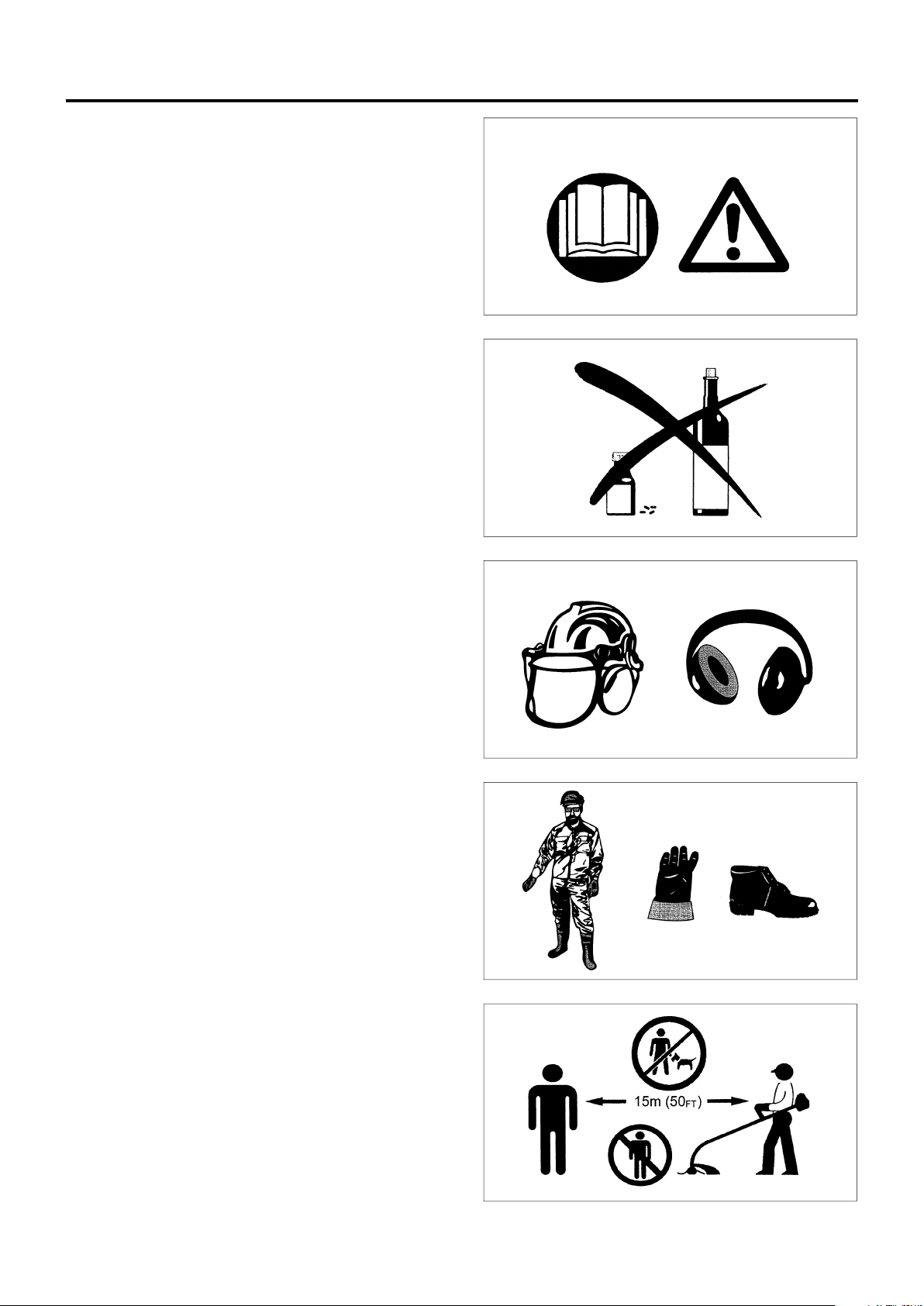

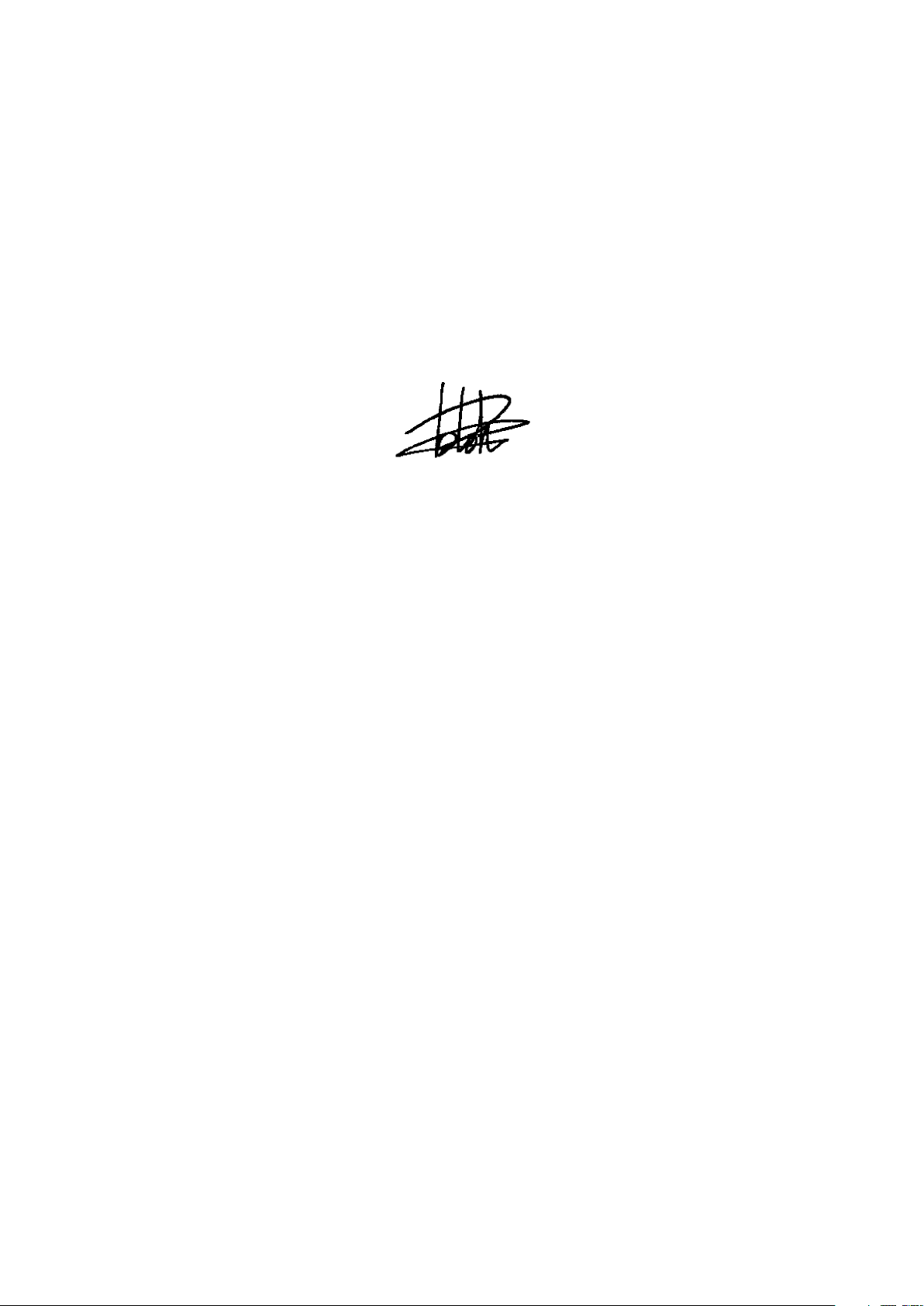

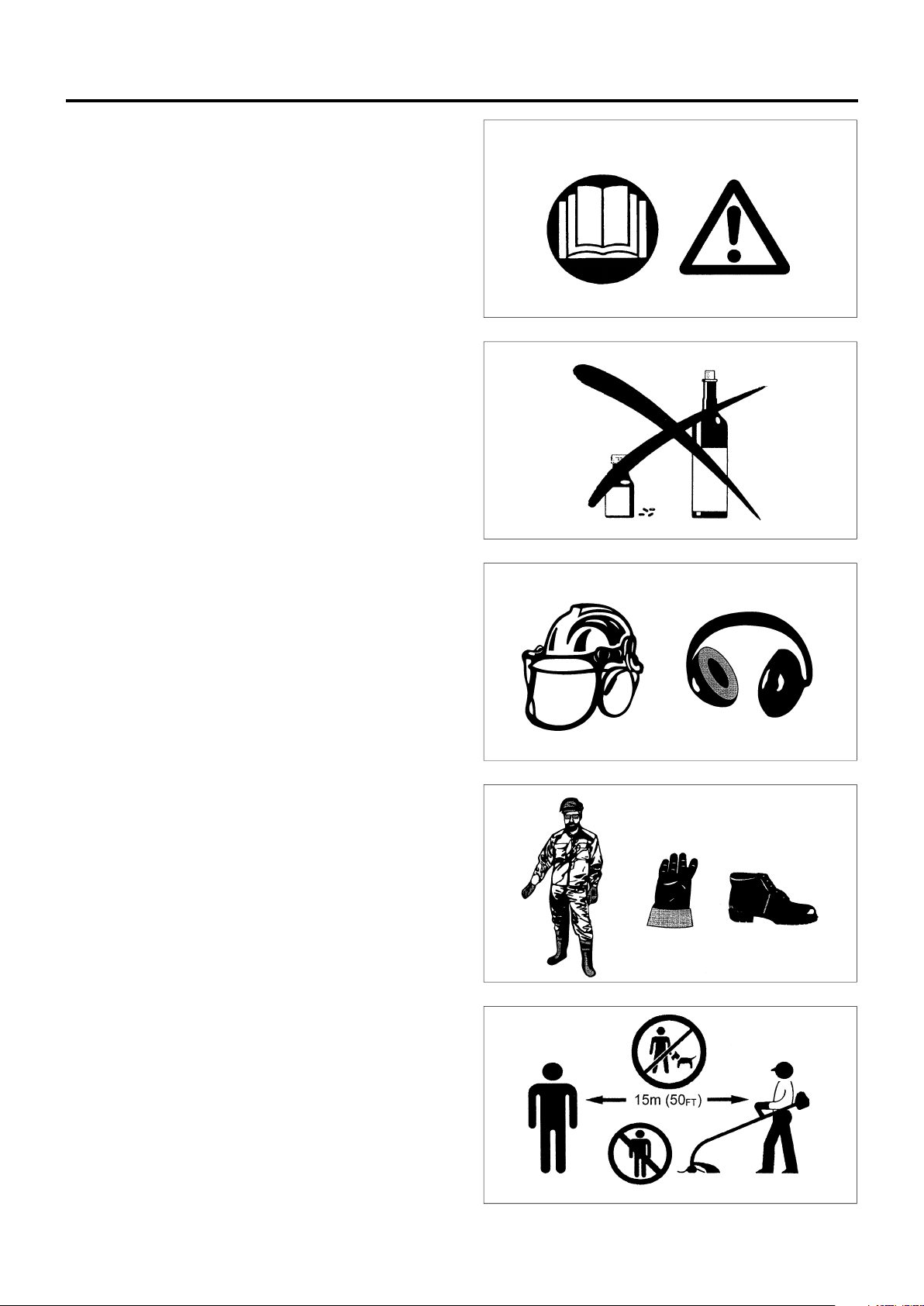

Personal protective equipment

– The clothing worn should be functional and appropriate, i.e. it

should be tight-fitting but not cause hindrance. Do not wear

jewelry, clothing or long hair which could become entangled

with bushes or shrubs.

– In order to avoid head-, eye-, hand- or foot injuries as well as to

protect your hearing the following protective equipment and

protective clothing must be used during operation of the brush

cutter.

– Always wear a helmet when working in the forest. The

protective helmet (1) is to be checed at regular intervals for

damage and is to be replaced at least every 5 years. Use only

approved protective helmets.

– The visor (2) of the helmet (or approved goggles) protects the

face from flying sticks, stones or other object. During operation

of the brush cutter always wear goggles, or a visor to prevent

eye injuries.

– Wear adequate noise protection equipment to avoid hearing

impairment (ear muffs (3), ear plugs etc.), especially during

extended work periods.

– The work overalls (4) protect against flying stones and

splinters.

We strongly recommend that the user wear work overalls.

– Special gloves (5) made of thick leather are part of the pre-

scribed equipment and must always be worn during operation

of the brush cutter.

– When using the brush cutter, always wear sturdy shoes (6)

with a non-slip sole. This protects against injuries and ensures

good footing.

Starting up the brush cutter

– Please make sure that there are no children or other people

within a working range of 50 ft. or 15 meters, also pay attention

to any animals in the working vicinity.

– Before operating, always check that the brush cutter is

safe for operation:

Check the security of the cutter blade. Be sure the blade

mounting nut is firmly secured. The throttle lever should be

checked for smooth and easy action. Check for proper

functioning of the throttle lever lock. The cutter blade must not

rotate during idling.

Consult idle adjustment instructions on page 16. Check for

clean and dry handles and test the function of the STOP switch.

Keep handles free of oil and fuel.

– Before operation, check and follow local; regulations concern-

ing sound level and hours of operations.

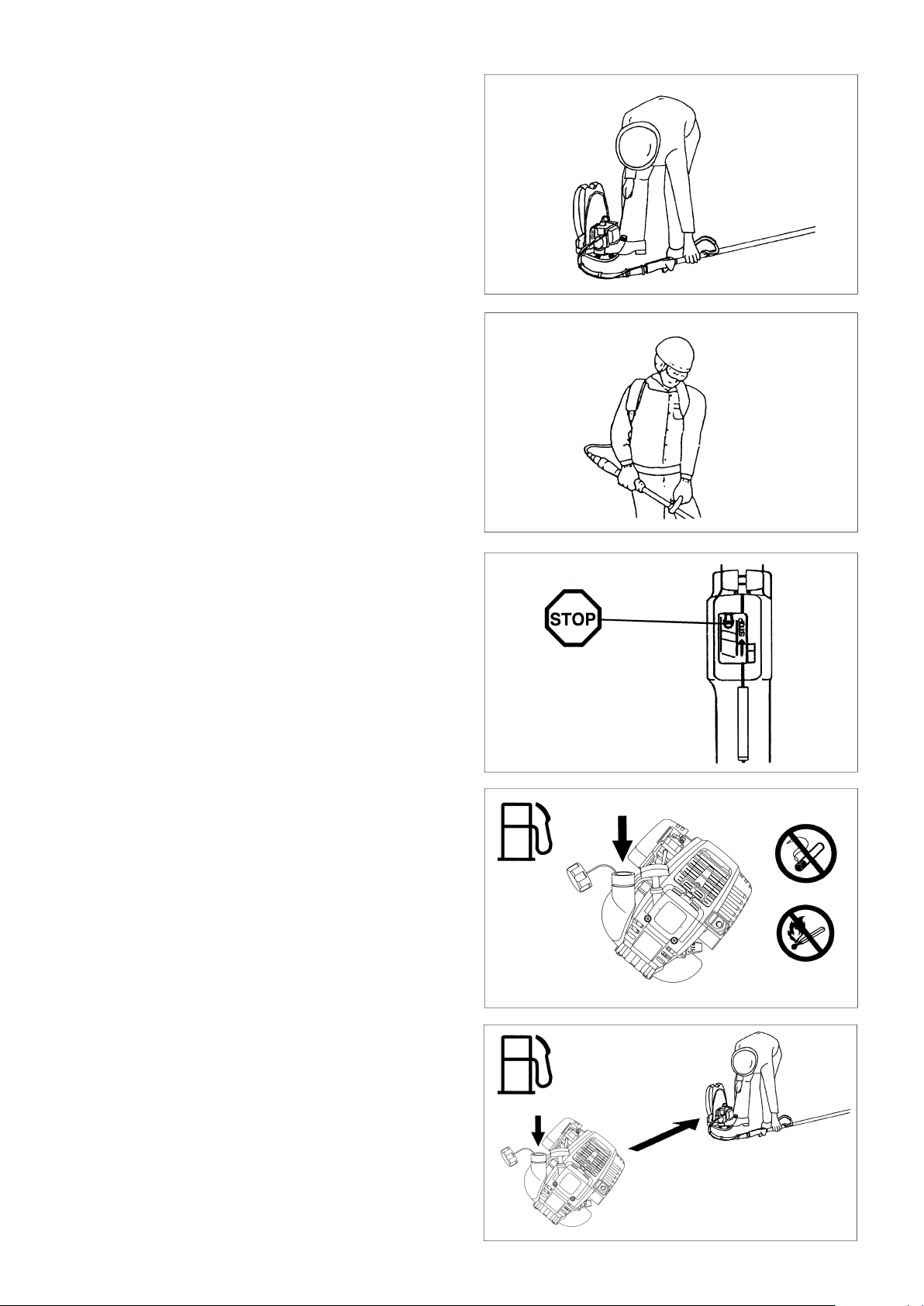

– Only start the brush cutter positioned on the ground.

– Do not start it on the back.

1

2

3

4

5

6

3

Page 4

Start the brush cutter only in accordance with the instructions.

Do not use any other methods for starting the engine!

– Use the brush cutter and the tools supplied only for applications

specified.

– Start the brush cutter engine only after the entire tool has been

assembled. Operation of the tool is permitted only after all the

appropriate accessories are attached!

– Before starting, make sure that the cutter blade will not contact

any objects such as branches, stones, etc.

– The engine is to be stopped immediately if there are any engine

problems.

– Should the cutter blade hit stones or any other objects immedi-

ately stop the engine and inspect the cutter blade.

– Inspect the cutter blade at frequent regular intervals for damage

(detect hairline cracks by means of a tapping-noise test).

– A familiar ringing sound should be heard.

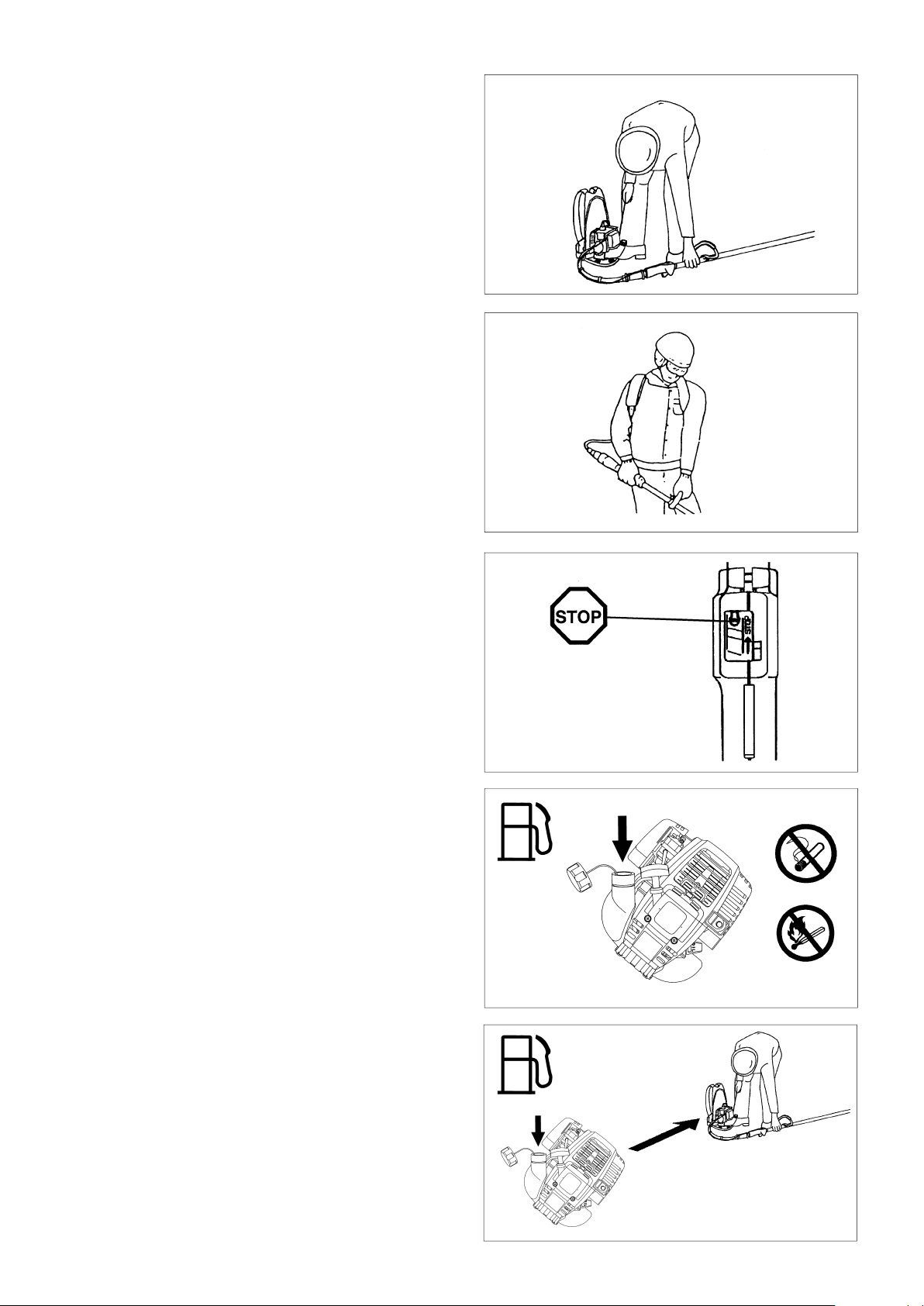

– Operate the brush cutter only with the shoulder strap attached.

It should be properly adjusted before putting the brush cutter

into operation. It is essential to adjust the shoulder strap to the

user’s size to prevent fatigue occurring during use or loss of

control of the tool. Never hold the tool with one hand during

use.

– During operation always hold the brush cutter with both hands.

Always ensure a safe, well-balanced footing.

– Operate the brush cutter in such a manner as to avoid inhalation

of the exhaust gases. Never run the engine in enclosed rooms

(risk of suffocation and gas poisoning). Carbon monoxide is an

odorless gas. Always ensure there is adequate ventilation.

– Stop the engine when resting and when leaving the brush

cutter unattended. Place it in a sale location to prevent danger

to others, setting fire to combustible materials, or damage to the

machine.

– Never lay down the hot brush cutter onto dry grass or onto any

combustible materials.

– The cutter blade must be used with its appropriate guard.

Never run the tool without this guard!

– All protective parts and guards supplied with the machine must

be used during operation.

– Never operate the engine with a faulty exhaust muffler.

– Stop the engine during transport.

– During transport over long distances the tool protection included

with the equipment must always be used.

– Put the brush cutter in upright position and fix it during care or

truck transportation to avoid damage.

– When transporting the brush cutter, ensure that the fuel tank is

completely empty, to avoid fuel leakage.

• Resting

• Transport

• Refuelling

• Maintenance

• Tool Repiacement

Refuelling

– To reduce the risk of fire and bum injury, handle fuel with care it

is highly flammable, Stop the engine during refuelling, keep well

away from open flame and do not smoke.

– Avoid skin contact with petroleum products. Do not inhale fuel

vapor. Always wear protective gloves during refuelling.

Change and clean protective clothing at regular intervals.

– Take care not to spill either fuel or oil. Always wipe unit dry

before starting engine. Allow wet cloths to dry before disposing in proper, covered container to prevent spontaneous

combustion.

– Avoid any fuel contact with your clothing. Change your clothing

immediately if fuel has spilled on it (danger hazard).

– Inspect the fuel cap at regular intervals making sure that stays

securely fastened.

– Carefully tighten the locking screw of the fuel tank. Change

locations to start the engine (at least 10ft. or 3 meters away

from the place of refueling).

– Never refuel in closed rooms. Fuel vapors accumulate at

ground level (risk of explosions).

– Only transport and store fuel in approved containers. Make

sure stored fuel is not accessible to children.

– Do not attempt to refuel a hot or a running engine.

– When mixing gasoline with two-stroke engine oil, use only

gasoline which contains no ethanol or methanol (types of

alcohol). This will help to prevent damage to fuel lines and other

engine parts.

3m (10FT)

4

Page 5

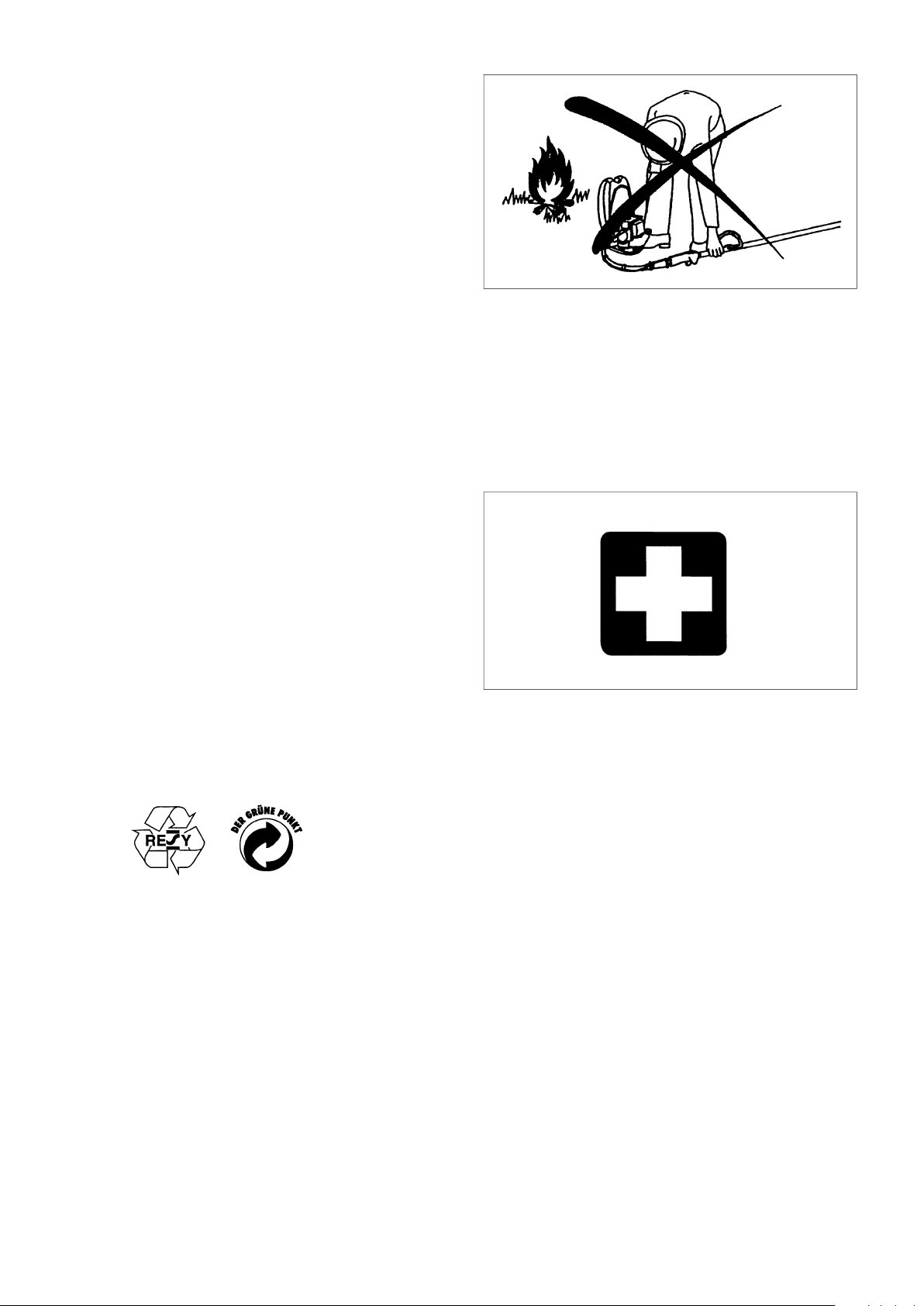

Method of operation

– Use the brush cutter only in good light and visibility. During cold

seasons beware of slippery or wet areas, ice and snow (risk

of slipping). Always ensure a safe footing.

– Do not overreach. Keep proper footing, balance and hand

control of the unit at all times.

– Never cut above waist level.

– Never stand on a ladder while running the brush cutter.

– never climb up into trees to perform any cutting operation with

the brush cutter.

– Never work on unstable surfaces or steep terrain.

– Remove all objects such as stones, nails, broken glass, wire,

etc. found within the working ares.

Foreign articles may damage the cutting tool, can cause

dangerous kickbacks, or could be thrown about dangerously.

– Before commencing cutting the cutting tool must have reached

full working speed.

– Never operate this tool while it is turned upside-down or when

it is at an extreme angle.

– !WARNING! — The cutter area is still dangerous while the

machine is coasting to a stop.

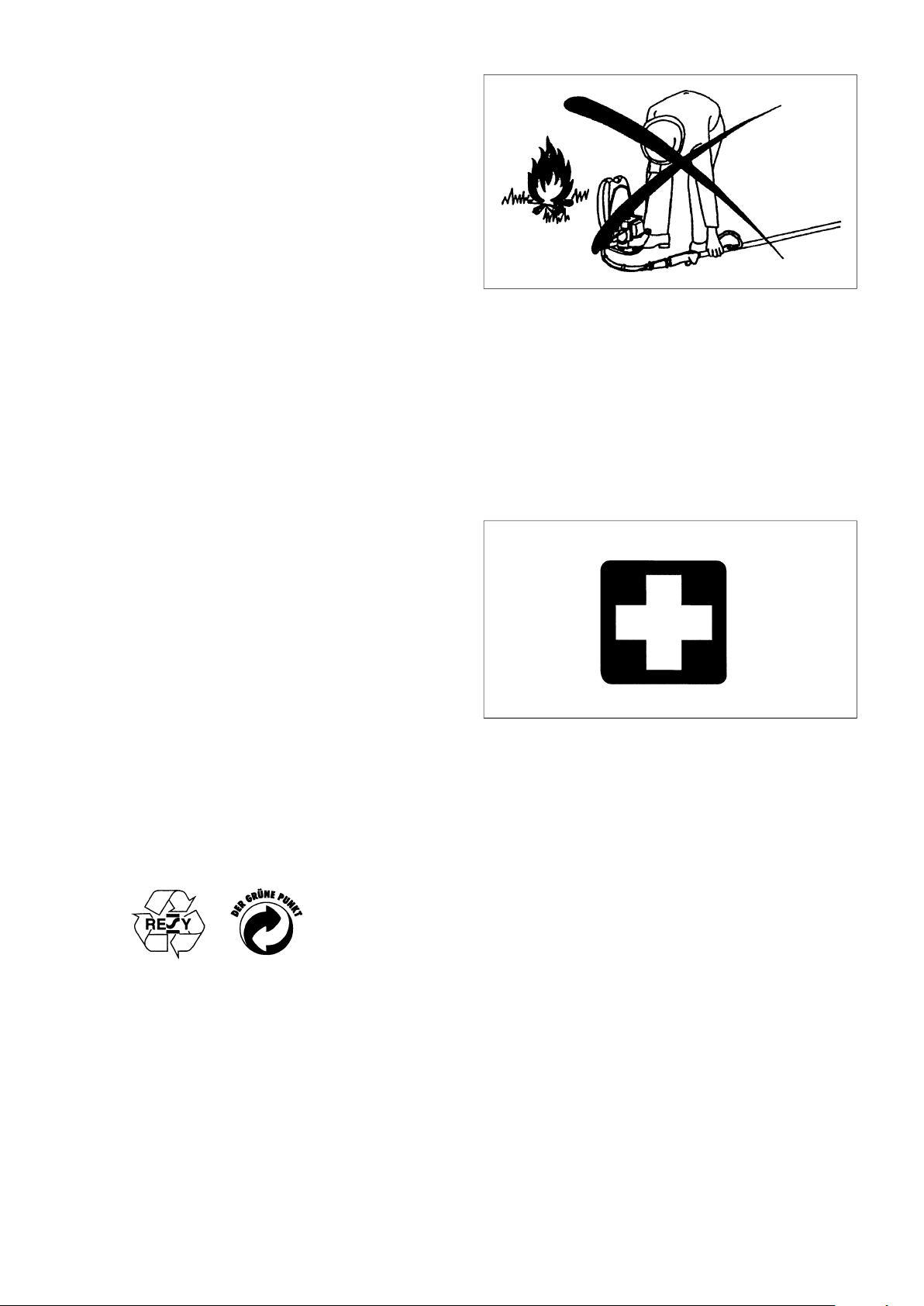

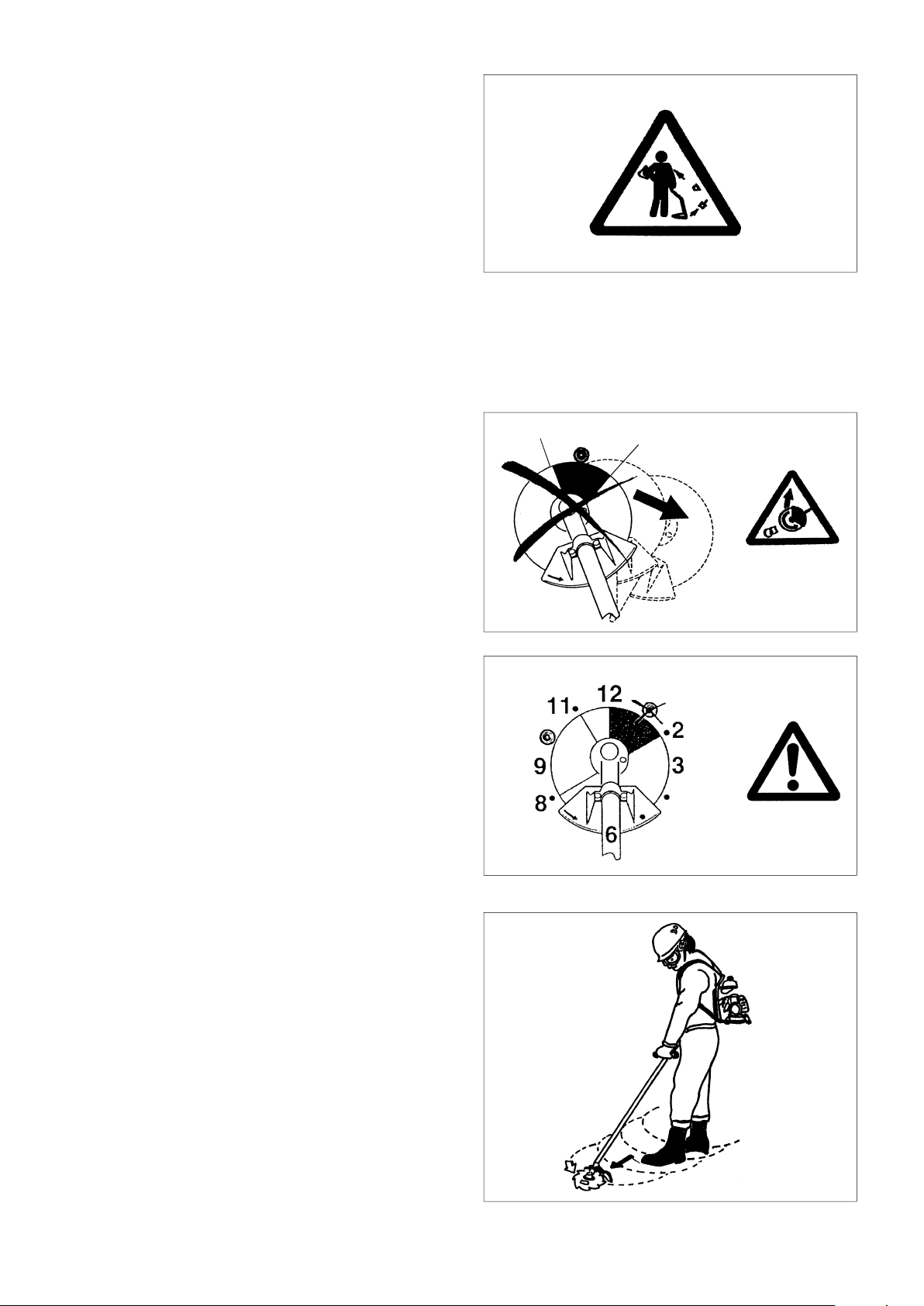

Kickback

– When operating the brush cutter, uncontrolled kickback can

occur.

– This particularly is the case when attempting to cut within a

blade segment between 12 and 2 o’clock as viewed from the

operator’s position.

– Never touch this segment of the brush cutter to solid objects,

such as bushes, stumps, trees, etc., with a diameter greater

than 3 cm.

– The brush cutter will then be deflected at great force and speed

with the potential risk of serious injuries.

– Never operate the brush cutter using the blade seg-

ment between the 12 and 2 o’clock position.

Kickback prevention

To avoid kickbacks, observe the following:

– Operation within the blade segment between 12 and 2 o’clock

can cause serious potential hazards, especially when using

metal cutting blades.

Use of this brush cutter utilizing blade segment positions from

11 to 12 o’clock and 2 to 5 o’clock can still cause a likely

potential for some kickback.

– Cutting operations attempted within the blade segments

between 11 and 12 o’clock, and between 2 and 5 o’clock,

should only be performed by trained and experienced opera-

tors, and only at their own risk. Smooth and easy cutting with

almost no kickback is possible using the blade segment be-

tween 8 and 11 o’clock.

12

2

Caution: Kickback

Diagrammatic figure

Diagrammatic figure

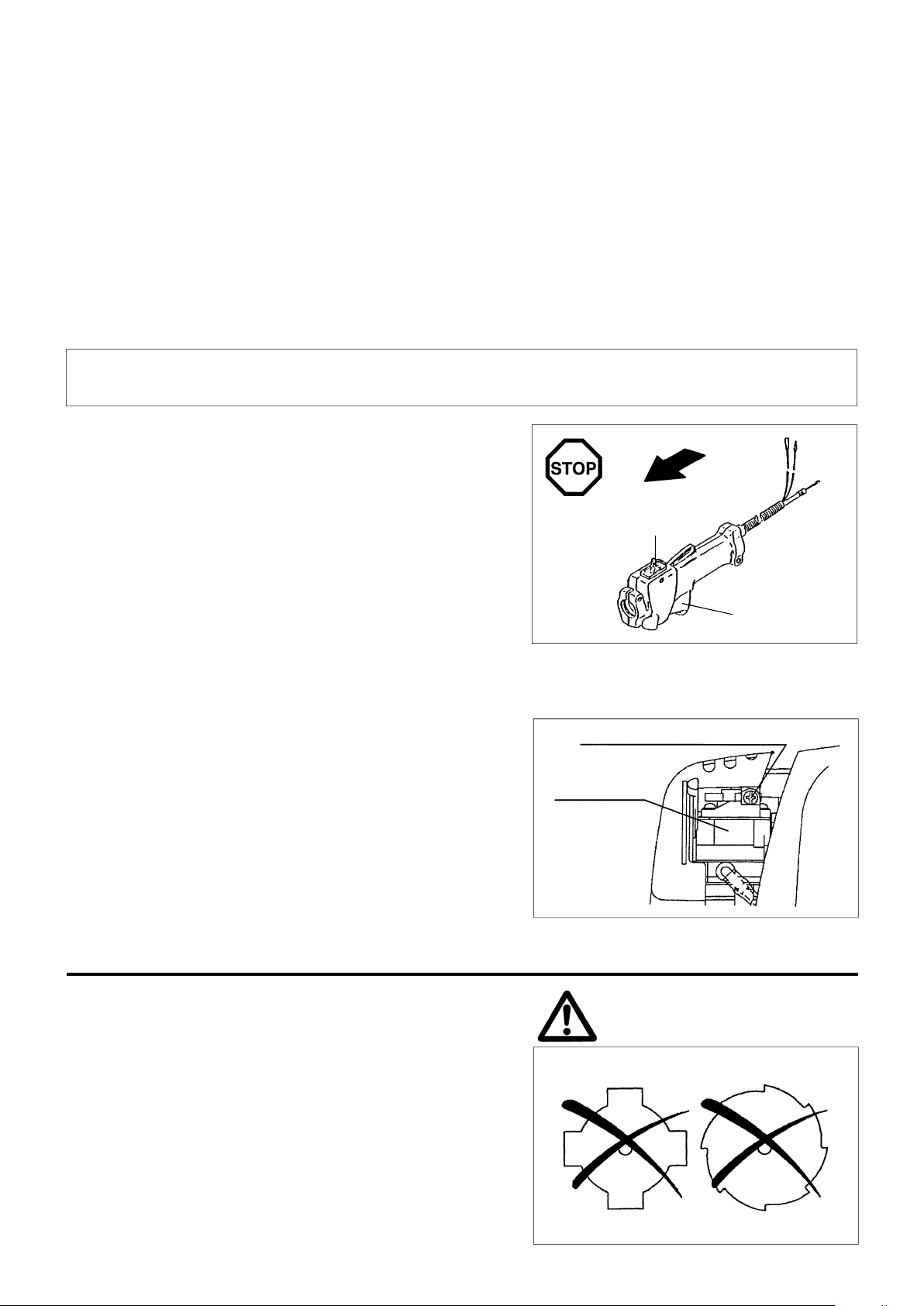

Cutting Tools

Use only the correct cutting tool for the specific job in hand.

Cutter blade (Star Blade (4 teeth), Eddy Blade (8 teeth)):

For cutting thick materials, such as weeds, high grass, bushes,

shrubs, underwood, thicket, etc. (max. 2 cm dia. thickness).

Perform this cutting work by swinging the brush cutter evenly in

half-circles from right to left (similar to using a scythe).

Maintenance instructions

– The condition of the cutter, in particular of the cutter blade,

guard and of the shoulder strap must be checked before

commencing work. Particular attention is to be paid to the

cutting blades which must be correctly sharpened.

– Turn off the engine and remove spark plug connectors when

replacing or sharpening cutting blade, and also when cleaning

the cutter or cutting tool.

5

Page 6

Never straighten or weld damaged cutting blades.

– Be kind to the environment. Operate the brush cutter with as

little noise and pollution as possible. In particular check the

correct adjustment of the carburetor.

– Clean the brush cutter at regular intervals and check that all

screws and nuts are securely tightened.

– Never service or store the brush cutter in the vicinity of open

flames, sparks, etc.

– Always store the brush cutter in a well-ventilated locked room

and with an emptied fuel tank.

Observe and follow all relevant accident prevention instructions

issued by the trade associations and by insurance companies.

Do not perform any modifications to the brush cutter as this will

risk your safety.

The performance of maintenance or repair work by the user is

limited to those activities s described in this instruction manual. All

other work is to be done by Authorized Service Agents.

Use only genuine spare parts and accessories supplied by

MAKITA.

Use of non-approved accessories and tools means increased risk

of accidents and injuries. MAKITA will not accept any liability for

accidents or damage caused by the use of any non-approved

cutting tools attachments or accessories.

First Aid

In case of accident make sure that a well-stocked first-aid kit is

available in the vicinity of the cutting operations. Immediately

replace any item taken from the first aid box.

When asking for help, please give the following information:

– Place of accident

– What happened

– Number of injured persons

– Extent of injuries

– Yo u r n a me

Packaging

The MAKITA brush cutter is delivered in two protective cardboard

boxes to prevent shipping damage.

Cardboard is a basic raw material and is therefore consequently

reusable or suitable for recycling (waste paper recycling).

6

Page 7

EC-DECLARATION OF CONFORMITY

Model; EBH341R

We declare under our sole responsibility that this product is in compliance with the following standards of

standardized documents, ISO14865, ISO14740, EN55012 in accordance with Council Directives, 89/392/

EEC, amended 98/37/EEC, 93/68/EEC, 89/336/EEC, amended 92/31/EEC.

Measured Sound Power: 108.4 dB

Guarantee Sound Power: 113.3 dB

These sound power levels wear measured in accordance with Council Directive, 2000/14/EC.

Conformity assessment procedure: Annex V.

CE2007

Tomoyasu Kato

Director

Responsible Manufacturer:

Makita Corporation.

3-11-8,Sumiyoshi-cho, Anjo, Aichi, JAPAN

Authorized Representative in Europe:

Makita International Europe Ltd.

Michigan Drive, Tongwell, Milton kyenes, Bucks MK15 8JD, ENGLAND

7

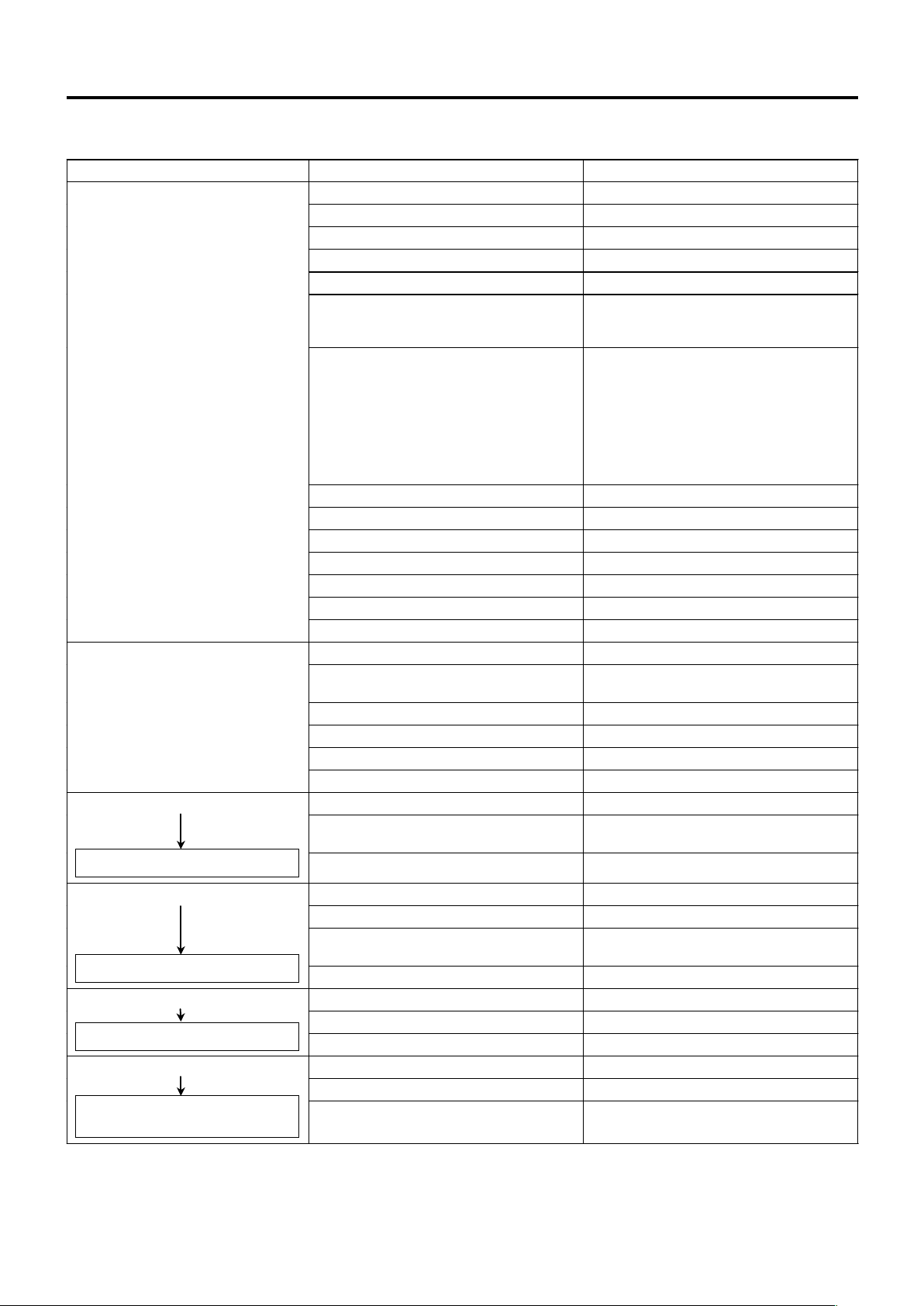

Page 8

TECHNICAL DATA

Model

Dimensions : length x width x height (without pipe case length) mm

Mass (without guard and cutting blade) kg

Volume (fuel tank) L

Cutting attachments (cutter blade dia.) mm

Engine displacement cm

Maximum engine performance kw

Engine speed at recommended max. spindle speed min

Maximum spindle speed (corresponding) min

Fuel consumption kg/h

Specific fuel consumption g/kwh

EBH341R

Loop handle

Cutter blade Nylon cutting head

430 x 280 x 430

10.2

0.65

255

3

-1

-1

33.5

1.07 at 7000 min

10000

7500

-1

0.458

426

Idling speed min

Clutch engagement speed min

Carburetor (Diaphragm - carburetor) type

Ignition system type

Spark plug type

Electrode gap mm

Right handle

1)

(Rear grip)

Vibration per

ISO 7916

Left handle

(Frontgrip)

Sound pressure level average to ISO 7917

Sound power level average to ISO 10884

Idling m/s

Racing or W.O.T m/s

Idling m/s

Racing or W.O.T m/s

1)

1)

dB

dB

Fuel

Engine oil

-1

-1

3000

4100

WALBRO WYL

Solid state ignition

NGK CMR6A

0.7 – 0.8

2

2

2

2

0.6 0.7

4.0 5.59

0.85 0.82

4.78 8.12

89.3 97.1

104.3 108.4

Automobile gasoline

SAE 10W-30 oil API Classification,

Class SF or higher (4-stroke engine for automobile).

Gear ratio

1) This data takes equally into account idling and full speed or wide open throttle operating modes.

8

15/20

Page 9

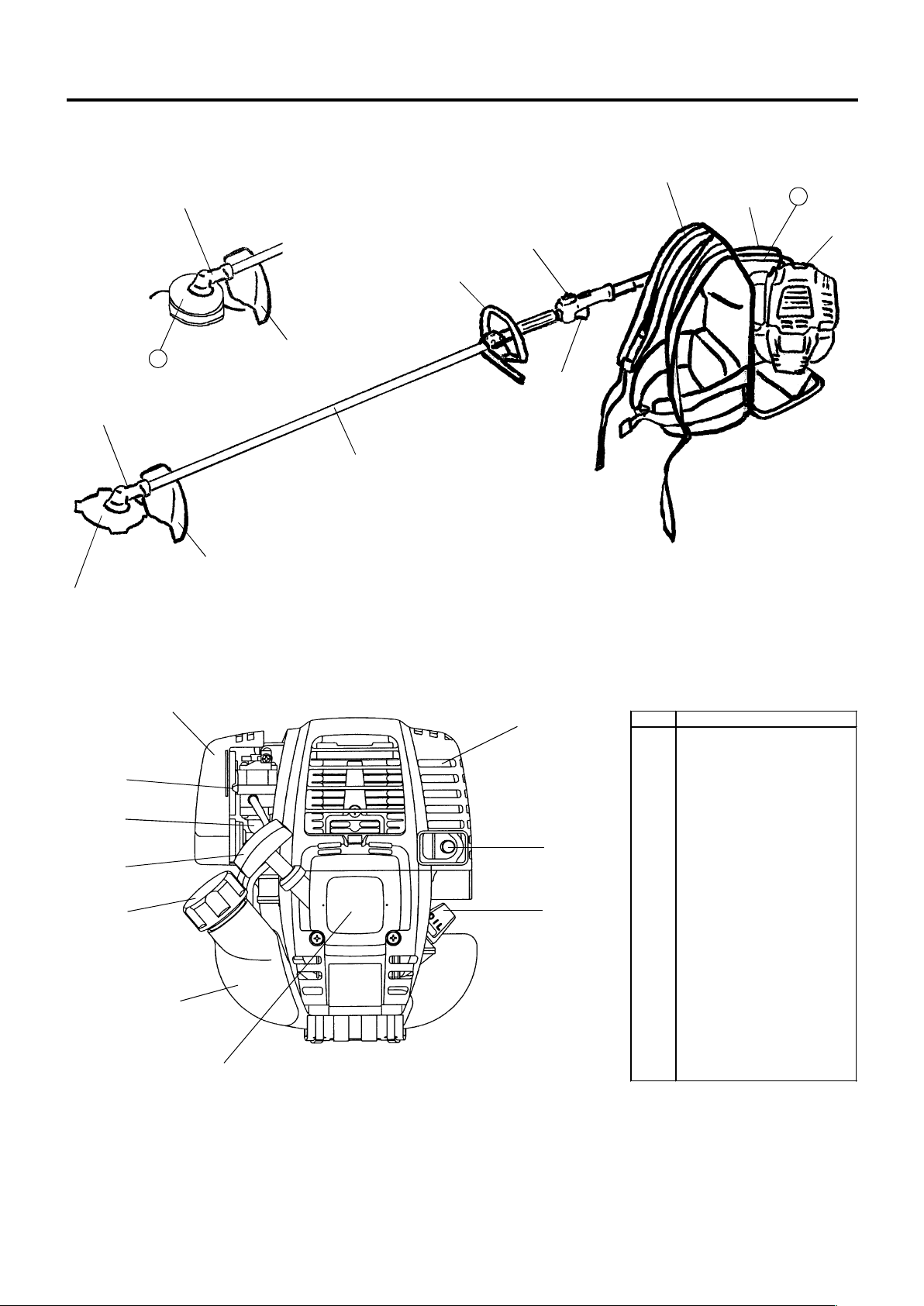

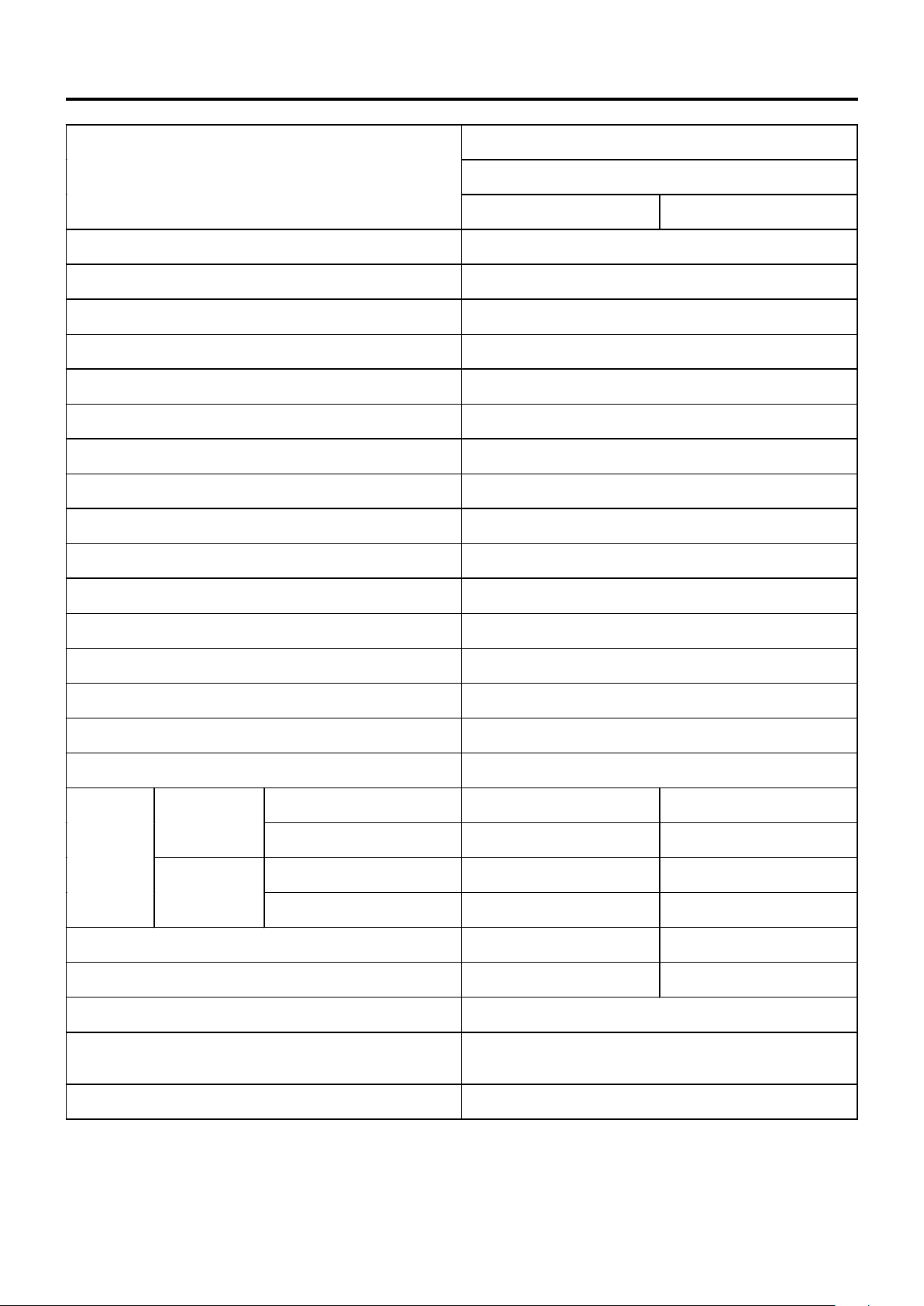

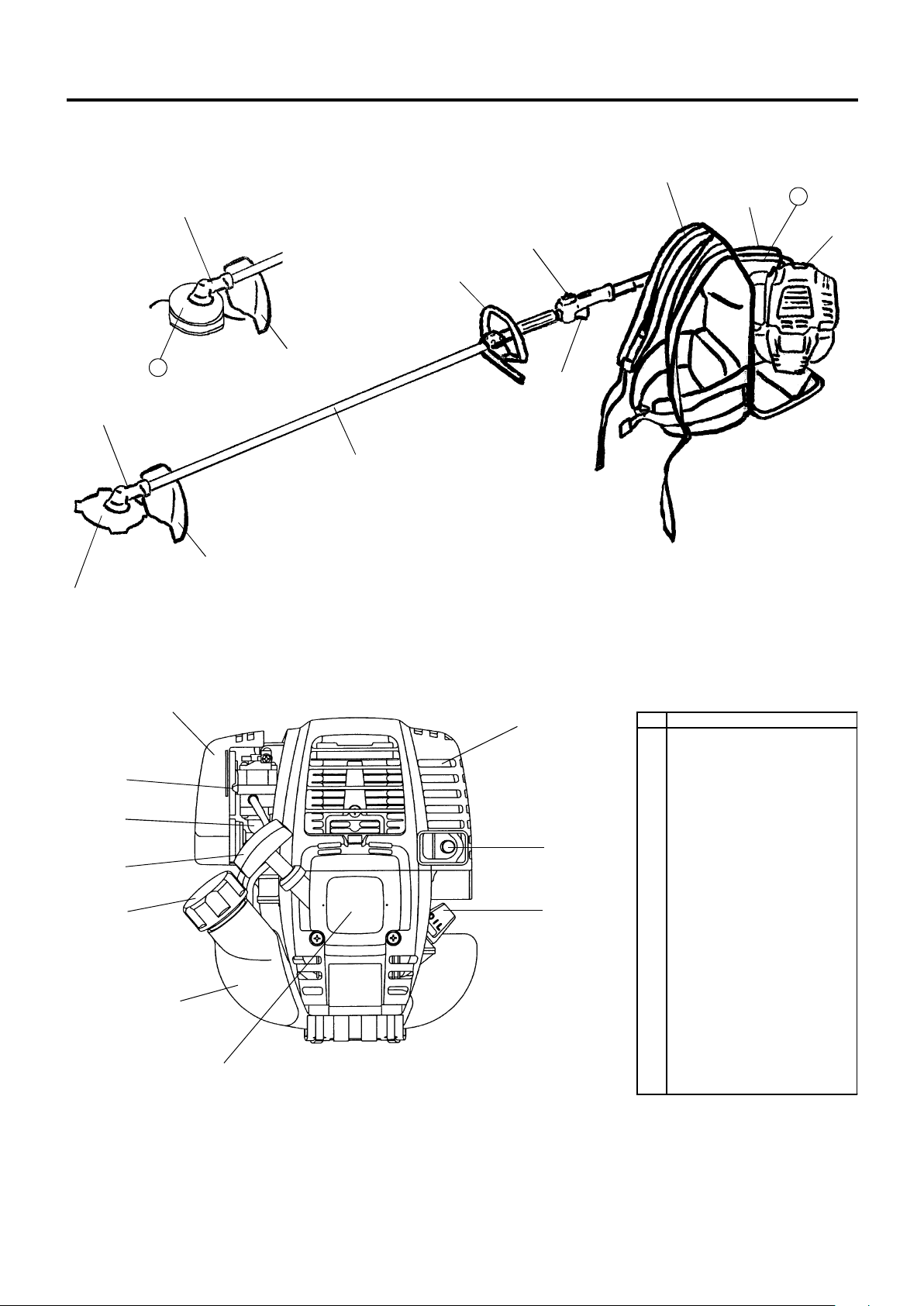

DESIGNATION OF PARTS

ԣ

ԥ

Ԡ

Ԥ

ԣ

ԛ

Ԝ

Ԟ

Ԣ

ԟ

ԡ

Ԣ

ԩ

Ԩ

ԧ

Ԧ

Ԛ

Ԙ

ԙ

ԝ

Ԫ

ԫ

GB DESIGNATION OF PARTS

1 Fuel Tank

2 Rewind Starter

3 Air Cleaner

4 I-O Switch (on/off)

5 Spark Plug

6 Exhaust Muffler

7 Handle

8 Control Lever

9 Control Cable

10 Shaft

11 Protector

12 Gear Case/Head Case

13 Cutter Blade

14 Shoulder Strap

15 Fuel Filler Cap

16 Starter Knob

17 Primmer Pump

18 Choke Lever

19 Exhaust Pipe

20 Oil Gauge

21 Flexible Pipe

22 Nylon Cutting Head

9

Page 10

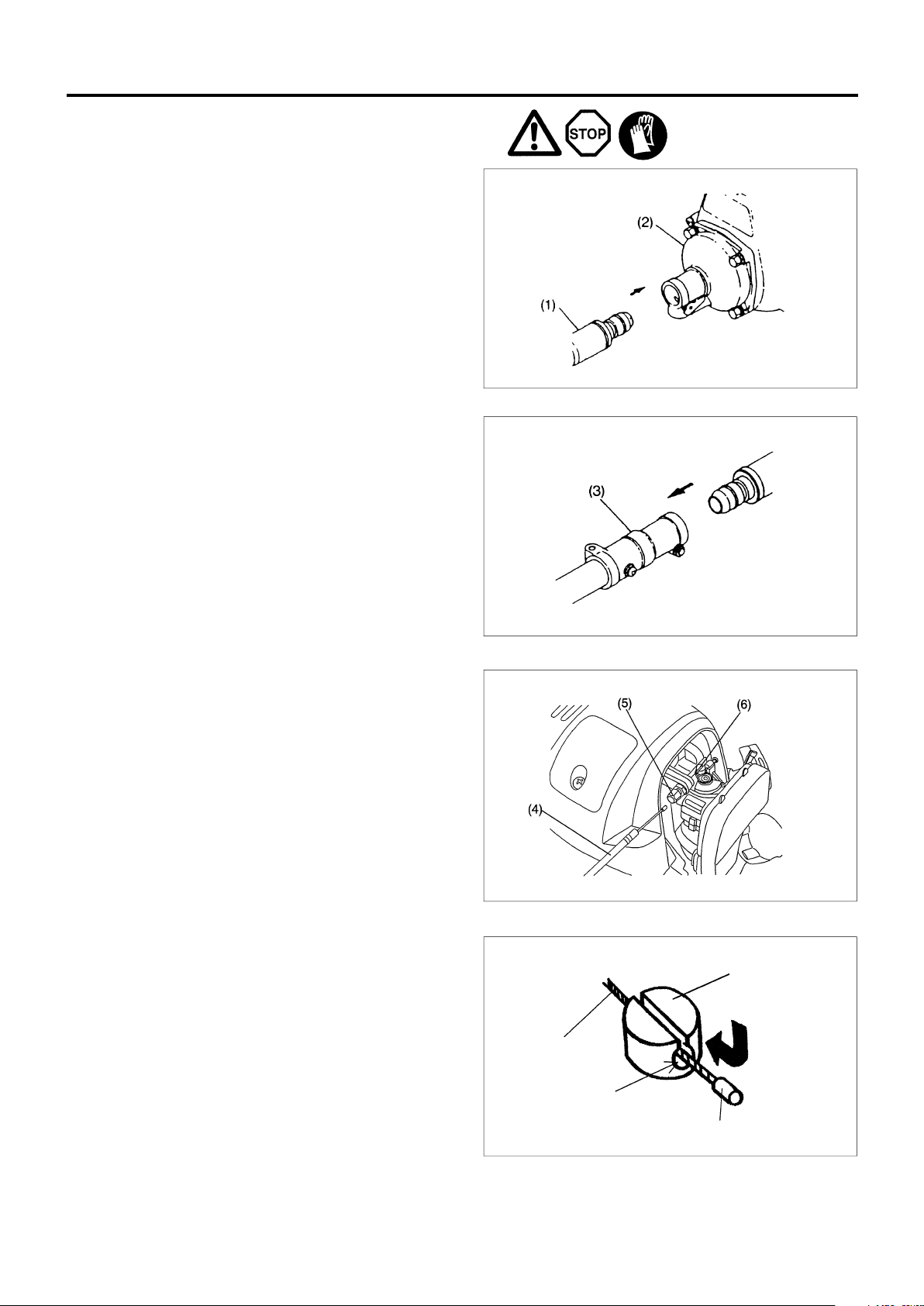

ASSEMBLY OF ENGINE AND DRIVE SHAFT

CAUTION : Before performing any work on the brush

CAUTION : Start the brush cutter only after having as-

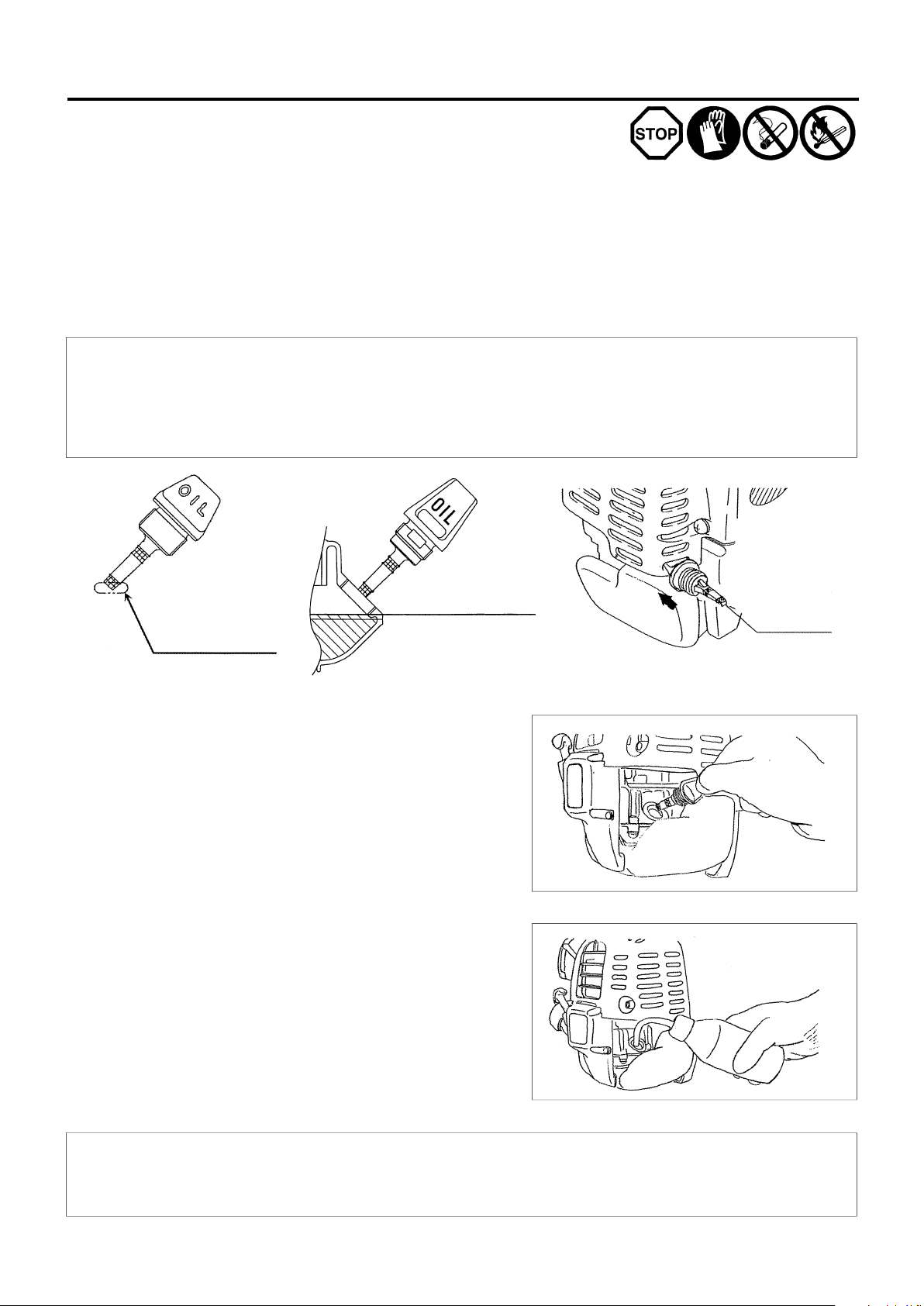

1. Joining flexible pipe with engine and pipe case holder

Insert on end of a flexible pipe (1) into a clutch housing (2) on

an engine until it locks with a slight “click” noise.

Insert the other end of the flexible pipe into a pipe case (3)

holder of a brush cutter until it locks.

Each end of the flexible pipe is interchangeable.

Make sure that a squsre end of a flexible shaft fits into the joint

of a drive shaft.

CAUTION : If you have difficulty to insert the flexible pipe

cutter, always switch off the motor and pull the

spark plug connectors off the spark plug.

Beware of hot engine pars and sharp blade

edges.

Always wear protective gloves!

sembled it completely.

properly, the square end of the flexible shaft

may not fit the drive shaft joint. Do not force to

push to avoid damage on the flexible shaft end.

Repeat the same procedure again until flexible

shaft and pipe fit properly.

2. Mounting of control cable

– Remove the air cleaner cover.

– Place the control cable (4) in the adjusting bolt (5), and shift the

swivel (6) so that the cable will be put in the swivel groove. At

this time, the round-hole side of the swivel will be oriented

toward the inner wire end-metal fitting.

– Release the swivel, and confirm that the inner wire-end metal

fitting will be placed in the hole.

– Mount the air cleaner cover.

Swivel

Control cable

Insert

Round-hole

End fitting

10

Page 11

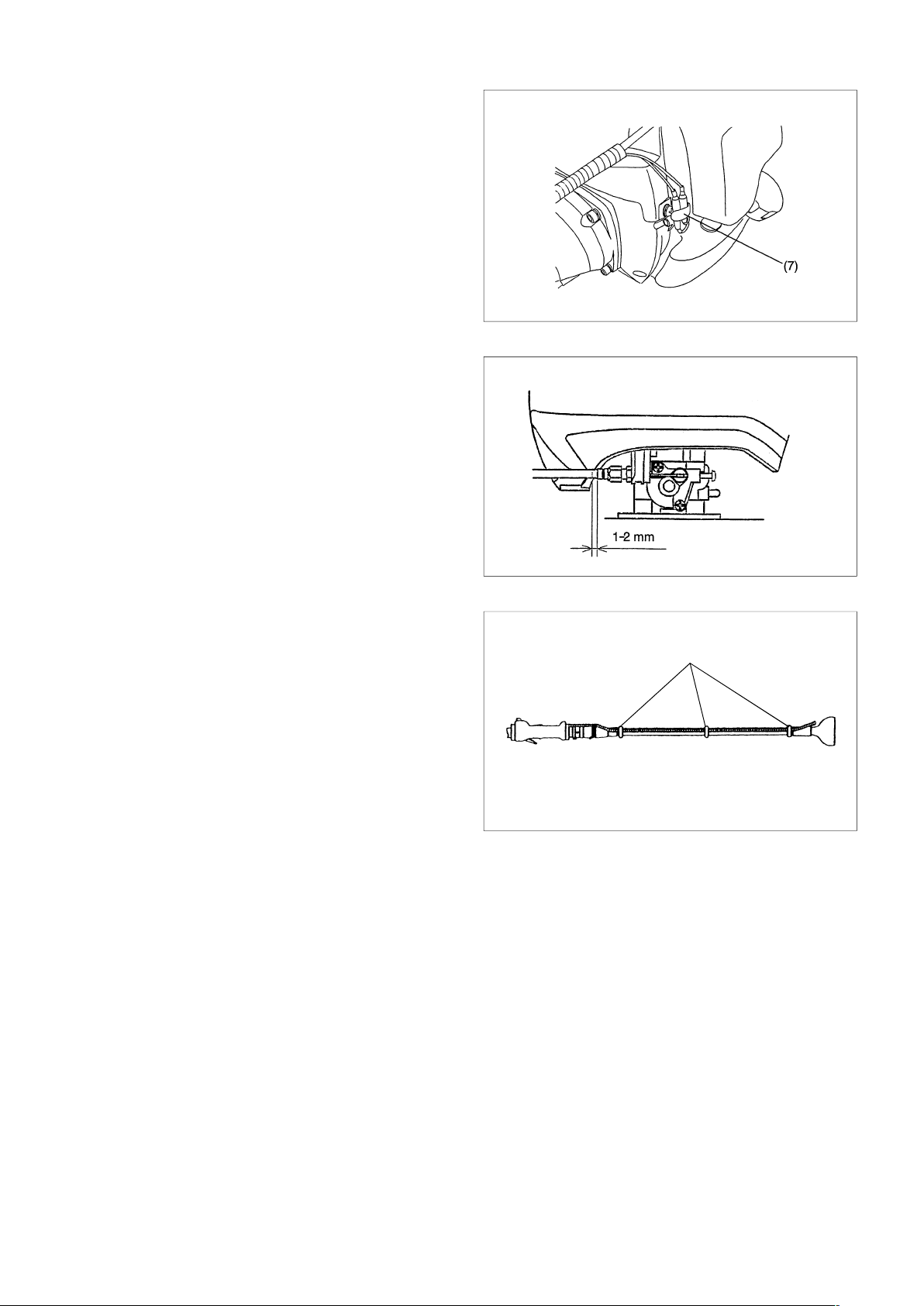

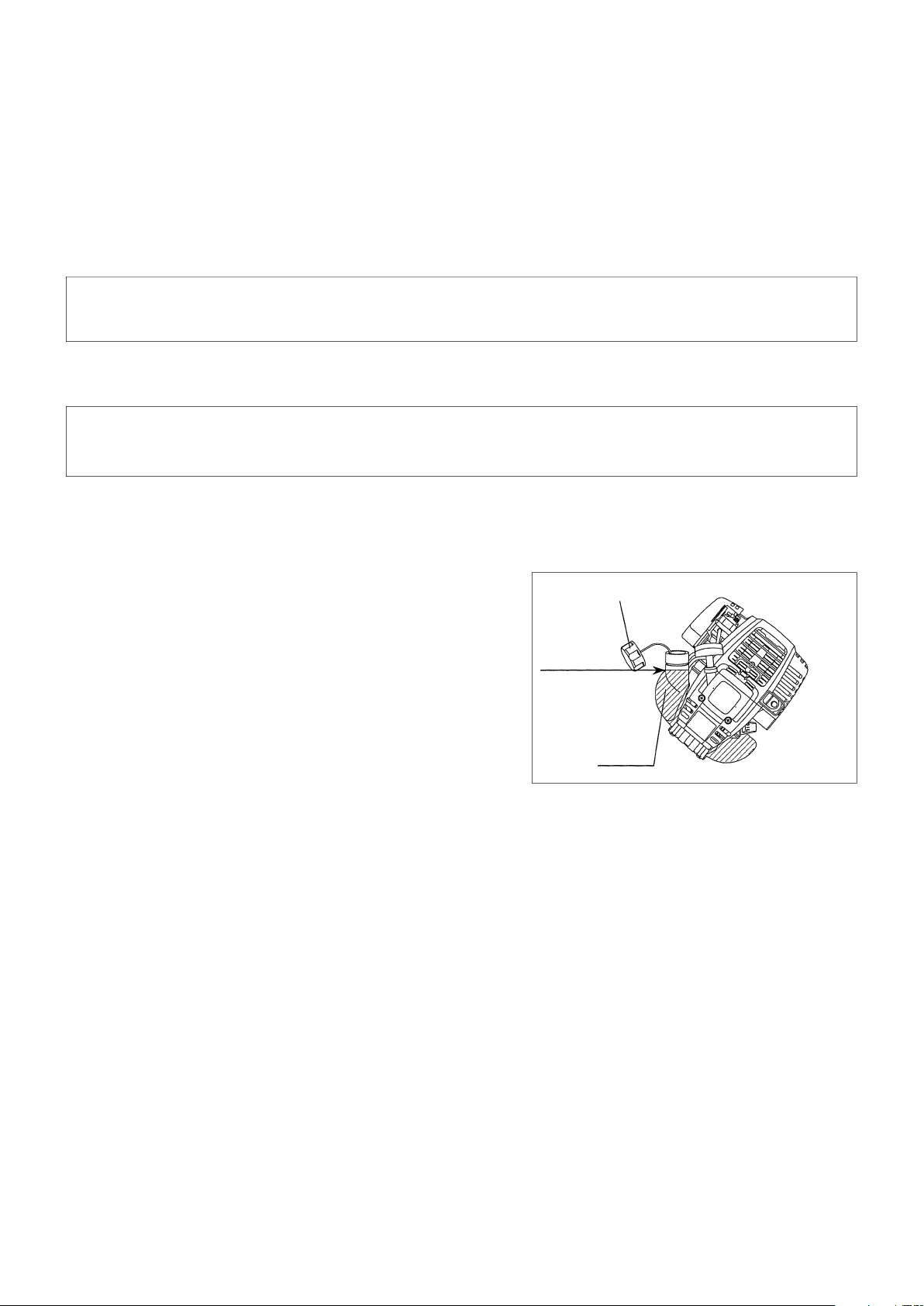

CONNECTION OF SWITCH CORD

– Connect the switch cords to the two cords from the engine by

inserting one into the other.

– Fix the cord connector by clamp (7).

ADJUSTMENT OF CONTROL CABLE

– Adjust the control cable by adjusting bolt so that it will have 1 to

2 mm play when the throttle lever is set to the low-speed

position by carburetor adjusting bolt. (Be careful that the cutter

blade will not turn in idling.)

Make the throttle wire and I-O switch cords go along the flexible

pipe and fix three point them on clip wire (8) tightly. If you do not

fix the throttle wire and I-O switch cords surely, there is fear that

they catch on the branch and so on it is dangerous.

11

Page 12

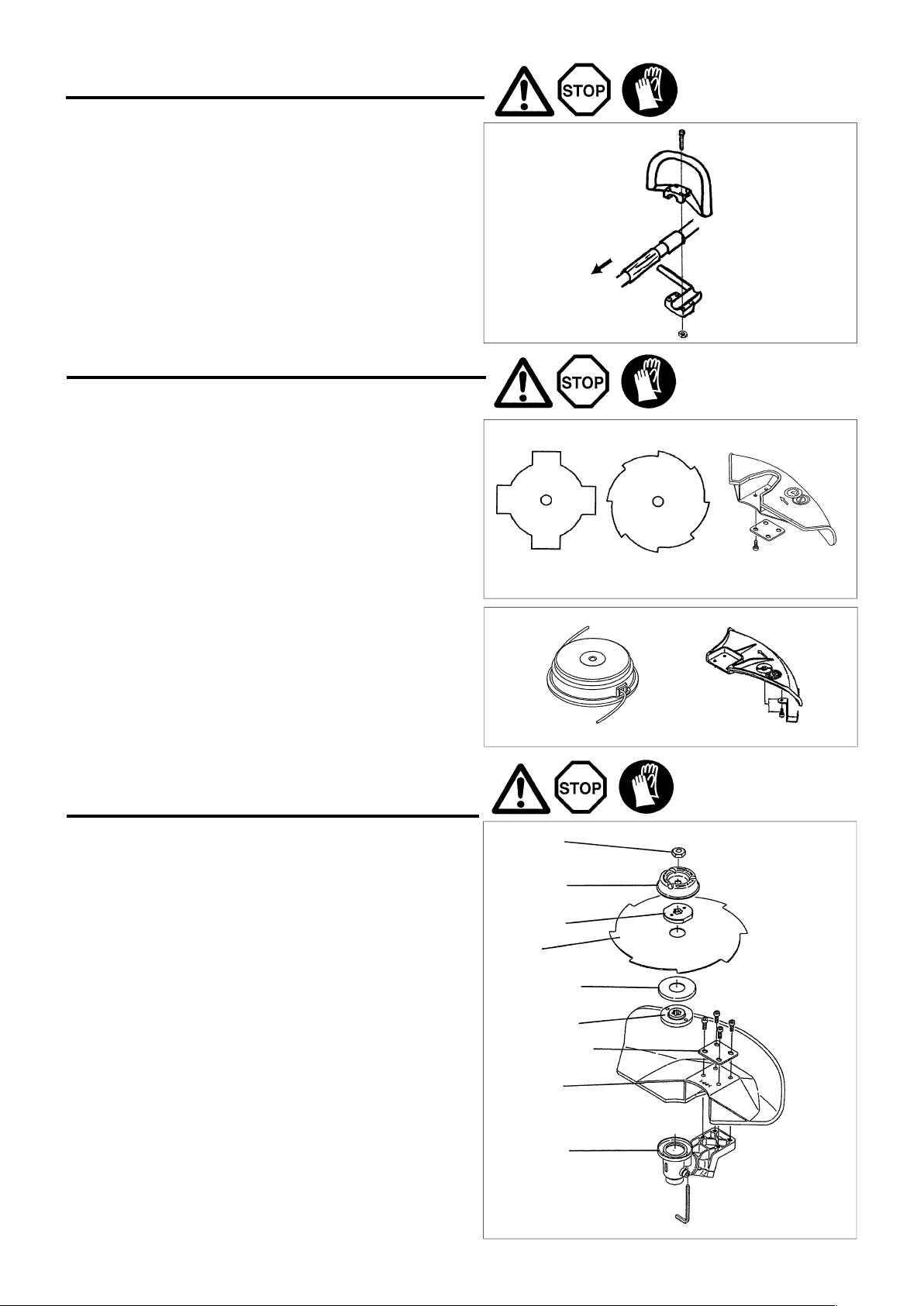

MOUNTING OF HANDLE

– Fix a barrier to the left side of the machine together with the

handle for operator’s protection.

– Do not adjust position of the loop handle too close to the control

grip. Keep not less than 25cm distance between the handle

and the grip.

(a distance collar is provided for this purpose.)

MOUNTING OF PROTECTOR

To meet the applicable safety provisions, only the tool/protector

combinations as indicated in the table must be used. Failure to do

so may result in serious injury or death to user or bystanders.

Be sure to use genuine MAKITA cutter blade or nylon

cutting head.

– The cutter blade must be well clean, sharp and free of cracks

or breakage.

If the cutter blade contacts any hard objects or stones during

operation, stop the engine and check the blade immediately.

– Clean and sharpen or replace the cutter blade at least every

three hours of operation.

– The outside diameter of the cutter blade must not exceed 255

mm (10-1/32”). Never use any blades surpassing 255 mm (10-

1/32”) in outside diameter.

CAUTION : The appropriate guard must always be in-

stalled, for your own safety and in order to

comply with accident-prevention regulations.

Operation of the equipment without the

protector being properly in place must never

be attempted.

– Fix protector to a gear case by 4 bolts firmly

Never use a blush cutter without a protector or with a broken

protector.

to engine

Star Blade

PART NO.

6418501400

Nylon cutting head

PART NO.6348003000 PART NO.174345800

Eddy Blade

PART NO.

6418501900

Protector for metal

blades

PART NO.

6118502000

MOUNTING OF CUTTER BLADE OR

NYLON CUTTING HEAD

Turn the machine upside down, and you can replace the cutter

blade or nylon cutting head easily.

Mounting of cutter blade

– Fit a cutting blade and other parts in the order as in the illustra-

tion. Thrust a bar or allen wrench into a hole of the gear case

until the cutting blade is locked and will not turn. Tighten a nut

by turning to counter-clockwise with a combination wrench.

(Note that the nut is tightened or loosened in the opposit

direction of a usual nut.)

– The nut must be re-tightened every time before use.

– For this brush cutter, we recommend the cutting attachments on

the right.

– Never attempt to cut a tree, a log, wood or other hard materials.

[Tightening torque: 28 – 48 N

NOTE : Always wear gloves when handling the cutter

blade.

Mounting of nylon cutting head

– The blade cap, bolt cover and nut are not necessary for

mounting the nylon cutting head. The nylon cutting head should

go on top of the grass cover.

– Insert the allen wrench through the hole in the gear case and

rotate the blade holder until it is locked with the alln wrench.

– Then screw the nylon cutting head onto the shaft by turning it

counter-clockwise.

– Remove the allen wrench.

m]

Nut

Bolt cover

Blade cap

Blade

Grass cover

Blade holder

Protector plate

Protector

Gear case

12

Page 13

BEFORE START OF OPERATION

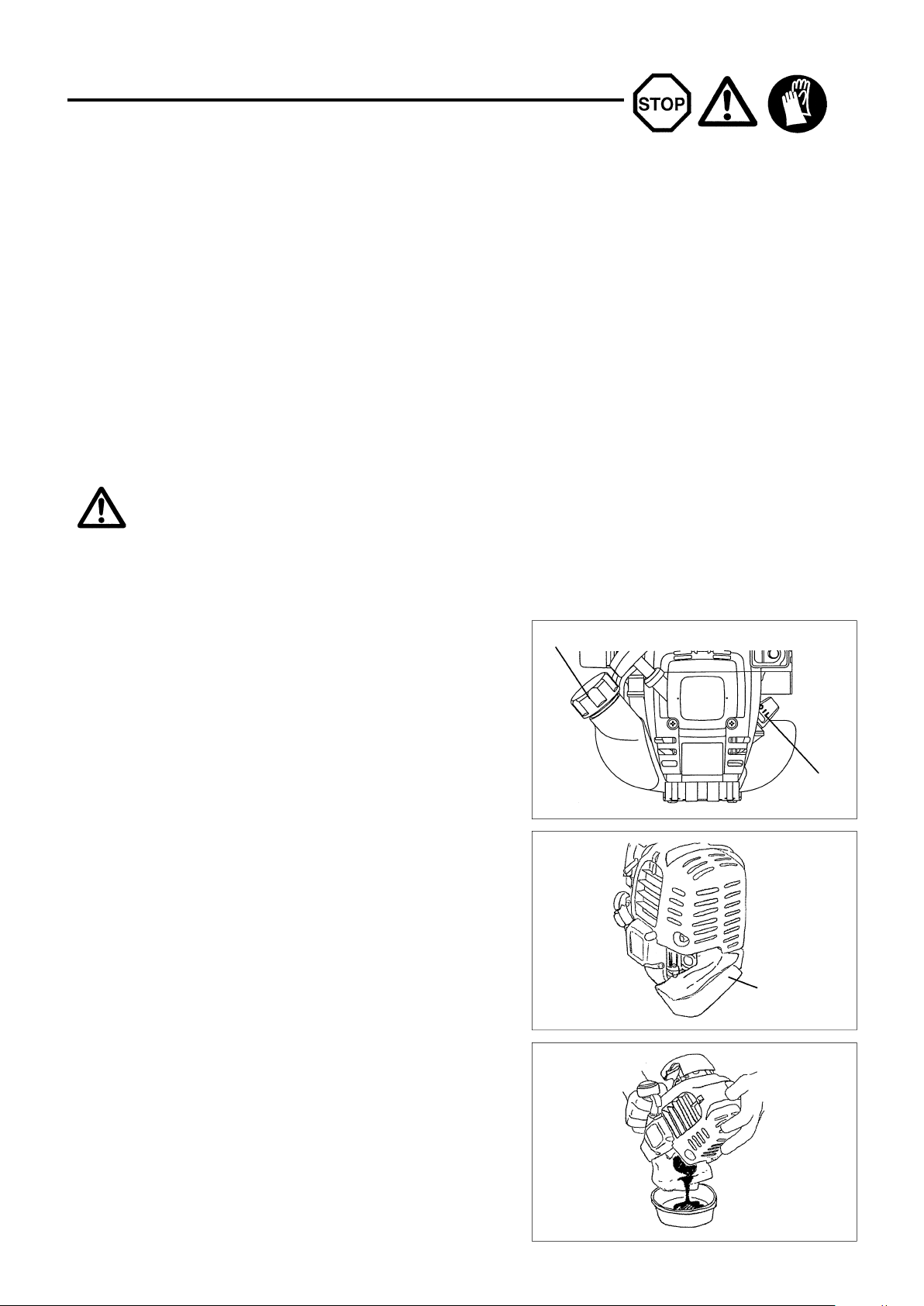

Inspection and Refill of Engine Oil

– Perform the following procedure, with the engine cooled down.

– While keeping the engine level, remove the oil gauge, and confirm that the oil is filled within the upper and lower limit marks.

When the oil is in short in such a way that the oil gauge touches the oil only by its tip, in particular with the oil gauge remaining inserted in the

crankcase without screwing-in (Fig. 1), refill new oil near the port (Fig. 2).

– For reference, the oil refill time is about 15 h (refill frequency: 15 times).

– If the oil changes in color or mixes with dirt, replace it with new one. (For the interval and method of replacement, refer to P. 1 7)

Recommended oil: SAE 10W-30 oil of API Classification, Class SF or higher (4-stroke engine for automobile)

Oil volume: Approx. 0.1 L

Note: If the engine is not kept upright, oil may go into around the engine, and may be refilled excessively.

If the oil is filled above the limit, the oil may be contaminated or may catch fire with white.

Point 1 in Replacement of Oil "Oil Gauge"

– Remove dust or dirt near the oil refill port, and detach the oil gauge.

– Keep the detached oil gauge free of sand or dust. Otherwise, any sand or dust adhering to the oil gauge may cause irregular oil

circulation or wear on the engine parts, which will result in troubles.

– As an example to keep the oil gauge clean, it is recommended to insert the oil gauge on its knob side into the engine cover, as shown in

Fig.3.

Upper limit of oil level

(Lower part of oil refill port

threaded part)

If oil adheres around

this tip refill new oil.

Fig.1

(1) Keep the engine level, and detach the oil gauge.

(2) Fill oil up to the edge of the oil refill port. (Refer to Fig.2 of the preceding

page).

Feed oil with the lubricant refill container.

Fig.2

Oil gauge

Fig.3

(3) Securely tighten the oil gauge. Insufficient tightening may cause oil leakage.

Point 2 in Replacement of Oil: “If oil spills out”

– If oil spills out between the fuel tank and engine main unit, the oil is sucked into through the cooling air intake port, which will contaminate

the engine. Be sure to wipe out spilt oil before start of operation.

13

Page 14

REFUELING

Handling of Fuel

It is necessary to handle fuel with utmost care. Fuel may contain substances similar to solvents. Refueling must be performed in a sufficiently

ventilated room or in the open air. Never inhale fuel vapor, and keep fuel away from you. If you touch fuel repeatedly or for a long time, the skin

becomes dry, which may cause skin disease or allergy. If fuel enters into the eye, clean the eye with fresh water. If your eye remains still irritated,

consult your doctor.

Storage Period of Fuel

Fuel should be used up within a period of 4 weeks, even if it is kept in a special container in a well-ventilated shade.

If a special container is not used or if the container is not covered, fuel may deteriorate in one day.

STORAGE OF MACHINE AND REFILL TANK

– Keep the machine and tank at a cool place free from direct sunshine.

– Never keep the fuel in the cabin or trunk.

Fuel

The engine is a four-stroke engine. Be sure to use an automobile gasoline (regular gasoline or premium gasoline).

Points for Fuel

– Never use a gasoline mixture which contains engine oil. Otherwise, it will cause excessive carbon accumulation or mechanical troubles.

– Use of deteriorated oil will cause irregular startup.

Refueling

WARNING: INFLAMMABLES STRICTLY PROHIBITED

Gasoline Usedl: Automobile gasoline (unleaded gasoline)

– Loosen the tank cap a little so that there will be no difference in atmospheric

pressure.

– Detach the tank cap, and refuel, discharging air by tilting the fuel tank so that

the refuel port will be oriented upward. (Never refill fuel full to the oil refill

port.)

– Wipe well the periphery of the tank cap to prevent foreign matter from

entering into the fuel tank.

– After refueling, securely tighten the tank cap.

• If there is any flaw or damage on the tank cap, replace it.

• The tank cap is consumable, and therefore should be renewed every two to

three years.

Fuel tank cap

Fuel upper limit

Fuel tank

14

Page 15

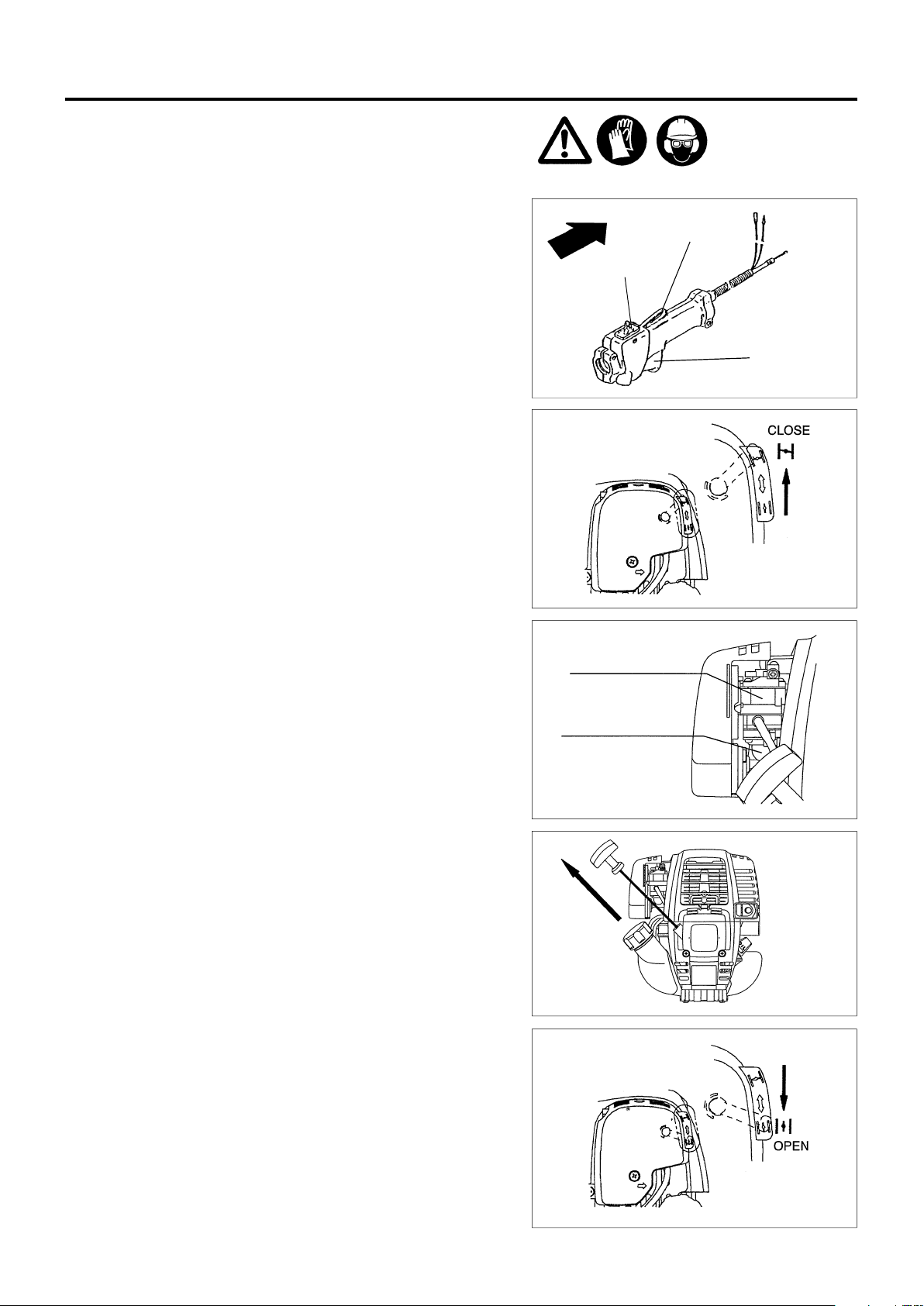

POINTS IN OPERATION AND HOW TO STOP

Observe all applicable accident prevention regulations!

STARTING

Move at least 3m away from the place of refuelling. Place the brush cutter on a clean piece of ground taking care that the cutting tool does

not come into contact with the ground or any other objects.

OPERATION

Lock-off lever

A:Cold start

1) Set this machine on a flat space.

2) Set the I-O switch (1) to OPERATION.

3) Choke lever

Close the choke lever.

Choke opening:

– Full closing in cold or when the engine is cold.

– Full or half opening in restart just after stop of operation.

I-O switch (1)

Throttle lever(6)

4) Primer pump

Continue to push the primer pump until fuel enters into the primer pump. (In

general, fuel enters into the primer pump by 7 to 10 pushes.)

If the primer pump is pushed excessively, an excess of gasoline returns to

the fuel tank.

5) Recoil starter

– Pull the start knob gently until it is hard to pull (compression point). Then,

return the start knob, and pull it strongly.

– Never pull the rope to the full. Once the start knob is pulled, never

release your hand immediately. Hold the start knob until it returns to its

original point.

6) Choke lever

When the engine starts, open the choke lever.

– Open the choke lever progressively while checking the engine operation.

Be sure to open the choke lever to the full in the end.

– In cold or when the engine is cooled down, never open the choke lever

suddenly. Otherwise, the engine may stop.

Caburettor

Primer Pump

7) Warm-up operation

Continue warm-up operation for 2 to 3 minutes.

15

Page 16

Note: – If the starter handle is pulled repeatedly when the choke lever remains at "CLOSE" position, the engine will not start easily due to

excessive fuel intake.

– In case of excessive fuel intake, remove the spark plug and pull the starter handle slowly to remove excess fuel. Also, dry the

electrode section of the spark plug.

Caution during operation:

If the throttle lever is opened fully in a no-load operation, the engine rotation is increased to 10,000rpm or more. Never operate the engine at

a higher speed than required and at an approximate speed of 6,000 - 8,500rpm.

B: Startup after warm-up operation

1) Push the primer pump repeatedly.

2) Keep the throttle lever at the idling position.

3) Pull the recoil starter strongly.

4) If it is difficult to start the engine, open the throttle by about 1/3.

Pay attention to the cutter blade which may rotate.

Attention in Operation

When the engine is operated upside down, white smoke may come out from the muffler.

STOPPING

1) Release the throttle lever (6) fully, and when the engine rpm has lowered,

set the I-O switch to STOP the engine will now stop.

2) Be aware that the cutting head may not stop immediately and allow it to

slow down fully.

STOP

I-O switch (1)

ADJUSTMENT OF LOW-SPEED ROTATION (IDLING)

When it is necessary to adjust the low-speed rotation (idling), perform it by the carburetor adjusting screw.

CHECKUP OF LOW-SPEED ROTATION

– Set the low-speed rotation to 3000min-1.

If it is necessary to change the rotation speed, regulate the adjusting screw

(illustrated on the left), with Phillips screwdriver.

– Turn the adjusting screw to the right, and the engine rotation will increase.

Turn the adjusting screw to the left, and the engine rotation will drop.

– The carburetor is generally adjusted before shipment. If it is necessary to

readjust it, please contact Authorized Service Agent.

Adjusting screw

Carburetor

RESHARPNING THE CUTTER BLADE

CAUTION : The cutter blade mentioned below must only be

resharpened by an authorized facility. Manual

resharpening will result in imbalances of the cutting

tool causing potentially dangerous vibrations and

damage to the equipment.

Throttle lever (6)

– Cutter blade (Star blade (4 teeth), Eddy blade (8 teeth))

An expert resharpening and balancing service is provided by

Authorized Service Agents.

NOTE : To increase the service life of the cutter blade (star blade,

eddy blade) it may be turned over once, until both cutting

edges have become dull. Never continue to use a dull

blade or kickback and serious injury may result.

16

Page 17

SERVICING INSTRUCTIONS

CAUTION : Before doing any work on the brush cutter, always stop the engine and pull the plug cap off the spark plug (see "checking the spark plug").

To ensure a long service life and to avoid any damage to the equipment, the following servicing operations should be performed at regular intervals.

Always wear protective gloves!

Daily checkup and maintenance

– Before operation, check the machine for loose screws or missing parts. Pay particular attention to the tightness of the cutter blade or

nylon cutting head.

– Before operation, always check for clogging of the cooling air passage and the cylinder fins.

Clean them if necessary.

– Perform the following work daily after use:

• Clean the brush cutter externally and inspect for damage.

• Clean the air filter. When working under extremely dusty conditions, clean the filter the severall times a day.

• Check the blade or the nylon cutting head for damage and make sure it is firmly mounted.

• Check that there is sufficient difference between idling and engagement speed to ensure that the cutting tool is at a standstill while the

engine is idling (if necessary reduce idling speed).

If under idling conditions the tool should still continue to run, consult your nearest Authorized Service Agent.

– Check the functioning of the I-O switch, the lock-off lever, the control lever, and the look button.

REPLACEMENT OF ENGINE OIL

Deteriorated engine oil will shorten the life of the sliding and rotating parts to a great extent. Be sure to check the period and quantity of replacement.

ATTENTION: In general, the engine main unit and engine oil still remain hot just after the engine is stopped. In replacement of oil,

Note: If the oil filled above the limit, it may be contaminated or may catch fire with white smoke.

Interval of replacement: Initially, every 20 operating hours, and subsequently every 50 operating hours

Recommended oil: SAE10W-30 oil of API Classification SF Class or higher (4-stroke engine oil for automobile)

In replacement, perform the following procedure.

1) Confirm that the tank cap is tightened securely.

2) Detach the oil gauge.

Keep the oil gauge free from dust or dirt.

confirm that the engine main unit and engine oil are sufficiently cooled down. Otherwise, there may remain a risk of scald.

Fuel tank cap

3) Place waste or paper near the oil refill port.

4) Detach the oil gauge, and drain oil, tilting the main unit toward the oil refill

port

Drain oil in a container.

Oil gauge

Waste or paper

17

Page 18

5) Keep the engine level, and feed new oil up to the edge of the oil refill port.

In refill, use a lubricant refill container.

6) After refill, securely tighten the oil gauge. Insufficient tightening of the oil

gauge will lead to oil leakage.

POINTS ON OIL

– Never discard replaced engine oil in garbage, earth or sewage ditch. Disposal of oil is regulated by law. In disposal, always follow the

relevant laws and regulations. For any points remaining unknown, contact Authorized Service Agent.

– Oil will deteriorate even when it is kept unused. Perform inspection and replacement at regular intervals (replace with new oil every 6

months).

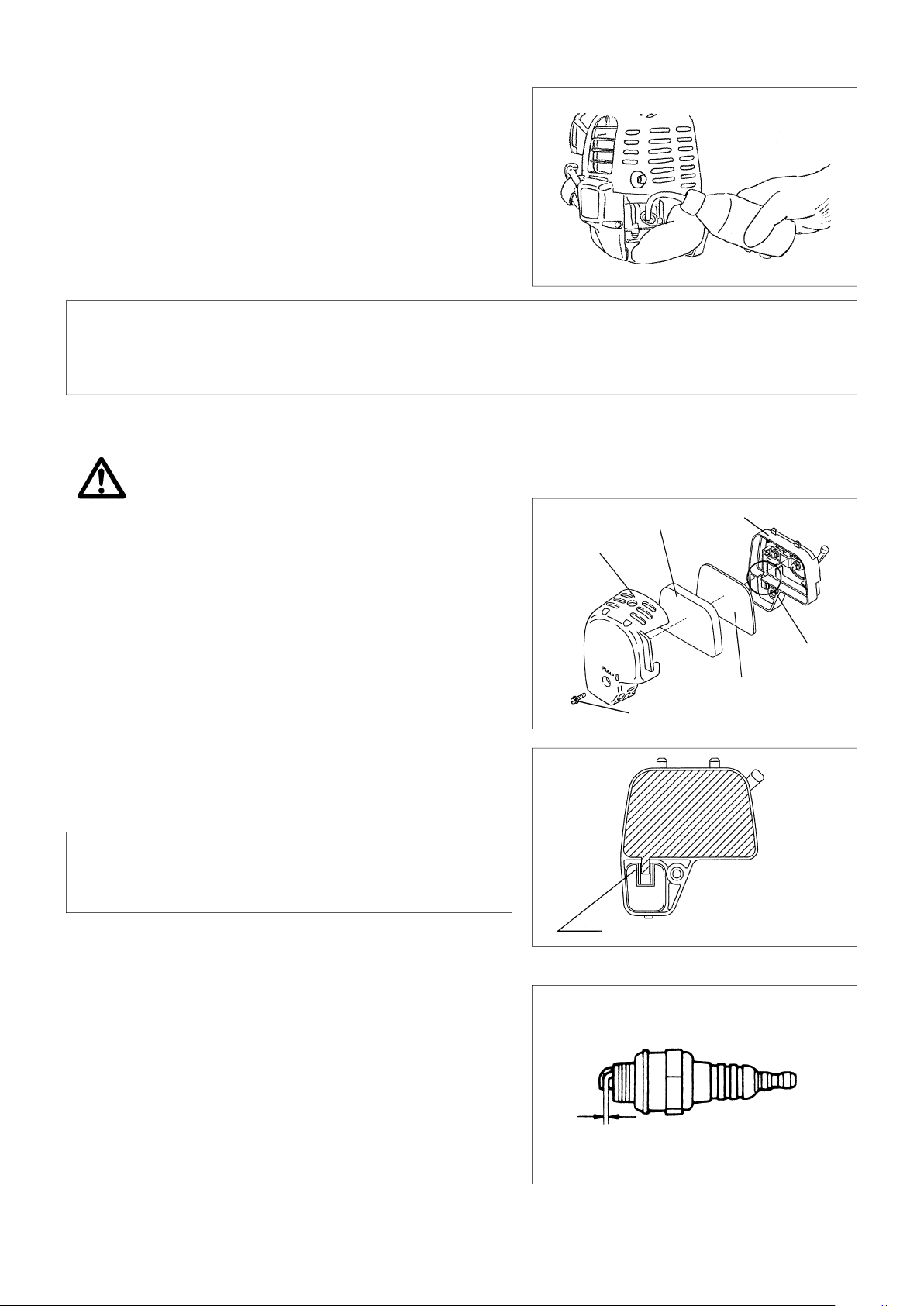

CLEANING OF AIR CLEANER

DANGER: INFLAMMABLES STRICTLY PROHIBITED

Interval of Cleaning and Inspection: Daily (every 10 operating hours)

– Turn the choke lever to the full close side, and keep the carburetor off

from dust or dirt.

– Remove the air cleaner cover-fixing bolts.

– Pull the cover lower side and detach the air cleaner cover.

– If oil adheres to the element (sponge), squeeze it firmly.

– For heavy contamination:

1) Remove the element (sponge), immerse it in warm water or in waterdiluted neutral detergent, and dry it completely.

2) Clean the element (felt) with gasoline, and dry it completely.

– Before attaching the element, be sure to dry it completely. Insufficient

drying of the element may lead to difficult startup.

– Wipe out with waste cloth, oil adhering around the air cleaner cover and

plate breather.

– Immediately after cleaning is finished, attach the cleaner cover and

tighten it with fixing bolts. (In remounting, first place the upper claw, and

then the lower claw.)

Points in Handling Air Cleaner Element

– Clean the element several times a day, if excessive dust adheres to it.

– If operation continues with the element remaining not cleared of oil, oil in

the air cleaner may fall outside, resulting in oil contamination.

Element (sponge)

Air cleaner cover

Fixing bolt

Pick this part and remove the element (felt).

Plate

Breather Part

Element (felt)

CHECKING THE SPARK PLUG

– Only use the supplied universal wrench to remove or to install the spark plug.

– The gap between the two electrodes of the spark plug should be 0.7-0.8mm

(0.028"-0.032"). If the gap is too wide or too narrow, adjust it. If the spark

plug is clogged with carton or fouled, clean it thoroubhly or replace it.

CAUTION : Never touch the spark plug connector while the engine is running

(danger of high voltage electric shock).

18

0.7 mm - 0.8 mm

(0.028”-0.032”)

Page 19

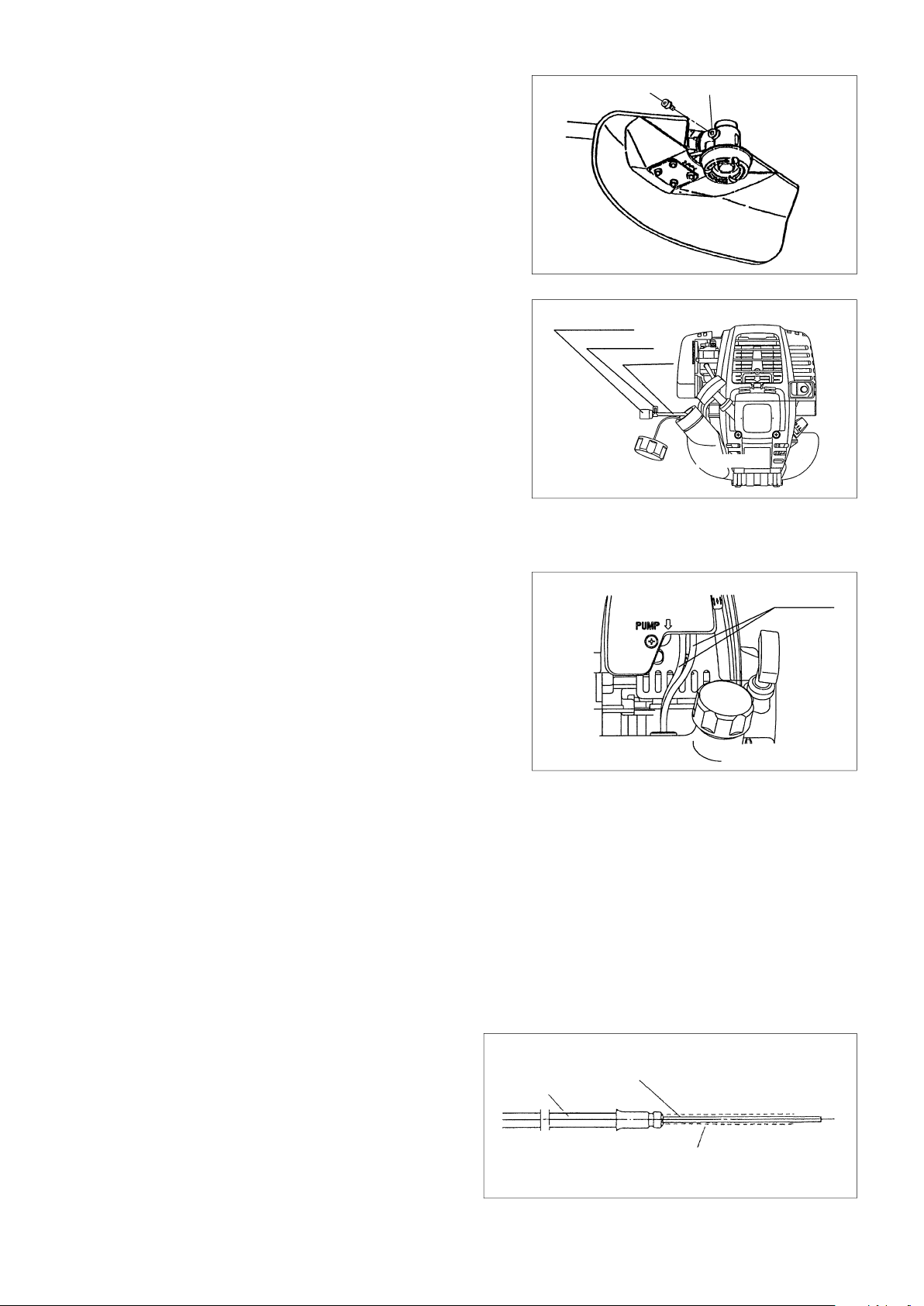

SUPPLY OF GREASE TO GEAR CASE

– Supply grease (Shell Alvania 2 or equivalent) to the gear case through the

grease hole every 30 hours. (Genuine MAKITA grease may be purchased

from your MAKITA dealer.)

Grease hole

CLEANING OF FUEL FILTER

WARNING: INFLAMMABLES STRICTLY PROHIBITED

Interval of Cleaning and Inspection: Monthly (every 50 operating hours)

Suction head in the fuel tank

– The fuel filler (1) of the suction head is used to filler the fuel required by the

carburetor.

– A periodical visual inspection of the fuel filter is to be conducted. For that

purpose open the tank cap, use a wire hook and pull out the suction head

through the tank opening. Filters found to have hardened, been polluted or

clogged up are to be replaced.

– Insufficient fuel supply can result in the admissible maximum speed being

exceeded. It is therefore important to replace the fuel filter at least quarterly to

ensure satisfactory fuel supply to the carburetor.

REPLACEMENT OF FUEL PIPE

CAUTION: INFLAMMABLES STRICTLY PROHIBITED

Interval of Cleaning and Inspection: Daily (every 10 operating hours)

Replacement: Annually (every 200 operating hours)

Replace the fuel pipe every year, regardless of operating frequency. Fuel leakage

may lead to fire.

If any leakage is detected during inspection, replace the oil pipe immediately.

INSPECTION OF BOLTS, NUTS AND SCREWS

– Retighten loose bolts, nuts, etc.

– Check for fuel and oil leakage.

– Replace damaged parts with new ones for safety operation.

Fuel filter (1)

Hose clamp

Fuel pipe

Fuel pipe

CLEANING OF PARTS

– Keep the engine always clean.

– Keep the cylinder fins free of dust or dirt. Dust or dirt adhering to the fins will cause seizure.

REPLACEMENT OF GASKETS AND PACKINGS

In reassembling after the engine is dismounted, be sure to replace the gaskets and packings with new ones.

SUPPLY OF GREASE TO THE FLEXIBLE SHAFT

- Pull out the flexible shaft from the flexible lining for every 20 hours,

and apply grease on the flexible shaft.

- The flxible shaft may be broken if no grease is applied.

Flexible liner

Any maintenance of adjustment work that is not been included and described in this manual is only to be performed by Authorized Service

Agents.

Flexible shaft

Apply grease

19

Page 20

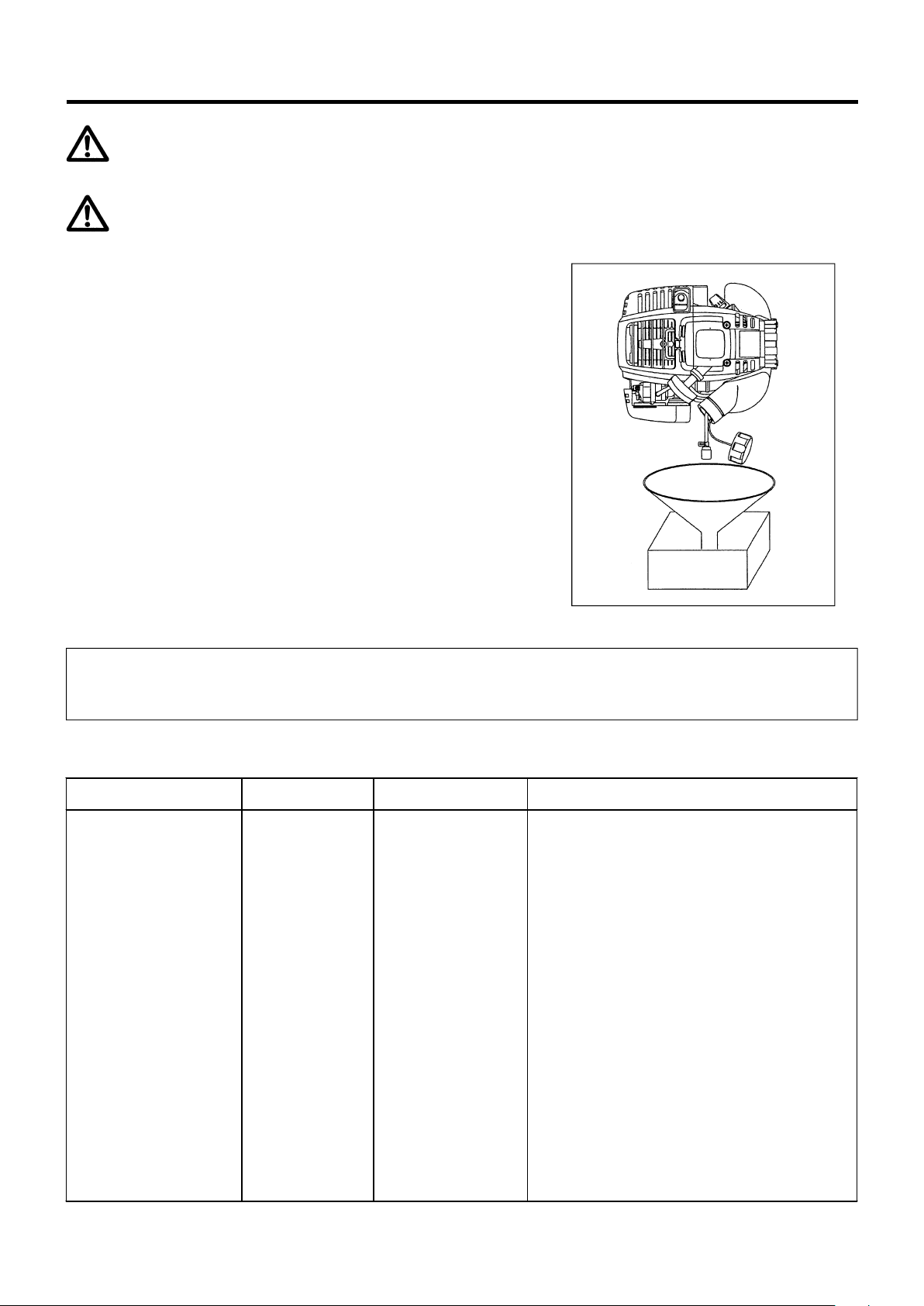

STORAGE

WARNING: When draining the fuel, be sure to stop the engine and confirm that the engine cools

down.

Just after stopping the engine, it may still hot with possibility of burns, inflammability and fire.

ATTENTION: When the machine is kept out of operation for a long time, drain up all fuel from the

fuel tank and carburetor, and keep it at a dry and clean place.

– Drain up fuel from the fuel tank and carburetor according to the following

procedure:

1) Remove the fuel tank cap, and drain fuel completely.

If there is any foreign matter remaining in the fuel tank, remove it

completely.

2) Pull out the fuel filter from the refill port using a wire.

3) Push the primer pump until fuel is drained from there, and drain fuel

coming into the fuel tank.

4) Reset the filter to the fuel tank, and securely tighten the fuel tank cap.

5) Then, continue to operate the engine until it stops.

– Remove the spark plug, and drip several drops of engine oil through the

spark plug hole.

– Gently pull the starter handle so that engine oil will spread over the engine,

and attach the spark plug.

– Attach the cover to the cutter blade.

– During storage, keep the rod horizontal or keep the machine upright with the

blade edge oriented upward. (In this case, pay full attention to prevent the

machine from falling.)

Never store the machine with the cutter blade edge oriented downward.

Lubricating oil may spill out.

– Keep the drained fuel in a special container in a well-ventilated shade.

Attention after long-time storage

– Before startup after long-time shutdown, be sure to replace oil (refer to P 17). Oil will deteriorate while the machine is kept out of

operation.

Fault location

Fault System Observation Cause

Engine not starting or with

difficulty

No ignition spark

Fuel supply Fuel tank filled

Compression

Mechanical fault Starter not engaging Broken starter spring, broken parts inside of the engine

Warm start problems

Engine starts but dies Fuel supply Tank filled Incorrect idling adjustment, carburetor contaminated

Ignition system Ignition spark O.K.

No compression when

pulled over

Tank filled ignition spark

existing

Fault in fuel supply or compression system, mechanical

defect

STOP-switch operated, wiring fault or short circuit, spark

plug or connector defective, ignition module faulty

Incorrect choke position, carburetor defective, fuel supply

line bent or blocked, fuel dirty.

Cylinder bottom gasket defective, crankshaft seals

damaged, cylinder or piston rings defective or improper

sealing of spark plug

Carburetor contaminated, have it cleaned

Fuel tank vent defective, fuel supply line interrupted,

cable or STOP-switch faulty

Insufficient performance

Several systems

may simultaneously

be affected

Engine idling poor

20

Air filter contaminated, carburetor contaminated, muffler

clogged, exhaust duct in the cylinder clogged

Page 21

Operating time

Item

Engine oil

Tightening parts

(bolt, nut)

Fuel tank

Inspect/clean

Before

operation

٤

Replace

Inspect

Clean/inspect

٤

٤

After

lubrication

Daily

(10h)

30h 50h 200h

Shutdown

/rest

13

*1

٤

17

19

Drain fuel

Corres-po

nding P

*3

٤

20

Throttle lever Check function

Stop switch Check function

Cutting blade Inspect

٤

٤ 12

Low-speed rotation Inspect/adjust

Air cleaner Clean

Ignition plug Inspect

Cooling air duct Clean/inspect

٤

15

٤

15

٤

16

٤

18

٤

18

٤

19

Inspect ٤ 19

Fuel pipe

Replace

Gear-case grease Refill

٤

19

*2

٧

Fuel filter Clean/replace ٤ 19

*2

Oil tube Inspect

Clearance between air intake

valve and air discharge valve

Adjust

Engine overhaul

٧

*2

٧

*2

٧

Carburetor Drain fuel

*3

٤

20

*1 Perform initial replacement after 20h operation.

*2 For the 200 operating hour inspection, request Authorized Service Agent or a machine shop.

*3 After emptying the fuel tank, continue to run the engine and drain fuel in the carburetor.

21

Page 22

TROUBLESHOOTING

Before making a request for repairs, check a trouble for yourself. If any abnormality is found, control your machine according to the description of

this manual. Never tamper or dismount any part contrary to the description. For repairs, contact Authorized Service Agent or local dealership.

State of abnormality Probable cause (malfunction) Remedy

Failure to operate primer pump Push 7 to 10 times.

Low pulling speed of starter rope Pull strongly.

Lack of fuel Feed fuel.

Clogged fuel filter Clean

Broken fuel tube Straighten fuel tube

Engine does not start

Engine stops soon

Engine speed does not increase

Cutter blade does not rotate

Stop engine immediately㩷

Deteriorated fuel

Excessive suction of fuel

Detached plug cap Attach securely

Contaminated spark plug Clean

Abnormal clearance of spark plug Adjust clearance

Other abnormality of spark plug Replace

Abnormal carburetor Make request for inspection and maintenance.

Starter rope cannot be pulled Make request for inspection and maintenance

Abnormal drive system Make request for inspection and maintenance

Insufficient warm-up Perform warm-up operation

Choke lever is set to “CLOSE” although engine

is warmed up

Clogged fuel filter Clean

Contaminated or clogged air cleaner Clean

Abnormal carburetor Make request for inspection and maintenance

Abnormal drive system Make request for inspection and maintenance

Loosened cutter blade-tightening nut Tighten securely

Twigs caught by cutter blade or

dispersion-preventing cover

Abnormal drive system Make request for inspection and maintenance.

Deteriorated fuel makes starting more difficult.

Replace with new one. (Recommended

replacement: 1 month)

Set throttle lever from medium speed to high

speed, and pull starter handle until engine

starts. Once engine starts, cutter blade

starts rotating. Pay full attention to cutter

blade.

If engine will not start still, remove spark plug,

make electrode dry, and reassemble them as

they originally are. Then, start as specified.

Set to “OPEN”

Remove foreign matter

Main unit vibrates abnormally.

Stop engine immediately㩷

Cutter blade does not stop immediately.

Stop engine immediately㩷

Engine does not stop.

Run engine at idling, and set choke

lever to CLOSE.

When the engine does not start after warm-up operation:

If there is no abnormality found for the check items, open the throttle by about 1/3 and start the engine.

㩷

Broken, bent or worn cutter blade Replace cutter blade

Loosened cutter blade-tightening nut Tighten securely

Shifted convex part of cutter blade and cutter

blade support fitting

Abnormal drive system Make request for inspection and maintenance

High idling rotation Adjust

Detached throttle wire Attach securely

Abnormal drive system Make request for inspection and maintenance

Detached connector Attach securely

Abnormal electric system Make request for inspection and maintenance.

Attach securely

22

Page 23

French

Nous vous remercions d’avoir porté votre choix sur une

débroussailleuse MAKITA. Cette débroussailleuse MAKITA est le

fruit d’un long programme de développement et de nombreuses

années d’expérience et d’accumulation de connaissances.

Lire attentivement ce manuel et suivre les instructions données. II

décrit en détail les divers points démontrant les exceptionnelles

performances de la débroussailleuse. Ceci vous permettra

d’obtenir les meilleurs résultats de cette débroussailleuse MAKITA.

Table of Contents Page

Symboles ..................................................................................... 23

Consignes de sécurité ............................................................ 24-27

Données techniques ................................................................... 29

Désignation des pièces ............................................................... 30

Montage moteur et arbre d’entrainement ................................ 31-32

Montage de la poignée ................................................................. 33

Montage du protecteur ................................................................ 33

Motage du couteau ...................................................................... 33

Avant mise en marche ............................................................ 34-35

Consignes de mise en marche et arret de la machine ............ 36-37

Aiguisage du couteau .................................................................. 37

Instructions relatives aux réparations .................................... 38-40

Remisage ................................................................................ 41-42

Guide de dépannage ................................................................... 43

SYMBOLES

La signification des symboles suivants est très importante pour la compréhension des instructions de ce manuel.

Lire attentivement ce manuel et

suivre les instructions données

Avertissement/Danger/Précoution

Interdit

Distance de sécurité

Danger de projection d’objets

Défence de fumer

Flammes vives interdites

Porter un casque de protection, des

protections visuelles et auditives

Vitesse maximale carburant et d’huile

Carburant (Essence)

Démarrage manuel du moteur

Arrêt d’urgence

Premiers secours

Recyclage

Porter des gants protecteurs

Réaction arrière

(pour la débroussailleuse uniquement)

Personnes et animaux interdits dans la

zone d’utilisation

SOUS TENSION/MA RCHE

HORS TENSION/A RRET

Logo de la CE

23

Page 24

CONSIGNES DE SÉCURITÉ

Consignes générales

– Lire attentivement ce manuel et suivre les instructions données

afin de se familiariser avec le maniement de la

d’ebroussailleuse. Ceci permettra d’utiliser correctement l’outil et

de travailler en sécurité. Un mauvais maniement de la

débroussailleuse par un utilisateur insuffisamment informé est

dangereux pour celui-ci et les personnes autour.

– Il est recommandé de ne pas prêter cette machine à des

personnes qui n’ont pas une expérience suffisante des

débroussailleuse. Toujours prêter le manuel d’instructions avec

la débroussailleuse.

– Utiliser la débroussailleuse uniquement si toutes ses protections

sont en place.

– Le premier utilisateur doit demander au revendeur de lui expliquer

le maniement de base d’une débroussailleuse à moteur.

– Les enfants et jeunes de moins de 18 ans ne doivent pas être

autorisés à utiliser la débroussailleuse. A partir de 16 ans, on

peut toutefois commencer à apprendre à I’utiliser, mais

uniquement sous la surveillance directe d’un instructeur qualifié.

– Utiliser la débroussailleuse avec les plus grandes précautions

et la plus grande attention.

– Ne pas utiliser la débroussailleuse si l’on n’est pas en parfaite

condition physique. Travailler consciencieusement et

prudemment. L’utilisateur doit être conscient de sa

responsabilité envers les autres.

– Ne jamais utiliser la débroussailleuse après avoir consommé de

l’alcoool ou pris des médicaments.

– Ne pas utiliser la débroussailleuse lorsqu’on est fatigué.

– Conserver ce manuel pour pouvoir le consulter ultérieurement.

Equipement de protection personnelle

– Les vêtements doivent être fonctionnels et adaptés. Ils doivent

être bien ajustés sans, toutefois, gêner les mouvements. Ne

pas porter de bijoux ou de vêtements qui pourraient se prendre

dans les broussailles ou les buissons. Si l’on a les cheveux

longs, les attacher.

– Afin de ne pas risquer des blessures à la tête, aux yeux,

auxmains et aux pieds ou des problèmes auditifs, porter

l’equipement et les vêtements protecteurs suivants lorsqu’on

utilise la débroussailleuse.

– Toujours porter un casque lorsqu’on travaille en forêt. Vérifier

régulièrement si le casque (1) n’est pas endommagé et le

remplacer au moins tous les 5 ans. N’utiliser qu’un casque

protecteur agréé.

– La visière (2) du casque ou des lunettes protectrices agréées

protègent les yeux et le visage contre les projections de

brindilles, pierres et autres objets. Lorsqu’on travaille avec la

débroussailleuse, toujours se protéger les yeux avec des

lunettes protectrices ou la visière du casque.

– Pour éviter des problèmes auditifs, porter un équipement

adéquat de protection contre le bruit (protège-oreilles (3),

protège-tympans, etc.), surtout en cas d’utilisation prolongée de

la débroussailleuse.

– Les combinaisons de travail (4) protègent le corps contre les

projections de pierres et les éclats de bois. Nous

recommandons vivement à l’utilisateur de porter une

combinaison de travail.

– Des gants spéciaux (5) en cuir épais font partie de I’equipement

prescrit et doivent toujours être portés pendant I’utilisation de la

débroussailleuse.

– Lors de l’utilisation de la débroussailleuse, toujours porter des

chaussures robustes (6) à semelle antidérapante. Ceci protège

contre les blessures et assure une bonne prise des pieds.

1

2

3

4

5

6

Mise en marche de la débroussailleuse

– S’assurer qu’il n’y a pas d’enfants ni d’autres personnes dans

un rayon de 50 pieds ou 15 mètres, et veiller également à ce

qu’il n’y ait pas d’animaux à proximté.

– Avant l’utilisation, toujours vérifier les points suivants

afin d’assurer la sécurité :

S’assurer que le couteau est bien fixé. Vérifier que I’écrou de

montage du couteau est serré à fond. S’assurer que la manette

des gaz est facile à manoeuvrer et que son mouvement est

régulier. S’assurer que le verrou de la manette des gaz

fonctionne correctement. Le couteau ne doit pas tourner

lorsque le moteur fonctionne au ralenti. Se reporter aux

instructions de réglage du ralenti à la page 37.

S’assurer que les poignées sont propres et sèches et vérifier le

fonctionnement de d’arrêt. Veiller à ce que de l’huile ou du

carburant ne vienne pas sur les poignées.

– Avant le travail, vérifier la réglementation locale relative au

niveau sonore et aux heures d’utilisation et la respecter.

– Ne mettre la débroussailleuse en marche que lorsqu’elle est

posée sur le sol.

– Ne pas la mettre en marche lorsqu’elle est retournée sur le dos.

24

Page 25

Mettre la débroussailleuse en marche en suivant rigoureusement

les instructions.

N’utiliser que la méthode indiquée pour mettre le moteur en marche.

– N’utiliser la débroussailleuse et les outils fournis que pour les

applications indiquées.

– Ne mettre le moteur de la débroussailleuse en marche qu’après

avoir terminé tout le montage de l’outil. L’utilisation de la

débroussailleuse n’est autorisée qu’une fois que tous les

accessoires appropriés ont été montés.

– Avant la mise en marche, s’assurer que le couteau ne viendra

pas en contact avec des objets tels que branches ou pierres.

– En cas de problème du moteur, l’arrêter immédiatement.

– Si le couteau heurte des pierres ou d’autres objets, arrêter

immédiatement le moteur et contrôler le couteau.

– Vérifier fréquemment si le couteau n’est pas endommagé.

Vérifier s’il n’est pas fêlé en donnant de petits coups sur le

couteau et en écoutant le bruit produit.

– On doit entendre un tintement familier.

– N’utiliser la débroussailleuse qu’aprés avoir attaché le harnais.

Régler correctement la longueur du hrnais avant de mettre la

débroussailleuse en marche. Pour éviter la fatigue ou une perte

de contrôle de l’outil, il est important que le harnais soit ajusté à

la taille de l’utilisateur. Ne jamais tenir la débroussailleuse d’une

seule main pendant l’utilisation.

– Pendant l’utilisation, toujours tenir la débroussailleuse des deux

mains.

Veiller à avoir toujours une bonne prise des pieds.

– Utiliser la débroussailleuse d’une manière telle que l’on ne

respire pas les gaz d’echappement. Ne jamais faire fonctionner

le moteur dans un local clos (risque d’asphyxie et d’intoxication

par les gaz). Le monoxyde de carbone est un gaz inodore.

Veiller à ce que l’aération soit toujours suffisante.

– Arrêter le moteur avant de faire une pause et de laisser la

débroussailleuse sans surveillance. Placer la débroussailleuse

dans un endroit où ils ne présentent pas de danger pour les autres

et où ils ne risquent pas d’enflammer des matières combustible ou

d’être endommagés.

– Ne jamais poser la débroussailleuse sur de l’herbe sèche ou

sur des matières combustibles.

– Le couteau doit toujours être utilisé avec le protecteur

approprié. Ne jamais utiliser le couteau sans son protecteur.

– Durant le fonctionnement, tous les protecteurs et autres pièces

de protection foumis avec la débroussailleuse doivent être

utilisés.

– Ne jamais faire fonctionner le moteur avec un pot

d’échappement défectueux.

– Arréter le moteur avant de transporter la débroussailleuse.

– Pour un long transport, toujours utiliser le protecteur d’outil foui

avec la débroussailleuse.

– Pour transporter la débroussailleuse dans une voiture ou un

camion, les placer à la verticale et les fixer de façon à éviter

tout dommage.

– Avant de transporter la débroussailleuse, s’assurer que le

réservoir est complètement vide pour éviter toute fuite de

carburant.

•Interruptions de travail

•Transport

•Plein de carburant

•Maintenance

•Remplacement d’outil

Renouvellement du carburant

– Pour éviter tout risque d’incendie et de brûlure, manipuler le

carburant avec précaution. Il est hautement inflammable.

– Avant de transporter la débroussailleuse, arrêter le moteur.

– Eviter le contact des produits pétroliers avec la peau. Ne pas

respirer les vapeurs de carburant. Toujours porter des gants

protecteurs lorsqu’on fait le plein du réservoir. A intervalls

reguliers, changer de vêtements protecteurs et les faire nettoyer.

– Veiller à ne pas souiller le sol avec du carburant ou de l’huile.

Laisser sécher les chiffons avant de les jeter. Les jeter dans un

récipient approprié muni d’un couvercle pour qu’ils ne puissent

pas s’enflammer spontanément. Toujours essuyer l’outil au sec

avant de mettre le moteur en marche.

– Veiller à ne pas renverser de carburant sur les vêtements. Si

du carburant vient sur les vêtements, se changer

immédiatement (danger de mort).

– S’assurer régulièrement que le bouchon du réservoir est serré à fond.

– Serrer avec soin la vis de verrouillage du réservoir. Changer

d’endroit avant de mettre le moteur en marche (à une distance

d’au moins 10 pieds ou 3 mètres de l’endroit où l’on a fait le plein).

– Ne jamais faire le plein dans un local clos. Les vapeurs de

carburant s’accumulent au niveau du sol (risque d’explosion).

– Ne transporter et ne stocker le carburant que dans des

récipients agréés. S’assurer que la réserve de carburant est

hors de portée des enfants.

– Ne pas faire le plein lorsque le moteur est chaud ou qu’il toume.

– L’essence utilisée (mélangée avec de l’huile moteur deux temps)

ne doit contenir ni éthanol ni méthanol (types d’alcool). Ceci a pour

but de protéger les canalisations et les autres pièces du moteur.

3m(10FT)

25

Page 26

Méthode d’utilisation

– N’utiliser la débroussailleuse qu’avec un éclairage et une

visibilité suffisants. En hiver, prendre garde aux endroits

glissants ou mouillés, à la glace et à la neige (risque de glisser).

Veiller a avoir toujours une bonne prise des pieds.

– Ne pas présumer de ses forces. Garder toujours une bonne

prise des pieds, un bon équilibre et un bon contrôle de la

débroussailleuse.

– Ne jamajs couper des ceintures.

– Ne jamais monter sur un arbre pour effectuer une opération de

coupe avec la débroussailleuse.

– Ne jamais travailler sur une surface instable ou un terrain très

en pente.

– Enlever des objets tels que, les pierres, les clous, gazon etc.,

de la zone de travail. De tels objets risquent d’endommager le

couteau et de provoquer des réactions arrière dangereuses. Ils

peuvent également être projetés.

– Avant de commencer à couper, veiller à ce que le couteau ait

atteint la vitesse normale de travail.

– Ne jamais utiliser la débroussailleuse à l’envers ou avec une

inclinaison excessive.

– ATTENTION! — La partie du couteau reste dangereuse

lors de la décélération de la machine précédant l’arrêt.

Réaction arrière

– Lors de l’utilisation de la débroussailleuse, il peut se produire

une réaction arrière incontrôlée.

– Ceci est particulièrement vrai si l’on essaie de couper avec le

secteur du couteau compris entre 12 et 2 heures Iorsqu’on

regarde depuis la position de l’utilisateur.

– Ne jamais mettre ce secteur du couteau en contact avec des

objets tels que buissons, souches, arbrisseaux, etc., de plus de

3 cm de diamètre.

– La débroussailleuse serait alors déviée brutalement et avec

force et risquerait de provoquer des blessures graves.

– Ne jamais essayer de couper avec le secteur du

couteau compris entre 12 et 2 heures.

Prévention de la réaction arrière

Pour éviter une réaction arrière, respecter les consignes

suivantes :

– Une utilisation dans le secteur du couteau compris entre 12 et 2

heures peut être très dangereuse, tout particulièrement avec

des couteaux en métal.

L’utilisation dans le secteur du couteau entre 11 et 12 heures, et

entre 2 et 5 heures présente aussi un certain risque de réaction

arrière.

– Des opérations de coupe dans le secteur du couteau compris

entre 11 et 12 heures, et entre 2 et 5 heures ne doivent être

effectuées que par des utilisateurs entraînés et expérimentés,

et ce à leurs propres risques. Il est possible de travailler

facilement presque sans aucune réaction arrière dans le

secteur du couteau compris entre 8 et 11 heures.

12

2

Attention :

Réaction arrière

Figure schématique

Figure schématique

Outils de coupe

Utiliser uniquement les outils de coupe corrects pour procéder aux

travaux.

Couteau (couteau à 4 dents, couteau à 8 dents)

Pour couper les matériaux épais, comme les mauvaises herbes,

hautes herbes, buissons, arbustes, sous-bois, fourrés, fourrés,

etc. (diamètre maximal de 2 cm). Pour de genre de travaux,

déplacer la débroussailleuse en demi-cercles réguliers, de droite à

gauche (comme avec une faux).

Instructions de maintenance

– Avant de commencer à travailler, vérifier l’état de la

débroussailleuse et en particulier celui du couteau, de son

protecteur et du harnais. Prêter une attention particulière aux

lames du couteau qui doivent être correctement aiguisées.

– Avant de remplacer ou d’aiguiser le couteau ou de nettoyer la

débroussailleuse ou l’outil de coupe, arrêter le moteur et retirer

les connecteurs des bougies.

26

Page 27

Ne jamais essayer de redresser ou souder des couteaux

endommagés.

– Etre attentif à l’environnement. Utiliser la débroussailleuse avec

le minimum de bruit et de pollution possible. Veiller tout

particulièrement à ce que le réglage du carburateur soit correct.

– Nettoyer régulièrement la débroussailleuse et s’assurer que

tous les écrous et vis sont bien serrés.

– Ne jamais procéder à une opération d’entetin ou remiser la

débroussailleuse à proximité de flammes vives, étincelles, etc.

– Toujours remiser la débroussailleuse dans un local fermé à clé

et bien aéré après avoir vidé le réservoir.

Observer les règles sur la prévention des accidents

prescrites par les associations commerciales

concernées et par les compagnies d’assurances.

N’effecture aucune modification sur la débroussailleuse

car ceci pourrait rendre son utilisation dangereuse.

L’entretien ou les réparations pouvant être effectués par

l’utilisateur se limitent aux opérations indiquées dans ce manuel

d’instructios. Toute autre opération doit être confiée à un agent de

service aprèsvente agréé.

N’utiliser que des pièces de rechange et des accessoires d’origine

fournis par MAKITA. L’utilisation d’accessoires et d’outils non

agréés augmente les risques d’accident et de blessures. MAKITA

décline toute responsabilité pour des accidents ou des dommages

causés par l’utilisation d’outils de coupe ou accessoires non

agréés.

Premiers secours

Pour être paré en cas d’accident, prévoir une trousse de premiers

de secours à proximité des opérations de coupe. Remplacer

immédiatement tout article pris dans la trousse de premiers secours.

Lorsqu’on demande de l’aide lors d’un accident, fournir

les informations suivantes :

– Lieu de l’accident

– Circontstances de l’accident

– Nombre de blessés

– Type de blessuresèra

– Nom de la personne qui appelle

Emballage

La débroussailleuse MAKITA est livrée dans deux cartons qui la

protègent contre les dommages pendant le transport. Le carton

est une matière primi de base et peut être réutilisé ou recyclé

(recyclage des vieux papiers).

27

Page 28

DECLARATION DE CONFORMITE CE

Modèle : EBH341R

Nous prenons la responsabilité pour déclarer que le présent produit est conforme aux normes suivantes

énoncées aux documents ISO14865, ISO14740, EN55012 conformément aux Drectives du Conseil, 89/392/

CEE, 98/37/CEE, 93/68/CEE, 89/336/CEE modifiées et 92/31/CEE modifiée.

Niveau sonore mesuré : 108.4 dB

Niveau sonore garanti : 113.3 dB

Niveaux sonores mesurés conformément à la Directive du Conseil, 2000/14/CE.

Procédure d’évaluation de conformité : Annexe V

CE2007

Tomoyasu Kato

Directeur

Producteur responsable:

Makita Corporation.

3-11-8, Sumiyoshi-cho, Anjo, Aichi, JAPAN

Représentant autorisé en Europe:

Makita International Europe Ltd.

Michigan Drive, Tongwell, Milton Keynes, Bucks MK15 8JD, ENGLAND

28

Page 29

DONNÉES TECHNIQUES

Modèle

Dimensions : longueur x largeur x hauteur (carter du tube) mm

Poids (sans protecteur en plastique et couteau) kg

Volume (réservoir) L

Accessoire de coupage (diam. de la lame de coupage) mm

Cylindrée du moteur cm

Puissance maximale du moteur kw

Régime moteur à la vitesse maximale de broche recommandée

min

Vitesse maximale de broche (correspondante) min

Consommation de carburant kg/h

Consommation spécifique de carburant g/kwh

EBH341R

Poignée simple

Lame de coupe Tête de coupe à fil

430 x 280 x 430

10.2

0.65

255

3

-1

-1

33.5

1.07 a 7000 min

10000

7500

-1

0.458

426

Régime de ralenti min

Vitesse d'embrayage min

Carburateur (carburateur à diaphragme) type

Système d'injection type

Bougie d'allumage type

Jeu électrodes mm

Marche à vide m/s

Emballement ou papilion des

gaz ouvent à fond m/s

Marche à vide m/s

Emballement ou papilion des

Vibration

selon

ISO 7916

Poignée droite

(prise arrière)

1)

Poignée gauche

(prise avant)

gaz ouvent à fond m/s

Moyenne du niveau de pression acoustique selon ISO 7917

Moyenne du niveau de puissance sonore selon ISO 10884

1)

dB

1)

dB

Carburant

-1

-1

3000

4100

WALBRO WYL

Type Allumage électronique

NGK CMR6A

0.7 – 0.8

2

2

2

2

0.6 0.7

4.0 5.59

0.85 0.82

4.78 8.12

89.3 97.1

104.3 108.4

Essence pour moteur

Huile pour moteur

huile de la classification API, classe SF ou supérieure

(moteur à quatre temps pour automobile)

SAE 10W- 30

Rapport d'engrenage

1) Ces donnée tiennent également compte des modes de fonctionnement au ralenti et à plein régime ou pleins gaz.

15/20

29

Page 30

DÉSIGNATION DES PIÈCES

ԣ

Ԟ

ԛ

ԥ

Ԡ

Ԝ

Ԥ

ԣ

ԩ

Ԩ

ԧ

Ԧ

Ԛ

Ԙ

Ԣ

ԙ

Ԣ

ԡ

ԝ

ԟ

Ԫ

ԫ

F Nomenclature des pièces

Réservoir de carburant

1

Poulie d'enroulement du câble

2

de démarrage

Filtre à air

3

Interrupteur I-O (marche/arrêt)

4

Bougie d'allumage

5

Protection d'échappement

6

Poignée

7

Levier de commande

8

Câble de commande

9

Arbre

10

Dispositif de protection

11

Carter de boîte de vitesse

12

Lame de coupe

13

14 Harmais

15

Bouchon de réservoir

Poignée lanceur

16

Pompe primare

17

Levier d’étranglement

18

Pot d’échappement

19

Jauge d’huile

20

21 Tube flexible

22 Tête de coupe à fil

30

Page 31

MONTAGE MOTEUR ET ARBRE D’ENTRAINEMENT

ATTENTION : Avant toute intervention sur la

ATTENTION : Ne mettre la débroussailleuse en marche

1. En joignant le tube flexible au moteur et au carter du

tube.

Introduire un bout du tube flexible dans le carte d’embrayage du

moteur jusqu’à ce qu’il soit bloqué avec son sec.

Introduire l’autre bout du tube flexible dans le carter du tube de

la débroussailleuse jusqu’au blocage.

On peut changer chaque bout du tube flexible.

Vérifier que l’extremité carrée de l’arbre flexible est appropiée

au joint de l’abre d’entraînement.

Attention : S’il vous semble difficile de mettre le tube

débroussailleuse, toujours arréter le

moteur et débrancher les connecteurs des

bougies. Faire attention aux pièces chaudes

du moteur et à la lame du couteau. Toujours

porter des gants protecteurs.

qu’après l’avoir complètement montée.

flexible proprement, l’extremité carrée de

l’arbre flexible ne peut forcément pas

toucher le joint de l’arbre d’entraînement. Il

ne faut pas pousser pour éviter du

dommage de l’extremité de l’arble flexible.

Répéter la même procedure jusqu’à ce qu’il

se conviennent.

2. Montage du câble de commande

– Déposer le couvercle du filter d’air.

– Poser le câble de commande (4) dans le boulon de réglage (5),

et déplacer l’émerillon (6) pour que le câble puisse entrer dans

la rainure de l’émerillon. En même temps, le côté trou rond de

l’émerillon sera orienté vers la ferrure à l’extrémité du fil

intérieur.

– Lâcher l’émerillon, et confirmer que la ferrure à l’extrémité du fil

intérieur soit posée dans le trou.

– Poser le couvercle du filtre d’air.

㩷

㩷

(4)

Câble de

commande

(5)

Trou rond

(6)

Émerillon

Insér㪼

Ferrure d’extrémité

31

Page 32

RACCORDEMENT DU CORDON D’INTERRUPTEUR

– Raccorder les cordons de l’interrupteur avec les cordons

venant du moteur en insérant l’uus dans les autres.

– Fixer le raccord de l’interrupteur avec l’agrafe (7).

REGLAGE DU CÂBLE DE COMMANDE

Régler le câble de commande avec boulon de réglage pour que il

puisse avoir un jeu de 1 à 2 mm lorsque le levier d’étranglement

est mis à la position de petite vitesse au moyen du boulon de

réglage du carburateur. (Prendre garde que la lame de coupe ne

tourne pas au ralenti.)

㩷

(7)

㩷

1-2 mm

Laisser le câble de commande et les câbles de I’interrupteur I-O